Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

115 results about "PHENOLSULFONIC ACID" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

PHENOLSULFONIC ACID, LIQUID is a yellowish liquid that becomes brown on exposure to air.Soluble in alcohol. Irritating to mucous membranes, skin, and eyes. Moderately toxic by ingestion. Used as a laboratory reagent, in water analysis and in the manufacture of pharmaceuticals. A mixture of ortho and para isomers.

Modified environment-friendly phenolic aldehyde thermal insulation material and preparation method thereof

The invention discloses a modified environment-friendly phenolic aldehyde thermal insulation material and a preparation method thereof. The method comprises the following steps of: sufficiently mixing 100 parts of resole, 5-15 parts of sodium sulfite, 10-30 parts of phenolsulfonic acid solution, 2-5 parts of stabilizer, 1-8 parts of nano calcium carbonate, 1-8 parts of calcium sulfate whisker, 0.1-3 parts of nano aluminum hydroxide, 0.1-3 parts of ethylene glycol and 15-30 parts of foaming agent by weight; uniformly spreading the mixture on a plane carrier; and uniformly heating through a lamination conveyor and performing foaming and curing molding. According to the invention, sodium sulfite and phenolsulfonic acid solution are used as composite catalysts; and since the sodium sulfite has the effects of deoxidizing and reducing the acidity of the mixed solution, under the joint effect of the sodium sulfite and phenolsulfonic acid solution, the corrosion of the phenolic aldehyde thermal insulation material on a metal component is avoided. The modified phenolic aldehyde thermal insulation material disclosed by the invention is far superior to the values stipulated by the national standard in terms of the indexes such as compression strength, bending strength, creep resistance, dimensional stability, water absorption and the like; and the corrosion on metals is obviously reduced in comparison with a common product.

Owner:BEIJING LIGAO WATERPROOF ENG CO LTD

Method for preparing stable tin methanesulfonate solution

InactiveCN103952718AImprove direct yieldQuality improvementElectrolysis componentsOrganic chemistryMeth-Ascorbic acid

The invention belongs to the field of tin chemical engineering and in particular relates to a method for preparing a stable tin methanesulfonate solution. The method comprises the steps of preparing anode and cathode sheets from refined tin, adding stabilizers into methanesulfonic acid to prepare an anolyte, adding electroplating additives into methanesulfonic acid to prepare the catholyte, shade, separating the anolyte from the catholyte by an anion separator, preparing a crude tin methanesulfonate solution by a direct current electric melting method, and concentrating the crude tin methanesulfonate solution in vacuum under the protection of inert gas to obtain the stable tin methanesulfonate solution, wherein the stabilizers are phenol, ascorbic acid or tartaric acid and the electroplating additives are phenol sulphonic acid, latex, gelatin, cresol, aloin, cresylic acid or beta-naphthol. The stable tin methanesulfonate solution prepared by the method disclosed by the invention has the characteristics of stable quality and no precipitation, is difficult to oxidize and discolor, and has the advantages of simple preparation process, low cost, environment friendliness and the like, and good popularization and application value are achieved.

Owner:YUNNAN TIN

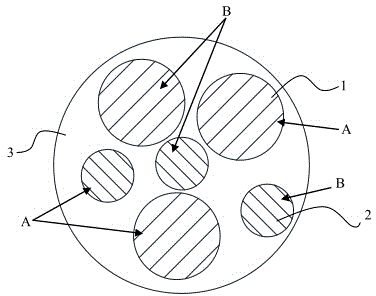

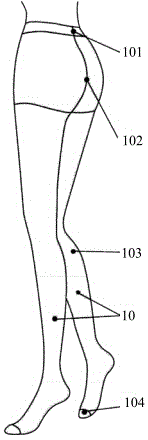

Composite snagging-resisting wear-resisting stretch yarn and silk stockings utilizing same

ActiveCN104532430AIncrease usage intensityImprove wear resistancePanty-hoseHosieryYarnPHENOLSULFONIC ACID

The invention discloses a composite snagging-resisting wear-resisting stretch yarn. The composite snagging-resisting wear-resisting stretch yarn comprises a plurality of high stretch yarns and a plurality of traction fibers, which are arranged in a quantity ratio of 5: (3-14), and a silk beam is coated with a film formed by drying sizing agent; the high stretch yarn is polyurethane high stretch yarn and comprises 5 to 15 percent by weight of phenolsulfonic acid and 5 to 25 percent of dyhydroxy phenyl sulfone. The composite stretch yarn is prepared by mixing a plurality of materials, so that the wear resistance is good; the external friction or snagging is resisted by utilizing Dacron low stretch yarn or polypropylene fiber low stretch yarn, the thorough fracturing difficultly occurs, the durability is good, and the prepared silk stockings are elastic and resistant to electrostatic, long in service life, high in cost performance, capable of giving different tightness to legs and capable of alleviating the fatigue of the legs and preventing varicosity; different sizes of the silk stockings can be provided according to different body forms, and the fitness of the silk stockings is maximized; the breathability is good, perspiration can volatize smoothly, and comfort in wearing can be realized; moreover, the silk stockings are smooth in surface, no silk end is exposed, and stocking toes, stocking heels and rip tops of the stockings are smooth.

Owner:浙江宝娜斯袜业有限公司

Accessory ingredient capable of removing and avoiding generating hexavalent chromium in leather and preparation method of accessory ingredient

InactiveCN103374634ALess componentsSolve the problem of excessive hexavalent chromiumTanning treatmentSodium acetateSulfite salt

The invention relates to an accessory ingredient capable of removing and avoiding generating hexavalent chromium in leather and a preparation method of the accessory ingredient, belonging to the technical field of chemical product manufacture. The accessory ingredient is mainly and technologically characterized by being prepared from raw materials including a reducing agent, an antioxidant, a dispersing agent, a masking agent and a pH value regulator. The reducing agent mainly comprises the following components: sodium sulfite, sodium hydrogen sulfite, sodium hyposulfate, sodium pyrosulfite and glucose; the antioxidant comprises the following components: sulfonated tannin extract, sulfited tannin extract, tea polyphenol, gallic acid, ellagic acid, vitamin C and vitamin E; the dispersing agent comprises the following components: an auxiliary naphthalene sulfonic acid synthetic tanning agent and an auxiliary phenolsulfonic acid synthetic tanning agent; the masking agent mainly comprises the following components: sodium formate, sodium acetate and sodium citrate; and the pH value regulator comprises the following components: citric acid and oxalic acid. The accessory ingredient is prepared through grinding, crushing and uniformly mixing. The accessory ingredient is few in raw material component, simpler in preparation method, free of pollution and capable of thoroughly removing and avoiding generating hexavalent chromium in leather.

Owner:咸阳银河无机材料有限公司

Precoated sand and burn-free regeneration technology thereof

ActiveCN103341587AHigh heat tensile strengthLow gasFoundry mouldsMould handling/dressing devicesHexamethylenetetramineDolomite

The invention belongs to the field of new materials and discloses precoated sand. The precoated sand is prepared from silica sand, pyrite powder, phenolic resin, bisphenol-A epoxy resin, phenolsulfonic acid, short peptide, boric acid, molybdenum disulfide, a methenamine solution, zinc stearate, dolomite powder, talcum powder and graphite powder. The invention also discloses a burn-free regeneration technology of the used precoated sand. The precoated sand prepared by the technoloyg has relatively high hot tensile strength, low gas-forming property and stable storage property; and the rejection rate of castings is relatively low.

