Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

1232 results about "Tin plating" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Metal Plating Composition and Method for the Deposition of Copper-Zinc-Tin Suitable for Manufacturing Thin Film Solar Cell

InactiveUS20090205714A1Easy to manufactureClear processSemiconductor/solid-state device manufacturingOrganic dyesCopper platingTin plating

To be able to form a copper-zinc-tin alloy which optionally comprises at least one chalcogenide and thus forms a semiconductor without the use of toxic substances a metal plating composition for the deposition of a copper-zinc-tin alloy is disclosed, wherein said metal plating composition comprises at least one copper plating species, at lease one zinc plating species, at least one tin plating species and at least one complexing agent and further, if the alloy contains at least one chalcogen, at least one chalcogen plating species.

Owner:ATOTECH DEUT GMBH

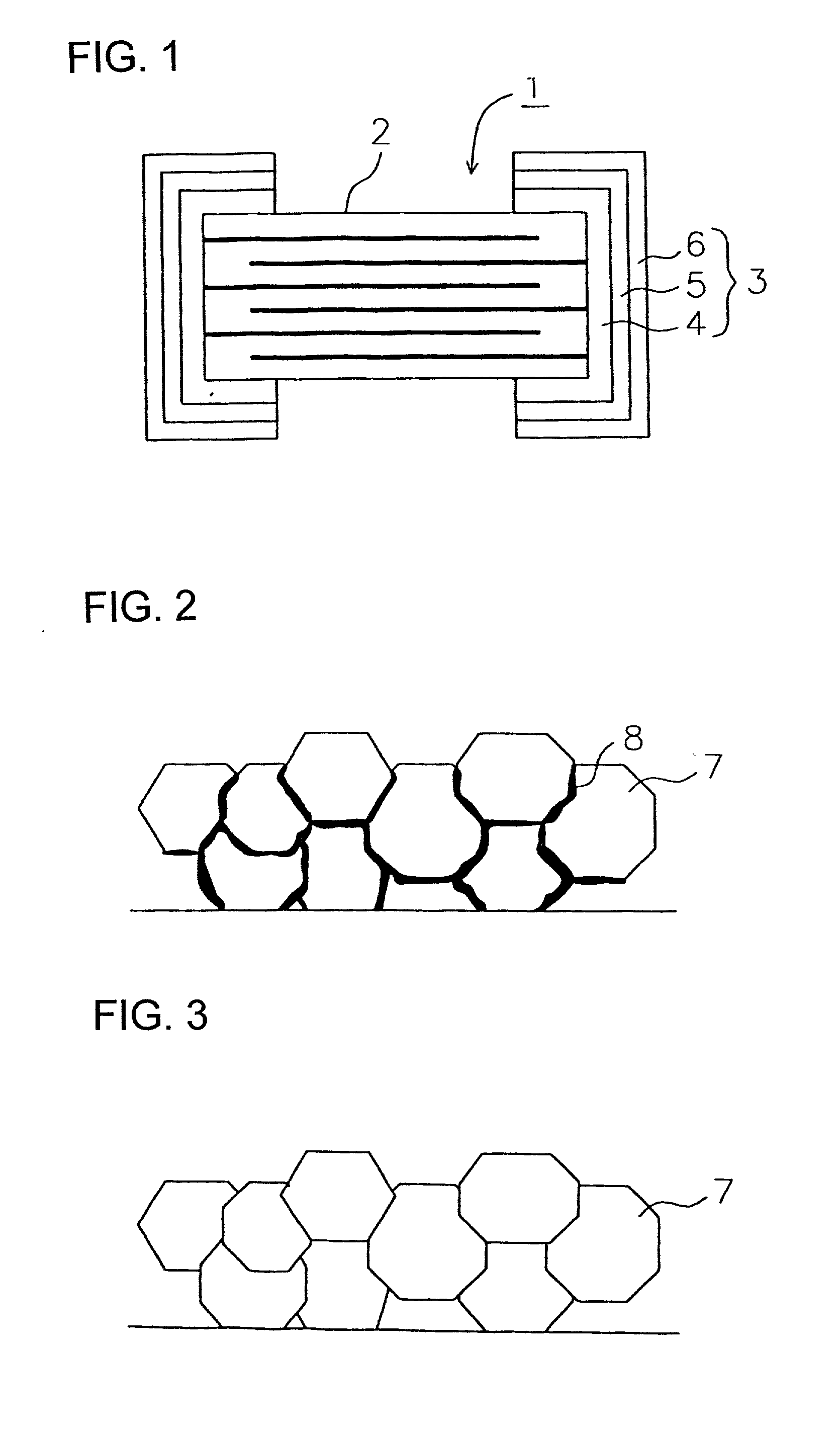

Electronic component, method for producing electronic component, and circuit board

InactiveUS20020001712A1Suppress generationEasy to spreadSurface reaction electrolytic coatingVacuum evaporation coatingTin platingNickel alloy

Owner:MURATA MFG CO LTD

Multi-functional half-white brightness tin-plated additive

The invention provides a multi-functional half-white brightness tin-plated additive which comprises the following components in parts by weight: 0.1-3 parts of a main brightener, 5-15 parts of a dispersing agent, 0.1-3 parts of a stabilizing agent, 0.1-2 parts of a leveling agent, 0.1-3 parts of a change agent, 0.1-2 parts of a low-foam wetting agent, 1-5 parts of an anti-crystal whisker agent, 0.05-0.5 part of a flocculating agent, 40-55 parts of an aqueous organic solvent, 0.1-2 parts of a functional auxiliary, 0.1-2 parts of acid and 25-40 parts of water. The multi-functional half-white brightness tin-plated additive has good dispersive capacity and coverage capacity, can enable the plating layer thickness to reach 3 micrometers or more, is fine, smooth and compact in crystal grains and has high bonding strength with a matrix; according to the multi-functional half-white brightness tin-plated additive, the performance of a plating layer can be obviously improved, the cost of a plating solution is low, and the electroplating liquid has wide operating temperature range and cathode current density range; the tin plating layer is compact is surface structure, high in white brightness and strong in bonding strength and has excellent weldability and oxidation resistance.

Owner:苏州禾川化学技术服务有限公司

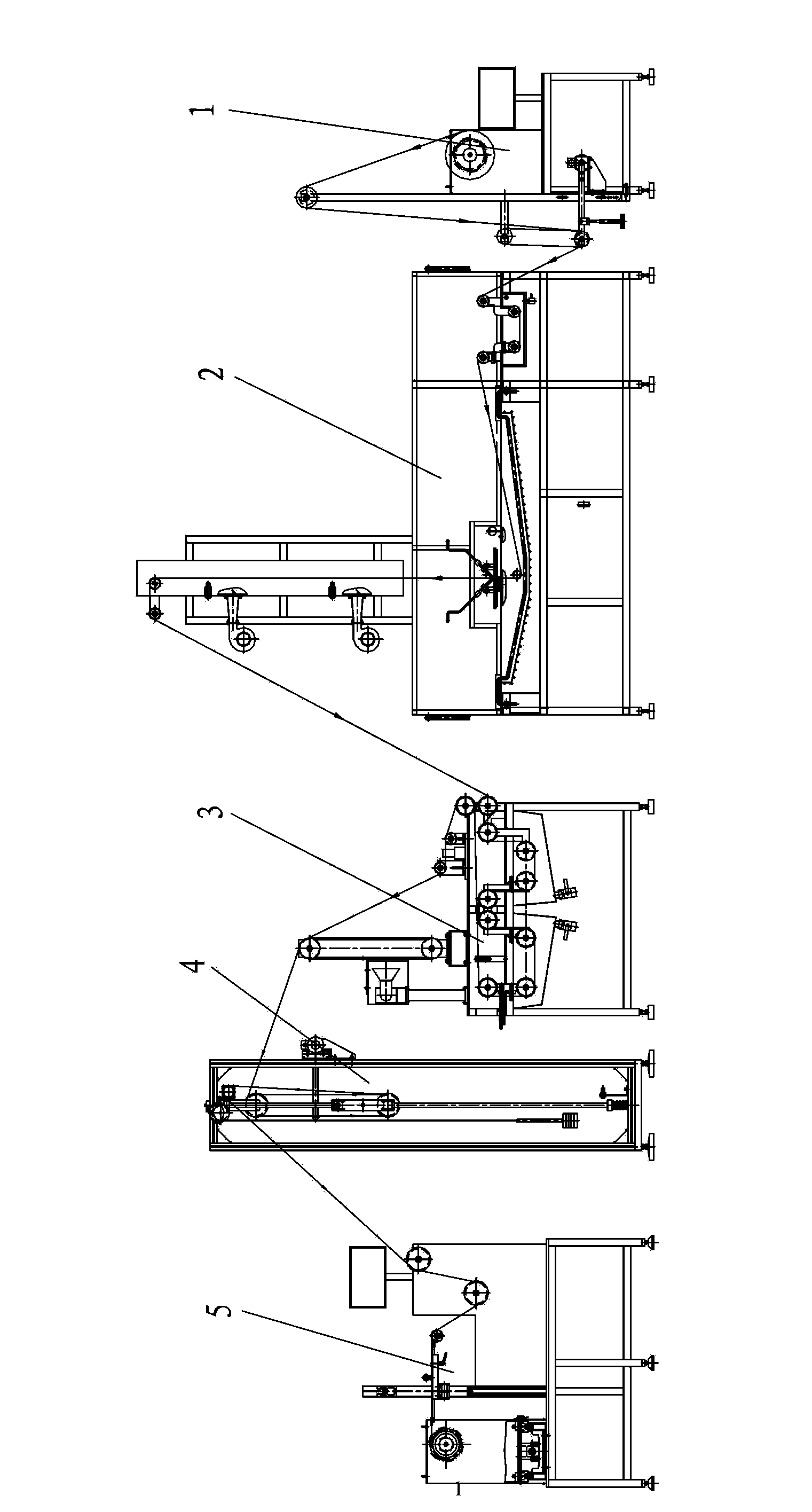

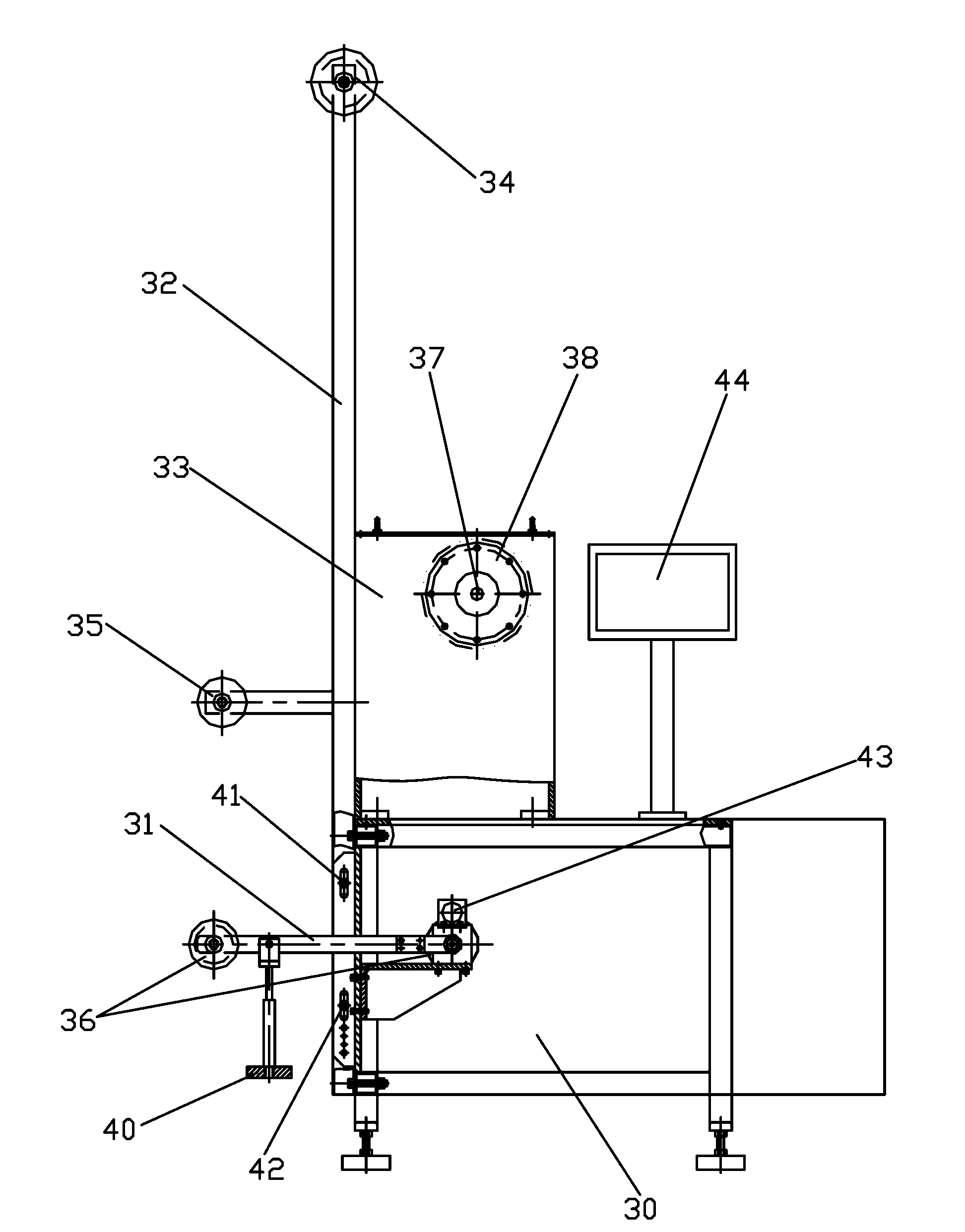

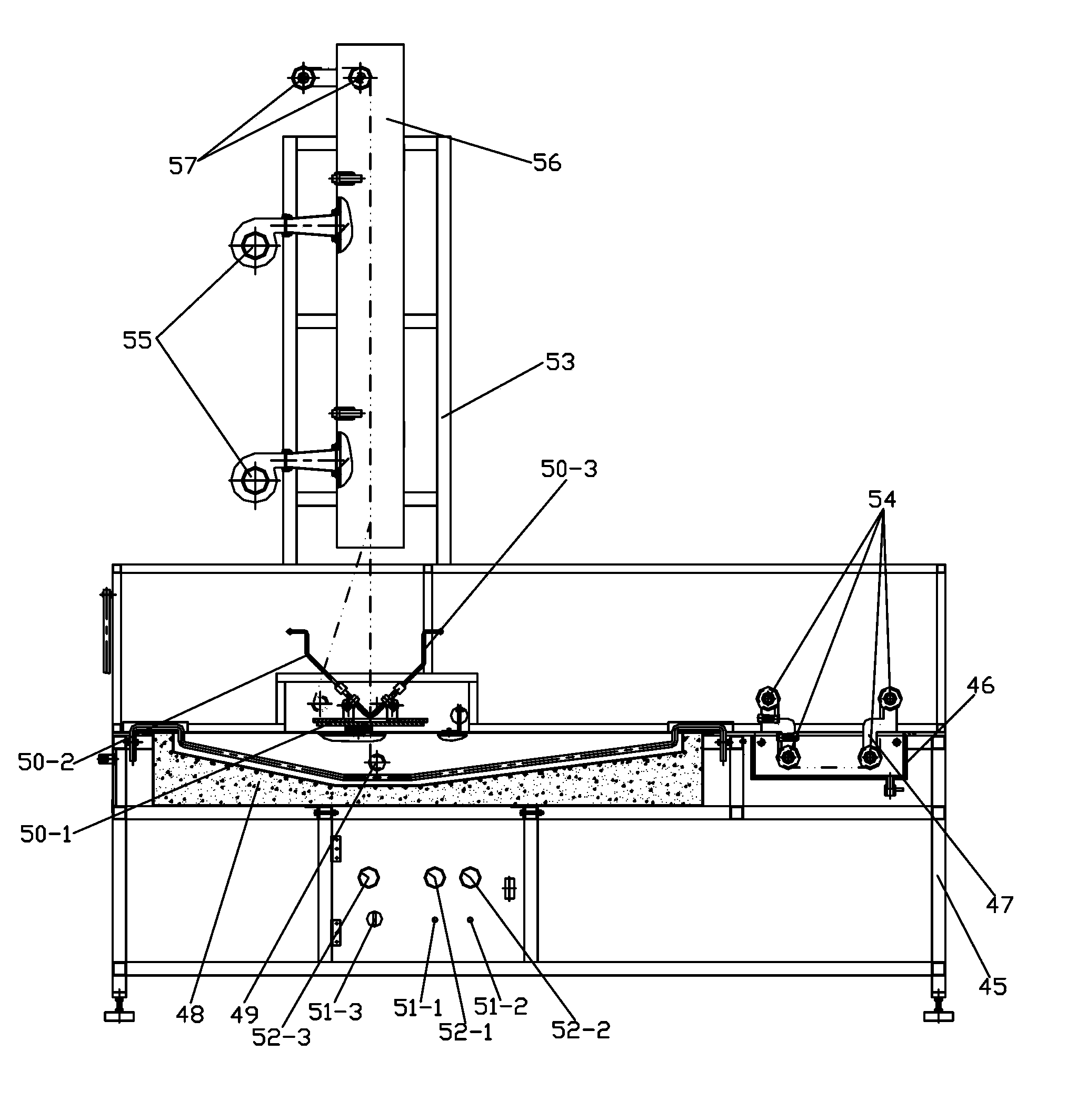

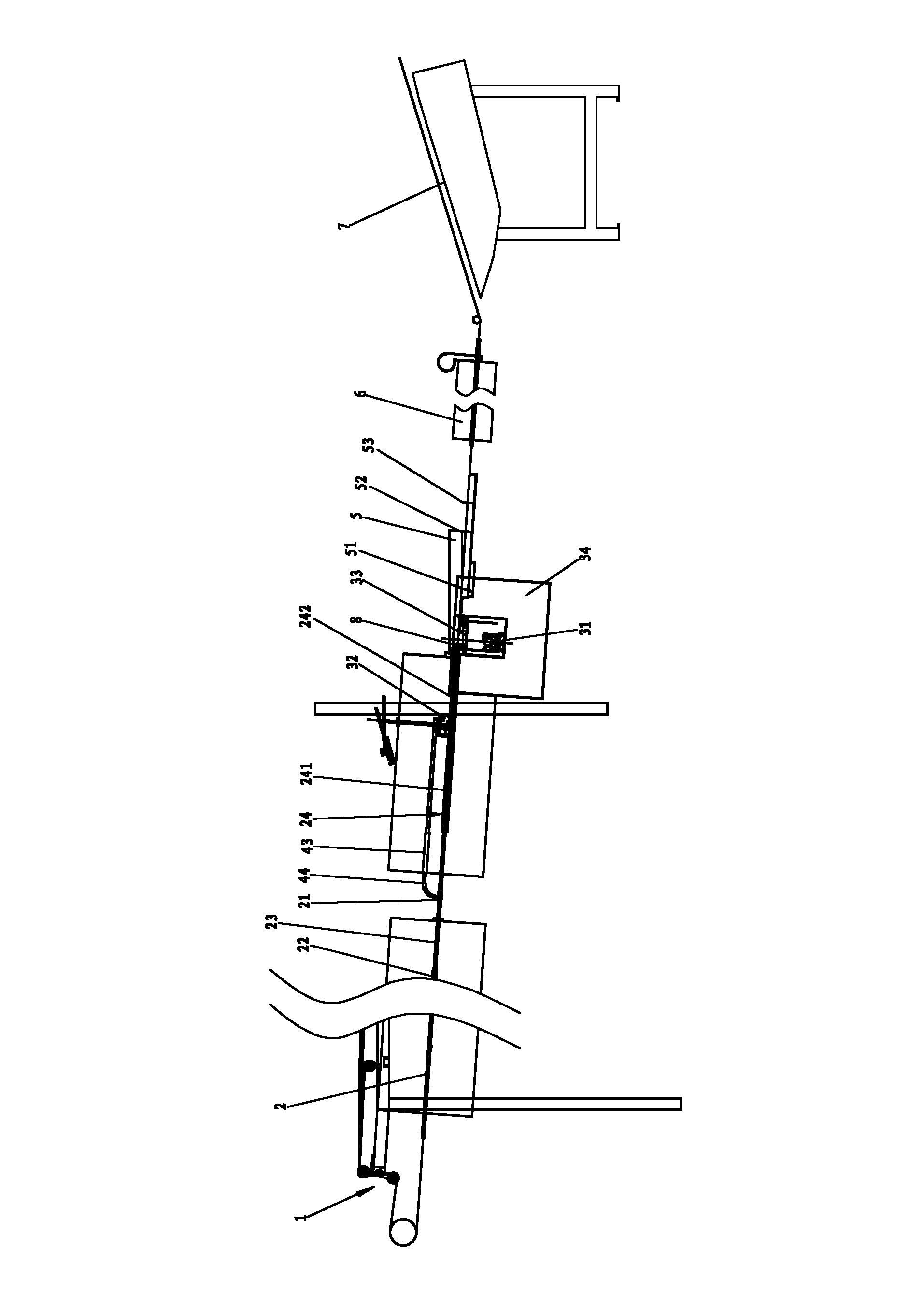

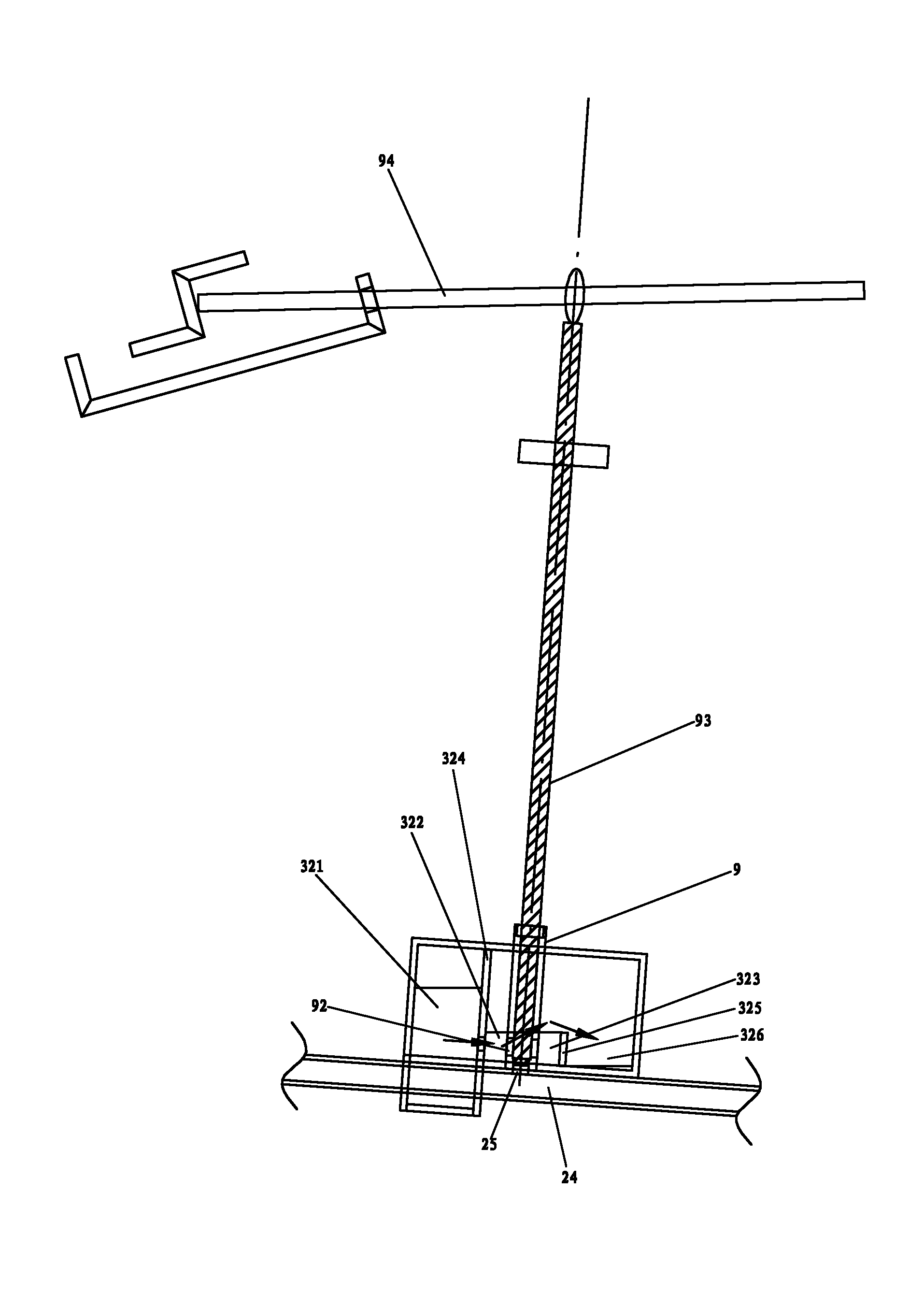

High speed automatic tin-plating machine

InactiveCN103834891ACompact structureNovel and reasonable designHot-dipping/immersion processesControl systemTin plating

The invention discloses a high speed automatic tin-plating machine which comprises an unreeling mechanism, a tin-plating mechanism, a driving and cleaning mechanism, a storage mechanism, a reeling mechanism and a control system sequentially arranged, wherein the unreeling mechanism comprises an unreeling frame, a paying off swing rod, an unreeling transitional wheel, an unreeling belt wheel, a tension adjusting wheel and an unreeling motor; the tin-plating mechanism comprises a tin-plating frame, an acidifying box, an acidifying transitional wheel frame, a solder machine, a pinch roller, a wind knife assembly and an air flue frame; the driving and cleaning mechanism comprises a cleaning frame, a cleaning agent groove, a cleaning transitional wheel bracket, a thickness measuring assembly and a traction assembly; the storage mechanism comprises a storage frame, a fixed wire storage wheel set, a mobile wire storage wheel set and a tension detection mechanism; the reeling mechanism comprises a reeling frame, a reeling guide rail bracket, a vertical wiring device and a horizontal wiring device. The high speed automatic tin-plating machine disclosed by the invention is novel and reasonable in design, ensures the quality and efficient production of tin-plating welding strips, is high in working reliability, better realizes continuous, efficient, high-quality and low-cost tin plating, and is convenient to popularize and use.

