Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

42results about How to "Well-balanced property" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

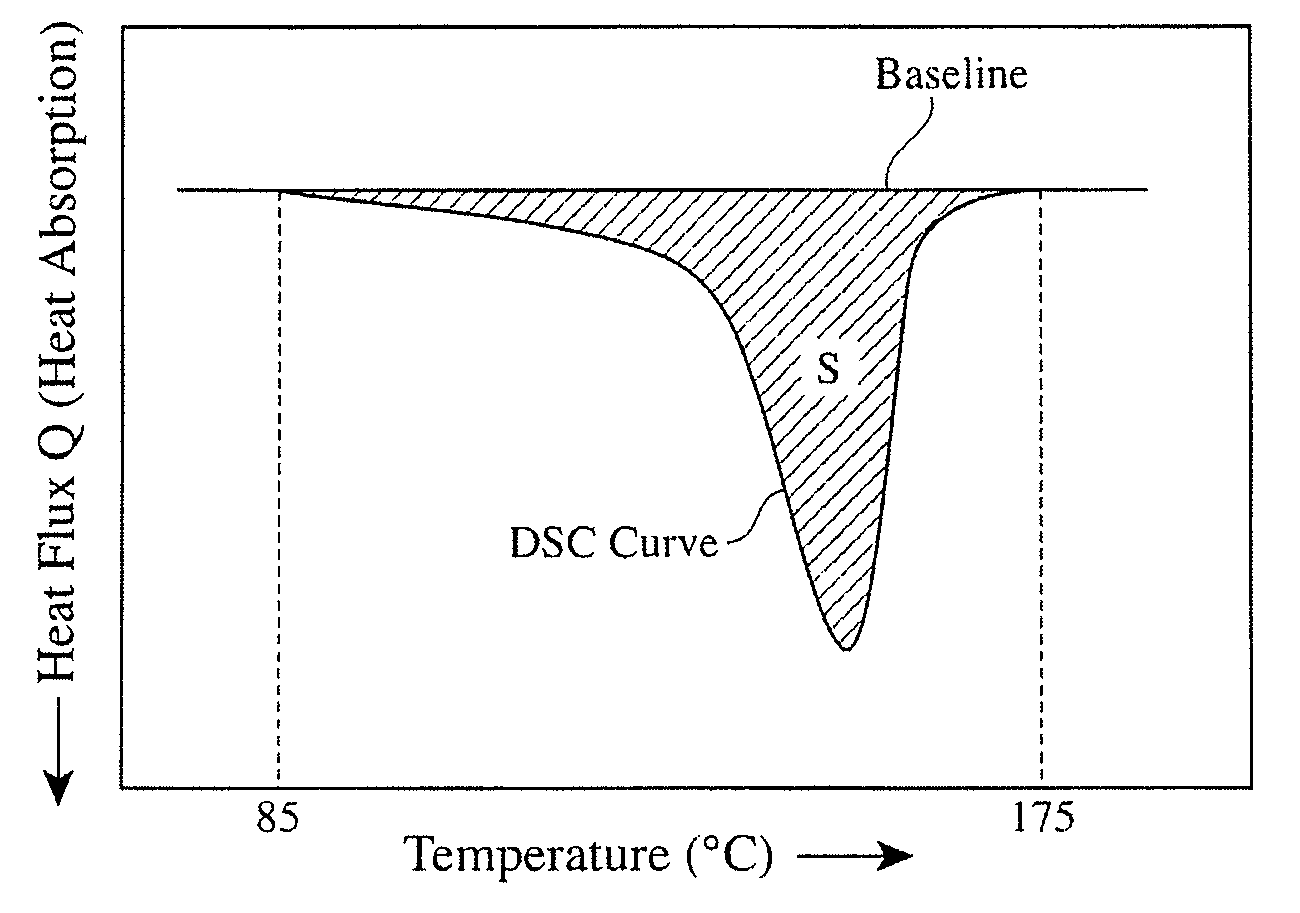

Multi-layer microporous polyolefin membrane and battery separator

ActiveUS20090274955A1Well-balanced propertyGood film formingMembranesSemi-permeable membranesSurface layerPolymer science

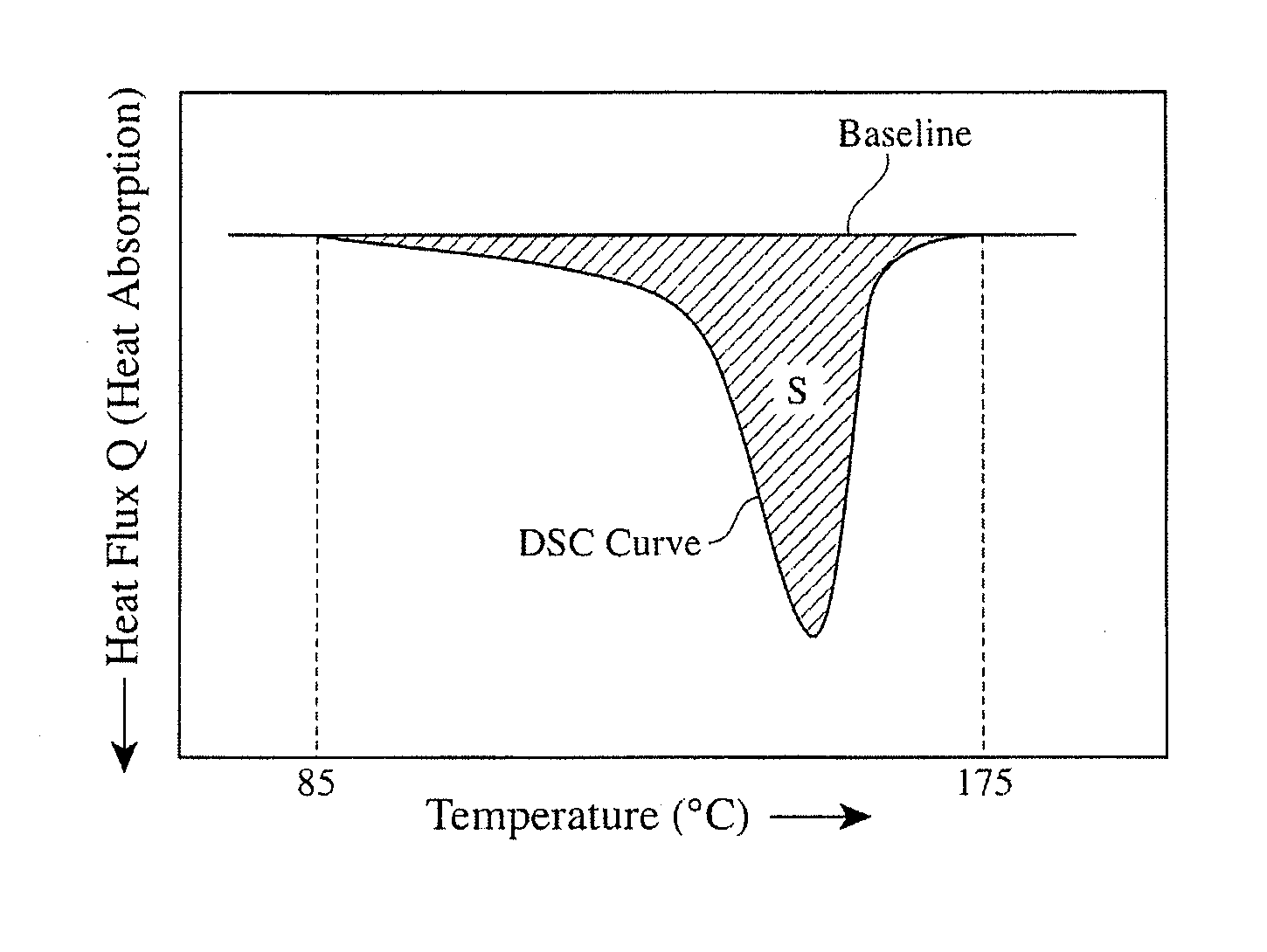

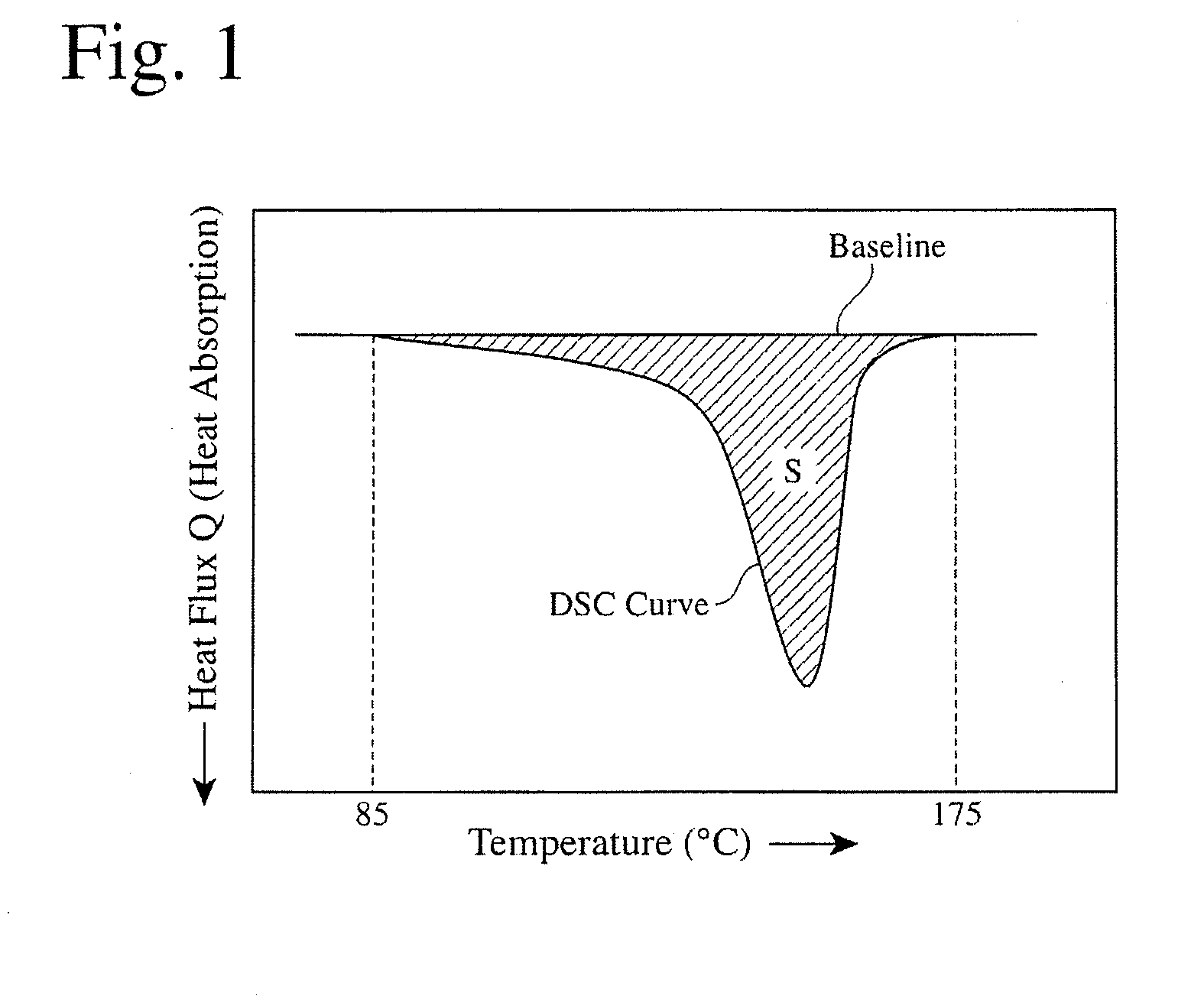

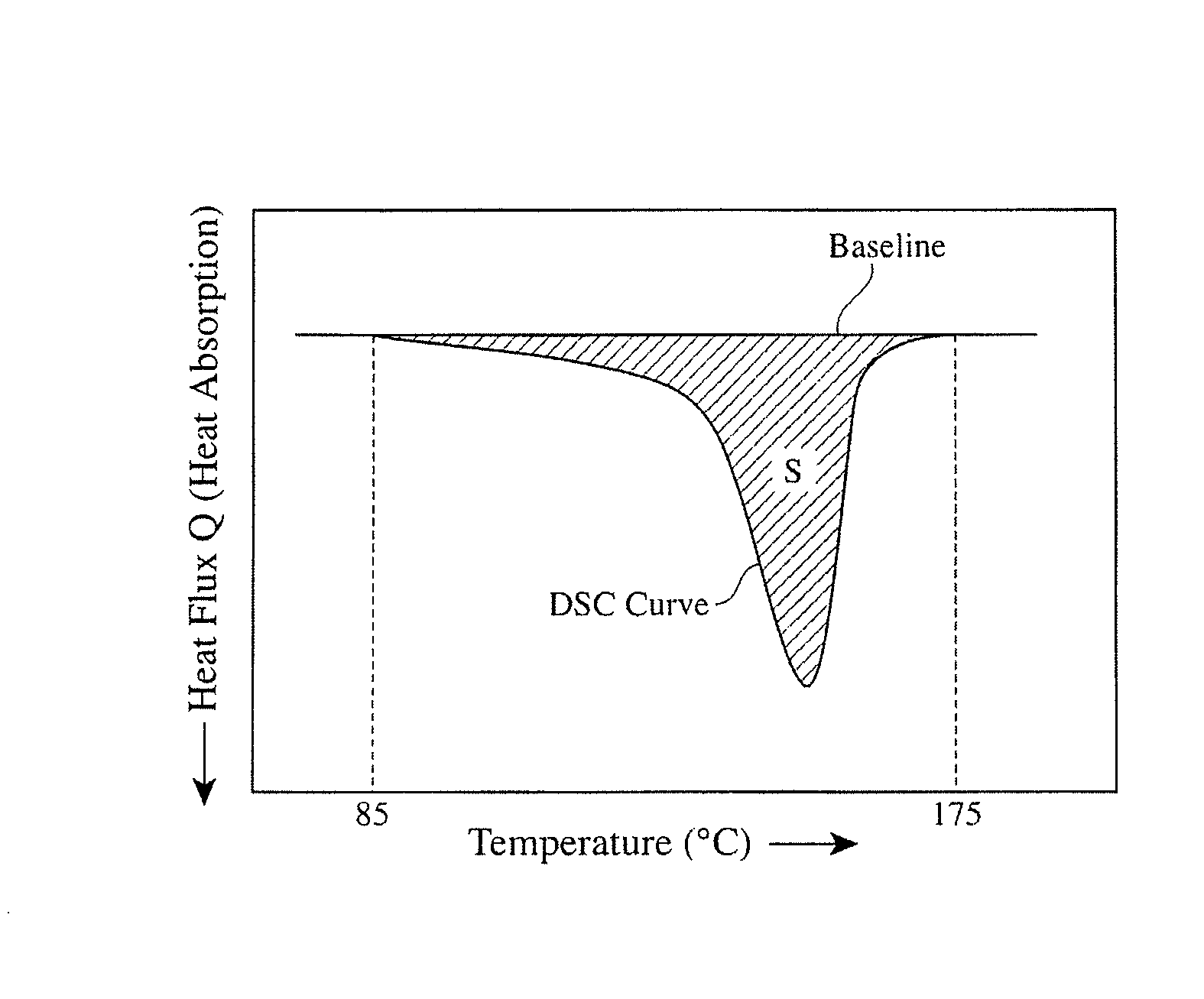

A multi-layer, microporous polyolefin membrane having at least three layers, which comprises first microporous layers made of a polyethylene resin for constituting at least both surface layers, and at least one second microporous layer comprising a polyethylene resin and polypropylene and disposed between both surface layers, the heat of fusion (ΔHm) of the polypropylene measured by differential scanning calorimetry being 90 J / g or more, and the polypropylene content in the second microporous layer being 50% or less by mass based on 100% by mass of the total of the polyethylene resin and the polypropylene.

