Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

603results about "Printed circuits repair/correcting" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

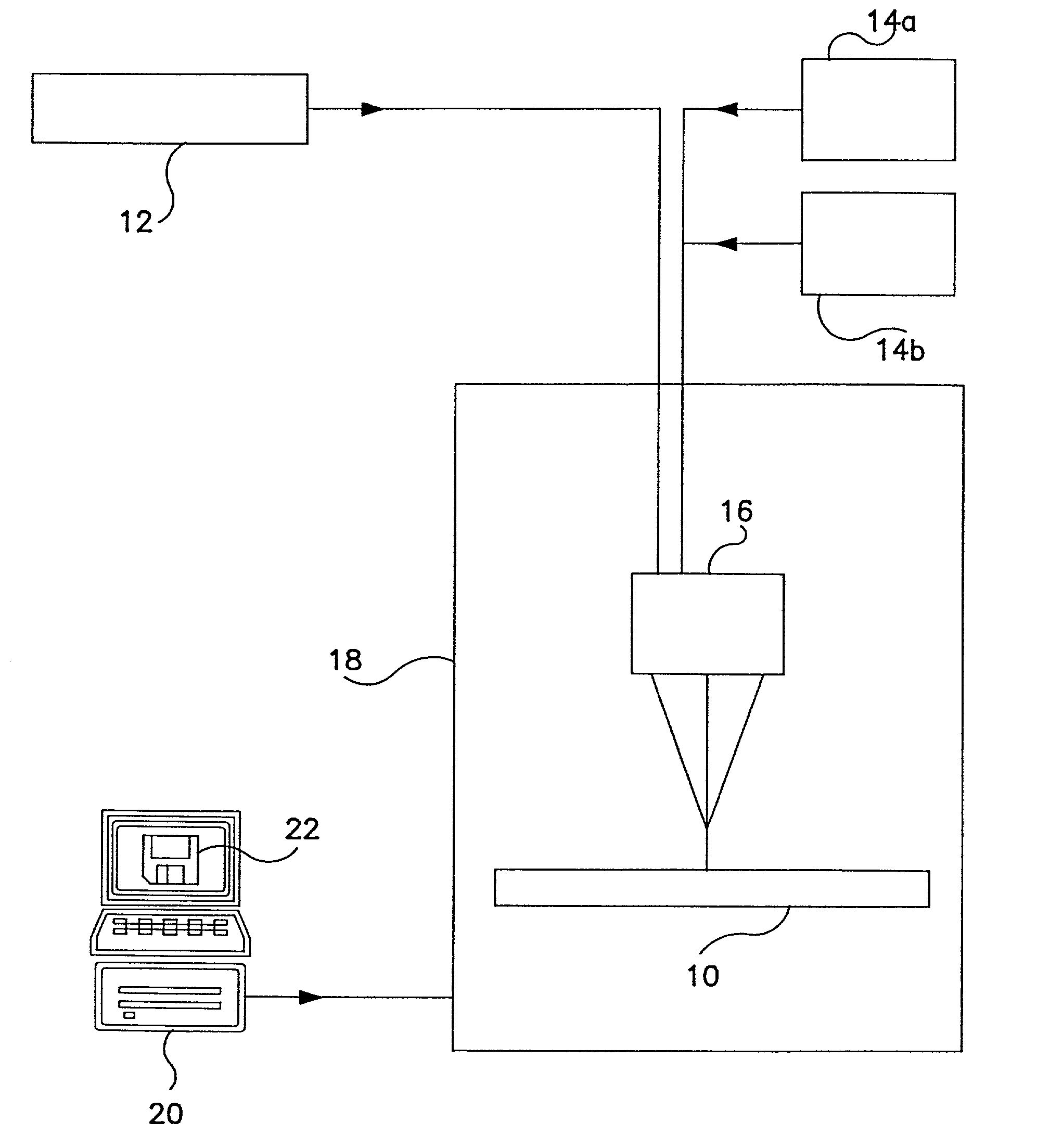

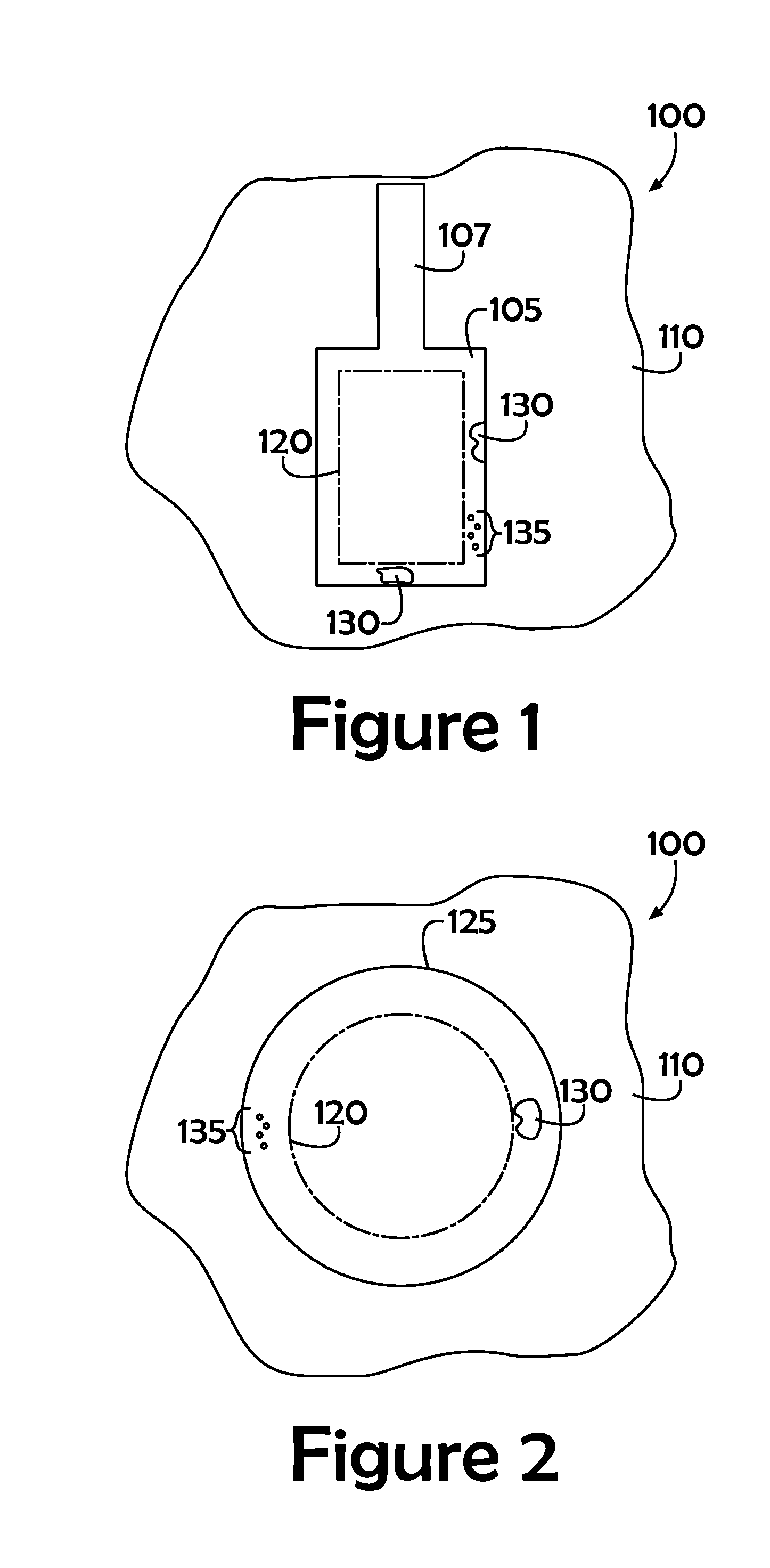

Electrochemical micromanufacturing system and method

InactiveUS7615141B2Additive manufacturing apparatusPrinted circuits repair/correctingImage resolutionEngineering

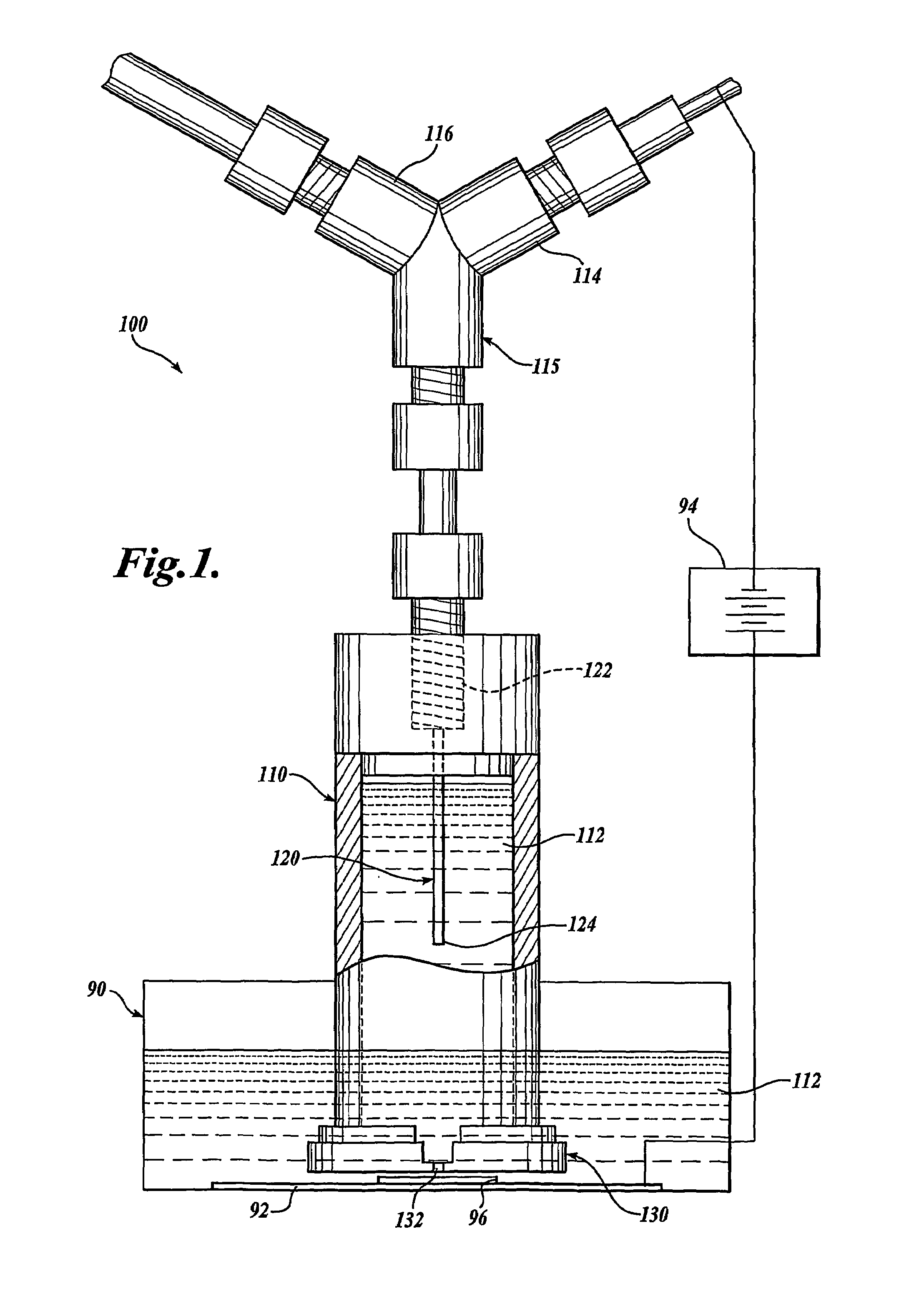

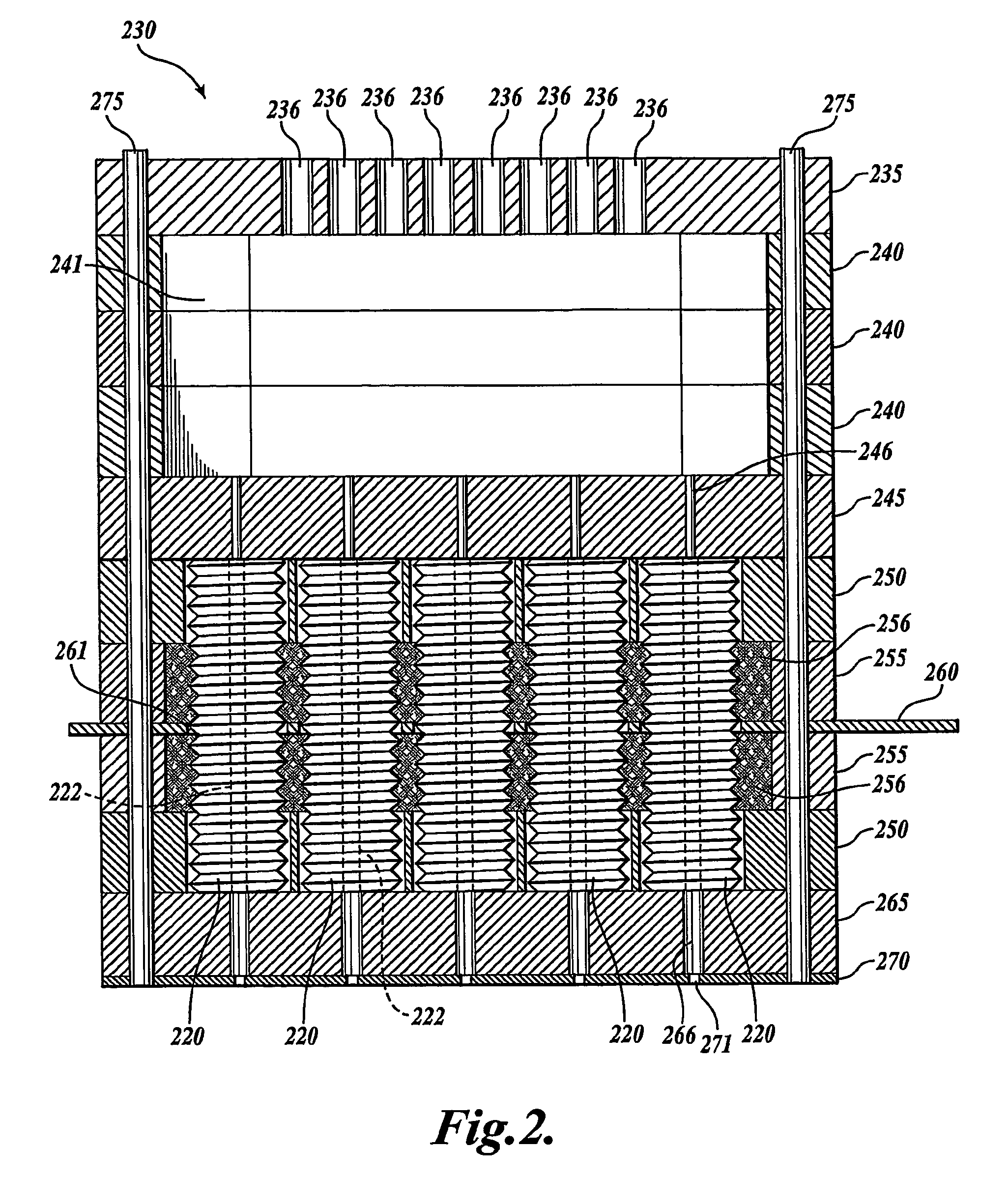

An electrochemical printing system (100, 200) and method are disclosed having a printer head (130, 230) that expels a small jet of electrolyte (112) towards a conductive substrate (92) to facilitate electrodeposition or removal of material from the substrate. In an embodiment of the invention the printer head includes a plurality of individually addressable electrodes (220), each electrode having a channel therethrough and wherein the electrodes are much larger than the electrolyte jet outlet. The printer head includes means for inhibiting cross talk between electrodes. For example, the printer head may include a plenum (241) and a nonconductive cross-talk inhibition layer (245) upstream of the electrodes. A resolution defining layer (270) having small apertures (271) is provided at the distal end of the printer head.

Owner:UNIV OF WASHINGTON

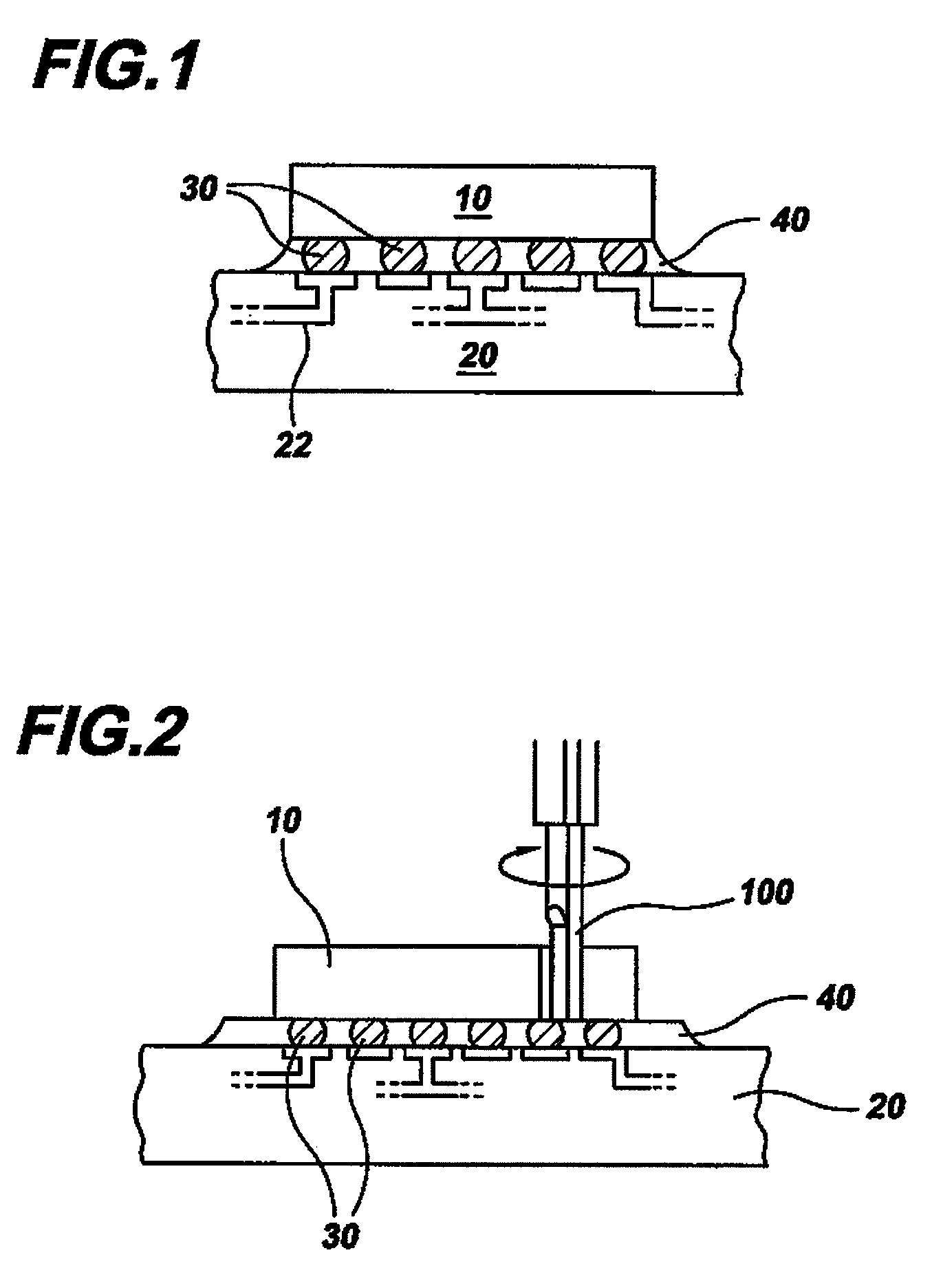

Flip chip and packaged memory module

InactiveUS6475830B1Printed circuit assemblingSemiconductor/solid-state device testing/measurementMemory chipSolder ball

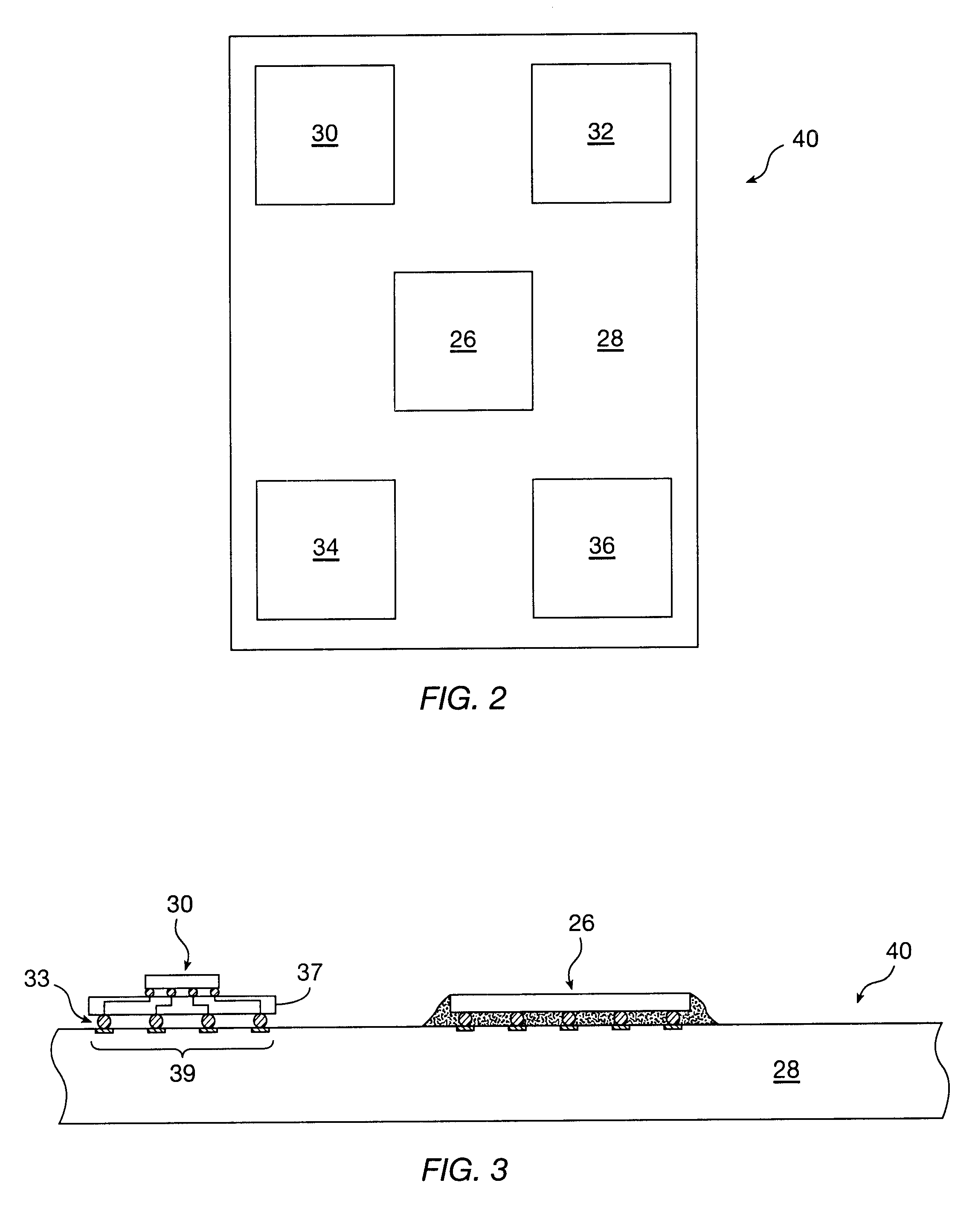

A multi-chip, module (MCM) having one or more high value chips such as ASICs, CPUs, DSPs or the like attached to the MCM substrate via a direct attach technology (such as flip chip) and one or more memory chips attached to the MCM substrate via a reworkable technology such as connector and receptacle-based package, wirebond package, chip scale package (CSP), leaded package, ball grid array package, or fine pitch ball grid array package. The MCM substrate may, in turn, be attached to a motherboard via solder balls (ball grid array); leads and / or connector interconnect technologies (such as compression sockets).

Owner:CISCO TECH INC

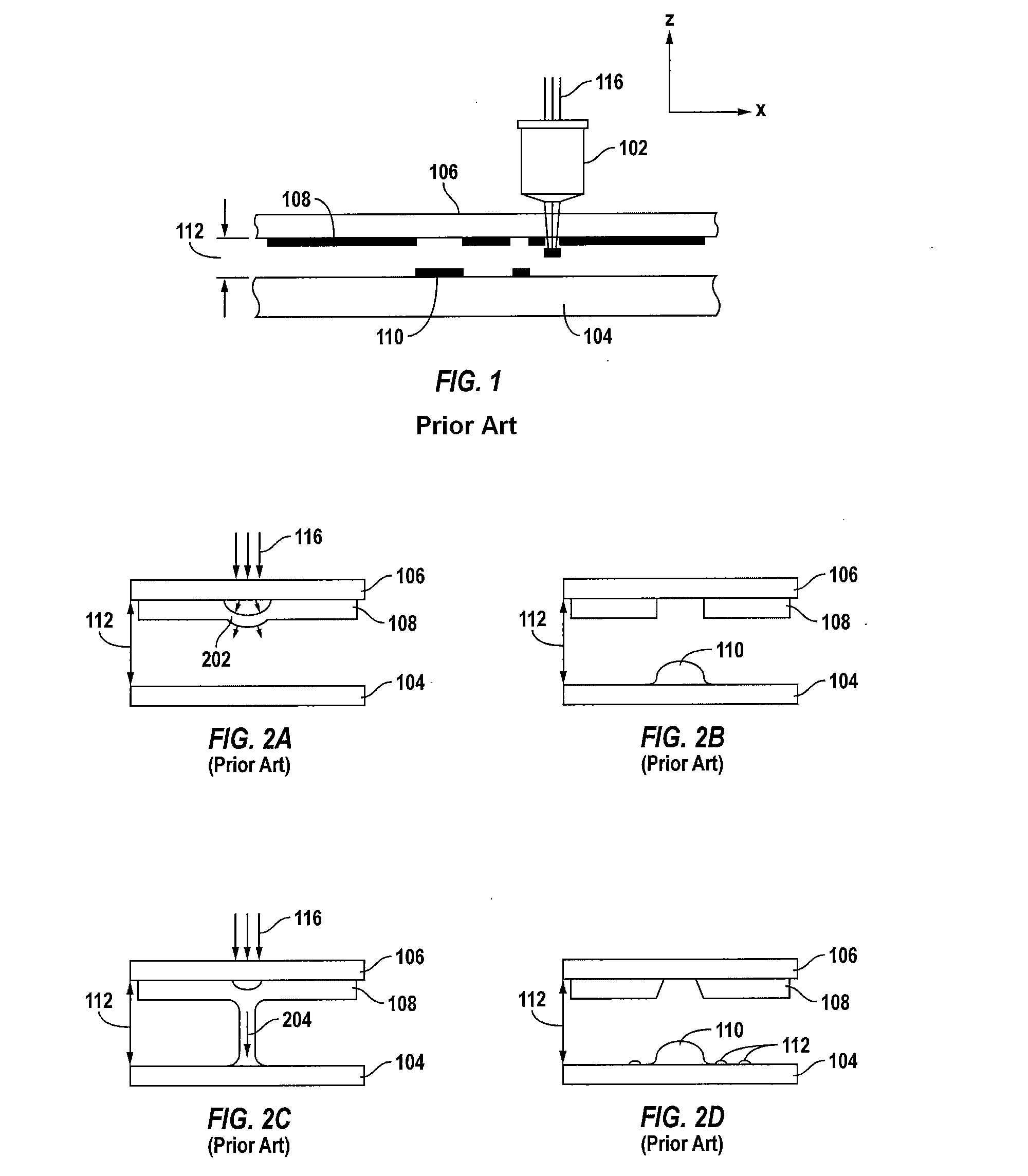

Laser decal transfer of electronic materials

ActiveUS20090074987A1Dampening any shear forceHigh viscosityElectric discharge heatingTransfer patterningThin layerOptoelectronics

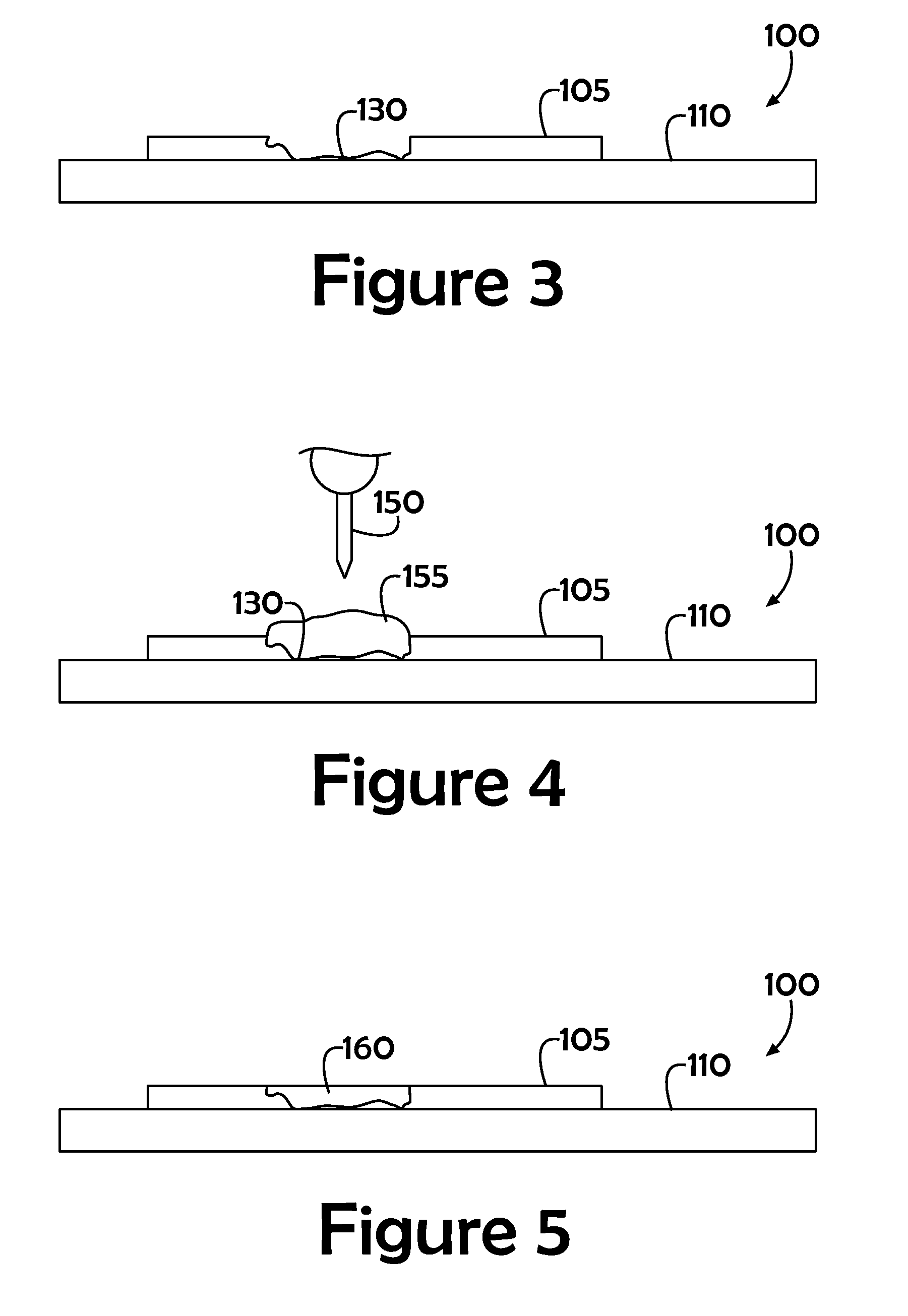

A laser decal transfer is used to generate thin film features by directing laser pulses of very low energy at the back of a target substrate illuminating an area of a thin layer of a high viscosity rheological fluid coating the front surface of the target. The illuminated area is shaped and defined by an aperture centered about the laser beam. The decal transfer process allows for the release and transfer from the target substrate to the receiving substrate a uniform and continuous layer identical in shape and size of the laser irradiated area. The released layer is transferred across the gap with almost no changes to its initial size and shape. The resulting patterns transferred onto the receiving substrate are highly uniform in thickness and morphology, have sharp edge features and exhibit high adhesion, independent of the surface energy, wetting or phobicity of the receiving substrate.

