Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

948results about "Resistors adapted for applying terminals" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

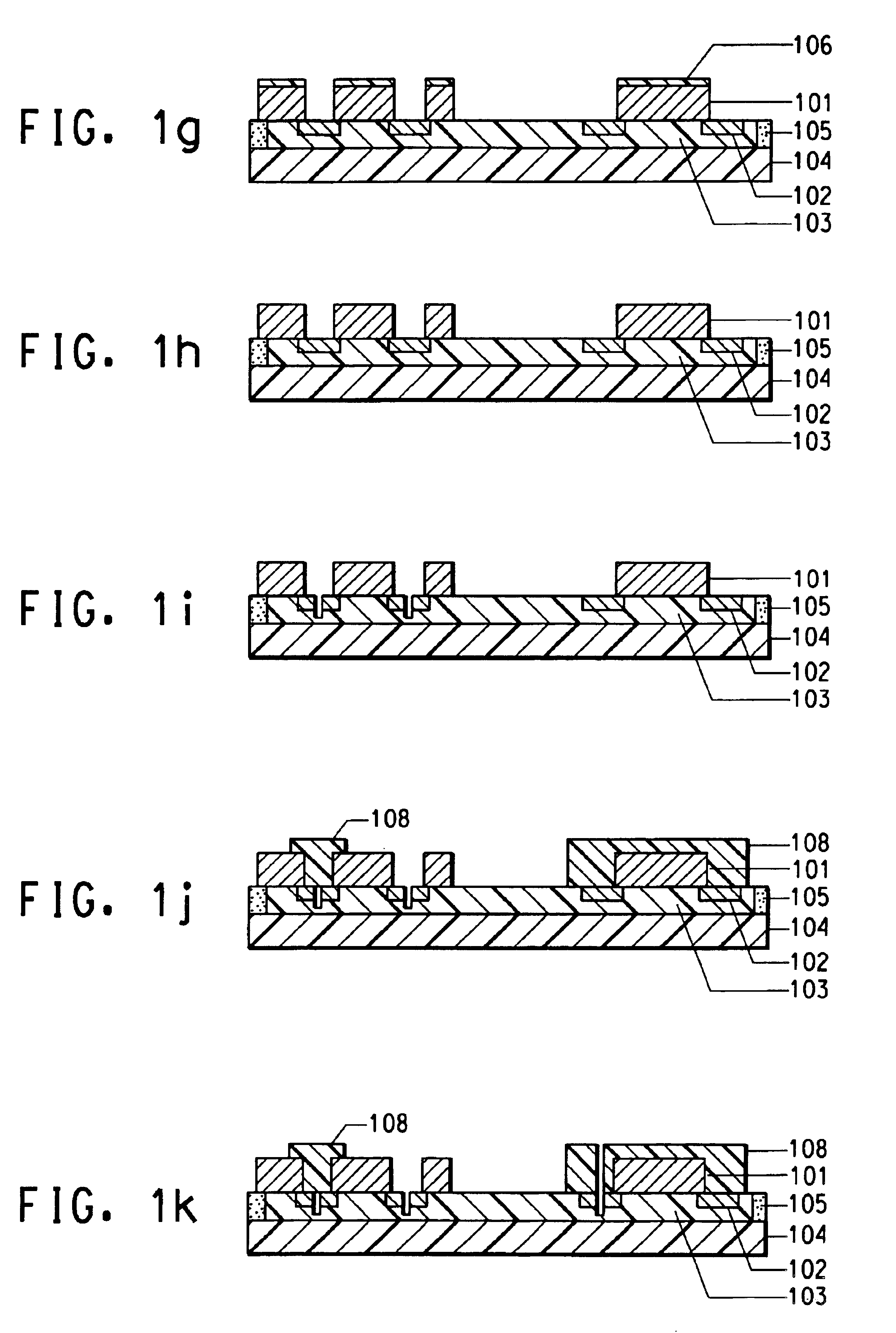

Plated terminations

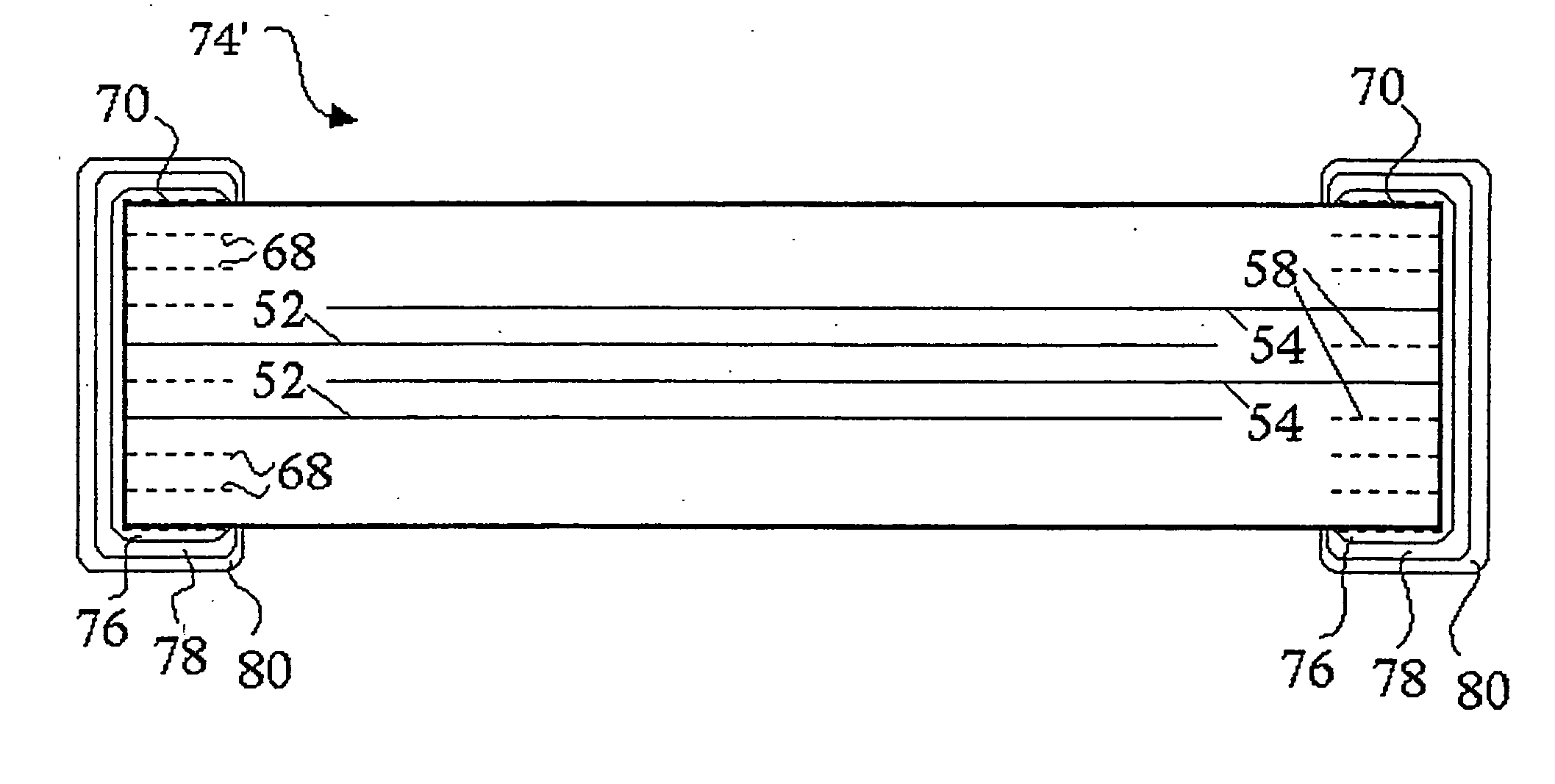

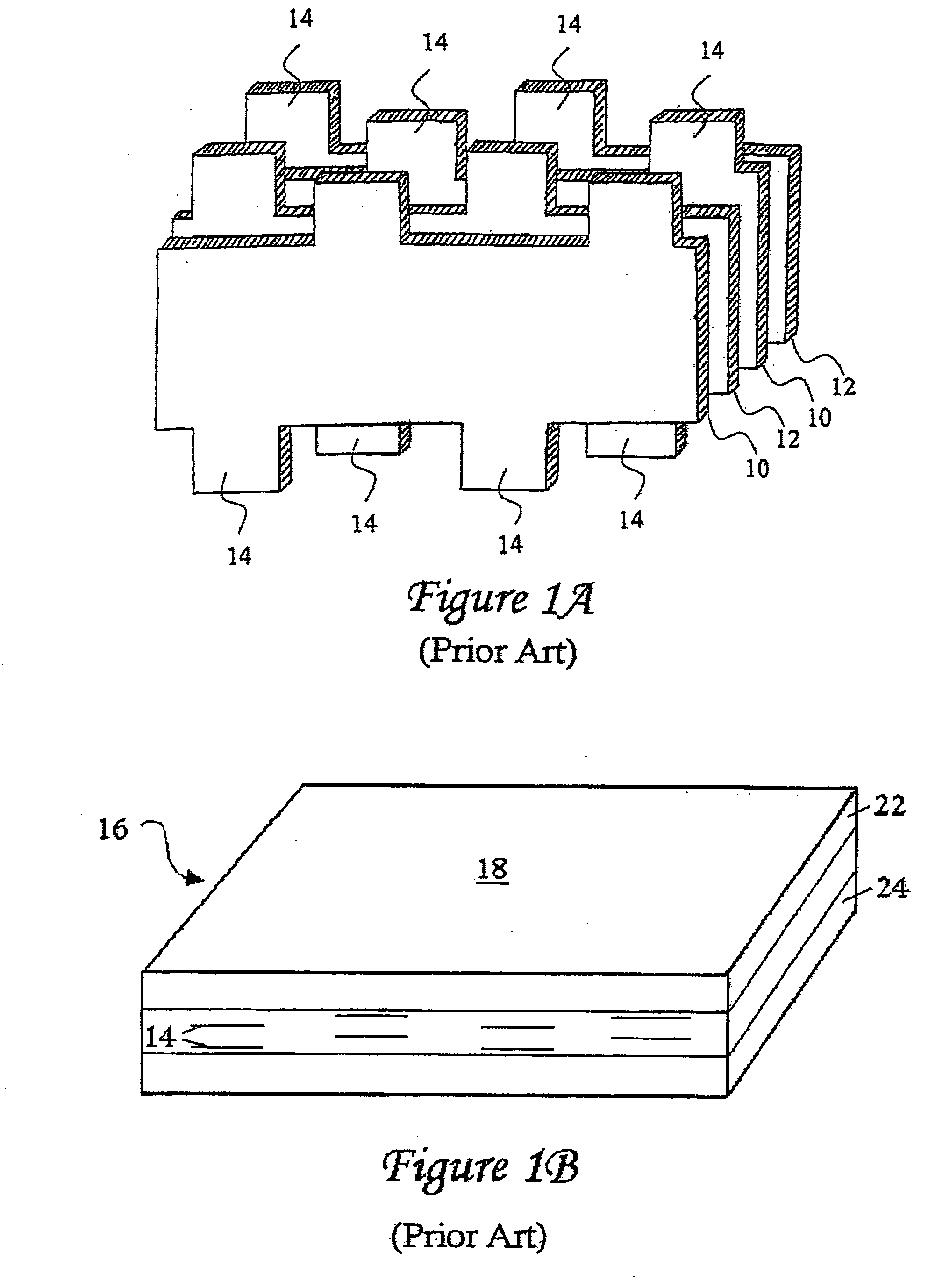

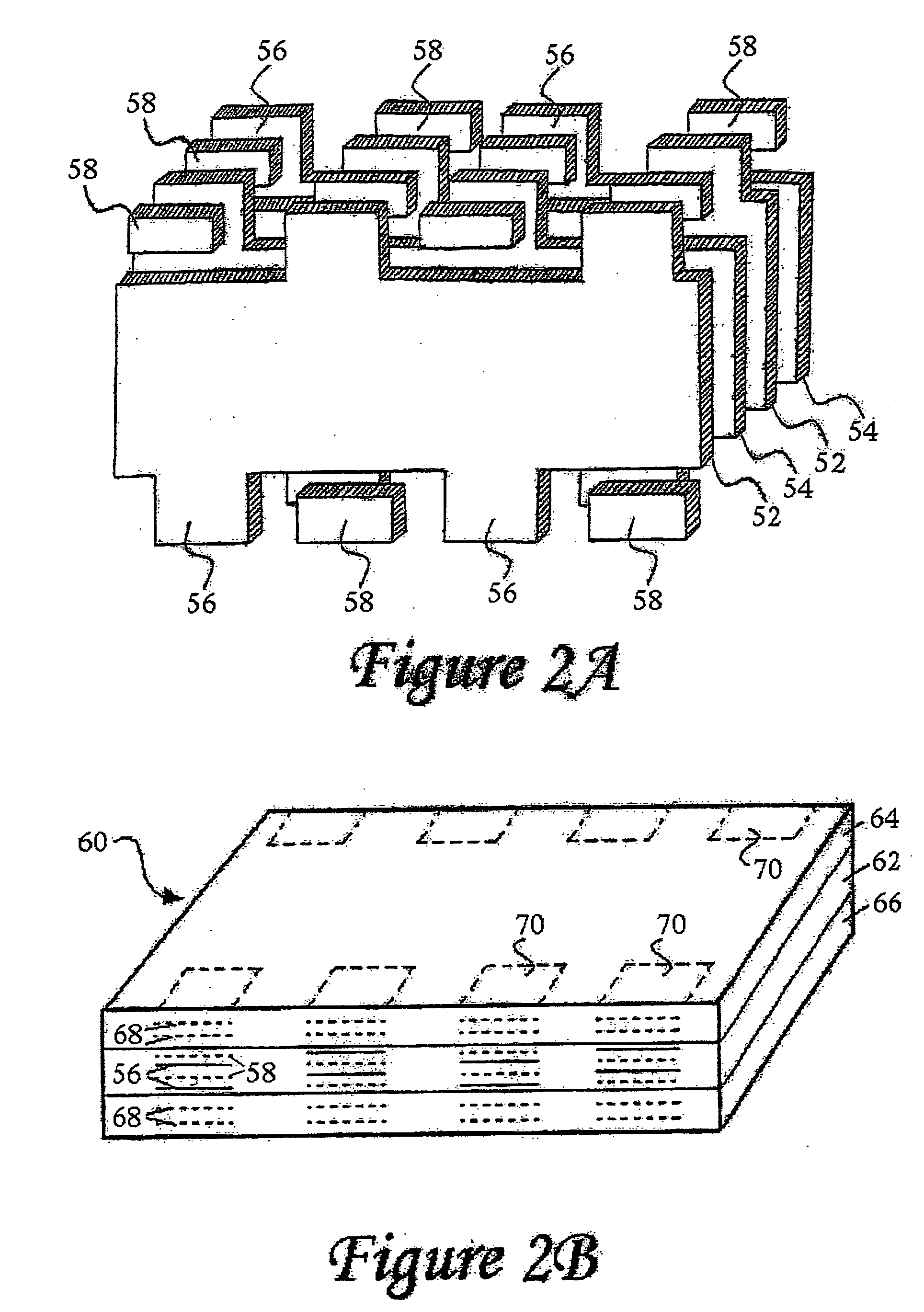

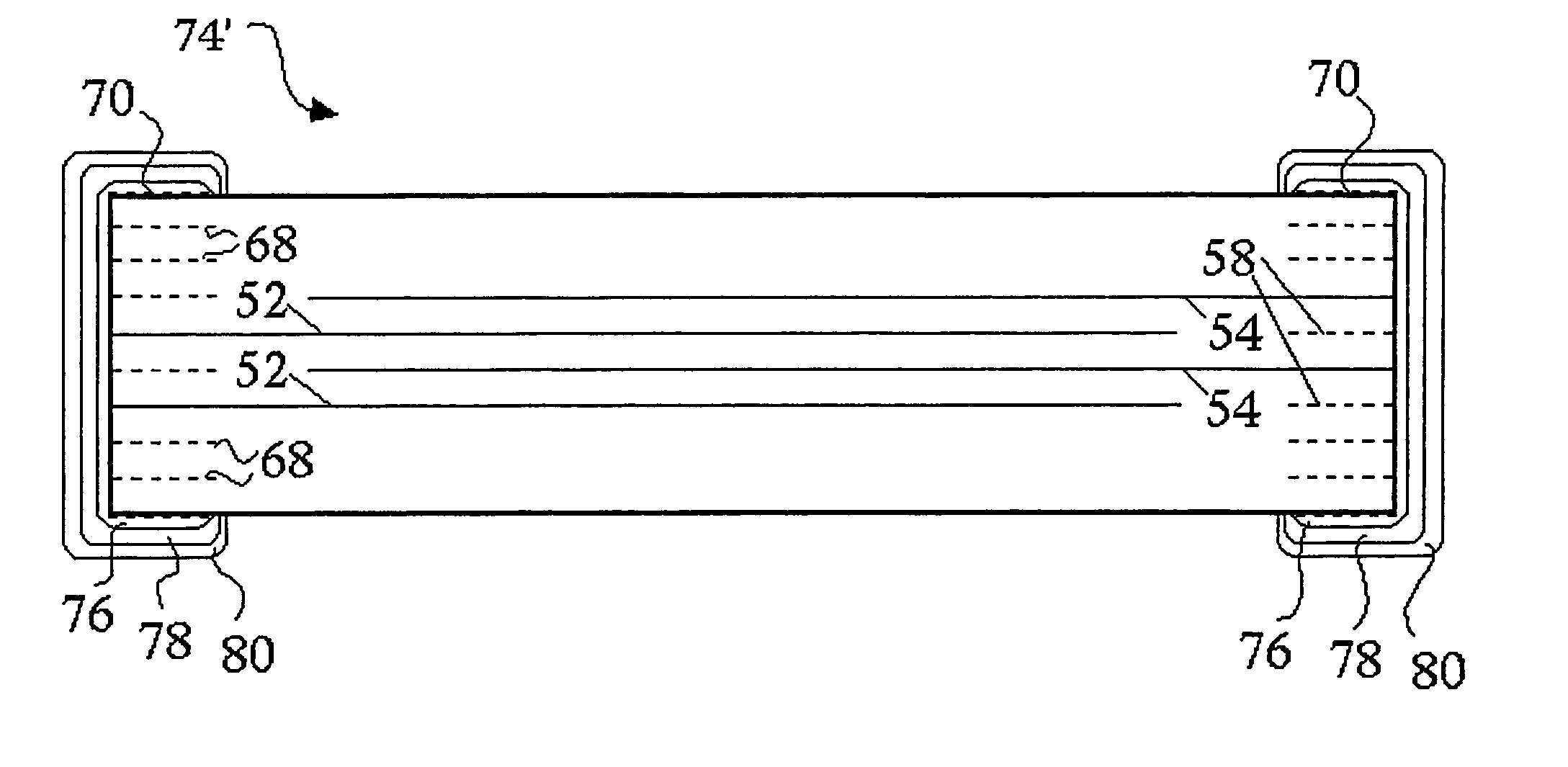

InactiveUS20050046536A1Improved termination featureEliminate and greatly simplifyWave amplification devicesResistor terminals/electrodesTermination problemEngineering