Owner:TORAY IND INC

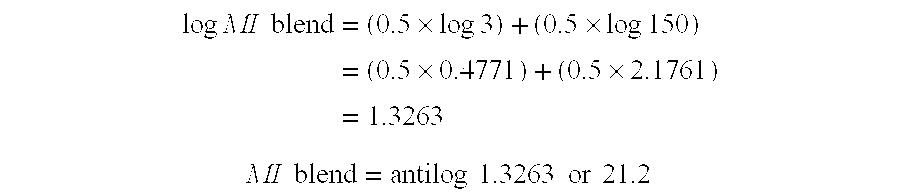

Delayed-tack adhesive composition

InactiveUS6080480AIncrease stickinessImprove the immunityNon-macromolecular adhesive additivesUnsaturated ether polymer adhesivesPolymer sciencePlasticizer

PCT No. PCT / JP96 / 02685 Sec. 371 Date Mar. 25, 1998 Sec. 102(e) Date Mar. 25, 1998 PCT Filed Sep. 18, 1996 PCT Pub. No. WO97 / 12010 PCT Pub. Date Apr. 3, 1997A delayed-tack adhesive composition exhibiting a high tack strength even for adherends made of non-polar materials such as polyethylene and polypropylene, which comprises a (co)polymer prepared by the use of a radical-polymerizable monomer having a straight-chain or branched alkyl group having 9 to 18 carbon atoms and a plasticizer being solid at ordinary temperatures.

Owner:TOYO INK SC HOLD CO LTD

Lubricant compositions

InactiveUS20030220206A1Increased transfer torque capacityWell-balanced capacityOrganic compound preparationLiquid carbonaceous fuelsHydrogenBase oil

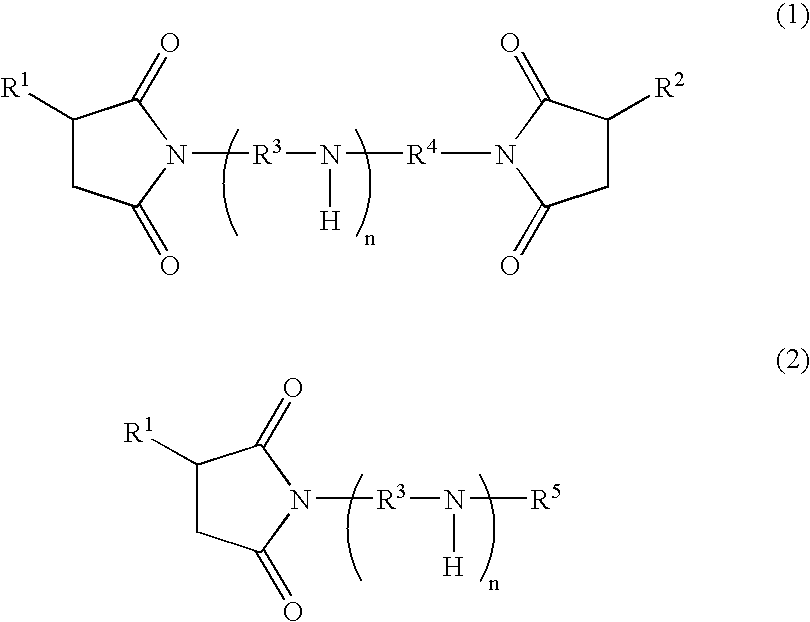

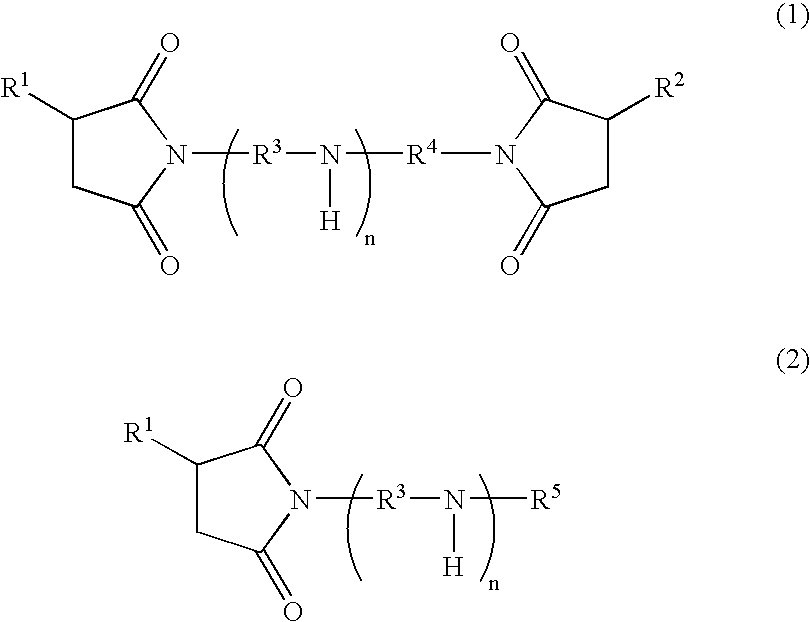

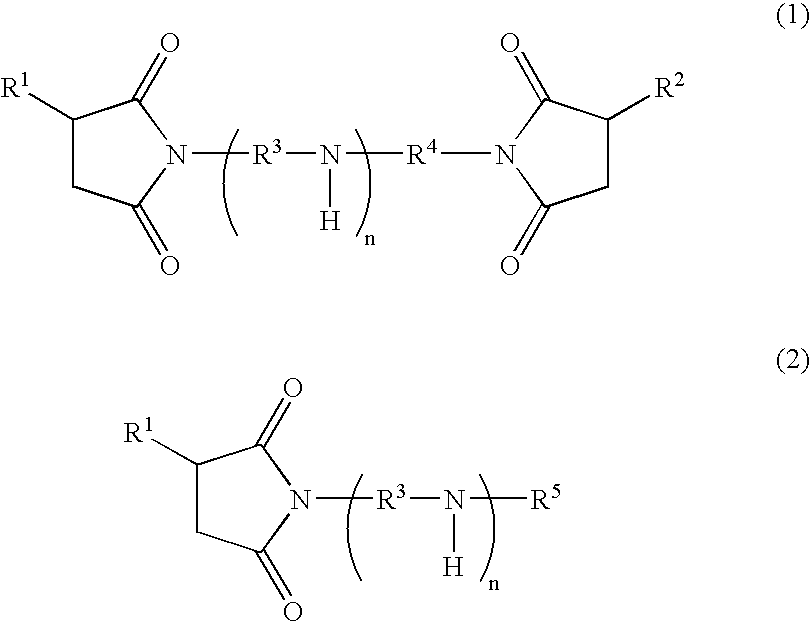

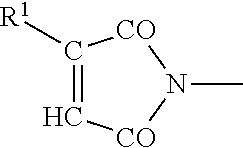

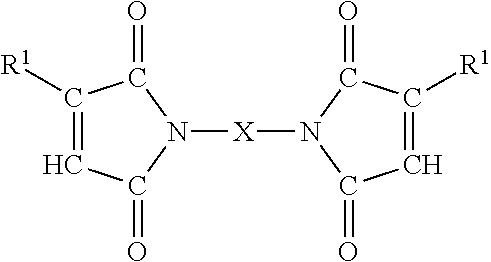

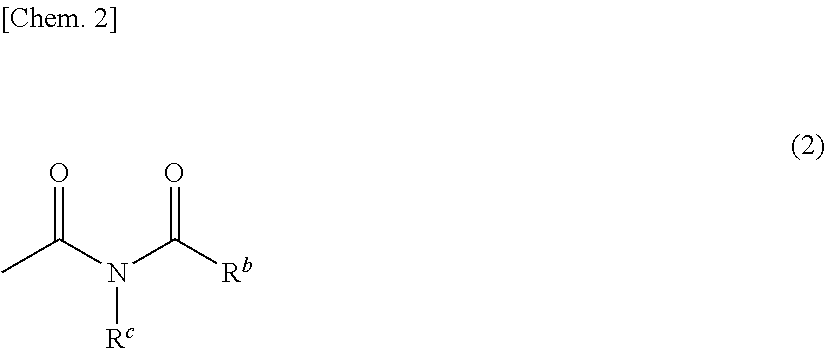

Lubricant compositions comprises a lubricant base oil and one or more compounds resulting the modification of a succinimide represented by formula (1) or (2) wherein R<1 >and R<2 >may be the same or different and are each independently a hydrocarbon group having 8 to 30 carbon atoms, R<3 >and R<4 >may be the same or different and are each independently a hydrocarbon group having 1 to 4 carbon atoms, R<5 >is hydrogen or a hydrocarbon group having 1 to 30 carbon atoms, n is an integer from 1 to 7. The lubricant compositions have a long-lasting anti-shudder property, an enhanced transmission capacity for a wet clutch, and an excellent shifting property.

Owner:NIPPON MITSUBISHI OIL CORP

Hot melt adhesive composition

A hot melt adhesive composition includes ethylene vinyl acetate copolymer(s) having average vinyl acetate content of from about 10% to about 30%, styrene-ethylene-butylene-styrene block copolymer, tackifying resin, and optionally, a plasticizer or a wax.

Owner:H B FULLER LICENSING & FINANCING INC

Composite nonwoven fabric for protective clothing and production method thereof

InactiveUS7022632B2High strengthWell-balanced propertyLayered productsWoven fabricsPolyolefinUltra fine

The composite nonwoven fabric for protective clothing of the present invention comprises (A) a water vapor-permeable, water-resistant nonwoven fabric made of polyolefin-based ultra-fine fibers having an average fiber diameter of 5 μm or less, (B) a heat-bonding nonwoven fabric made of thermoplastic elastomer ultra-fine fibers, and (C) a porous fabric. The nonwoven fabric B is interposed between the nonwoven fabric A and the porous fabric C, and the fabrics A, B and C being integrally bonded to each other. The composite nonwoven fabric is suitable for a protective clothing because it is water vapor-permeable and water-resistant on its outer side to be exposed to outside air, and is of high strength, sweat-absorbable and antistatic on its inner side, and also well-balanced in these properties.

Owner:KURARAY CO LTD +1

Heat-Curable Urethane Resin Composition

InactiveUS20070293636A1Improve adhesionWell-balanced propertyPolyurea/polyurethane coatingsNon-metallic protective coating applicationEpoxyResist

The invention provides a heat-curable resin composition comprising (A) a polyurethane having two or more carboxyl groups in one molecule, in particular a polyurethane having one or more carboxyl groups at a molecular terminal and (B) a heat-curable component, a cured product thereof, a solder resist and a protective film consisting of the cured product and a printed wiring board coated with the cured product. The polyurethane(A), preferably has a number average molecular weight of 500 to 100,000 and an acid value of 5 to 150 mgKOH / g. The heat-curable component (B) is preferably an epoxy resin. The heat-curable resin composition of the invention is excellent in adhesion with a substrate, low-warpage property, flexibility, resistance to moisture and heat, soldering heat resistance and resistance to tin plating.