Owner:LINYI ZHUBAO WATER METER

Flow back aids

ActiveUS20150047849A1Increase gas productionIncrease oil productionFluid removalFlushingEthyl groupPhenol

The present invention discloses liquid quaternary ammonium salts that can be used to treat and coat the surfaces of the proppant sand or inorganic particles that are used in down-hole oil well fracturing operations as well as the containment structure and that these treated surfaces will cause water and oils to flow faster through the porous structure. These liquid quaternary ammonium salts can be chosen from a list that includes but is not limited to cocobis(2-hydroxyethyl)ethylammonium ethyl sulfate, benzylcocobis(hydroxyethyl)ammonium 2-ethyl-hexylsulfate, dibenzylcocobishydroxyethyl ammonium phenolsulfonate, didecyldimethyl-ammonium dodecylbenzenesulfonate and tallow-bis(2-hydroxyethyl)ethylammonium ethyl sulfate.

Owner:ETHOX CHEM LLC

Furane self-hardening sand

The invention relates to a furane self-hardening sand, comprising crude sand, binding agent, curing agent, coupling agent and lubricating agent, wherein the dosage of the curing agent is 40-60% of that of the binding agent, the dosage of the coupling agent is 0.1-0.5% of that of the binding agent, the dosage of the binding agent is 1-1.5% of that of the crude sand, the dosage of the lubricating agent is 2-4% of that of the crude sand, and the binding agent comprises the following components according to parts by weight: 60-70 parts of furane resin, 20-30 parts of phenolic aldehyde resin, and 5-15 parts of PEO resin; the curing agent comprises the following components according to parts by weight: 60-70 parts of sulfuric acid triacetin, 20-30 parts of phenolsulfonic acid, and 5-15 parts of phosphoric acid; the soil content of the crude sand is less than or equal to 0.4%; the water content is less than or equal to 0.5%; the tensile strength of the furane self-hardening sand is more than or equal to 0.7MPa; and the gas evolution is less than or equal to 14ml / g. The invention is not only high in strength and good in permeability, but also strong in fire resistance.

Owner:WUJIANG HYDRAULIC COMPONENTS FOUNDRY

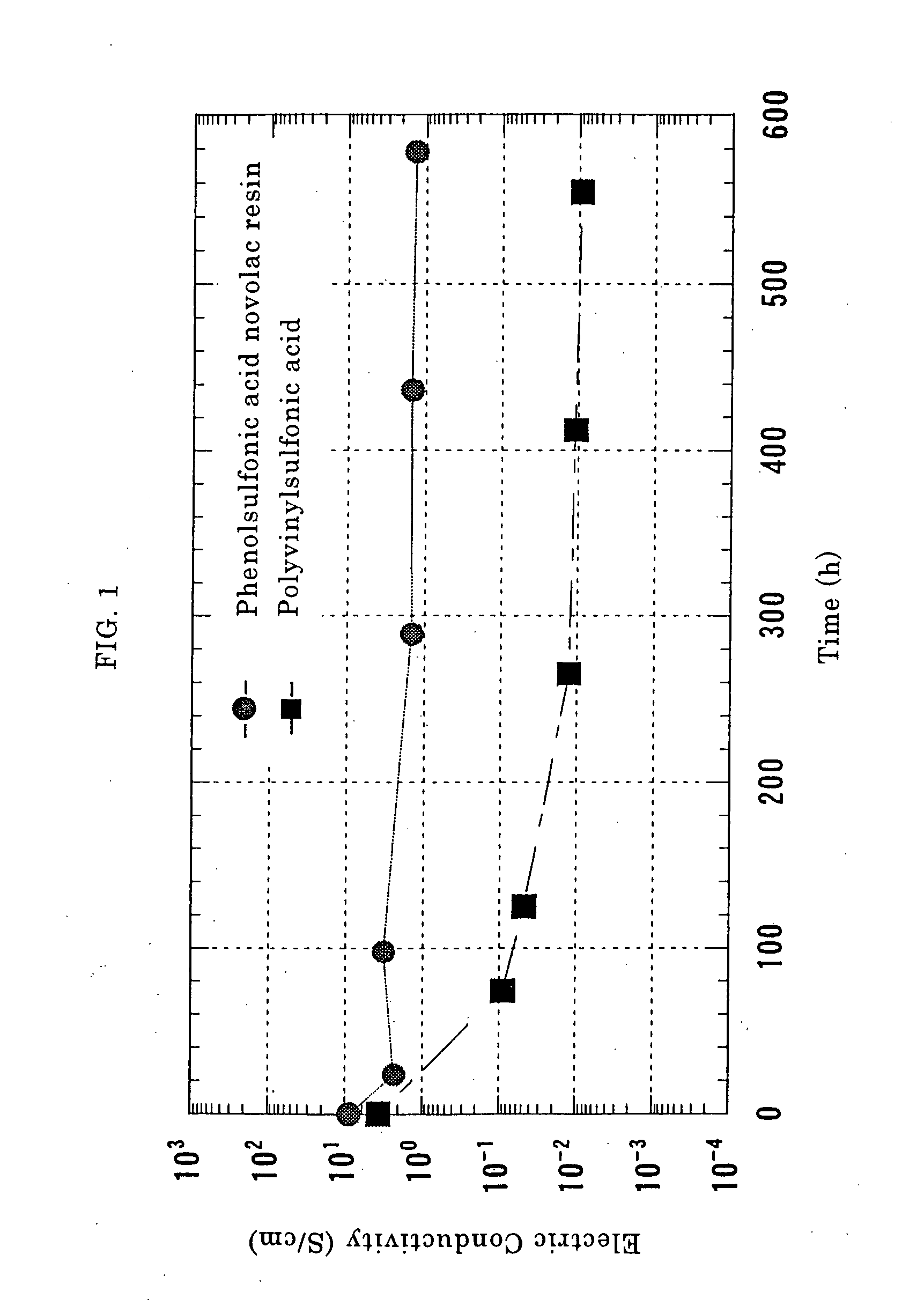

Conductive polyaniline composition, film thereof and processes for producing these

InactiveUS20050062020A1Improve heat resistanceImprove water resistanceOrganic chemistryOrganic compound preparationDopantPHENOLSULFONIC ACID

The invention provides an electrically conductive polyaniline composition comprising polyaniline which contains at least one of novolac resins selected from the group consisting of phenolsulfonic acid novolac resin and naphtholsulfonic acid novolac resin as a dopant. The electrically conductive polyaniline composition is obtained by contacting polyaniline with an aqueous solution of the novolac resin to dope the polyaniline with the novolac resin. The invention further provides an electrically conductive polyaniline film which comprises the polyaniline containing the novolac resin as a dopant. The electrically conductive polyaniline film is obtained by contacting film of polyaniline with an aqueous solution of the novolac resin to dope the polyaniline.

Owner:NITTO DENKO CORP

Plating solution formula of lead tin plating process for electronic components and lead tin plating process

ActiveCN107099825AImprove antioxidant capacityGive full play to the strong reducibilitySuperimposed coating processTin platingPolyethylene glycol

The invention provides a plating solution formula of a lead tin plating process for electronic components and the lead tin plating process. The plating solution formula comprises the following components by mass-volume concentration: 70-120 g / L sulfuric acid (AR), 45-60 g / L stannous mono-sulphate, 0.2-0.8 g / L sodium hypophosphite, 0.5-1.5 g / L ascorbic acid, 2-6 g / L of polyethylene glycol, 1-1.5 g / L catechol, 1-1.5 g / L beta-naphthol, 3-6 g / L cerium sulfate, an 8-10 g / L OP-10 emulsifier, 10-30 g / L phenolsulfonic acid and pure water. According to the lead tin plating process, hot-melt drawing passivation treatment is adopted after tin plating. A tin plating layer of a product produced by adoption of both the formula and the production process is greatly improved in compactness, so that the tin whisker growth prevention performance, the high temperature resistance, the anti-tarnishing capability and the neutral salt spray resistance of the product are improved.

