Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

415 results about "Hexanediol diacrylate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

HDDA (HEXANEDIOL DIACRYLATE) is a difunctional reactive diluent that is commonly used as a component of ultraviolet light (UV) and electron beam (EB) curable coatings and inks. HDDA is particularly useful in coatings and inks where improved elasticity, weathering and adhesion are desired in combination with excellent water resistance.

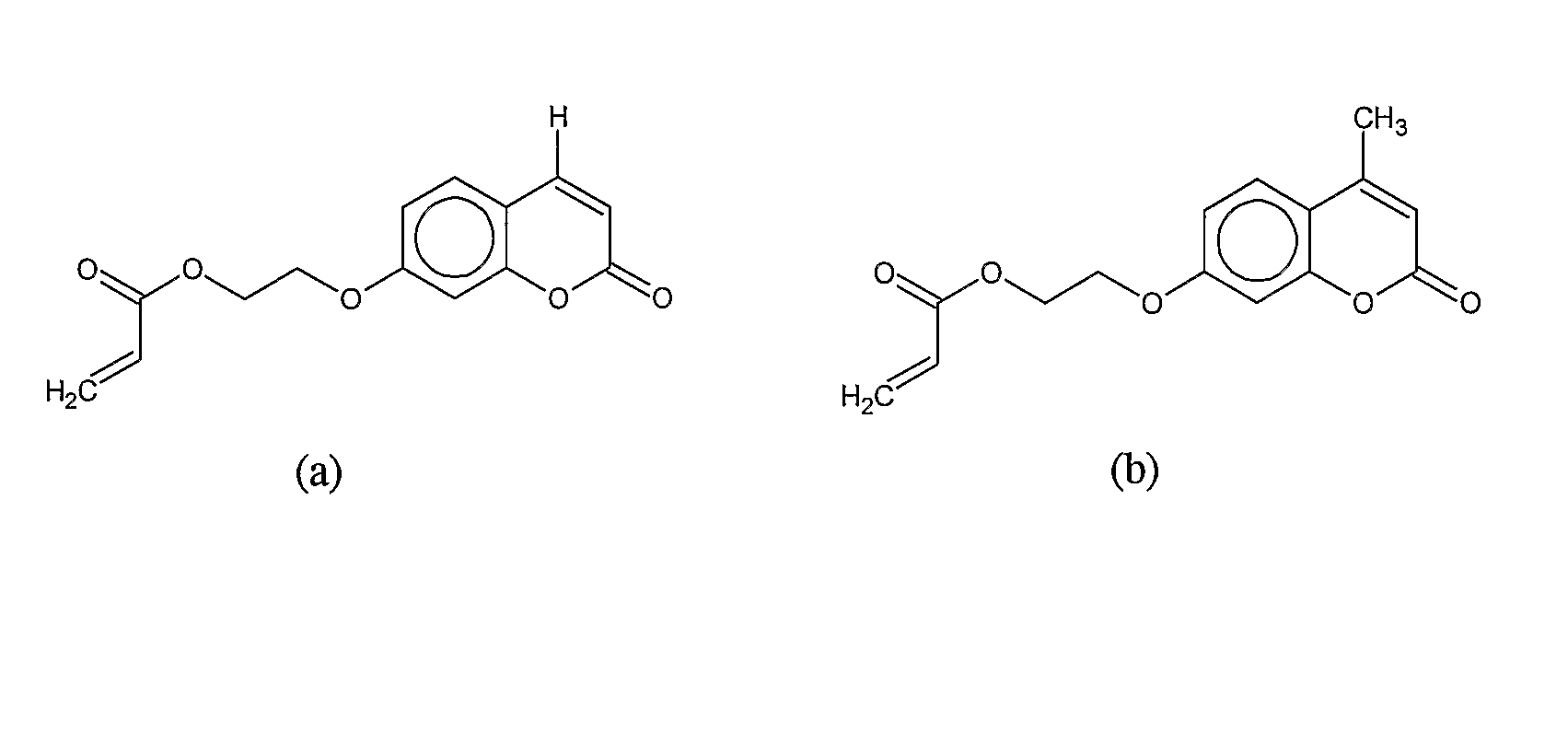

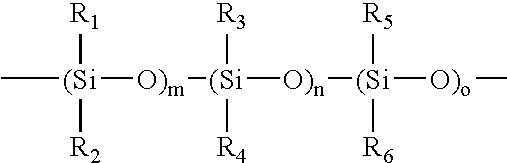

Light Activated Shape Memory Co-Polymers

The present discovery uses monomers which contain reversible photo-crosslinkable groups in addition to primary polymerizable groups. The mechanical properties of these materials and the reversibility of the photo-activated shape memory effect demonstrate the effectiveness of using photo-irradiation to effect change in modulus and shape memory effect. In the preferred embodiment the reaction mixture includes a photo-reactive monomer comprising a photo reactive group and a polymerizable group; a second monomer, which is more preferably a mixture of monomers, which are acrylate based; a multi-functional crosslinking agent, preferably 1,6 hexanediol diacrylate (HDODA); an initiator, preferably a free radical initiator; and a fifth, optional, component which is a modifying polymer. The mixture of the second monomer, crosslinking agent, and initiator comprise the base polymer matrix into which the photo-reactive monomer is incorporated. The polymeriziable group of the photo reactive monomer allows the photo reactive monomer to polymerize with the base polymer matrix.

Owner:CORNERSTONE RES GROUP

High-quality strawberry planting dedicated slow-release compound fertilizer

InactiveCN104030800AImprove the phenomenon of single fixationGood release effectFertilizer mixturesMicrobial agentGluconates

The invention relates to the compound fertilizer field, and particularly relates to a high-quality strawberry planting dedicated slow-release compound fertilizer. The fertilizer is prepared from the following raw materials in parts by weight: 10-15 parts of a 1250-2000 mesh diatomite, 4-5 parts of borax, 2-3 parts of ammonium molybdate heptahydrate, 10-12 parts of sodium humate, 20-25 parts of urea, 18-22 parts of potassium nitrate, 25-28 parts of organic compost, 2-4 parts of fish meal, 1-3 parts of sesame leaves, 8-10 parts of alfalfa meal, 15-18 parts of corn distiller grains, 2-4 parts of brine, 8-10 parts of an erythromycin fungi residue, 1-2 parts of an EM microbial agent, 4-6 parts of a fern root residue, 1-3 parts of nano silver, 1-2 parts of a semen ginkgo powder, 4-6 parts of 1,6-hexanediol diacrylate, 10-12 parts of an acrylic resin dispersion liquid, 1-2 parts of isocyanate, 1-2 parts of calcium stearoyl lactate, 2-4 parts of zinc gluconate, 6-8 parts of table vinegar, and 4-5 parts of an auxiliary agent. The compound fertilizer has multiple nutrients, is low in production cost and good in slow-release effect, allows double coating to be formed on the nutrients by utilizing diatomite and a coating agent in the process, also contains various trace elements, has no toxicity and no pollution, and is excellent in quality of planted strawberry and obvious in yield and income increasing effects.