Owner:SHOWA DENKO KK

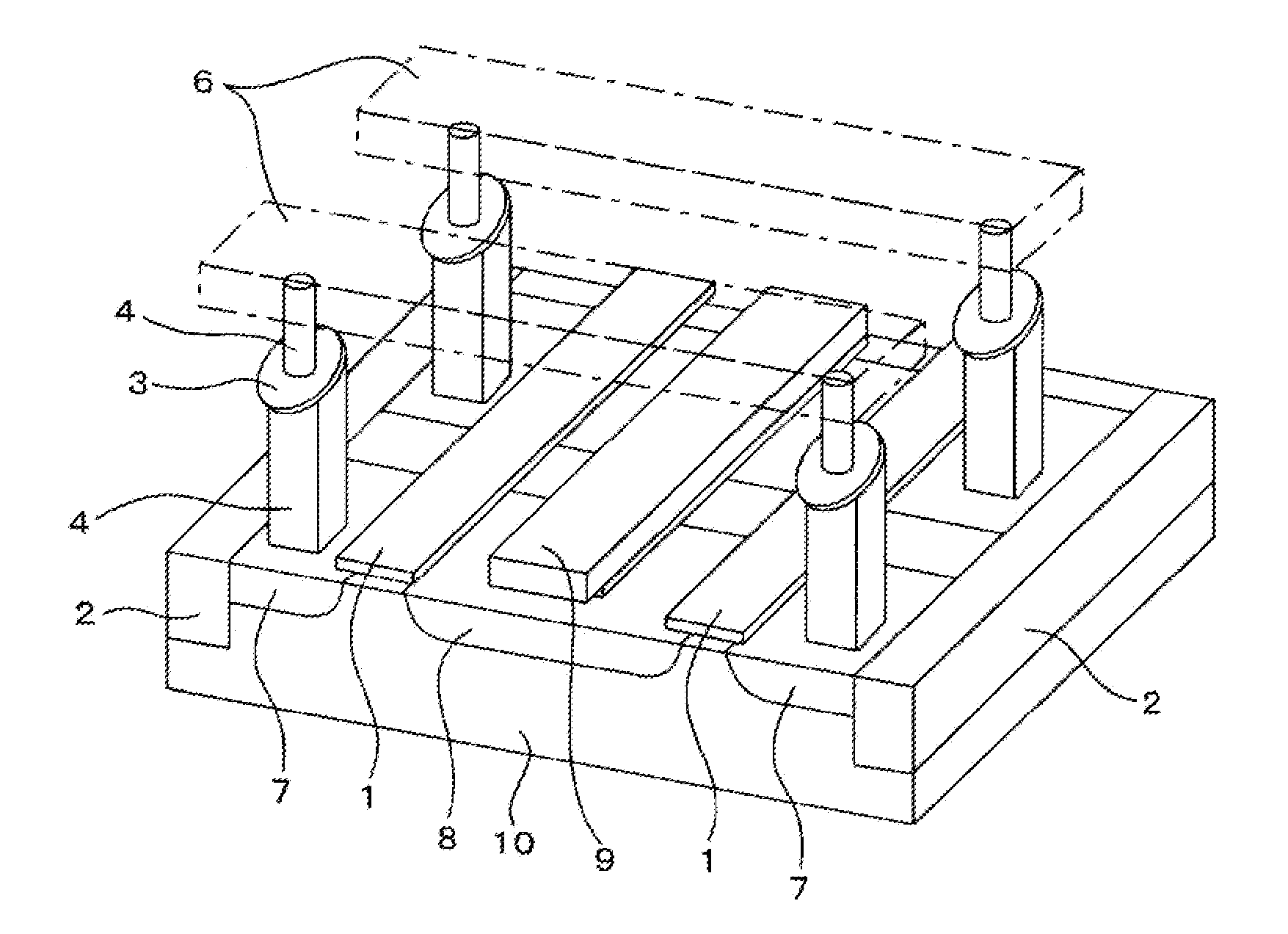

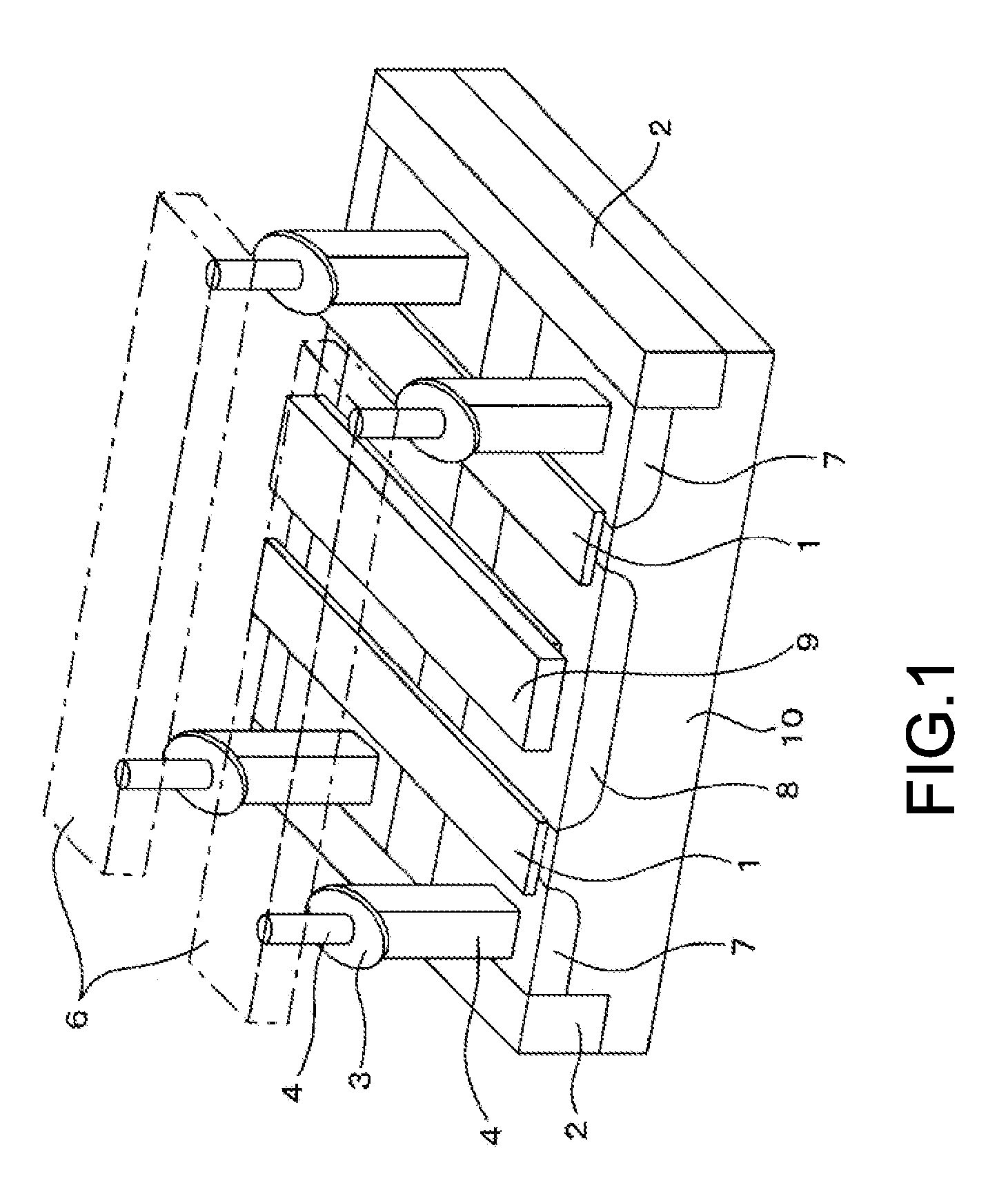

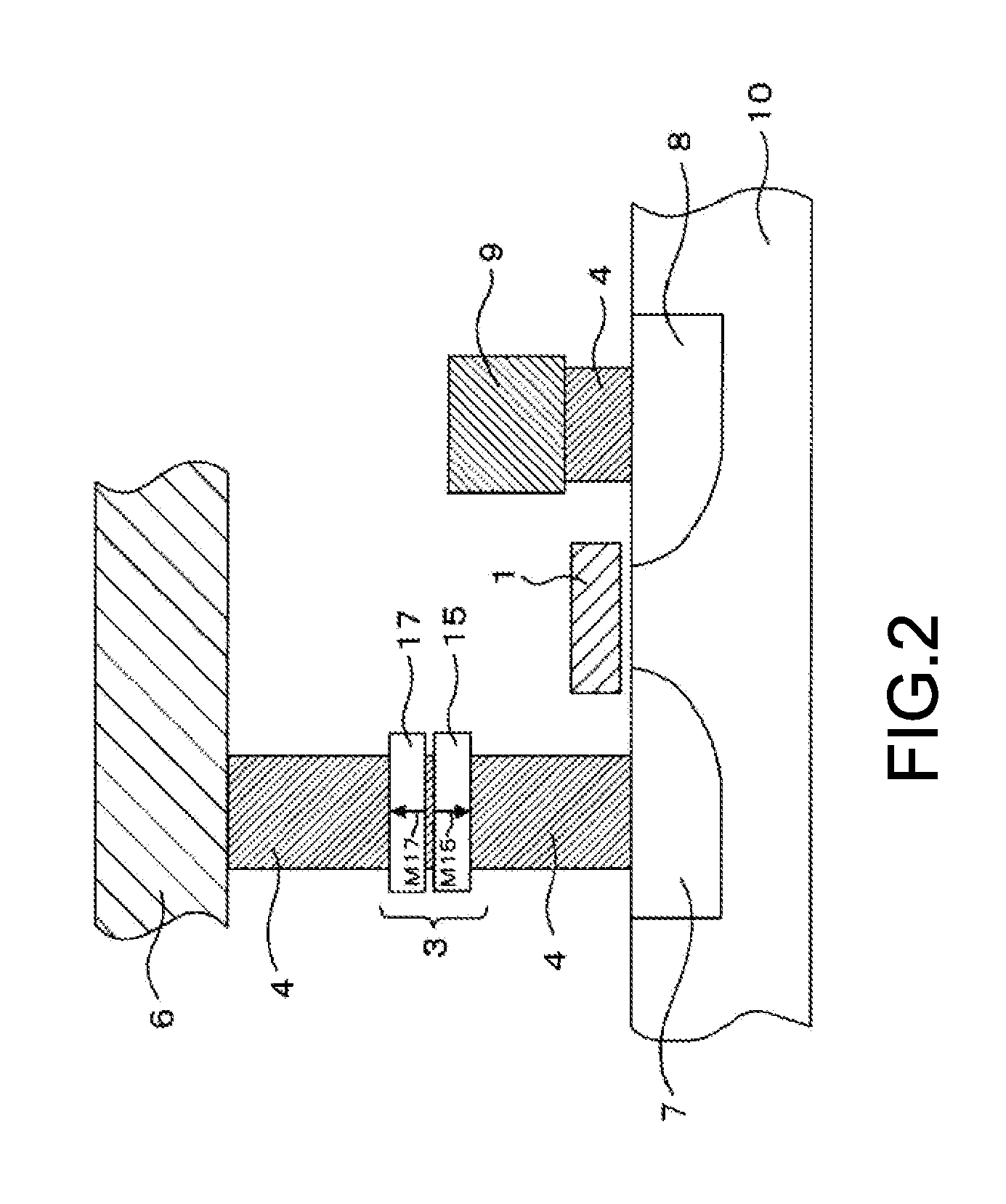

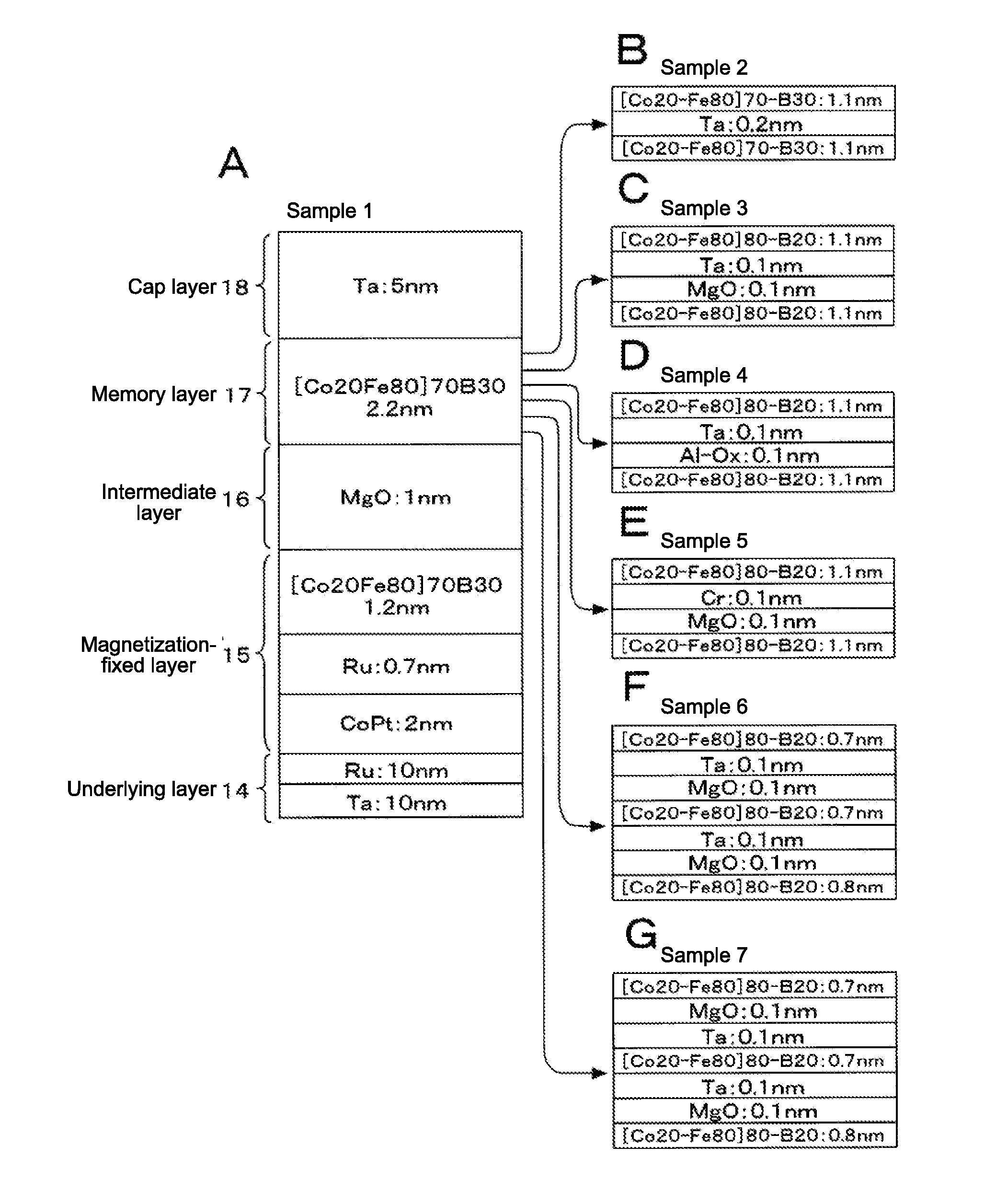

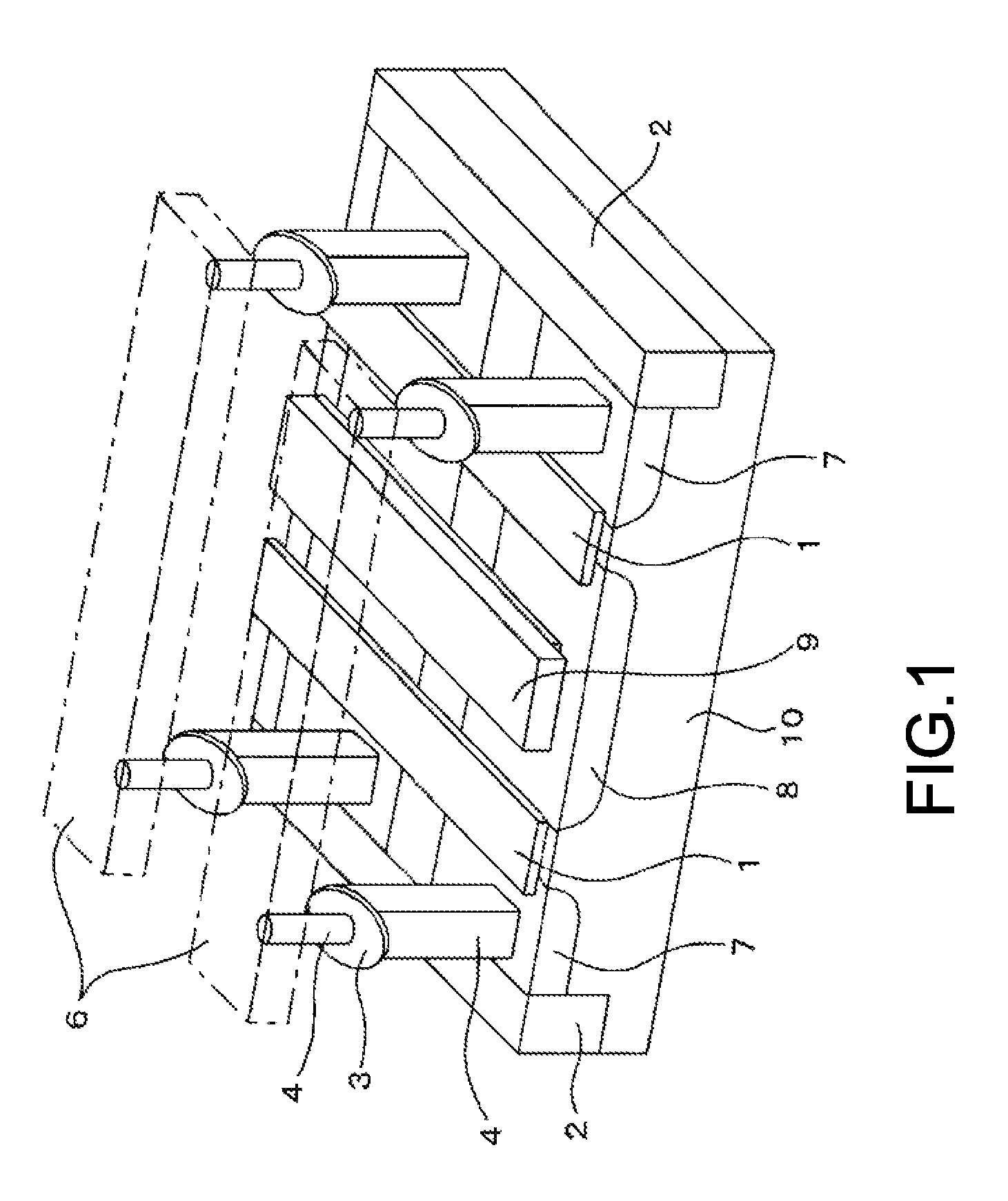

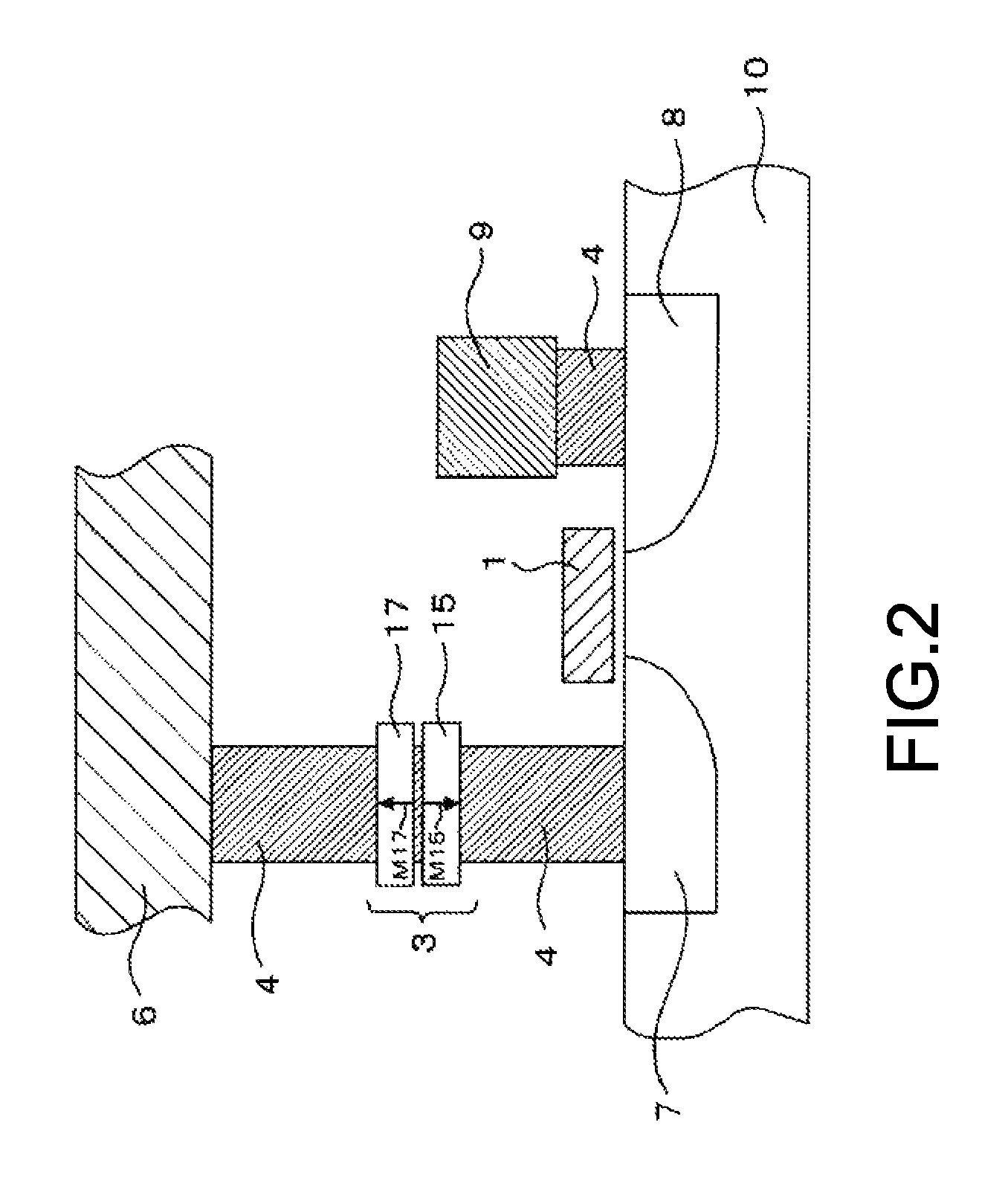

Memory element, memory apparatus

ActiveUS20140319521A1Well-balanced propertyThermal stabilityMagnetic measurementsGalvano-magnetic material selectionSoftware engineeringMechanical engineering

[Object] To provide a memory element having well-balanced properties while ensuring the thermal stability.[Solving Means] A memory element includes a layered structure including a memory layer having magnetization perpendicular to a film face in which a direction of the magnetization is changed depending on information, a magnetization-fixed layer having magnetization perpendicular to the film face, which becomes a base of the information stored in the memory layer, and an intermediate layer that is formed of a non-magnetic material and is provided between the memory layer and the magnetization-fixed layer.Then, the memory layer includes a multilayer structure layer in which a non-magnetic material and an oxide are laminated, the direction of the magnetization of the memory layer being changed by applying a current in a lamination direction of the layered structure to record the information in the memory layer.

