Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

51 results about "Electroless nickel immersion gold" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Electroless nickel immersion gold (ENIG) is a type of surface plating used for printed circuit boards. It consists of an electroless nickel plating covered with a thin layer of immersion gold, which protects the nickel from oxidation.

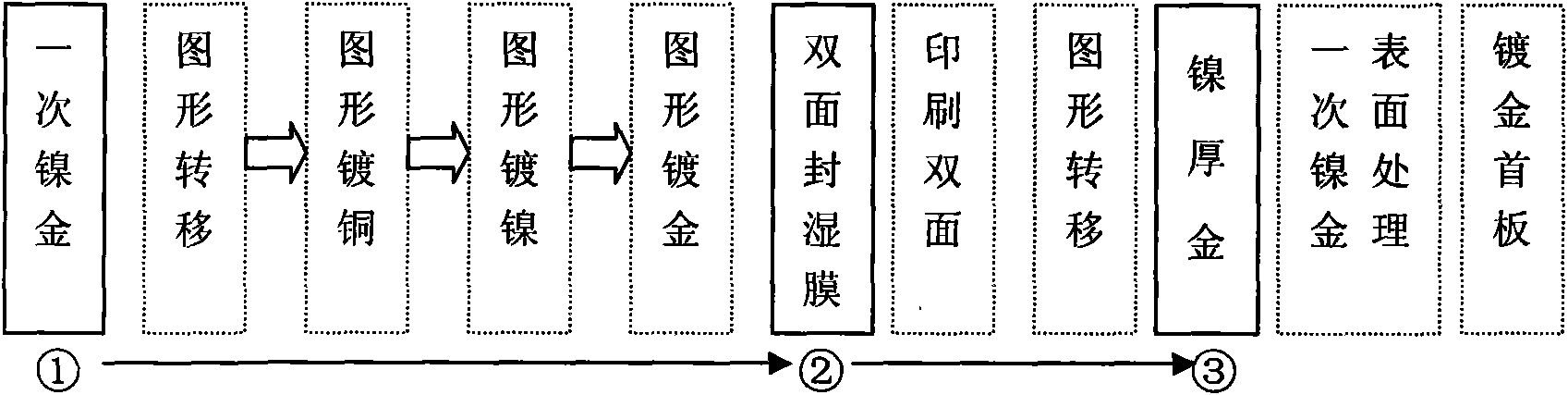

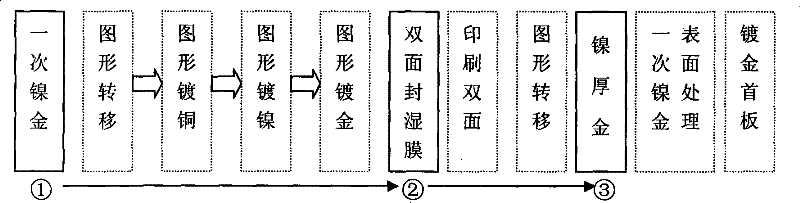

Method for plating thick gold layer in circuit board manufacturing process

InactiveCN101631427ANo pollutionImprove plating resistancePrinted circuit manufactureElectroless nickel immersion goldEtching

The invention discloses a method for plating a gold thick layer in a circuit board manufacturing process, which comprises the following steps of: A, firstly, subjecting a circuit board to pattern tin plating, circuit wire etching, solder-mask printing and chemical nickel and gold processing treatments of depositing a nickel layer and depositing a gold layer; B, carrying out the anti-oxidation post treatment of the circuit board subjected to the chemical nickel and gold processing treatments; C, covering a non-gold plated area of the circuit board; and D, after pre-treating the surface of the circuit board, plating the thick gold layer on a lead of the circuit board by a post drawing process. The invention provides a method for plating thick gold layer in the circuit board manufacturing process, which has advantages of pollution prevention, environment protection, gold salt conservation, good quality and easily controllable gold color.

Owner:深圳市九和咏精密电路有限公司

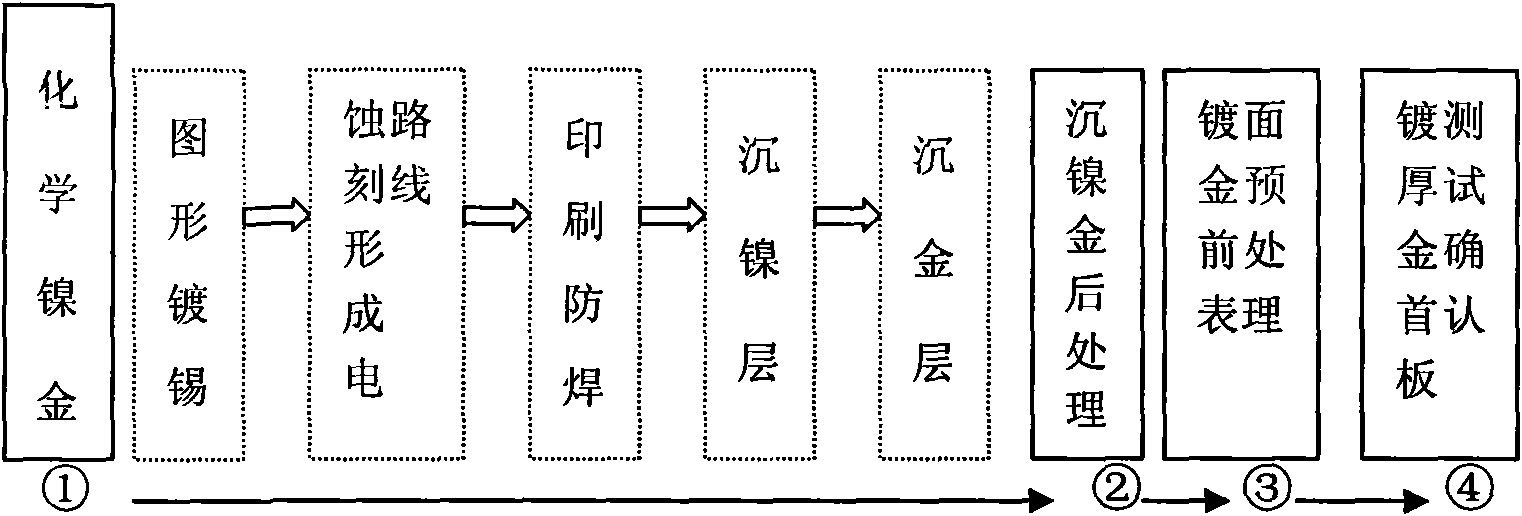

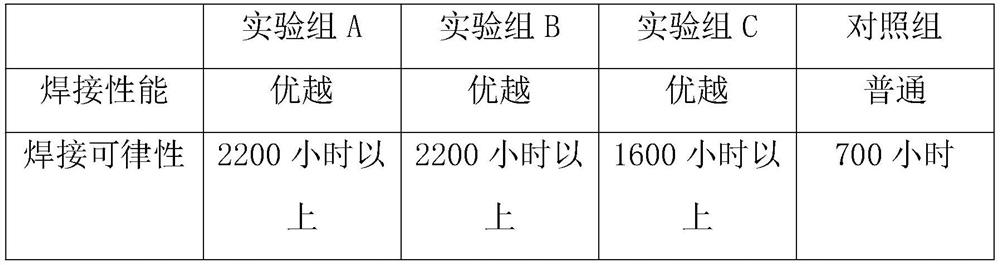

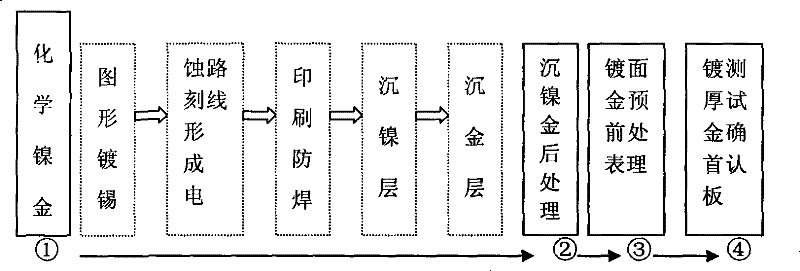

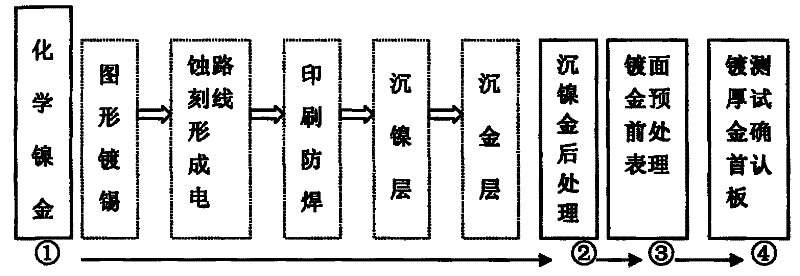

Novel chemical nickel gold production process and chemical nickel plating liquid

InactiveCN109628913AFast deposition rateSolve the difficulty of levelingLiquid/solution decomposition chemical coatingEtchingNickel deposition

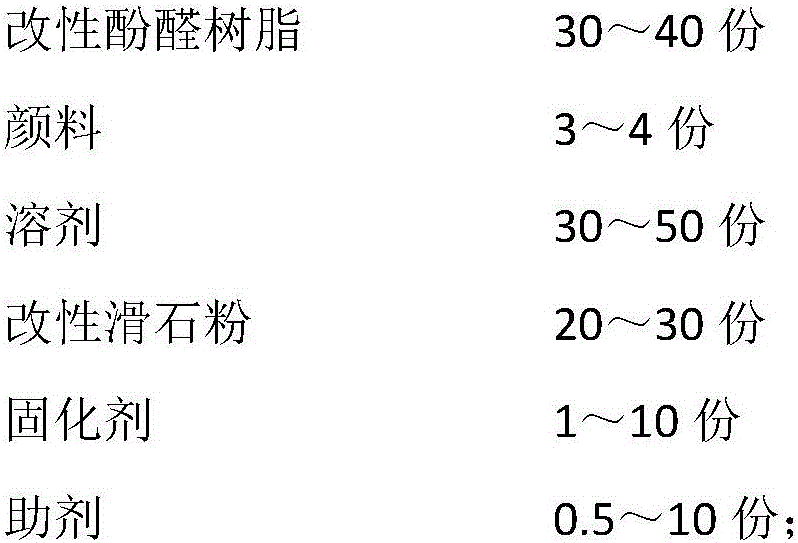

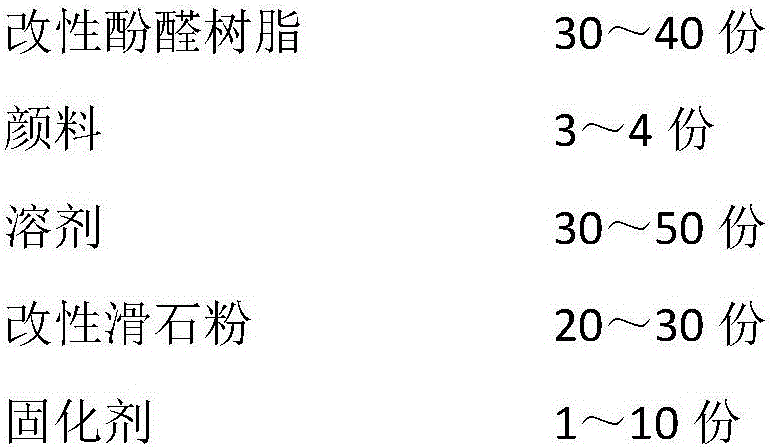

The invention discloses a PCB or package substrate chemical nickel gold production new process. The new process comprises the steps of chemical gold pretreatment, deoiling, micro-etching, activation,alkaline chemical nickel, nickel activation, acid chemical nickel, chemical gold, gold surface hole sealing and chemical gold aftertreatment. The invention further provides novel chemical nickel plating liquid. The process is low in nickel cylinder temperature and high in chemical nickel deposition speed; nickel simple substances are difficultly separated out from the wall of a chemical nickel plating liquid stabilizing tank; the horizontal production of chemical nickel gold can be realized; a production line is shortened; the emission of waste water is reduced; and the comprehensive production cost of the production line is reduced. In the novel chemical nickel plating liquid, through adjustment of types of complexing agents and stabilizing agents in the chemical nickel plating liquid, even if under the conditions of higher PH and higher deposition speed, higher P content is achieved to meet various performance requirements of existing chemical nickel gold for the surface treatment ofPCBs and package substrates.

Owner:湖南互连微电子材料有限公司

PWB manufacture

InactiveUS6926922B2Preventing electroless metal depositionInsulating substrate metal adhesion improvementPrinted circuit aspectsElectroless nickel immersion goldEngineering

A process and composition for manufacturing printed wiring boards that reduces or eliminates the problem of depositing electroless nickel in through holes that are not designed to be metal plated is provided. Also provided by the present invention is a method and composition for depositing a final finish that is even and bright. The present invention is particularly suitable for the manufacture of printed circuit boards containing one or more electroless nickel-immersion gold layers.

