Metal gasket material sheet

A metal backing and material board technology, applied in the direction of metal layered products, thin material treatment, surface pretreatment bonding methods, etc., can solve the problems of toxicity, negative impact on human body, etc., and achieve the effect of excellent adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

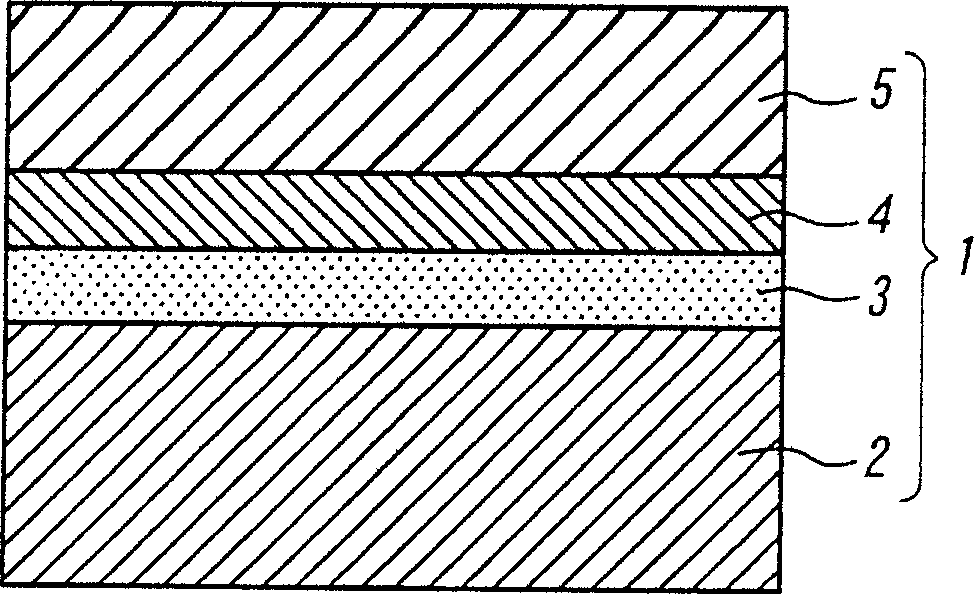

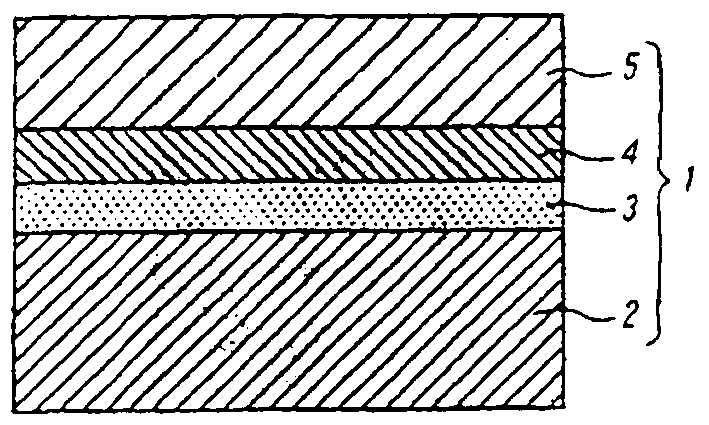

[0022] Below, three examples of silane-based chemical conversion coatings 3 made of different silane coupling agents, seven comparative examples using the aforementioned different conditions, and a silane-based chemical conversion coating with phosphorous chromate coating instead A reference example of layer 3 will be described. The method adopted is the cooling after the real engine temperature cycle experiment (a kind of cooling experiment), in which the metal gasket made of the corresponding material is put into the sealing area between the cylinder head and the intake pipe, and then repeated for a predetermined number of times The earth expands with heat and contracts with cold. In this way, the adhesion of each rubber layer and the sealing performance of each metal gasket after the temperature drop test can be separately obtained and compared.

[0023] In particular, in the metal backing material plate 1 of Example 1, a stainless steel plate (SUS301H) is used as the meta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com