Owner:SONY CORP

Lubricant compositions

InactiveUS6828286B2Increased transfer torque capacityWell-balanced capacityOrganic compound preparationLiquid carbonaceous fuelsHydrogenBase oil

Owner:NIPPON MITSUBISHI OIL CORP

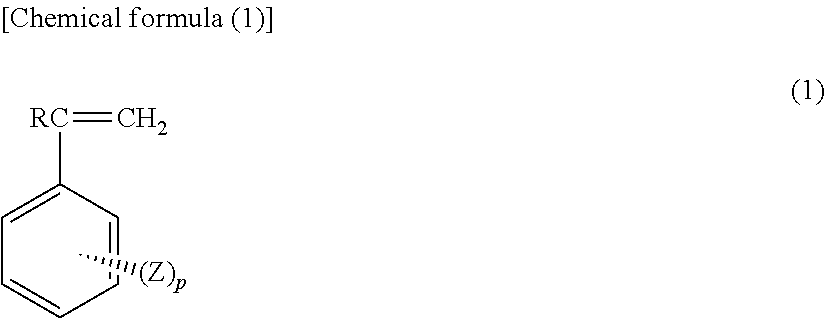

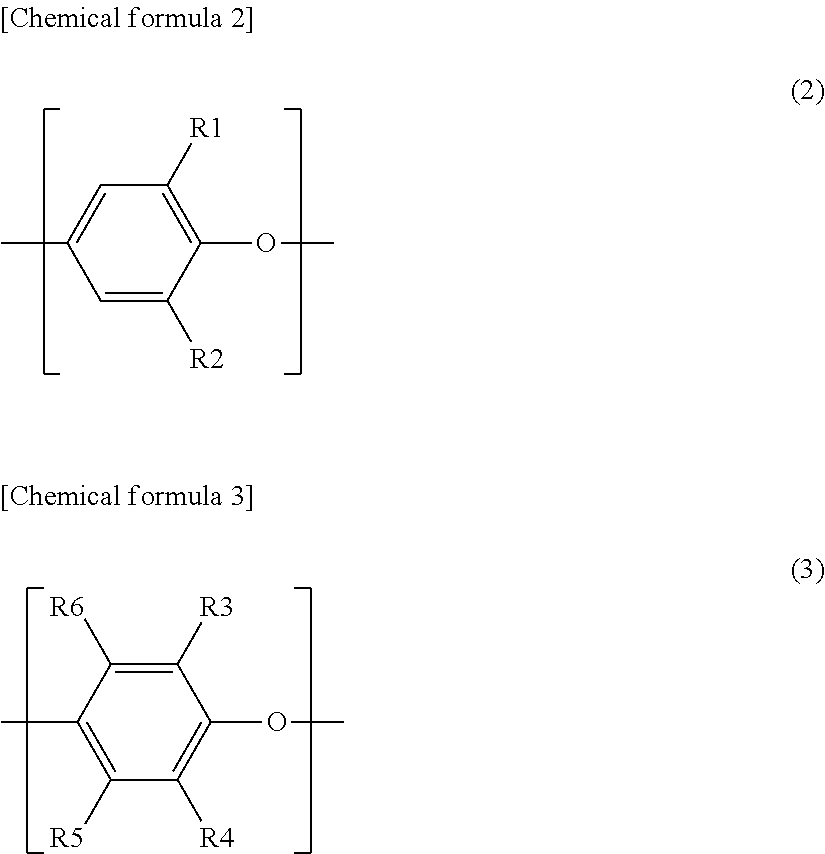

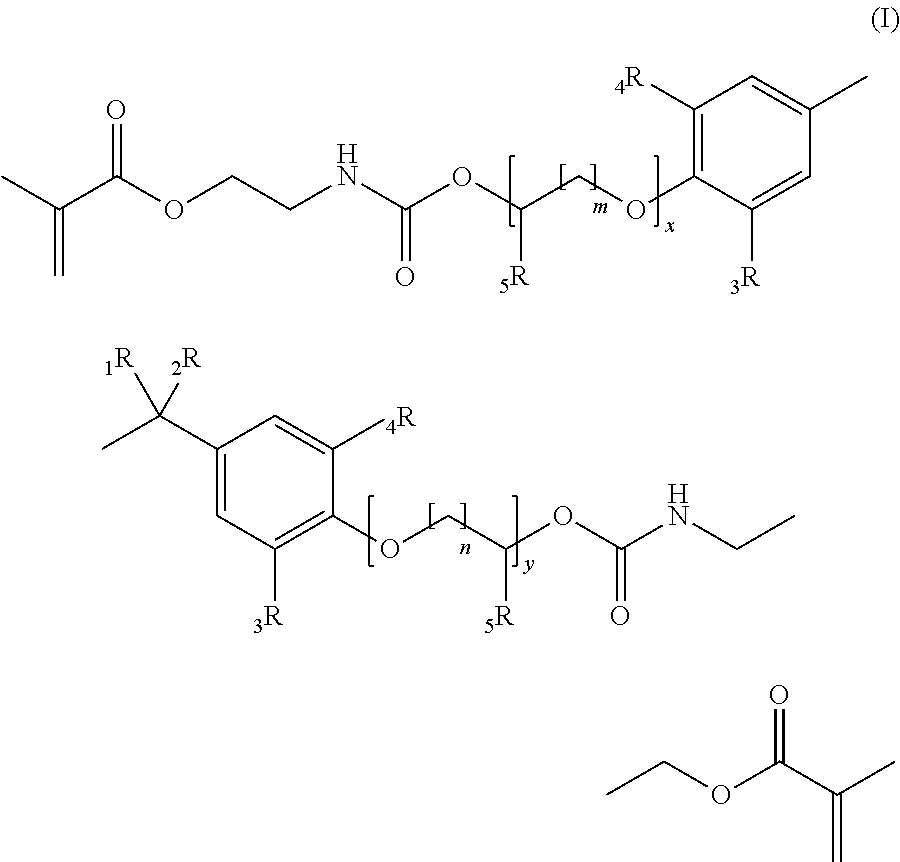

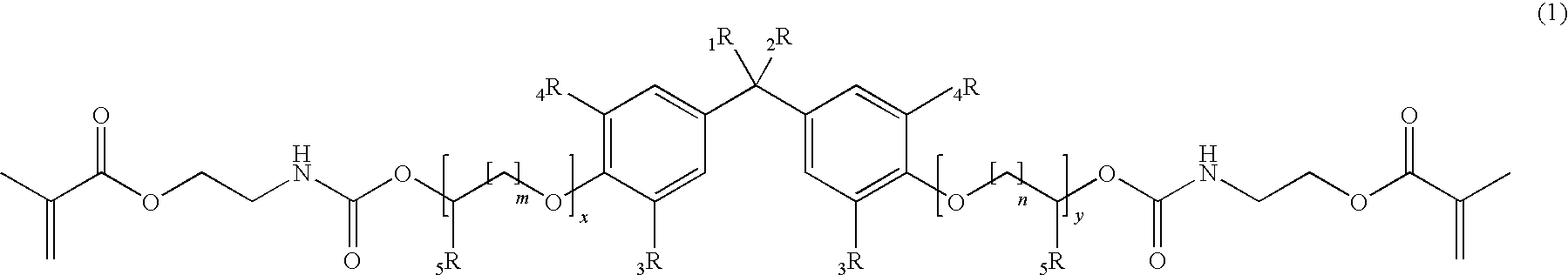

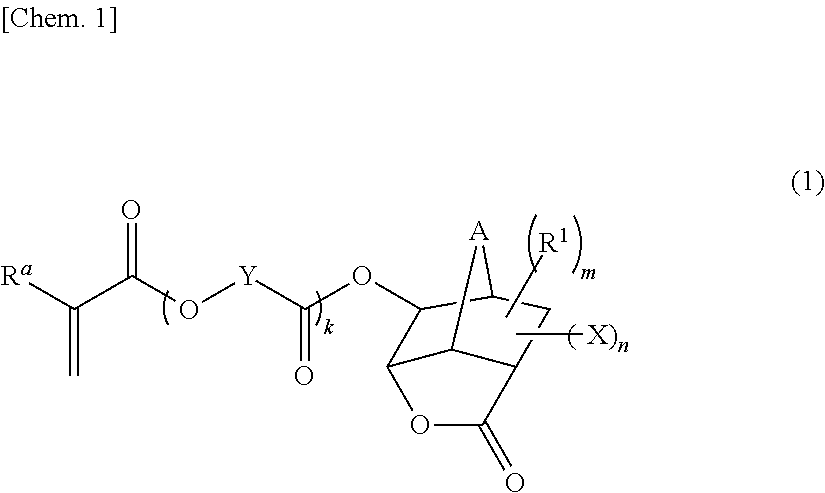

Methacrylate based monomers containing a urethane linkage, process for production and use thereof

ActiveUS20100197824A1Well-balanced propertyReduce polymerizationCosmetic preparationsImpression capsMethacrylatePhenyl group

The invention relates to a dental composition comprising a monomer or mixture of monomers represented by the following structure(1) with 1,2R independently selected from H, alkyl (e.g. CH3C2H5), and Phenyl, 3,4R independently selected from H, alkyl (e.g. CH3), and halogen (Cl, Br, F), 5R independently selected from H, alkyl (e.g. CH3), m, n=1, 2 and x+y=2 to 10, with the proviso that if m=n=2, than x+y=2 and if m=n=1, than x+y=4 to 10. The invention also relates to a process for producing the monomer or mixture of monomers and the use thereof especially as dental composition.

