Photosensitive resin pool, photocuring 3D (three-dimensional) printer using photosensitive resin pool and printing method

A 3D printer and photosensitive resin technology, applied in the field of 3D printing, can solve problems such as the temperature rise of the beam irradiated part, affecting the quality of solidified solid molding, poor high temperature resistance of silica gel, etc., to achieve improved printing quality, simple structure, and easy separation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

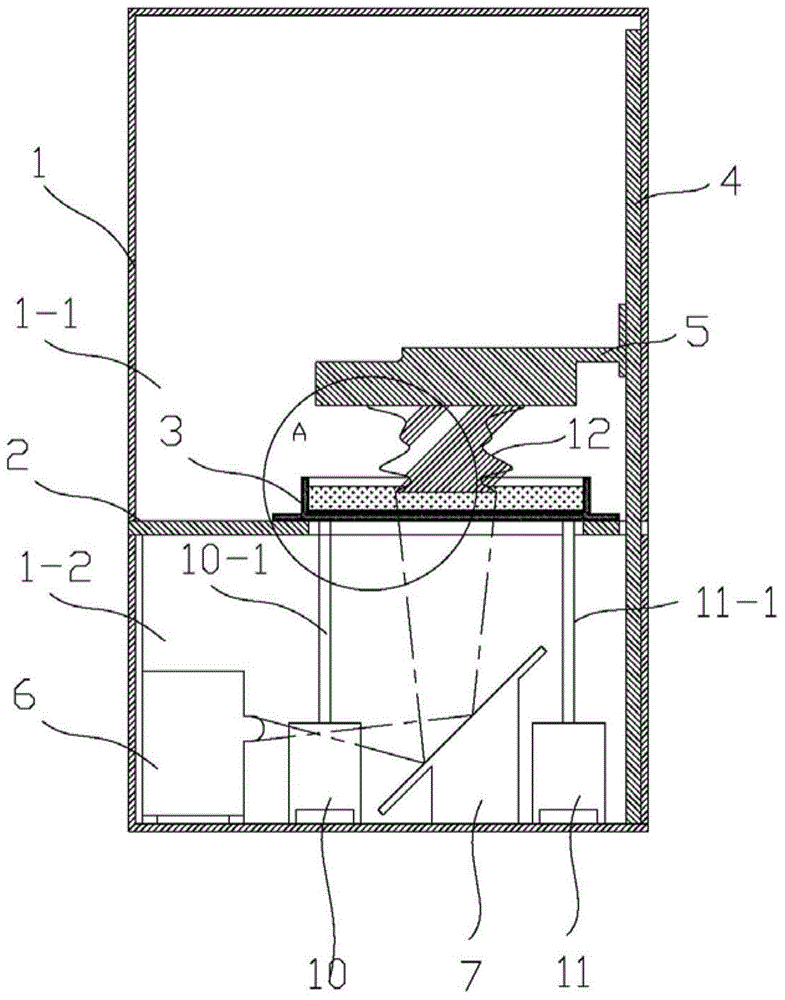

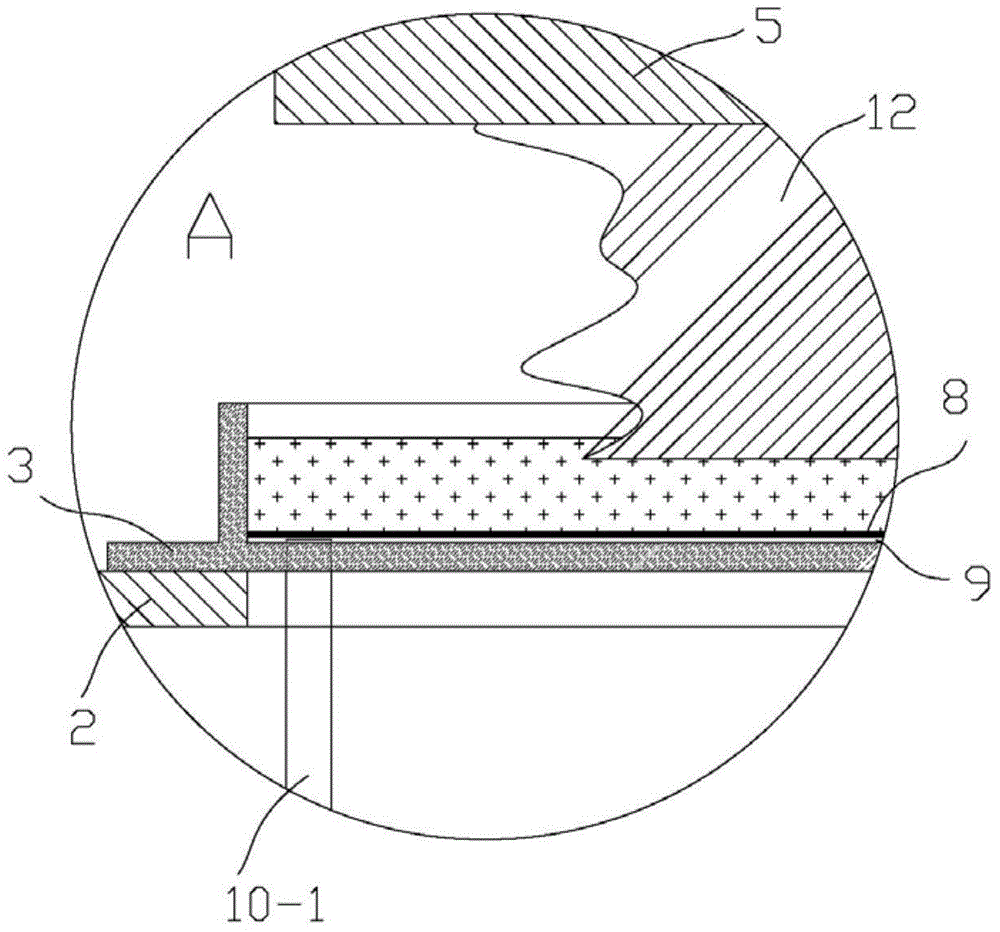

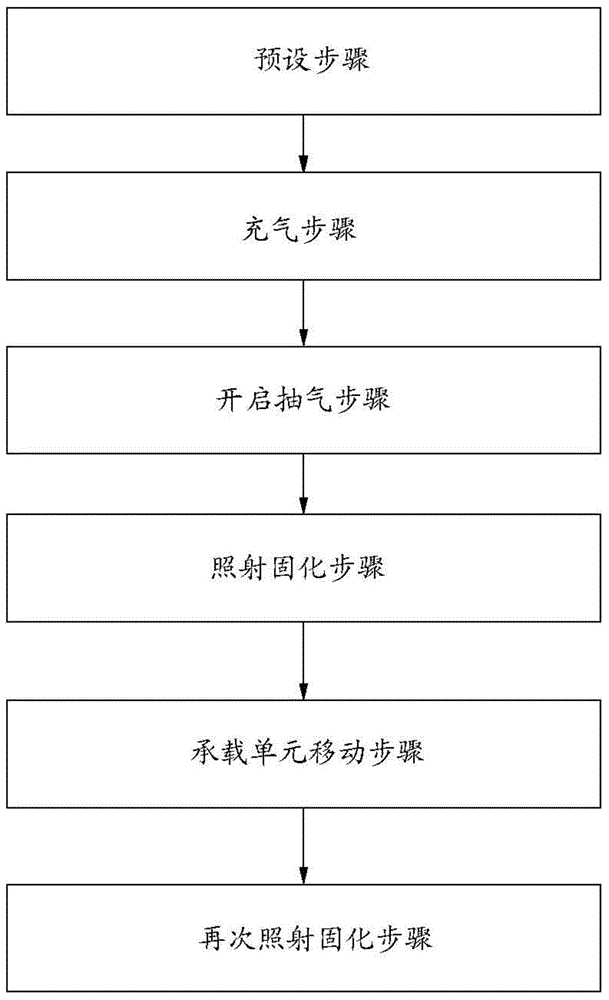

[0035] Reference figure 1 with figure 2 The light-curing 3D printer provided in this embodiment has a frame 1 and a middle layer board 2 which is arranged inside the frame 1 and divides the internal space into an upper space 1-1 and a lower space 1-2. A photosensitive resin pool 3 for containing liquid photosensitive resin is provided on the middle layer board 2. A guide rail column 4 is provided along the right side of the frame 1. The guide rail column 4 extends from the lower space 1-2 through the middle plate 2 to the upper space 1-1. The bearing platform 5 is associated with the guide rail column 4 and can move vertically in the upper space 1-1 relative to the photosensitive resin pool 3. The bearing platform 5 and the guide rail column 4 can be matched with a screw and a screw nut seat. Whenever the guide rail column 4 rotates under the driving of a motor, the bearing platform 5 can produce vertical movement. The aforementioned motion coordination can be controlled by a...

Embodiment 2

[0060] Reference Figure 4 with Figure 5 The same parts of Example 2 and Example 1 will not be repeated. The difference is that the bottom inner surface of the liquid photosensitive resin pool 3 is covered with an LCD liquid crystal display unit 13, and the polymer semi-transparent 8 film is covered on the LCD Above the liquid crystal display unit 13. The aforementioned cavity 9 is formed between the polymer semi-permeable membrane 8 and the LCD liquid crystal display unit 13. Similarly, the air pump 10 and the air pump 11 communicate with the cavity 9 through the air inflation pipe 10-1 and the air pump 11-1, respectively. The opening, closing and pattern switching of the LCD liquid crystal display unit are controlled by the control unit.

[0061] The LCD liquid crystal display unit 13 can display the pattern of any cross section of the object 12 to be printed, that is, the shape of the printed thin layer according to the instruction of the control unit. This pattern is compo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com