Release film having excellent peelability

A release film, peeling technology, applied in the direction of adhesive type, film/sheet release liner, film/sheet adhesive, etc., can solve the problem of discontinuous silicone release layer, silicone peeling, The problem of reduced adhesive force of the adhesive layer, etc., achieves the effect of excellent peelability and anti-blocking, small peeling force, and high use value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

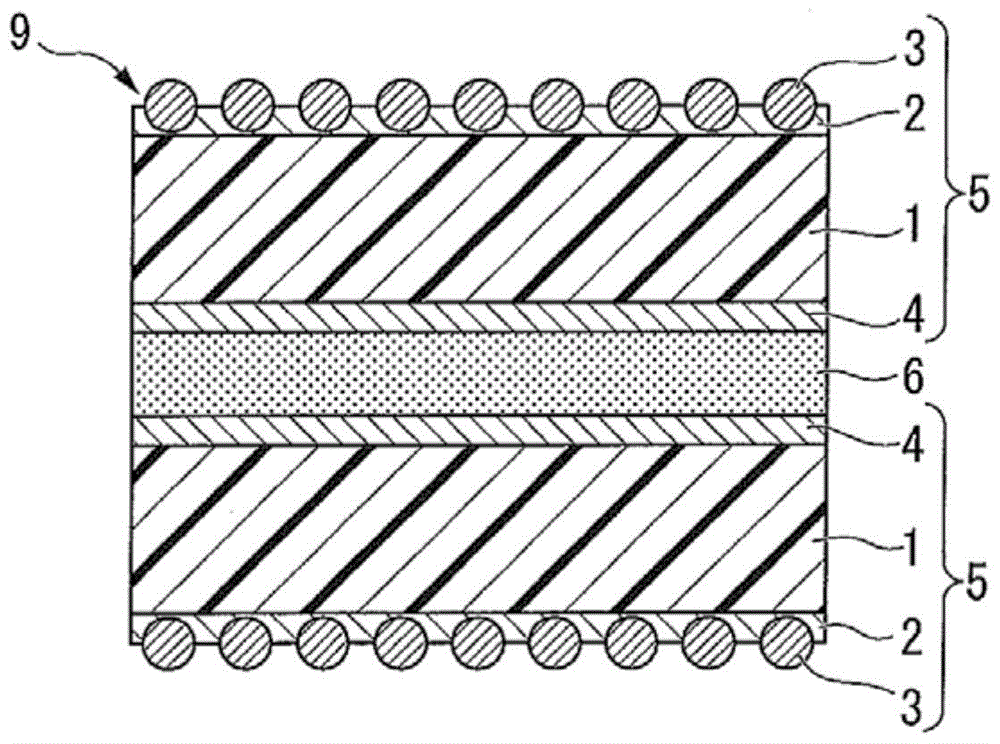

[0065] (release film of embodiment 1)

[0066] 7.5 parts by weight of ethyl cellulose (manufactured by DOW Chemical, trade name: ETHOCEL (registered trademark) 100FP), and 0.0375 parts by weight of a silicone-based resin polymer with an average particle diameter (volume-based average particle diameter) of 2 μm were put into a beaker. Microparticles (manufactured by Momentive Performance Materials, trade name: Tospearl (registered trademark) 120) and 92.5 parts by weight of a 50 / 50 mixed solvent of toluene / ethyl acetate were mixed and stirred until ethyl cellulose was dissolved to prepare a paint. Next, on the corona-untreated surface of a single-sided corona-treated polyester film with a thickness of 50 μm, the dried binder resin was coated by the Meyer rod method to a thickness of 1.0 μm, and then hot air was circulated at 120°C. Dryer was heated for 1 minute to obtain a polyester film having surface irregularities on one surface. Then, on the opposite surface (corona treate...

Embodiment 2

[0088] The release film of Example 2 was produced in the same manner as in Example 1 except that the thickness of the release agent layer was 0.4 μm.

Embodiment 3

[0090] The release film of Example 3 was produced in the same manner as in Example 1 except that the thickness of the release agent layer was 0.5 μm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| peel strength | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com