Owner:PHOTON DYNAMICS +1

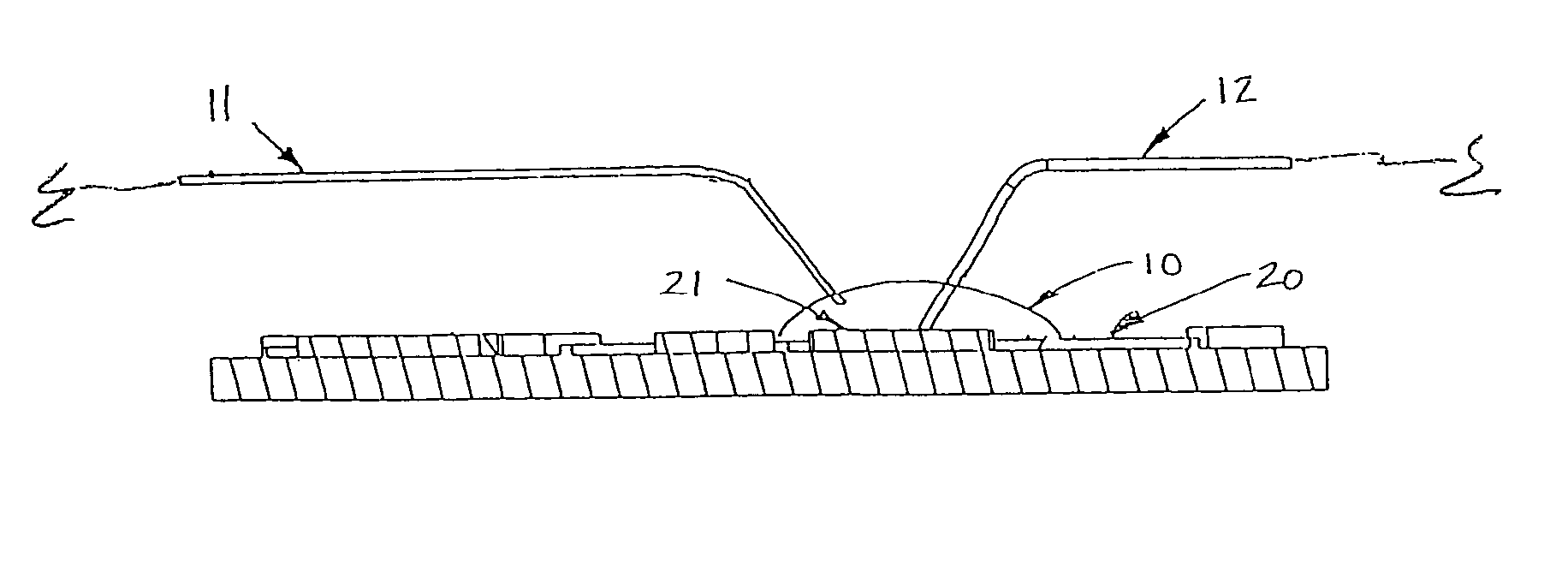

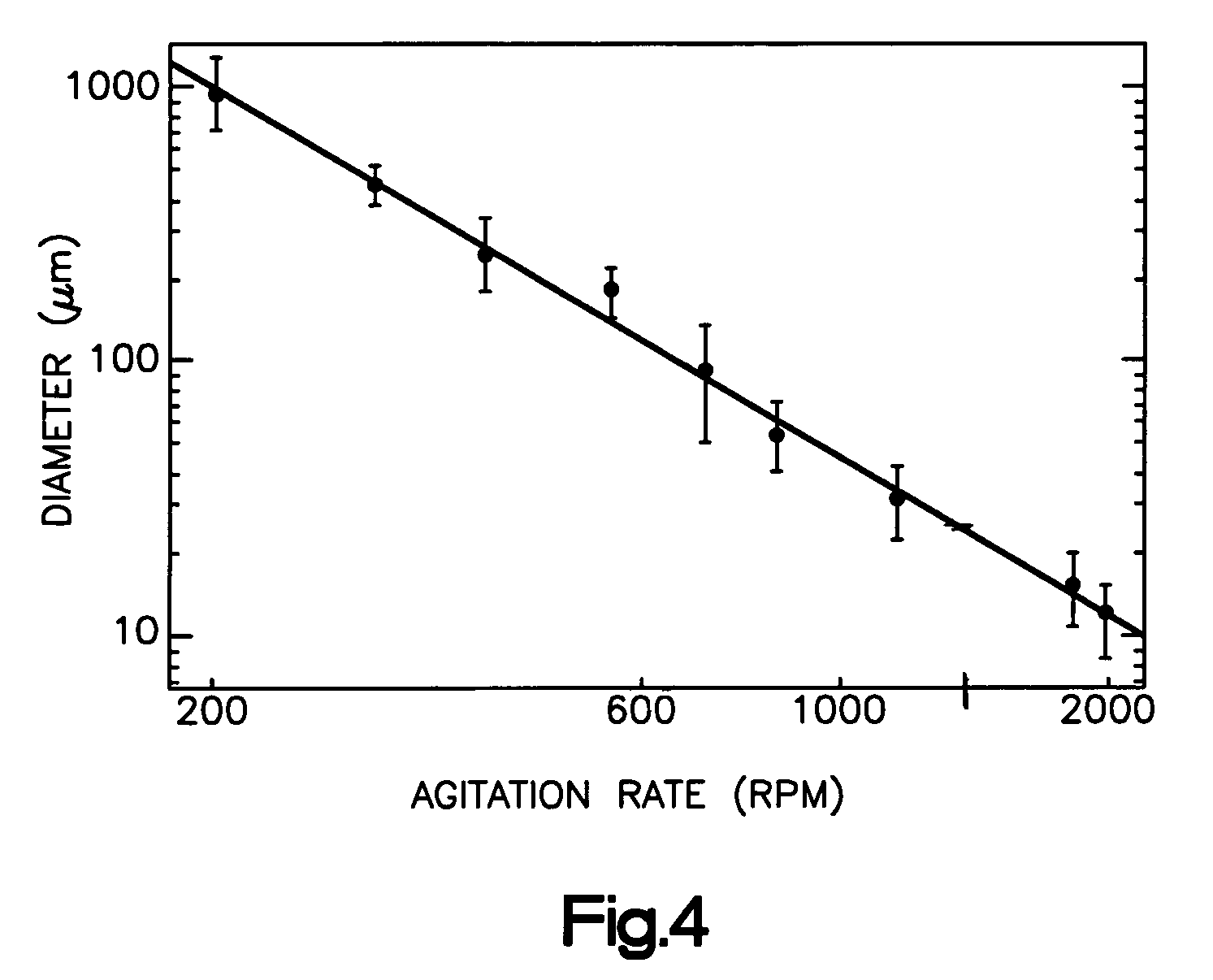

Electrochemical deposition method utilizing microdroplets of solution

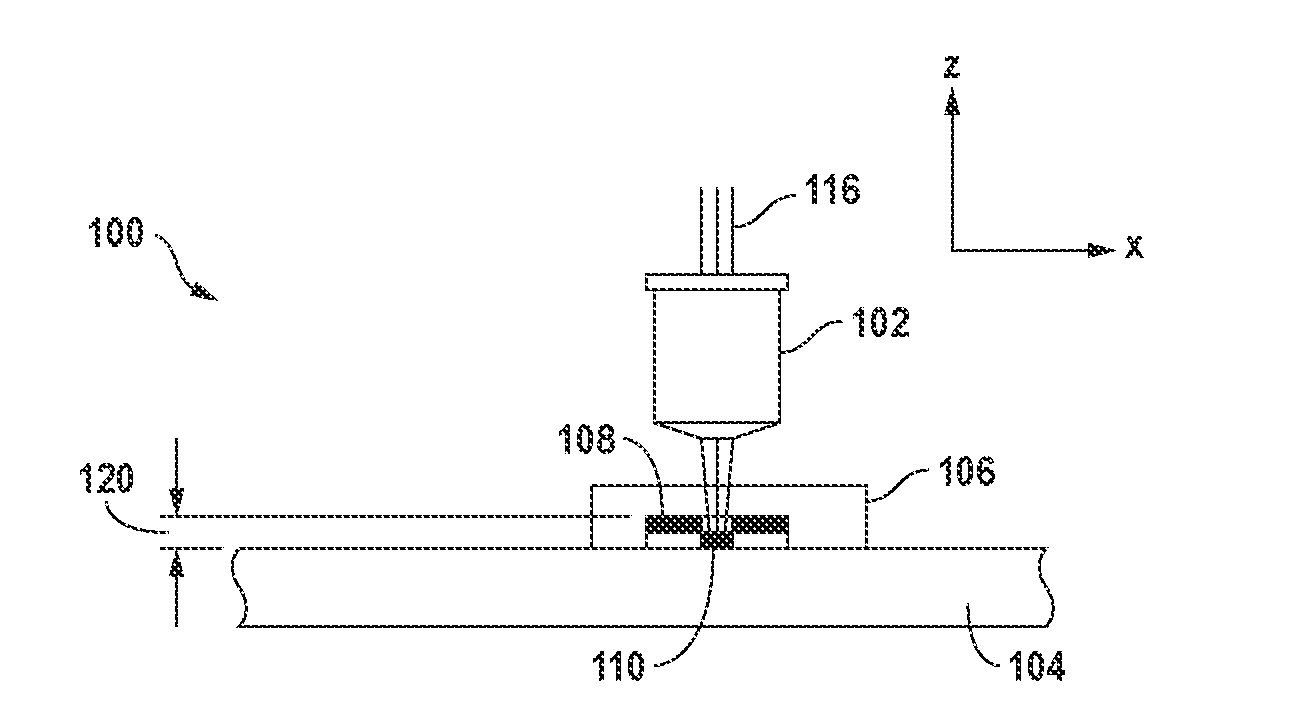

ActiveUS7628902B2Less electrolyte solutionUnwanted depositionMaterial nanotechnologySemiconductor/solid-state device manufacturingElectrolysisEngineering

A method of electrochemical deposition uses microdroplets of electrolytic solution over a targeted small circuit element. Only the targeted circuit element is electrically biased so that deposition occurs on the surface of that element, underneath the microdroplet, and nowhere else unless it is under other microdroplet(s). The invented method achieves extremely accurate and selective electrochemical deposition with a tiny amount of electrolytic solution, compared to conventional submersive and / or immersive methods, and eliminates the need for masking or etching, reducing the costs of manufacture and amount of waste electrolytic solution produced.

Owner:BOISE STATE UNIVERSITY

Precision spray processes for direct write electronic components

InactiveUS20020170890A1Keep for a long timeIncrease probabilityMolten spray coatingPrinted electric component incorporationElectrical resistance and conductanceElectronic component

This invention combines the precision spray process with in-flight laser treatment in order to produce direct write electronic components. In addition to these components, the process can lay down lines of conductive, inductive, and resistive materials. This development has the potential to change the approach to electronics packaging. This process is revolutionary in that components can be directly produced on small structures, thus removing the need for printed circuit boards.

Owner:OPTOMEC DESIGN CO

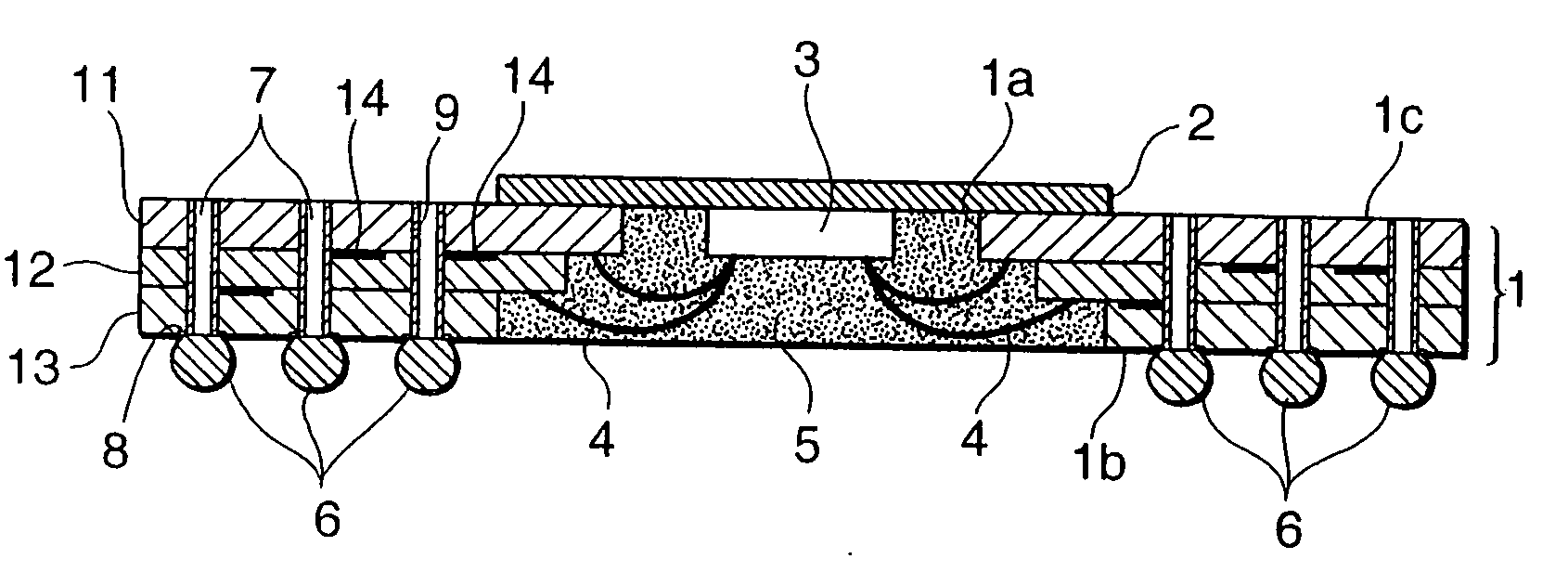

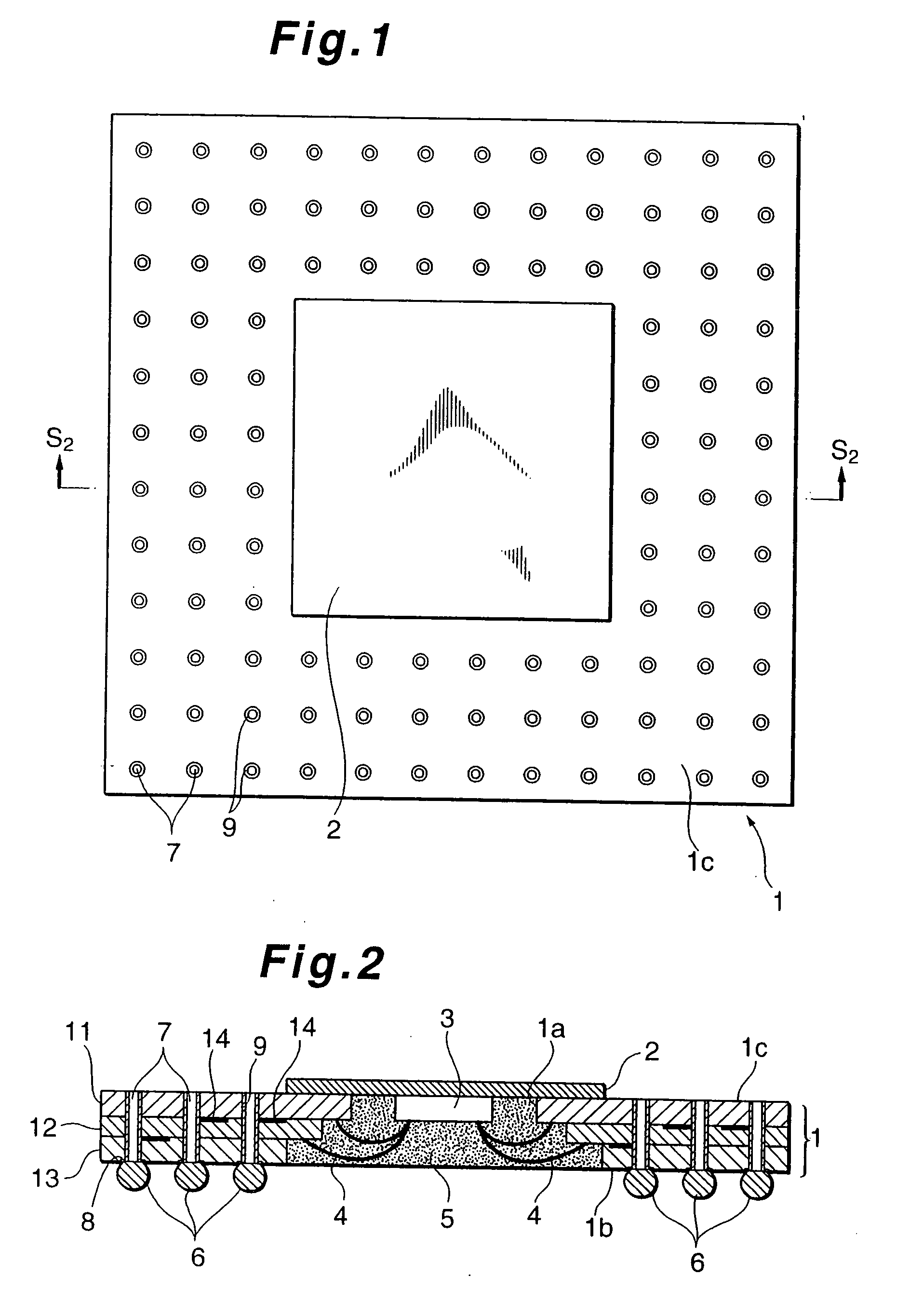

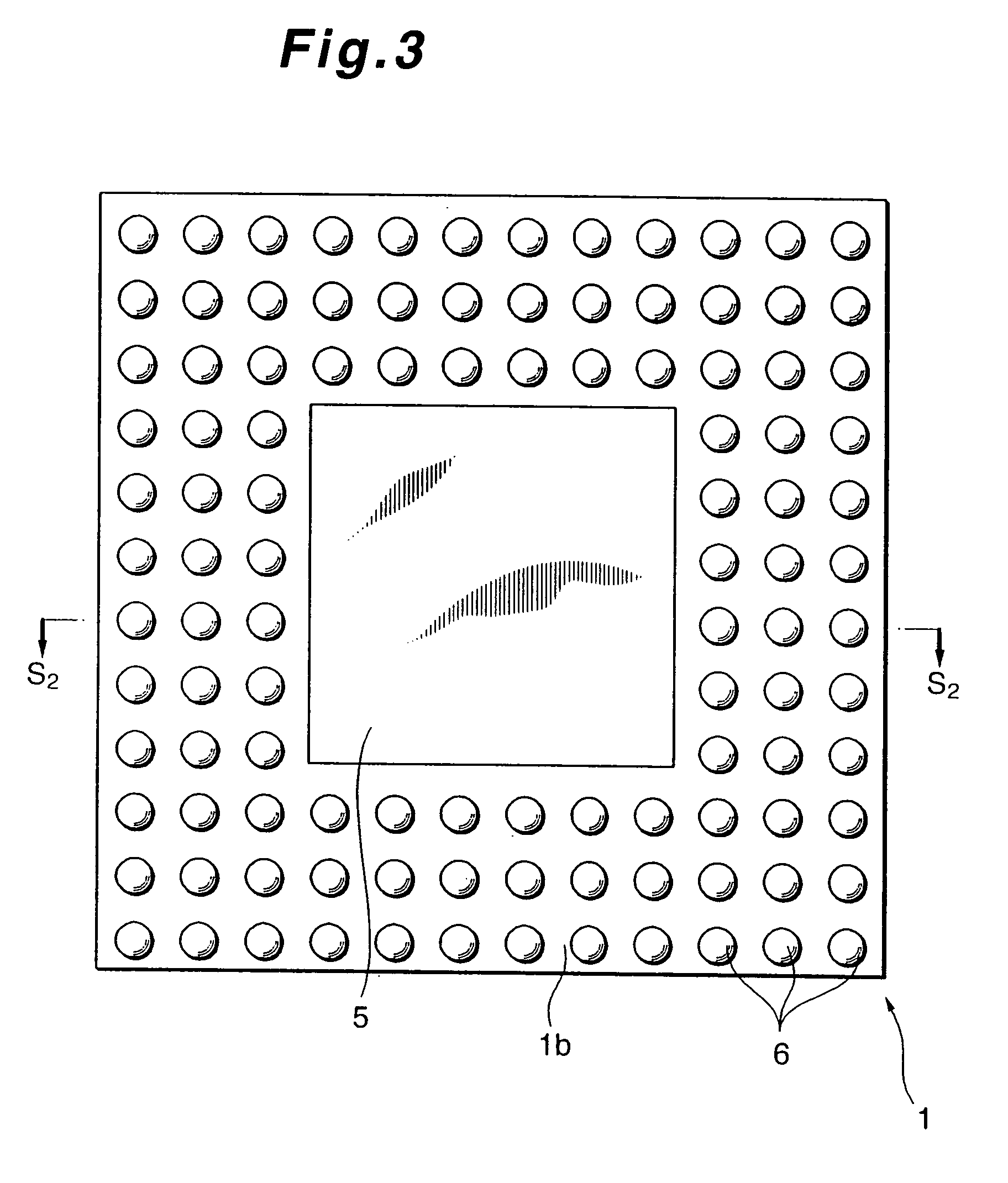

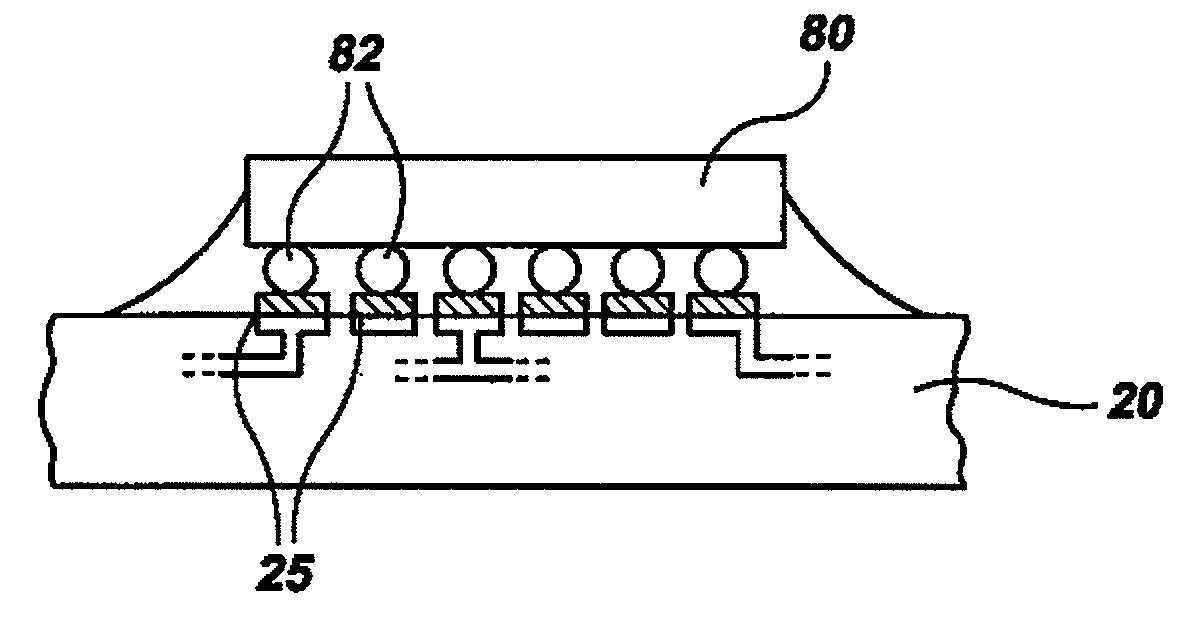

Semiconductor device, method for mounting the same, and method for repairing the same

InactiveUS20050258526A1Reduce incidenceEasy to failPrinted circuit assemblingSemiconductor/solid-state device testing/measurementDevice materialSolder ball

A method for mounting a semiconductor device, which can decrease the occurrence rate of failures, a method for repairing a semiconductor device, which can easily repair defective solder joints, and a semiconductor device which makes those methods feasible. A substrate 1 has formed therein through-holes 7 lined on the internal walls with a wiring layer 9, and solder balls 6 are fusion-bonded to the substrate 1 in such a manner as to cover the through-holes 7. In the mounting process or in the repair process, heating probes 41 are passed through the through-holes 7 and thrust into the solder balls 6 to thereby melt the solder balls, and the heating probes are pulled out of the solder balls to let the solder balls cool down. In those processes, only the solder balls 6 can be heated, thereby averting adverse effects on the IC chip 3. In the repair process, the solder balls 6 can be restored to an initial condition free of intermetallic compounds.