Owner:3M INNOVATIVE PROPERTIES CO

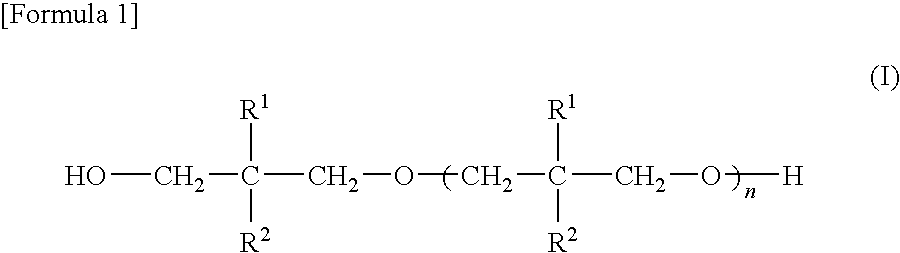

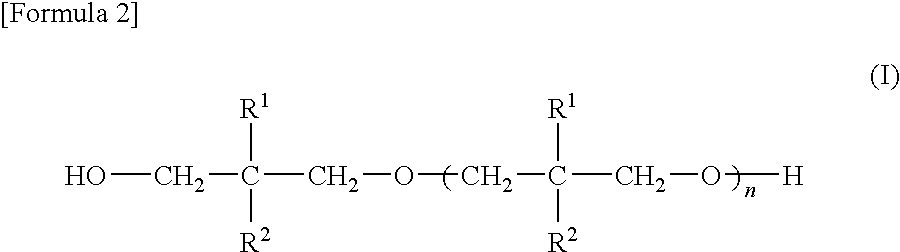

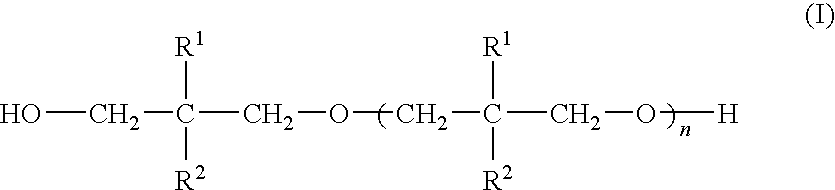

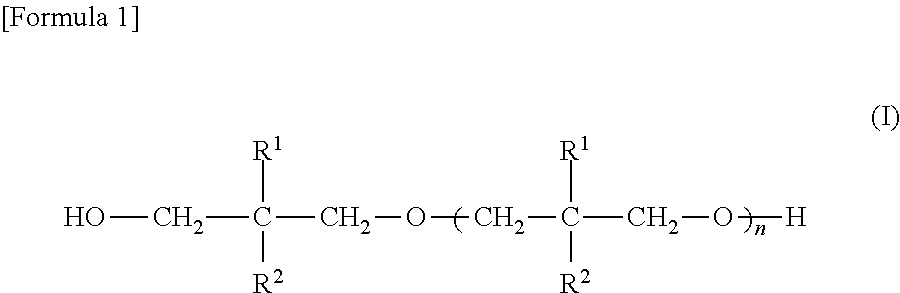

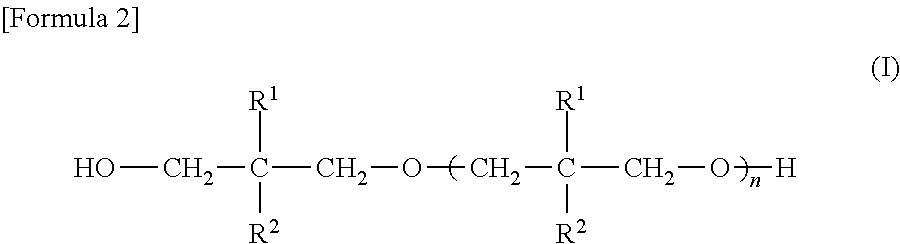

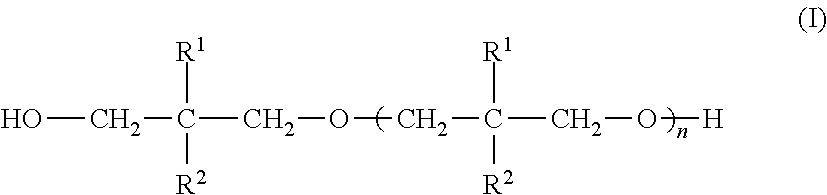

Liquid polyethercarbonatediol compound and thermoplastic polyurethane obtained therefrom

A liquid polyethercarbonatediol compound, useful for producing a thermoplastic polyurethane having excellent weathering resistance, softness and stretchability, comprises a reaction product of (1) a carbonate-ester compound with (2) a polyetherdiol compound having, in the molecular structure thereof, structural units of -RO-(a) and structural units of —(CH2)—O-(b) and / or —CH2CH(CH3)—O-(c), in which reaction product, average molecular numbers n and m of the structural units (b) and (c), per mole of the structural units (a) satisfy the requirements: O≦n≦5, O≦m≦5 and 1<(n+m)≦5.

Owner:UBE IND LTD

Puncture sealant

The present invention provides a tire puncture sealant including a rubber latex and 1,3-propanediol, which has a reduced viscosity at low temperatures, has better injectability at low temperatures, and is also excellent in storage stability, initial sealing performance, and seal retention performance.