Owner:ANHUI SUNSON CHEM

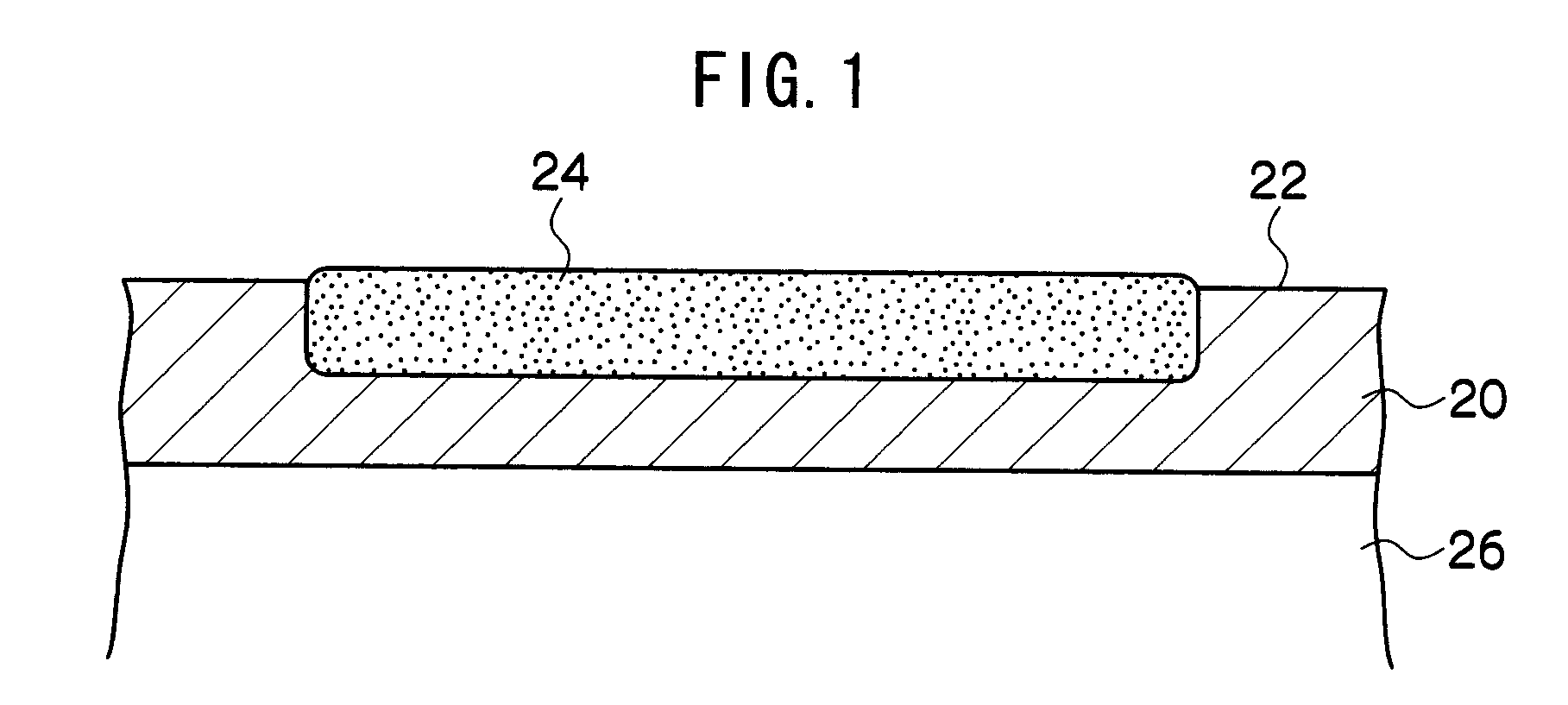

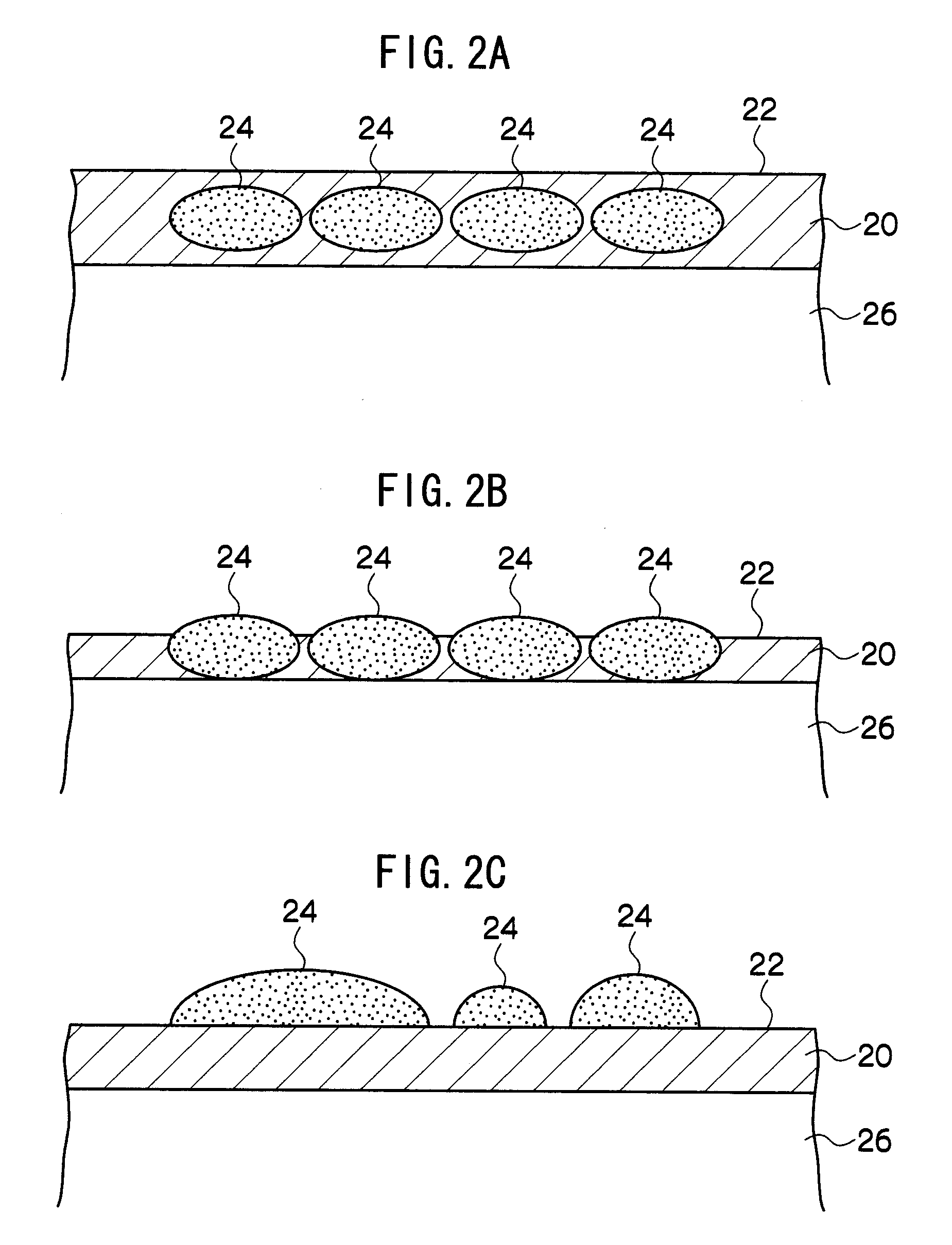

Methods and Compositions for Providing Preferential Adhesion and Release of Adjacent Surfaces

The present invention provides a method and composition for providing preferential adhesion and release of adjacent surfaces, that features solidifying a composition to form a solidified layer having first and second opposed sides, with the first side facing a first surface and being adhered thereto with a first adhesive forces and the second side facing the second surface and being adhered thereto with a second adhesive force, with the first and second adhesive forces establishing a predetermined preferential adhesion ratio. Generally, the first surface is covalently bonded to the first side and adhesion between the second side and the second surface occurs through Van der Waal forces. It has been found that the use of a fluorine group for enhancing the release properties (as a priori fluorinated release layer or a fluorinated release agent) is no longer needed for such method and composition. In one embodiment, the composition can be formed from an isobornyl acrylate component; an aliphatic urethane acrylate component; a 1,6-hexanediol diacrylate component; and a 2-hydroxy-2-methyl-1-phenyl-propan-1-one component. The first surface can be formed by polymerizing a compound formed from a multi-functional component that contains functional groups facilitating the formation of covalent bonds with the above mentioned polymerizable composition during an imprinting process, a cross-linking agent component, a catalyst component, and a solvent component. The second surface is usually a patterned or smoothed portion of a quartz mold.

Owner:MOLECULAR IMPRINTS

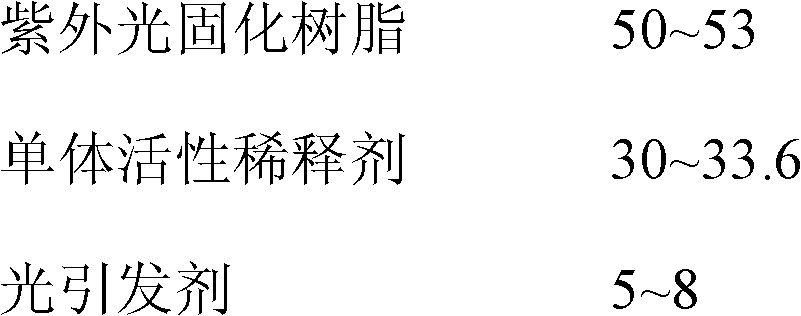

Ultraviolet light cured silk screen snowflake printing ink and preparation method thereof