Owner:SHIPLEY CO LLC

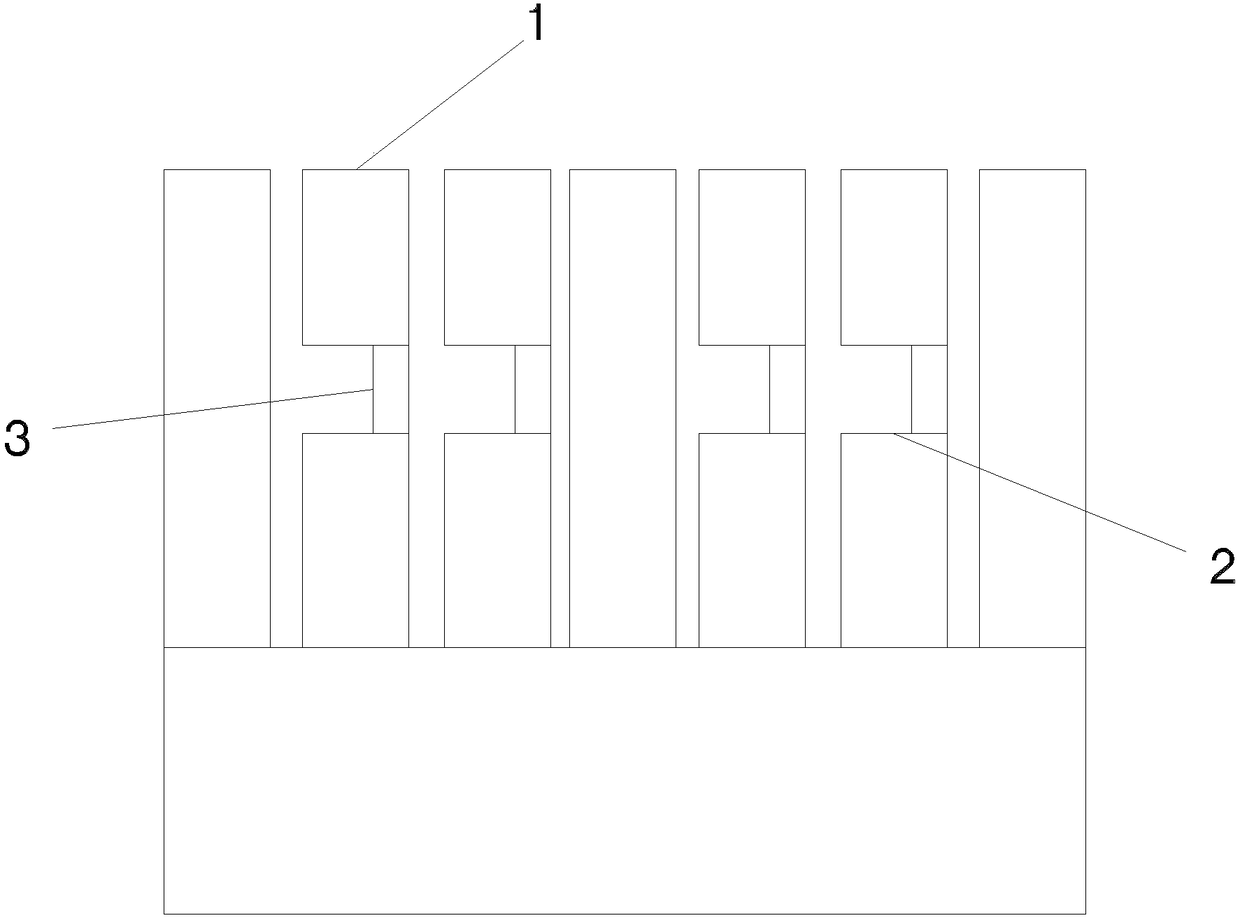

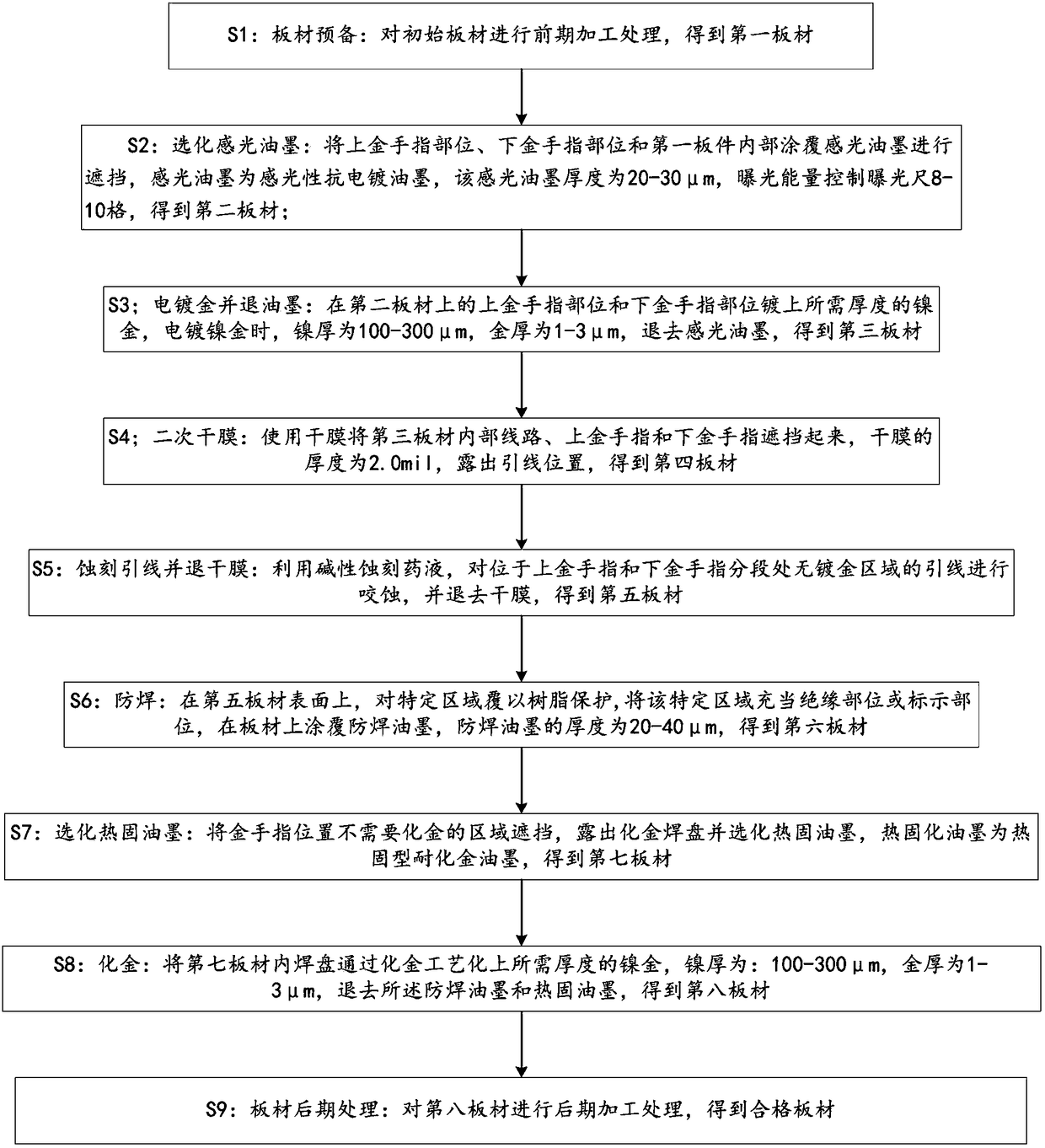

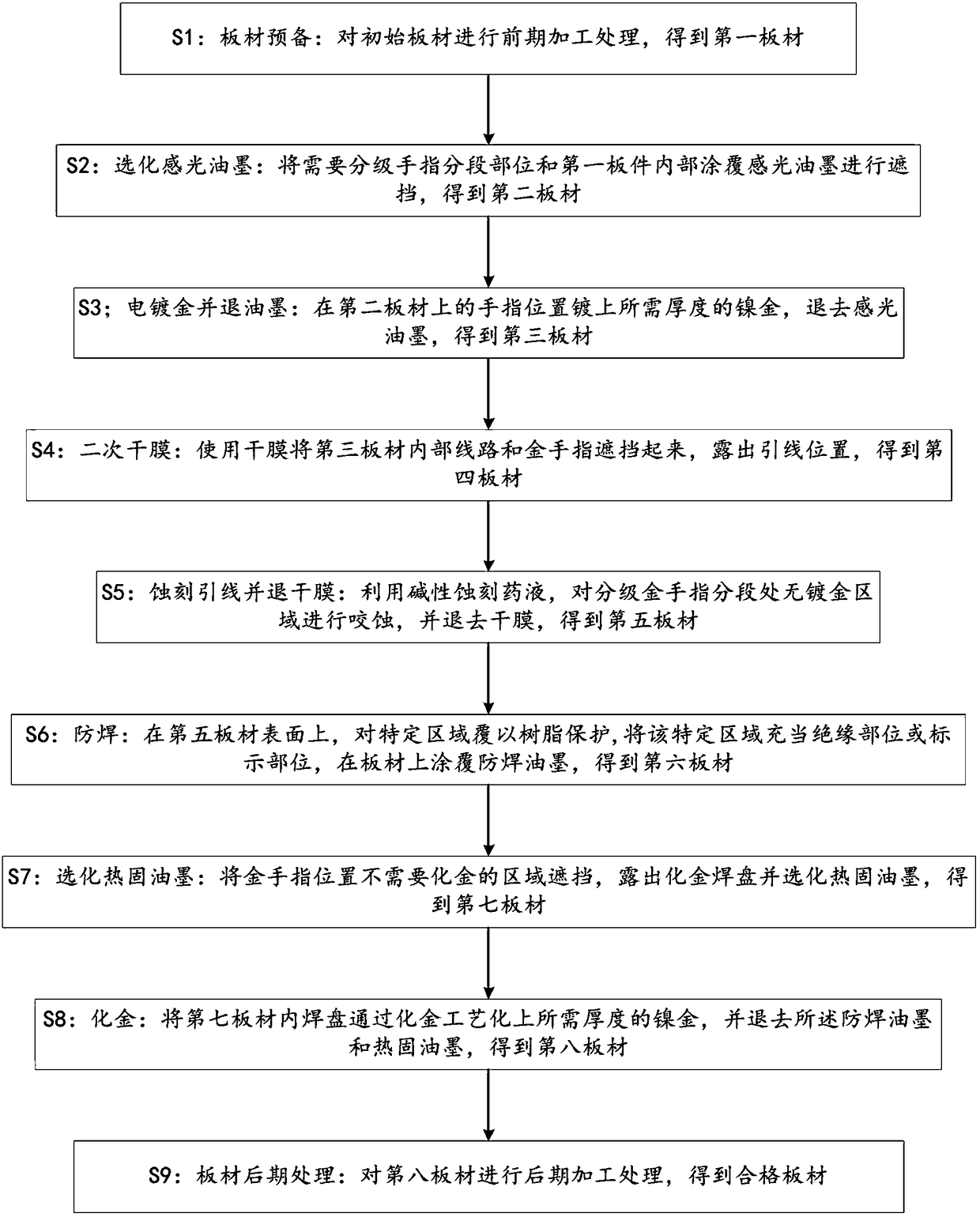

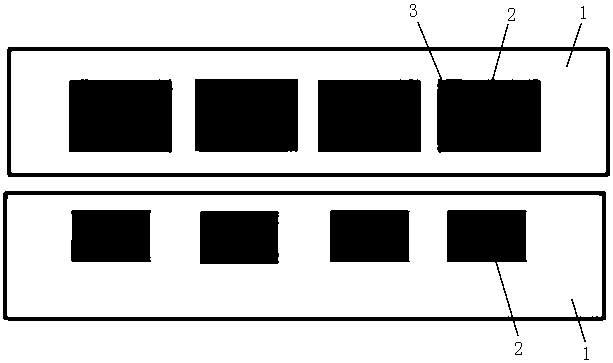

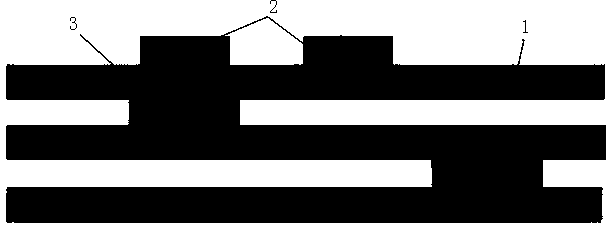

Graded gold finger and manufacturing method of optical module PCB comprising graded gold finger

InactiveCN108174510AStable deliveryReduce widthPrinted circuit aspectsElectrical connection printed elementsElectroless nickel immersion goldOptical Module

The invention discloses a graded gold finger. The graded gold finger comprises upper golden fingers, lower gold fingers, and leads, wherein the upper gold fingers, the lower gold fingers, and the leads are all rectangular. The graded gold finger is characterized in that the leads are arranged between the upper gold fingers and the lower gold fingers; the upper sides and lower sides of the lead arefixedly connected with the upper gold fingers and the lower gold fingers respectively; and the width of the leads is smaller than the width of the gold fingers. The invention also discloses a manufacturing method of an optical module PCB comprising the graded golden finger. The method comprises the following steps of: plate preparation; selective electroless nickel immersion gold of photosensitive ink; electroplating gold and ink removal; secondary dry film treatment; lead etching and dry film removal; solder masking; selective electroless nickel / immersion gold of heat-set ink; electroless nickel / immersion gold; and plate after-treatment. The method is based on the structural characteristics of the above graded gold finger. With the method adopted, the problem of the falling off of soldermasking sites of a finished board can be solved; and the quality of a PCB manufactured by the method can be further improved.

Owner:深圳欣强智创电路板有限公司

Method for producing printing circuit board

Owner:SHIPLEY CO INC

Chemical nickel, palladium and gold plating technique for printed circuit board

InactiveCN105112892AAvoid contactPrevent black disk problemLiquid/solution decomposition chemical coatingEtchingAlloy

The invention discloses a chemical nickel, palladium and gold plating technique for a printed circuit board. The chemical nickel, palladium and gold plating technique for the printed circuit board comprises the steps of deoiling, hot water washing, dual water washing, micro-etching, dual water washing, presoaking, treatment through a palladium activating agent, dual water washing, deposition of chemical nickel, dual water washing, deposition of chemical palladium, dual water washing, deposition of chemical gold and the like. According to the chemical nickel, palladium and gold plating technique for the printed circuit board, chemical palladium plating is introduced, diffusion and migration of nickel are prevented by means of a palladium layer, contact between the nickel and a gold leaching solution is also prevented, and thus the common problem of black discs of existing chemical nickel and gold surface treatment techniques is effectively solved; a chemical plated palladium layer is completely dissolved in welding flux, no hyperphosphate layer appears at an alloy connector, a new chemical plated palladium layer can be exposed to be used for generating good nickel-tin alloy when the original chemical plated palladium is dissolved, and thus the reliability of welding spots is improved; a plated palladium layer with larger hardness is introduced, a thin clad layer can has good abrasion resistance and gold line printing performance, can serve as a key touch surface and is suitable for being applied to products with high connection reliability, and meanwhile surface treatment cost is reduced.

Owner:黄石西普电子科技有限公司

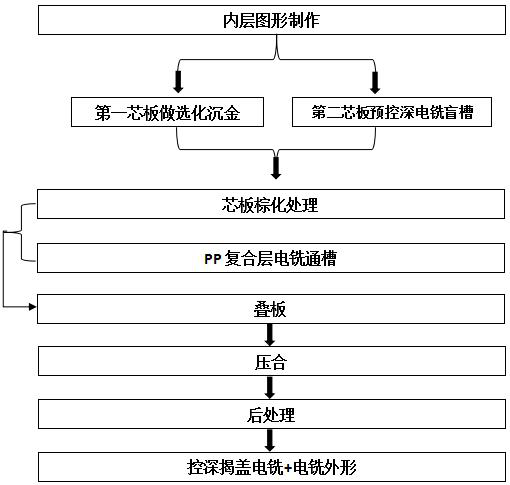

Processing method for nickel gold immersion at bottom of PCB step groove

ActiveCN111741618APrecise Control of DepthAvoid glue residueConductive material chemical/electrolytical removalMultilayer circuit manufactureElectroless nickel immersion goldEngineering

The invention discloses a processing method for nickel gold immersion at the bottom of a PCB step groove. The method comprises the steps: carrying out selective gold immersion on a first core plate, and carrying out pre-controlled deep electric milling of a blind groove on a second core plate; respectively carrying out browning treatment on the first core plate and the second core plate; carryingout electric milling through groove treatment on a pp composite layer; enabling the gold immersion PAD of the first core plate, the through groove of the pp composite layer and the blind groove of thesecond core plate to correspond in position; sequentially laminating the first core plate, the pp composite layer and the second core plate to obtain a PCB inner plate; carrying out post-processing on the PCB inner plate; and carrying out depth-controlled uncovering electric milling treatment on the second core plate to expose the gold immersion PAD of the first core plate. The method has the advantages that the depth of the step groove is accurately controlled, the problem of residual glue at the bottom of the step groove is avoided, and the requirement of a PAD at the bottom of the PCB stepgroove for chemical nickel-gold plating is met; and according to the detailed processing steps of the invention, no special high-standard requirement on equipment exists, the method is suitable for the existing conditions of general factories, and batch production can be realized without adding other equipment.

Owner:BOMIN ELECTRONICS CO LTD

Preparation method of electroless nickel immersion gold for printed circuit board

InactiveCN107995802AHigh corrosion sensitivityErosion is goodPrinted element electric connection formationAcid washingElectroless deposition

The invention discloses a preparation method of electroless nickel immersion gold for a printed circuit board. The preparation method comprises the following steps of 1, pretreatment of the circuit board; 2, circuit board installation; 3, immersion and oil removing, wherein the circuit board is immersed into a exchange tank, so that the board surface of the circuit board is wetted, and an oxide layer and oil dirt on the board surface of the circuit board are removed; 4, acid washing; 5, pre-immersion; 6, activation; 7, post-immersion; 8, electroless deposition of nickel, palladium and gold, wherein a nickel layer is deposited on a copper surface of the circuit board by using sodium dihydric hypophosphite and hydrochloric nickel, a palladium layer is electrolessly deposited on the nickel layer of the circuit board, a gold layer is immersed into the palladium layer so as to form a gold layer on the nickel layer of the circuit board, and the electroless nickel immersion gold is prepared.