Owner:THE NORTHWEST MACHINE

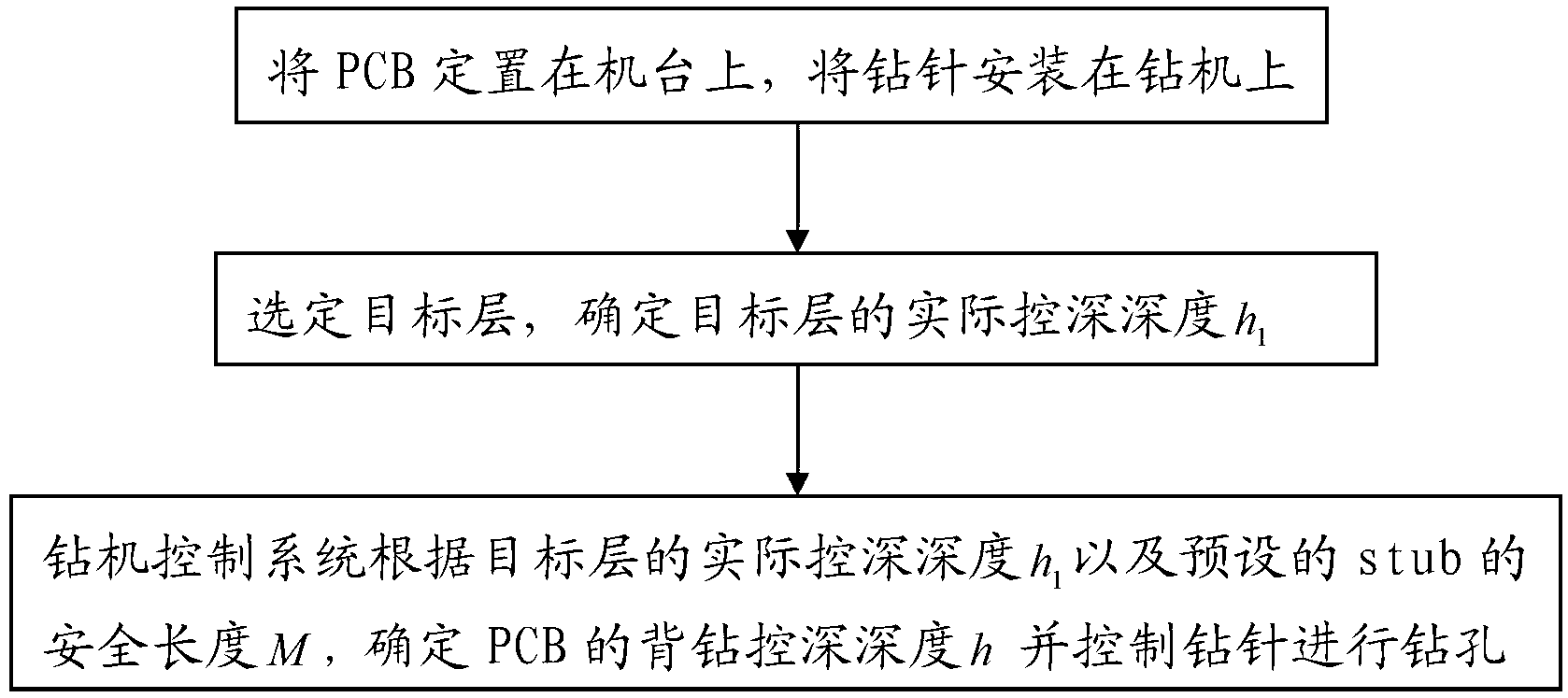

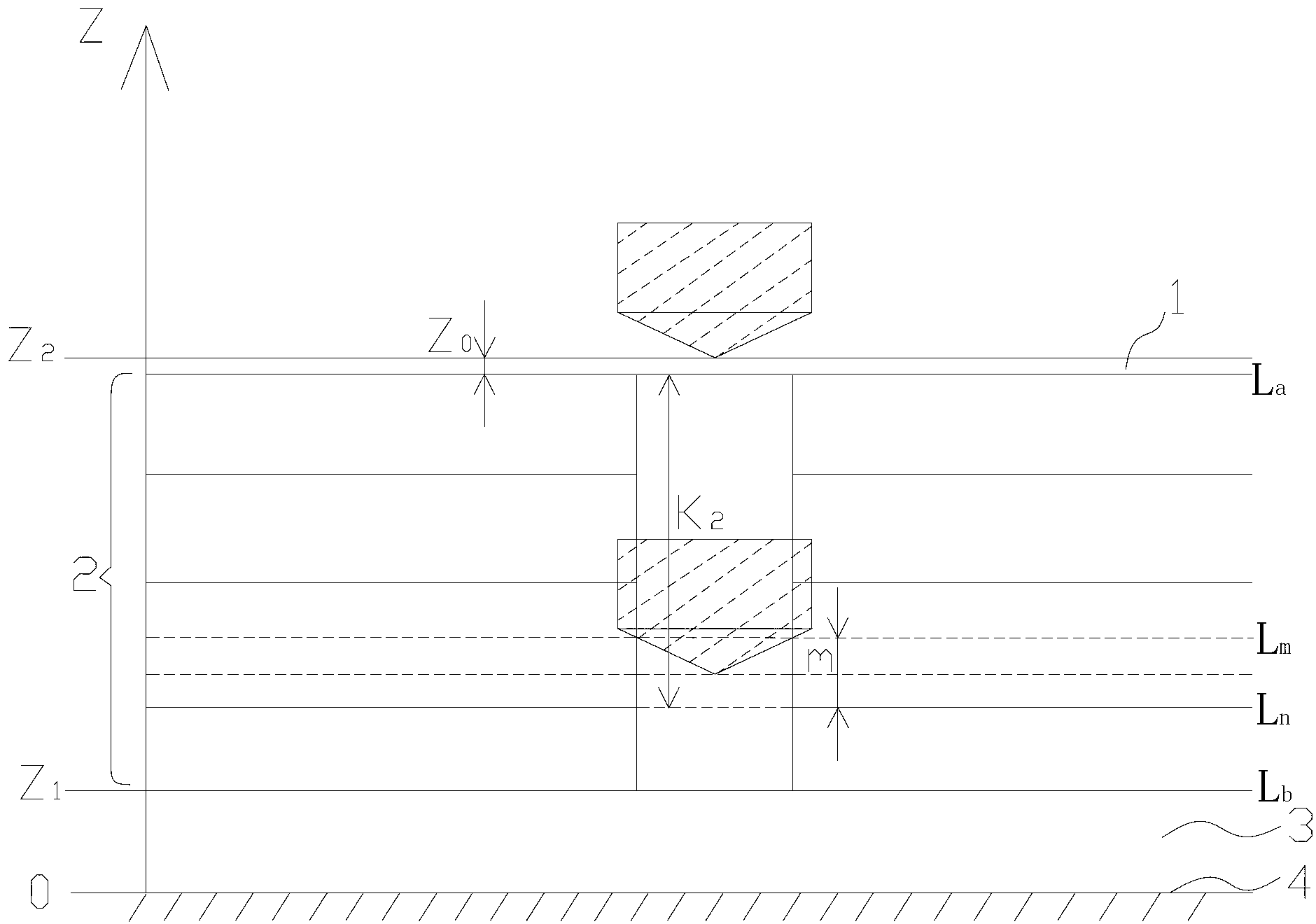

PCB (printed circuit board) back drilling method

The invention relates to a PCB (printed circuit board) back drilling method. The PCB back drilling method comprises the following steps: fixing a PCB on a machine table, and mounting a drill bit on a drilling machine; selecting a target layer, and determining an actual control depth h1 of the target layer; and determining a back drilling control depth h of the PCB according to the actual control depth h1 of the target layer and a preset safety length M of a stub and controlling the drill bit to drill a hole drilling machine control system. According to the PCB back drilling method, influence of thickness uniformity of the board, cone height of a drill tip and copper / tin-plating process variation on the accuracy of the control depth can be reduced; and through introduction of the safety length M of the stub, the precision of the PCB back drilling control depth h can be effectively controlled, thus achieving precision control of the stub and eliminating adverse effects of the stub on a signal.

Owner:GUANGZHOU FASTPRINT CIRCUIT TECH

Addictive for electroplating tin and tin nickel alloy

The additive for electrolytic tin plating and Sn-Ni alloy belongs to the monohydroxy carboxylic acid or hydroxy polycarboxylic acid or polyhydroxy carboxylic acid or polyhydroxy polycarboxylic acid or their alkaline-earth metal, carboxylic acid or polycarboxylic acid or their alkaline-earth metal, non-sulfur amino acid or it alkaline-earth metal, polyamino carboxylic acid or it alkaline-earth metal. Wherein, the dosage is 5-100g for every liter plating solution. This invention can modify plating liquid nature, improves solution stability, and realizes large-scale control to alloy intergradient.

Owner:TIANJIN UNIV

Tin-plated film and method for producing the same

InactiveUS20060016694A1Improve reliabilityHard to generate whiskerSemiconductor/solid-state device detailsSolid-state devicesTin platingThin membrane

The present invention has an object to provide a tin-plated film and a method for producing the same, capable of preventing whiskers from being generated and simultaneously preventing the surface of a substrate to be plated, which is not covered with a tin-plated film, from discoloring due to oxidation, by which prevention of whisker generation, suppression of whisker growth, and prevention of discoloring of a substrate to be plated are compatible with simplified operations ensuring excellent productivity. The method is provided with the steps of removing a part of a tin-plated film formed on copper or copper alloy; processing to prevent discoloring of the copper or copper alloy from which the tin-plated film is removed; and applying heat energy to the tin-plated film of the copper or copper alloy which is processed to prevent discoloring.

Owner:PANASONIC CORP

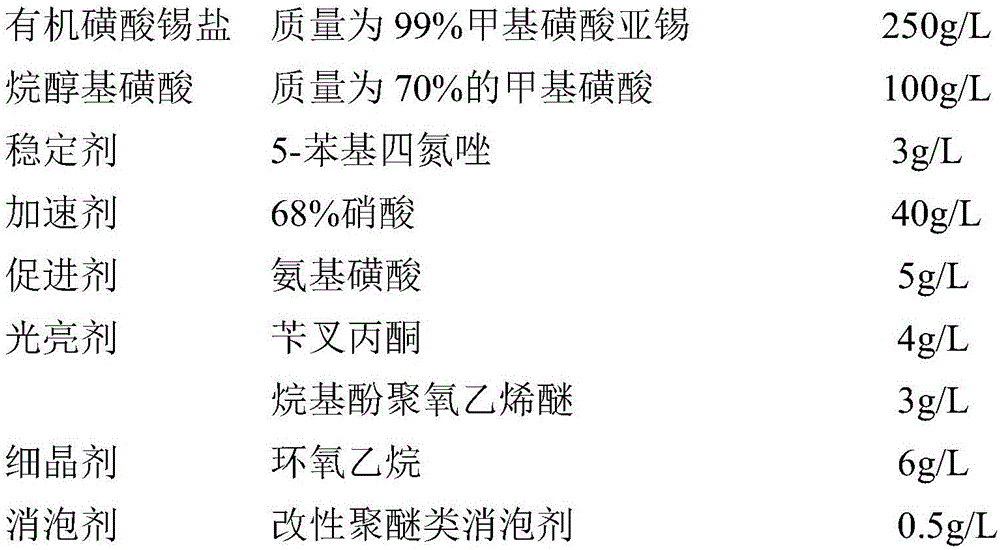

Tin stripping and tin plating liquid, preparing method of tin stripping and tin plating liquid and cyclic regeneration method for adopting tin stripping and tin plating liquid for recycling metal tin

ActiveCN105734620AEasy to handleImprove antioxidant capacityPhotography auxillary processesProcess efficiency improvementOrganic sulfonic acidFoaming agent

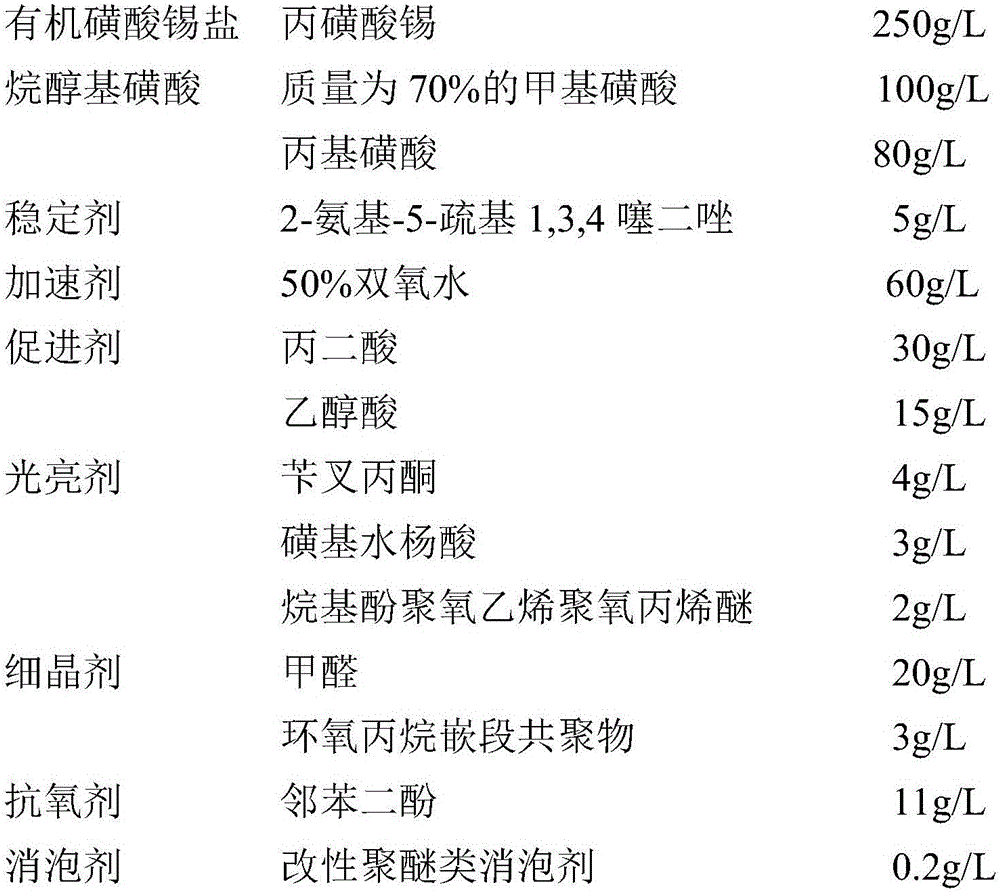

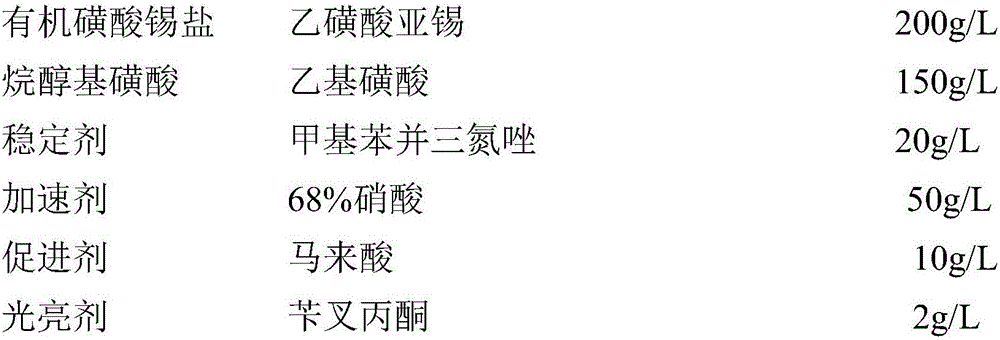

The invention discloses tin stripping and tin plating liquid, a preparing method of the tin stripping and tin plating liquid and a method for adopting the tin stripping and tin plating liquid for recycling metal tin from tin-containing waste. The tin stripping and tin plating liquid includes various effective components such as organic sulfonic acid tin salt, alkanol group sulfoacid, a stabilizing agent, an accelerating agent, an accelerator, a brightening agent, a grain fining agent, antioxidant and a foaming agent, and all the components are in synergy. The defect of traditionally recycling tin from tin stripping waste liquid is overcome, interference of other metal impurities is avoided, and high-purity metal tin can be efficiently recycled from the waste liquid. In addition, the operation steps for adopting the tin stripping and tin plating liquid for recycling the metal tin from the tin-containing waste are simple and convenient and fast to implement, the high-quality metal tin can be recycled, furthermore, the tin stripping liquid can be regenerated at the same time to be repeatedly utilized, and the problems that traditional tin stripping waste liquid is large in amount, resources are wasted, and the environment is seriously polluted are solved.

Owner:SHENZHEN CYPRESS IND DEV CO LTD

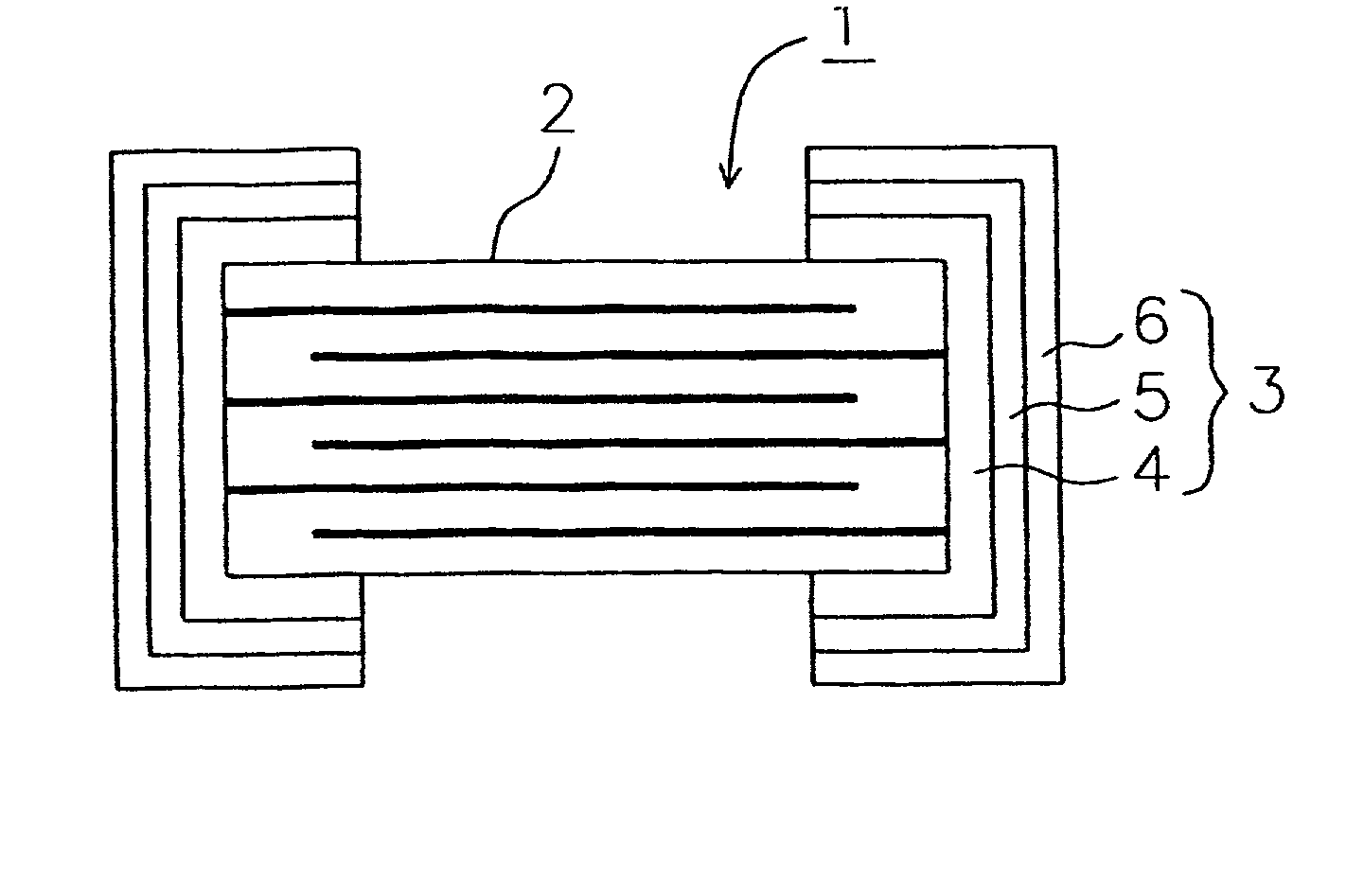

Semiconductor package and substrate having multi-level vias

ActiveUS7145238B1Reducing via diameterMaintaining aspect ratioSemiconductor/solid-state device detailsSolid-state devicesThin metalDielectric

A semiconductor package and substrate having multi-level plated vias provide a high density blind via solution at low incremental cost. Via are half-plated atop a circuit pattern and then a second via half is added to complete the via after isolation of elements of the circuit pattern. Successive resist pattern applications and etching are used to form a via tier atop a circuit pattern that is connected by a thin plane of metal. After the tier is deposited, the thin metal plane is etched to isolate the circuit pattern elements. Dielectric is then deposited and the top half of the via is deposited over the tier. The tier may have a larger or smaller diameter with respect to the other half of the via, so that the via halves may be properly registered. Tin plating may also be used to control the etching process to provide etching control.