Owner:烟台东牧精密线材有限公司

Leather retaining-filling agent prepared by means of phenolsulfonic acid hydrolysis leather-making waste

ActiveCN105586444AModerate degree of degradationTake advantage ofTanning treatmentPHENOLSULFONIC ACIDProtein hydrolysates

The invention discloses a leather retaining-filling agent prepared by means of phenolsulfonic acid hydrolysis leather-making waste. According to the retaining-filling agent, a phenolic compound is firstly molten, and then sulfuric acid is added for sulfonation; then cooling is carried out, and after obtained phenolsulfonic acid is diluted with deionized water, leather-making waste is added for a hydrolysis reaction; and then a phenolic solution is added dropwise for a condensation reaction, and after the reactant is sequentially subjected to neutralization with alkali, concentration adjustment with deionized water and cooling, the phenolsulfonic acid-protein hydrolysate condensation composite retaining-filling agent is obtained. The obtained leather retaining-filling agent has the property of an aromatic synthetic tanning agent, has the performance of protein filler, is a novel composite performance leather retaining-filling agent and has a good retaining-filling effect on cowhide and sheepskin. The preparing process is simple, cost is low, the resource of chromium is fully utilized, environment pollution caused by emission is reduced, and double benefits are achieved.

Owner:SICHUAN UNIV

Sodium nitrite determination method

InactiveCN104777111ALow toxicityEasy to operateColor/spectral properties measurementsEthyl groupVolumetric flask

The invention discloses a sodium nitrite determination method. The method comprises the following steps: taking a water sample to be determined, standing the water sample to be determined for 30min, transferring 10.0mL of the above obtained supernatant into a 25mL colorimetric pipe through a pipet, sequentially adding 1.0mL of an aqueous potassium bromide solution, 1.0mL of an aqueous sulfanilic acid solution and 1.0mL of an aqueous hydrochloric acid solution, shaking up, and standing to obtain a solution of diazo salt of the sample to be determined; taking a 25mL volumetric flask, and adding 3mL of an aqueous sodium carbonate solution and 1.0mL of an aqueous 2-N-ethyl-5-naphthol-7-sulfonic acid solution; transferring the solution of diazo salt of the sample to be determined into the volumetric flask, adding deionized water to a certain volume, and determining the absorbance of the above obtained orange diazo compound solution at a wavelength of 480nm by using 1cm cuvette with a blank reagent as a reference; and calculating according to the curve regression equation of standard sodium nitrite to obtain the content of sodium nitrite in the sample to be determined. The determination method has the advantages of convenient operation, high sensitivity, accurate result, and small toxicity of used reagents.

Owner:UNIV OF SHANGHAI FOR SCI & TECH

Automobile carbon deposit cleaning agent capable of being used for cleaning without dismantling automobile engine

ActiveCN104877831AReduce fuel consumptionIncrease motivationSurface-active non-soap compounds and soap mixture detergentsCleansing AgentsCarbon deposit

The invention provides an automobile carbon deposit cleaning agent capable of being used for cleaning without dismantling an automobile engine, relates to a carbon deposit cleaning agent and aims to solve the problem that the service life of an engine is shortened due to extremely high temperature in a cylinder when the conventional hydrogen method is used for removing carbon deposit. The automobile carbon deposit cleaning agent is formed by mixing dodecyl phenolsulfonic acid isopropylamine salt, nonylphenol polyglycol ether, ethylene glycol monopropyl ether, petroleum ether, petroleum hydrogenated light distillate, methenamine and deionized water. The cleaning agent has the advantages as follows: the automobile carbon deposit cleaning agent is gasified into nanoscale liquid drops through atomizing equipment to enter the engine along an engine gas inlet pipeline to achieve the purpose of cleaning, the interior of the engine, the pipeline and a three-element catalytic device can be cleaned without dismantling the engine. The invention is mainly used for preparing the automobile carbon deposit cleaning agent capable of being used for cleaning without dismantling the automobile engine.

Owner:HARBIN INST OF TECH

Biomass oil suitable for modifying thermosetting resin and preparation method thereof

ActiveCN105860428AEasy to prepareMild reaction conditionsLiquid carbonaceous fuelsHydrocarbon oils treatmentDistillationSalicylic acid

The invention discloses biomass oil suitable for modifying thermosetting resin and a preparation method thereof. The biomass oil is prepared from the following raw materials in parts by weight: 150-350 parts of biomass briquette, 280-520 parts of reaction medium A, 30-120 parts of reaction medium B, 5-20 parts of catalyst C, 2-8 parts of catalyst D and 2-9 parts of neutralizing agent, wherein the reaction medium A is one or more of methanol, ethanol, butanol and glycerin; the reaction medium B is one or more of ethyl acetate, acetone, toluene and petroleum ether; the catalyst C is one or more of phenolsulfonic acid, p-toluenesulfonic acid, benzenesulfonic acid, phenyl phosphate and salicylic acid; the catalyst D is one or more of inorganic acids; and the biomass oil is prepared by the steps of charging, heating for reacting, cooling, separation and distillation. With relatively good quality indexes, the biomass oil does not need secondary processing and can be directly applied to the modification of thermosetting resin; and moreover, the preparation method is simple, the reaction conditions are mild, and the production cost is reduced.

Owner:四川景文材料科技有限公司

Preparation method of sulfone bridge type synthetic tanning agent

ActiveCN103255242ATake advantage ofReduce manufacturing costTanning treatmentPHENOLSULFONIC ACIDDistillation

The invention relates to a preparation method of a sulfone bridge type synthetic tanning agent, which comprises the following steps: reacting phenol and fuming sulfuric acid to obtain a first reaction solution, wherein a main product of the first reaction solution is p-phenolsulfonic acid; performing vacuum reduced pressure distillation on the first reaction solution to remove fractions, thus obtaining a second reaction solution, wherein a main product of the second reaction solution is 4,4'-dihydroxydiphenylsulfone; and adding fuming sulfuric acid into the second reaction solution, thus obtaining a third reaction solution, wherein a main product of the third reaction solution is 3,3'-sulfo-4,4'-dihydroxydiphenylsulfone, and the third reaction solution is the sulfone bridge type synthetic tanning agent. The sulfone bridge type synthetic tanning agent prepared by the invention has fewer byproducts; and the produced leather has favorable grain effect and hand feeling.

Owner:QINGDAO LINK OIL PROD

Preparation method of dispersant with high efficiency and low formaldehyde

InactiveCN101632907AImprove hydrophilic abilityReduce colorTransportation and packagingMixingTrappingDiethylenetriamine

The invention relates to a preparation method of a dispersant with high efficiency and low formaldehyde, which is mainly used for assisting leather chemicals, i.e. a retanning agent and the like, to disperse in leathers when the leathers are processed and tanned. The method is characterized by comprising the following steps: (1) the synthetic reaction of a naphthalene sulfonic acid (A), i.e. firstly, adding naphthalene into a reaction kettle, and dripping a sulphuric acid into the reaction kettle to generate the naphthalene sulfonic acid (A); (2) the synthetic reaction of a phenolsulfonic acid (B), i.e. adding phenol into the reaction kettle, and dripping the sulphuric acid into the reaction kettle to generate the phenolsulfonic acid (B); (3) mixing the naphthalene sulfonic acid (A) and the phenolsulfonic acid (B), adding a right amount of water into the mixture for dilution, controlling the acidity of the mixed solution, then adding formaldehyde into the mixed solution, controlling the temperature of the mixed solution from 95 DEG C to 100 DEG C, preserving the temperature of the mixed solution for 8-9 hours, and then neutralizing the mixed solution to a pH value from 7.5 to 8.5 by NaOH; and (4) adding a formaldehyde trapping agent into the mixed solution so as to obtain an offwhite powdery dispersant finish product with high efficiency and low formaldehyde after drying processing, wherein the formaldehyde trapping agent is soyabean protein powder, isinglass, carbamide, melamine, quadrol, polyene and polyamine or diethylenetriamine. The dispersant with high efficiency and low formaldehyde has lighter colour and luster, strong dispersion force and little content of free formaldehyde.

