Method for producing laminate

A manufacturing method and laminated body technology, applied in the direction of printed circuit manufacturing, chemical instruments and methods, layered products, etc., can solve problems such as insufficient increase in roller surface temperature, difficult stable operation, and increased temperature difference

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

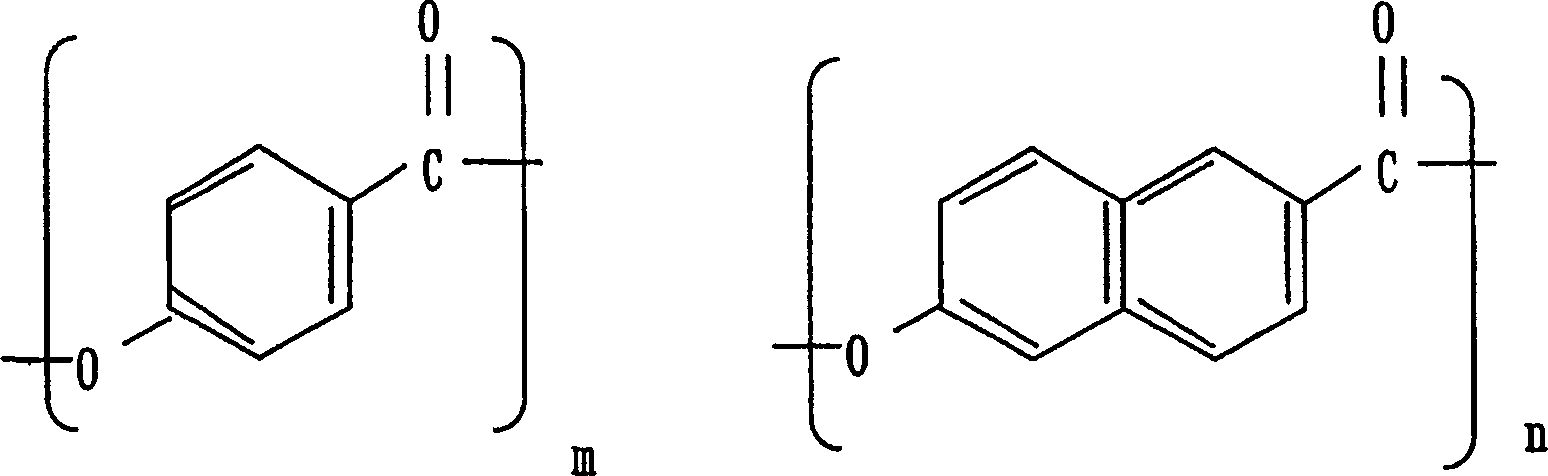

Method used

Image

Examples

Embodiment 1~3

[0063] Copper foils were superimposed on both surfaces of the liquid crystal polymer film, and were simultaneously and continuously supplied between a pair of pressure rollers at a speed of 1 m / min during superimposition. As a pair of pressure rollers, two resin-coated metal rollers uniformly coated with fluororubber with a thickness of 1 mm were used, and the roller surfaces were heated to a predetermined temperature by a heating mechanism inside the metal rollers. In addition, both the liquid crystal polymer film and the copper foil are formed into rolls, and as raw materials, a laminate is continuously produced by a roll-to-roll method in which pressure is applied by thermocompression bonding in an intermediate process.

[0064] Table 1 shows the surface temperature of the pressure roller coating resin and the evaluation results of the obtained laminate.

Embodiment 4~5

[0066] The procedure was carried out in the same manner as in Example 1 except that a pair of pressure rollers coated with a silicone rubber having a thickness of 3 mm were used as the resin-coated metal roller.

Embodiment 6

[0068] It carried out similarly to Example 1 except having used the resin-coated metal roller whose coating resin layer was a pair of pressure rolls coated with polyimide in thickness 25 micrometers.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com