Pressure sensitive adhesive and pressure sensitive adhesive tape

A pressure-sensitive adhesive, unsaturated technology, applied in the field of adhesive tape, can solve the problems of deterioration of coating working conditions, coating unevenness, coating surface appearance deterioration, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example

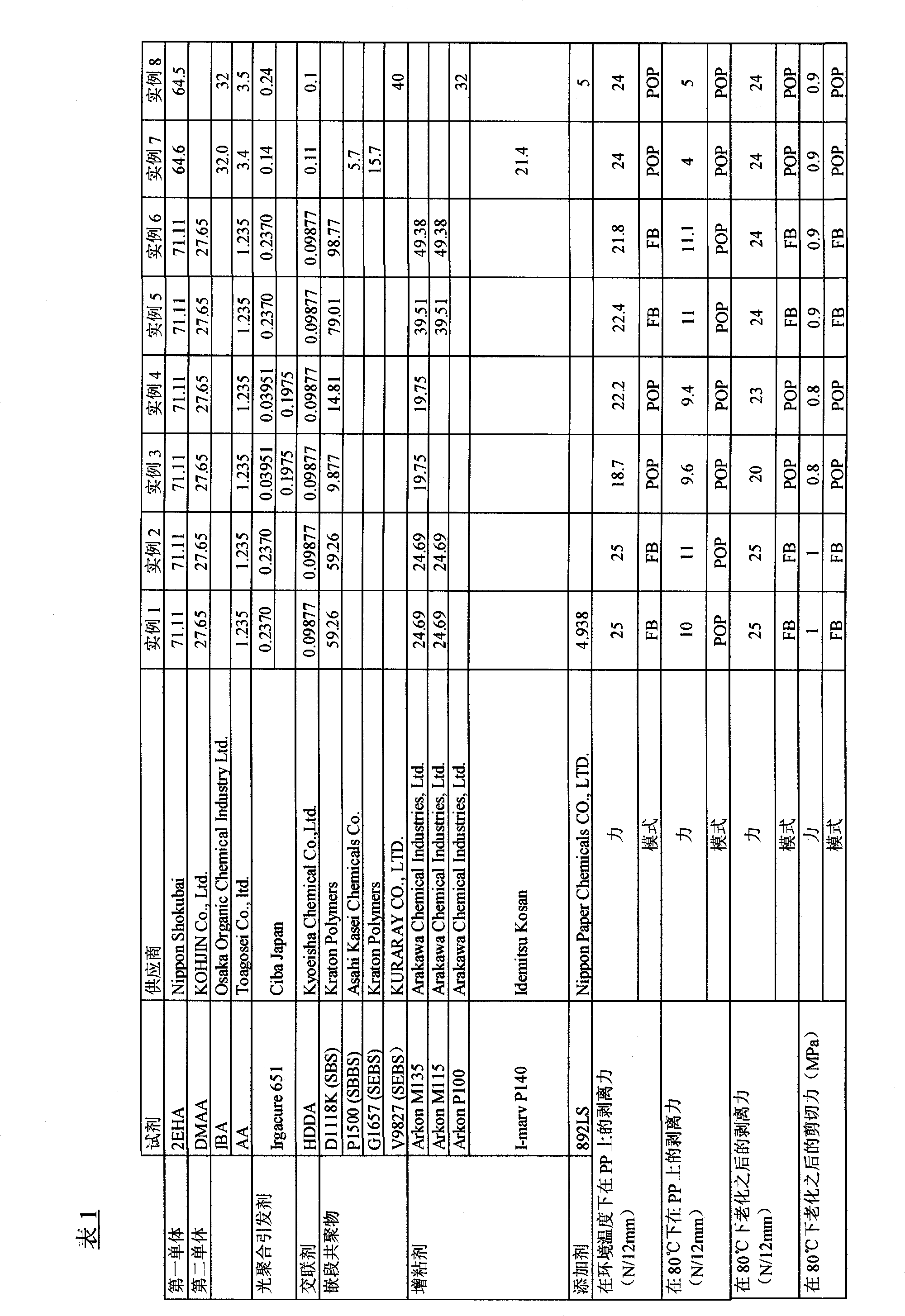

[0066] Description of ingredients used:

