Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

622 results about "Glass transition point" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Definition of Glass Transition Temperature: The glass transition temperature is the temperature at which an amorphous solid becomes soft upon heating or brittle upon cooling. The glass transition temperature is lower than the melting point of its crystalline form, if it has one.

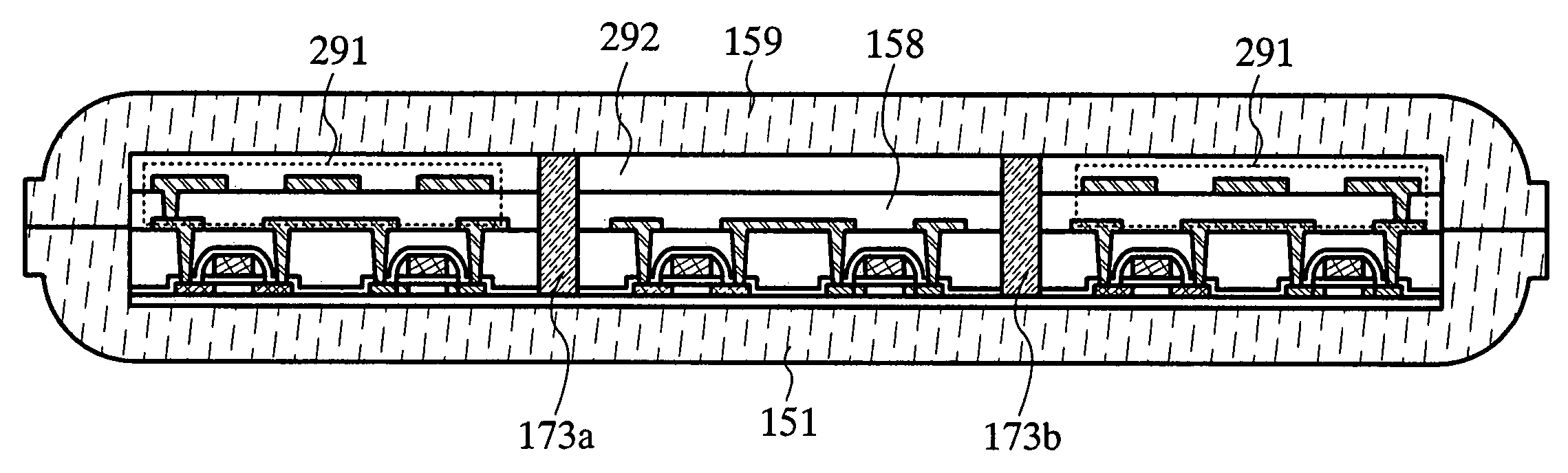

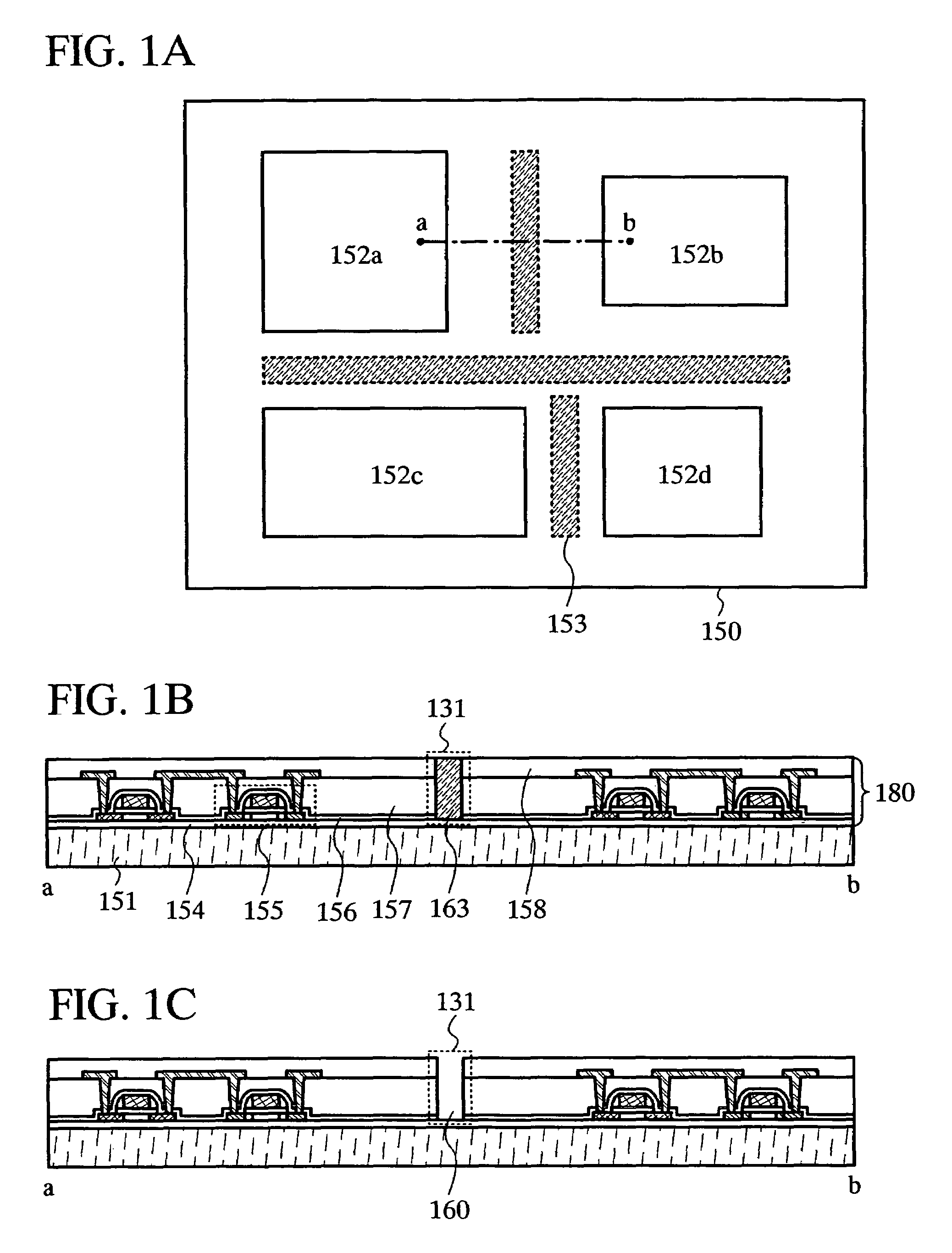

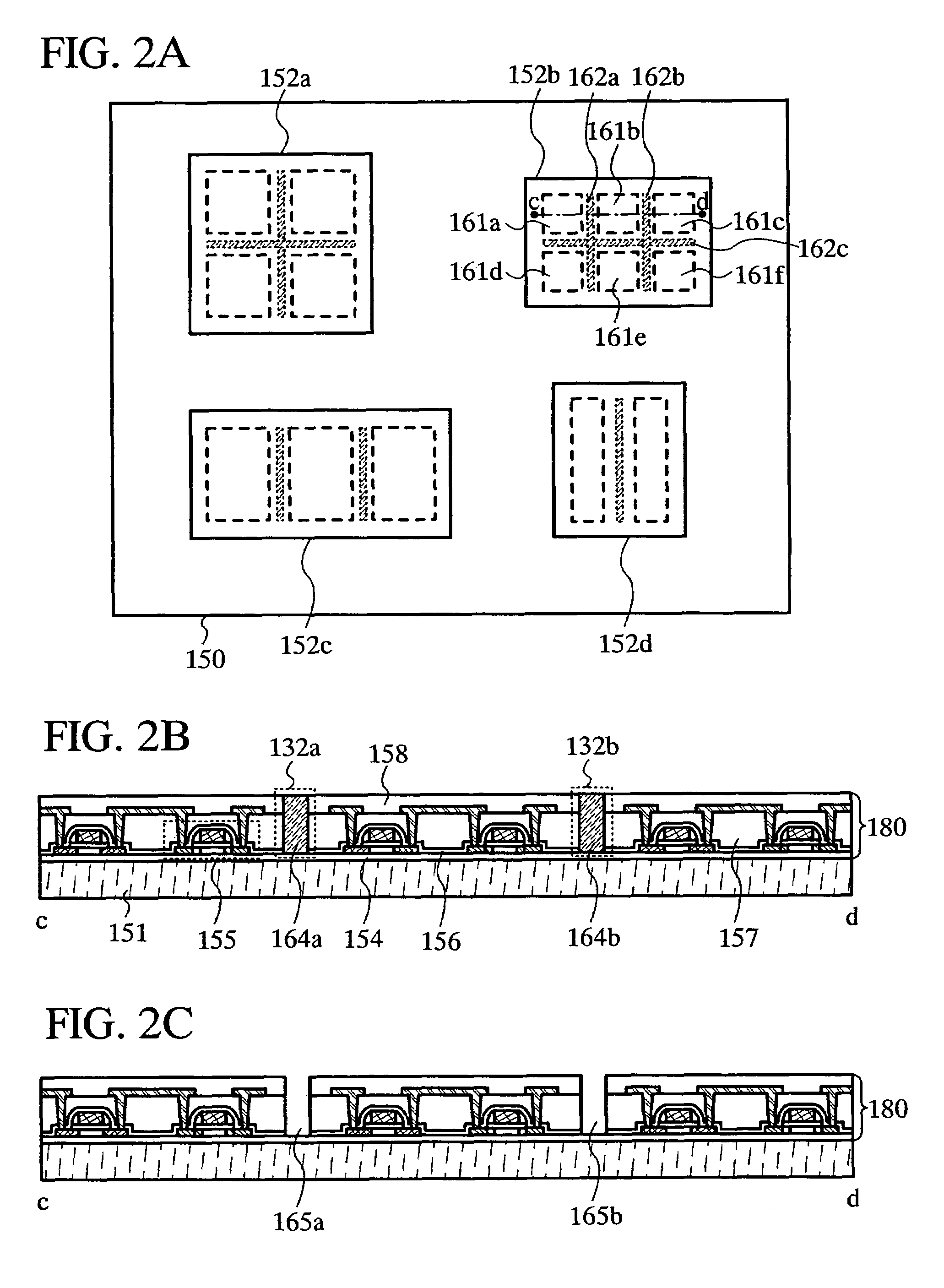

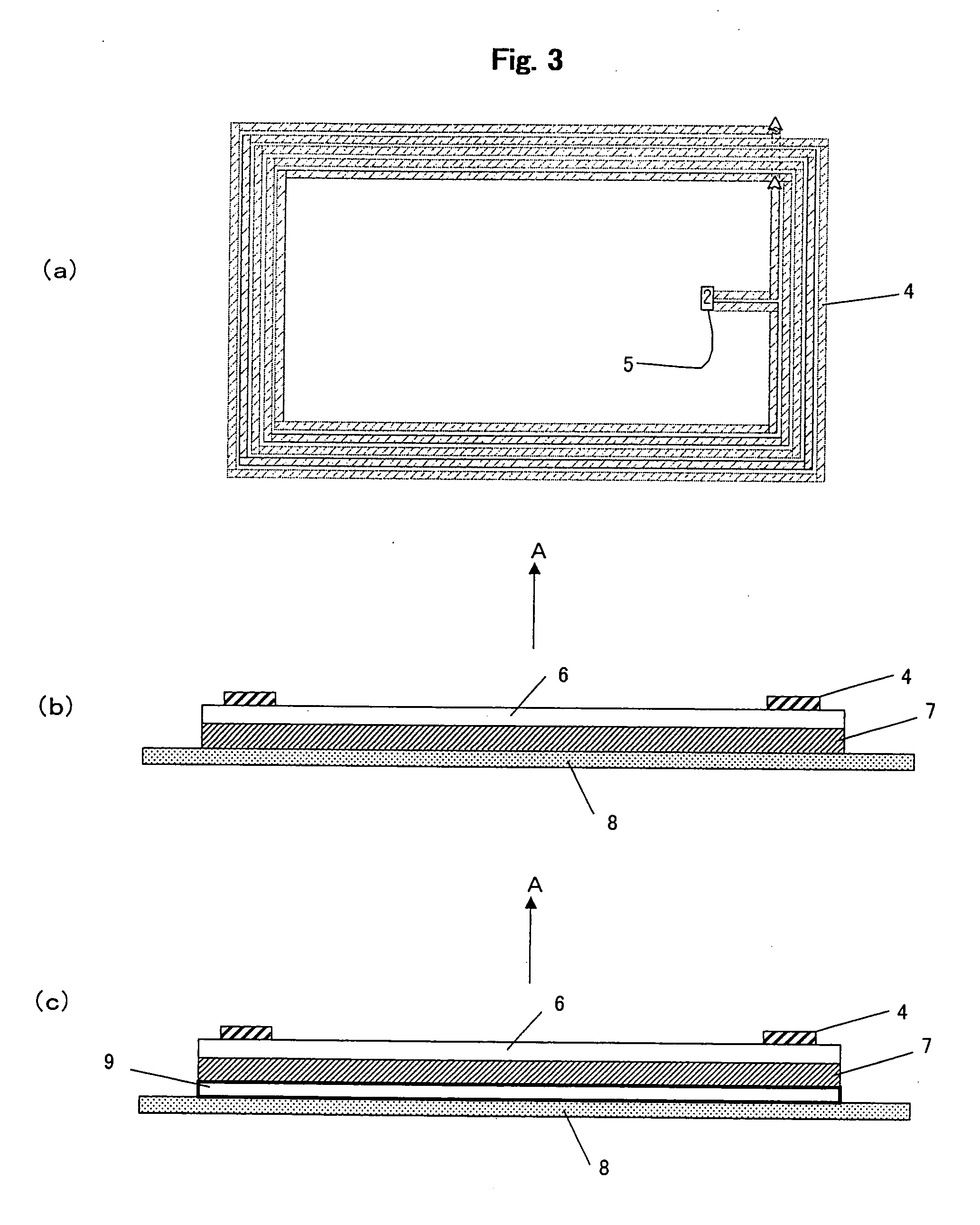

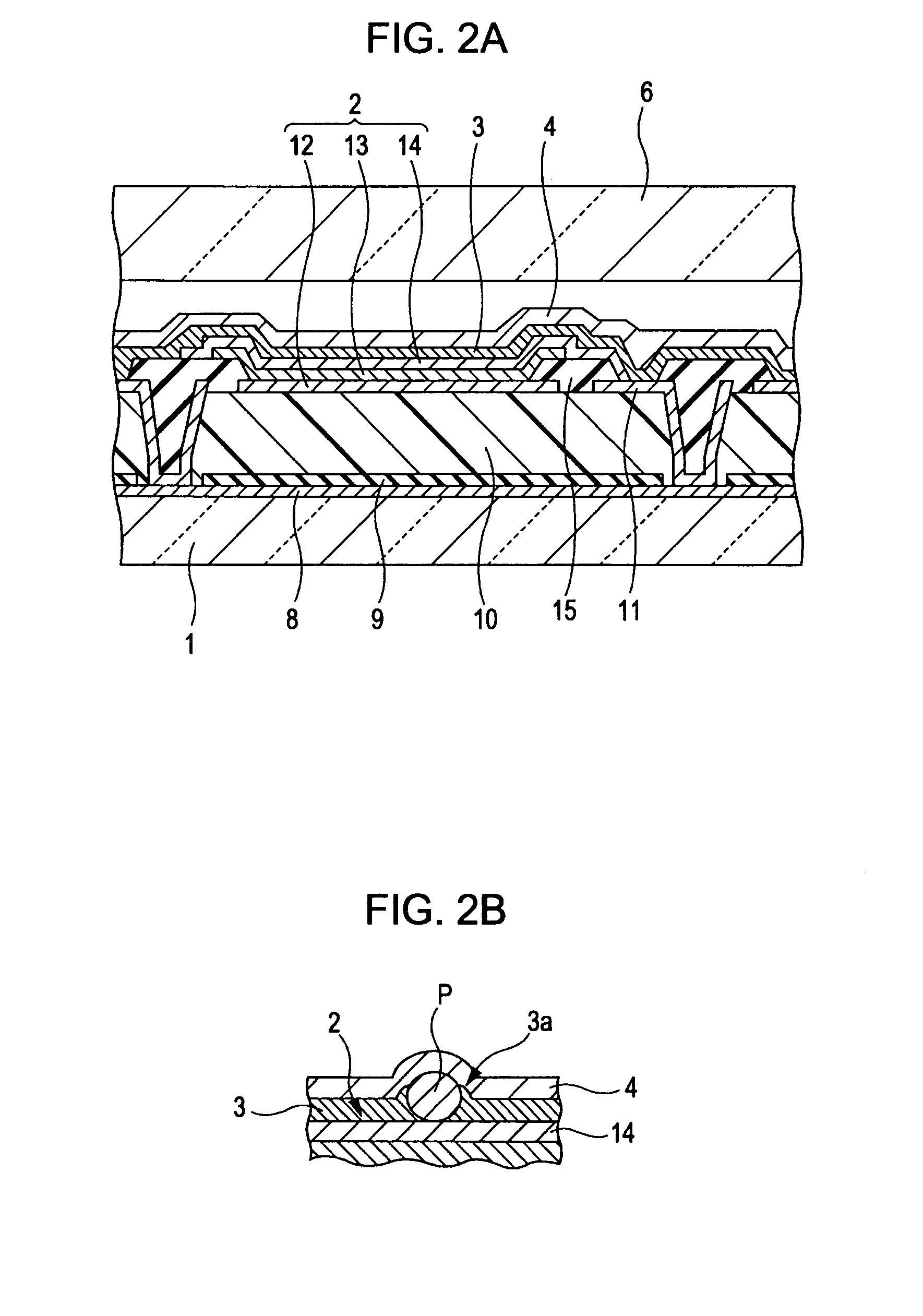

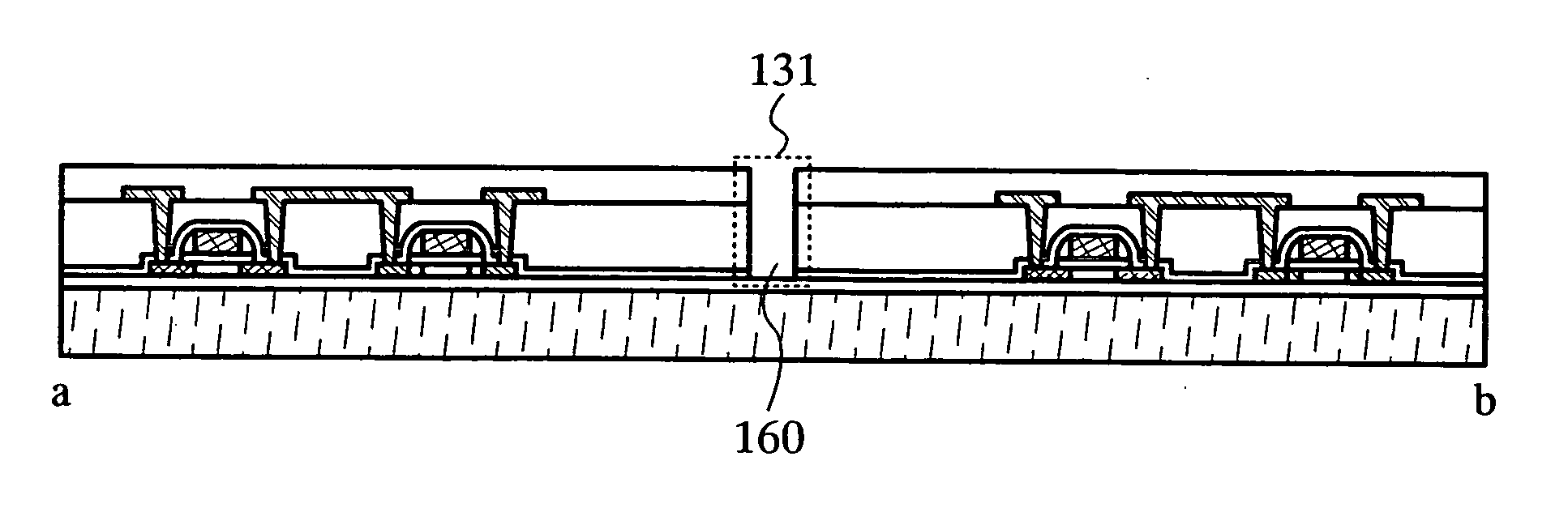

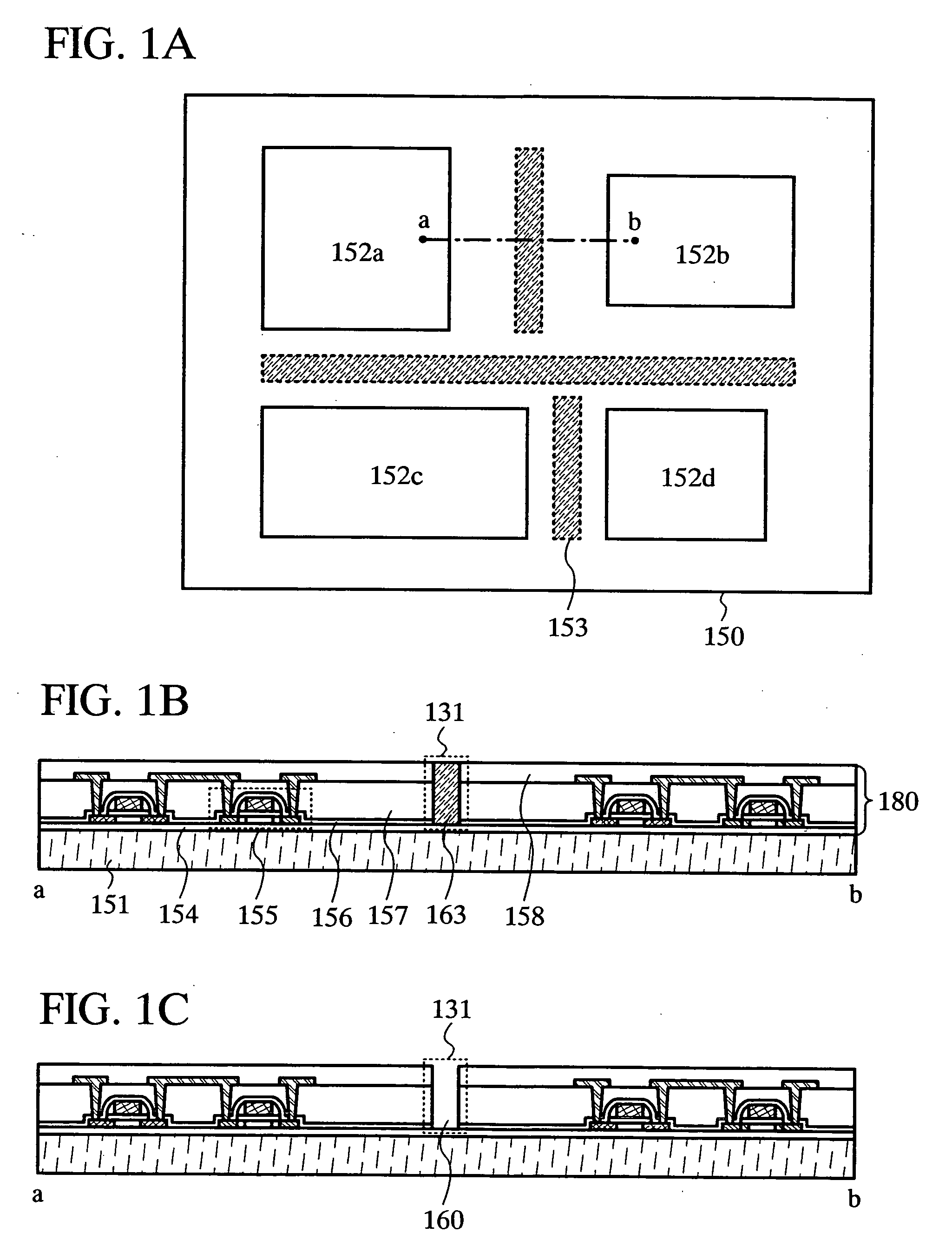

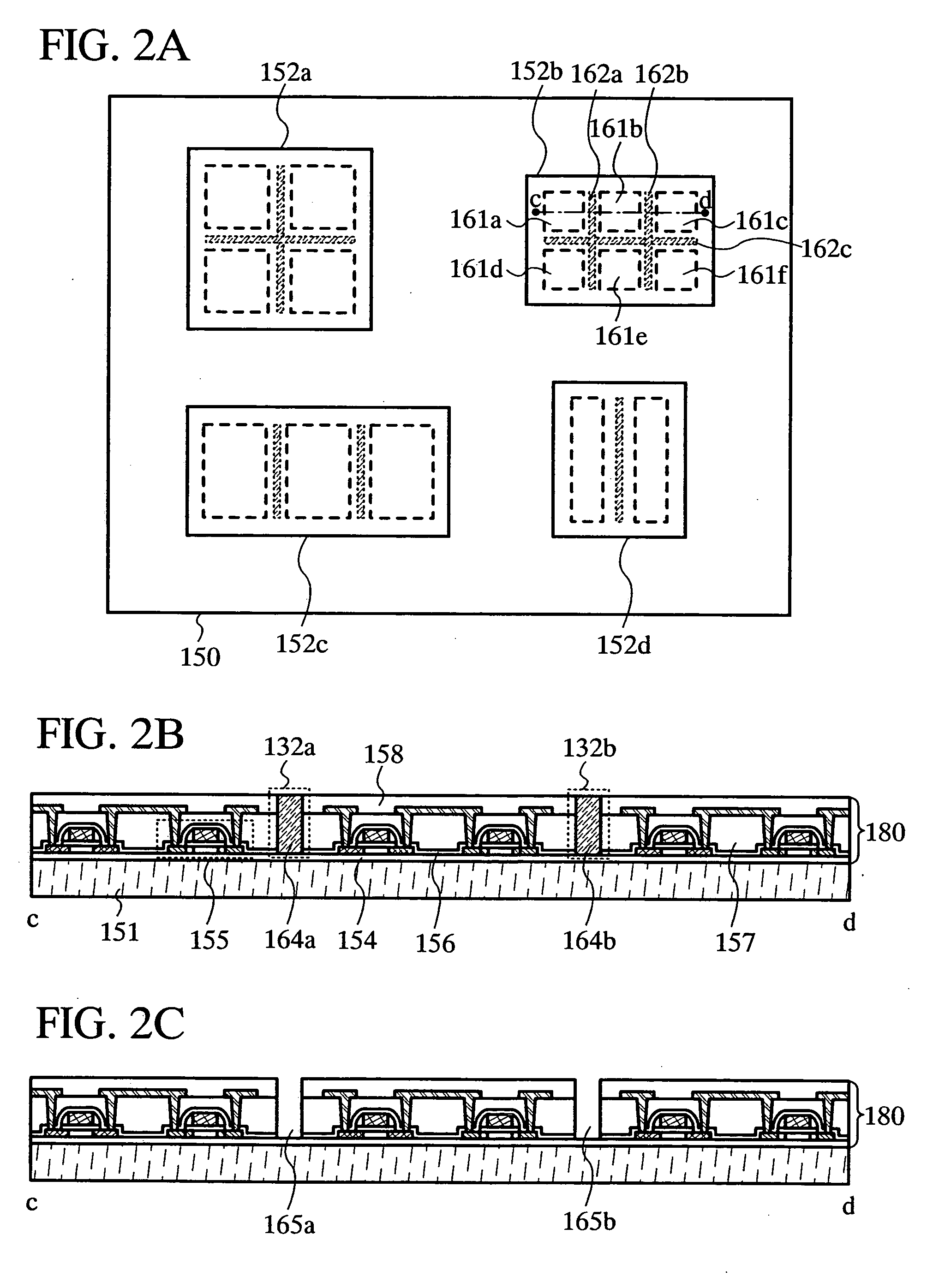

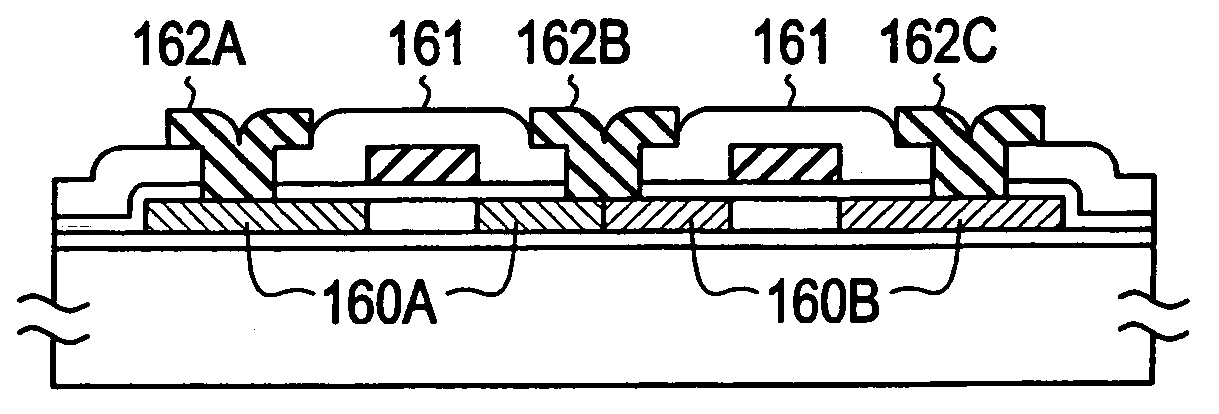

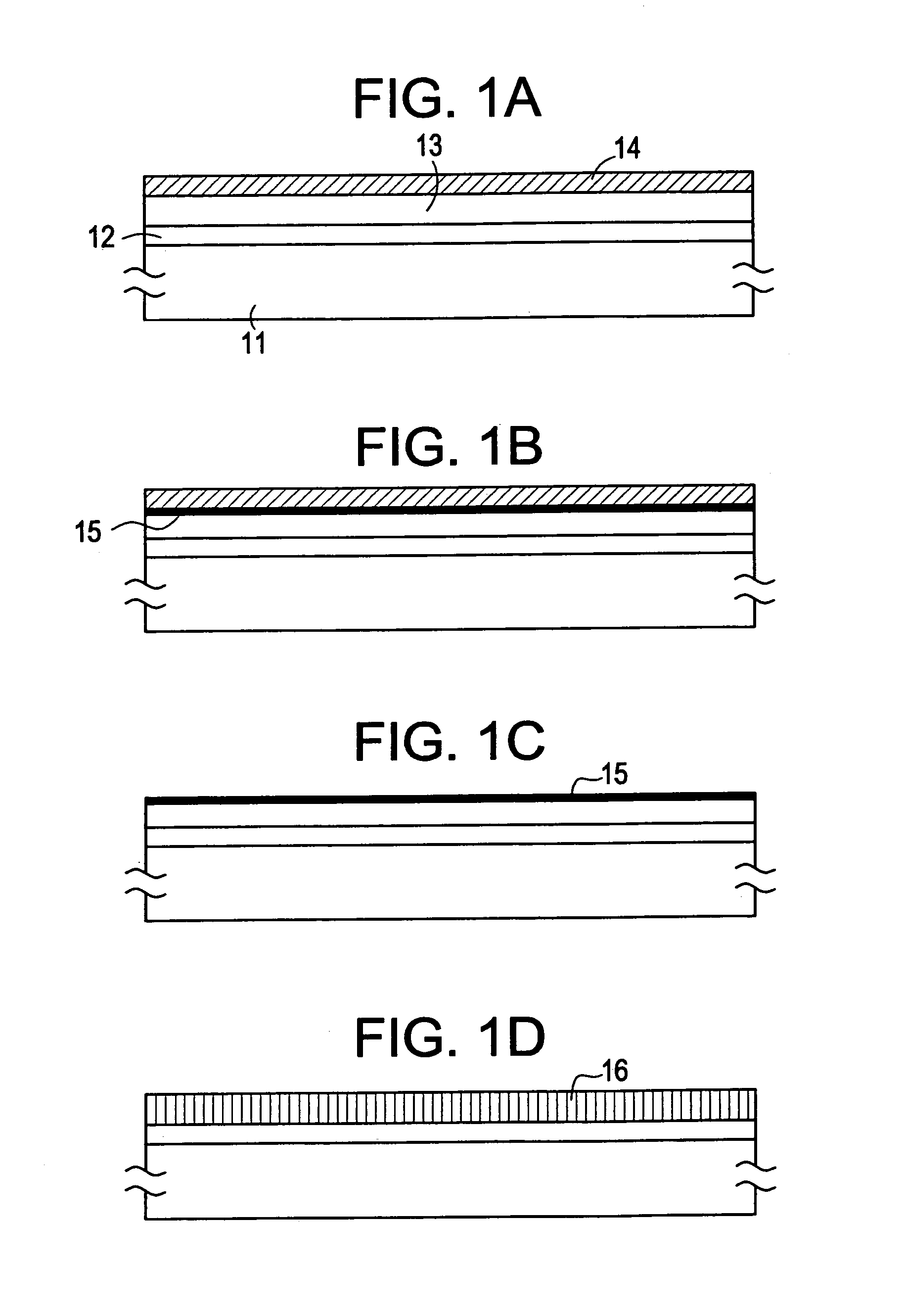

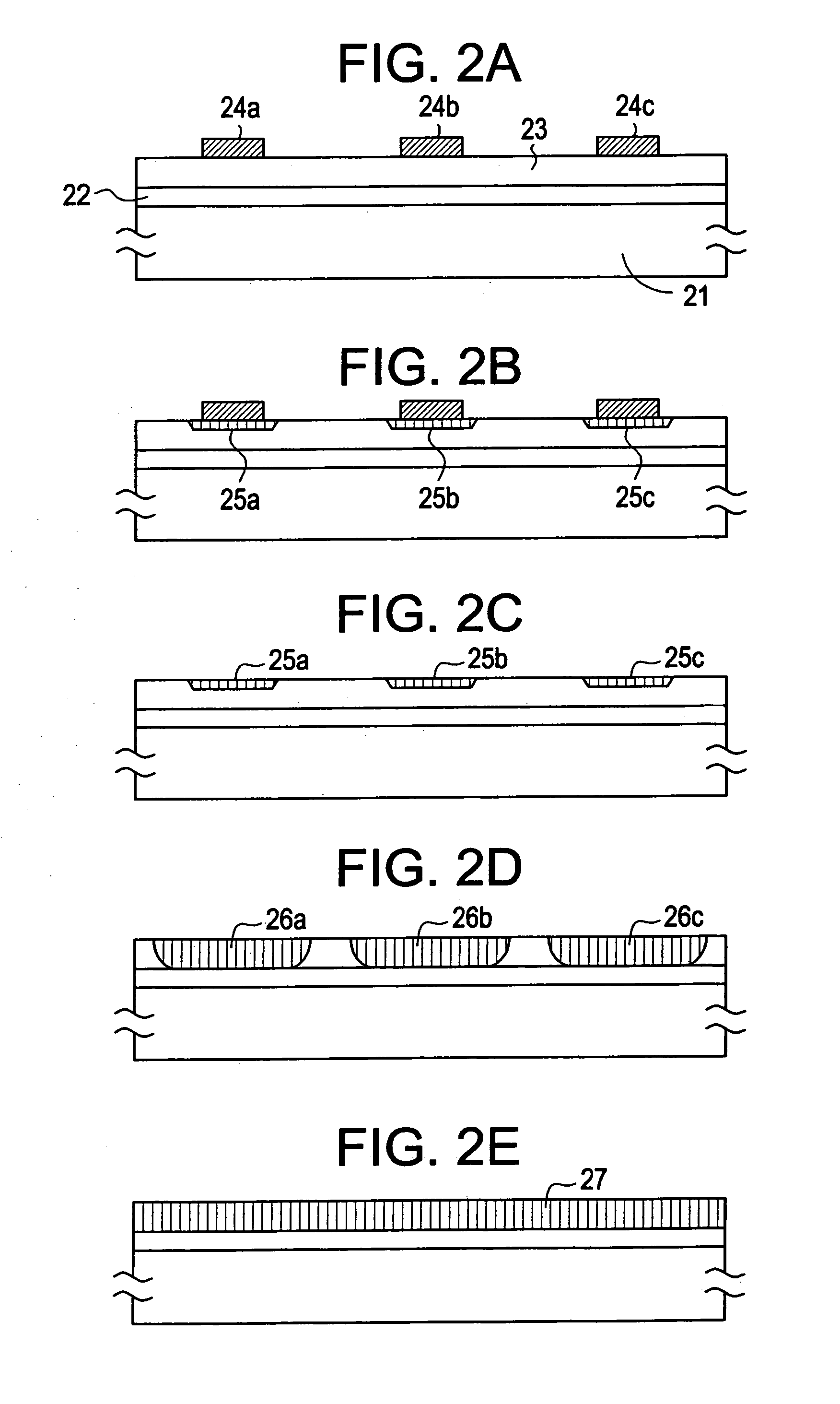

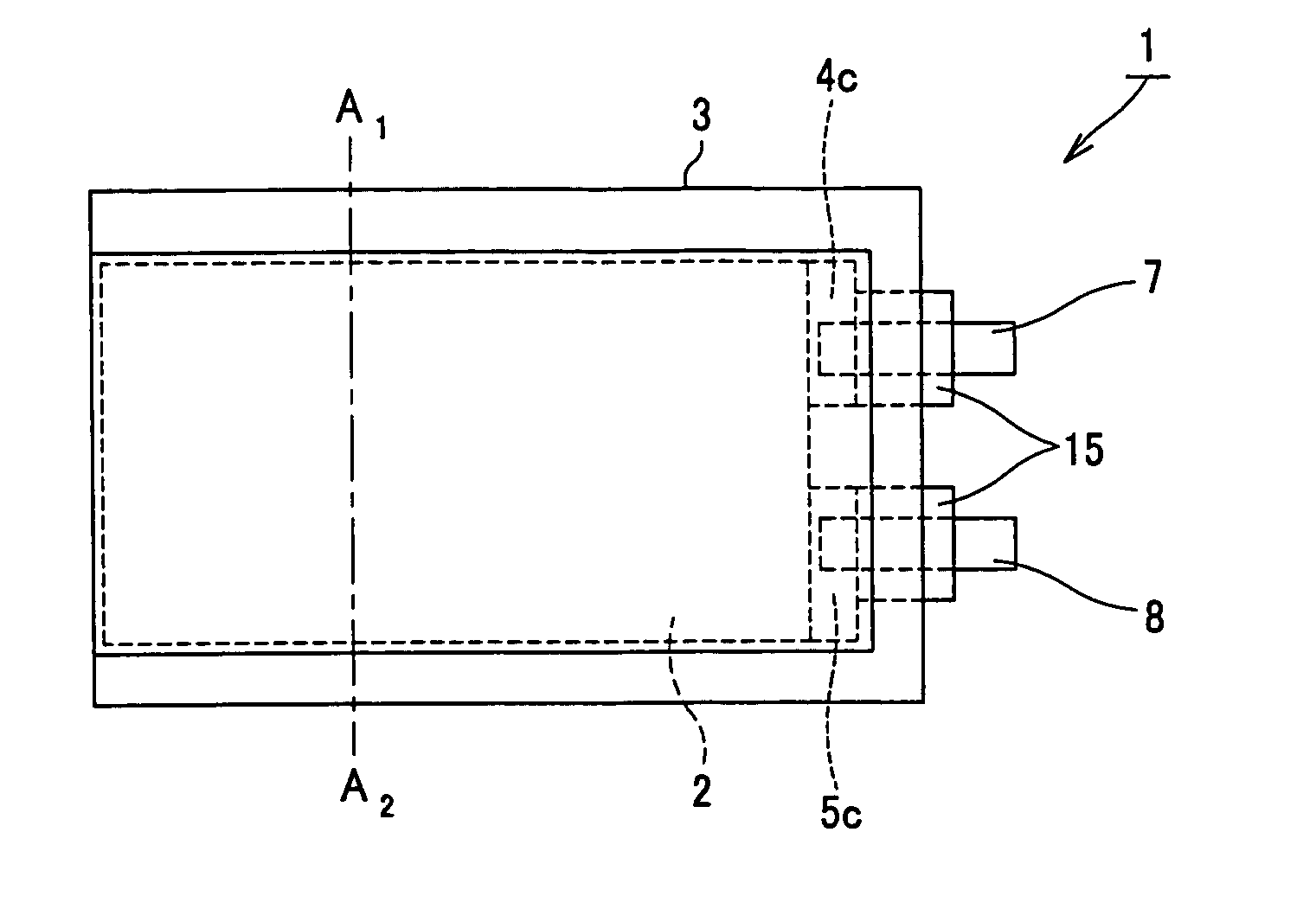

Semiconductor device and method for manufacturing the same

InactiveUS7566633B2Change flexibilityChange resistanceFinal product manufactureSolid-state devicesEngineeringGlass transition point

An object of the present invention is to provide a semiconductor device which has flexibility and resistance to a physical change such as bending and a method for manufacturing the semiconductor device. A semiconductor