Owner:AMKOR TECH SINGAPORE HLDG PTE LTD

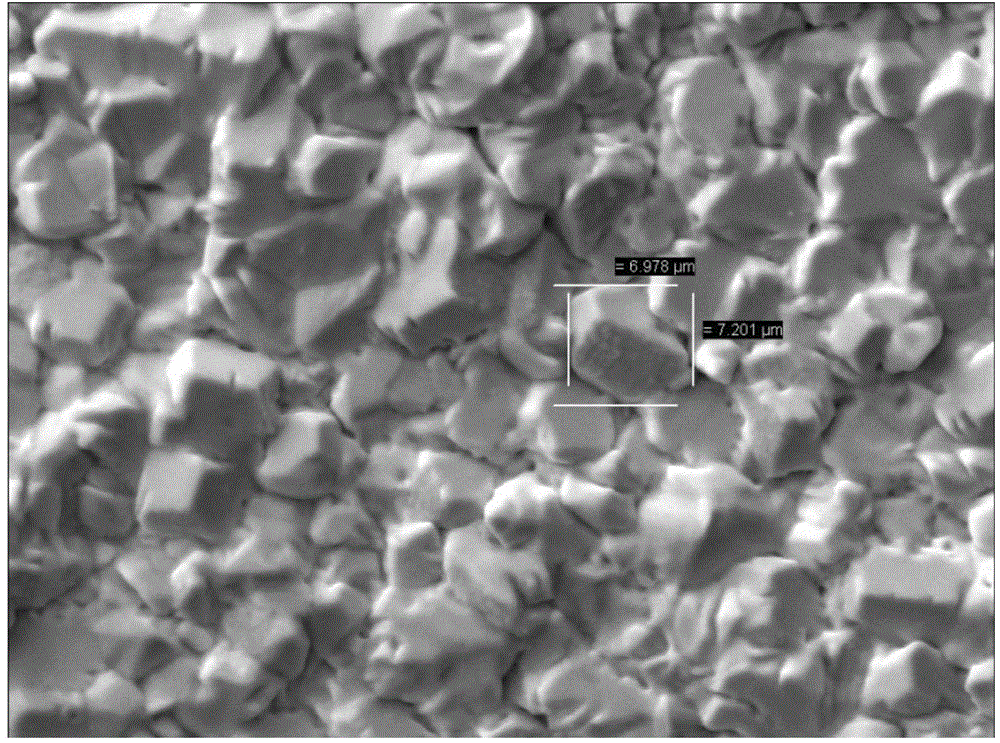

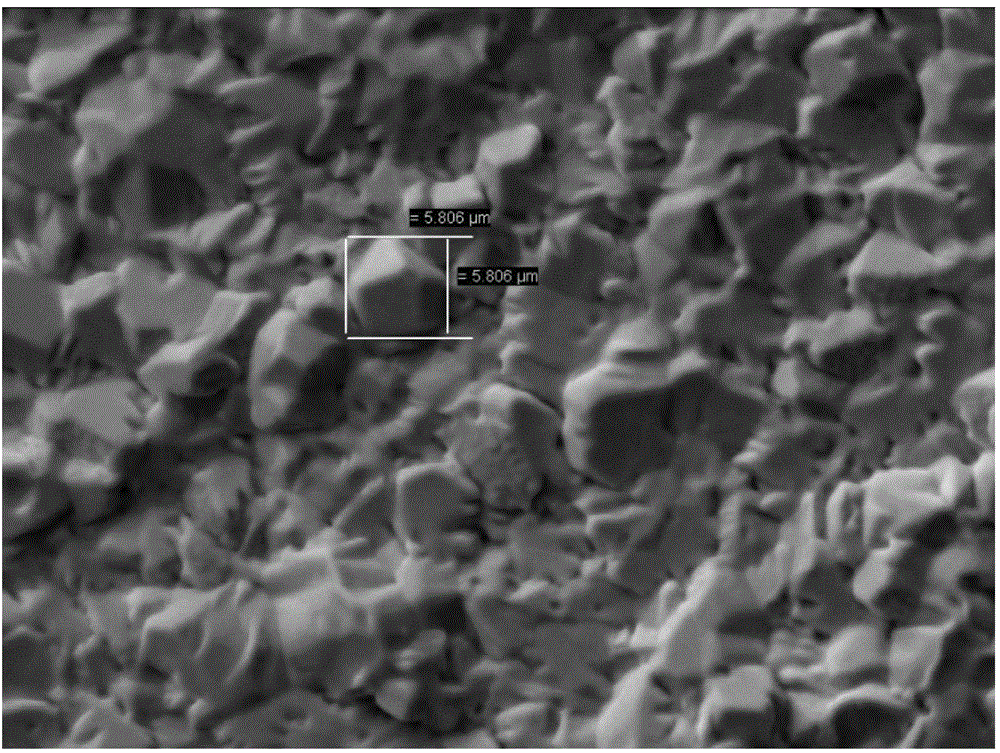

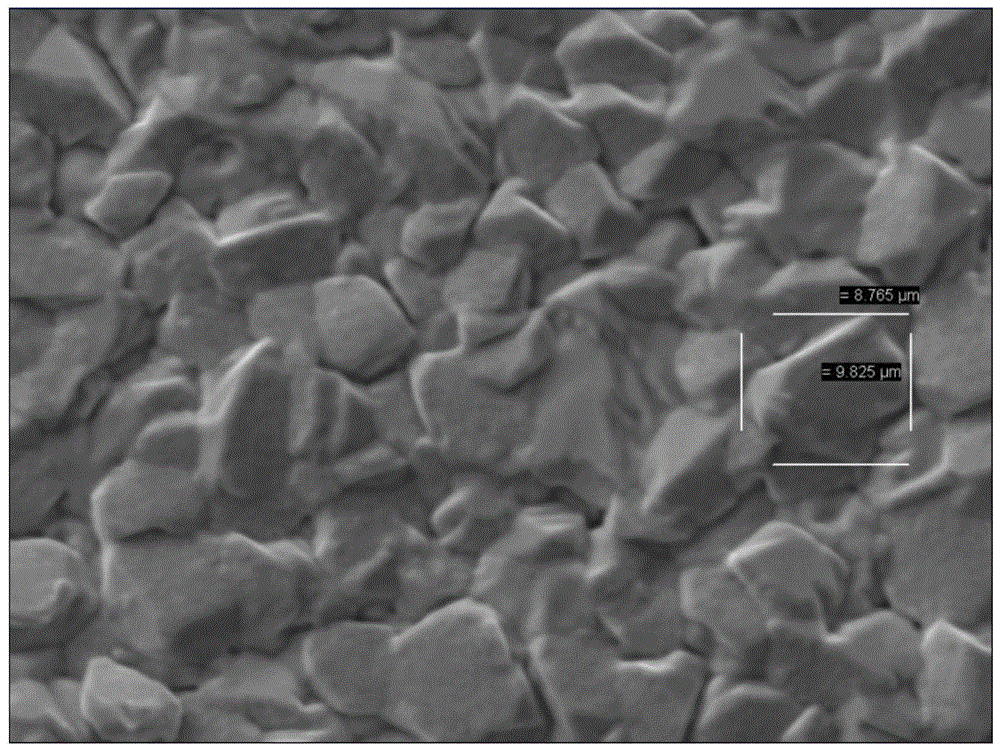

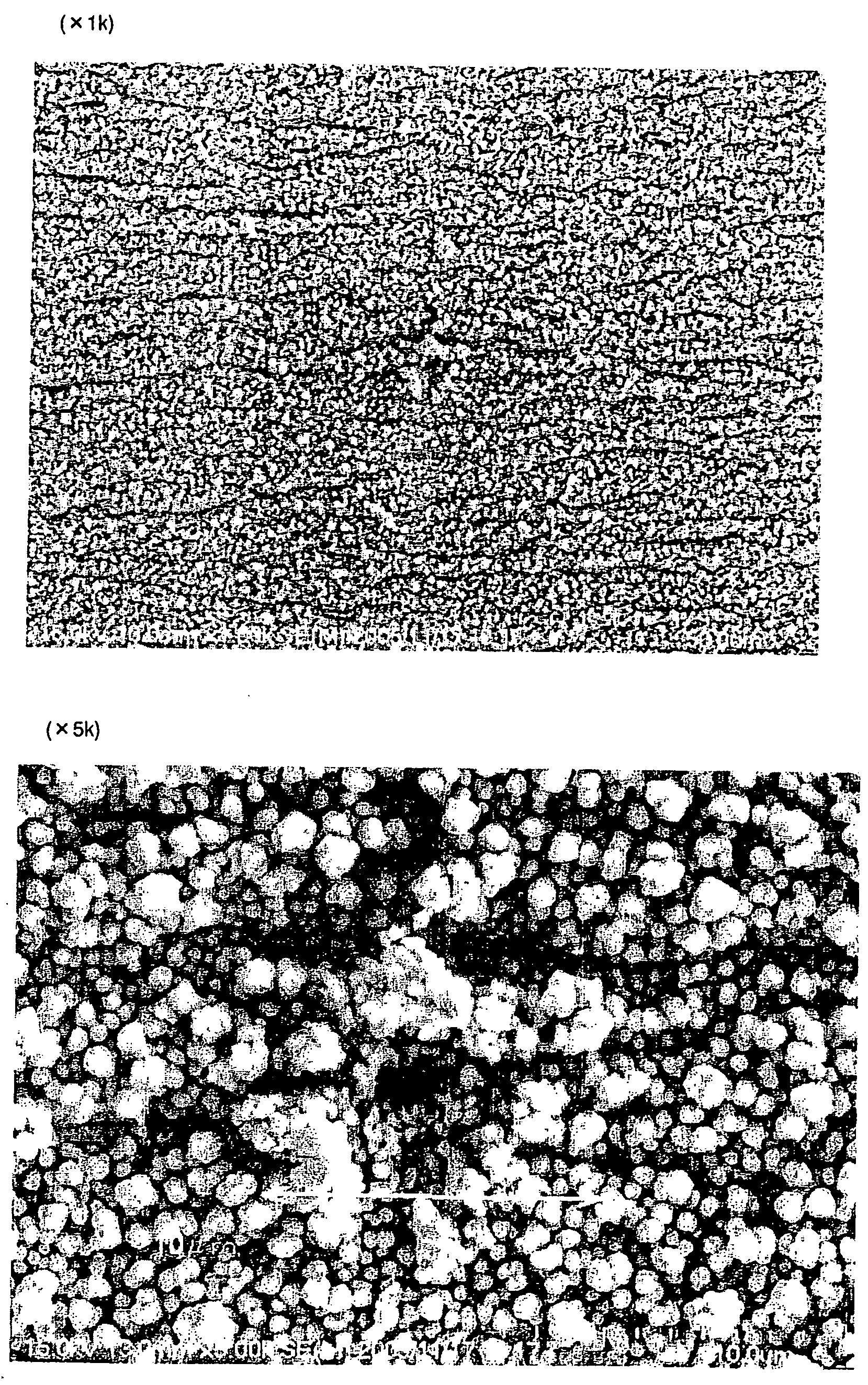

Rolled Copper or Copper Alloy Foil with Roughened Surface and Method of Roughening Rolled Copper or Copper Alloy Foil

ActiveUS20090162685A1Improve featuresInhibition formationPrinted circuit aspectsPrinted circuit manufactureTin platingCopper sulfate

Provided is a rolled copper or copper alloy foil having a roughened surface formed of fine copper particles, obtained by subjecting a rolled copper or copper alloy foil to roughening plating with a plating bath containing copper sulfate (Cu equivalent of 1 to 50 g / L), 1 to 150 g / L of sulfuric acid, and one or more additives selected among sodium octyl sulfate, sodium decyl sulfate, and sodium dodecyl sulfate under the conditions of a temperature of 20 to 50° C. and a current density of 10 to 100 A / dm2. The provided rolled copper or copper alloy foil subject to roughening is reduced in craters which are obvious defects unique to rolled copper or copper alloy foils having a roughened surface, has high strength, adhesive strength with the resin layer, acid resistance and anti-tin plating solution properties, high peel strength, favorable etching properties and gloss level, and also suits for use in producing a flexible printed wiring board capable of bearing a fine wiring pattern. Additionally provided is a method of roughening the rolled copper or copper alloy foil.

Owner:JX NIPPON MINING& METALS CORP

Method for etching outer circuit of PCB product with high aspect ratio

The invention discloses a method for etching an outer circuit of a PCB (printed circuit board) product with high aspect ratio, which comprises the following steps of: A) cutting a circuit board substrate, sticking a dry film, browning the inner layer, treating a pressing board, and then drilling the circuit board substrate; B) performing copper deposition plating on the full board or adding a board for plating; C) performing first film removal treatment on the pattern plated board; D) performing alkali etching treatment on the outer circuit after development; and E) performing tin removal treatment on the PCB obtained in the step D), inspecting qualification, and obtaining a finished product. The method for etching the outer circuit of the PCB product with the high aspect ratio can manufacture the product with aspect ratio of 15:1 to 30:1 or over by sticking the film again after the pattern plating is finished, using hole covering film exposure, covering the dry film on the hole for protection, adopting alkali etching and then removing the film and the tin; and the method has no defect of the PCB with high aspect ratio manufactured by prolonging the tin plating time or increasing the tin plating current density in the prior art.

Owner:DALIAN CHONGDA CIRCUIT

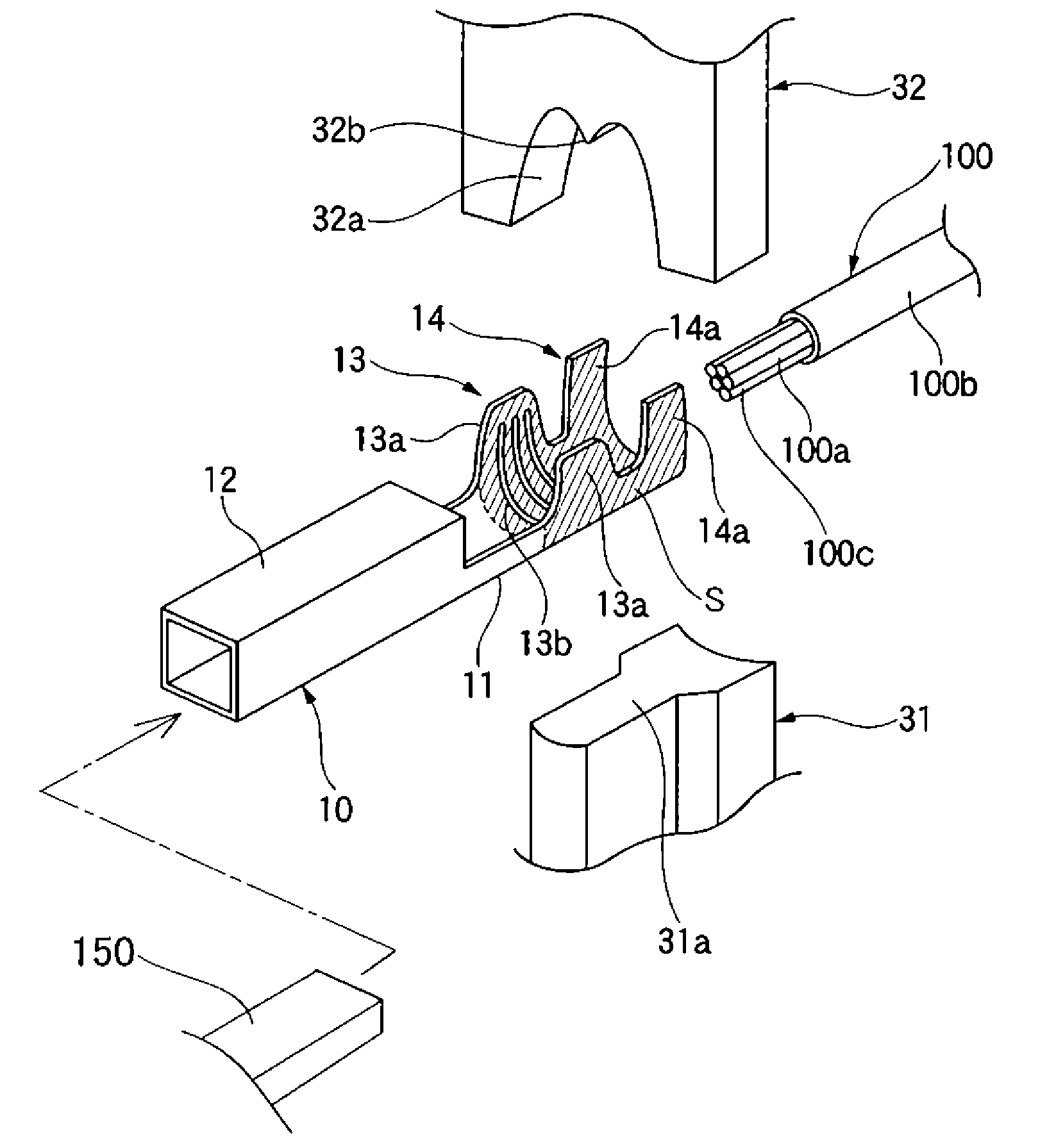

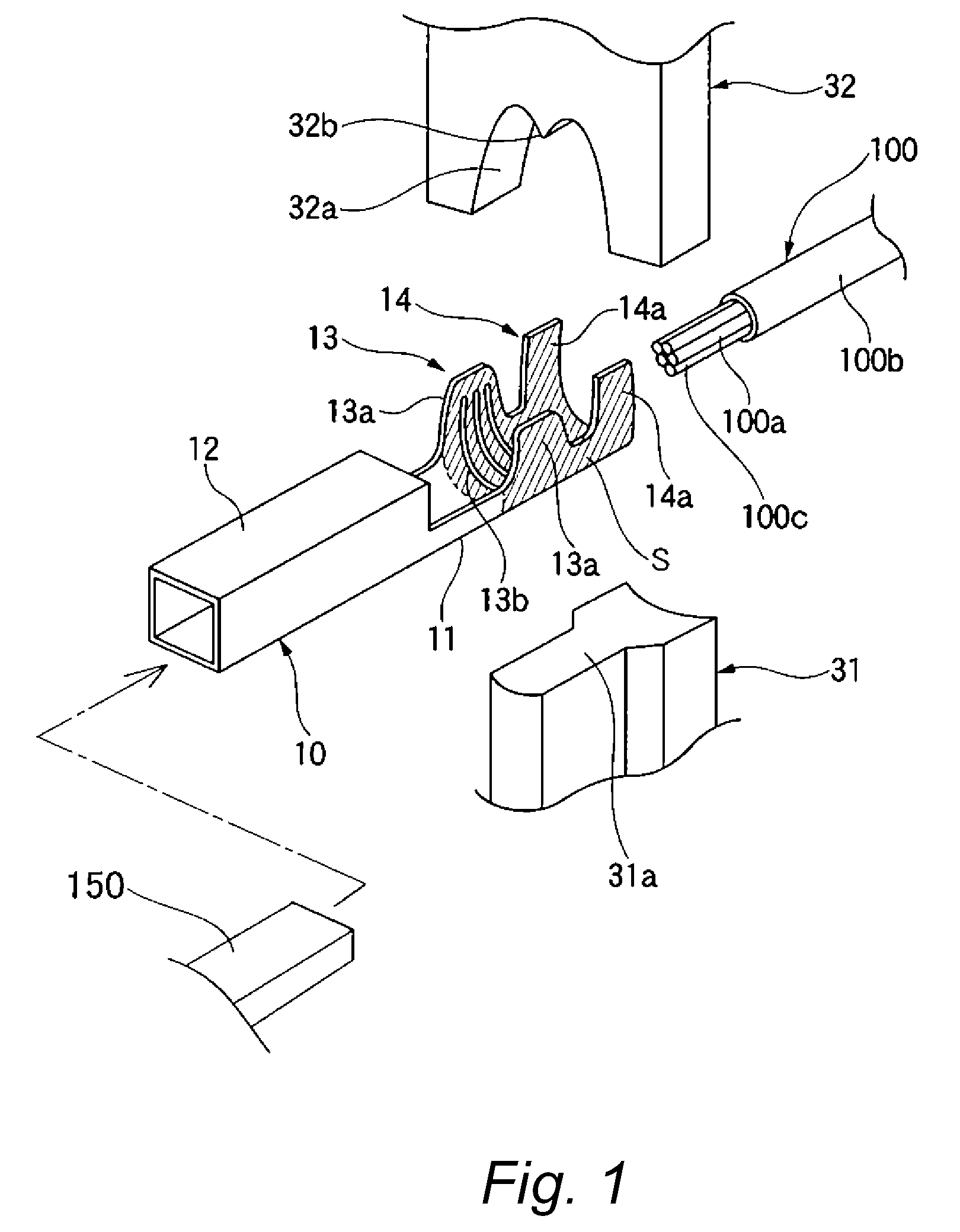

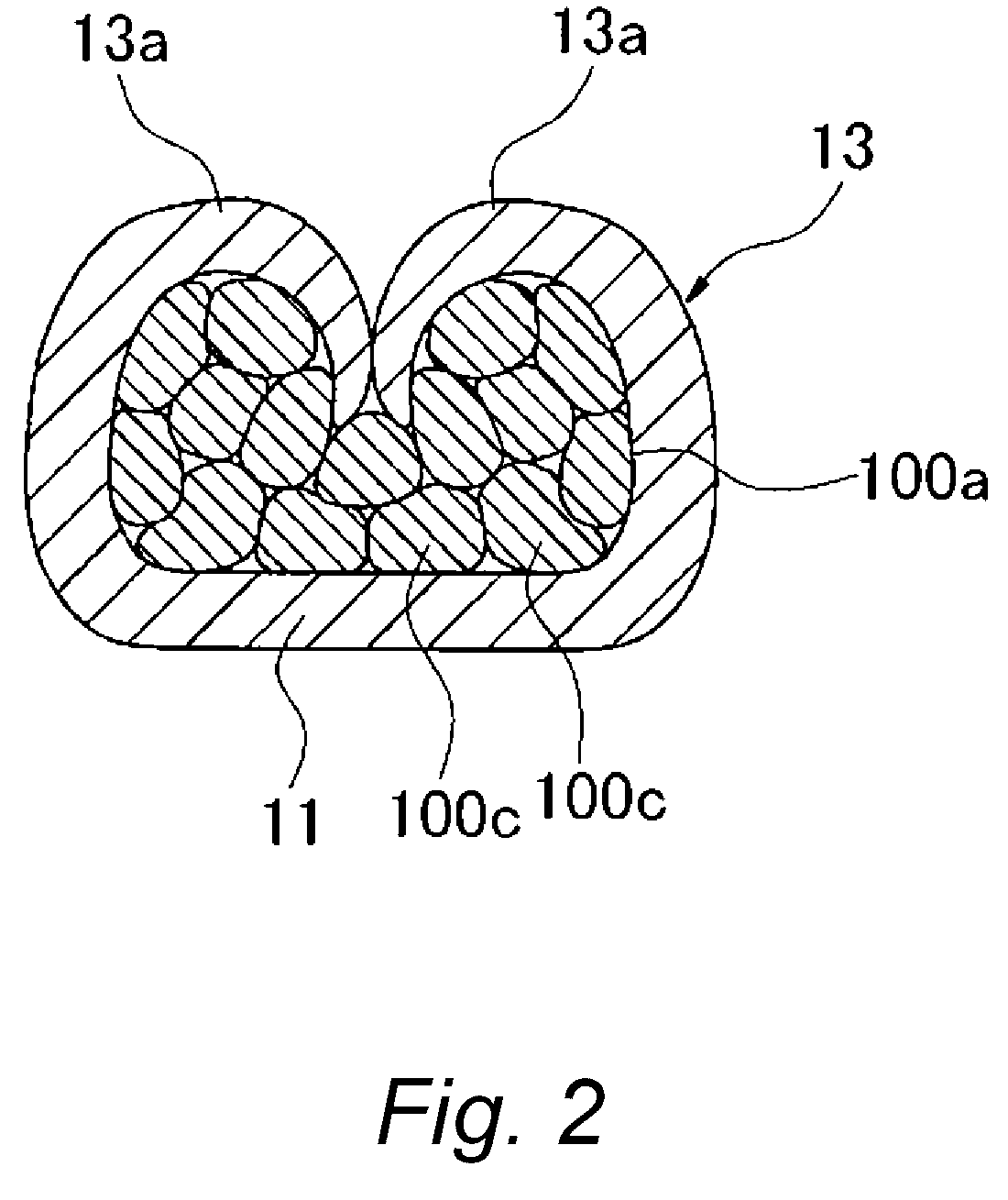

Method for crimping terminal to aluminum electric wire

ActiveUS8245396B2Improve electrical connection reliabilityCoupling device detailsCable junctionsElectricityElectrical conductor

In order to promote the adhesion of a crimp terminal (10) to an aluminum electric wire (100) by virtue of crimping to thereby realize an improvement in electric connecting performance, the thickness of tin plating applied to an inner surface of a conductor crimping portion (13) of the crimp terminal (10) is set to be in the range from 2.1 μm to 5.0 μm, and then, the conductor crimping portion (13) is crimped to a conductor (100a) of the aluminum electric wire (100).

