Radiation-resistance high-elastic resilience polyvinyl chloride composition and preparation method thereof

A technology of polyvinyl chloride and polyvinyl chloride resin, which is applied in the field of radiation-resistant and high-resilience polyvinyl chloride composition and its preparation field, can solve the problems of unfavorable production of industrialized products, complicated preparation process and the like, and achieves low cost and good quality. The effect of radiation resistance and high resilience

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

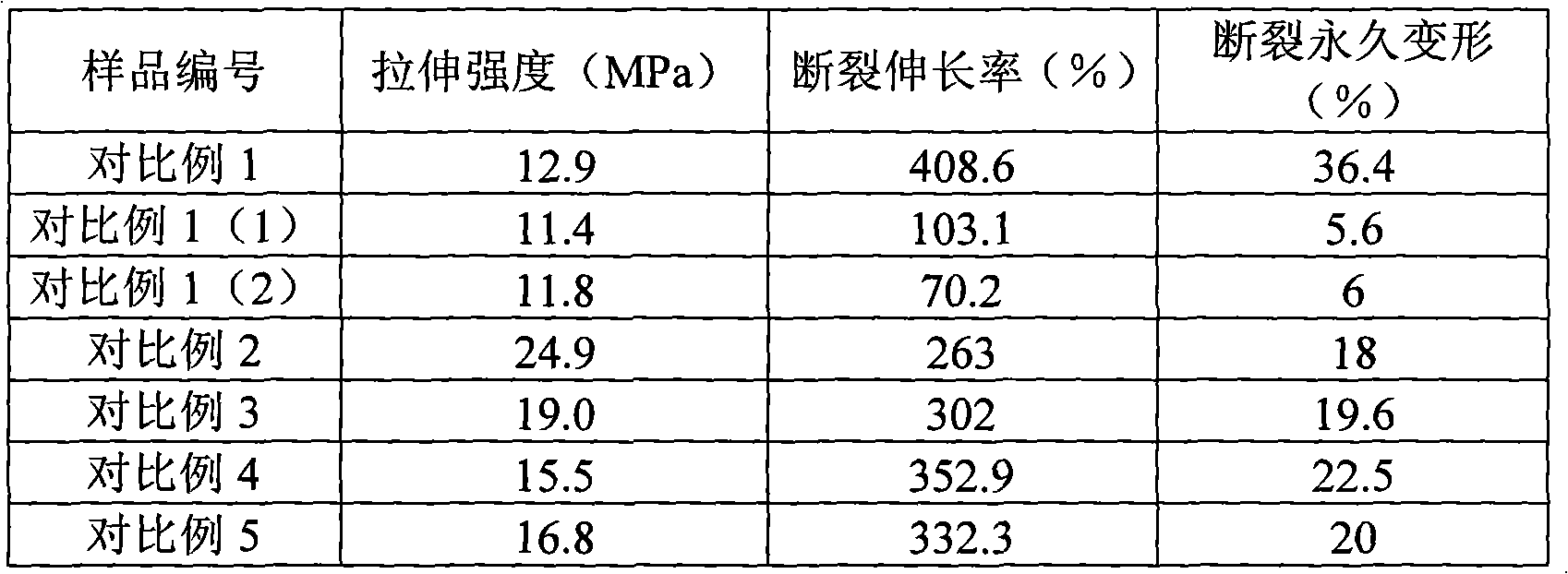

Examples

Embodiment 1

[0040] With 100 parts by weight of PVC powder (Hangzhou Electrochemical Group, DH-2500), 5 parts of calcium zinc heat stabilizer (Kai Misen company, product brand: 5515), 0.4 part of internal lubricant calcium stearate (Tianjin Yong Changsheng Chemical Co., Ltd., industrial grade), 0.1 part of external lubricant polyethylene wax (Beijing University of Chemical Technology Fine Chemical Factory, LPE-F), put it into a high-speed mixer, stir at a high speed until 65 ° C, at this time slowly pour plasticizer 120 parts of agent (DOP / IPPP weight ratio 60:60), so that PVC can completely absorb the plasticizer. Stir at high speed until the temperature reaches 105°C and discharge.

[0041] The material was stirred and cooled to room temperature (about 25° C.), and then mixed with 30 parts of powdered nitrile rubber P83 (French Ilio company, acrylonitrile content 33%, average particle size 0.6 mm) at room temperature and stirred evenly.

[0042] Mastication is carried out using a two-ro...

Embodiment 2

[0046] With the PVC powder (with embodiment 1) of 100 parts by weight, 5 parts of calcium-zinc thermal stabilizers (with embodiment 1), 0.4 part of interior lubricant calcium stearate (with embodiment 1), 0.1 part of external lubrication Add polyethylene wax (same as Example 1), put it into a high-speed mixer, and stir it at a high speed until 65°C, at this time, slowly pour 100 parts of plasticizer (the weight ratio of DOP / IPPP is 70:30), so that PVC can be completely absorbed plasticizer. Stir at high speed until the temperature reaches 105°C and discharge.

[0047] The material is placed to room temperature, and then mixed with 50 parts of powdered nitrile rubber P83 (same as Example 1) at room temperature.

[0048] Using twin-screws for ordinary PVC, put the mixed material containing pre-swelled PVC into the hopper, extrude, cool, and granulate with hot air to obtain a radiation-resistant high-resilience polyvinyl chloride composition. The extrusion temperature is 170~ 1...

Embodiment 3

[0052] With the PVC powder (with embodiment 1) of 100 parts by weight, 5 parts of calcium-zinc thermal stabilizers (with embodiment 1), 0.4 part of interior lubricant calcium stearate (with embodiment 1), 0.1 part of external lubrication Add polyethylene wax (same as Example 1), put it into a high-speed mixer, and stir it at a high speed until 65°C, at this time, slowly pour 100 parts of plasticizer (the weight ratio of DOP / IPPP is 30:70), so that PVC can be completely absorbed plasticizer. Stir at high speed until the temperature reaches 105°C and discharge.

[0053] The material is placed to room temperature, and then mixed with 50 parts of powdered nitrile rubber P83 (same as Example 1) at room temperature.

[0054] Mastication is carried out using a two-roll mill. Weigh the mixed material containing pre-swelled PVC and put it into the double-roller open mill, thin pass plasticization, the resin film is passed through the rollers, and then placed on the plate, and then pa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com