Owner:SUMITOMO RUBBER IND LTD

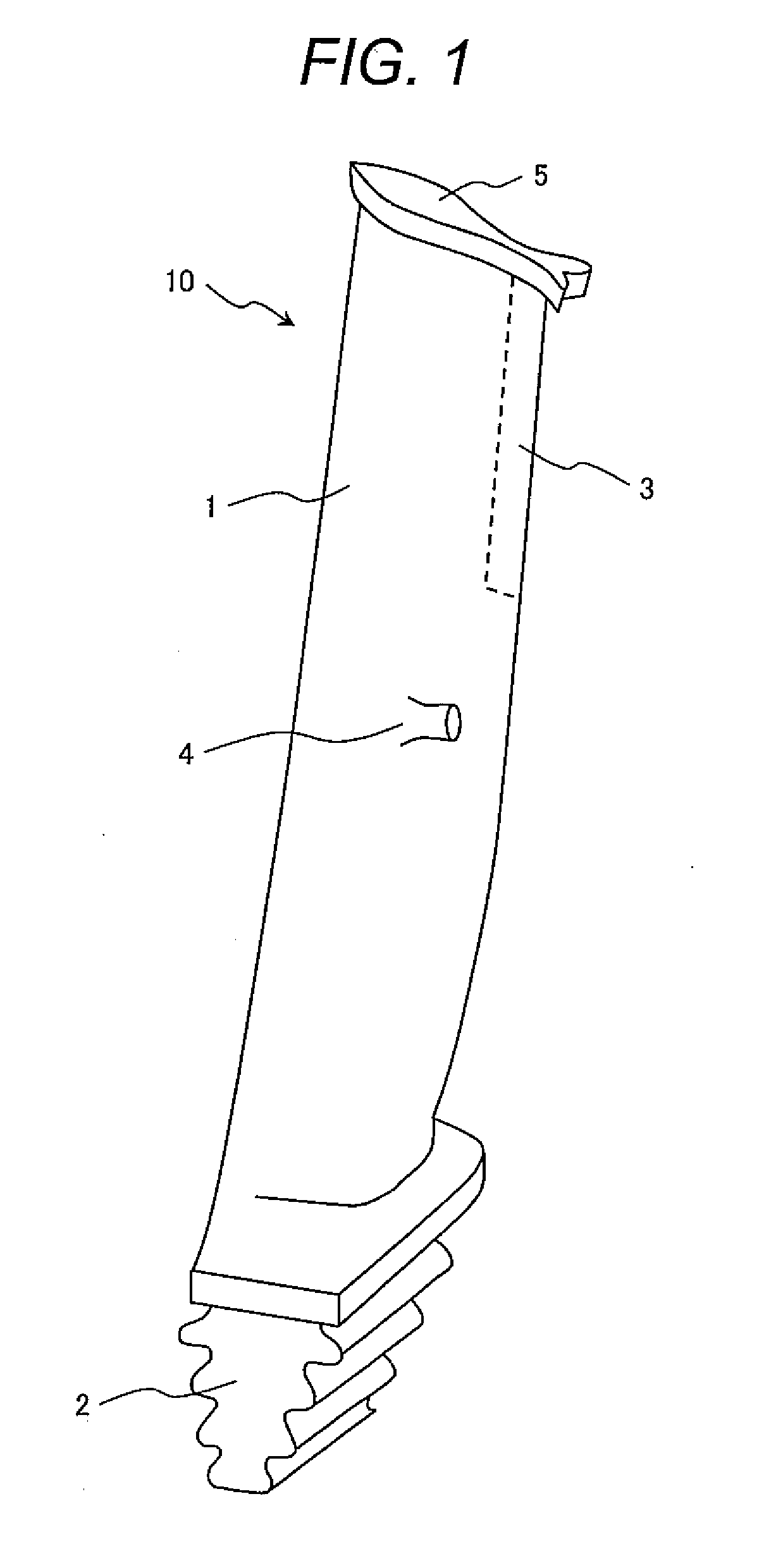

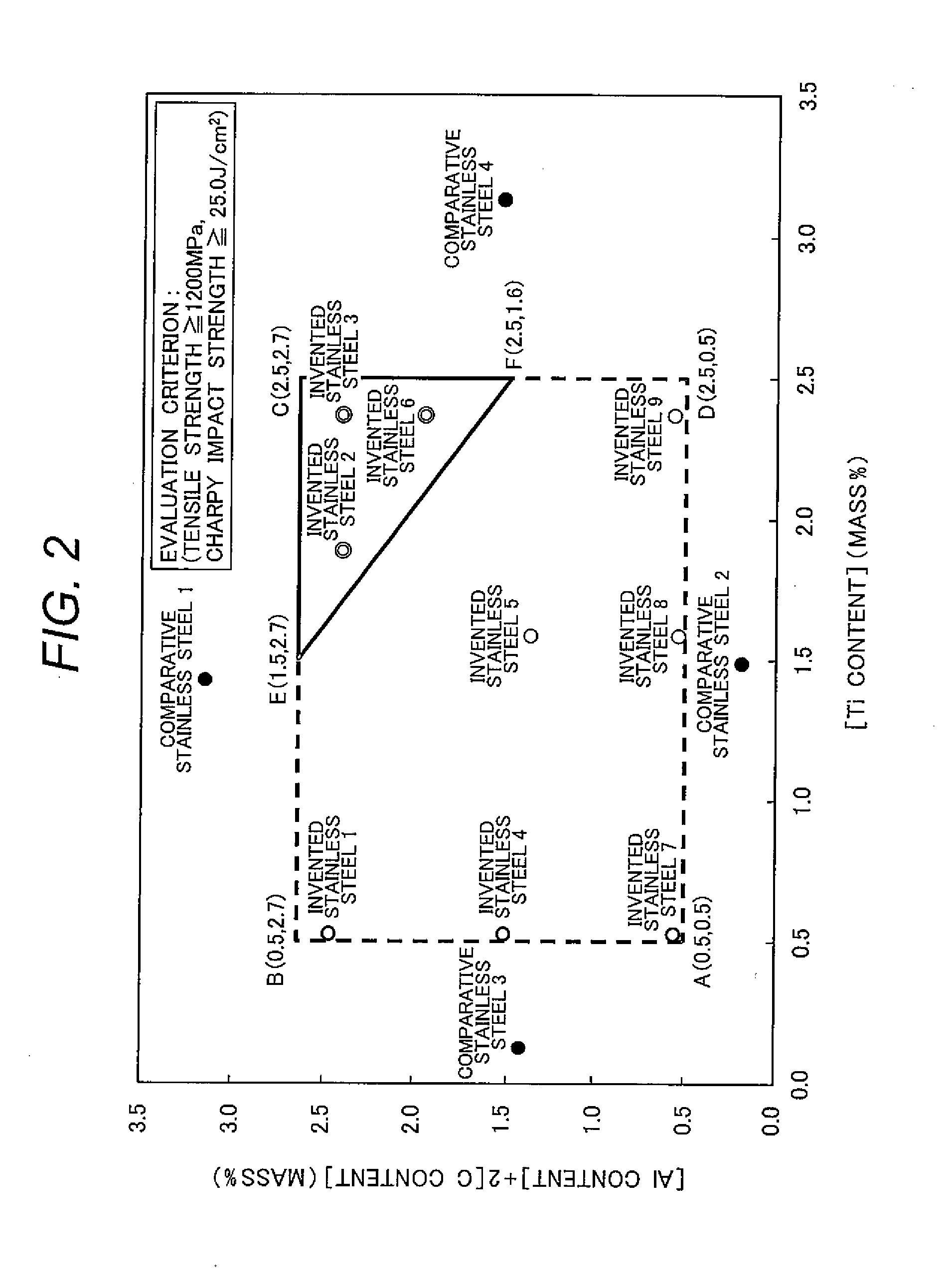

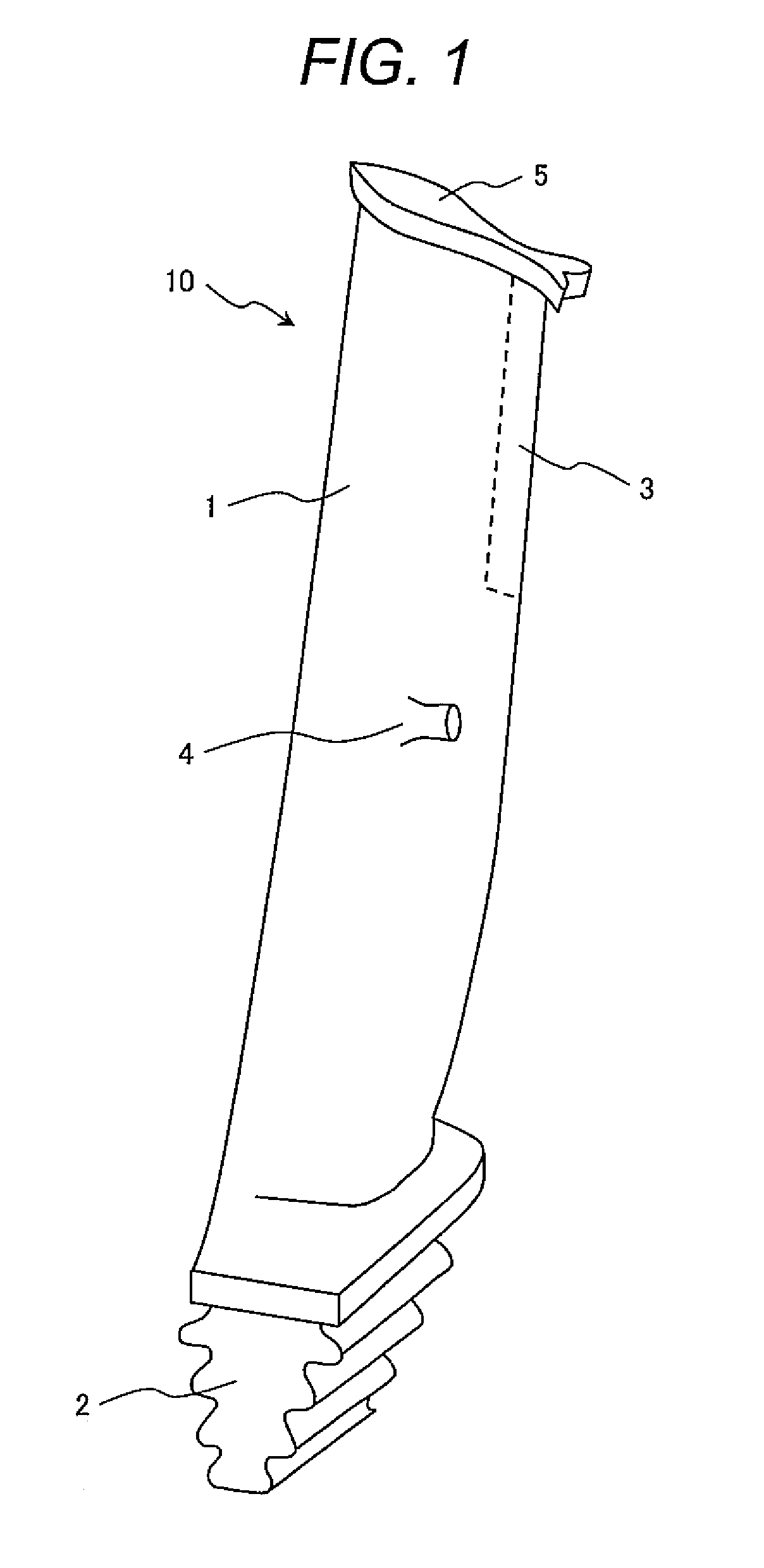

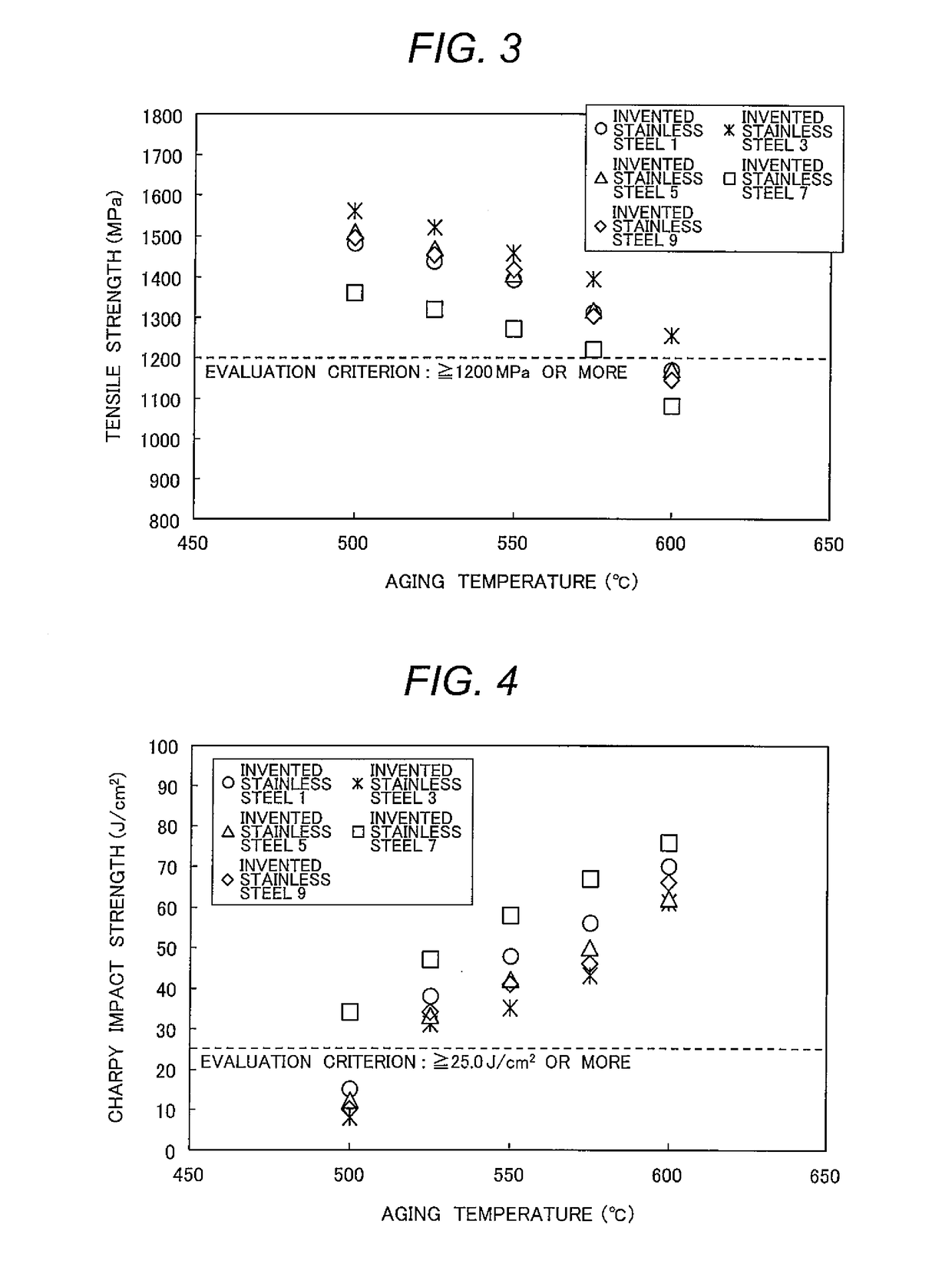

Precipitation Hardening Martensitic Stainless Steel and Steam Turbine Component Made Thereof

InactiveUS20120114496A1Well-balanced propertyHigh mechanical strengthPropellersRotary propellersMartensitic stainless steelUltimate tensile strength

It is an objective of the present invention to provide a precipitation-hardening martensitic stainless steel having well-balanced properties of high mechanical strength, high toughness and good corrosion resistance properties. There is provided a precipitation-hardening martensitic stainless steel comprising: 0.10 mass % or less of C; 13.0 to 15.0 mass % of Cr; 7.0 to 10.0 mass % of Ni; 2.0 to 3.0 mass % of Mo; 0.5 to 2.5 mass % of Ti; 0.5 to 2.5 mass % of Al; 0.5 mass % or less of Si; 0.1 to 1.0 mass % of Mn; and the balance including Fe and incidental impurities, in which the mass % content of the Ti (represented by [Ti content]), the mass % content of the Al (represented by [Al content]) and the mass % content of the C (represented by [C content]) satisfy relationships of “0.5≦[Ti content]≦2.5” and “0.5≦[Al content]+2[C content]≦2.7”.

Owner:MITSUBISHI HITACHIPOWER SYST LTD

Hot melt adhesive compositions based on propylene-based polymers and methods for using same

ActiveUS20190144719A1High peel strengthImprove thermal stabilityAdhesive articlesMedical devicesPolymer scienceAntioxidant

A polymer composition for use in a hot melt adhesive comprises at least one semierystalline, low molecular weight (LMW) propylene-based polymer; at least one essentially amorphous, high molecular weight (HMW) propylene-based polymer; and at least one essentially amorphous, LMW propylene-based polymer. A hot melt adhesive composition further contains a tackifier, a plasticizer, an antioxidant, and optionally a wax, a filler, a colorant, a UV absorber, another polymer, or combinations thereof The hot melt adhesive is useful for a variety of industrial applications where bonding of low surface energy substrates is encountered, including disposable nonwoven hygienic articles, labeling and other assembly applications. Particularly preferred applications include nonwoven disposable diaper and feminine sanitary napkin construction, diaper and adult incontinent brief elastic attachment, diaper and napkin core stabilization, diaper backsheet lamination, industrial filter material conversion, and surgical gown and surgical drape assemblies. The composition demonstrates improved peel strength while maintaining very good creep resistance.

Owner:BOSTIK INC

Reinforced flame retardant resin composition and molded article

ActiveUS20120252945A1Improve flame retardant performanceImprove heat resistancePlastic/resin/waxes insulatorsMicaPhosphoric Acid EstersFire retardant

A reinforced flame retardant resin composition including 20 to 87% by mass of an (A) thermoplastic resin, 3 to 20% by mass of a (B) aromatic phosphoric acid ester-based flame retardant agent, 5 to 40% by mass of (C) mica powder, and 0.5 to 30% by mass of (D) hydrous mineral powder having a dehydration starting temperature for crystallization water in a range of 400 to 600° C.

Owner:ASAHI KASEI CHEM CORP

Methacrylate based monomers containing a urethane linkage, process for production and use thereof

ActiveUS8426490B2Well-balanced propertyReduce polymerizationCosmetic preparationsImpression capsMethacrylateHalogen

The invention relates to a dental composition comprising a monomer or mixture of monomers represented by the following structure(1) with 1,2R independently selected from H, alkyl (e.g. CH3C2H5), and Phenyl, 3,4R independently selected from H, alkyl (e.g. CH3), and halogen (Cl, Br, F), 5R independently selected from H, alkyl (e.g. CH3), m, n=1, 2 and x+y=2 to 10, with the proviso that if m=n=2, than x+y=2 and if m=n=1, than x+y=4 to 10. The invention also relates to a process for producing the monomer or mixture of monomers and the use thereof especially as dental composition.

Owner:3M INNOVATIVE PROPERTIES CO

Biodegradable lubricating oil composition

InactiveUS20090176670A1Promote degradationHigh indexAdditivesBase-materialsCarboxylic acidBase Number

[PROBLEMS] To provide a biodegradable lubricating oil composition which has excellent biodegradability, a high viscosity index, a low pour point, a high flash point, being satisfactory with lubricity, oxidative stability, property of preventing the corrosion of iron and non-ferrous metals, and suitability for use with sealing materials.[MEANS FOR SOLVING THE PROBLEMS] A biodegradable lubricating oil composition comprising (A) a synthetic ester base oil comprising at least 50 mass % hindered ester of an aliphatic monocarboxylic acid with an aliphatic hindered polyol which has one or more quaternary carbon atoms per molecule and in which at least one of the quaternary carbon atoms has one to four methylol groups bonded thereto and (B) ingredients which are (a) 0.1 to 5.0 mass % phenolic antioxidant, (b) 0.01 to 2.0 mass % calcium sulfonate having a low base number, and (c) 0.01 to 1.0 mass % triazole compound, and has the degree of biodegradation of 60% or higher when examined by the test for the degree of microbial degradation of chemical substances according to the OECD Test Guideline 301C method.

Owner:IDEMITSU KOSAN CO LTD

Thermoplastic resin composition having excellent chemical resistance and easy vacuum formability

InactiveUS20040054077A1Good physical propertiesGood vacuum formabilityDomestic articlesCyanide compoundEmulsion polymerization

The resin composition according to the present invention comprises (A) a graft polymer prepared by grafting in emulsion polymerization 100 parts by weight of monomer mixture comprising 20-30% by weight of vinyl cyanide compound and 70-80% by weight of vinyl aromatic compound to 20-60 parts by weight of diene rubber, (B) a graft polymer prepared by grafting in emulsion polymerization 100 parts by weight of monomer mixture comprising 20-30% by weight of vinyl cyanide compound and 70-80% by weight of vinyl aromatic compound to 20-60 parts by weight of acrylic rubber, (C) a linear copolymer prepared by polymerizing 40-50% by weight of vinyl cyanide compound and 50-60% by weight of vinyl aromatic compound, and (D) a branched copolymer prepared by 30-35% by weight of vinyl cyanide compound and 65-70% by weight of vinyl aromatic compound.

Owner:CHEIL IND INC

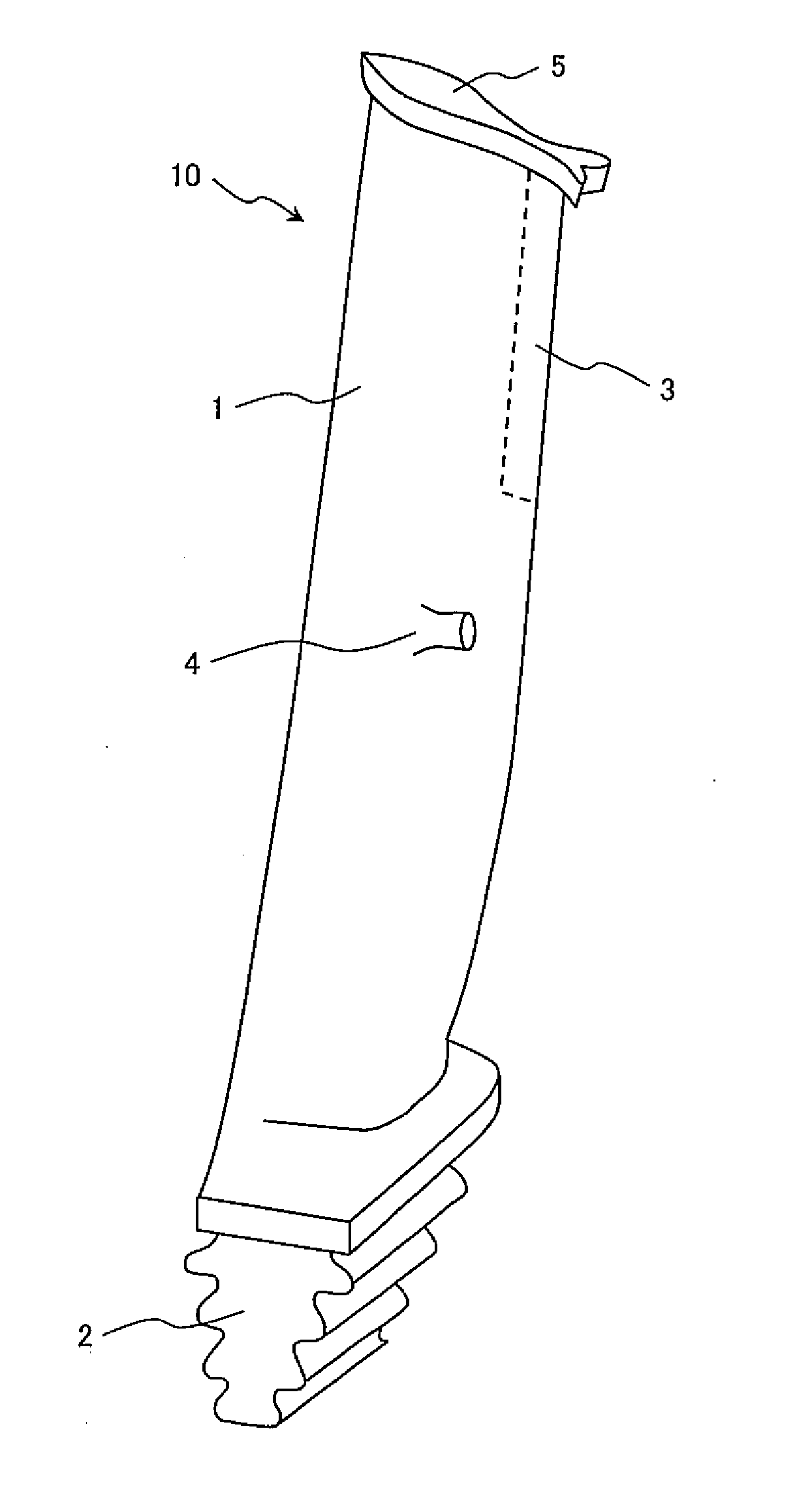

Polymer composition

A polymer composition obtainable by subjecting a particular crosslinkable polymer composition to dynamic crosslinking. The crosslinkable polymer composition contains. (a) a block copolymer comprising two or more polymer blocks of a vinyl aromatic compound and one or more (hydrogenated) polymer blocks of a conjugated diene; (b) an olefin copolymer having a density of 0.88 to 0.92 g / cm2 and obtained through copolymerization of ethylene and an α-olefin having 4 to 12 carbon atoms; (c) a softening agent; and (d) an organic peroxide in respective amounts that satisfy the following relational expressions ① to ③:0.66≦Wb / Wa≦4①0≦Wc / (Wa+Wb+Wc)≦0.25②0.001≦Wd / (Wa+Wb+Wc)≦0.01③wherein Wa, Wb, Wc and Wd represent the respective amounts (by mass) of the components (a), (b), (c) and (d), that are present in the polymer composition prior to the dynamic crosslinking.The polymer composition of the present invention is based on a thermoplastic elastomer that has various improved properties, including moldability, abrasion resistance, scratch resistance, hydrolysis resistance, softness, rubber elasticity, grip, shock absorbance, oil resistance, lightweightness and mechanical strength, and has these properties in a well-balanced manner.

