Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

308results about "Printed circuit drying" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

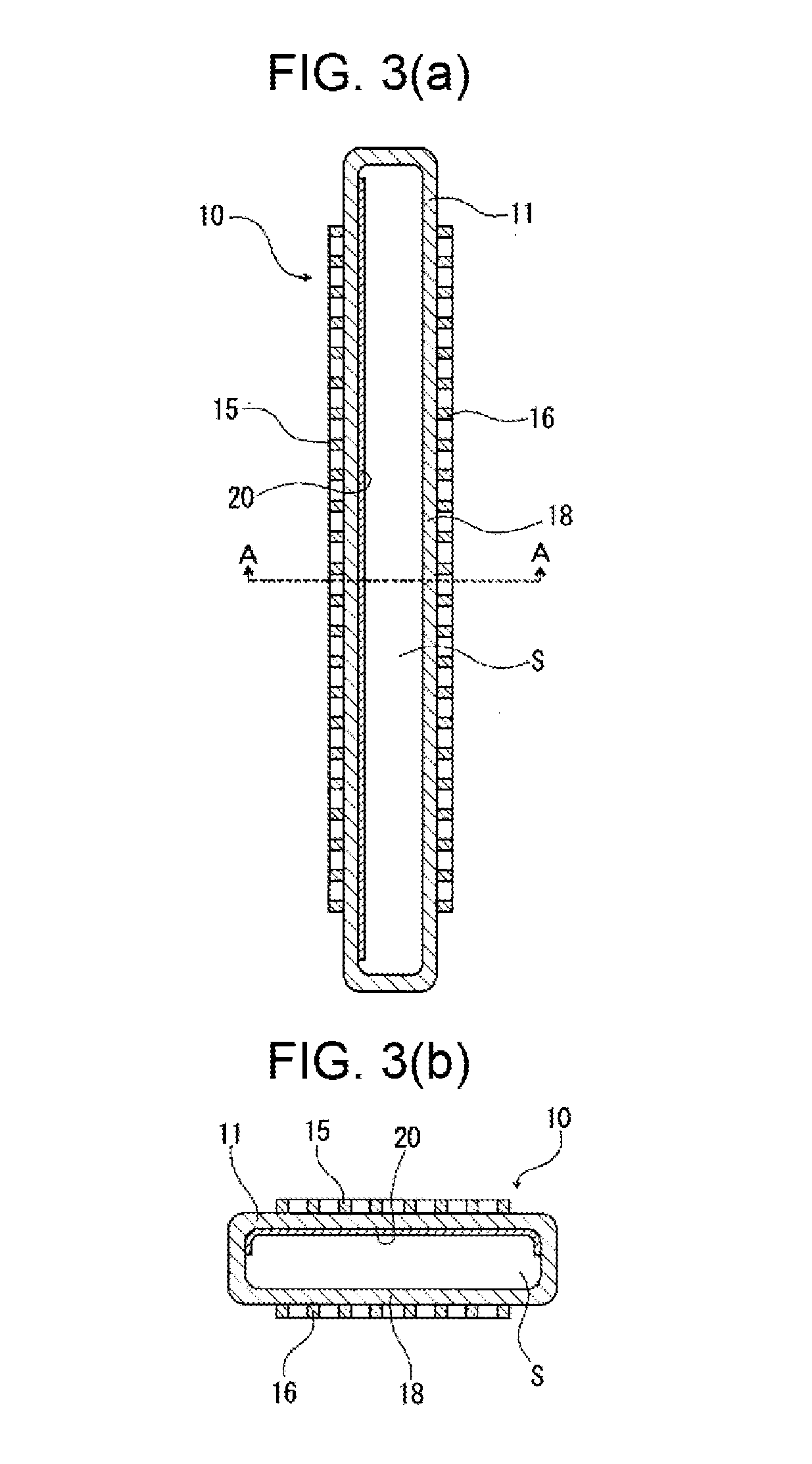

Method and system of drying materials and method of manufacturing circuit boards using the same

InactiveUS6893530B2Efficient dryingImprove reliabilityAdhesive processesDrying solid materials with heatElectricityElectrical connection

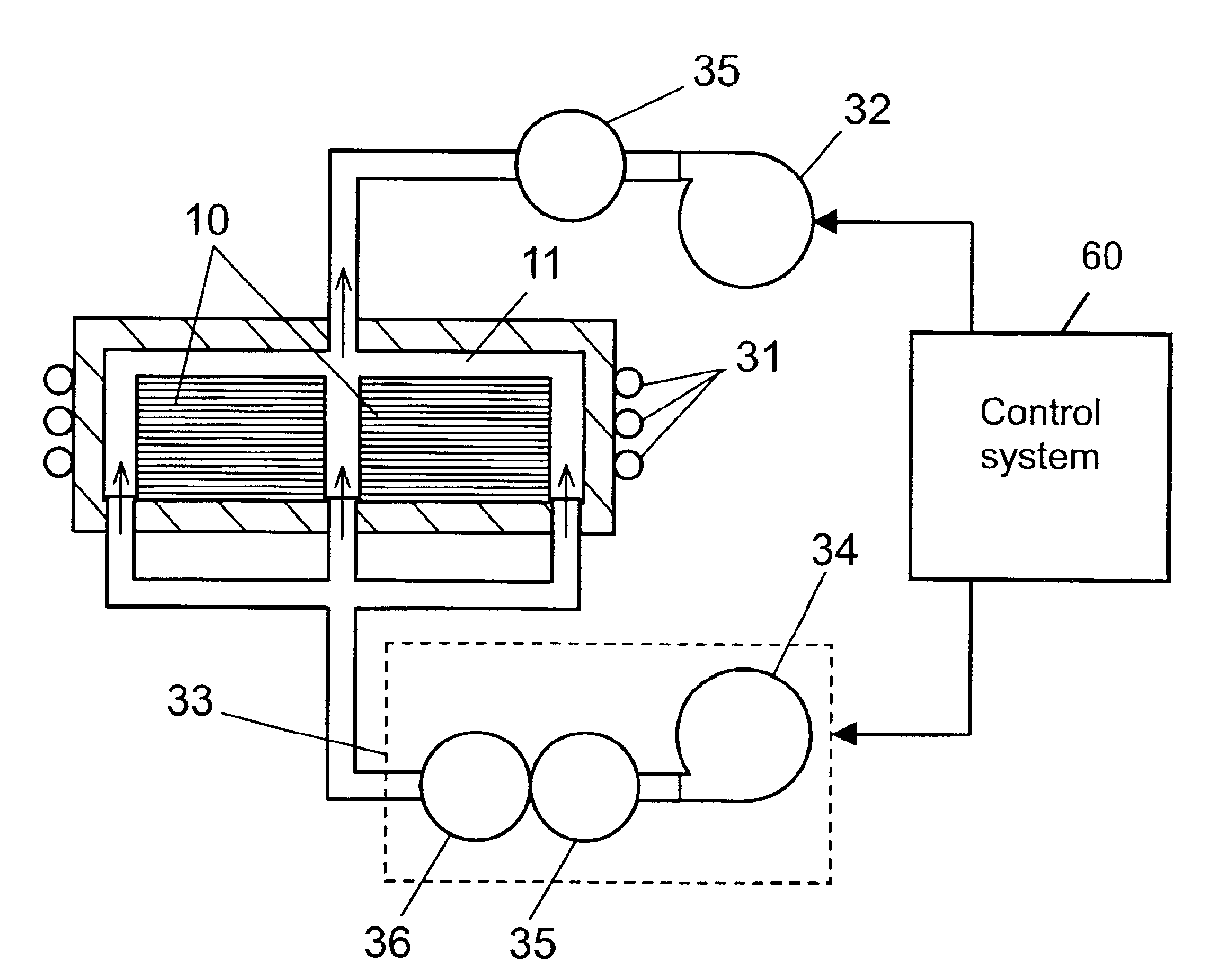

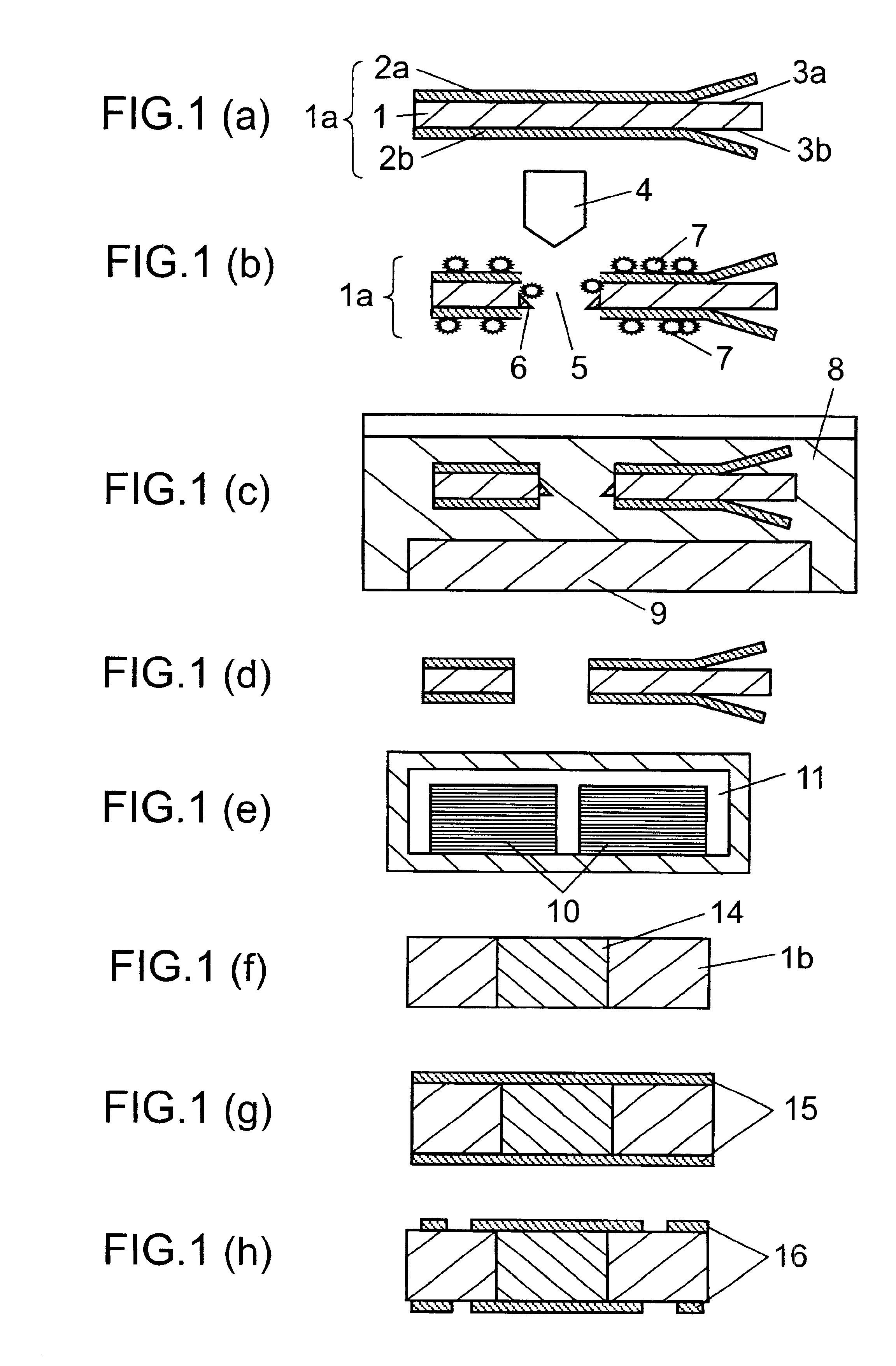

A method and system of cleaning to remove cutting dust and the like generated and adhering to a board material (1a) during drilling for electrical connection, and drying the board material, in a process of manufacturing a circuit board for small electronic equipment and the like. A large amount of board materials can be treated without receiving thermal damage by performing the steps of: placing sheets of the board material that have absorbed moisture resulting from cleaning, like a stack in a vacuum chamber (11); and drying the board material by repeating evacuation and pressurization under predetermined conditions while heating the board material.

Owner:PANASONIC CORP

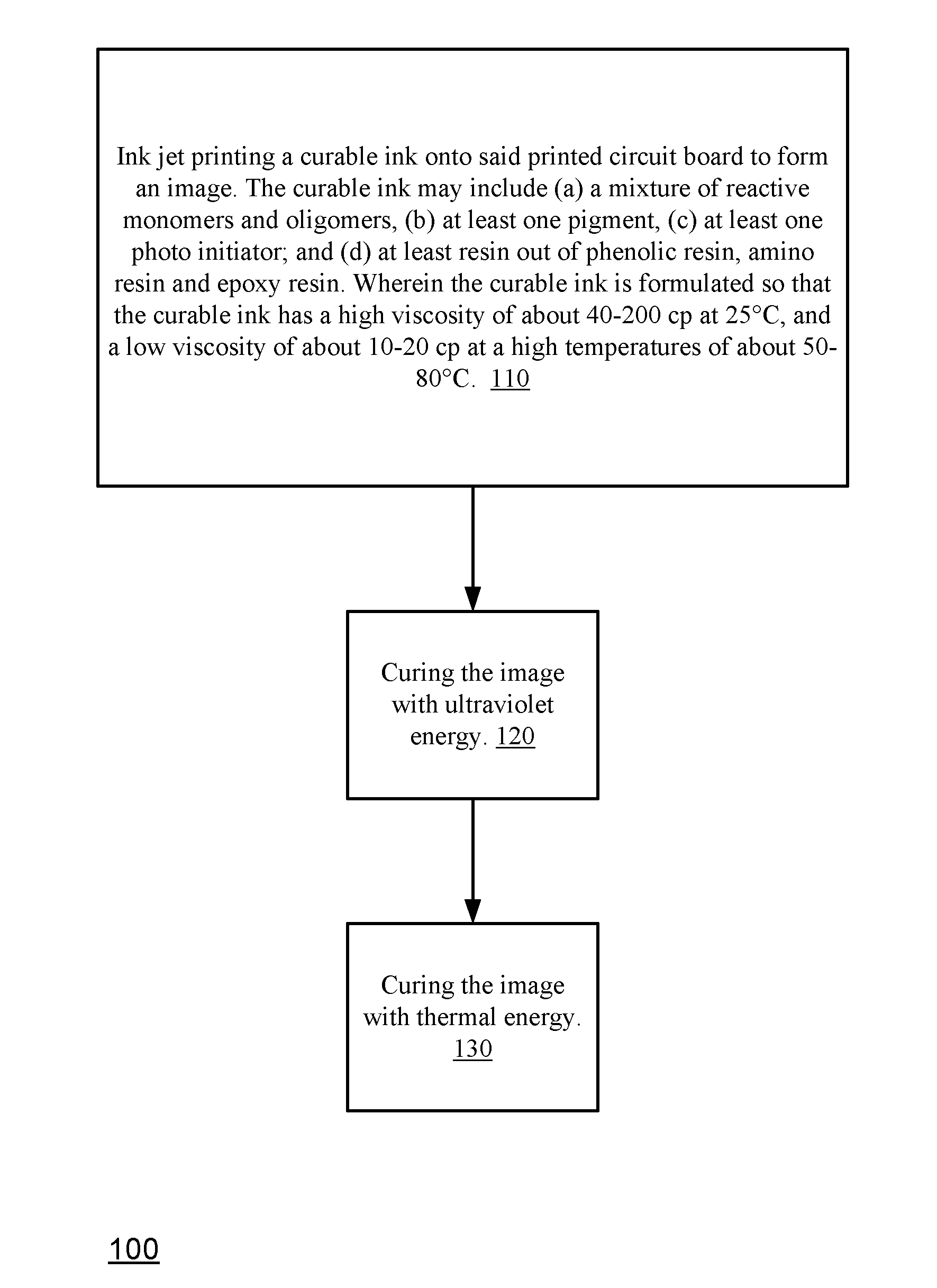

Curable ink and a method for printing and curing the curable ink

InactiveUS20140055544A1Improve hiding powerHigh optical densityInksPhotodevelopable thick filmEpoxyOligomer

A method for printing a curable ink, the curable ink comprises a mixture of reactive monomers and oligomers; at least one pigment; at least one photo initiator; and at least a resin out of phenolic resin, amino resin and epoxy resin.