Owner:JIANGYIN CITY NINE CATTLES TECH

Antifouling papermaker's fabric

ActiveUS20040040612A1Adhesive strengthGood antifoulingFibre treatmentSynthetic resin layered productsEpoxyPHENOLSULFONIC ACID

In an antifouling papermaker's fabric woven from a warp and weft made of synthetic resin filament, the fabric is coated with a resin composition made by blending a two-liquid reaction type epoxy resin with a prepolymer of phenolsulfonic acid as a curing agent to form on the surface of a constituent yarn an antifouling coating film constituted by a reaction product of the composition.

Owner:NIPPON FILCON

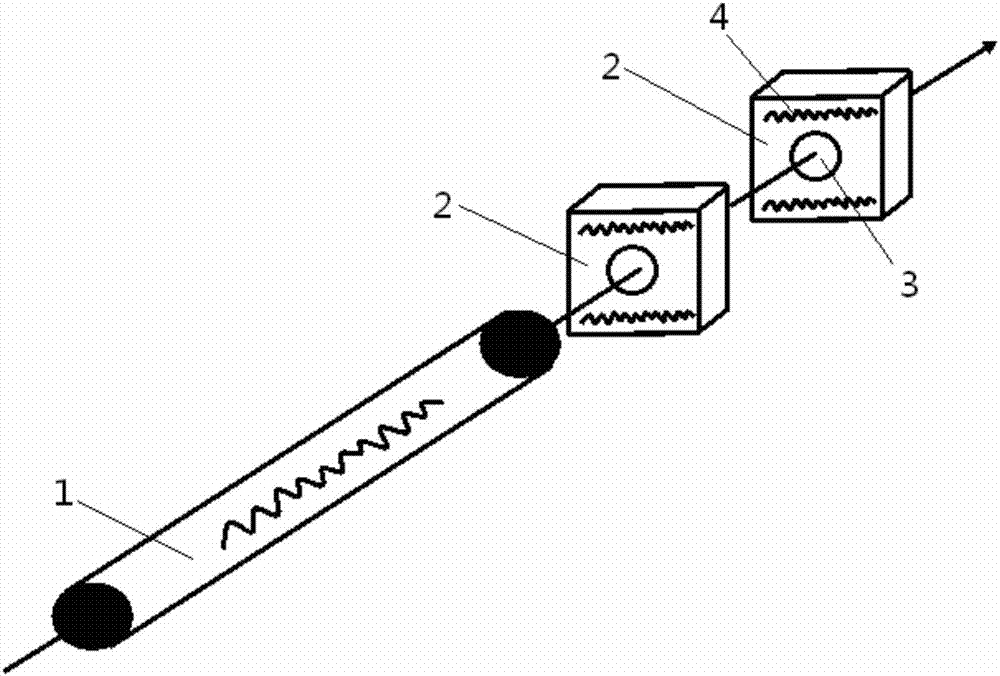

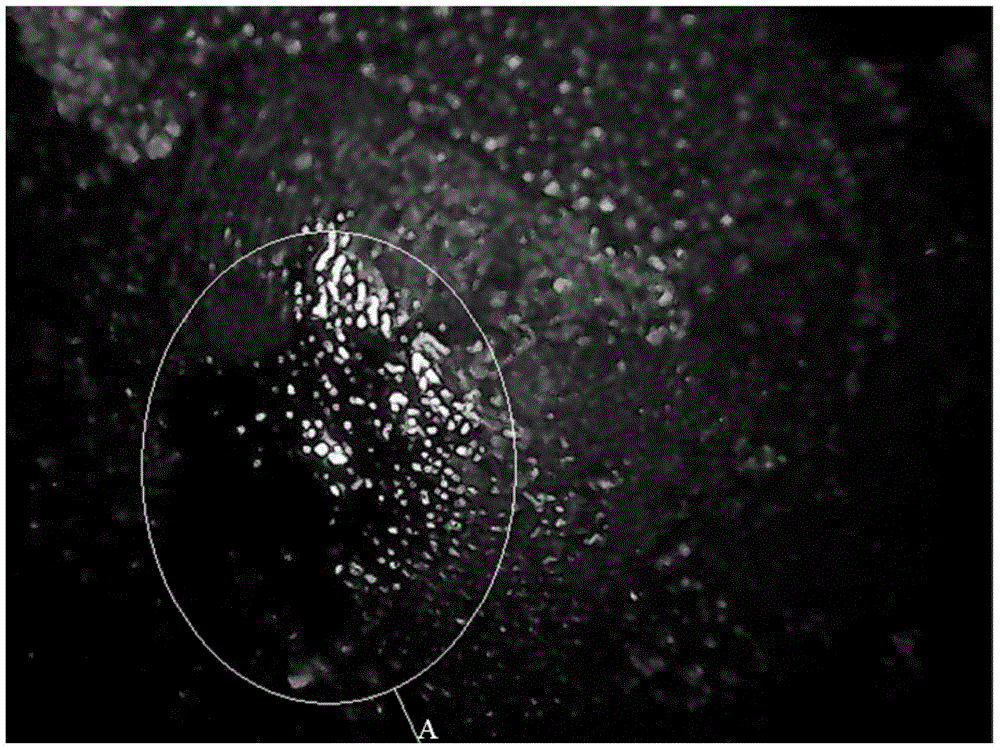

Flame-retardation and heat-insulation material and preparation method thereof

InactiveCN105936727AImprove flame retardant performanceLow thermal conductivityPolyvinyl alcoholSilicon dioxide

The invention discloses a flame-retardation and heat-insulation material. The flame-retardation and heat-insulation material comprises, by weight, 80-120 parts of styrene, 200-350 parts of water, 80-120 parts of a polyvinyl alcohol solution, 3-6 parts of calcium stearate, 0.8-1.2 parts of tributyl phosphate, 2.4-3.6 parts of melamine cyanurate, 2-4.3 parts of aerosil, 1.4-2.6 parts of dicumyl peroxide, 1.5-2.5 parts of sodium dodecylbenzene sulfonate, 10-18 parts of pentane, 79.7-99.3 parts of a compound flame retardant, 2-4 parts of phenolsulfonic acid, 3-5 parts of 3-aminopropyltriethoxysilane, 10-20 parts of sodium silicate, 4-6 parts of a Ca / Zn composite stabilizer and 2-4 parts of an antioxidant 1010. The invention also discloses a preparation method of the flame-retardation and heat-insulation material. The flame-retardation and heat-insulation material has the advantages of good flame retardation property, high heat insulation performance, simple operation and industrial production facilitation.

Owner:望江县精美欣钢构有限公司

Modified phenolic resin injecting paste material for coal and rock mass reinforcing and preparation method

The invention discloses a modified phenolic resin injecting paste material for coal and rock mass reinforcing and a preparation method and aims to solve the problem that a reinforcing effect is not ideal by adopting a traditional material. The preparation method is characterized by comprising the following steps of preparing a component A from phenol, formaldehyde, barium hydroxide, urea and oxalic acid, preparing a component B from phenolsulfonic acid, phosphoric acid and para-toluenesulfonic acid, and then, mixing the component A and the component B in weight ratio of (1-4):1. The material disclosed by the invention is low in viscosity and extremely excellenent in liquidity, can permeate into very thin cracks, and is adjustable on site in curing time. The heat value of the material disclosed by the invention is lower than similar materials in markets for at least 250 DEG C, and is good in fire resistance. The raw materials are completely domesticated, and are autonomous in property right, and any technical barriers do not exist. The material disclosed by the invention is strong in operability, small in viscosity and strong in permeability and is simple to operate.