device of the present invention includes a plurality of transistors provided over a flexible substrate, each of which has a semiconductor film, a gate electrode provided over the semiconductor film with a gate insulating film therebetween, and an interlayer insulating film provided to cover the gate electrode, and a bending portion provided between the plurality of transistors, in which the bending portion is provided by filling an opening formed in the interlayer insulating film with a material having a lower elastic modulus, a material having a lower glass transition point, or a material having a higher plasticity than that of the interlayer insulating film.

Owner:SEMICON ENERGY LAB CO LTD

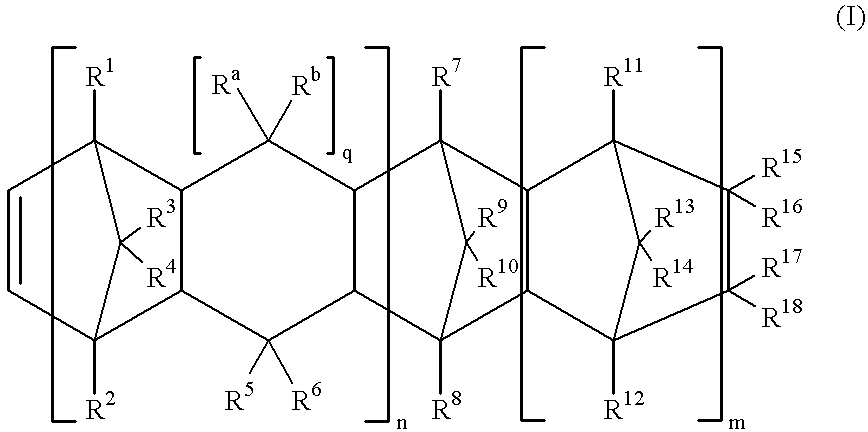

Cycloolefin resin pellets and a process for producing a molded product thereof

InactiveUS6342549B1High transparencyReduce the amount requiredAluminium compoundsSolesVitrificationShell molding

Cycloolefin resin pellets of the present invention comprises a cycloolefin resin pellet and a powdery coating material and / or a liquid coating material, the melting point or the glass transition point of the coating material being 200° C. or lower, and the coating material being adhered onto the surface of the cycloolefin resin pellets, so that the molded product thereof is excellent in transparency.