Owner:CAMTEK LTD

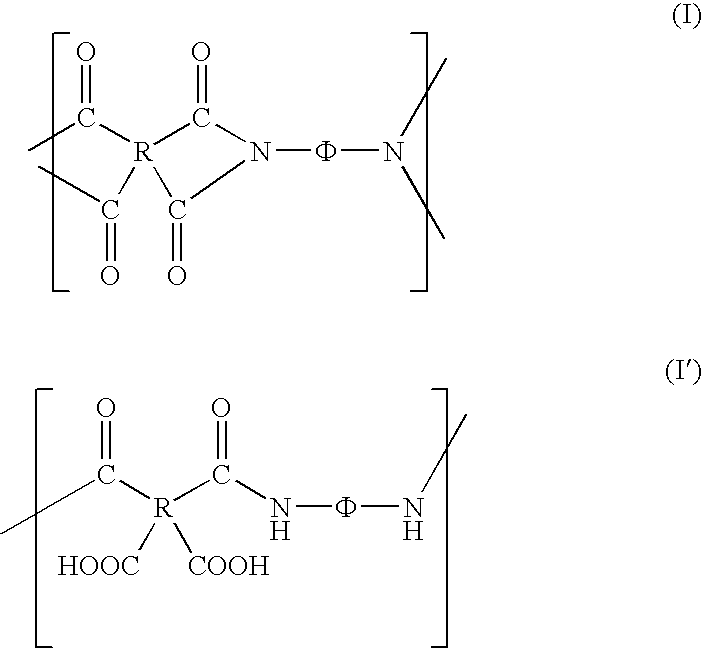

Process and apparatus for production of colorless transparent resin film

ActiveUS20100187719A1Improve flatnessImprove heat resistanceFilament/thread formingTransparent dielectricsOrganic solventGas passing

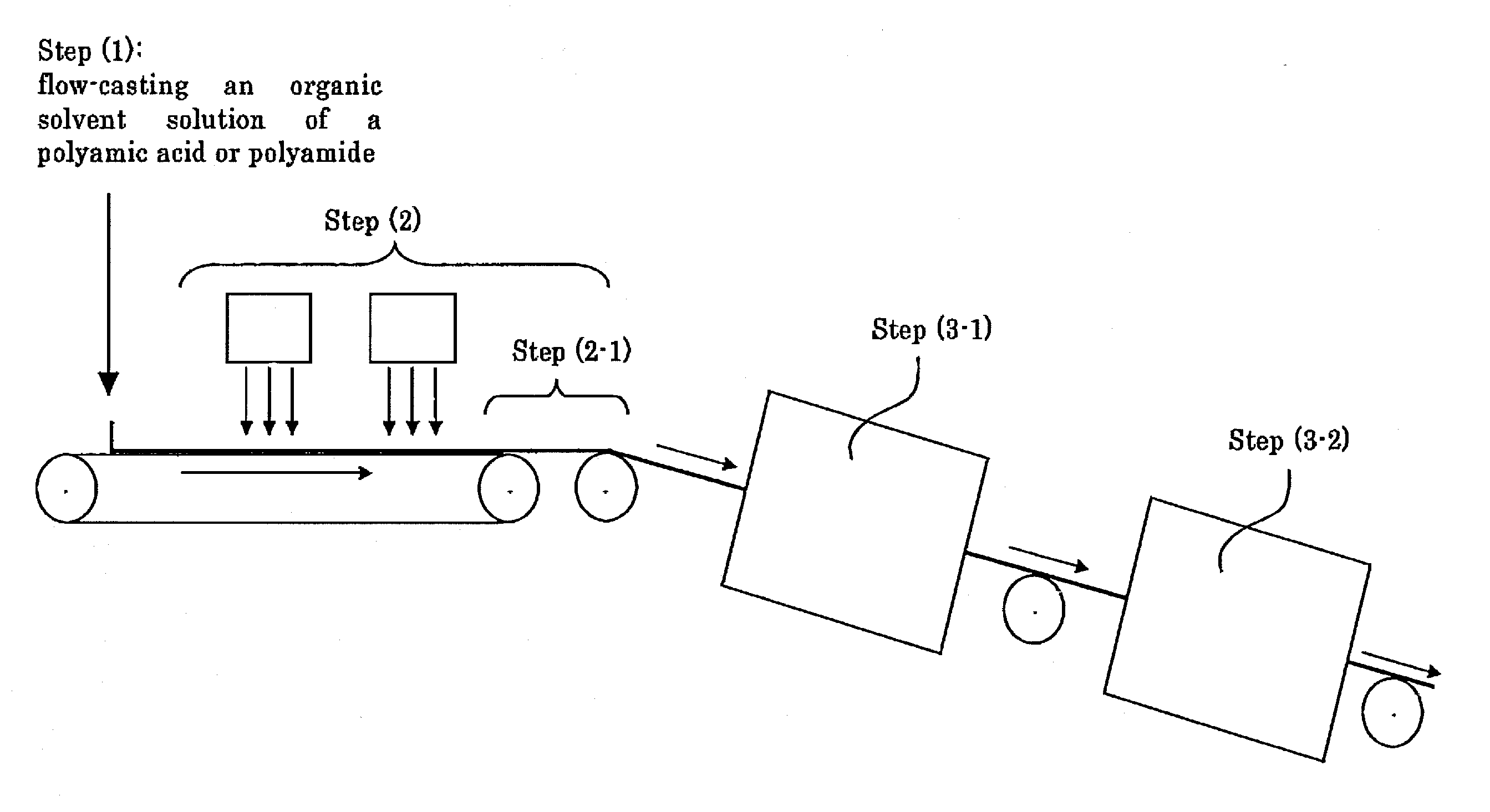

A method for producing a colorless transparent resin film by a solution flow casting method containing: flow-casting an organic solvent solution of a polyamic acid or a polyimide on a support; and drying, the method containing at least the following step (1), step (2) and step (3) in this order, and an apparatus therefor:(1) a step of flow-casting an organic solvent solution of a polyamic acid or polyamide on a support,(2) a step of evaporating the organic solvent while blowing a gas having an oxygen content of from 0.001 to 15% by volume at a temperature of from 100 to 170° C. onto the flow-cast material, and releasing as a self-supporting film from the support, and(3) a step of performing the following step (3-1) and step (3-2) in this order:(3-1) a step of lowering a residual ratio of the organic solvent in the self-supporting film while blowing a gas having an oxygen content of 15% by volume or less at a temperature of from 100 to 250° C. onto the film by using at least one dryer of a type of blowing a heated gas, and(3-2) a step of lowering the residual ratio of the organic solvent in the self-supporting film while blowing a gas having an oxygen content of 5% by volume or less at a temperature of from 150 to 400° C. onto the film by using at least one dryer of a type of blowing a heated gas.

Owner:MITSUBISHI GAS CHEM CO INC

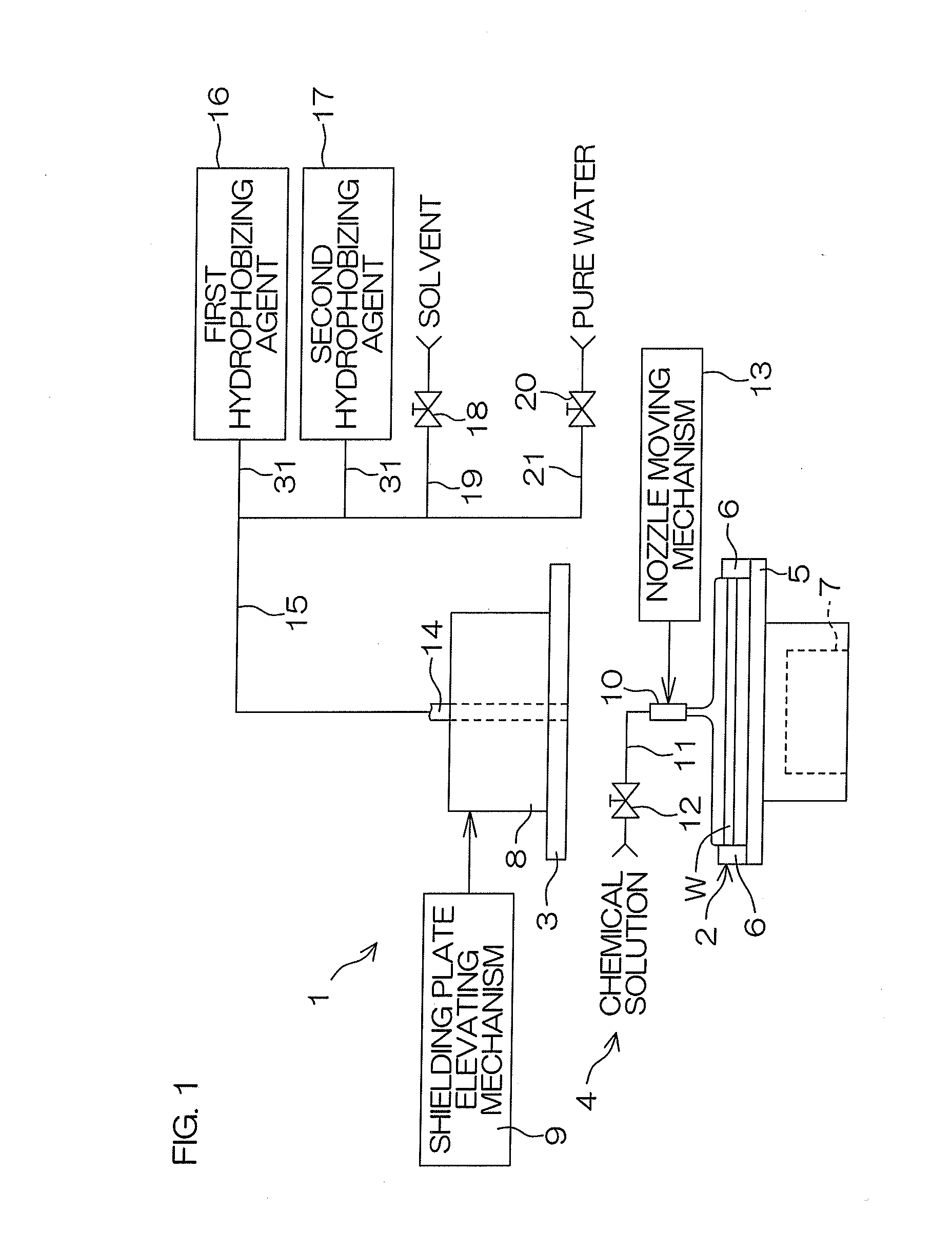

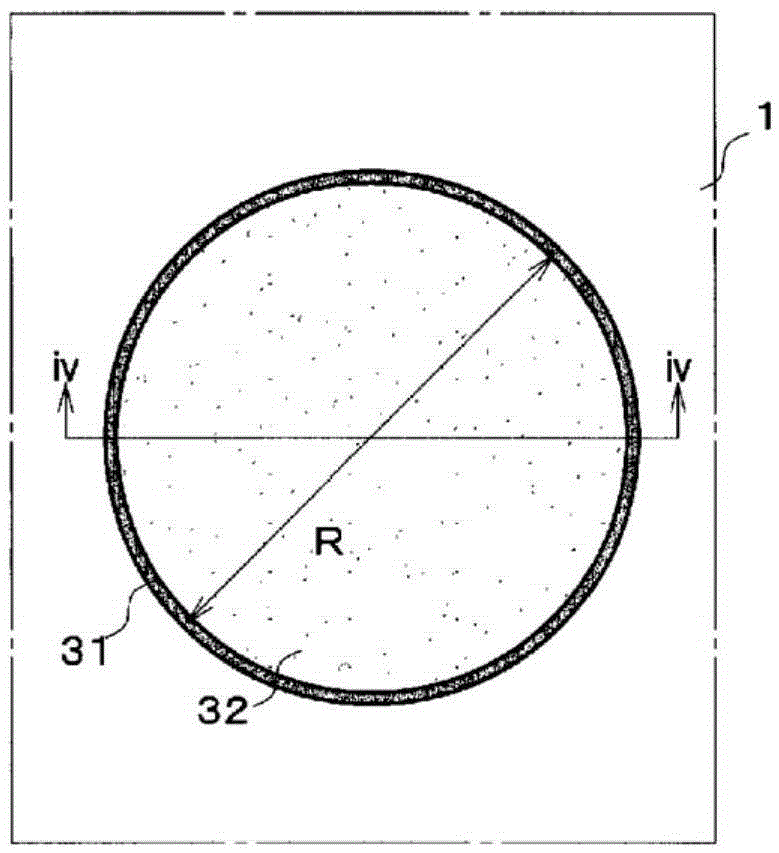

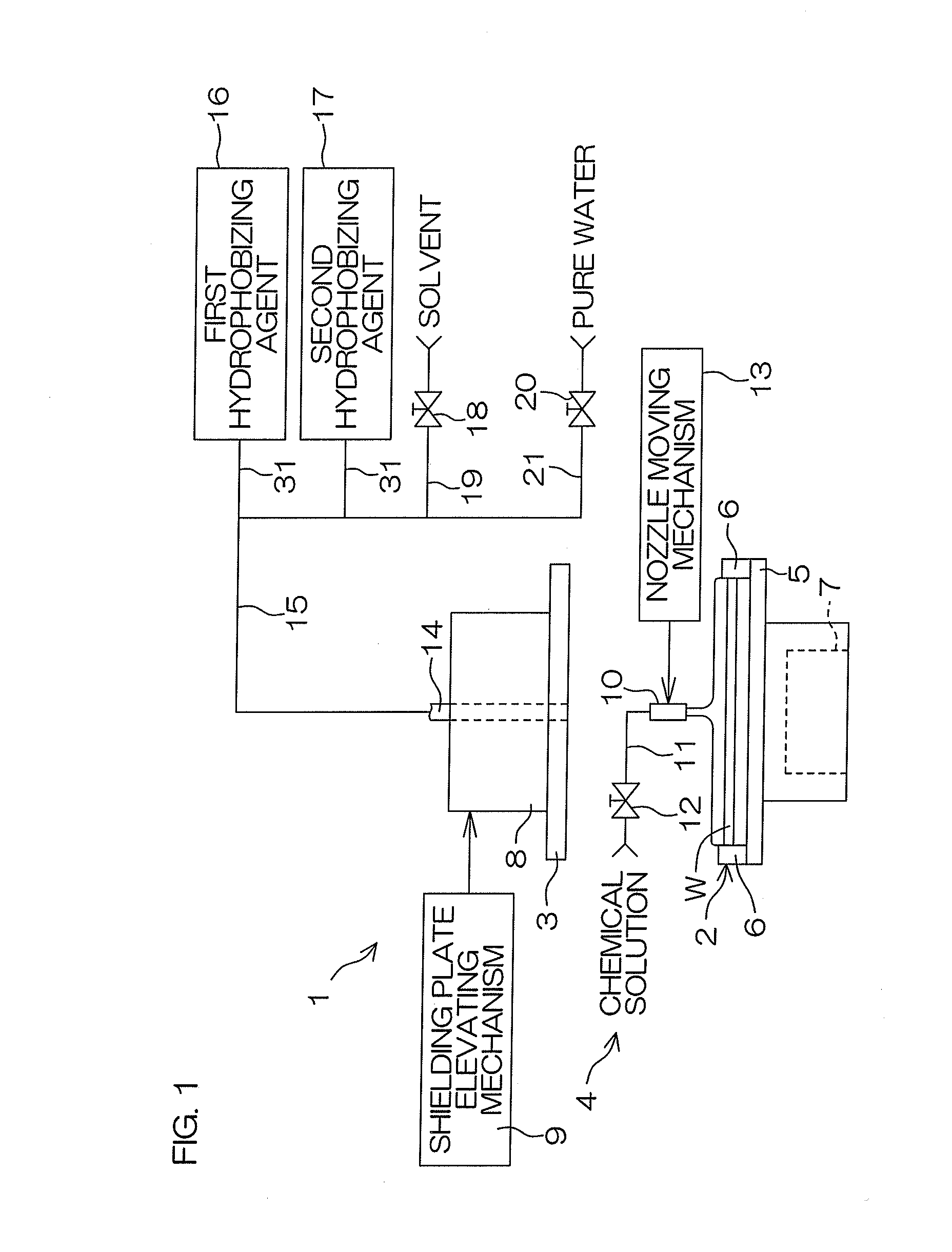

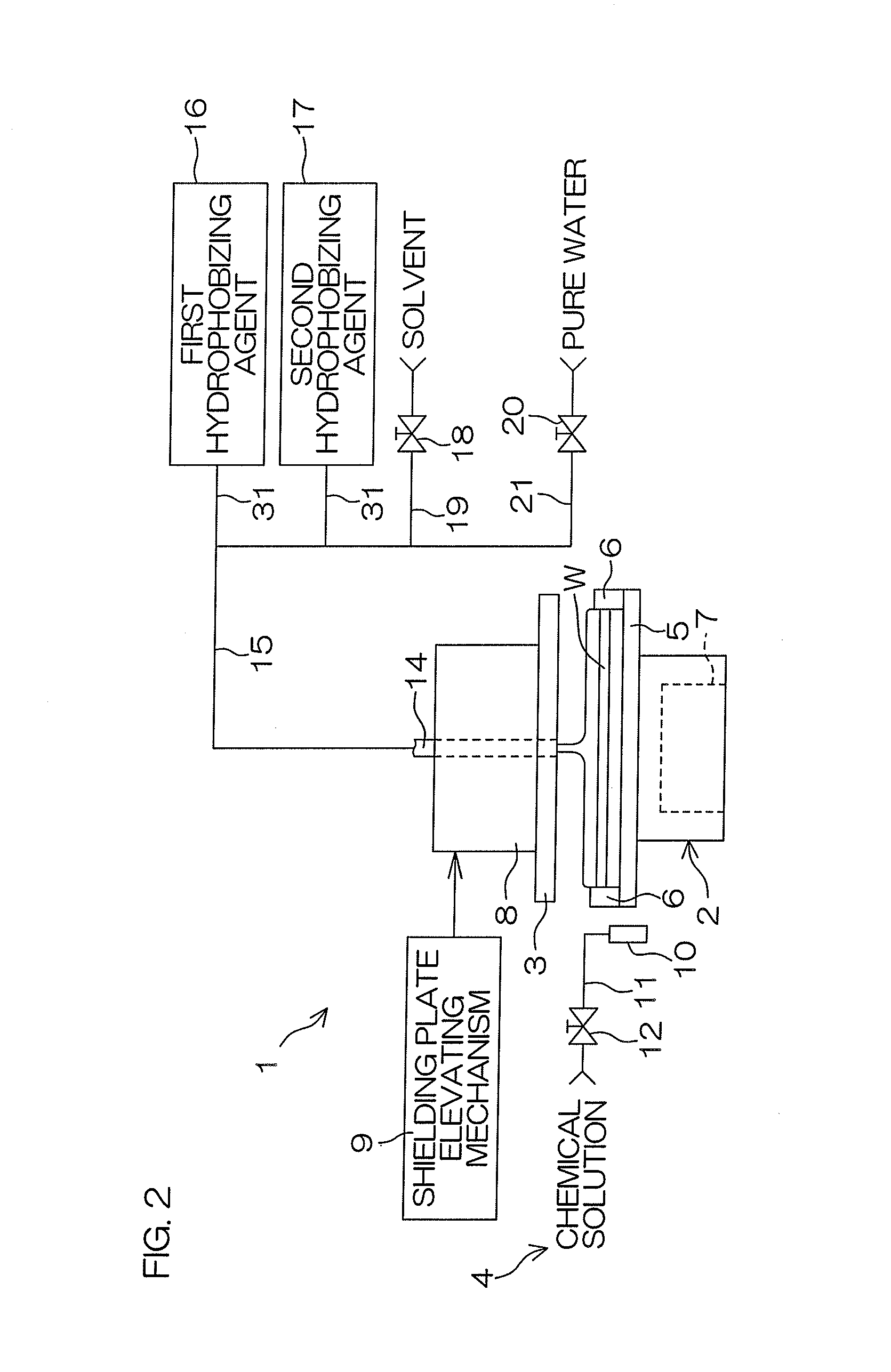

Substrate processing method and substrate processing apparatus

ActiveUS20120045581A1Shorten substrate processing timeShort timeOther chemical processesPhotomechanical apparatusEngineeringSubstrate surface

A hydrophobizing agent is supplied to a substrate and a surface of the substrate is hydrophobized. Thereafter, the substrate is dried. The substrate to be processed is maintained in a state of not contacting water until it is dried after being hydrophobized. Collapse of a pattern formed on the substrate surface is thereby suppressed or prevented.