Owner:江西鑫力华数码科技有限公司

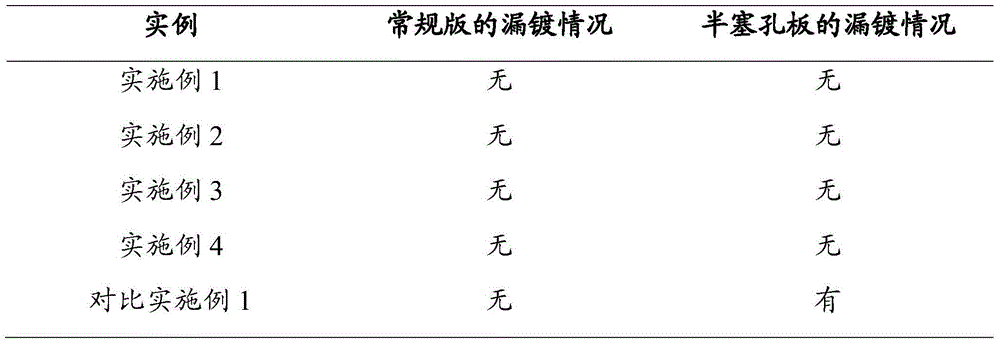

Post-immersing liquid of circuit board electroless nickel immersion gold and post-immersing method

ActiveCN104470236AImprove stabilitySolve the technical problems of missing plating phenomenonLiquid/solution decomposition chemical coatingPrinted circuit manufactureEtchingElectroless nickel immersion gold

The invention discloses a post-immersing liquid of circuit board electroless nickel immersion gold. The post-immersing liquid comprises the components of 1 to 10V / V% of sulfuric acid, 1 to 30g / L of a reducing agent and 10 to 80g / L of a complexing agent. According to the post-immersing liquid of the invention, the reducing agent and the complexing agent are added so as to modify the post-immersing liquid, so that oxidation substances such as micro etching solution, Cu<2+> and activated Pd<2+> left in semi-plugged holes can be removed, and therefore, plating omission in the electroless nickel immersion gold can be avoided, and the yield of high-density printed-circuit boards can be improved.