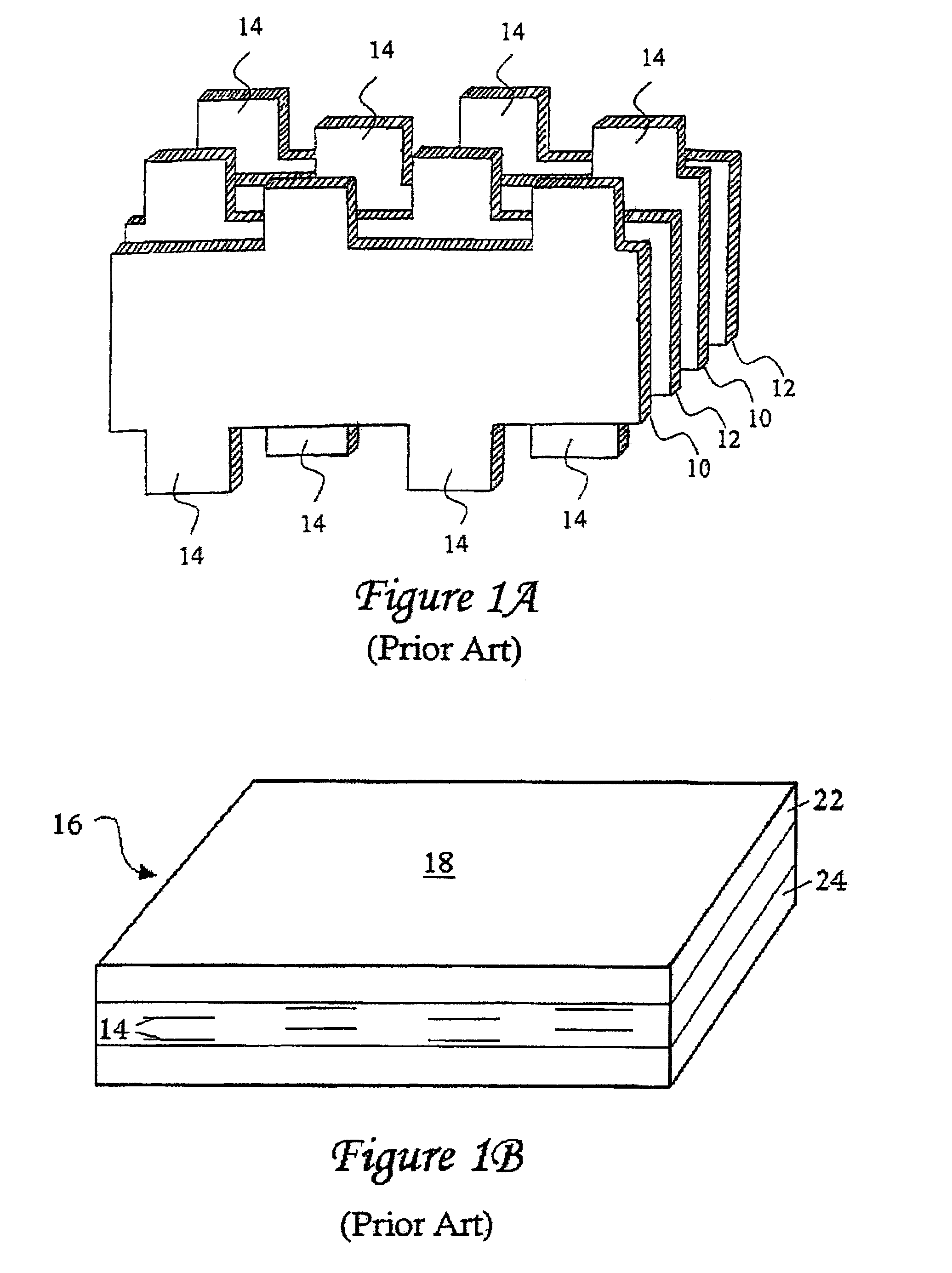

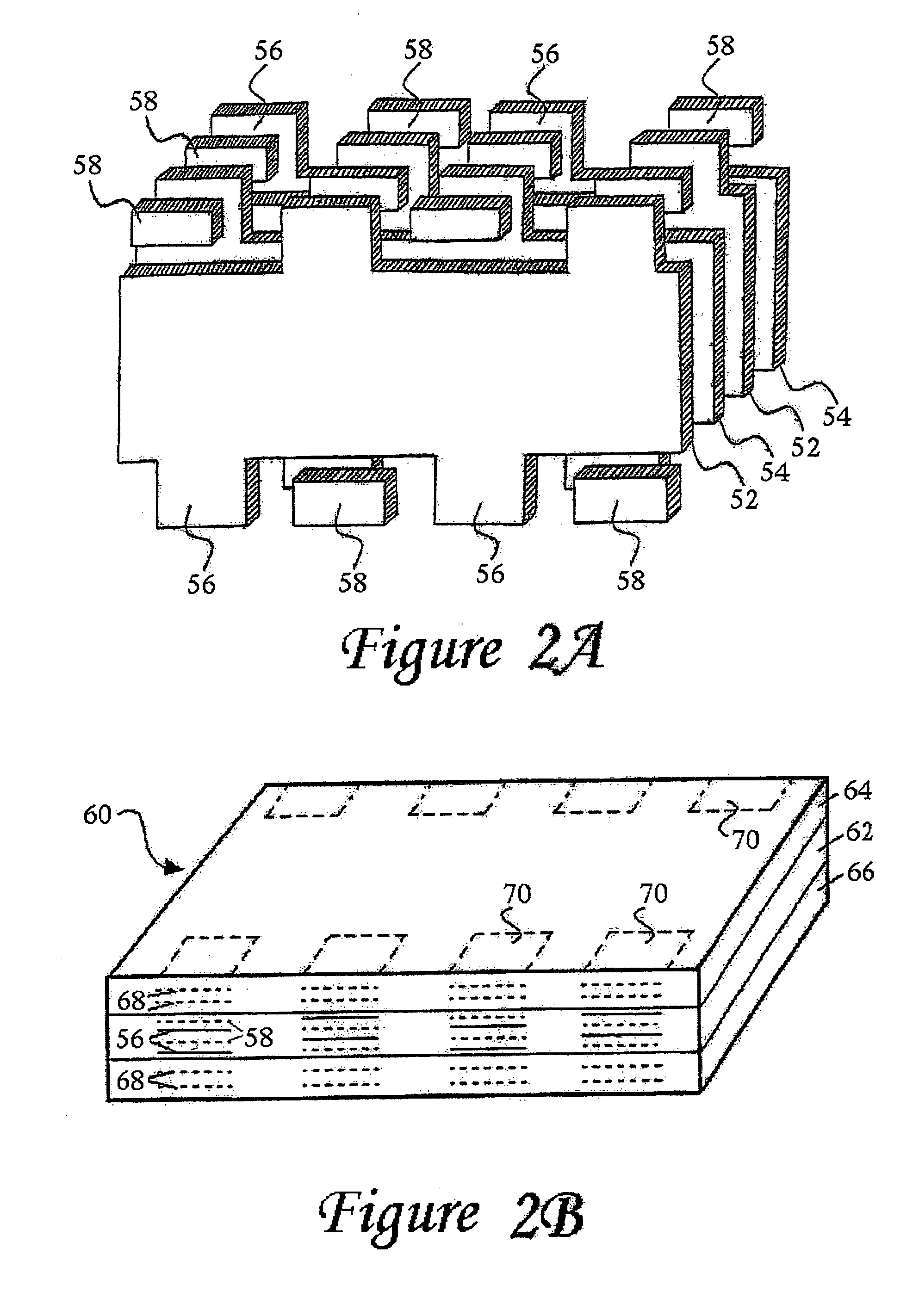

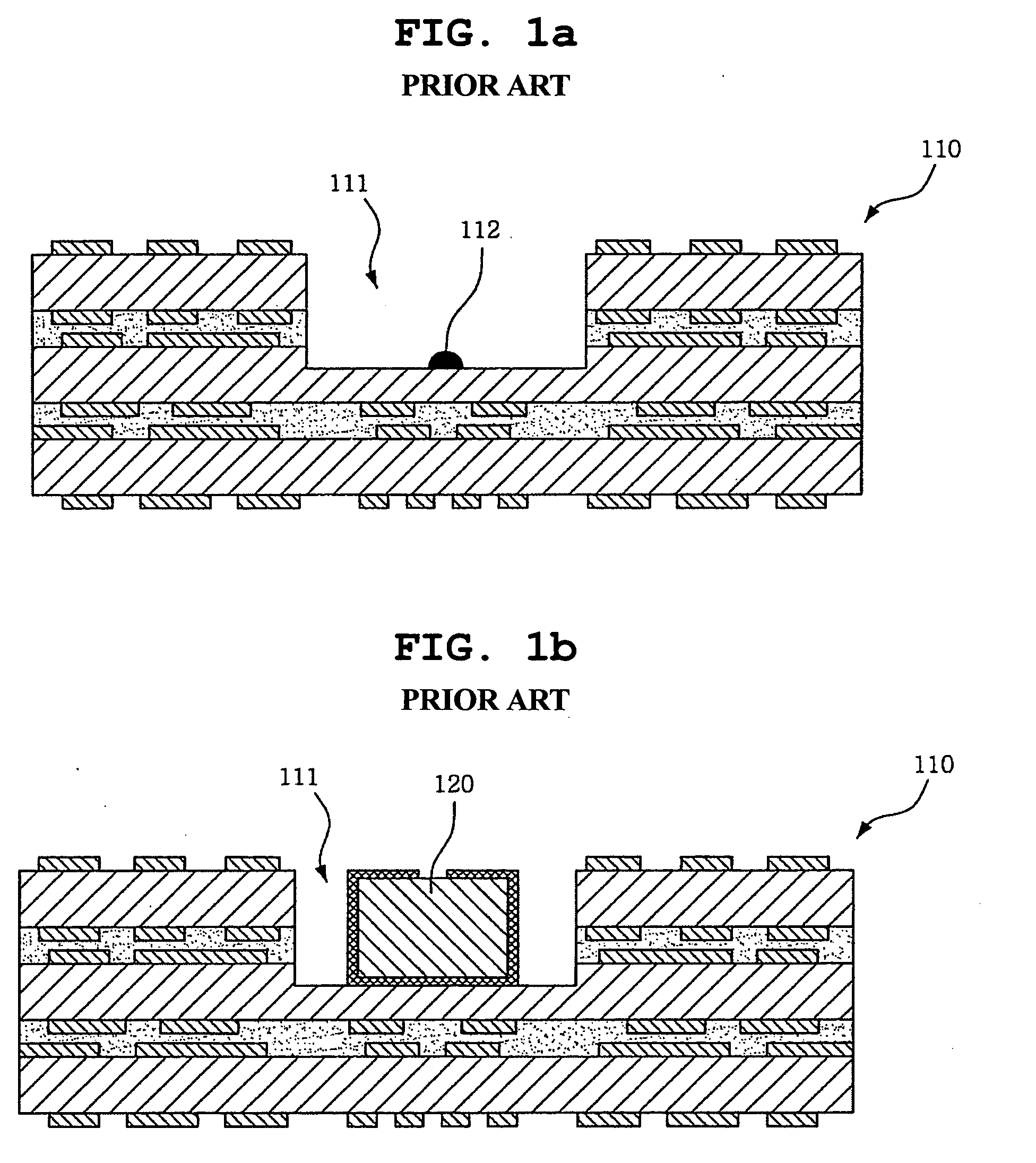

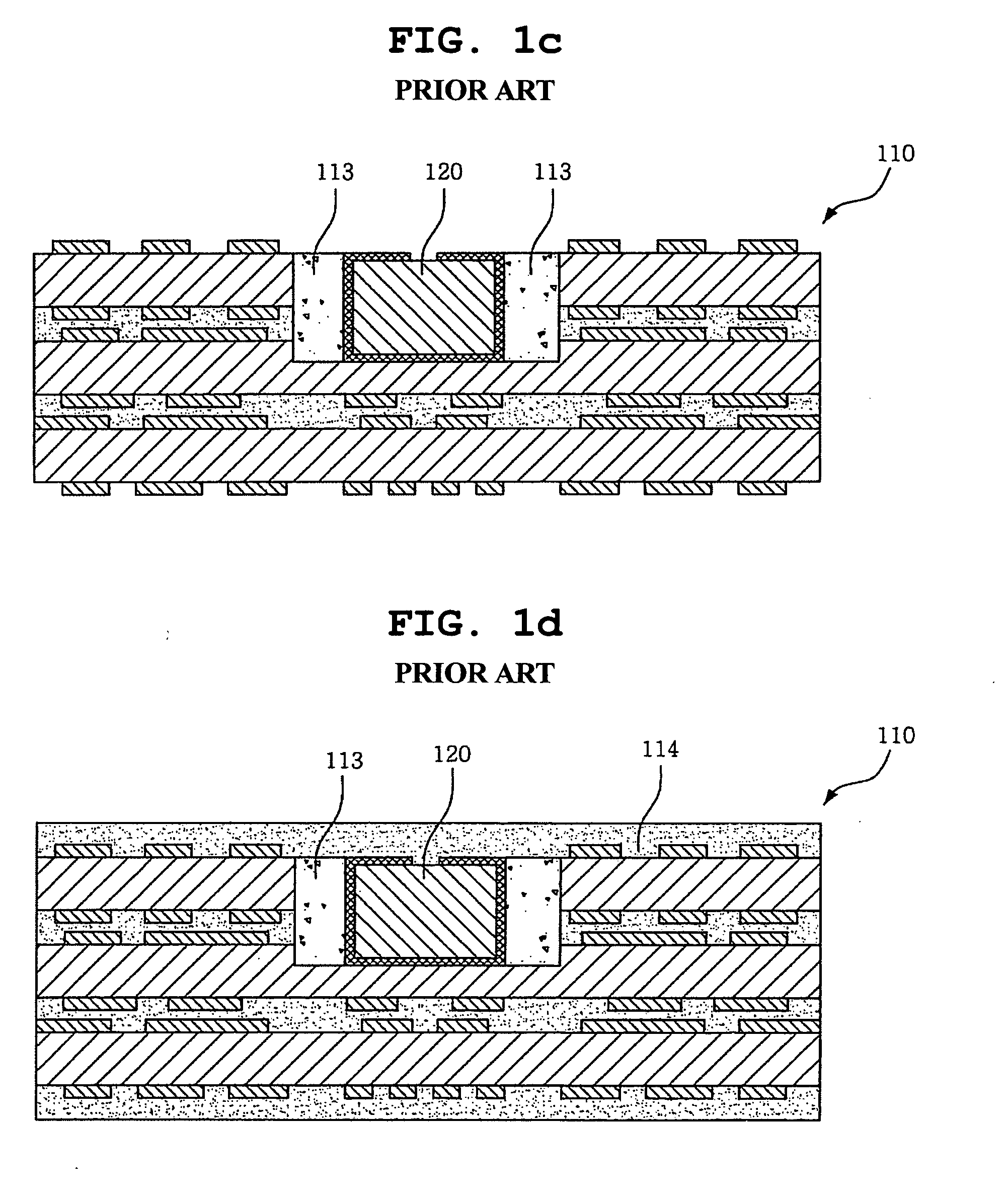

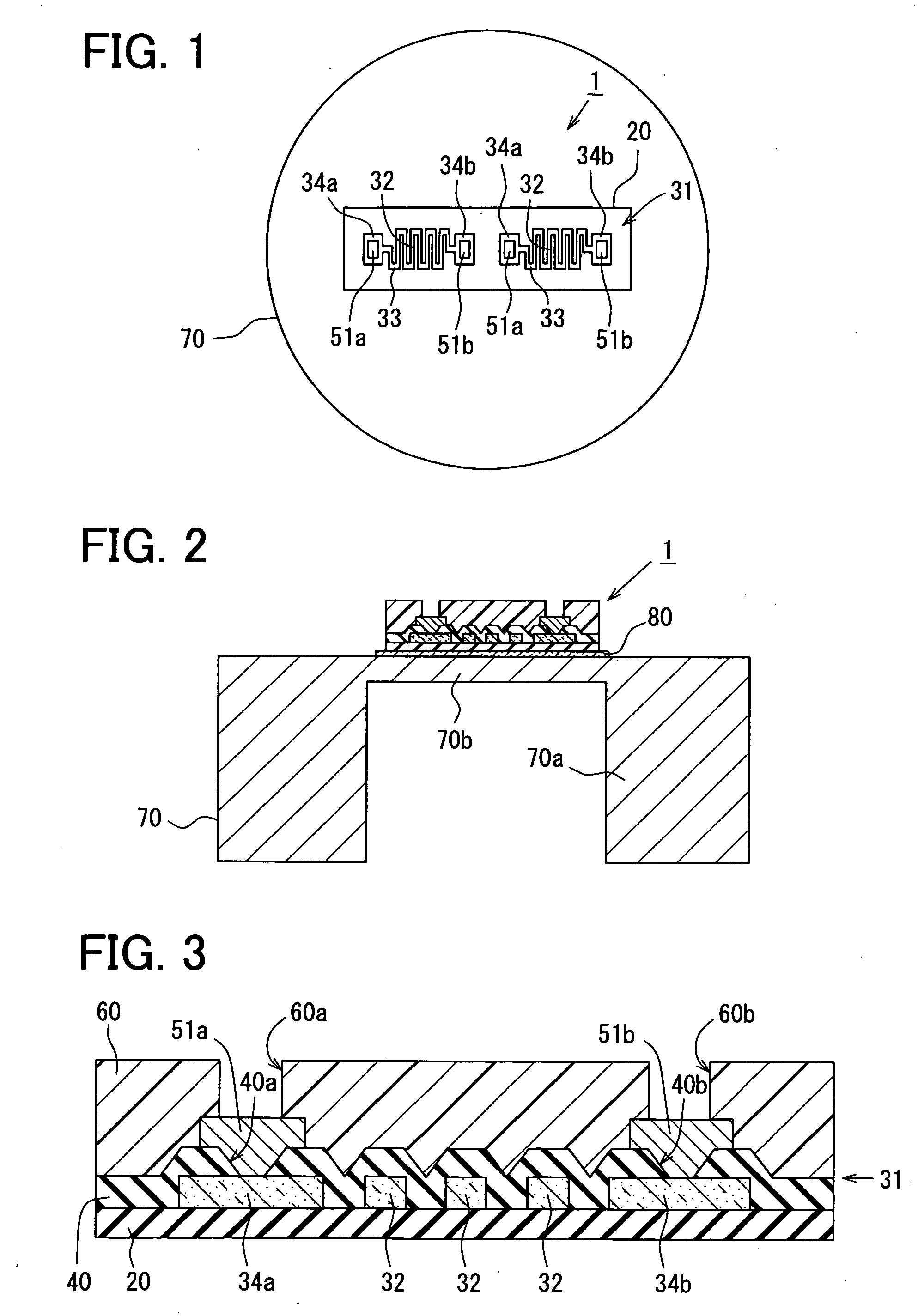

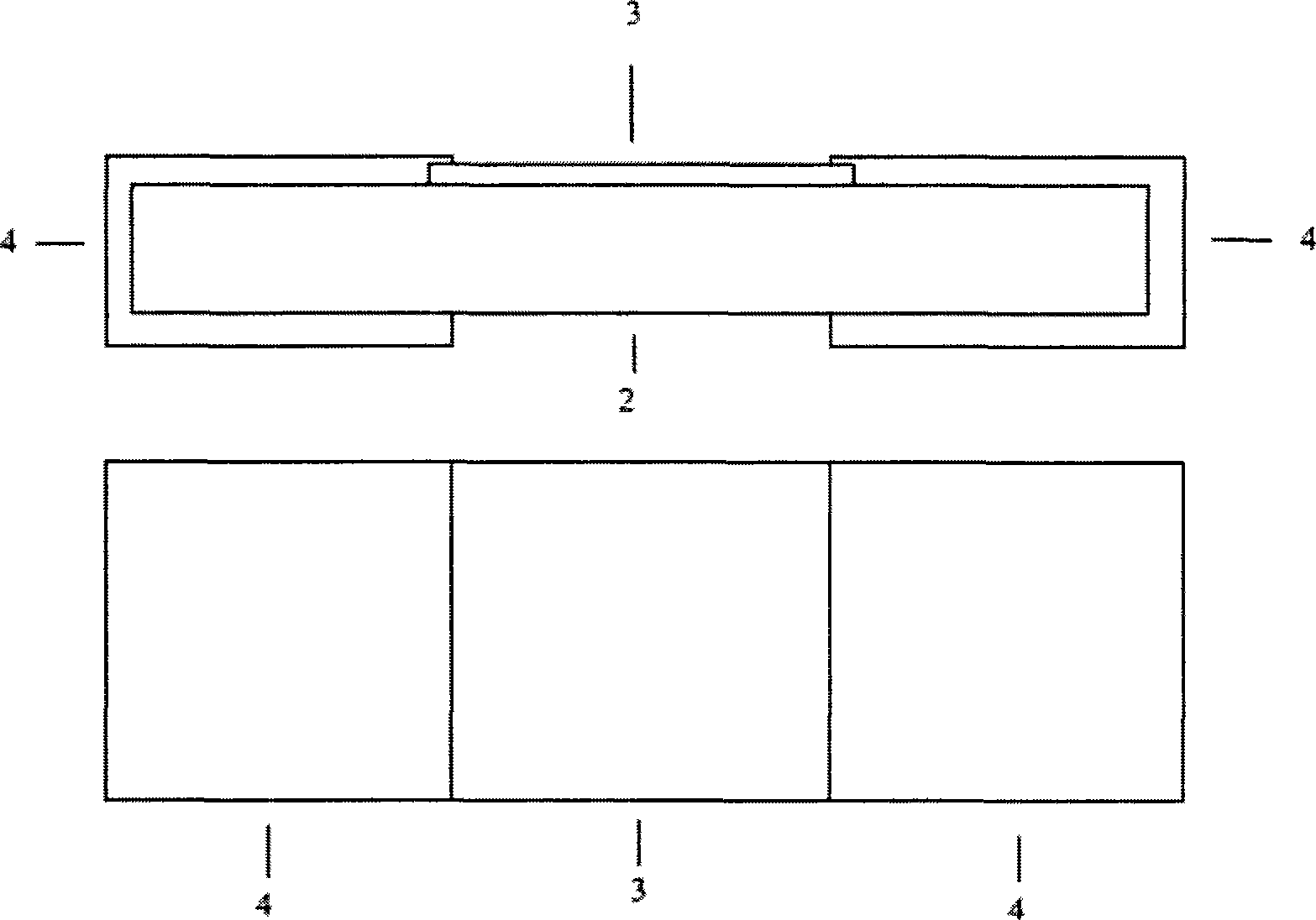

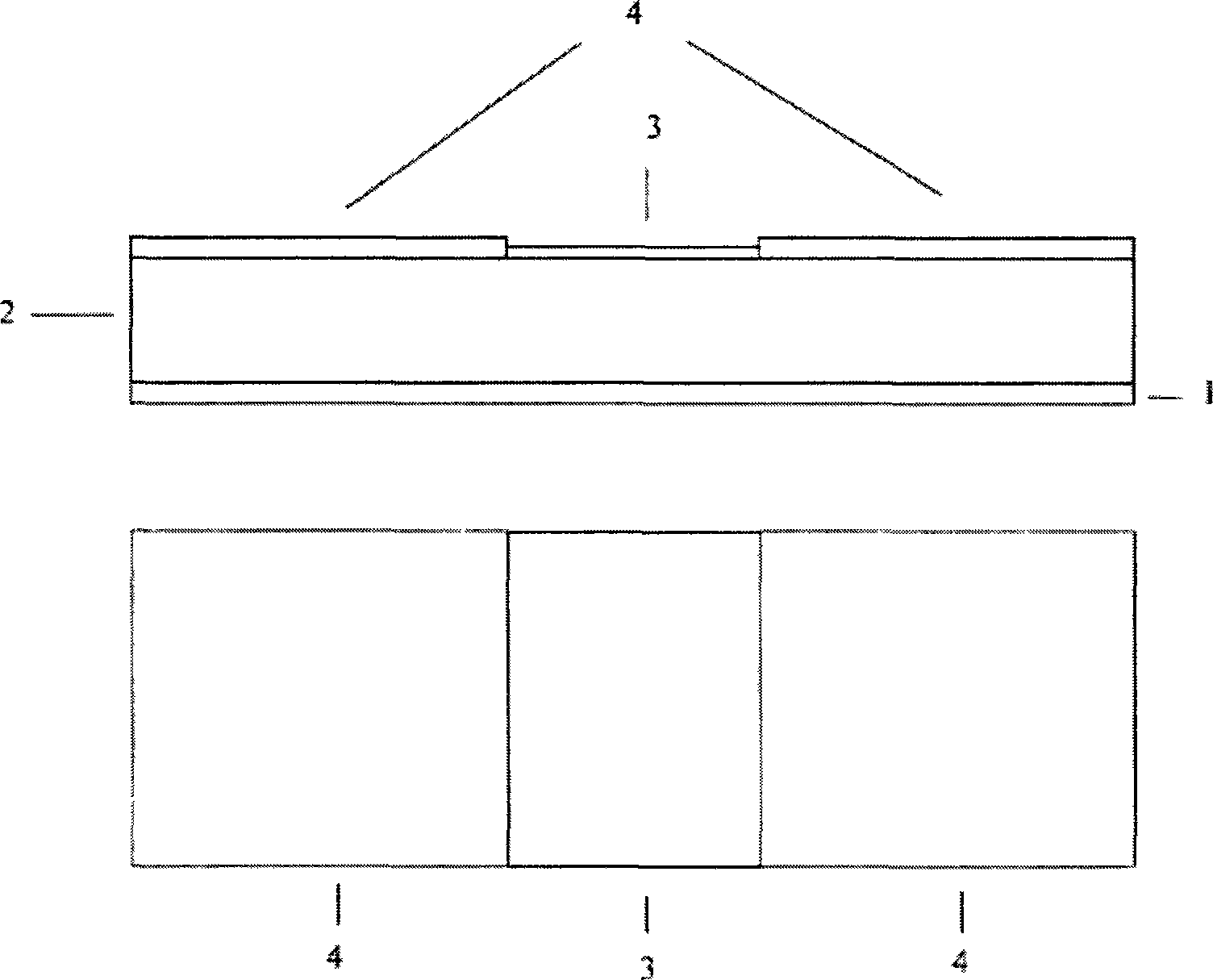

Improved termination features for multilayer electronic components are disclosed. Monolithic components are provided with plated terminations whereby the need for typical thick-film termination stripes is eliminated or greatly simplified. Such termination technology eliminates many typical termination problems and enables a higher number of terminations with finer pitch, which may be especially beneficial on smaller electronic components. The subject plated terminations are guided and anchored by exposed internal electrode tabs and additional anchor tab portions which may optionally extend to the cover layers of a multilayer component. Such anchor tabs may be positioned internally or externally relative to a chip structure to nucleate additional metallized plating material. External anchor tabs positioned on top and bottom sides of a monolithic structure can facilitate the formation of wrap-around plated terminations. The disclosed technology may be utilized with a plurality of monolithic multilayer components, including interdigitated capacitors, multilayer capacitor arrays, and integrated passive components. A variety of different plating techniques and termination materials may be employed in the formation of the subject self-determining plated terminations.

Owner:KYOCERA AVX COMPONENTS CORP

Plated terminations

InactiveUS7154374B2Improved termination featureEliminate or greatly simplify thick-film stripesResistor terminals/electrodesSemiconductor/solid-state device detailsTermination problemEngineering

Improved termination features for multilayer electronic components are disclosed. Monolithic components are provided with plated terminations whereby the need for typical thick-film termination stripes is eliminated or greatly simplified. Such termination technology eliminates many typical termination problems and enables a higher number of terminations with finer pitch, which may be especially beneficial on smaller electronic components. The subject plated terminations are guided and anchored by exposed internal electrode tabs and additional anchor tab portions which may optionally extend to the cover layers of a multilayer component. Such anchor tabs may be positioned internally or externally relative to a chip structure to nucleate additional metallized plating material. External anchor tabs positioned on top and bottom sides of a monolithic structure can facilitate the formation of wrap-around plated terminations. The disclosed technology may be utilized with a plurality of monolithic multilayer components, including interdigitated capacitors, multilayer capacitor arrays, and integrated passive components. A variety of different plating techniques and termination materials may be employed in the formation of the subject self-determining plated terminations.

Owner:KYOCERA AVX COMPONENTS CORP

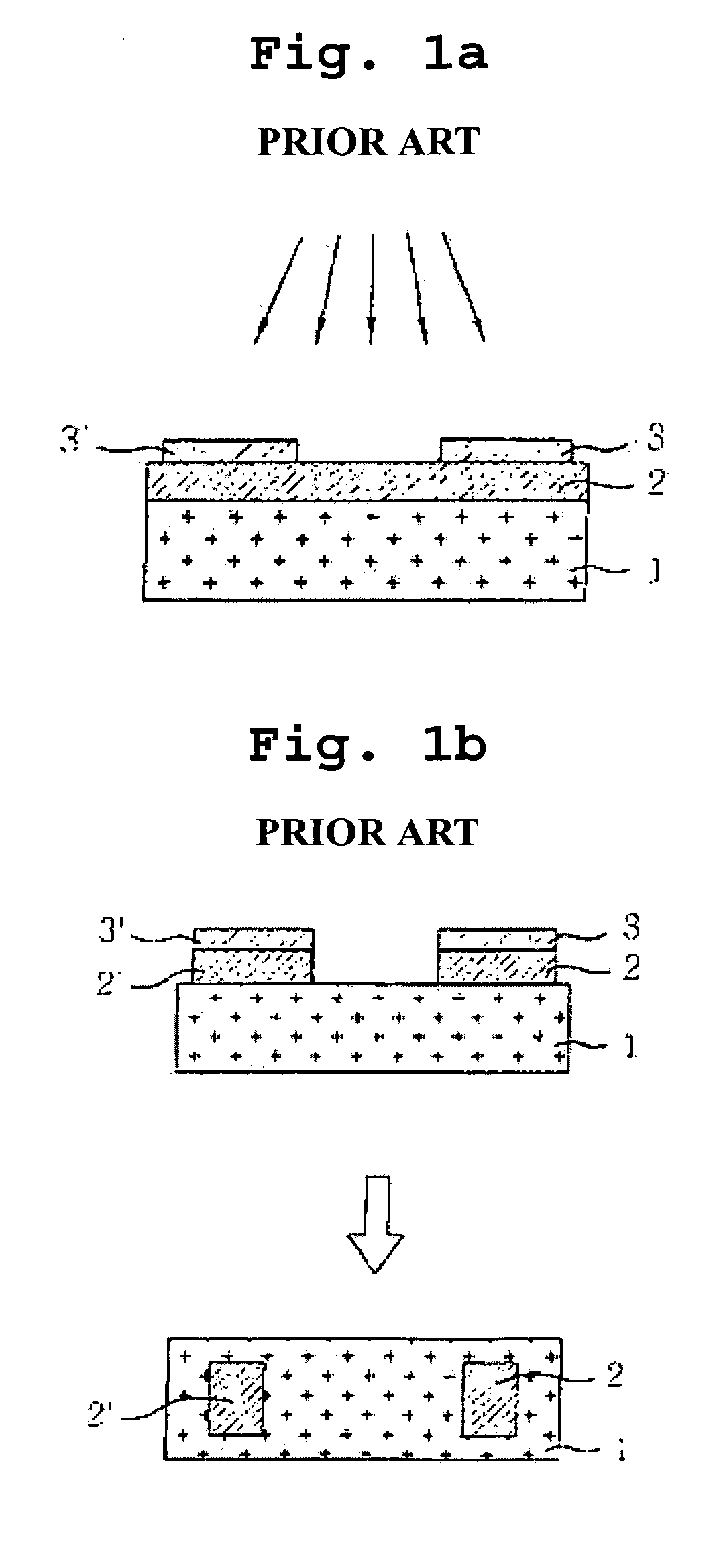

Method of manufacturing a sensor detecting a physical action as an applied force

InactiveUS6185814B1Low costSimple circuit configurationAcceleration measurement using interia forcesForce measurement using piezo-resistive materialsSignal processing circuitsSemiconductor chip