Owner:DAINIPPON SCREEN MTG CO LTD

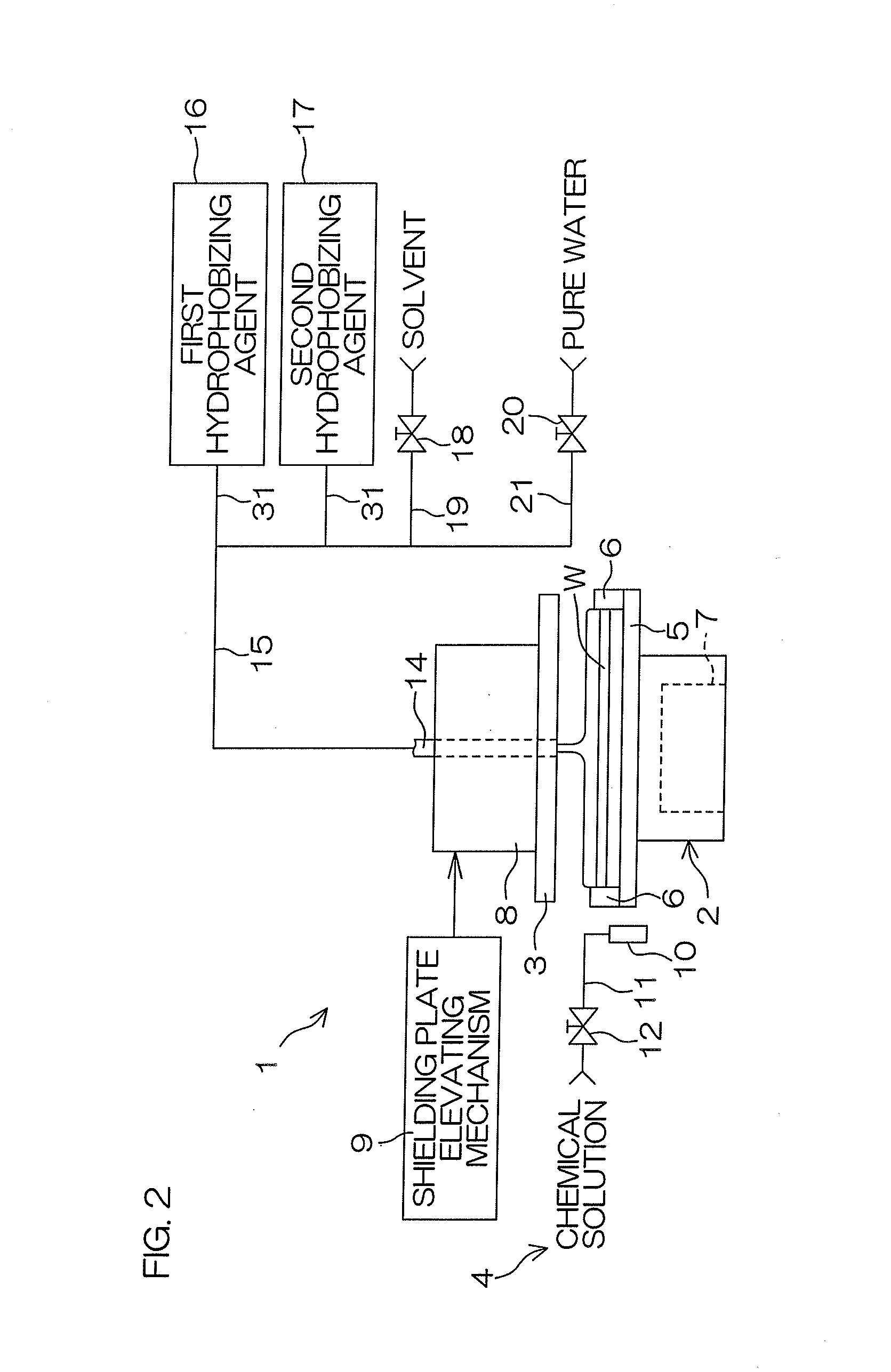

Apparatus for coating board-shaped articles, especially printed circuit boards

InactiveUS6159294ACompact structureSmall space requirementPrinted circuit assemblingLiquid surface applicatorsLacquerAir treatment

An apparatus for coating board-shaped articles, especially printed circuit boards, is described which comprises at least one coating station having a pouring table for coating one surface of the printed circuit boards with preferably UV-hardenable plastics, lacquer or the like, and, adjoining that station, a vapor-removal and drying station having a vapor-removal drier for the removal of vapor from and drying of the coated surfaces of the printed circuit boards in the stream of hot air. The vapor-removal and drying station has an air processing module which is arranged in a housing which adjoins the entrance side of the housing of the vapor-removal drier and extends over the free space above the pouring table.

Owner:VANTICO

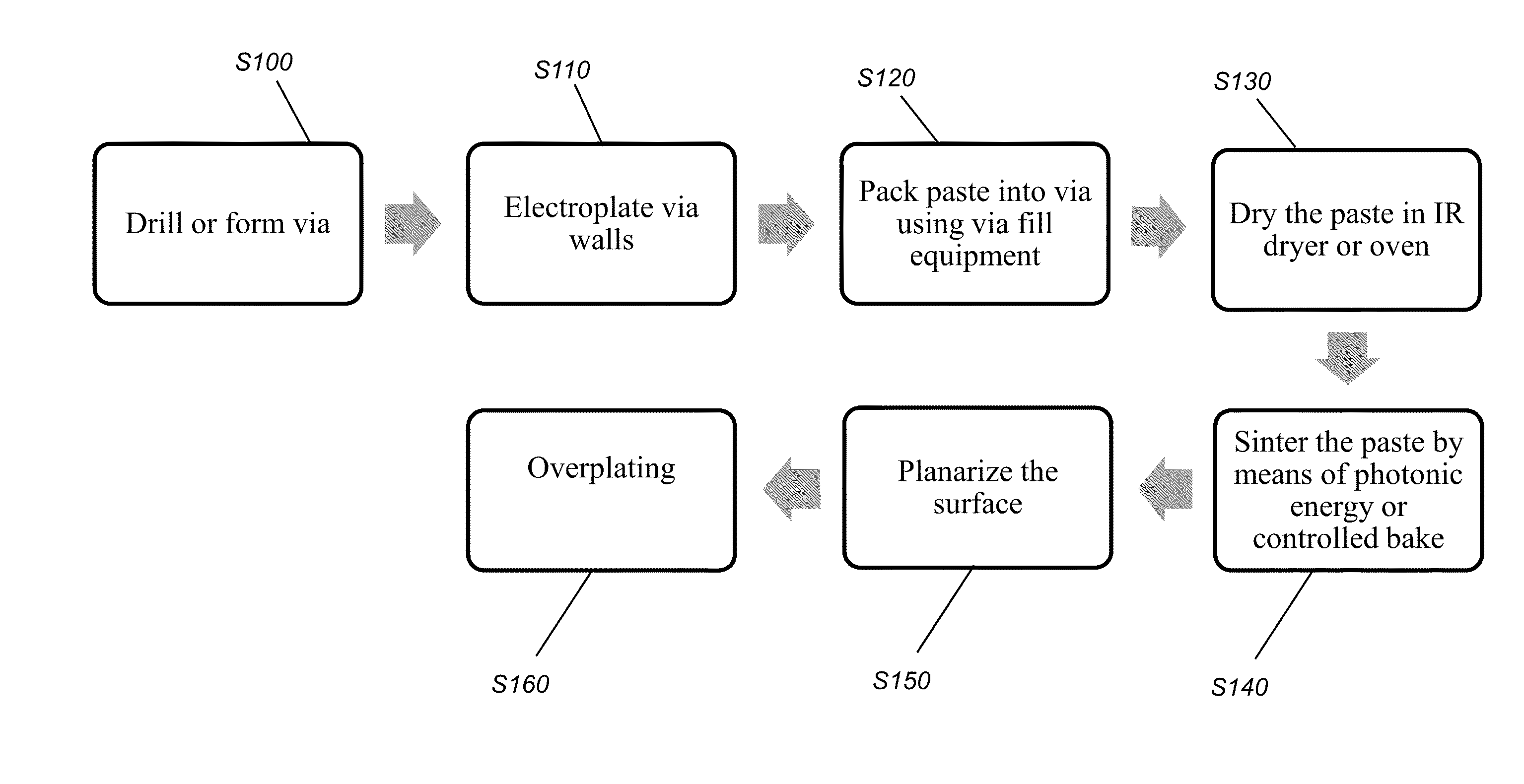

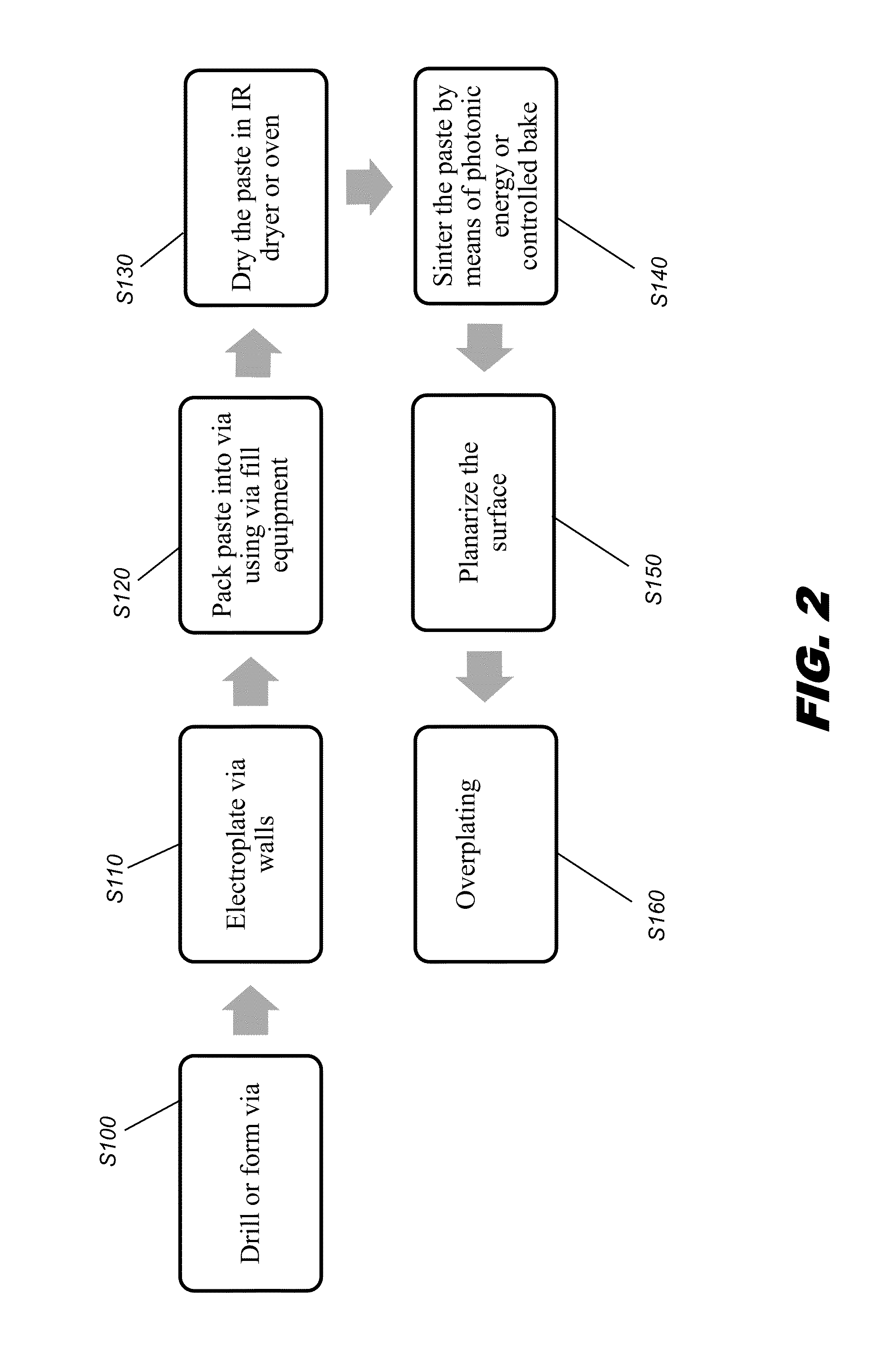

Method for forming vias on printed circuit boards

InactiveUS20160128201A1Improve conductivityFast fillPrinted circuit aspectsPrinted circuit dryingParticulatesSolvent

A method for filling a via on a printed circuit board formulates a paste as a dispersion of copper particulate that includes nanocopper particles in a solvent and a binder and depositing the paste into a via cavity formed in the printed circuit board. Heating the paste-filled cavity removes most of the solvent. The method sinters the deposited paste in the via cavity, planarizes the sintered via, and overplates the filled via with copper.

Owner:NCC NANO LLC

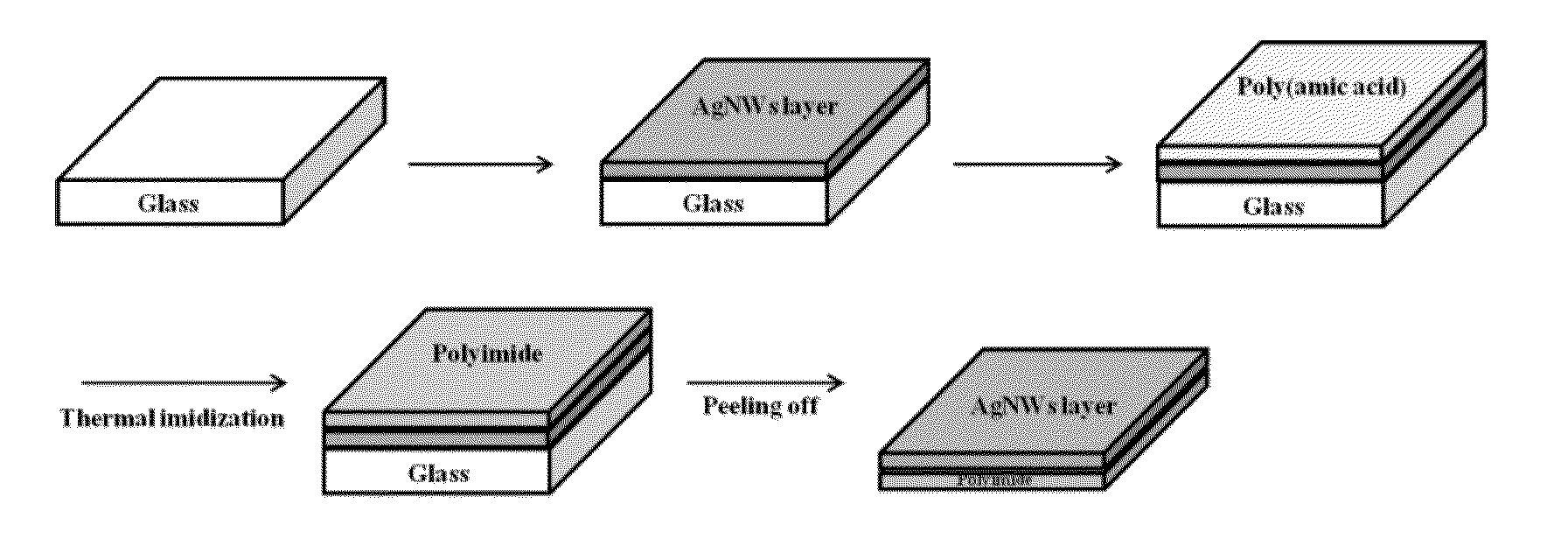

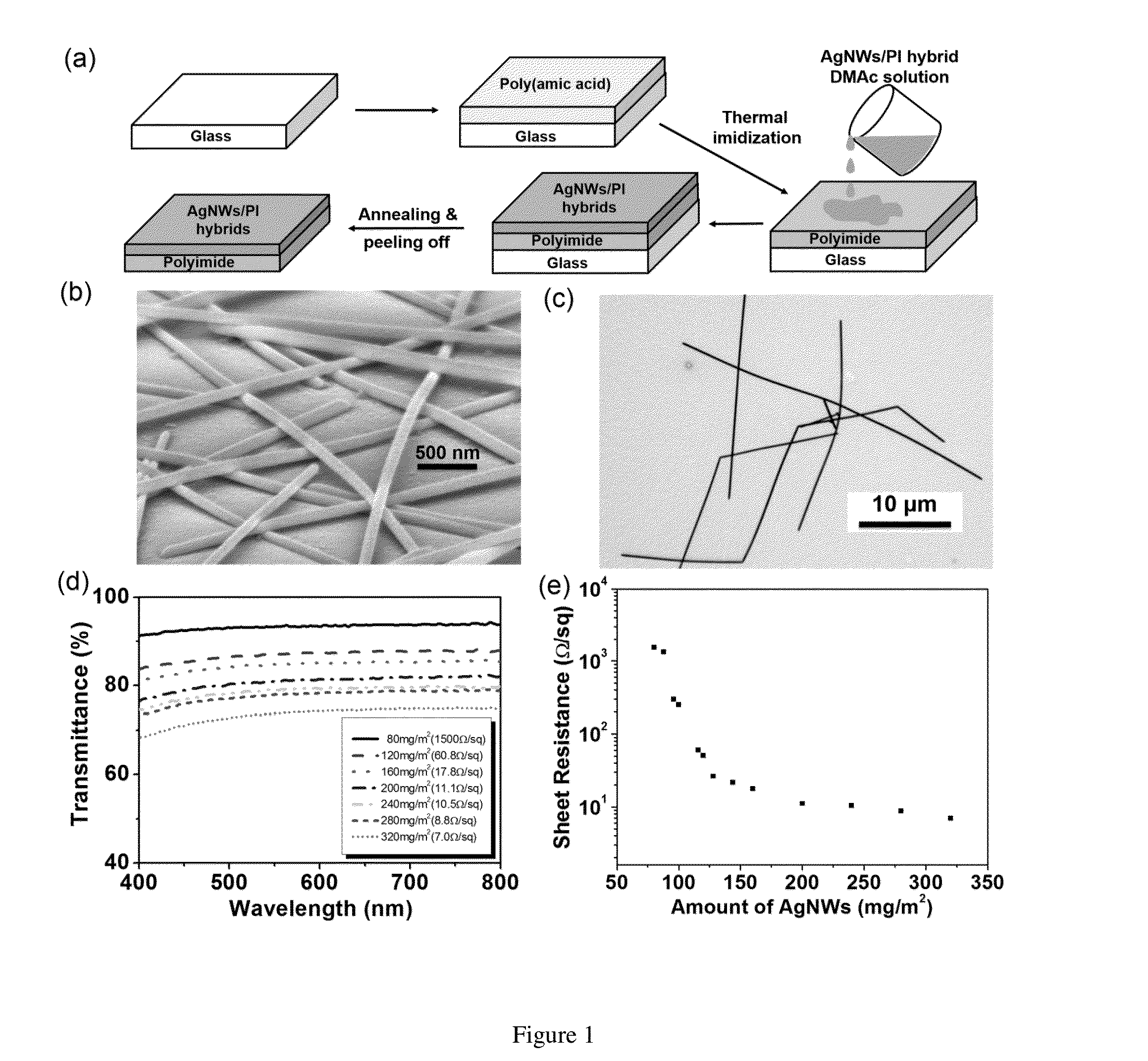

Flexible and transparent electrode and manufacturing method thereof

InactiveUS20160128187A1High glass transition temperatureHigh operating requirementsDielectric materialsPrinted circuit dryingOrganic solventMetal nanowires

The present invention relates to a flexible and transparent electrode and manufacturing method thereof. The flexible transparent electrode comprises an insoluble polyimide film as a substrate and metal nanowires as a conductor, wherein the insoluble polyimide film is polymerized by aromatic diamines and alicyclic diamines of thermal imidization. In addition, the coating method of polyimides of the present invention not only improves the adhesion and dispersion between metal nanowires and substrate, but also exhibits good thermal stability; moreover, the transparent electrode keeps the effectiveness even in high temperature processing conditions such as annealing, laser, plasma or other severe operation environment. Using the step transfer printing method can produces the transparent electrode product with smooth surfaces, thermo stability, and organic solvent resistance, so as to improve the adhesion of metal nanowires and lower the resistance of the transparent electrode.