[0067] 892LS: Chlorinated polyolefin

[0068] Arkon M115: Partially Hydrogenated Petroleum Resin

[0069] Arkon P125: fully hydrogenated petroleum resin

[0070] Arkon M135: Partially Hydrogenated Petroleum Resin

[0071] Arkon P100: fully hydrogenated petroleum resin

[0072] HDDA: 1,6-hexanediol diacrylate

[0073] Irgacure 651: 2,2-dimethoxy-1,2-diphenylethan-1-one

[0074] Viscoat #158: 3-methoxybutyl acrylate

[0075] Viscoat #190: 2-Ethoxyethoxyethyl acrylate

[0076] I-marv P140: fully hydrogenated petroleum resin

[0077] Piccolyte A-135: a-pinene resin

[0078] Regalrez 6108: hydrogenated hydrocarbon resin

[0079] Regalrez 1085: hydrogenated hydrocarbon resin

[0080] CP343-1: Chlorinated polyolefin

[0081] ED-502S: Monofunctional epoxy resin

example 1、2、5-12 and 14-55

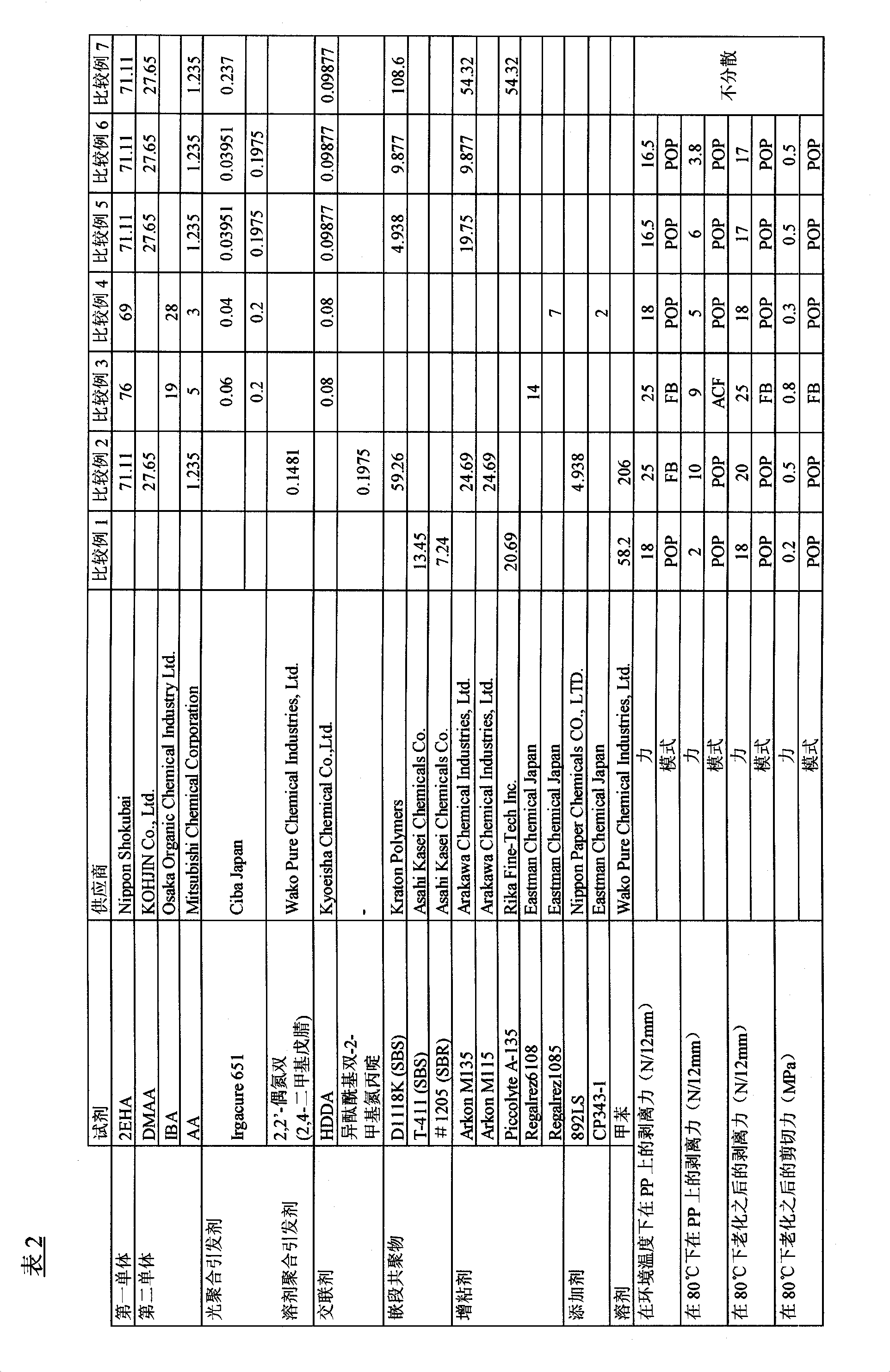

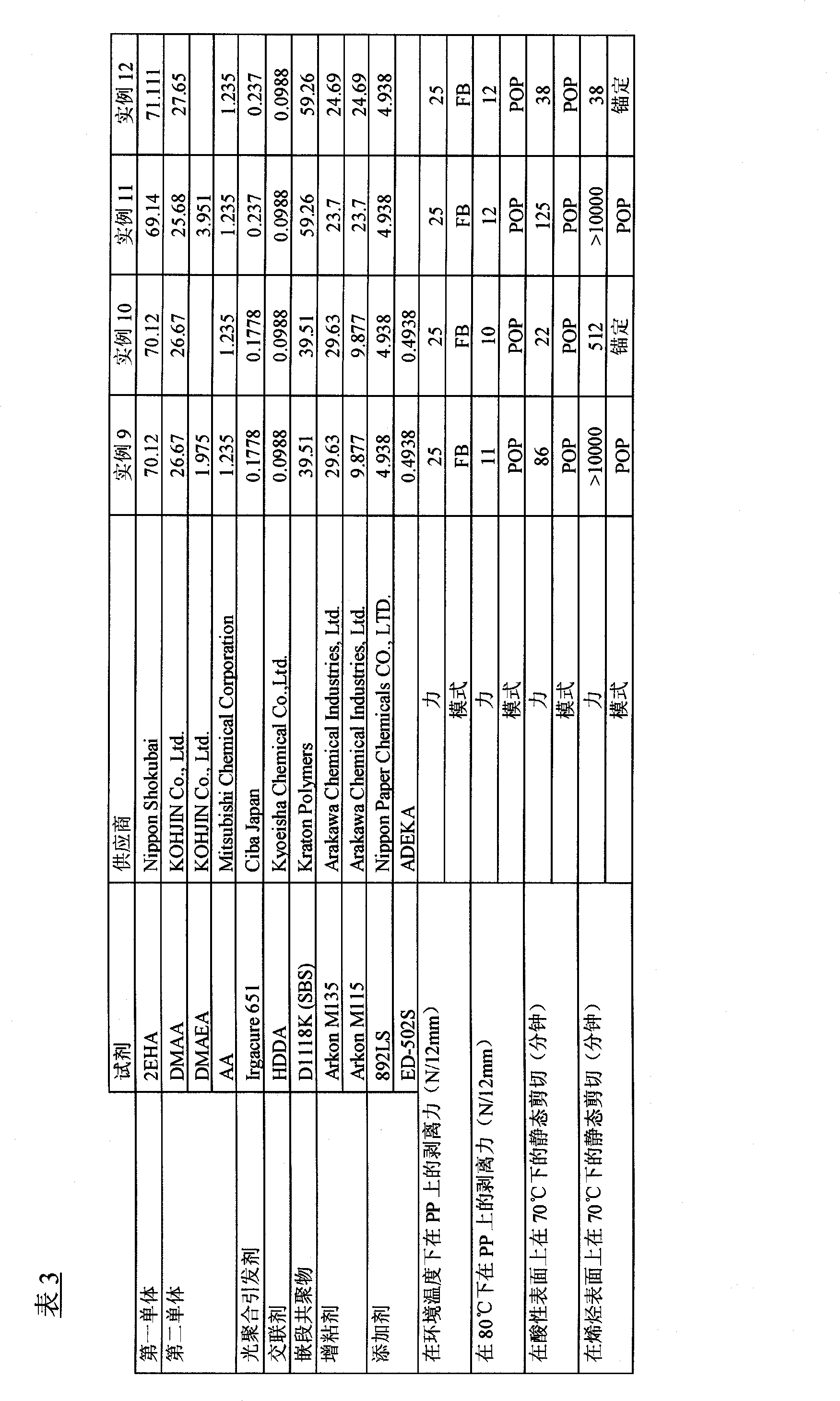

[0082] Examples 1, 2, 5-12 and 14-55, Comparative Examples 7-16

[0083] The monomers and other components shown in Tables 1-12 were mixed and dissolved in a vessel with stirring (24 hours at 65°C). If the components include chlorinated polyolefins (available as 892LS from Nippon Paper Chemicals Co.LTD.), mix and stir the monomer and chlorinated polyolefins in a vessel (65°C for 60 minutes), then mix the remaining components The chlorinated polyolefin solution was added and dissolved with stirring.

[0084] The resulting mixture was placed between 50 micron thick release-treated PET films (from Mitsubishi Chemical), and then coated by knife coating. Subsequently, the sample was treated with UV radiation (wavelength 300 to 400 nm, power 0.5 to 7 mW / cm2) for 6 minutes and cured, and then a pressure-sensitive adhesive was obtained. The resulting sample had a thickness of 100 micrometers.

[0085] One PET film of the resulting pressure sensitive adhesive was peeled off and a ...

example 3 and 4, comparative example 3-6

[0096] A photopolymerization initiator was added to the monomers listed in Tables 1 and 2 with the content indicated in the above column, then replaced with nitrogen (deoxygenation), and then cured with UV to obtain a prepolymer with a viscosity of about 1000 cps to about 5000 cps. Then the photopolymerization initiator, crosslinking agent, block copolymer and hydrogenated tackifier were added with the contents indicated in the following column and stirred in the vessel at 65° C. for 24 hours to dissolve. Subsequently, samples were obtained in the same manner as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com