Easily adhesive polyester film for solar cell back surface-protecting film and solar cell back surface-protecting film obtained using the same

A technology of solar cells and polyester films, applied in circuits, photovoltaic power generation, electrical components, etc., can solve problems such as insufficient effect and inability to use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~7 and comparative example 1

[0154] Polyethylene terephthalate (intrinsic viscosity: 0.62) was melt-extruded onto a rotating cooling drum maintained at 20° C. to make an unstretched film. Next, after stretching to 3.3 times at 100° C. in the longitudinal direction, an aqueous coating liquid having a concentration of 8% by weight of the following composition for a coating film (Table 1) was uniformly applied to both sides by a roll coater. Next, the coated film was stretched further, dried at 95°C, stretched to 3.6 times in the transverse direction at 110°C, shrunk by 3% in the width direction at 220°C, and heat-set to obtain a thickness of 50 μm polyester film. In addition, the thickness of the coating film was 0.05 micrometers. These evaluation results are shown in Table 2.

[0155] Table 1

[0156]

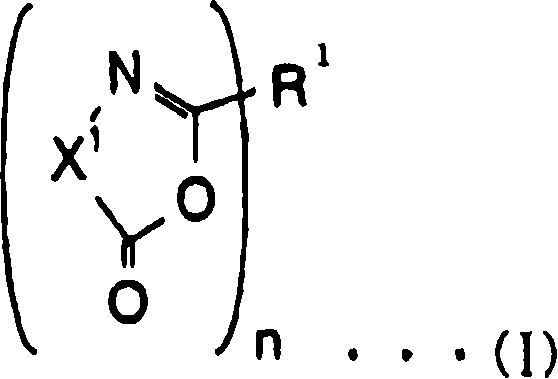

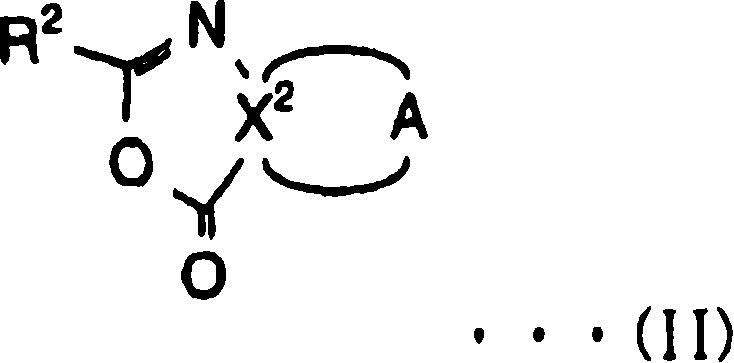

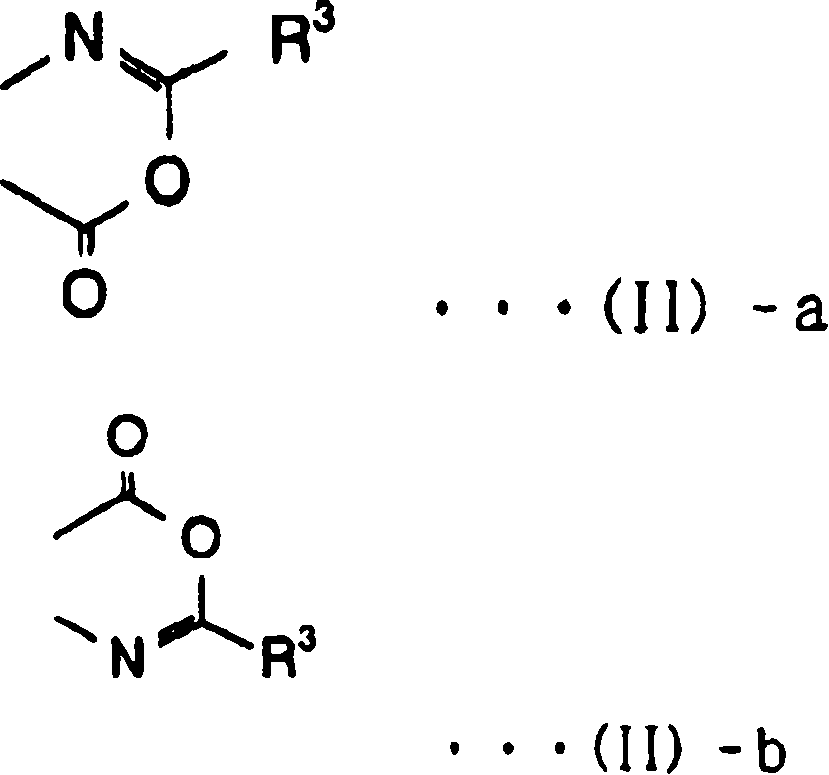

[0157] Crosslinking agent A-1: 30 mol% of methyl methacrylate / 2-isopropenyl-2-oxazoline 30 mol% / polyethylene oxide (n=10) methacrylate 10 mol% / A polymer having an oxazoline group composed of 30 mo...

Embodiment 8

[0170] Polyethylene terephthalate (intrinsic viscosity: 0.62) containing 1% by weight of an ultraviolet absorber represented by the following formula was melt-extruded onto a rotating cooling drum maintained at 20° C. to form an unstretched film.

[0171]

[0172] Thereafter, a film was obtained in the same manner as in Example 3. Table 2 shows the evaluation results of the polyester film.

Embodiment 9

[0176] Polyethylene 2,6-naphthalate (intrinsic viscosity: 0.58) was melt-extruded onto a rotating cooling drum maintained at 60° C. to make an unstretched film. Next, after stretching to 3.3 times in the longitudinal direction at 140° C., the aqueous coating liquid used in Example 3 was uniformly applied to one surface with a roll coater. Next, the coated film was stretched, dried at 130°C, stretched to 3.6 times in the transverse direction at 150°C, shrunk by 3% in the width direction at 240°C, and heat-set to obtain a thickness 50μm polyester film. In addition, the thickness of the coating film was 0.05 micrometers. These evaluation results are shown in Table 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Glass transition point | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com