Owner:LAPIS SEMICON CO LTD

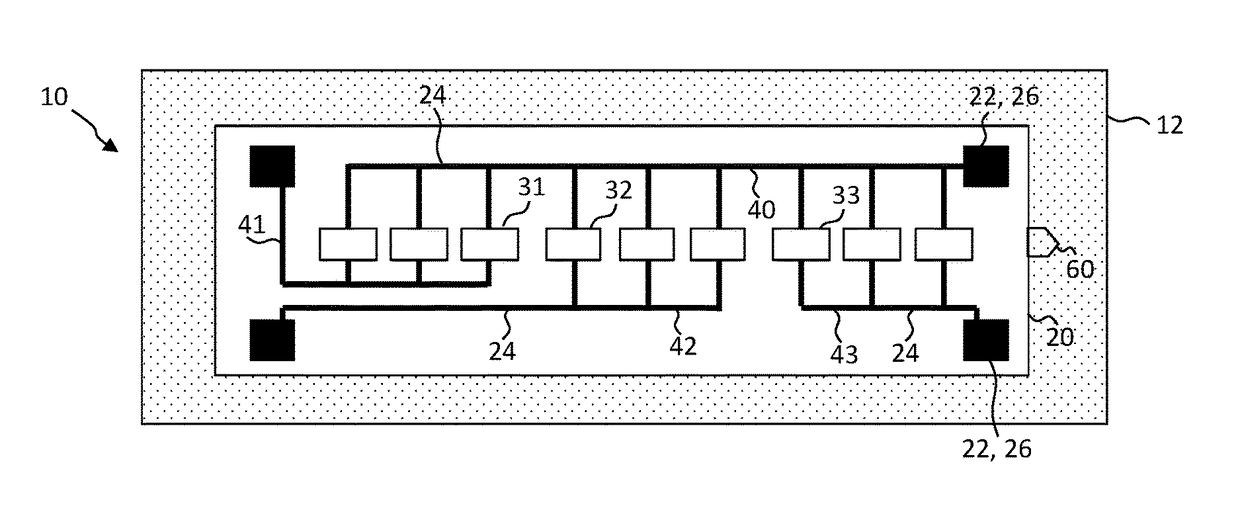

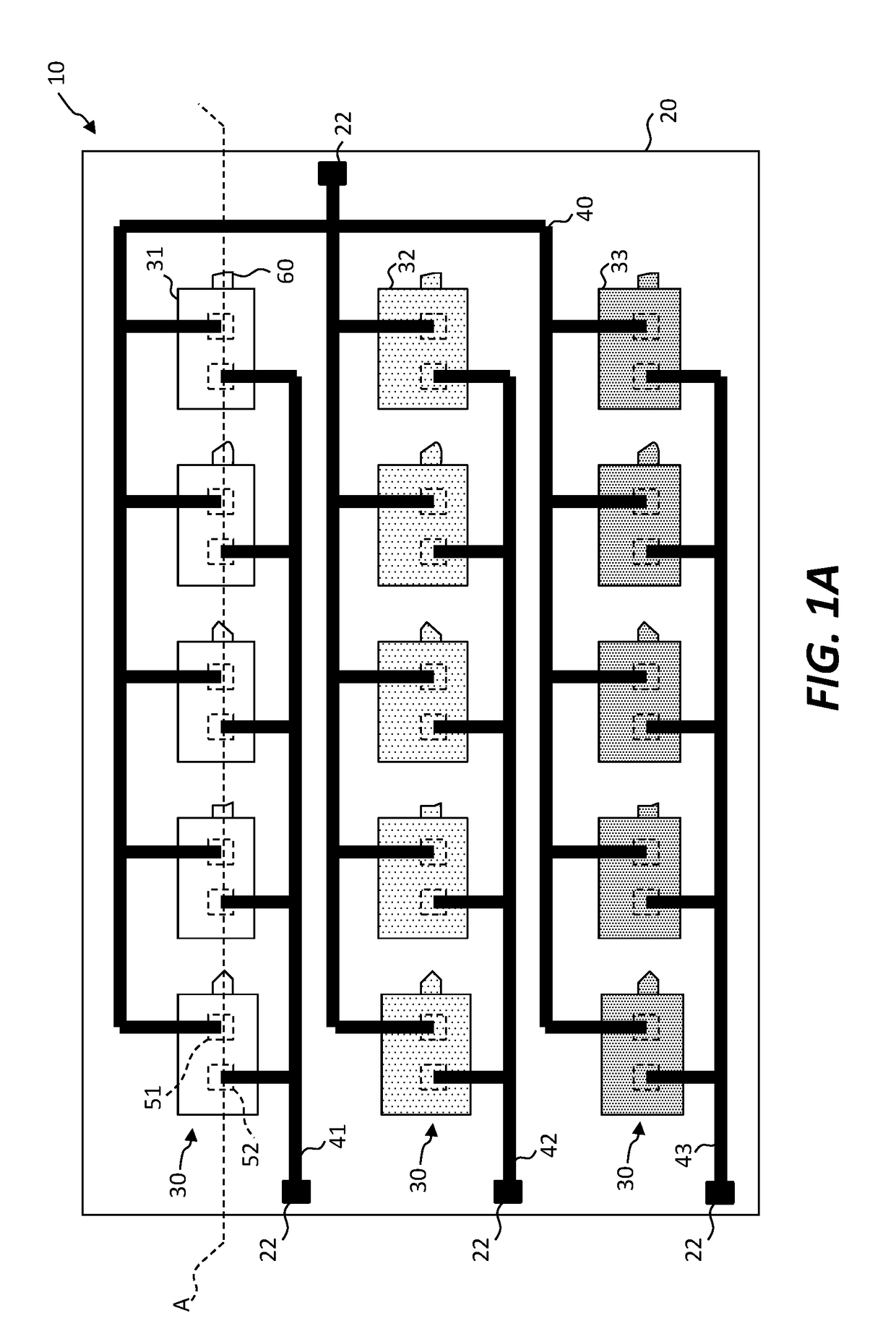

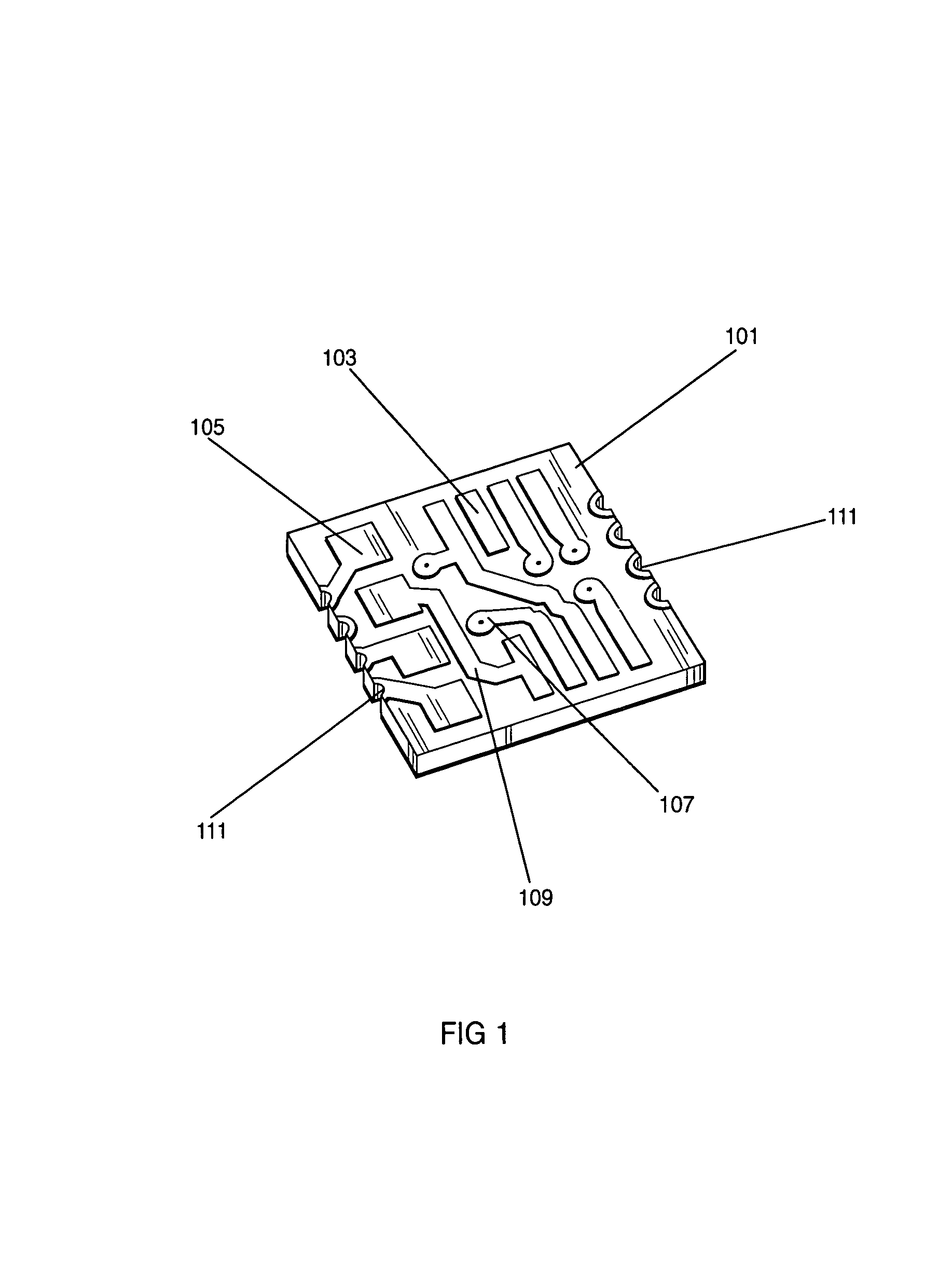

Multi-led components

ActiveUS20180084614A1Good colorElectroluminescent light sourcesPrinted circuit aspectsLight-emitting diodeMaterials science

A multi-LED component comprises a component substrate comprising a common electrode, a first electrode, a second electrode, a plurality of first LEDs, and a plurality of second LEDs all disposed on the component substrate. Each first LED and each second LED comprises first and second LED contacts for providing power to each corresponding LED to cause the LED to emit light. The first LED contact of each first LED and each second LED is electrically connected to the common electrode. The second LED contacts of the first LEDs are electrically connected to the first electrode. The second LED contacts of the second LEDs are electrically connected to the second electrode so that the first LEDs are electrically connected in parallel and the second LEDs are electrically connected in parallel.

Owner:X DISPLAY CO TECH LTD

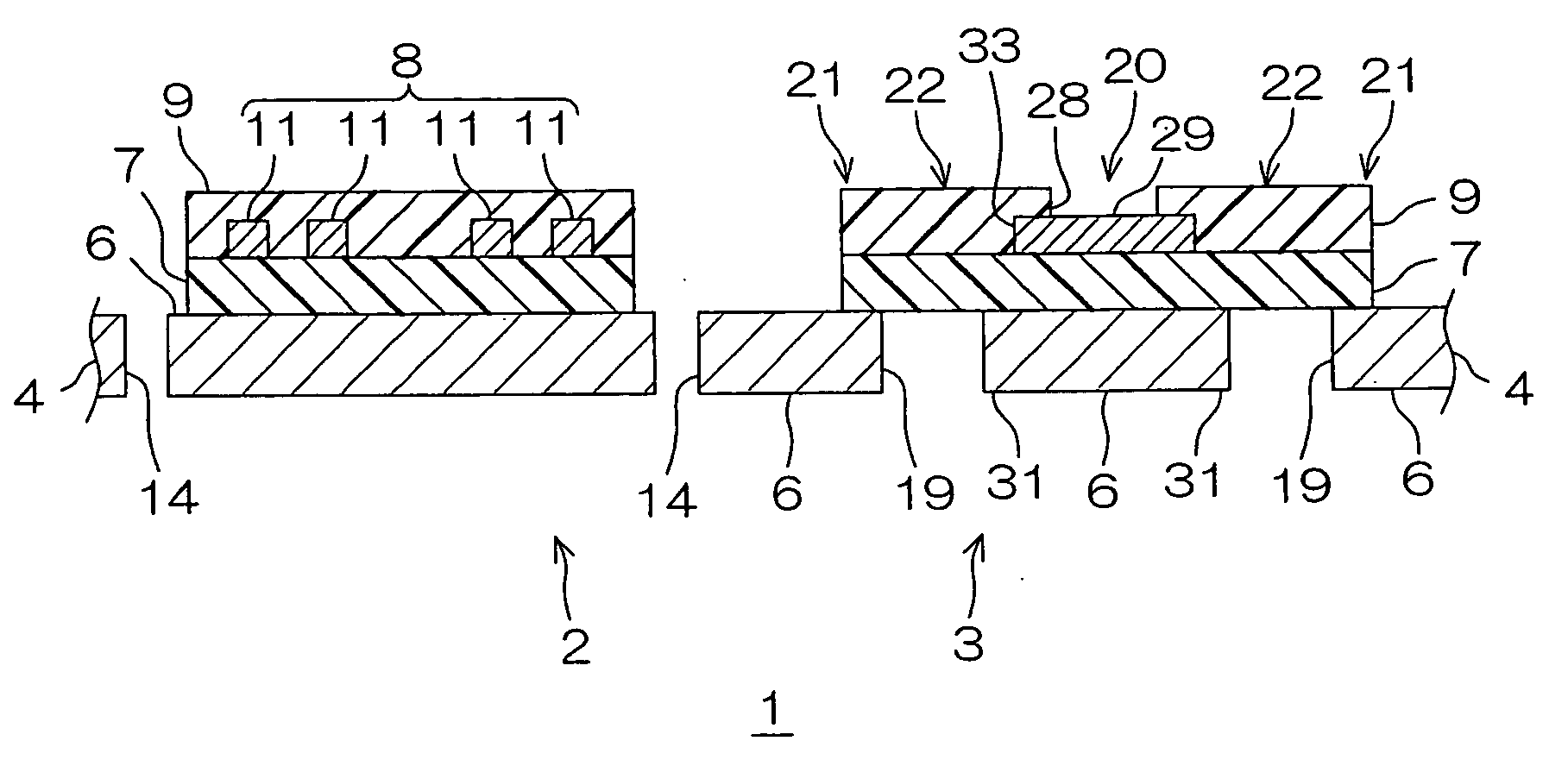

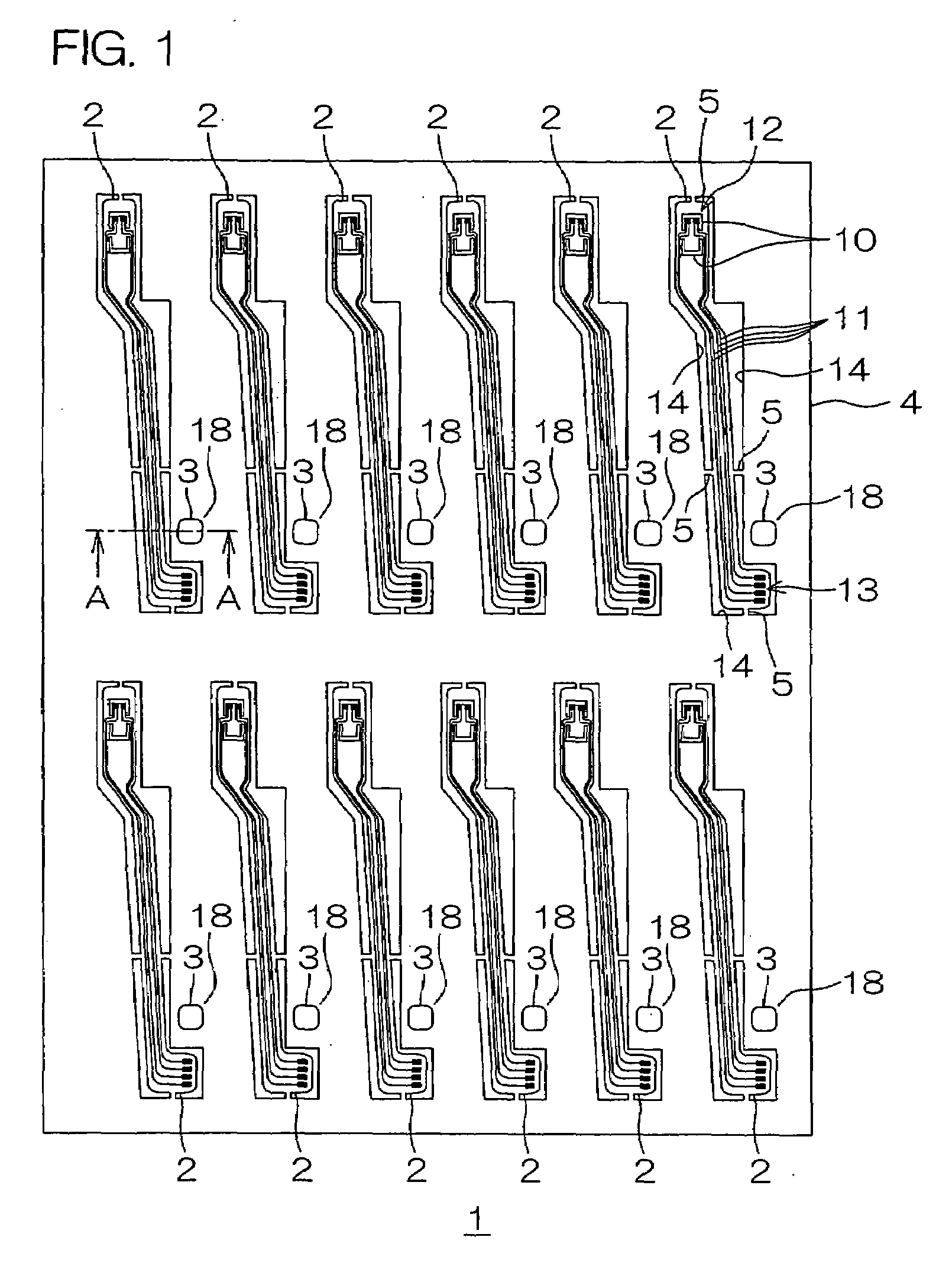

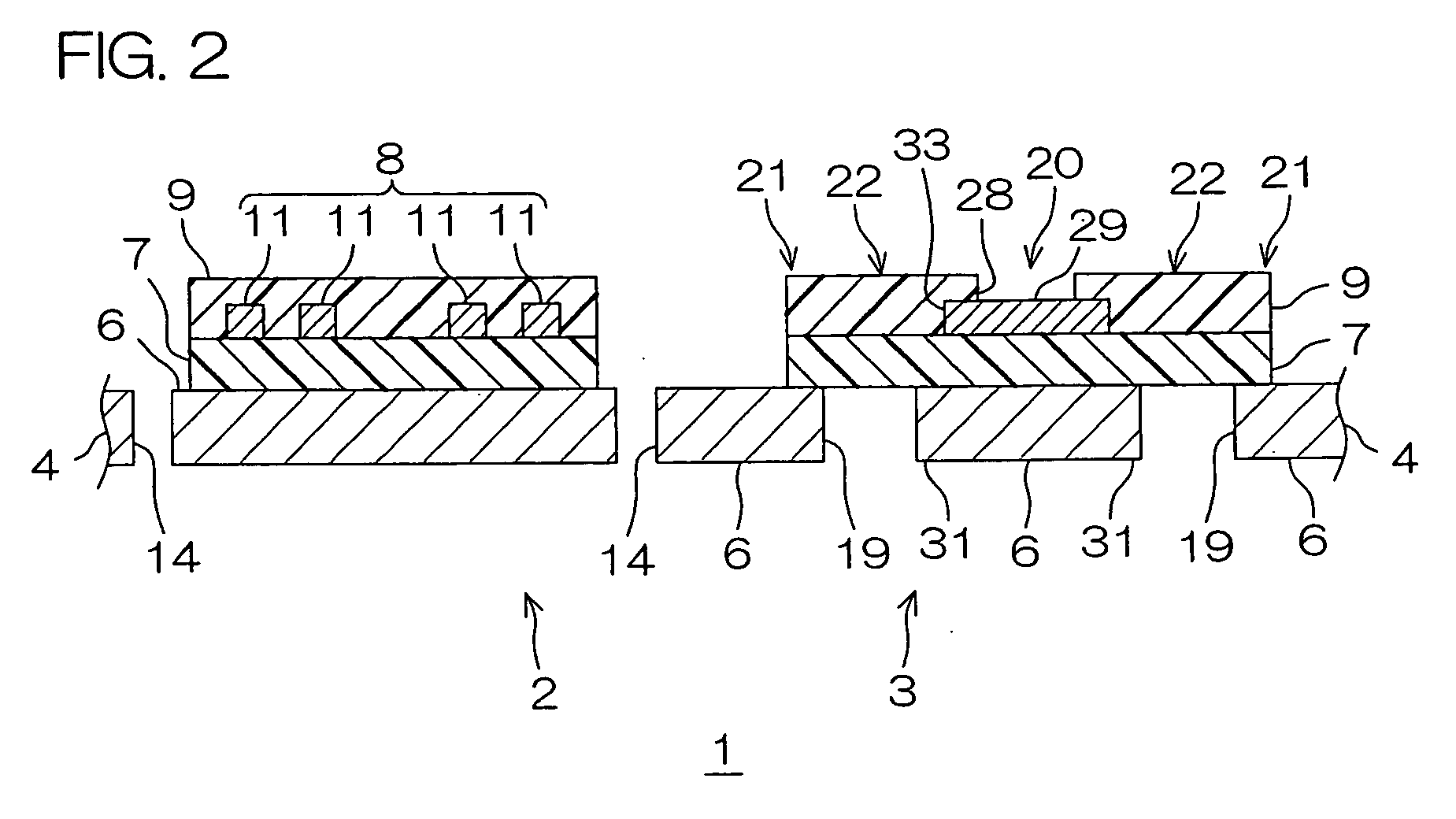

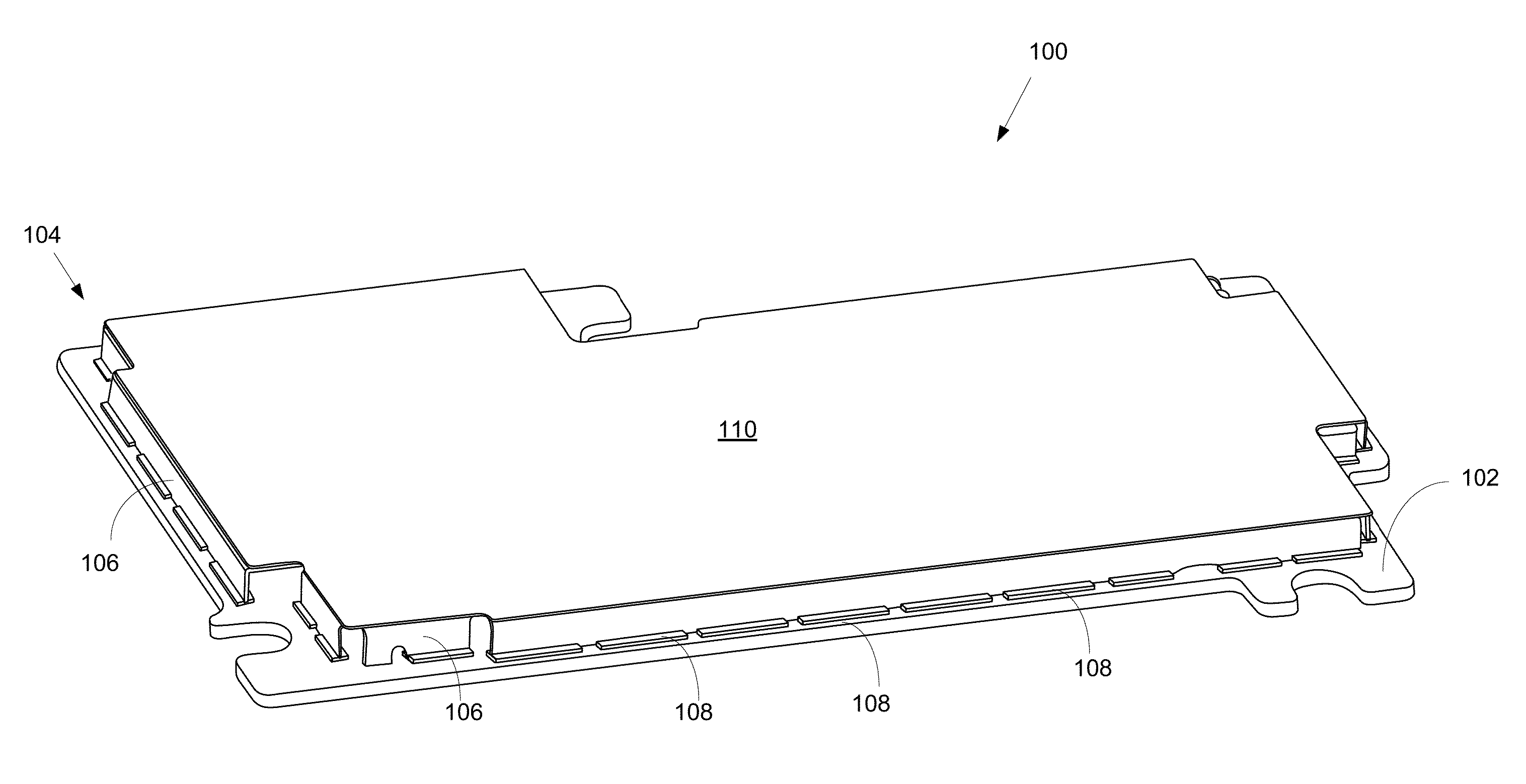

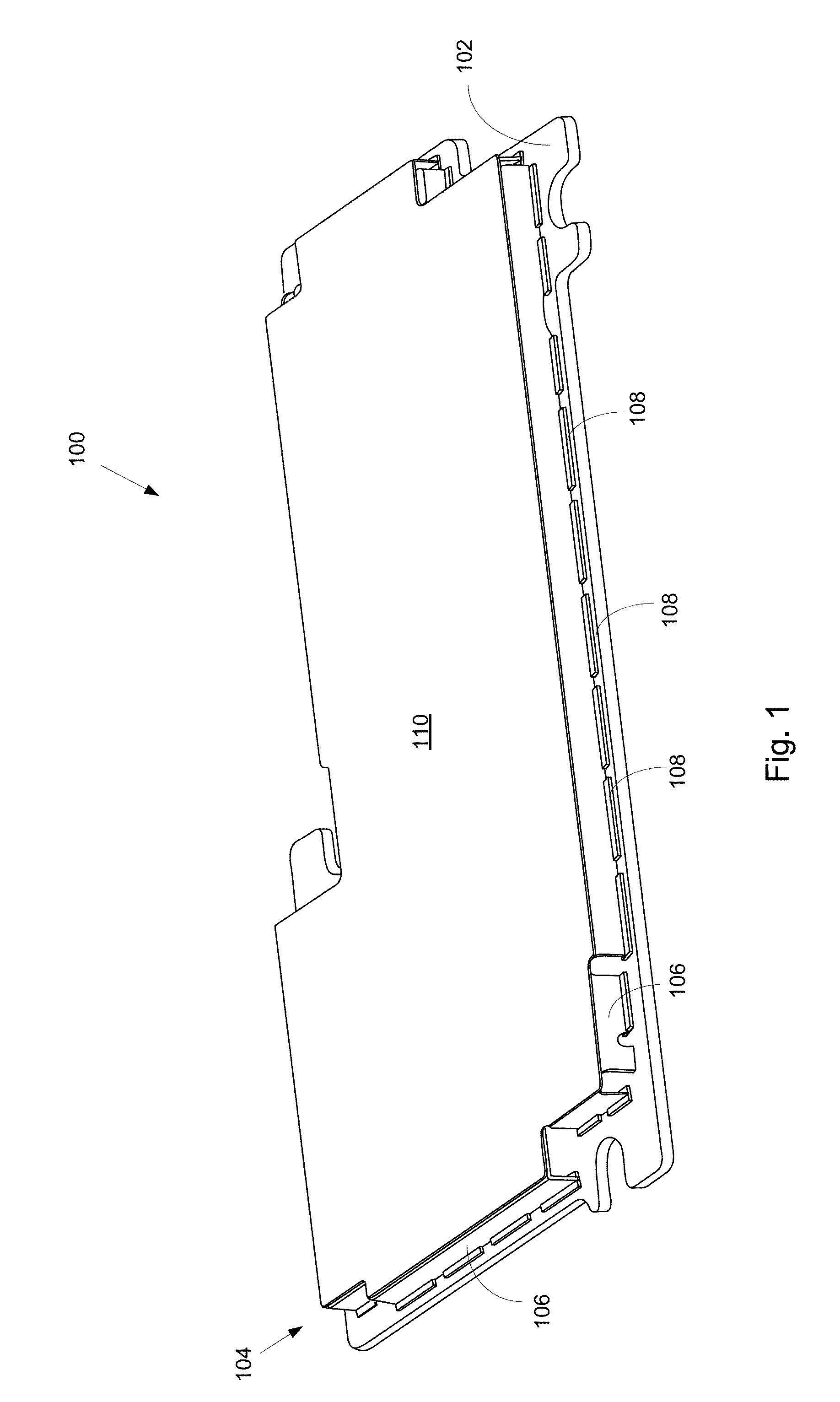

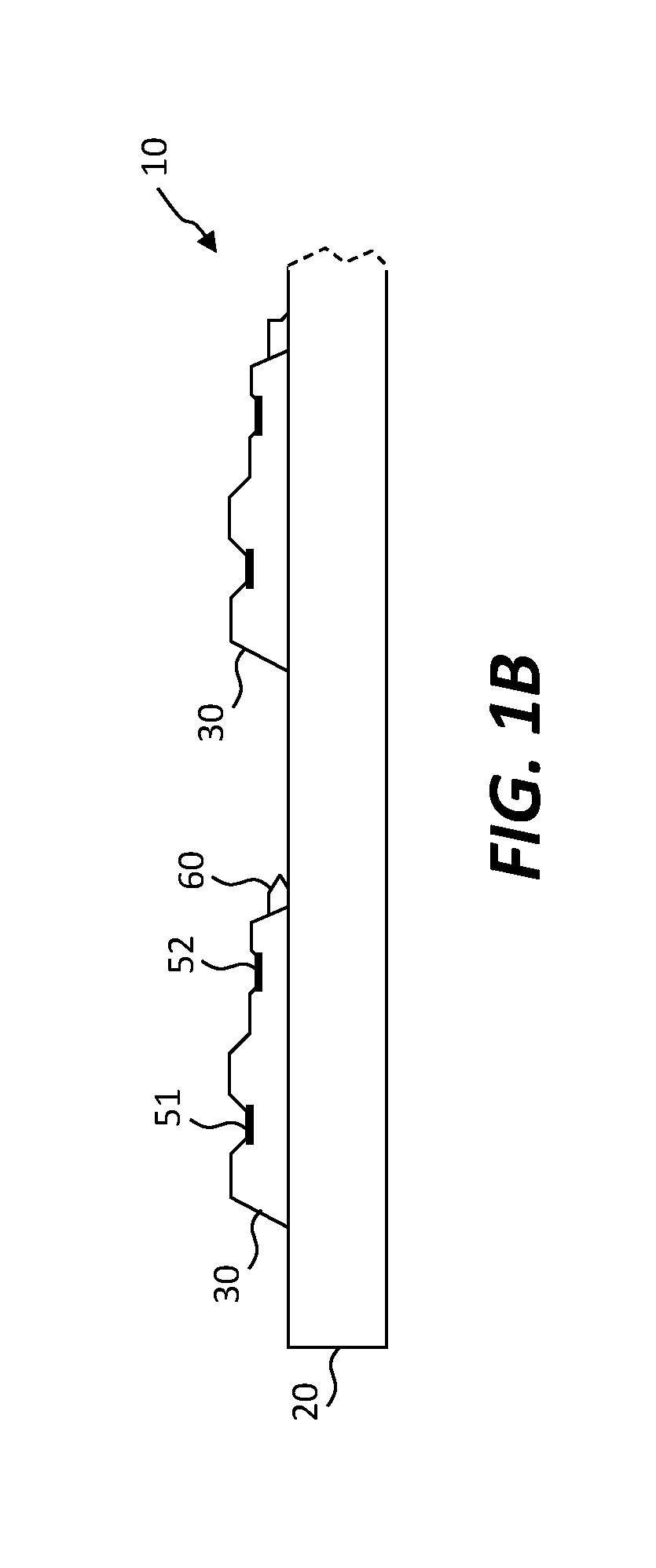

Wired-circuit-board assembly sheet

InactiveUS20070170911A1Easy to disassembleReduce wearPrinted circuit aspectsRecord information storageEngineeringMetal powder

A wired-circuit-board assembly sheet is provided having removable portions that are easily removable without any generation of metal powder. The wired-circuit-board assembly sheet comprises a plurality of suspension boards with circuits, distinguishing marks for distinguishing defectiveness of the suspension boards with circuits, and a supporting sheet for supporting the suspension boards with circuits and the distinguishing marks, wherein openings are formed in the supporting sheet, and removable portions which are to be removed when the suspension boards with circuits are judged defective are located in the openings and also supported by the supporting sheet via joint portions formed of resin.

