Adhesive polyester film for optical use

A technology of polyester film and adhesiveness, which is applied in the direction of optics, optical components, polyester coatings, etc., and can solve the problems of manufacturing cost and weak absorption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~4 and comparative example 1~6

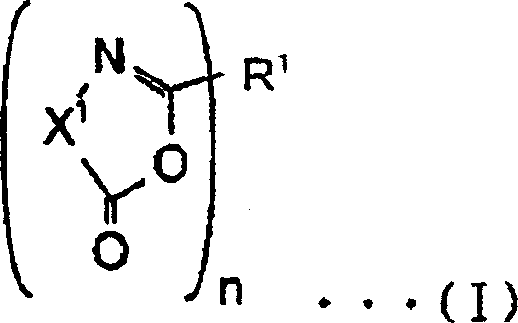

[0269] Polyethylene terephthalate (intrinsic viscosity: 0.62) containing 1% by weight of an ultraviolet absorber represented by the following formula (A) was melt-extruded onto a rotating cooling drum maintained at 20°C to form an unstretched membrane.

[0270]

[0271] Then, after stretching 3.4 times in the longitudinal direction, an aqueous coating liquid having a concentration of 8% of the following film coating composition (Table 1) was uniformly coated on both surfaces using a roll coater.

[0272] Table 1

[0273]

[0274] Polyester A-1: an acid component consisting of 2,6-naphthalene dicarboxylic acid 65 mol % / isophthalic acid 30 mol % / isophthalic acid 5-sodium sulfonate 5 mol %; and ethylene glycol 90 mol % / diethylene glycol 10 mol% of diol component composition (Tg=80 degreeC).

[0275] Polyester A-2: an acid component consisting of terephthalic acid 80 mol% / isophthalic acid 15 mol% / isophthalic acid 5-sodium sulfonate 5 mol%; and eth...

Embodiment 5、6 and comparative example 8

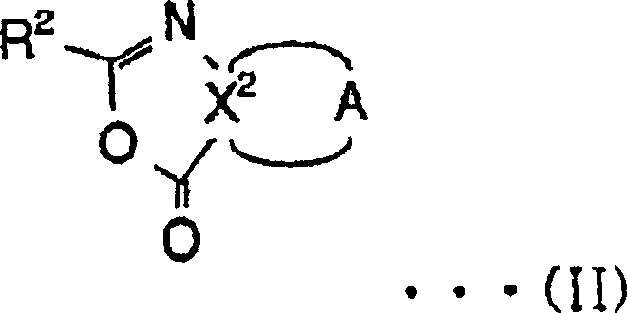

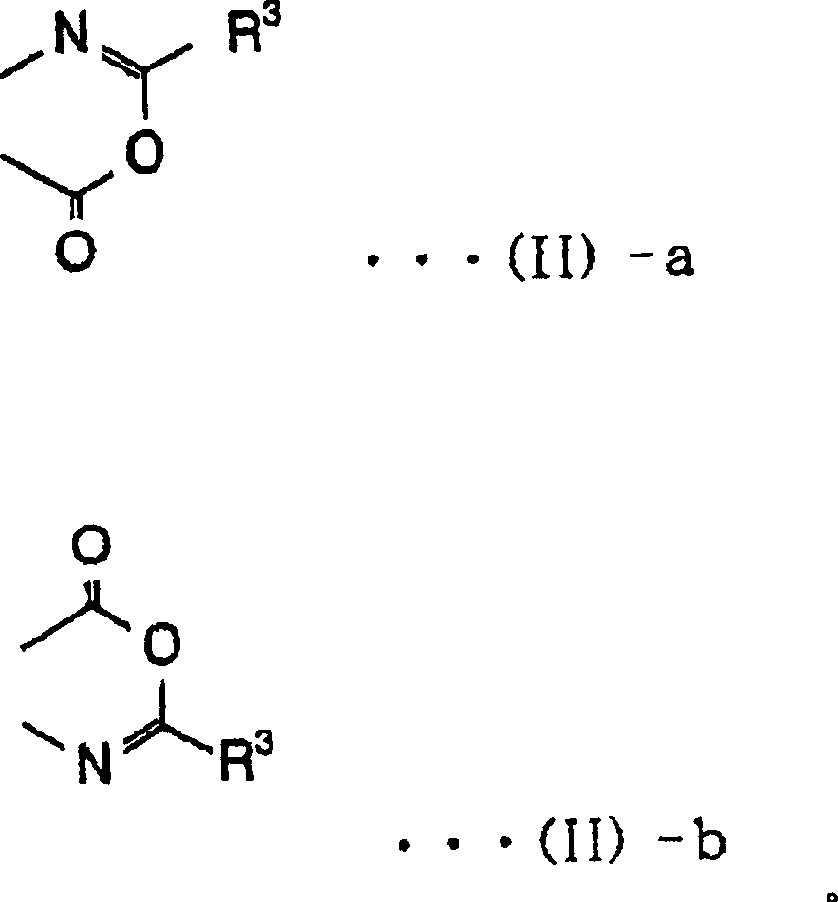

[0292] In addition to using the ultraviolet absorber contained in the polyester and its content, the ultraviolet absorber of the following structural formula (B) was changed to a content of 1% by weight in Example 5, and the content was changed to 1 in Example 6. A laminated film was obtained in the same manner as in Example 1, except that the ultraviolet absorber of the following structural formula (C) was changed to polyester not containing an ultraviolet absorber in Comparative Example 8. Table 2 shows the properties of the obtained laminated film.

[0293]

[0294] Table 2

[0295]

[0296] As can be seen from the results shown in Table 2, the optical adhesive laminated film of the present invention is excellent in weather resistance, adhesiveness, transparency, and scratch resistance, and is useful as an optical adhesive base film. of.

Embodiment 7~11 and comparative example 9~18

[0298] Polyethylene terephthalate (intrinsic viscosity 0.62) containing 1% by weight of the ultraviolet absorber represented by the above formula (A) was melt-extruded on a rotating cooling drum maintained at 20°C to form an unstretched membrane.

[0299] After stretching 3.4 times in the longitudinal direction, an aqueous coating solution having a concentration of 8% of the following film coating composition (Table 3) was uniformly applied to both surfaces using a roll coater.

[0300] polyester

filler

Additive D

weight%

Additive E

weight%

weight%

type

weight%

type

weight%

Example 7

A-5

75

C-1

10

3

2

10

Example 8

A-5

65

C-1

15

8

2

10

Comparative Example 9

A-5

55

C-1

20

5

5

15

Example 9

A-6

80

...

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com