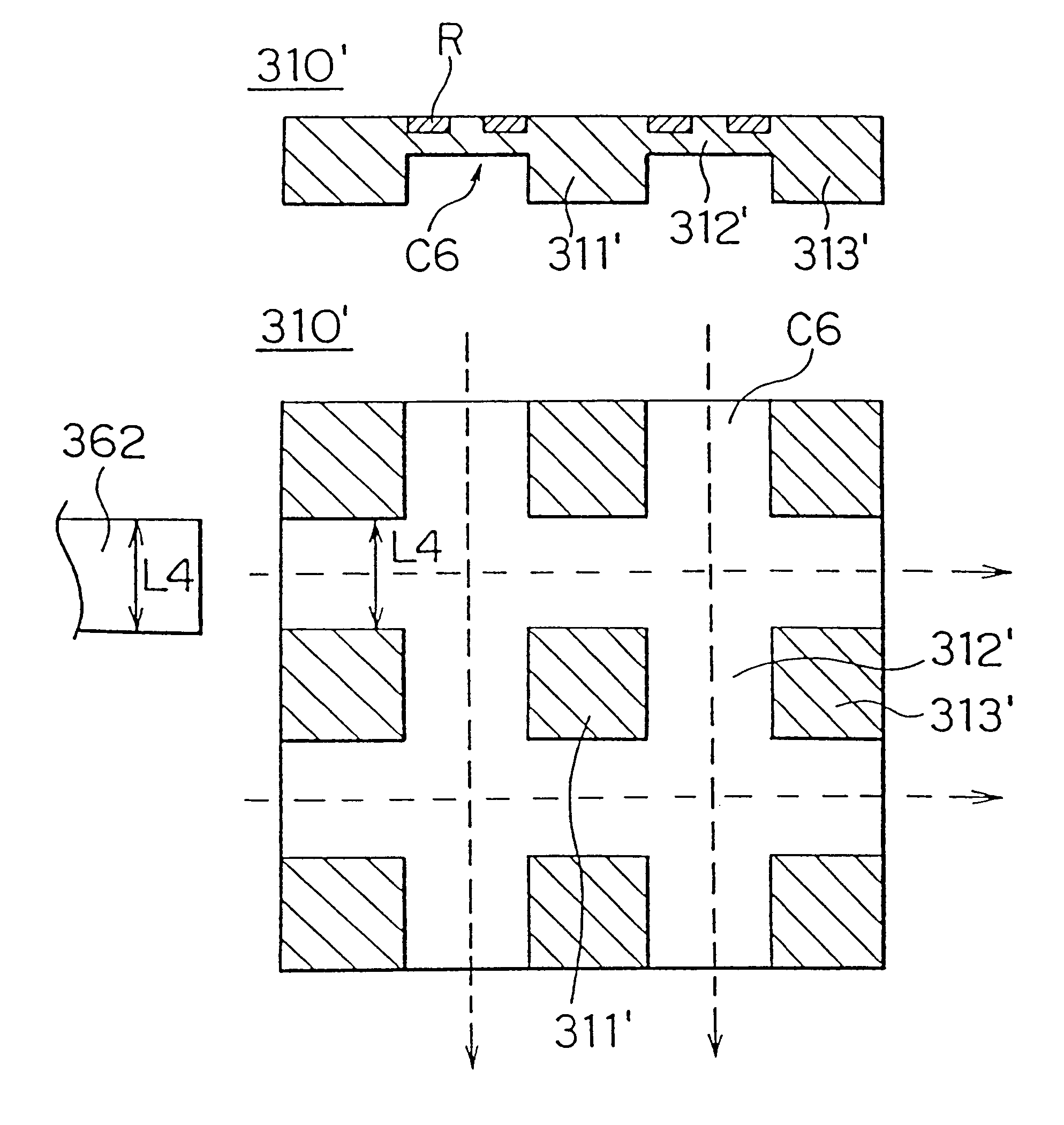

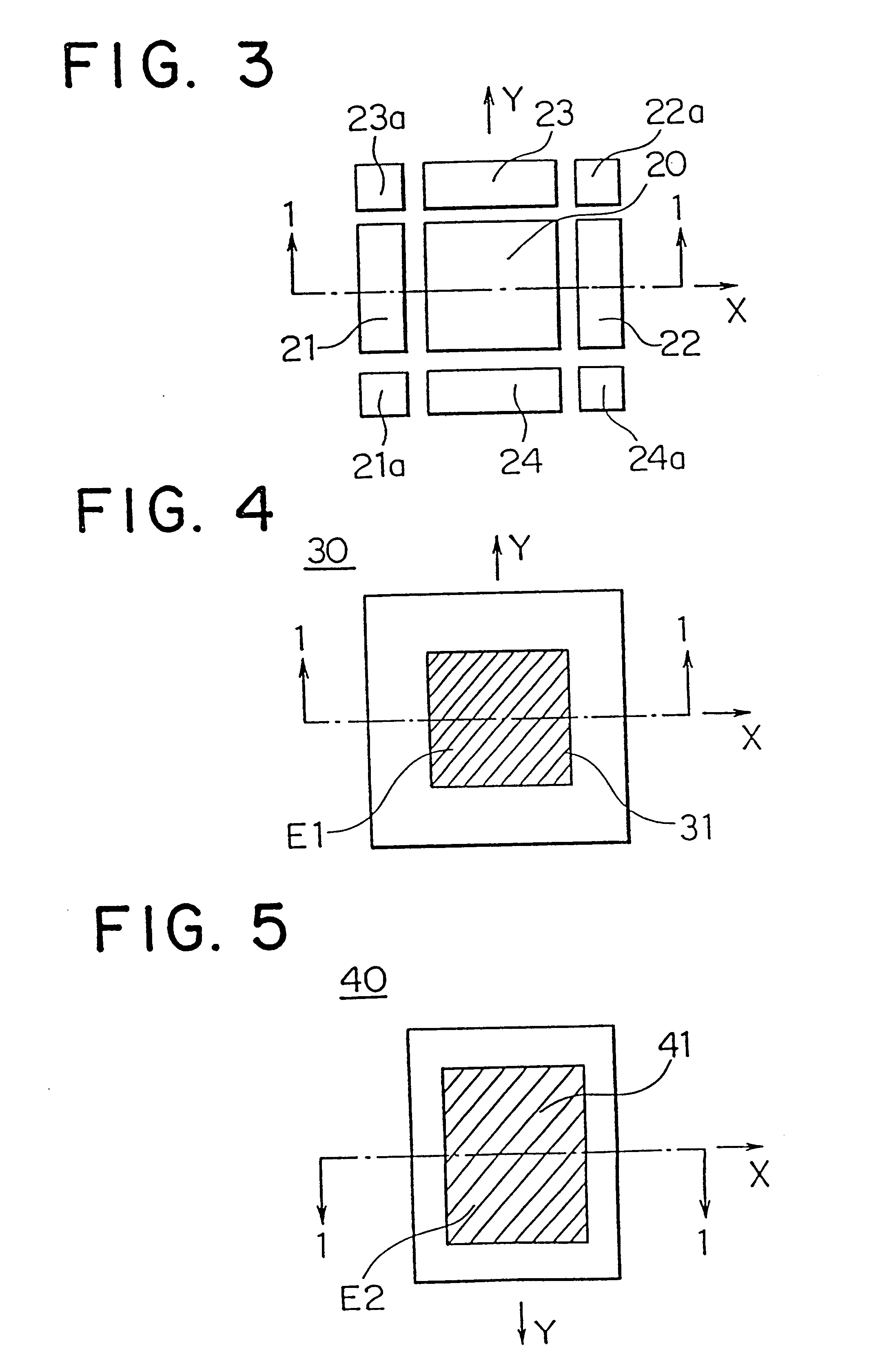

A sensor comprises a semiconductor pellet (10) including a working portion (11) adapted to undergo action of a force, a fixed portion (13) fixed on the sensor body, and a flexible portion (13) having flexibility formed therebetween, a working body (20) for transmitting an exterted force to the working portion, and detector means (60-63) for transforming a mechanical deformation produced in the semiconductor pellet to an electric signal to thereby detect a force exerted on the working body as an electric signal. A signal processing circuit is applied to the sensor. This circuit uses analog multipliers (101-109) and analog adders / subtracters (111-113), and has a function to cancel interference produced in different directions. Within the sensor, two portions (E3, E4-E8) located at positions opposite to each other and producing a displacement therebetween by action of a force are determined. By exerting a coulomb force between both the portions, the test of the sensor is carried out. Further, a pedestal (21, 22) is provided around the working body (20). The working body and the pedestal are located with a predetermined gap or spacing therebetween. A displacement of the working body is caused to limitatively fall within a predetermined range corresponding to the spacing. The working body and the pedestal are provided by cutting a same common substrate (350, 350')

Owner:OKADA KAZUHIRO

Bending sensor and method for fabricating the same

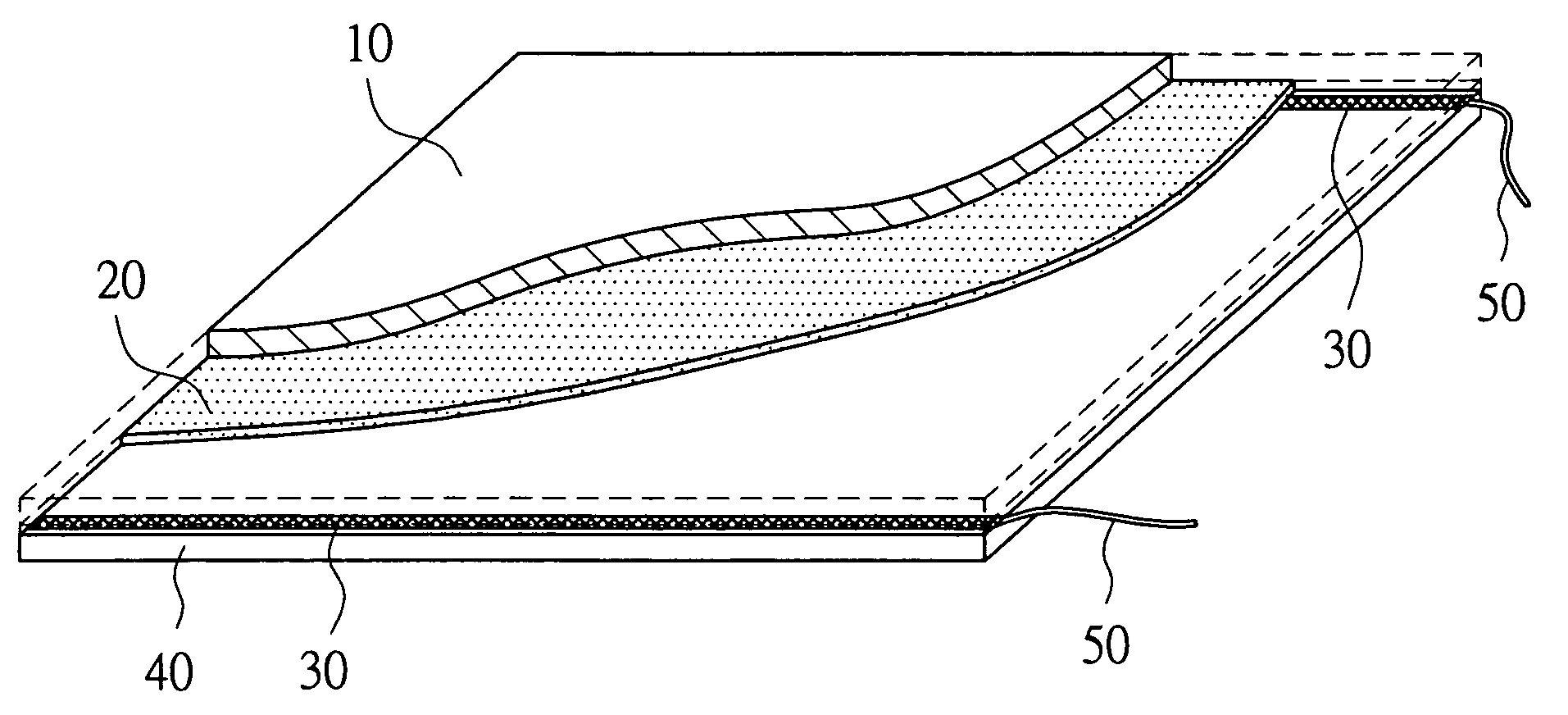

InactiveUS20120256720A1Small sizeResistance/reactance/impedenceForce measurementEngineeringFlexible display

A bend-detecting (bending) sensor is provided, including a flexible substrate, at least a pair of electrode patterns spaced apart from each other provided on the flexible substrate, and a paste layer containing conductive particles. The paste layer is coated onto the flexible substrate where the electrode patterns are formed, such that when the flexible substrate is bent, the density of the conductive particles between the electrode patterns changes and an electric resistance between the electrode patterns also changes, thereby sensing deformation of the flexible substrate, and eventually, a target to which the flexible display element or the flexible substrate is attached. When the bending sensor is applied to the flexible display device, the electrode patterns and the paste layer may be formed on the flexible substrate which is to form the flexible display element, thus forming a bending sensing structure with a thickness of the flexible display element or less.

Owner:SAMSUNG ELECTRONICS CO LTD

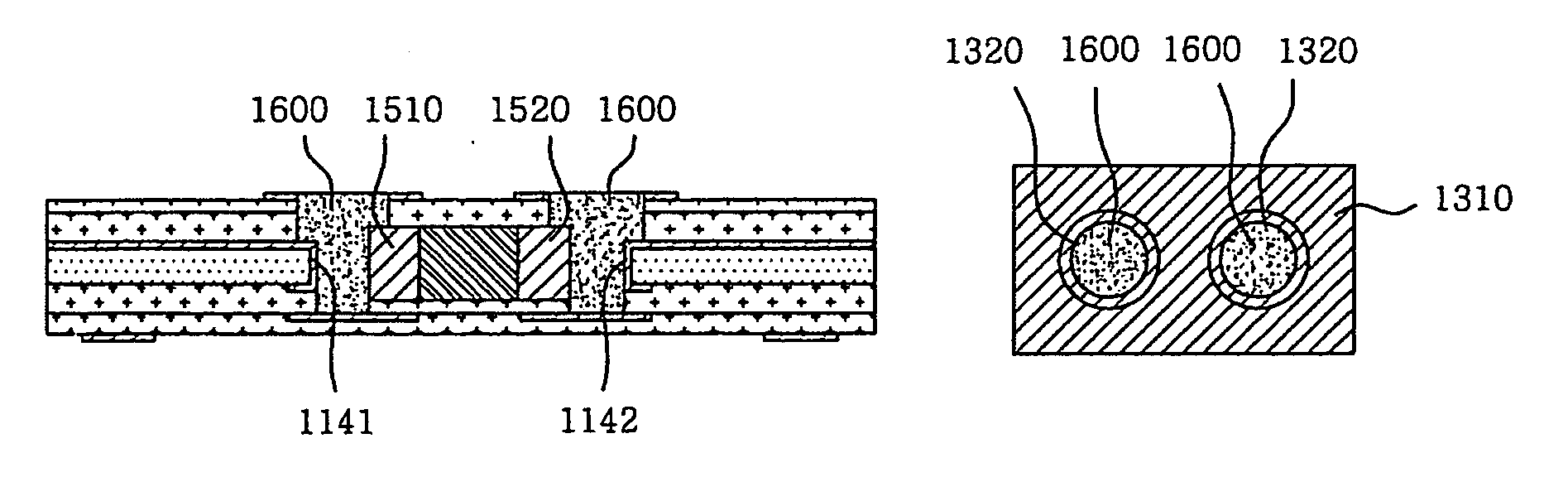

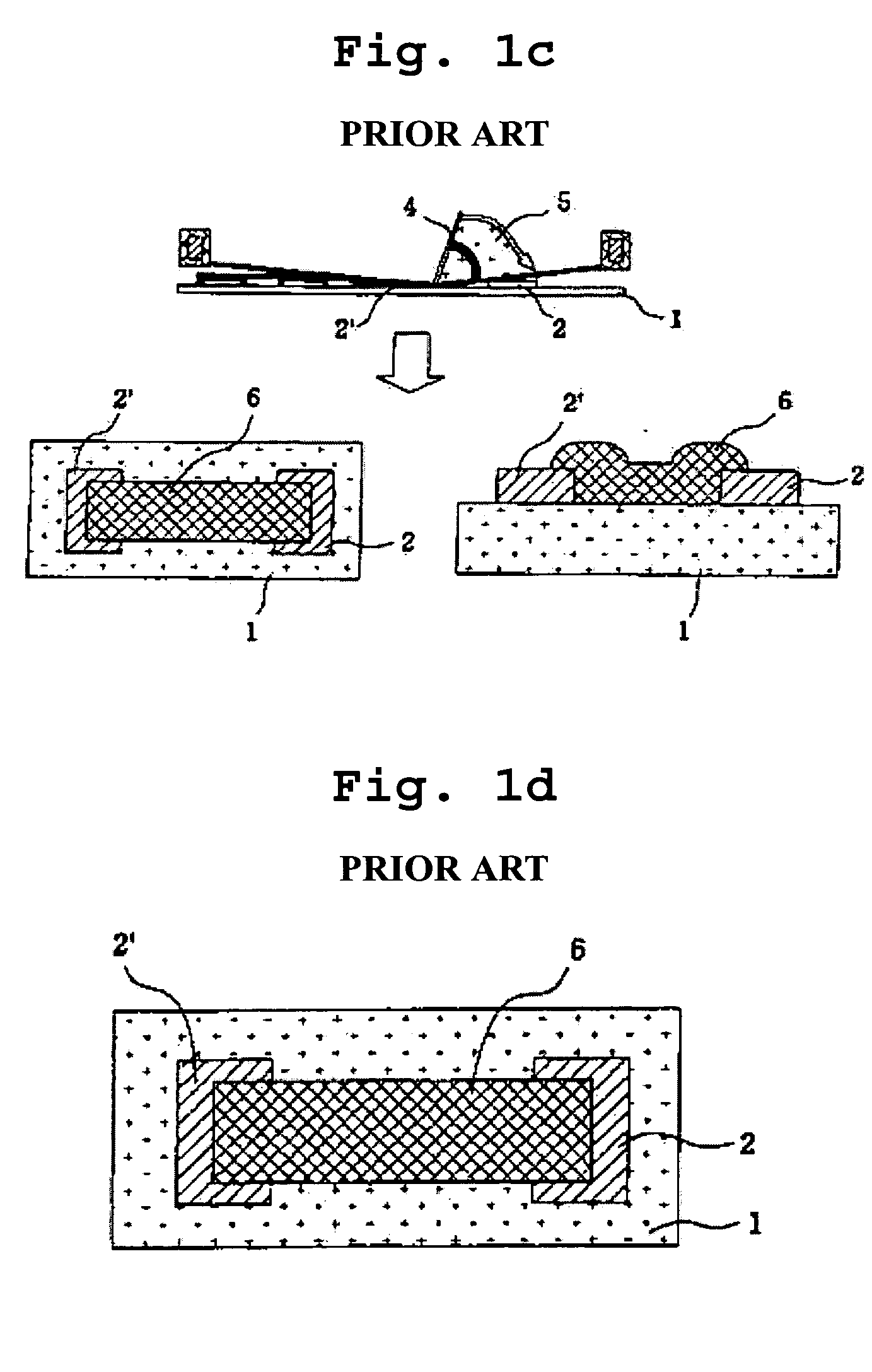

Printed circuit board including embedded passive component and method of fabricating same

InactiveUS20060054352A1Accurately and easily achievedPrinted circuit assemblingFinal product manufactureConductive materialsPrinted circuit board

Disclosed is a PCB including an embedded passive component and a method of fabricating the same. The PCB includes at least two circuit layers in which circuit patterns are formed. At least one insulating layer is interposed between the circuit layers. A pair of terminals is vertically formed through the insulating layers, plated with a first conductive material, and separated from each other by a predetermined distance. The embedded passive component is interposed between the terminals and has electrodes formed on both sides thereof. The electrodes are separated from the terminals by a predetermined distance and electrically connected to the terminals through a second conductive material.

Owner:SAMSUNG ELECTRO MECHANICS CO LTD

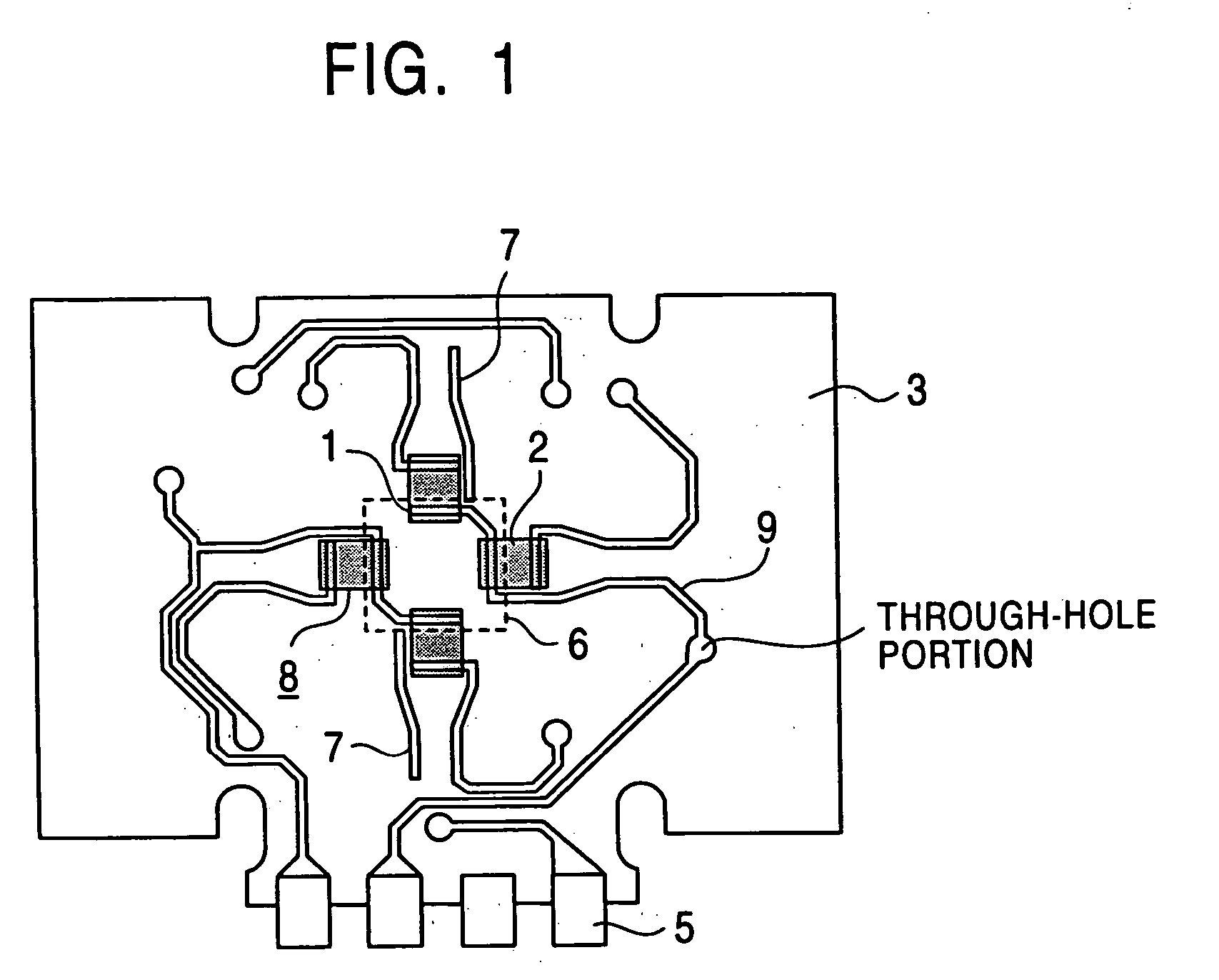

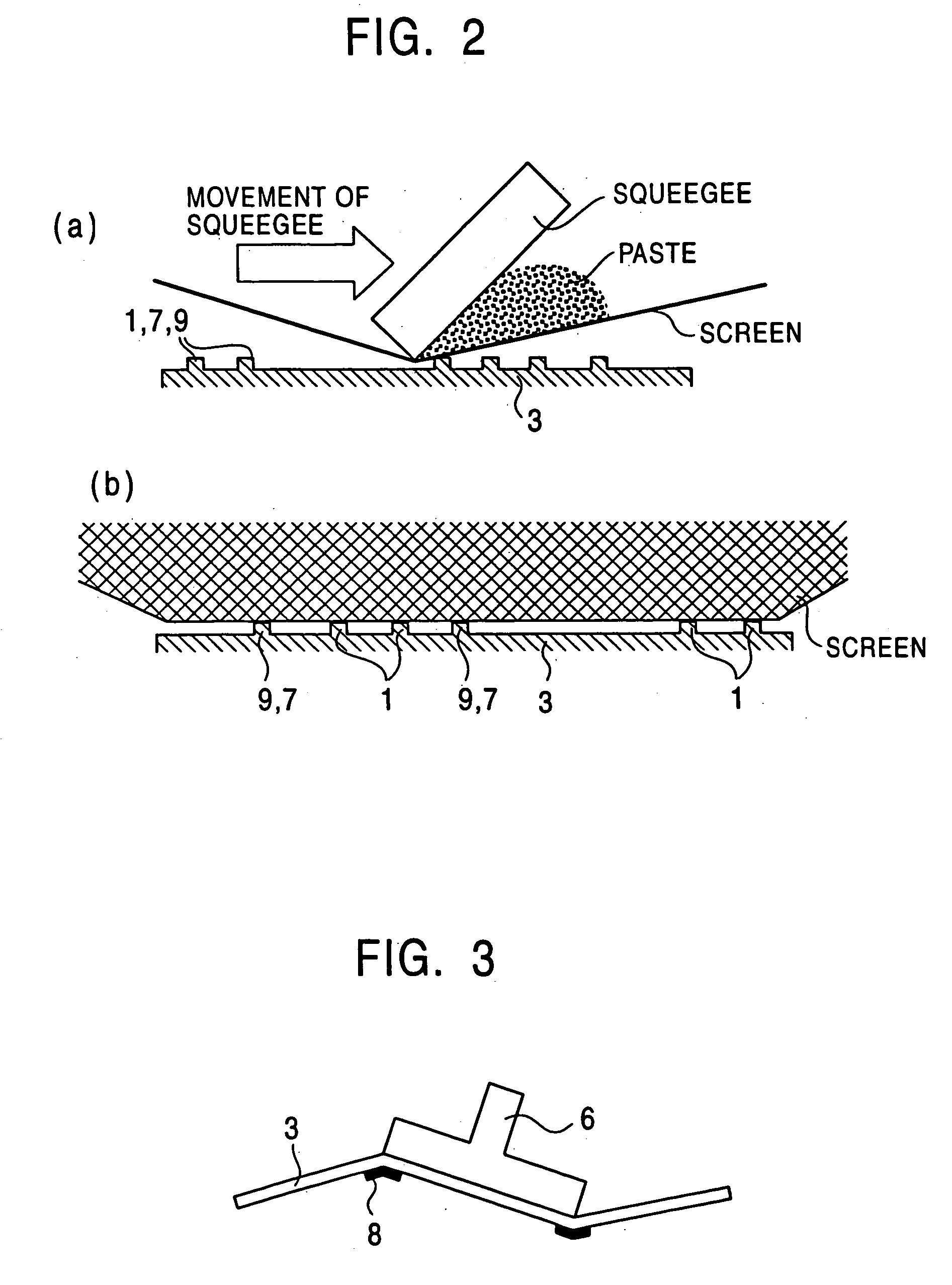

Resistor element, stress sensor, and method for manufacturing them

InactiveUS20060218779A1Easily and elastically changedPrinted circuit aspectsForce measurementElectrical resistance and conductanceScreen printing

A stress sensor in which the direction and magnitude of a stress being applied to a post bonded to or integrated with an insulating board can be grasped from variation in the resistance of resistor elements being stimulated by application of the stress while suppressing variation in the shape of each resistor. The resistor element comprises a resistor formed, by screen print, between a pair of electrodes for the resistor element, i.e. circuit pattern electrodes, arranged on the surface of the insulating board. The electrode is connected, through a conductor, with a board terminal part arranged at one end of the insulating board. The electrode and the conductor or a print accuracy adjusting member have a constant height from the surface of the insulating board. Arrangement of the conductor, electrode and print accuracy adjusting member is entirely identical or similar for the resistor elements in the vicinity thereof.

Owner:ELAN MICROELECTRONICS CORPORATION

Electrothermal film and manufacturing method thereof

ActiveCN101668359ASimple processEfficient processHeating element materialsResistors adapted for applying terminalsTitanium chlorideMetallurgy

The invention relates to an electrothermal film and a manufacturing method thereof, belonging to the technical field of semiconductor heating. The electrothermal film is mainly prepared by adopting stannic chloride, titanium tetrachloride, stannic chloride, titanium trichloride, ferric chloride, antimony trichloride, calcium chloride, potassium chloride, cadmium chloride, stannic dioxide, stannictetroxide, hydrofluoric acid, boric acid, ethanol, isopropyl alcohol and inorganic water. By adopting the above formula, the mixture is mixed, stirred and heated to prepare into electrothermal film treating fluid, a semi-finished product of the electrothermal film is obtained by spraying the electrothermal film treating fluid at negative pressure on the electrothermal film carrier, and then silveroxide slurry is coated on the semi-finished product of the electrothermal film for baking to form a finished product of the electrothermal film. The electrothermal film has reasonable proportion andsimple manufacturing process, can be manufactured into various electrothermal film heating devices, has a working temperature capable of being up to 500 DEG C, and has wider application range. The electrothermal film of the invention also has the function of far infrared radiation, can play a role of physical therapy and health care to human body, and can help improve the quality and output of agricultural products.