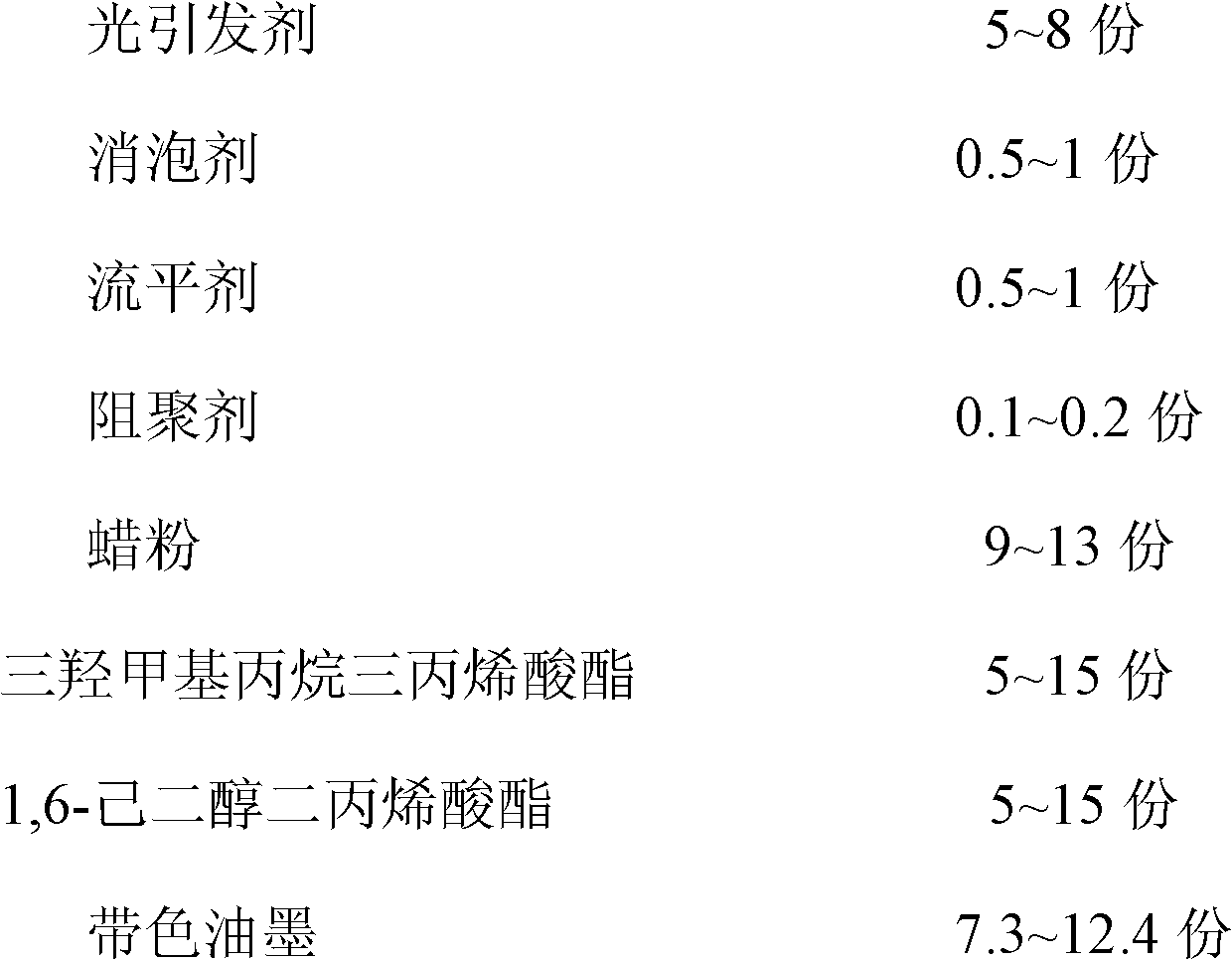

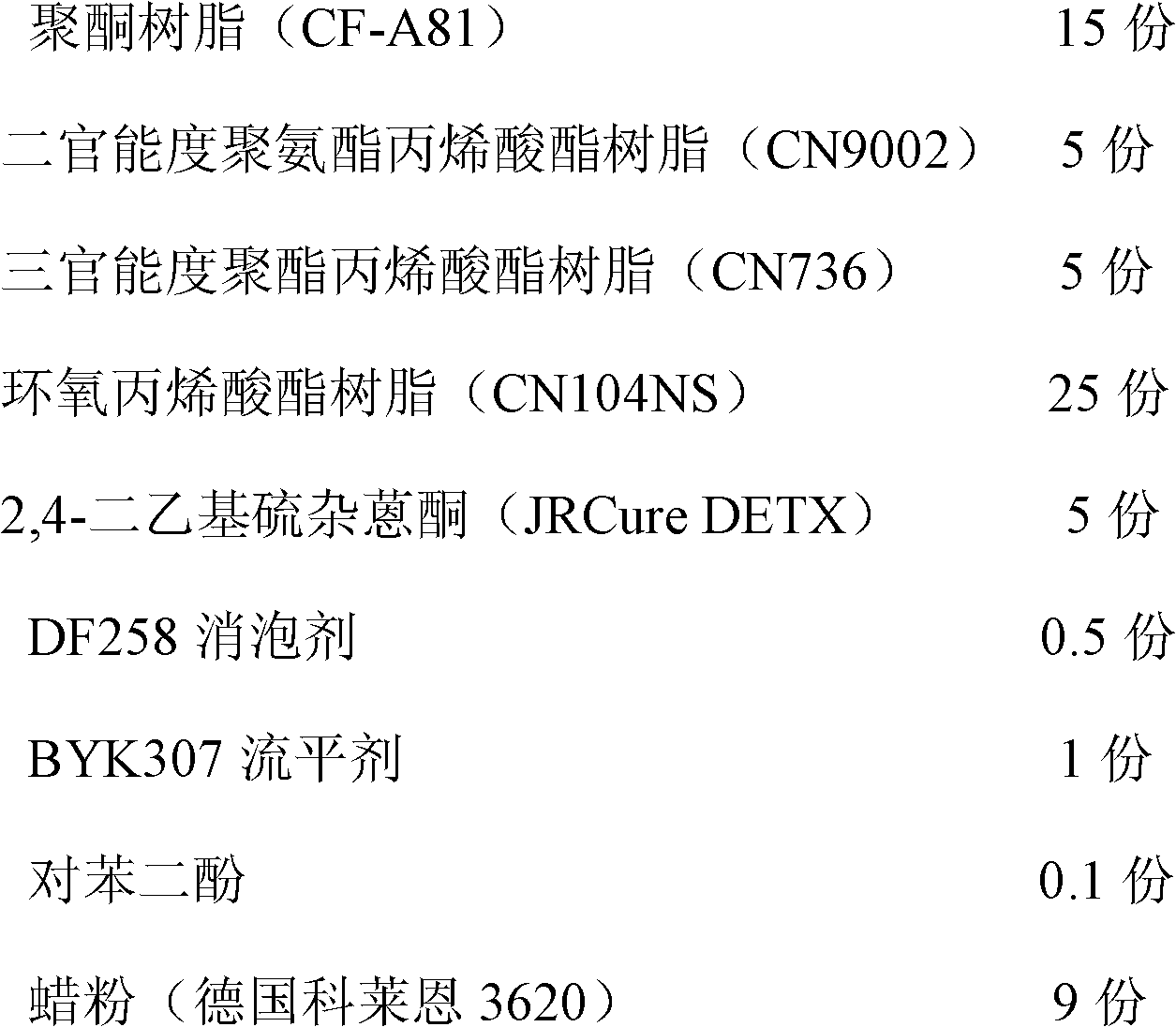

The invention provides an ultraviolet light cured silk screen snowflake printing ink and a preparation method thereof. The ultraviolet light cured silk screen snowflake printing ink which has a viscosity of 1500-3000cps at the temperature of 25 DEG C is prepared by materials of 50-60 parts of ultraviolet light curable resins, 5-8 parts of photoinitiators, 0.5-1 part of defoamers, 0.5-1 part of flatting agents, 0.1-0.2 part of polymerization inhibitors, 9-13 parts of wax powders, 5-15 parts of trimethylolpropane triacrylate, 5-15 parts of 1, 6-hexanediol diacrylate and 7.3-12.4 parts of colored printing ink which are firstly subjected to a predispersion at a medium speed of 200rpm to 500rpm for 30 minutes in a disc mixer, and then subjected to a dispersion at a high speed of 3000rpm to 3500rpm for one hour. The ultraviolet light cured silk screen snowflake printing ink has the advantages that the appearance is unique, the decorative pattern is delicate, the weather resistance is good, the smell is mild, the printing ink is environment-friendly, printed products touch smooth, and the like.

Owner:WUHAN HONGZHICAI PACKAGING PRINTING

High gloss high abrasion resistance ultra-violet curing overprinting varnish of mobile phone and preparation method thereof

InactiveCN101967338AImprove wear resistanceHigh gloss and high wear resistancePolyurea/polyurethane coatingsPolyester coatingsIsooctyl acrylatePolyester

The invention discloses a high gloss high abrasion resistance ultra-violet (UV) curing overprinting varnish of mobile phone and a preparation method thereof. The method of the invention uses low-viscosity polyester acrylate and aliphatic polyurethane acrylate as base resin which combines with ethoxylated pentaerythritol tetraacrylate, Trimethylolpropane triacrylate, Tri(propylene glycol) diacrylate, 1,6-hexanediol diacrylate and 2-ethylhexyl acrylate which are used as active diluent, alcohol and ethyl acetate which are used as diluent, benzophenone and 1-hydroxycyclohexyl phenyl ketone which are used as photoinitiator, reactive amine coinitiator, defoaming agent, flatting agent, slip agent and other agents to mix evenly and prepare the UV overprinting varnish. The overprinting varnish of the invention adopts the special raw material formula and has good lustrousness, adhesive force and mechanical stability; as some polyfunctional resins and resins with special functional groups are added, the crosslink density of the UV varnish is increased in the curing process and the hardness of the product is up to 5-7H; and as solid wax powder used as the slip agent is added, the coefficients of friction can be reduced and the product can have extremely high wear resistance.

Owner:苏州凯康化工科技有限公司

Ultraviolet (UV) offset tin printing ink and method for preparing same

The invention relates to the technical field of ink, and in particular relates to an ultraviolet (UV) offset tin printing ink and a method for preparing the same. The UV offset tin printing ink consists of the following raw materials in parts by weight: 28-38 parts of urethane acrylate, 20-30 parts of polyester acrylate, 2-10 parts of 2-propenoic acid, 1, 1'-[(1-methyl-1, 2-ethanediyl) bis [oxy(methyl-2, 1-ethanediyl)]] ester (TPGDA), 5-12 parts of trimethyl propane triacrylate (TMPTA), 1-9 parts of hexanediol diacrylate (HDDA), 14-22 parts of pigment powder, 1-3 parts of dispersing agent, 0.2-1.2 parts of organic silicon defoamer, 1-4 parts of organic silicon flatting agent, 1-3 parts of photoinitiator and 0.2-1.5 parts of adhesion promoter. The UV offset tin printing ink has low adhesiveness, improved fluidity, good ink flexibility, good transfer printing performance and good adaptability to metal product printing.

