Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

812results about How to "Solve processing" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Wood-plastic composite material and prepration method thereof

The invention discloses a wood-plastic composite material and a preparation method thereof, and the wood-plastic composite material comprises the following raw materials according to the mixing ratio by parts by weight: 30-80 parts of modified fiber powder; 15-80 parts of plastics; 2-10 parts of phase solvent; 2-10 parts of lubricant; 0-10 parts of stabilizer; 0.2-1.0 part of antioxidant; 5-15 parts of filler; and 2-20 parts of flame retardant. Lignin is utilized for modifying fiber powder, then composition with the plastics is carried out, and a finished-product material is formed by extrusion. The preparation method can solve the problems of the compatibility of wood fibers with the thermoplastic plastics, the surface treatment technology of the raw materials by utilizing the lignin and the like, realize the comprehensive utilization of the lignin and the waste plastics, be capable of replacing wood, increase the additional value of the lignin and solve the utilization problem of the lignin wastes. The manufactured wood-plastic composite material can significantly improve the mechanical performance, the tensile strength, the flexural strength and the impact resistance, and realize the industrial production of high-performance products, such as construction materials.

Owner:BEIJING FORESTRY UNIVERSITY

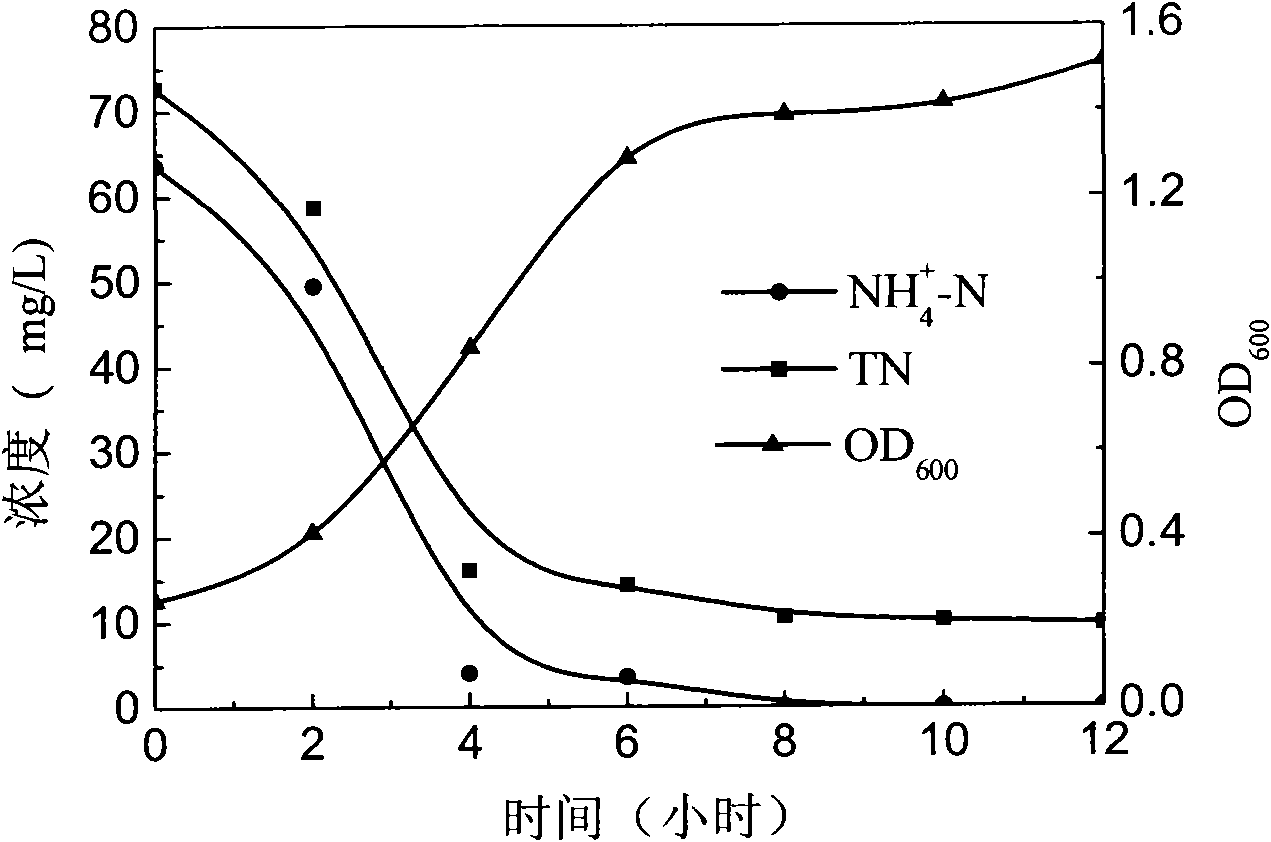

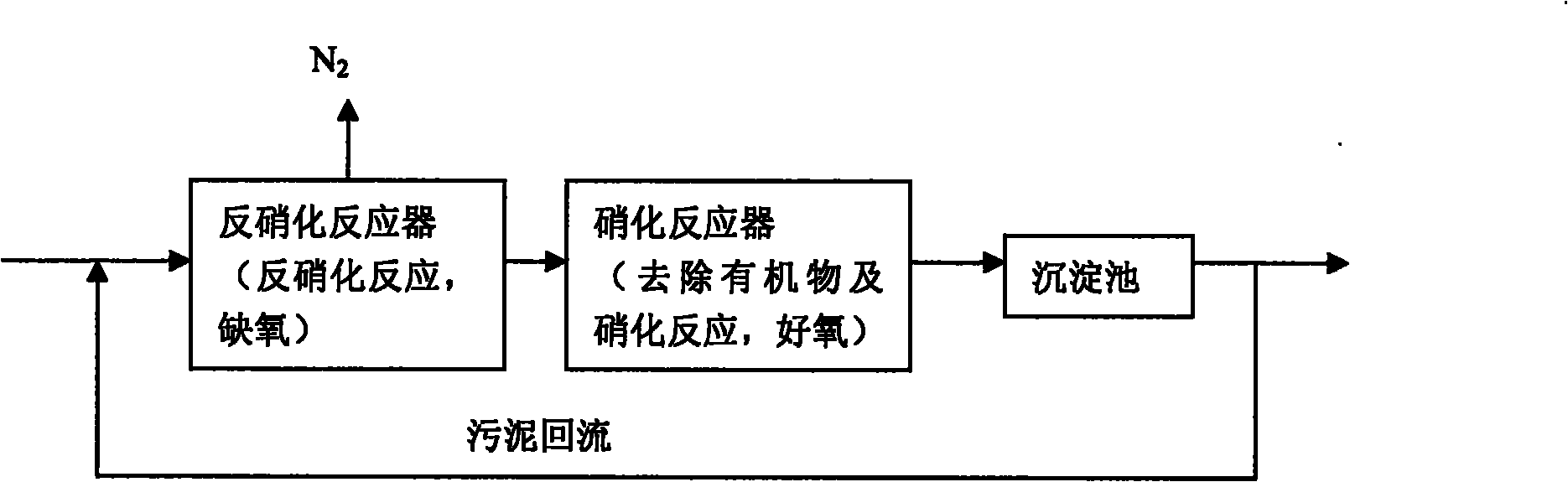

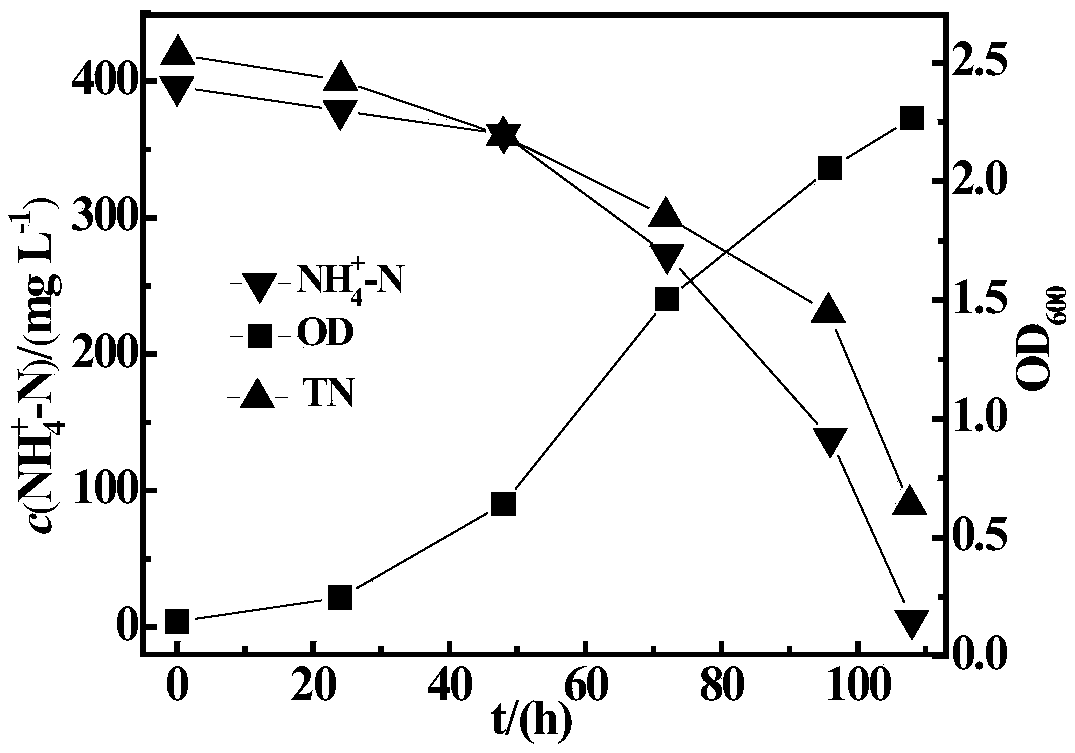

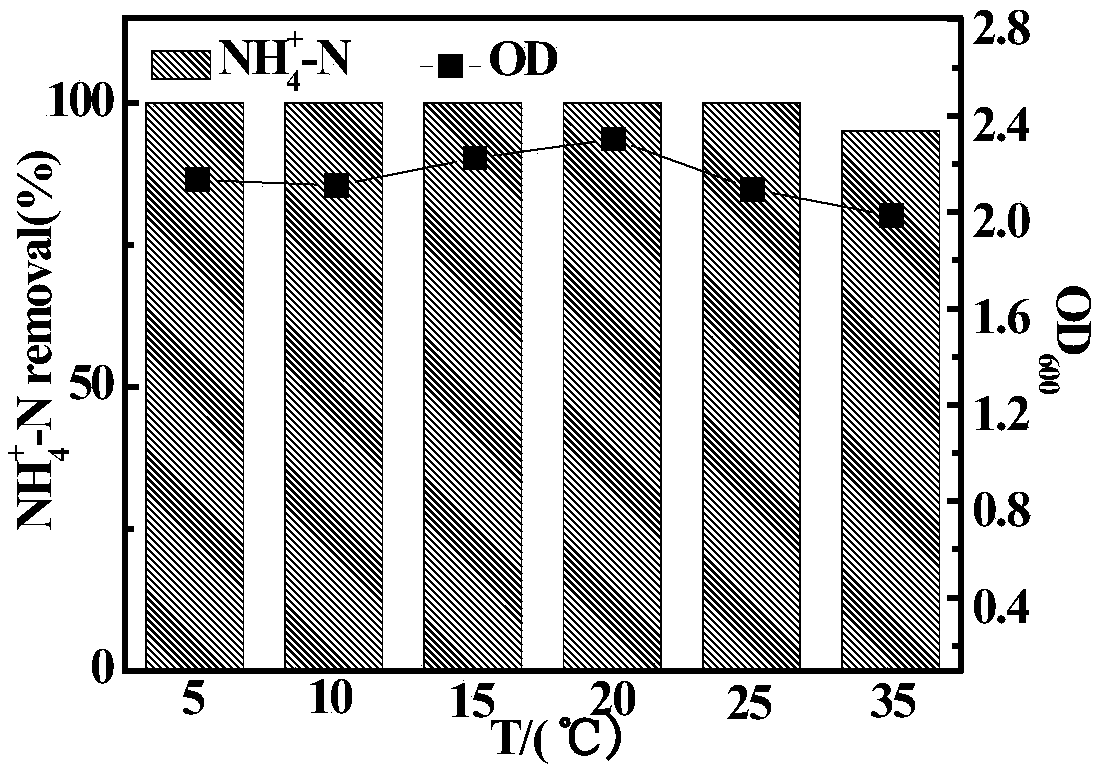

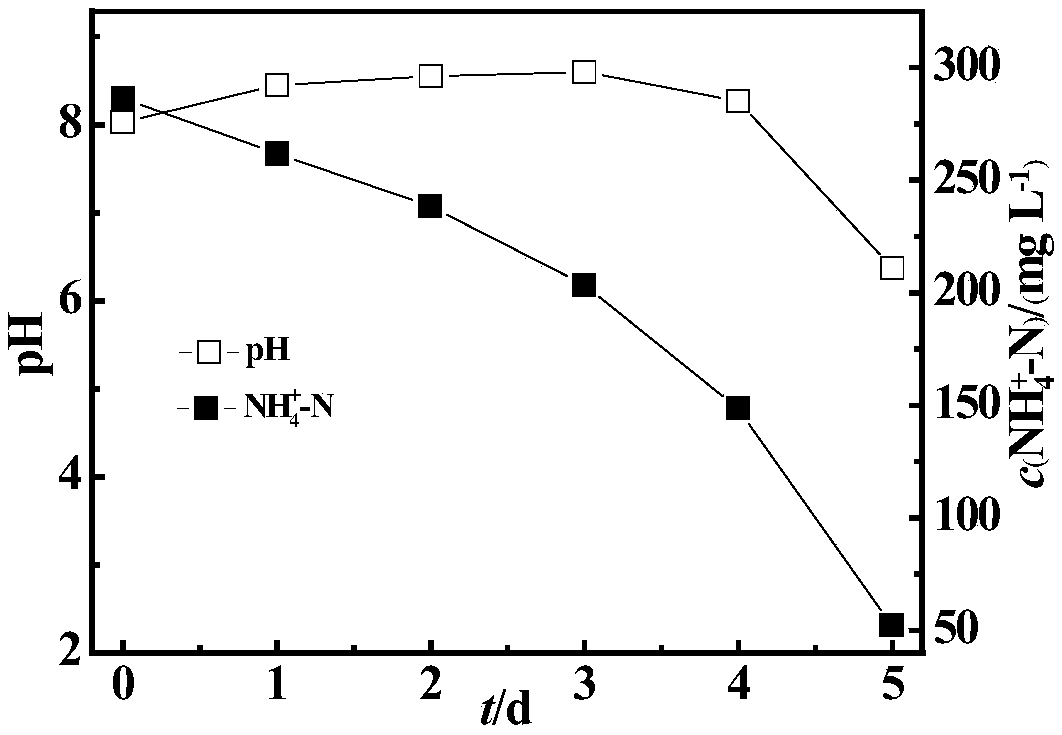

Agrobacterium with heterotrophic nitrification-aerobic denitrification capability and application thereof in nitrogenous effluent treatment

InactiveCN101570738AAnoxic denitrification is needed to solve biological denitrificationSolve processingBacteriaWater contaminantsNucleotideBacterial strain

The invention relates to an agrobacterium strain (Agrobacterium sp.) with heterotrophic nitrification-aerobic denitrification capability and an application thereof in nitrogenous effluent treatment. The bacterial strain is characterized in that: 16S rRNA gene contains nucleotide sequence shown in sequence table with a sequence length of 1418bp and a accession number FJ639330 in Genbank. The preservation number thereof is CGMCC No.2962. The agrobacterium of the invention has not only heterotrophic nitrification capability but also aerobic denitrification capability. During nitrogenous effluent treatment, and one aerobic phase can cause ammonian to change into gaseous product with high denitrification efficiency and easy operation and tremendous economic benefit compared with the traditional biological denitrification process.