Owner:NITTO DENKO CORP

Method to recover underfilled modules by selective removal of discrete components

InactiveUS20090184407A1Avoid damageSurface cleaningFinal product manufactureSemiconductor/solid-state device detailsFilling materialsMaterials science

Methods and reworked intermediate and resultant electronic modules made thereby, whereby a component in need of rework is located and removed from the module to reveal encapsulated solder connections residing within an underfill matrix. Heights of both the solder connections and underfill matrix are reduced, followed by etching the solder out of the solder connections to form openings within the underfill matrix. The underfill material is then removed to expose metallurgy of the substrate. A blank having a release layer with an array of solder connections is aligned with the exposed metallurgy, and this solder array is transferred from the blank onto the metallurgy. The transferred solder connections are then flattened using heat and pressure, followed by attaching solder connections of a new component to the flattened solder connections and underfilling these reworked solder connections residing between the new chip and substrate.

Owner:GLOBALFOUNDRIES INC

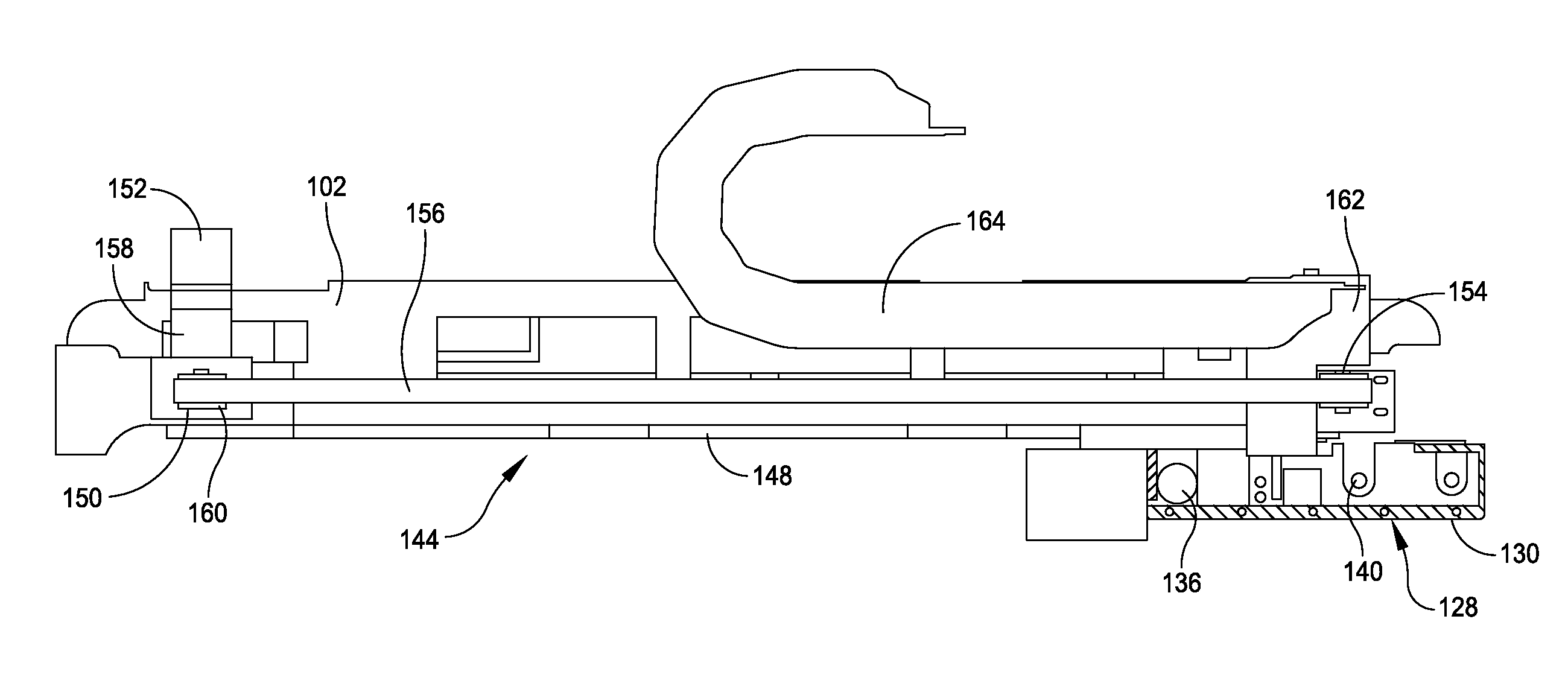

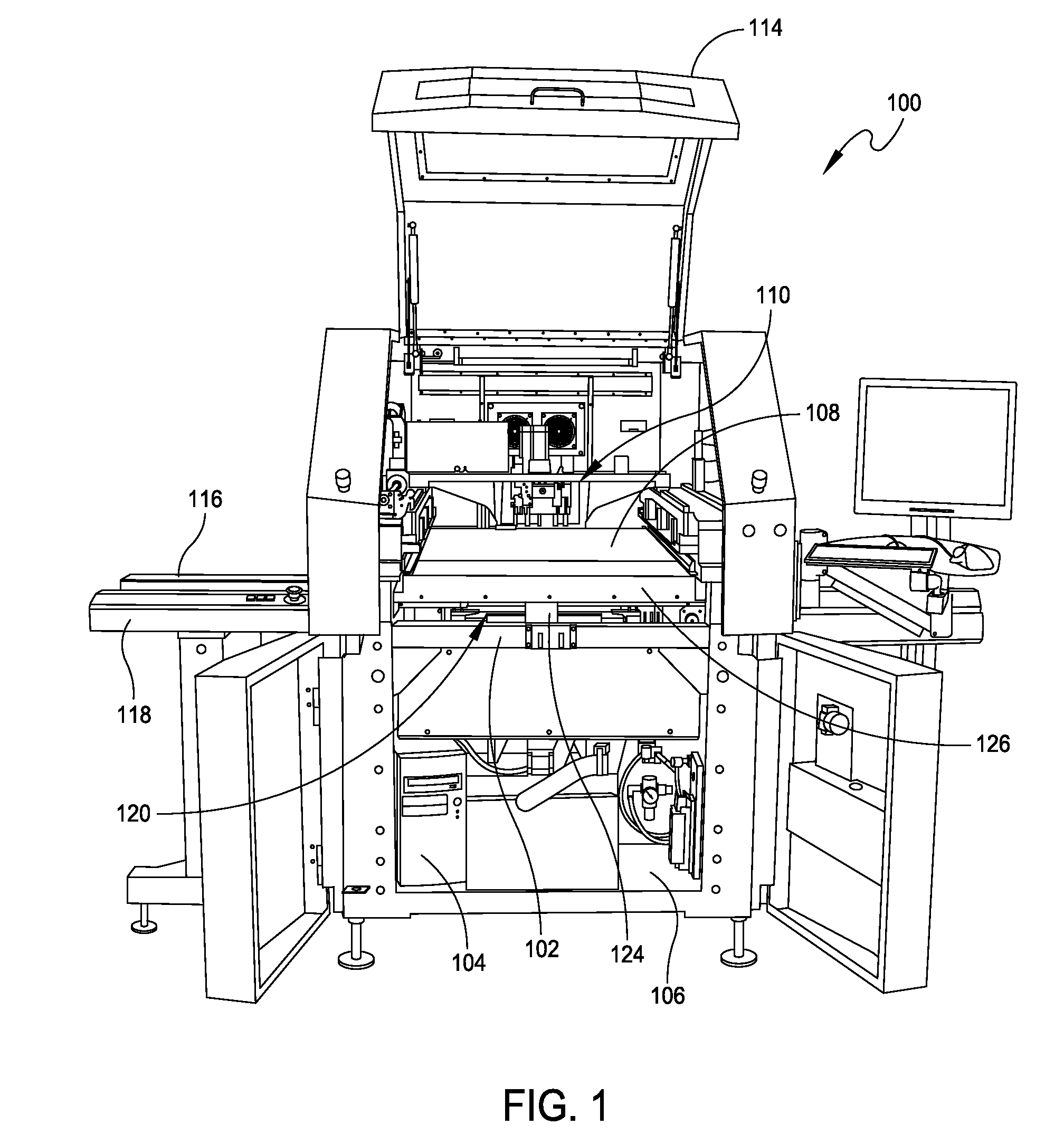

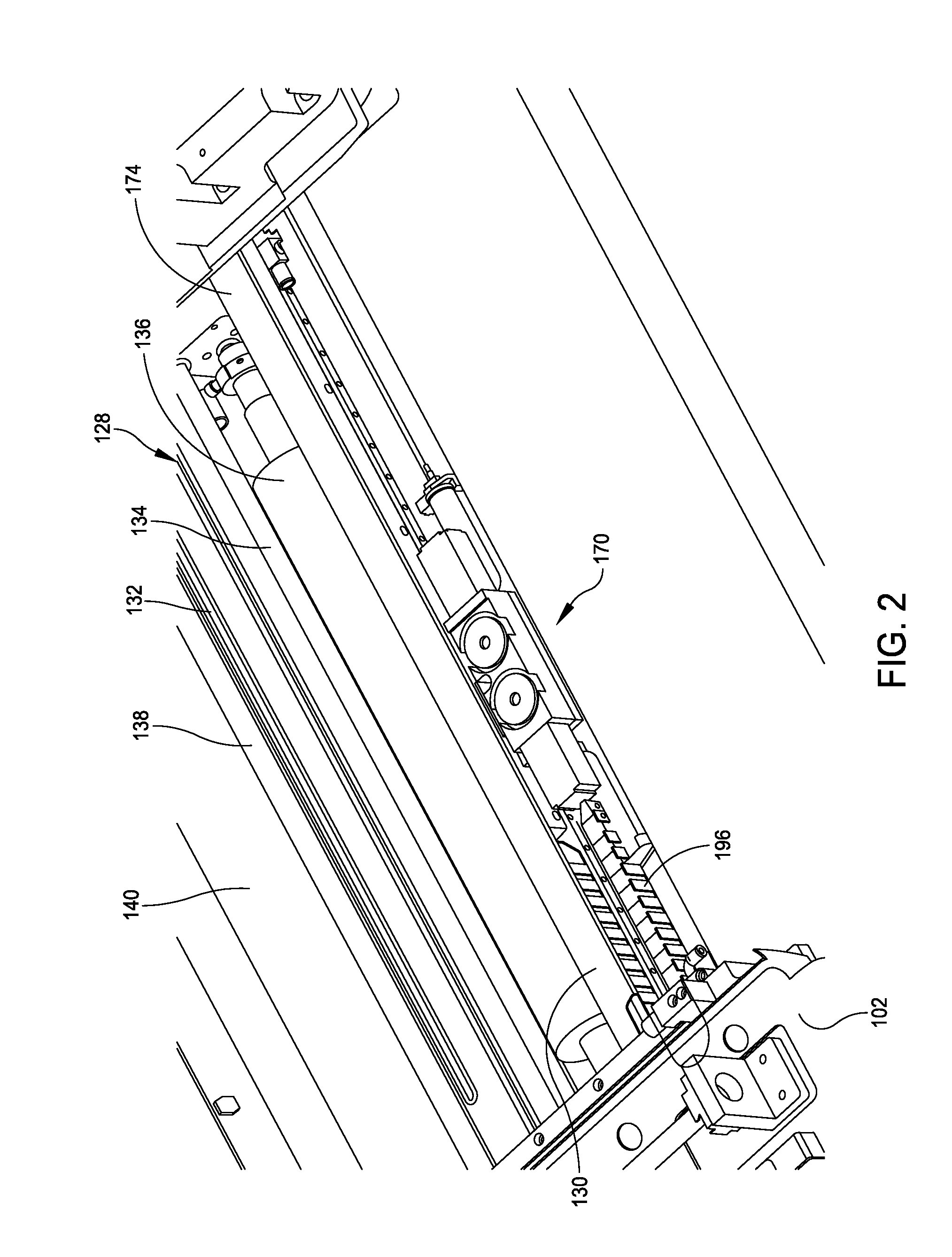

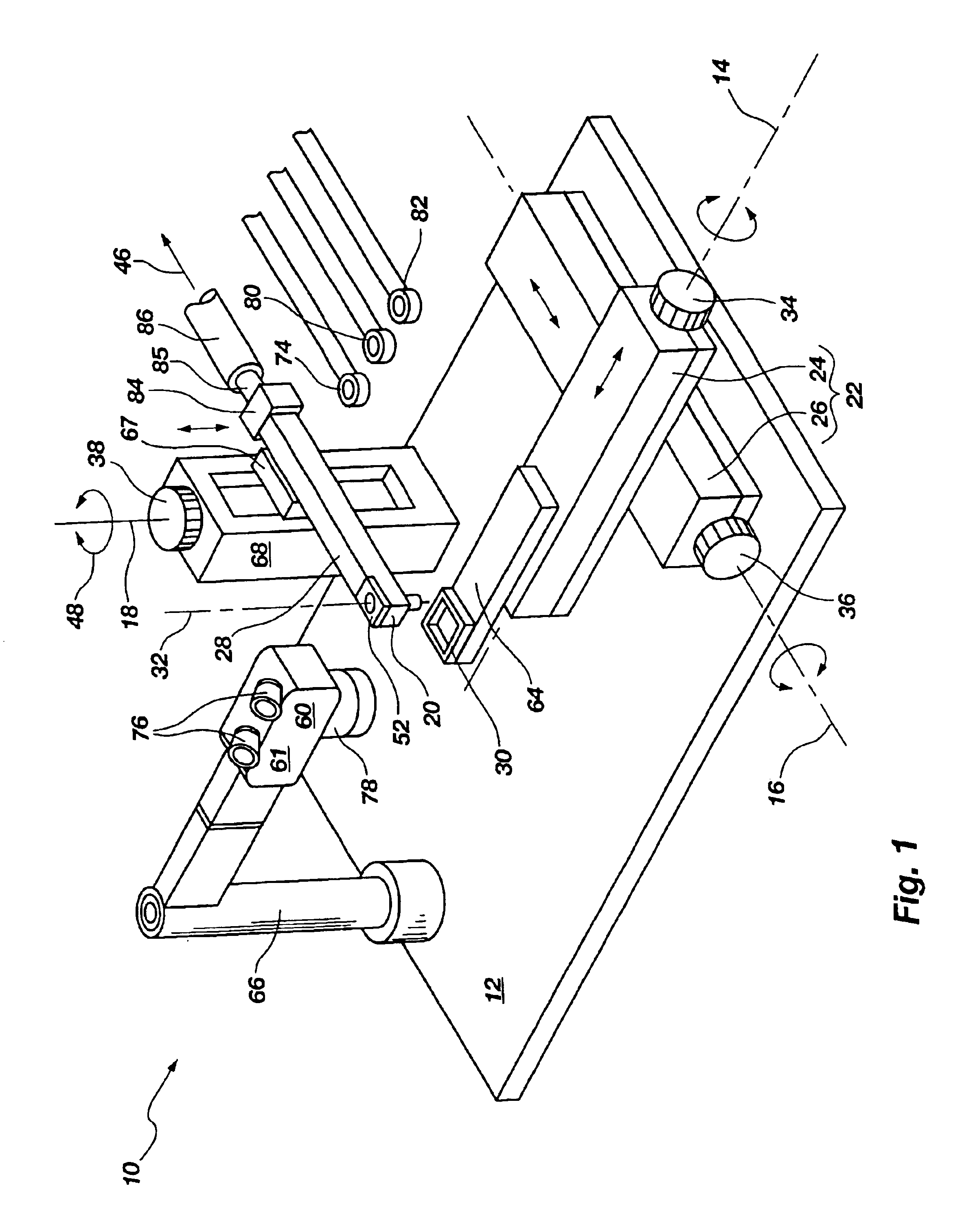

Combination stencil printer and dispenser and related methods

A combination stencil printer and dispenser includes a frame, a movable stencil coupled to the frame, a substrate support coupled to the frame to support a substrate in a print position, and a print head coupled to the frame to deposit and print viscous material over the stencil. The combination stencil printer and dispenser further includes a dispenser mounted on the movable stencil to dispense viscous material on the substrate when the substrate is in the print position. In other embodiments, the dispenser can be mounted on a stencil wiper or on an independent gantry provided within the combination stencil printer and dispenser.

Owner:ILLINOIS TOOL WORKS INC

RF shielding for electronic components

InactiveUS20130120957A1Easily broken jointPrinted circuit assemblingMagnetic/electric field screeningEngineeringElectronic component

An RF shield formed of RF opaque material that permits access to components on a printed circuit board is described. The RF shield can include a first portion attached to the PCB and a removable top portion attached to the first portion at an interface. The top portion is removed from the first portion to expose the components on the PCB. In one aspect of the described embodiment, the top portion is peeled away from the first portion. The components are enclosed within the RF shield after the removal of the top portion by attaching and sealing another top portion to the first portion at the interface by, for example, laser attaching the first portion and the other top portion at the interface.

Owner:APPLE INC

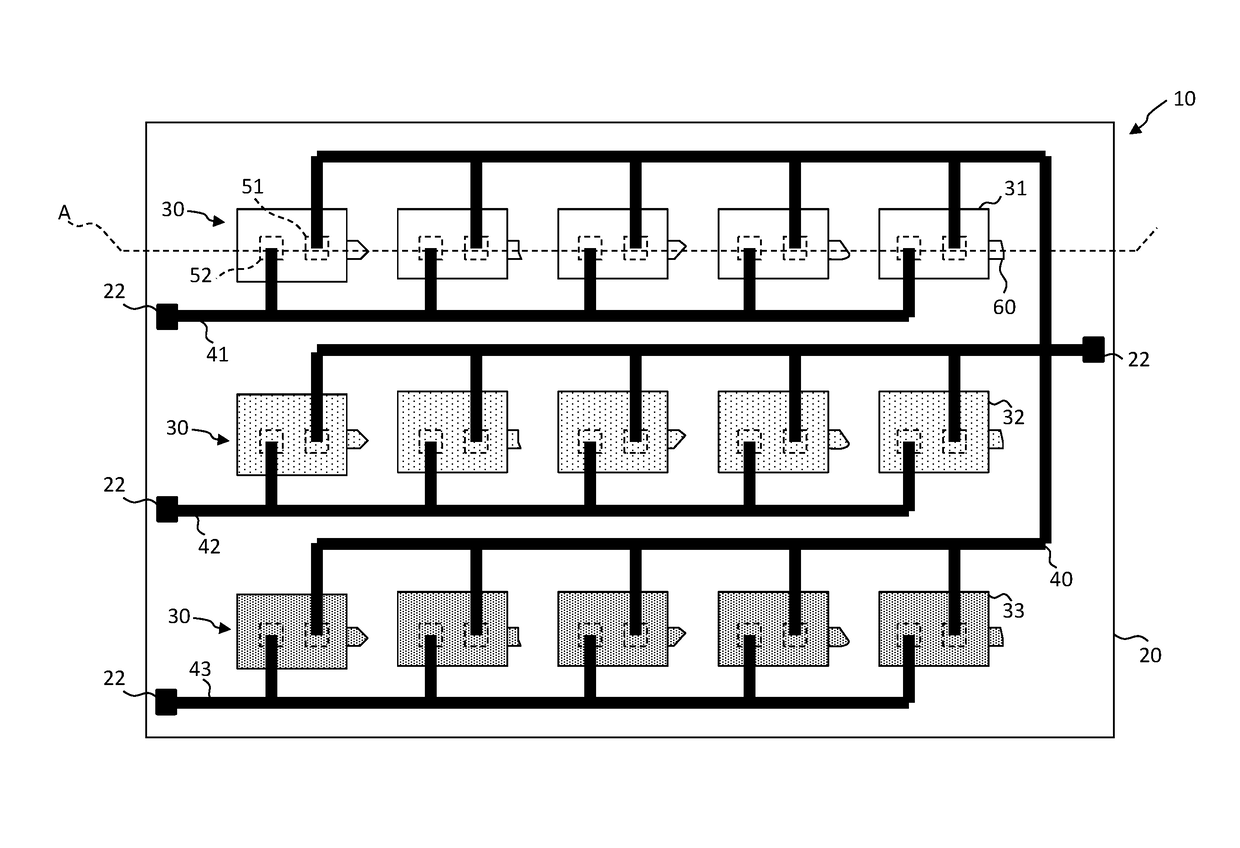

Multi-LED components

ActiveUS9980341B2Good colorElectroluminescent light sourcesPrinted circuit aspectsLight-emitting diodeMaterials science

A multi-LED component comprises a component substrate comprising a common electrode, a first electrode, a second electrode, a plurality of first LEDs, and a plurality of second LEDs all disposed on the component substrate. Each first LED and each second LED comprises first and second LED contacts for providing power to each corresponding LED to cause the LED to emit light. The first LED contact of each first LED and each second LED is electrically connected to the common electrode. The second LED contacts of the first LEDs are electrically connected to the first electrode. The second LED contacts of the second LEDs are electrically connected to the second electrode so that the first LEDs are electrically connected in parallel and the second LEDs are electrically connected in parallel.