Owner:东莞市佳烨化工科技有限公司

Light-cured three dimensional printing material and preparation method thereof

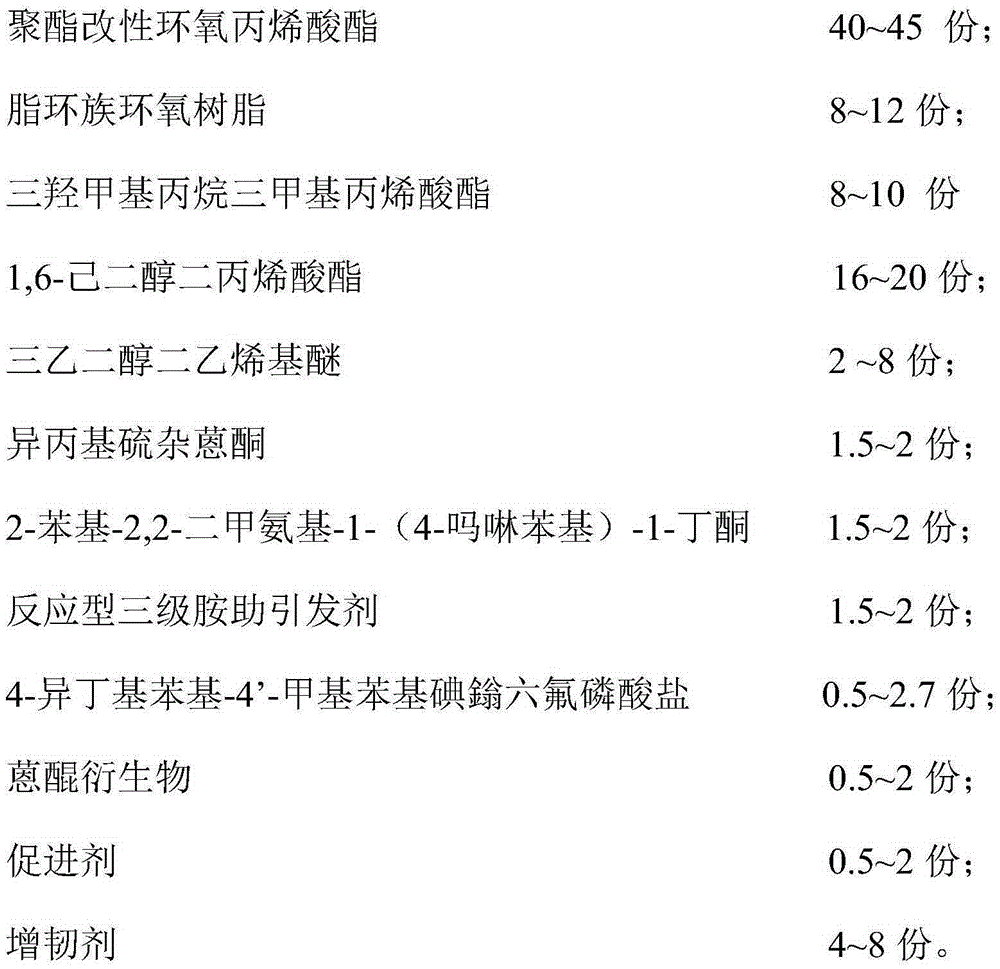

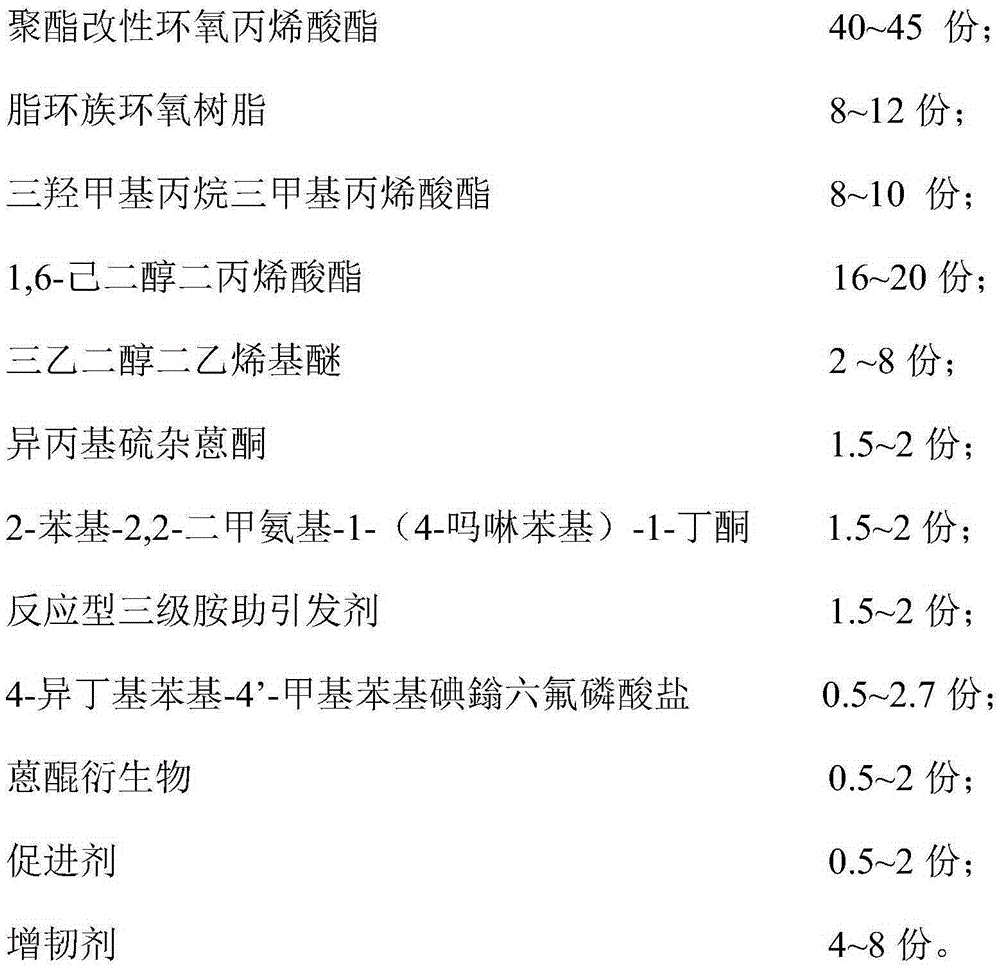

The invention discloses a light-cured three dimensional printing material and a preparation method thereof. The light-cured three dimensional printing material comprises, by mass, 40-45 parts of polyester modified epoxy acrylate, 8-12 parts of cycloaliphatic epoxy resin, 8-10 parts of trihydroxymethylpropyl trimethylacrylate, 16-20 parts of 1,6-hexanediol diacrylate, 2-8 parts of triethyleneglycol divinyl ether, 1.5-2 parts of isopropylthioxanthone, 1.5-2 parts of 2-phenyl-2,2-dimethylamino-1-(4-morpholinylphenyl)-1-butanone, 1.5-2 parts of a reactive tertiary amine co-initiator, 0.5-2.7 parts of 4-isobutylphenyl-4'-methylphenyliodonium hexafluorophosphate, 0.5-2 parts of an anthraquinone derivative, 0.5-2 parts of a promoter and 4-8 parts of a flexibilizer. Shaped parts made by using the light-cured three dimensional printing material have the advantages of low shrinkage, high toughness and high shaping precision.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS +2

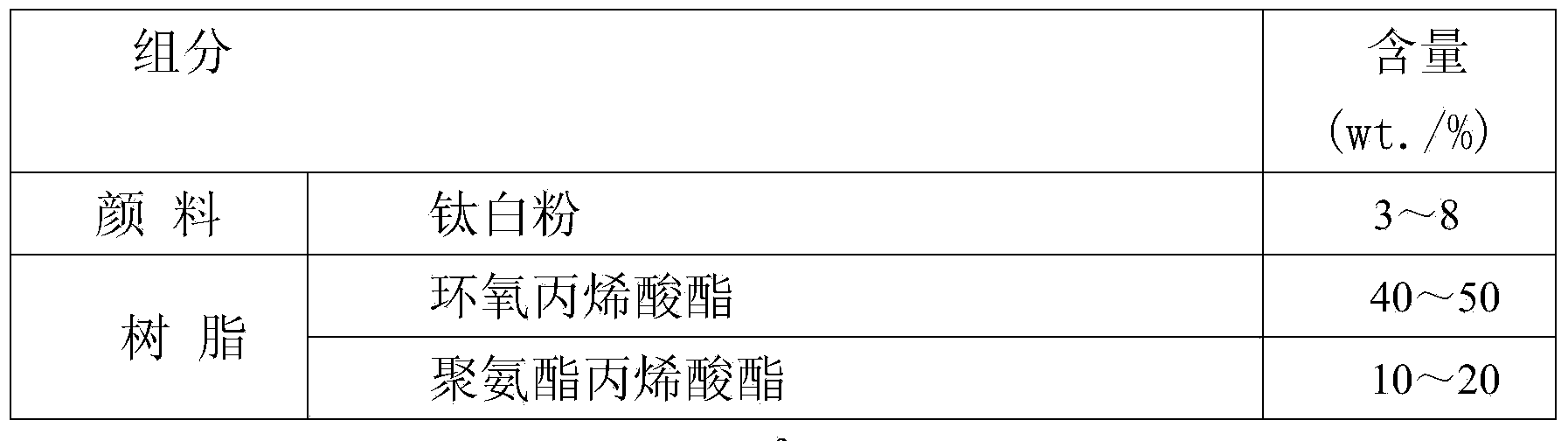

Ultraviolet (UV) cured plastic coating

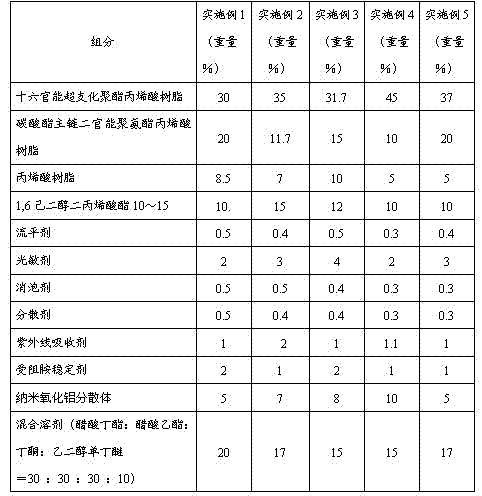

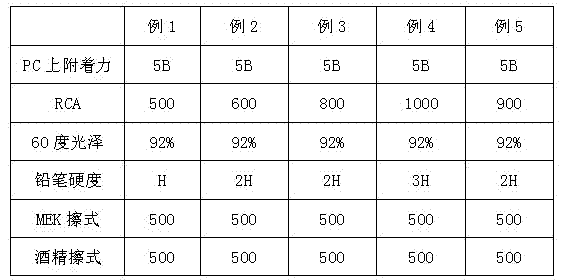

InactiveCN102533067AAddressing deficiencies in finishing coatingsAvoid defectsPolyurea/polyurethane coatingsPolyester coatingsAcrylic resinNano al2o3

The invention discloses an ultraviolet (UV) cured plastic coating. The coating consists of the following components in percentage by weight: 30 to 45 percent of hexadefunctional hyperbranched polyester acrylic resin, 10 to 20 percent of carbonate main chain bifunctional polyurethane acrylic resin, 5 to 10 percent of acrylic resin, 10 to 15 percent of 1,6-hexanediol diacrylate, 2 to 4 percent of photosensitizer, 1 to 2 percent of ultraviolet absorbent, 1 to 2 percent of hindered amine stabilizer, 0.9 to 1.5 percent of aid, 5 to 10 percent of nano-alumina dispersion and 15 to 20 percent of mixed solvent. When the coating is used, the components are uniformly mixed in a ratio, and the mixture is sprayed on a plastic workpiece and cured by a UV light curing machine. The coating can be used for coating on acrylonitrile-butadiene-styrene (ABS) plastic and polycarbonate (PC) plastic, and the coating layer has the characteristics of high hardness, high wear resistance, hard object scratch resistance, high gloss, yellowing resistance, environment friendliness and the like.