Owner:WUHAN CHUANGXINTE TECH CO LTD

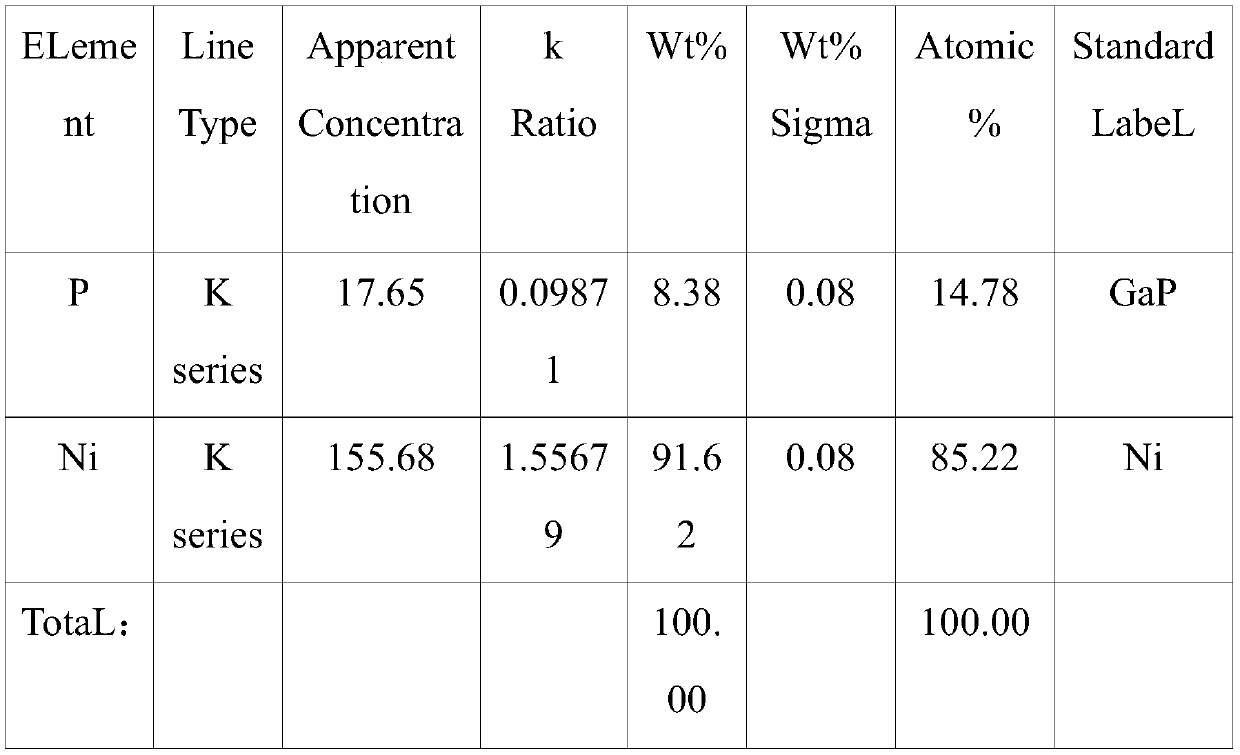

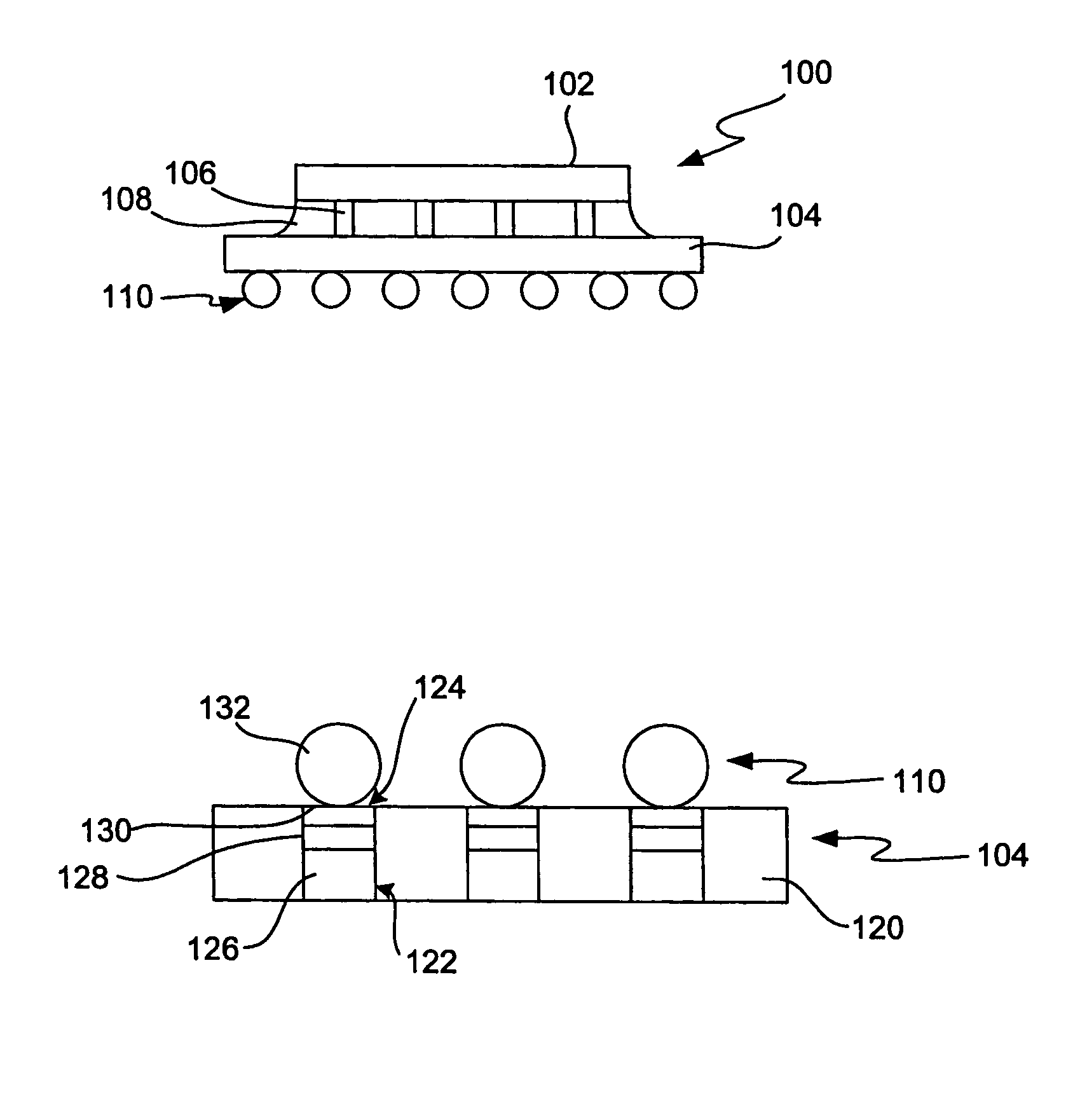

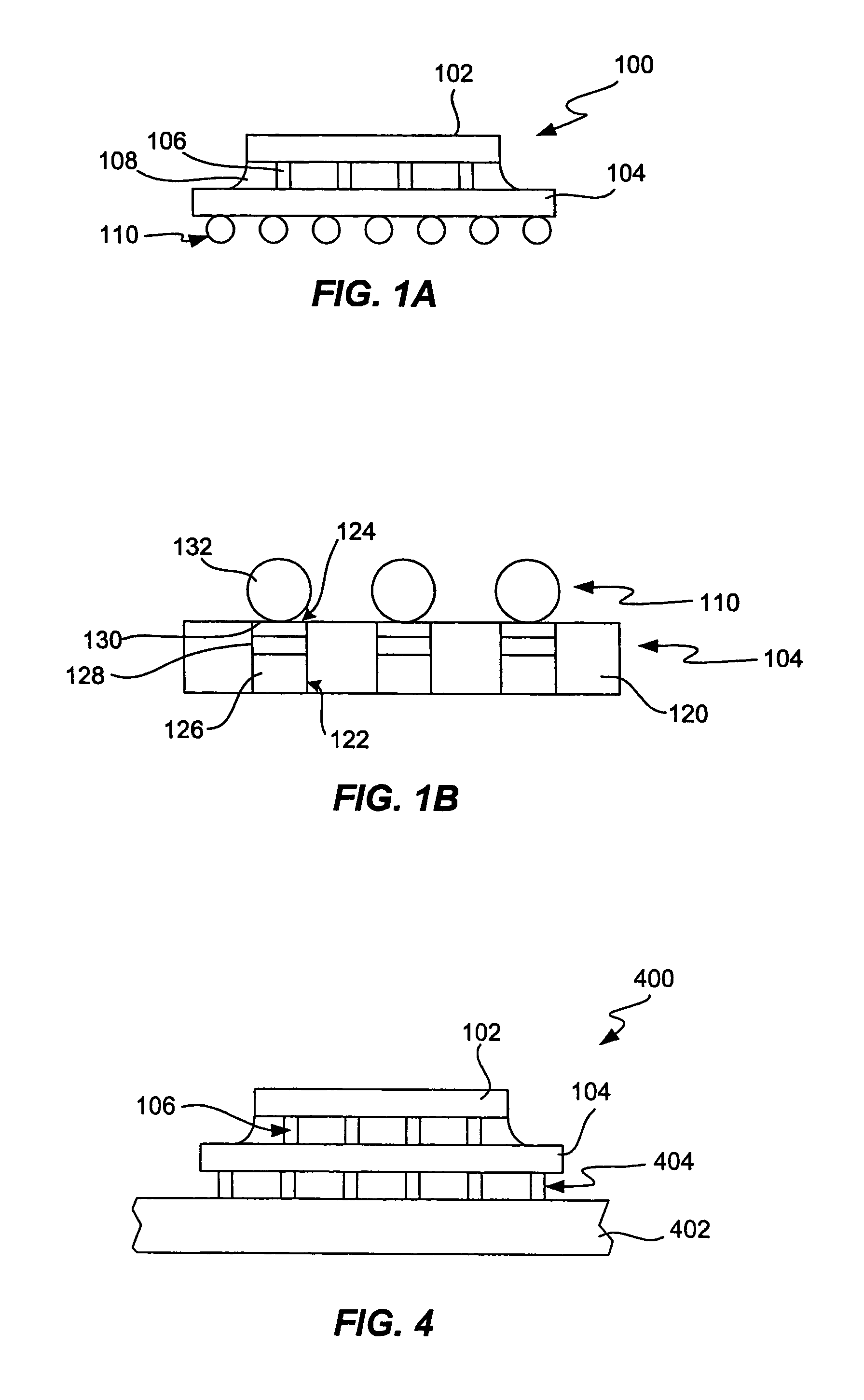

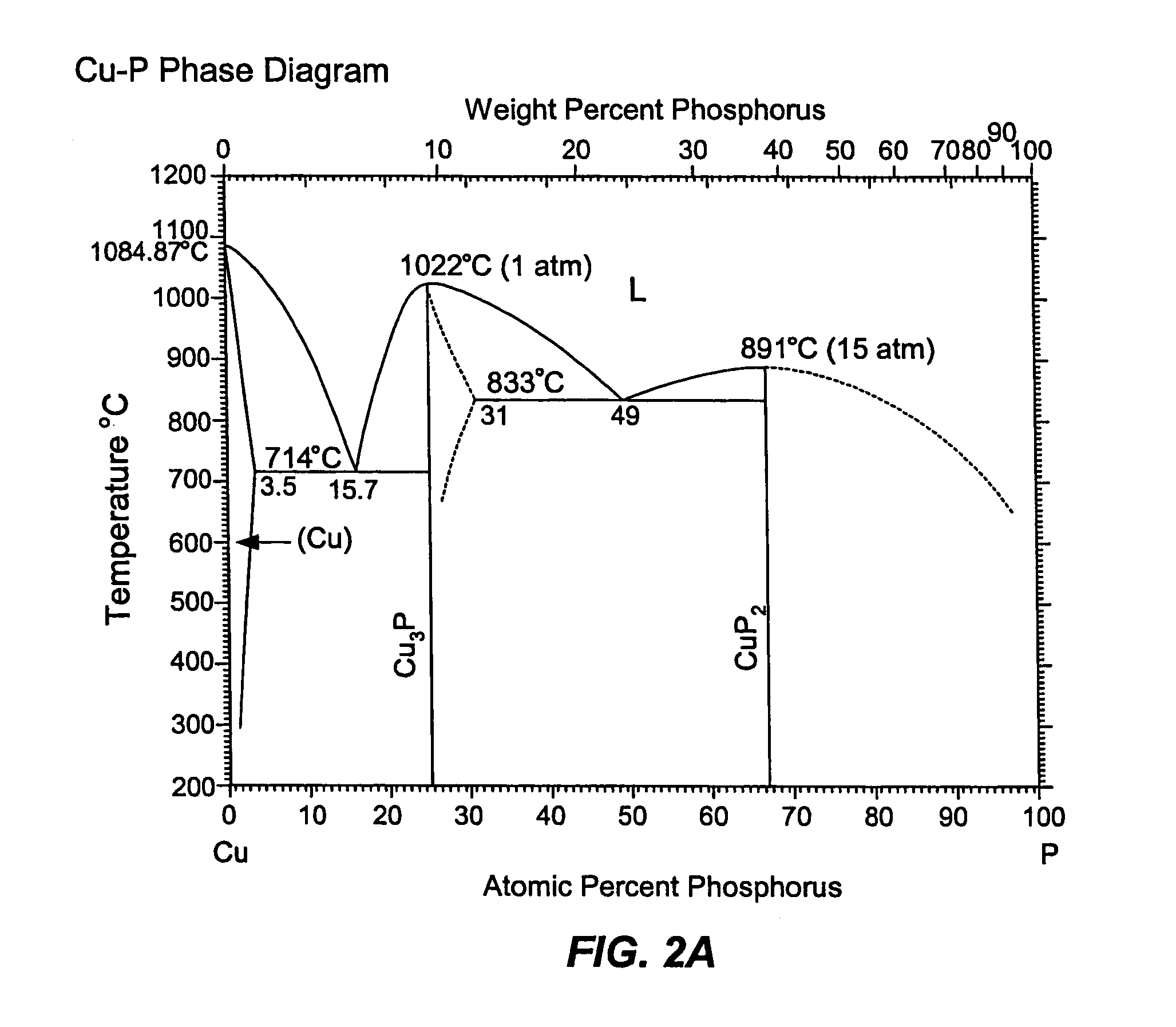

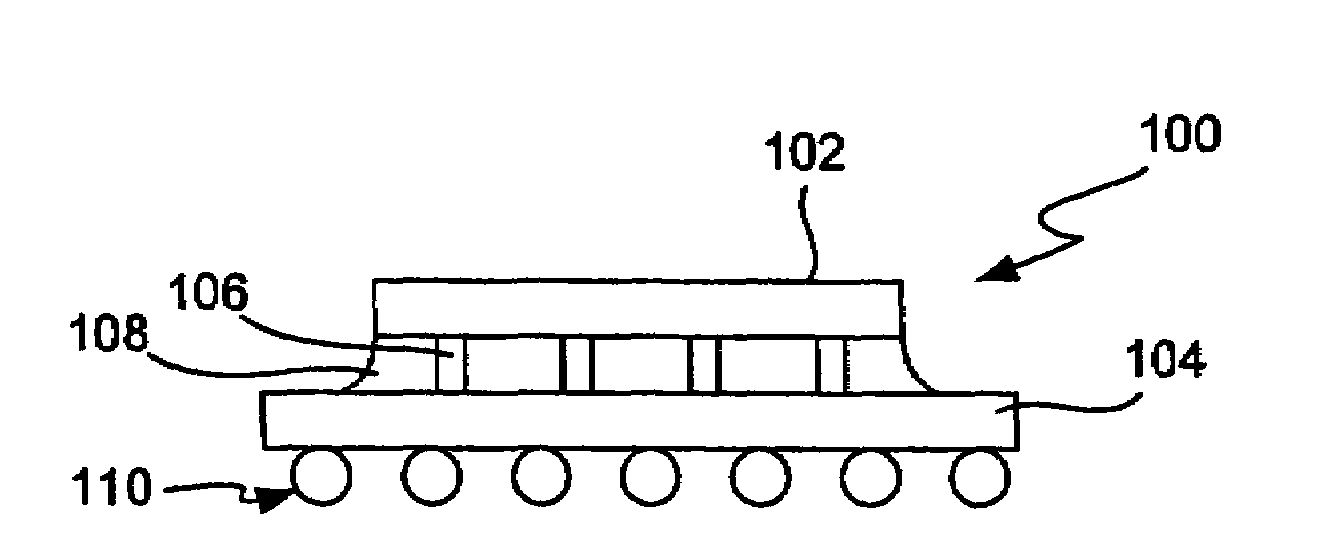

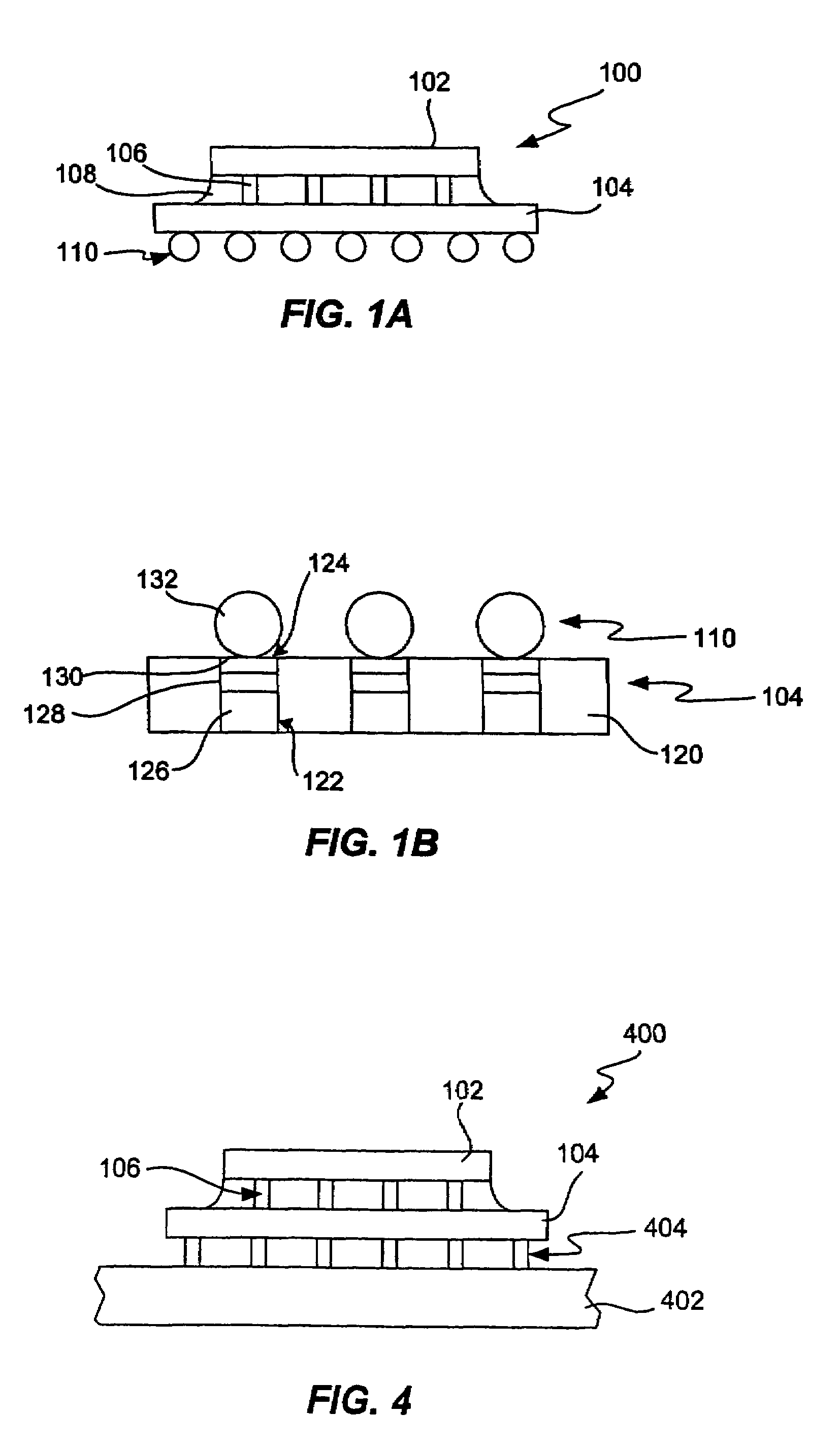

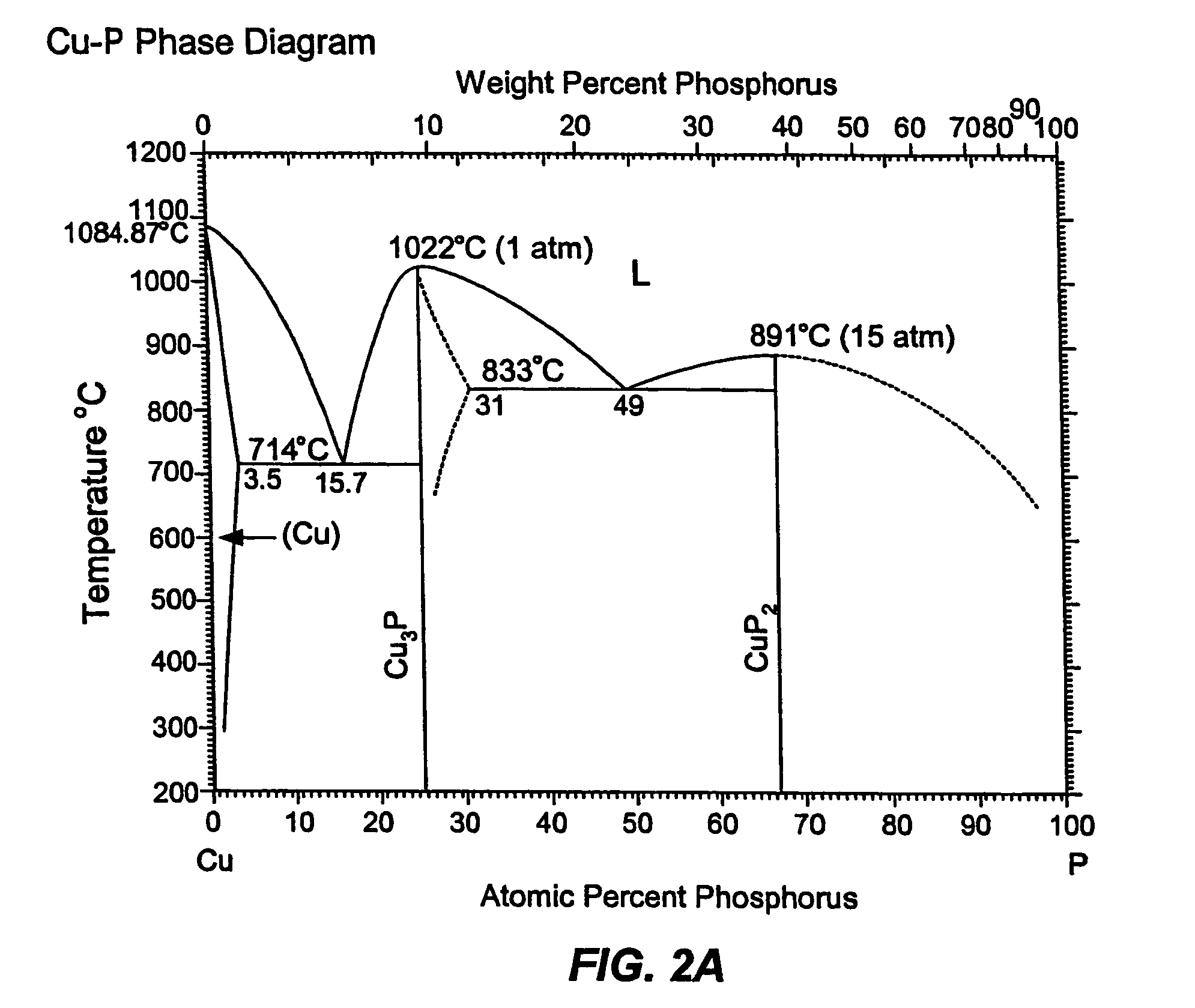

Electroless nickel immersion gold semiconductor flip chip package

InactiveUS6992397B1Few fractured solder bondImprove package reliabilitySemiconductor/solid-state device detailsSolid-state devicesDopantElectroless nickel immersion gold

A flip chip package, apparatus and technique in which a ball grid array composed of a doped eutectic Pb / Sn solder composition is used. The dopant in the Pb / Sn solder forms a compound or complex with the phosphorous residue from the electroless nickel plating process that is mixable with the Pb / Sn solder. The phosphorous containing compound or complex prevents degradation of the solder / under bump metallization bond associated with phosphorus residue. The interfacial solder / under bump metallization bond is thereby strengthened. This results in fewer fractured solder bonds and greater package reliability.