Owner:GUANGDONG HALLSMART INTELLIGENCE TECH CORP LTD

Precursor compositions and methods for the deposition of passive electrical components on a substrate

InactiveUS7524528B2Conductive materialSemiconductor/solid-state device manufacturingElectronic componentViscosity

Precursor compositions for the deposition of electronic features such as resistors and dielectric components and methods for the deposition of the precursor compositions. The precursor compositions have a low viscosity, such as not greater than about 1000 centipoise and can be deposited using a direct-write tool. The precursors also have a low conversion temperature, enabling the formation of electronic features on a wide variety of substrates, including low temperature substrates.

Owner:CABOT CORP

Method to embed thick film components

InactiveUS6860000B2Printed circuit assemblingInsulating substrate metal adhesion improvementEngineeringMetallic substrate

The invention is directed to a method to embed a thick film resistor composition into a printed wiring board comprising the steps of applying a reinforcing composition onto a resistor composition disposed on a metallic substrate forming an assembly wherein the resistor composition is at least partially coated with the reinforcing composition; processing the assembly; and applying the assembly onto at least one side of an organic substrate forming a component wherein the organic substrate is at least partially coated with an adhesive layer and wherein the reinforcing composition side of the assembly is embedded into the adhesive layer. The reinforcing composition allows laser trimming of the fired resistor and also eliminates cracking during lamination steps of the invention.

Owner:CHEMTRON RES

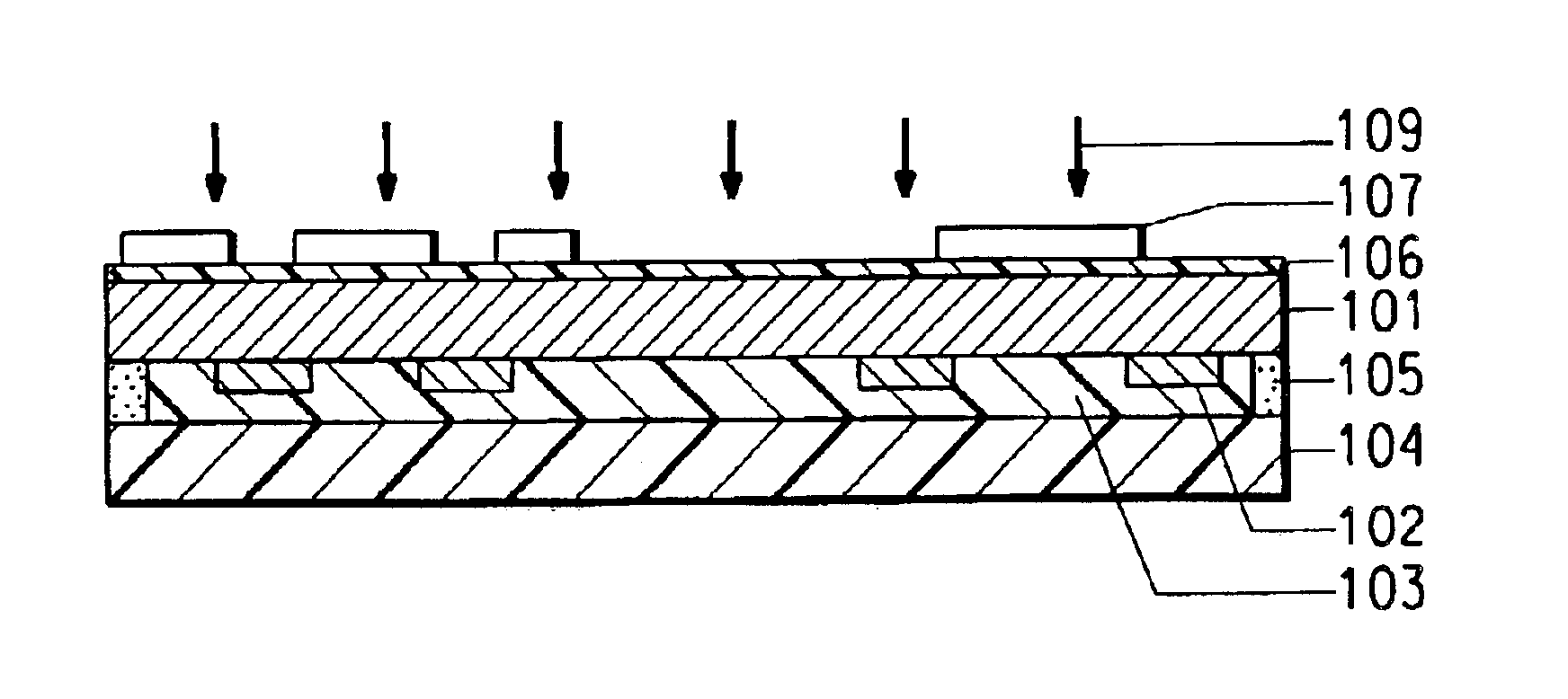

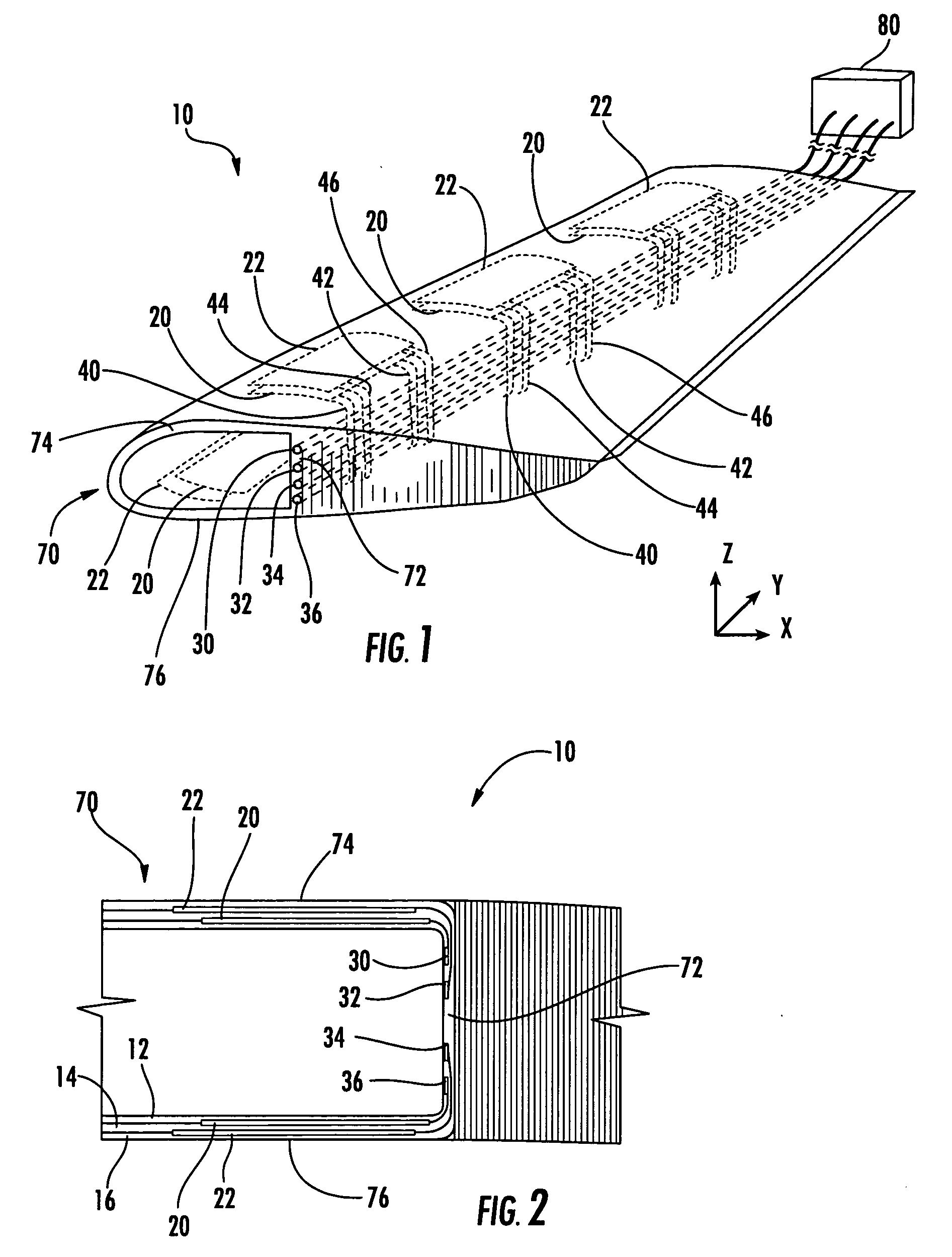

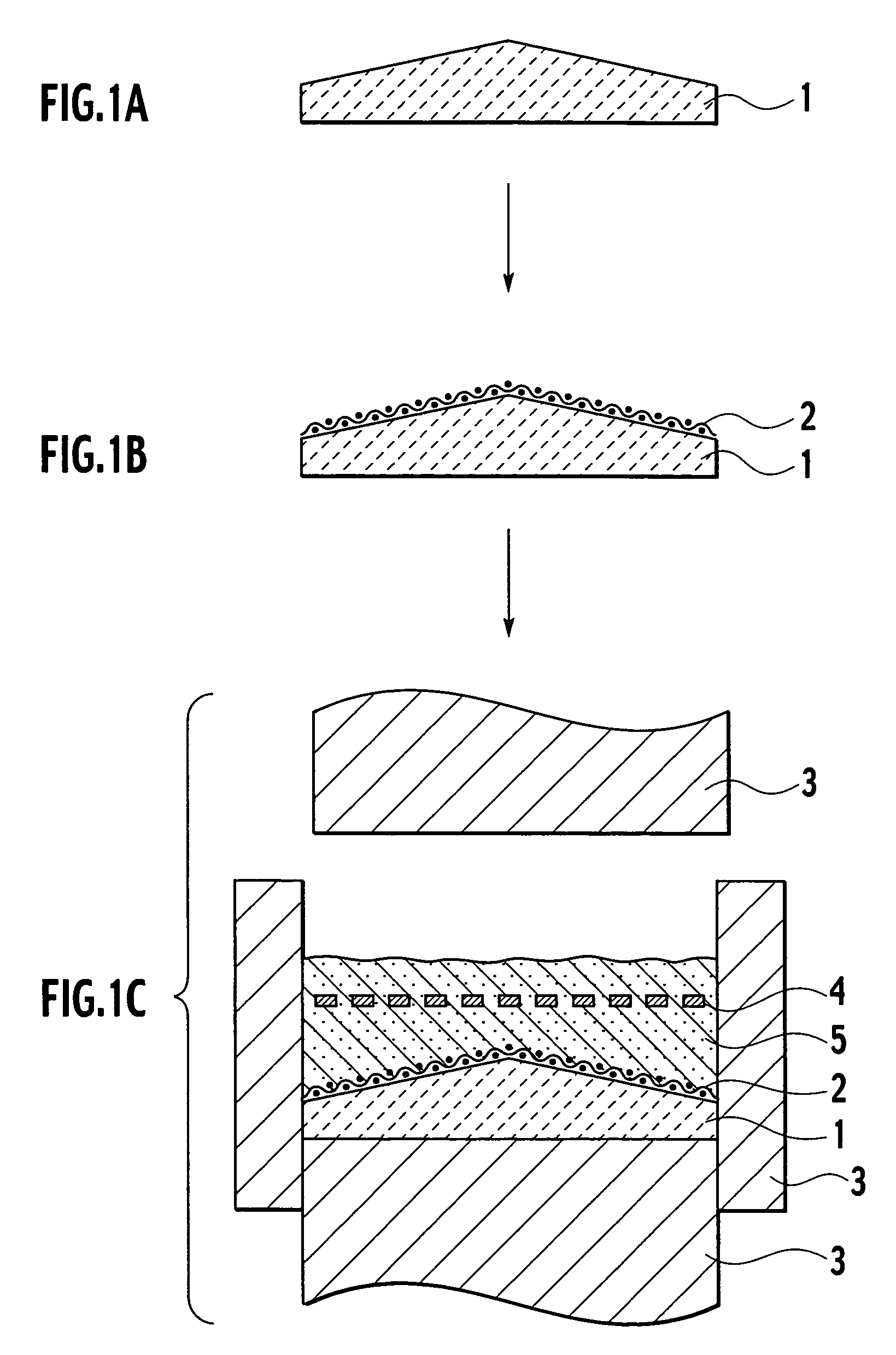

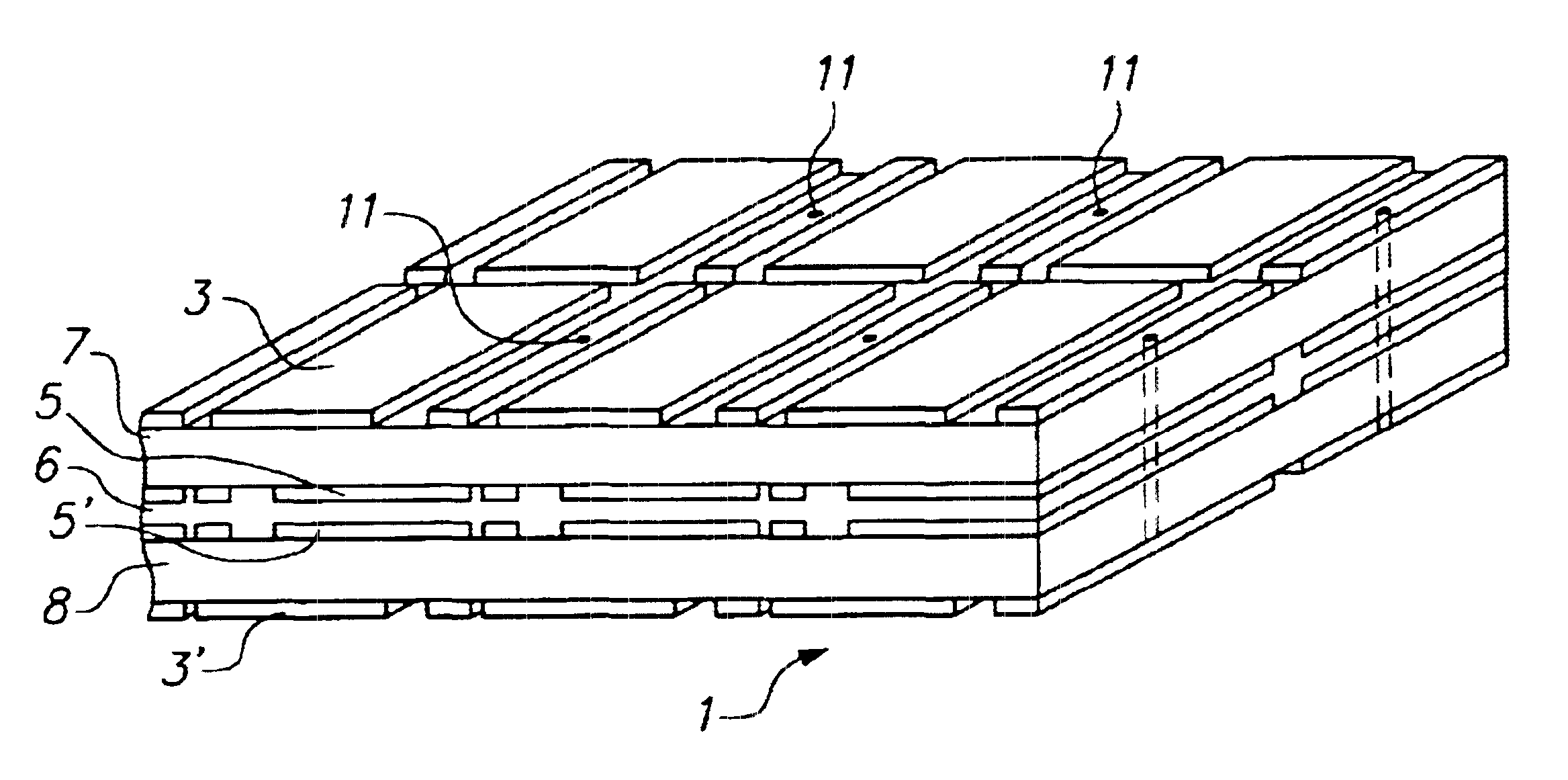

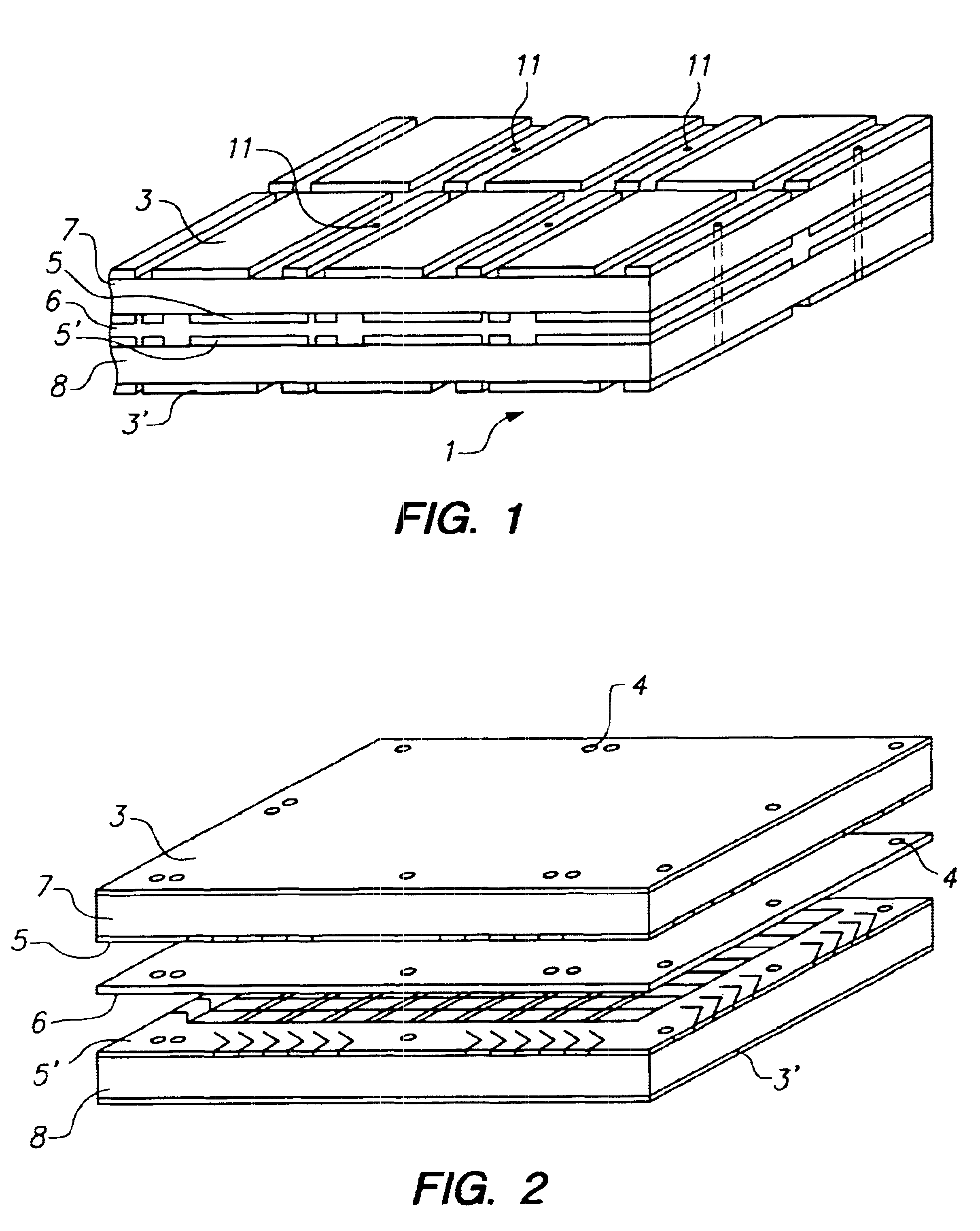

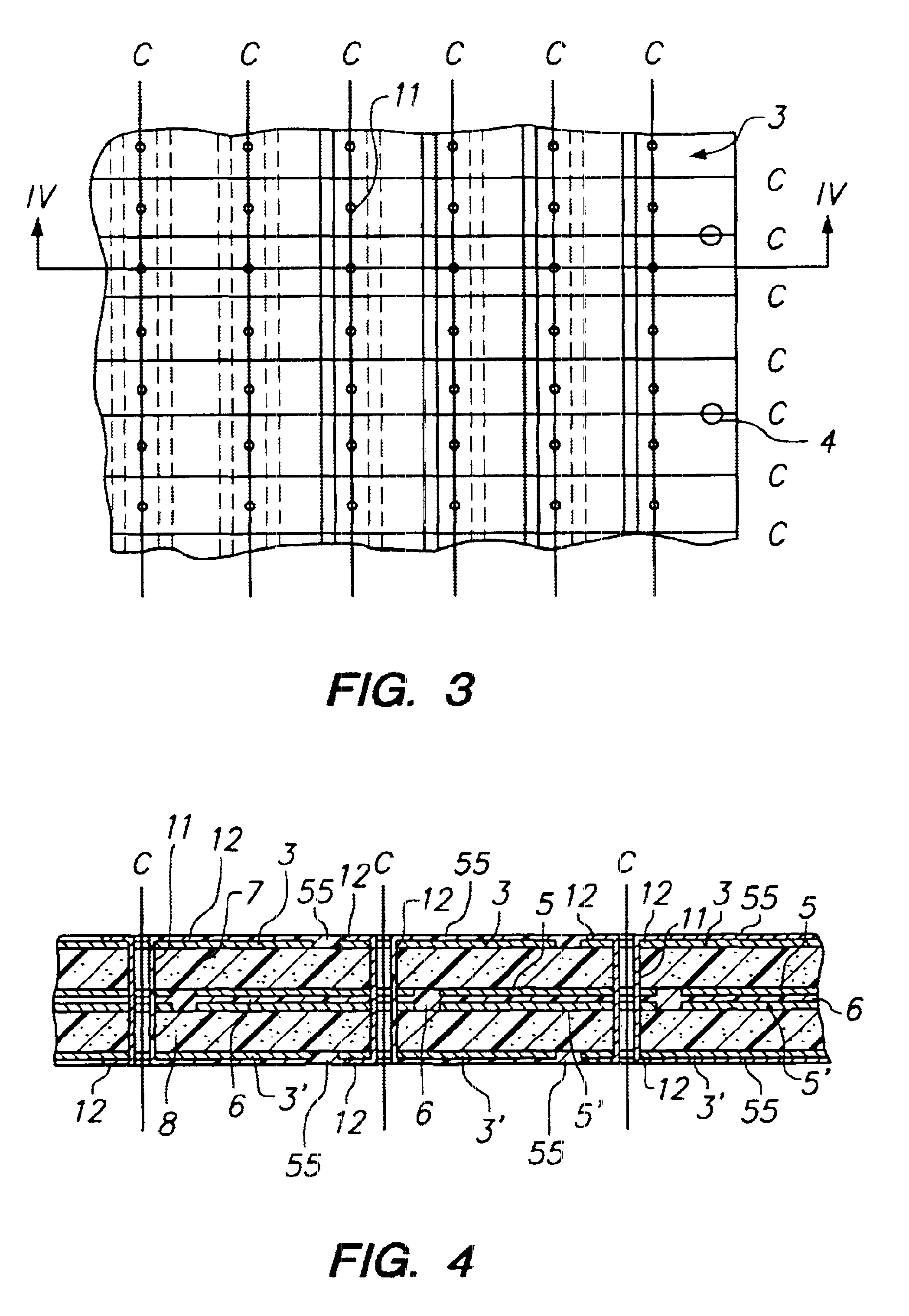

Structurally integrated circuit and associated method

ActiveUS20050257956A1Envelope/housing resistor manufactureLaminating printed circuit boardsElectrical devicesIntegrated circuit

A composite structural member with an integrated electrical circuit and an associated method of manufacture are provided. The structural member includes a plurality of layers of structural reinforcement material, and two or more electrical devices are disposed at least partially between the layers with an intermediate layer of the structural reinforcement material disposed between the electrical devices. At least one electrical bus is disposed in the structural member, and each electrical device is connected to the bus by a conductive electrode. Thus, the electrodes can extend through the intermediate layer of the structural reinforcement material to connect each of the electrical devices to one or more of the buses.

Owner:THE BOEING CO

Production method of high-power precision alloy SMD (surface mount device) resistor

InactiveCN104051099AImprove cooling effectHigh precisionResistors adapted for applying terminalsAlloyThermal transmittance

The invention provides a production method of a high-power precision alloy SMD (surface mount device) resistor. The production method comprises the steps: respectively combining two oxygen-free copper strips with two sides of a resistor alloy strip to form an integrated strip-shaped resistor strip, and wrapping a high-heat-conductivity substrate with the integrated strip-shaped resistor strip; etching a basic resistor structure on a wrapping body; precisely adjusting the resistance value of the basic resistance structure; coating, terminal electroplating and printing a resistor body to form a high-power precision alloy SMD resistor. The material with high heat radiation capability and high heat conductivity such as a metal substrate, a high-heat-conductivity ceramic substrate is used as the substrate, so that the actual load capacity of the resistor is greatly increased; the oxygen-free copper strip is partially arranged on the side surface and below the substrate and used as an electrode lead, so that the contact area is increased, and the heat conductivity of the resistor body is also increased on the other hand.