Owner:YAZAKI CORP

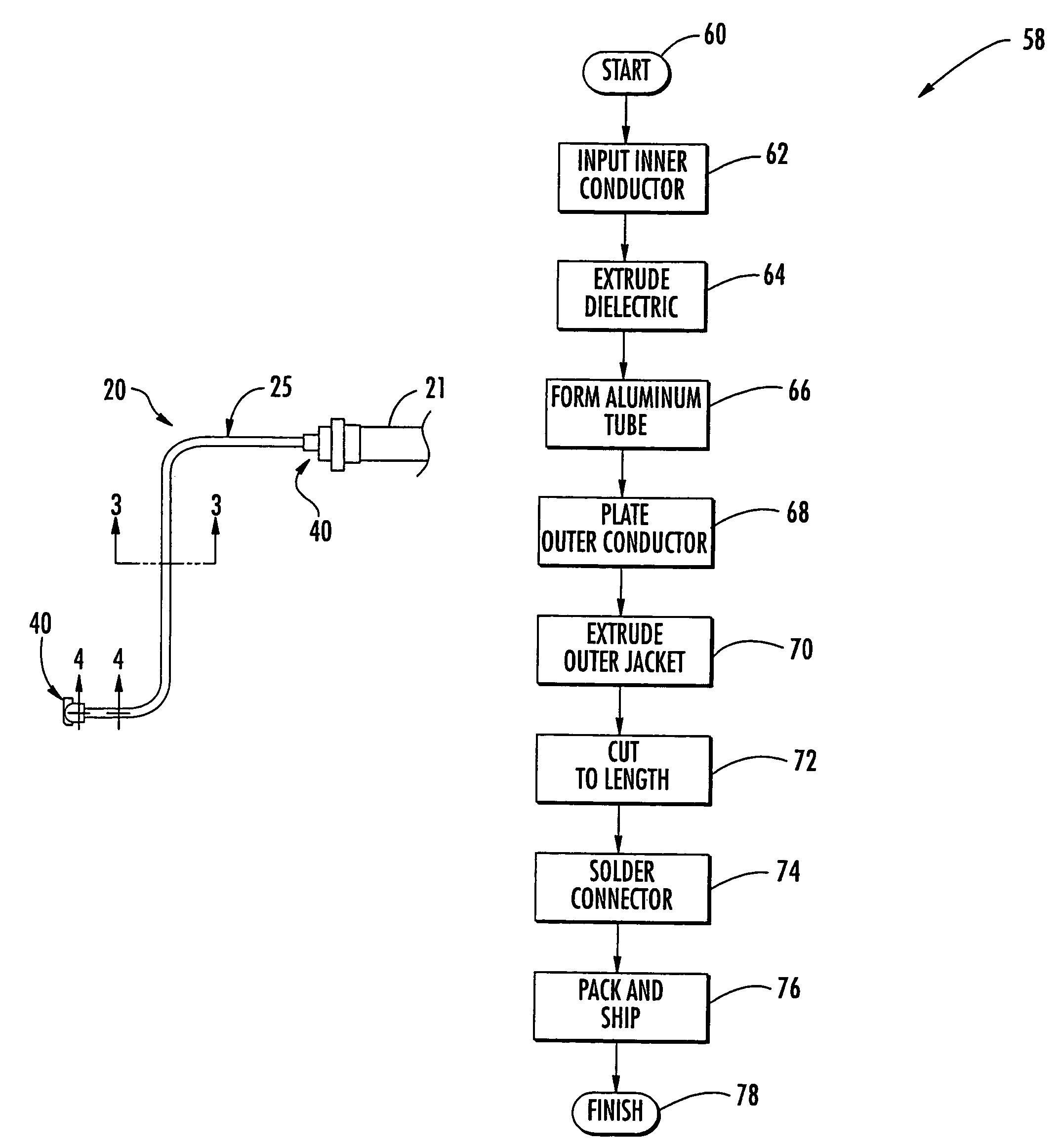

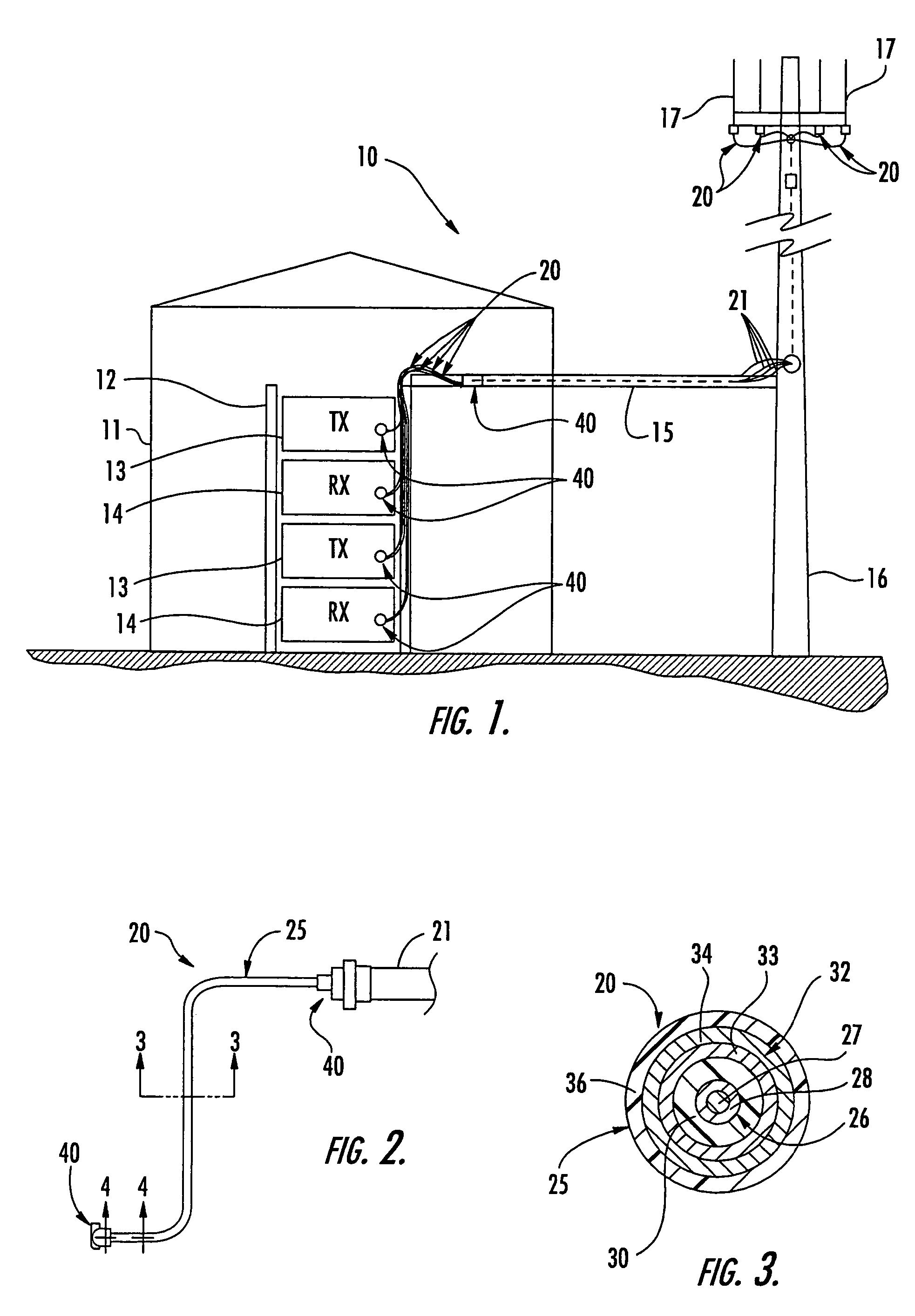

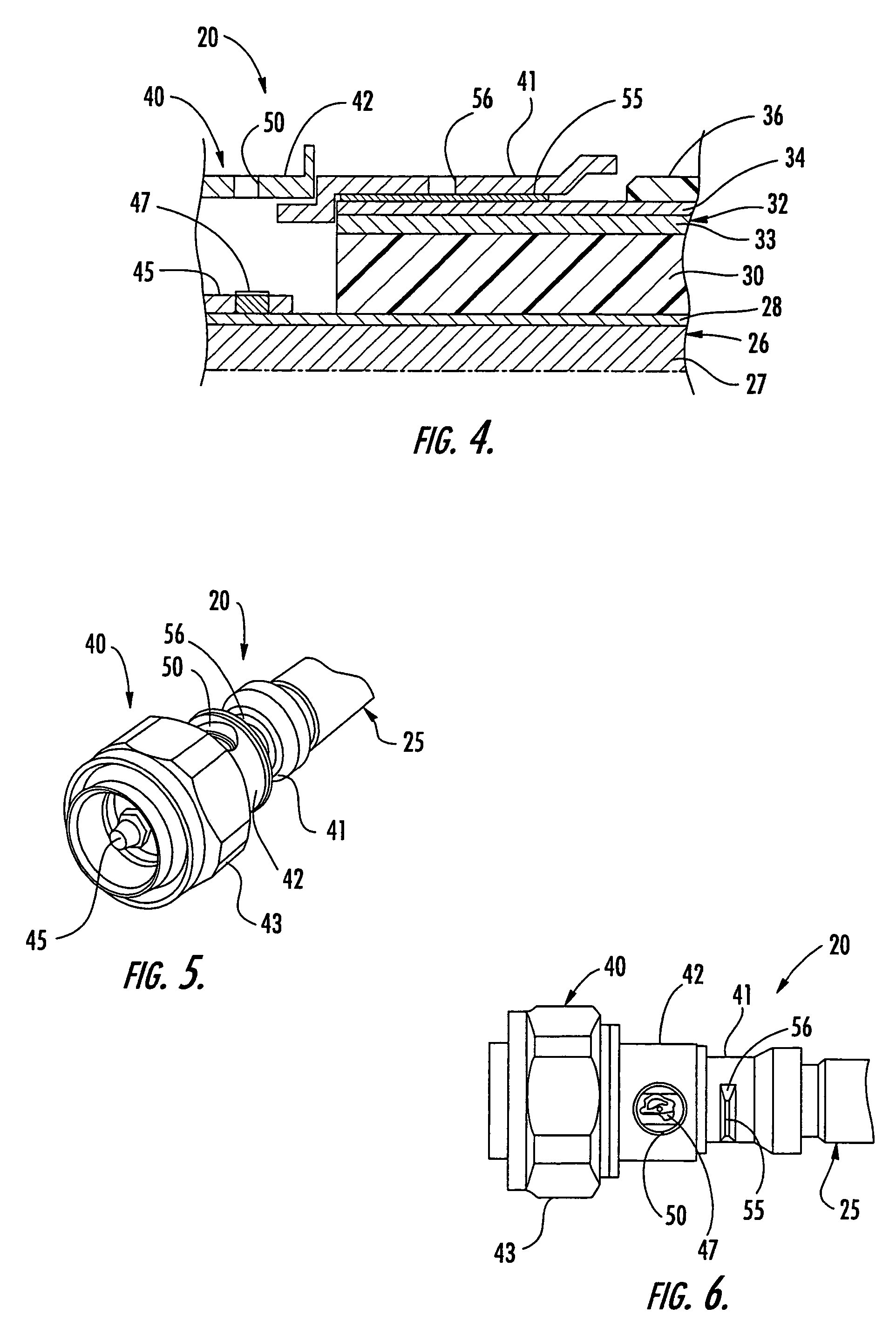

Method for marking coaxial cable jumper assembly including plated outer assembly

InactiveUS7127806B2Easy to manufactureShape-retaining qualityEngagement/disengagement of coupling partsPrinted circuit assemblingCoaxial cableElectrical conductor

A jumper coaxial cable assembly includes a jumper coaxial cable and at least one solder-type connector secured thereto. The cable may include an outer conductor, which, in turn, includes aluminum with a tin layer thereon. The tin layer permits an aluminum outer conductor to be used, yet facilitates soldering of the solder-type connector onto the outer conductor. The tin layer may be a tin alloy, such as a tin / lead alloy, for example. The outer conductor may have a continuous, non-braided, tubular shape, and the tin layer may extend continuously along an entire length of the outer conductor. The tin layer may be readily formed by tin plating during manufacturing of the jumper coaxial cable. The jumper coaxial cable assembly may be joined to a main coaxial cable and / or to electronic equipment.

Owner:COMMSCOPE INC

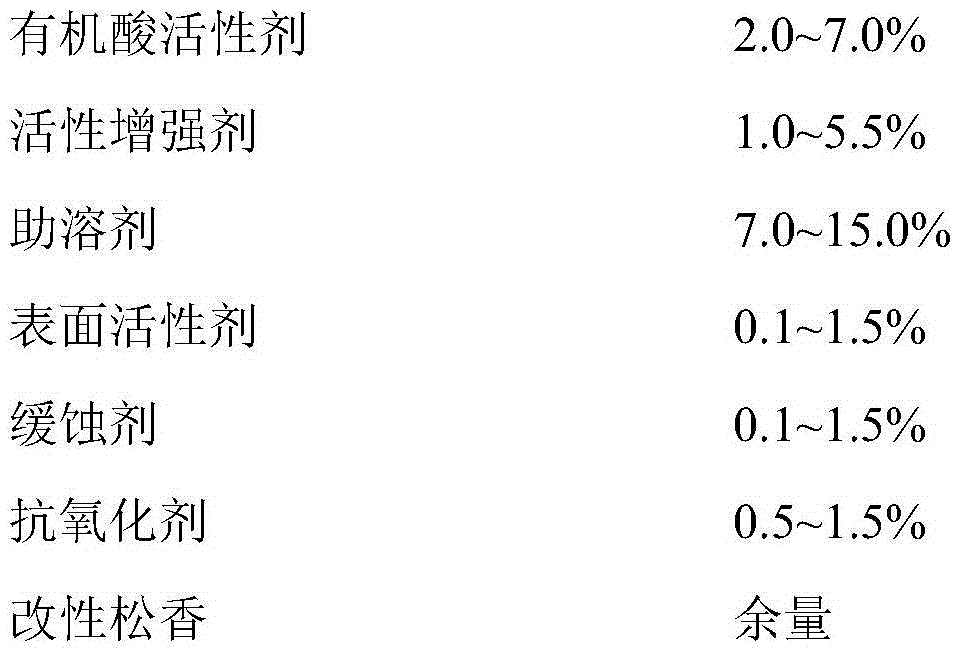

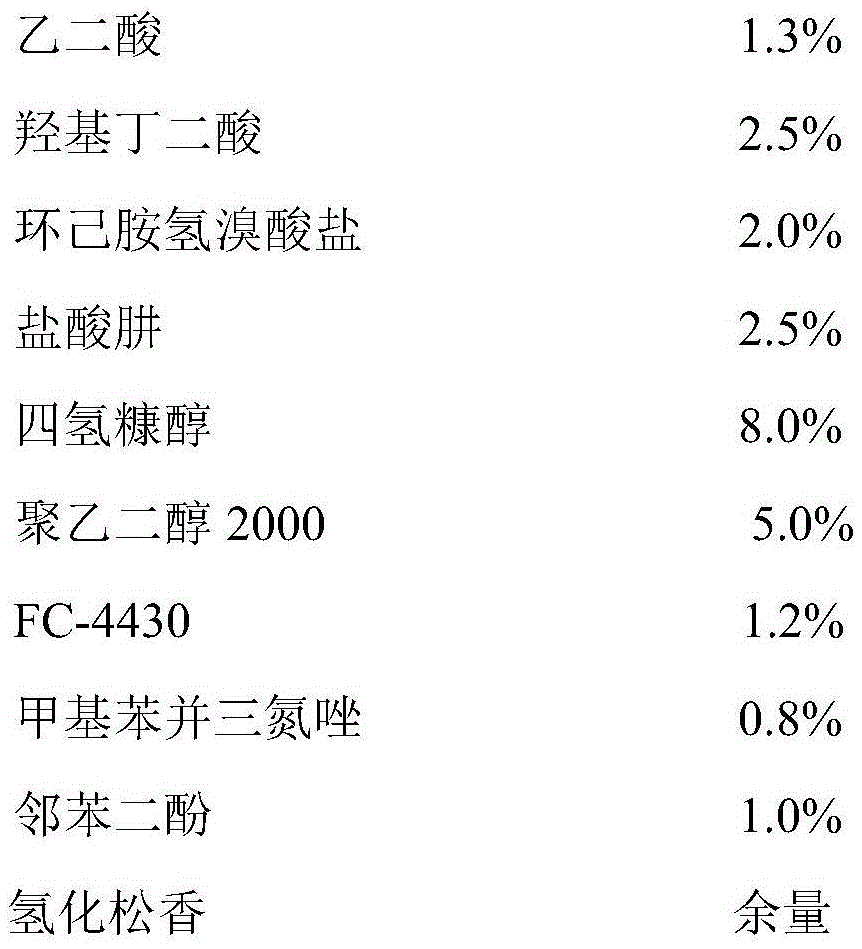

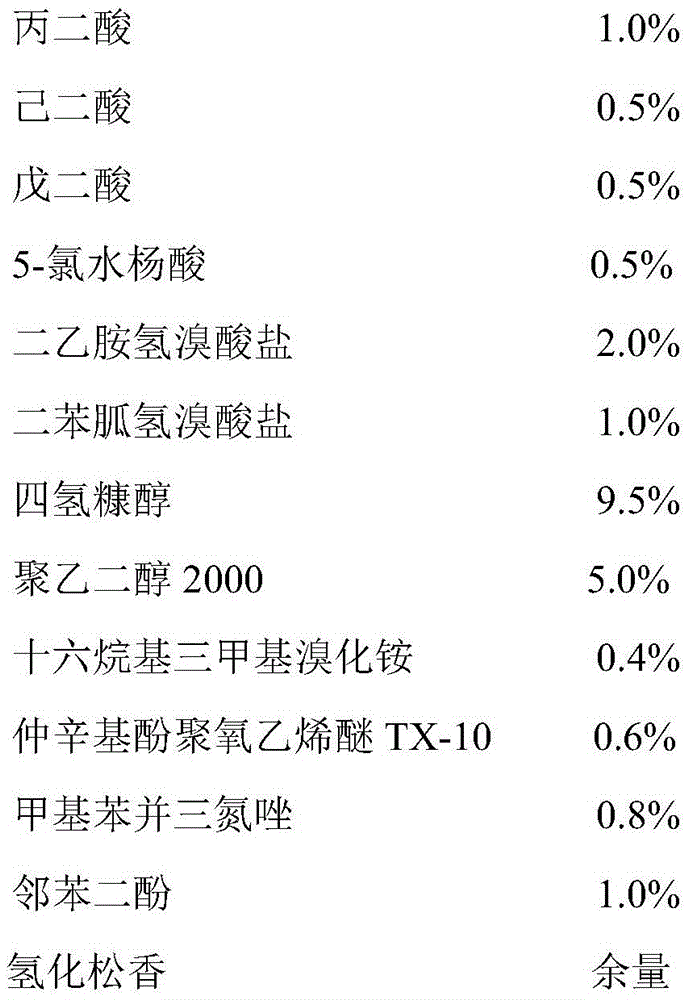

High-performance tin wire soldering flux for automatic tin soldering and preparation method of high-performance tin wire soldering flux

ActiveCN105458552ASuccessful realization of automatic solderingFast tinningWelding/cutting media/materialsSoldering mediaElectrical resistance and conductanceOrganic acid

The invention relates to a high-performance tin wire soldering flux for automatic tin soldering and a preparation method of the high-performance tin wire soldering flux. The high-performance tin wire soldering flux is prepared from the following components in percentage by weight: 2.0-7.0% of an organic acid active agent, 1.0-5.5% of an activity enhancer, 7.0-15.0% of a solubilizer, 0.1-1.5% of a surfactant, 0.1-1.5% of an inhibitor, 0.5-1.5% of an antioxidant, and the balance being modified rosin. A tin wire made by adopting the soldering flux disclosed by the invention has the characteristics of high tin plating speed, good spreadability, low empty soldering and false soldering rate, high insulation resistance after soldering, and the like; the soldering flux is particularly suitable for automation tin soldering for assembling of electronic parts and components in specific structures, printed circuit boards in specific structures and the like, and can be widely applied for the automatic tin soldering of batteries, instruments, meters and various in-home electric appliances in the electronic / electrical industry; the production efficiency is easy to improve, and the production cost is reduced.