Owner:X DISPLAY CO TECH LTD

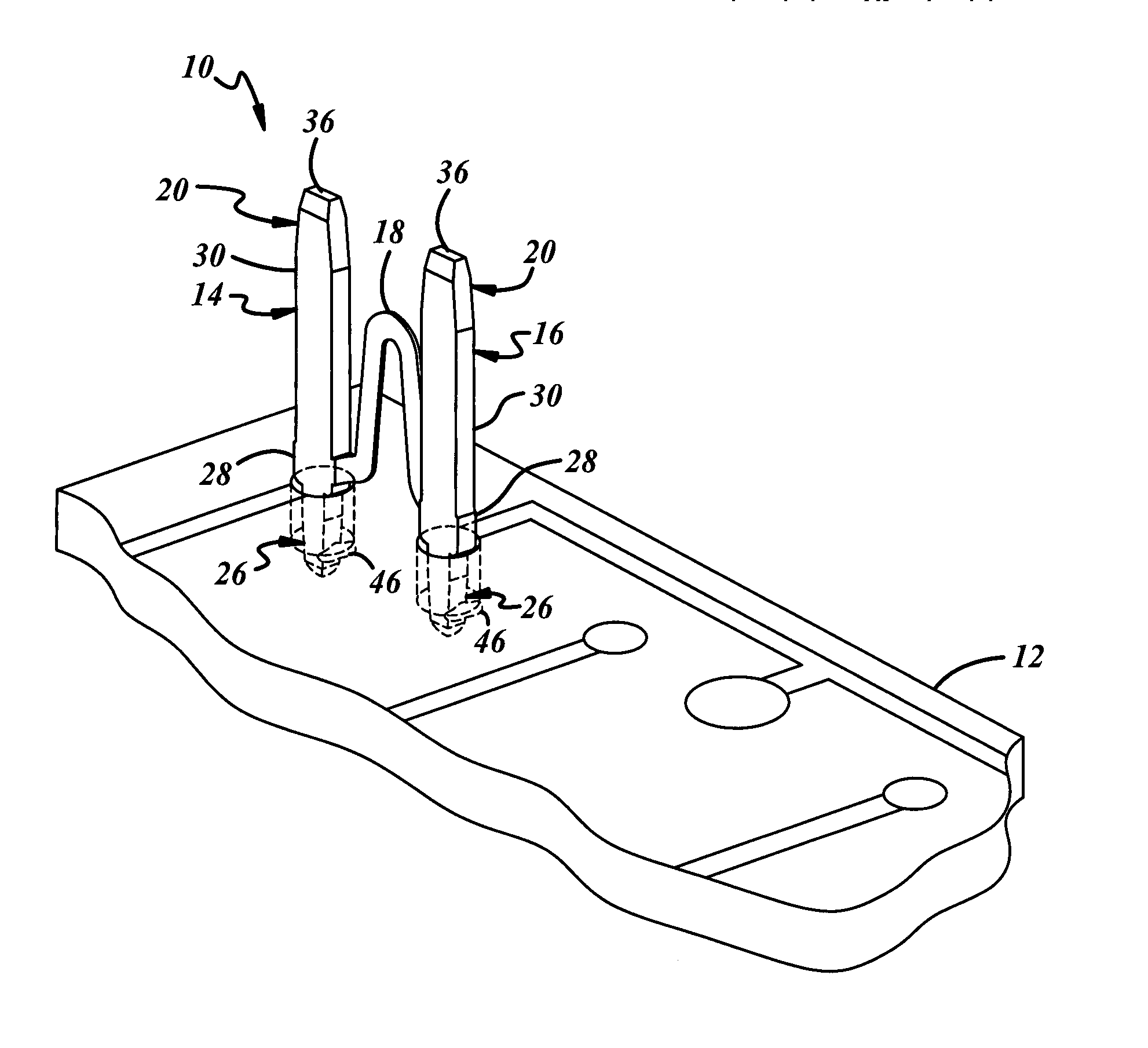

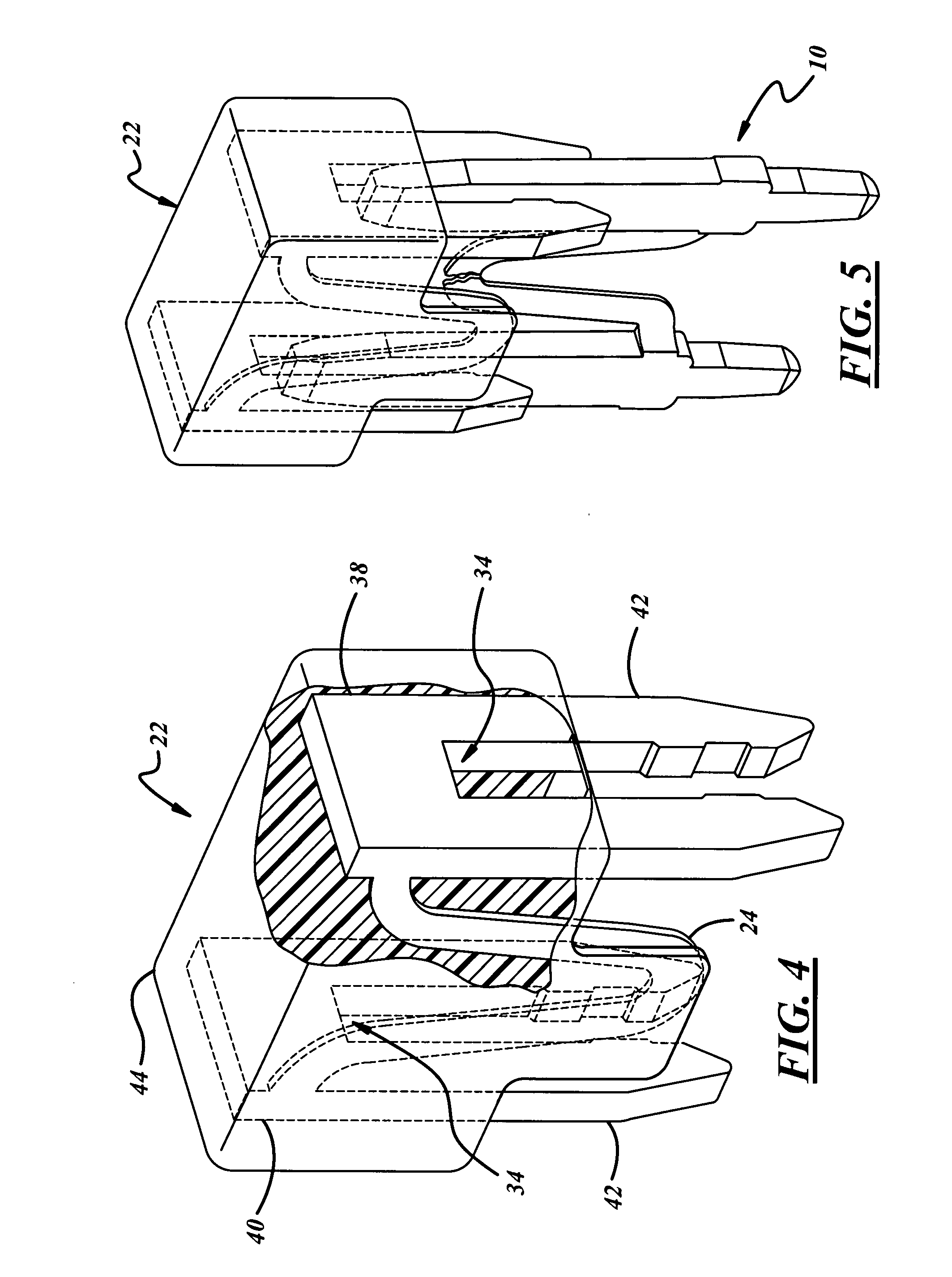

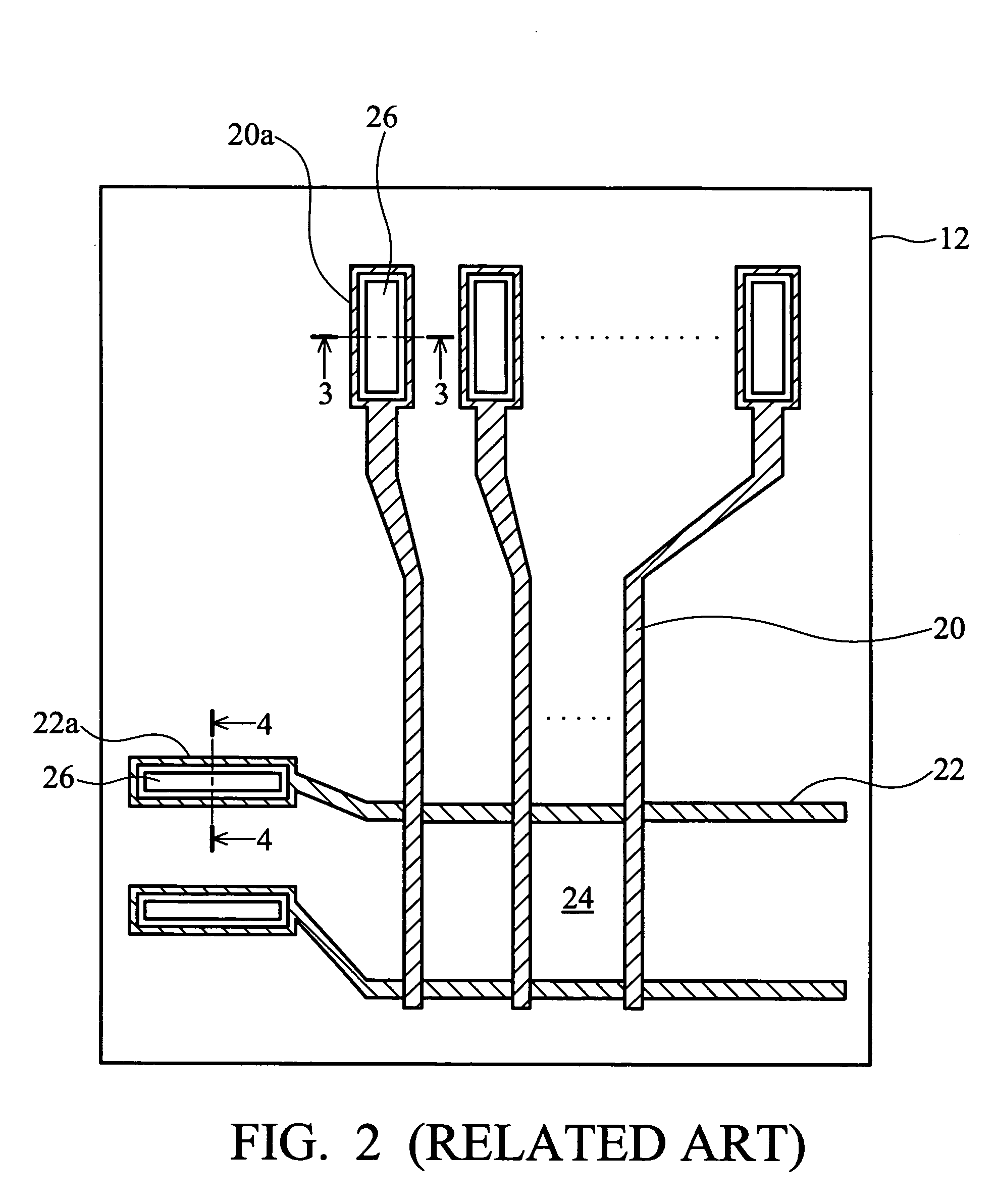

System and method for interconnecting a plurality of printed circuits

ActiveUS20080278276A1Printed circuit aspectsNon-printed jumper connections additionElectricityEngineering

A primary electrical fuse is attached to a printed circuit board. The primary electrical fuse comprises a first and second terminal, a fusible element disposed between the first and second terminals electrically linking the first terminal and the second terminal, and receiving tip sections located on the first and second terminals that receive a replacement electrical fuse to electrically connect the first and second terminals with a replacement fusible element.

Owner:APTIV TECH LTD

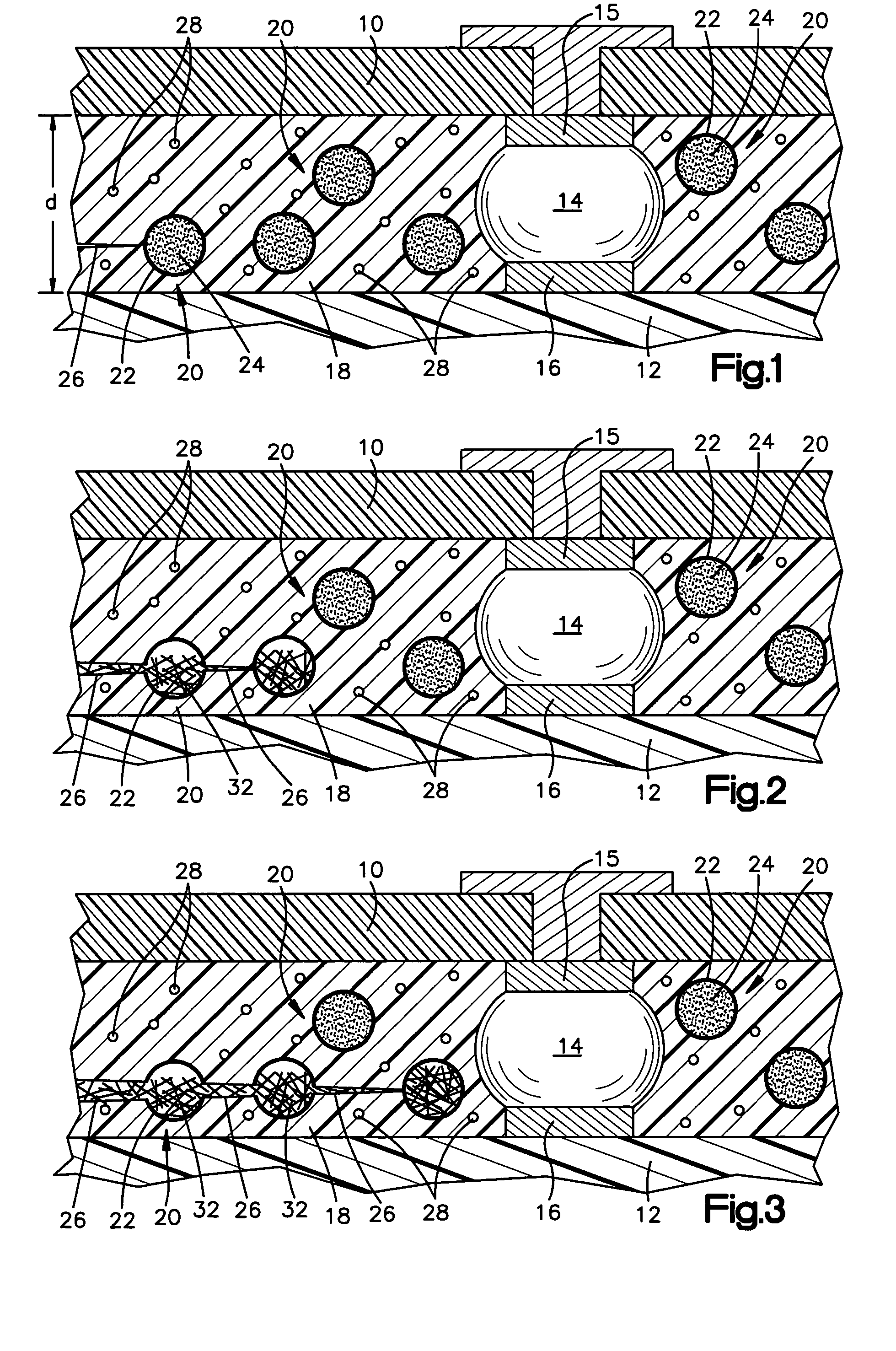

Method and structure for self healing cracks in underfill material between an I/C chip and a substrate bonded together with solder balls

A method of self-healing cracks in a cured epoxy base underfill material between an I / C chip and a substrate is provided. A plurality of capsules is dispersed in the epoxy base. Each capsule has a curable thermosetting adhesive encapsulated in a rupturable shell to disperse the thermosetting adhesive in a crack in the epoxy base when the shell ruptures. Each capsule is less than 25 microns in diameter. A curing agent that will cause a reaction of the thermosetting adhesive on contact is dispersed in the epoxy to form a cured adhesive in a crack in said epoxy base. The shell will rupture when encountering a crack being propagated in the underfill material, which will at least partially fill the crack with the adhesive, and cure the adhesive with the curing agent to bond the edges of the crack together. The invention also includes the structure for crack self-healing.

Owner:IBM CORP

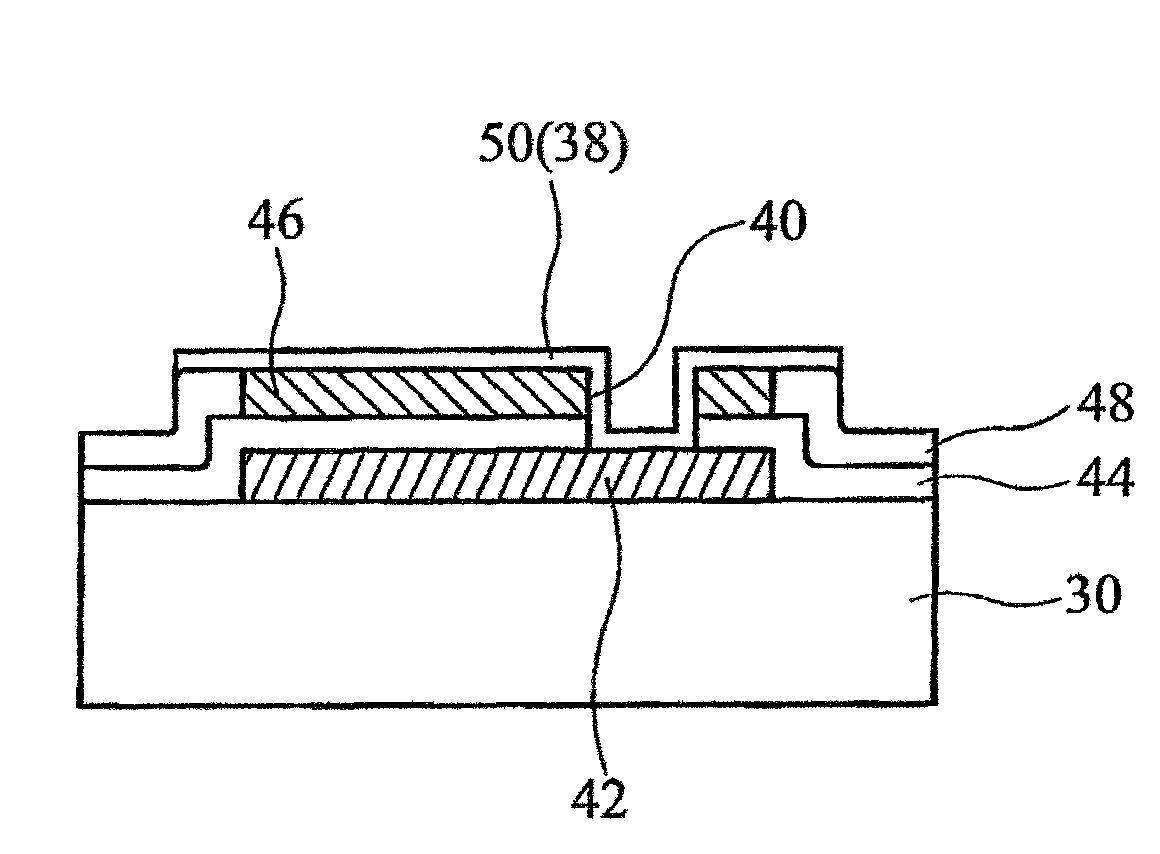

Bonding pad structure for a display device and fabrication method thereof

ActiveUS7211738B2Printed circuit assemblingSemiconductor/solid-state device detailsElectrical connectionDisplay device

A bonding pad structure of a display device. A first conductive layer is formed overlying a substrate, a protection layer is formed overlying the substrate and the first conductive layer, and a second conductive layer is formed overlying the protection layer. An opening structure penetrates the second conductive layer and the protection layer to expose the first conductive layer. A third conductive layer is formed overlying the second conductive layer to contact the sidewall and bottom of the opening structure. Thus, the third conductive layer is electrically connected to the second conductive layer to provide a first electrical-connection path, and the third conductive layer is electrically connected to the first conductive layer to provide a second electrical-connection path.

Owner:AU OPTRONICS CORP

Defective conductive surface pad repair for microelectronic circuit cards

An electrically conductive adhesive (ECA) for repairing electrically conductive pad and trace interconnects and a method of repairing interconnect locations. The method of repairing at least one defect within the area of electrically conductive circuitized substrate traces and pads outside of a pristine center area incorporates an ECA and a forming gas plasma. The ECA contains a mixture of components that allow the adhesive to be adapted to specific requirements. Curing the adhesive results in effective electrical connections being formed between the adhesive and the base pad so that the metallurgies of the conductors and of the ECA are effectively combined to engage and repair the conductor defect.

Owner:I3 ELECTRONICS

Laser repair process for printed wiring boards

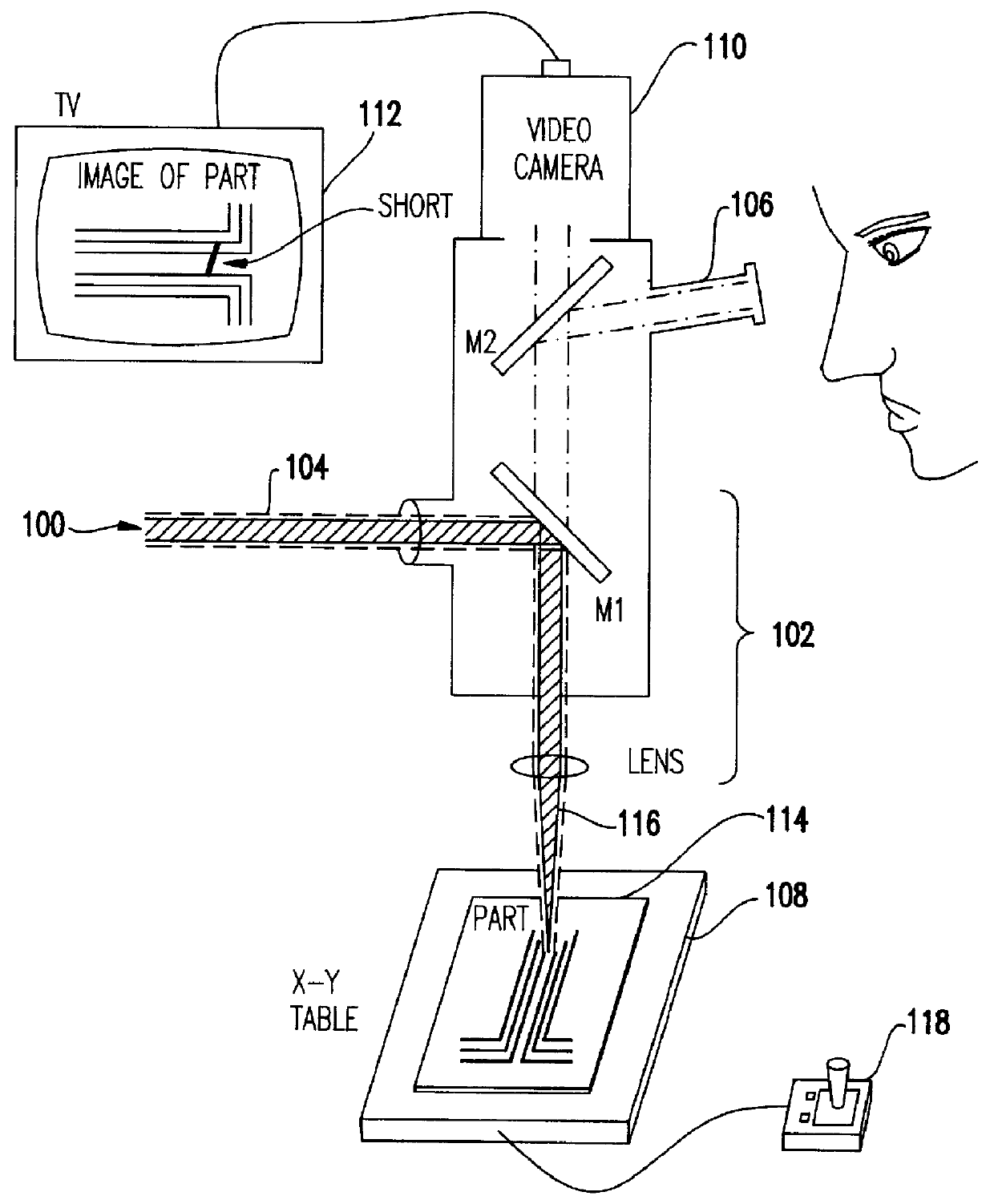

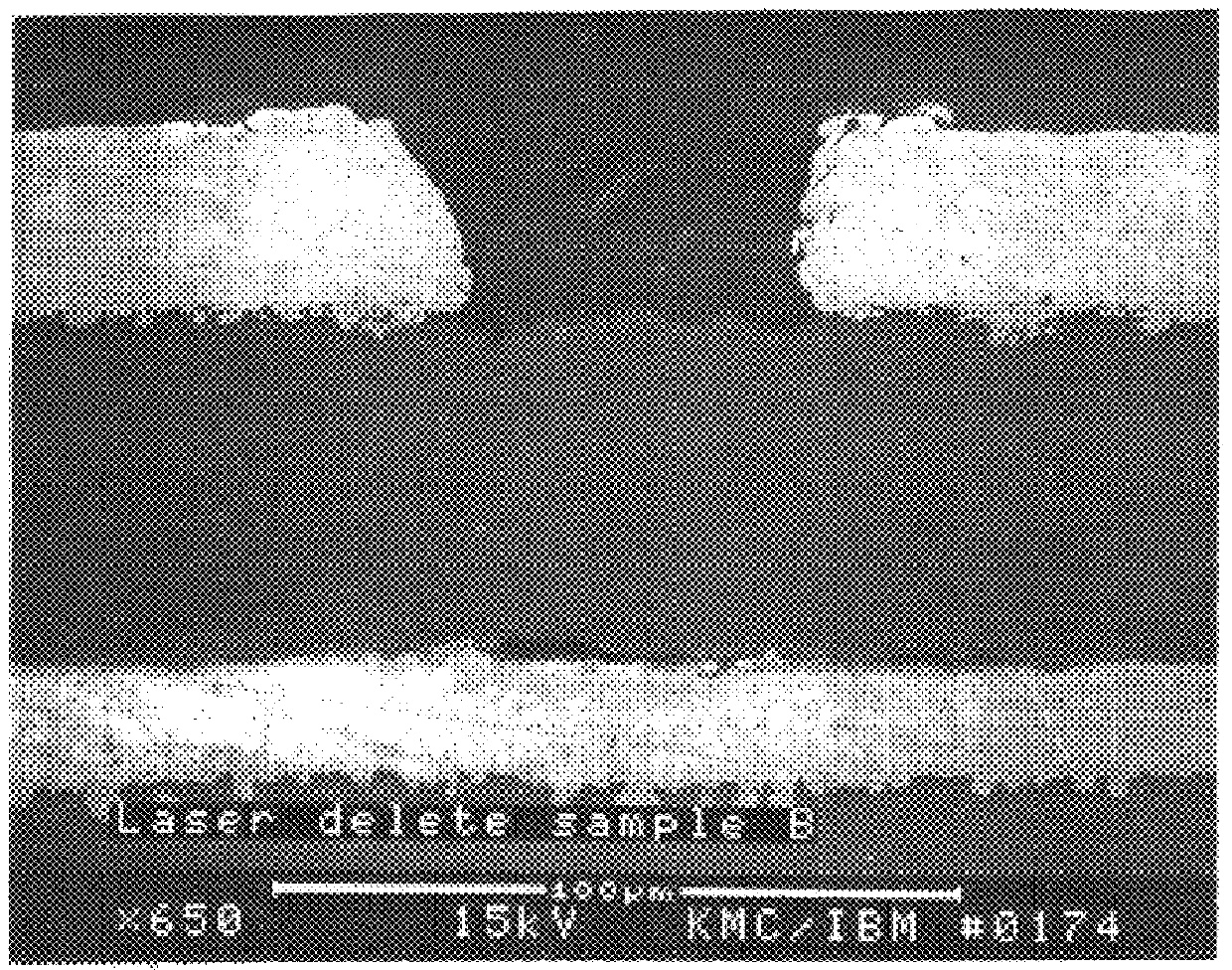

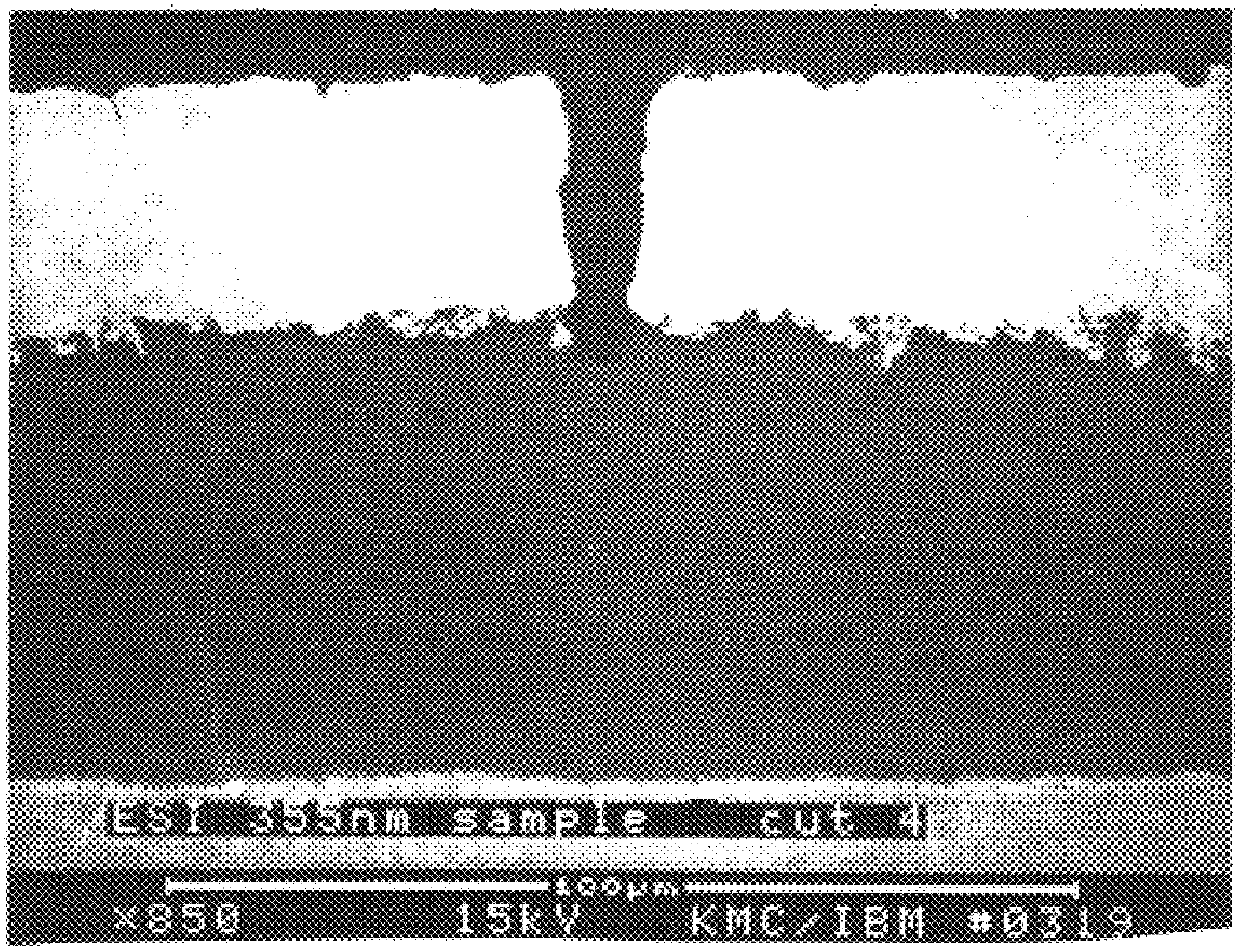

InactiveUS6046429AIncrease productionLow costSemiconductor/solid-state device manufacturingPrinted circuits repair/correctingSurface layerOrganic layer

A method of repairing wiring shorts on a surface of an organic layer. The organic layer, which is preferably a SLC / ASM layer, may be a surface layer of a Printed Circuit (PC) board. The absorption spectrum of the organic layer is examined. Based on that absorption spectrum, a laser is selected with a wavelength such that the surface layer slightly absorbs, 1-10%, laser energy striking it. Thus, the laser removes metal on the surface, while slightly etching the surface layer and without effect on any metal buried in or beneath the surface layer. Preferably, the laser is an Nd:YAG laser having a wavelength in a range where the ASM layer absorption is between 2-5%, and the copper ablation rate is high.