Owner:LANGFANG GAIA ENVIRONMENTAL TECH

Method for comprehensively treating high salt content organic industrial wastewater

ActiveCN101585620AUnique methodSimple processMultistage water/sewage treatmentWater/sewage treatment by neutralisationSocial benefitsIndustrial effluent

The present invention provides a method for comprehensively treating high salt content organic industrial wastewater, and relates to the field of the organic material preparing technique. The method of the invention mainly comprises the following steps: executing acid-alkali adjustment to the organic wastewater until pH=7-9, preheating to 30-60 DEG C; introducing the wastewater into a triple effect evaporator for executing triple effect evaporation, executing salting out to the evaporated wastewater which is condensed to a certain degree so that the solid and liquid are separated; separating the concentrated liquid for continuing the condensation; when the separated liquid satisfies a certain requirement, atomizing into an incinerator for incinerating and discharging according to the standard, and introducing the triple effect evaporation condensation water into a biochemical treating system. The method of the invention can totally dispose and remove the organic matter in the high salt content organic industrial wastewater so that the high salt content organic industrial wastewater can be charged according to the standard. The method of the invention has the advantages of unique method, simple technical process, easy operation, low operation cost, large treating capacity, low regeneration energy consumption, no easy forming of secondary pollution after abandon, better economic and social benefit, and wide application range. The method of the invention can be widely applied for the treating of the high salt content organic wastewaters of garbage penetrating fluid, dye intermediate wastewater, etc.

Owner:HEBEI JIANXIN CHEM IND CO LTD

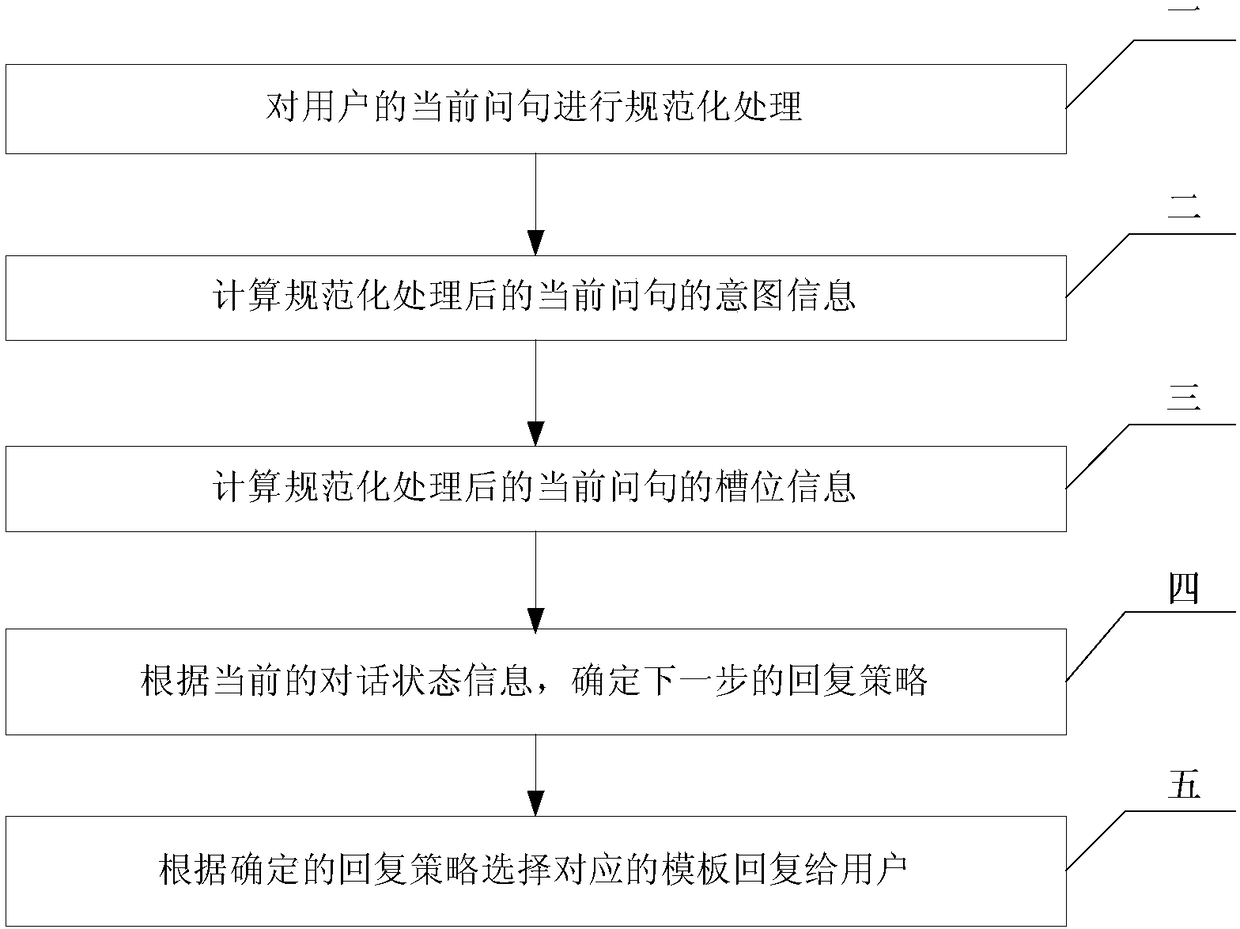

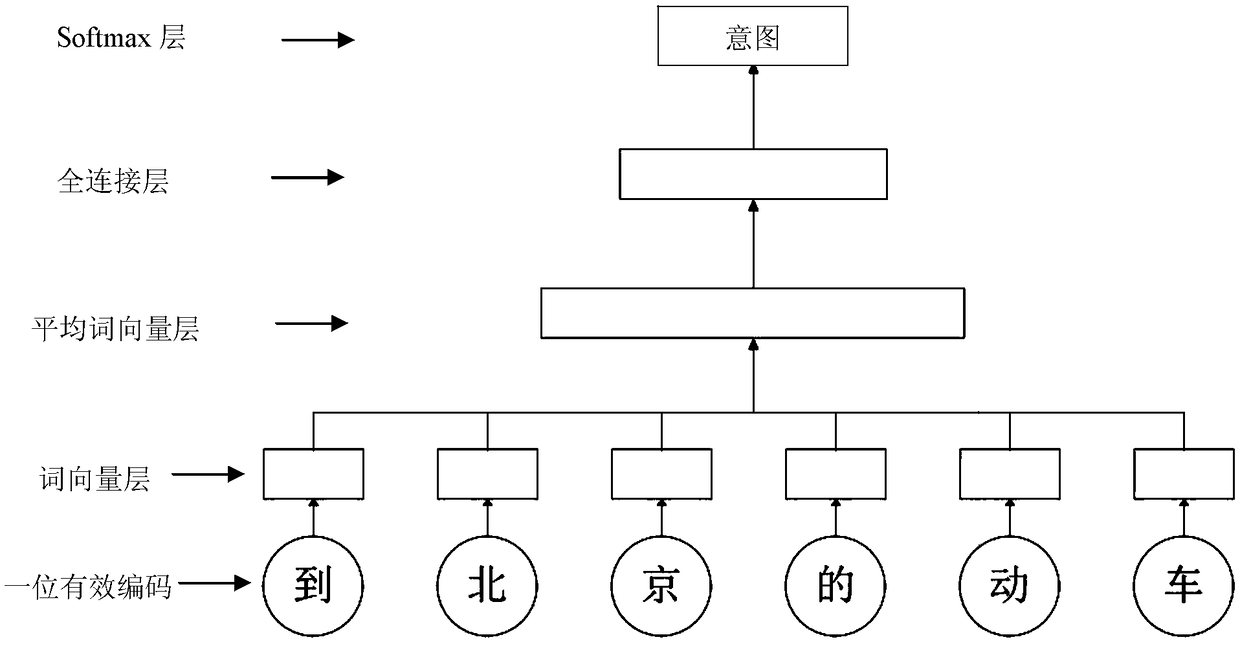

Man-machine multi-round dialogue method oriented to travel field

ActiveCN109063035ASolve processingResolve intent informationMathematical modelsCharacter and pattern recognitionDialog systemMan machine

The invention relates to a man-machine multi-round dialogue method oriented to the travel field, which is used in the information technology field. The invention solves the problem that the current multi-round conversation system has difficulty in extracting the intention information and the slot information of the user question. The invention normalizes the short text question, extracts the intention information of the normalized short text question by using DAN, CNN or BLSTM model, and obtains Micro. F1 value was 93.47%. Using the BLSTM-CRF model to extract the slot information of the normalized short text questions, and the model achieves the ideal effect with F1 value of 89.47%. Taking the historical slot information and the slot information of the current question as inputs, the current conversation state information is determined, and the next reply strategy is determined according to the intention information of the current question. According to the determined reply strategy, the corresponding template is selected to reply to the user. The invention can be applied to the field of information technology.

Owner:HARBIN INST OF TECH

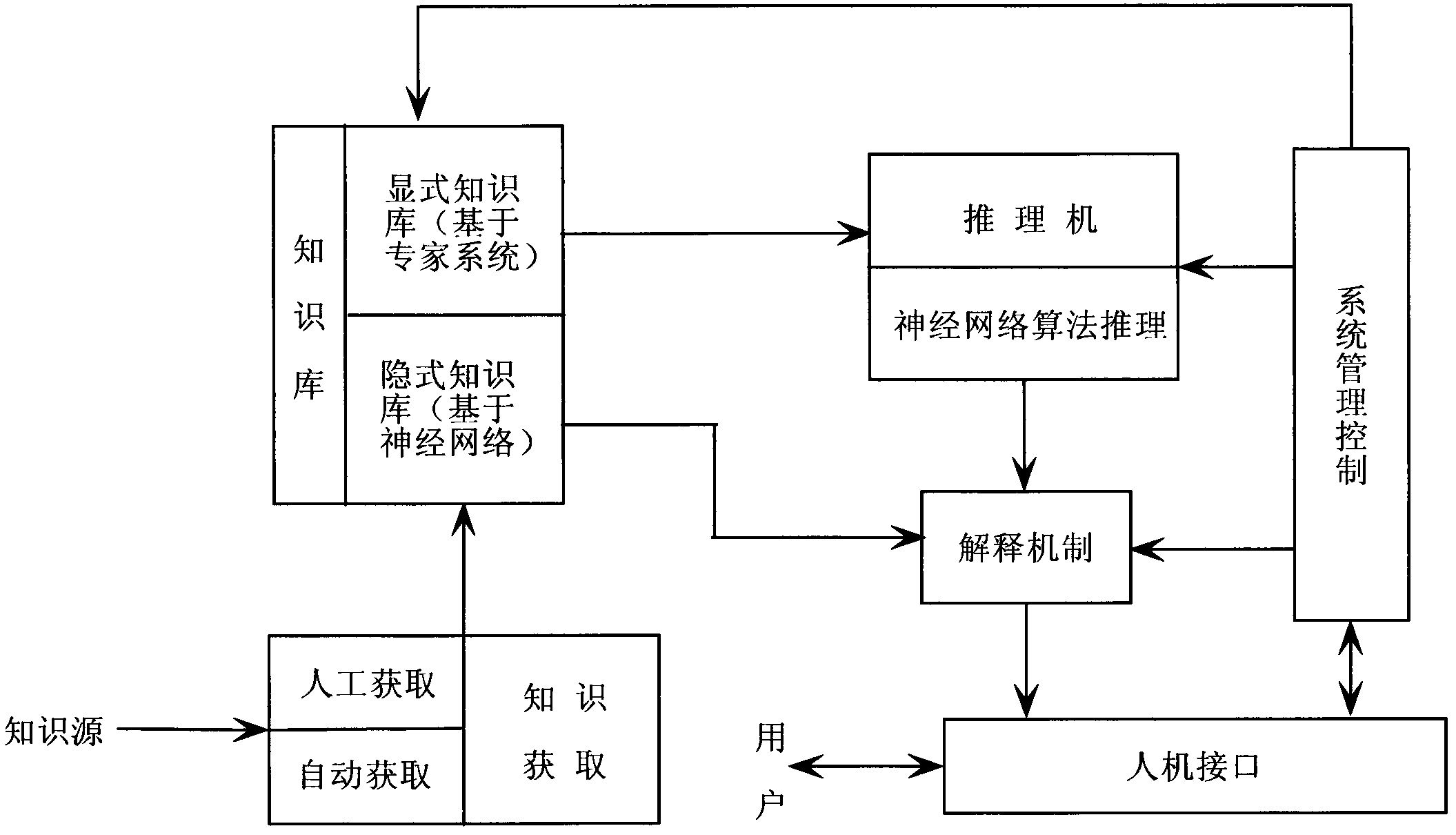

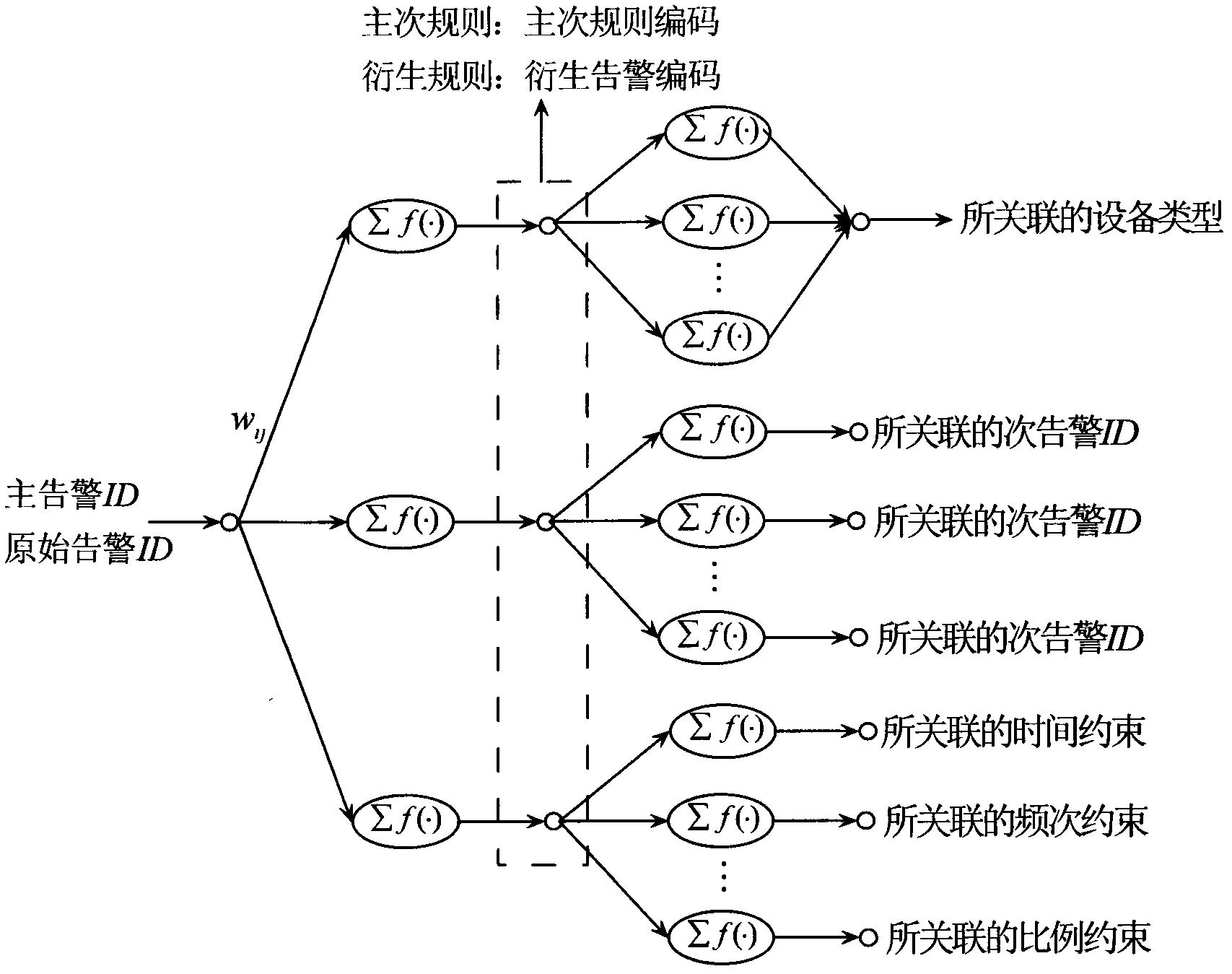

Intelligent alarm monitoring method of neural network

ActiveCN102130783AImplementation of association analysisImprove accuracyData switching networksPositional TechniquePositioning system