Owner:TICONA GMBH +1

Electromagnetic Interference Suppressor, Antenna Device and Electronic Information Transmitting Apparatus

InactiveUS20070252771A1High densitySuperior electromagnetic interference suppressing effectMagnetic/electric field screeningLayered productsElastomerVitrification

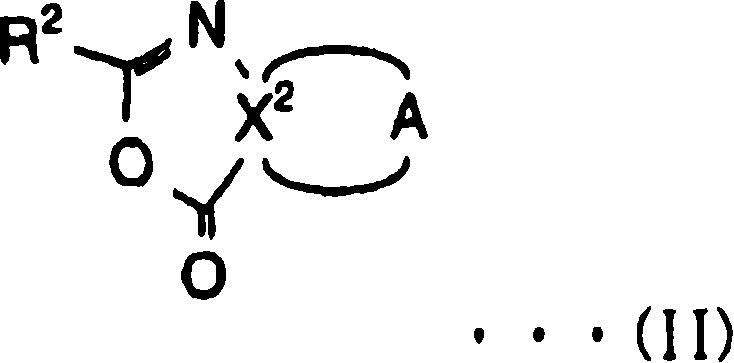

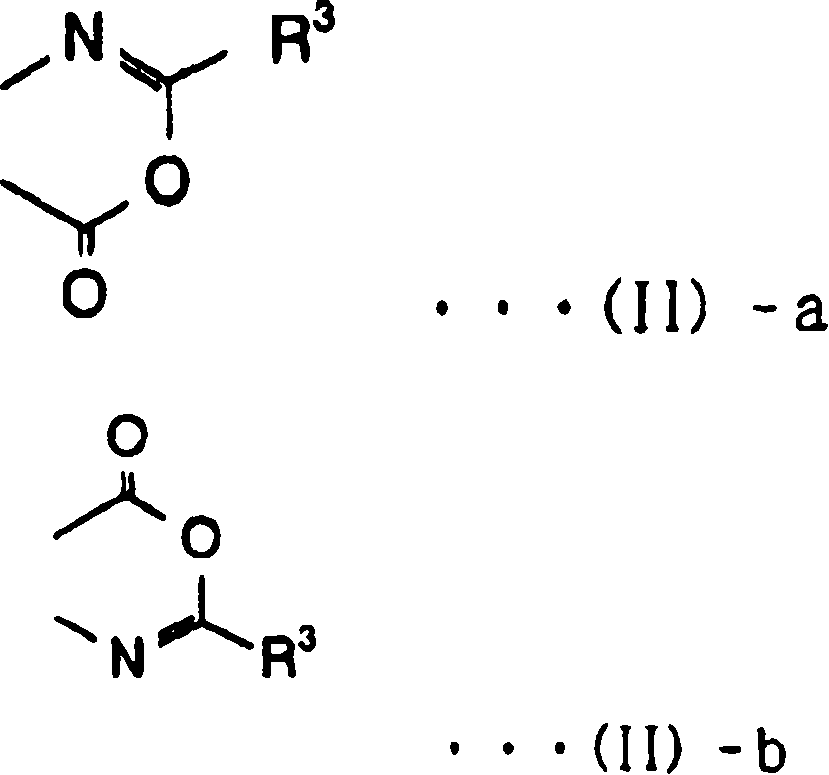

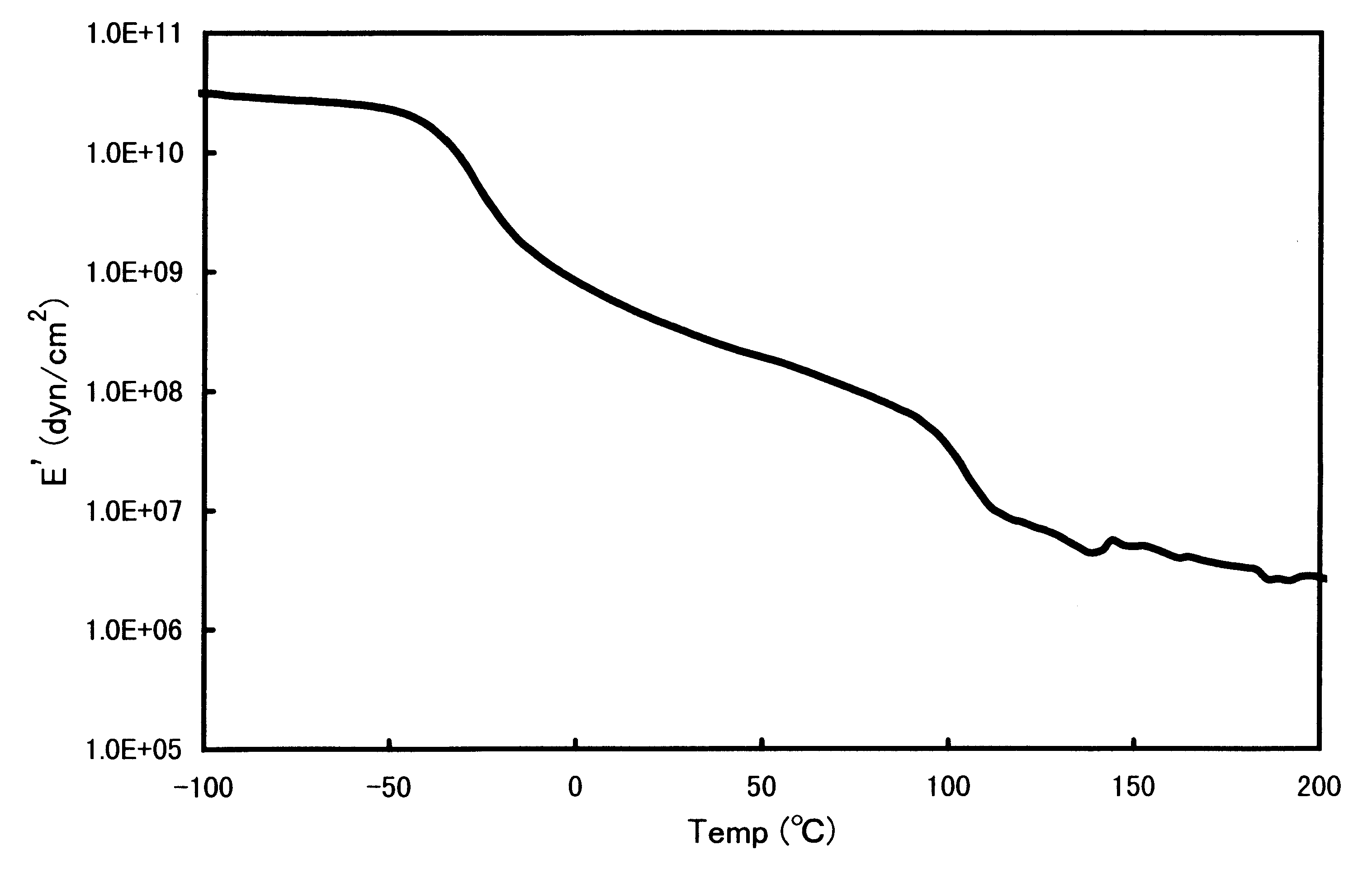

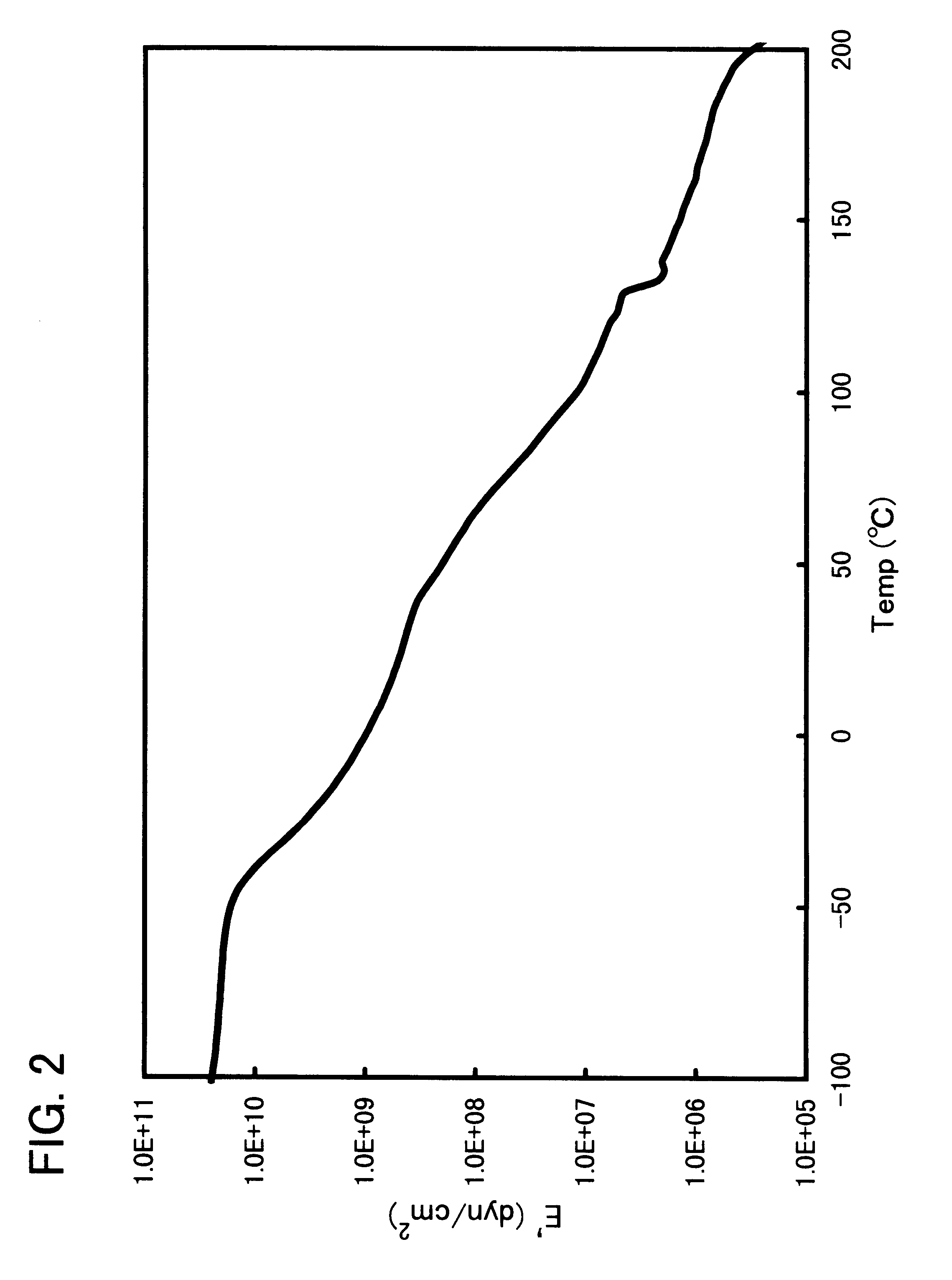

An electromagnetic interference suppressor of substantially unpressurized sheet form is obtained by applying and drying a magnetic paint, and comprises 30 to 80% by volume of soft magnetic powder and 20 to 70% by volume of a binder. The binder is an elastomer or a resin that a glass transition point and / or a softening point is 50° C. or more and a storage modulus (E′) is 107 Pa (JIS K 7244-1) or more in a state containing neither solvent nor filler at room temperature. This electromagnetic interference suppressor exerts a superior electromagnetic interference suppressing effect.

Owner:NITTA CORP

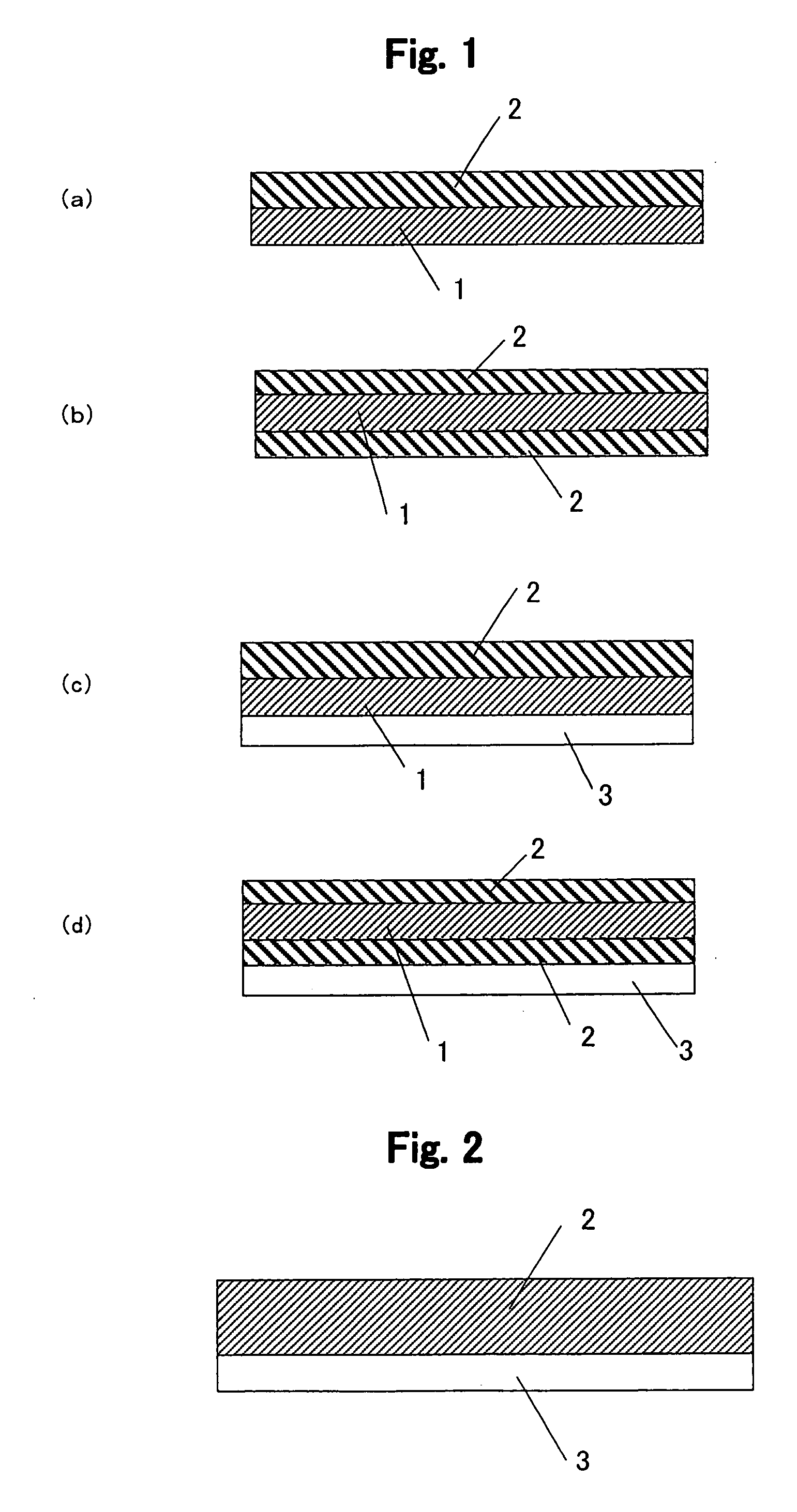

Process for the production of thinned wafer

InactiveUS20020127821A1Improve surface accuracyLittle warpingSolid-state devicesSemiconductor/solid-state device manufacturingWaferingHemt circuits

A process for the production of a thinned wafer, comprising bonding the circuit surface (surface A) of a semiconductor wafer (a) to a holding substrate (b) with an adhesive film (c), grinding and polishing the back surface (surface B) of the semiconductor wafer to thin the semiconductor wafer, carrying out the metallization of the back surface (surface B) and the like as required, and then separating the thinned wafer from the holding substrate (b), wherein a thermoplastic resin film is used as the adhesive film (c) and the above bonding of the circuit surface (surface A) of the semiconductor wafer (a) to the holding substrate (b) is carried out at a bonding temperature selected from the range of from +10.degree. C. to +120.degree. C. of glass transition point of the thermoplastic resin film or the range of from -40.degree. C. to +20.degree. C. of melting point of the thermoplastic resin film.

Owner:MITSUBISHI GAS CHEM CO INC

Glass ceramic composition

A glass ceramic composition which consists essentially of an inorganic material powder having a melting point or a glass transition point of at least 1,000° C. and a glass powder having a glass transition point of from 450 to 800° C., wherein the average of the major axes L of particles of the above inorganic material powder is from 0.5 to 15 μm, and the average of the ratios L / W of the major axes L to the minor axes W is at most 1.4. Further, a glass ceramic composition which consists essentially of, as represented by mass percentage, from 10 to 58% of an inorganic material powder having a melting point or a glass transition point of at least 1,000° C. and from 42 to 90% of a glass powder having a glass transition point of from 450 to 800° C., wherein the glass powder consists essentially of, as represented by mol %, SiO2: 35 to 70%, B2O3: 0 to 30%, Al2O3: 3 to 18%, MgO: 0 to 40%, CaO: 0 to 19%, BaO: 0 to 35% and ZnO: 0 to 9%.

Owner:ASAHI GLASS CO LTD

Organic EL display and manufacturing method thereof

ActiveUS20080129194A1Improve sealingDischarge tube luminescnet screensLamp detailsOrganic layerGlass transition point

An organic EL display comprises an element substrate, an organic EL element formed on the element substrate, comprising an organic layer including a light emitting layer and a pair of electrode layers disposed on both sides of the organic layer. The organic layer comprises a first organic material. The organic EL display further comprises a capping layer comprising a second organic material having a glass transition point lower than one of the first organic material and a protective layer on the capping layer.

Owner:LG DISPLAY CO LTD

Easily Adhesive Polyester Film and Film for Protecting Back Side of Solar Cell Using the Same

InactiveUS20080050583A1Improve adhesionEasy to stickFilm/foil adhesivesSynthetic resin layered productsVitrificationPolyvinyl alcohol

An easily adhesive polyester film is provided which is used for protection of the back side of a solar cell, the adhesive polyester film comprising a polyester film and a resin film situated on a surface of the polyester film, the resin film comprising a crosslinking agent and a resin selected from the group consisting of a polyester resin having a glass transition point of 20 to 100° C., an acrylic resin having a glass transition point of 20 to 100° C., a combination of the resins and a combination of at least one of the resins and a polyvinyl alcohol having a saponification degree of 70 to 90 mol %. This film has excellent adhesion to EVA while having excellent mechanical properties, heat resistance and moisture resistance.