Owner:KURARAY CO LTD

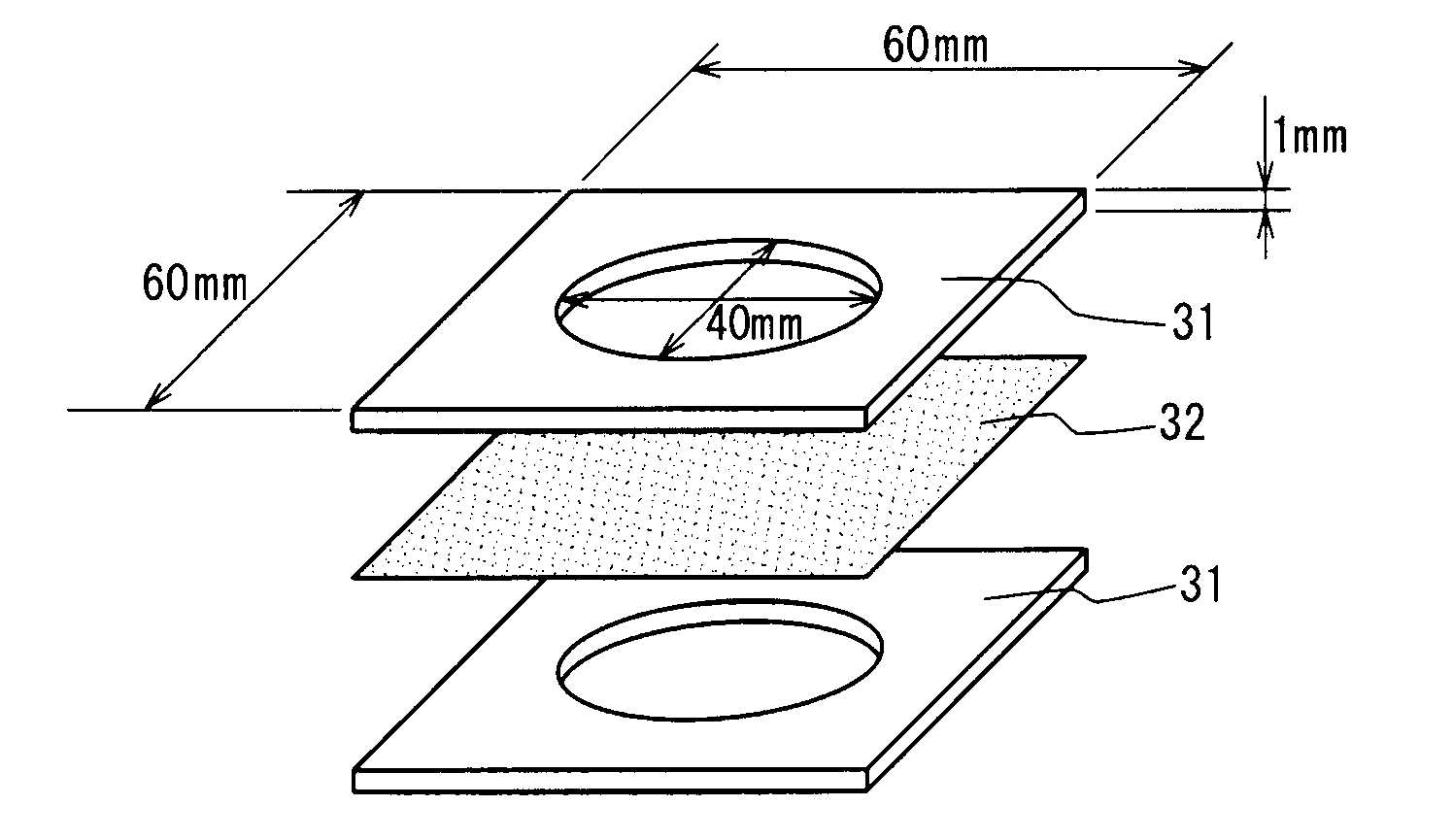

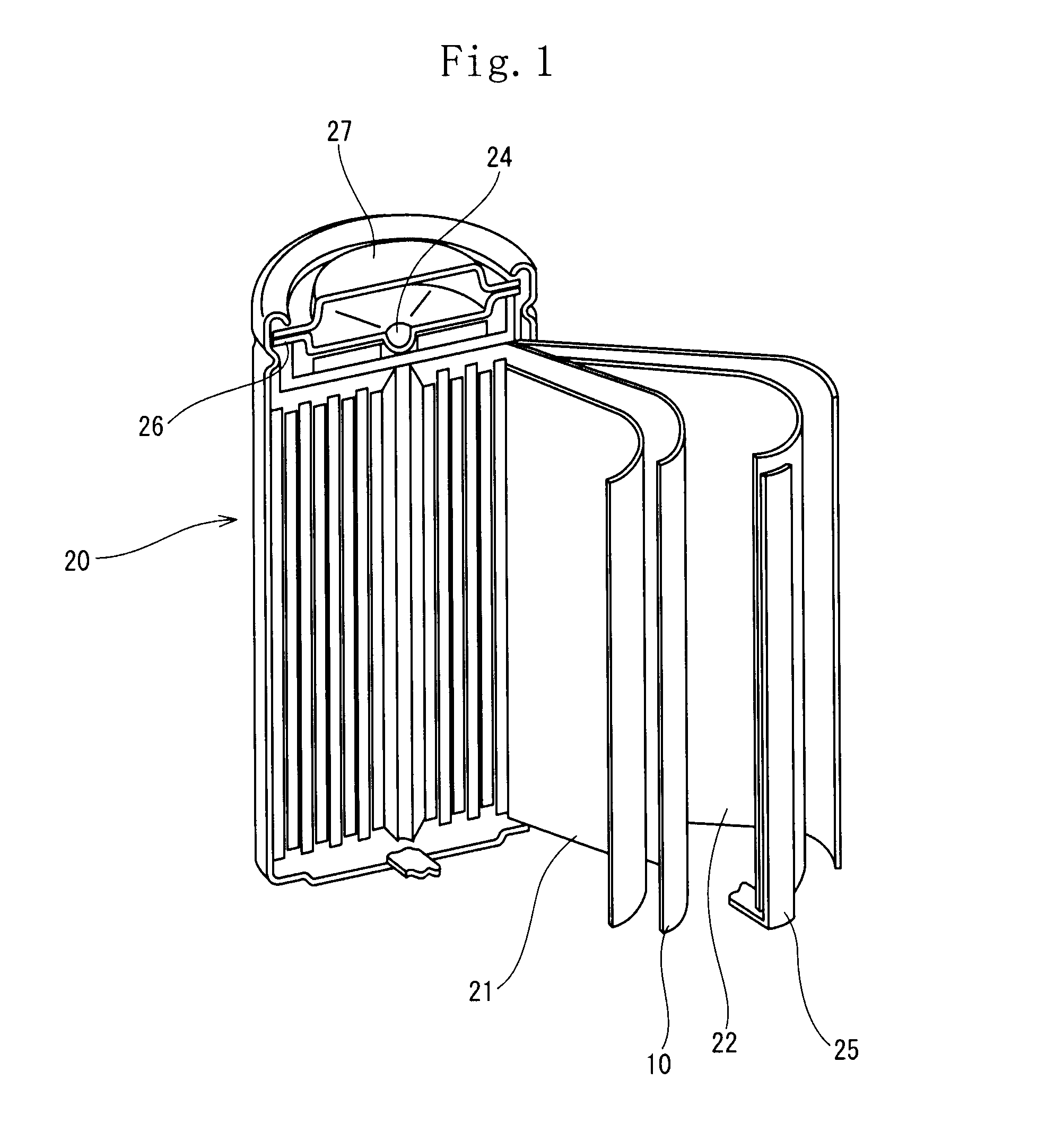

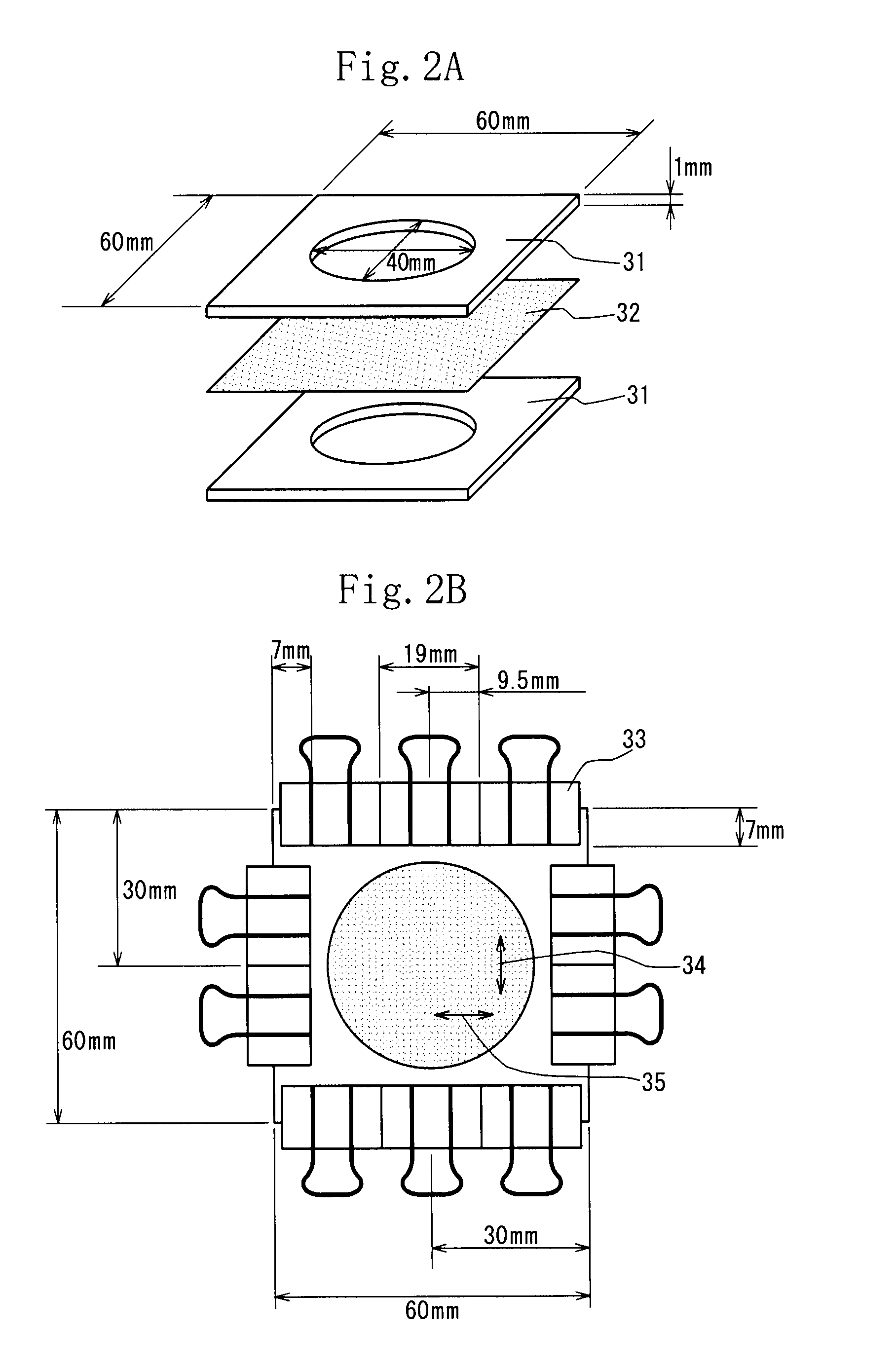

Laminated porous film, separator for lithium cell, and cell

ActiveUS20110217584A1Maintain propertiesAccurate temperature rangeLamination ancillary operationsSynthetic resin layered productsLithiumUltimate tensile strength

Provided is a laminated porous film having excellent shutdown characteristics and breakdown characteristics, good tearing strength and dimensional stability, and B activity. The laminated porous film comprises layer A, the main component of which is a polypropylene resin, and layer B which contains a polyethylene resin, and the ratio of the rearing strength (HMD) in the machine direction (MD) of the laminated porous film and the tearing strength (HTD) in the transverse direction (TD) of the laminated porous film with respect to the machine direction (HMD) (HTD) is 0.08 to 2.0.