Owner:NAT TAIWAN UNIV

Dry Cabinets for Use in Moisture Sensitive Device Management in Electronics Manufacturing

InactiveUS20070068035A1Prevent moisture-induced failureLow costDrying gas arrangementsDrying machines with progressive movementsNitrogen generatorEngineering

A dry cabinet for storing surface mount devices in a low humidity environment containing an integrated dry gas forming means in the form of a desiccator or a nitrogen generator which can receive a source of compressed air and form a dry air stream or a concentrated dry nitrogen stream which can be directed into the interior space of the cabinet to maintain the environment within the cabinet a low relative humidity. The cabinet with it self contained dry gas forming source is more economical than prior art dry cabinets which require a centralized nitrogen source.

Owner:THERIAULT MARTIN

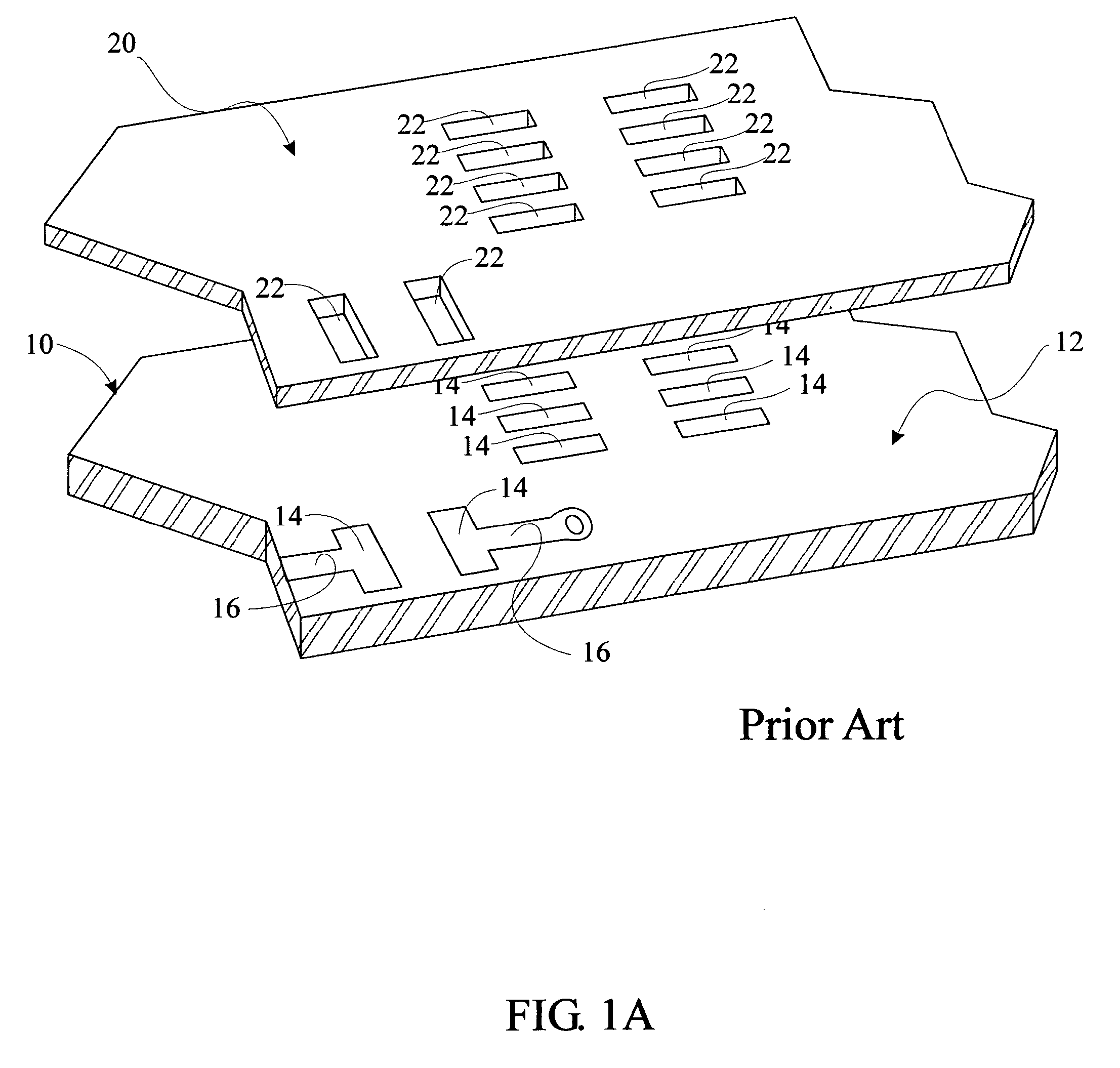

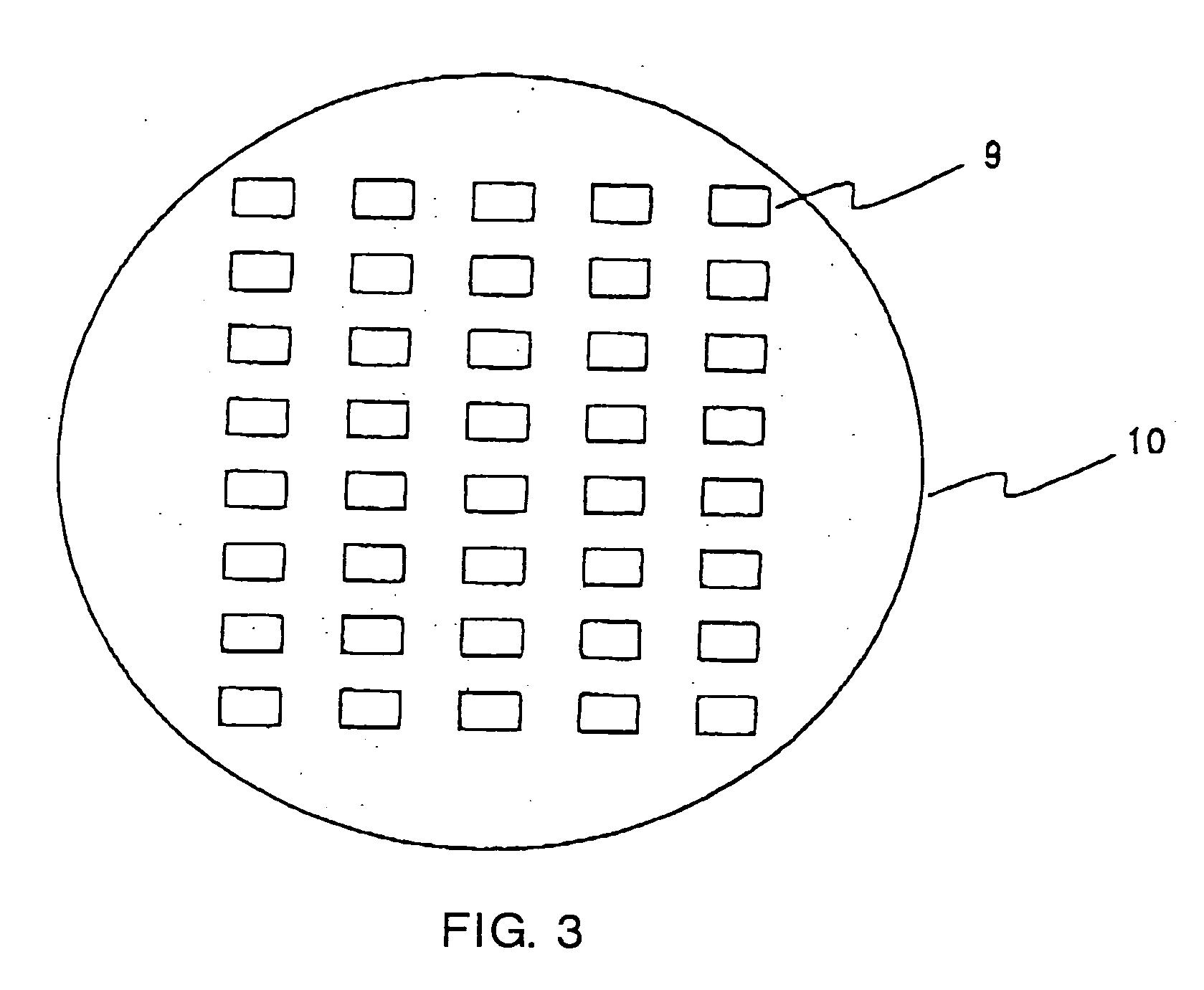

Application of acoustic and vibrational energy for fabricating bumped IC die and assembly of PCA's

InactiveUS7293567B2Easy to separateSolve lowDrying solid materials without heatHollow article cleaningScreen printingTransducer

A method and apparatus are disclosed for improving a screen printing process by applying vibrational energy to assist in the print release, cleaning, and drying processes. The vibrational energy or acoustic pressure waves may be created by a transducer where the waves are transferred to the stencil or printable material through air or a vibrational interface medium. The vibrational energy in turn assists with separating the printable material from the side walls of the apertures of the stencil. The vibrational energy can further assist in the process of cleaning the stencil. The acoustic pressure can also be used in the drying process by having the waves impinge on the water droplets to atomize the droplets on the surface of the stencil. The technology can be used for the assembly of Printed Circuit Assemblies, Ball Grid Array IC Packages, Flip Chip, etc. The same technology may be applied to other cleaning processes for cleaning Printed Circuit Assemblies, tooling, and the like, whereby the cleaning processes can assist in cleaning within the cracks, crevices and hard to reach areas of connectors and other components, without undesirable heat.