Owner:SHENZHEN XINGHONGTAI TIN +1

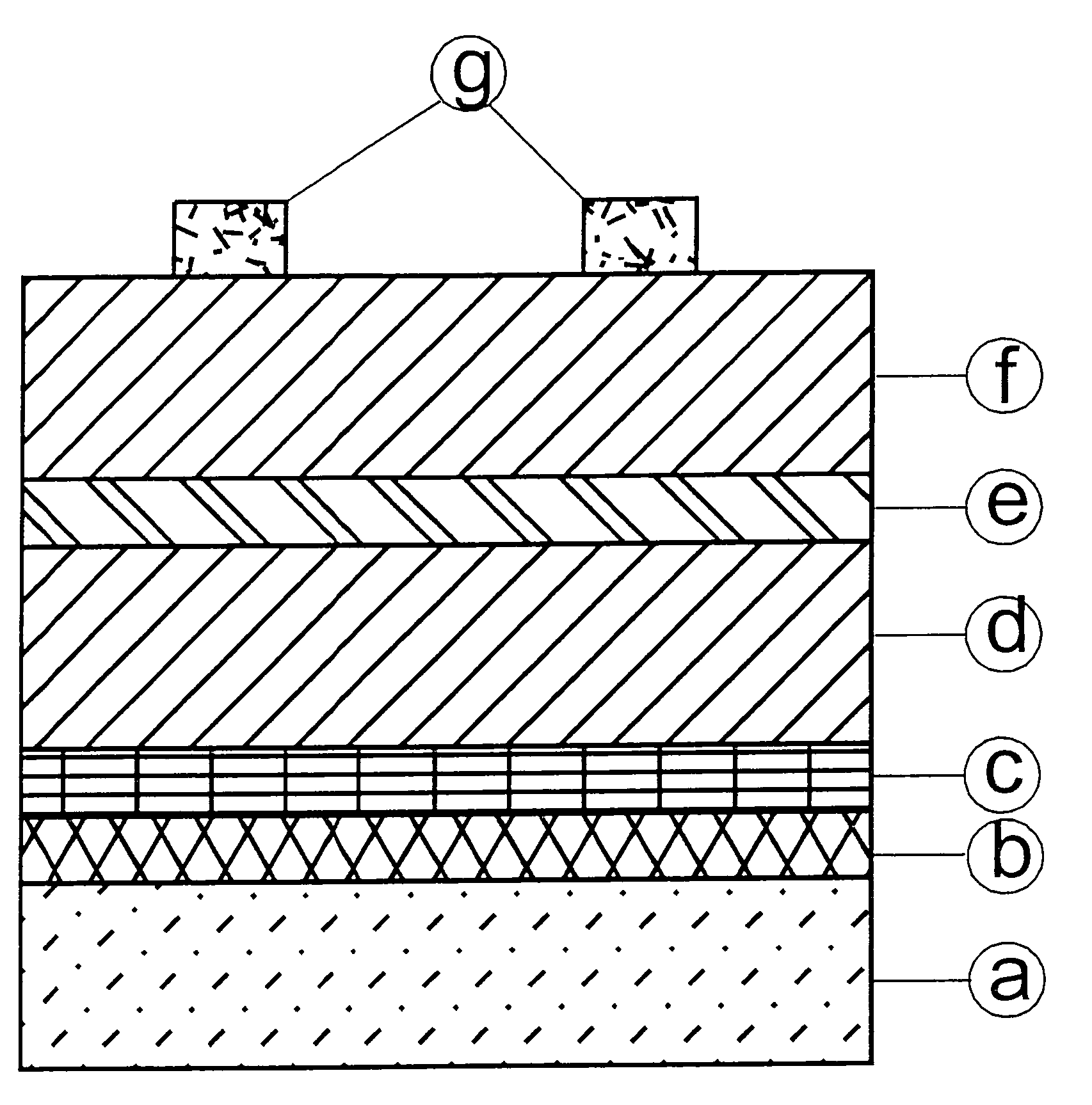

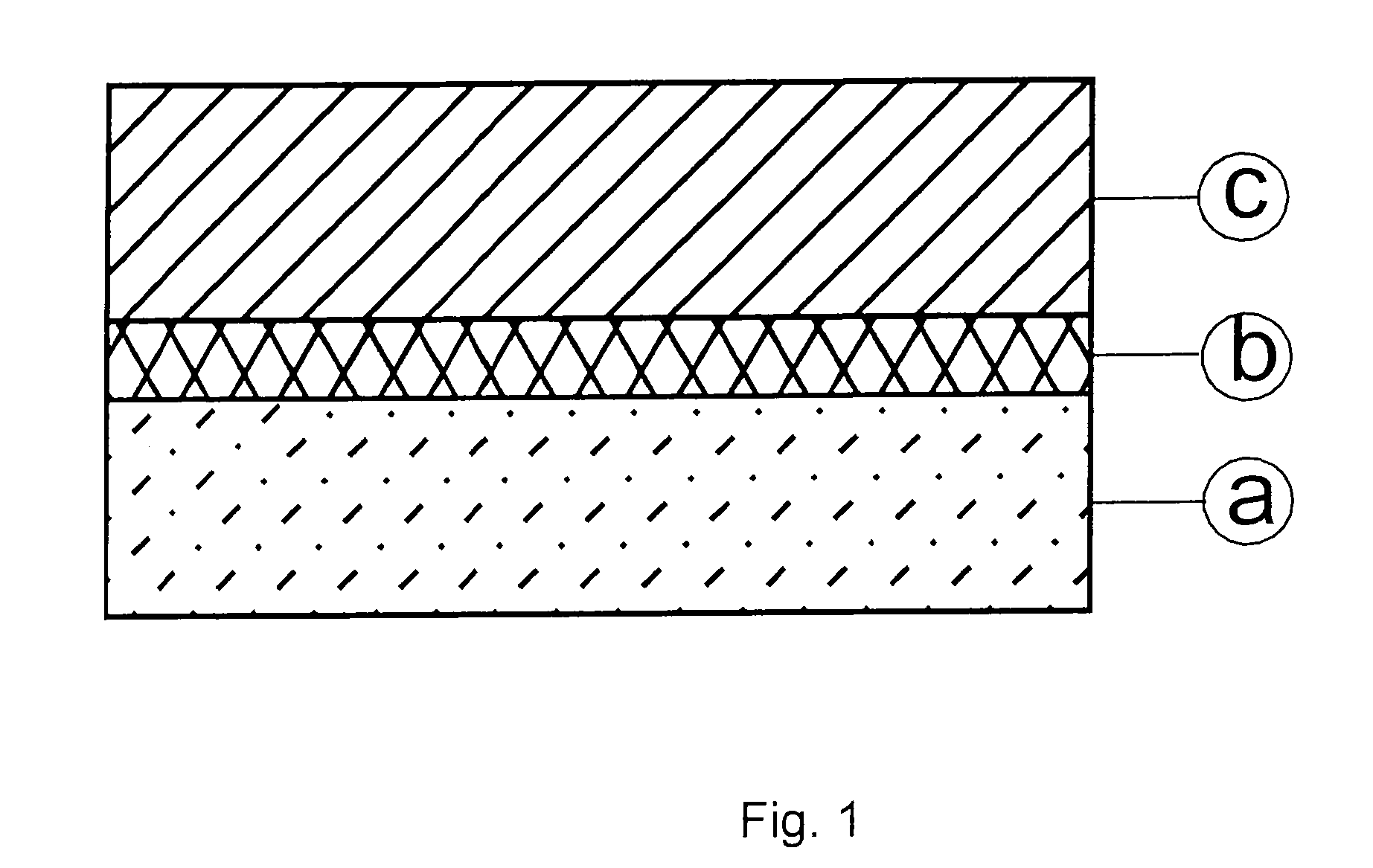

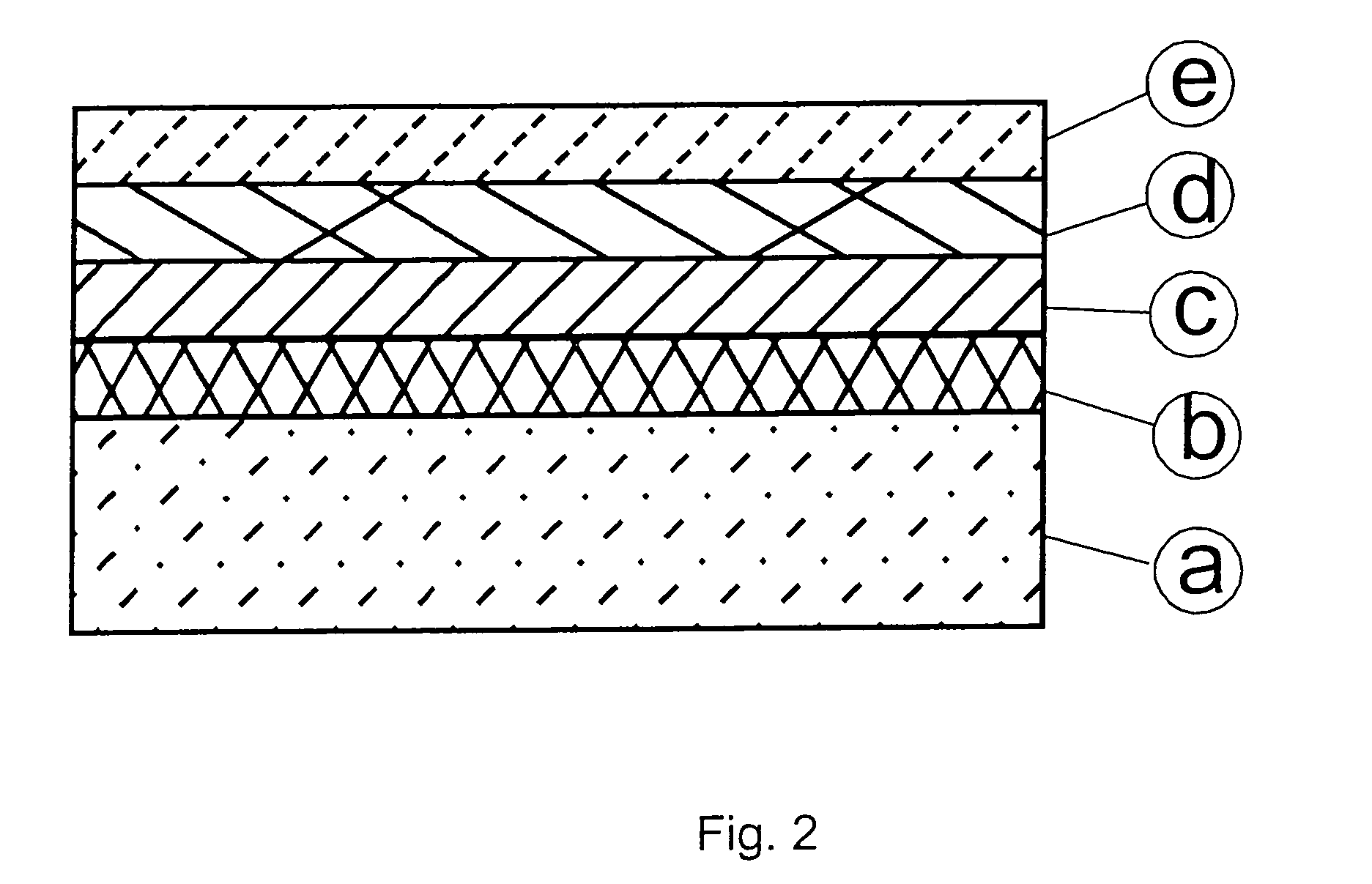

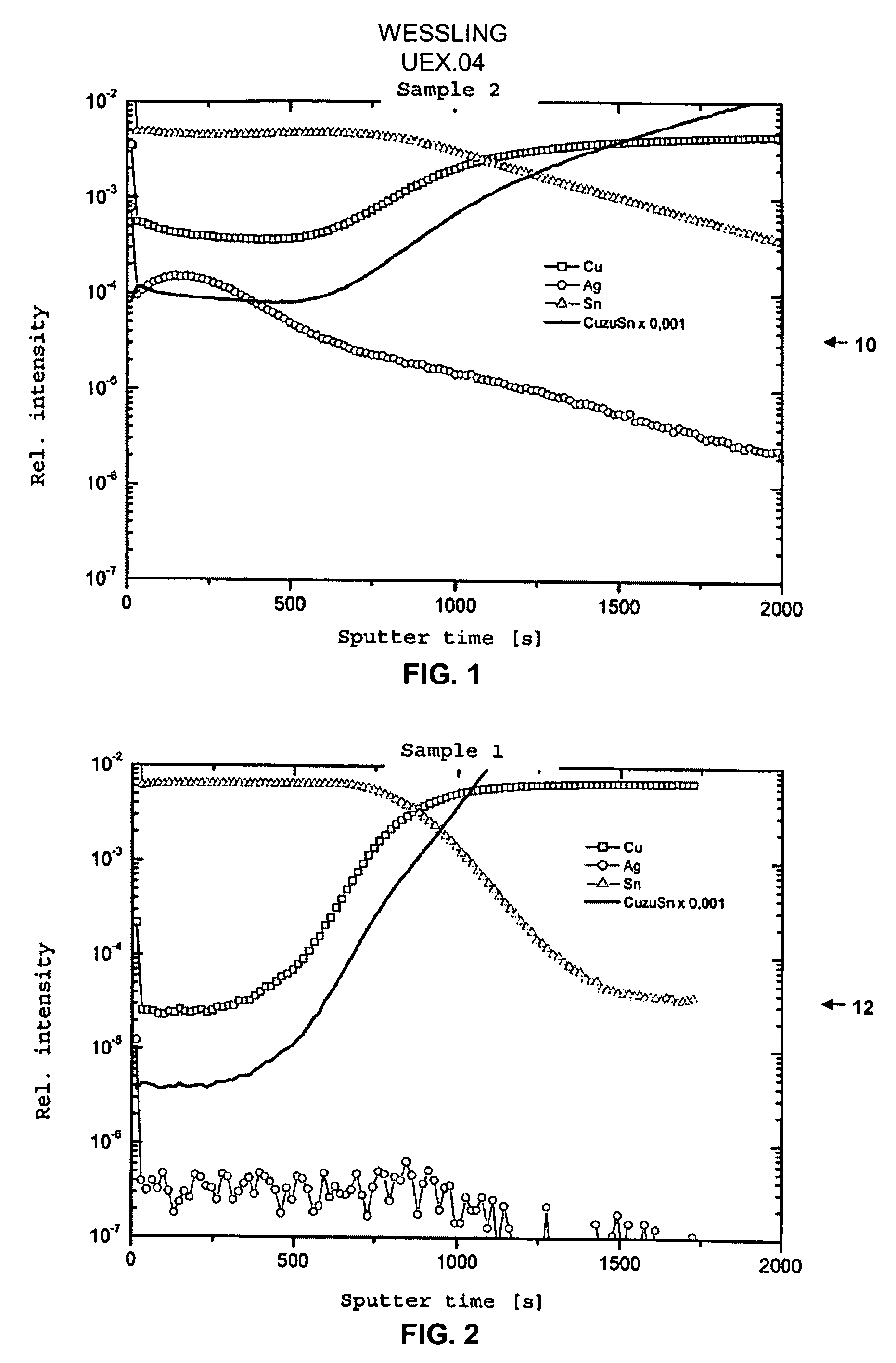

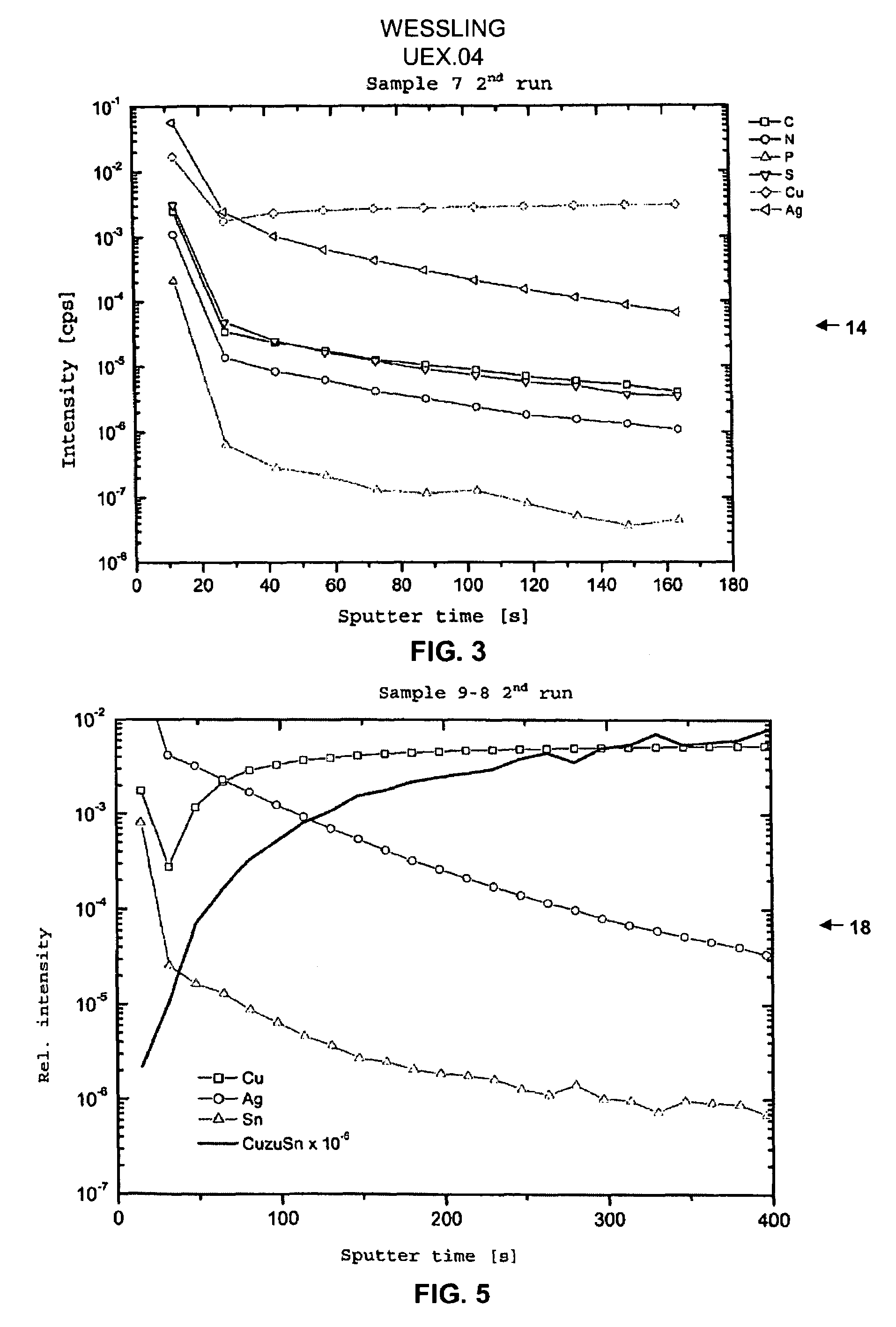

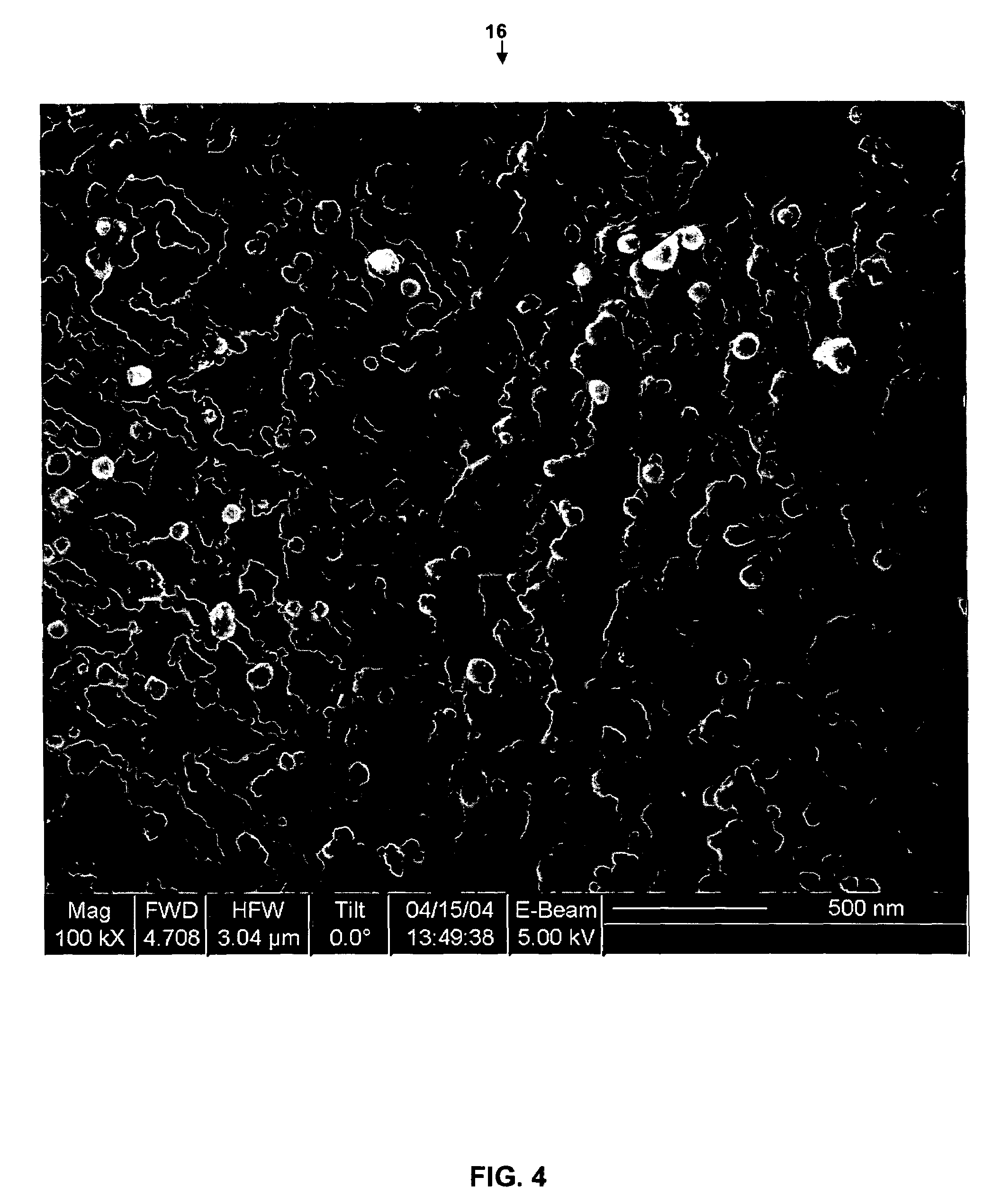

Tin-coated printed circuit boards with low tendency to whisker formation

ActiveUS7547479B2Thermometers using material expansion/contactionPrinted circuit aspectsTin platingEngineering

A coated article, which contains (i) at least one electrically non-conductive base layer, (ii) at least one layer of copper and / or a copper alloy, and (iii) a tin-containing layer, wherein the layer (ii) is positioned between the layer (i) and the layer (iii). The article is characterized in that the tin-containing layer (iii) contains at least one other metal.

Owner:ENTHONE GMBH

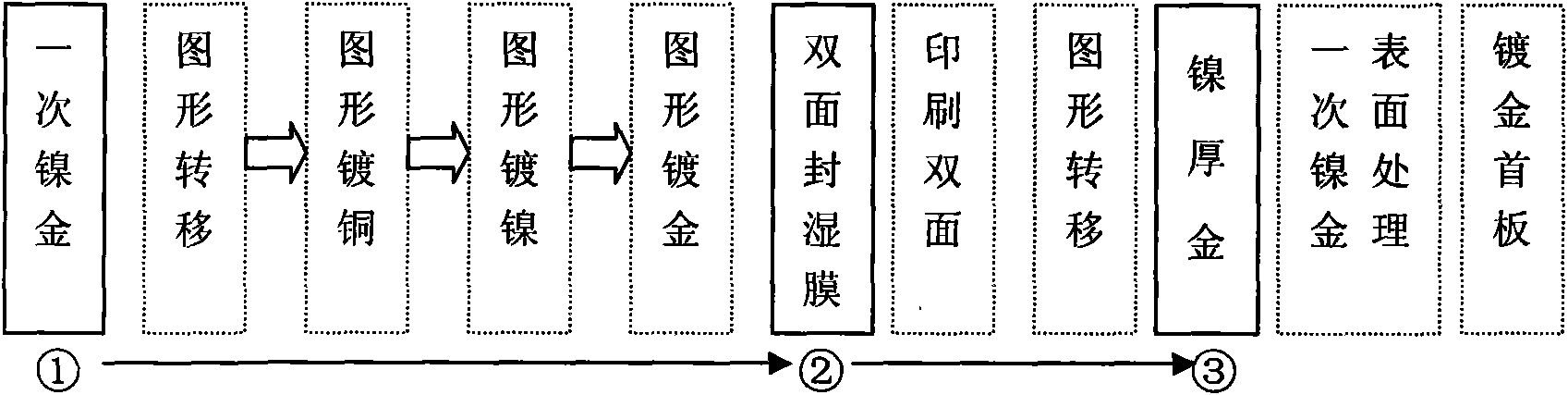

Method for plating thick gold layer in circuit board manufacturing process

InactiveCN101631427ANo pollutionImprove plating resistancePrinted circuit manufactureElectroless nickel immersion goldEtching

The invention discloses a method for plating a gold thick layer in a circuit board manufacturing process, which comprises the following steps of: A, firstly, subjecting a circuit board to pattern tin plating, circuit wire etching, solder-mask printing and chemical nickel and gold processing treatments of depositing a nickel layer and depositing a gold layer; B, carrying out the anti-oxidation post treatment of the circuit board subjected to the chemical nickel and gold processing treatments; C, covering a non-gold plated area of the circuit board; and D, after pre-treating the surface of the circuit board, plating the thick gold layer on a lead of the circuit board by a post drawing process. The invention provides a method for plating thick gold layer in the circuit board manufacturing process, which has advantages of pollution prevention, environment protection, gold salt conservation, good quality and easily controllable gold color.

Owner:深圳市九和咏精密电路有限公司

Tin plating method

ActiveUS20050249967A1Tendency increaseReduce formationConductive pattern reinforcementThin material handlingTin platingWhiskers

Owner:ROHM & HAAS ELECTRONICS MATERIALS LLC

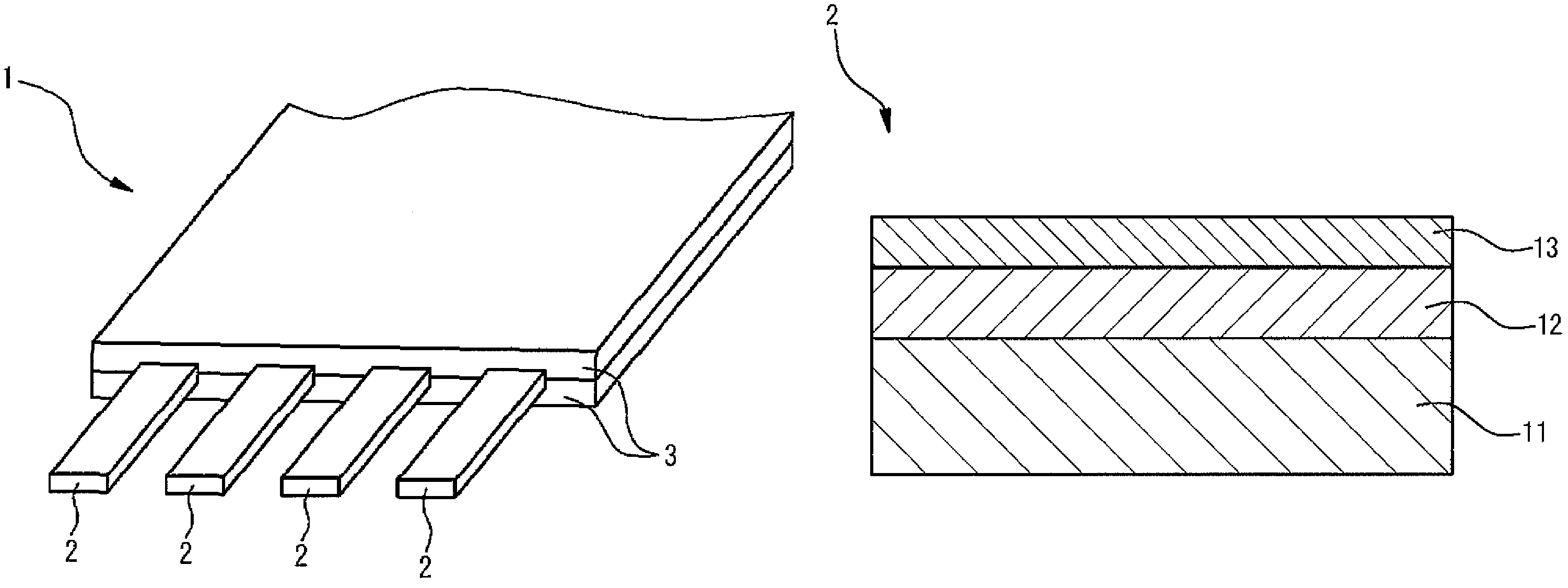

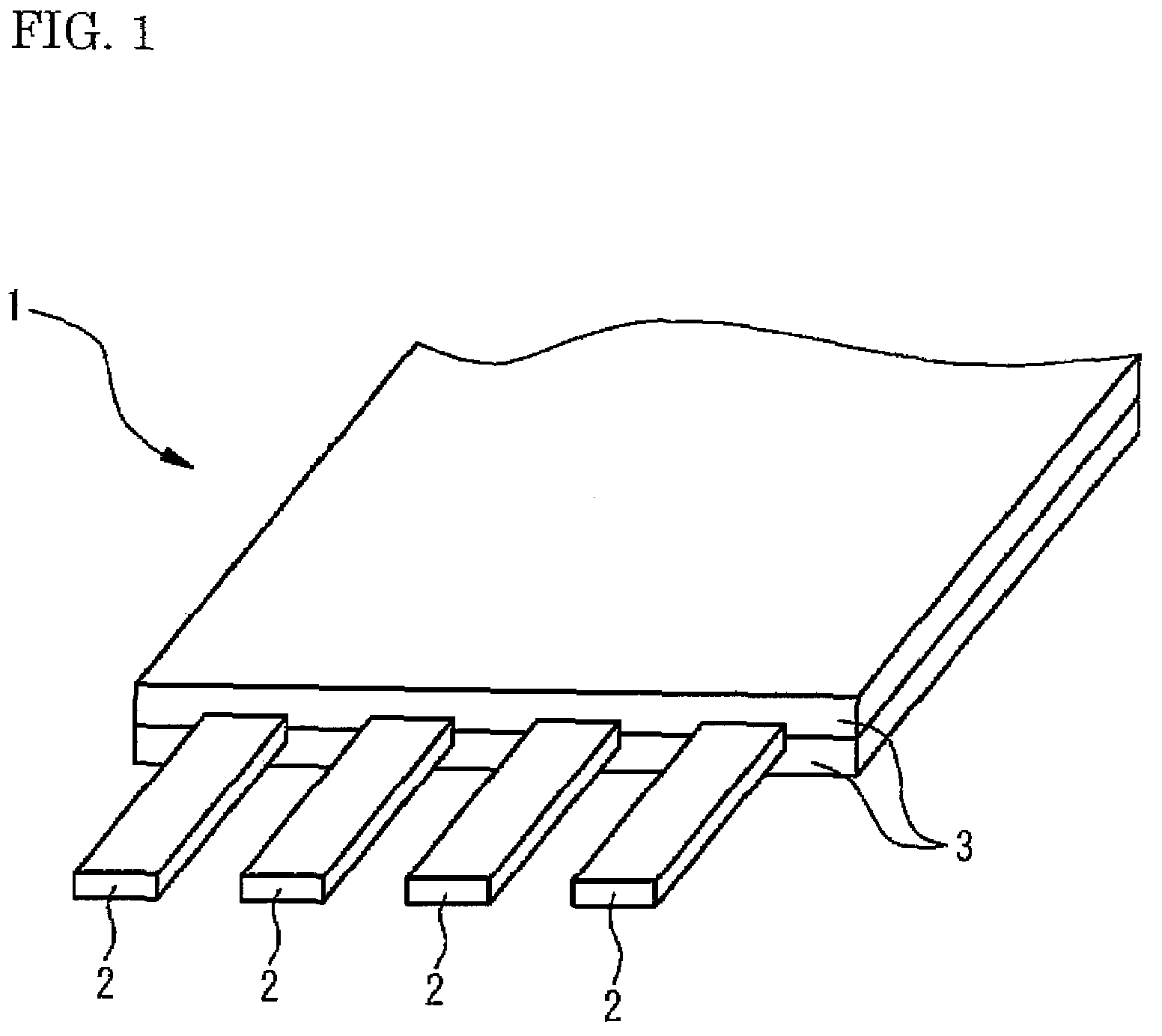

Flat cable

InactiveUS7482540B2AmountReduce formationStrip/foil conductorsFlat/ribbon cablesElectrical conductorTin plating

A flat cable includes a plurality of flat conductors each including a copper substrate, the flat conductors being aligned in a plane, and an insulating resin that covers the flat conductors. At least a terminal part of each of the flat conductors has a tin-copper alloy layer on the copper substrate, and a zinc-containing tin plating layer on the tin-copper alloy layers. The thickness of the tin-copper alloy layer is at least 0.2 μm and not greater than 1.0 μm. The thickness of the zinc-containing tin plating layer is at least 0.2 μm and not greater than 1.5 μm. The total thickness of the tin-copper alloy layer and the zinc-containing tin plating layers is at least 0.4 μm and not greater than 1.7 μm.