The invention provides an intelligent alarm monitoring method of a neural network. A brand-new intelligent communication network comprehensive monitoring analysis and fault locating system is built by adopting an alarm correlation analysis and locating technology based on an expert system of the neural network. The system guarantees effective monitoring of repeated alarming, alarm oscillation, alarm flash and alarm storm by collecting the alarm data of each piece of equipment of each network element system of each major, and filters out a storm alarm, a flash alarm, an invalid alarm and a secondary alarm correctly; and the system can pick out an important alarm event which is really required to be processed from the collected mass alarms based on a deep correlation rule analysis and neural network technology, and can locate and remove a network fault quickly and correctly. The correction rate of network alarm analysis and fault diagnosis can be improved obviously, customer satisfaction is improved, and operating cost and maintenance cost are reduced greatly, so that the aims of reducing the work load of an operator and a maintainer and improving the efficiency of fault management are fulfilled.

Owner:INSPUR TIANYUAN COMM INFORMATION SYST CO LTD

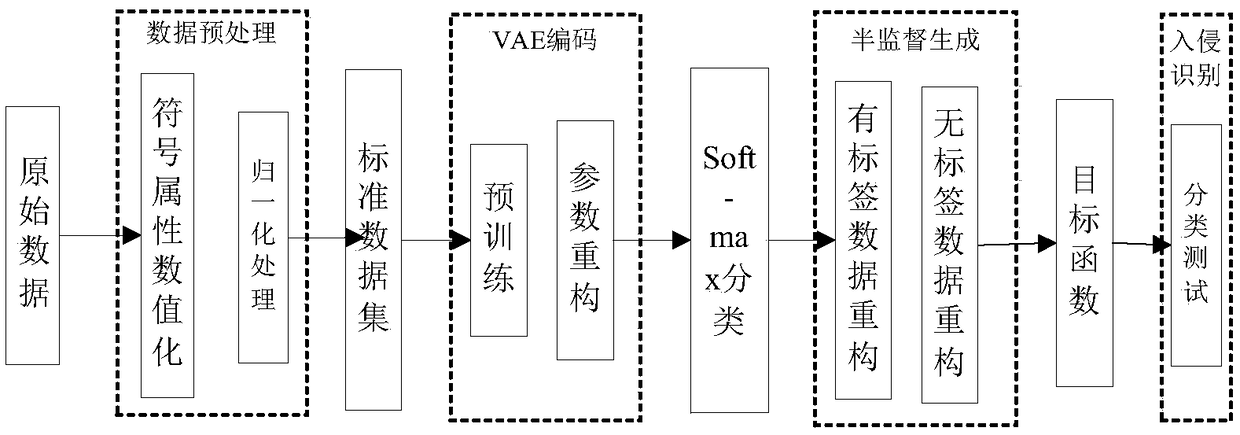

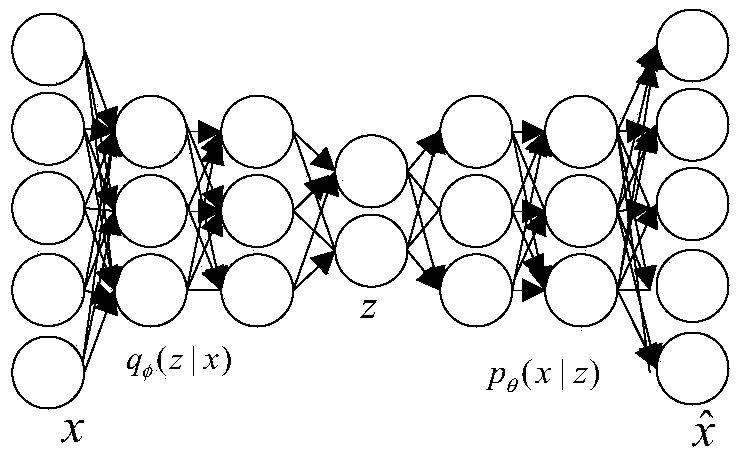

Semi-supervised intrusion detection method based on depth generation model

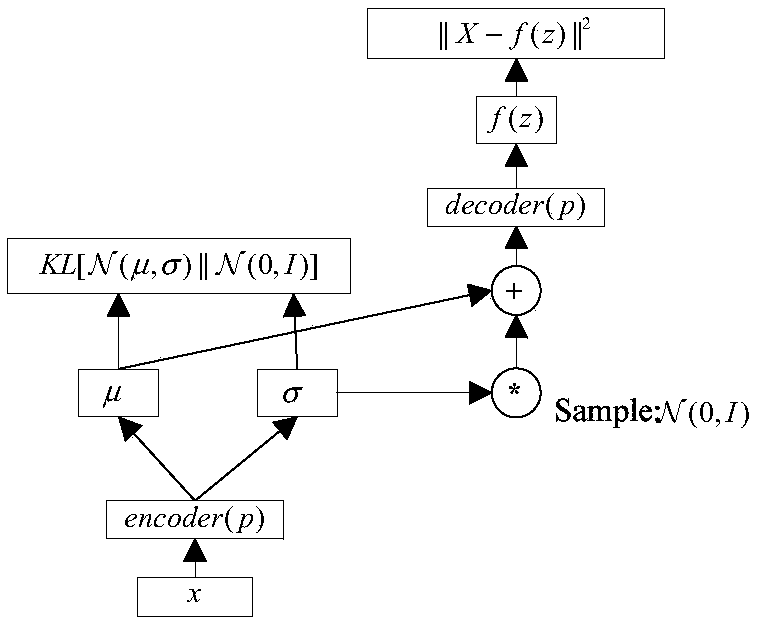

ActiveCN108881196AImprove classification accuracyReduce demandCharacter and pattern recognitionTransmissionFeature vectorComputational model

The invention discloses a semi-supervised intrusion detection method based on a depth generation model. The method comprises the steps of: 1, preprocessing data: converting symbol attributes in a dataset into numerical attributes, and then normalizing all the numerical attributes; 2, converting high-dimensional feature representations of labeled and unlabeled data into low-dimensional representations of a new feature space by using the variational self-encoding technology in the generation model, adding a constraint to low-dimensional feature vectors to obey Gaussian positive distribution soas to obtain a hidden variable z, and training a classifier by using the hidden variable z in combination with a labeled sample; 3, reconstructing labeled sample data: jointly generating a new labeledsample by using the hidden variable z in combination with label class information; 4, reconstructing an unlabeled sample: predicting the probability of each class of an unlabeled sample by using thehidden variable z, and then generating a new unlabeled sample in combination with the hidden variable z; and 5, calculating a reconstruction error of the model with the newly generated labeled and unlabeled samples, and training and optimizing model parameters in combination with a classification error till convergence.

Owner:CIVIL AVIATION UNIV OF CHINA

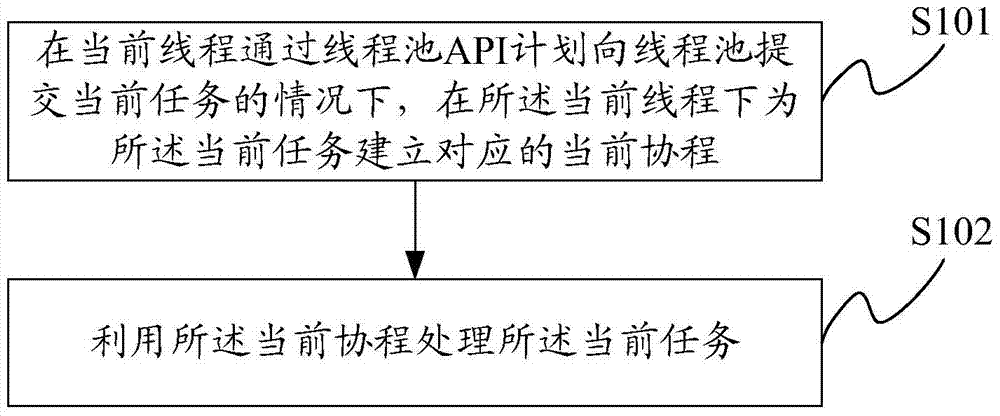

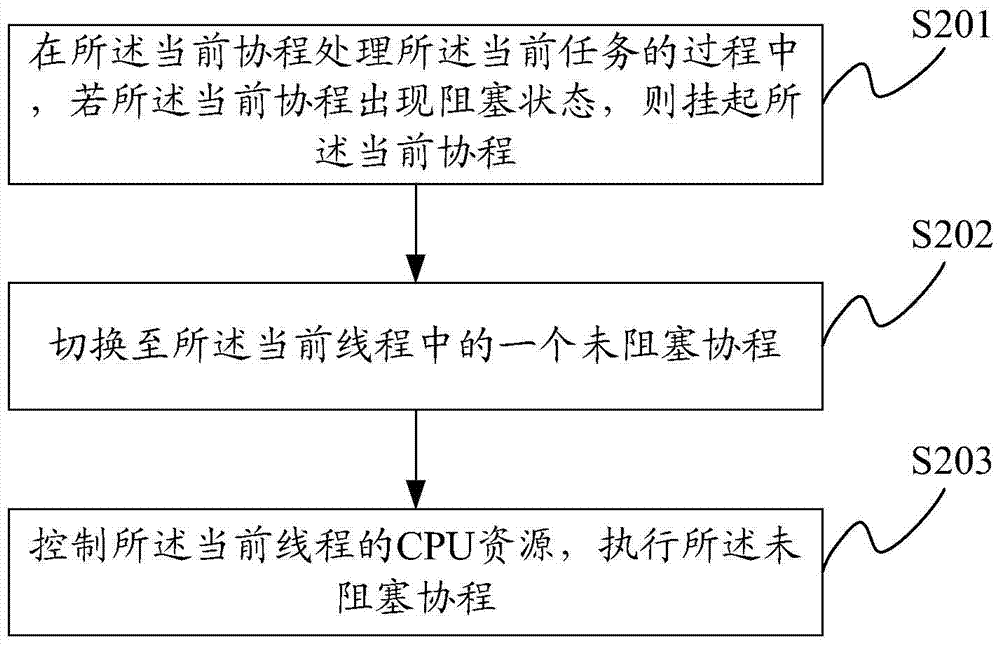

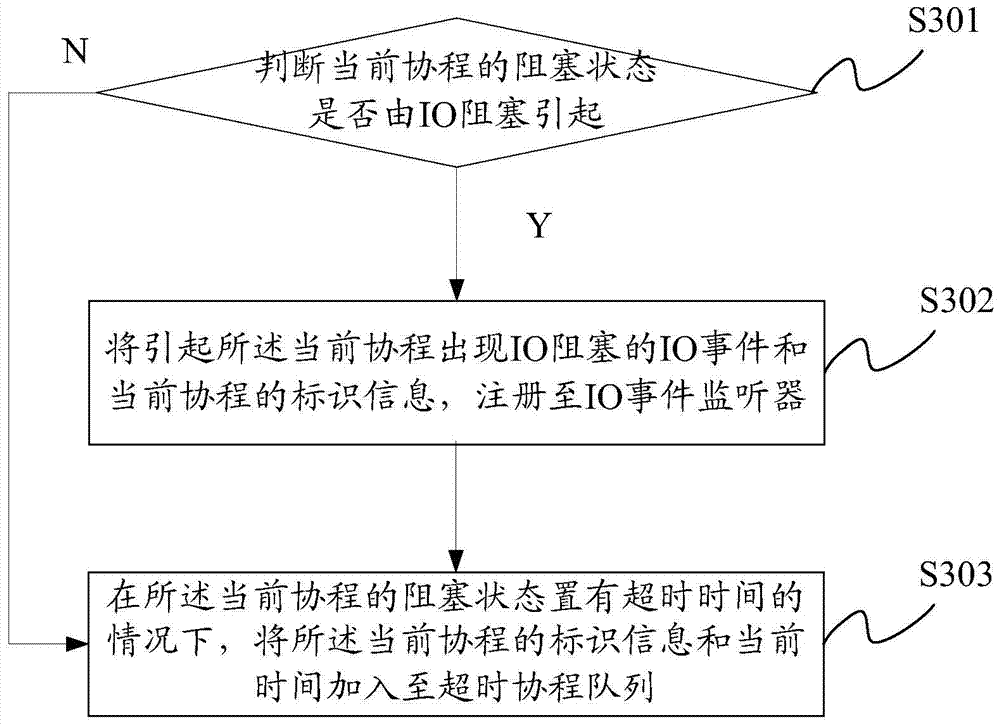

Asynchronous task execution method, device and system

ActiveCN106980546ASolve increased CPU consumptionSolve processingResource allocationInterprogram communicationApplication softwareThread pool

The invention provides an asynchronous task execution method, device and system. The method comprises the following steps of: when the current thread submits the current task to a thread pool through a thread pool API, establishing a corresponding current coroutine for the current task under the current thread, wherein the current task is a task, possible to be blocked, determined by the current thread in the execution process; and processing the current task by utilizing the current coroutine. According to the method, device and system, when the current thread of an application program determines that the execution of the current task is possible to be blocked, the current task is not sent to a task queue of the thread pool, namely, the current task is not scheduled and processed by the thread pool; and a coroutine is newly established under the current thread and the current task is processed by the coroutine. Therefore, the method, device and system can solve the problems that the consumption of a CPU is increased and the performance of a processor is influenced as the task possible to be blocked is processed by the thread pool.