Owner:深圳市美丽华科技股份有限公司

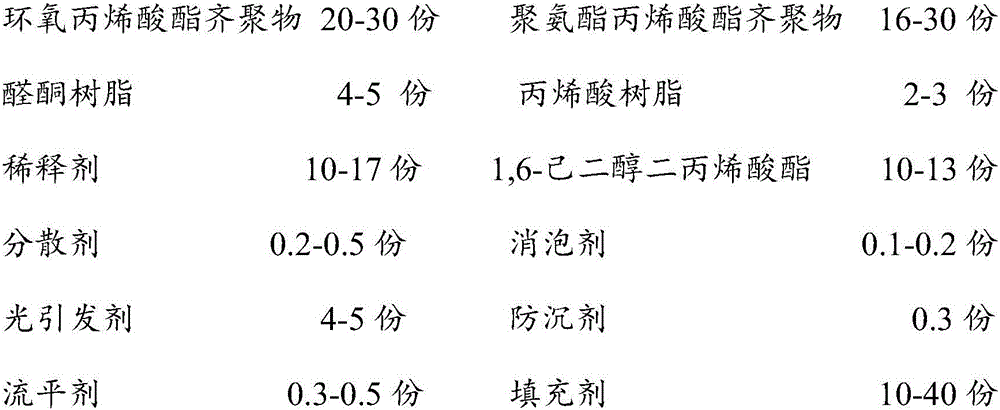

UV (ultraviolet) primer composition attached to melamine board and preparation method of UV primer composition

InactiveCN106519919AStrong adhesionAchieve diversificationPolyurea/polyurethane coatingsEpoxy resin coatingsOligomerUV curing

An embodiment of the invention discloses UV (ultraviolet) primer composition attached to a melamine board and a preparation method of the UV primer composition. The composition is prepared from components by mass as follows: 20-30 parts of an epoxy acrylate oligomer, 16-30 parts of urethane acrylate oligomer, 4-5 parts of aldehyde ketone resin, 2-3 parts of acrylic resin, 10-17 parts of a diluent, 10-13 parts of 1,6-hexanediol diacrylate, 0.2-0.5 parts of a dispersant, 0.1-0.2 parts of an antifoaming agent, 4-5 parts of a photoinitiator, 0.3 parts of an anti-setting agent, 0.3-0.5 parts of a leveling agent and 10-40 parts of filler. According to the UV primer composition attached to the melamine board and the preparation method of the UV primer composition, the melamine board which is not subjected to surface treatment is directly coated with the prepared primer, the coating manner is quick and convenient, the primer can be directly subjected to UV curing after coating without standing, and short time is consumed.

Owner:GUANGDONG LANYANG SCI & TECH

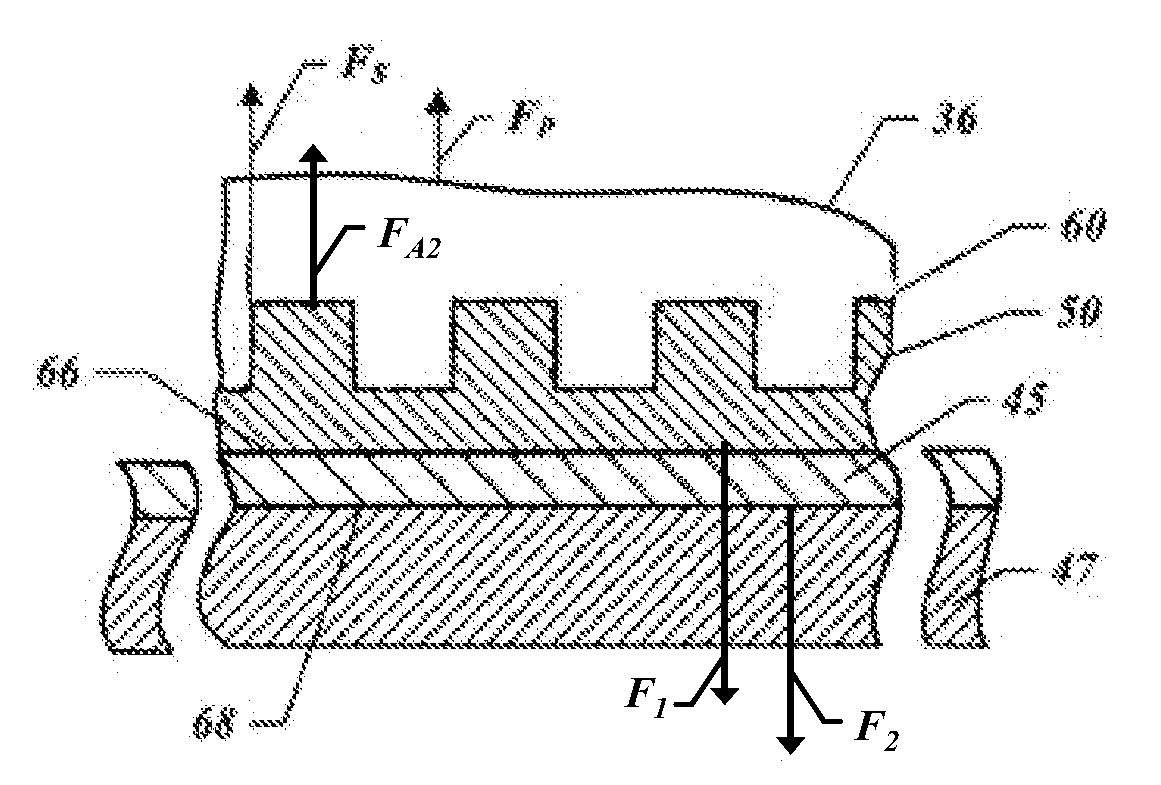

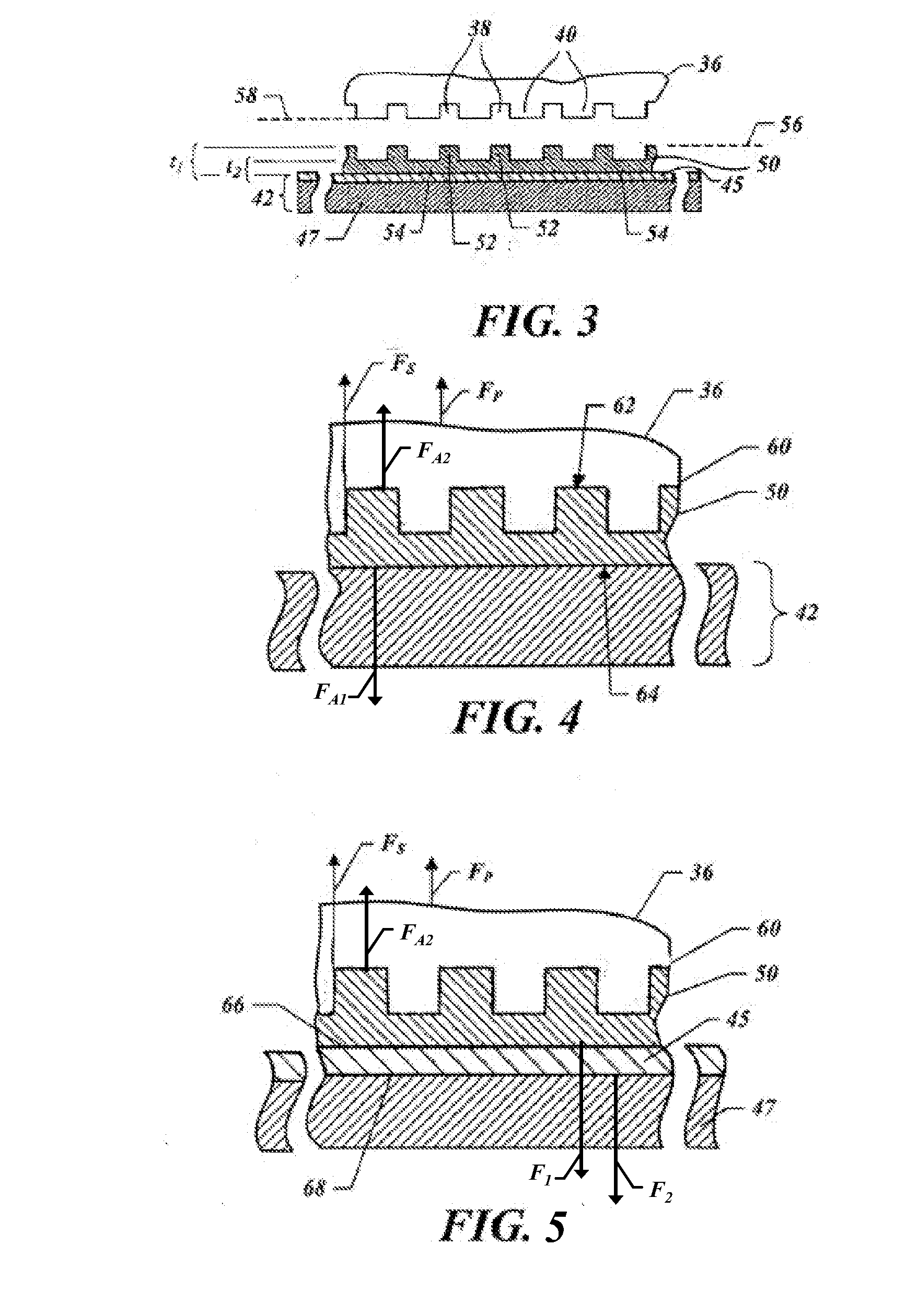

System, apparatus and method for curing of coatings in heavy gas

InactiveUS20060201017A1Increase productionChanged out quickly and easilyDrying solid materials with heatDrying gas arrangementsHexanediol diacrylatePolymer chemistry

A system, apparatus, and method is provided for curing ultraviolet (UV) curable coatings on articles using UV lamps while the article is immersed in an atmosphere of inert gas heavier than air. One example of a UV curable coating includes 35 weight % Laromer™ LR 8987, 20 weight % urethane acrylate hexandioldiacrylate, 38.5 weight % Laromer™ LR 8863, 3.5 weight % polyetheracrylate Iragucure™ 184, 0.5 weight % of a Photoinitiator Lucirin™ TPO, 2 weight % Tinuvin™ 400 and 1.5 weight % UV absorber Tinuvin™ 292. Examples of the inert gas used in the process disclosed include carbon dioxide, nitrogen, argon, hydrocarbon and halogen gases. An example of an apparatus provided by the invention includes a suspended track system; a housing, wherein the housing comprises an internal portion of the suspended track system and a curing chamber having highly reflective surfaces of favorable geometry. Further provided is a plurality of UV lamps, wherein the lamps are disposed on a slidably removable curing caddy system, wherein the slidable curing caddy enables lamp replacement and general interior maintenance of the apparatus. Further provided is an evaporator and alternatively, a vaporizer for providing a heavy gas supply. Further provided is a controller and software to coordinate the functions of the apparatus disclosed.

