Oil soluble composite corrosion inhibitor

A composite corrosion inhibitor, oil-soluble technology, applied in the field of petroleum refining, can solve the problems of affecting film formation and neutralization, not achieving the comprehensive effect of anti-corrosion of the tower top system, etc., and achieves low cost and neutralization ability. The effect of strong, enhanced adsorption capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

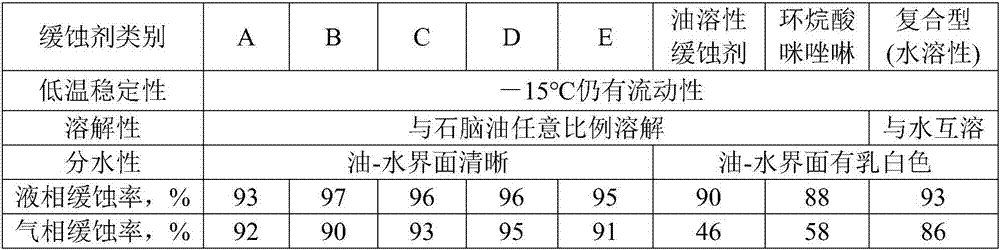

Embodiment 1

[0035] Vegetable oleic acid and naphthenic acid are prepared respectively with tertiary alkyl primary amines to form carboxylic acid amine salts, and alkylbenzenesulfonic acid and petroleum sulfonic acid are respectively prepared with tertiary alkyl primary amines to form sulfonic acid amine salts. Add 70g each of amine salt and naphthenic acid amine salt into the three-necked flask, add 50g each of heavy alkylbenzenesulfonate amine salt and petroleum sulfonate amine salt, 90g each of morpholine and methylmorpholine, heavy aromatic solvent and dimethylformaldehyde Take 90g of methyl formamide, stir at room temperature and pressure for 30 minutes, and then filter to remove impurities to obtain composite corrosion inhibitor A.

Embodiment 2

[0037] Animal oleic acid, naphthenic acid and tertiary alkyl primary amine are prepared respectively to form carboxylic acid amine salt, nonylphenol sulfonic acid amine salt and petroleum sulfonic acid are respectively prepared from tertiary alkyl primary amine to form sulfonic acid amine salt. Add 70g each of amine salt and amine salt of naphthenic acid into a three-necked flask, add 50g each of nonylphenol sulfonic acid amine salt and petroleum sulfonic acid amine salt, 90g each of morpholine and ethyl morpholine, heavy aromatic solvent, two Methylformamide and propylene glycol each 60g, stirred at normal temperature and pressure for 30min, then filtered to remove impurities to obtain composite corrosion inhibitor B.

Embodiment 3

[0039] Vegetable oleic acid, animal oleic acid, naphthenic acid are prepared respectively with tertiary alkyl primary amines Carboxylic acid amine salt, heavy alkylbenzene sulfonic acid, petroleum sulfonic acid and nonylphenol sulfonic acid are prepared respectively with tertiary alkyl primary amines Sulfonic acid amine salt, first add 50g of vegetable oleic acid amine salt, 50g of animal oleic acid amine salt and 40g of naphthenic acid amine salt into the three-necked flask, then add 30g of heavy alkylbenzene sulfonic acid amine salt, nonylphenol sulfonic acid amine salt 30g, 40g of petroleum sulfonic acid amine salt, 100g of morpholine, 30g of methylmorpholine, 30g of ethyl morpholine, 100g of heavy aromatic solvent, 50g of dimethylformamide, 50g of propylene glycol, stirred at room temperature and pressure for 30min and then filtered Composite corrosion inhibitor C is obtained by removing impurities.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com