Owner:ALIBABA GRP HLDG LTD

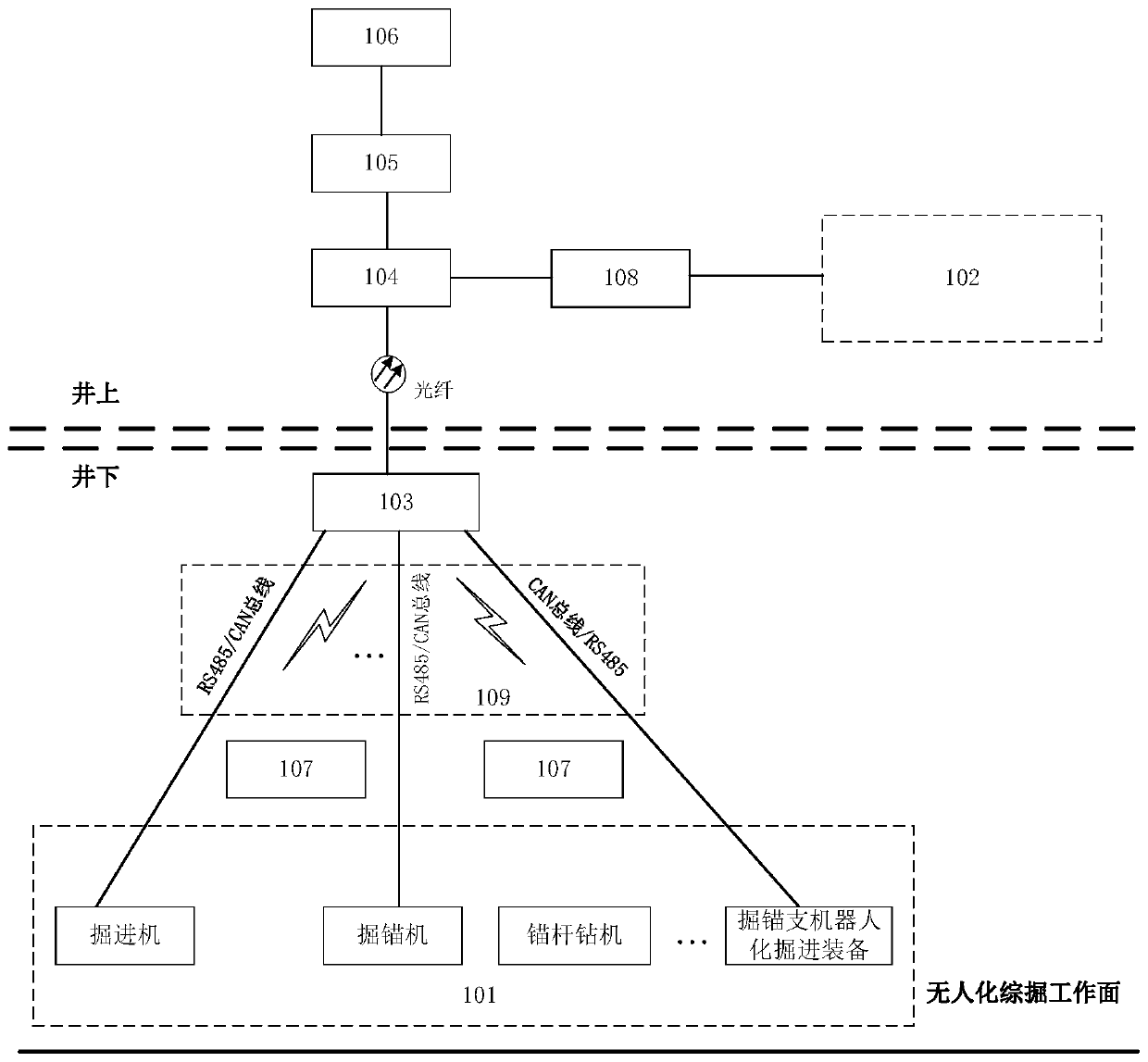

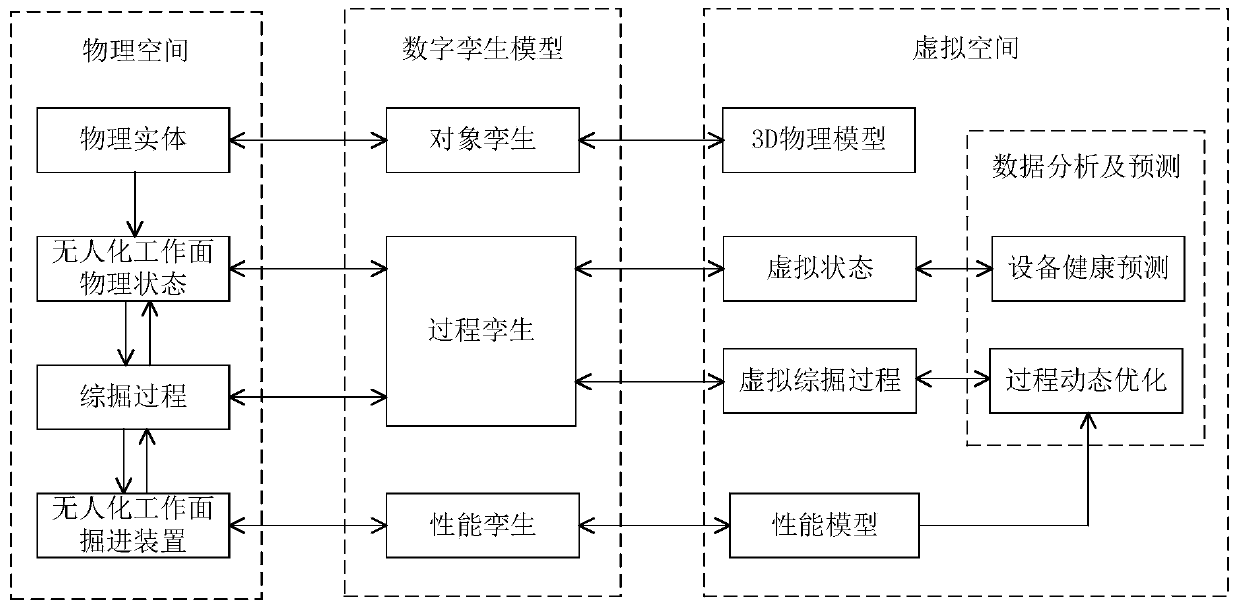

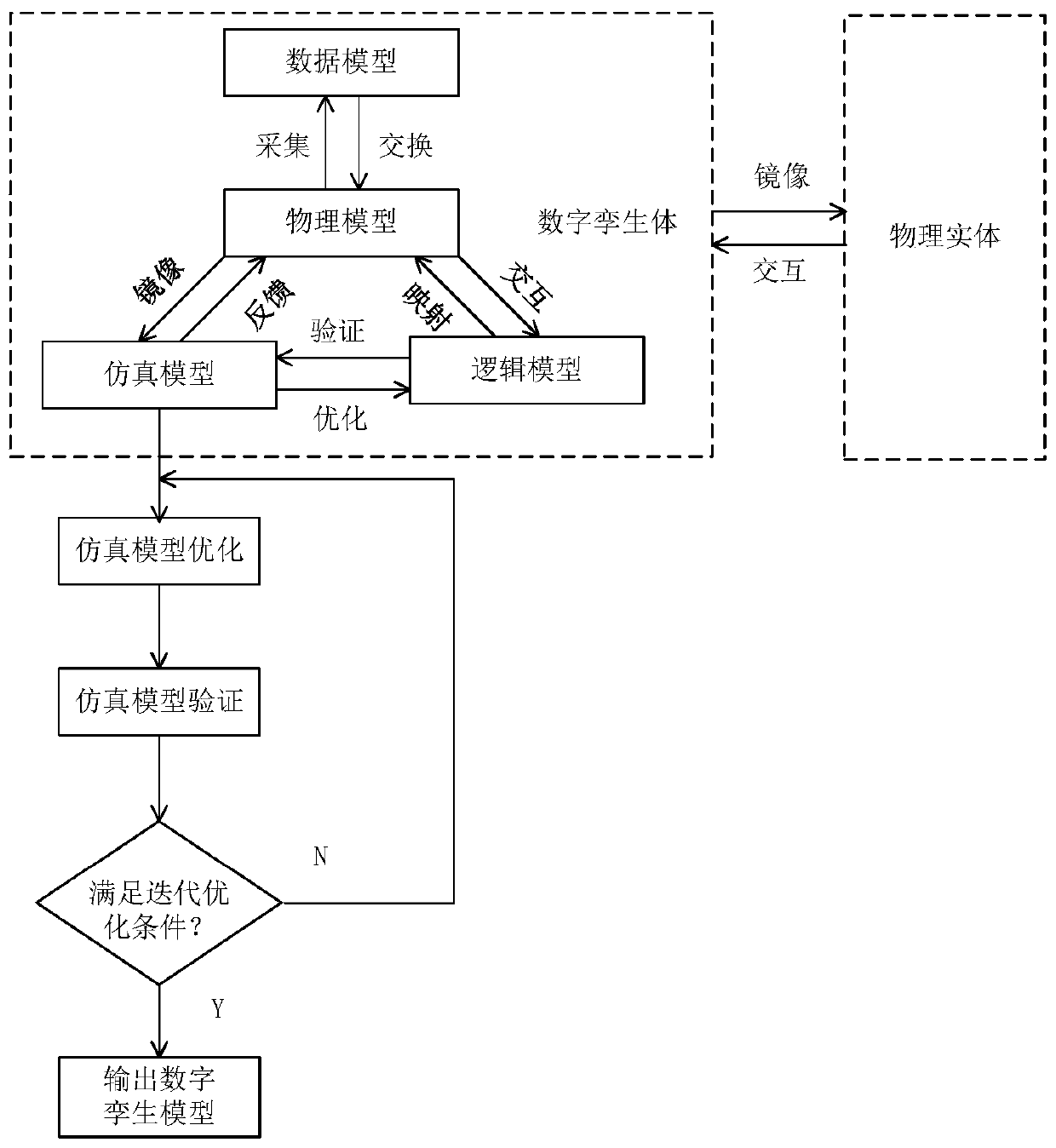

Digital twinning intelligent monitoring system for unmanned fully mechanized excavation face of mine

ActiveCN111177942ARealize intelligent monitoringRealize intelligent navigationData processing applicationsDigital data information retrievalVideo monitoringDecision control

The invention discloses a digital twinning intelligent monitoring system for an unmanned fully mechanized excavation face of a mine. The system is composed of a physical entity, a digital twinning body, an intrinsic safety type intelligent gateway, a cloud server, a cloud database, an intrinsic safety type 5G base station, a machine vision device, a communication interface, a network switch and avideo display terminal. According to the method, a digital twinning model is constructed, and perception analysis, analogue simulation, iterative optimization and decision control are carried out by utilizing a deep learning algorithm based on machine vision and edge calculation; based on data twinning and data driving, real-time monitoring, intelligent sensing, accurate positioning and health prediction of the remote physical space mine unmanned fully mechanized excavation face are achieved through the virtual space digital twinning unmanned fully mechanized excavation face. According to theinvention, the problems of non-uniform communication interfaces, weak equipment integration capability, poor video monitoring real-time performance, fuzzy video images and the like of the existing monitoring system are solved, and the real-time performance, accuracy and robustness of the intelligent monitoring system for the unmanned fully mechanized excavation face of the mine are improved.

Owner:CHINA UNIV OF MINING & TECH (BEIJING)

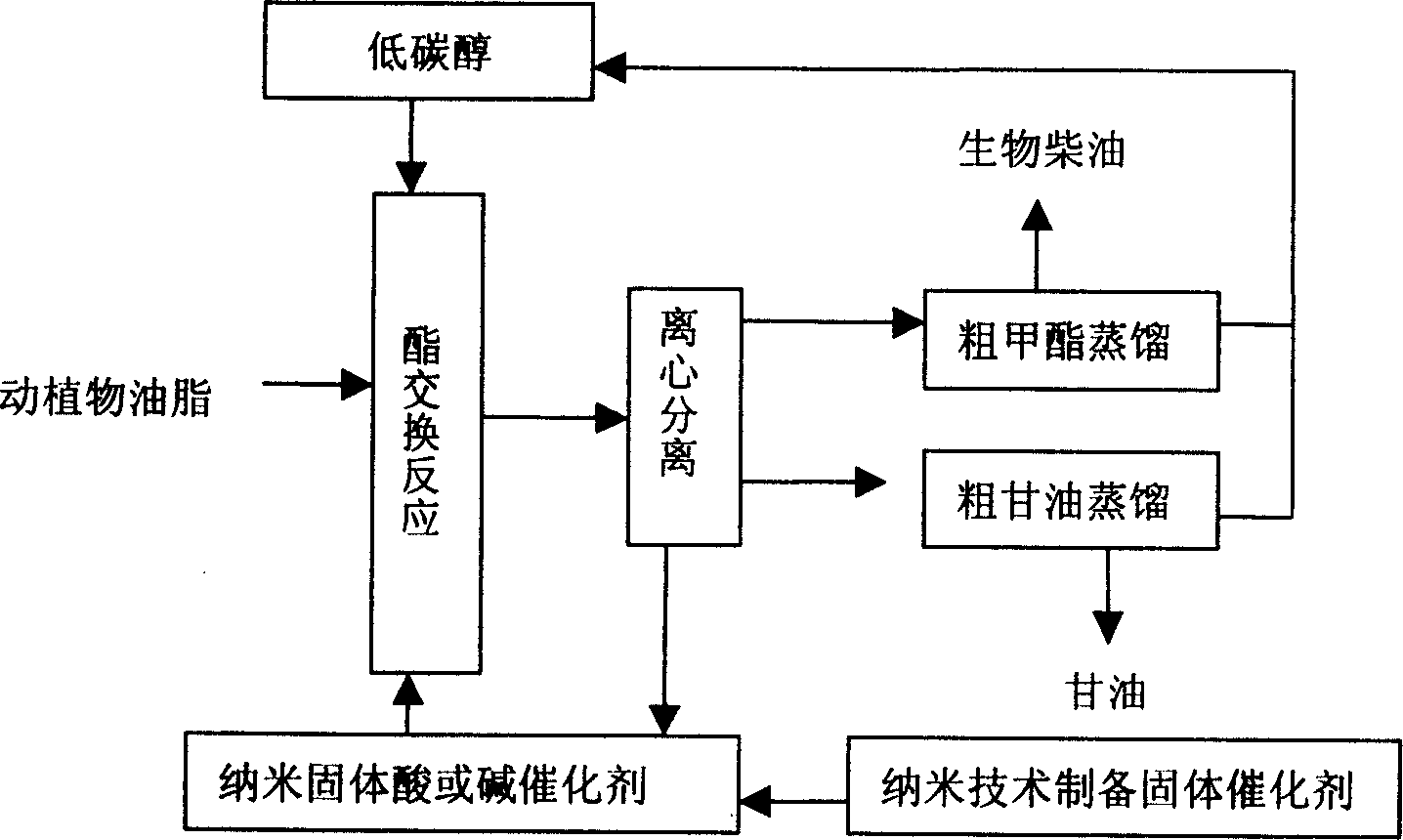

Method for preparing biological diesel oil using nano solid acid or alkali catalyst

InactiveCN1858160AEasy to useSolve corrosiveBiofuelsLiquid hydrocarbon mixture productionBiodieselVegetable oil

The present invention relates to process of preparing low carbon alkyl ester and biological diesel oil by means of nanometer solid acid or alkali catalyst. Under the action of catalyst in the amount of 1-20 wt% of animal and vegetable oil, low carbon alcohol and animal and vegetable oil in the molar ratio of 3.5-40 to 1 are reacted at the pressure from normal to 25 MPa and temperature of 40-100 deg.c to produce coarse methyl ester and glycerin, which are centrifugally separated and distilled to obtain low carbon alcohol, or neutral biological diesel oil and glycerin, separately. The present invention has biological diesel oil converting rate up to 96% and yield up to 99%, and the product meets the ASTM D 6751-02 standard. The nanometer solid acid or alkali catalyst may be used repeatedly for 3-100 times in producing biological diesel oil, and the product needs no neutralization and washing.

