White ultraviolet curing finishing coat

An ultraviolet light, white technology, applied in coatings, epoxy resin coatings, polyurea/polyurethane coatings, etc., can solve problems such as unsatisfactory drying speed and curing effect, and achieve environmental protection, reduce production costs, and improve enterprises. The effect of productivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

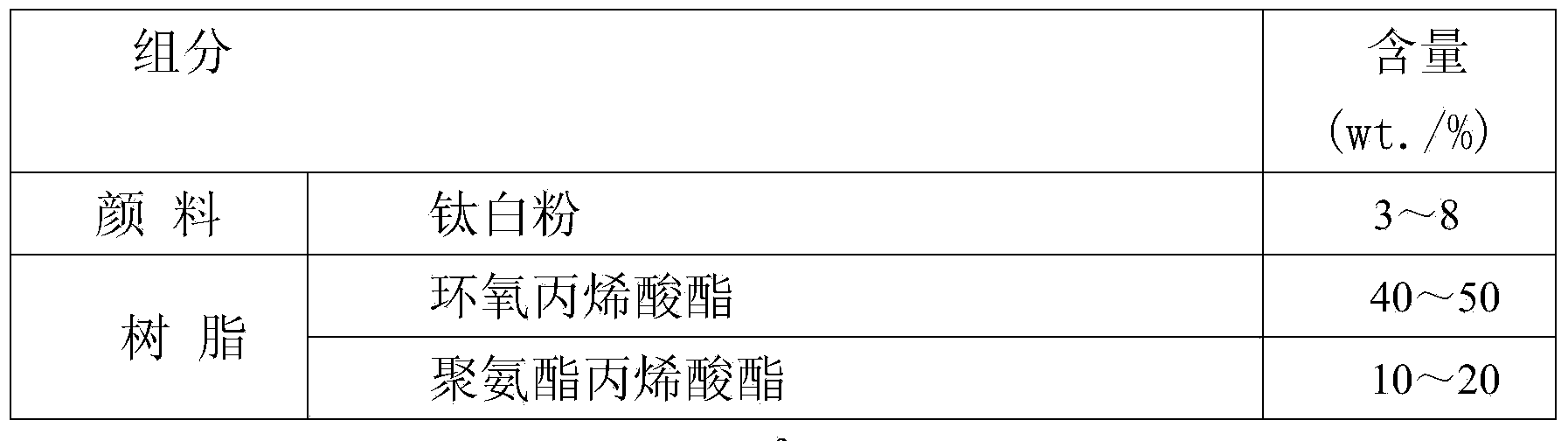

[0020] Table 1 shows the composition and weight percentage of the UV-curable white topcoat according to this embodiment.

[0021] Table 1

[0022]

[0023]

[0024] The preparation method of the ultraviolet-curable white finish paint of the present embodiment comprises the following steps: first, the pigment, a part of the monomer and the resin are ground into a color paste, and then the photoinitiator and a part of the monomer are stirred and dissolved, and then the resin, the remaining The monomer, the color paste, and the auxiliary agent are finally stirred for more than 30 minutes to obtain the ultraviolet-curable white topcoat.

Embodiment 2

[0026] Table 2 shows the composition and weight percentage of the UV-curable white topcoat according to this embodiment.

[0027] Table 2

[0028]

[0029]

[0030] The preparation method of the ultraviolet-curable white finish paint of the present embodiment comprises the following steps: first, the pigment, a part of the monomer and the resin are ground into a color paste, and then the photoinitiator and a part of the monomer are stirred and dissolved, and then the resin, the remaining The monomer, the color paste, and the auxiliary agent are finally stirred for more than 30 minutes to obtain the ultraviolet-curable white topcoat.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com