Owner:ELLIS GREGORY PAGE +1

Ultraviolet cured wood paint and preparation method thereof

The invention discloses ultraviolet cured wood paint and a preparation method thereof. The raw material formula of the ultraviolet cured wood paint comprises the following components in percentage by weight: 30 to 35 percent of modified unsaturated polyester resin, 10 to 20 percent of polyester acrylate, 10 to 15 percent of 1,6-hexanediol diacrylate, 5 to 10 percent oftrimethylolpropane propoxylate triacrylate, 3 to 5 percent of polyhydroxyethyl methacrylate, 0.2 to 0.6 percent of settling agent, 10 to 20 percent of transparent powder, 3 to 6 percent of talcpowder, 0.5 to 1.5 percent of photoinitiator 1, 3 to 5 percent of photoinitiator 2 and 0.2 to 0.6 percent of flatting agent. The ultraviolet cured wood paint can be used as a transparent base coat, is low in cost, simple in preparationmethod and environmentally-friendly, has high transparency, high film performance, high rubbing property and high leveling property, and can create huge economic and social benefit.

Owner:HUIZHOU CHANGRUNFA PAINT

UV (ultraviolet) curing ink and application thereof

ActiveCN103232751ALow tolueneA low-concentration acid solution can quickly detoxifyInksPhotosensitizerUV curing

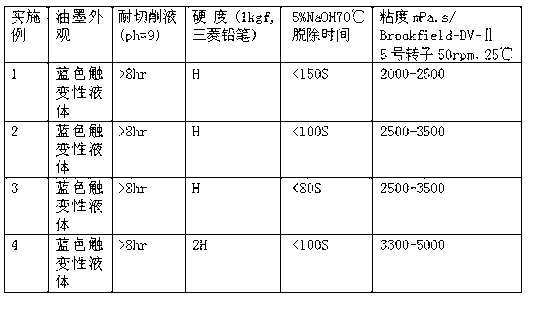

The invention discloses a UV (ultraviolet) curing ink and application thereof. The UV curing ink comprises the following components in percentage by weight: 30-40% of high-functionality polyurethane acrylate, 10-20% of dual-functionality polyurethane acrylic resin, 5-10% of amine-modified polyether acrylate prepolymer, 5-10% of thermoplastic acrylic resin, 10-15% of 1,6-hexanediol diacrylate, 2-4% of photosensitizer, 1-2% of nano aluminum oxide dispersion and 15-20% of filler. The UV photocuring ink is used for temporary protection in the glass surface working process; and after the UV photocuring ink is subjected to UV photocuring, a tough ink layer can be formed on the glass surface, thereby effectively ensuring the glass not to be scratched in the surface working process. After finishing the glass working, the glass can be soaked in 5% sulfuric acid solution, which is heated to 50 DEG C, to remove the UV curing ink on the glass surface without influencing the glass.

Owner:深圳市美丽华科技股份有限公司

UV cured aqueous plastic coating and preparation method thereof

ActiveCN105419624AAvoid water resistanceAvoid stabilityPolyurea/polyurethane coatingsAdhesion forceDiacrylate ester

A UV-cured aqueous plastic coating comprises a polyurethane acrylate prepolymer, an active diluent, a light initiator, a levelling agent, a dispersant, an antifoaming agent, and deionized water, wherein the active diluent is hexanediol diacrylate. The active diluent (hexanediol diacrylate) has a very good osmotic swelling effect on polyurethane acrylate prepolymer and increases the adhesion force of the plastic coating on a plastic plate. Without any emulsifier, UV cured aqueous plastic coating having the advantages of small particle size, high stability, good film-forming property and high adhesiveness can be obtained, and thus the shortage that waterproof property and stability of plastic coating are influenced by a conventional emulsifier is overcome. The invention also provides a preparation method of the UV cured aqueous plastic coating.

Owner:CHINA ACADEMY OF ENG PHYSICS FUNCTION MATERIAL RES INST

High-gloss abrasion-resisting ultraviolet (UV) gold-stamping gloss oil for the field of cigarette packet printing and preparation method thereof

The invention provides high-gloss abrasion-resisting ultraviolet (UV) gold-stamping gloss oil for the field of cigarette packet printing and a preparation method thereof. The high-gloss abrasion-resisting UV gold-stamping gloss oil is gold-stamping gloss oil with the viscosity of 130-150 cps / 25 DEG C and is prepared by mixing and stirring, by mass, 20-25 parts of CN9006 N six-functionality polyurethane acrylate, 25-30 parts of CN117 modified epoxy acrylate, 15-15.6 parts of SR399NS dipentaerythritol senary acrylic ester, 15-18 parts of SR238NS 1,6- hexylene glycol diacrylate, 5-8 parts of photoinitiator, 5-10 parts of photosensitivity sensitizer and1-3 parts of auxiliaries. The high-gloss abrasion-resisting UV gold-stamping gloss oil adopts monomers and resin with small acid value and corrosivity, has the advantages of being high in glossiness, good in adhesive force, friction-resisting, quick in drying speed and the like and has good gold-stamping effect when used for the cigarette packet printing.

Owner:WUHAN HONGZHICAI PACKAGING PRINTING

Ultraviolet (UV) screen plastic film printing ink and method for preparing same

The invention relates to the technical field of ink, and in particular relates to an ultraviolet (UV) screen plastic film printing ink and a method for preparing the same. The UV screen plastic film printing ink consists of the following raw materials in parts by weight: 18-28 parts of urethane acrylate, 16-25 parts of polyester acrylate, 6-15 parts of solid acrylic resin, 2-8 parts of 2-propenoic acid, 1, 1'-[(1-methyl-1, 2-ethanediyl) bis [oxy(methyl-2, 1-ethanediyl)]] ester (TPGDA), 7-15 parts of trimethyl propane triacrylate (TMPTA), 4-12 parts of hexanediol diacrylate (HDDA), 14-22 parts of pigment powder, 1-3 parts of dispersing agent, 0.2-1.2 parts of organic silicon defoamer, 1-4 parts of organic silicon flatting agent, 1-3 parts of photoinitiator and 0.2-1.5 parts of adhesion promoter. The UV screen plastic film printing ink adopts the solid acrylic resin as one basic material and has good flexibility and adhesiveness, the printing adaptability of the plastic film printing ink is greatly improved, moreover, the basic materials of the urethane acrylate and the polyester acrylate all have excellent adhesiveness, the adhesion firmness of the UV screen plastic film printing ink is further increased, and the UV screen plastic film printing ink has a good printing adaptability and a good printing effect.

Owner:东莞市佳烨化工科技有限公司

Ultraviolet curing coating formula for eliminating formaldehyde in air and preparation technology thereof

ActiveCN103305115AWork quicklyStrong adhesionPolyurea/polyurethane coatingsUltravioletHexanediol diacrylate

The invention relates to the technical field of ultraviolet curing coatings, and particularly relates to an ultraviolet curing coating formula for eliminating formaldehyde in air and a preparation technology thereof. The coating consists of the following components in percentage by weight: 20-40% of urethane acrylate, 10-30% of 1,6 hexanediol diacrylate, 1-10% of trimethylolpropane triacrylate, 1-5% of 2-phenoxy ethyl acrylate, 1-5% of dispersing agent, 2-6% of superfine silicon dioxide, 1-4% of superfine aluminum oxide powder, 1-12% of matte powder, 1-4% of wax powder, 4-6% of 2-hydroxyl-2-methyl-1-phenyl-1-acetone, 0.1-2% of surface aid and 1-15% of formaldehyde removal aid. The preparation technology of the coating comprises the steps of sequentially feeding the raw materials and stirring for uniformly mixing. Through the formula and the technology provided by the invention, the prepared coating is applicable to the fast operation of a factory production line, and also has the protection functions such as good adhesion, scratch resistance and the like.

Owner:韶关市和荣化工有限公司

Ultraviolet curable water-based paint used for wooden products

InactiveCN104877552AFast curingNo pollutionAntifouling/underwater paintsPaints with biocidesWater basedAcrylic resin

The invention belongs to the field of paint and in particular relates to ultraviolet curable water-based paint used for wooden products. The water-based paint comprises the following raw materials in parts by weight: 40-65 parts of water-based polyurethane acrylate, 10-15 parts of rosin-based hyperbranched polyester acrylic resin, 5-10 parts of 1,6-hexanediol diacrylate, 5-10 parts of acrylic resin, 5-10 parts of nano aluminium oxide dispersion, 2-4 parts of photoinitiators, 0.2-0.5 part of levelling agent, 10-20 parts of water-based organic assistants, 0.2-0.5 part of anti-settling agent, 0.5-1 part of defoaming agent and 10-15 parts of graphene. The water-based paint can meet the requirements of high performance and environmental protection, has high gloss and longer valid time, and has good compatibility with ultraviolet curable resin.

Owner:CHENGDU NASHUO TECH

UV (ultraviolet) curing ink and application thereof

The invention discloses a UV (ultraviolet) curing ink and application thereof. The UV curing ink comprises the following components in percentage by weight:30-40% of high-functionality polyurethane acrylate, 10-20% of dual-functionality polyurethane acrylic resin, 5-10% acidic acrylate prepolymer, 5-10% of thermoplastic acrylic resin, 10-15% of 1,6-hexanediol diacrylate and 2-4% of photosensitizer. When being printed on a glass workpiece, the UV photocuring ink is used for temporary protection in the glass surface working process. After the UV photocuring ink is subjected to UV photocuring, a tough ink layer, which has the advantages of favorable adhesion to glass, high surface hardness, favorable scratch resistance and favorable cutting fluid resistance, can be formed on the glass surface, and can effectively ensure the glass not to be scratched in the surface working process. After finishing the glass working, alkaline water can quickly remove the UV photocuring ink layer, so that the glass can not be influenced.

Owner:深圳市美丽华科技股份有限公司

Ultraviolet (UV) light-cured elastic-feeling paper gloss oil and construction method thereof

ActiveCN103590280AIncrease elasticityLow viscosityPaper coatingCoatingsPolymer scienceUltraviolet lights

The invention relates to the technical field of coatings and particularly relates to an elastic-feeling coating. Ultraviolet (UV) light-cured elastic-feeling paper gloss oil is composed of the following components in parts by weight: 18-22 parts of UV elastic resin, 22-28 parts of monomer, 8-12 parts of active amine, 3-7 parts of photoinitiator, 5-10 parts of elastic powder, 3-7 parts of gas phase silica matting powder, 0.5-2 parts of assistant and 22-26 parts of solvent, wherein the monomer is a mixture of isobornyl acrylate and 1,6-hexanediol diacrylate. The ultraviolet light-cured elastic-feeling paper gloss oil provided by the invention is suitable for high-speed roller coating, thereby improving the working efficiency, reducing the coating operation difficulty and avoiding personal injury.