Owner:INST OF OIL CROPS RES CHINESE ACAD OF AGRI SCI

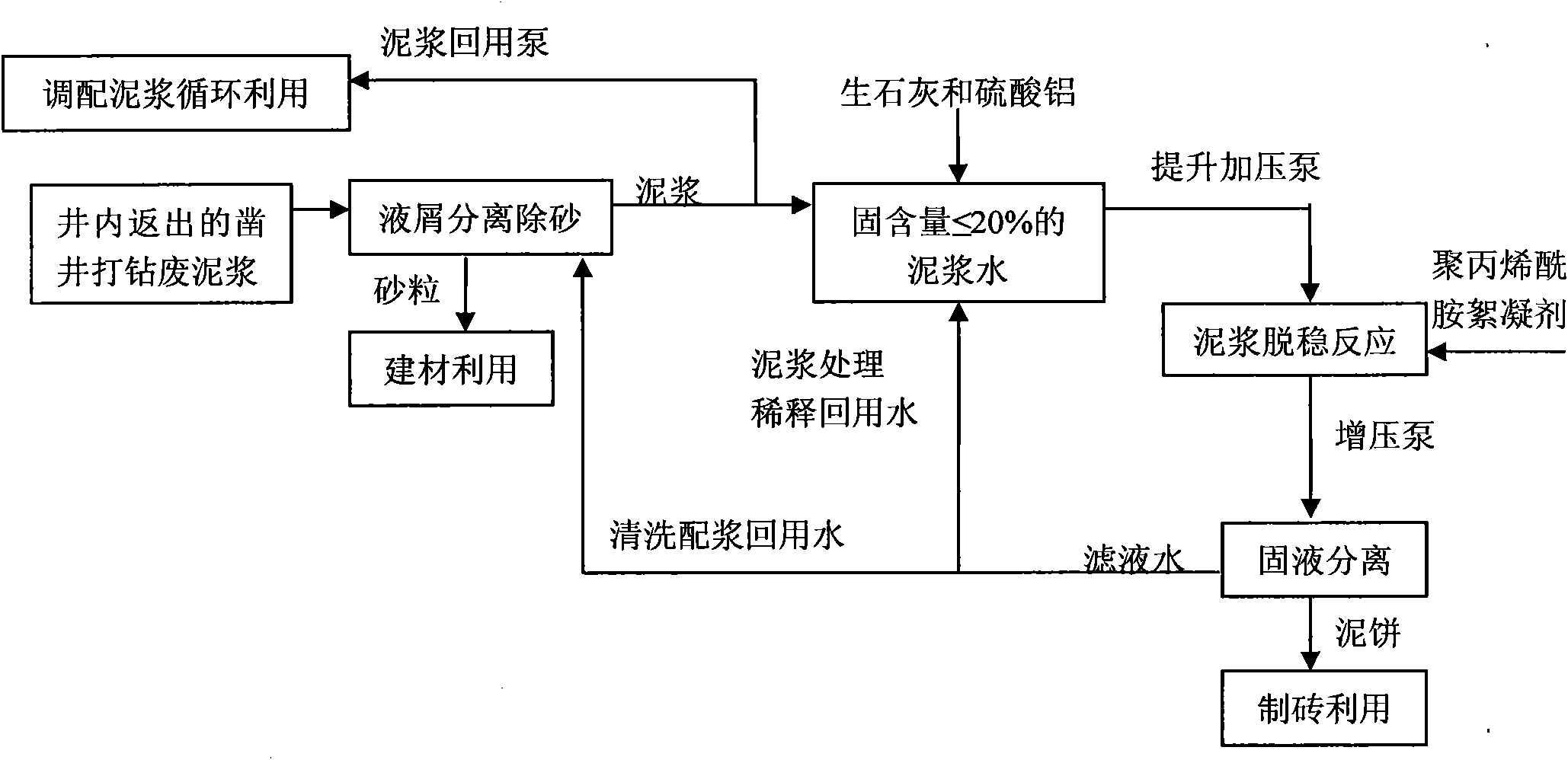

Treatment method of waste slurry generated by gigging well and drilling

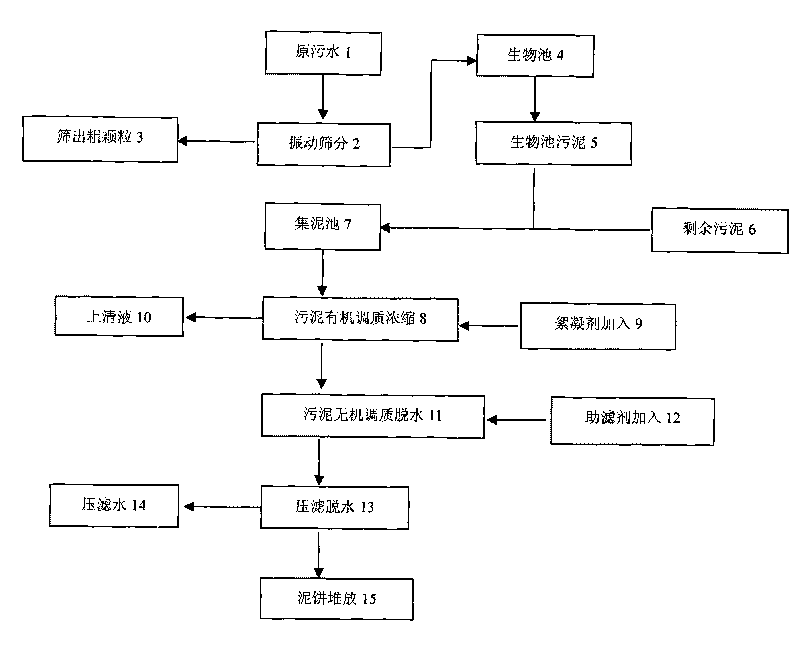

ActiveCN101774746ASolve processingSolve the use problemSludge treatment by de-watering/drying/thickeningSlurryCement paste

The invention discloses a treatment method of waste slurry generated by gigging a well and drilling, which comprises the following steps of: separating liquid from scraps to remove sands in waste slurry which is generated by gigging a well and drilling and is reflowed from the well; adding inorganic flocculating agent and water in the sanded-removed waste slurry generated by gigging the well and drilling to dilute, stir and damage stability to obtain cement paste with solid content which is less than or equal to 20%; adding polyacrylamide flocculant into the obtained cement paste to stir and perform a cement paste destabilization reaction; after the cement paste destabilization reaction, separating solid from liquid in the cement paste; and returning filter water to the step of separating liquid from scraps to remove the sands as cleaning proportioned water to recycle and / or return to the step of diluting, stirring and damage stability as water for treating and diluting the cement paste. The method can solve the problem for treating and using the waste slurry generated by gigging the well and drilling, can separate sands from mud and water in the waste slurry generated by gigging the well and drilling, can reach the standard and be comprehensively utilized, has large treatment amount to reach 1000 m<3> / h, can treat the waste slurry on a large scale, thereby being capable of reducing the treatment cost of the system. The method can comprehensively utilize and recycle all the waste slurry generated by gigging the well and drilling.

Owner:PUYANG TIANDIREN ENVIRONMENTAL PROTECTION TECH CO LTD +1

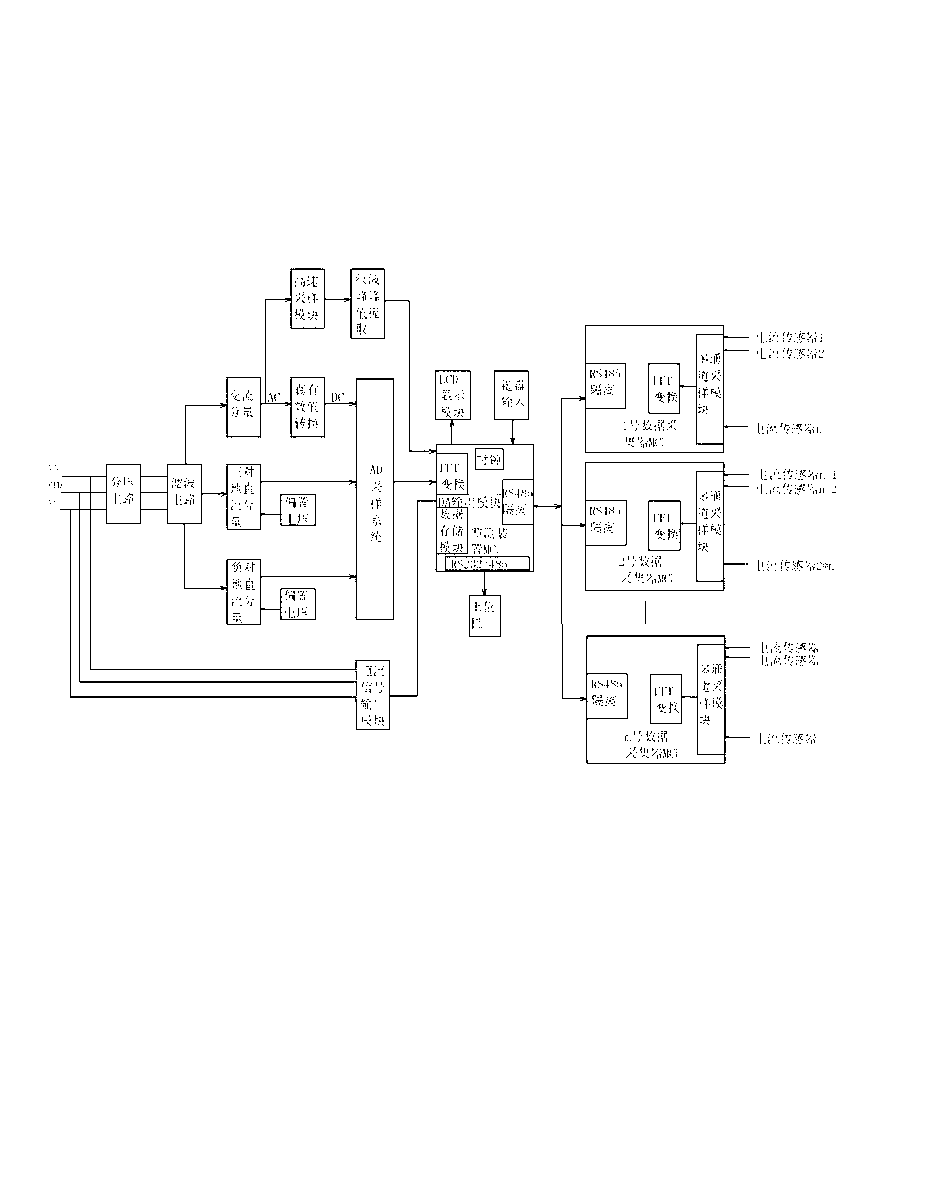

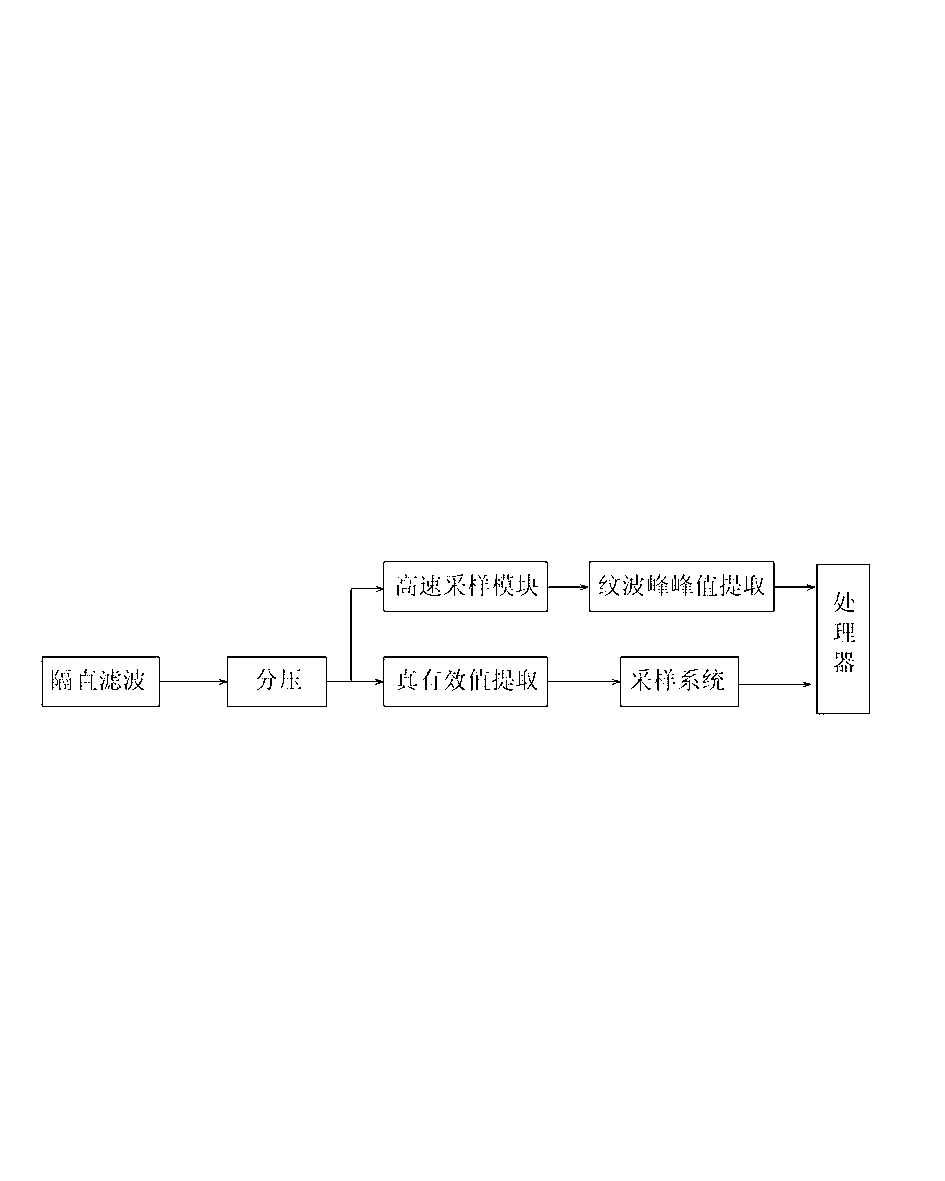

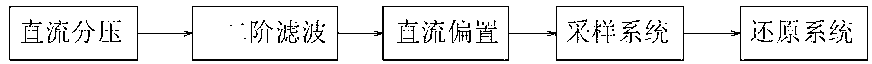

Alternative current electric crosstalk and insulation fault monitoring line selection method of direct current system

ActiveCN103135038ARealize line selection functionObvious ground faultCurrent/voltage measurementEarth resistance measurementsCurrent sensorData acquisition

The invention relates to an alternative current electric crosstalk and insulation fault monitoring line selection method of a direct current system. The direct current system is formed by an upper computer, a monitoring device, a sampling system and a current sensor. The alternative current electric crosstalk and insulation fault monitoring line selection method includes the steps of extracting a ripple crest value in the direct current system through extracting of an alternating component effective value, adopting the alternative current and direct current component separation digital filtering technology, the direct current leakage current detection technology, the recommend standard 485 (RS485) isolation communication technology and the fast fourier transform algorithm (FFT) conversion technology to monitor system bus over-the-ground alternative and direct current voltage and a ripple voltage peak value in real time to give an alarm, receiving loop leakage current information uploaded by a data collector, carrying out intelligent analysis through mode matching technology, calculating grounding resistance, carrying out artificial intelligence mode matching on feature status information of each loop and configured feature rules in the system, enabling the alternative current electric crosstalk faults, ripple voltage peak value monitoring data, grounding fault and insulation fault loop status information, loop information and the like which to be displayed on a liquid crystal display, assisting operation and maintenance workers to accurately know the current status to rapidly remove the faults.