Owner:MITSUBISHI CHEM CORP

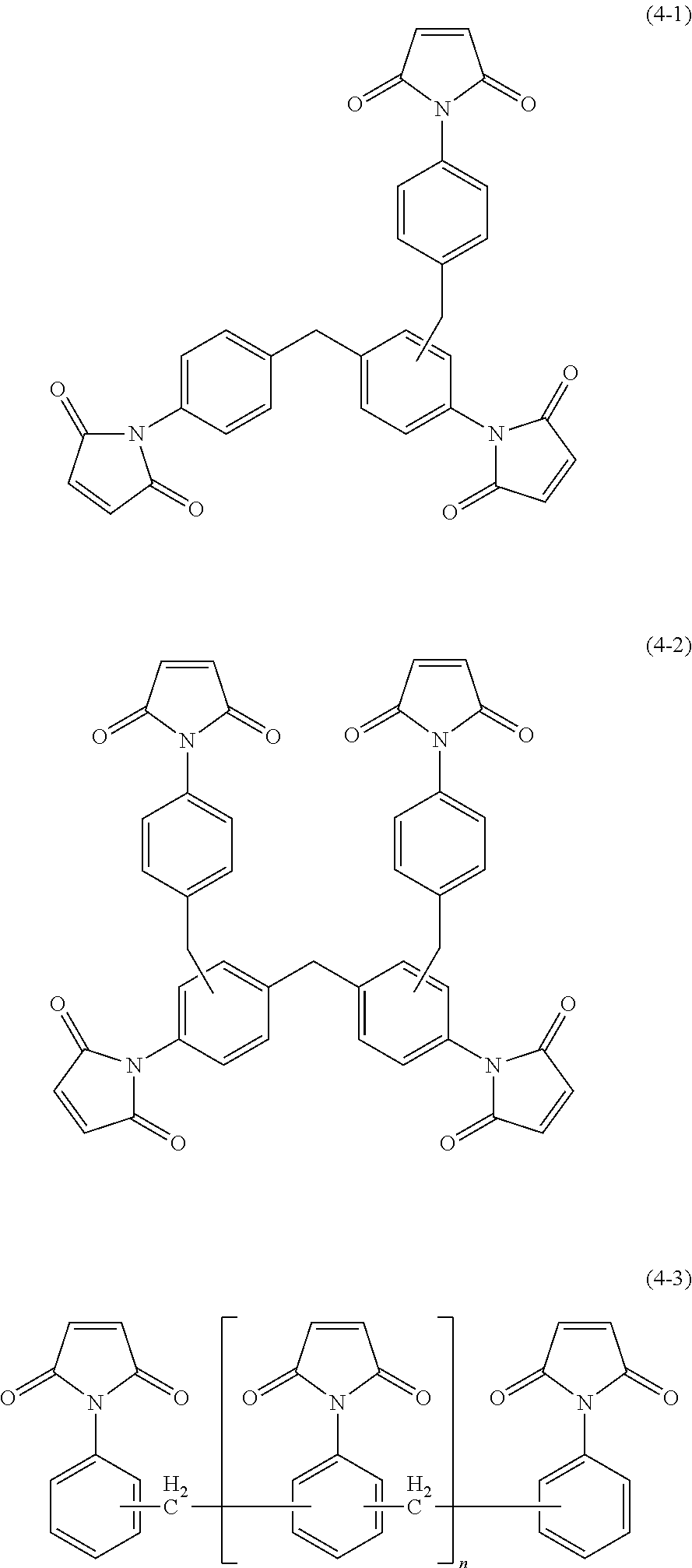

Thermosetting polyimide resin composition, cured product, and adhesive

To provide a thermosetting polyimide resin composition that can provide a cured product which generates a small amount of decomposition gas even when exposed to, for example, a high-temperature environment of about 250° C., and which exhibits high heat resistance, high durability, favorable flexibility, and favorable adhesive property; a cured product produced from the thermosetting polyimide resin composition; and an adhesive produced from the thermosetting polyimide resin composition. The thermosetting polyimide resin composition containing (a) a polyimide produced through reaction between a tetracarboxylic acid component containing a tetracarboxylic dianhydride and / or a tetracarboxylic acid, and a diamine; and (b) a maleimide composition containing at least one polymaleimide compound represented by any of formulas (4-1) to (4-3).

Owner:MITSUBISHI GAS CHEM CO INC

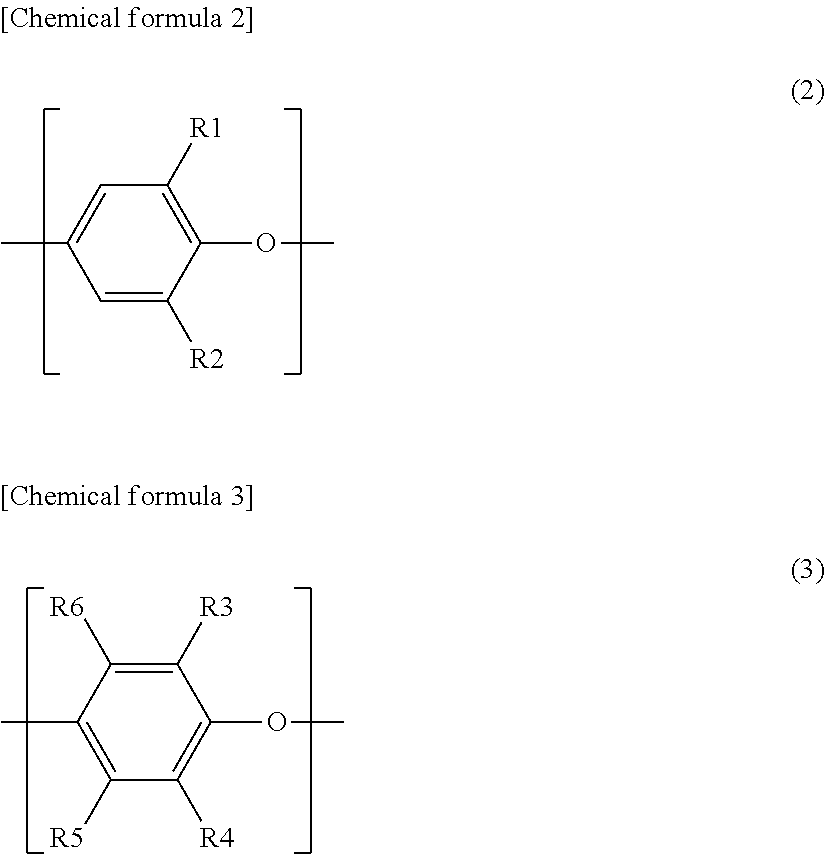

Halogen Free Thermoset Resin System for Low Dielectric Loss at High Frequency Applications

InactiveUS20140057086A1Well-balanced propertyPlastic/resin/waxes insulatorsSynthetic resin layered productsPolymer scienceDevice material

The present disclosure provides a thermosetting resin composition including a polymaleimide prepolymer and a poly(arylene ether) prepolymer characterized in that a resultant cured product formed by curing the thermosetting resin composition possesses high heat resistance and low dielectric loss at high frequency. The thermosetting resin composition is especially suited for use in high speed printed circuit boards, semiconductor devices and radome composites for aerospace applications.

Owner:HUNTSMAN ADVANCED MATERIALS AMERICAS INC

Multilayer Film, Laminate Using the Same, and Method for Producing the Laminate

InactiveUS20080138613A1Improve adhesionAdvantageously producedFilm/foil adhesivesSynthetic resin layered productsThermal expansionInorganic materials

Disclosed is a multilayer film for a strain-free laminate that is used for flexible TFT substrates or the like. Also disclosed are a laminate obtained by arranging such a multilayer film on a substrate made of an inorganic material, and a method for producing such a laminate. Specifically disclosed is a multilayer film wherein an adhesive resin layer that can be adhered to inorganic materials is arranged on a base film made of a resin. This multilayer film has a first average thermal expansion coefficient at temperatures from 60° C. to 80° C. measured during a first raise of the temperature of the multilayer film from 30° C. to 130° C. by heating the multilayer film, which first average thermal expansion coefficient is larger by 30 to 400 ppm / ° C. than a second average thermal expansion coefficient measured at temperatures from 60 to 80° C. during a second raise of the temperature from 30° C. to 130° C. after cooling the multilayer film from 130° C. to 30° C. subsequent to the first raise. Also specifically disclosed is a laminate obtained by sticking such a multilayer film onto at least one surface of a substrate made of an inorganic material. Further specifically disclosed is a method for producing such a laminate wherein the multilayer film is stuck to the substrate of an inorganic material at a temperature of not less than 40° C. and not more than the glass temperature of the resin of the adhesive resin layer.

Owner:ZEON CORP

Inorganic fiber molded body

InactiveUS20140272363A1Increase resistanceWell-balanced propertyThermal insulationFibre treatmentFiberSpinel

The present invention aims at providing an inorganic fiber molded body that is excellent in scale resistance, thermal shock resistance and mechanical shock resistance, and prevented from suffering from shrinkage when used under high-temperature heating conditions. The inorganic fiber molded body of the present invention is produced by impregnating a needle blanket of inorganic fibers with a liquid material of a precursor of a spinel-based compound represented by the general formula: MgxAlyO4 wherein an atomic ratio (y / x) is not less than 2 (y / x≧2); drying the thus impregnated needle blanket; and firing the dried needle blanket to convert the precursor into an oxide thereof.

Owner:MITSUBISHI PLASTICS INC

Multi-layer microporous polyolefin membrane and battery separator

ActiveUS9431642B2Well-balanced propertyGood film formingMembranesSemi-permeable membranesSurface layerPolyolefin

A multi-layer, microporous polyolefin membrane having at least three layers, which comprises first microporous layers made of a polyethylene resin for constituting at least both surface layers, and at least one second microporous layer comprising a polyethylene resin and polypropylene and disposed between both surface layers, the heat of fusion (ΔHm) of the polypropylene measured by differential scanning calorimetry being 90 J / g or more, and the polypropylene content in the second microporous layer being 50% or less by mass based on 100% by mass of the total of the polyethylene resin and the polypropylene.

Owner:TORAY IND INC

Reinforced flame retardant resin composition and molded article

ActiveUS8557899B2Improve flame retardant performanceImprove heat resistancePlastic/resin/waxes insulatorsMicaPhosphoric Acid EstersPolymer science

A reinforced flame retardant resin composition including 20 to 87% by mass of an (A) thermoplastic resin, 3 to 20% by mass of a (B) aromatic phosphoric acid ester-based flame retardant agent, 5 to 40% by mass of (C) mica powder, and 0.5 to 30% by mass of (D) hydrous mineral powder having a dehydration starting temperature for crystallization water in a range of 400 to 600° C.

Owner:ASAHI KASEI CHEM CORP

Precipitation hardening martensitic stainless steel and steam turbine component made thereof

InactiveUS9873930B2Well-balanced propertyHigh mechanical strengthFurnace typesHeat treatment furnacesMartensitic stainless steelUltimate tensile strength

It is an objective of the present invention to provide a precipitation-hardening martensitic stainless steel having well-balanced properties of high mechanical strength, high toughness and good corrosion resistance properties. There is provided a precipitation-hardening martensitic stainless steel comprising: 0.10 mass % or less of C; 13.0 to 15.0 mass % of Cr; 7.0 to 10.0 mass % of Ni; 2.0 to 3.0 mass % of Mo; 0.5 to 2.5 mass % of Ti; 0.5 to 2.5 mass % of Al; 0.5 mass % or less of Si; 0.1 to 1.0 mass % of Mn; and the balance including Fe and incidental impurities, in which the mass % content of the Ti (represented by [Ti content]), the mass % content of the Al (represented by [Al content]) and the mass % content of the C (represented by [C content]) satisfy relationships of “0.5≦[Ti content]≦2.5” and “0.5≦[Al content]+2[C content]≦2.7”.

Owner:MITSUBISHI HITACHIPOWER SYST LTD

Memory element, memory apparatus

ActiveUS9553255B2Well-balanced propertyThermal stabilityMagnetic measurementsMagnetic-field-controlled resistorsPower flowMagnetization

A memory element includes a memory layer having magnetization perpendicular to a film face of the memory layer in which a direction of the magnetization configured to be changed. The memory element includes a magnetization-fixed layer having a magnetization perpendicular to the film face. The memory element includes an intermediate layer that is formed of a non-magnetic material and is provided between the memory layer and the magnetization-fixed layer. The memory layer includes a multilayer structure in which a non-magnetic material and an oxide are laminated. The direction of the magnetization of the memory layer is configured to be changed by applying a current in a lamination direction of the layered structure to record information in the memory layer.

Owner:SONY CORP

Biodegradable lubricating oil composition

InactiveUS20140155307A1Promote degradationWell-balanced propertyAdditivesBase-materialsCarboxylic acidBase Number

[PROBLEMS] To provide a biodegradable lubricating oil composition which has excellent biodegradability, a high viscosity index, a low pour point, a high flash point, being satisfactory with lubricity, oxidative stability, property of preventing the corrosion of iron and non-ferrous metals, and suitability for use with sealing materials.[MEANS FOR SOLVING THE PROBLEMS] A biodegradable lubricating oil composition comprising (A) a synthetic ester base oil comprising at least 50 mass % hindered ester of an aliphatic monocarboxylic acid with an aliphatic hindered polyol which has one or more quaternary carbon atoms per molecule and in which at least one of the quaternary carbon atoms has one to four methylol groups bonded thereto and (B) ingredients which are (a) 0.1 to 5.0 mass % phenolic antioxidant, (b) 0.01 to 2.0 mass % calcium sulfonate having a low base number, and (c) 0.01 to 1.0 mass % triazole compound, and has the degree of biodegradation of 60% or higher when examined by the test for the degree of microbial degradation of chemical substances according to the OECD Test Guideline 301C method.

Owner:IDEMITSU KOSAN CO LTD

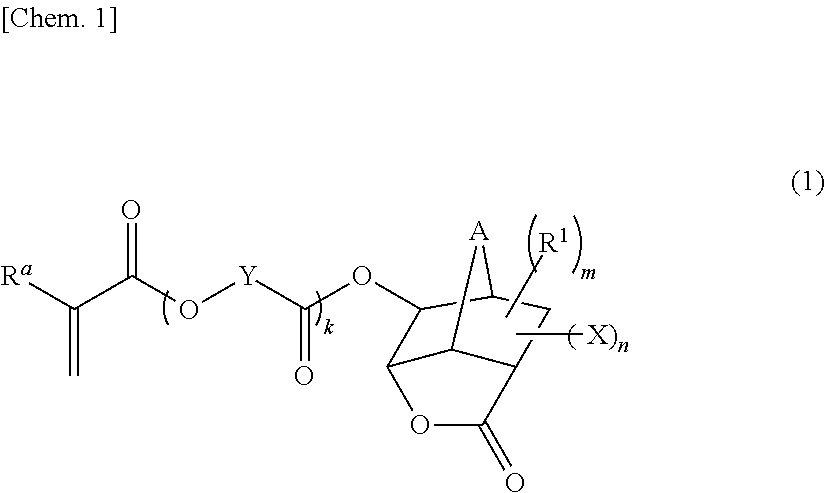

Monomer having n-acyl carbamoyl group and lactone skeleton, and polymeric compound

Disclosed is a monomer containing an N-acylcarbamoyl group and a lactone skeleton. The monomer is exemplified by Formula (1):where Ra is selected typically from hydrogen and C1-C6 alkyl; R1 is, independently in each occurrence, selected typically from halogen and optionally halogenated C1-C6 alkyl; “A” is selected from C1-C6 alkylene, oxygen, sulfur, and non-bond; m represents an integer of 0 to 8; X represents, independently in each occurrence, specific N-acylcarbamoyl; n represents an integer of 1 to 9; and Y represents a C1-C6 divalent organic group.

Owner:TOKYO OHKA KOGYO CO LTD +1

Method of producing inorganic fiber molded body

InactiveUS20150299938A1Improve thermal shock resistanceWell-balanced propertyThermal insulationFibre treatmentFiberSpinel

The present invention aims at providing an inorganic fiber molded body that is excellent in scale resistance, thermal shock resistance and mechanical shock resistance, and prevented from suffering from shrinkage when used under high-temperature heating conditions. The inorganic fiber molded body of the present invention is produced by impregnating a needle blanket of inorganic fibers with a liquid material of a precursor of a spinel-based compound represented by the general formula: MgxAlyO4 wherein an atomic ratio (y / x) is not less than 2 (y / x 2); drying the thus impregnated needle blanket; and firing the dried needle blanket to convert the precursor into an oxide thereof.

Owner:MITSUBISHI CHEM CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com