Owner:HERTZ ALLEN DAVID +2

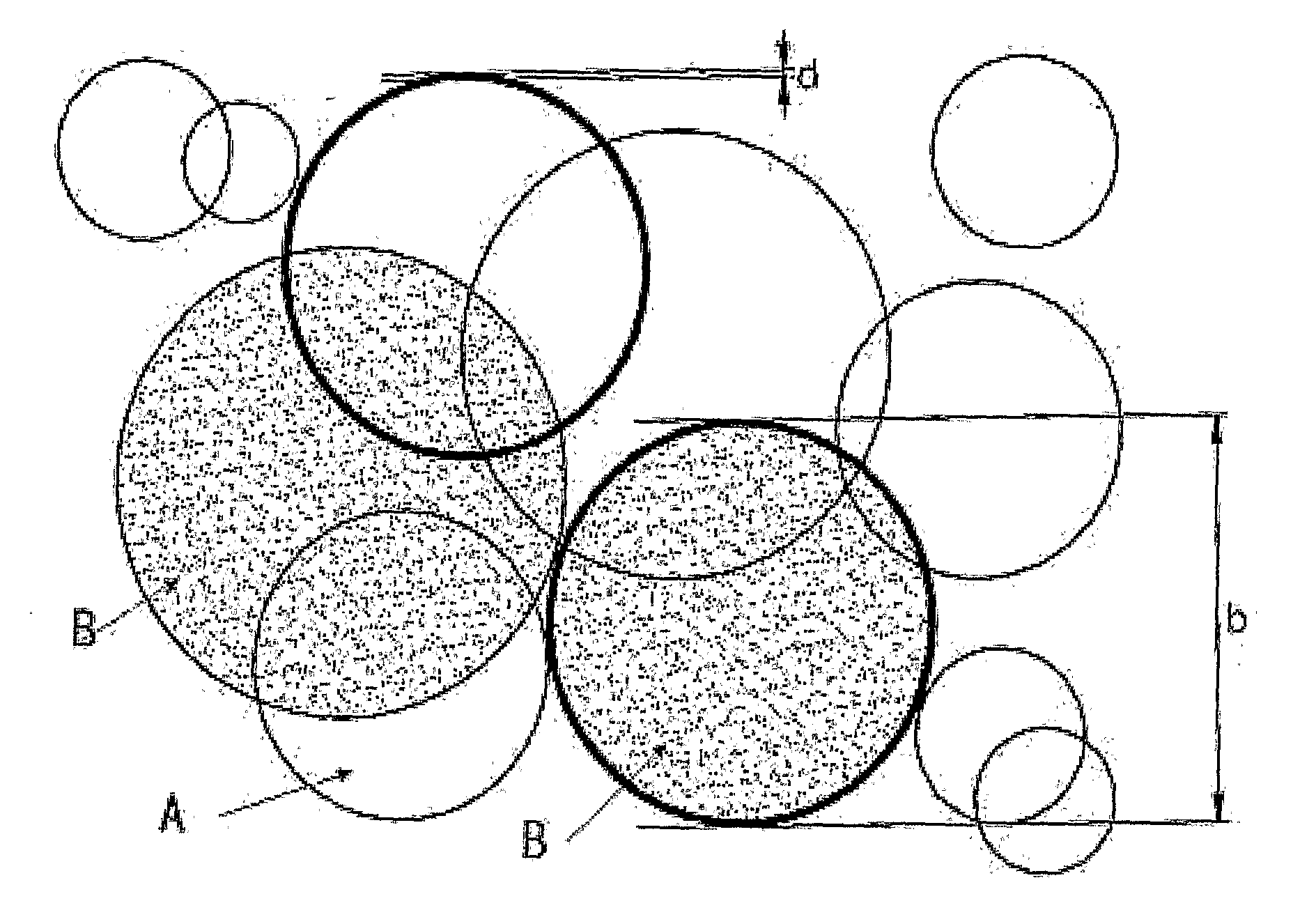

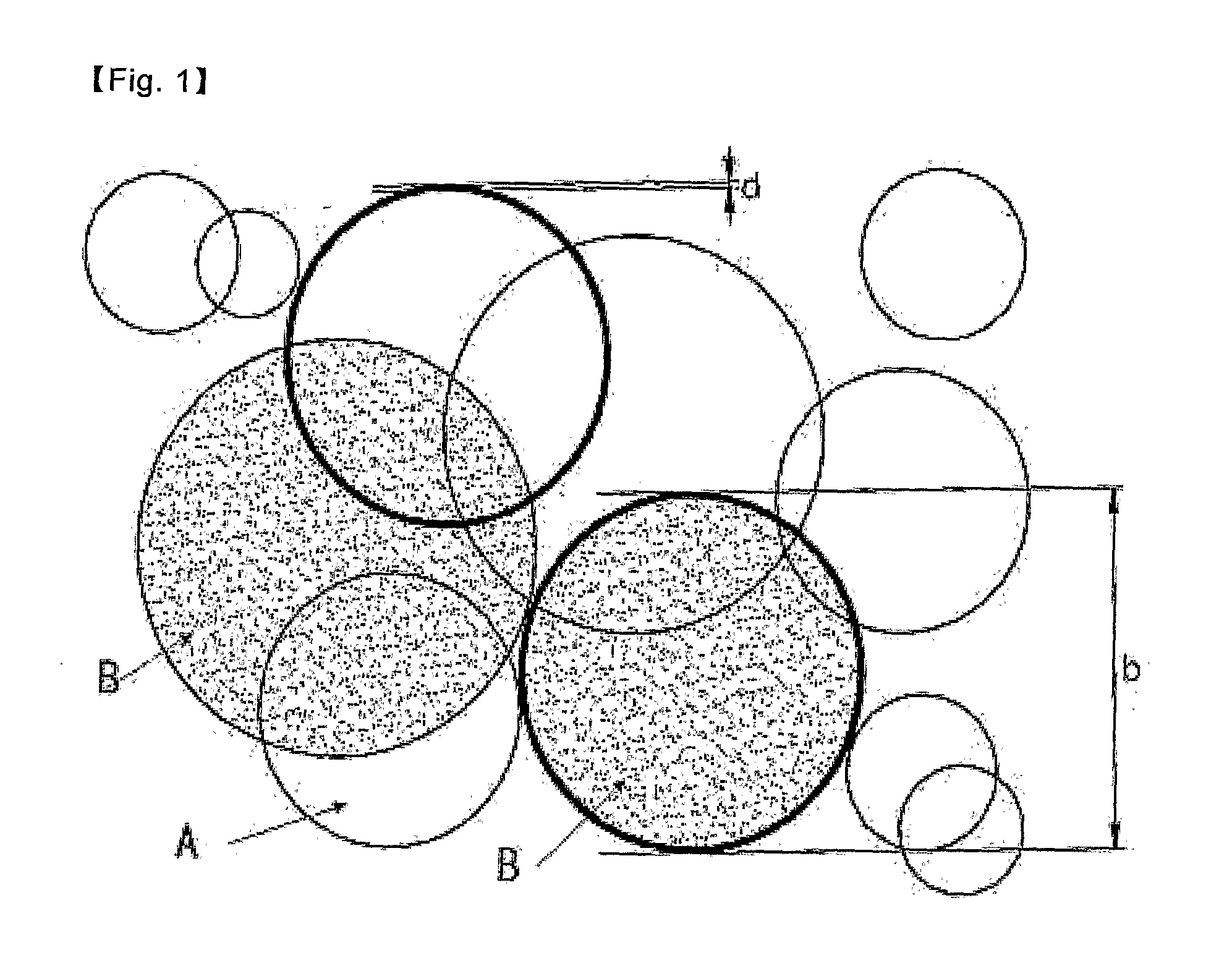

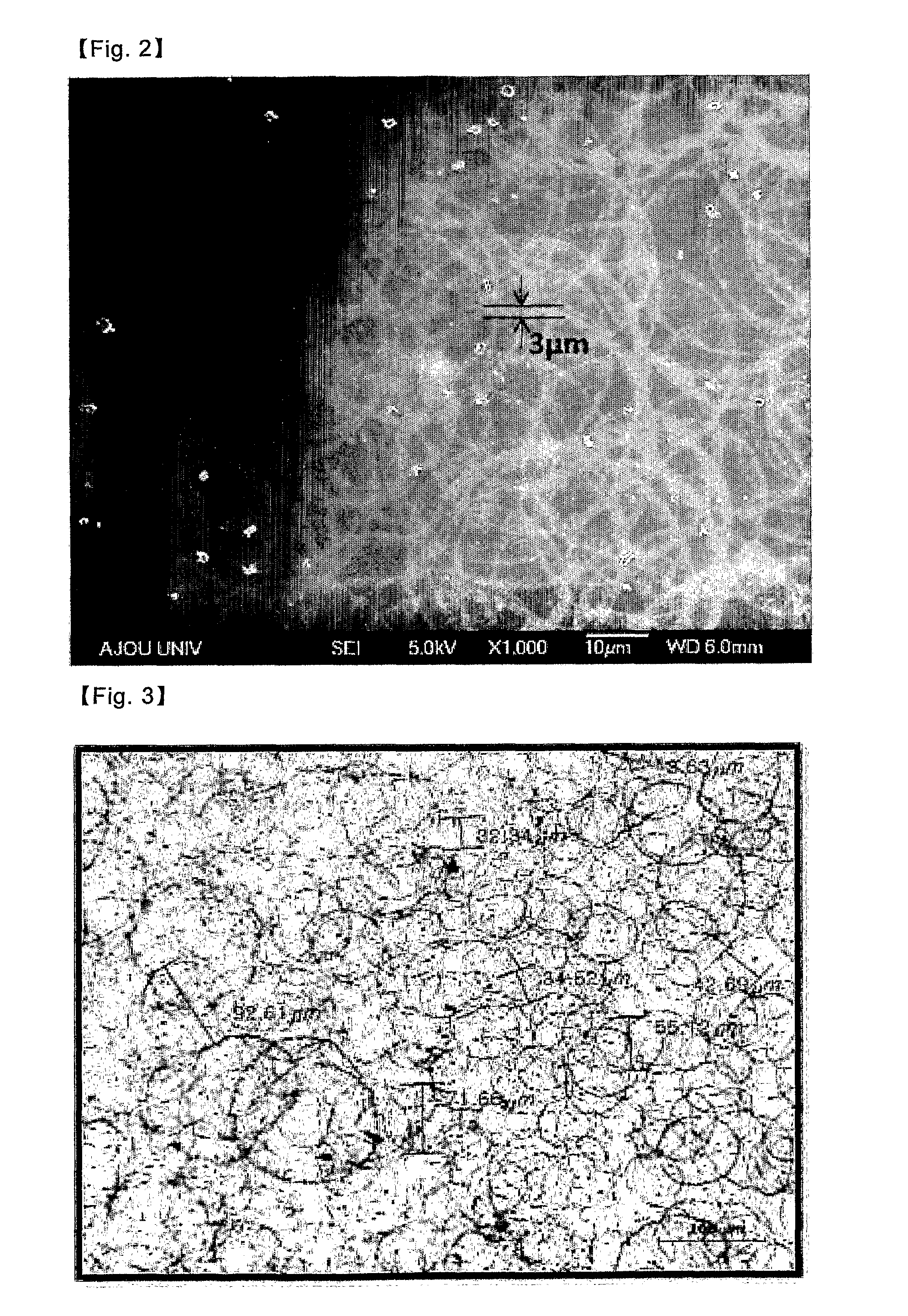

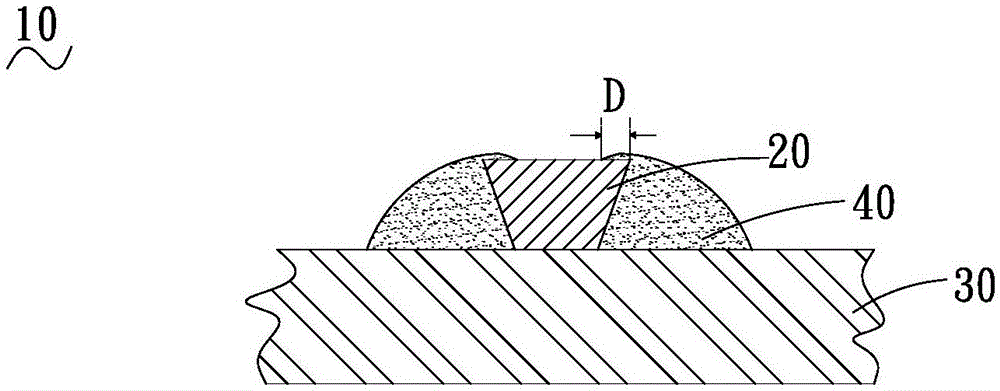

Carbon nanotube conductive layer using spray coating and preparing method thereof

InactiveUS20100221531A1High transparencyImprove conductivityPretreated surfacesRecord information storageElectrical resistance and conductanceRing pattern

Provided is a carbon nanotube (CNT) transparent conductive layer having a loop pattern in which a plurality of loops are at least partially connected to one another, and a fabrication method thereof. The loops in the pattern are generated by a spray-coating method and partially connected with one anther, and thus improving transparency and conductivity of the CNT transparent conductive layer. In Addition, the CNT transparent conductive layer has conductivity and sheet resistance highly suitable for a transparent electrode.

Owner:TOP NANOSYS

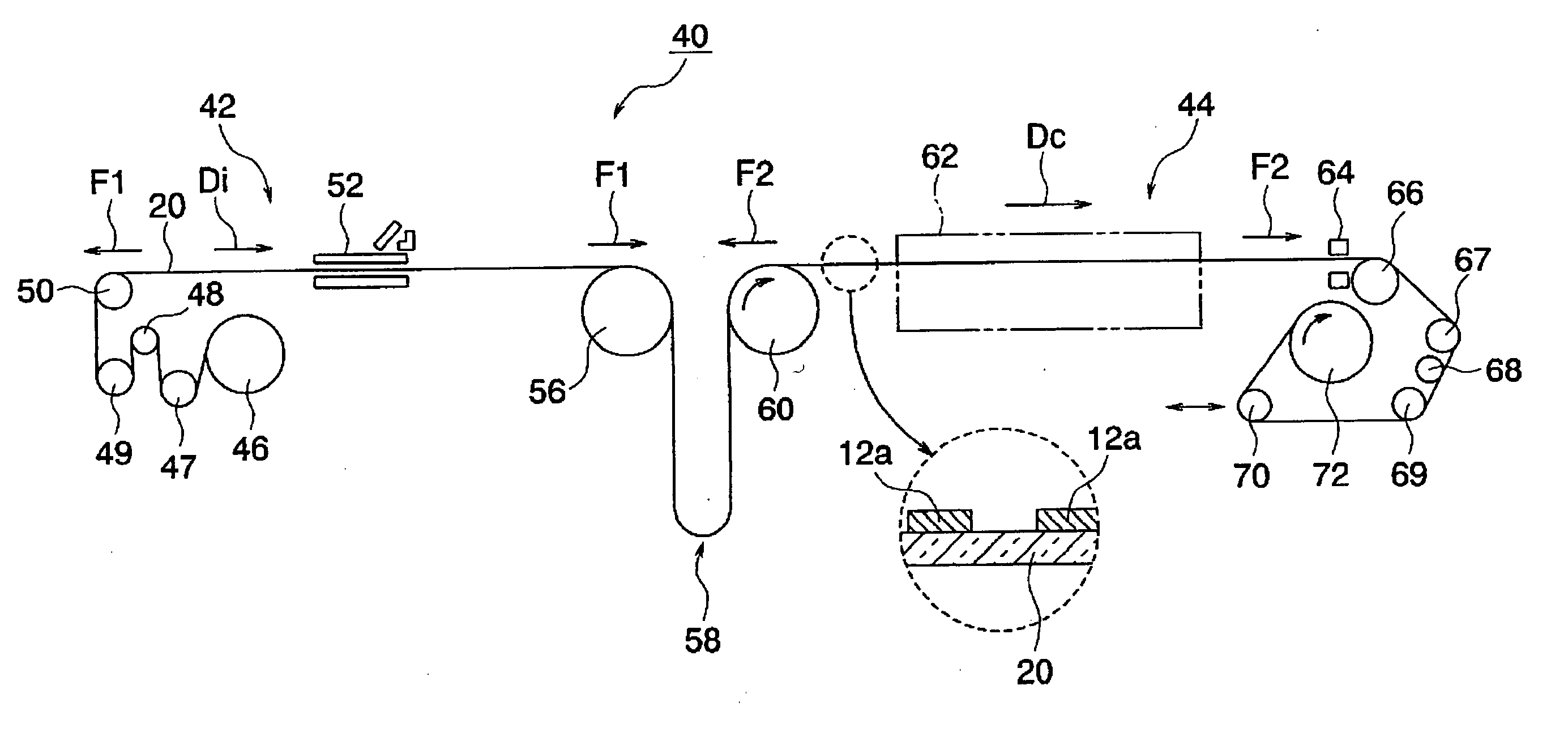

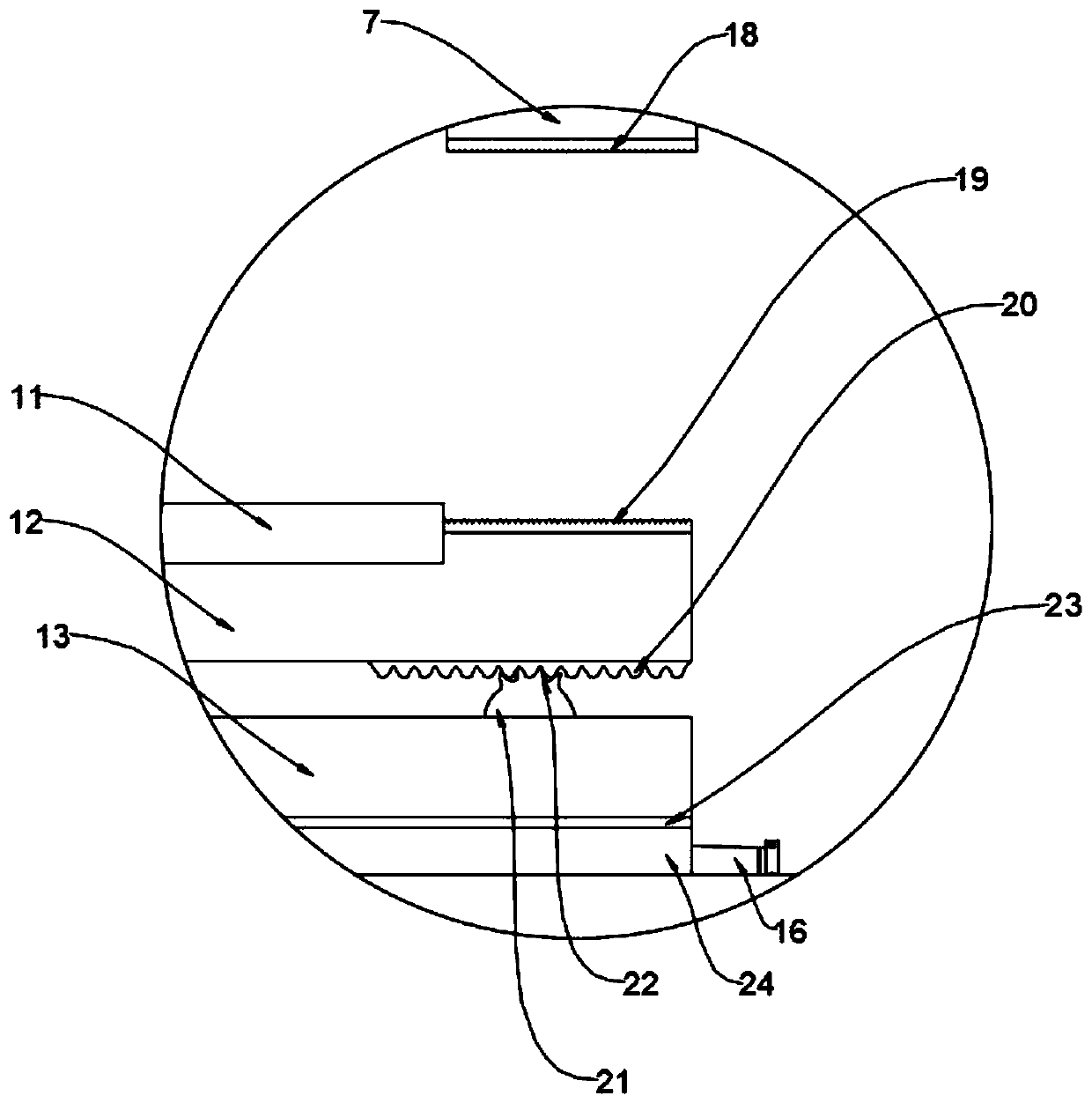

Printing and drying method, method of production of electronic device, and printing and drying system

ActiveUS20060213382A1Prevent dust depositionAvoid defectsDrying/impregnating machinesPrinted circuit dryingEngineeringMethods of production

A printing and drying method comprising laying a support sheet 20 elongated in the long direction so as to bridge both a printing zone 42 and a drying zone 44, in the printing zone 42, giving the support sheet 20 a first tension F1, in that state, printing the support sheet 20 with predetermined patterns, then feeding the support sheet 20 toward the drying zone 44, in the drying zone 44, giving the support sheet 20 on which the predetermined patterns were printed a second tension F2, and in that state, drying it in a drying chamber 62. The first tension F1 and the second tension F2 are given by separate tension giving means, and the second tension F2 is tension given along the support sheet 20 in the long direction and able to prevent shrinkage of the support sheet 20 in the long direction while passing through the drying zone 44.

Owner:TDK CORPARATION

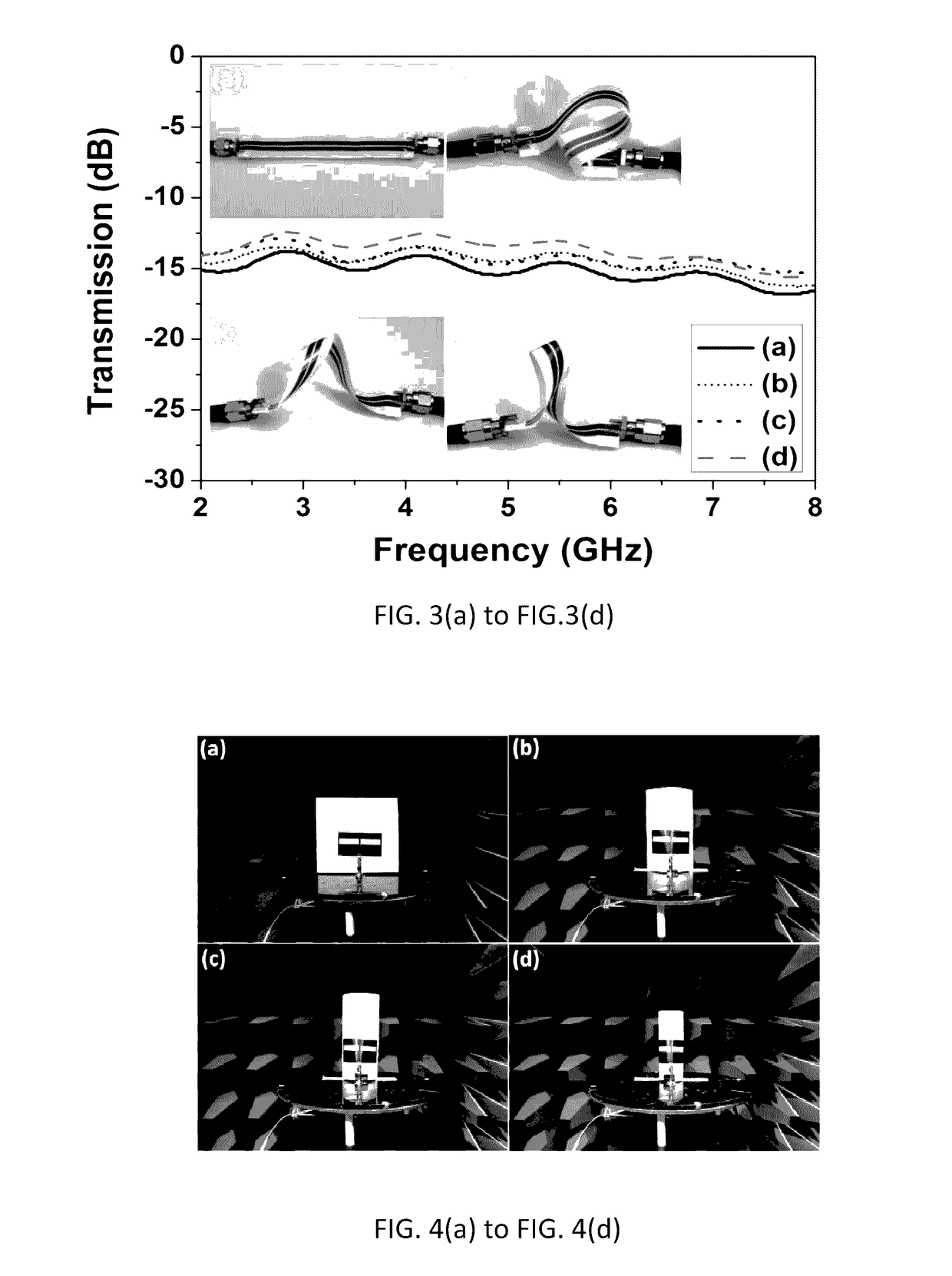

Method of Making Highly Flexible and Conductive Printed Graphene-Based Laminate for Wireless Wearable Communications

ActiveUS20170156215A1High enough conductivityHigh enough flexibilityPorous dielectricsLaminating printed circuit boardsCommunications systemEngineering

A printed graphene-based laminate for wireless wearable communications can be processed at low temperature so that it is compatible with heat-sensitive flexible materials like papers and textiles. The printed graphene-based laminate is of high conductivity, high flexibility, light weight and low cost, making it perfect candidate for wireless wearable devices. As a proof of concept, printed graphene-based laminate enabled transmission lines (TLs) and antennas were designed, fabricated and characterized. To explore its potentials in wearable communications applications, mechanically flexible transmission lines and antennas under various bended cases were experimentally studied. The measurement results demonstrate that the printed graphene laminate can be used for RF signal transmitting, radiating and receiving, which represents some of the essential functionalities of RF signal processing in wireless wearable communications systems. This work brings a step closer the prospect to implement all graphene enabled wireless wearable communications systems in the near future.