Owner:HUAIBEI WANYUAN IND TRADE

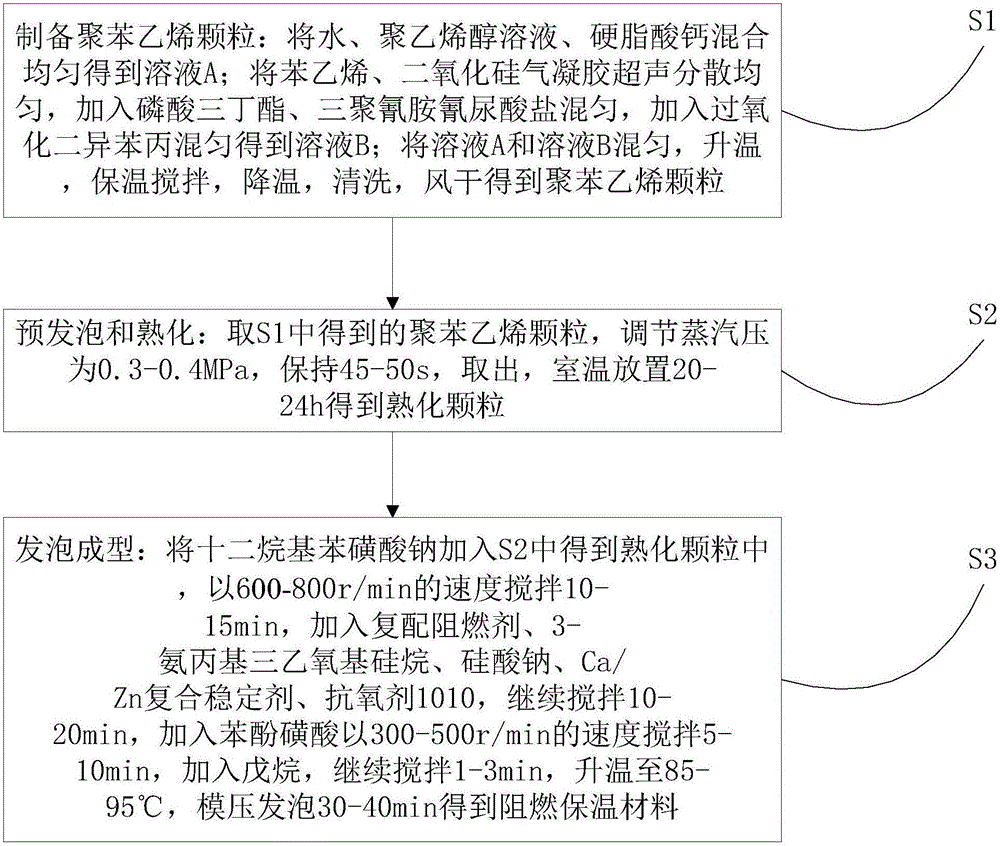

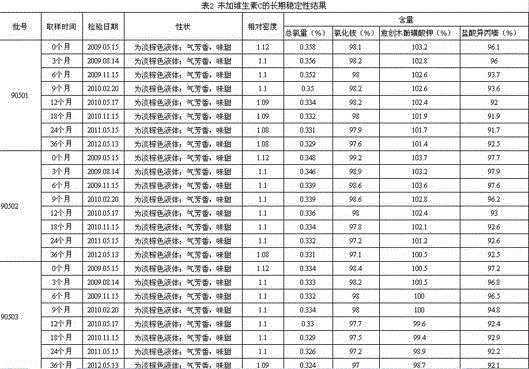

High stability composite guaiacol phenolsulfonic acid oral liquid and preparation method thereof

InactiveCN103142645AImprove stabilityImprove product qualityPharmaceutical delivery mechanismPharmaceutical non-active ingredientsBenzoic acidFormulary

The invention relates to a high stability composite guaiacol phenolsulfonic acid oral liquid and a preparation method thereof, and belongs to the technical field of pharmaceutics. The oral liquid is prepared by adopting promethazine hydrochloride, guaiacol phenolsulfonic acid, ammonium chloride, sodium citrate, benzoic acid, ethylparaben, cane sugar, caramel, Litchi chinensis essence and banana essence as raw and auxiliary materials, adding an antioxidant cysteine hydrochloride or vitamin C and adopting ethanol and water as a solvent. According to the invention, deficiencies of conventional formula are improved, and the antioxidant is added to effectively prevent promethazine hydrochloride form being oxidized. The guaiacol phenolsulfonic acid oral liquid prepared by the formula and process is high in stability in the placing process, so that the medicine quality and medication safety of patients can be effectively ensured.

Owner:广东南国药业有限公司

Dehydration control method for synthesis of bisphenol S

ActiveCN104557637AGood decolorizationEasy to refine and purifyOrganic chemistryOrganic compound preparationPlatinumPHENOLSULFONIC ACID

The invention discloses a dehydration control method for synthesis of bisphenol S, which is implemented by calculating a theoretical amount of dehydrated water according to a synthetic reaction equation of the bisphenol S and the feeding molar ratio of phenols and sulfuric acid; and controlling the early stage of the reaction to be in a rapid dehydration state and the late stage of the reaction to be in a slow dehydration state, wherein preferably, in one third of the dehydration process, 75-85% of water is dehydrated, and in the rest two thirds of the dehydration process, 25-15% of water is further dehydrated. The purity of the bisphenol S after being refined is 99.5% or over, and the chromaticity is less than 20 (platinum-cobalt colorimetric method). By controlling the dehydration speed in the process of bisphenol S synthesis, the excessive oxidation of phenols and phenolsulfonic acid can be avoided, and the purity of bisphenol S in a crude product can be improved. A synthetic bisphenol S crude-product is shallow in appearance color and low in chromaticity; and the purity of the bisphenol S crude-product is relatively high, so that the bisphenol S crude-product is easily further decolored, refined and purified.