Owner:TEIJIN DUPONT FILMS JAPAN

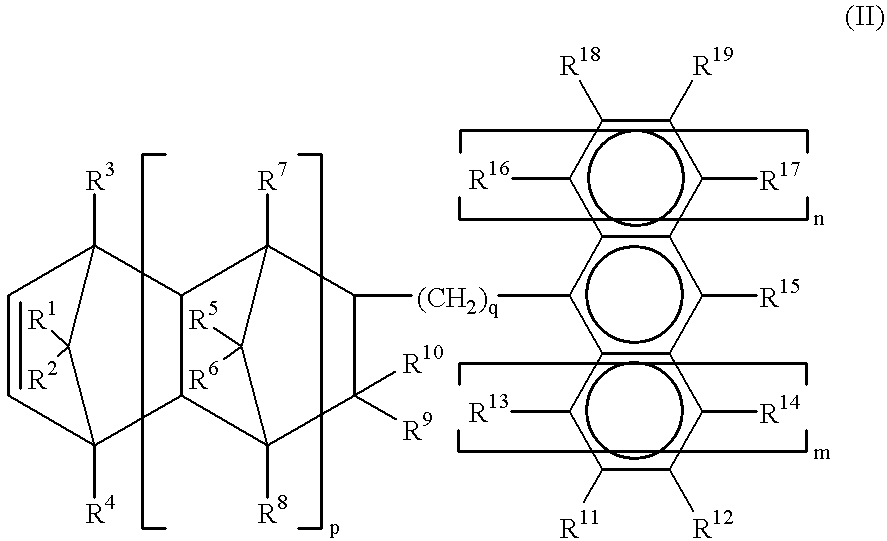

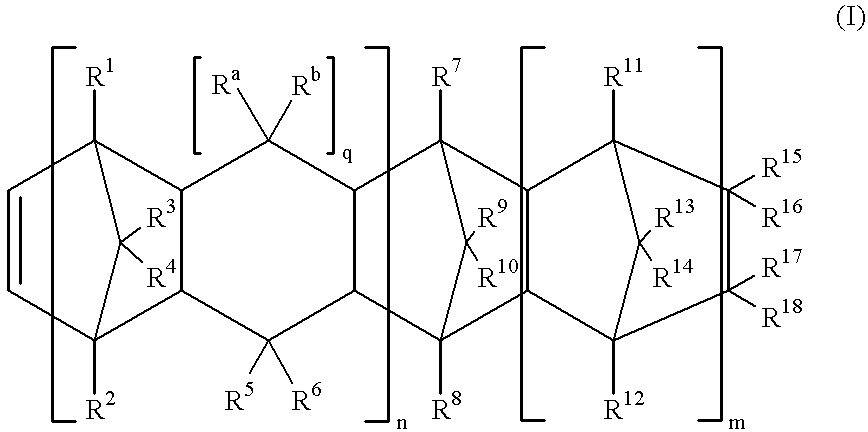

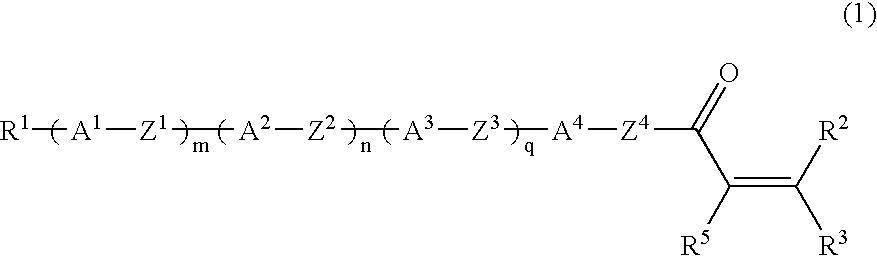

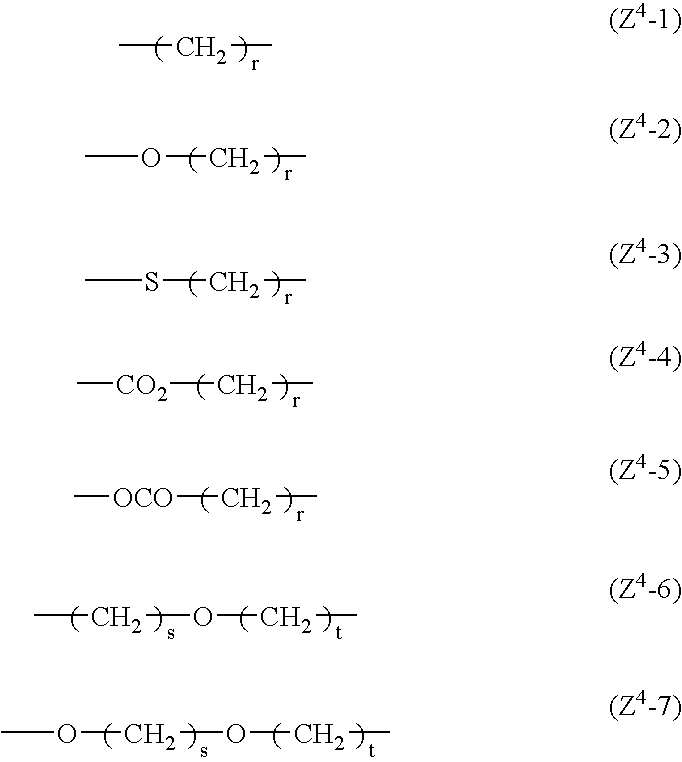

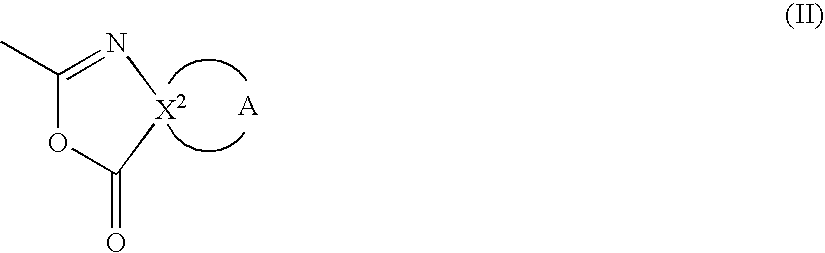

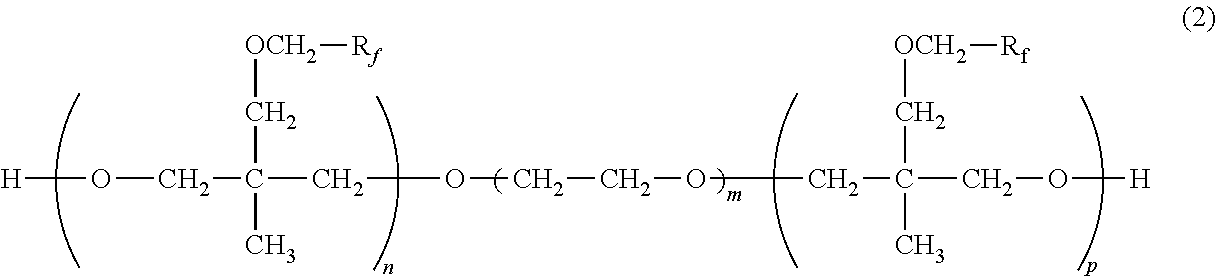

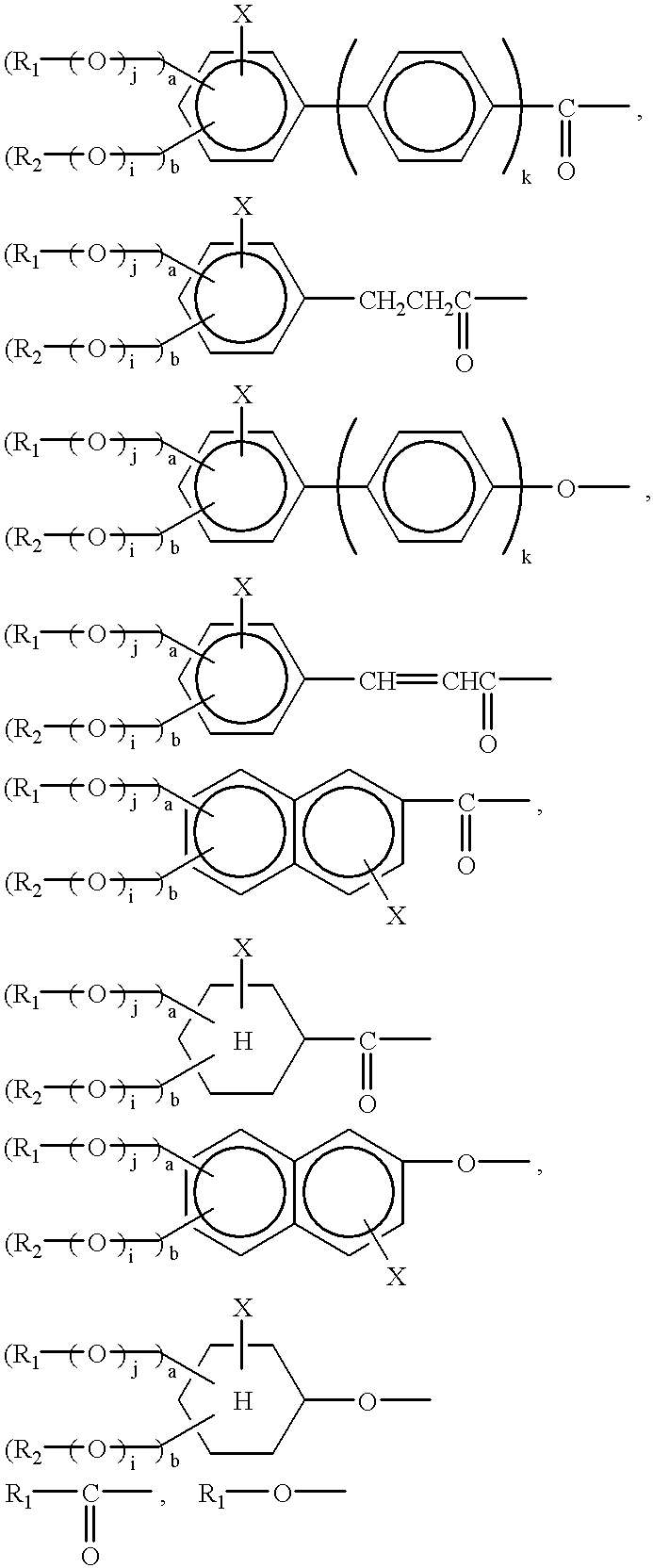

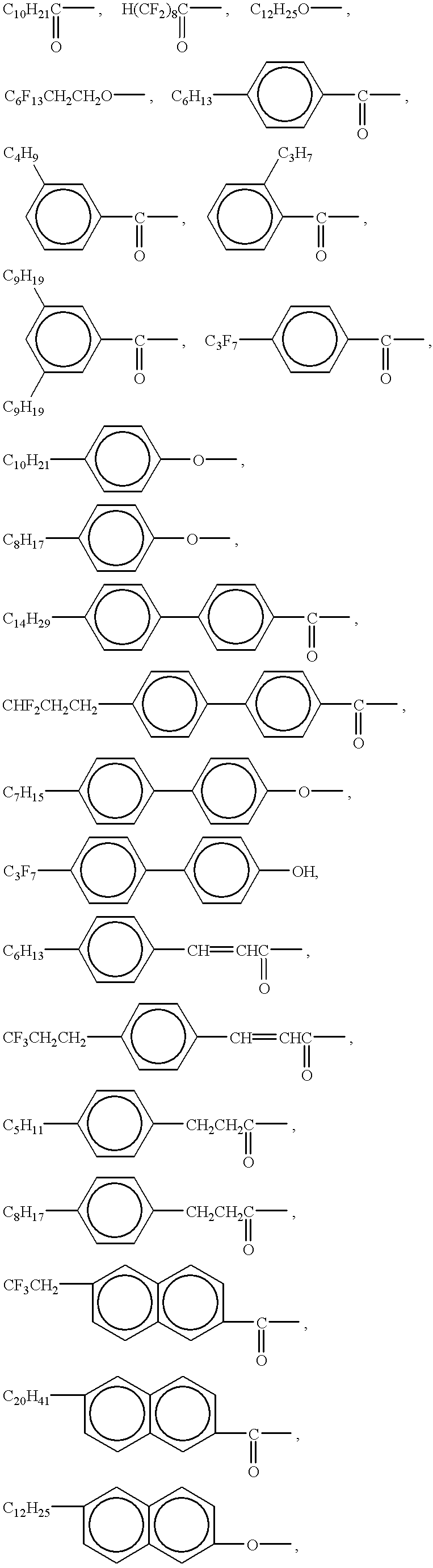

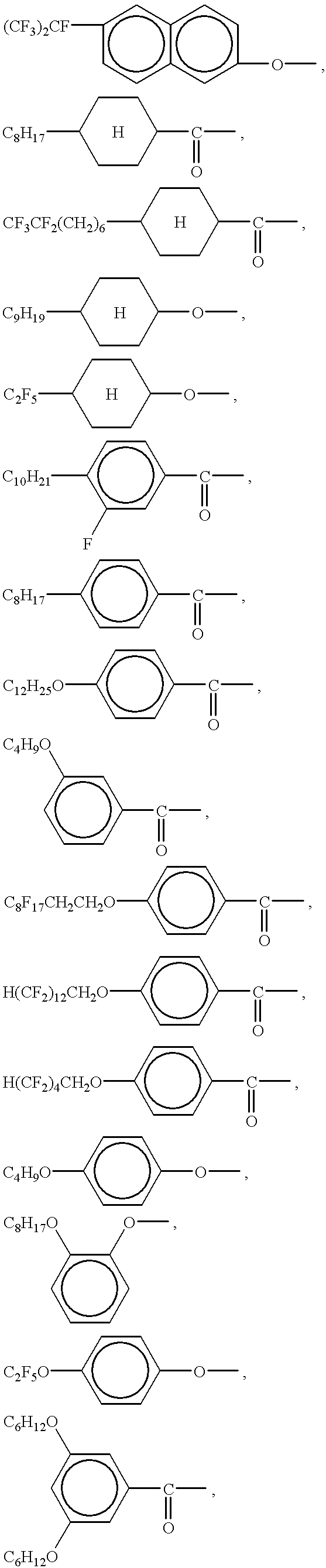

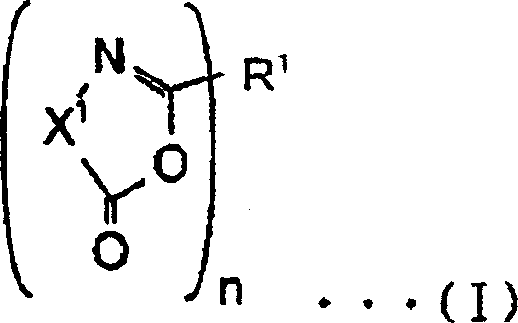

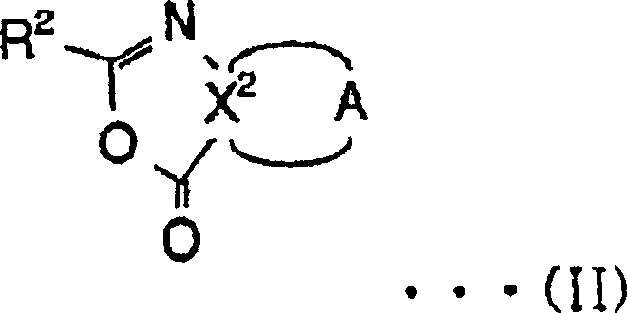

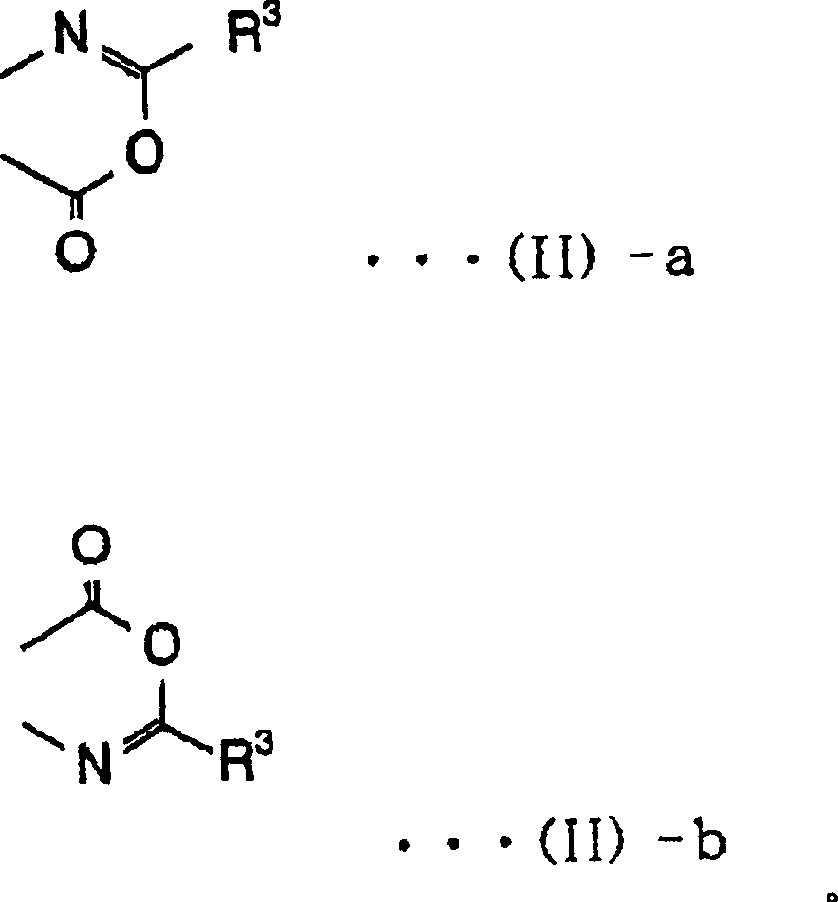

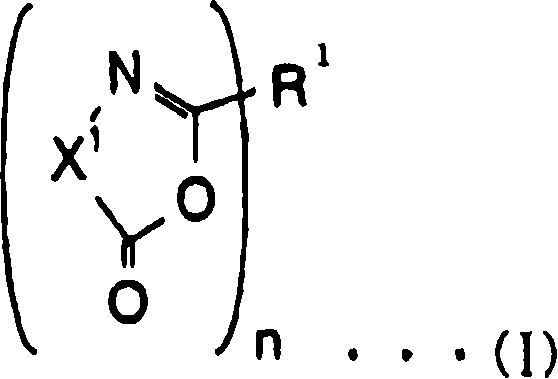

Liquid-crystalline vinyl ketone derivatives and their polymers

ActiveUS20050012070A1Improve compatibilityExcellent characteristicsLiquid crystal compositionsOrganic chemistrySolubilityLiquid crystalline

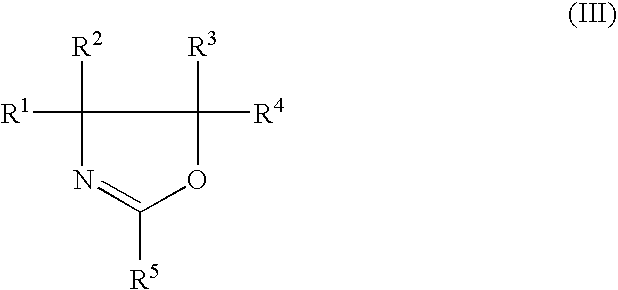

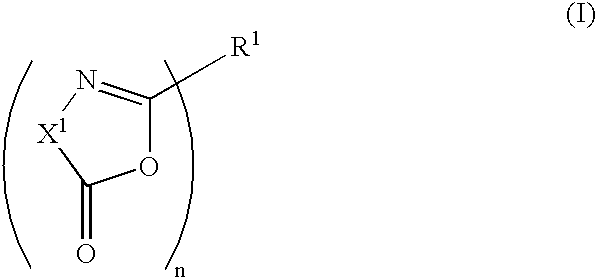

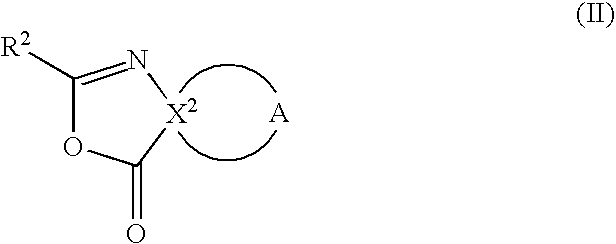

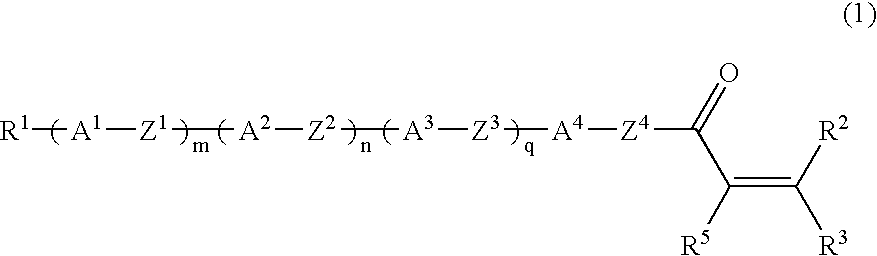

Provided is a liquid-crystalline, polymerizable vinyl ketone compound of formula (1): Preferably, R1 is hydrogen, halogen, —CN, —CF3, —CF2H, —CFH2, —OCF3, —OCF2H, or alkyl, alkoxy, alkoxyalkyl or alkenyl having from 1 to 10 carbon atoms; R2, R3 and R5 are hydrogen; A1 to A4 are independently 1,4-cyclohexylene, 1,4-cyclohexenylene or 1,4-phenylene where any hydrogen may be substituted with halogen; Z1 to Z3 are independently a single bond, —(CH2)2—, —CH═CH—, —CF═CF—, —OCF2— or —CF2O—; Z4 is a single bond, —(CH2)3— or —(CH2)4—; m, n and q are independently 0, 1 or 2. The uppermost temperature of the liquid crystalline phase of the compound is high, and the compound has good compatibility with other compounds and has the necessary characteristics such as optical anisotropy. Also provided are a polymer having many good characteristics of transparency, mechanical strength, coatability, solubility, crystallinity, shrinkage, water permeability, water absorption, melting point, glass transition point, clearing point and chemical resistance; an optically-anisotropic material of the polymer; a liquid-crystal display device that comprises the polymer; and a method for producing the liquid-crystalline compound.

Owner:JNC CORP +1

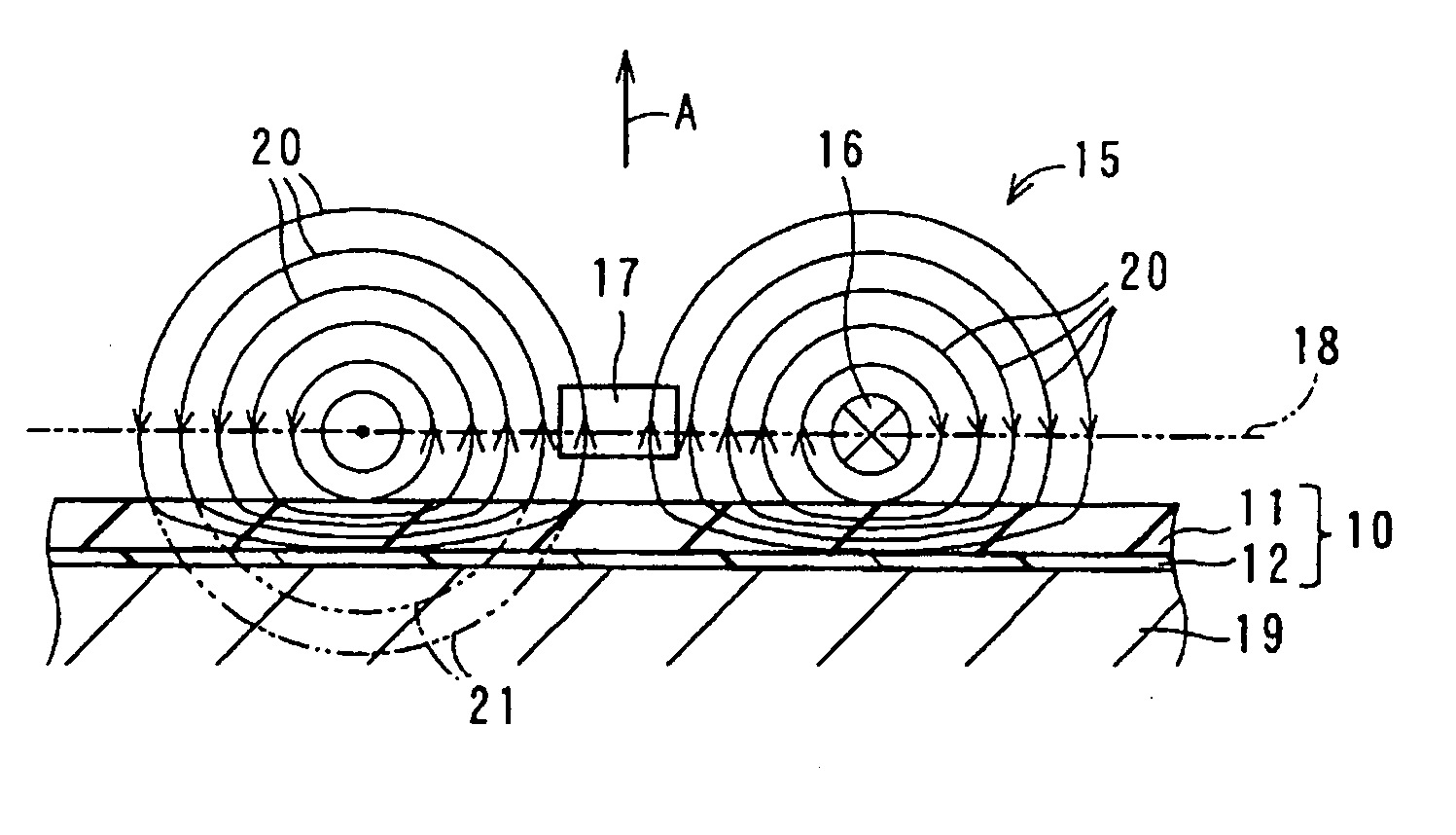

Semiconductor device and method for manufacturing the same

InactiveUS20060202206A1Less forceReduce stress exertedFinal product manufactureSolid-state devicesDevice materialGlass transition point

An object of the present invention is to provide a semiconductor device which has flexibility and resistance to a physical change such as bending and a method for manufacturing the semiconductor device. A semiconductor device of the present invention includes a plurality of transistors provided over a flexible substrate, each of which has a semiconductor film, a gate electrode provided over the semiconductor film with a gate insulating film therebetween, and an interlayer insulating film provided to cover the gate electrode, and a bending portion provided between the plurality of transistors, in which the bending portion is provided by filling an opening formed in the interlayer insulating film with a material having a lower elastic modulus, a material having a lower glass transition point, or a material having a higher plasticity than that of the interlayer insulating film.