Owner:IBM CORP

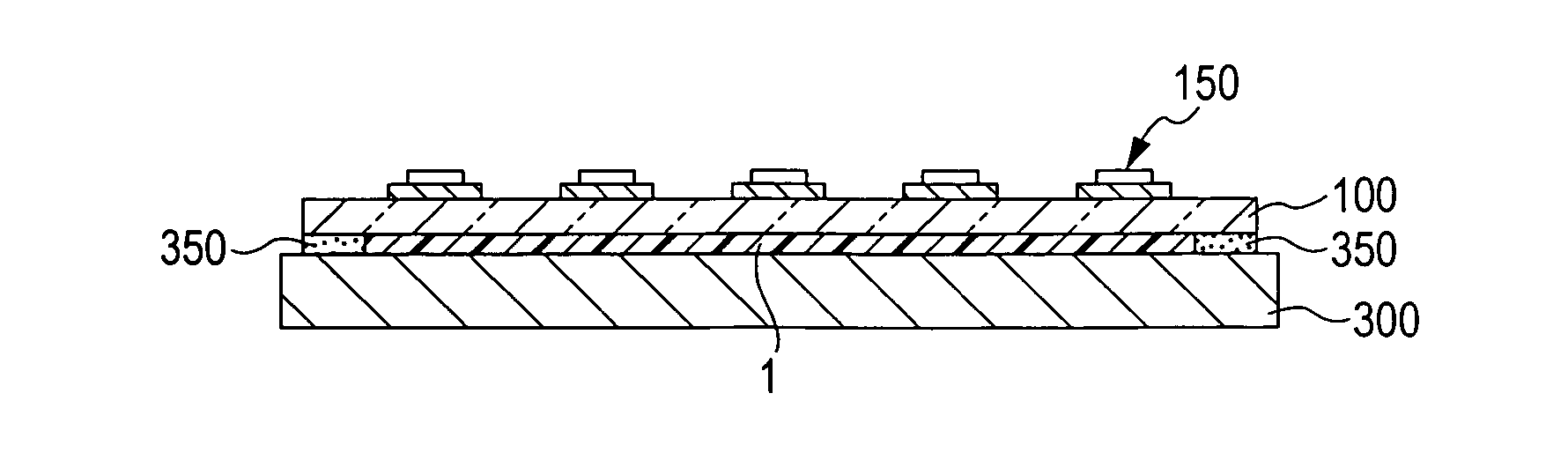

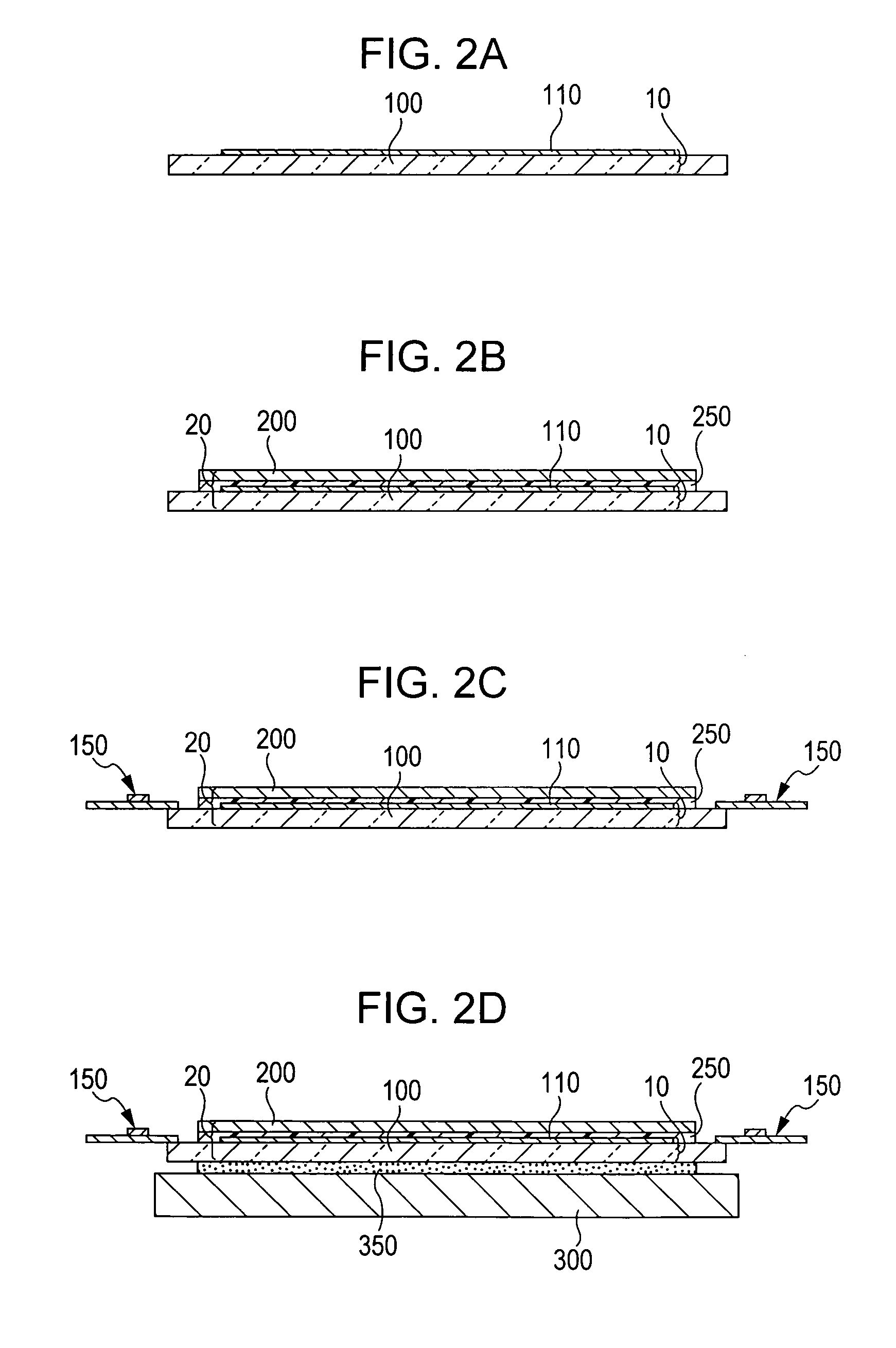

Semiconductor device, radiographic imaging apparatus, and method for manufacturing the same

InactiveUS20060108683A1Improve impact resistanceImprove adhesionSemiconductor/solid-state device detailsLaminating printed circuit boardsDevice materialElectrical connection

A semiconductor device or a radiographic imaging apparatus includes a substrate and a supporting member, the substrate having a semiconductor element or a conversion element and being bonded to the supporting member with a laminating member. The semiconductor device or the radiographic imaging apparatus further includes at least one cushioning member in at least one space between the substrate and the supporting member at least in a region including an electrical connection portion connected to at least one electrical component. Thus, when a malfunction or a defect is found in the at least one electrical component, such as TCP, on the periphery of the substrate, the defective electrical component can easily be replaced.

Owner:CANON KK

Burning-free non-cyaniding method for treating waste printed circuit board

ActiveCN102676822ACompletely separate and recycleHigh recovery rateFinal product manufactureTransportation and packagingPlatinumElectrostatic separation

The invention provides a burning-free non-cyaniding method for treating a waste printed circuit board. The method comprises the following steps of: sealing-off, lead and tin separation, crushing and electrostatic separation, and respective extraction of antimony, aluminum, copper, nickel, silver, gold, platinum and palladium. By the method disclosed by the invention, the maximization of valued metal resource recycling is realized, metallic lead and tin can be thoroughly separated and recovered, and at the same time the recovery rate of metallic palladium is improved.

Owner:JIANGXI GEM RESOURCES RECYCLING CO LTD

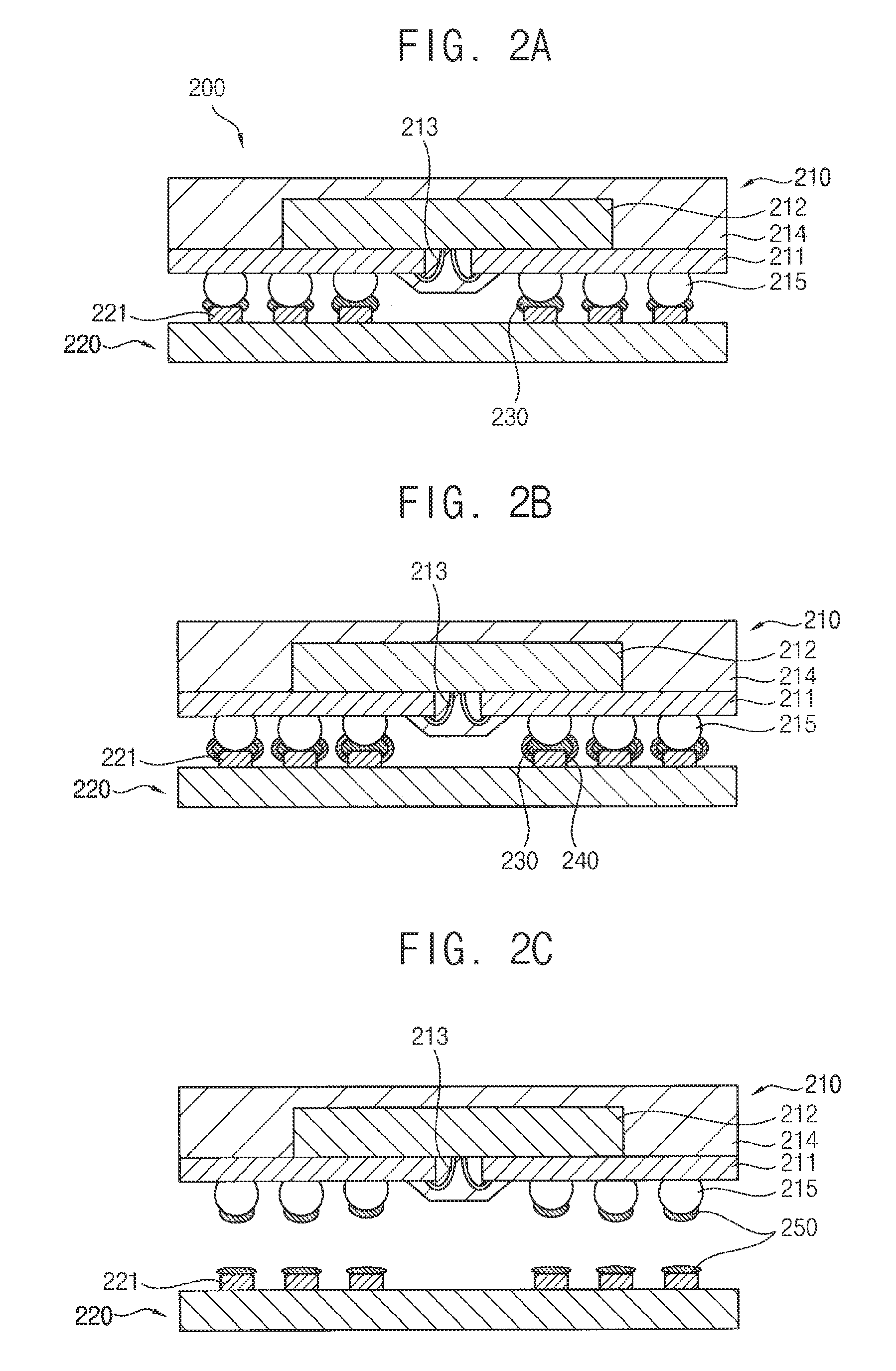

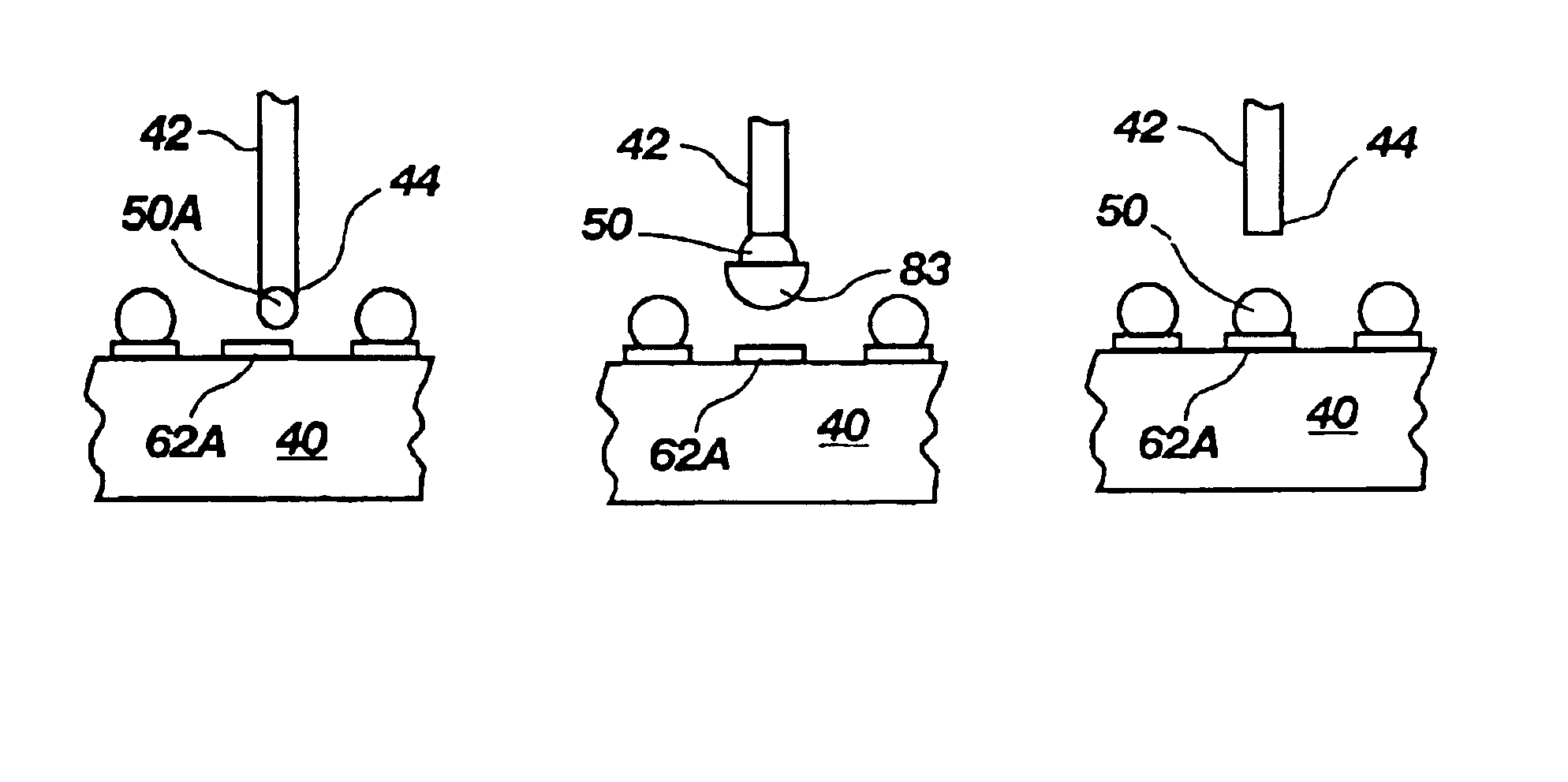

Method of attaching a solder ball and method of repairing a memory module

InactiveUS20110068151A1Avoid crackingFinal product manufactureSemiconductor/solid-state device detailsMetallurgySolder ball

In a method of attaching a solder ball, a first material is coated on a solder ball. A second material is coated on a pad of a substrate where the solder ball is to be attached to exothermically react with the first material. The solder ball makes contact with the pad such that the first material and the second material exothermically react with each other to release heat to adhere the solder ball to the pad using the heat.

Owner:SAMSUNG ELECTRONICS CO LTD

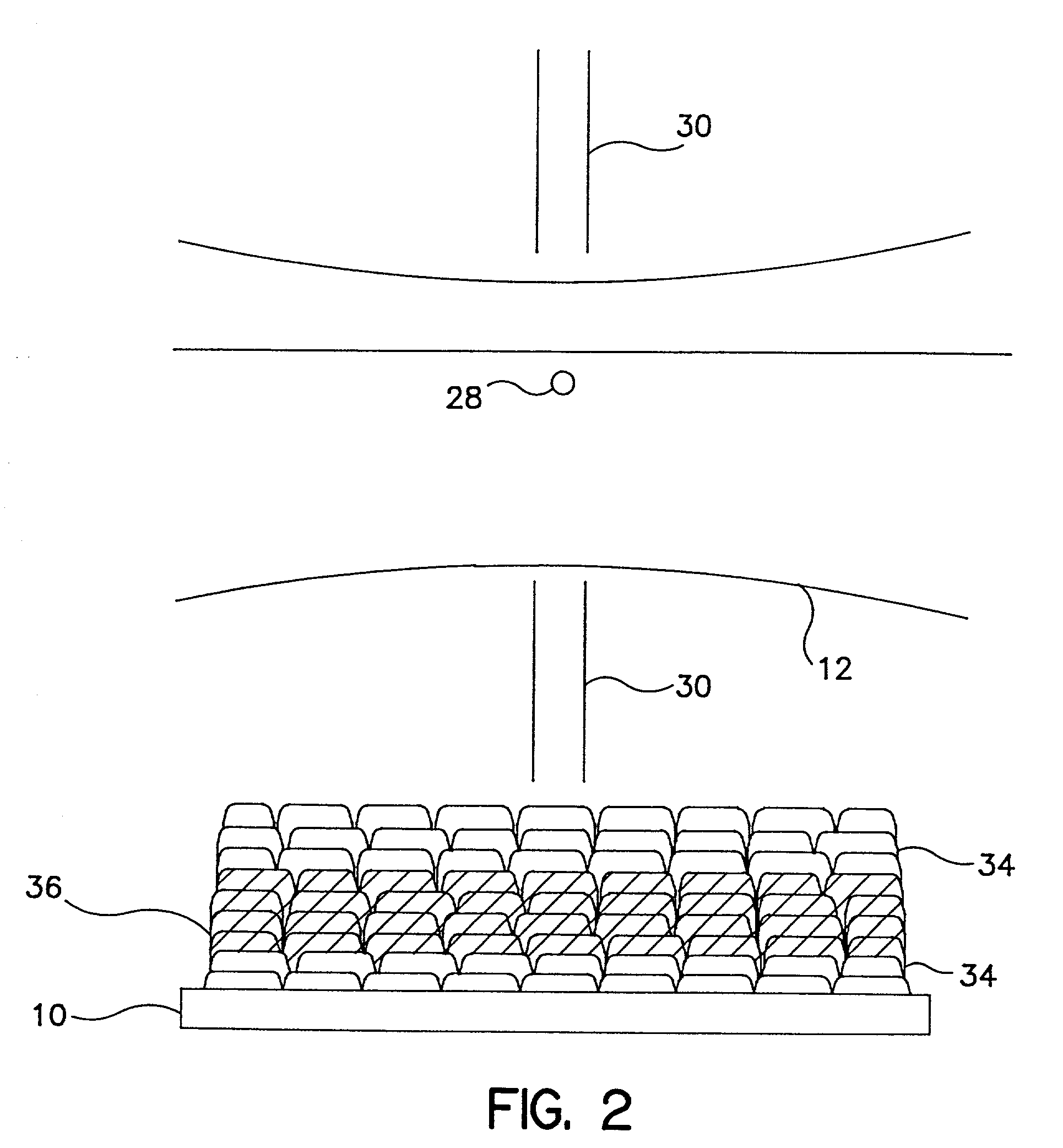

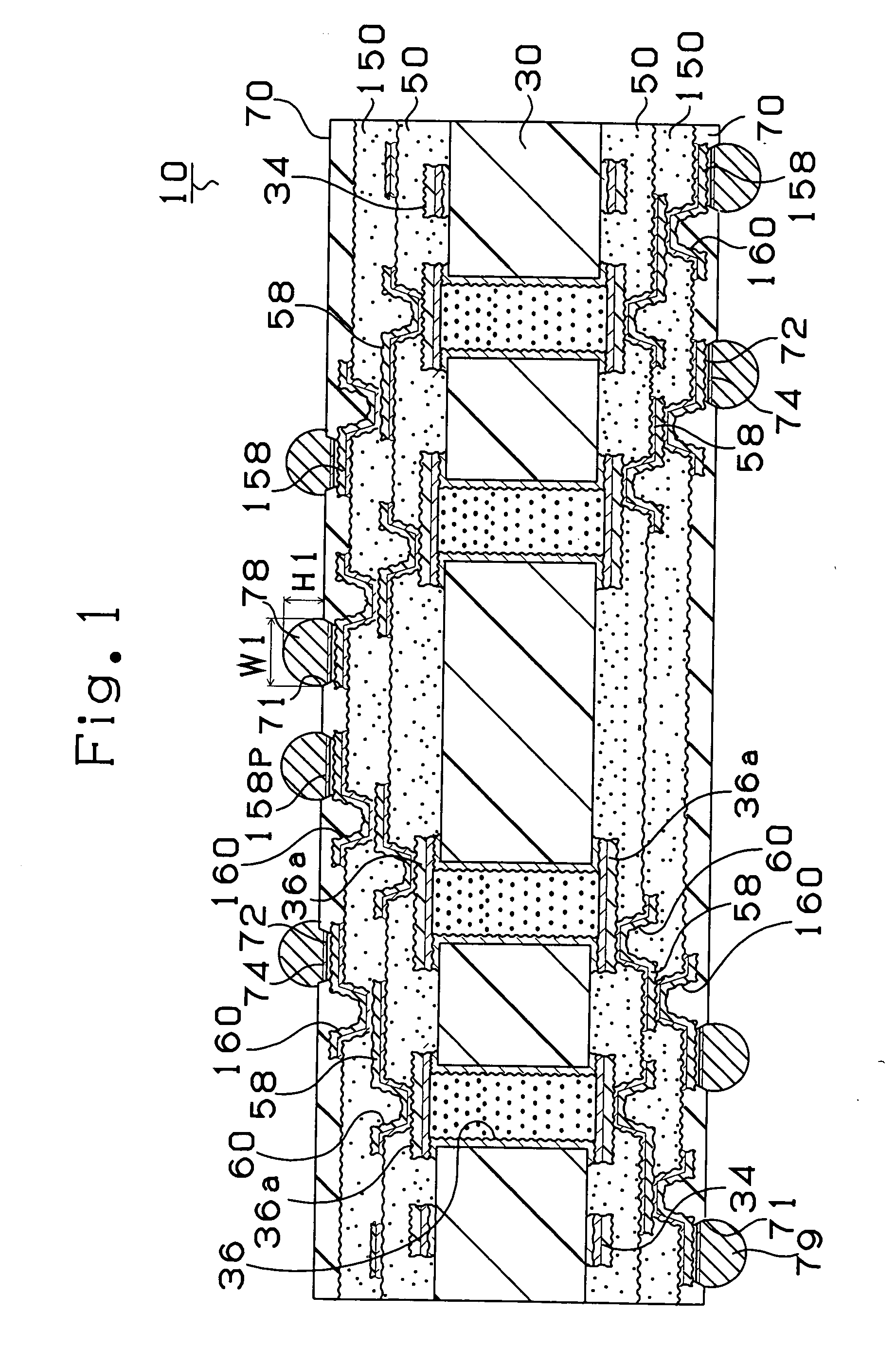

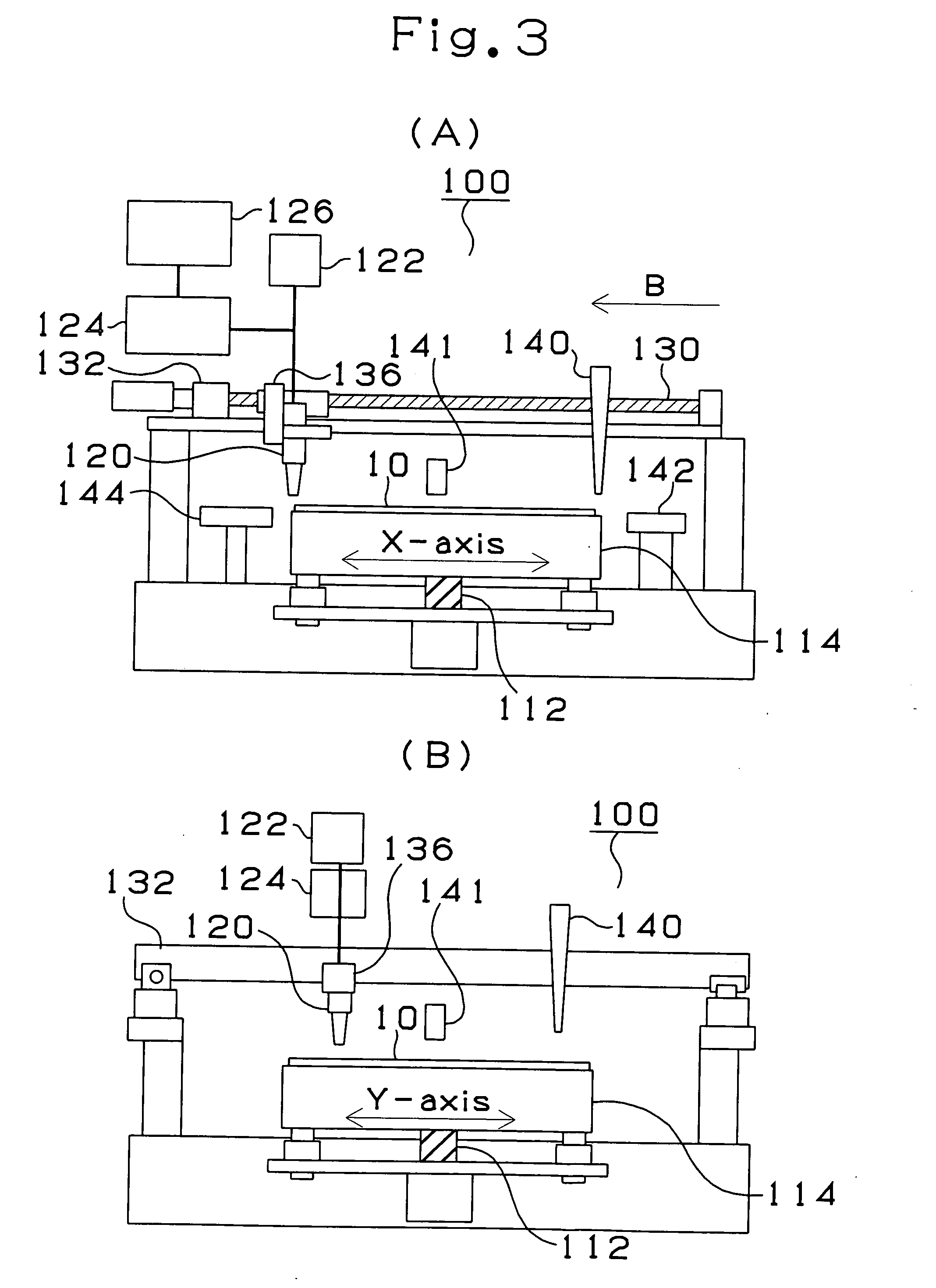

Manufacturing method and manufacturing apparatus of printed wiring board

ActiveUS20080078810A1Intensify the height of the bumpFirmly connectedCooking-vessel materialsSolid-state devicesSolder ballLaser heating

A solder ball is loaded on a bump having a small height (FIG. 5(B)) and the height of the bump is intensified by melting the solder ball by heating with laser (FIG. 5(C)). Thus, the heights of the bumps are adjusted within a requested allowable range. Because the bump is not removed by heating when the height of the low bump is intensified, the printed wiring board is not subjected to local heat history thereby intensifying reliability of the bump of a printed wiring board.