Owner:HUIZHOU CHANGRUNFA PAINT

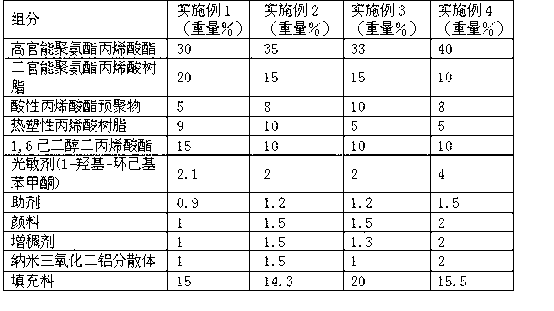

Low-temperature-resistant oil-resistant low-smoke halogen-free flame-retardant polyolefin cable material

InactiveCN103524868AGood oil resistanceEliminate cracksPlastic/resin/waxes insulatorsLinear low-density polyethylenePolyolefin

The invention provides a low-temperature-resistant oil-resistant low-smoke halogen-free flame-retardant polyolefin cable material. The low-temperature-resistant oil-resistant low-smoke halogen-free flame-retardant polyolefin cable material is prepared by using the following raw materials, by weight, 30-60 parts of metallocene linear low density polyethylene, 20-30 parts of POE, 5-10 parts of maleic anhydride grafted polyethylene, 10-20 parts of low temperature resistant silicone rubber, 2-3 parts of N,N'-m-phenylene bismaleimide, 50-60 parts of aluminum hydroxide, 10-15 parts of molybdenum trioxide, 4-6 parts of copper oxide, 5-10 parts of a modification filler, 0.3-0.5 parts of nanometer silicon carbide, 1-2 parts of ferrocene, 1.0-3.0 parts of PE wax, 1-2 parts of 1,6-hexanediol diacrylate, 0.5-2 parts of an antioxidant 1076, and a proper amount of a processing assistant. Compared with common low-smoke halogen-free polyolefin cable materials, the low-temperature-resistant oil-resistant low-smoke halogen-free flame-retardant polyolefin cable material has the advantages of improvement of the oil resistance, substantial improvement of the low temperature resistance of a product, and elimination of the cracking problem of the common low-smoke halogen-free polyolefin cable materials at a low temperature.

Owner:WUHU HANGTIAN SPECIAL CABLE FACTORY

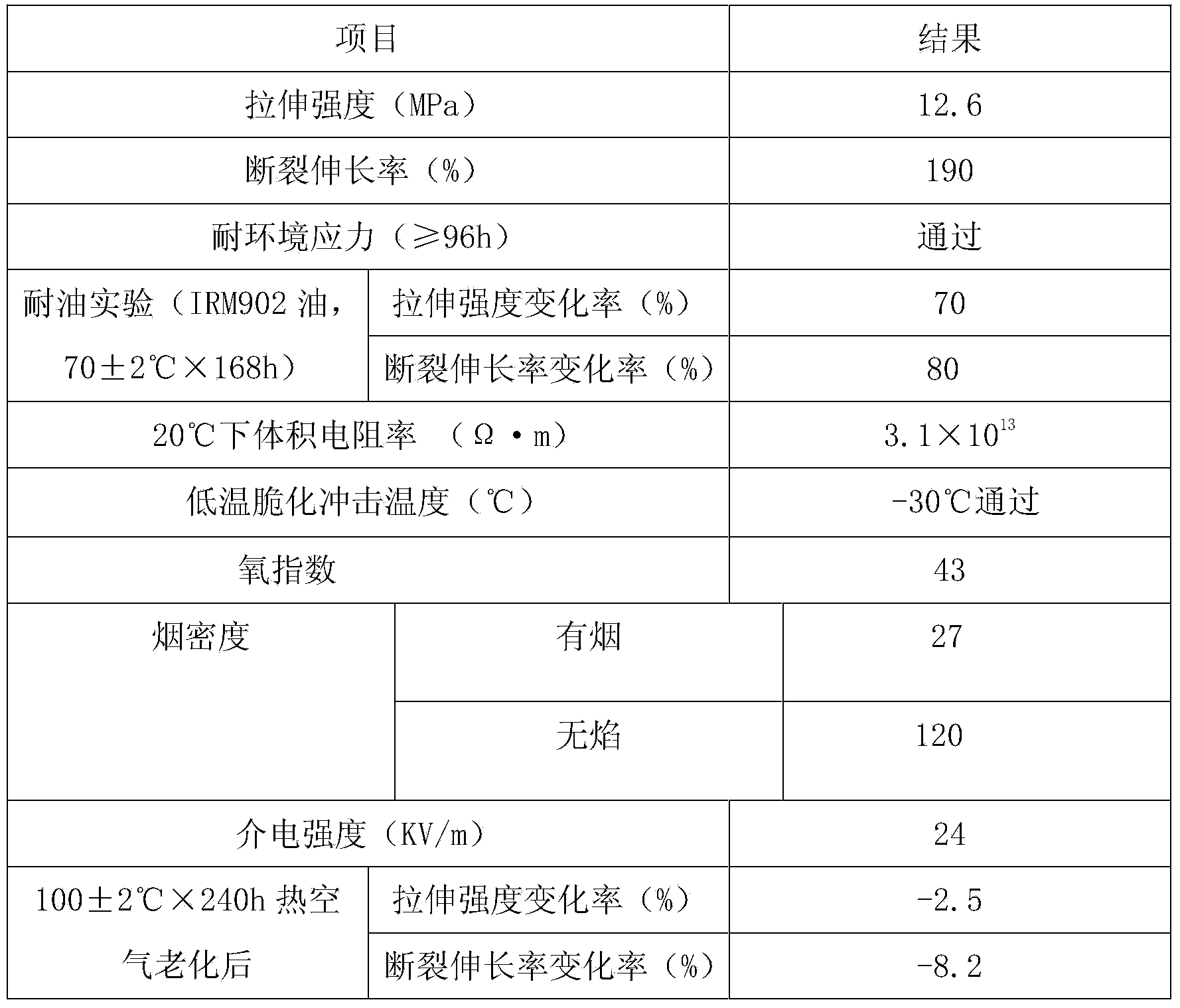

Radiation grafting long-chain branch polylactic acid and preparation method thereof

InactiveCN104448154AAvoid adverse effects such as radiation degradationSimple manufacturing methodOxygenHexanediol diacrylate

The invention discloses a radiation grafting long-chain branch polylactic acid which comprises a polylactic acid and 1,6-hexanediol diacrylate. The preparation method comprises the following steps: performing air blast drying on the polylactic acid, adding 1,6-hexanediol diacrylate in a molten PLA (Polylactic Acid) in a twin-screw extruder, extruding, air cooling, granulating, and performing the processing steps such as Co60 radiation irradiation under the oxygen limiting condition to obtain the long-chain branch polylactic acid. The production process is simple, the time for extruding and granulating is relatively short, the irradiation dose can be controlled, and the prepared long-chain branch polylactic acid is wide in molecular weight distribution, has relatively high storage moduli and relatively low loss angles, improves the strength of a melt made of a polylactic acid material, and is an environmental-friendly high-polymer material applied widely.

Owner:BEIJING RADIATION APPL RES CENT

Inkjet recording method and inkjet recording apparatus

ActiveUS20080079796A1Achieve effectDuplicating/marking methodsCoatingsCritical micelle concentrationActinic Rays

The present invention provides: an inkjet recording method comprising: applying an undercoating liquid on a recording medium, the undercoating liquid containing at least one surfactant in an amount of from 0.001% to the critical micelle concentration, the surfactant achieving a surface tension of 25 mN / m or smaller when dissolved in 1,6-hexanediol diacrylate at a critical micelle concentration; semi-curing the applied undercoating liquid; and recording an image by ejecting an ink onto the semi-cured undercoating liquid, the ink being curable by irradiation with an actinic ray; and an inkjet recording apparatus.

Owner:FUJIFILM CORP

White ultraviolet curing finishing coat

ActiveCN103709906AFast curingIncrease productivityPolyurea/polyurethane coatingsEpoxy resin coatingsTripropylene glycol(Hydroxyethyl)methacrylate

The invention discloses a white ultraviolet curing finishing coat which consists of the following components by weight percent: 50-70 percent of resin, 23-40 percent of an acrylate compound monomer, 4.5-9.5 percent of a photo-initiator and 0.3-3.0 percent of an aid, wherein the resin is a mixture consisting of epoxy acrylate and urethane acrylate; the acrylate compound monomer is one or a mixture of two of hydroxyethyl methylacrylate, tripropylene glycol diacrylate, 1,6-hexanediol diacrylate, dipropylene glycol diacrylate and trimethylolpropane triacrylate. The white ultraviolet curing finishing coat can be sprayed instead of the conventional solvent based coating, and has the advantages of high curing speed, high production efficiency, lower plate production cost, energy saving, carbon reduction and the like.

Owner:东周化学工业(昆山)有限公司

Biodegradable oil absorbing composite material and preparation method therefor

InactiveCN105001515AImprove adsorption capacityImprove adsorption speedSodium bicarbonatePotassium persulfate

The present invention discloses a biodegradable oil absorbing composite material and a preparation method therefor. The biodegradable oil absorbing composite material is characterized by being prepared by using the following raw materials in parts by weight: 3-5 parts of sodium bentonite, 0.3-0.5 parts of cetyl trimethyl ammonium bromide (CTAB), 4-6 parts of methacrylate, 3-5 parts of styrene, 0.1-0.5 parts of 1,6-hexanediol diacrylate, 3-4 parts of ethyl acetate, 1-3 parts of polyvinyl alcohol, 0.8-1.2 parts of organophosphorus ester, 0.01-0.05 parts of potassium persulfate, 0.5-1 parts of sodium bicarbonate, 2-5 parts of polyethylene wax, 2-3 parts of stearic acid, 1-2 parts of calcium sulfate, 80-95 parts of polypropylene, 0.1-0.3 parts of antioxidant 1010, 10-15 pats of azodicarbonamide, 0.5-1 parts of silane coupling agent KH550, 3-4 parts of chitosan, 2-4 parts of bamboo fiber, 0.5-1 parts of sodium alginate, and an appropriate amount of water. The biodegradable oil absorbing composite material provided by the present invention is environmentally friendly, simple in preparation method, wide in material sources, and worth popularizing.