Owner:KEMAI CHEM +1

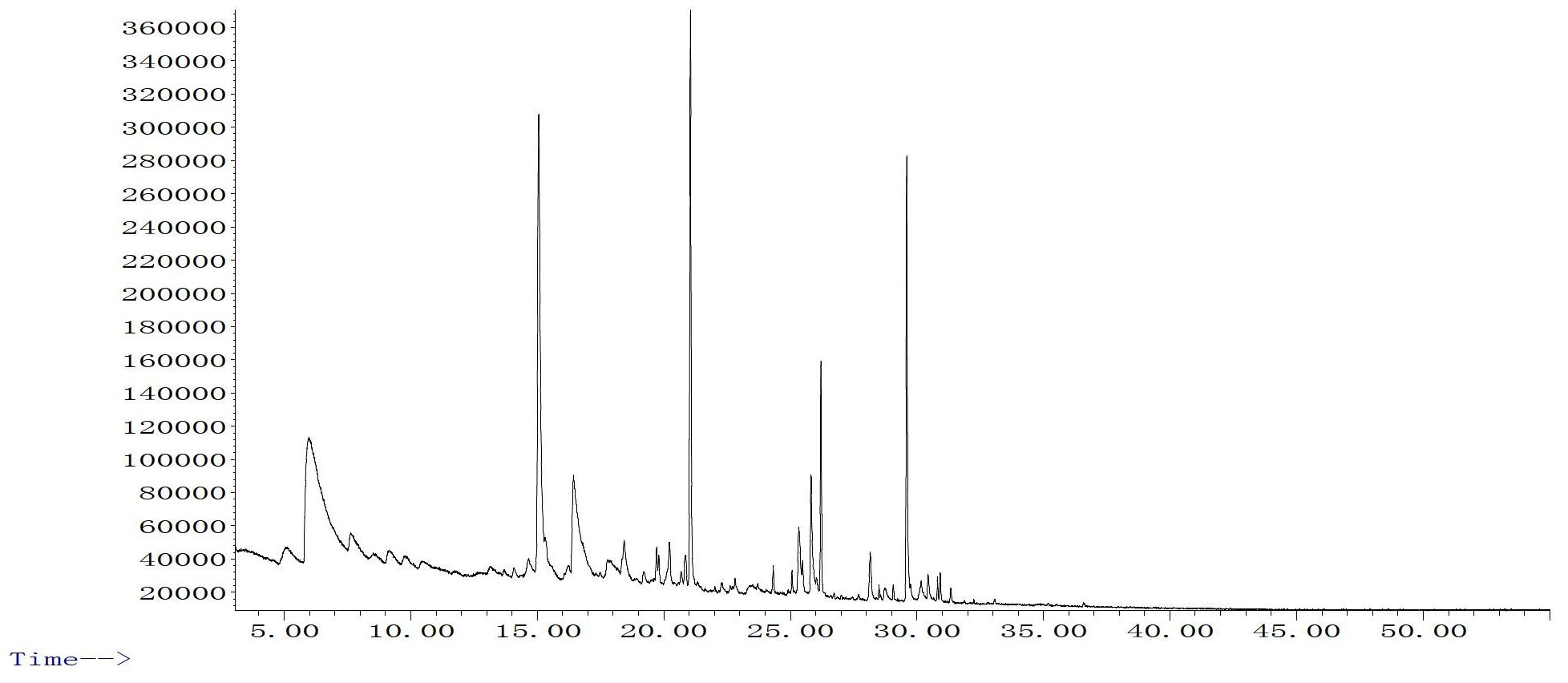

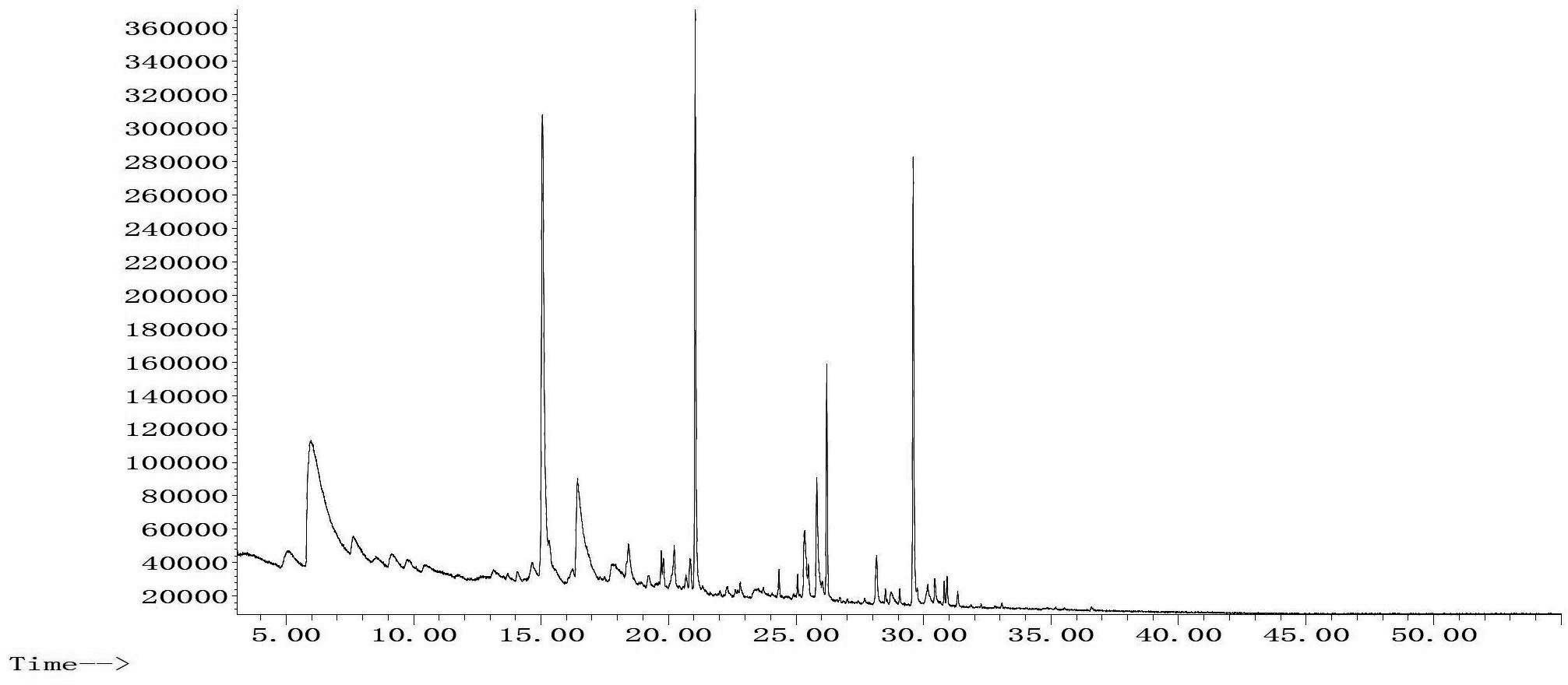

Pretreatment method for combined detecting on gas chromatograph and mass spectrum of powdered essence

The invention relates to a pretreatment method for combined detecting on gas chromatograph and mass spectrum of a powdered essence. The method is characterized by comprising the following steps of: after crushing and drying a powdered essence sample, weighing the essence sample into a 50 mL centrifuge tube with a plug, adding anhydrous sodium sulfate into the tube to be vortex stirred and mixed evenly, adding an acetone / n-hexane extracting solution, vortex stirring and ultrasonically extracting twice, centrifuging to remove suspended particles, taking the supernatant liquor into a centrifuge tube, adding phenolsulfonic acid (PSA) and anhydrous magnesium sulfate to carry out purifying treatment, vortex mixing and ultrasonically extracting, and centrifuging to take the supernatant liquor, so that a liquor to be detected which is used for detecting the ingredients of the essence by a gas Chromatography and mass spectrometer is obtained. The sample pretreatment method adopted by the invention is easy to operate, short in time and good in reproducibility, and can obviously improve the experiment efficiency.

Owner:TIANJIN CHUNFA BIO TECH GRP

Environment-friendly tin electrolytic refining electrolyte

InactiveCN107675209AImprove stabilityImprove the labor environmentPhotography auxillary processesEnvironmentally friendlyPHENOLSULFONIC ACID

The invention discloses an environment-friendly tin electrolytic refining electrolyte. The electrolyte is composed of 80-140 g / L of H2SO4, 20-40 g / L of Sn2+(added in a mode of SnSO4), 0-10 g / L of beta-naphthol, 0-10 g / L of latex, 0-20 g / L of phenolsulfonic acid and 2-15 g / L of gallic acid or derivatives of the gallic acid. 20-40 g / L of phenolsulfonic acid or cresolsulfonic acid is generally addedinto traditional tin electrolytic refining electrolyte so as to inhibit oxidization of Sn2+ in the electrolyte, improve the stability of the electrolyte and improve the cathode morphology. However, the phenolsulfonic acid is strong in smell, toxic and harmful, thereby making the working environment in an electrolysis workshop poor. Accordingly, the environment-friendly electrolyte is provided by the invention, and the gallic acid or the derivatives of the gallic acid is / are adopted to partially or completely replace the phenolsulfonic acid or the cresolsulfonic acid. The environment-friendly tin electrolytic refining electrolyte has the advantages of being safe, environmentally friendly, good in stability and compact and even in cathode morphology and can be applied and popularized in thetin electrolysis industry.

Owner:JIANGXI UNIV OF SCI & TECH

Environment-friendly color fading resisting agent

The invention discloses an environment-friendly color fading resisting agent which is prepared from, by weight, 3-7 parts of sodium silicate, 10-20 parts of phenol, 12-15 parts of phenolsulfonic acid, 7-9 parts of composite catalyst, 12-18 parts of brine, 7-11 parts of cocoon silk and 2-4 parts of modifying agent. The composite catalyst is the mixture of potassium hydroxide and boric acid. Silkworm cocoons are soaked in warm water for 1-2 h, and one layer of silk on the outer surface of the soaked silkworm cocoons is drawn to become cocoon silk. According to the color fading resisting agent, the phenol, the phenolsulfonic acid and the composite catalyst are adopted for a condensation reaction, the modifying agent is added into the mixture for modification, and the acid reaction resisting type color fading resisting agent is obtained; chemical damage is small, the brine has the certain color fixing effect on the fabric, alkaloid in mulberry leaf water has the antibacterial effect on the fabric, and the cocoon silk can increase the color brilliance of the fabric.