Owner:ALTERA CORP

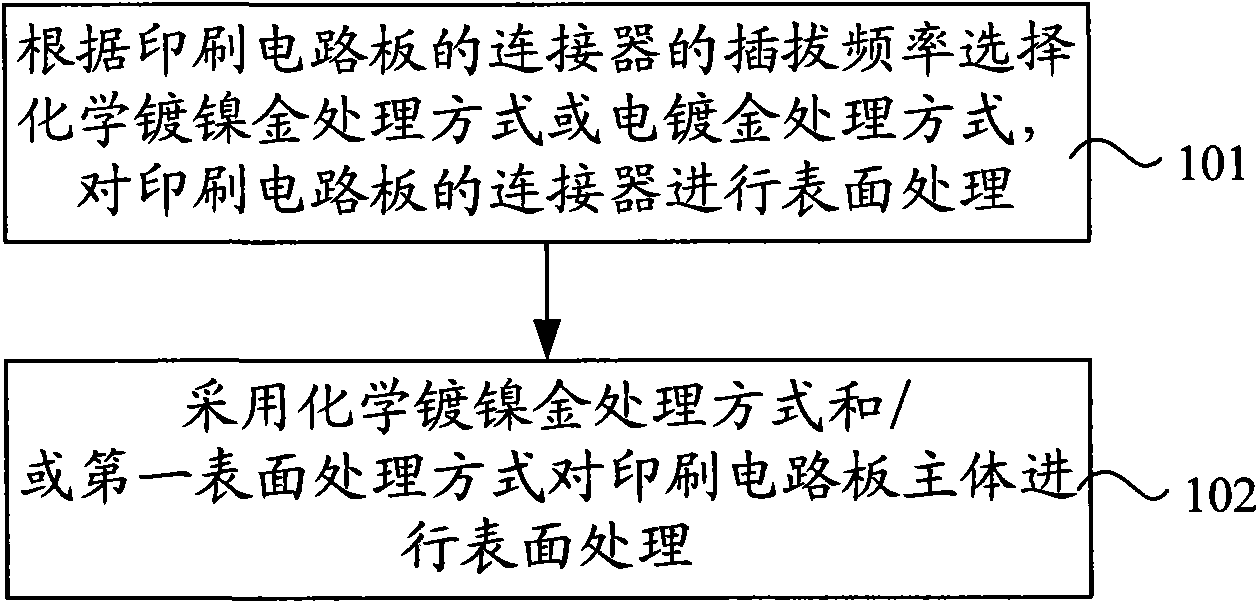

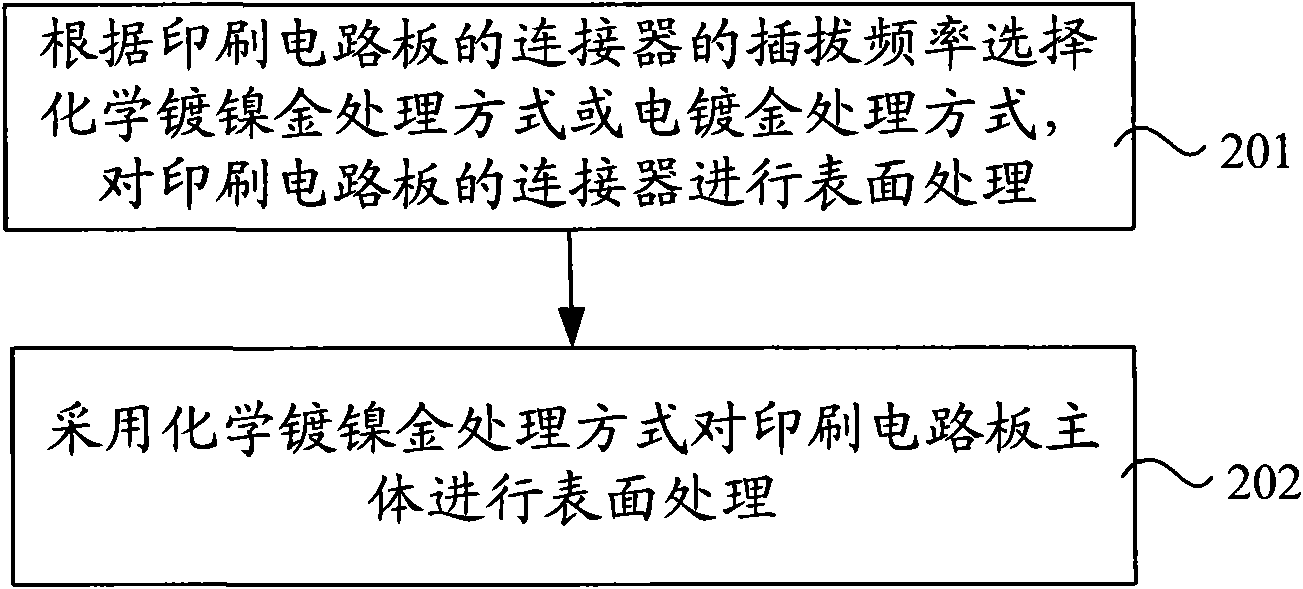

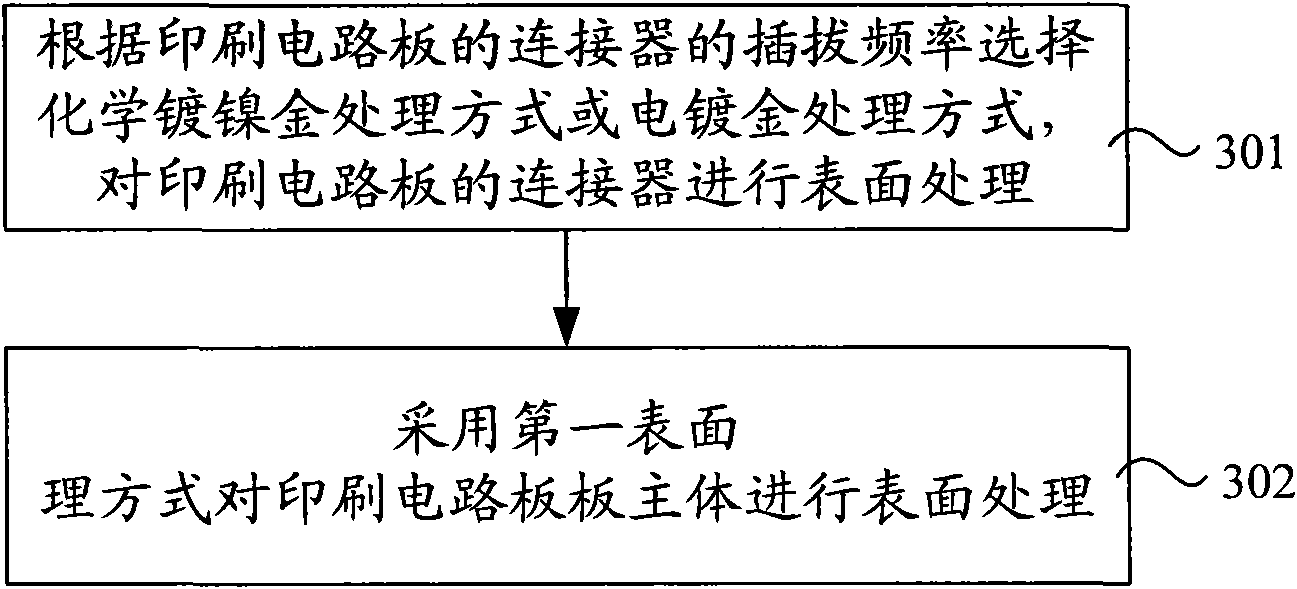

Surface processing method for printed circuit board and corresponding printed circuit board

ActiveCN101657069AReduce manufacturing costOvercome the disadvantages of high costPrinted circuit secondary treatmentElectrical connection printed elementsElectroless nickel immersion goldPrinted circuit board

Embodiment of the invention discloses a surface processing method for a printed circuit board and the corresponding printed circuit board, wherein the surface processing method for a printed circuit board comprises selecting electroless nickel immersion gold processing mode or electrogilding processing mode according to plug frequency of connectors on the printed circuit board, performing surfaceprocessing on the connectors of the printed circuit board. The printed circuit board comprises a main body of PCB and the connectors, the surface processing mode of the connectors is electroless nickel immersion gold processing mode or electrogilding processing mode selected according to plug frequency of the connectors, and the surface processing mode of the main body of PCB is electroless nickelimmersion gold processing mode and / or a first surface processing mode. The invention differentiates the surface processing modes of the connectors of PCB with different plug frequencies, which reduces waste of resources.

Owner:HUAWEI DEVICE CO LTD

In-plate electroless nickel-immersion gold classification connecting finger optical module PCB manufacturing method

InactiveCN108235590AReduce attackReduce sheddingProcessing steps orderConductive pattern reinforcementFriction weldingElectroless nickel immersion gold

The invention discloses an in-plate electroless nickel-immersion gold classification connecting finger optical module PCB manufacturing method which comprises steps of plate preparation, partial photosensitive ink treatment, gold electroplating, removing ink, secondary membrane drying, lead etching, dried membrane removal, protection welding, partial thermosetting ink treatment, electroless nickel-immersion gold and later plate treatment. Compared with a conventional common manufacturing process, the method is capable of reducing the cost on the one hand since production procedures are adjusted, that is, the step of protection welding is carried out after the step of lead etching, and thus the three times of membrane removal steps after protection welding are reduced into once; and on theother hand, attack of a strong-alkali eluant to the welding protection ink can be reduced, the bonding force of protection welding parts can be improved, and the problem that protection welding partsof finished plates are peeled off can be reduced.

Owner:深圳欣强智创电路板有限公司

Method of mounting an electroless nickel immersion gold flip chip package

InactiveUS7309647B1Few fractured solder bondImprove package reliabilitySemiconductor/solid-state device detailsPrinted circuit aspectsDopantElectroless nickel immersion gold

Owner:ALTERA CORP

Method for producing environment-friendly lead-free electroless nickel immersion gold

InactiveCN102877044ANo solder defect occursWon't decomposeLiquid/solution decomposition chemical coatingElectroless nickel immersion goldSolder mask

The invention provides a method for producing environment-friendly lead-free electroless nickel immersion gold. The method comprises the following steps of: etching a line, and treating a circuit board by using solder mask ink; performing pretreatment, namely polishing and brushing or blasting sand; placing the circuit board in an oil removal trough and treating for 5 minutes; washing by using tap water and conveying into a microetching trough for 2 minutes; washing by using deionized water, and feeding into a preimpregnation trough for 1 minute; directly feeding into an activation trough and treating for 1 minute; washing by using the deionized water, and treating in chemical nickel at the temperature of 80 DEG C for 20 minutes; and washing by using the deionized water, and treating in immersion gold which is prepared from 10 percent KOZO 806 and citric acid gold with density of 2g / L. By the method, the technical problem that the conventional production method is not environment-friendly can be solved; lead in the chemical nickel is replaced and is totally environment-friendly; and the condition that tin is not soldered well can be avoided. The toxic potassium aurous cyanide in the immersion gold is replaced, and the immersion gold is totally environment-friendly; and a solution is stable and is prevented from being decomposed.

Owner:湖南领湃科技股份有限公司

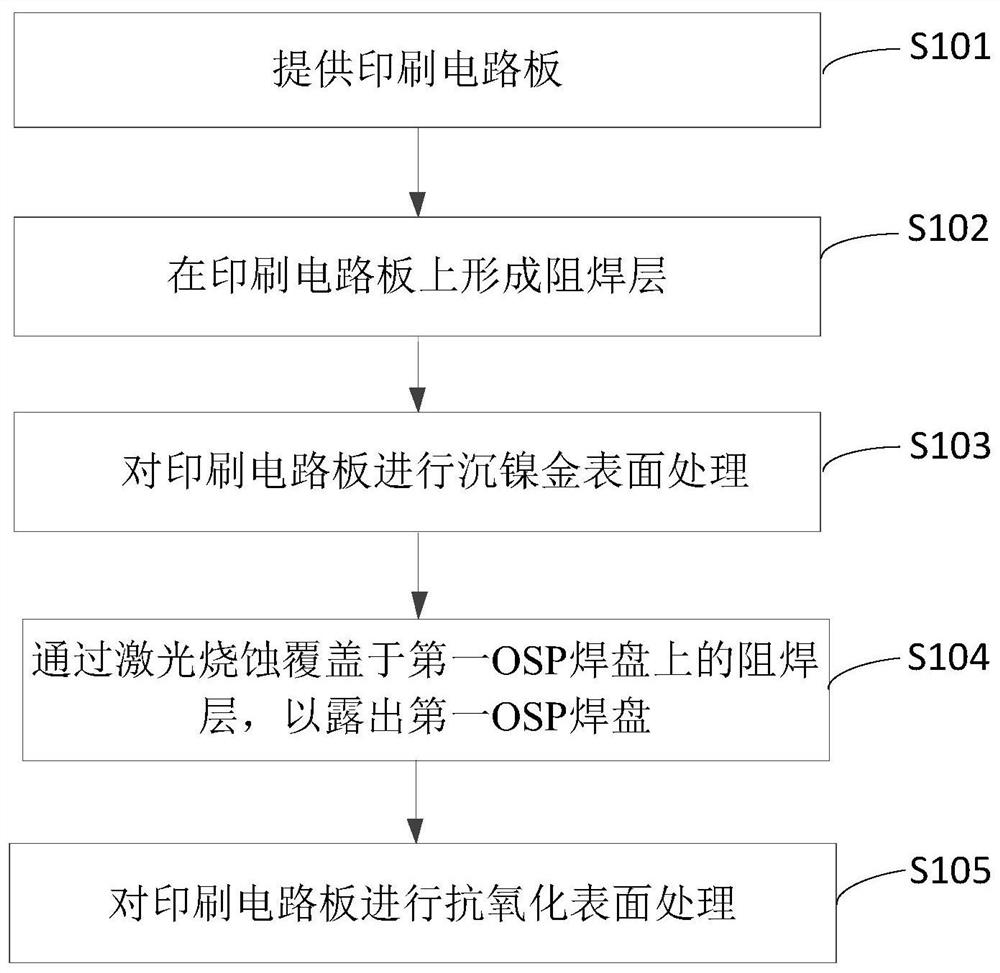

Surface treatment method of printed circuit board and printed circuit board

ActiveCN113141723ASolve the problem that immersion nickel gold cannot be carried outSolve processingNon-metallic protective coating applicationElectroless nickel immersion goldSolder mask

The invention is suitable for the technical field of printed circuit boards, and provides a surface treatment method of a printed circuit board, which comprises the following steps: providing a printed circuit board, the printed circuit board comprising an outer layer circuit pattern, and the outer layer circuit pattern comprising an electroless nickel immersion gold (ENIG) pad and a first OSP pad; forming a solder mask layer on the printed circuit board, wherein the solder mask layer covers the first OSP bonding pad and exposes the ENIG pad; performing ENIG surface treatment on the printed circuit board; ablating the solder mask layer covering the first OSP bonding pad through laser so as to expose the first OSP bonding pad; and carrying out anti-oxidation surface treatment on the printed circuit board. According to the surface treatment method of the printed circuit board, ENIG treatment and anti-oxidation mixed surface treatment can be carried out on the printed circuit board with relatively high integration level, and the production efficiency is relatively high. The invention further provides a printed circuit board.

Owner:SHENZHEN KINWONG ELECTRONICS

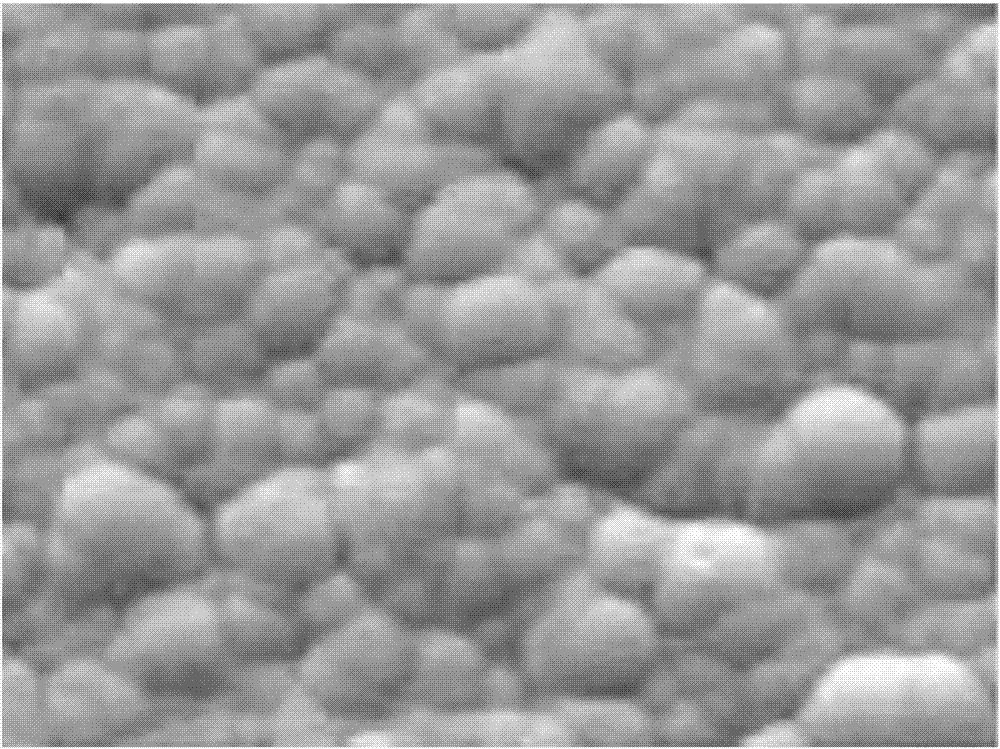

Palladium activation method for electro-less nickel immersion gold of PCB (printed circuit board)

ActiveCN113046733AImprove corrosion resistanceSolving Palladium Corrosion ProblemsLiquid/solution decomposition chemical coatingPrinted circuit manufactureElectroless nickel immersion goldPhosphoric acid

The invention relates to the technical field of printed circuit boards, in particular to a palladium activation method for electro-less nickel immersion gold of a PCB (printed circuit board). The palladium activation method for electro-less nickel immersion gold of the PCB comprises the following steps of: putting a product into an acid cleaning agent for de-oiling and cleaning; pickling with a pickling solution to remove surface oxides, and performing hydrogen removal treatment; putting the product into hot water of 50-60 DEG C for cleaning, then putting the product into ionized water for circularly cleaning for 1-3 minutes, and draining the cleaning water; carrying out micro-etching on the product to form a microstructure; putting the product into ionized water for circularly cleaning for 1-3 minutes, and draining the cleaning water; putting the product into a phosphoric acid solution for 0.5-1 minutes, transferring the product into an activation tank with a palladium activator, treating the product at 25-30 DEG C for 1-3 minutes, and depositing activated palladium on the surface of the product; putting the product into ionized water for circularly cleaning for 1-3 minutes, and draining cleaning water; and adding a chemical palladium plating solution into a product chemical palladium plating tank for palladium plating, and then transferring to a subsequent process.