Owner:SUMITOMO ELECTRIC IND LTD

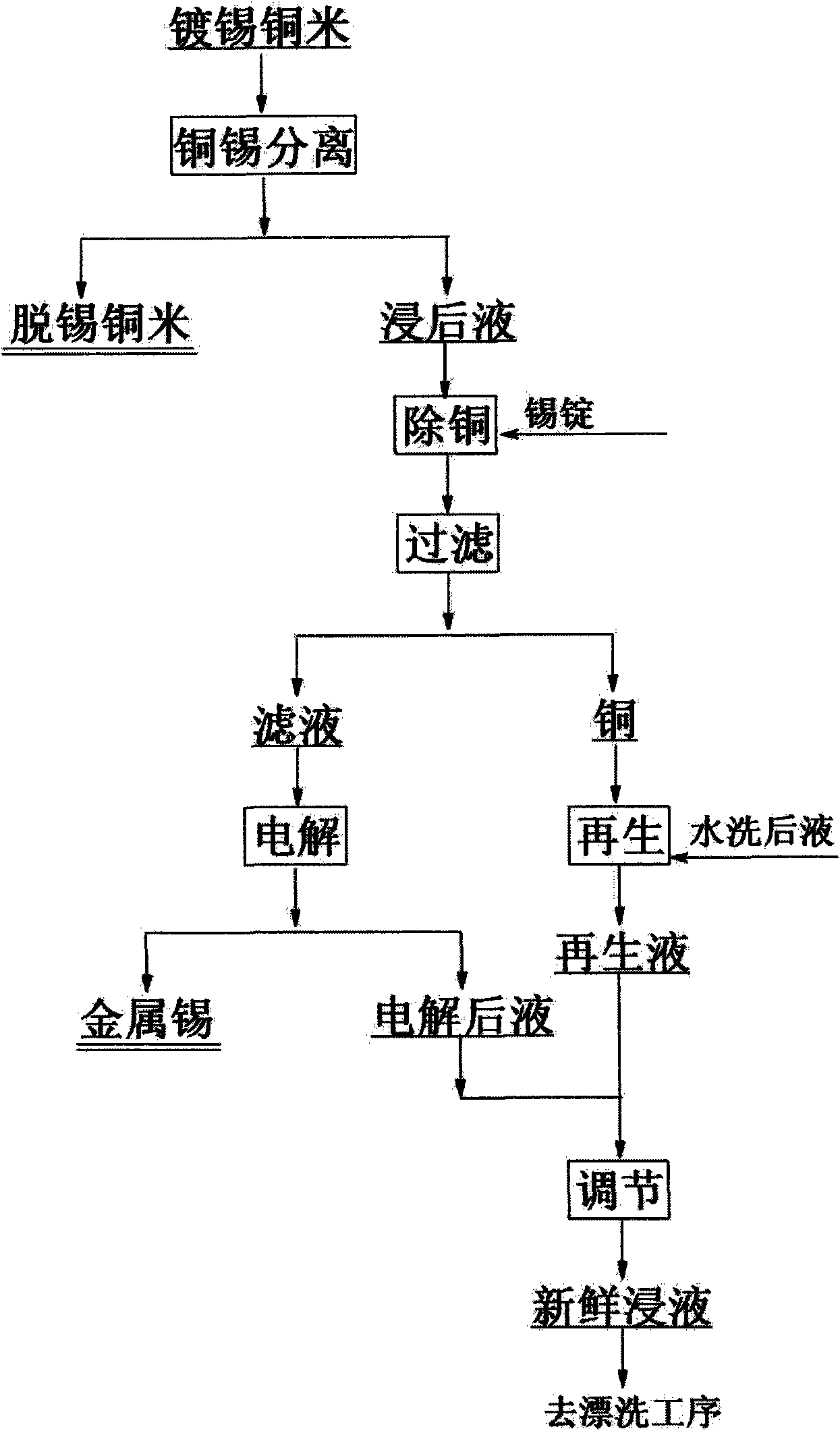

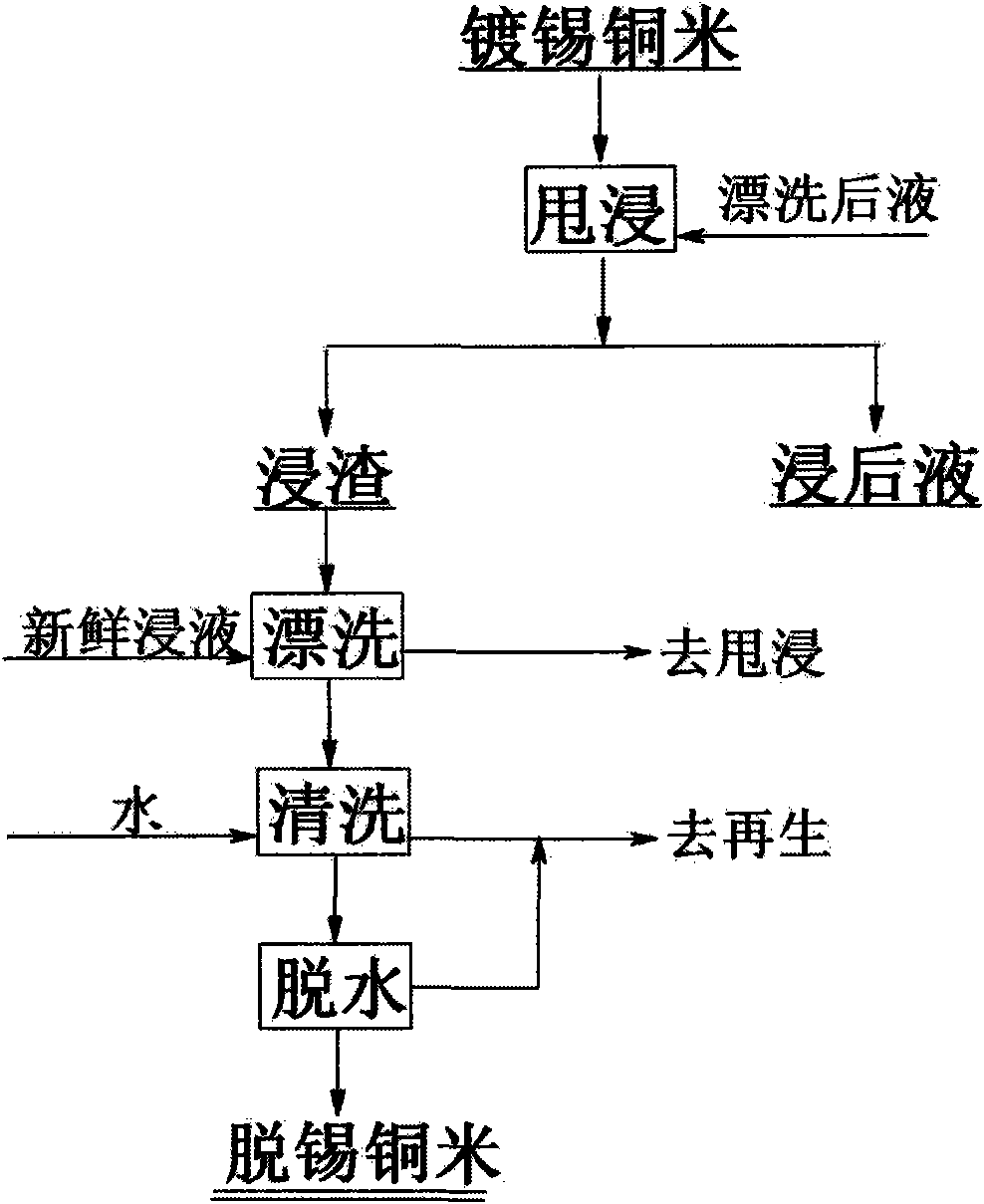

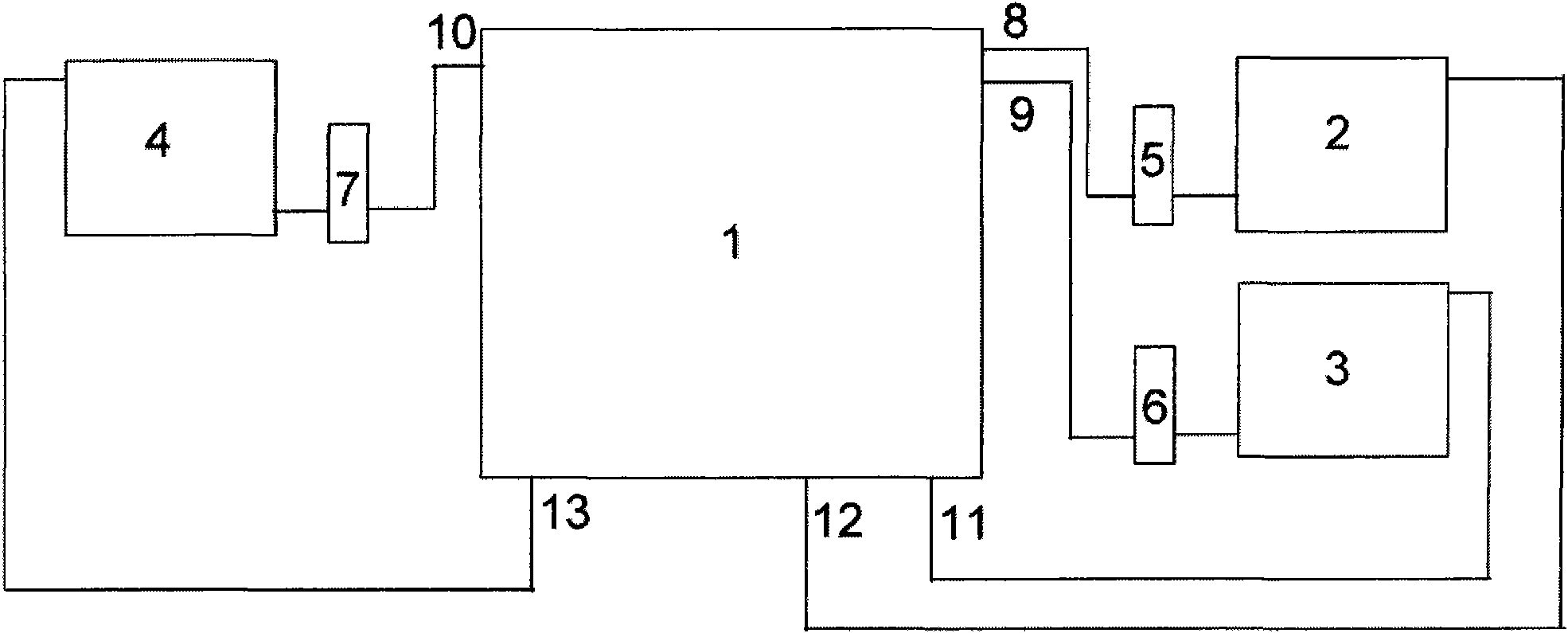

Method and device for separating and recovering metallic copper and tin in tinplating copper rice

InactiveCN101937742AHigh removal rateHigh recovery rateBasic electric elementsElectronic waste recyclingTinningIngot

The invention relates to a method and a device for separating and recovering metallic copper and tin in the tinplating copper rice by a wet method. The method comprises the following steps: placing the tinplating copper rice into a dedicated leaching plant for copper and tin separation according to the design requirement; adding excessive tin ingot to the immersion liquid to remove the copper until the blue of the immersion liquid is completely eliminated; filtering to obtain filter liquor and copper powder; electrolyzing the filter liquor in an electrolytic cell to obtain the metallic tin and liquid after electrolyte; adding a proper amount of copper powder and blowing air into the liquid for regeneration after being washed with water; mixing the regenerated liquid and the liquid after the electrolyte; regulating the concentration of copper sulfate and sulfuric acid in the solution by utilizing water, copper sulfate and 98% of sulfuric acid to obtain fresh immersion liquid to be used in the next tinplating copper process. The copper and tin separation processing device is composed of the dedicated leaching plant, an immersion liquid trough, a fresh immersion liquid trough and a rinsing bath. The method and the device have simple and feasible process; and all the raw materials and equipment are more common and have low price.