Owner:GUANGZHOU PREFECT SERVICE ELECTRONICS TECH

A treating method of waste cathode charcoal blocks

InactiveCN106166560ARealize harmless treatmentEliminate pollutionSolid waste disposalSolid fuelsElectrolysisSlag

A treating method of waste cathode charcoal blocks is provided. The waste cathode charcoal blocks are from electrolytic tank heavy maintenance slag of an electrolytic aluminium factory. The method includes treating the electrolytic tank heavy maintenance slag to obtain powdered waste cathode charcoal blocks, subjecting the powdered waste cathode charcoal blocks to water leaching to obtain a leachate and cathode charcoal blocks after leaching, performing solid liquid separation after the leachate and a fluorine removal agent are subjected to a curing reaction, returning the filtrate to the leaching step for circulated use, and stacking filter cakes or adopting the filter cakes as a raw material for preparing calcium fluoride. The method adopts a manner of a plurality of times of leaching, thus achieving innocent treatment of the waste cathode charcoal blocks. The filtrate and the filter cakes after leachate treatment can be reused, and the cathode charcoal blocks after leaching can be adopted as fuel for producing alumina. The method overcomes a series of problems caused by stacking of a large amount of the waste cathode charcoal blocks, achieves efficient utilization of the waste cathode charcoal blocks, and is obvious in economic benefit and suitable for industrial production.

Owner:DATANG INT HIGH ALUMINA COAL R & D CENT

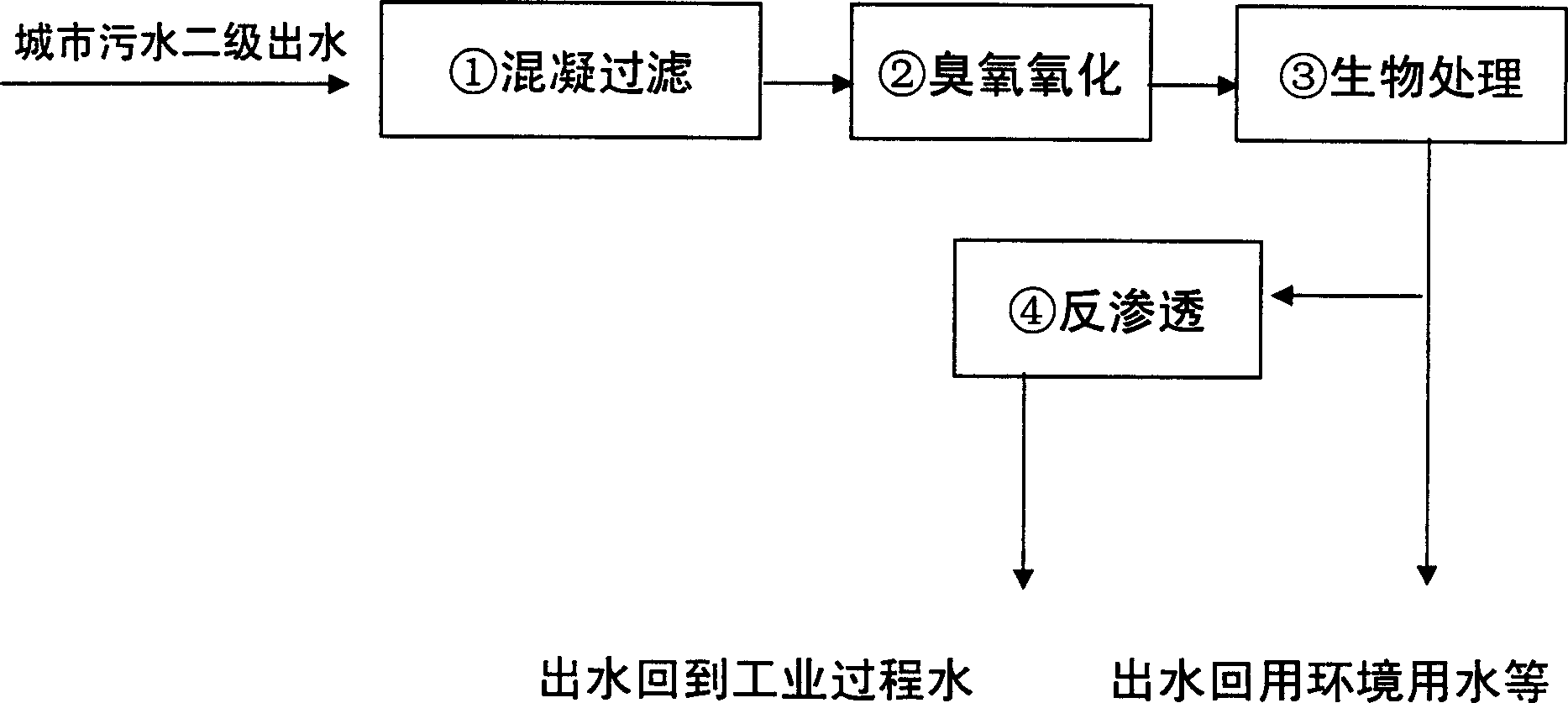

Method for processing urban sewage deeply

ActiveCN1796314AChange sizeChange structureTreatment using aerobic processesWater/sewage treatment bu osmosis/dialysisFiltrationReverse osmosis

This invention is related to a process of disposing urban sewage, which comprise the steps of coagulate filtration, ozone oxidation, biological oxidation to dispose urban sewage, so that the residual undegradable organic substances, bacteria and virus in the second-class urban sewage can be removed and the water can be recycled. According to different usages of the recycled water, the process also comprises reverse osmosis or nanoscale filtration treatment to further remove the residual organic and inorganic substances in the water. The process is a combination of coagulate filtration, ozone oxidation, biological oxidation and reverse osmosis, designed to resolve such problems as urban sewage disposal and water recovery. The process can obtain high-quality recycled water with a low cost, showing high cost performance, which is important to resolving urban water depletion, raising the utilization rate of water resources, reducing environmental pollution and promoting sustainable development of the society.

Owner:北京国中科创环境科技有限责任公司

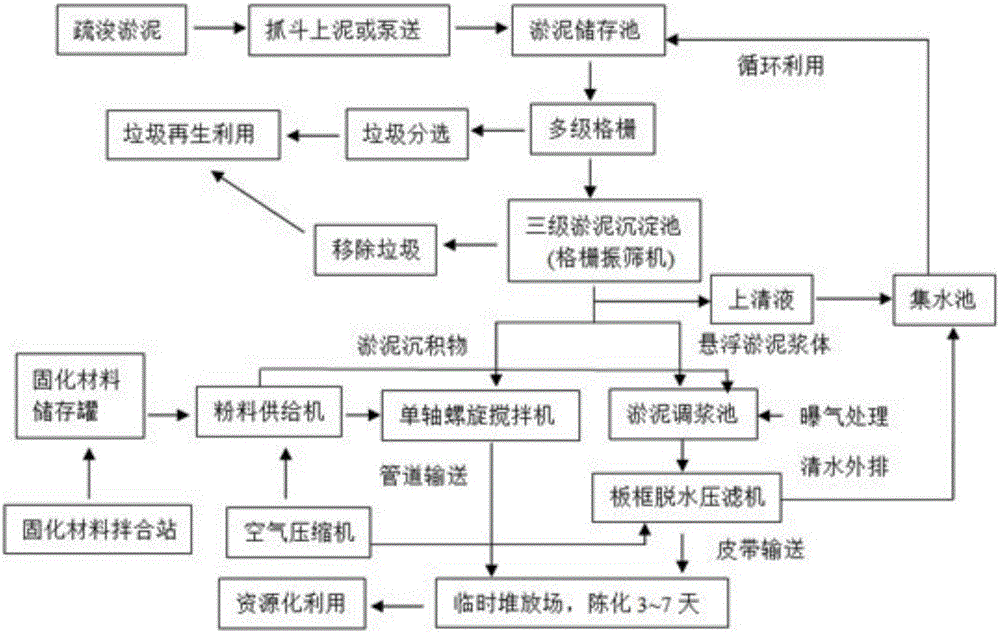

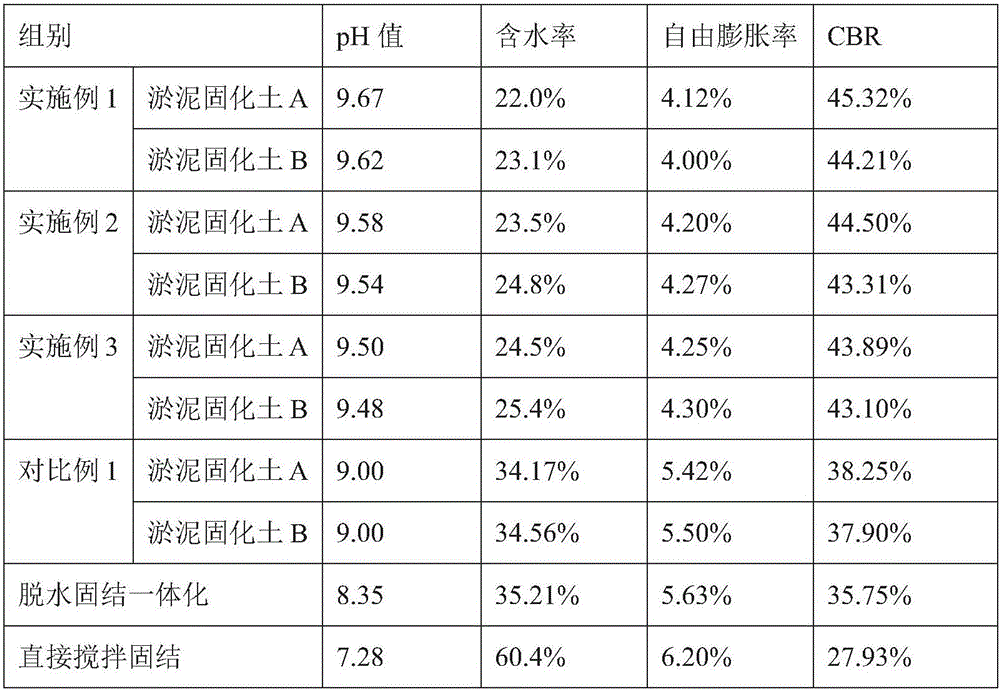

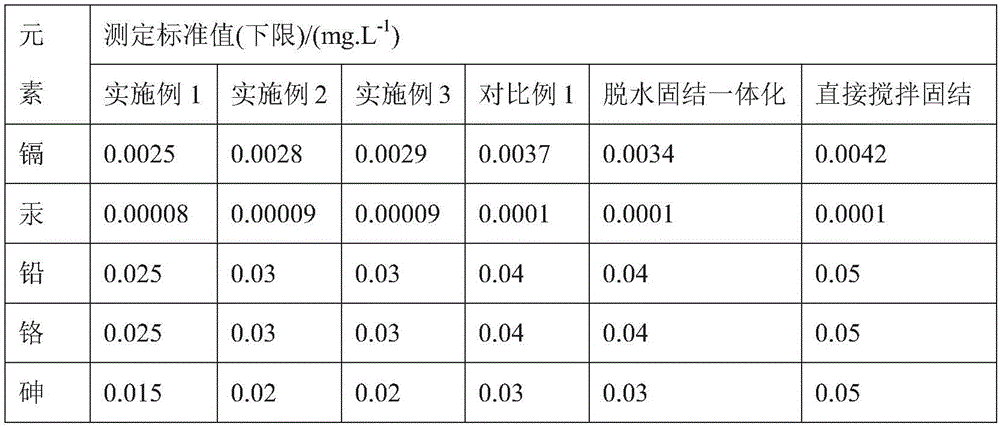

Sludge treatment process

The invention belongs to the field of environmental protection, and in particular relates to a sludge treatment process. The sludge treatment process comprises the following steps: 1) impurity removal: use multi-stage grille to filter out the garbage in the sludge; 2) pretreatment: utilize the three-stage sludge settling tank to pretreat the sludge to obtain the first, second, and The sludge in the three-stage sludge settling tank, the sludge slurry and the supernatant after being settled in the three-stage sludge settling tank; 3) solidification treatment: respectively adopt mixing solidification and dehydration solidification methods for the first, second, and third-stage sludge sedimentation The silt and silt slurry in the pond are dehydrated and solidified to obtain silt-solidified soils A and B; 4) stacking and aging: transport the silt-solidified soils A and B to a temporary storage yard and age them for 3 to 7 days to complete the treatment. The sludge treatment process of the present invention can simultaneously process particles and sludge with high viscosity and low water content, as well as sludge slurry with fine particles, organic matter and high water content, and is especially suitable for river courses with complex components, wide particle distribution, and large water content differences silt.

Owner:GUANGZHOU WATER CONSERVANCY & HYDROPOWER STATION CONSTR ENG

Method for screening and dewatering urban sludge efficiently

ActiveCN101696077ARealize automatic controlRealize managementSludge treatment by de-watering/drying/thickeningRemote controlWastewater

Owner:SAFECLEEN TECH

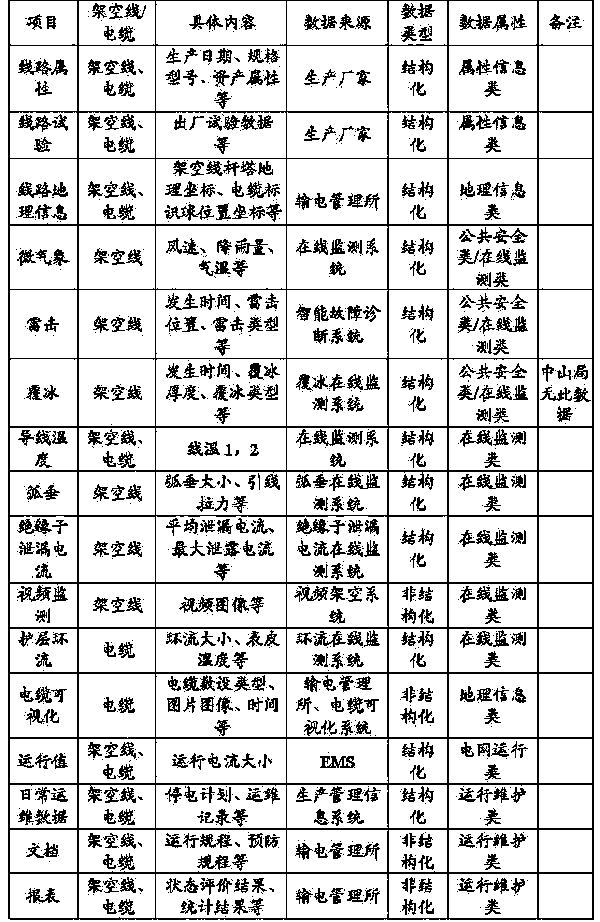

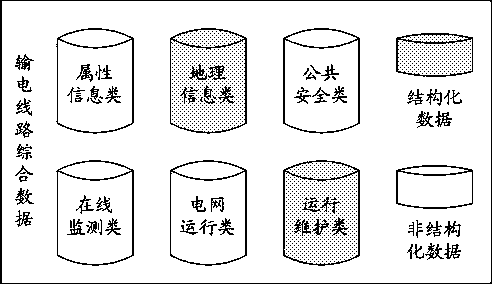

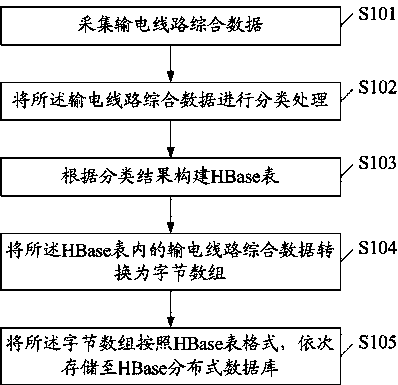

Method for storing transmission line integrated data based on HBase

ActiveCN104216989AEffective mergerAchieve deleteData processing applicationsDatabase distribution/replicationArray data structureInformation sharing

The invention discloses a method for storing transmission line integrated data based on HBase. The method comprises the steps of collecting the transmission line integrated data, wherein the transmission line integrated data comprise structural data and unstructured data; classifying the transmission line integrated data; building an Hbase table according to the classifying result; converting the transmission line integrated data in the Hbase table as byte arrays; sequentially storing the byte arrays into an HBase distributed database according to the format of the Hbase table, wherein the HBase distributed database is built on an HDFS (Hadoop Distributed File System). By adopting the method, the transmission line integrated data can be integrated with the HDFS and HBase; the problems that the original data are poor in information sharing, the information is in isolated island, and the unstructured data are difficult to process can be solved.