Owner:SHENZHEN CHENGGONG CHEM

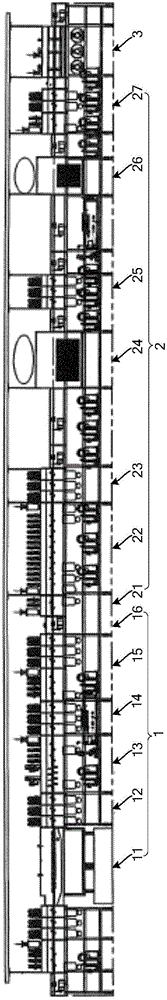

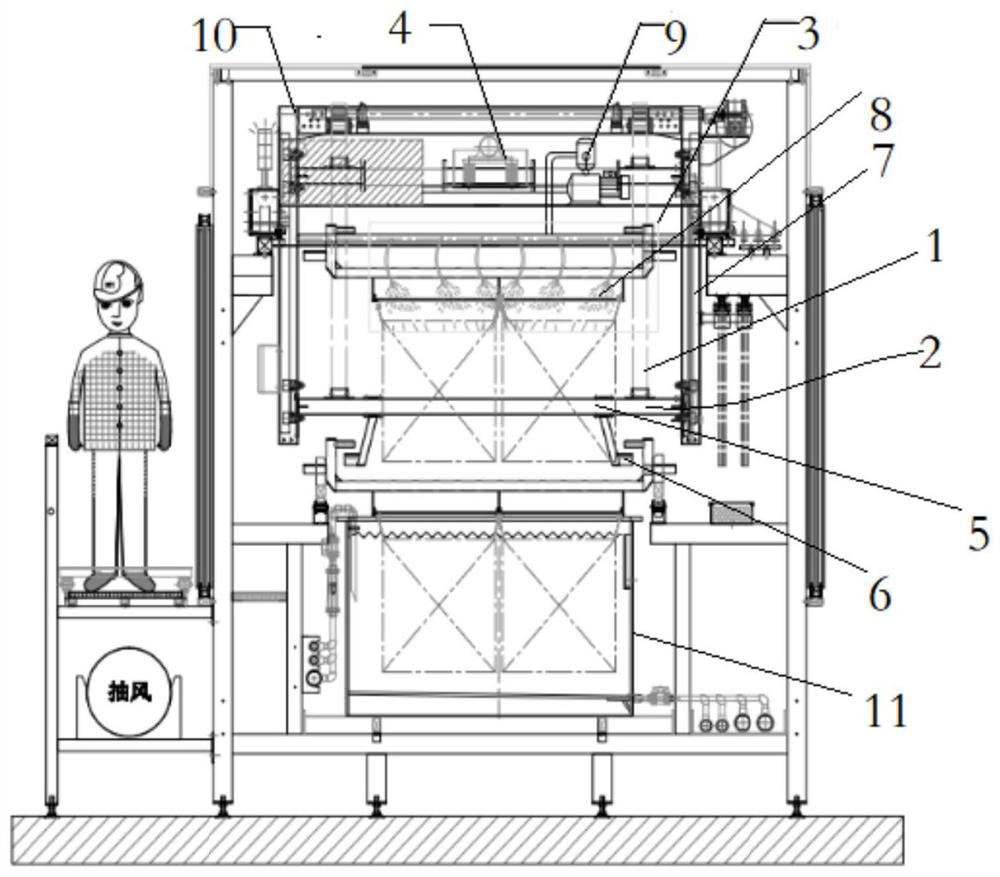

Production line and production process of electroless nickel immersion gold

InactiveCN106835088AReduce manufacturing costAvoid damageLiquid/solution decomposition chemical coatingProduction lineElectroless nickel immersion gold

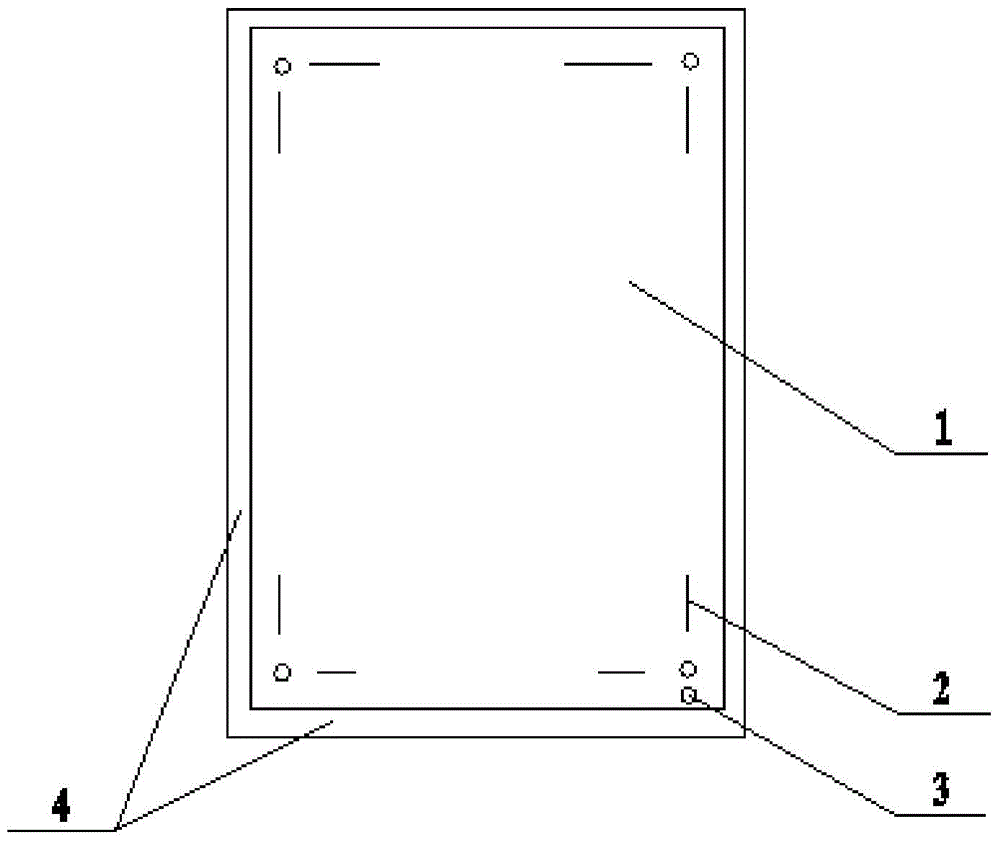

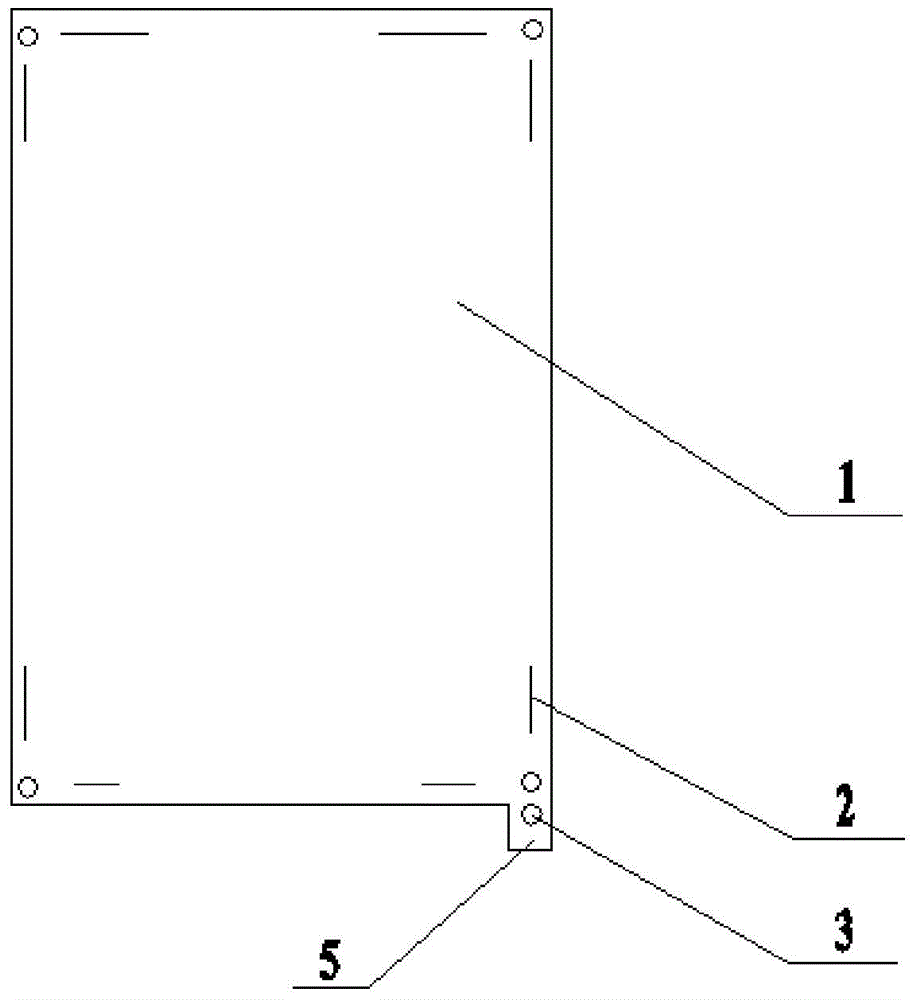

The invention discloses a production line and a production process of electroless nickel immersion gold. The production line comprises a conveying mechanism, a pretreatment area, an electroless nickel immersion gold area and an aftertreatment area, wherein the pretreatment area, the electroless nickel immersion gold area and the aftertreatment area are adjacently arranged on a movement path of the conveying mechanism sequentially. Pretreatment, electroless nickel immersion gold treatment and aftertreatment are integrated to the same production line and operations for transferring and frequently loading and unloading boards during production are not needed, so that manpower can be saved, treatment process can be shortened, and damage such as pollution and scratching of circuit boards can be avoided; a lot of repeated cleaning equipment on the front portions of the electroless nickel immersion gold area and the aftertreatment area in the prior art is omitted, so that the objectives of simplifying equipment, shortening the production line, reducing occupied area, reducing personnel and reducing sewage discharge are achieved, and both the manufacturing cost and production cost of the production line are greatly lowered.

Owner:SHENZHEN FARCIEN APPLIED MATERIALS

No-board-edge nickel-gold technology of circuit board

InactiveCN105072818AGuaranteed orientationReduce dosageConductive pattern reinforcementElectroless nickel immersion goldSolder mask

The invention discloses a no-board-edge nickel-gold technology of a circuit board. The no-board-edge nickel-gold technology of a circuit board comprises steps of performing cutting on a substrate of the circuit board, exposing an inner layer circuit, laminating, boring, precipitating copper and electroplating, adopting a positive technology to perform copper plating, tin plating, removing films, etching, removing tin, performing solder mask, and performing character back baking on the outer layer circuit. The steps before the chemical nickel-gold technology comprises steps of removing the technology edges on the circuit board, performing chemical nickel-gold processing on the circuit board, and testing and checking the electric performance and appearance of the finished board. The invention can save the nickel amount in the nickel gold technology so as to save the cost.

Owner:湖北建浩科技有限公司

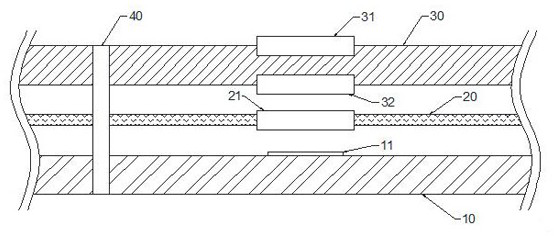

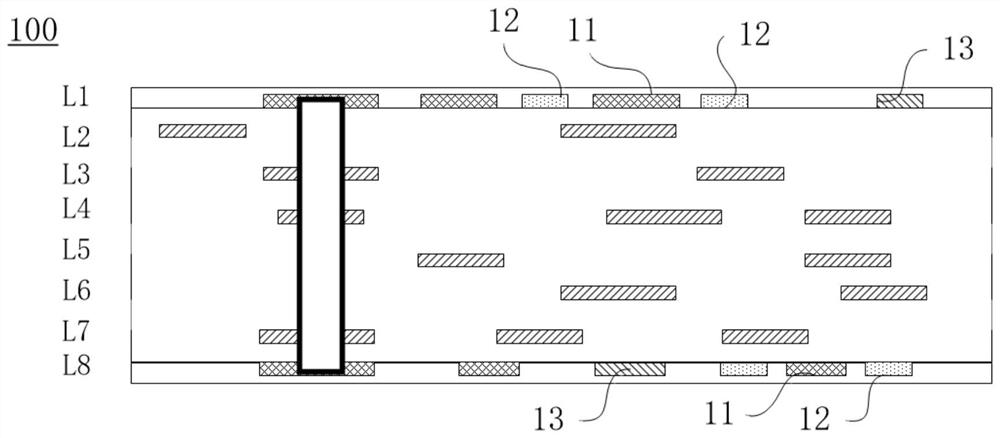

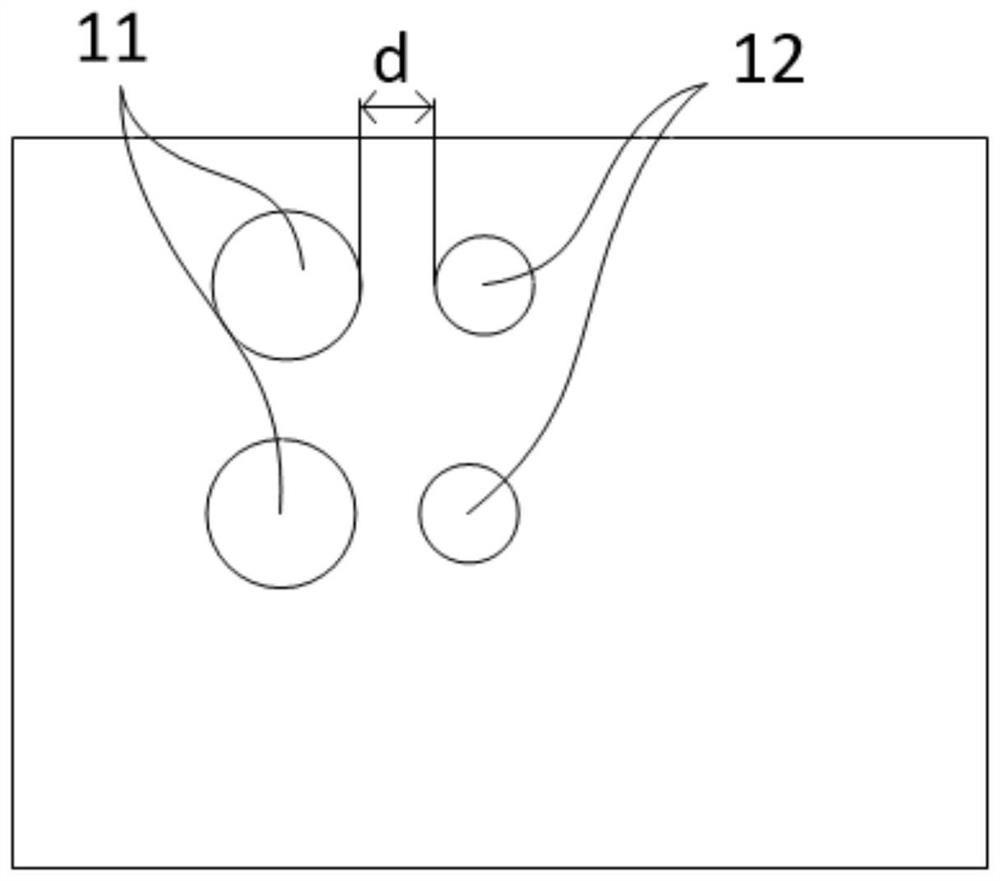

Embedded element circuit board and manufacturing method thereof

PendingCN114449781AImprove reliabilityFacilitate high-density deploymentPrinted circuit assemblingMultilayer circuit manufactureElectroless nickel immersion goldStructural engineering

The embedded element circuit board comprises an inner layer circuit substrate, an embedded element and an adhesive layer, the inner layer circuit substrate is provided with an opening penetrating through the inner layer circuit substrate along a first direction, and the adhesive layer is filled in the opening; the embedded element is completely embedded into the opening, the embedded element comprises an electronic element and two connecting pads arranged on one side of the electronic element at intervals, and the connecting pads are exposed from one end of the opening; the circuit board with the embedded element further comprises a first outer layer circuit structure and a second outer layer circuit structure which are respectively stacked on two opposite sides of the inner layer circuit substrate along the first direction so as to package the embedded element and the adhesive layer, and the connecting pad comprises a copper pad and a chemical nickel-gold layer. And the chemical nickel-gold layer coats the copper pad except the area away from the surface of the second outer layer circuit structure. The invention further provides a manufacturing method of the embedded element circuit board.