Owner:UNIV OF SCI & TECH BEIJING

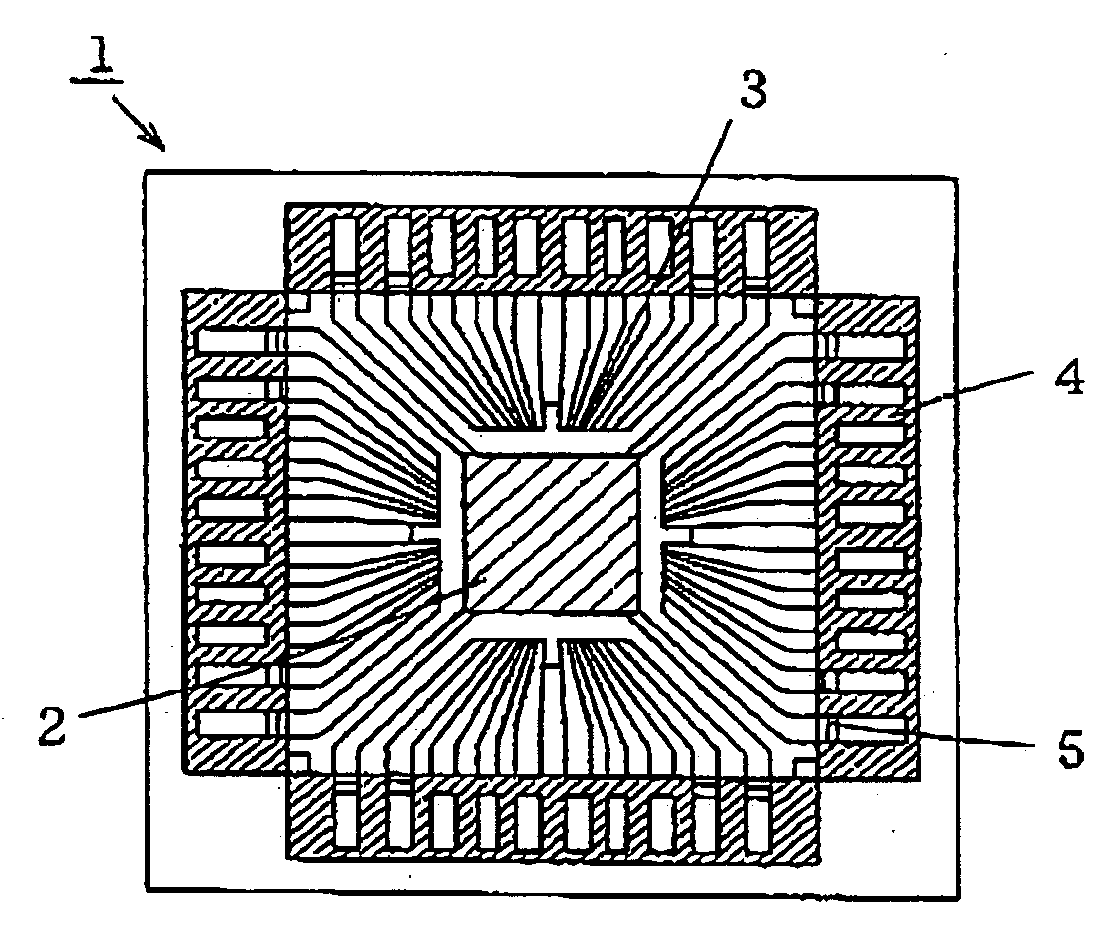

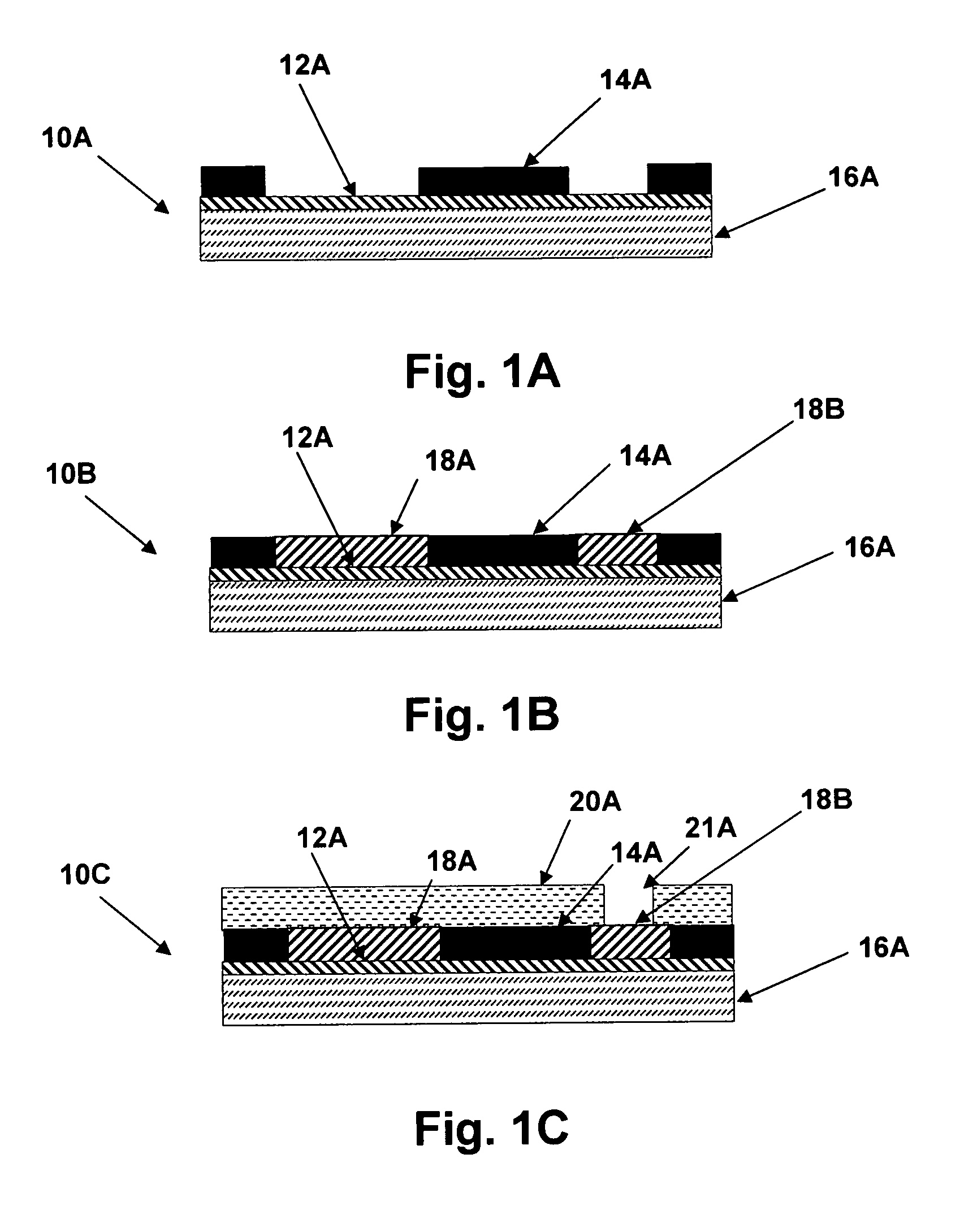

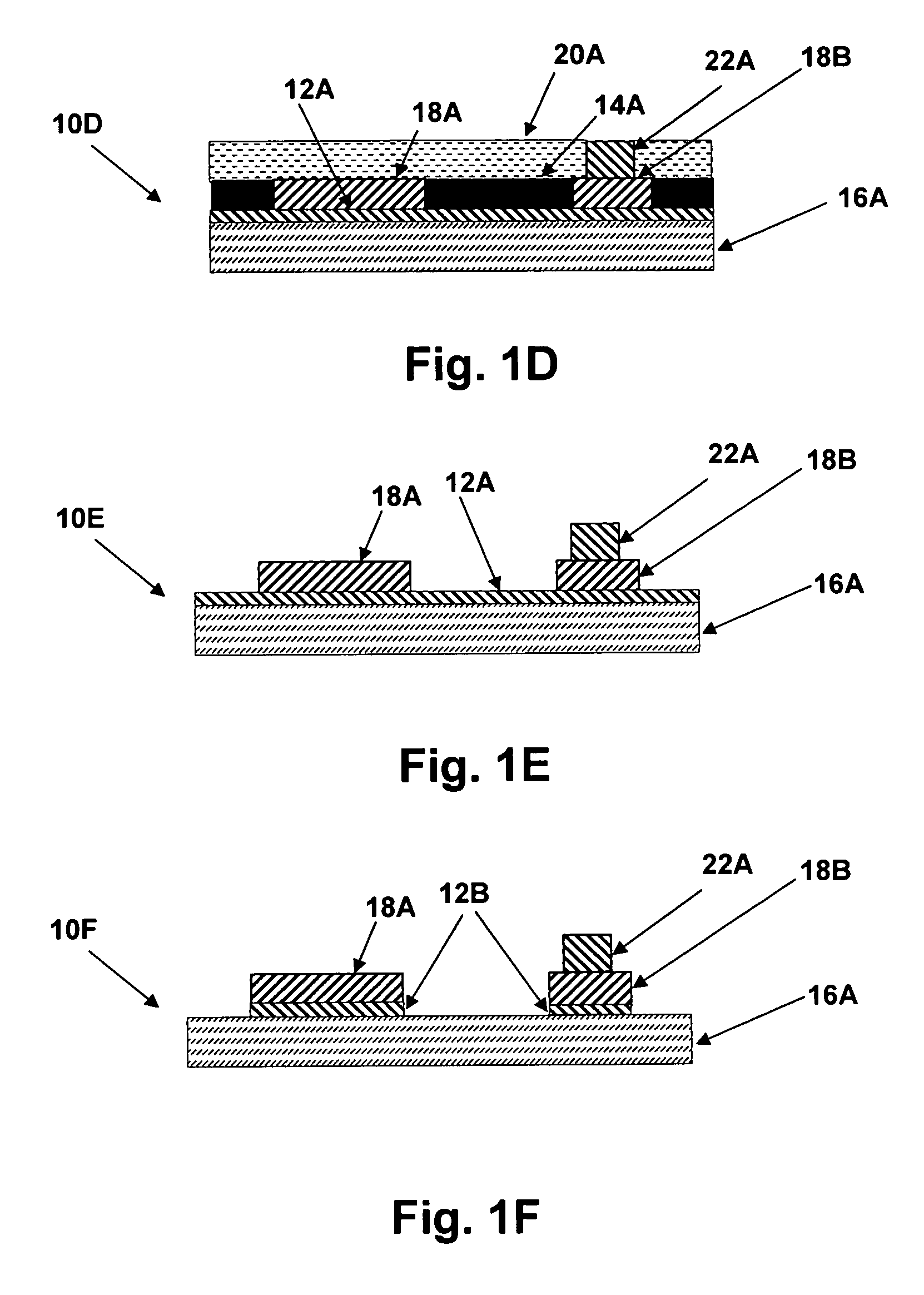

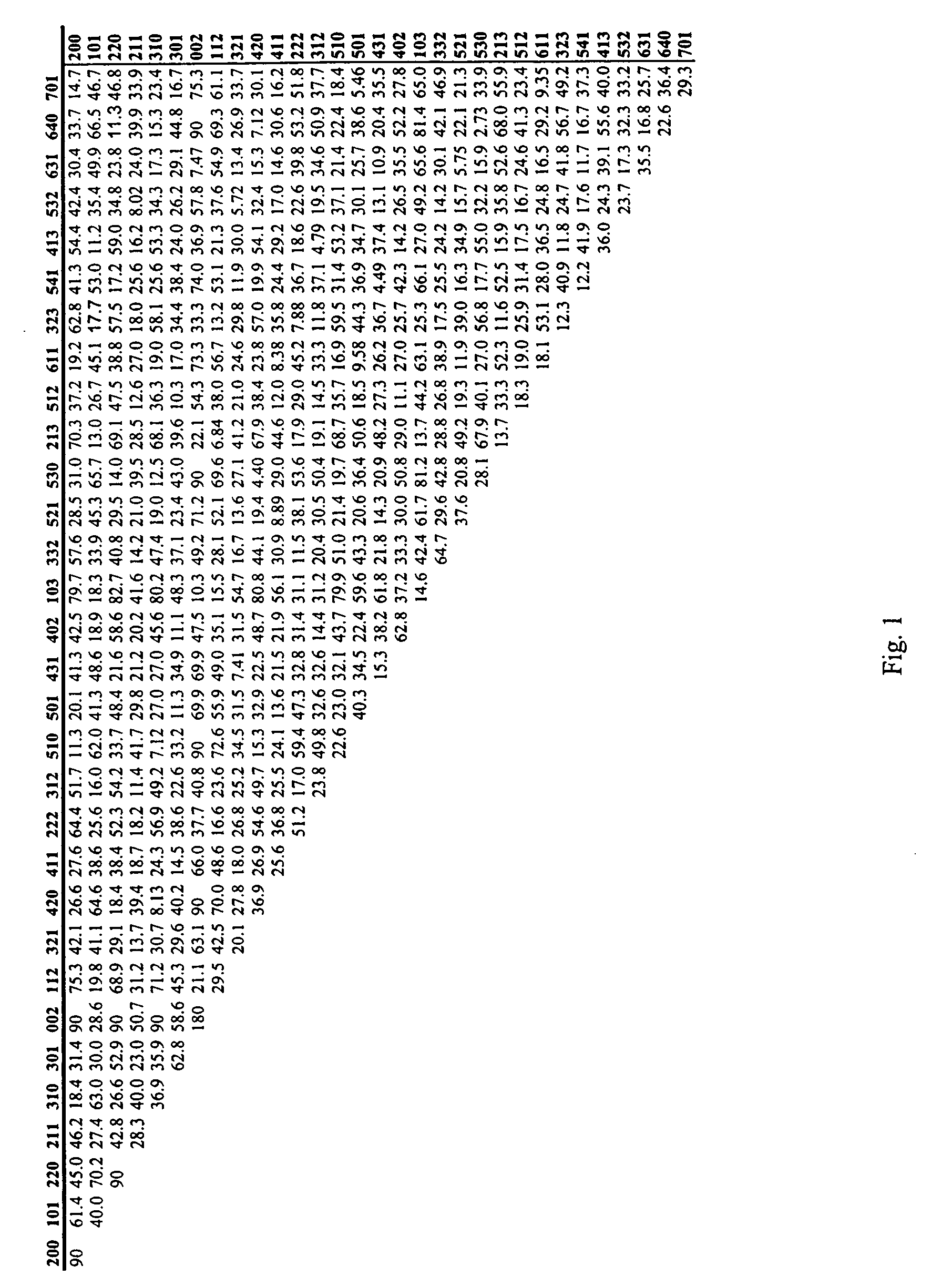

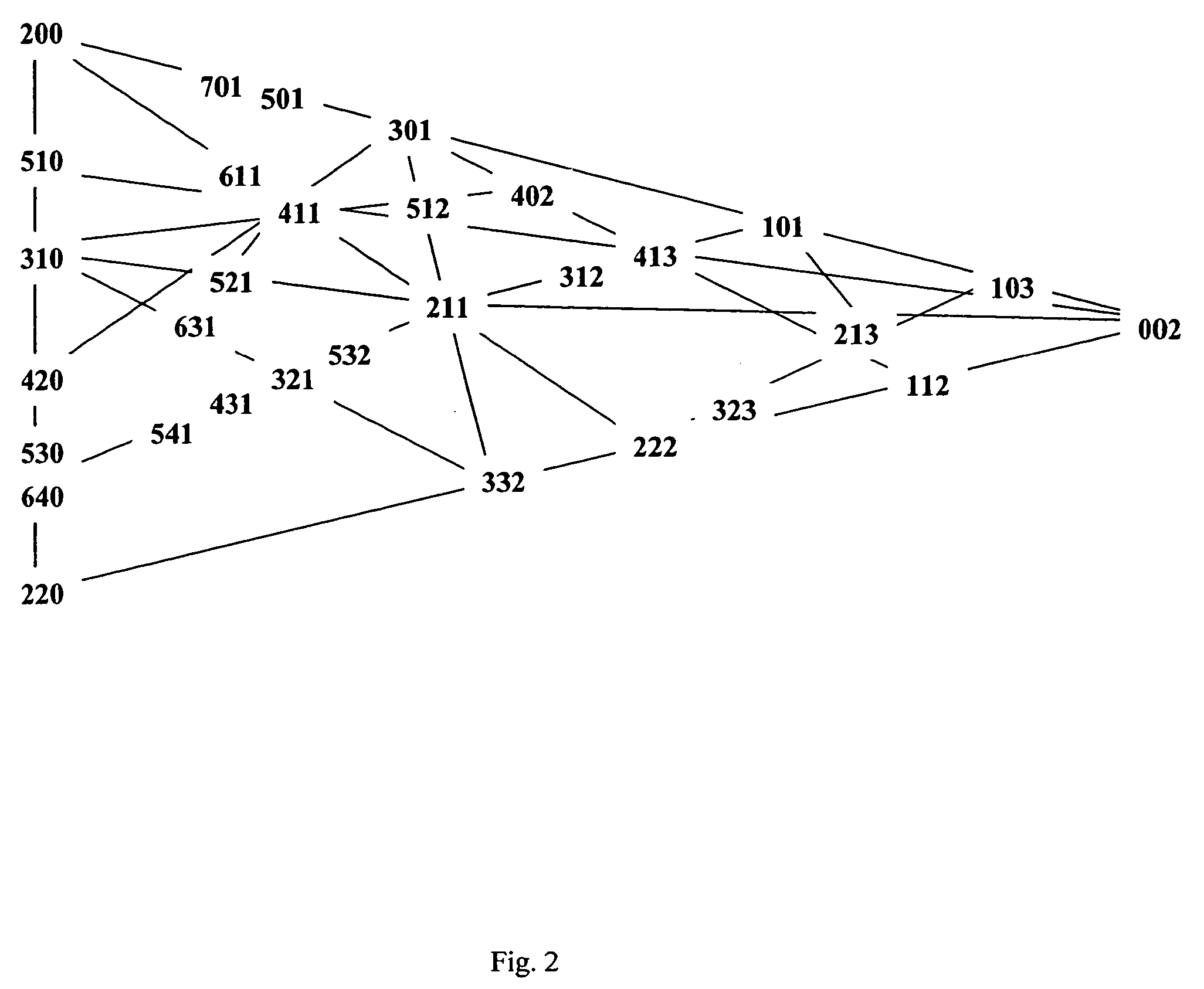

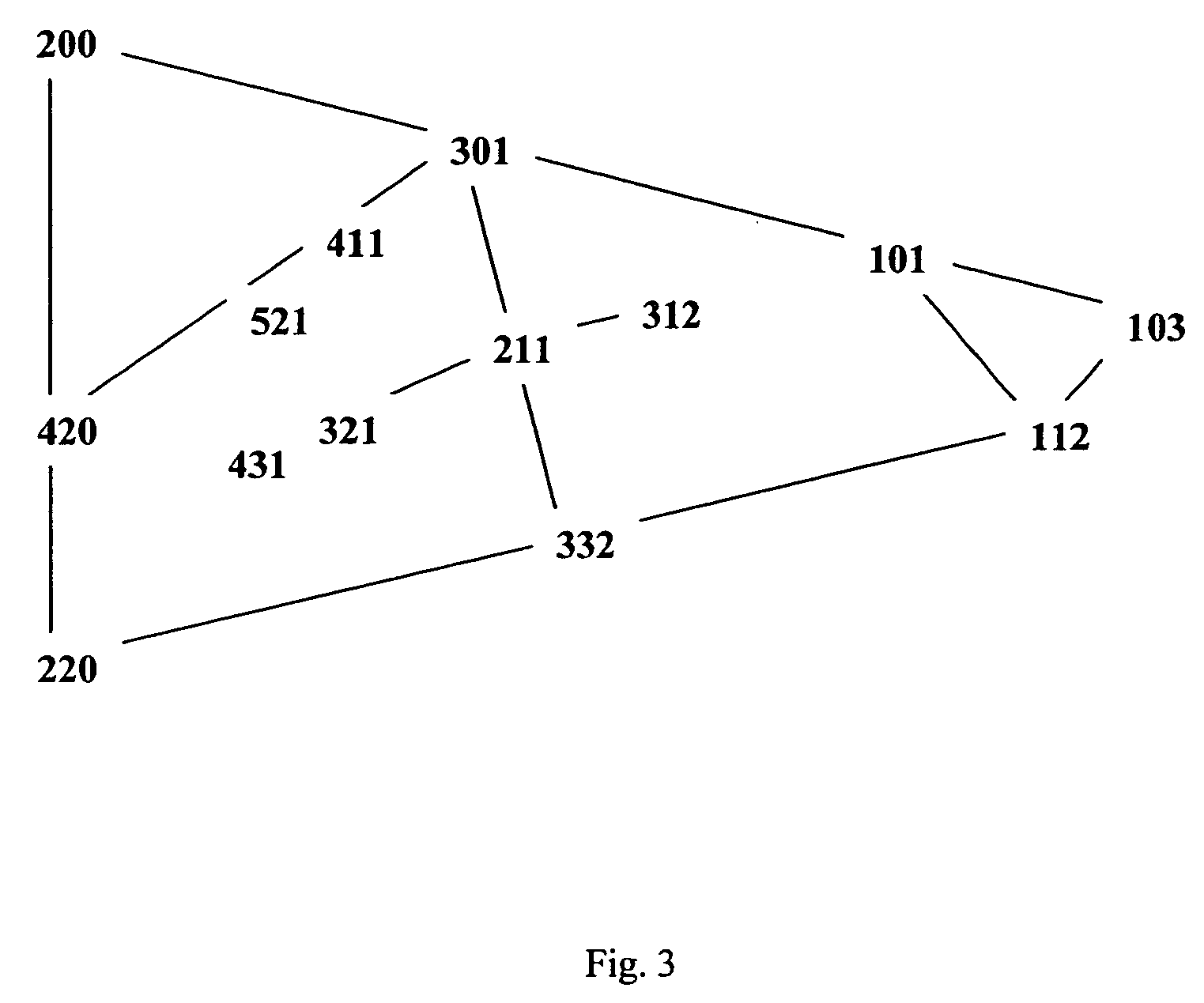

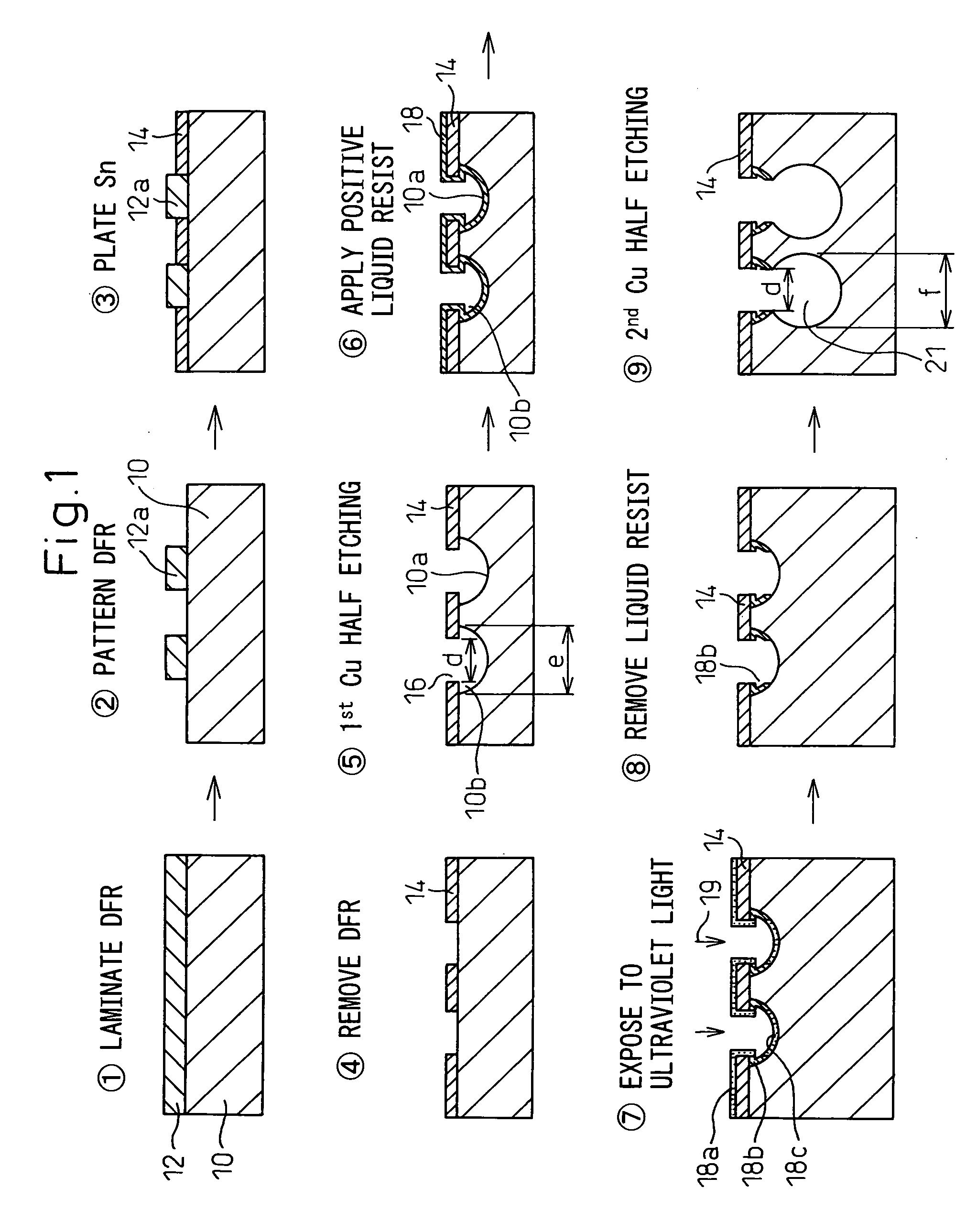

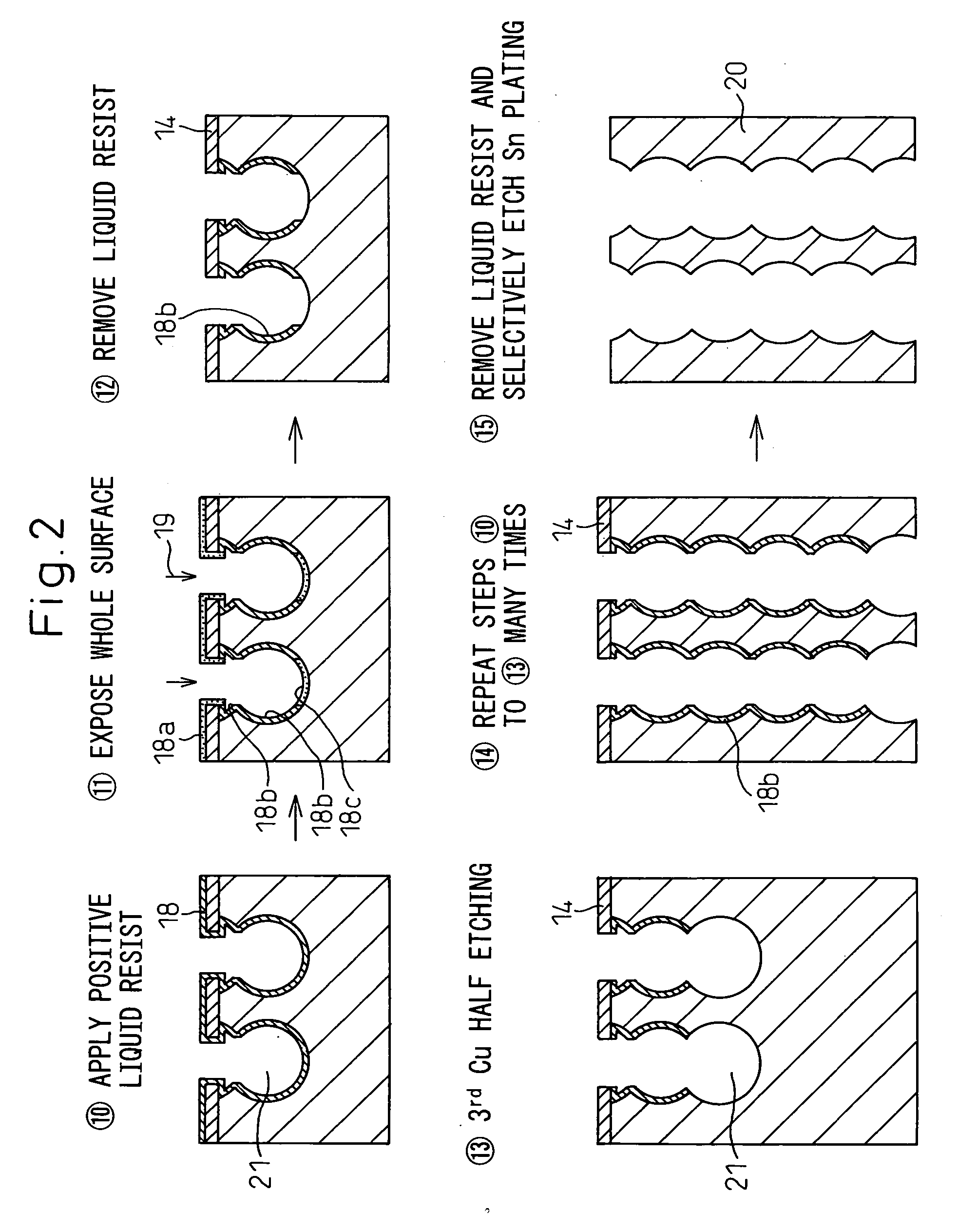

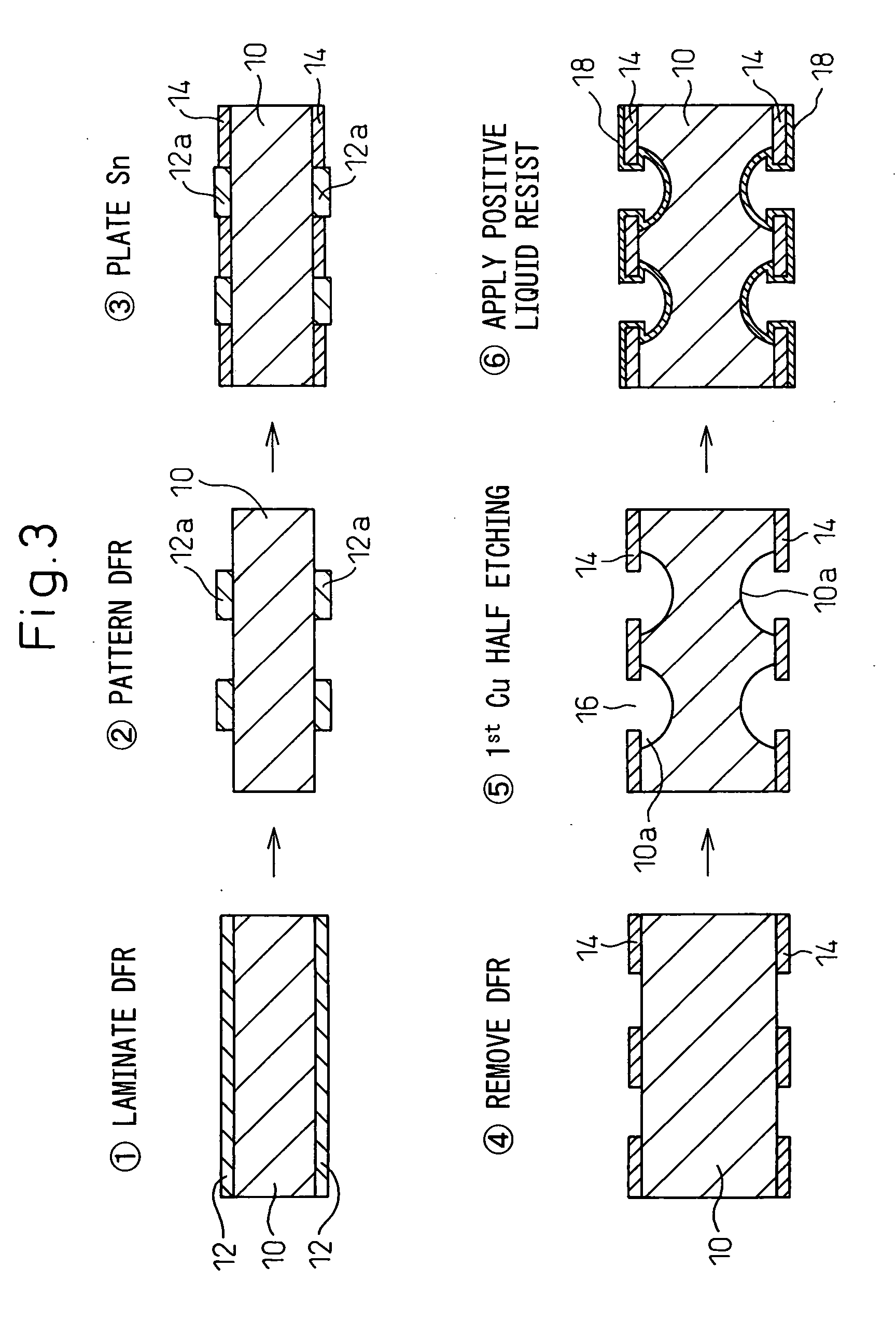

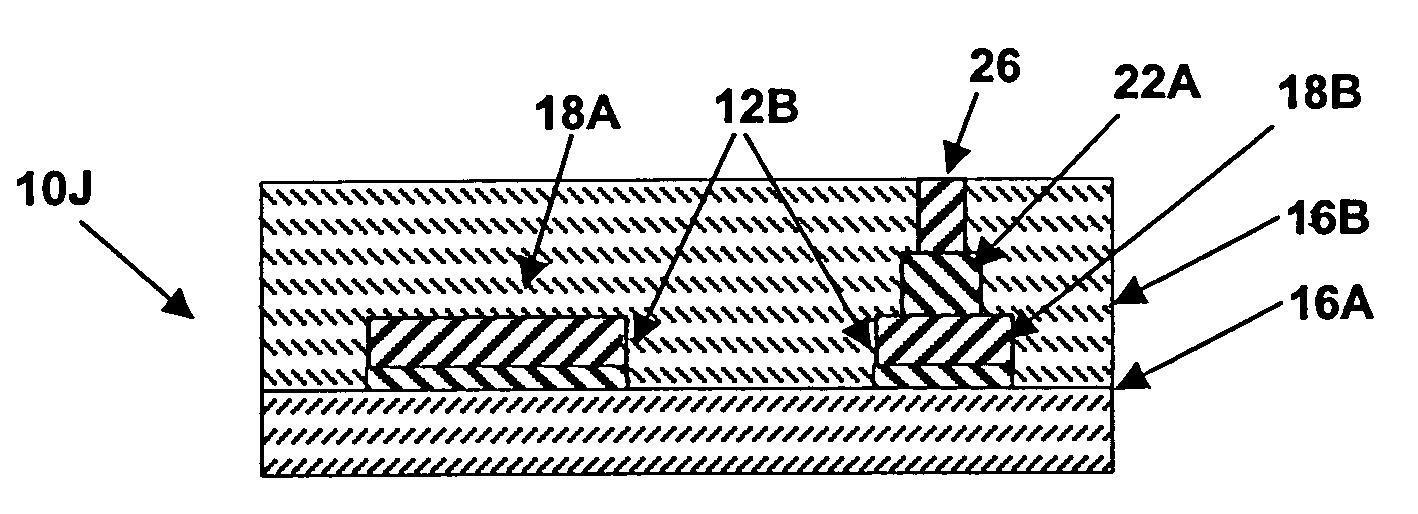

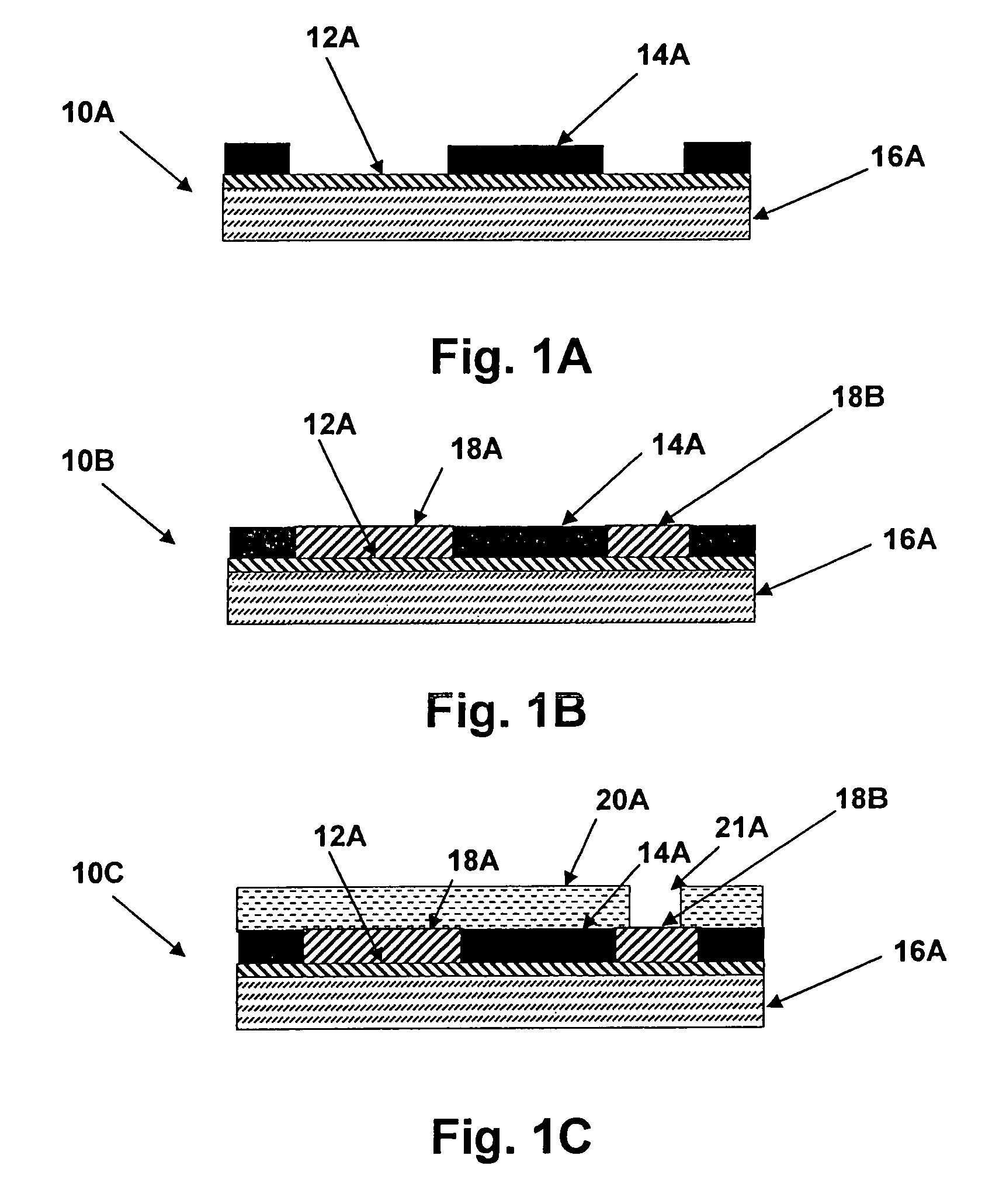

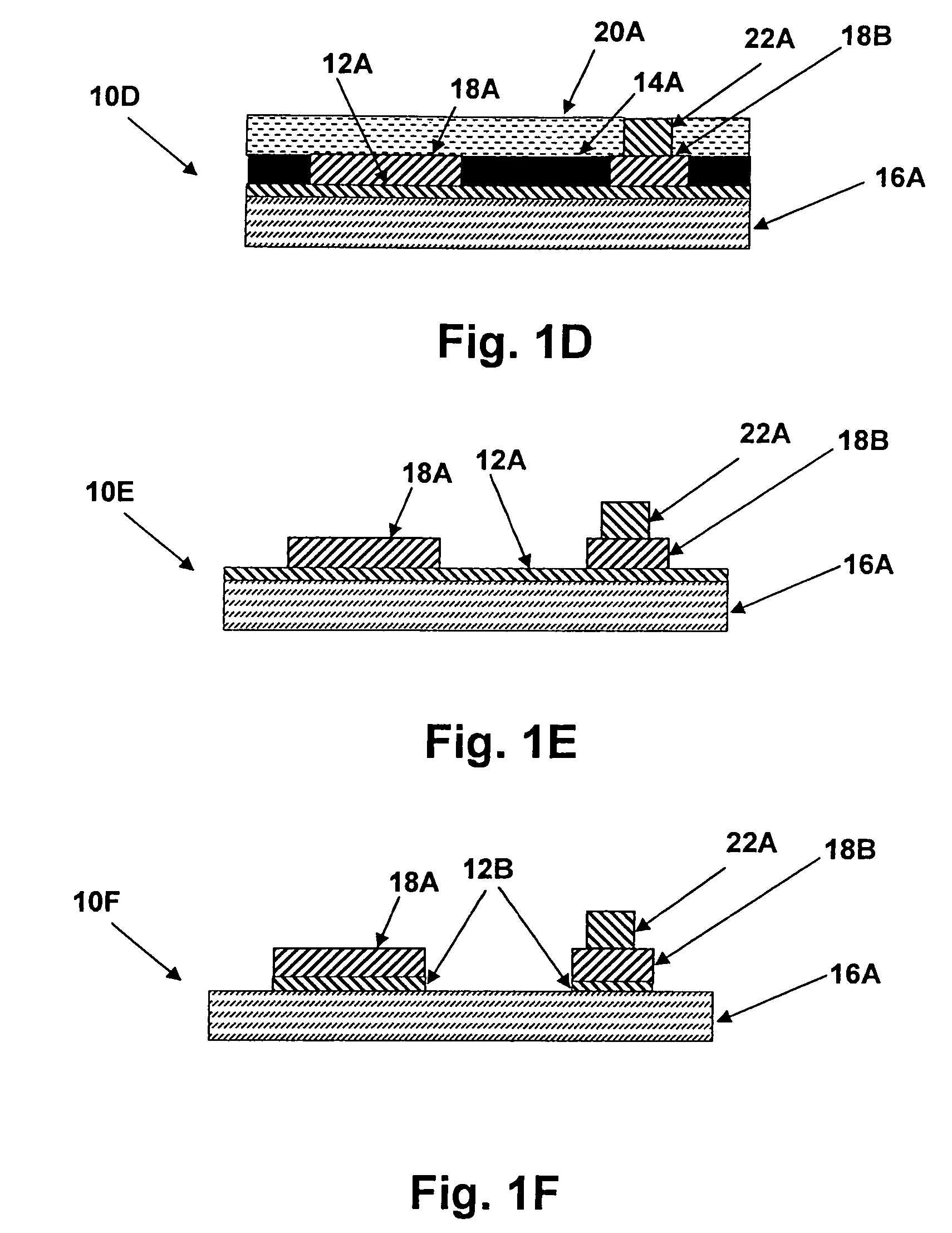

Method of forming metal plate pattern and circuit board

A method of forming a high aspect ratio metal plate pattern and a circuit board by multi-stage etching with a metal mask is disclosed. A resist (12) is coated on one of two surfaces of a copper plate (10) and patterned to form a resist pattern. A tin plating layer (14) is formed using this resist pattern, and with this tin plating layer as a mask, the copper plate is selectively half etched. By coating, exposing and developing the positive resist (18), the side etched portion under the tin plating layer is protected by the positive resist. With the tin plating layer and the protective resist layer as a mask, the half etching is executed again. This process is repeated until the resist and the tin plating layer used as a mask are finally removed to produce a metal pattern (20).

Owner:SHINKO ELECTRIC IND CO LTD

Soft tin-plate and its making process

ActiveCN1888114AExcellent plate passabilityStable mechanical propertiesRoll mill control devicesFurnace typesTin platingContinuous annealing

The soft tin-plate consists of C not more than 0.006 wt%, Mn 0.10-0.20 wt%, Al 0.025-0.075 wt%, Si not more than 0.03 wt%, Ti 0.03-0.08 wt%, P not more than 0.015 wt%, S not more than 0.015 wt%, N not more than 0.003 wt%, and O not more than 0.004 wt%, except Fe and inevitable impurities. Its production process includes the following steps: smelting steel, continuous casting and rolling, hot rolling, acid pickling and rolling, continuous annealing, flattening and tin plating.

Owner:BAOSHAN IRON & STEEL CO LTD

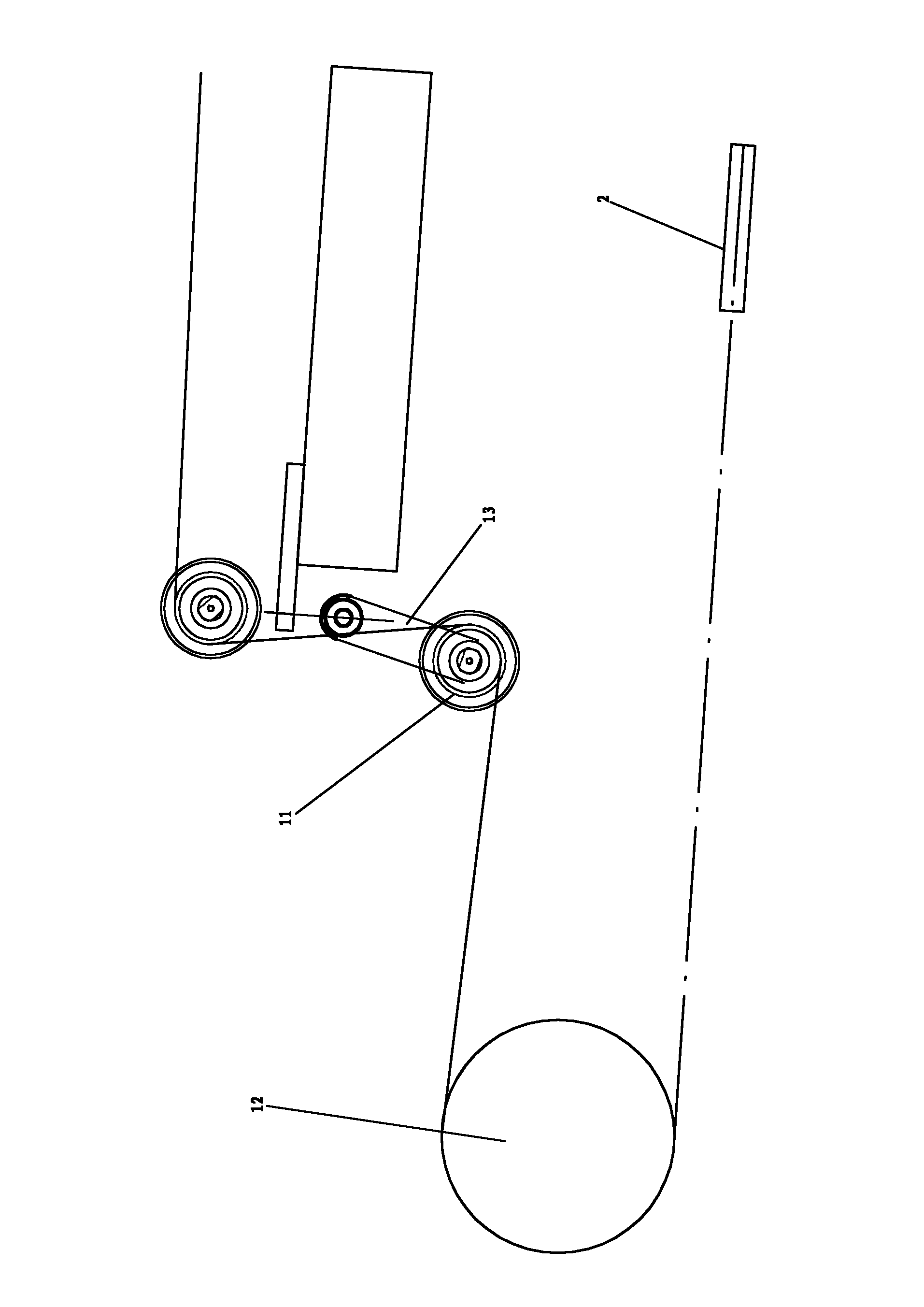

Circulating tin plating process and device

The invention relates to the technical field of tin plating of copper wires, in particular to a circulating tin plating process and device. The circulating tin plating process comprises the following steps of: setting speed and stabilizing speed and tension in a tension buffer area; annealing in a high-temperature annealing area at high temperature; initially cooling in an annealing and cooling area; pre-plating tin in an inlet tin heating area; finally plating tin in an outlet tin heating area; scraping residual tin by using a tin plating mold for sizing; protecting reducing gas to deoxidize liquid tin and protecting a wire rod from being oxidized; cooling a hot plated tin wire with water; scraping water on the tin-plated wire with rubber; scraping water and possible tin beads by using a mold; drying residual water by using a drier; cooling the tin-plated wire to room temperature by using a cooling wind scoop; and rolling into a finished product, and the like. By adopting the circulating tin plating process, the product quality of the tin-plated wire is ensured, use of a soldering flux causing pollution can be avoided, noble rare earth metals are avoided or reduced, a large amount of electric energy is saved, waste of tin dross is reduced, operation is simplified and concealed danger of quality is reduced.