Owner:BGT MATERIALS

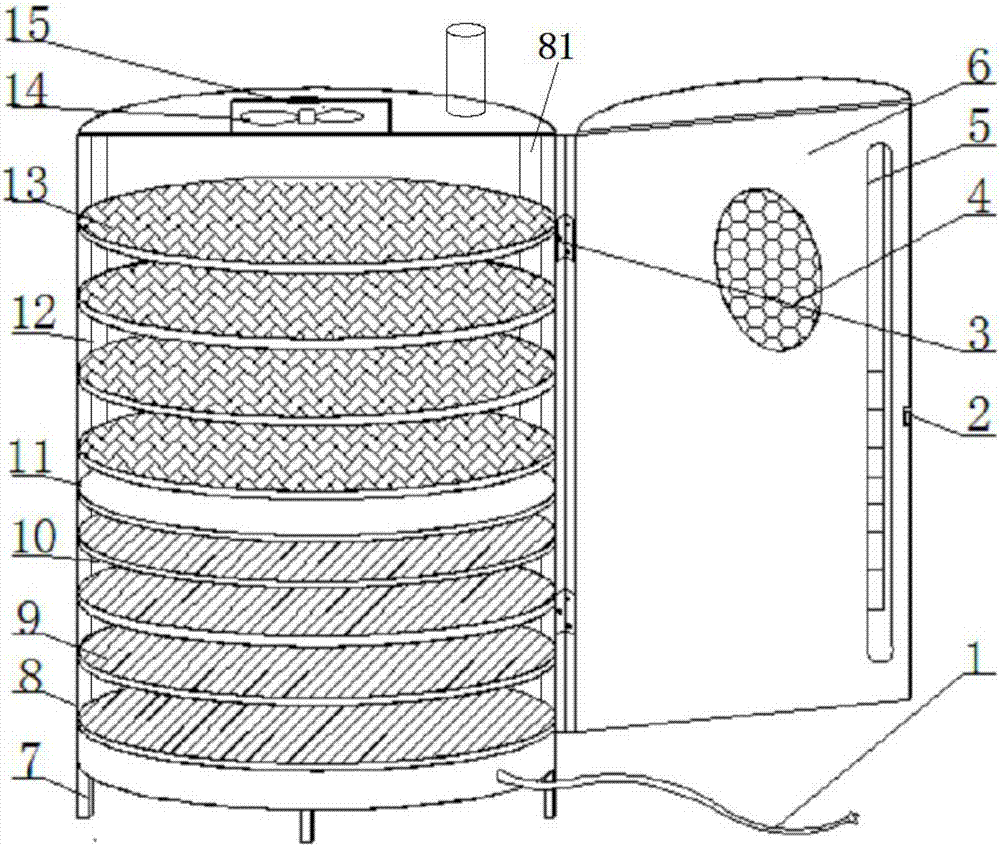

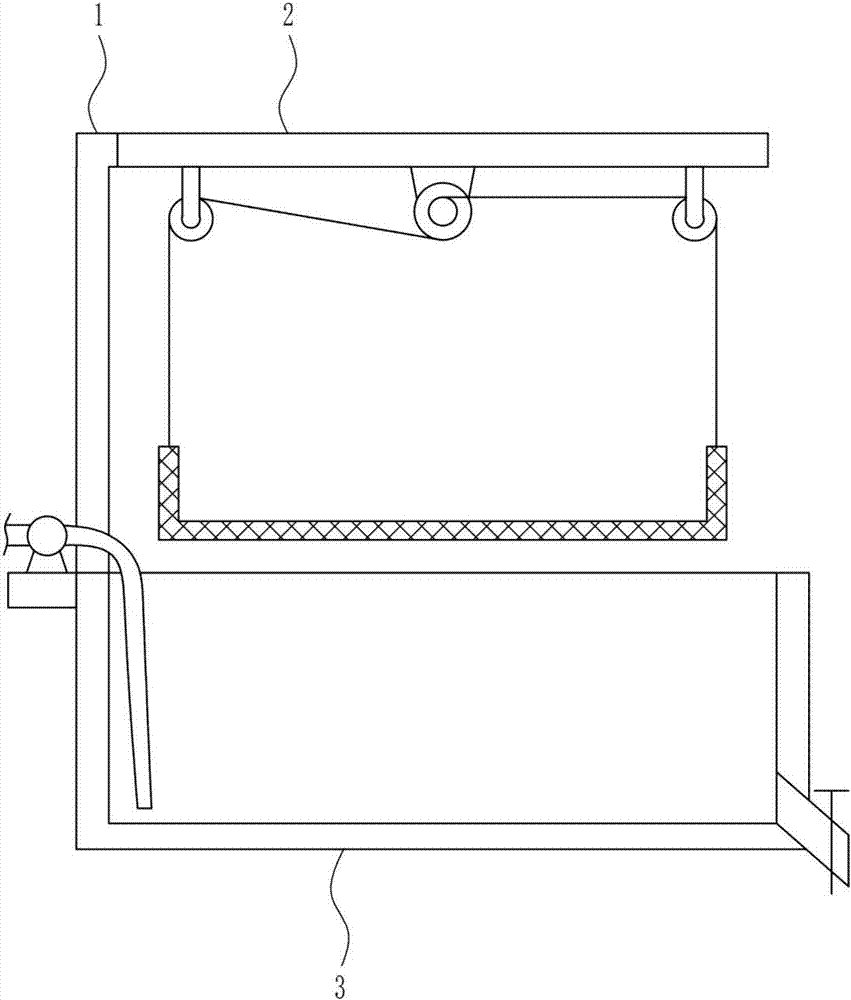

PCB (Printed Circuit Board) drying device

InactiveCN107231759AShorten drying timeImprove work efficiencyDrying gas arrangementsPrinted circuit dryingSocial benefitsEngineering

The invention discloses a PCB board drying device, comprising a power cord, a handle, a hinge, an observation window, a thermometer, a box door, a bracket, a box body, a first PCB placement board, a drying layer, a partition, an air-drying layer, a first Two PCB placement boards, a fan, a vent, a first card slot and a second card slot. The beneficial effects of the present invention are as follows: the present invention divides the box into a drying layer and an air-drying layer, which is beneficial for different PCB boards to be dried in the box due to different drying environments, and a fan and a ventilation port are installed on the top of the air-drying layer. , provides an air-drying environment for the air-drying layer, shortens the air-drying time, and improves the work efficiency. The first PCB placement board and the second PCB placement board are connected to the inside of the box by card slots, which are slidable, easy to clean, compact in structure, and can be installed and removed. It is convenient, improves efficiency, has good economic and social benefits, and is conducive to promotion.

Owner:姚潘涛

Method for producing flexible metal foil-polyimide laminate

InactiveCN1753775AImprove heat resistanceGood chemical resistanceInsulating substrate metal adhesion improvementSynthetic resin layered productsAdhesiveMetal foil

Owner:SHIN ETSU CHEM IND CO LTD

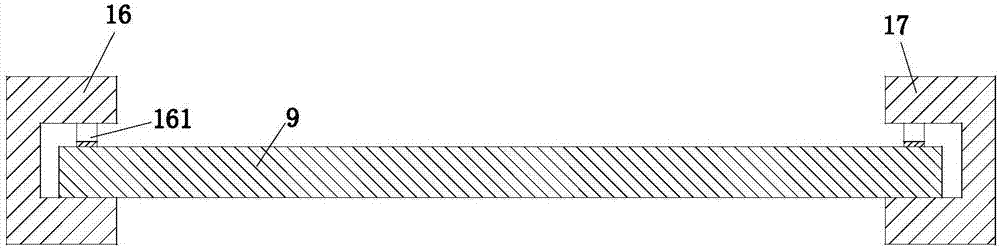

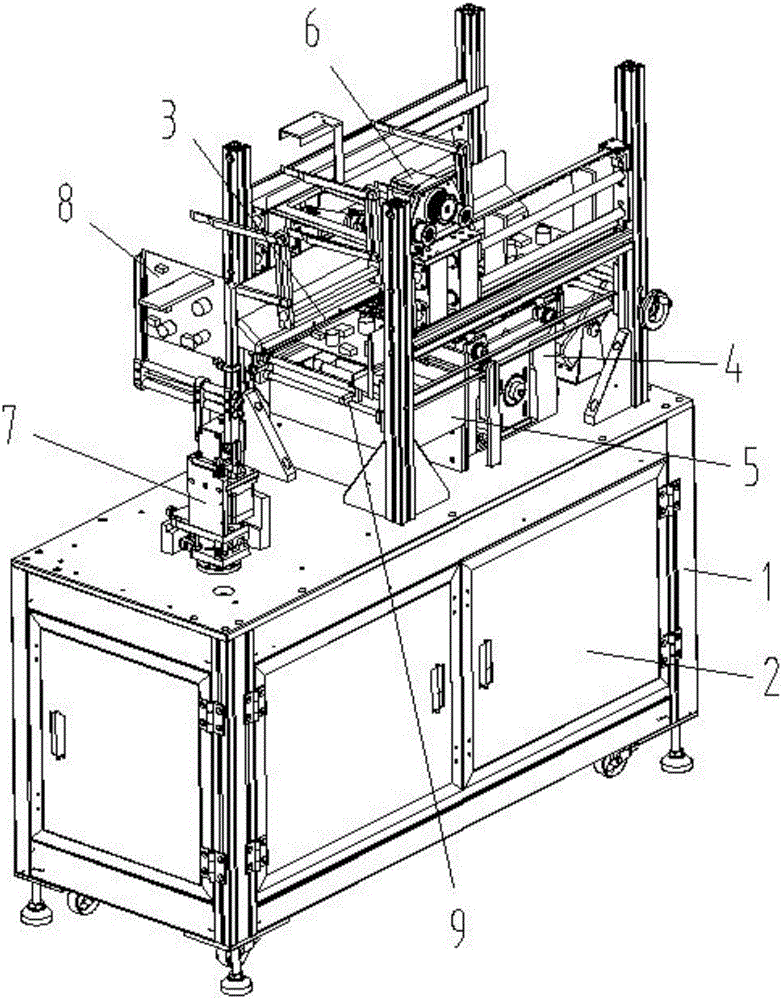

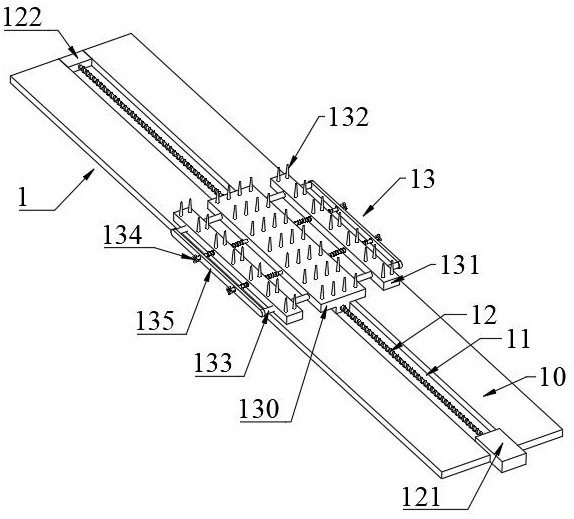

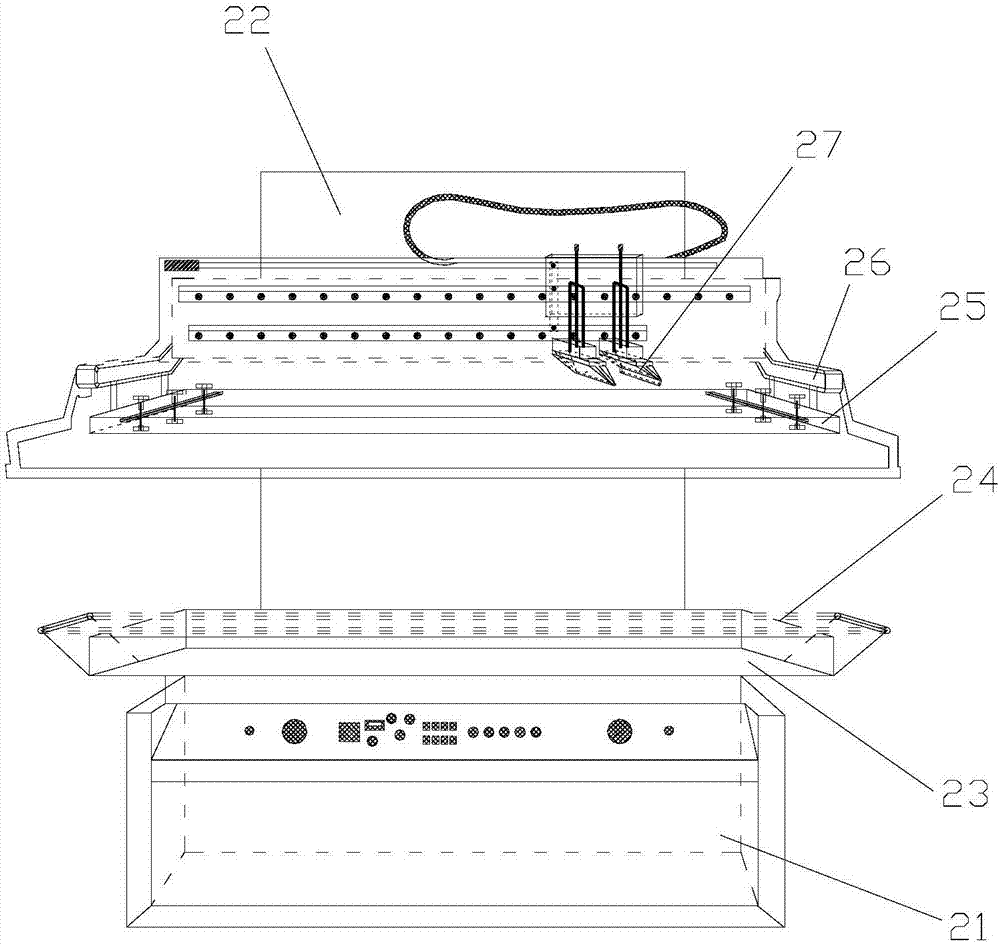

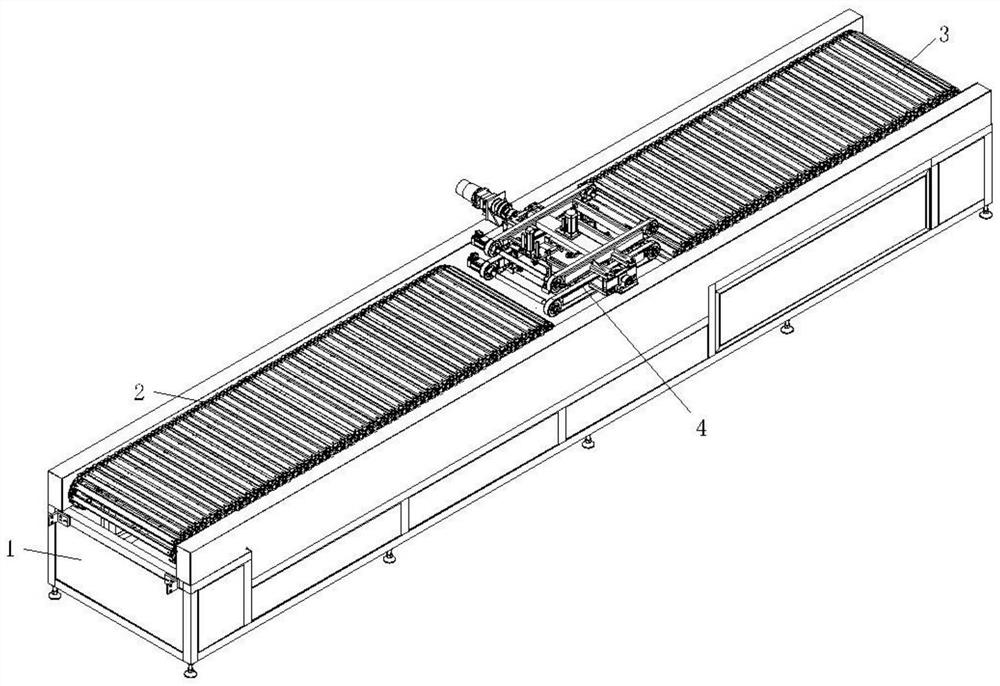

PCB washing mechanism capable of realizing automatic taking and transferring

ActiveCN106793542AImprove reclaimImprove efficiencyPrinted circuit dryingConductive pattern polishing/cleaningDistribution controlButt joint

The invention relates to a PCB washing mechanism capable of realizing automatic taking and transferring. The PCB washing mechanism comprises a rack and a distribution control box. A conveying trough cooperating with a PCB product is formed in the rack; a washing tin-brushing device and a baking device that cooperate with the product arranged above the washing tin-brushing device and the baking device are arranged below the conveying trough successively; a feeding device cooperating with the product arranged above the feeding device is arranged above the conveying trough; and the tail end of the conveying trough is in a butt joint with a drying device of the product by a cooperative overturning and transferring device. The washing tin-brushing device consists of a brush motor and a brush rotating cylinder, wherein the brush motor and the brush rotating cylinder are arranged at the rack and cooperate with each other; and a brush cooperating with the product at the conveying trough sleeves the brush rotating cylinder. According to the PCB washing mechanism, on the basis of cooperation of the conveying trough with the feeding device, feeding of a PCB is realized; automatic material taking and transferring are realized by the overturning and transferring device at the tail end of the conveying trough, so that the PCB taking and transferring efficiency can be improved; and a scratch caused by manual taking and placing can be avoided, so that the yield of the PCB after washing can be guaranteed.

Owner:DONGGUAN UNIV OF TECH

Method for bonding reinforcing plate

InactiveUS20050000645A1Rule out the possibilityPrevent surfaceInsulating substrate metal adhesion improvementPrinted circuit detailsAdhesiveEngineering

A method for bonding a reinforcing plate to a flexible substrate, the method comprising the steps of: laminating a sheet-shaped thermosetting adhesive on a plate-like polyimide resin to prepare a reinforcing plate; drying the reinforcing plate so that its water content is decreased to the maximum allowable level or less; bonding the reinforcing plate to the flexible substrate through the adhesive by thermocompression bonding; and actually curing the adhesive by heating.

Owner:SHARP KK

Etching and cleaning integrated equipment for flexible circuit boards

ActiveCN107318227AImprove etching effectGood etching effectPrinted circuit dryingConductive material chemical/electrolytical removalFlexible circuitsEngineering

The invention relates to a piece of integrated equipment, in particular to a piece of etching and cleaning integrated equipment for flexible circuit boards. The technical problem to be solved is to provide a piece of etching and cleaning integrated equipment for flexible circuit boards which can protect flexible circuit boards and can clean and dry flexible circuit boards in time after etching. In order to solve the technical problem, the invention provides a piece of etching and cleaning integrated equipment for flexible circuit boards, which includes a mounting rack, and the like. A reaction mechanism is connected to the bottom of the mounting rack. A lifting mechanism is connected to the right end of the mounting rack. As the etching and cleaning integrated equipment for flexible circuit boards has the lifting mechanism and a screen frame, a flexible circuit board can be etched without sacrificing the original shape, and the etching effect is good. As the reaction mechanism is arranged, a flexible circuit board can be fully etched. As a second mounting box and a stirring rod are arranged, a flexible circuit board can be cleaned in time after etching.