Owner:QING DING PRECISION ELECTRONICS HUAIAN CO LTD +1

Electroless nickel immersion gold surface treatment method for polyphenyl ether-containing printed circuit board

ActiveCN110719694ALittle effect of sedimentationReduce the impact of goldConductive pattern reinforcementConductive pattern layout detailsElectroless nickel immersion goldCopper foil

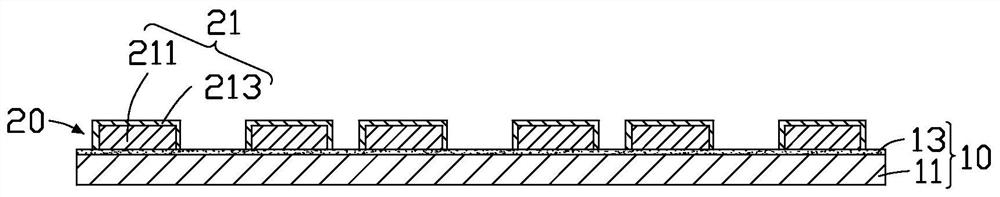

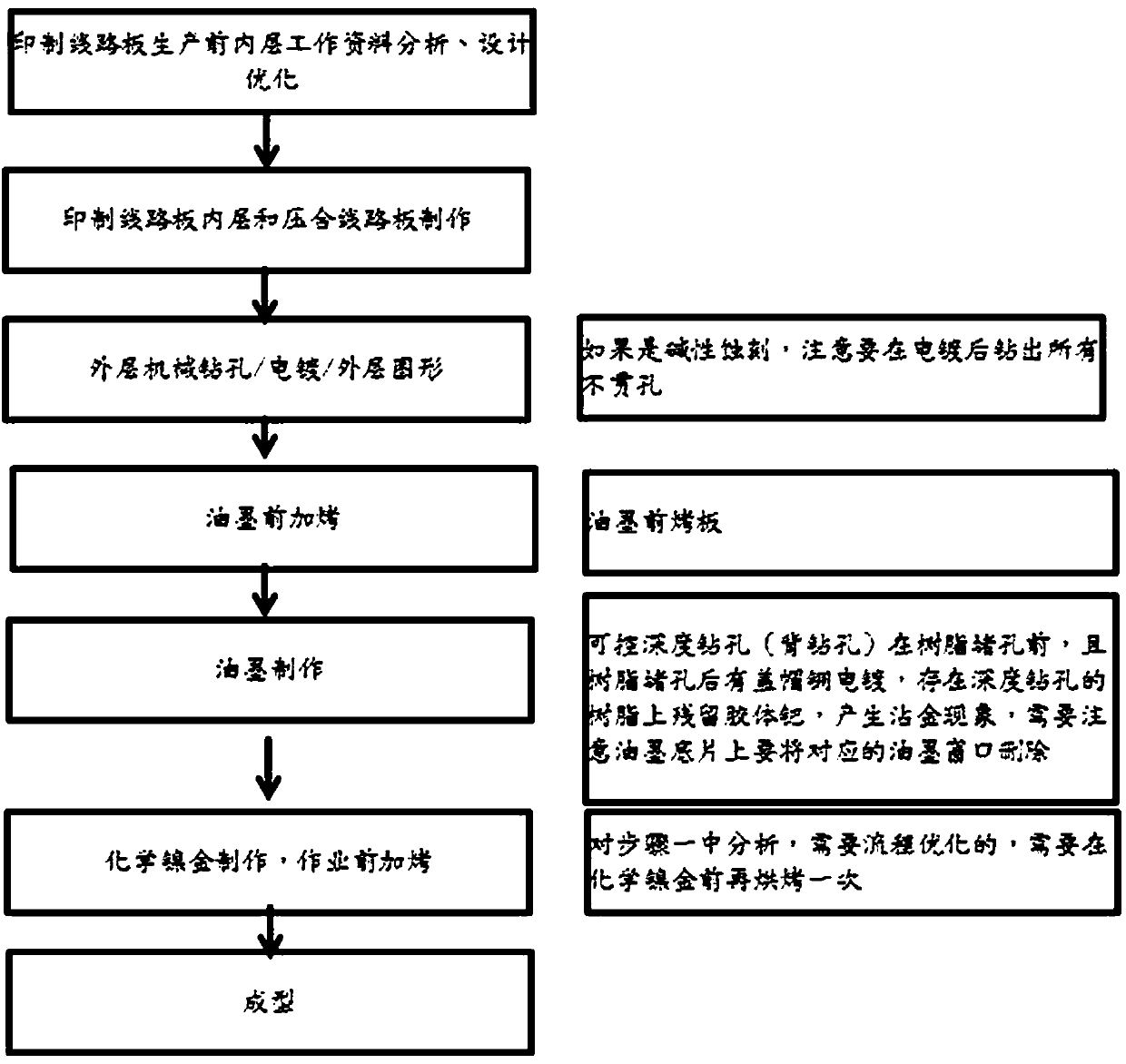

The invention discloses an electroless nickel immersion gold surface treatment method for a polyphenyl ether-containing printed circuit board in the technical field of surface treatment of printed circuit boards, and aims to solve the technical problem of electroless nickel immersion gold whitening and gold removing of a polyphenyl ether-containing printed circuit board after electroless nickel immersion gold treatment in the prior art. The method comprises the following steps: carrying out circuit board inner layer data analysis and optimal design; printing an inner layer of a circuit board and laminating the circuit board; mechanically drilling an outer layer of the circuit board, electroplating copper and manufacturing an outer layer pattern; executing a baking process; preparing printing ink; executing a baking process; and carrying out electroless nickel immersion gold. According to the invention, a shielding copper foil and a dummy pad are additionally arranged on a secondary outer layer, and a baking process is added to the board after etching. Because the board is baked after etching, it is guaranteed that material precipitates are reduced, and it is also guaranteed that the influence on nickel deposition is the minimum during electroless nickel immersion gold. Moreover, by carrying out secondary drilling and covering holes with ink, the influence of the baking processon gold staining of non-through holes and gold staining in a deep drilling resin hole-plugging process is reduced.

Owner:WUS PRINTED CIRCUIT (KUNSHAN) CO LTD

Method for removing burrs of metallized half-hole of gold plating plate

PendingCN114040598ANo cloak residueGuaranteed qualityPrinted element electric connection formationElectroless nickel immersion goldTin plating

The invention discloses a method for removing burrs of a metallized half hole of a gold plating plate. The method comprises the following steps of: drilling a hole in a production board, and then metallizing the hole through copper deposition and full-plate electroplating in sequence; plating a tin layer on the board surface of the production board; forming half holes in the production board through a forming process; removing burrs in the holes and at the hole openings through alkaline etching, and then removing the tin layers; pasting a film on the production board, and then sequentially performing exposure and development to form an outer layer circuit pattern; carrying out chemical nickel-gold treatment on the production board; pasting a second layer of film on the production board, and windowing the position, needing gold plating, of the corresponding outer layer circuit pattern; carrying out local gold plating treatment on the production board, and retreating the film; and etching the production board to form an outer-layer circuit. According to the method, a tin plating procedure, half-hole milling and alkaline etching are added before outer layer circuit manufacturing, under the condition of tin layer protection, half-hole burrs are etched and removed firstly, and metalized half-hole manufacturing is achieved.

Owner:JIANGMEN SUNTAK CIRCUIT TECH

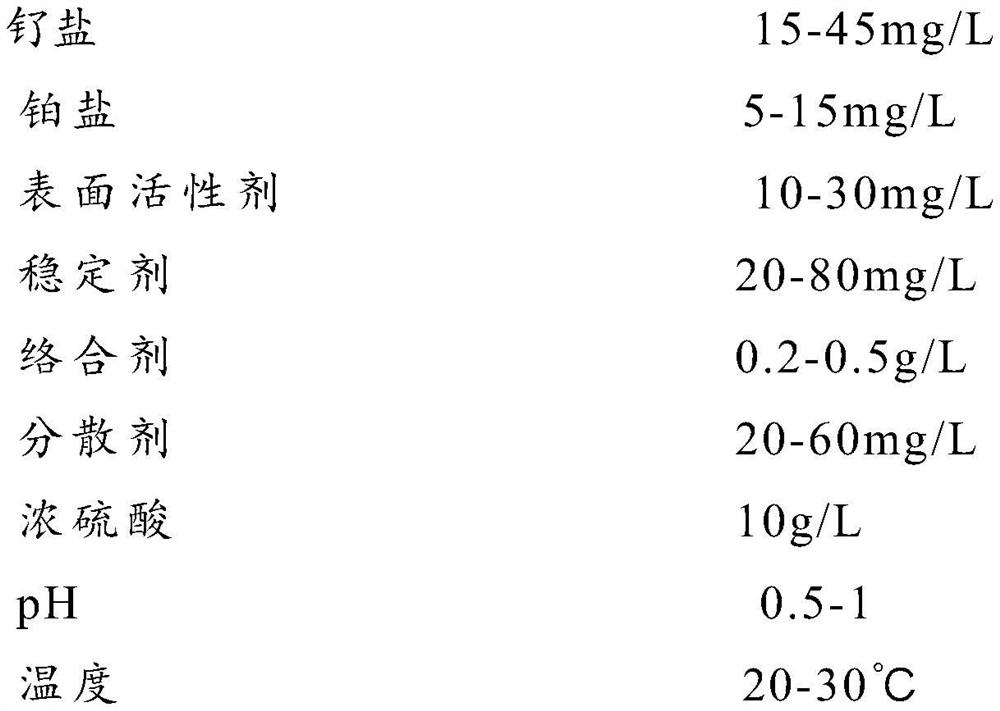

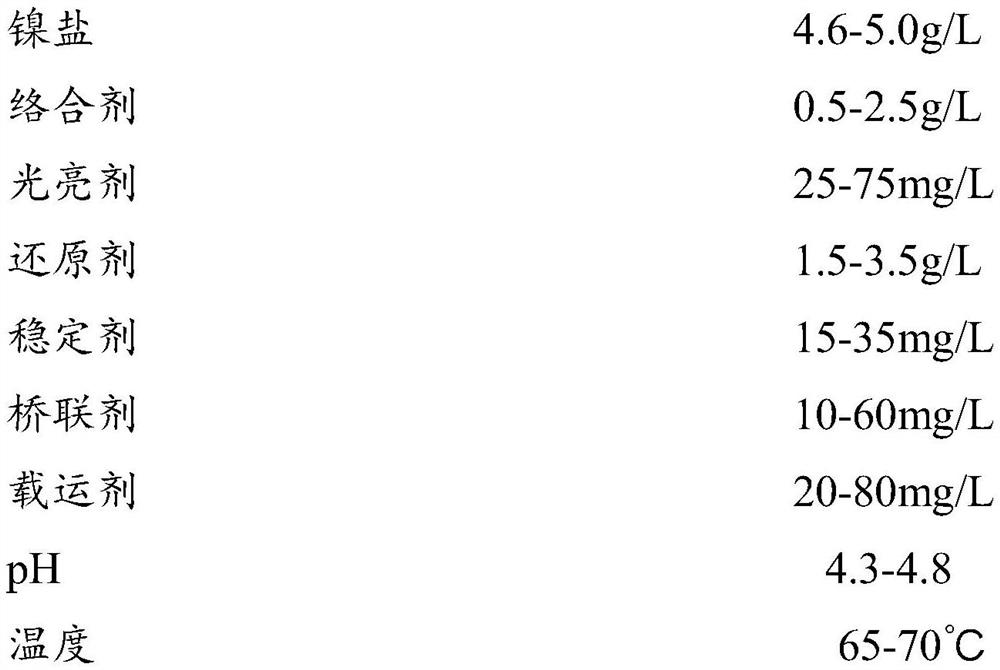

Chemical nickel-gold process applied to wafer aluminum-copper base material in field of IGBT (Insulated Gate Bipolar Translator) power devices

ActiveCN114481106ASolve the real problemImprove adsorption capacityLiquid/solution decomposition chemical coatingSuperimposed coating processNickel saltChemical plating

The invention discloses a chemical nickel-gold process of a wafer aluminum-copper base material applied to the field of IGBT power devices. The chemical nickel-gold process comprises a process flow, an activating solution formula, a chemical nickel formula, a chemical gold formula and the like. The technological process comprises the steps of oil removal, water washing, micro-etching, water washing, presoaking, activation, water washing, vacuum water washing, dry ice spray washing, thin copper electroplating, water washing, chemical nickel plating, water washing and chemical gold plating. The formula of the activating solution comprises ruthenium salt, platinum salt, concentrated sulfuric acid, a surfactant, a stabilizer, a complexing agent and a dispersing agent. The nickel plating formula comprises nickel salt, a complexing agent, a brightening agent, a reducing agent, a stabilizing agent, a bridging agent and a carrying agent. The gold plating formula comprises gold salt, a complexing agent, a stabilizing agent, an underpotential agent, a reducing agent and a nucleating agent. The excellent chemical nickel-gold plating process of the wafer aluminum-copper base material in the field of IGBT power devices can be realized, and the chemical nickel-gold plating process has the characteristics of being excellent in stability, bright and smooth, free of skip plating and diffusion plating, good in oxidation resistance, good in weldability and the like.

Owner:珠海市创智芯科技有限公司

Method for plating thick gold layer in circuit board manufacturing process

InactiveCN101631427BNo pollutionImprove plating resistancePrinted circuit manufactureElectroless nickel immersion goldEtching

The invention discloses a method for plating a gold thick layer in a circuit board manufacturing process, which comprises the following steps of: A, firstly, subjecting a circuit board to pattern tin plating, circuit wire etching, solder-mask printing and chemical nickel and gold processing treatments of depositing a nickel layer and depositing a gold layer; B, carrying out the anti-oxidation post treatment of the circuit board subjected to the chemical nickel and gold processing treatments; C, covering a non-gold plated area of the circuit board; and D, after pre-treating the surface of the circuit board, plating the thick gold layer on a lead of the circuit board by a post drawing process. The invention provides a method for plating thick gold layer in the circuit board manufacturing process, which has advantages of pollution prevention, environment protection, gold salt conservation, good quality and easily controllable gold color.