Owner:ANHUI CHENGFANG NEW MATERIAL TECH

Photocuring adhesive and its preparation method

ActiveCN102485822AGood temperature characteristicsReduced Optical Power RequirementsNon-macromolecular adhesive additivesPolyureas/polyurethane adhesivesAdhesiveHexanediol diacrylate

The invention discloses a photocuring adhesive, which comprises the following ingredients by weight percentage: 15-60% of polyurethane acrylate, 10-40% of epoxy acrylate, 20-65% of hexanediol diacrylate, 0.1-0.5% of 2(2,4,6-trimethylbenzoyl)-phenylphosphine oxide and 0.5-5% of SiO2 or CaCO2 particles. The invention also discloses a method for preparing the photocuring adhesive. The photocuring adhesive of the present invention has good temperature characteristic, is in favor of enhancing the intensity of mutual bonding of each part, has less requirement on optical power of solidification equipment, and is suitable for narrowband UV light source, the light source life is long. So that the bonding efficiency of the photocuring adhesive with unit volume is higher, the irradiation apparatus cost is reduced and the product rate of the device production can be increased.

Owner:WUHAN YILUT TECH CO LTD

LED-UV printing ink and preparation method and using method thereof

The invention discloses LED-UV printing ink. The printing ink is prepared from hexa-functional aliphatic polyurethane acrylate, difunctional epoxy resin, polyester resin, an active monomer, an adherence promoter, a photoinitiator and other auxiliaries, wherein the active monomer is a mixture prepared from 1,6-hexanediol diacrylate, propoxylated trimethylolpropane triacrylate and neopentyl glycol diethoxyl diacrylate according to the mass ratio of (2-4.5):1:(2-3.5). The printing ink capable of utilizing an LED light source as a curing light source can form a cured film layer after being cured for 10-20 s under the LED light source, the technological process is the same as that of common UV printing ink, no new equipment needs to be additionally arranged, energy consumption of the curing process of the printing ink is less than 10% of that of the traditional curing process completed under an ultraviolet lamp, carbon dioxide emitted in the technological process is greatly reduced, and both the economical efficiency and the environmental protection property are achieved.

Owner:FOSHAN CITY GREEND CHEM

UV gloss oil used for laser embossing transfer equipment

ActiveCN105315731ALow viscosityHigh viscosityPolyether coatingsPrinting after-treatmentHyperbranched polyesterPliability

The invention discloses UV gloss oil used for laser embossing transfer equipment. The UV gloss oil is characterized by comprising the following components in parts by weight: 2-10 parts of a light initiator, 1-5 parts of 2-ethylhexyl acrylate, 1-5 parts of a base material lubricant, 45-75 parts of a pre-polymer and 18-35 parts of a monomer, wherein the pre-polymer is amine modified polyether acrylate or ester-epoxy acrylate or superbranched polyester acrylate or a combination of the amine modified polyether acrylate and the ester-epoxy acrylate in same parts by weight; the monomer is 1,6-hexanediol diacrylate or ethoxylated trimethylolpropane triacrylate. The UV gloss oil disclosed by the invention is fast in curing speed, good in flexibility and high in glossiness and can satisfy an embossing transfer laser process, so that the laser embossing transfer effect is good.

Owner:杜广清

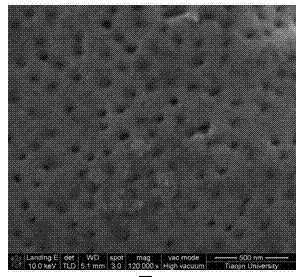

Solvent-free preparation method of aperture controllable porous film

InactiveCN102886211ALow costEasy to manufactureSemi-permeable membranesCross-link(Hydroxyethyl)methacrylate

The invention discloses a solvent-free preparation method of an aperture controllable porous film. The process of the method comprises the following steps of: using 1-hydroxy-cyclohexyl phenyl ketone as an initiator, using hexanediol diacrylate as a cross-linking agent, and by ultraviolet light, initiating polymerization cross-linking curing film formation of a film forming monomer hydroxyethyl methacrylate and pore forming silicon dioxide nano particles between two glass sheets; and carrying out pore forming by removing a pore forming agent, i.e. the silicon dioxide particles. The method does not require an organic solvent in the preparation process, is green and has no pollution; and the solvent cost can be saved and a solvent recovery process is not required. The particle size of the prepared silicon dioxide nano particles can be regulated and controlled by the sol-gel process conditions; the aperture of the prepared porous film is consistent with the particle size of the pore forming agent, i.e. silicon dioxide nano particles; and the aperture of the film can be regulated and controlled by regulating the particle size of the silicon dioxide nano particles.

Owner:TIANJIN UNIV

Antibacterial and anti-fingerprint paint for mobile phones

PendingCN110791194AImprove cure rateImprove adhesionAntifouling/underwater paintsPaints with biocidesPolymer scienceMeth-

The invention discloses an antibacterial and anti-fingerprint paint for mobile phones. The paint comprise the following raw materials by weight: 20-38 parts of a urethane acrylate oligomer, 10-30 parts of epoxy acrylic resin, 2.5-5.5 parts of an antibacterial agent, 15-28 parts of trimethylolpropane triacrylate, 5-9 parts of N-vinyl pyrrolidone, 13-30 parts of 1, 6-hexanediol diacrylate, 3-4.8 parts of a photoinitiator, 8-14 parts of nano-filler, and 0.5-1.3 pars of an assistant. The antibacterial and anti-fingerprint paint for mobile phones provided by the invention has good antibacterial properties and scratch resistance, and excellent antifouling and anti-fingerprint properties.

Owner:SHAOXING XUYUAN NEW MATERIAL TECH

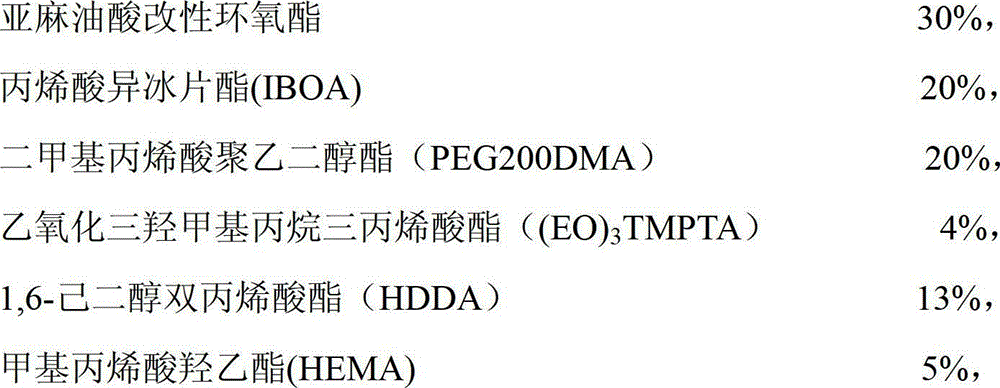

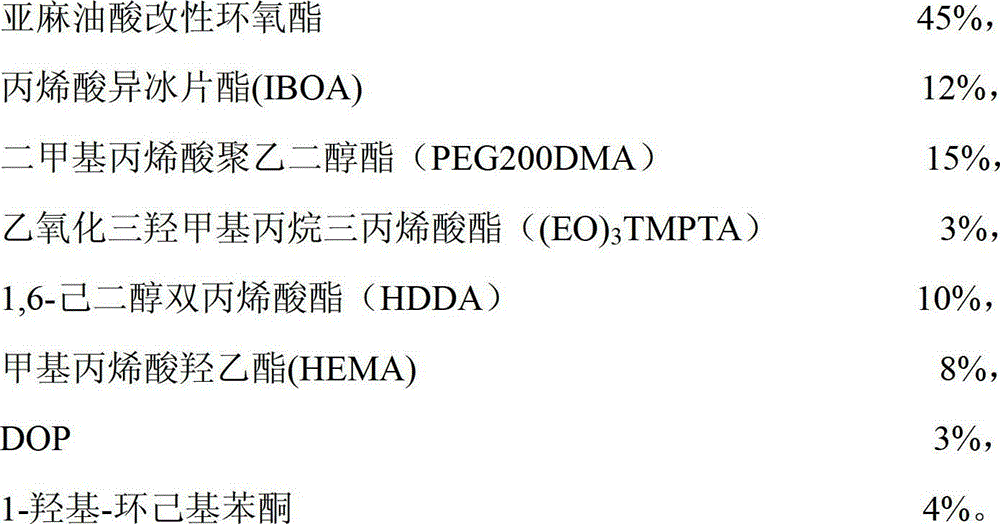

Hydrophilic aluminum foil coating and method for preparing and curing same

InactiveCN102876200AFast curingNon-volatileEpoxy resin coatings(Hydroxyethyl)methacrylateUltraviolet lights

The invention discloses a hydrophilic aluminum foil coating and methods for preparing and curing the hydrophilic aluminum foil coating. The coating comprises the following components by weight: 30-45% of linolenic-acid modified epoxy ester, 12-20% of isobornyl acrylate, 15-20% of dimethacrylate polyethylene glycol ester, 3-8% of ethoxylated trimethylolpropane triacrylate, 10-15% of 1,6-hexanediol diacrylate, 5-10% of methylhydroxyethyl acrylate, 2-5% of a toughening agent and 4-8% of photoinitiator. The method for preparing the hydrophilic aluminum foil coating comprises the following steps: mixing 33-56 parts by weight of bisphenol A epoxy resin, 12-18 parts by weight of diethanolamine and 32-49 parts by weight of linoleic acid to obtain the linolenic-acid modified epoxy ester, adding the isobornyl acrylate as well as the thinning agent, the toughening agent and the photoinitiator with different activities in sequence, and dispersing and mixing at high speed to obtain the hydrophilic aluminum foil coating. The hydrophilic aluminum foil coating can be applied to the surface of the aluminum foil and irradiated by the ultraviolet light, and the coating layer which is cured into the film has strong hydrophilicity, moderate hardness and good adhesion.

Owner:JIANGSU UNIV OF SCI & TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com