Owner:ZHONGSHAN POWER SUPPLY BUREAU OF GUANGDONG POWER GRID +1

Process for preparing foamed glass form titan-containing blast furnace slag

The invention provides a method for preparing foam glass by utilization of titaniferous blast furnace slag, belonging to the metallurgical resource comprehensive utilization and material preparation field. The method mainly is to take the blast furnace slag containing 14 to 29 percent of TiO2 as base material, to adequately introduce silicious raw materials to generate vitreous substances, to add foaming agent, foam stabilizer and fluxing agent, and to prepare the foam glass with a specified heat treatment system. The method solves the problems that the prior titaniferous blast furnace slag is difficult to utilize and process and the utilization rate of the titaniferous blast furnace slag in the material preparation field is low, not only creates a novel path for utilization of the titaniferous blast furnace slag but also finds very cheap raw materials for production, and has the advantages of low production cost, good product quality, simple production operation, no secondary pollution and so on.

Owner:NORTHEASTERN UNIV

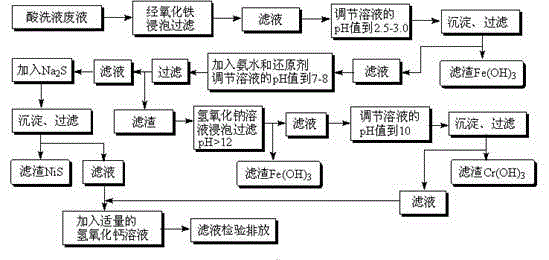

Method for treating stainless steel pickling waste liquor and recovering iron, chromium and nickel

InactiveCN104805291AHigh puritySolve processingWater contaminantsWaste water treatment from metallurgical processFerric hydroxideFractional Precipitation

The invention discloses a method for treating stainless steel pickling waste liquor and recovering iron, chromium and nickel. According to the method, a sodium hydroxide solution is adopted to control the pH of the stainless steel pickling waste liquor to achieve the purpose of recovery of iron, chromium and nickel through fractional precipitation. Because pH ranges of deposition of the iron, chromium and nickel elements are overlapped, part of iron oxide-hydroxide is precipitated firstly in a separation and recovery process, residual iron and chromium elements are co-precipitated out, and then chromium is precipitated and dissolved under the strong alkaline condition to realize final separation of iron and chromium. Due to presence of ammonia water and a reducing agent, the nickel element exists in the form of ions or a nickel ammine complex, is dissolved in the waste liquor, and finally reacts with a sulfide to precipitate NiS. The method has the characteristics of low cost, easiness in control, high separation and recovery rate of the iron, chromium and nickel elements and the like. The method can treat the stainless steel pickling waste liquor effectively, and the natural environment cannot be polluted after emission; the recovered metal elements have the recycling economic benefits, and the method has high application value and important technological innovation meaning.

Owner:NANYANG NORMAL UNIV

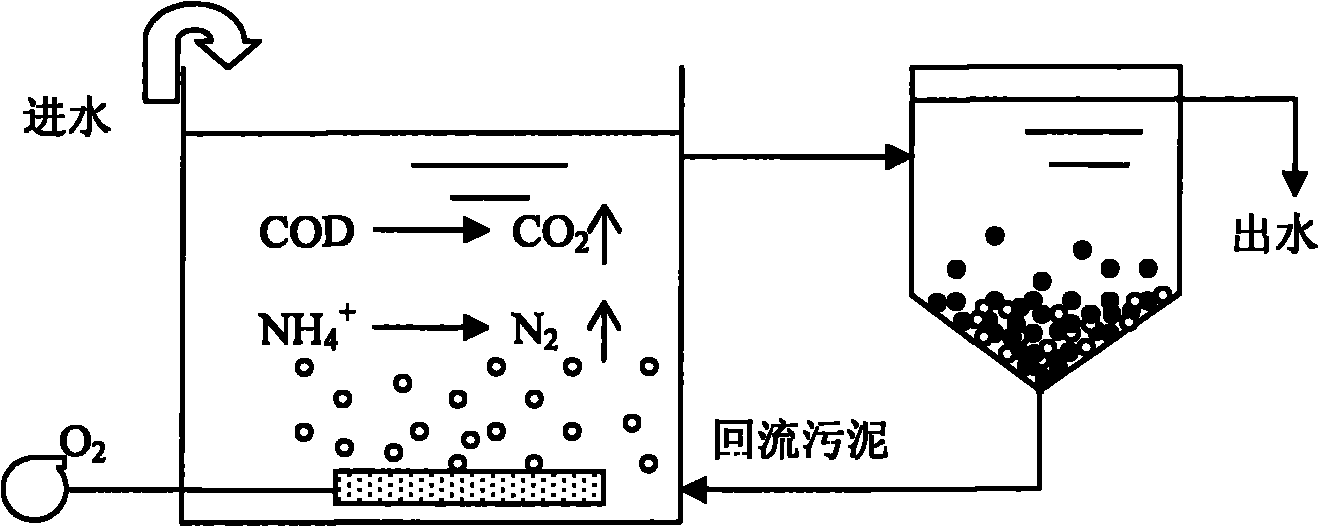

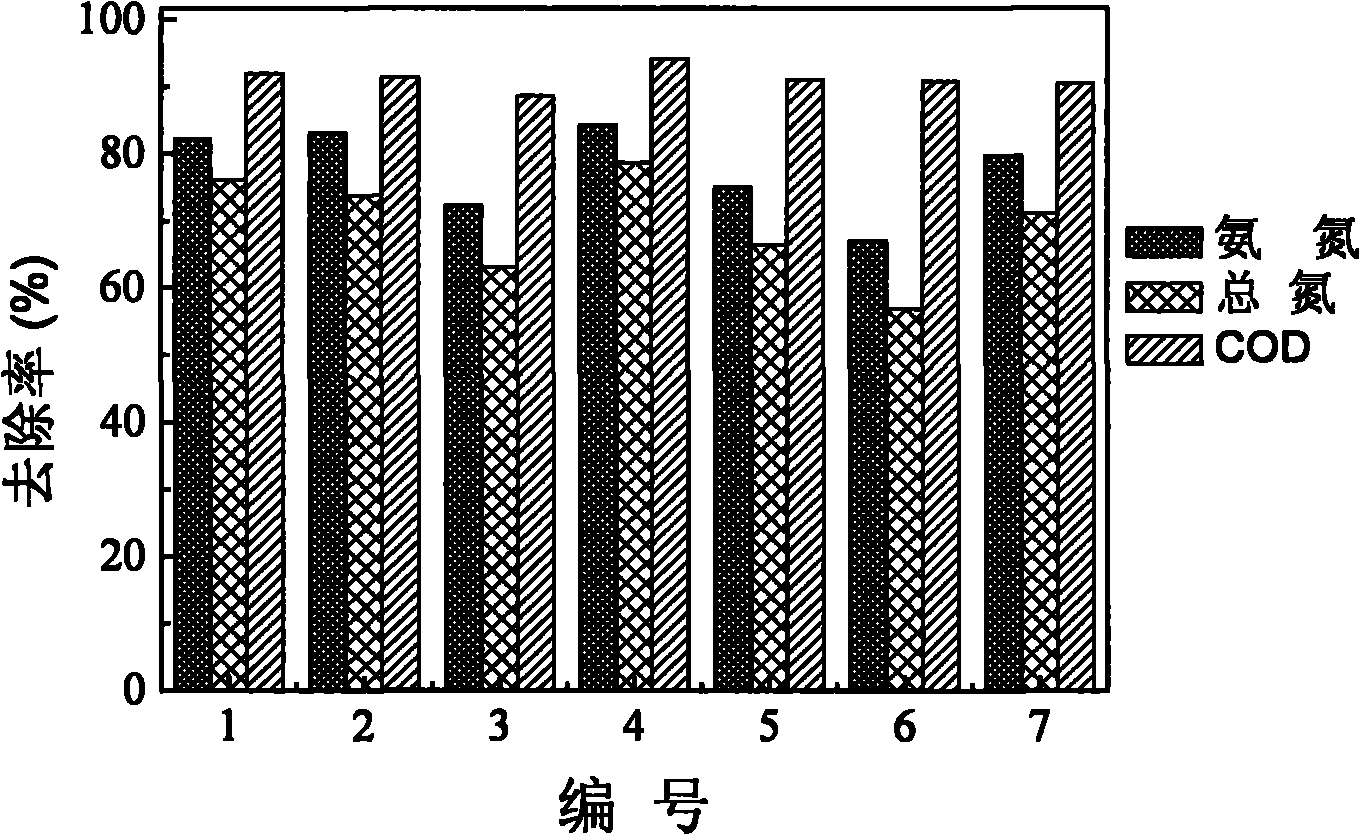

Method for removing carbon and nitrogen pollutants in waste water in one step

ActiveCN101985376AOvercoming slow proliferationOvercome nitrificationTreatment with aerobic and anaerobic processesSustainable biological treatmentSludgeNitrifying bacteria

The invention breaks through the restriction of the traditional autotrophic nitrification and anoxic denitrifying metabolism principle, and discloses a method for removing carbon and nitrogen pollutants in waste water in one step according to physiological feature and metabolism principle of heterotrophic nitrification-aerobic denitrification bacteria. In a single biochemical reactor, mixed solution of the heterotrophic nitrification-aerobic denitrification bacteria and active slurry in a certain proportion is inoculated, after a certain period of aeration is performed, nitrogen and organic substances are removed at the same time, and the efficiency of denitrification and carbon removal is high. By using the method, a traditional biochemical treatment system can be updated and transformedwithout constructing a new building based on the traditional biochemical treatment system, and the operation is convenient and fast. The method overcomes the bottleneck problems that the nitrobacteria propagate slowly, the nitrification and denitrification reactions are performed in sections, and the like.