Owner:SEMICON ENERGY LAB CO LTD

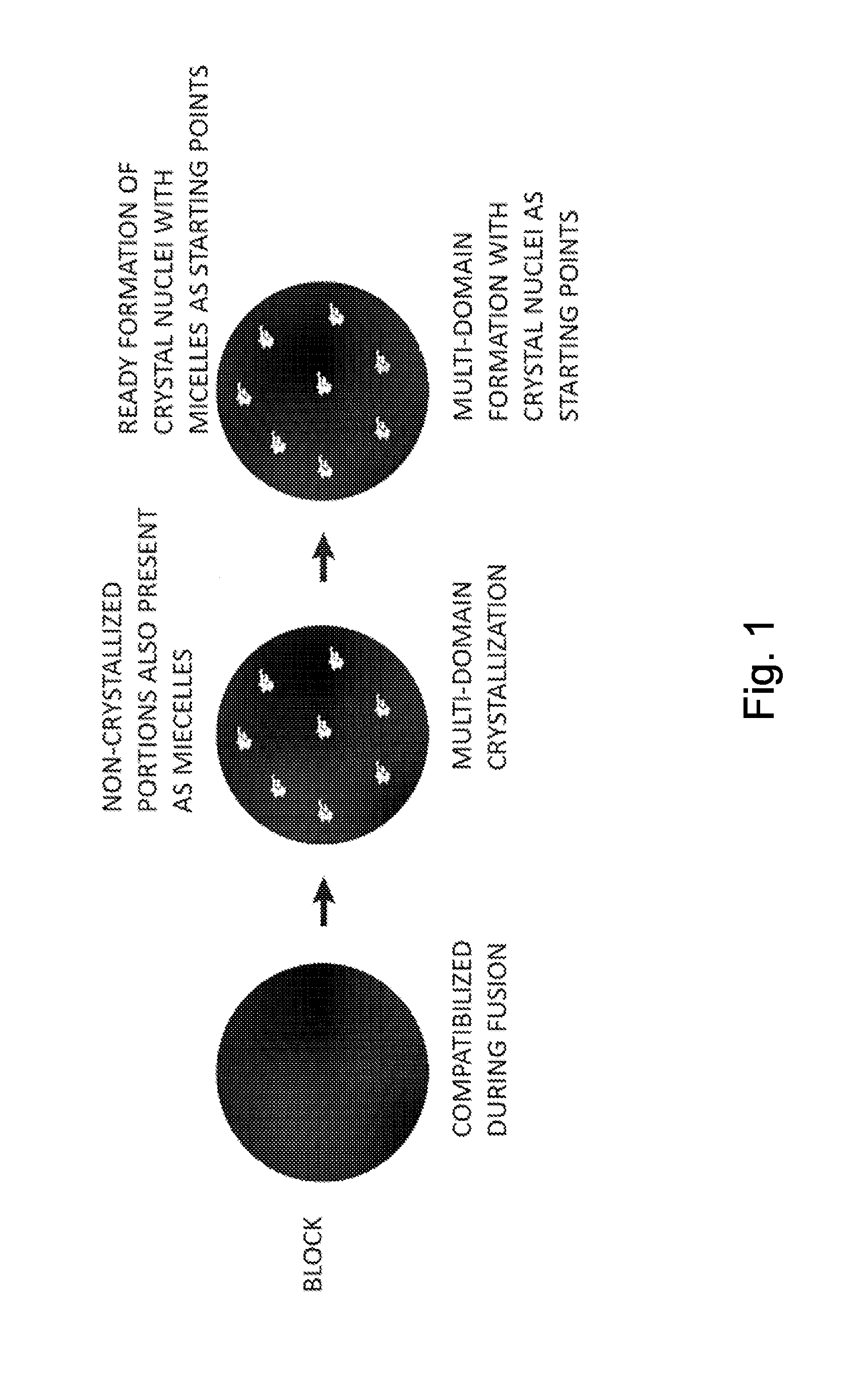

Semiconductor, semiconductor device, and method for fabricating the same

InactiveUS6997985B1Improve continuityImprove solubilityTransistorFrom gel stateGlass transition pointCobalt

Method of fabricating semiconductor devices such as thin-film transistors by annealing a substantially amorphous silicon film at a temperature either lower than normal crystallization temperature of amorphous silicon or lower than the glass transition point of the substrate so as to crystallize the silicon film. Islands, stripes, lines, or dots of nickel, iron, cobalt, or platinum, silicide, acetate, or nitrate of nickel, iron, cobalt, or platinum, film containing various salts, particles, or clusters containing at least one of nickel, iron, cobalt, and platinum are used as starting materials for crystallization. These materials are formed on or under the amorphous silicon film.

Owner:SEMICON ENERGY LAB CO LTD

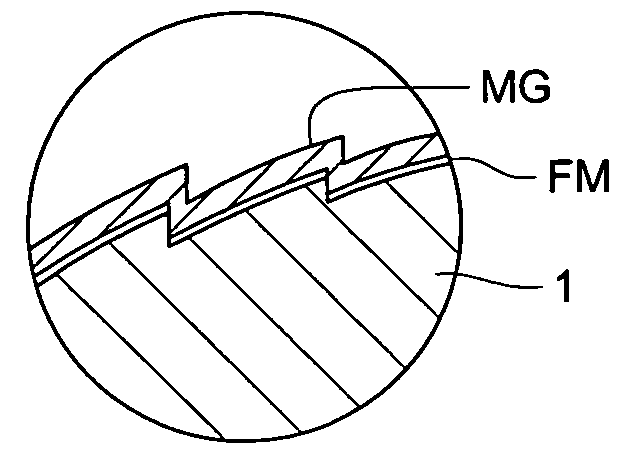

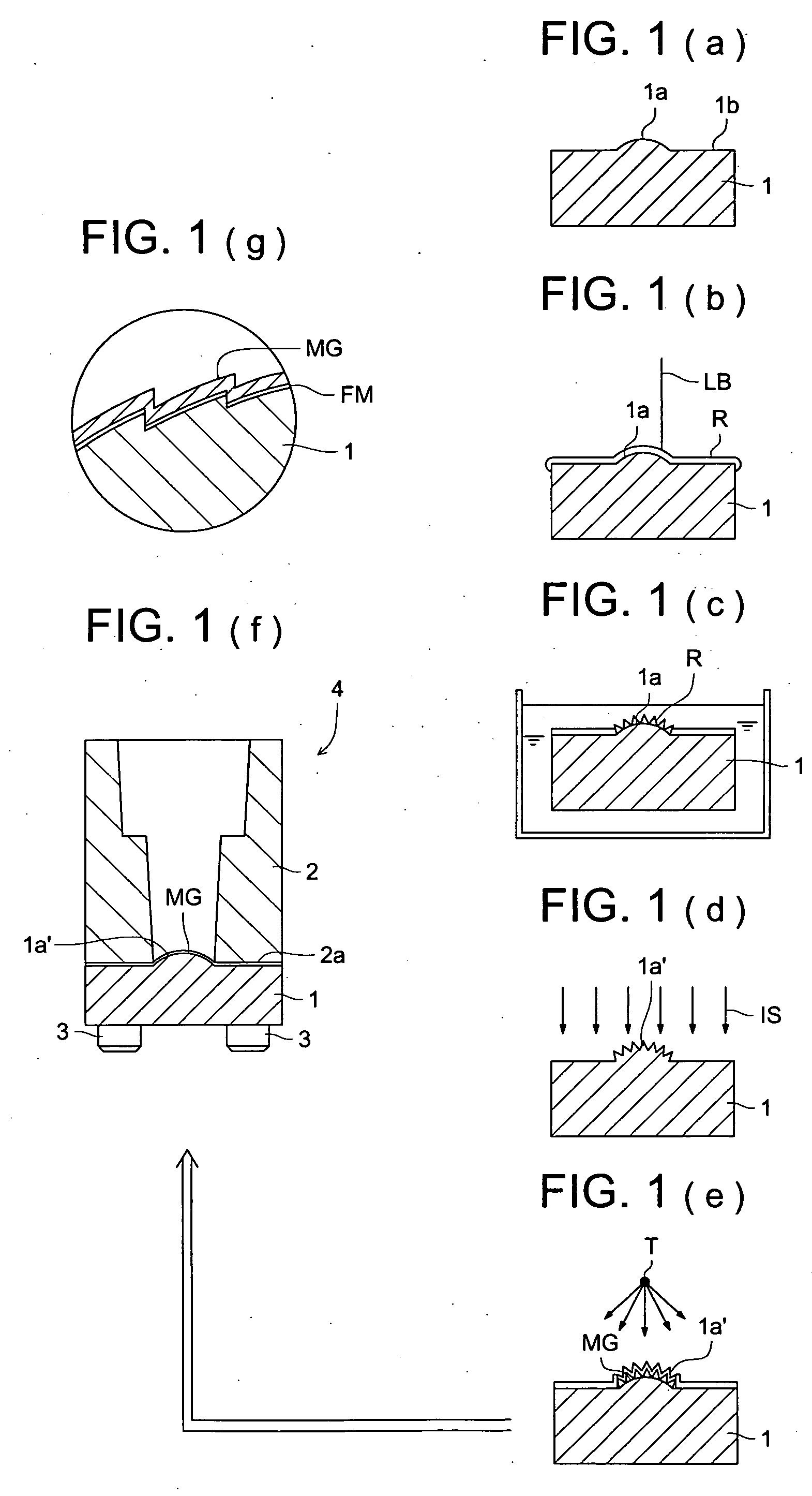

Manufacturing method of die for optical element molding

InactiveUS20050242454A1Reduce the possibilityPerformanceVacuum evaporation coatingAlcoholic beverage preparationSuper coolingVitrification

The invention relates to a manufacturing method of a die for molding an optical element. The manufacturing method comprising: forming the first film layer of an amorphous allow having a super-cooling liquid phase onto a master transfer surface of a master die for molding a molding transfer surface of the die; heating the first film layer more than a glass transition point of the amorphous alloy having the super-cooling liquid phase while a surface of the first film layer and a transferred surface of a base material of the die being faced and pressed; and peeling the first film layer from the master die and transferring the first film layer onto the base material of the die to form the molding transfer surface of the die.