Owner:江门市创睿应用技术研究有限公司

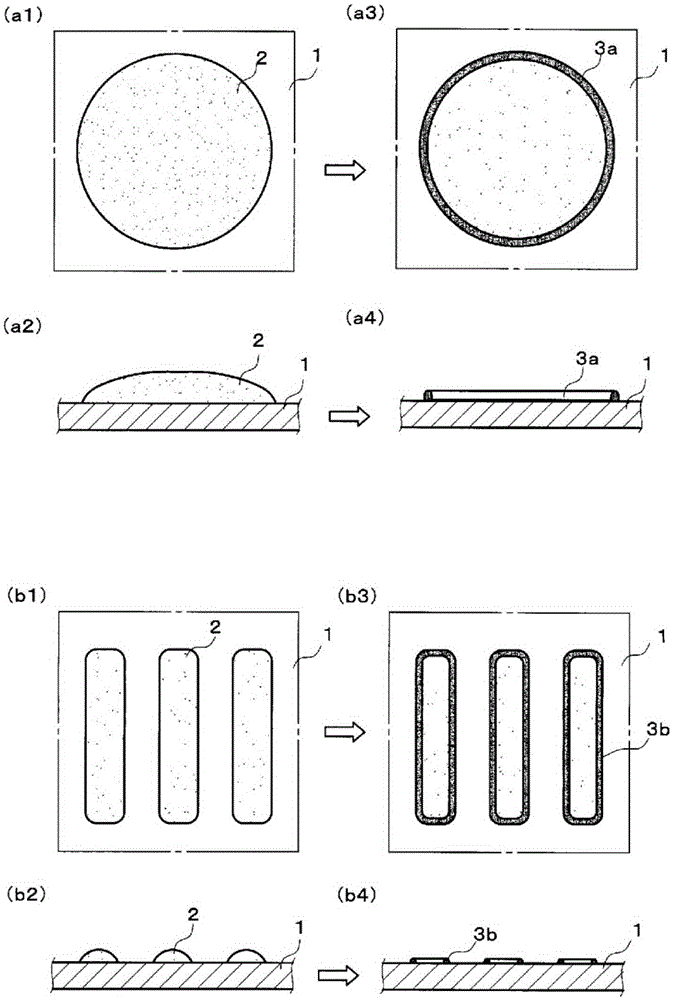

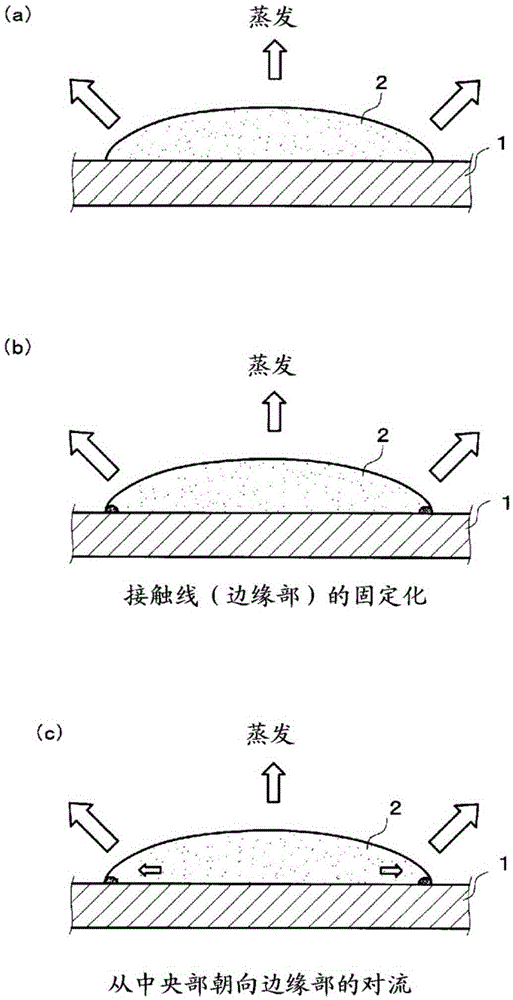

Coating film formation method, base material with transparent conducting film, device and electronic apparatus

ActiveCN105377449AConductive layers on insulating-supportsTransparent dielectricsWire widthEngineering

The purpose of the present invention is to provide a coating film formation method that is capable of stably forming a pattern that includes fine wires having a fine wire width, and is capable of reducing solid residue outside a prescribed patterning position for a fine wire part. In the coating film formation method of the present invention, a coating film with a functional material selectively deposited on an edge part is formed by coating the top of a base material (1) with a liquid that includes the functional material to form a pattern (2) and then drying the pattern. The functional material is caused to deposit on the edge part of the coating film because the liquid includes a solvent with a high degree of affinity for the functional material and a solvent with a low degree of affinity for the functional material.

Owner:KONICA MINOLTA INC

Substrate processing method

ActiveUS8821974B2Pattern collapse can be suppressed or preventedOther chemical processesPhotomechanical apparatusSolventChemistry

A liquid hydrophobizing agent is supplied to a substrate and a surface of the substrate is hydrophobized. A solvent, lower in surface tension than water and capable of dissolving the hydrophobizing agent, is supplied to the substrate in a pre-drying rinsing step. Thereafter, the substrate is dried. The substrate to be processed is maintained in a state of not contacting water until it is dried after being hydrophobized.

Owner:DAINIPPON SCREEN MTG CO LTD

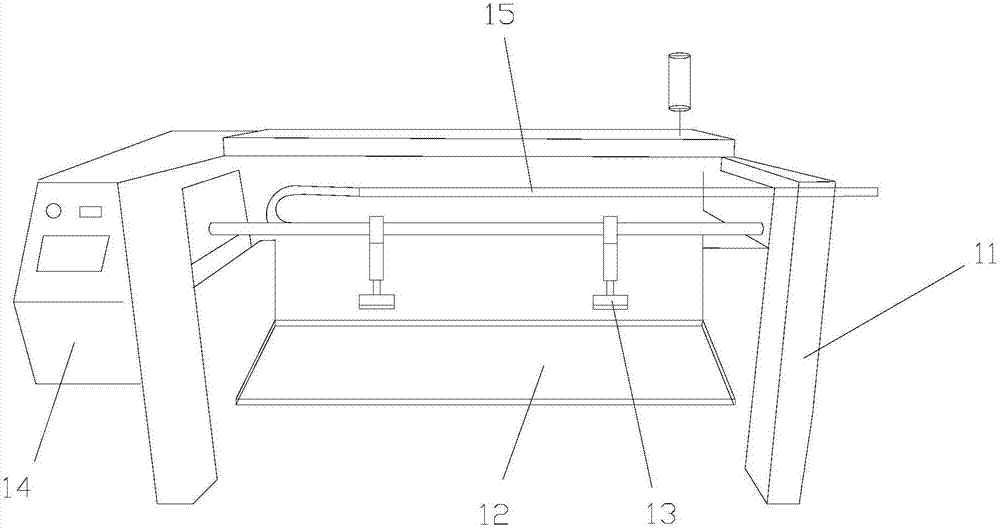

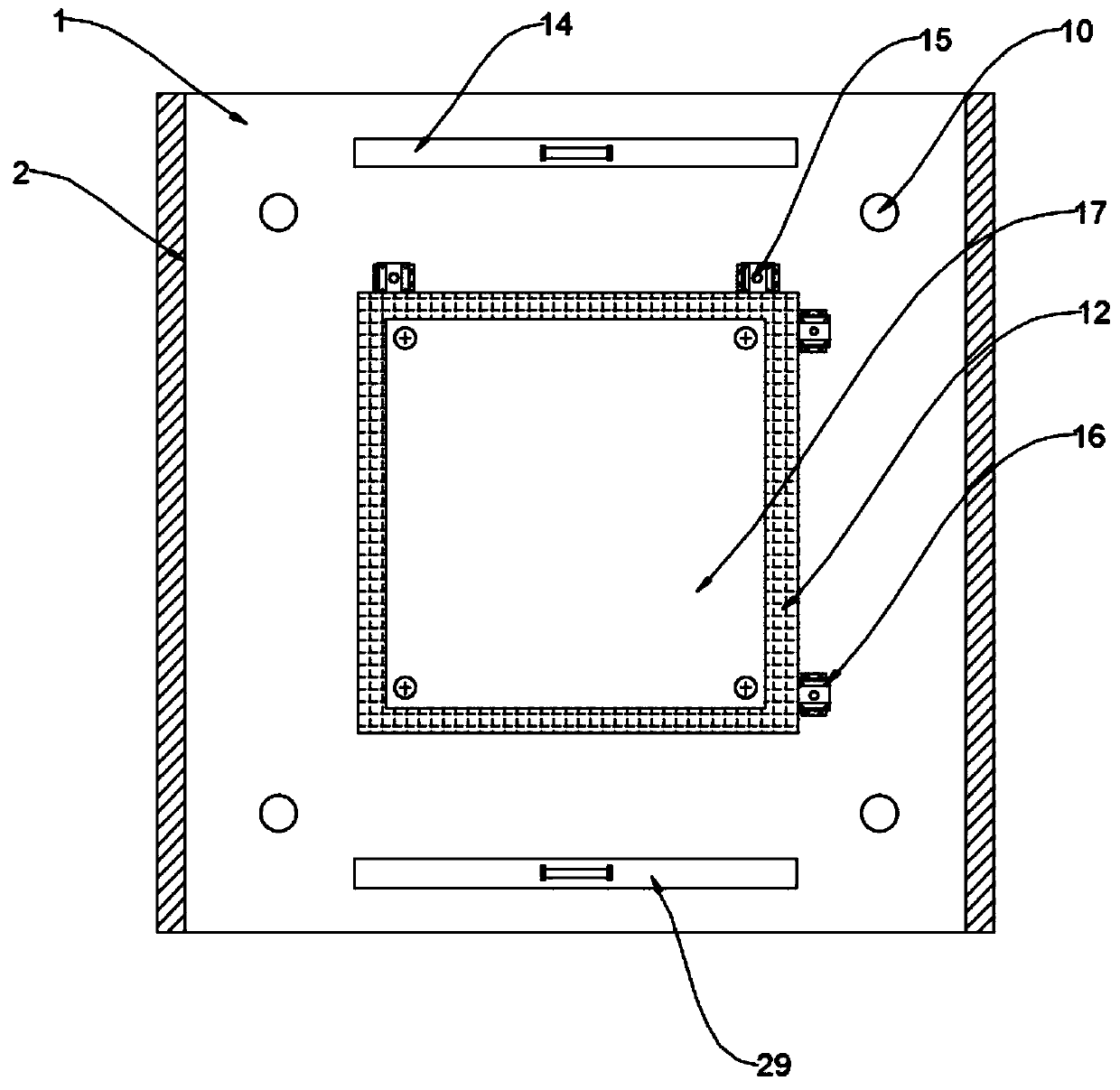

Printed circuit board via hole semi-windowing processing device and processing method

ActiveCN113038728AEnsure complete removalAvoid affecting the welding areaGrinding machinesPrinted circuit dryingScreen printingElectric machinery

The invention provides a printed circuit board via hole semi-windowing processing device and method. The device comprises a first conveying mechanism, a baking mechanism, a second conveying mechanism, and a board grinding mechanism; the first conveying mechanism comprises a conveying guide rail and a printed circuit board supporting assembly arranged on the conveying guide rail, and the printed circuit board supporting assembly is used for bearing and supporting a printed circuit board to be dried; the second conveying mechanism comprises a pair of longitudinal linear mechanisms arranged in a spaced mode and an adjusting frame connected to linear guide rails of the longitudinal linear mechanisms, and two clamping assemblies are arranged on the adjusting frame; and the board grinding mechanism comprises a transverse linear assembly, a grinding lifting air cylinder, a grinding lifting air cylinder, a grinding motor and a grinding head. Between a hole plugging process of semi-windowing via hole processing and a screen printing plate surface resistance welding process, printed circuit board hole plugging ink is dried in an automatic mode, the situation that after-baking is carried out after development, ink overflows and influences a welding area is avoided, board grinding is automatically carried out on an intersecting windowing area to remove ink, and the resistance welding quality is guaranteed.

Owner:四川英创力电子科技股份有限公司

Screen printing method of thick copper printed circuit board

ActiveCN106211609AReduce consumptionSolve the problem of substandard thicknessConductive pattern formationPrinted circuit dryingCooking & bakingScreen printing

The invention relates to a screen printing method of a thick copper printed circuit board. The method comprises the following steps of board polishing, oil mixing, first ink screen printing, first pre-baking, second ink screen printing, second pre-baking, alignment and exposure and developing. According to the screen printing method of the thick copper printed circuit board, twice ink screen printing is carried out. In the first ink screen printing, an ink ribbon surrounding a copper circuit is formed in a base material region and close to the edge of the copper circuit; and the ink ribbon is used for reducing the fall between the relatively thick copper circuit and the base material surface. In the second ink screen printing, coverage ink screen printing is carried out on a copper circuit region and a base material region. Through the method, the problem that the ink thickness on the edge of the copper circuit of the thick copper printed circuit board is not up to standard is solved; and the yield of a product is improved.

Owner:东莞万钧电子科技有限公司

Method for producing flexible metal foil-polyimide laminate

InactiveUS20060191632A1Increase resistanceHigh bonding strengthInsulating substrate metal adhesion improvementSynthetic resin layered productsAdhesiveMetal foil

A method for preparing a flexible metal foil / polyimide laminate is characterized by laminating a metal foil and a polyimide film, with a heat resistant adhesive interleaved therebetween, on a heating roll press, and heat treating the laminate for removing the residual solvent from the adhesive layer and heat curing the adhesive layer.