Owner:SHENZHEN YEZHAN ELECTRONICS

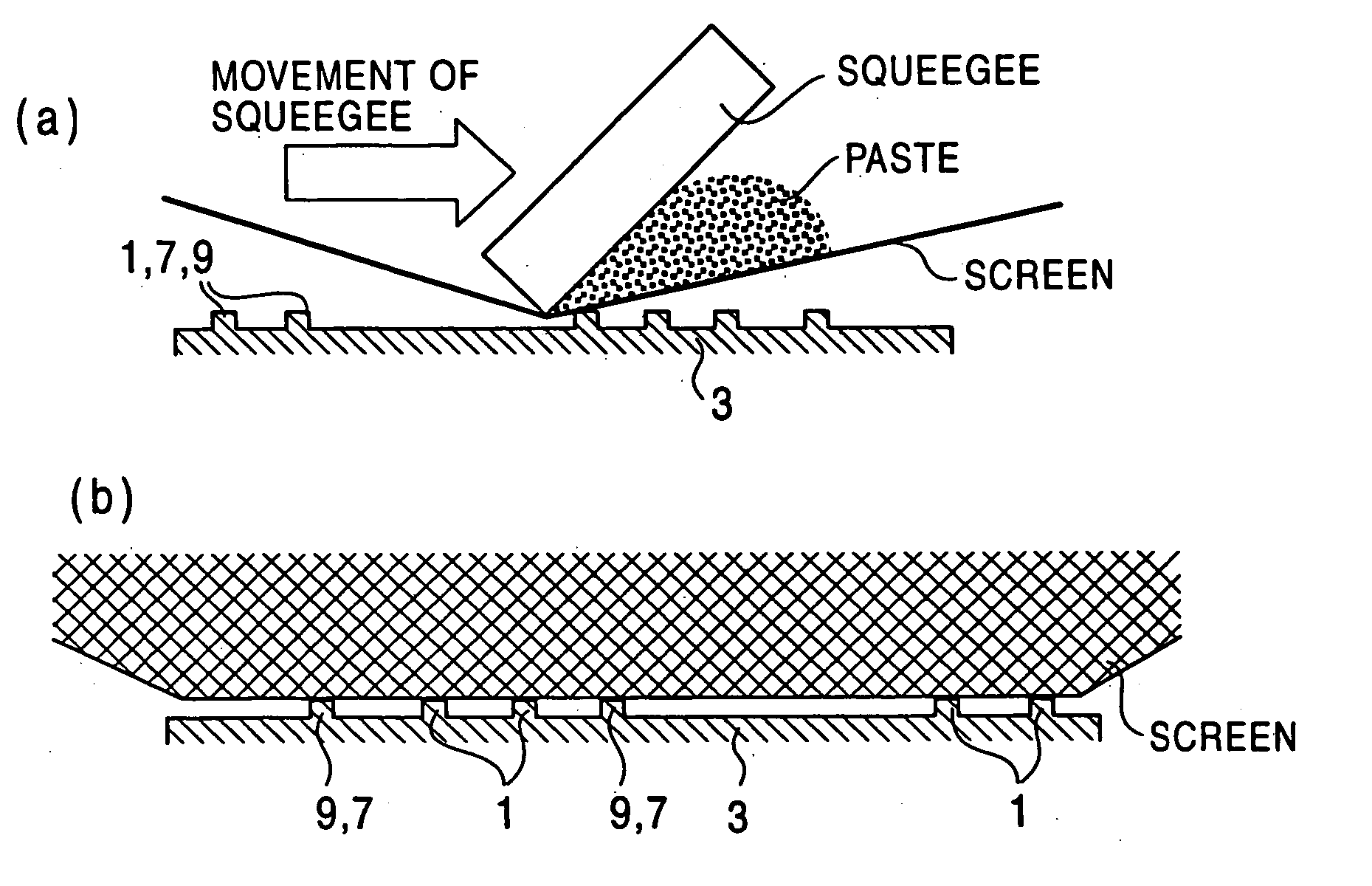

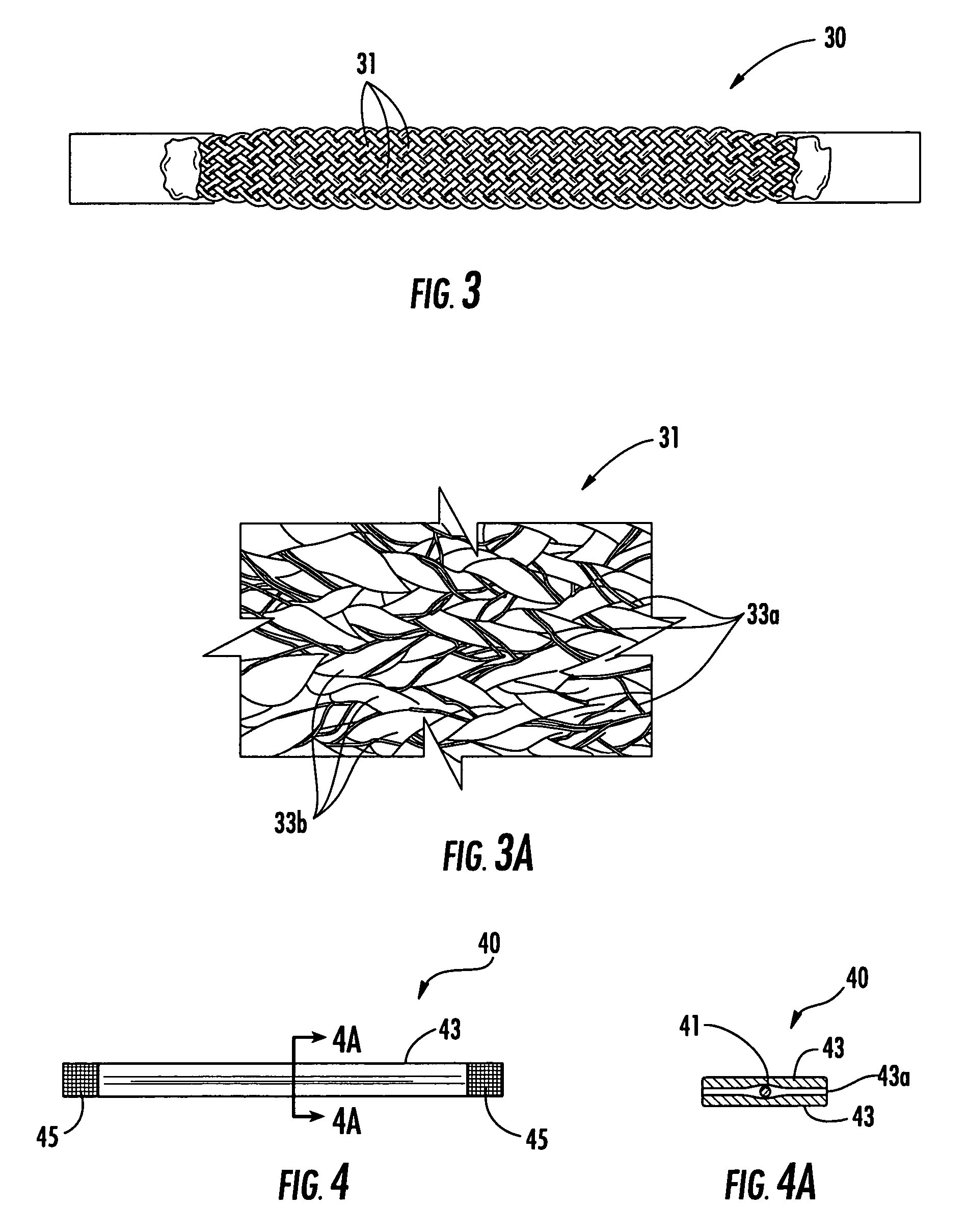

Method for manufacturing long force sensors using screen printing technology

InactiveUS7984544B2Avoid bubblingAvoid separationPrinted circuit assemblingManufacture of electrical instrumentsScreen printingElectrical conductor

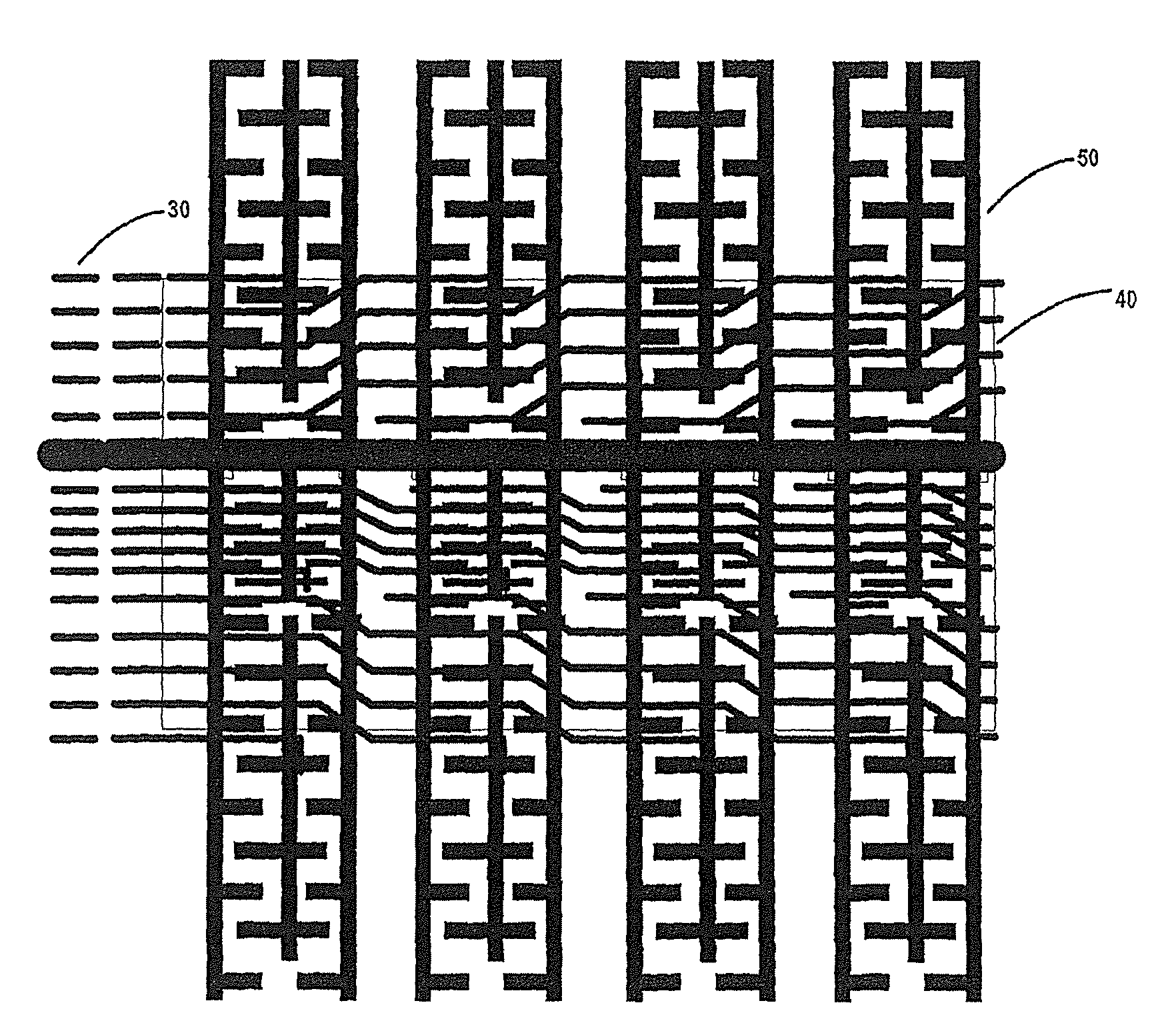

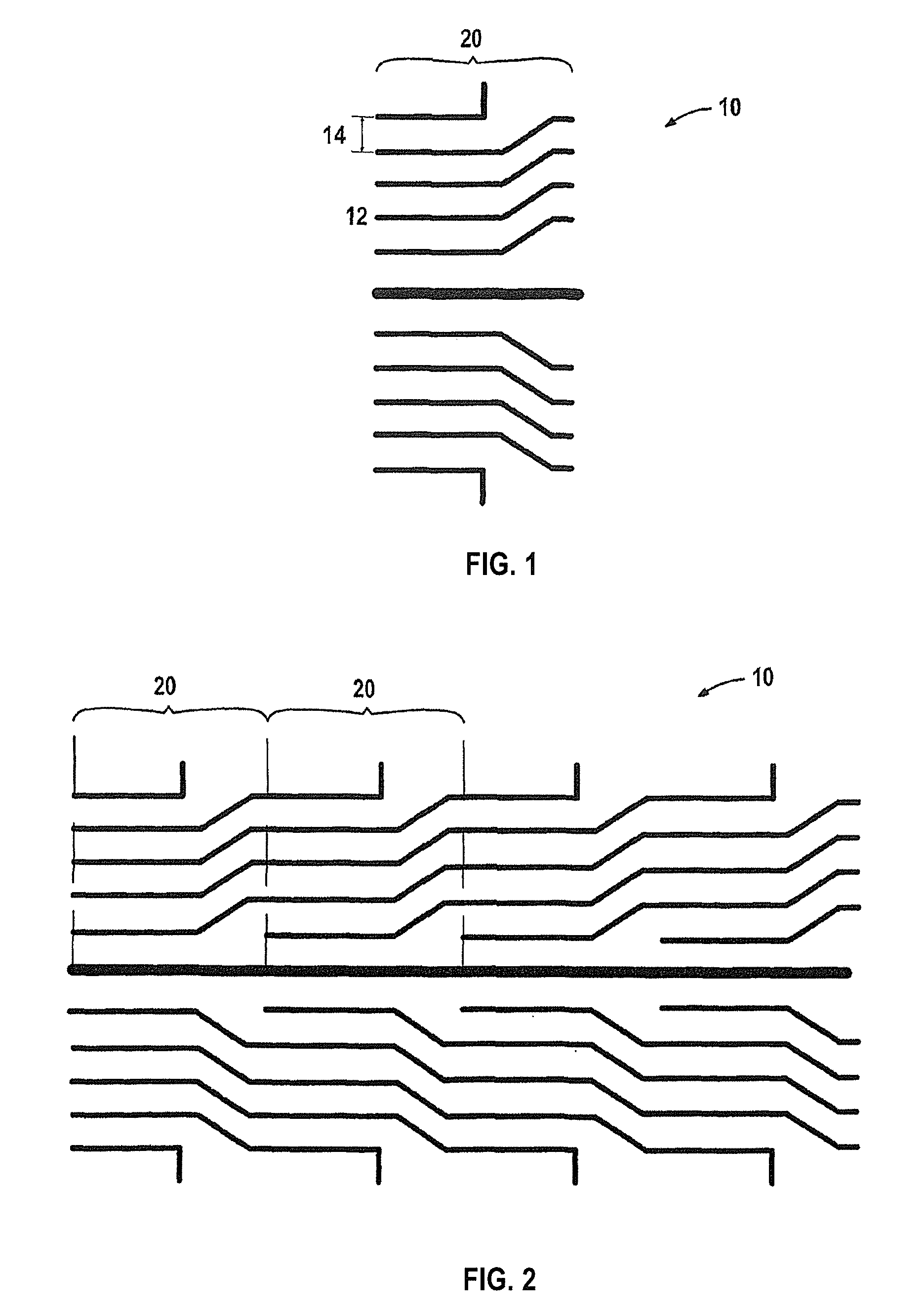

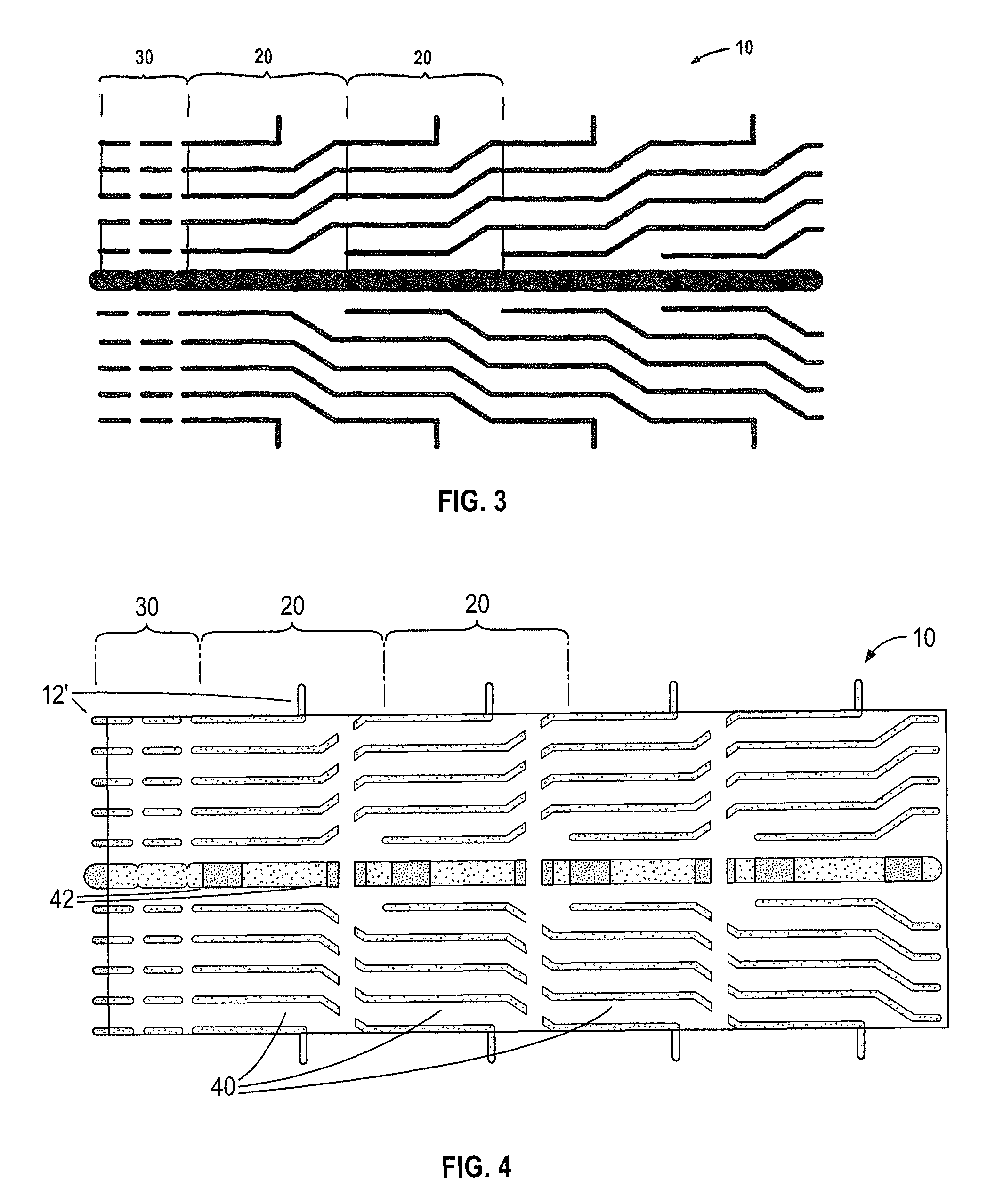

A force or pressure sensor and appertaining method for manufacturing are provided in which the sensor comprises a repeating conductive trace pattern that can be replicated to produce a consistent conductive trace across more than one adjacent pattern section forming an electrical bus, wherein more than one section of a series of conductive traces are printed on a thin and flexible dielectric backing using the pattern. The thin and flexible dielectric backing has a repeated pattern of conductive traces printed above the dielectric backing and one or more dielectric layers provided above the conductive traces, the dielectric layers having access regions permitting contact of conductors above the one or more dielectric layers, and a sensor conductor layer printed above the one or more dielectric layers that contacts the conductive traces via at least one of the access regions or regions not covered by the one or more dielectric layers.

Owner:ROSENBERG ILYA D +2

Method of fabricating a printed circuit board including an embedded passive component

InactiveUS7350296B2Accurately and easily achievedPrinted circuit assemblingFinal product manufactureConductive materialsPrinted circuit board

Disclosed is a method of fabricating a PCB including an embedded passive component and a method of fabricating the same and a method of fabricating the same. The PCB includes at least two circuit layers in which circuit patterns are formed. At least one insulating layer is interposed between the circuit layers. A pair of terminals is vertically formed through the insulating layers, plated with a first conductive material, and separated from each other by a predetermined distance. The embedded passive component is interposed between the terminals and has electrodes formed on both sides thereof. The electrodes are separated from the terminals by a predetermined distance and electrically connected to the terminals through a second conductive material.

Owner:SAMSUNG ELECTRO MECHANICS CO LTD

Chip resistor

InactiveUS6943662B2Resistor chip manufactureResistor terminals/electrodesFilm resistanceChemical reaction

Resistance or side electrodes of a chip resistor is prevented from being lost due to chemical reaction with NaCl contained in human sweat and so on when human sweat, seawater, etc. are adhered thereto. The chip resistor comprises an insulating substrate, thick-film upper surface electrodes formed at opposite ends of the top surface of the insulating substrate, a thin-film resistance made of a constituent material not reacting with NaCl, and formed so as to be extended over the upper surface of the insulating substrate and respective portions of the upper surface of the thick-film upper surface electrodes, thick-film back surface electrodes formed at spots on the back surface of the insulating substrate, corresponding to the thick-film upper surface electrodes, respectively, and thick-film side surface electrodes connecting the thick-film back surface electrodes with respective portions of the thick-film upper surface electrodes, exposed out of the thin-film resistance, respectively.

Owner:ROHM CO LTD

Method and apparatus for manufacturing thin film heaters

A method and apparatus for manufacturing thin film heaters. According to one embodiment of the present invention, the method and apparatus includes an automated process for applying at least one conductor to a conductive substrate, where the conductor and the conductive substrate are in electrical communication. In alternate embodiments, a flexographic printing process is used to overlay two similar layers of ink on a carbon impregnated substrate and cure the ink to form at least one electrode conductor.

Owner:TOTAL ELECTRONICS

Method of producing printed circuit board with embedded resistor

InactiveUS20050175385A1Improve workabilityResistance value change remains constantSemiconductor/solid-state device detailsSolid-state devicesProduction rateScreen printing

Disclosed is a method of producing a printed circuit board (PCB) with an embedded resistor, in which a resistor with a desired shape and volume is precisely formed using a resistor paste so that resistance values according to a position of the PCB are uniform, thereby a laser trimming process is omitted or minimally utilized. The method has advantages in that a production time of the PCB is shortened and productivity is improved because an operation condition is rapidly set without being greatly affected by the position precision of a printing device. Other advantages of the method are that the resistor paste with a relatively uniform thickness is secured through a screen printing process, thereby easily forming the resistor and improving resistance tolerance.

Owner:SAMSUNG ELECTRO MECHANICS CO LTD

Methods for manufacturing resistors using a sacrificial layer

InactiveUS7165316B2Wave amplification devicesSemiconductor/solid-state device detailsResistorElectrical and Electronics engineering

An electrical resistor is made by providing a sacrificial layer and conductive pads disposed on a first surface of the sacrificial layer. An electrically resistive material is deposited over the pads and on the first surface of the sacrificial layer to form at least one unit including the resistive material and the pads. At least part of the sacrificial layer is then removed so as to expose one or more of the pads.

Owner:TESSERA INC

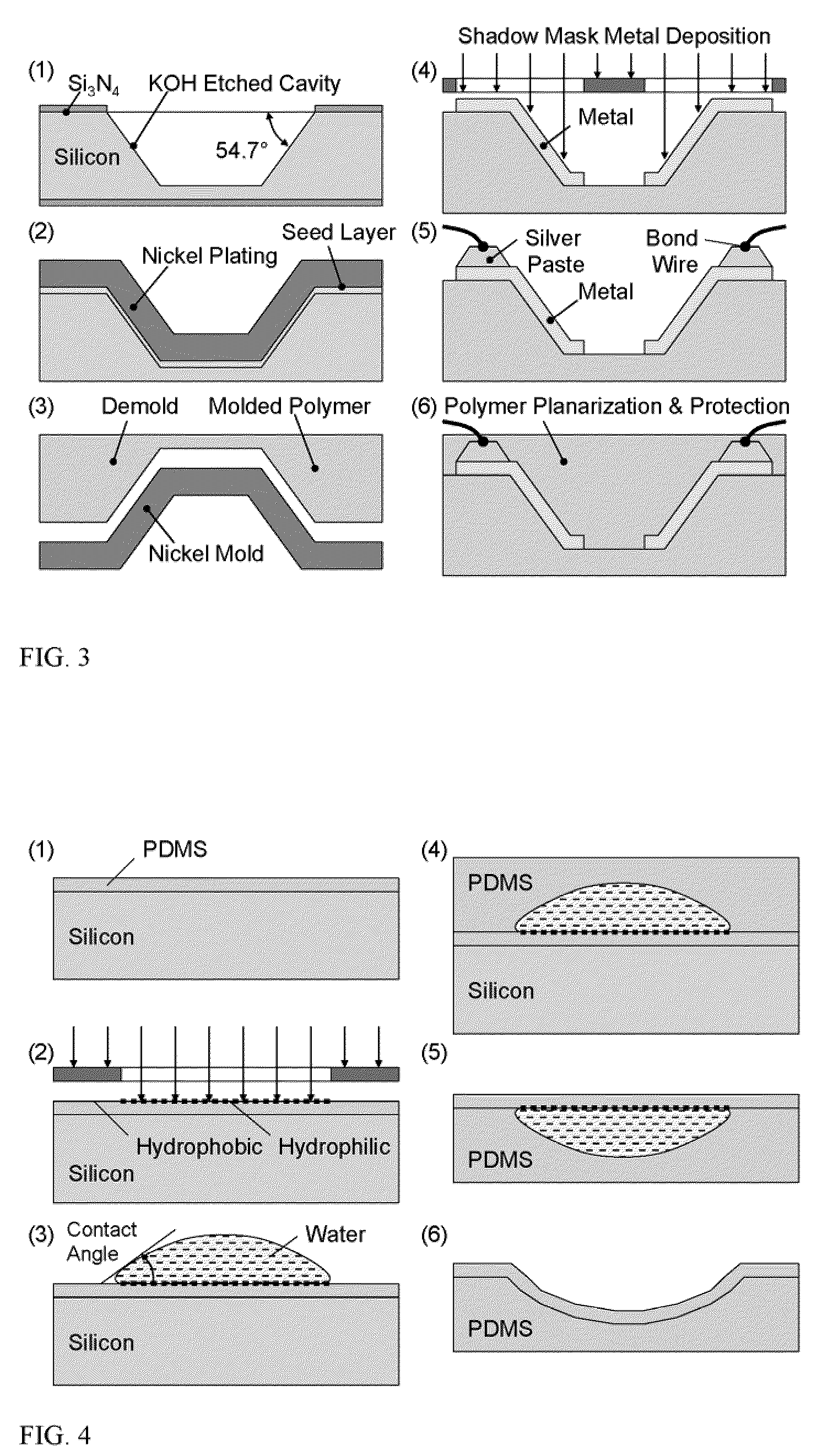

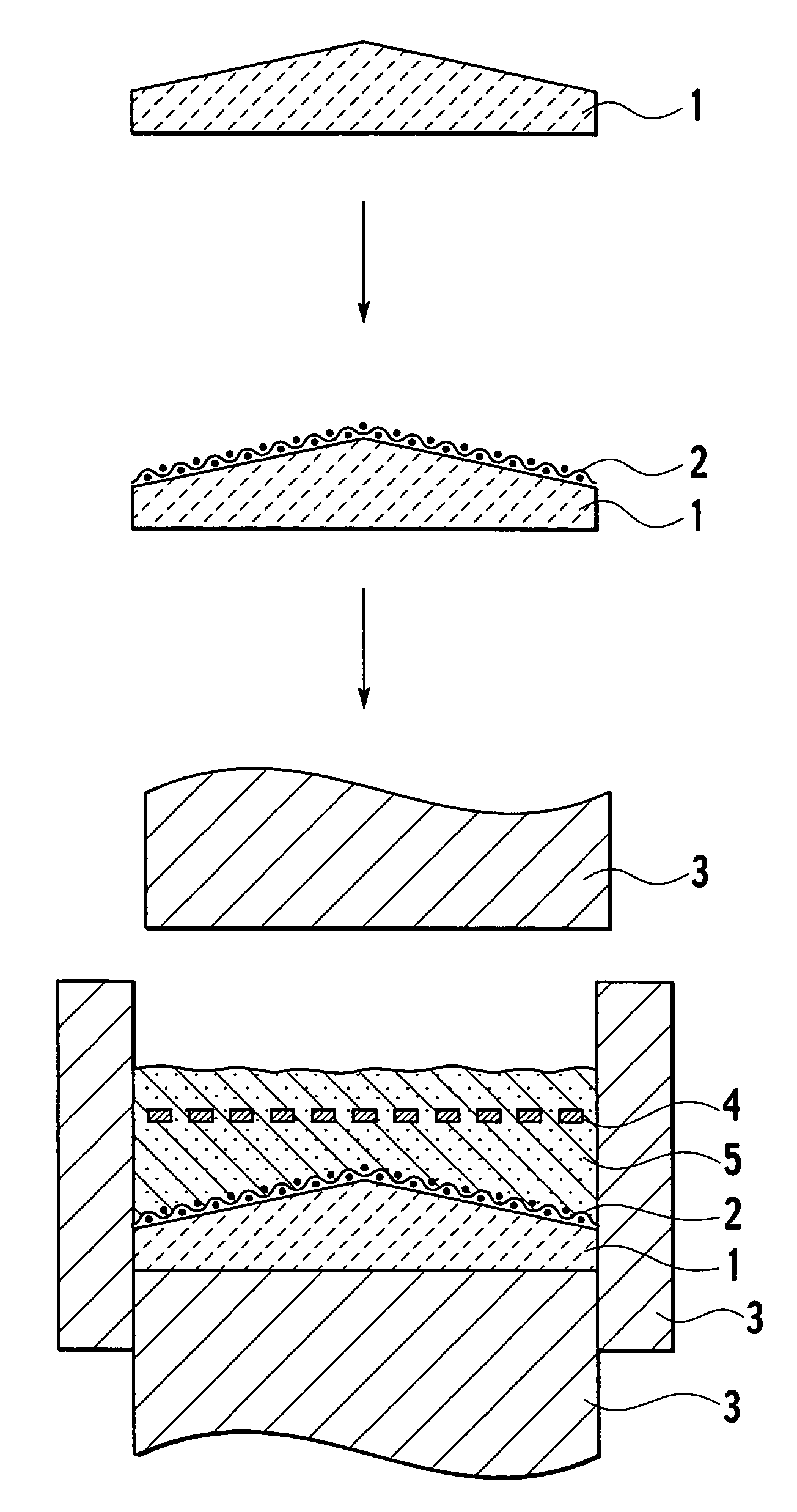

Flexible piezoresistive interfacial shear and normal force sensor and sensor array

ActiveUS20090282930A1Force measurement using piezo-resistive materialsDiagnostic recording/measuringSensor arrayContact pad

A force sensor includes a polymeric substrate including a cavity with a tilt plane, at least two metal piezoresistors on the tilt plane, and a contact pad connected to the metal piezoresistors. The tilt plane may include a measured interface of from 15° to 75°.