Owner:季华

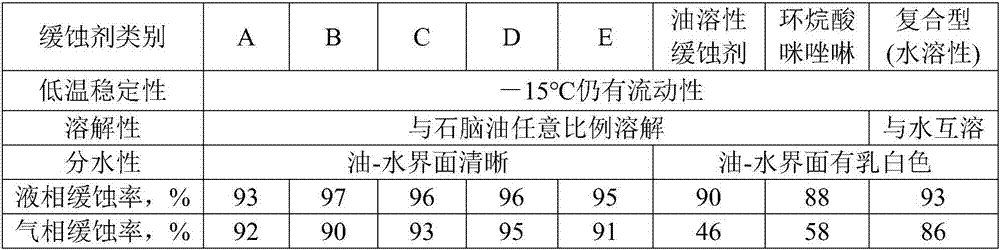

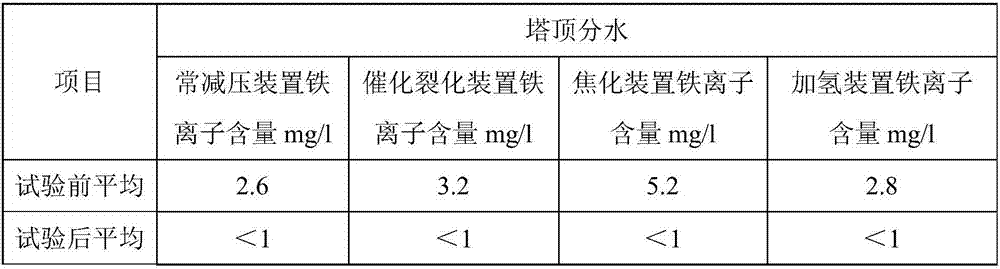

Oil soluble composite corrosion inhibitor

The invention relates to an oil soluble composite corrosion inhibitor, and belongs to the field of petroleum refining. The oil soluble composite corrosion inhibitor is composed of following components including 20-40 wt% of carboxylic acid amine salt, 5-20 wt% of sulfonic acid amine salt, 15-40 wt% of organic amine and 20-40 wt% of an organic solvent. The carboxylic acid amine salt is a mixture formed through combination of two or more of carboxylic acid amine salt prepared through vegetable oleic acid and tertiary alkyl primary amine, carboxylic acid amine salt prepared through animal oleic acid and tertiary alkyl primary amine and carboxylic acid amine salt prepared through naphthenic acid and tertiary alkyl primary amine according to any proportion. The sulfonic acid amine salt is a mixture formed through combination of sulfonic acid amine salt prepared through heavy alkylbenzene sulfonic acid and tertiary alkyl primary amine, sulfonic acid amine salt prepared through nonyl phenol sulfonic acid and tertiary alkyl primary amine and sulfonic acid amine salt prepared through mahogany acid and tertiary alkyl primary amine according to any proportion. The product is stable in performance, good in oil solubility, high in anti-corrosion capability and neutralization ability and good in film forming performance, and when a tower roof system is used, an organic amine neutralizer or ammonium hydroxide does not need to be additionally injected.

Owner:南京万象新材料科技有限责任公司

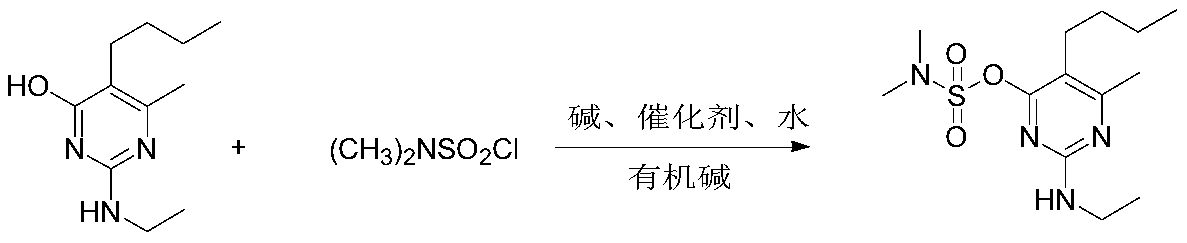

Synthetic method of bupirimate

ActiveCN111303050AReduce stepsReduce manufacturing costOrganic chemistryChemical recyclingBupirimatePHENOLSULFONIC ACID

The invention discloses a synthetic method of bupirimate. The synthetic method comprises the following steps of sequentially adding ethirimol, alkali, a solvent and water into a reaction bottle, heating to 50-80 DEG C while stirring, slowly dropwise adding N, N-dimethylsulfonyl chloride, heating until reflux reaction after finishing dropwise adding, adding organic alkali to control the pH value ofthe system to be alkaline when 5-50% of the raw materials are left, and continuously reacting until the reaction is finished, and cooling the system to 50-60 DEG C, washing with water to adjust the system to be neutral, removing the water phase, removing the solvent to obtain an oily substance, and separating out a solid at low temperature, thereby obtaining the bupirimate. The synthetic method provided by the invention has the advantages of mild conditions, simple operation, less three wastes and high yield, and is a synthetic method suitable for industrialization of bupirimate.

Owner:XIAN MODERN CHEM RES INST

Anti-fading plastic for color woven bag production

The invention discloses an anti-fading plastic for color woven bag production, and belongs to the technical field of woven bag production. The anti-fading plastic comprises the following raw materialsby weight: 5-20 parts of polymethyl methacrylate, 4-15 parts of polycarbonate, 3-12 parts of a phase solvent, 6-12 parts of tea polyphenol, 3-8 parts of acetic acid, 5-9 parts of brine, 8-18 parts ofmulberry leaf water, 4-12 parts of sodium silicate, 10-15 parts of phenolsulfonic acid, and 2-9 parts of a composite catalyst. The specific preparation method of the anti-fading plastic comprises thefollowing steps: equipment treatment and burdening: cleaning used container equipment with tap water, and performing washing with deionized water once. The anti-fading plastic has the advantages of the good anti-fading effect, the good optical performance, the good chemical corrosion resistance, no shedding, fading or other phenomena, good chemical stability and strong tinting strength; and the anti-fading plastic is low in material cost and high in environmental protection property, and has an antibacterial effect on fabrics.

Owner:福建海嘉包装有限公司

Copper wire surface tinning method

The invention discloses a copper wire surface tinning method. The method comprises the following steps: 1, alkaline oil removal; 2, running water cleaning; 3, drying at 85-90DEG C; 4, tinning by using a solution containing 65-70g / L of sulfuric acid, 40-44g / L of stannous sulfate, 0.6-1.0g / L of beta-naphthol, 20-30g / L of phenolsulfonic acid, 4-6g / L of formaldehyde and 8-12g / L of a brightener under a current density of 1.4-1.8A / dm<2> at 12-18DEG C; and 5, deionized water cleaning. Copper wires with the surface tinned through the method have the advantages of effective corrosion and wear resistance, and good electricity and heat conduction; and the increase of Pb, Ni and P elements can effectively prevent the diffusion of copper atoms to the above tin solution, so the tinning quality is guaranteed, the tin cost is reduced, and the cost is saved.