Owner:KONICA MINOLTA OPTO

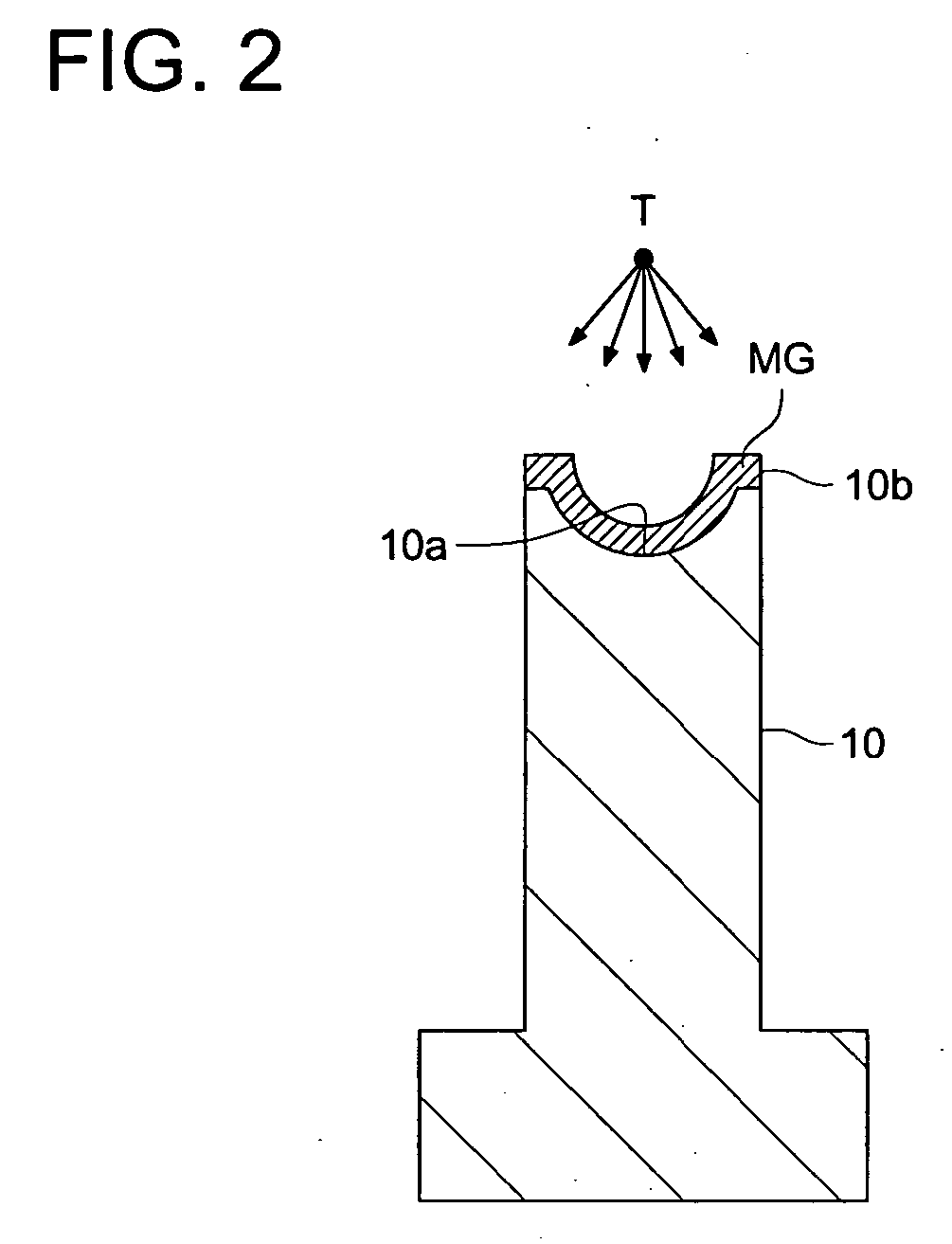

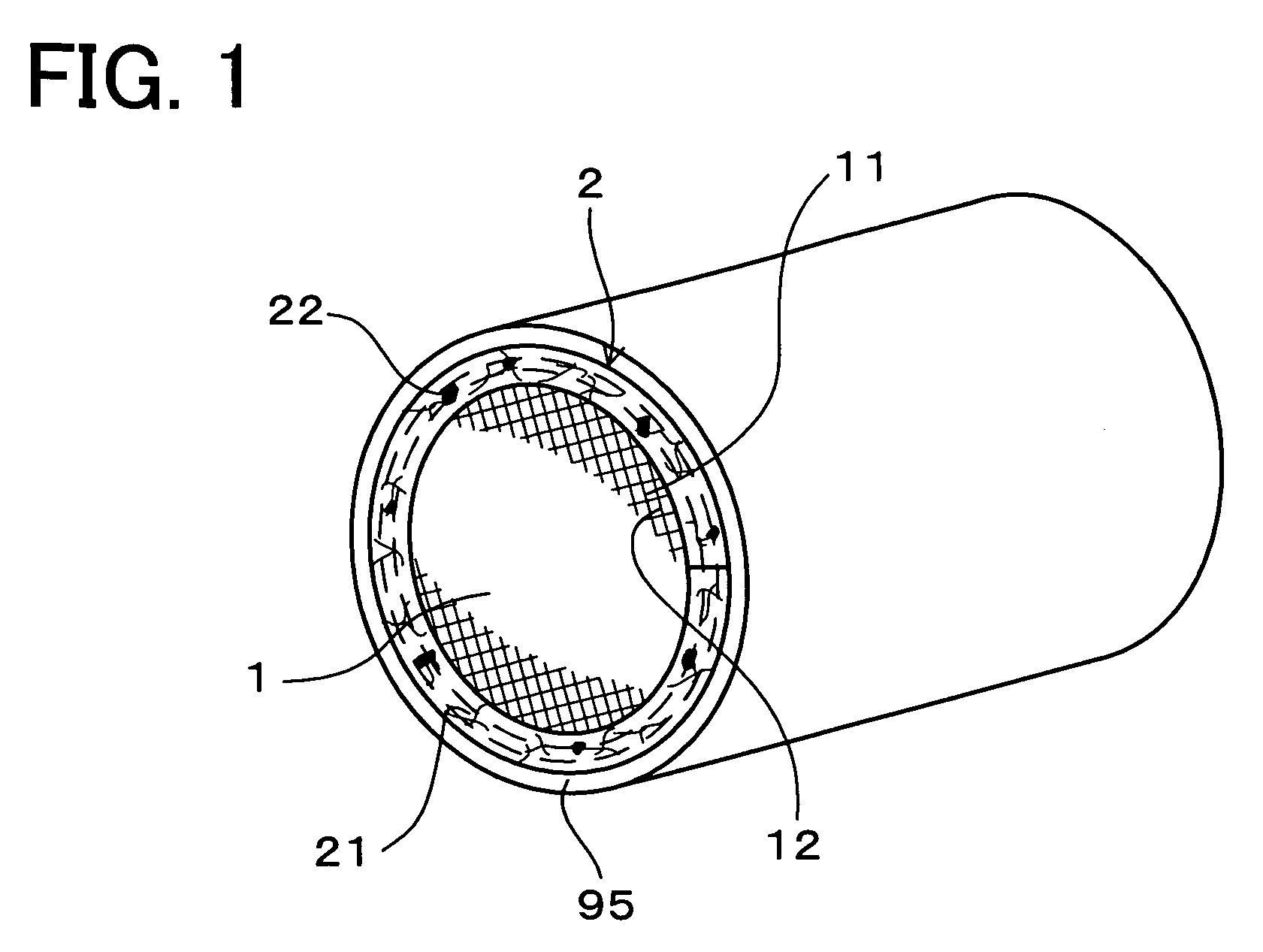

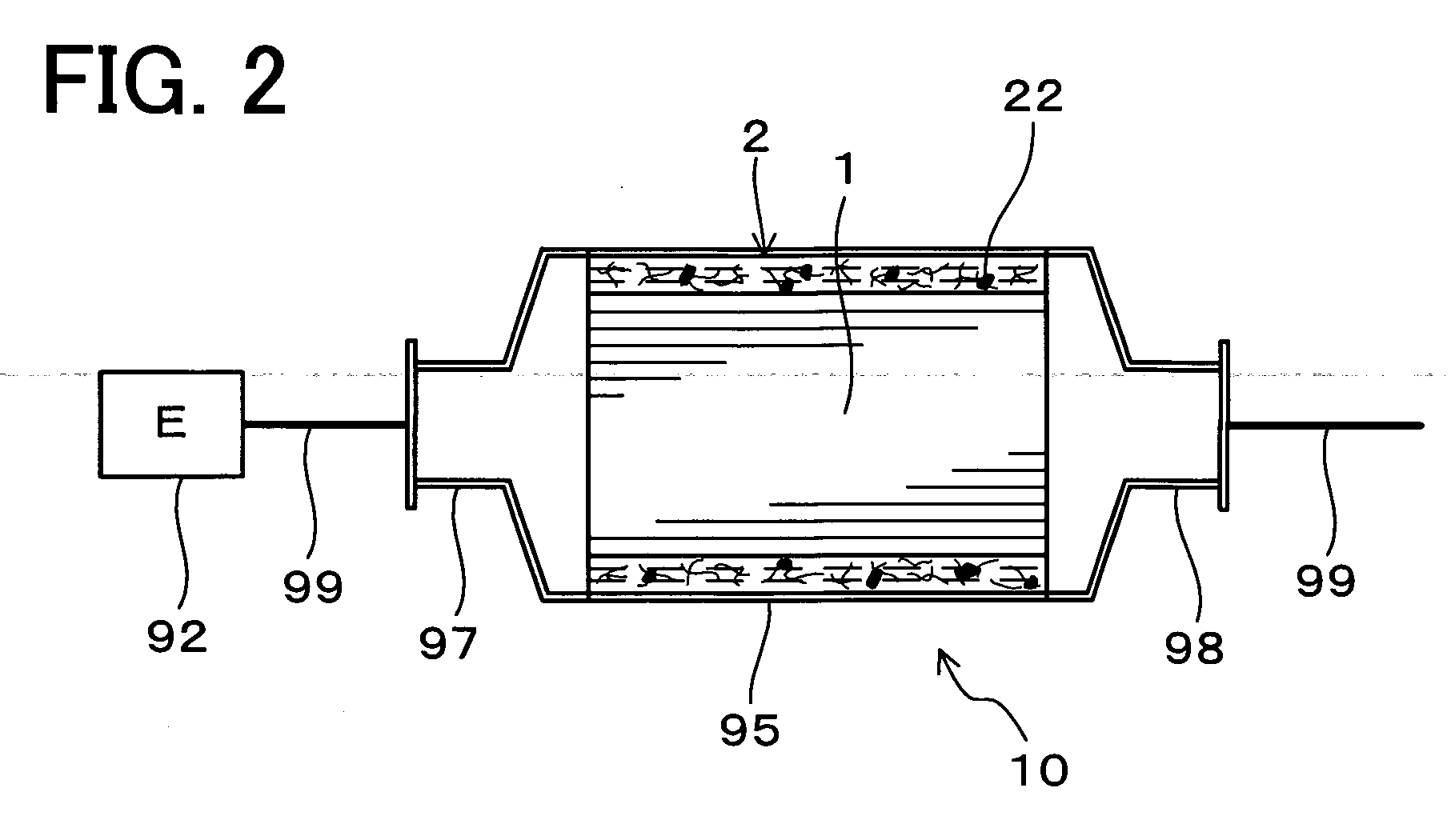

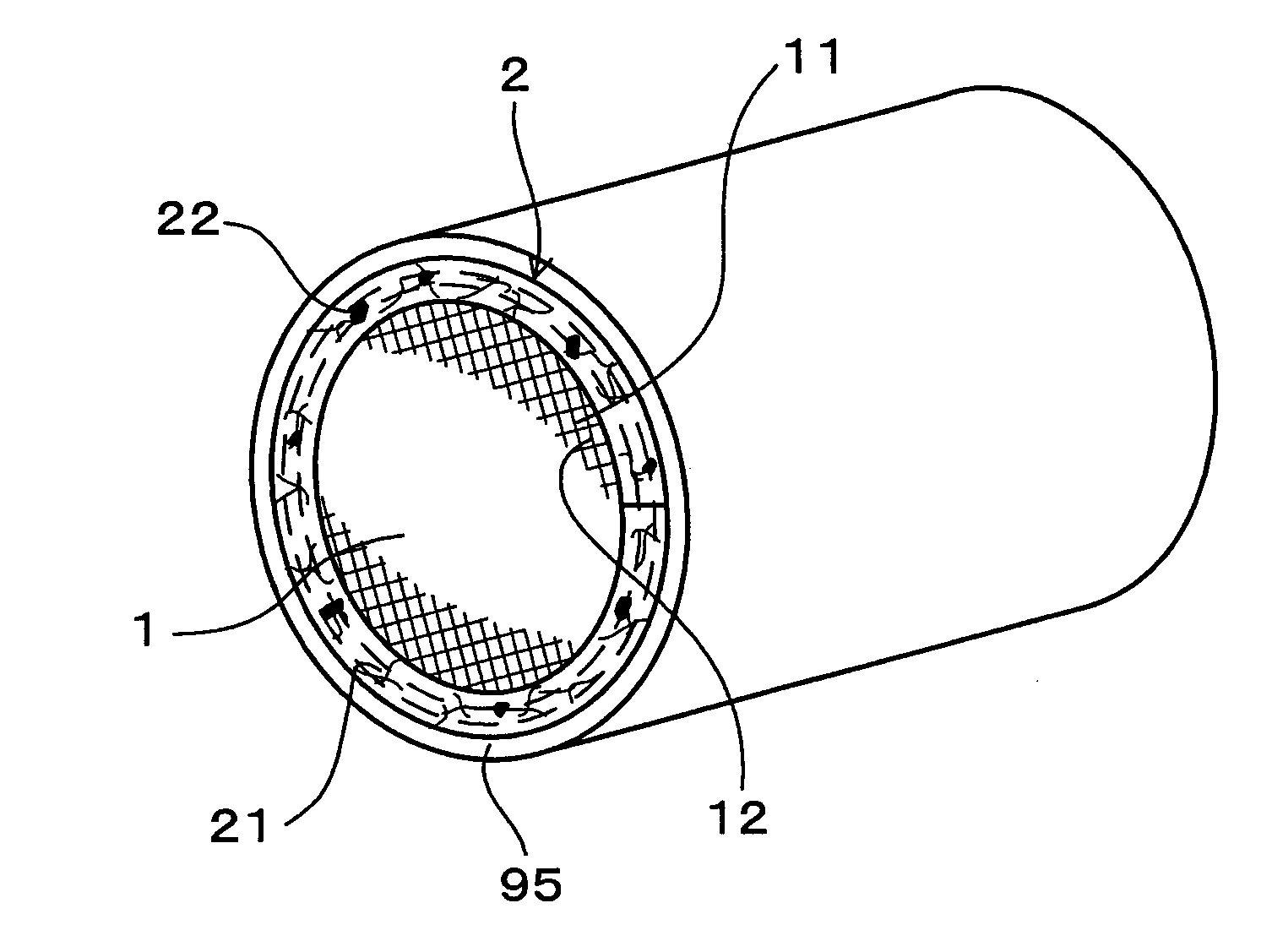

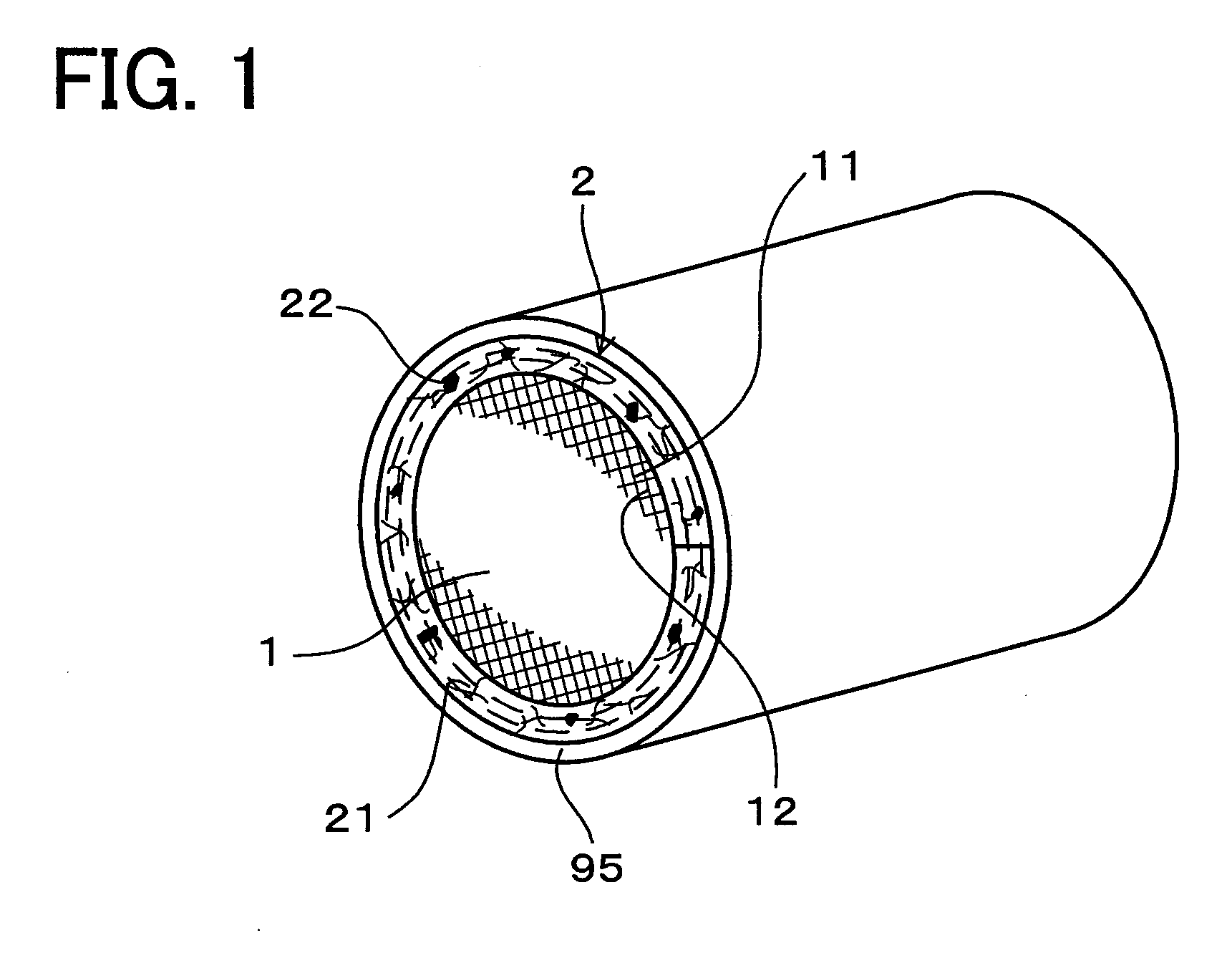

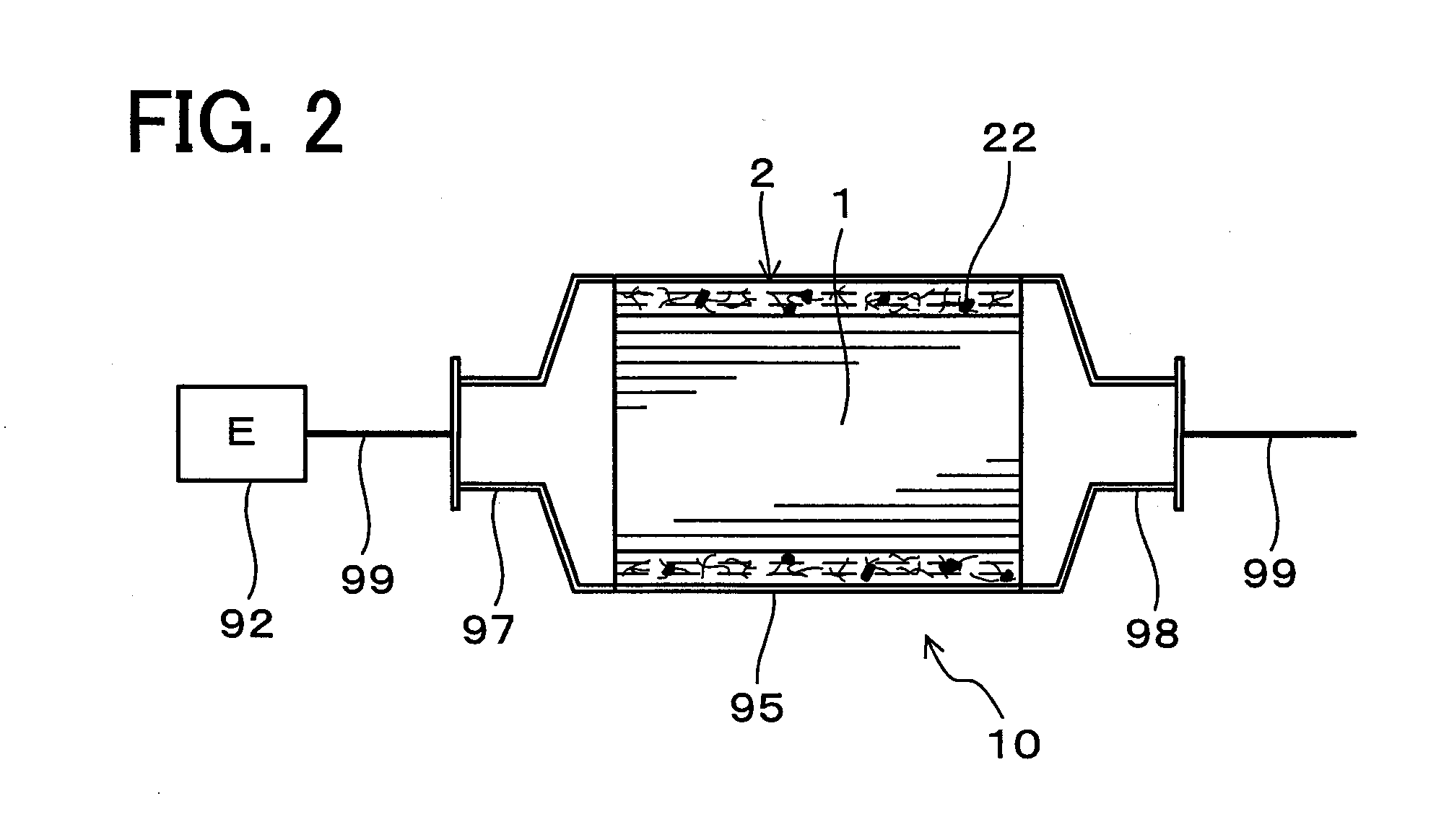

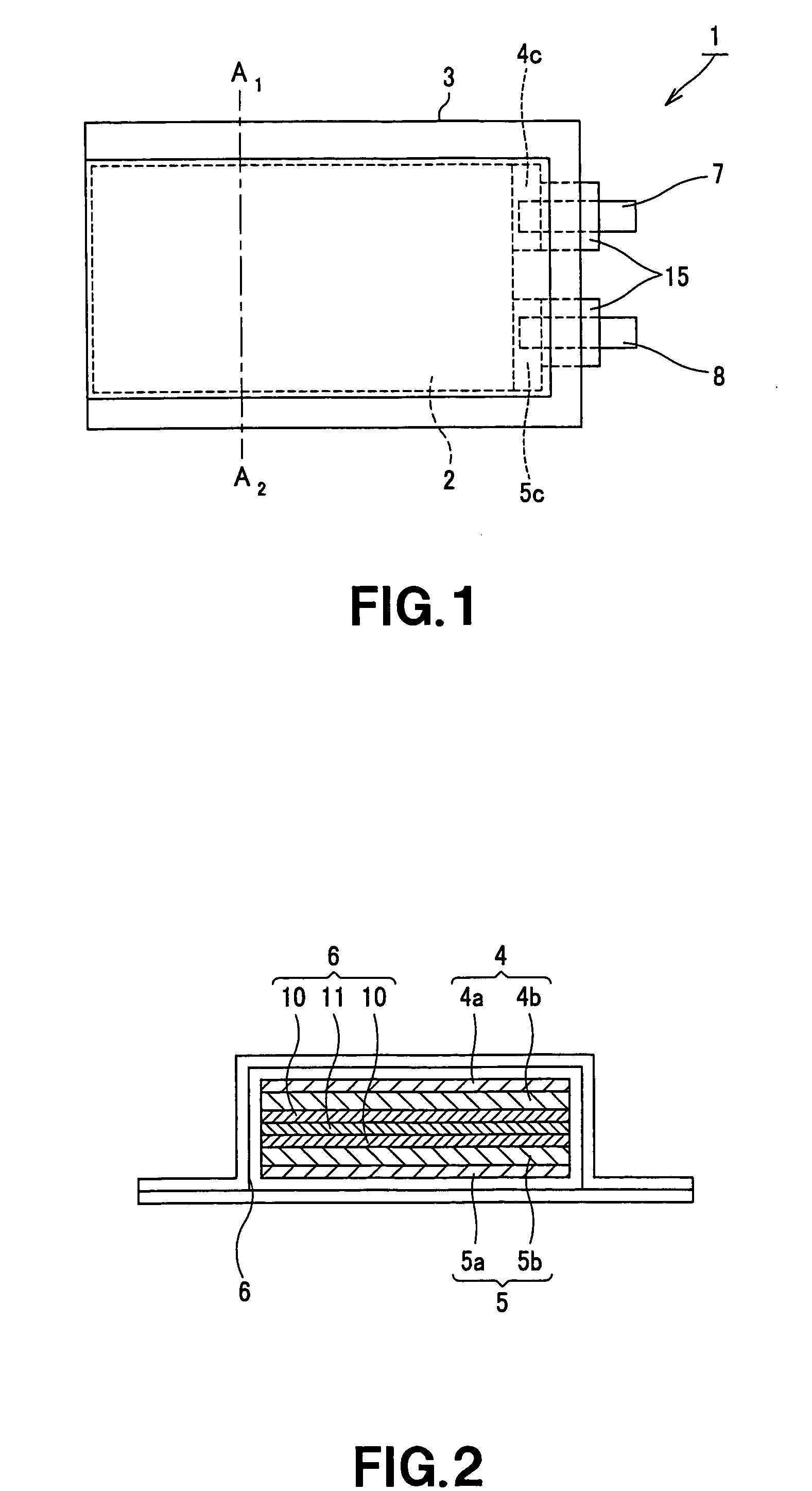

Holding and sealing material and manufacturing method thereof

InactiveUS20060278323A1Improve athletic abilityImprove good performanceInternal combustion piston enginesExhaust apparatusEmulsionEngineering

The present invention relates to a holding and sealing material 2 set between a catalyst carrier 1 and a shell 95 which covering the outside of the catalyst carrier 1 in a catalytic converter for purifying an exhaust gas and manufacturing method thereof. An organic binder 22 on the holding and sealing material 2 has the glass transition point Tg (° C.) of less than or equal to approximately 5° C. In addition, an infiltrating step and a drying step are conducted during the manufacturing. In the infiltrating step, the mat-like material is infiltrated with emulsion containing the organic binder. In the drying step, the mat-like material containing the emulsion is dried.

Owner:IBIDEN CO LTD

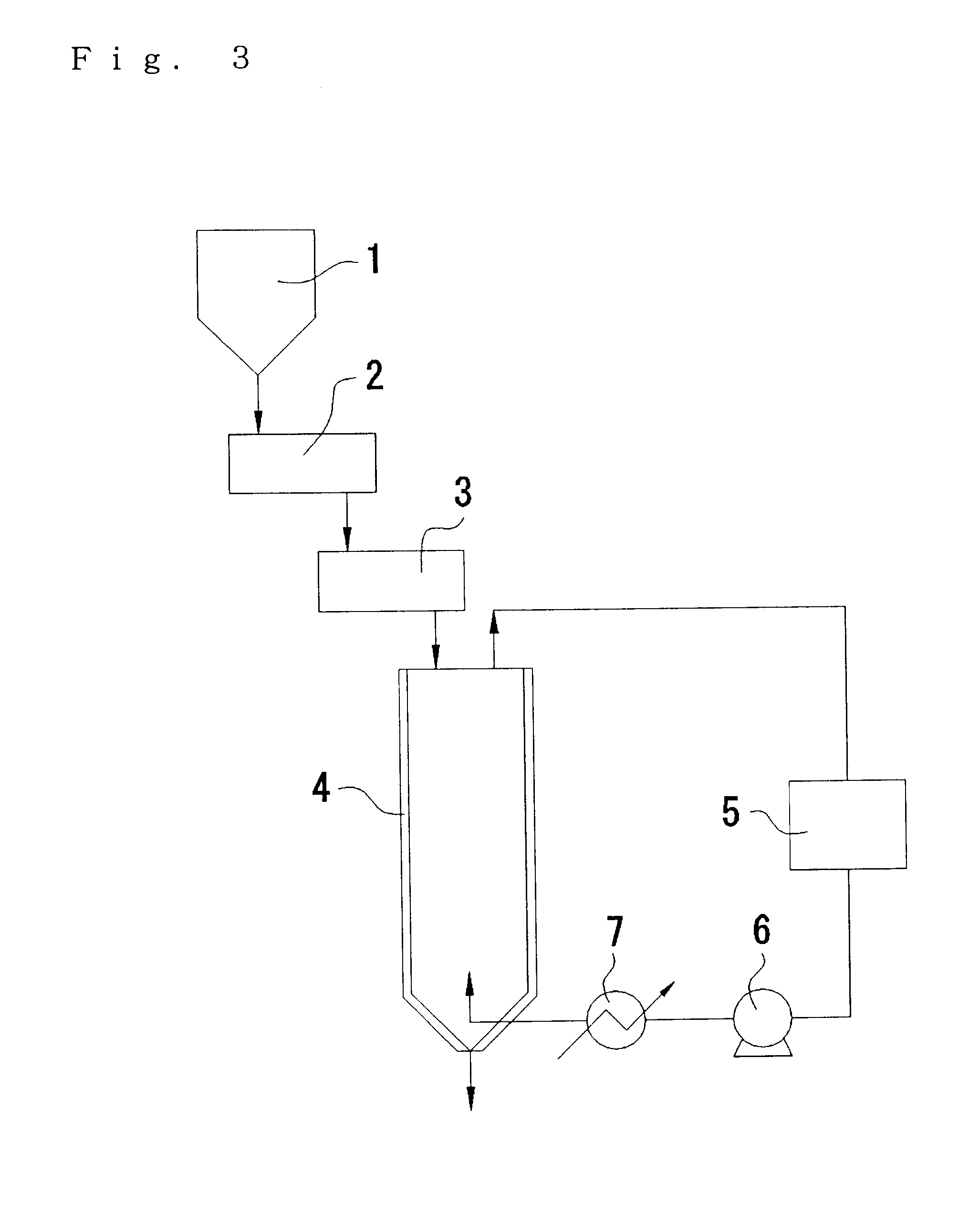

Method for producing toner particles

Owner:CANON KK

Adhesive polyester film for optical use

InactiveUS20040076844A1Suitable for useImprove the winding effectOptical filtersSynthetic resin layered productsPolyesterPolymer science

An optical adhesive polyester film comprising (A) a polyester film layer containing an aromatic polyester and an ultraviolet absorber and (B) a coating formed on at least one surface of the polyester film (A). The coating (B) contains at least one polymer selected from the group consisting of a coating polyester having a glass transition point of 40 to 100° C. and an acryl polymer having a glass transition point of 20 to 80° C. in an amount of 50 to 95% by weight based on the coating. The optical adhesive polyester film is disposed on the front of a plasma display so as to block externally incoming ultraviolet light.

Owner:TEIJIN DUPONT FILMS JAPAN

Holding and sealing material and manufacturing method thereof

ActiveUS20090049690A1Improve athletic abilitySuppress interruptCombination devicesInternal combustion piston enginesEmulsionGlass transition point

The present invention relates to a holding and sealing material 2 set between a catalyst carrier 1 and a shell 95 which covering the outside of the catalyst carrier 1 in a catalytic converter for purifying an exhaust gas and manufacturing method thereof. An organic binder 22 on the holding and sealing material 2 has the glass transition point Tg (° c) of less than or equal to approximately 5° C. In addition, an infiltrating step and a drying step are conducted during the manufacturing. In the infiltrating step, the mat-like material is infiltrated with emulsion containing the organic binder. In the drying step, the mat-like material containing the emulsion is dried.

Owner:IBIDEN CO LTD

Optical adhesive polyester film

InactiveUS7005176B2Improve adhesionSuitable for useOptical filtersSynthetic resin layered productsPolyesterPolymer science

An optical adhesive polyester film comprising (A) a polyester film layer containing an aromatic polyester and an ultraviolet absorber and (B) a coating formed on at least one surface of the polyester film (A). The coating (B) contains at least one polymer selected from the group consisting of a coating polyester having a glass transition point of 40 to 100° C. and an acryl polymer having a glass transition point of 20 to 80° C. in an amount of 50 to 95% by weight based on the coating. The optical adhesive polyester film is disposed on the front of a plasma display so as to block externally incoming ultraviolet light.

Owner:TEIJIN DUPONT FILMS JAPAN

Solid electrolyte, lithium-ion battery and method for producing lithium-ion battery

InactiveUS20050019666A1Improve adhesionImprove ionic conductivityNon-metal conductorsSolid electrolytesElectrical batteryOptoelectronics

A lithium-ion battery includes a cathode and an anode capable of being doped with and dedoped from lithium and a solid electrolyte provided between the cathode and the anode. The solid electrolyte comprises a multi-layer structure having three layers or more. A layer nearest to the cathode side and a layer nearest to the anode side of the layers include first polymers which have a low glass transition point, do not have functional groups capable of being crosslinked and are not crosslinked. At least one layer except the layers located at positions nearest to the cathode side and the anode side of the layers includes a second polymer that has a functional group capable of being crosslinked and is crosslinked. Thus, the electrode utilization factor of the cathode and the anode is improved.

Owner:SONY CORP

Polyolefin resin composition and shrink film made from the same

InactiveUS6855406B2High transparencyReduce surface tackSynthetic resin layered productsDomestic articlesVitrificationPolyolefin

A polyolefin resin composition comprises (A) 10 to 100 wt % of a propylene / α-olefin random copolymer obtained by random copolymerization of propylene and a C2 to C20 α-olefin, and having a melting point as measured by DSC of 40 to 115° C. and an α-olefin content of 5 to 70 mol %, (B) 0 to 90 wt % of a random propylene resin having a melting point as measured by DSC of 120 to 150° C., and (C) an alicyclic saturated hydrocarbon resin having a glass transition point of 20 to 100° C. and a number average molecular weight of 1200 or less, the component (C) being used in an amount of 5 to 100 weight parts per 100 weight parts of the total amount of the components (A) and (B). A single-layer or multilayer film obtained from the polyolefin resin composition can be stretched at a lower temperature than in the conventional one, and a shrink film obtained by such a low-temperature stretching has a higher shrinkage factor than one stretched at a high temperature, and also has a small natural shrinkage factor.

Owner:MITSUI CHEM INC

Ink for inkjet textile printing

InactiveUS20100214352A1Improve concentrationViscosity of ink increaseDuplicating/marking methodsInksVitrificationTextile printer

An ink for inkjet textile printing comprising a pigment, a water-dispersible resin, water, and a water-soluble organic solvent, wherein the water-soluble organic solvent comprises a polyol having an SP value within a range from 10 to 15.5 (cal / cm3)1 / 2, and the water-dispersible resin comprises a urethane resin having a glass transition point within a range from −35 to 10° C.