Owner:THE HONG KONG POLYTECHNIC UNIV

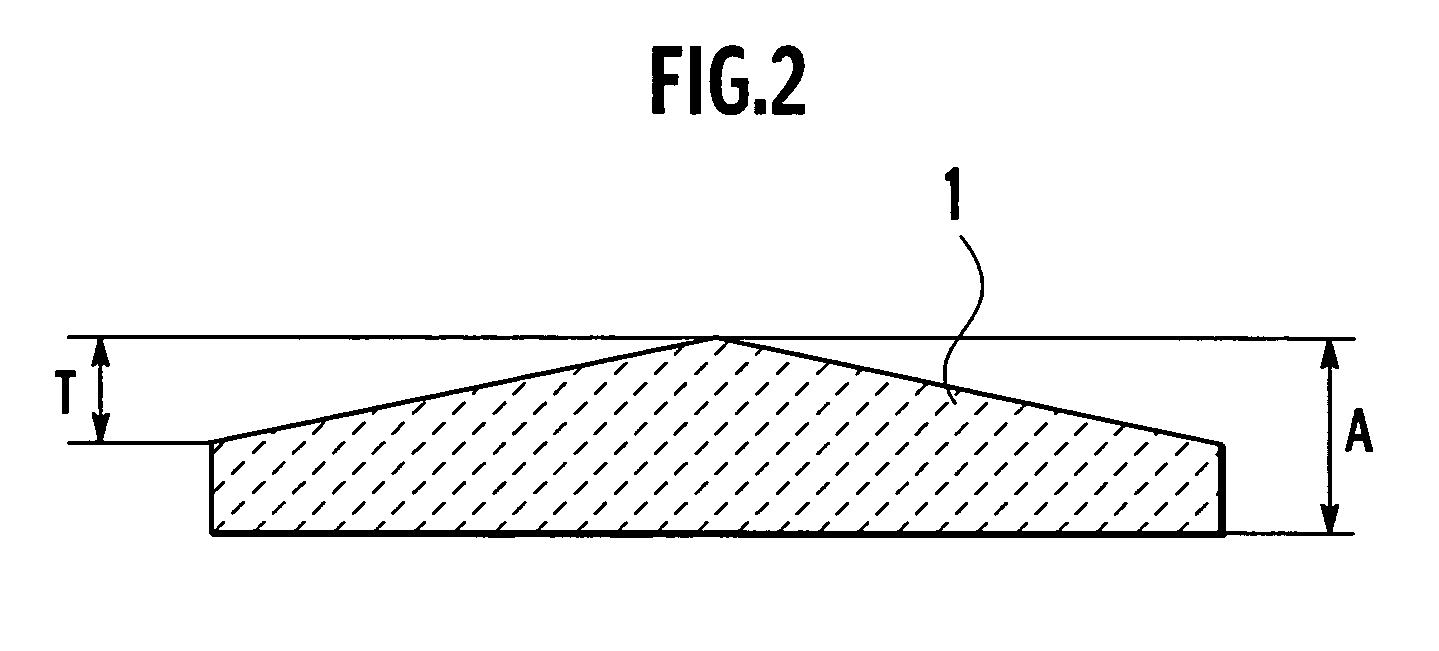

Method of manufacturing electrical resistance heating element

ActiveUS7275309B2Reducing range variationPrevent the sintered ceramicsEnvelope/housing resistor manufactureSemiconductor/solid-state device manufacturingMetalMelting point

A method of manufacturing an electrical-resistance heating element includes forming sintered ceramics or calcined ceramics, forming an electrode on the sintered ceramics or the calcined ceramics, and forming a ceramic base material having mainly a high melting point metal on the electrode embedded therein, thereby forming a heating element with built-in electrode.