Owner:IBIDEN CO LTD

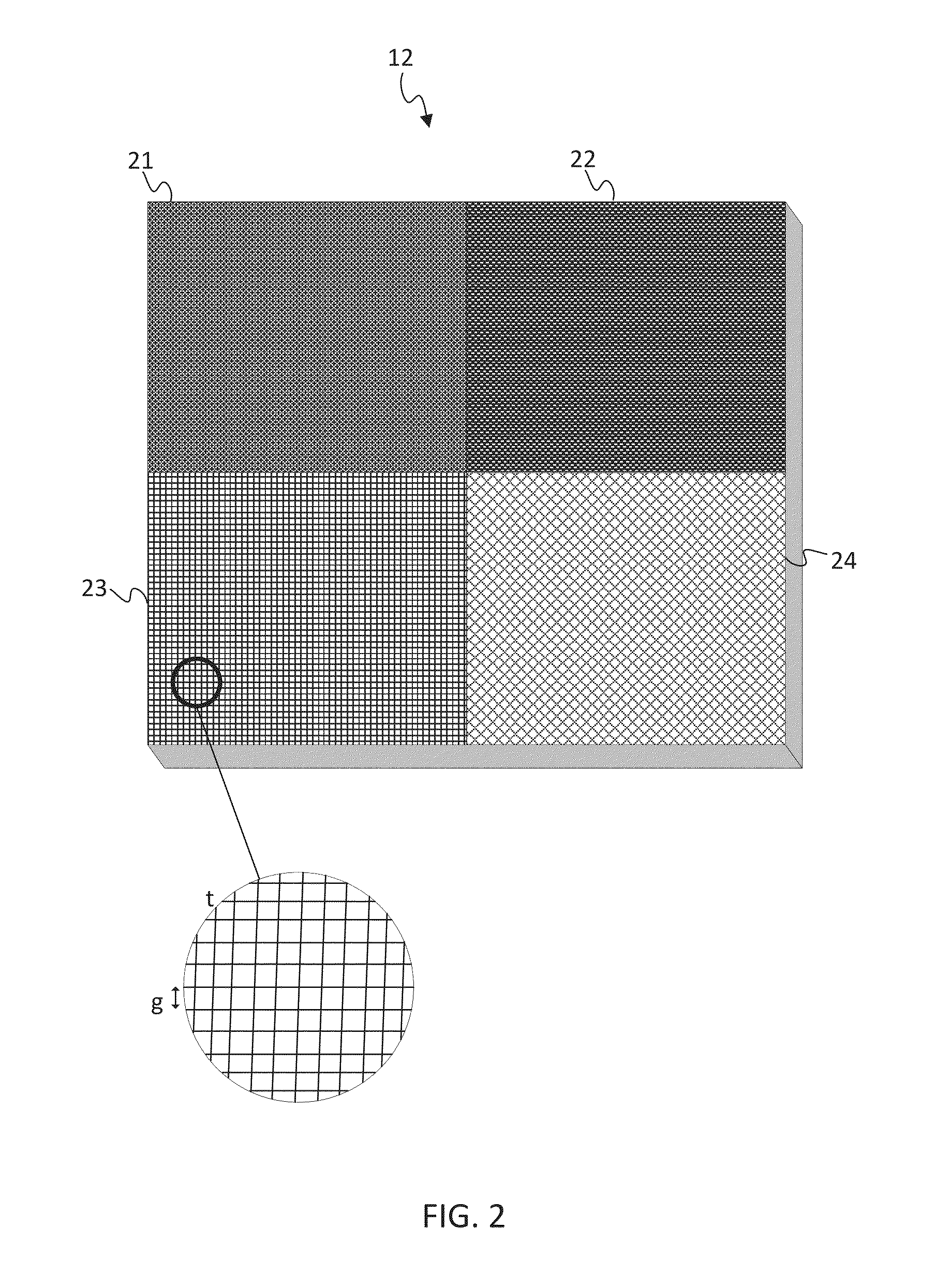

Current Redistribution in a Printed Circuit Board

ActiveUS20140118962A1Printed circuit aspectsHigh current circuit adaptationsElectrical resistance and conductanceGrid pattern

In one implementation, a multilayered printed circuit board is configured to redirect current distribution. The current may be distributed by steering, blocking, or otherwise manipulating current flows. The multilayered printed circuit board includes at least one power plane layer. The power plane layer does not distribute current evenly. Instead, the power plane layer includes multiple patterns with different resistances. The patterns may include a hatching pattern, a grid pattern, a directional pattern, a slot, a void, or a continuous pattern. The pattern is a predetermined spatial variation such that current flows in a first area differently than current flows in a second area.

Owner:CISCO TECH INC

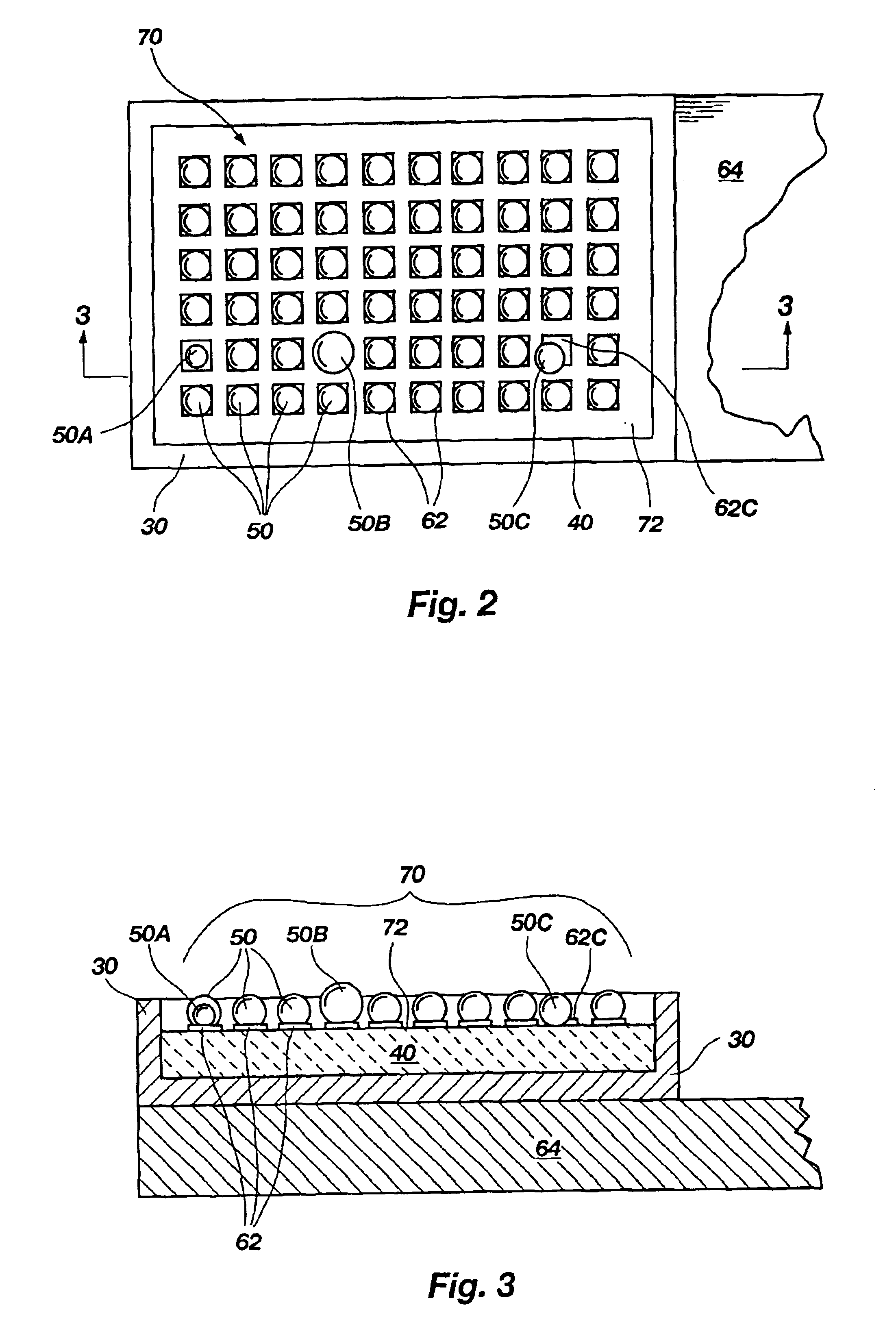

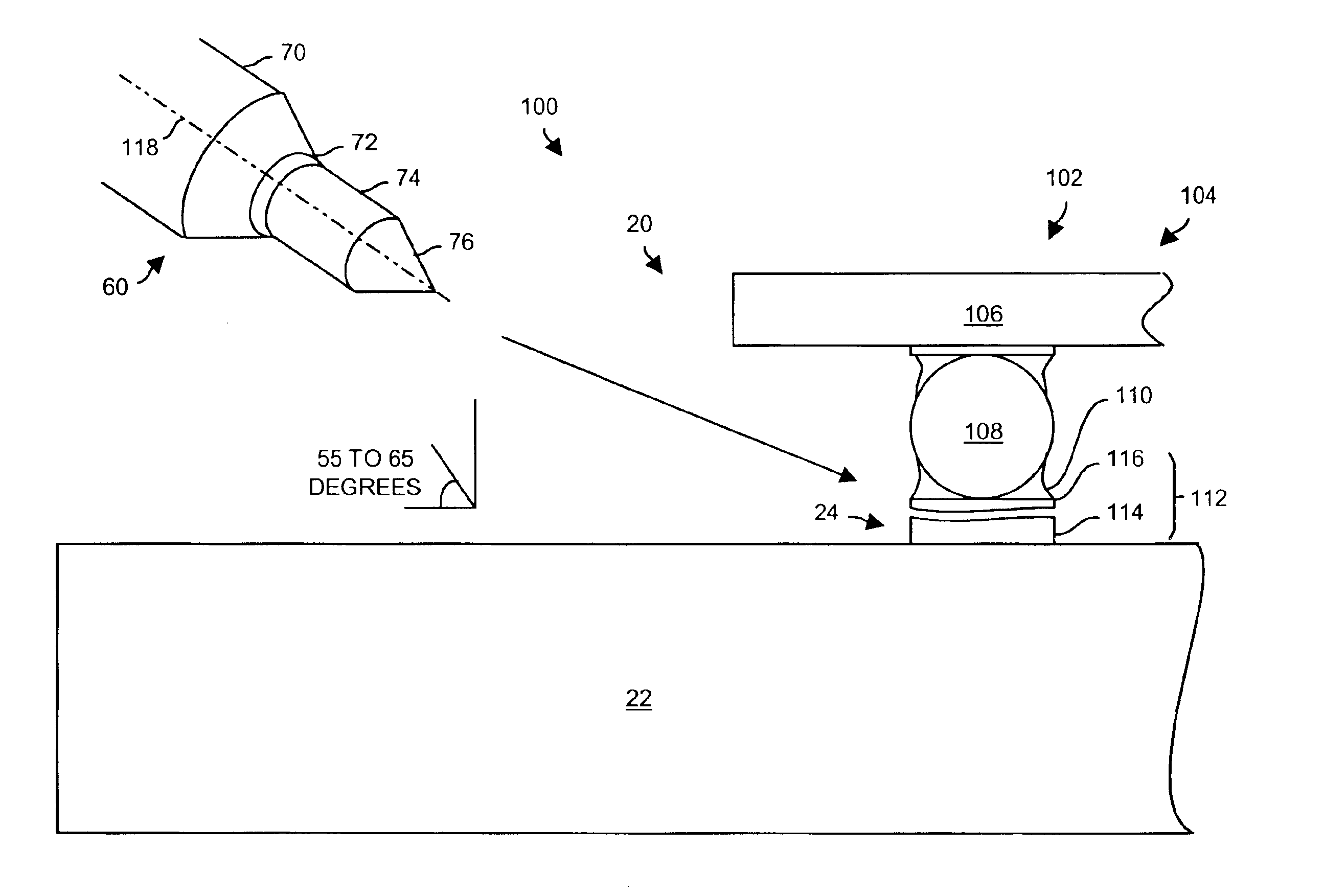

Individual selective rework of defective BGA solder balls

InactiveUS6911388B2Quickly and inexpensively replacedAccurate placementPrinted circuit assemblingSemiconductor/solid-state device manufacturingSolder ballEngineering

A method for reworking a ball grid array (BGA) of solder balls is provided including one or more defective solder balls on an electronic component workpiece using a single-ball extractor / placer apparatus having a heatable capillary tube pickup head optionally augmented with vacuum suction. A defective solder ball is identified, extracted by the pickup head and disposed of. A nondefective solder ball is picked up by the pickup head, positioned on the vacated attachment site, and thermally softened for attachment to the workpiece. Flux may be first applied to the replacement solder ball or to the vacated attachment site. The extractor / placer apparatus may be automated to locate, extract and replace defective balls for completion of a fully operable BGA.

Owner:MICRON TECH INC

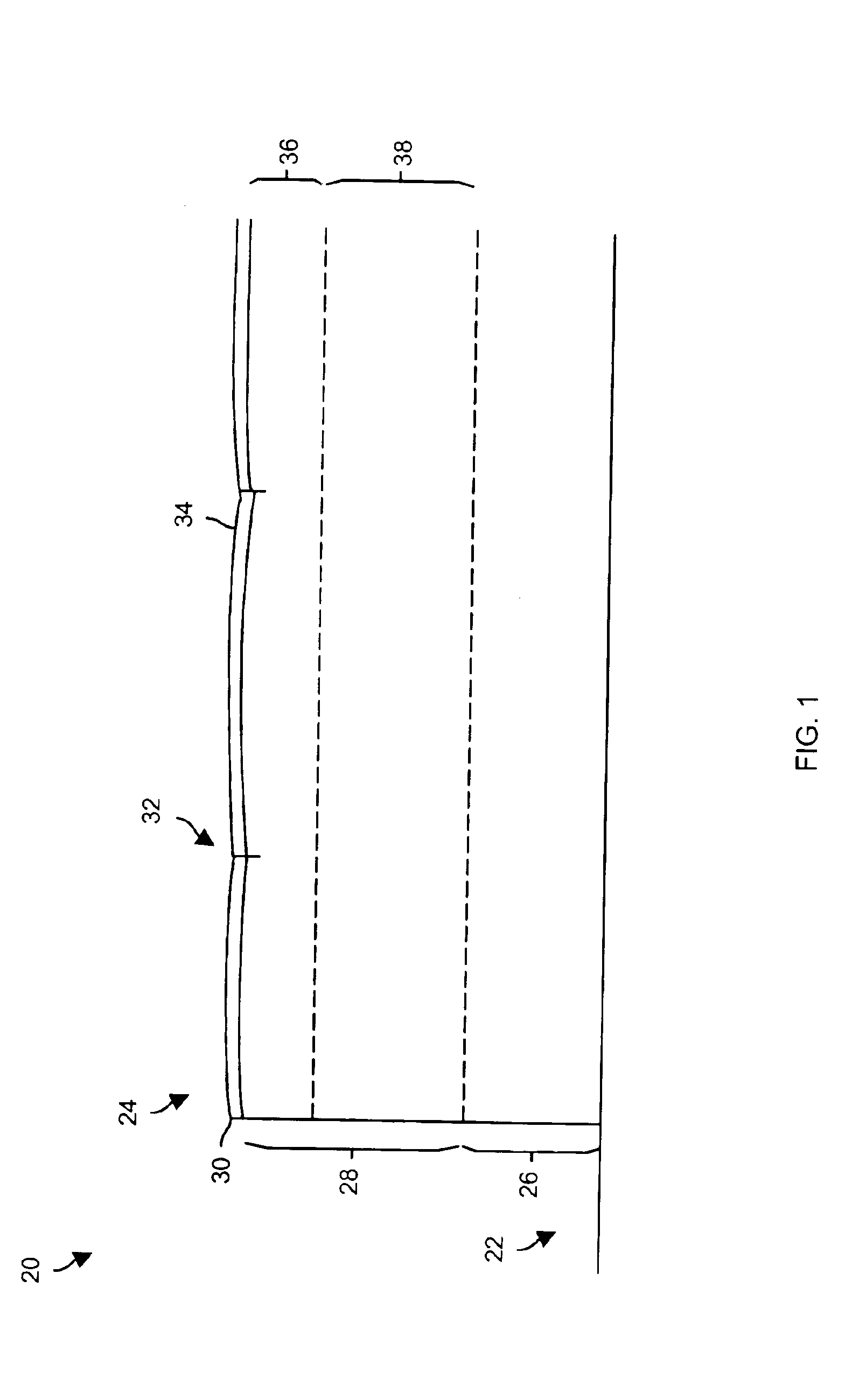

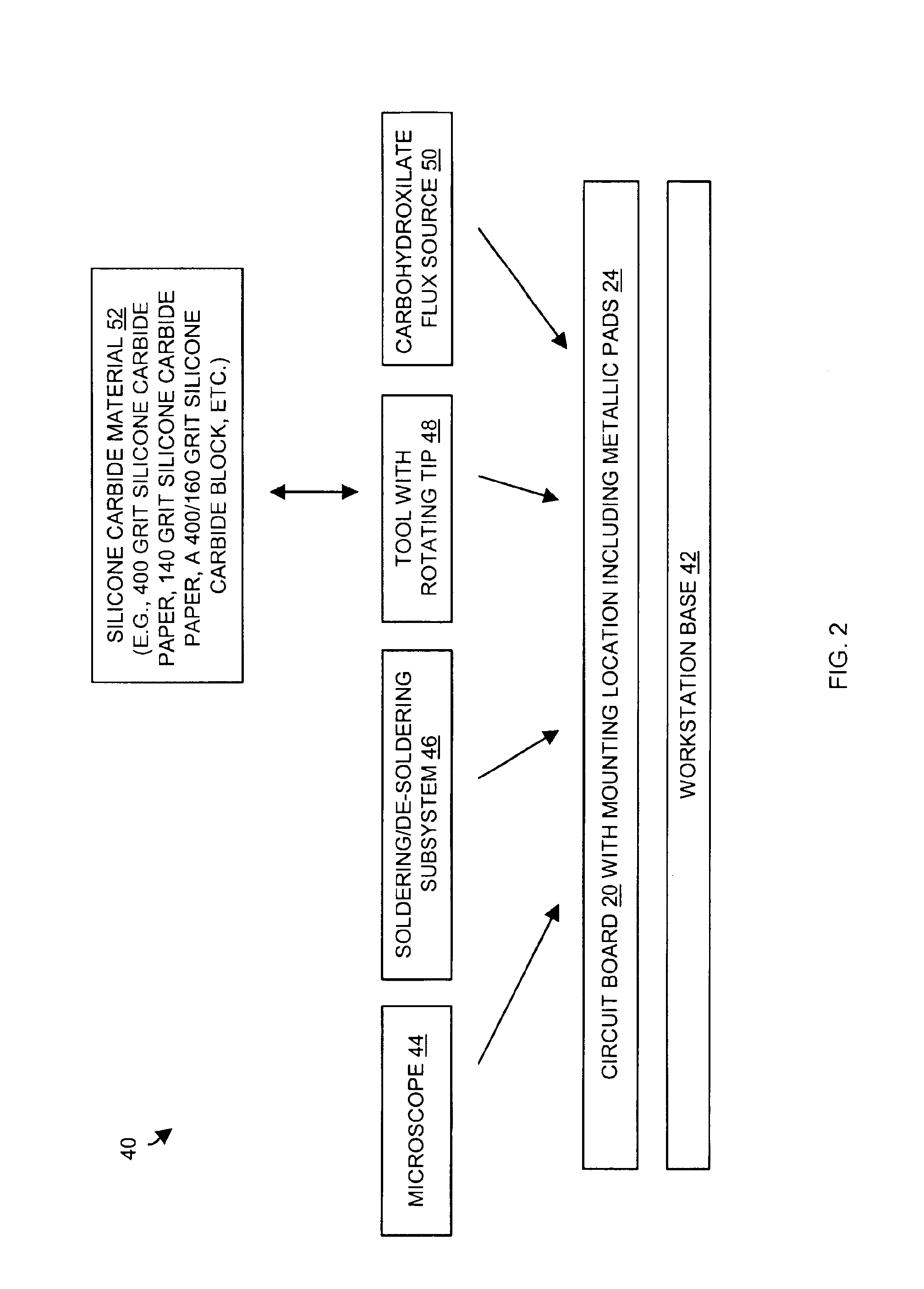

Techniques for reworking circuit boards with ni/au finish

InactiveUS6845556B1Avoid corrosionThe right amountValve arrangementsSemiconductor/solid-state device detailsMetalMaterials science

Circuit board reworking techniques involve removing original solder from the metallic pad, removing an outer portion of the metallic pad to expose an inner portion of the metallic pad, and applying new solder to the metallic pad. Removal of the original solder and the outer portion of the metallic pad exposes the inner portion which has non-corroded and non-contaminated metal. The application of new solder to this inner portion of the pad enables wettability of the pad as well as provides a protective coating to prevent corrosion of the inner portion (e.g., oxidation, reaction with contaminants, etc.). Accordingly, circuit board abnormalities such as “Black Pad” defects can be cured.

