Flame retardant organic glass and preparation method thereof

A plexiglass, flame retardant technology, applied in the field of flame retardant plexiglass and its preparation, can solve the problems of sacrificing the thermal properties and transparency of materials, health hazards, and reducing thermal properties of materials, and achieve good flame retardant properties, The effect of delaying combustion and reducing spillage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] According to the components specified in Table 1 below, weigh the raw materials according to the parts by weight, add phenyl phosphate dichloride and 1 / 3 part by weight of tetrahydrofuran into the mixer, the temperature is 0 °C, and the speed is 50-60r / min , time 20-30min; then add triethylamine, continue to stir; then slowly dropwise add hydroxyethyl acrylate and 1 / 3 parts by weight of tetrahydrofuran, dropwise time 1.5-2h; After reacting for 10 hours, remove the triethylamine salt by filtration, remove the unreacted monomer by evaporation; then add azobisisobutylcyanide and mix evenly, put the mixture in an oven at 80-90°C for 5-6 hours to obtain a linear homopolymer ; Add the linear homopolymer to 1 / 3 parts by weight of tetrahydrofuran, add water and hydrochloric acid to catalyze, react and stir for 5-6h; pour the above liquid into the mold, keep the room temperature for 70-72h, and then put it into a vacuum oven Dry in medium for 5-6h to get the synthetic flame reta...

Embodiment 2

[0022] The method of Example 1 was repeated according to the content of each component specified in Table 1 below, and the test results are listed in Table 1.

Embodiment 3

[0024] The method of Example 1 was repeated according to the content of each component specified in Table 1 below, and the test results are listed in Table 1.

[0025] 1. Performance testing.

[0026] 1. Testing and Characterization.

[0027] Oxygen index test: Measured according to GB / T 2406-1993 standard.

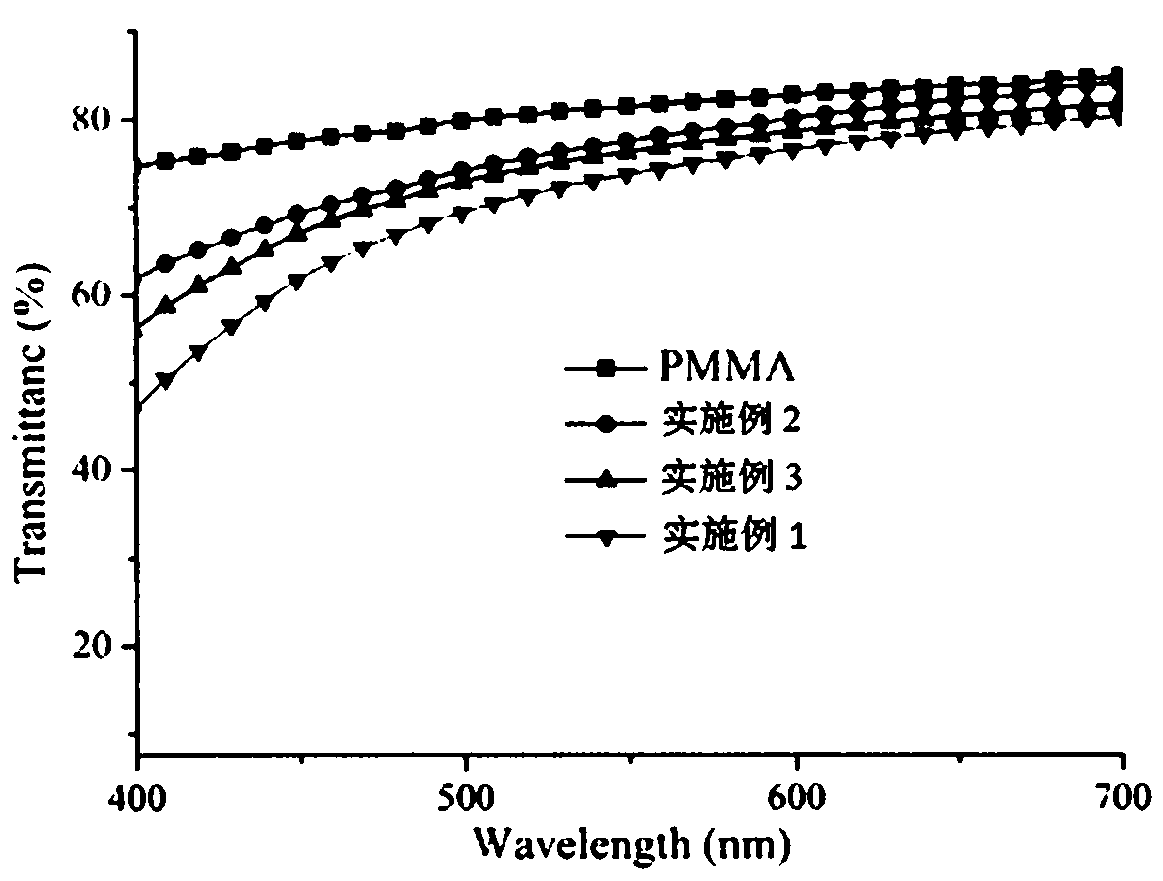

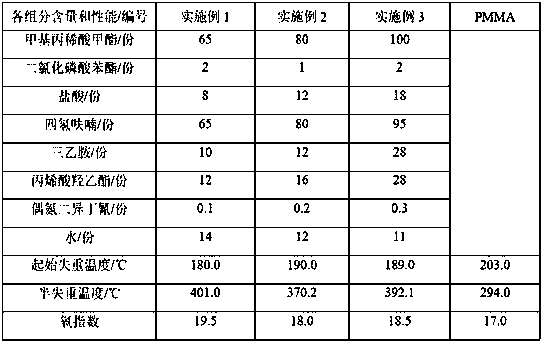

[0028] 2. The flame-retardant plexiglass prepared in Examples 1-3 was tested for performance, and the results are shown in Table 1.

[0029] Table 1 Physical and chemical indicators of flame-retardant plexiglass.

[0030]

[0031] It can be seen from Table 1 that the initial weight loss temperature of the flame-retardant plexiglass of the present invention is ≥ 180 ° C, the half weight loss temperature is > 370 ° C, the initial weight loss temperature of PMMA is 203.0 ° C, and the half weight loss temperature is > 294.0 ° C, the weight loss area of the present invention Compared with pure PMMA, the migration to high temperature shows that the introduction of the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com