Owner:NGK INSULATORS LTD

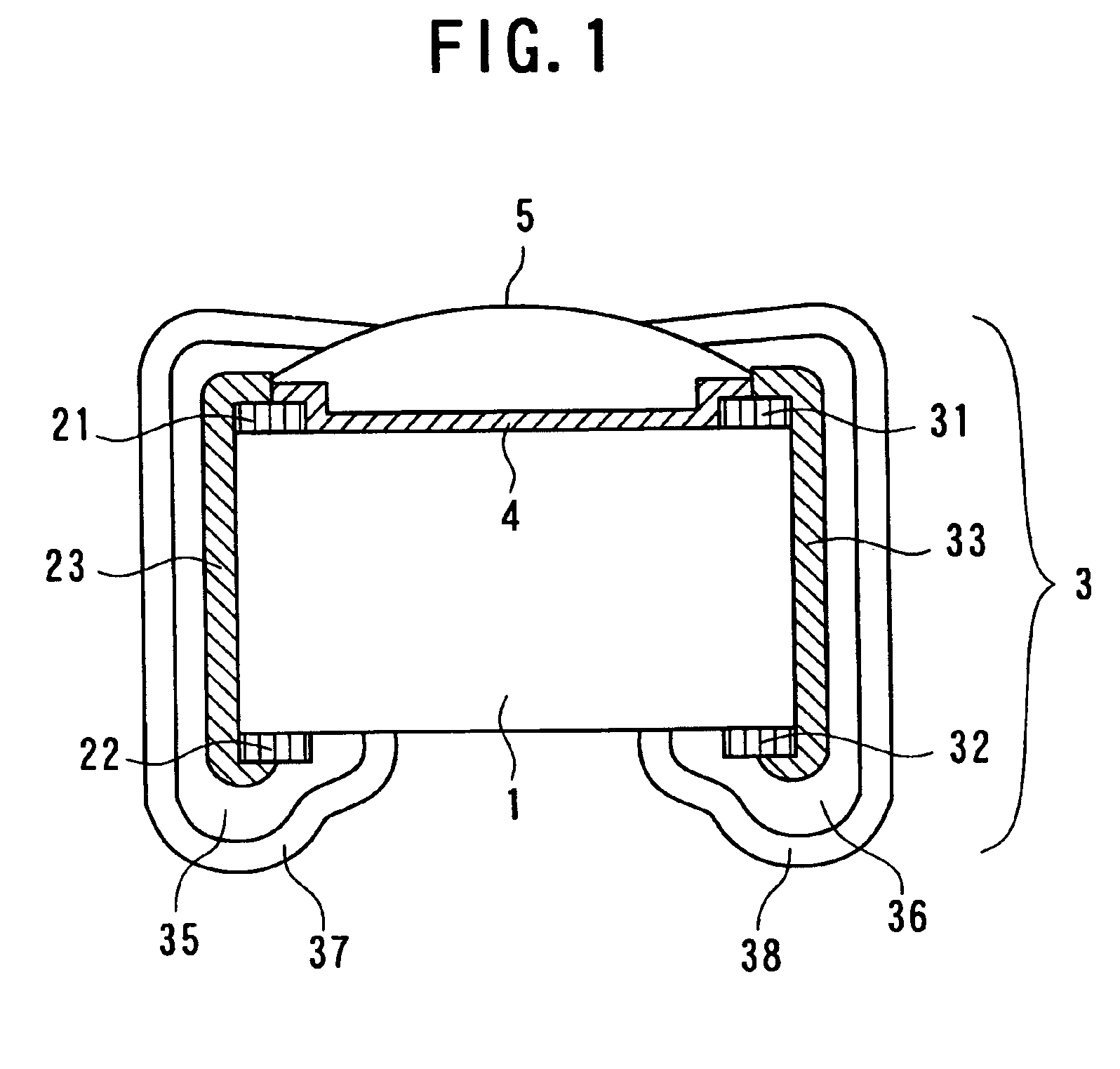

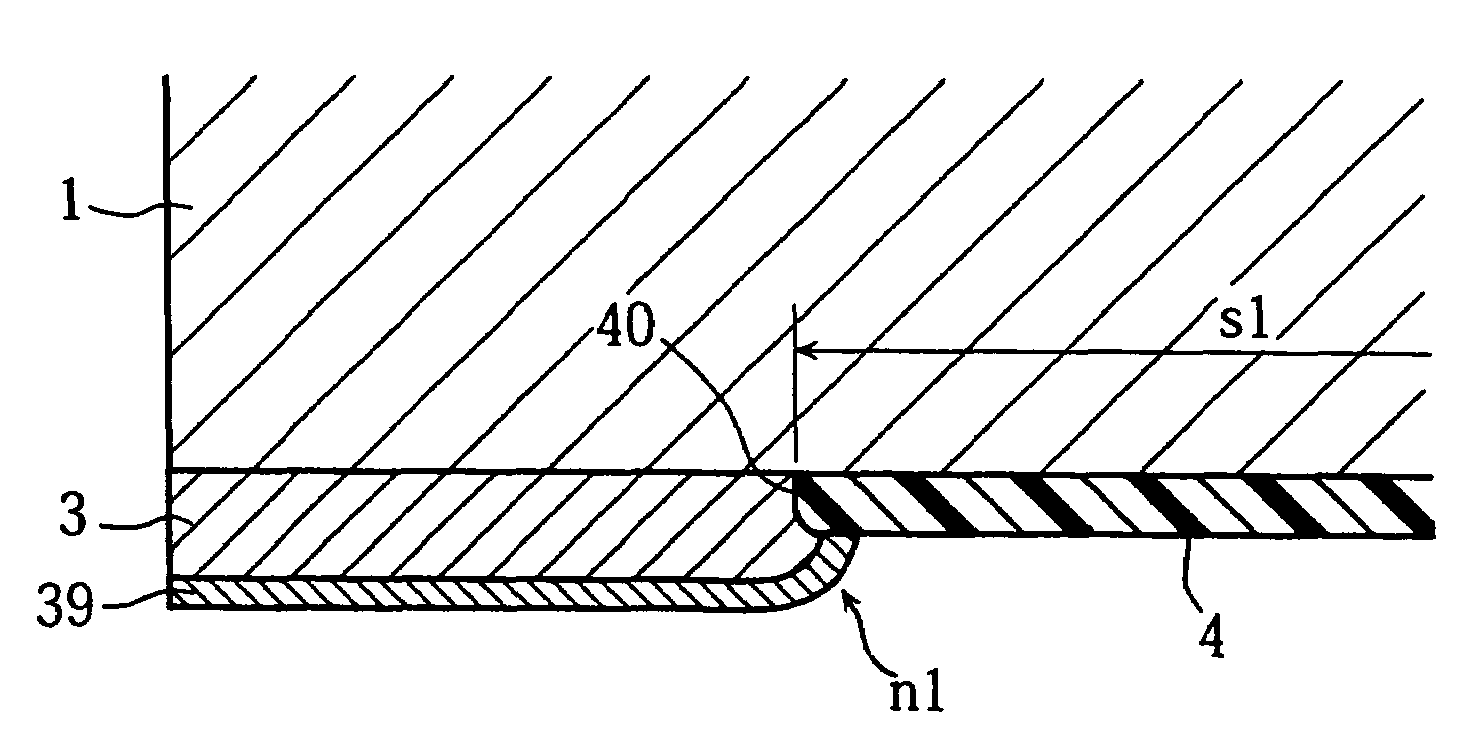

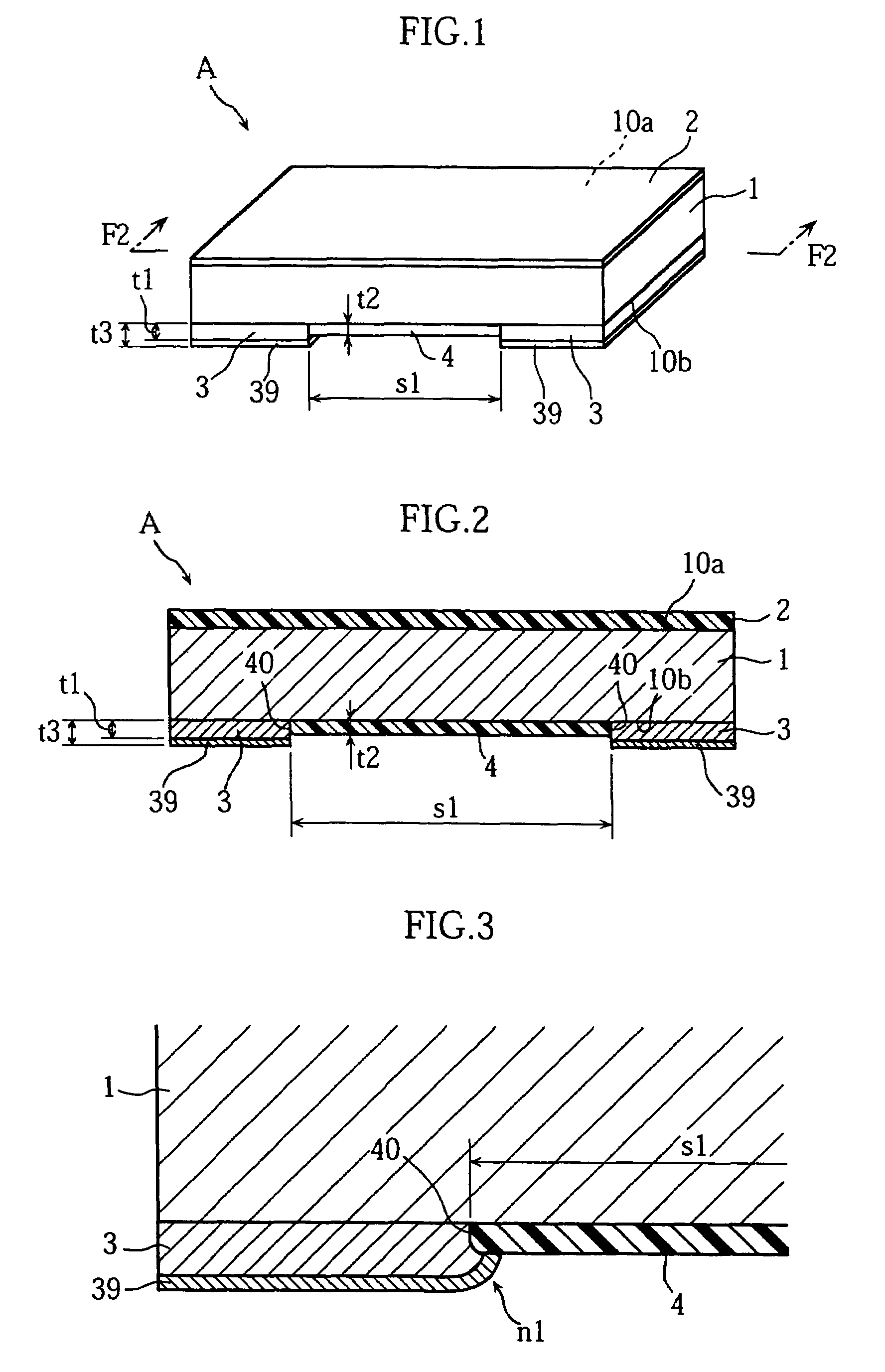

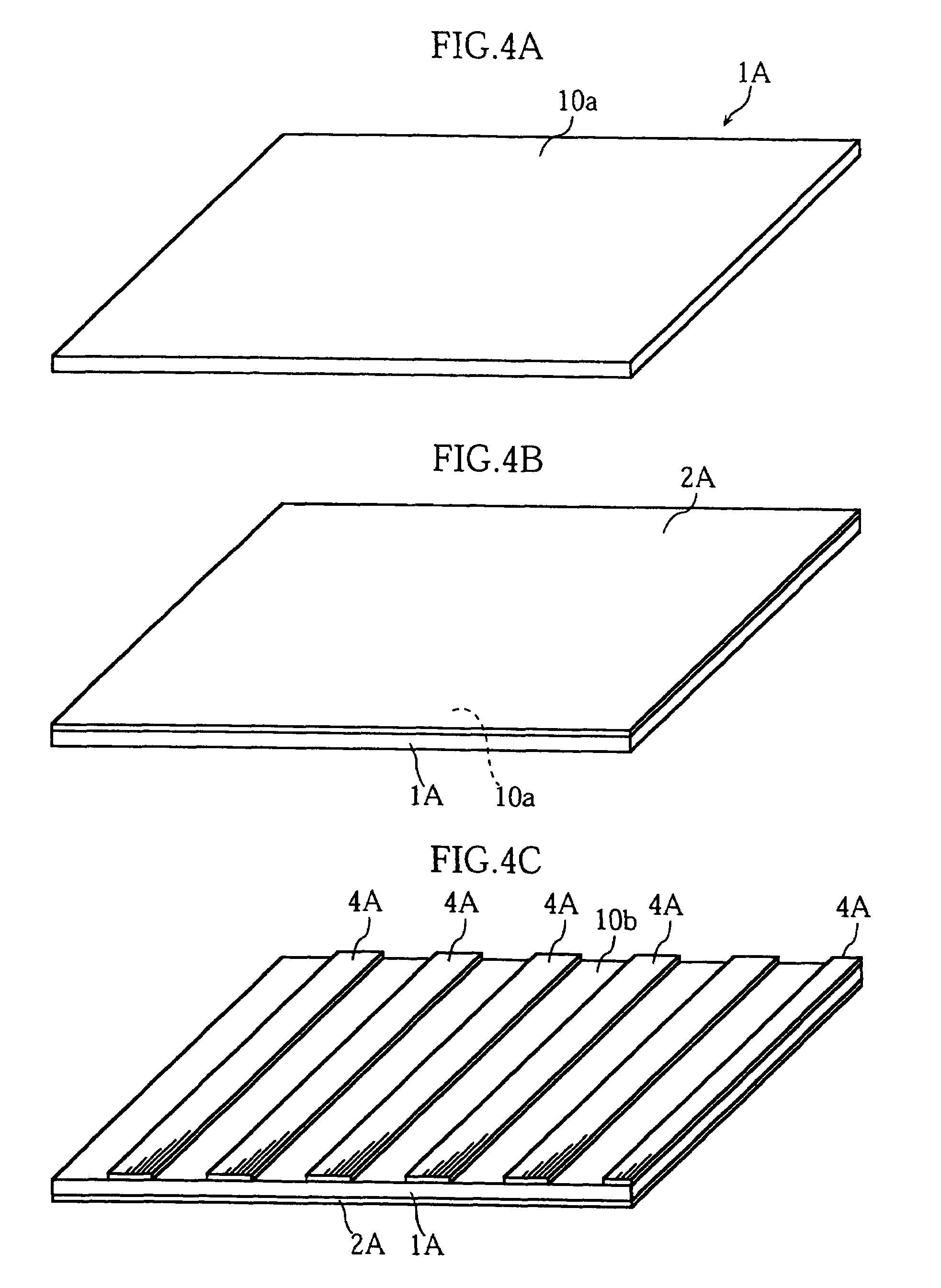

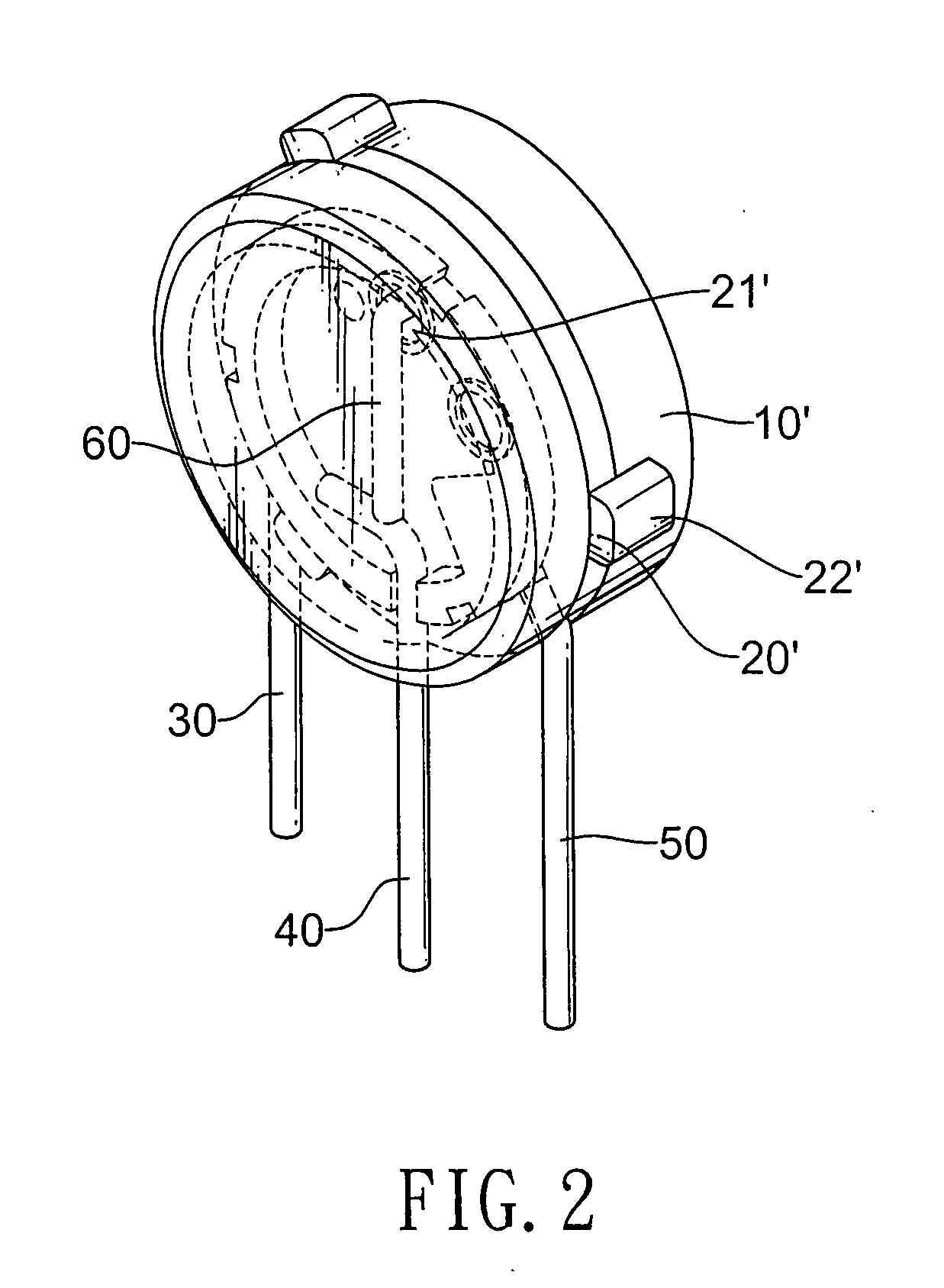

Force sensor

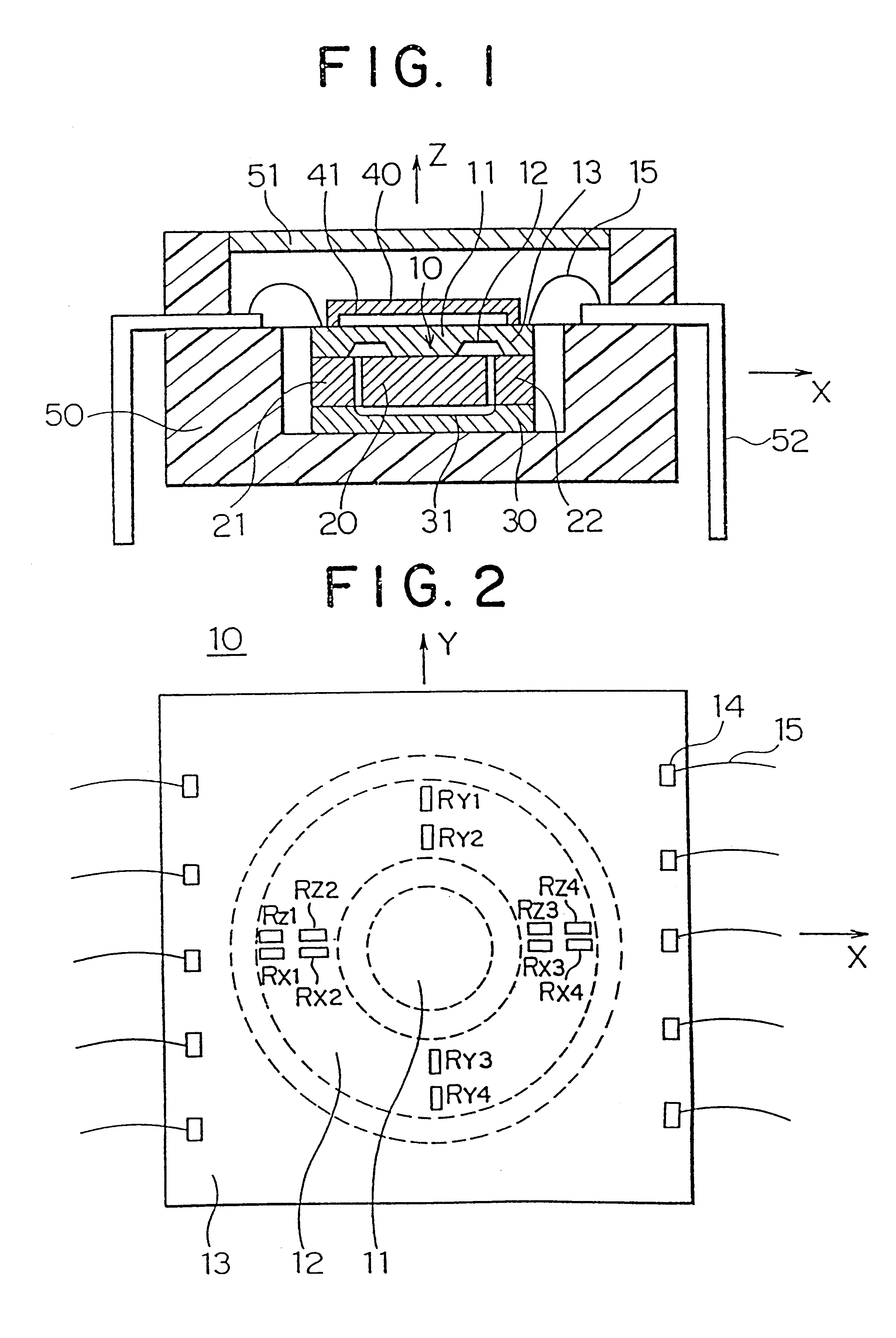

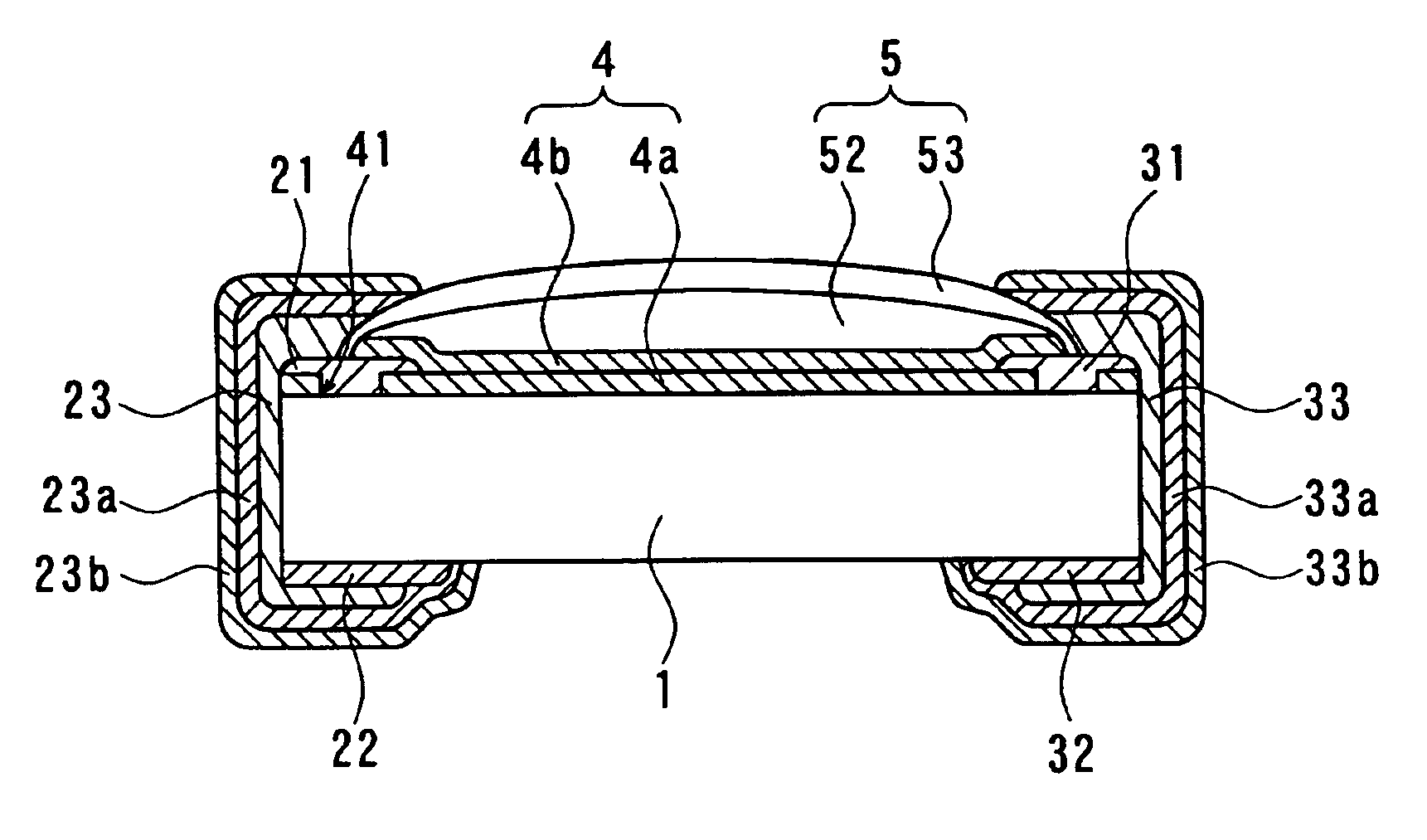

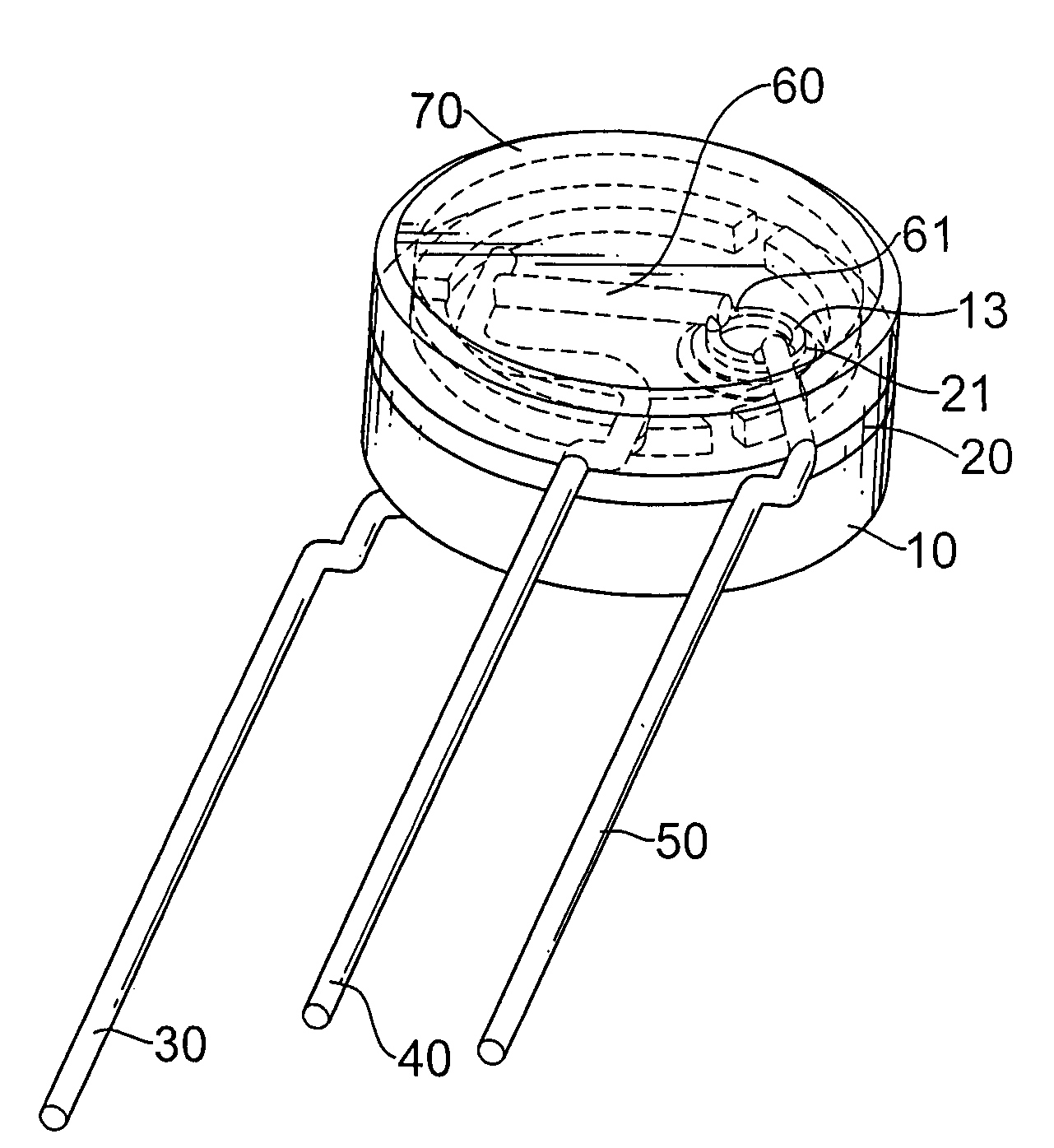

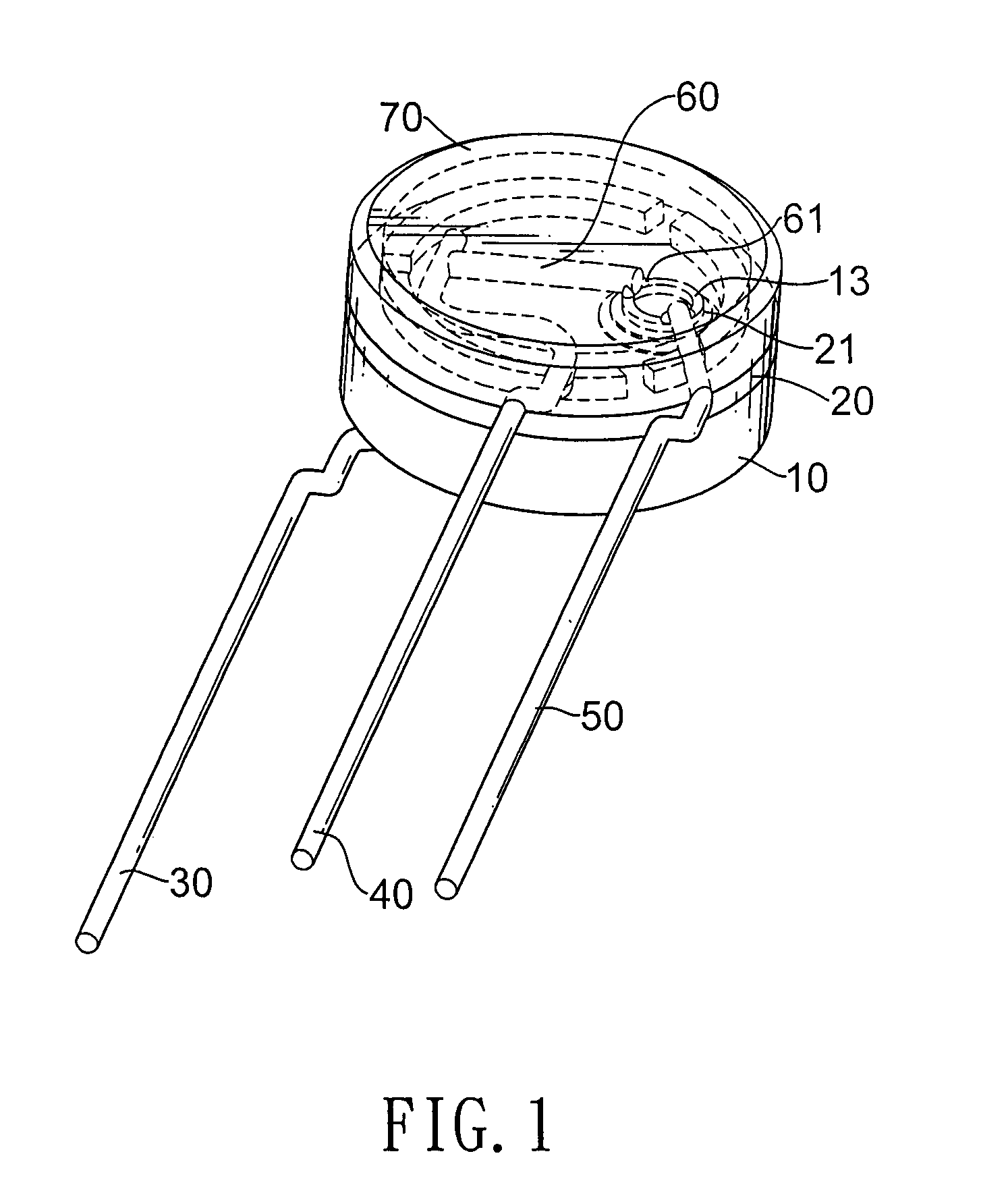

ActiveUS8113065B2Reduce the number of partsHelp positioningWave amplification devicesForce measurement using piezo-resistive materialsEngineeringForce sensor

A force sensor 1 includes: a force sensor chip 2 including an action portion 21, a connecting portion 23 on which strain resistive elements are disposed, and a support portion 22 for supporting the action portion 21 and the connecting portion 23; an attenuator 3 including an input portion 30 to which an external force is input, a fixing portion 32 for fixing the force sensor chip 2, and a transmission portion 31 for attenuating the external force and transmitting the attenuated external force to the action portion 21; a first glass member 11 disposed between the action portion 21 and the transmission portion 31 and a second glass member 12 disposed between the support portion 22 and the fixing portion 32, through which glass members 11, 12 the force sensor chip 2 and the attenuator 3 are joined. A single or more glass beams 13 joins the first glass member 11 and the second glass member 12 together as a single member.

Owner:HONDA MOTOR CO LTD

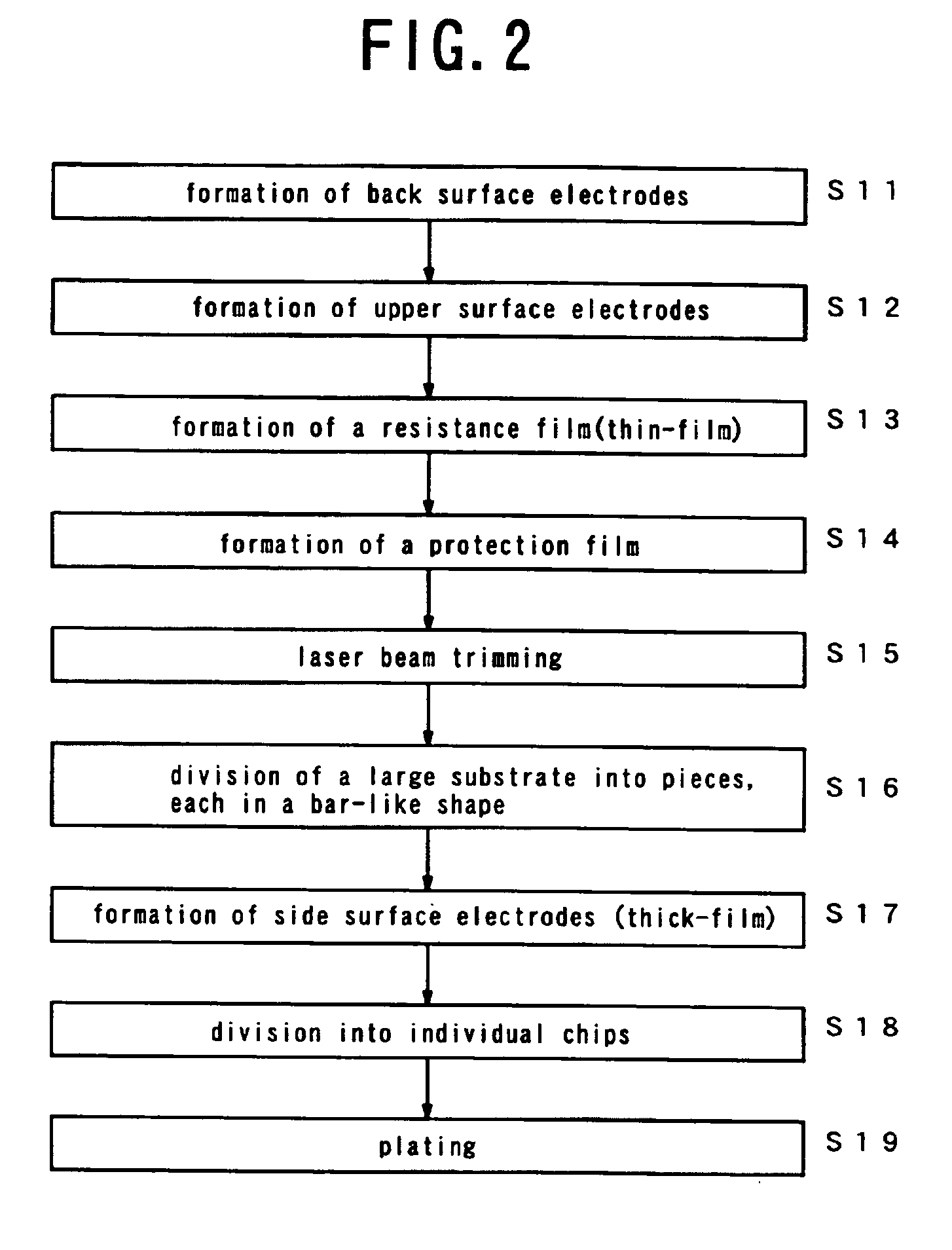

Chip resistor and manufacturing method therefor

ActiveUS7330099B2Easy to manufacturePrinted circuit assemblingResistor chip manufactureInsulation layerEngineering

Owner:ROHM CO LTD

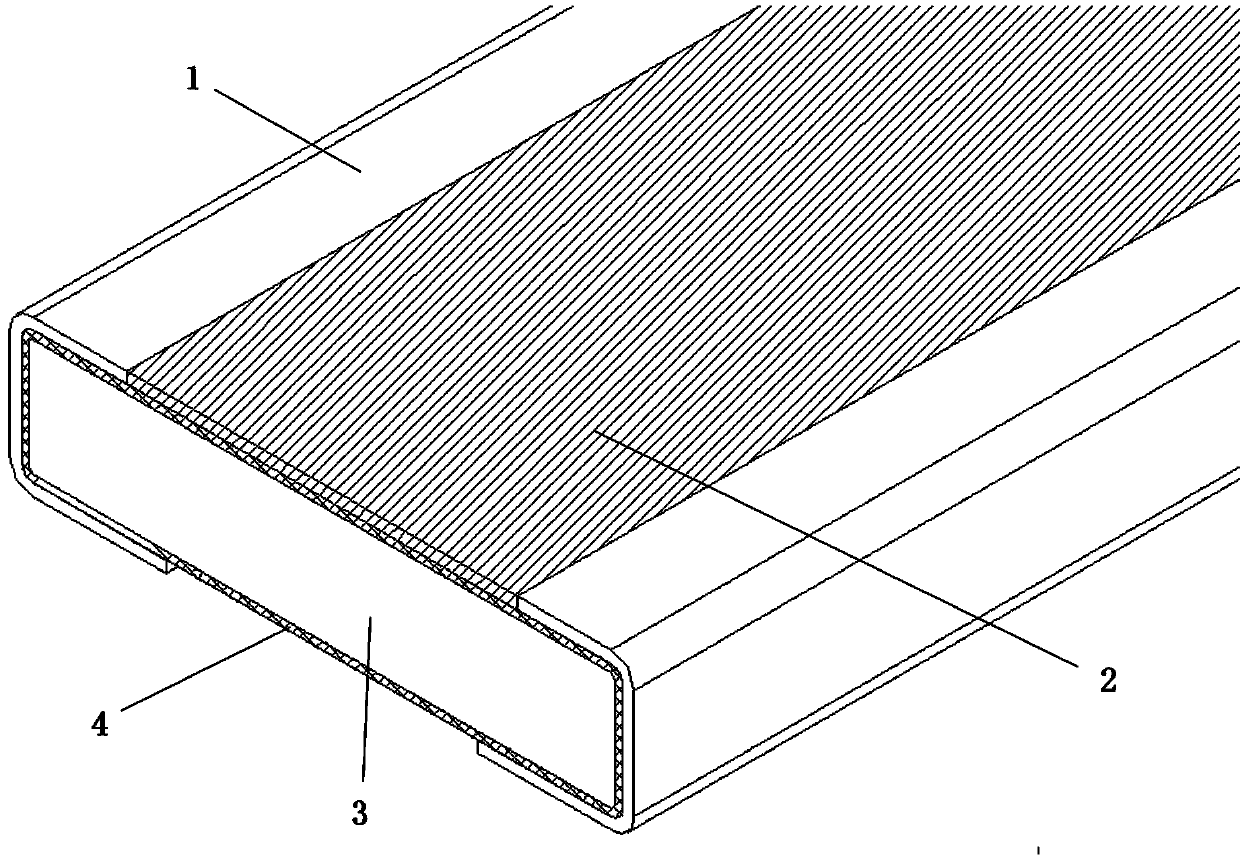

Activated carbon fiber soft electric heating product and manufacturing method thereof

InactiveUS20100062667A1Light weightUniform electric heating performanceEnvelope/housing resistor manufactureMedical devicesFiberEpoxy

An activated carbon fiber soft electric heating product and its manufacturing method for overcoming existing problems including uneven temperature rise and heat dissipation at surfaces of the product, unbendable feature, short life and poor safety. An activated carbon fiber cloth and a woven fiber cloth of the activated carbon fiber soft electric heating product are fixed by an epoxy resin layer, and a conducting copper net is disposed between the activated carbon fiber cloth and the epoxy resin layer and coupled to a power input wire. The manufacturing method includes the steps of: (1) spraying an epoxy resin on a surface of the woven fiber cloth, and bake-drying and hot pressing the woven fiber cloth; and (2) connecting the conducting copper net and the power input wire, laying the activated carbon fiber cloth, and performing a second-time hot pressing. Meanwhile, carbon fiber constitutes a heat generating surface with the advantages of a light weight, a soft texture, a bendable feature, a uniform electric heating performance, a fast temperature rise, a highly safe, reliable and long life feature. In addition, the method of the invention involves a simple technical skill and an easy operation.

Owner:PAN

Process for manufacturing a composite polymeric circuit protection device

InactiveUS6640420B1Easy to buildInexpensively mass-producedResistor chip manufactureResistor terminals/electrodesConductive polymerElectrical and Electronics engineering

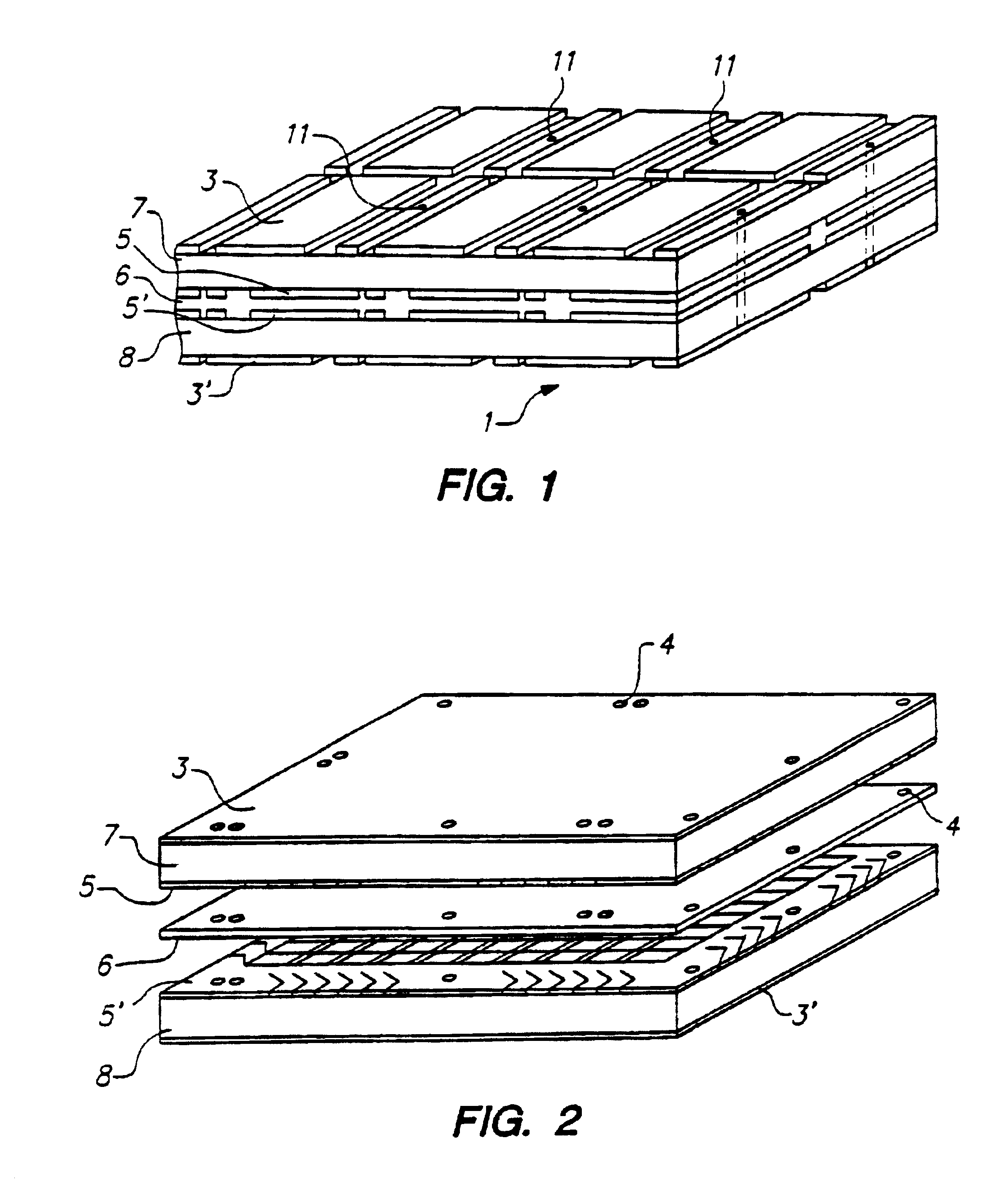

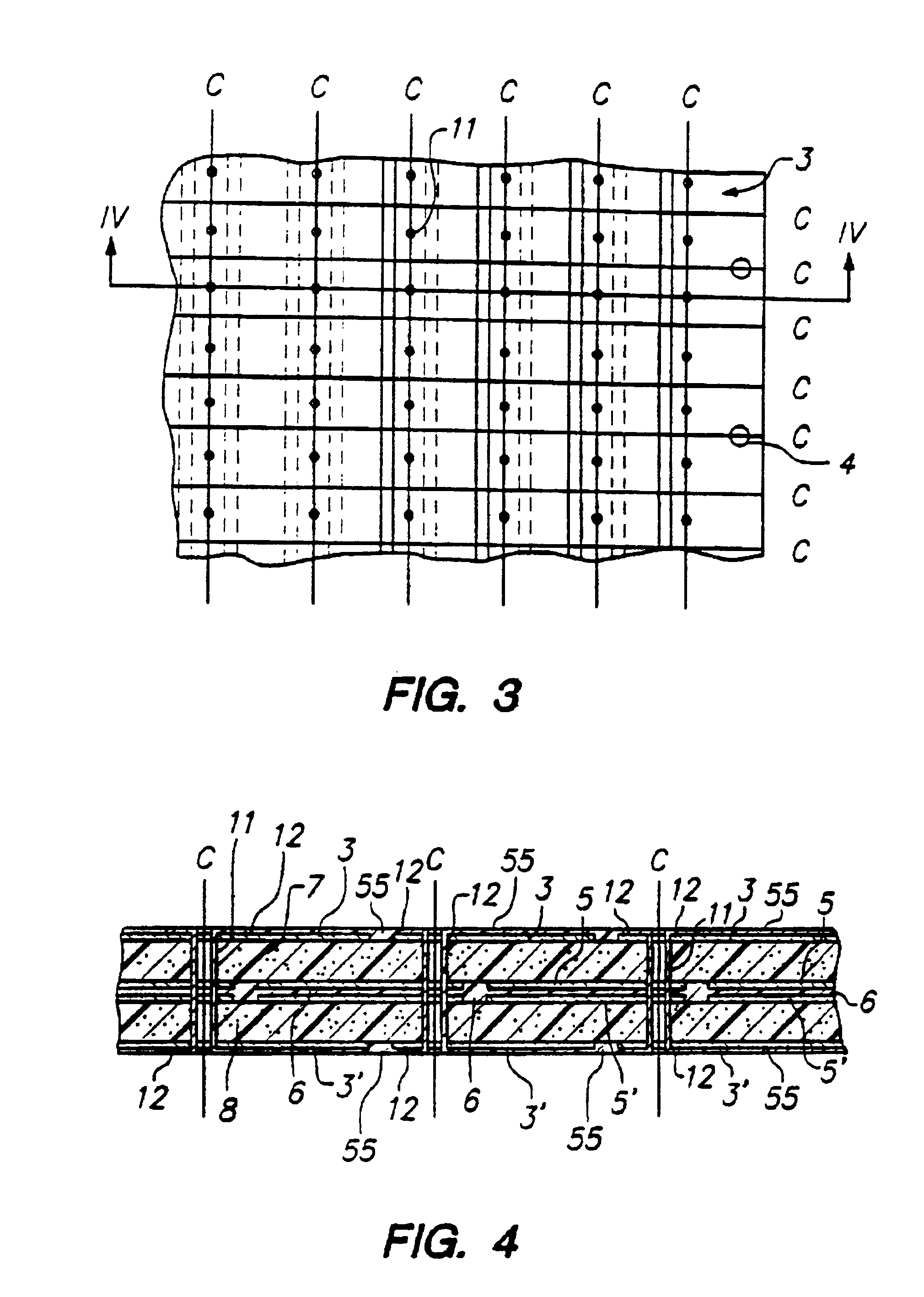

A process for manufacturing a composite polymeric circuit protection device in which a polymeric assembly is provided and is then subdivided into individual devices. The assembly is made by providing first and second laminates, each of which includes a laminar polymer element having at least one conductive surface, providing a pattern on at least one of the conductive surfaces on one laminate, securing the laminates in a stack in a desired configuration, at least one conductive surface of at least one of the laminates forming an external conductive surface of the stack, and making a plurality of electrical connections between a conductive surface of the first laminate and a conductive surface of the second laminate. The laminar polymer elements may be PTC conductive polymer compositions, so that the individual devices made by the process exhibit PTC behavior.