Owner:RISO KAGAKU CORP

Optical glass and process for the production of optical products

An optical glass having high-refractivity and low-dispersion optical properties and having a low glass transition point so that a heat-treating furnace can be operated for a long period of time. The optical glass has a refractive index nd of at least 1.875, an Abbe's number nud of at least 39.5 and a glass transition point Tg of 700° C. or lower, and contains at least one of La2O3, Gd2O3, Y2O3 or Yb2O3 and at least one of ZrO2, Ta2O5 or Nb2O5, with a weight ratio of the total content of La2O3, Gd2O3, Y2O3 and Yb2O3 to the total content of SiO2 and B2O3 of from 3.2 to 5 and the weight ratio of the total content of ZrO2, Ta2O5 and Nb2O5 to the total content of SiO2 and B2O3 is from 1.1 to 1.5.

Owner:HOYA CORP

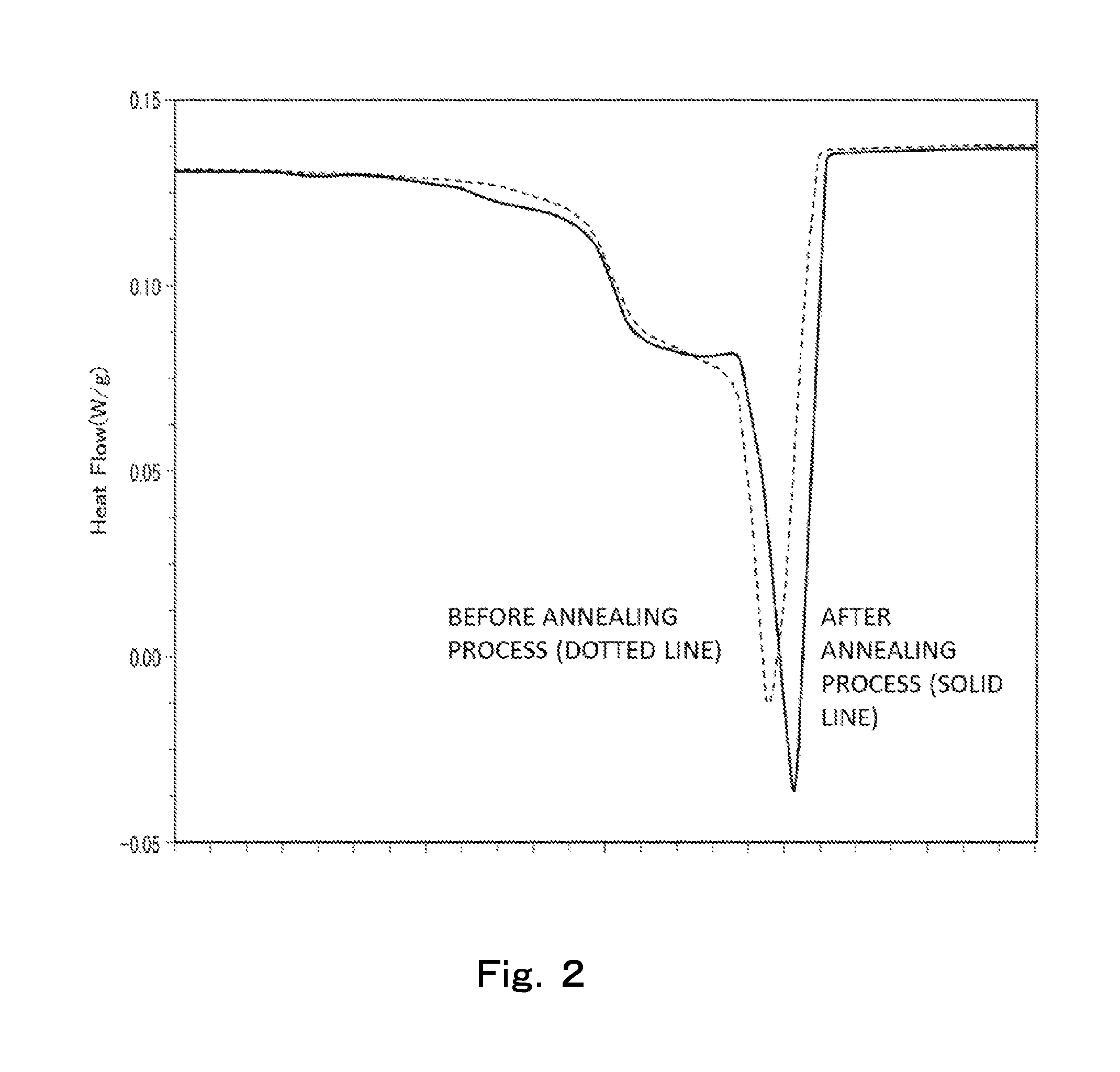

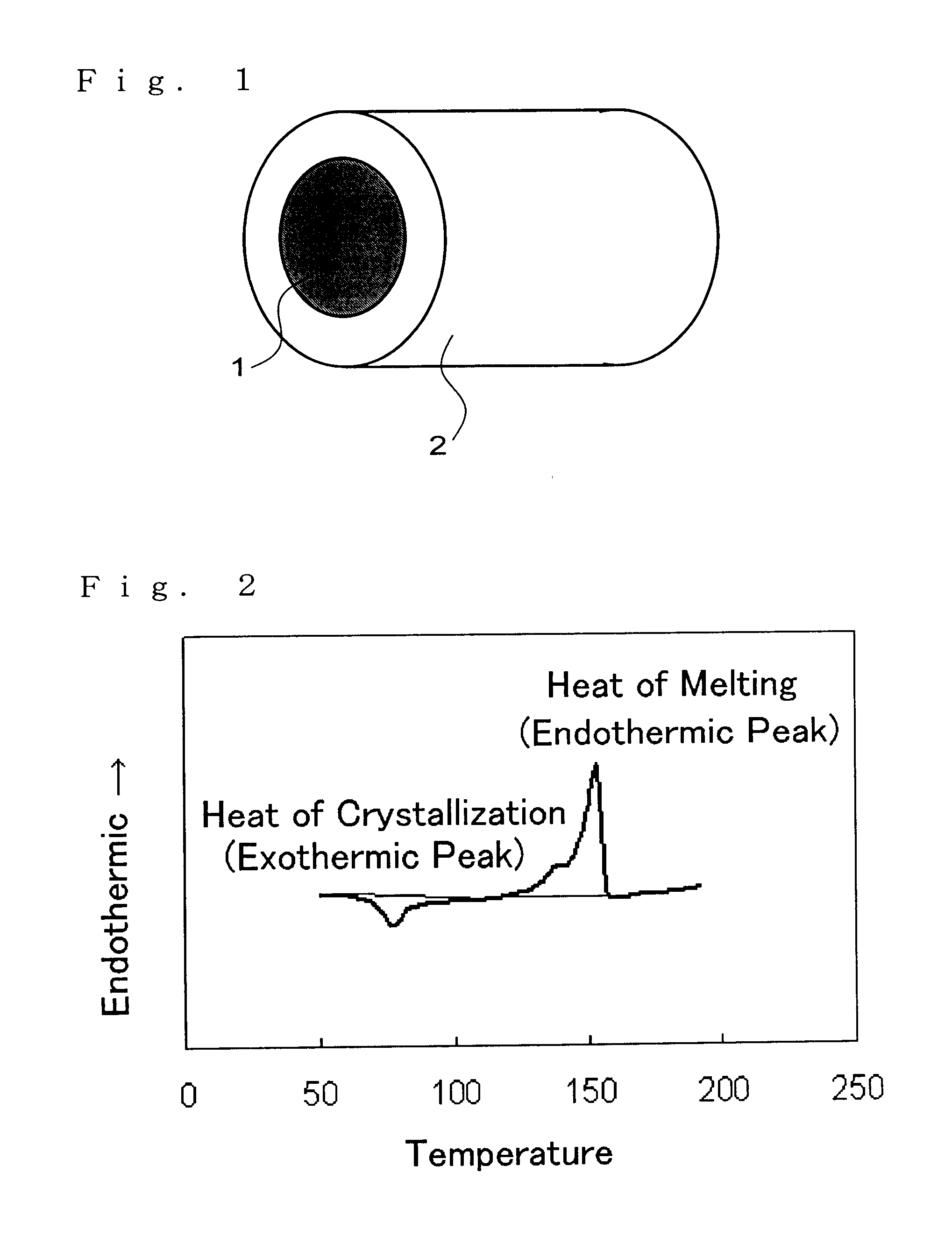

Process for preparing polyhydroxycarboxylic acid

InactiveUS6429280B1High molecular weightEfficient preparationCoatingsVitrificationReaction temperature

A process for preparing a polyhydroxycarboxylic acid having a weight average molecular weight of 50,000 to 1,000,000, which comprises a crystallizing step comprising (A) a step of heating pellets of a polyhydroxycarboxylic acid having a weight average molecular weight of 2,000 to 100,000 under stirring to a temperature from glass transition point or higher to a melting point or lower and heating until a defined result is attained, and (B) a step of heating the polyhydroxycarboxylic acid to a temperature of solid phase polycondensation reaction temperature, and a solid phase polycondensation reaction step of reacting the crystallized polyhydroxycarboxylic acid at an endothermic start temperature or lower of an endothermic peak as recognized upon temperature elevation analysis of the crystallized polyhydroxycarboxylic acid by using a differential scanning calorimeter.

Owner:MITSUI CHEM INC

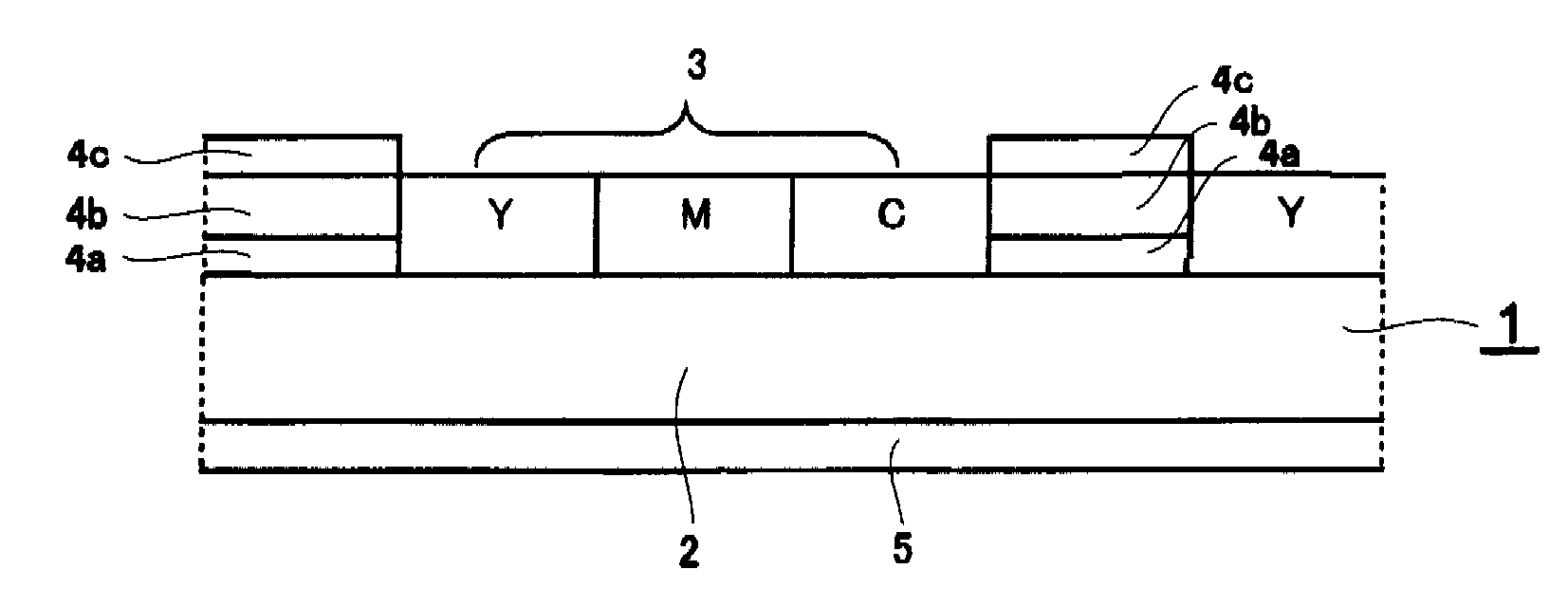

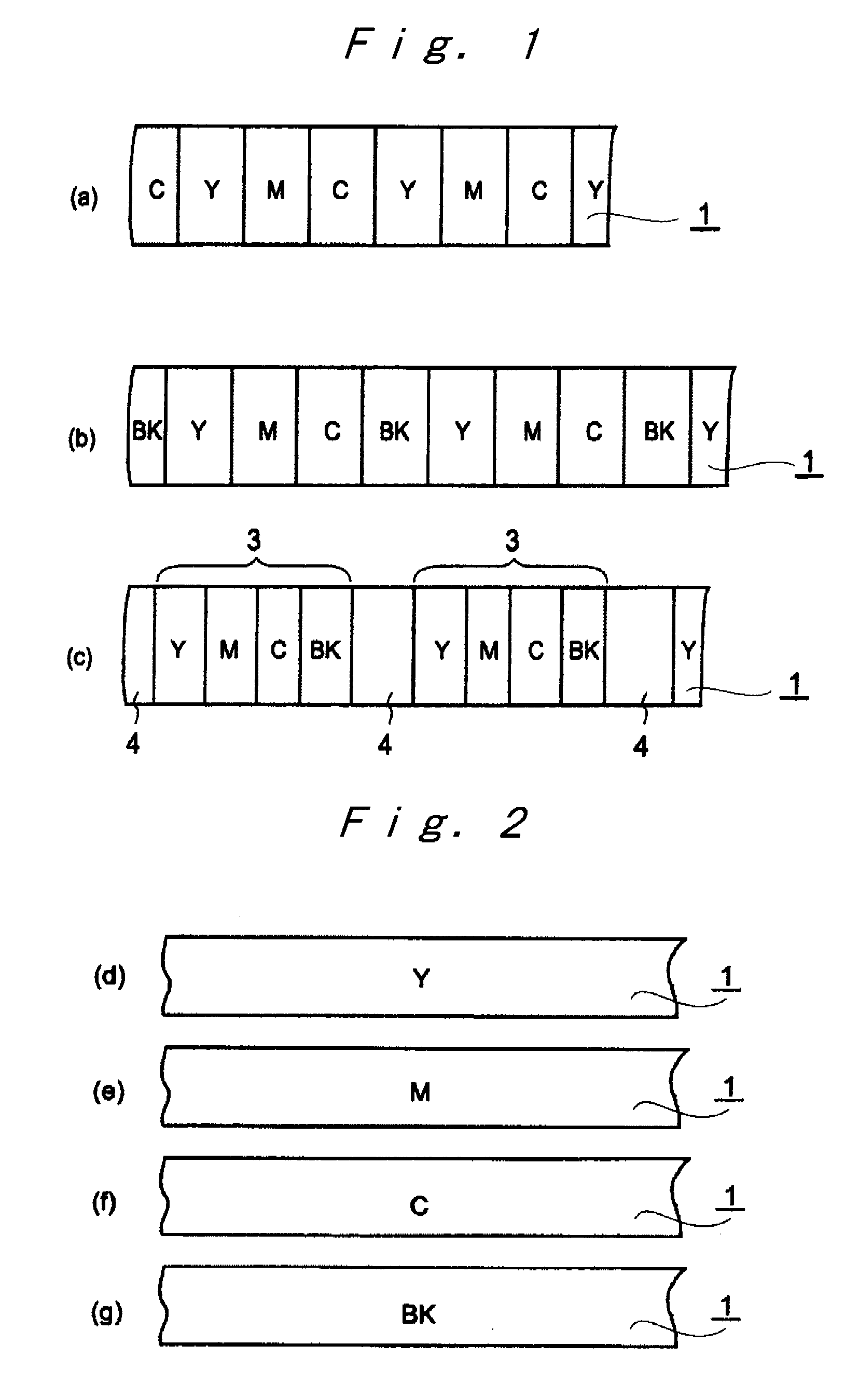

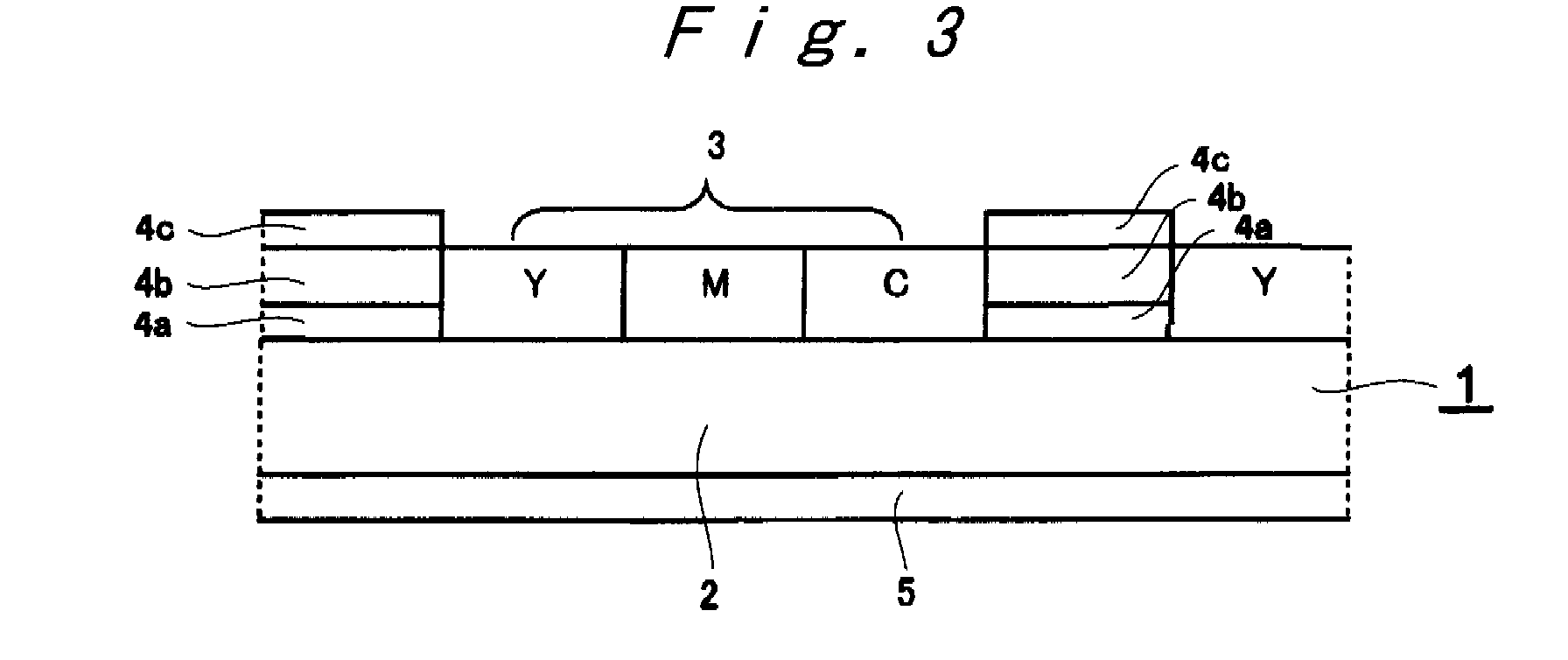

Image-forming method using heat-sensitive transfer system

InactiveUS20080254383A1Diffusion transfer processesRadiation applicationsVitrificationHydrophilic polymers

An image-forming method applying a heat-sensitive transfer system which uses a heat-sensitive transfer image-receiving sheet and a heat-sensitive transfer sheet,in which the heat-sensitive transfer image-receiving sheet has a support, at least one dye receptor layer on the support, and at least one heat insulation layer containing both hollow polymer particles and a hydrophilic polymer that is disposed between the dye receptor layer and the support; and the heat-sensitive transfer sheet has at least one yellow heat transfer layer, at least one magenta heat transfer layer, and / or at least one cyan heat transfer layer on a support:comprising controlling each glass transition point (Tg-A) of three heat transfer layers so that they decrease in area order; andcomprising transferring at least three kinds of heat transfer dyes contained in the heat transfer layers to the dye receptor layer in order.

Owner:FUJIFILM CORP

Ink composition and ink jet recording method

An ink composition contains a pigment, first wax particles, second wax particles, and a resin emulsion, in which the first wax particles have a melting point of 120° C. or higher and 170° C. or lower, the second wax particles have a melting point of 70° C. or higher and less than 120° C., the resin emulsion has a glass transition point of 50° C. or higher and 150° C. or lower, the first wax particles contain one or more kinds of wax particles selected from the group consisting of polyethylene wax particles or polypropylene wax particles, and the second wax particles contain one or more kinds of wax particles selected from the group consisting of polyethylene wax particles.

Owner:SEIKO EPSON CORP

Optical film

InactiveUS6261649B1Easy to exportEasily raw materialLiquid crystal compositionsStatic indicating devicesCrystallographyLiquid crystalline

A high-quality optical compensator for use in liquid crystal display elements can be prepared from a film comprising an end unit modified liquid crystalline polymer which has a monofunctional structural unit and which exhibits an optically positive uniaxiality, and, as needed, a liquid crystalline polymer which has a logarithmic viscosity at least 0.01 dl / g higher than that of the end unit modified liquid crystalline polymer and a glass transition point at least 5° C. higher than that of the end unit modified liquid crystalline polymer and which exhibits an optically positive uniaxiality, wherein a nematic hybrid orientation which is formed in the liquid crystal state is immobilized.

Owner:NIPPON MITSUBISHI OIL CORP

Adhesive polyester film for optical use

An optical adhesive polyester film comprising (A) a polyester film layer containing an aromatic polyester and an ultraviolet absorber and (B) a coating formed on at least one surface of the polyester film (A). The coating (B) contains at least one polymer selected from the group consisting of a coating polyester having a glass transition point of 40 to 100 DEG C. and an acryl polymer having a glass transition point of 20 to 80 DEG C. in an amount of 50 to 95% by weight based on the coating. The optical adhesive polyester film is disposed on the front of a plasma display so as to block externally incoming ultraviolet light.