Owner:EMC IP HLDG CO LLC

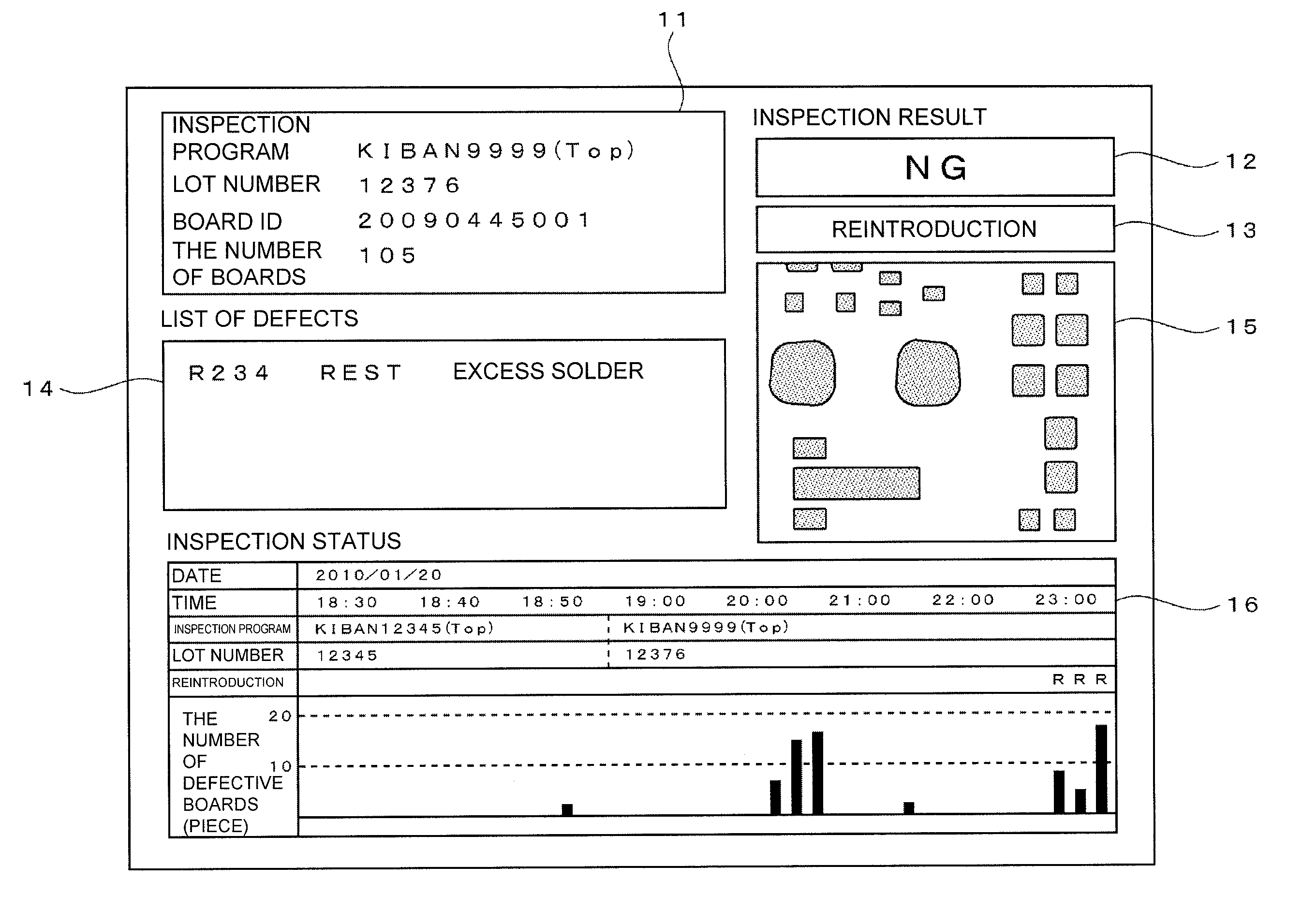

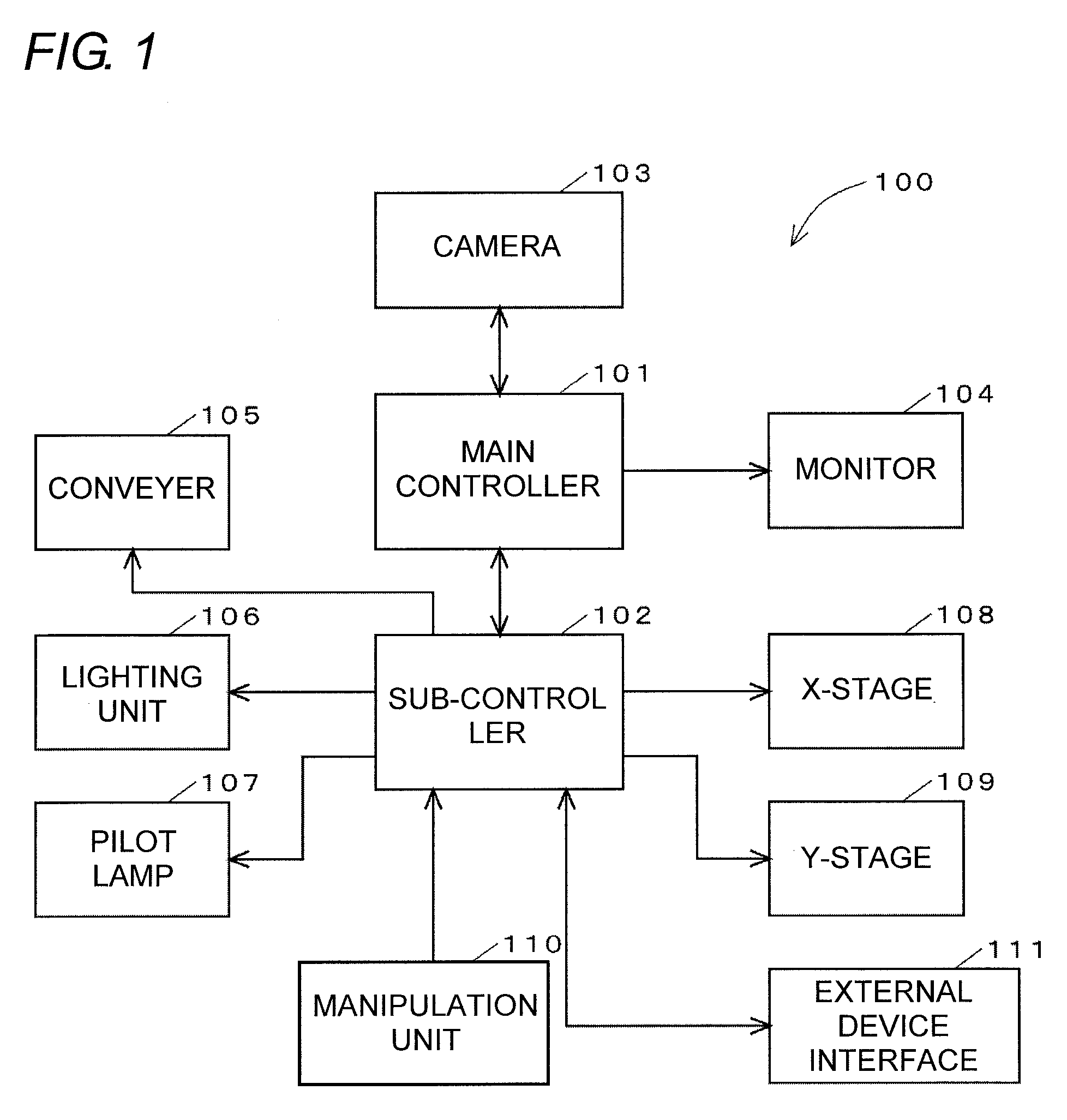

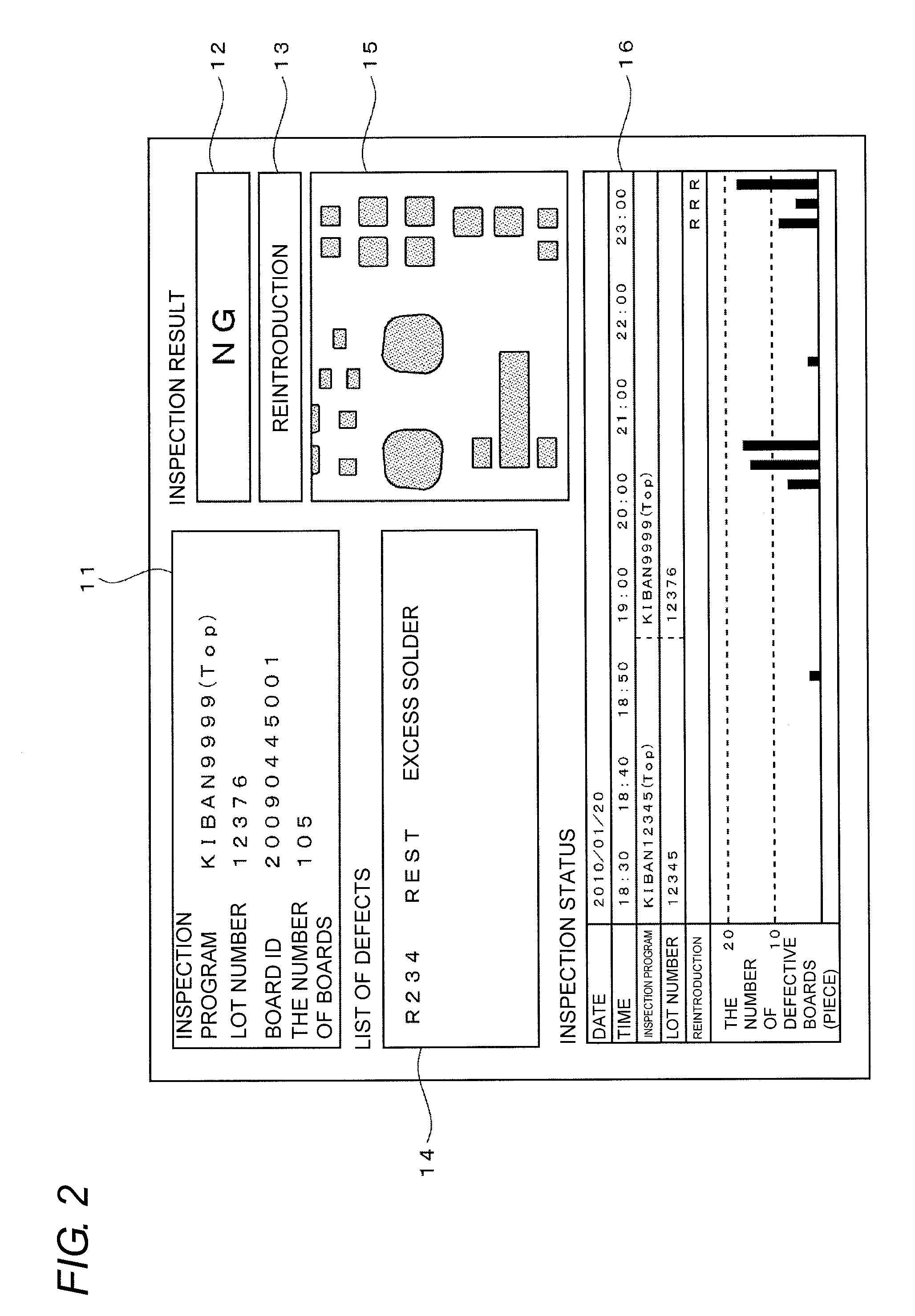

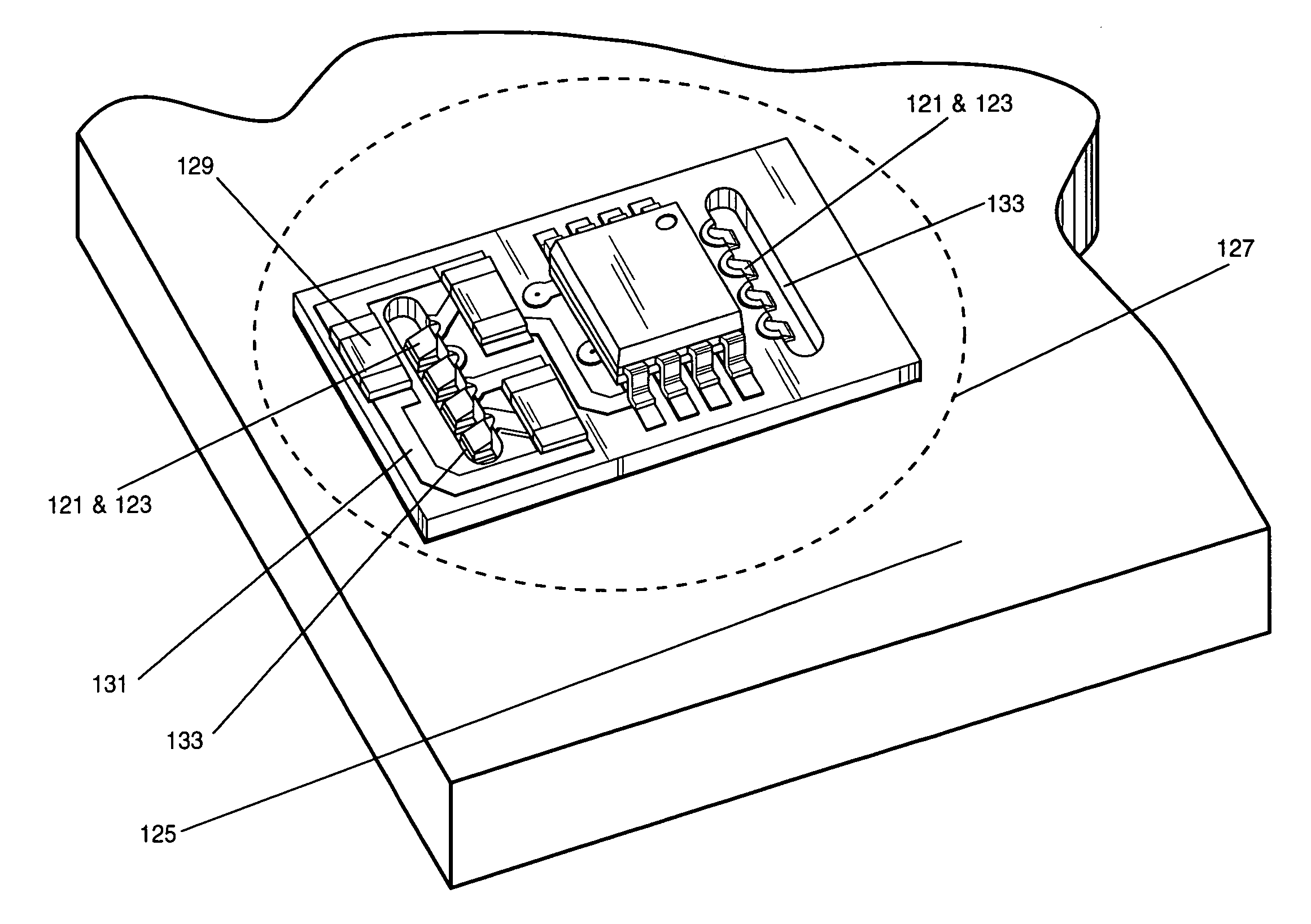

Method for supporting analytical work of solder printing state and solder printing inspection machine

InactiveUS20110218754A1Easy to identifyEasily relationshipPrinted circuit assemblingImage analysisEngineeringAnalysis working

In a solder printing inspection machine, an identification code and an inspection time of an inspection target board are accumulated in a memory. The accumulated data, whose identification code is matched with that of the current inspection target board, is searched while the accumulated data is traced back one by one. When the corresponding board is found, it is recognized that the board is extracted because of the defective board and the inspection target board is the reintroduced board that was previously extracted. A graph, in which pieces of information expressing the pieces of quality of the boards are arrayed in time series, is produced based on each time of inspection result and the graph is displayed on a monitor. In the pieces of data included in the graph, the data corresponding to the board that is recognized as the reintroduction is explicitly shown by a letter “R”.

Owner:ORMON CORP

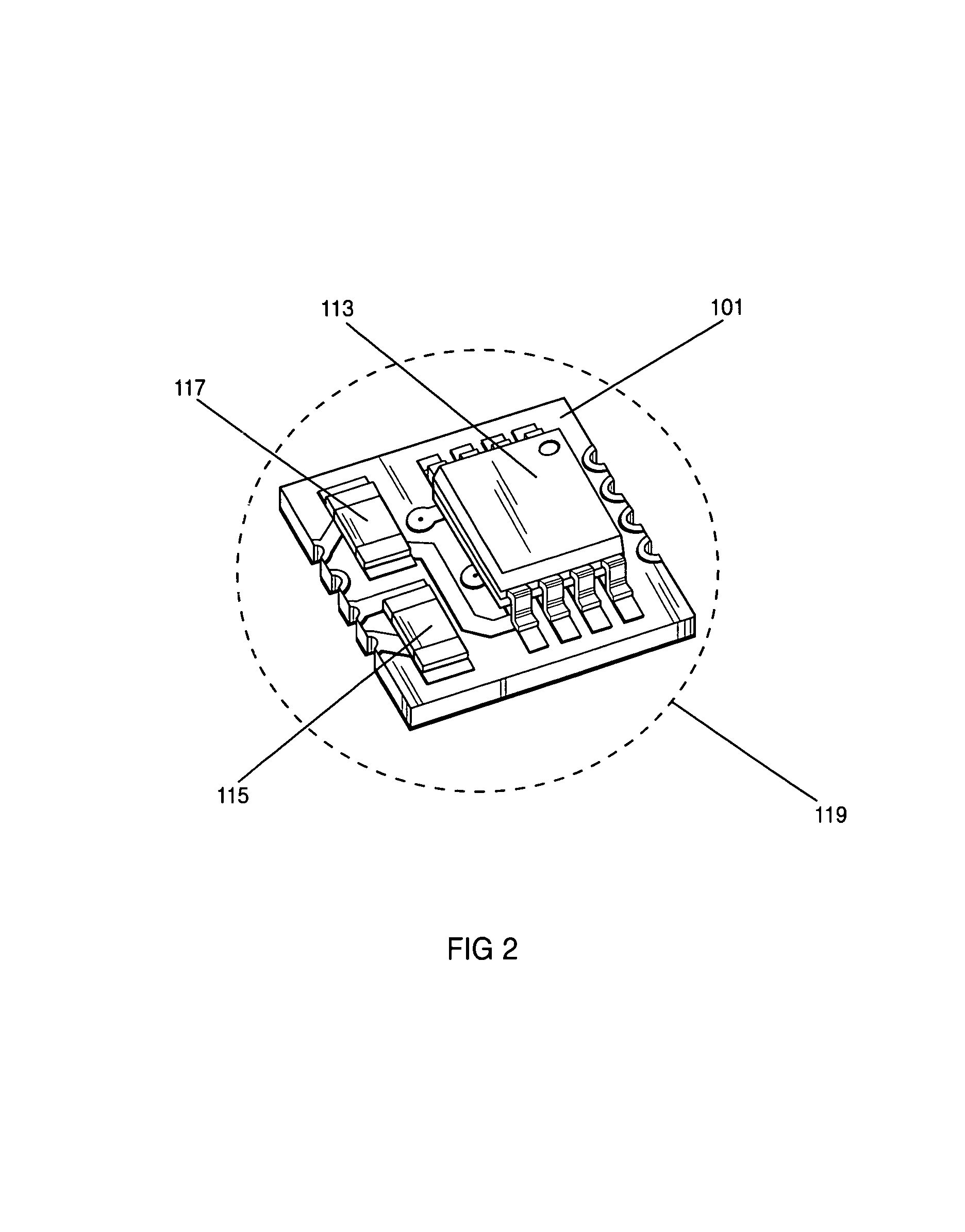

Micro-castellated interposer

ActiveUS7507914B2Low costHighest reliability without compromising performancePrinted electric component incorporationSemiconductor/solid-state device detailsSurface mountingEngineering

A miniature PWB with features that incorporate the required circuitry changes and component footprints, which has been enhanced with micro-castellations such as those found on ceramic surface mount packages. The miniature PWB is mounted on the circuit board using techniques well known in the art. This combination of technologies provides an adaptable, durable interconnect methodology, which allows for circuit and part changes without changing the layout of the base printed wiring board.

Owner:HONEYWELL INT INC

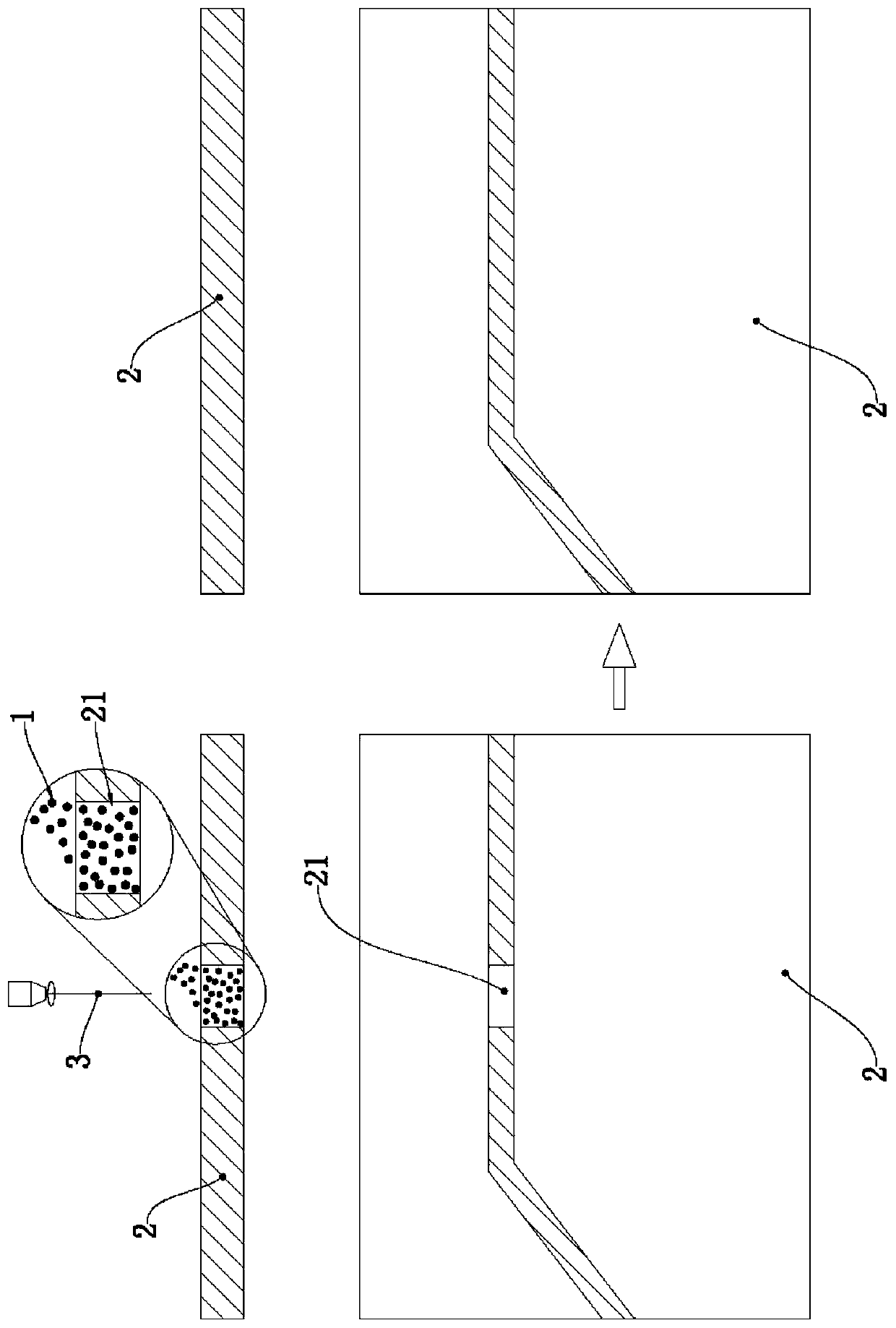

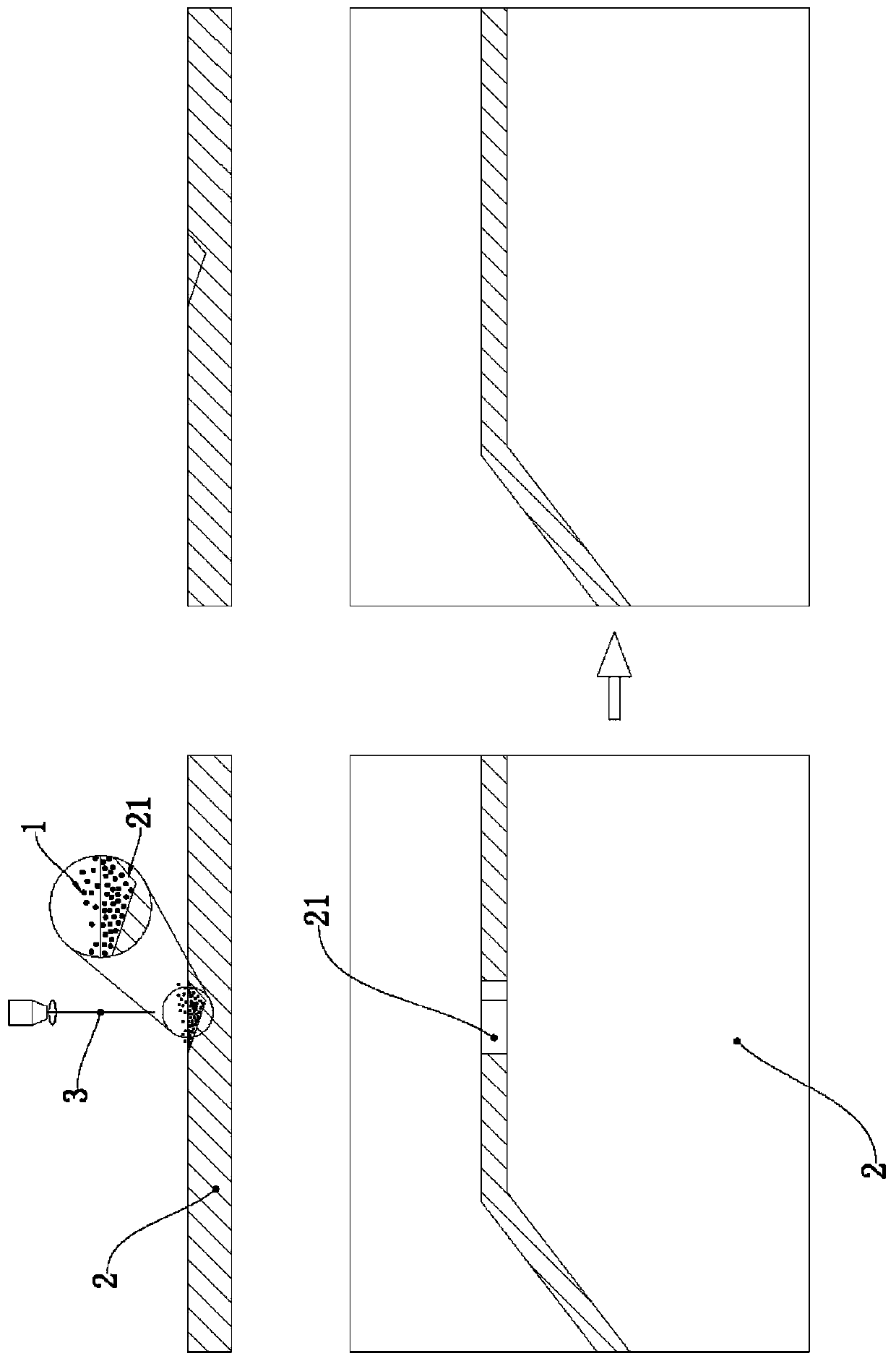

Method for repairing fine line

The invention discloses a method for repairing a fine circuit. The method comprises the following steps: the step A, filling nano-copper particles in a circuit defect position of a circuit board; thestep B, performing laser irradiation or direct heating on the nano-copper particles at the line defect position to enable the nano-copper particles to be metallurgically bonded with the original lineat the line defect position; and the step C, cleaning the surface of the circuit board, and removing residual nano-copper particles at an unsintered part to complete line repair. According to the invention, a fine line can be repaired, and the method has the advantage of low operation difficulty.

Owner:GUANGDONG UNIV OF TECH

UV-curable solvent free compositions and use thereof in ceramic chip defect repair

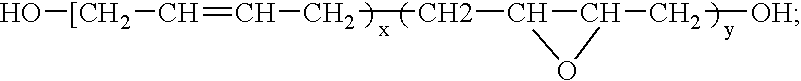

InactiveUS20060069177A1Improve performance reliabilityPrevent product yieldImpression capsSemiconductor/solid-state device detailsThermoplasticElastomer

Solvent-free UV-curable polymer materials derived from miscible blends of reactive organic monomeric, oligomeric and low molecular polymeric systems and organic and inorganic fillers such as polytetrafluoroethylene and talc are provided to form polymer-filler composite compositions for use in the fabrication and repair of electronic components and microelectronic assembly processes. The composition contains a preformed thermoplastic or elastomeric polymer / oligomer with reactive end groups, a monofunctional and / or bifunctional acrylate monomer, a multifunctional (more than two reactive groups) acrylated / methacrylated monomer, a photoinitiator and a fluorocarbon polymer powder as an organic filler which is preferably PTFE and an inorganic filler such as talc. A nano-filler may also be used as the inorganic filler alone or in combination with another inorganic filler such as talc A method is also provided for repairing defects on ceramic substrates using the composition of the invention or other curable polymeric compositions.

Owner:TAIWAN SEMICON MFG CO LTD

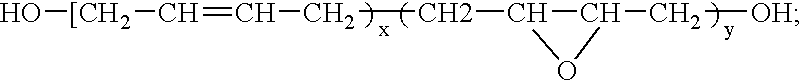

PCB Online testing and maintain system and method thereof

InactiveCN1967275AHigh degree of automationImprove test efficiencyElectronic circuit testingPrinted circuit aspectsBarcodeOnline test

The invention discloses an on-line circuit board test and maintenance system for testing circuit boards with barcode and automatically uploading test information in real-time and repairing bad circuit board, including an online testing machine, a workshop control server, connected to the online testing machine, and a maintenance workstation. The workshop control server includes a functional module for the collection, transmission and handling the test data generated by the online testing machine. The maintenance workstation sets up at least one maintenance computer to show error information about bad circuit boards. The maintenance computer is connected to the workshop control server.

Owner:HONG FU JIN PRECISION IND (SHENZHEN) CO LTD +1

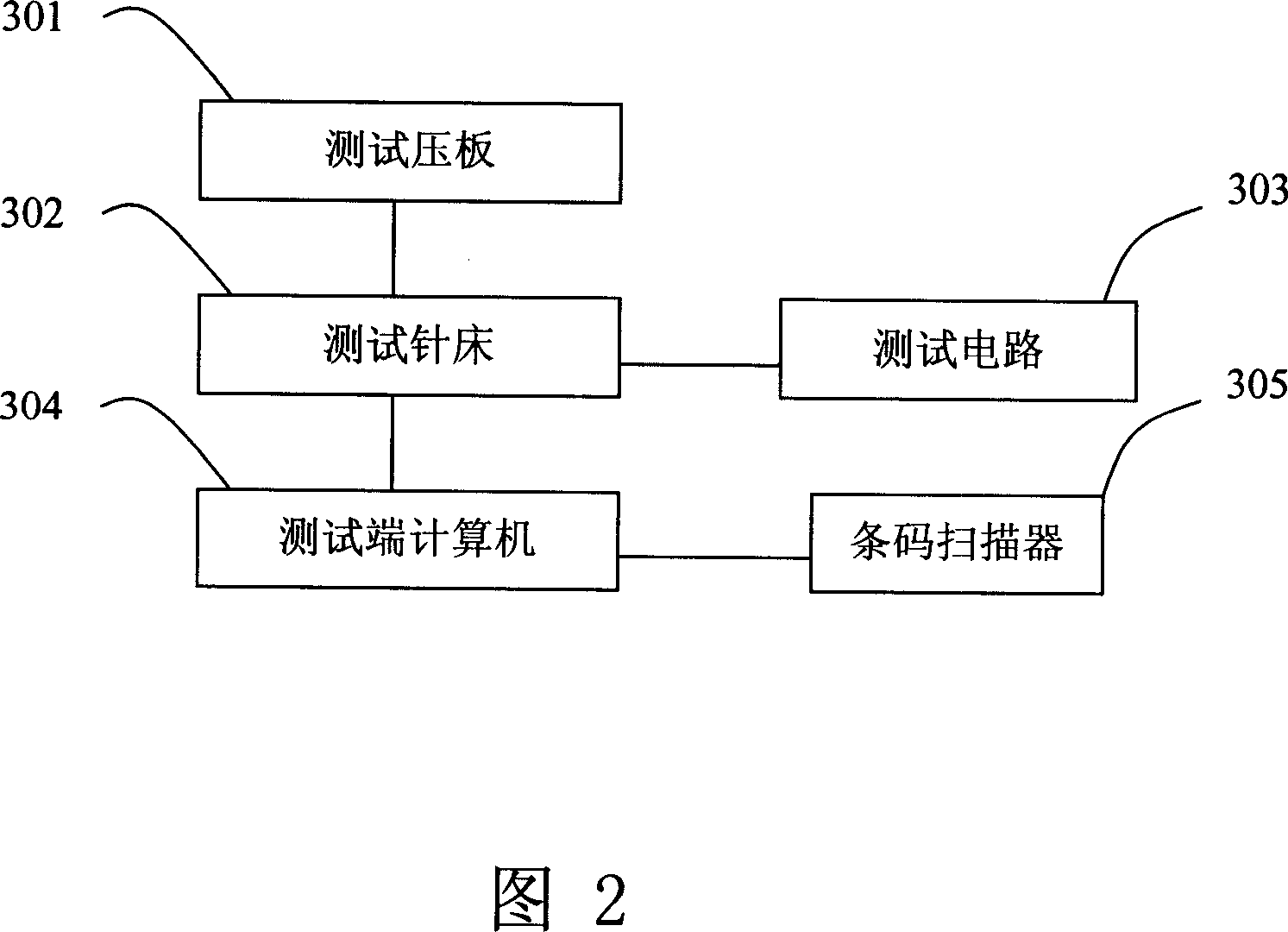

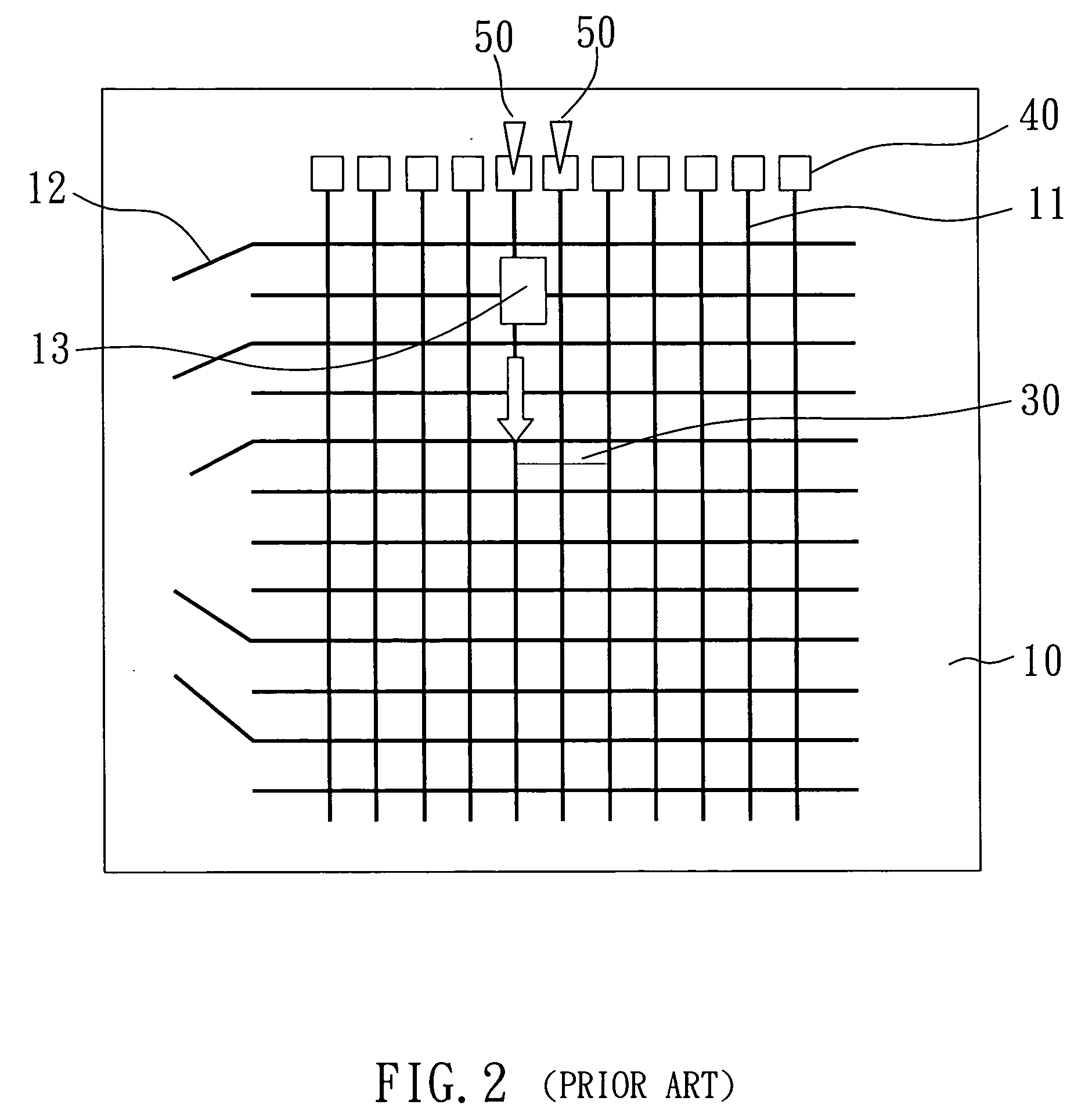

Apparatus and method for inspecting and repairing a circuit defect

InactiveUS20050121429A1Reduce spacingReduce inspectionPrinted circuits repair/correctingWelding/soldering/cutting articlesEngineeringContact sensor

An apparatus for inspecting and repairing a circuit defect is disclosed, which has a base; a substrate-supporting platform mounted on the base; a contact inspection module having at least one contact probe and a first driving-system that drives at least one contact probe to contact the circuits formed on the glass substrate and thereby inspect a circuit defect; a non-contact inspection module having at least one non-contact sensor and a second driving-system that drives at least one non-contact sensor to inspect the circuit defect in a non-contact manner; and a laser repair module having a laser head and a third driving-system that drives the laser head to go to the circuit defect and repair the circuit defect. A method for inspecting and repairing a circuit defect is also disclosed therewith.

Owner:AU OPTRONICS CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com