Owner:LITTELFUSE INC

Method for fabricating negative temperature coefficient thermistor

ActiveUS20090165289A1Easy to adjustEasy to obtainNegative temperature coefficient thermistorsPositive temperature coefficient thermistorsElectrical resistance and conductanceNegative temperature

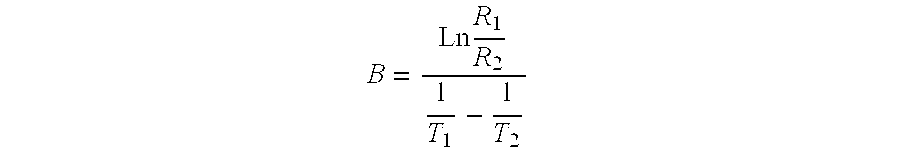

A method for fabricating a negative temperature coefficient thermistor is provided, including the steps of: (A) combining ceramic powders having a negative temperature coefficient of resistance, a polymer binder and a solvent to form a mixture; (B) removing the solvent and granulating the mixture to form granulous powders; (C) compressing the granulous powders to obtain a thermistor material with a specific shape; (D) curing the thermistor material at 80° C. to 350° C.; and (E) mounting an electrode to the thermistor material to form the negative temperature coefficient thermistor. The method can be performed in a low temperature without the problem of interface diffusion. Further, the desired resistance value and thermistor constant (B) can be easily adjusted and obtained by mixing ceramic powders with different characteristics of temperature coefficient of resistance and / or the addition of conductive metal powder.

Owner:IND TECH RES INST

Process for manufacturing a composite polymeric circuit protection device

InactiveUS6854176B2Easy to buildInexpensively mass-producedResistor chip manufactureBatteries circuit arrangementsConductive polymerElectrical connection

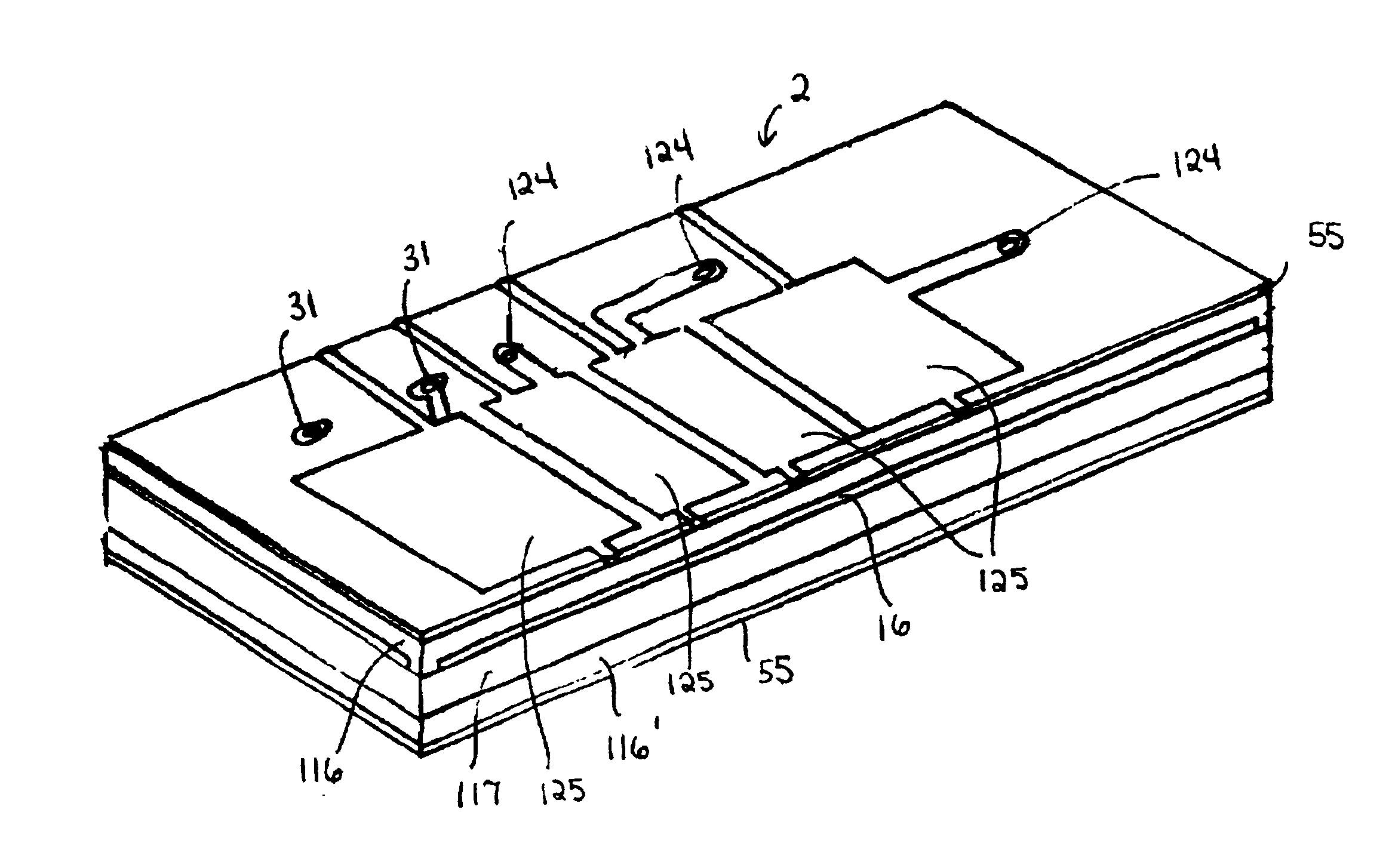

A process for manufacturing a composite polymeric circuit protection device in which a polymeric assembly is provided and is then subdivided into individual devices (2). The assembly is made by providing first and second laminates (7,8), each of which includes a laminar polymer element having at least one conductive surface, providing a pattern on at least one of the conductive surfaces on one laminate, securing the laminates in a stack (1) in a desired configuration, at least one conductive surface of at least one of the laminates forming an external conductive surface (3) of the stack, and making a plurality of electrical connections (31,51) between a conductive surface of the first laminate and a conductive surface of the second laminate. The laminar polymer elements may be PTC conductive polymer compositions, so that the individual devices made by the process exhibit PTC behavior. Additional electrical components may be attached directly to the surface of the device or assembly.

Owner:LITTELFUSE INC

Semiconductor sensor and method of manufacturing the same

InactiveUS20080202249A1Accurately detecting physical quantityFluid pressure measurement using ohmic-resistance variationThermometers using material expansion/contactionPressure senseEngineering

A semiconductor pressure sensing apparatus includes a metallic stem having a diaphragm and a semiconductor sensor bonded to the diaphragm. The semiconductor sensor includes a gauge section and first and second bonding pads. The gauge section is configured to be deformed according to a deformation of the diaphragm. The first and second bonding pads are respectively connected to different positions of the gauge section so that an electrical resistance between the first and second bonding pads can change with a change in the deformation of the diaphragm. The gauge section is formed to a semiconductor layer of an silicon-on-insulator substrate. The semiconductor sensor is directly bonded to the diaphragm by activating contact surfaces between the semiconductor sensor and the diaphragm.

Owner:DENSO CORP

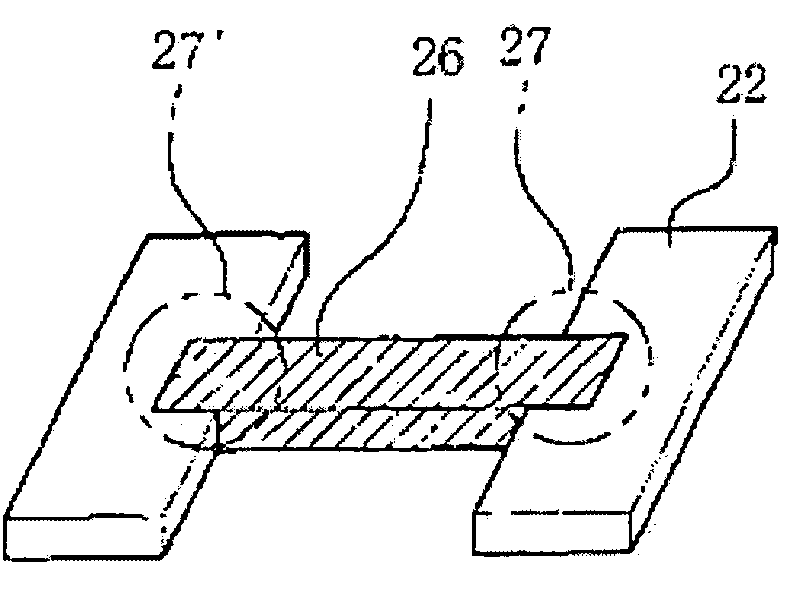

Chip resistor

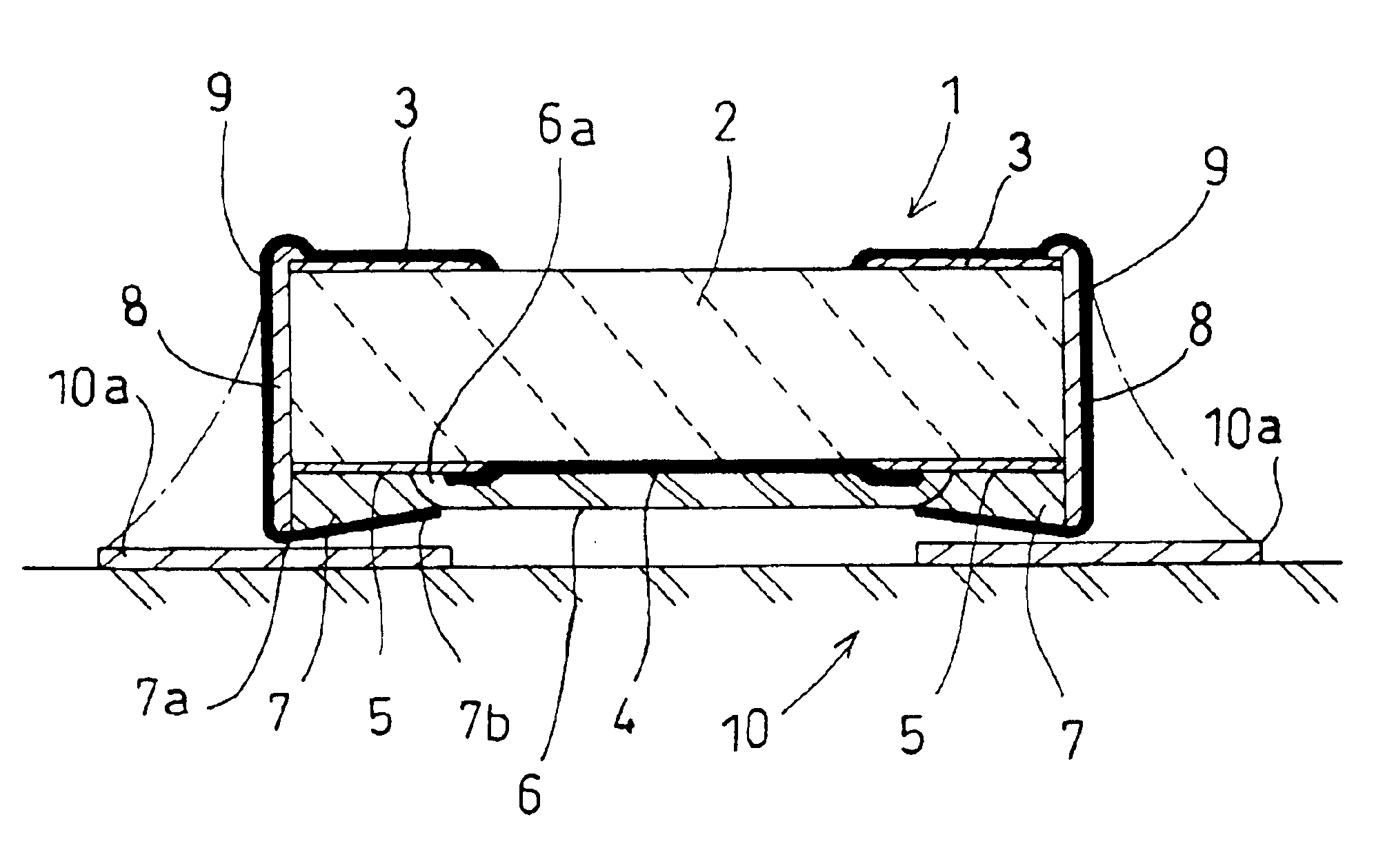

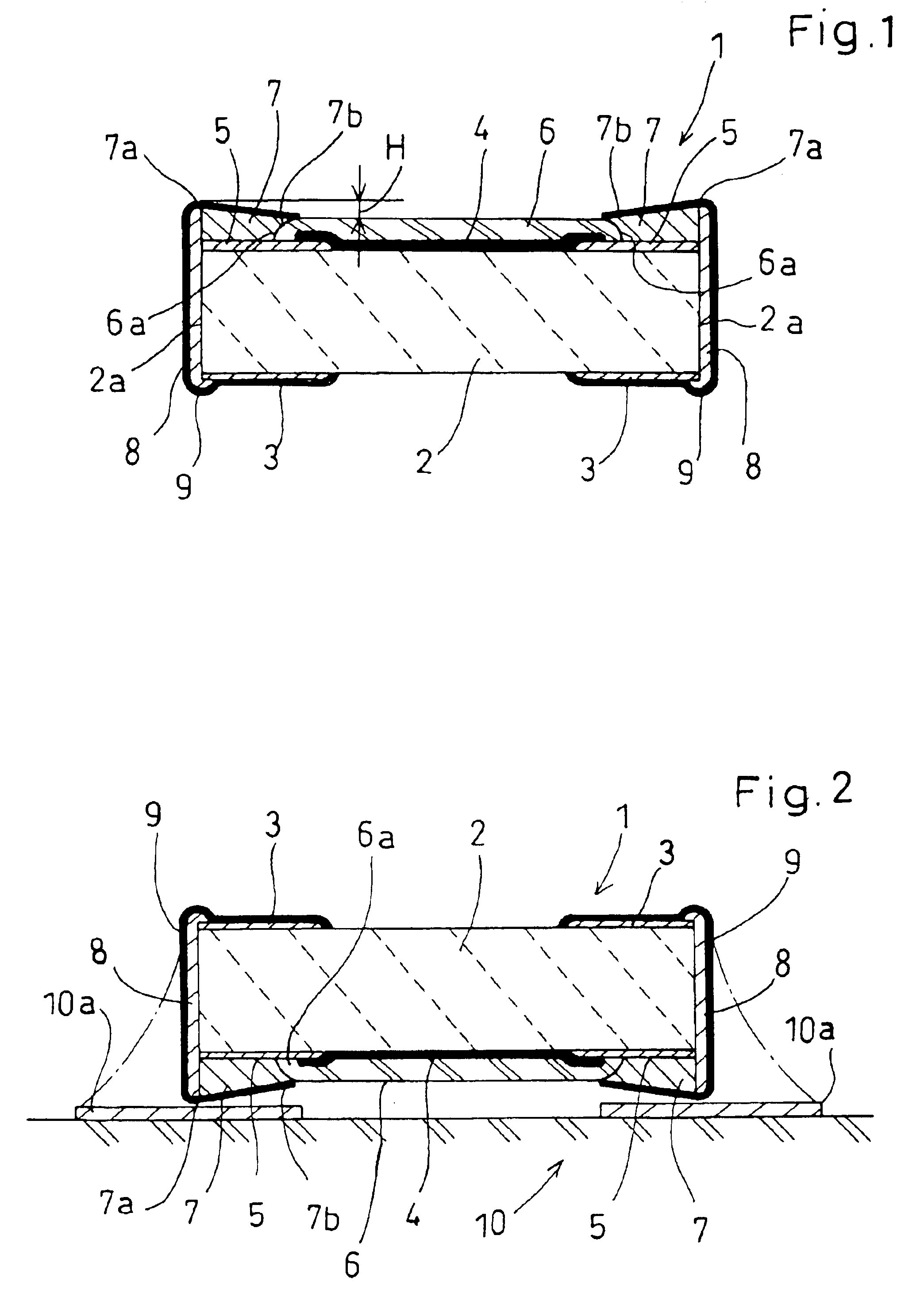

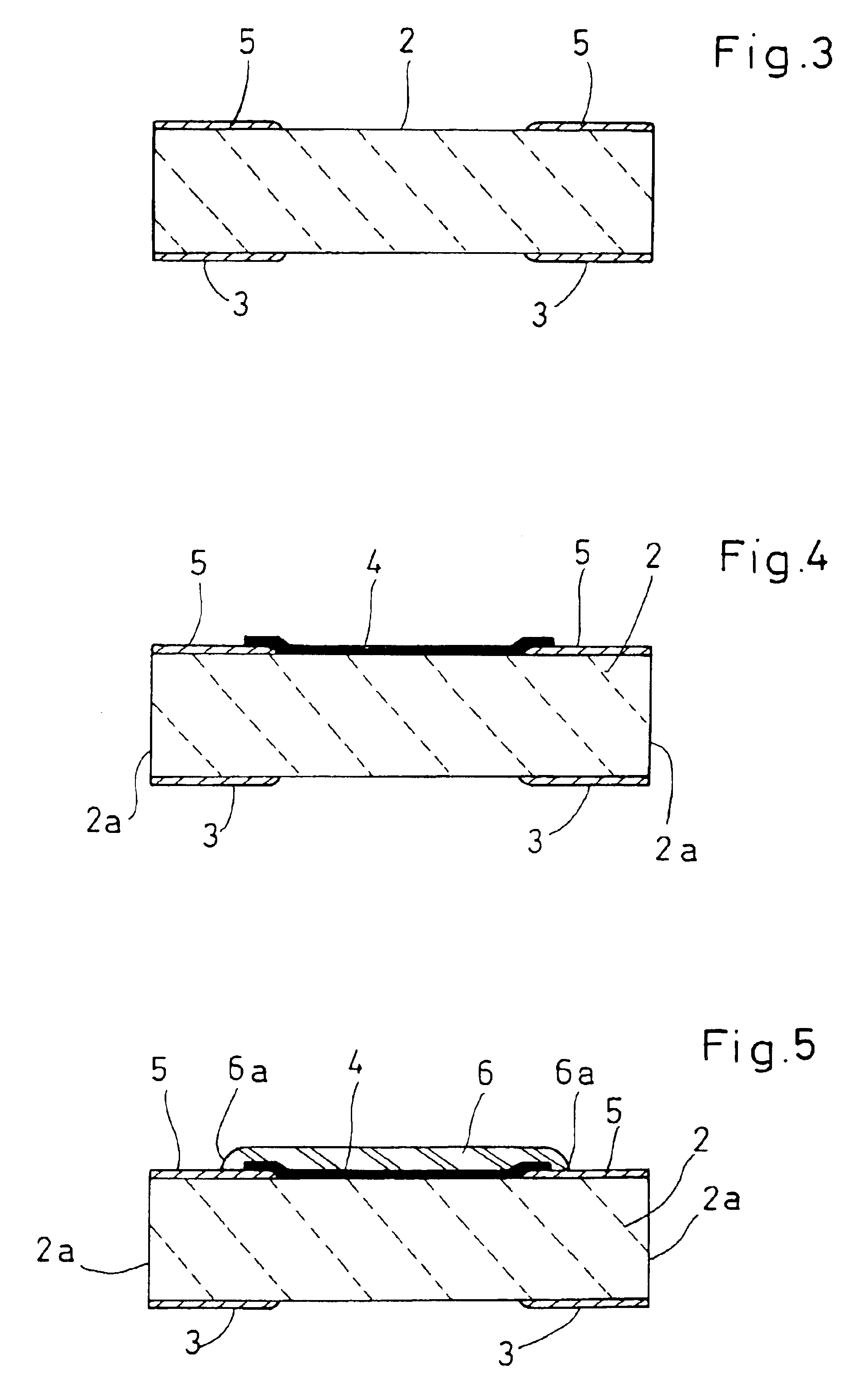

ActiveUS6856234B2Reduce manufacturing costPrevent rising of one endResistor chip manufactureResistor terminals/electrodesElectrical connectionElectrode

A chip resistor includes an insulating substrate 2 in the form of a chip having an upper surface and an opposite pair of side surfaces, a resistor film 4 formed on the upper surface of the insulating substrate 2, a pair of upper electrodes 5 formed on the upper surface of the insulating substrate 2 to flank the resistor film 4 in electrical connection thereto, a cover coat 6 covering the resistor film 4, an auxiliary upper electrode 7 formed on each of the upper electrodes 5 and including a first portion 7a adjoining the relevant side surface of the insulating substrate 2 and a second portion 7b overlapping the cover coat 6, and a side electrode 8 formed on each of the side surfaces of the insulating substrate 2 and electrically connected to at least the upper electrode 5 and the auxiliary upper electrode 7. The first portion 7a of the auxiliary upper electrode 7 has an obverse surface positioned higher than an obverse surface of the second portion 7b for projecting above an obverse surface of the cover coat 6.

Owner:ROHM CO LTD

Micromechanical pressure-sensor element and method for its production

ActiveUS20110209555A1Without riskLess spaceFluid pressure measurement using ohmic-resistance variationFluid pressure measurement by mechanical elementsMiniaturizationEngineering

A very robust sensor element for an absolute-pressure measurement is described, which is suitable for high temperatures and able to be miniaturized to a large extent. The micromechanical pressure-sensor element includes a sensor diaphragm having a rear-side pressure connection and at least one dielectrically insulated piezo resistor for signal acquisition. Furthermore, the pressure-sensor element has a front-side reference volume, which is sealed by a cap structure spanning the sensor diaphragm. The cap structure is realized as thin-film structure.

Owner:ROBERT BOSCH GMBH

Microwave film resistor, microwave film resistor network module and manufacturing method thereof

InactiveCN101533693AReduce microwave lossReduce areaOther resistor networksResistors adapted for applying terminalsFilm resistanceHigh resistance

The invention discloses a microwave film resistor and a manufacturing method thereof, and belongs to the field of circuit elements. The microwave film resistor comprises a ceramic substrate, a film resistance layer which is adhered to the upper surface of the ceramic substrate and an electrode layer which is adhered to the film resistance layer. The film resistor has the advantages of high precision, high using frequency and high resistance stability. In addition, the invention also discloses a microwave film resistor network module and a manufacturing method thereof, wherein the microwave film resistor network module is formed by integrating three or more microwave film resistors on one module.

Owner:广州翔宇微电子有限公司

Metal oxide varistor with heat protection

InactiveUS20090027153A1Open fastCurrent responsive resistorsHeating/cooling contact switchesElectrical resistance and conductanceEngineering

A metal oxide varistor with heat protection has a body, an insulated washer, a first lead, a second lead and a thermal fuse. The body has two sides and two contacts respectively on the sides. The insulated washer is attached to one contact and has a through hole. The first lead is mounted on the other contact. The second lead is mounted on the insulated washer. The thermal fuse is mounted on the insulated washer and electrically connects to the second lead and the second contact. When the body overloads and overheats, the thermal fuse causes the circuit to open quickly, and the insulated washer keeps the thermal fuse from electrically connecting to the second contact again.

Owner:THINKING ELECTRONICS INDAL

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com