Owner:SHIN ETSU CHEM IND CO LTD

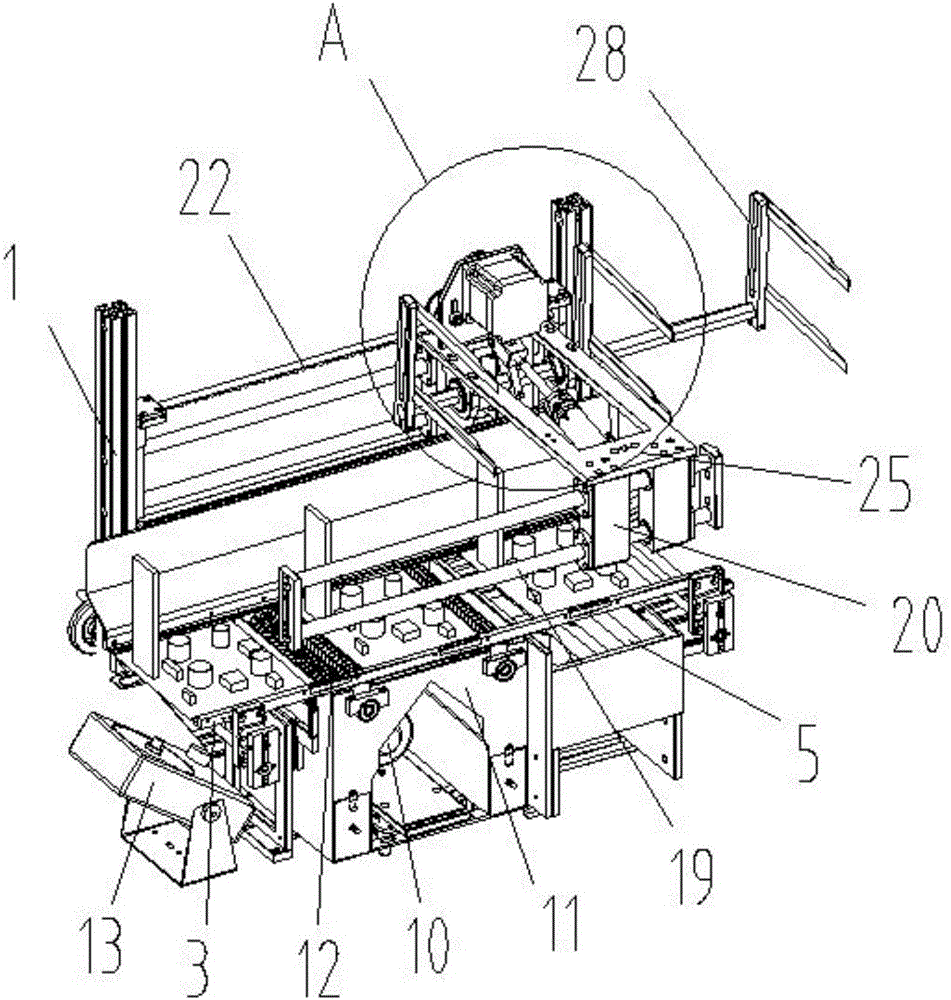

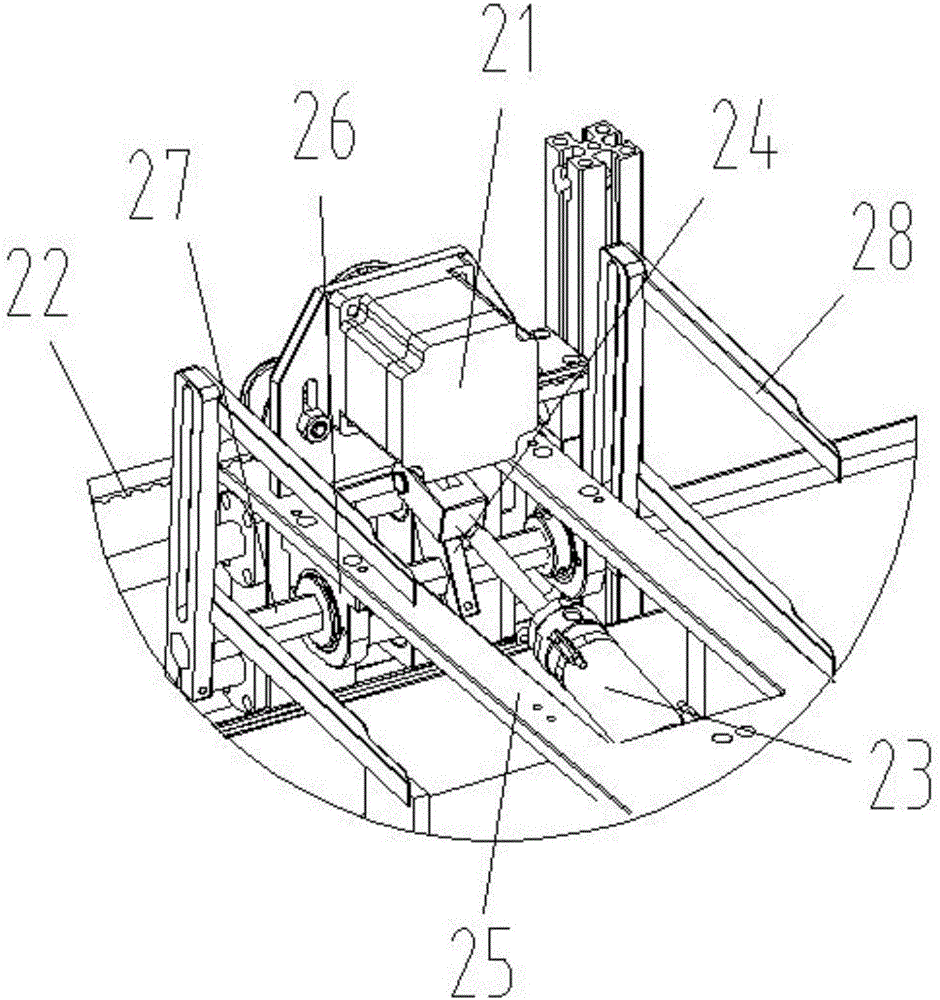

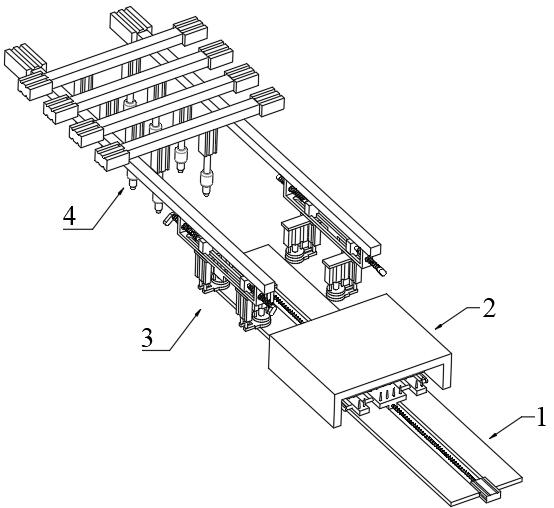

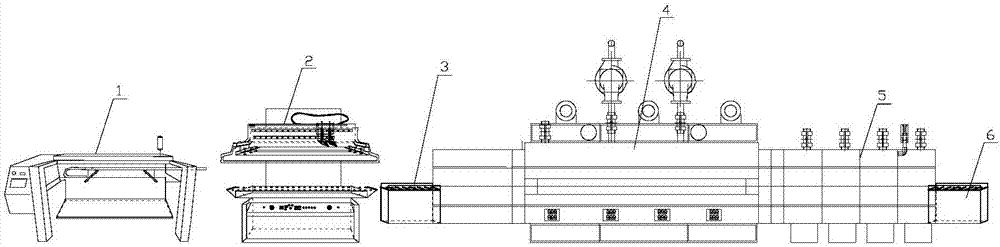

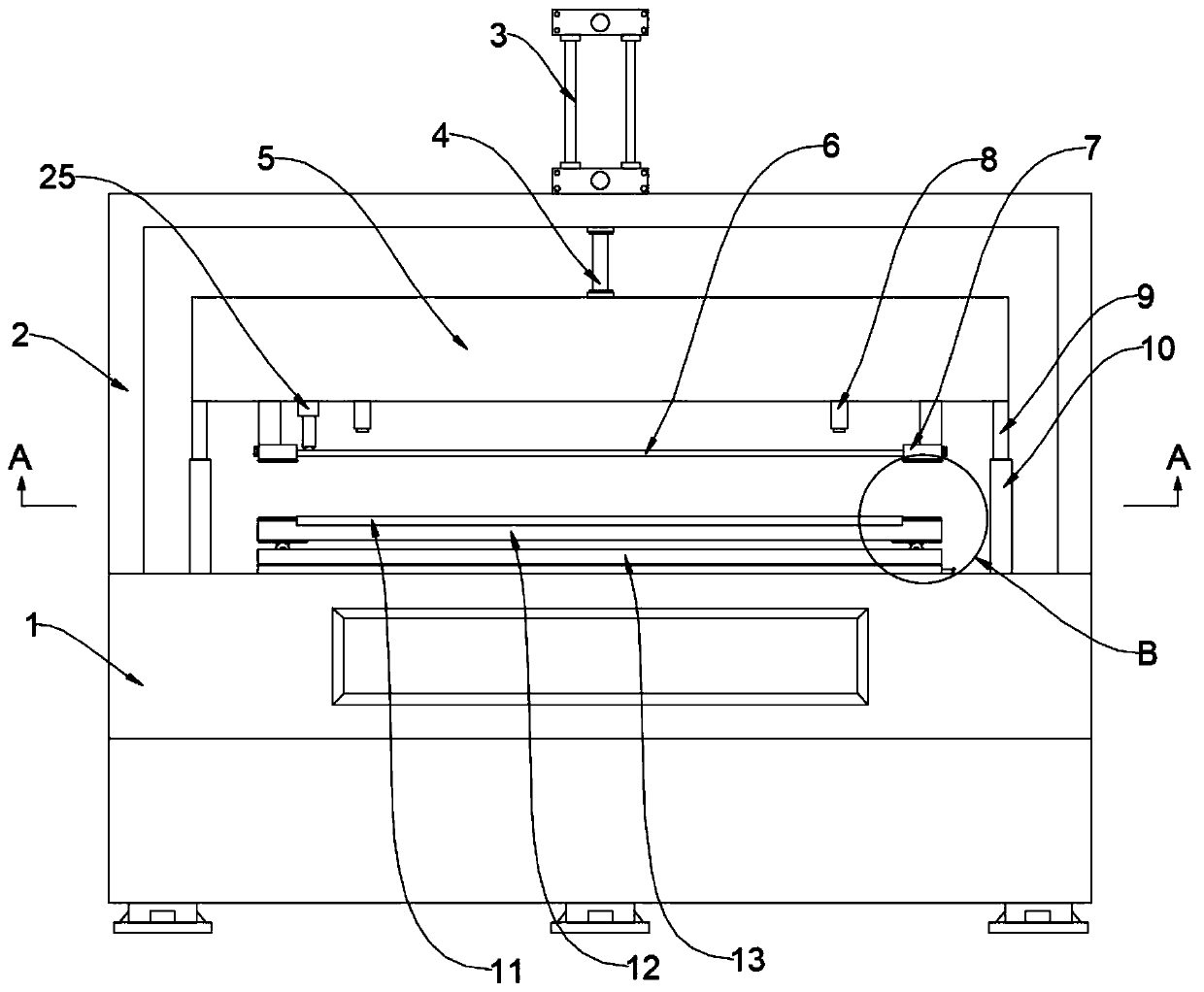

Fast and automatic production system and method for procedures of screen printing and baking of circuit board

ActiveCN107454755AImprove the level of intelligenceHigh degree of automationPrinted circuit dryingScreen printingAtmospheric pressure

The invention discloses a fast and automatic production system and method for procedures of screen printing and backing of a circuit board, and relates to the technical field of circuit board production. The fast and automatic production system comprises an electric pneumatic manipulator, a screen printing machine, an inspection conveyer belt, a tunnel furnace, a cooling device and a movable board collecting platform, and is characterized in that the screen printing machine is arranged at the rear side of the electric pneumatic manipulator, the inspection conveyor belt is arranged at the rear side of the screen printing machine, the tunnel furnace is arranged at the rear side of the inspection conveyor belt, the cooling device is arranged at the rear side of the tunnel furnace, and the movable board collecting platform is arranged at the rear side of the cooling device. The fast and automatic production system is high in production speed, high in efficiency and low in labor cost. The actions such as board taking, board sleeving, printing and conveying are all completed by the machinery, and even the baking and curing time is reduced from 1 hour in a vertical oven to 5 minutes in the tunnel furnace. Abnormities brought about by handling are reduced, and the quality is improved. The fast and automatic production system can avoid abnormities caused by scratching or wiping off the character ink and can avoid abnormities such as board falling in the transportation process, the quality is improved, and the yield is more guaranteed.

Owner:厦门利德宝电子科技股份有限公司

Circuit board printing device

PendingCN110789220AImprove drying efficiencyReduce the valueScreen printersConductive pattern formationEngineeringDrying time

The invention discloses a circuit board printing device, and relates to the related field of circuit board printing. The problem that in the prior art, in the drying process, heat is dissipated, heatis not concentrated on the printing portion, and consequently, drying time is long can be solved. The middle of the rear end of the upper end face of a worktable is provided with a first drying device, a second drying device is arranged in the middle of the front end of the upper end face of the worktable, the first drying device and the second drying device are connected with the worktable through sliding strips, the first drying device and the second drying device are embedded in the worktable, and the first drying device and the second drying device each comprise an outer frame, a placing groove, a connecting telescopic rod, a drying plate, a moving groove, a drying area, a drying device supporting plate and a pressure spring.

Owner:SUZHOU HUILIYUAN TECH CO LTD

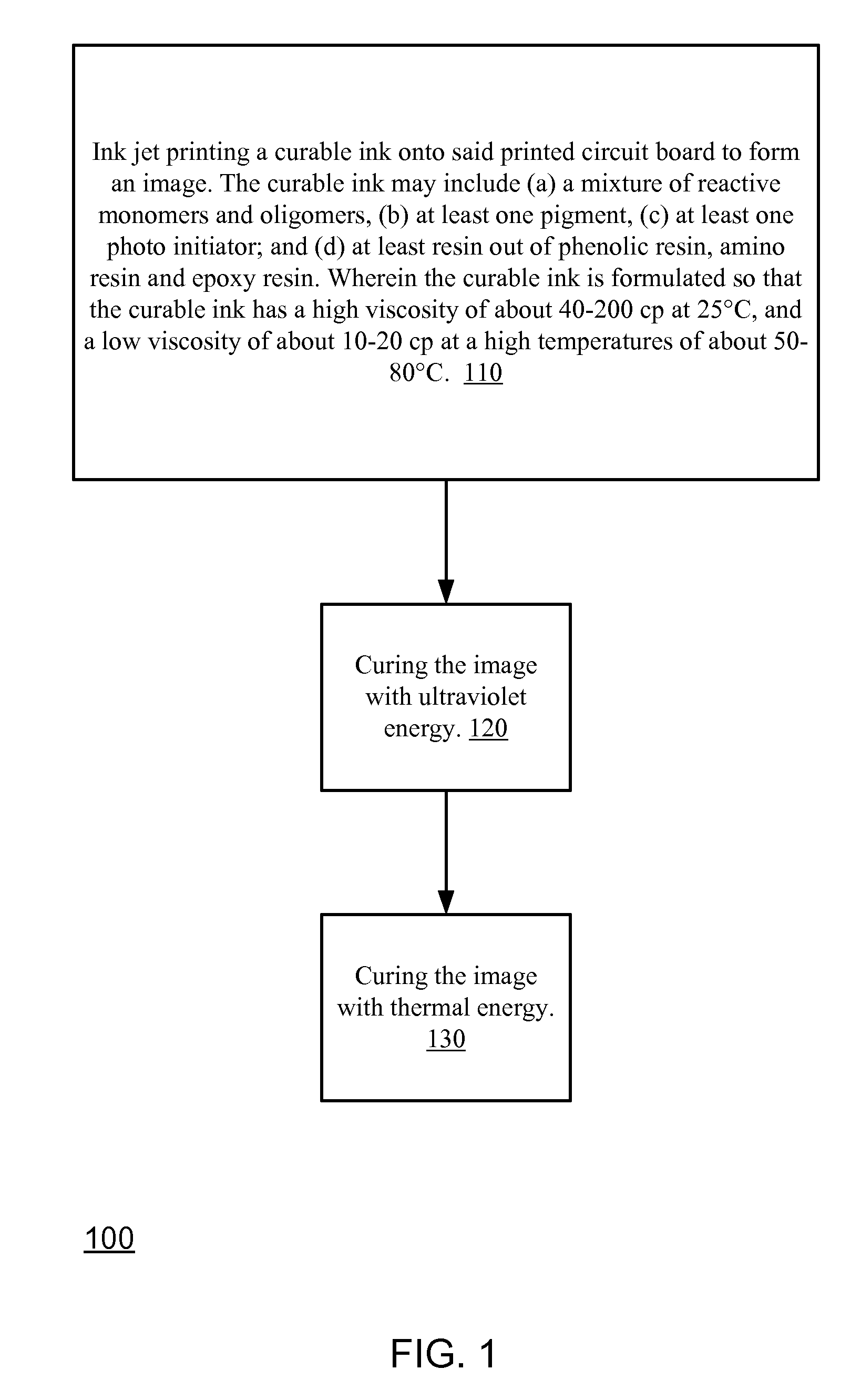

Curable ink and a method for printing and curing the curable ink

A method for printing onto a printed circuit board comprising: ink jet printing a curable ink onto said printed circuit board, ultraviolet curing of the curable ink; and curing the curable ink with thermal energy; wherein the curable ink comprises a mixture of reactive monomers and oligomers; at least one pigment; at least one photo initiator; and at least one resin out of phenolic resin, amino resin and epoxy resin.

Owner:CAMTEK LTD

Method for bonding reinforcing plate

InactiveCN1578584AProtection against surface mount defectsInsulating substrate metal adhesion improvementPrinted circuit detailsAdhesiveEngineering

A method for bonding a reinforcing plate to a flexible substrate, the method comprising the steps of: laminating a sheet-shaped thermosetting adhesive on a plate-like polyimide resin to prepare a reinforcing plate; drying the reinforcing plate so that its water content is decreased to the maximum allowable level or less; bonding the reinforcing plate to the flexible substrate through the adhesive by thermocompression bonding; and actually curing the adhesive by heating.

Owner:SHARP KK

Process for producing conductive coating film, and conductive coating film

InactiveUS20140141238A1Efficient removalReduce oxideConductive layers on insulating-supportsSurface layering apparatusConductive coatingMetal powder

An object of the present invention is to provide a conductive coating film formed on a polyimide-based insulating substrate by using a metal powder paste which can exhibit a good conductivity and good adhesion to the insulating substrate. By forming a resin cured layer having a solvent-soluble content of not more than 20% by weight and a thickness of not more than 5 μm on a polyimide-based insulating substrate; forming a metal powder-containing coating layer on the resin cured layer by using a metal powder paste; and then subjecting the resulting coating layer to heat treatment with superheated steam, it is possible to obtain a conductive coating film which can exhibit a good conductivity and good adhesion to the insulating substrate.

Owner:TODA IND +1

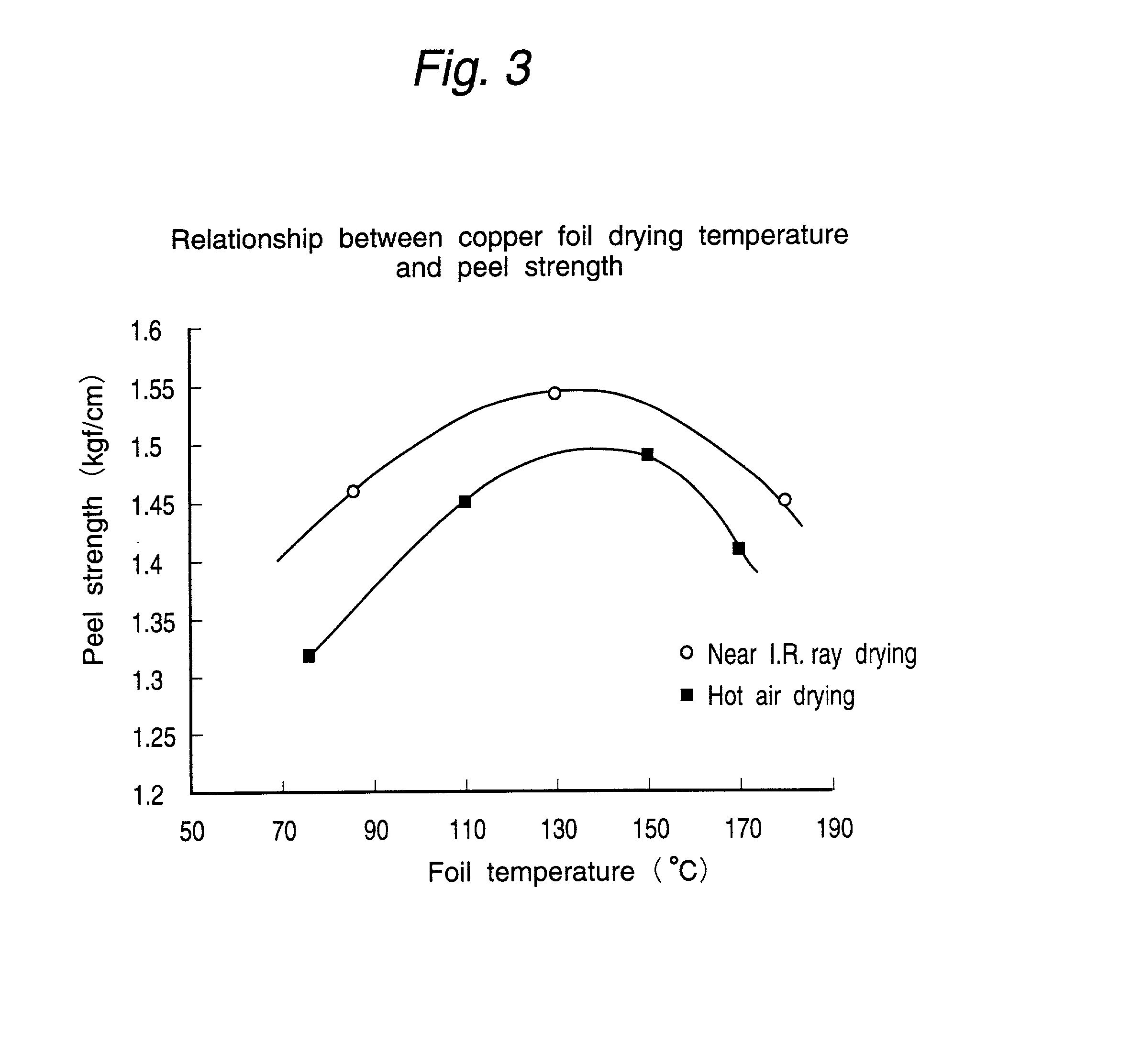

Method of drying copper foil and copper foil drying apparatus

InactiveUS20010046458A1High bonding strengthCapability of heating and dryingInsulating substrate metal adhesion improvementDrying solid materials with heatInfraredCopper foil

A method employed to dry a copper foil having been subjected to various surface treatments, which method comprises irradiating at least one surface-treated side of the copper foil with near infrared rays to dry the copper foil, and an apparatus suitable to the method. The drying of the copper foil having undergone surface treatments can be accomplished by a simple apparatus with low electric power while controlling the heating of the surface of the copper foil so that the drying temperature can be held at 100° C. or higher at which a eutectic alloying of rust preventive metal and copper foil, for example, alloying (brass formation) of zinc and copper on the surface of the copper foil is effected.

Owner:IMADA NOBUYUKI +1

Desmearing method and desmearing device

ActiveUS20150351251A1Great oxidizabilityReliable removalCarpet cleanersFloor cleanersUltravioletVibration treatment

Provided are a desmearing method and a desmearing device which are able to reliably remove a smear derived from any of an inorganic substance and an organic substance, and eliminate the need to use a chemical that requires a waste liquid treatment. The desmearing method of the present invention is directed to a desmearing method for a wiring substrate material that is a laminated body of insulating layers made from resin containing a filler and a conductive layer, and includes an ultraviolet irradiation treatment step for irradiating the wiring substrate material with ultraviolet beams with a wavelength of 220 nm or less, and a physical vibration treatment step for applying physical vibrations to the wiring substrate material which has undergone the ultraviolet irradiation treatment step.

Owner:USHIO DENKI KK

PCB tunnel drying device

InactiveCN112595080ARealize automatic flipSave time in transitDrying machines with progressive movementsDrying solid materialsClassical mechanicsEngineering

The invention discloses a PCB tunnel drying device. The PCB tunnel drying device comprises a base, a first electric conveying belt, a second electric conveying belt, a turnover mechanism, a feeding mechanism, a tunnel drying box, a first electric gate, an infrared grating, a cooling device and a second electric gate plate. The first electric conveying belt is arranged on the front side of the topend of the inner side of the base in the front-back direction. The second electric conveying belt is arranged on the rear side of the top end of the inner side of the base in the front-back direction.The turnover mechanism is arranged in an inner cavity of the base and located on the inner side of the first electric conveying belt and the inner side of the second electric conveying belt. The feeding mechanism is arranged on the front side of the base. According to the PCB tunnel drying device, integrated operation of feeding, drying and cooling of PCBs can be achieved, manual operation itemsof workers and transfer time between different devices are reduced, automatic overturning of the circuit boards during tunnel drying can be achieved, the workers do not need to manually turn over thecircuit boards for secondary drying, the drying period is shortened, and the machining efficiency is improved.

Owner:董立喜

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com