Owner:深圳市九和咏精密电路有限公司

Method for reducing gold salt waste by electroless nickel immersion gold treatment of PCB

InactiveCN105873372AReduce wasteAvoid wastingPrinted circuit aspectsPrinted circuit manufactureElectroless nickel immersion goldMilling cutter

The invention relates to a method for reducing the waste of gold salt in a nickel-gold PCB, comprising the following steps: 1) removing or reducing the width of the choke strips near the edge of the inner core board when making the PCB, and then presetting the Reserve a certain width of copper-free area for edge milling; 2) Use a milling cutter to perform edge milling in the copper-free area reserved on the edge of the board to avoid exposed copper on the edge of the board; 3) Treat the surface of the PCB with nickel-gold, at this time , Since there is no exposed copper on the edge of the board, it can prevent gold from attaching to the edge of the board and reduce the waste of gold salt. This method does not require glued paper when nickel-gold is deposited, so the processing cost can be reduced, and the quality of PCB products will not be affected by the reduction of the board edge baffle strips.

Owner:KINWONG ELECTRONICS TECH LONGCHUAN

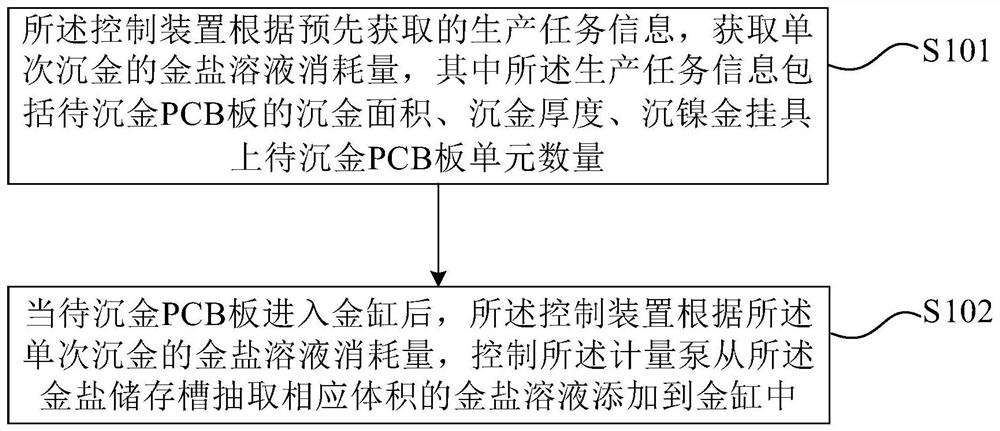

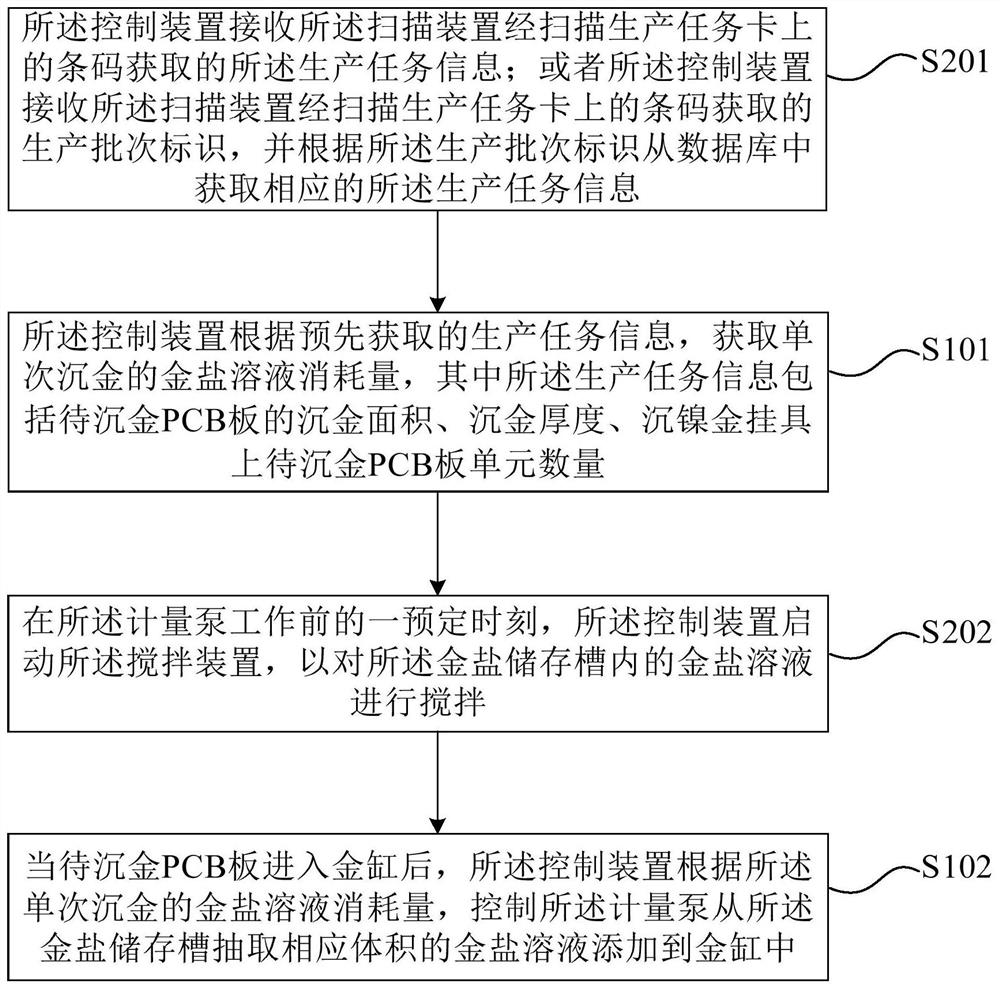

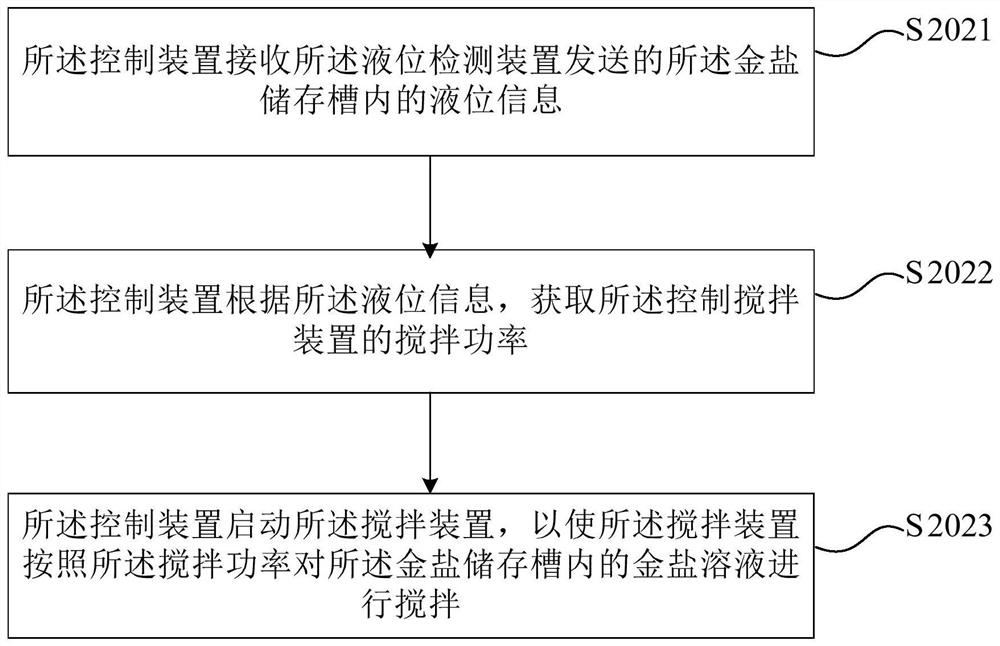

Method and system for adding gold salt to chemically deposited nickel gold wire

ActiveCN109729650BReduce take-out consumptionStable concentrationConductive pattern reinforcementElectroless nickel immersion goldMetallurgy

The invention provides a gold salt adding method and system for an electroless nickel immersion gold line, and the method comprises the steps: obtaining the consumption of a gold salt solution for single gold immersion through a control device according to the pre-obtained production task information which comprises the gold immersion area and thickness of a PCB to be subjected to gold immersion,and the unit number of the PCB be subjected to gold immersion on an electroless nickel immersion gold hanger; and after the PCB to be subjected to gold immersion enters a gold cylinder, the control device controls a metering pump to extract the gold salt solution of the corresponding volume from a gold salt storage tank and add the gold salt solution into the gold cylinder according to the consumption of the gold salt solution for a single process of gold immersion. By adding the gold salt solution after the PCB to be subjected to gold immersion enters the gold cylinder every time, control over repeated addition of a small amount of the gold salt solution is achieved, the concentration of the gold salt solution in the gold cylinder can be controlled to be kept within a relatively stable range, uniformity of a plating is guaranteed, the taking-out consumption of gold salt can be reduced, and the cost is reduced.

Owner:NEW FOUNDER HLDG DEV LLC +1

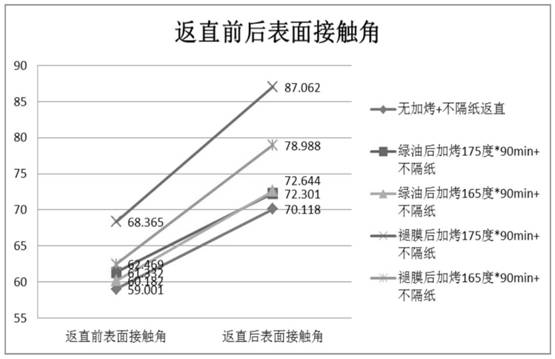

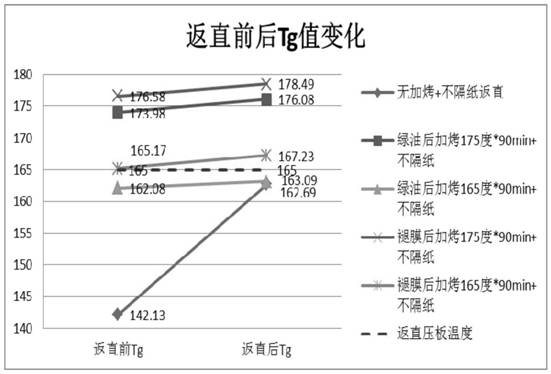

Printed circuit board (PCB) manufacturing process

ActiveCN113141724AHigh glass transition temperatureAvoid pollutionPrinted circuits repair/correctingPrinted circuit dryingElectroless nickel immersion goldSolder mask

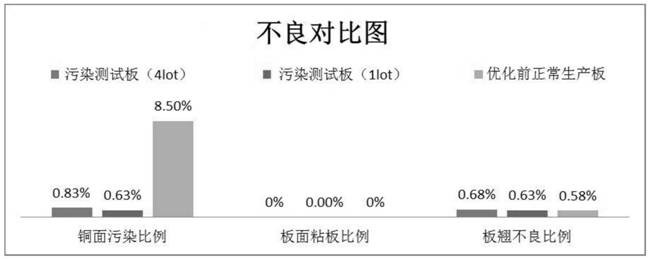

The invention discloses a PCB manufacturing process, which comprises a solder mask manufacturing step, a electroless nickel immersion gold (ENIG) step, a baking step, a dividing step and a straightening step, and can avoid the defect of copper exposure on PCB unit boards caused by bonding of solder resist ink on adjacent PCB unit boards in a straightening process. And meanwhile, the plate surface pollution and the expansion and shrinkage size out-of-tolerance are avoided.

Owner:GUANGZHOU MEADVILLE ELECTRONICS

Non-toxic and environment-friendly electroless nickel immersion gold solution applied to field of printed circuit boards

InactiveCN112695306AReduce health impactReduce security risksLiquid/solution decomposition chemical coatingPrinted circuit manufactureElectroless nickel immersion goldPotassium cyanide

The invention discloses a non-toxic and environment-friendly electroless nickel immersion gold solution applied to the field of printed circuit boards. The non-toxic and environment-friendly electroless nickel immersion gold solution comprises, by mass concentration ratios, 0.2-1.0g / L of cyanide-free gold salt based on Au content, 20-100g / L of complexing agent, 1-5g / L of stabilizer, and the balance water. After the components are uniformly mixed according to the mass concentration ratios, a buffer agent is utilized to adjust a pH value to 7.0-8.0, and then an immersion gold solution is formed. The system of the electroless nickel immersion gold solution does not use high-toxicity substances such as gold potassium cyanide and is free of cyanide, thereby reducing the impact on the health of operators and potential safety hazards in the working environment, and greatly reducing the burden and impact on the environment. Meanwhile, plating of a gold plating layer is stable, good in adhesion and uniform in distribution.

Owner:成功环保科技(南通)有限公司

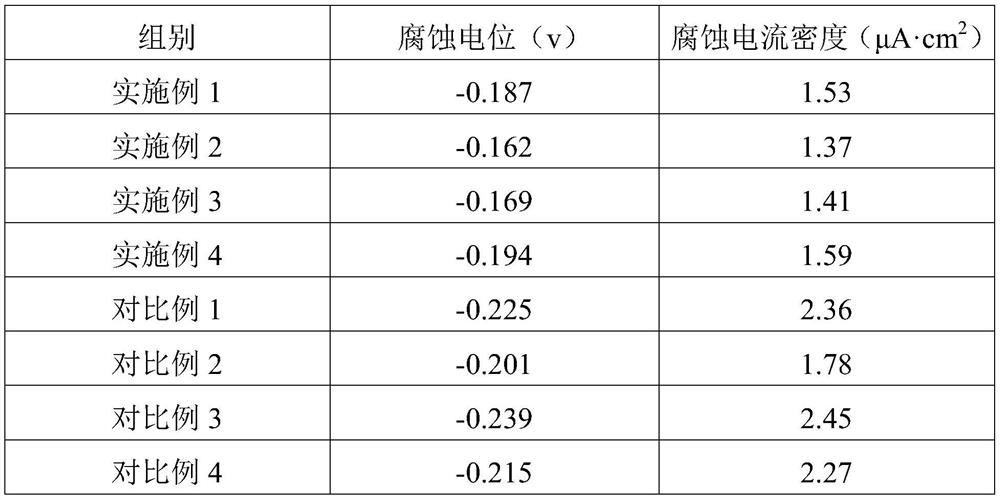

A chemical nickel-gold process with ultra-low nickel corrosion

ActiveCN112941496BReplacement period is longExtended service lifeLiquid/solution decomposition chemical coatingPrinted circuit manufactureElectroless nickel immersion goldElectroless plating

The invention belongs to the technical field of chemical nickel and gold, and in particular relates to an ultra-low nickel corrosion chemical nickel and gold process. An ultra-low nickel corrosion chemical nickel-gold process is characterized in that it comprises the following steps: S1) pretreatment; S2) chemical nickel plating; S3) water washing; S4) chemical gold plating; S5) post-treatment. The plating layer obtained by the chemical nickel gold process of the present invention has high corrosion resistance, and the chemical gold plating solution in the chemical nickel gold process has good stability and long service life, which meets the quality requirement of PCB "nickel corrosion".

Owner:广州皓悦新材料科技有限公司

Gold salt saving equipment and method for PCB manufacturing chemical nickel gold process

InactiveCN113395838AReduce carryoverLabor savingPrinted circuit liquid treatmentCleaning using liquidsElectroless nickel immersion goldProcess engineering

The invention discloses gold salt saving equipment for a PCB manufacturing chemical nickel gold process. The equipment comprises a suspension arm connected with a PCB hanging basket fixing device. A spraying structure is installed above the PCB hanging basket fixing device, and the PCB hanging basket fixing device is connected with a vibration device. According to the invention, the carrying-out amount of gold liquid is effectively reduced in a vibrating and flushing manner, and evaporation water in the gold immersion cylinder is supplemented by spraying and flushing water, so that the labor is saved.

Owner:AOSHIKANG TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com