Owner:NINGGUO XINBONENG ELECTRONICS

Environment-friendly oilfield reinjection water corrosion and scale inhibitor and preparation method thereof

InactiveCN105152367AExtend the effective protection periodGood slow releaseScale removal and water softeningOil additiveGluconic acid

The invention relates to an environment-friendly oilfield reinjection water corrosion and scale inhibitor and a preparation method thereof, and belongs to the technical field of petroleum additives. The environment-friendly oilfield reinjection water corrosion and scale inhibitor is prepared by using an erycibe obtusifolia extract, dihydro arteannuic acid methyl ester, citric acid, tannic acid, sodium hydrosulfuryl benzothiazole, gluconic acid-delta-lactone, potassium guaiacolsulfonate, sulfosuccinate, N-(3-triethoxysilylpropyl)gluconamide, ethyl acetate, ethanol and water as raw materials through a series of steps. The prepared corrosion and scale inhibitor has excellent scale inhibition performance and corrosion inhibition performance; through experiment measurement, the corrosion inhibition rate is greater than or equal to 97%, and the scale inhibition rate is greater than or equal to 96%. The preparation method is simple, and the prepared environment-friendly oilfield reinjection water corrosion and scale inhibitor is phosphine-free, environment-friendly, and excellent in thermostability. The condition required by the preparation process is easy to control, the energy consumption is low, the operation is simple, the preparation process is free of discharge of the 'three wastes', and belongs to the cleaner production technology, and popularization and application are facilitated.

Owner:无棣华信石油技术服务有限公司

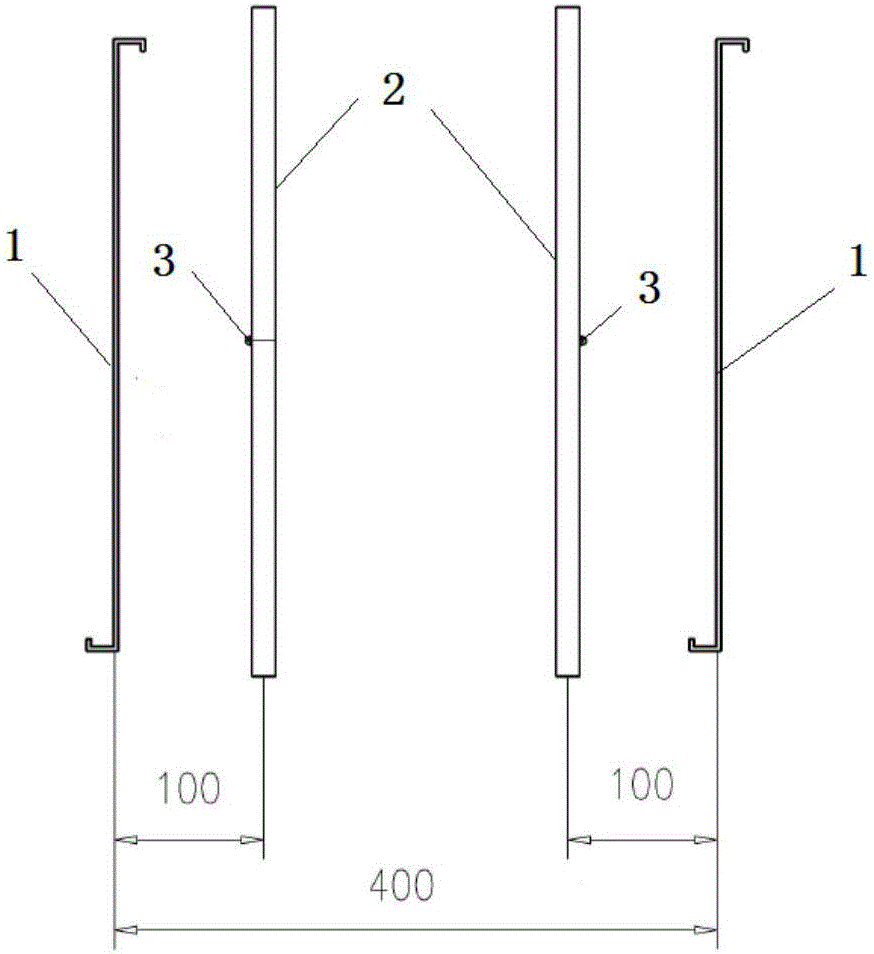

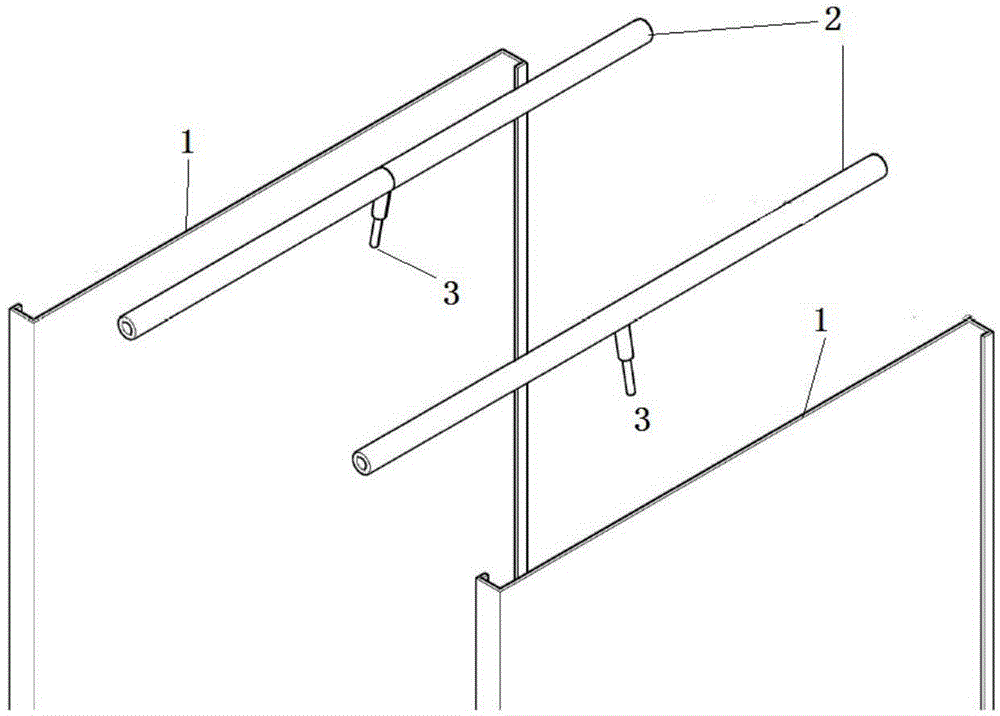

Online dust cleaning device and method for anode plate of electrical dust remover

InactiveCN104593167AIncrease online flushingEfficient removalInorganic/elemental detergent compounding agentsNon-ionic surface-active compoundsSodium metasilicateSodium phosphates

The invention discloses an online dust cleaning device and an online dust cleaning method for an anode plate of an electrical dust remover. The online dust cleaning is performed by virtue of a spray-rinsing agent. The spray-rinsing agent comprises the following components in percentage by weight: 1-5% of dodecyl mercaptan ethoxylate, 1-5% of dodecylphenol sulfonic isopropylamine salt, 1-5% of potassium hydroxide, 3-8% of ethylene glycol monobutyl ether, 5-10% of sodium metasilicate pentahydrate, 1-5% of sodium phosphate and the balance of water. In addition, the invention also discloses the online dust cleaning device and the online dust cleaning method for the anode plate of the electrical dust remover by using the spray-rinsing agent. The online dust cleaning method has the characterized that production halts is not needed, the dust cleaning is completely and cleanly performed, secondary dust raising is hardly caused and the production efficiency is increased during the cleaning.

Owner:北京浦亿思特科技有限责任公司

Novel phenolsulfonic acid aryl ester derivative, and heat-sensitive recording material using same

ActiveUS20130237414A1High color sensitivityHigh image densityOrganic chemistryOrganic compound preparationArylPHENOLSULFONIC ACID

The invention provides a phenolsulfonic acid aryl ester represented by formula (1)wherein each symbol is as defined in the description. The phenolsulfonic acid aryl ester is useful as a developer to provide a thermal recording material with good color-developing sensitivity, image density when printed at a low application energy (i.e., high start-up sensitivity), and heat and plasticizer resistance. The invention also provides a thermal recording material using the developer.

Owner:NIPPON PAPER IND CO LTD +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com