Owner:TEIJIN DUPONT FILMS JAPAN

Easily adhesive polyester film for solar cell back surface-protecting film and solar cell back surface-protecting film obtained using the same

InactiveCN101065849AImprove adhesionExcellent adhesionPhotovoltaic energy generationSemiconductor devicesPolyvinyl alcoholAcrylic resin

Disclosed is a highly adhesive polyester film which is used for protecting the back side of a solar cell and composed of a polyester film and a resin coating arranged on one side of the polyester film. This highly adhesive polyester film is characterized in that the resin coating is made of a crosslinking agent and a resin selected from polyester resins having a glass transition point of 20-100 DEG C, acrylic resins having a glass transition point of 20-100 DEG C, combinations of those resins, and combinations of at least one of those resins and a polyvinyl alcohol having a saponification degree of 70-90 mol%. This highly adhesive polyester film is excellent in adhesion to EVA while achieving excellent mechanical properties, heat resistance and moisture resistance.

Owner:TEIJIN DUPONT FILMS JAPAN

Block copolymer and polymer composition comprising the same

A block copolymer comprising, in a main chain thereof, a crystalline polymer block A obtained by hydrogenation of at least 80% of unsaturated bonds of a butadiene-based polymer block having a 1,2-bond content less than 20%, a polymer block B having a glass transition point of 20° C. or lower and a polymer block C composed mainly of a methacrylate ester unit and / or an acrylate ester unit and having a glass transition point exceeding 20° C. has good elastomeric properties, excellent weather resistance, solvent resistance and heat resistance and has good affinity with each of a polar polymer and non-polar polymer. A polymer composition comprising said block copolymer effectively exhibits the above-described characteristics of the block copolymer.

Owner:KURARAY CO LTD

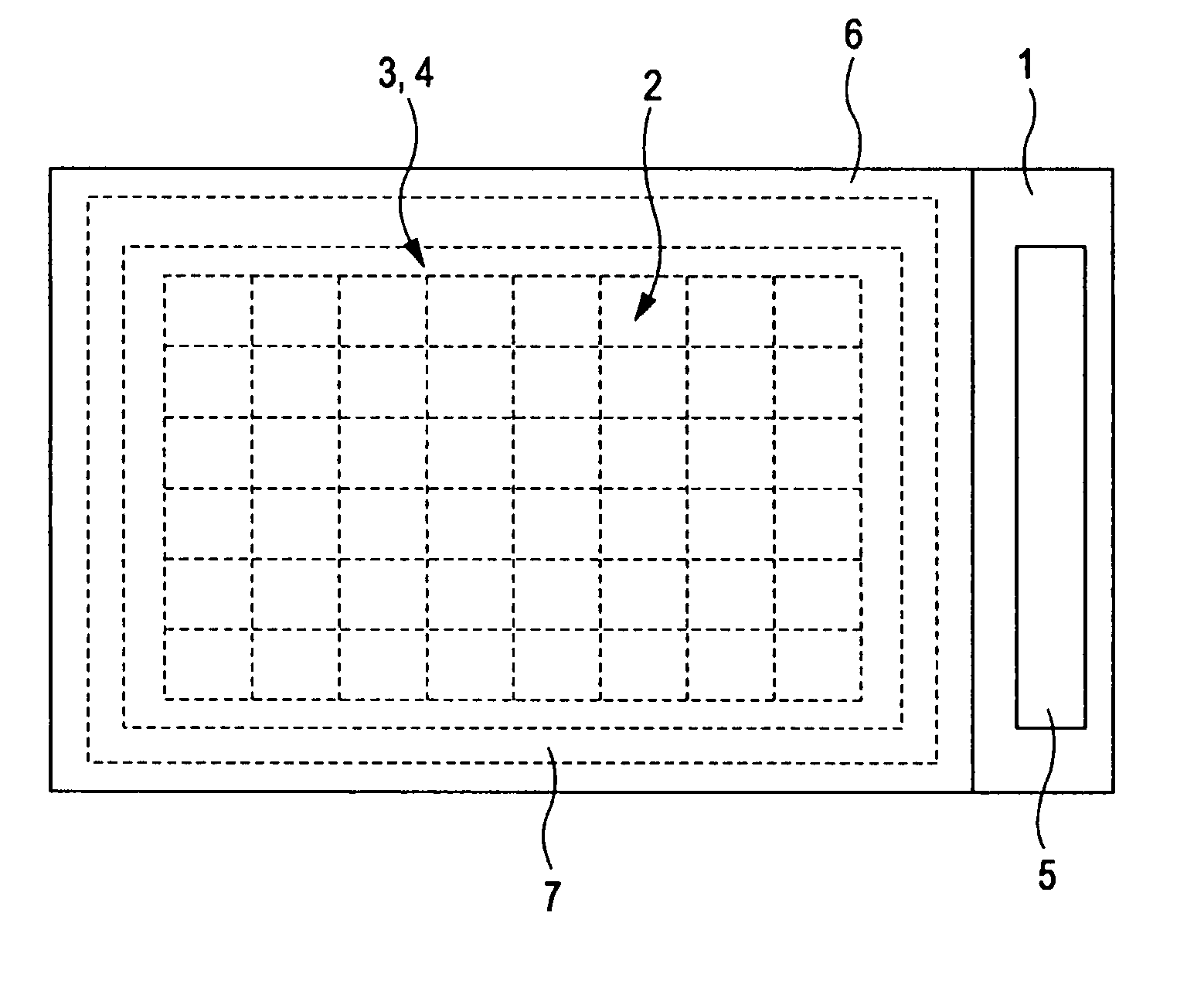

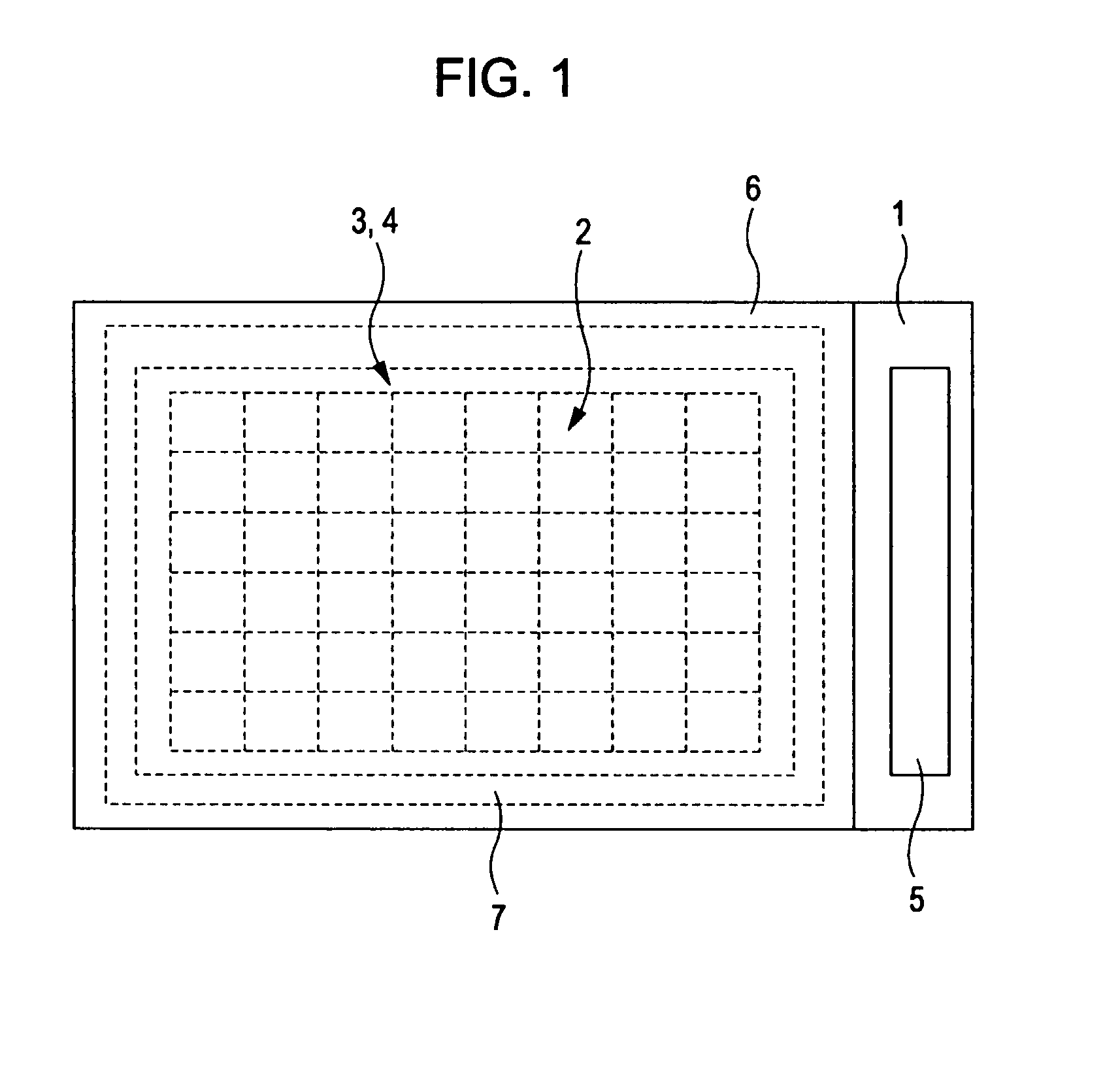

Optical laminate, illuminating device, liquid crystal display device, and method for manufacturing optical laminate

InactiveUS20120268687A1Less film thicknessAvoid it happening againOrnamental structuresSpecial ornamental structuresDistribution controlLiquid-crystal display

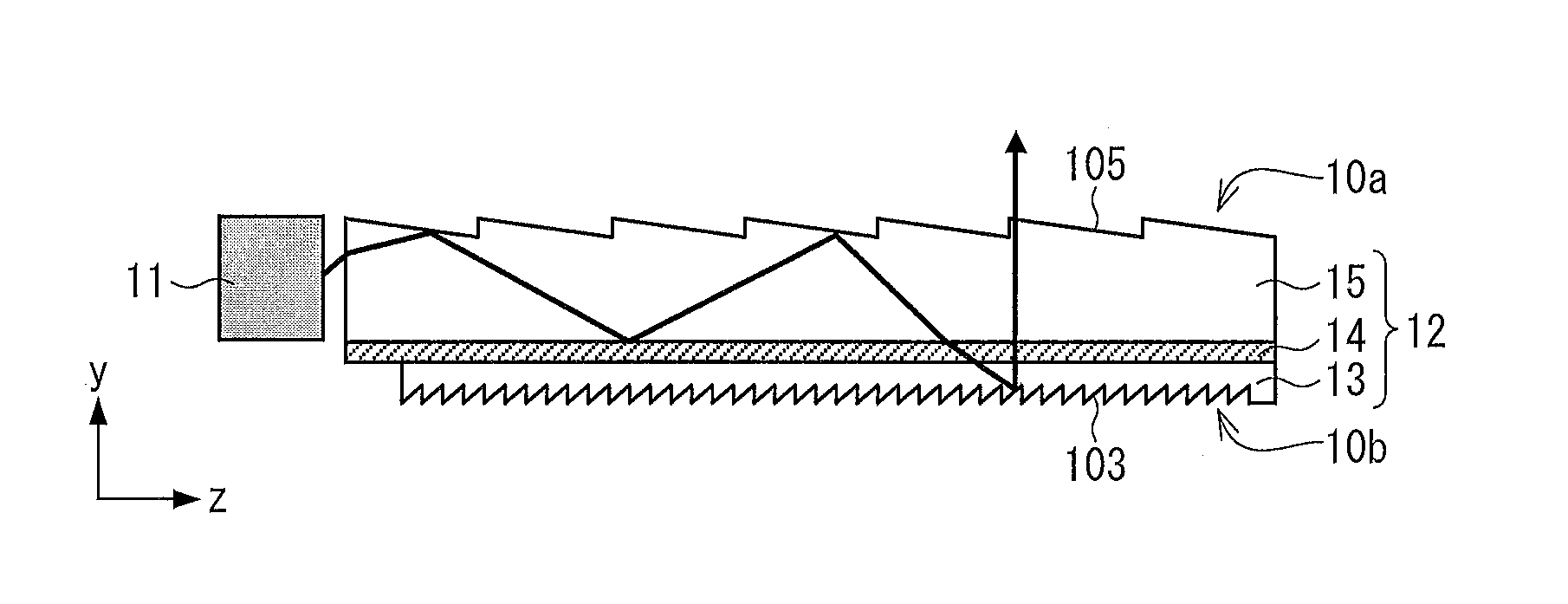

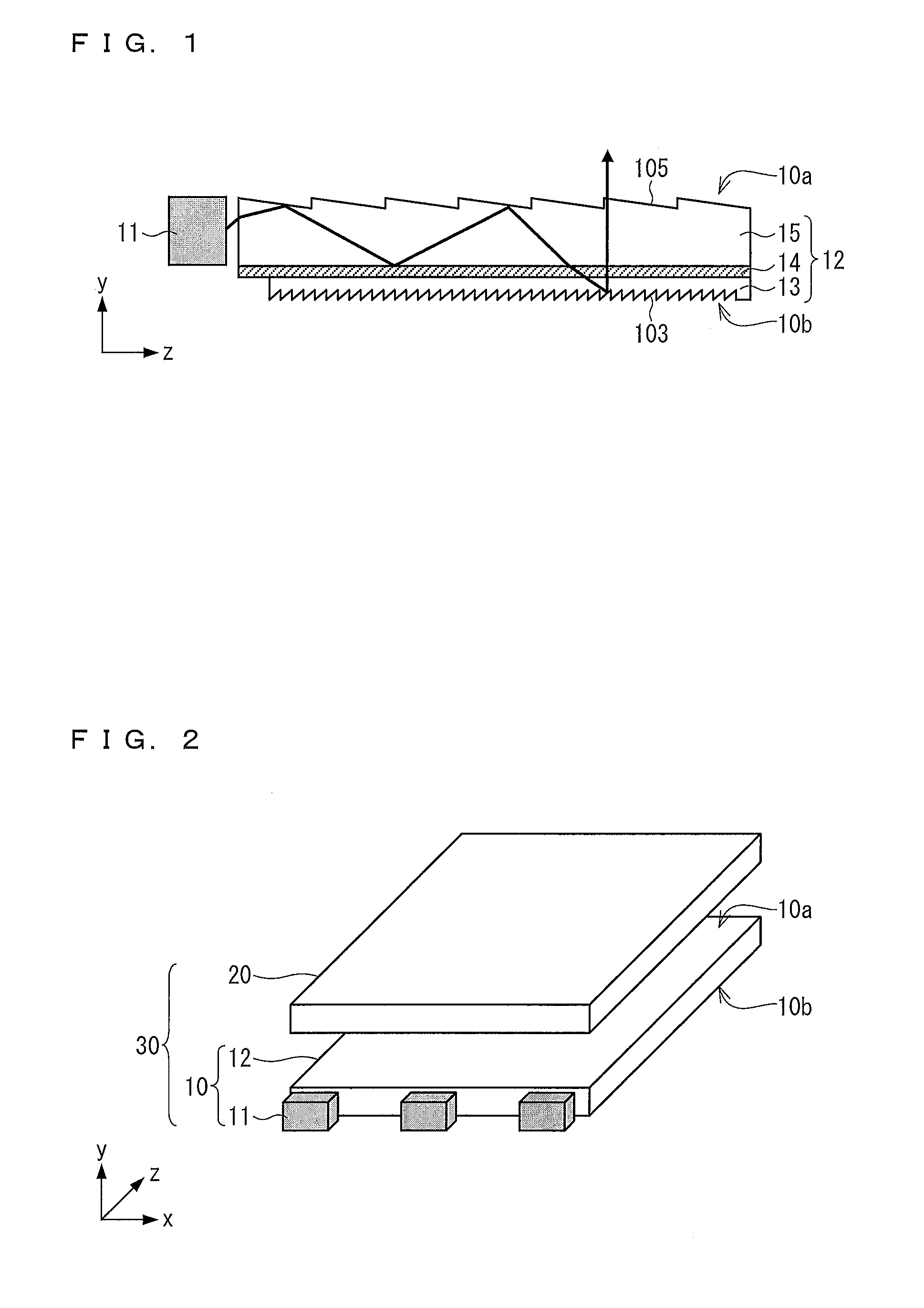

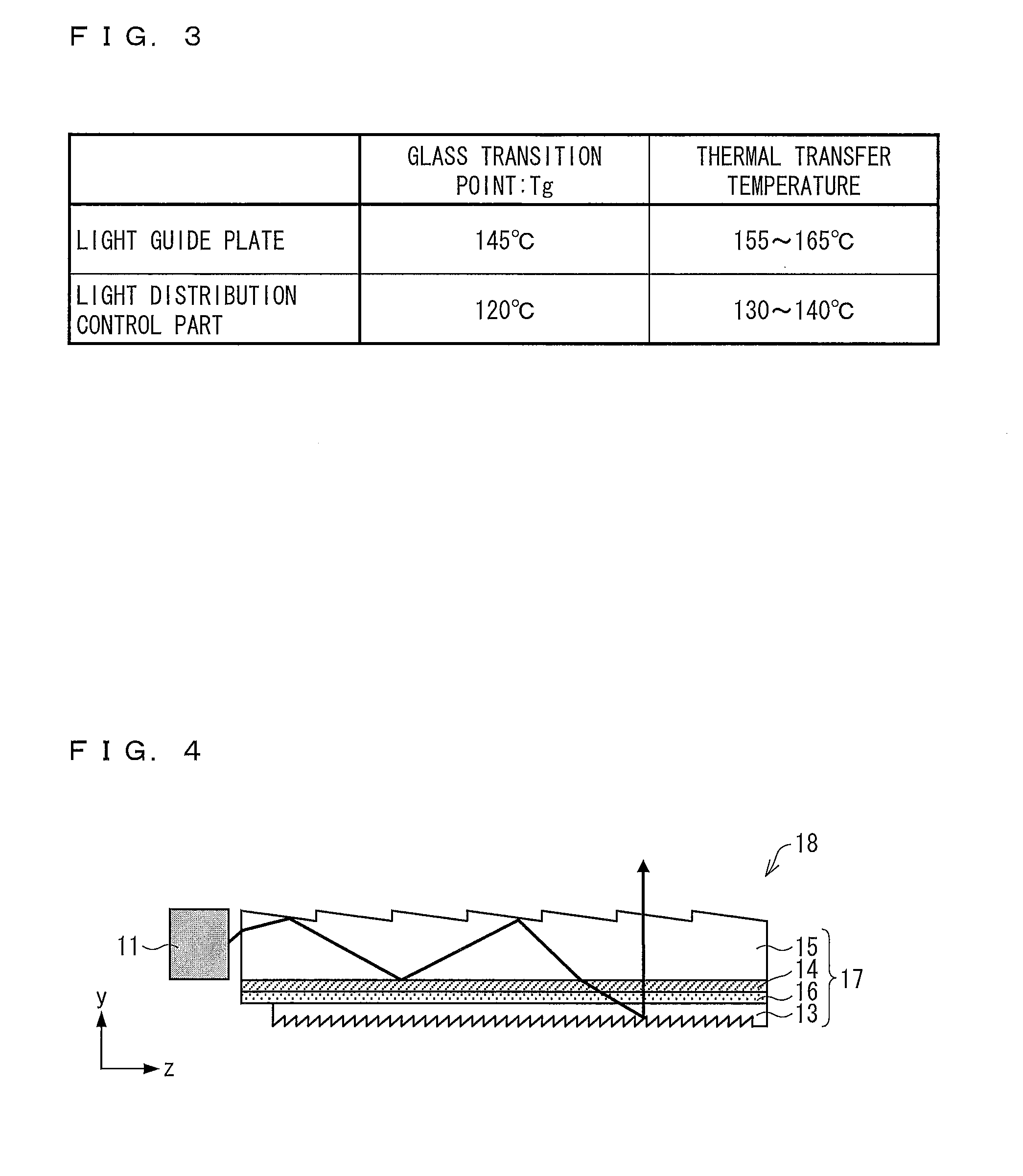

An light guide (12) has an indented pattern (105) on its front surface (10a) and an indented pattern (103) on its back surface (10b), and includes: a light guide plate (15) including the indented pattern (105) provided on the front surface (10a); a light distribution control part (13) including the indented pattern (103) provided on the back surface (10b); and a middle layer (14) provided between the light guide plate (15) and the light distribution control part (13), the light distribution control part (13) being less in film thickness than the light guide plate (15), and the light distribution control part (13) having a glass transition point lower than that of the light guide plate (15). This makes it possible to form indented patterns on the front surface and the back surface of an optical laminate constituted by a stack of a plurality of layers, while preventing occurrence of defects.

Owner:SHARP KK

Lithium aluminosilicate glass with high modulus of elasticity, and method for producing same

A lithium aluminosilicate glass and a method for producing such lithium aluminosilicate glass are provided. The glass has a composition, in mol %, of: SiO2 60-70; Al2O3 10-13; B2O3 0.0-0.9; Li2O 9.6-11.6; Na2O 8.2-less than 10; K2O 0.0-0.7; MgO 0.0-0.2; CaO 0.2-2.3; ZnO 0.0-0.4; ZrO2 1.3-2.6; P2O5 0.0-0.5; Fe2O3 0.003-0.100; SnO2 0.0-0.3; and CeO2 0.004-0.200. Further, the composition complies with the following relations and conditions: (Li2O+Al2O3) / (Na2O+K2O) greater than 2; Li2O / (Li2O+Na2O+K2O) greater than 0.47 and less than 0.70; CaO+Fe2O3+ZnO+P2O5+B2O3+CeO2 greater that 0.8 and less than 3, where at least four out of the six oxides are included. The glass exhibits a modulus of elasticity of at least 82 GPa and has a glass transition point below 540° C. and / or a working point below 1150° C.

Owner:SCHOTT AG

Toner and developer for developing electrostatic image, process for production thereof and image forming method

InactiveUS6077638AImprove the lubrication effectExcellent in releasabilityRadiation applicationsDevelopersLatent imageImage formation

A toner for developing an electrostatic image is formed of toner particles; wherein each toner particle includes (i) 100 wt. parts of a binder resin having a glass transition point (Tg) of 50-70 DEG C., (ii) 0.2-20 wt. parts of solid wax, and (iii) colorant particles or magnetic powder carrying a liquid lubricant, so that the toner particle retains at its surface the liquid lubricant gradually released from the particles (iii). The toner may be further blended with an organically treated inorganic fine powder to provide a developer. The toner or developer retains good lubricity and releasability so that it is suitable to be used in an image forming method including means contacting a latent image-bearing means, such as a contact charging means, a contact transfer means or a contact cleaning means.

Owner:CANON KK

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com