Owner:周开勇

Manufacturing method for plate type thin film resistor

InactiveCN101593588AImprove productivityReduce manufacturing costResistors adapted for applying terminalsResistive material coatingSheet resistanceLaser trimming

The invention discloses a manufacturing method for a plate type thin film resistor, which belongs to a manufacturing method for a plate type resistor. The invention aims to provide a manufacturing method for producing the plate type thin film resistor with high productivity and low cost. The manufacturing method comprises the manufacture of a gauge, a back electrode and a resistor body, encapsulating, trimming, splintering, sintering, end coating and electroplating; and the concrete steps comprise substrate burnishing and cleaning, printing for the gauge and the back electrode, electrode sintering, baffle layer printing, vacuum sputtering, baffler layer removing, thermal treatment, laser trimming, protective layer printing, protective layer curing, primary splintering, end coating for the electrode, end electrode sintering, secondary splintering, nickel plating and tinlead plating. The manufacturing method has the advantages of high productivity, low cost and the like, and is an ideal method for producing the plate type thin film resistors on a large scale.

Owner:CHINA ZHENHUA GRP YUNKE ELECTRONICS

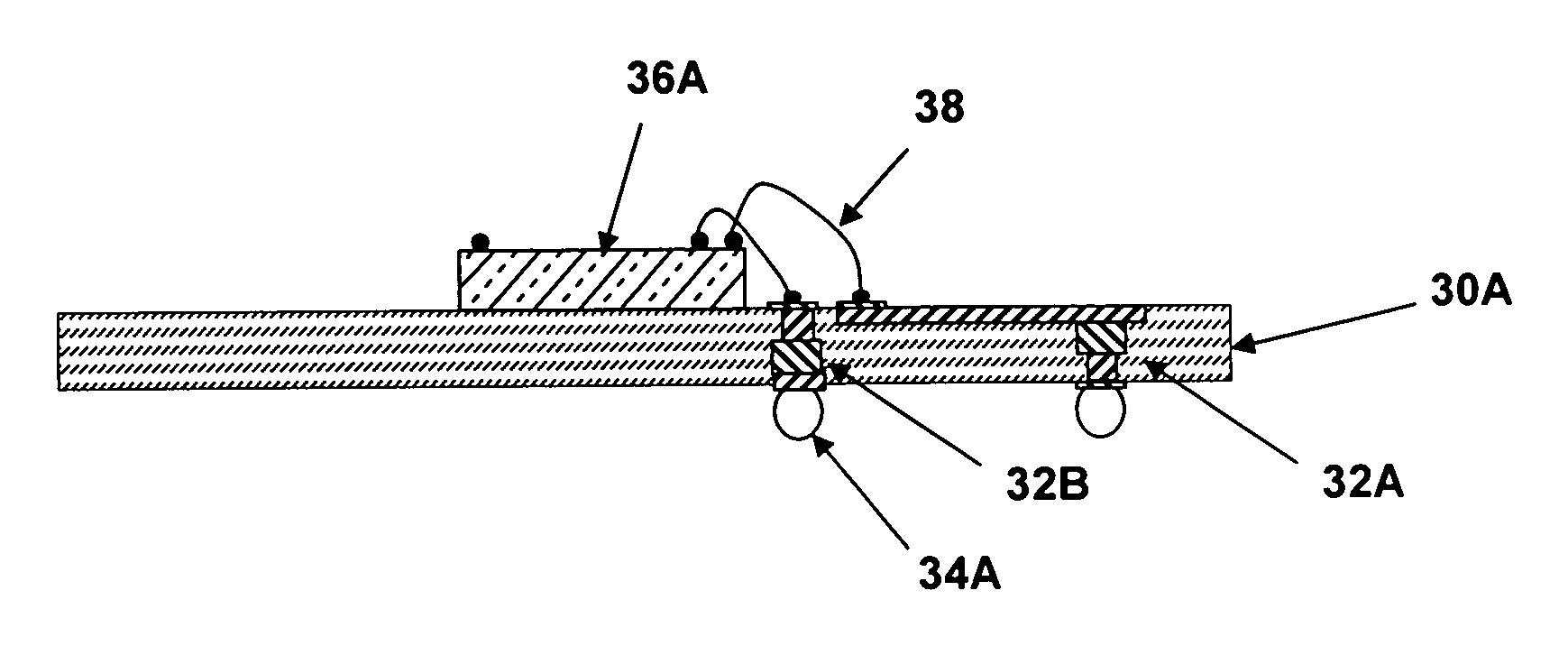

Semiconductor package and substrate having multi-level vias fabrication method

A semiconductor package and substrate having multi-level plated vias provide a high density blind via solution at low incremental cost. Via are half-plated atop a circuit pattern and then a second via half is added to complete the via after isolation of elements of the circuit pattern. Successive resist pattern applications and etching are used to form a via tier atop a circuit pattern that is connected by a thin plane of metal. After the tier is deposited, the thin metal plane is etched to isolate the circuit pattern elements. Dielectric is then deposited and the top half of the via is deposited over the tier. The tier may have a larger or smaller diameter with respect to the other half of the via, so that the via halves may be properly registered. Tin plating may also be used to control the etching process to provide etching control.

Owner:AMKOR TECH SINGAPORE HLDG PTE LTD

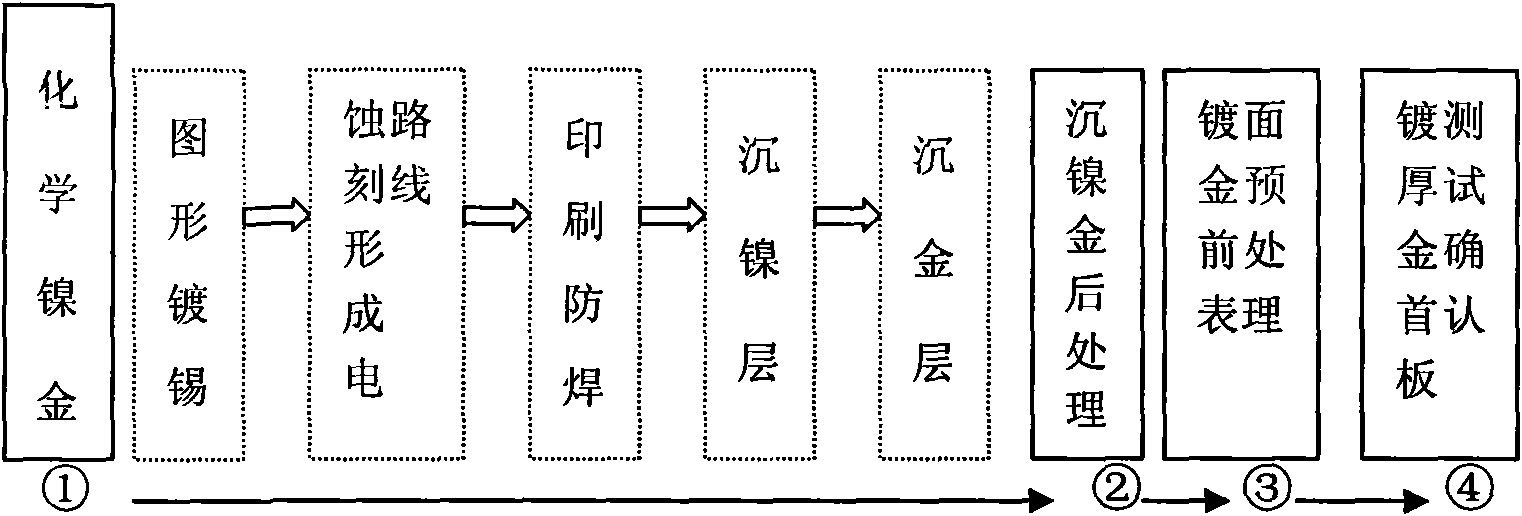

Chemical tin plating liquor for copper and copper alloy

ActiveCN101403112ALower electrode potentialPrevent oxidationLiquid/solution decomposition chemical coatingChemical platingTin plating

The invention discloses a copper and a chemical plating tin liquor of copper alloys and each liter of chemical plating tin liquor consists of materials with the following components: organic mixed acid: 150g / 1 to 500g / 1; organic pink salt: 50g / 1 to 100g / 1; organic silver salt: 1g / 1 to 5g / 1; complex agent: 45g / 1 to 200g / 1; reducing agent: 30g / 1 to 60g / 1; stabilizing agent: 10g / 1 to 80g / 1; emulsifying agent: 5g / 1 to 20g / 1; brightening agent: 3g / 1 to 20g / 1 and de-ionized water as the rest. With the chemical plating tin liquor, the copper and alloy surfaces can simply and rapidly form a bright and flat tin layer which does not form tin whiskers and has a certain thickness only needing chemical tin plating treatment for 4 to 8 minutes. The copper and the chemical plating tin liquor are suitable for not only circuit boards which are coated with coppers or copper alloys but also tinning corrosion resistance of other copper materials, etc.

Owner:昆山成利焊锡制造有限公司

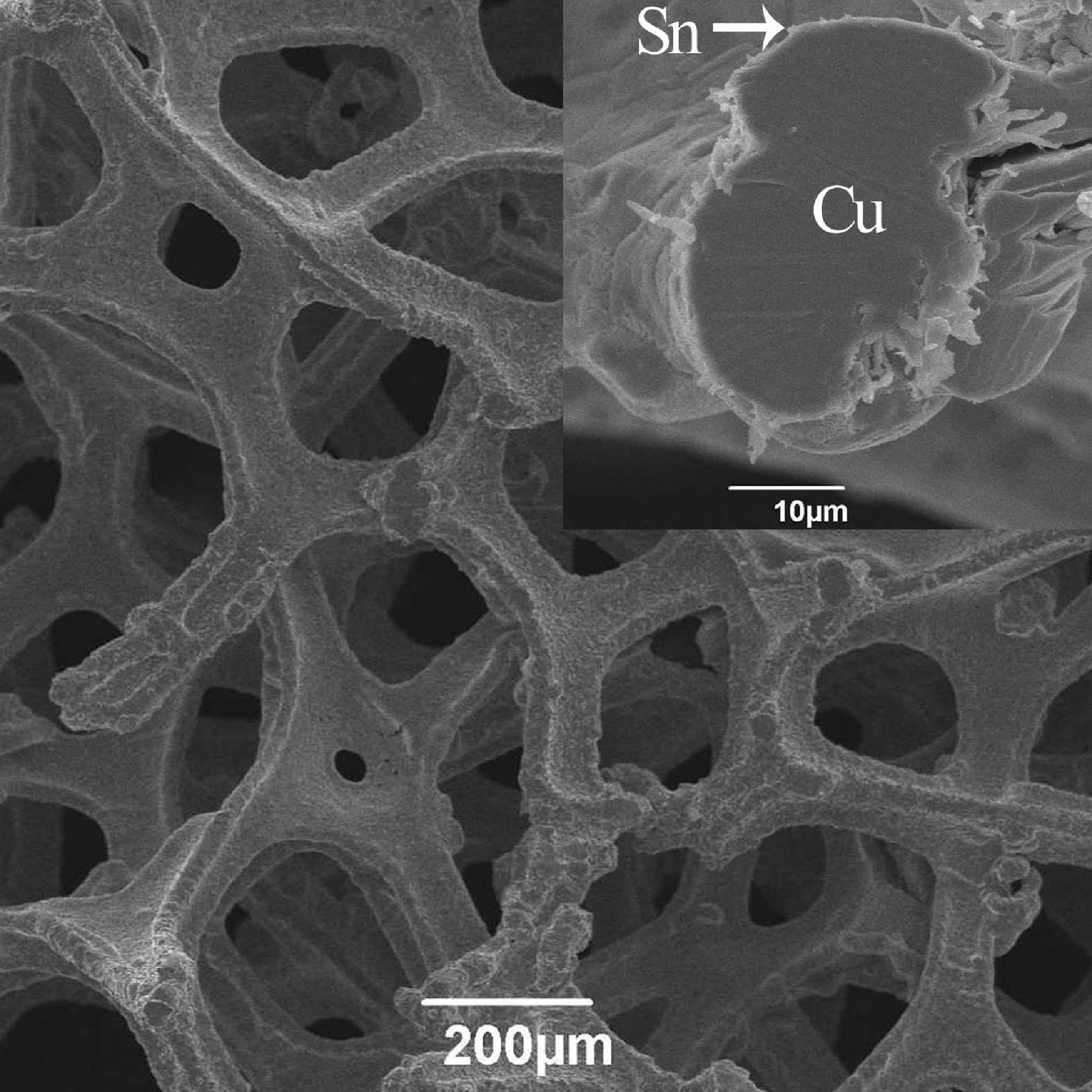

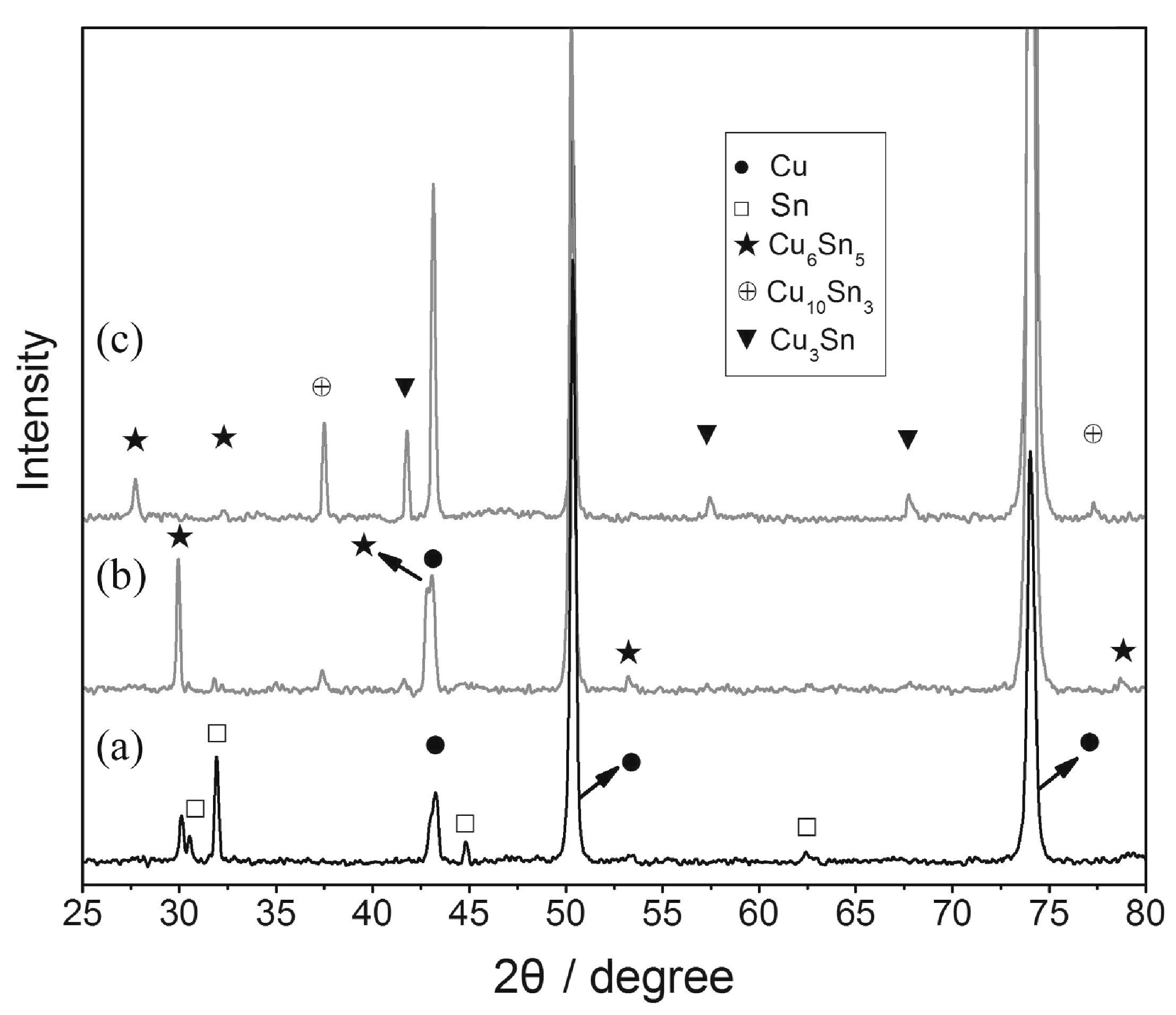

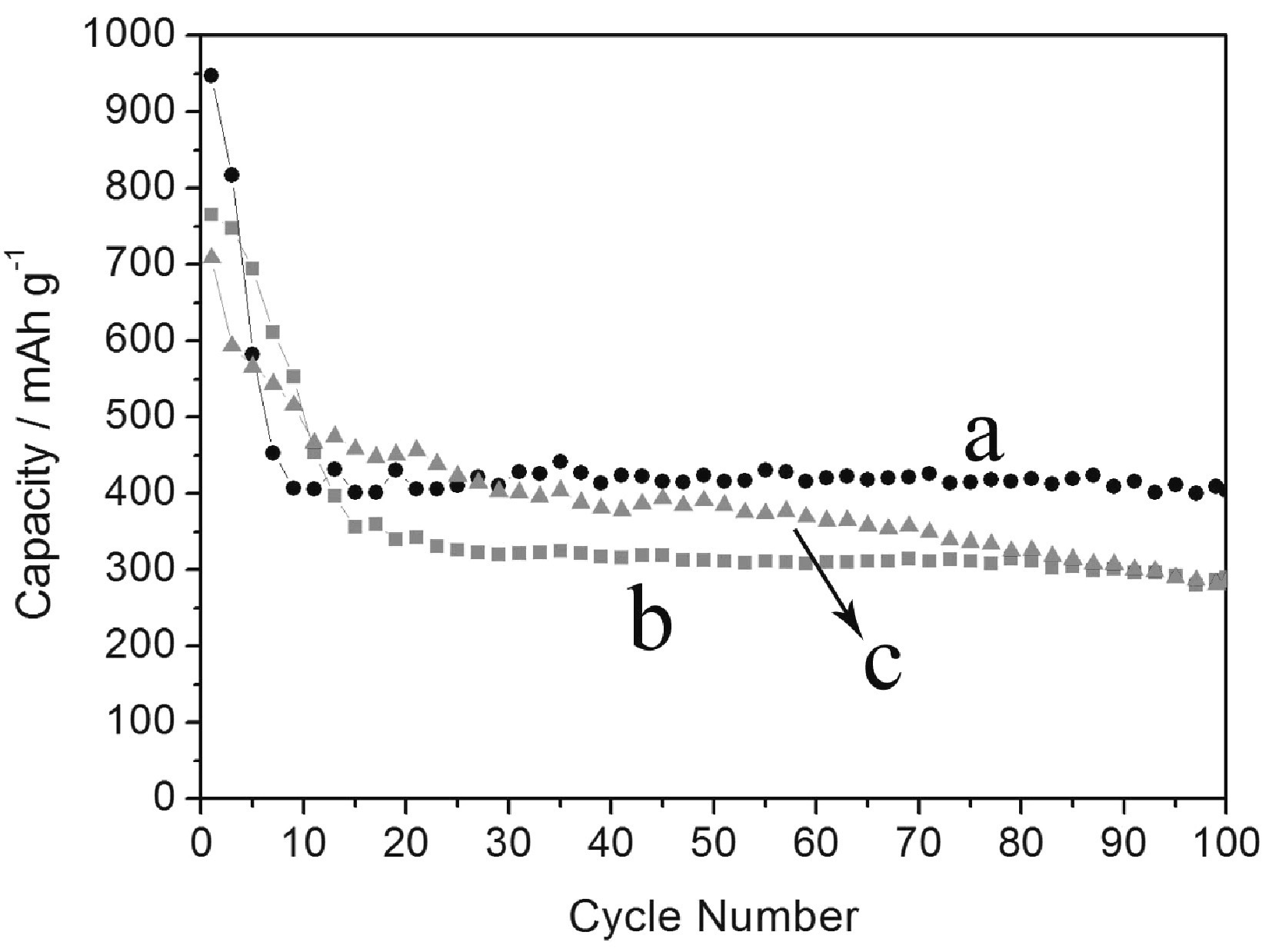

Preparation method of three-dimensional porous tin-copper alloy cathode materials for lithium ion battery

InactiveCN101877399AImprove cycle performanceImprove bindingElectrode carriers/collectorsElectrical batteryTin plating

The invention belongs to the technical field of electrochemistry and particularly relates to a preparation method of three-dimensional porous tin-copper alloy cathode materials for a lithium ion battery. In the invention, foamy copper is adopted as a current collector, a tin layer is deposited on the foamy copper through a method of electroless tin plating, and then the three-dimensional porous tin-copper alloy cathode materials are prepared through a method of vacuum heat treatment. Formation of three-dimensional porous tin-copper alloy and excellent bonding force between active materials and a three-dimensional porous current collector are both beneficial to buffering the volume expansion effect in the charging and discharging process, and therefore, the circulation performance of the battery is dramatically improved. The invention has the advantages of simple method, low cost and easy scale production and has wide application prospect in the field of lithium ion battery cathodes.

Owner:FUDAN UNIV

Transformer production process

The invention discloses a transformer production process and belongs to the technical field of transformer processing. The transformer production process includes (A) a preparation process (B) coiling I, (C) coiling II, (D) encapsulation, (E) reshaping encapsulation, (F) wire cutting and paint peeling, (G) iron core assembly, (H) inductance high voltage measurement, (I) steel strip binding and inductance high voltage measurement, (J) appearance inspection and vacuum paint dipping, (K) wire cutting, paint peeling and tin plating, (L) lead stranding, (M) lead welding and encapsulation, (N) wire folding, heat-shrinkable sleeving and wire binding, (O) QC electrical testing, (P) model mark sticking, (Q) appearance inspection and (R) packaging. The transformer production process has the advantages of being simple, efficient and high-qualified. Manufactured transformers are attractive in appearance, reliable and safe in insulating treatment, small in flux leakage, high in efficiency and particularly suitable for mass production.

Owner:XUZHOU GLORIA TECH

Tin plating

InactiveUS7160629B2More resistant to whiskeringLow and reduced whiskeringSemiconductor/solid-state device detailsSolid-state devicesElectrolyte compositionTin plating

Electrolyte compositions for the deposition of tin and tin-alloys on a substrate are disclosed, along with methods of electroplating tin and tin-alloys using such compositions. These electrolyte compositions are useful for high speed tin plating.

Owner:SHIPLEY CO LLC

Preparation of nano silicon dioxide lubricating grease

The invention discloses a preparation method of high-performance silicon dioxide grease, which comprises the following components, base oil of 70 to 90 weight percent, silica of 5 to 30 weight percent, modifying agent is in a dose of 5-30 weight percent of the silicon dioxide. The silicon dioxide grease of the invention has a very good storage stability and shear stability, good colloidal stability, water resistant properties of high temperature and low temperature performance. The silicon dioxide grease can be used for electrical insulation, damping system lubrication, vacuum sealed, instruments and cock sealing and lubricating, can also be used for resistant chemical media site lubricating and sealing, and so on. In addition, the silicon dioxide grease can also be used for preparing valves grease, methanol resistance grease, and is applicable in lubrication and interrupter of the metal contact of switch silvering, silver plating, and tinning and other.

Owner:益田润石(北京)化工有限公司

Heat-Curable Urethane Resin Composition

InactiveUS20070293636A1Improve adhesionWell-balanced propertyPolyurea/polyurethane coatingsNon-metallic protective coating applicationEpoxyResist

The invention provides a heat-curable resin composition comprising (A) a polyurethane having two or more carboxyl groups in one molecule, in particular a polyurethane having one or more carboxyl groups at a molecular terminal and (B) a heat-curable component, a cured product thereof, a solder resist and a protective film consisting of the cured product and a printed wiring board coated with the cured product. The polyurethane(A), preferably has a number average molecular weight of 500 to 100,000 and an acid value of 5 to 150 mgKOH / g. The heat-curable component (B) is preferably an epoxy resin. The heat-curable resin composition of the invention is excellent in adhesion with a substrate, low-warpage property, flexibility, resistance to moisture and heat, soldering heat resistance and resistance to tin plating.

Owner:SHOWA DENKO KK

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com