Owner:PEKING UNIV

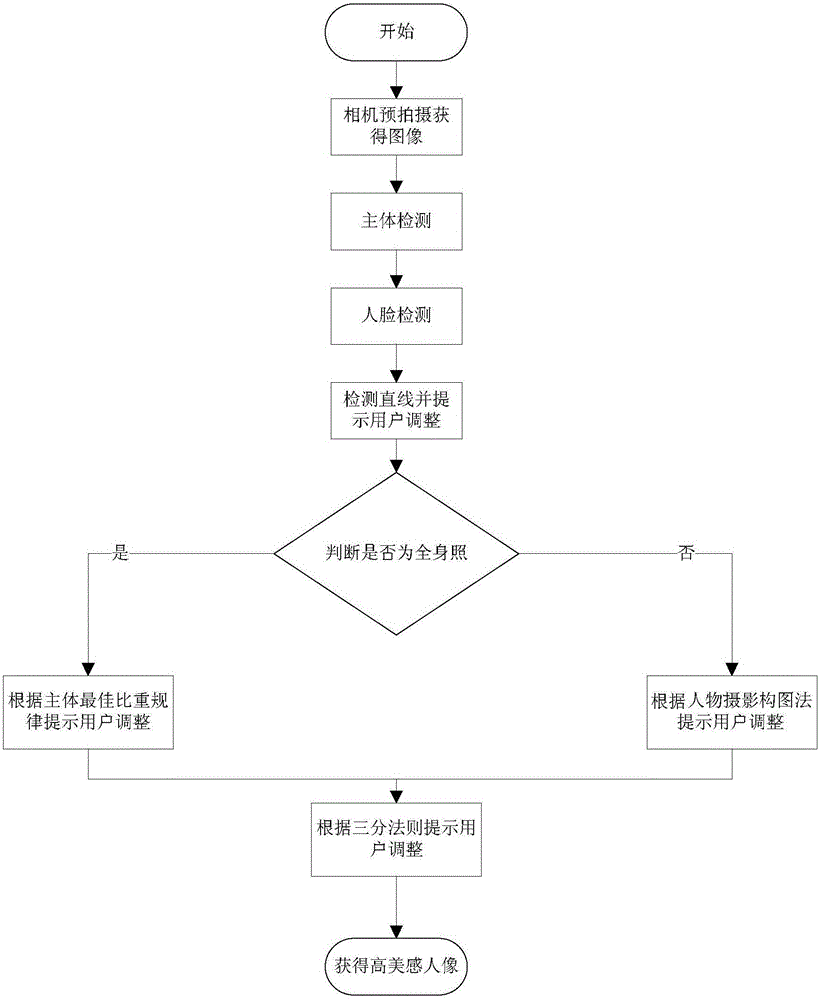

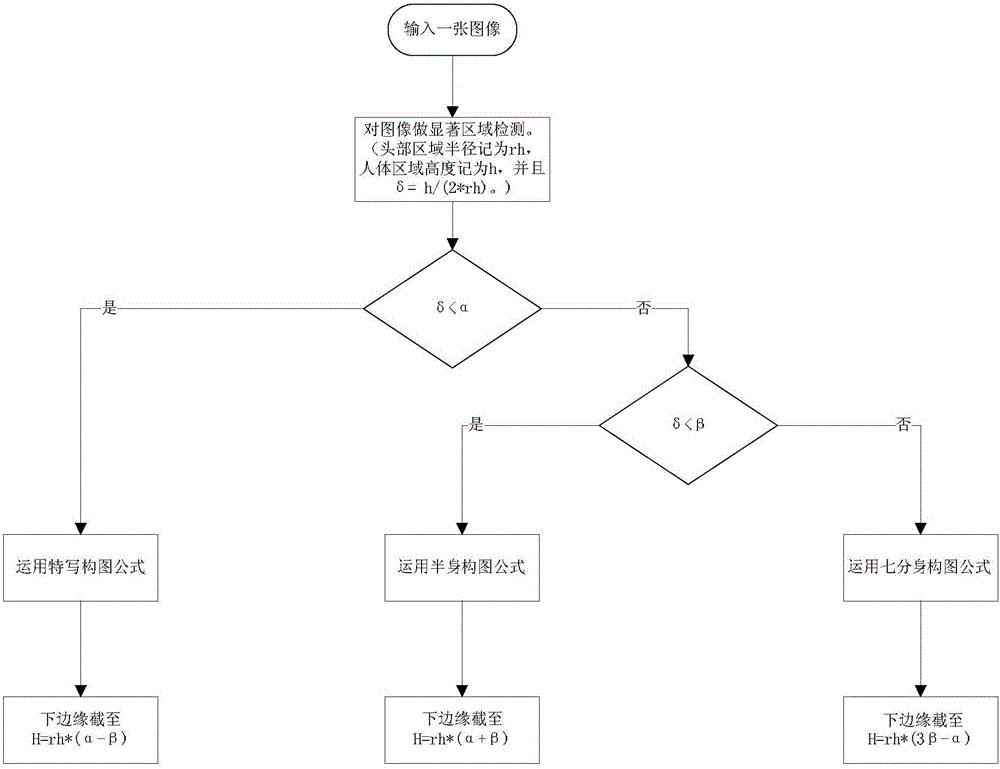

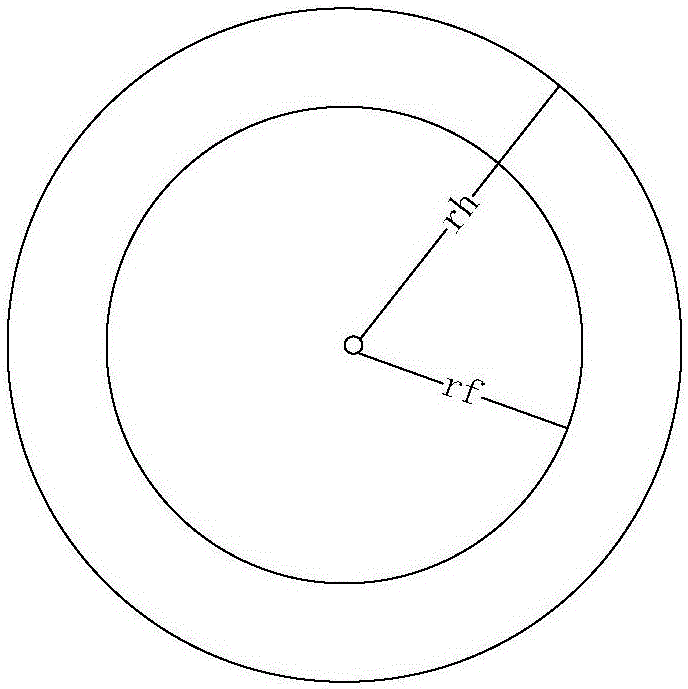

Figure image auxiliary shooting method and system based on image aesthetics

ActiveCN105100625ASolve the problem of not following the rules of aesthetic composition wellAfter solving the shootingTelevision system detailsImage analysisFace detectionShooting method

The invention discloses a figure image auxiliary shooting method and system based on image aesthetics. The method comprises the following steps: (1) framing a model through a viewing frame to perform pre-shooting, and performing face detection and human body region detection on a pre-shot image to obtain a face image and a human body area image; (2) detecting whether or not a straight line passes through a figure head background in the face image, and if so, prompting a user; (3) judging whether or not the pre-shot image is a whole-body image, prompting the user according to a main body optimal proportion rule if the pre-shot image is the whole-body image, judging whether or not a human body proportion meets a composition requirement if the pre-shot image is not the whole-body image, and prompting the user if the human body proportion does not meet the composition requirement; and (4) detecting the location of the model and the size of a human body region, and prompting the user according to a rule of the thirds in composition aesthetics. The invention also discloses a figure image auxiliary shooting system based on the image aesthetics. The figure image auxiliary shooting method and system are simple and effective, high in running speed and high in feasibility. Images shot by the user after guidance can meet a composition rule, and are more aesthetic.

Owner:SOUTH CHINA UNIV OF TECH

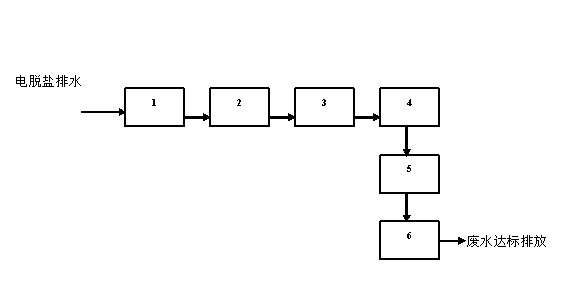

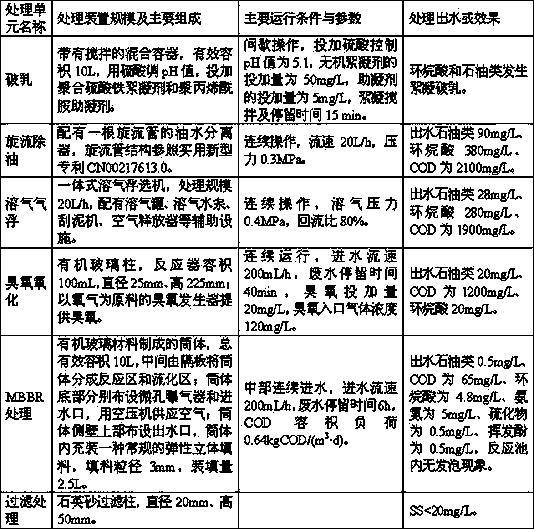

Treatment method for waste water from processing acid-containing crude oil

ActiveCN103771652ASolve the failure to meet the standardSolve processingMultistage water/sewage treatmentAfter treatmentOil separation

The invention relates to a treatment method for waste water from processing acid-containing crude oil, and the method is used in the treatment of waste water containing naphthenic acid from the refining process of acid-containing crude oil. The method adopts a combined process including demulsification, cyclone oil removal, dissolved air flotation, ozone oxidation, MBBR and filtering to treat the wastewater containing naphthenic acid discharged from an electric desalting device in the crude oil refining process, and the outlet water after treatment reaches discharge standards. The method can prevent the treatment process of other waste water, such as oil-containing sewage and salt-containing waste water from the influence from naphthenic acid, and benefit the stable operation of oil separation, flotation, biochemical treatment and depth treatment units in final sewage works, so as to solve the problems of unqualified waste water from processing acid-containing crude oil and foaming of biochemical treatment, and provide a good basis for waste water reuse.

Owner:CHINA PETROLEUM & CHEM CORP +1

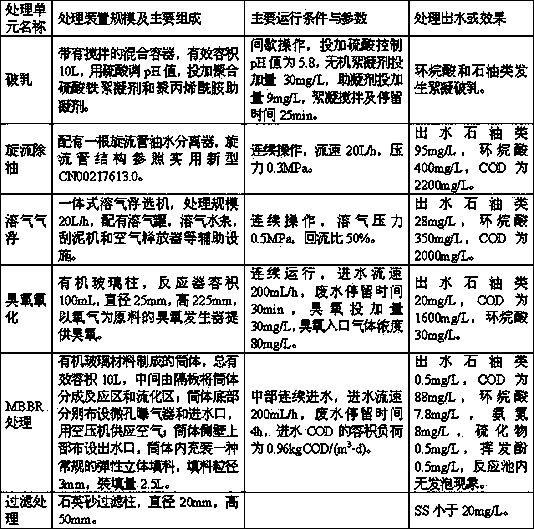

Biomass supercritical and subcritical combined continuous type pretreatment and hydrolysis equipment and method

InactiveCN101613377AAchieving processing powerAchieve hydrolysis conversionSugar derivativesSugar derivatives preparationFiberElectronic temperature

The invention relates to biomass supercritical and subcritical combined continuous type pretreatment and hydrolysis equipment and a method. The equipment comprises a water storage tank, a material storage tank with a stirring device, a preheating system, a supercritical reaction system, a primary cooling system, a subcritical reaction system, a final cooling system, a product collection system and an electronic temperature controlling system. The method comprises the following processing steps: water reaching preheat temperature and biomass material paste are rapidly mixed and then injected into the supercritical reaction system to be pretreated under supercritical condition; the reaction product is cooled through the primary cooling system and depressurized through a pressure reducing valve and then enters into the subcritical reaction system to be hydrolyzed sequentially, therefore fermentable sugars are continuously generated and collected. The invention utilizes the advantages of the supercritical method that the reaction is rapid, activator is not required and product inhibition does not exit, realizes that the continuous hydrolysis conversion of wood fiber biomass can generate fermentable sugars, is the foundation of subsequent resource recovery technologies, such as ethanol production by fermentation and the like, and has wide application prospect.

Owner:TSINGHUA UNIV

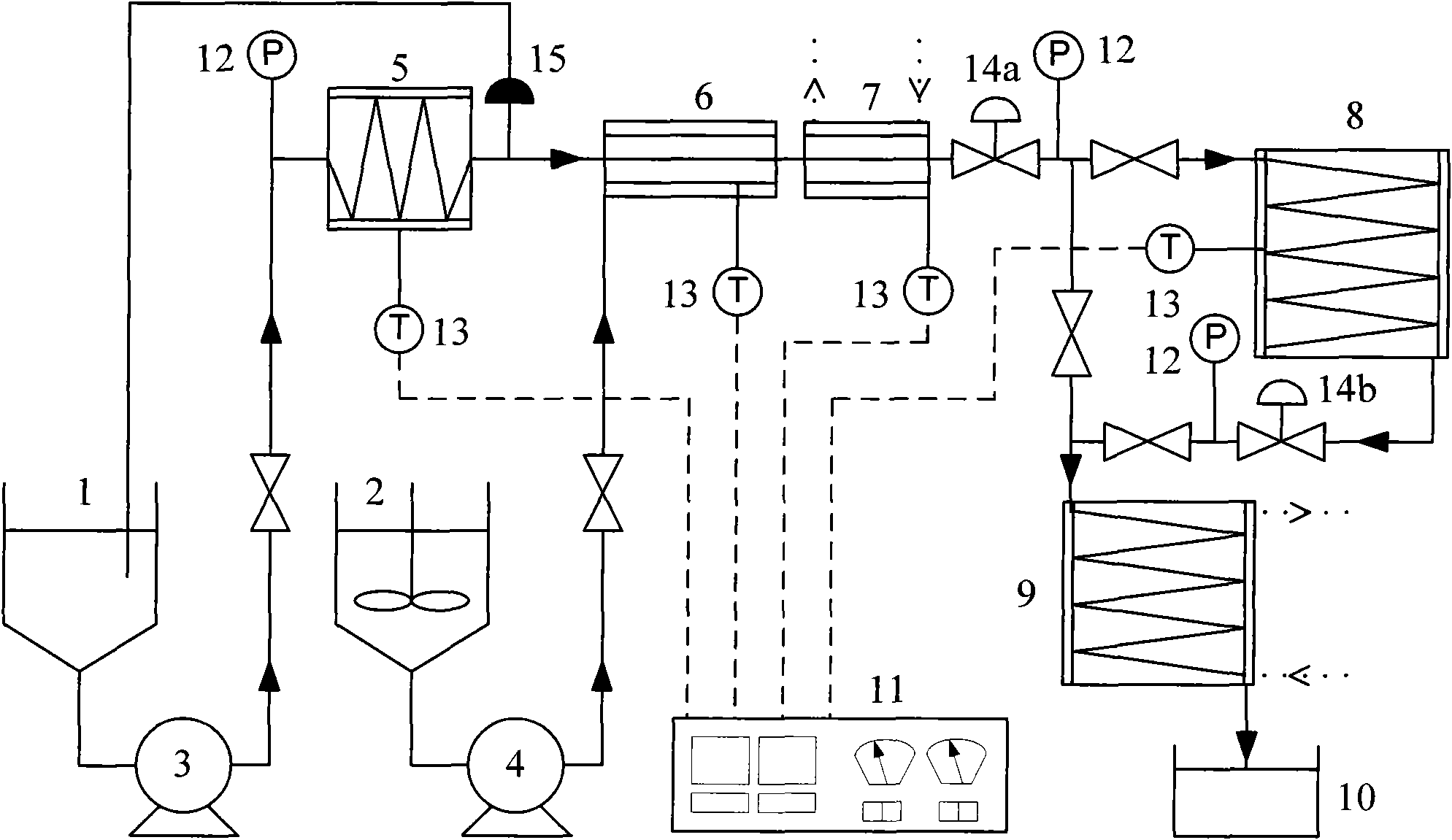

Method for recycling waste concrete

InactiveCN101560073ASolve processingSolve environmental problemsSolid waste managementEcological environmentCost of transport

The invention provides a method for recycling waste concrete, which comprises four steps of vibration screening, reshaping treatment, grinding treatment and mixing compounding. The method can reasonably solve the problem of the reutilization of the waste concrete; on the one hand, the problems of difficult treatment on a large amount of discarded waste concrete, adverse influence on the environment caused by the difficult treatment of a large amount of discarded waste concrete and the like are solved, so that the huge cost of transporting and treating wastes is saved; and on the other hand, the exploitation of natural sandstone is reduced, so that the method protects ecological environment and facilitates the sustainable development of human society.

Owner:长兴清华粉体及新材料工程中心有限公司

Tin stripping agent based on sulfuric acid-ferric salt system and preparing method of tin stripping agent

The invention discloses a tin stripping agent based on a sulfuric acid-ferric salt system and a preparing method of the tin stripping agent, and belongs to the technical field of metal coating stripping. The tin stripping agent based on the sulfuric acid-ferric salt system is prepared by following components including, by content, 150-300 g / L of concentrated sulfuric acid, 100-200 g / L of the ferric salt, 0.1-1 g / L of ferrous sulfate, 0.1-5 g / L of a copper organic corrosion inhibitor, 2-10 g / L of an organic acid complexing agent, 2-3 g / L of a surface active agent, 10-100 g / L of an accelerant and the balance water. The water serves as a solvent of the tin stripping agent based on the sulfuric acid-ferric salt system, nitric acid and fluoride are not contained, toxic gas containing oxynitride is not generated in the tin stripping process, sludge is not generated, the corrosion to copper is extremely low, the copper face is bright, and the tin stripping agent is an environment-friendly tin stripping agent.

Owner:GUANGDONG LEAR ELECTROCHEM LTD

Method for producing marsh gas by utilizing corn cob fungi slag as raw material through anaerobic fermentation

InactiveCN102153261AIncrease profitSolve the problem of random discarding and polluting the environmentBio-organic fraction processingWaste based fuelBiotechnologySlag

The invention discloses a method for producing marsh gas by utilizing corn cob fungi slag as a raw material through anaerobic fermentation. The method comprises the following steps: mixing the fungi slag wasted after corn cob is used as a main raw material to cultivate edible fungus with pig manure or cow dung, adding a methane reagent, and carrying out pile fermentation; and putting fermentationraw materials in a household methane-generating pit or an anaerobic reactor, wherein the addition amount of the raw materials is 80-130 kg per cubic meter of pit volume. In the invention, generation of methane via anerobic fermentation is achieved by carrying out reasonable proportioning, pretreatment, pile outside the pit, fermentation starting and the like on the fermentation raw materials, thereby effectively solving the problem that the pollution is caused by discarding the fungi slag at random and simultaneously turning waste into wealth. After the method is utilized, the gas can be normally generated by the fungi slag in the household, and the method is simple with no need of special equipment and can be applied and disseminated in edible fungus cultivating households.

Owner:INST OF SOIL & FERTILIZER SHANDONG ACAD OF AGRI SCI

Heterotrophic nitrification-aerobic denitrification compound bacterial agent for low-temperature high ammonia-nitrogen removal and application

ActiveCN109082387AActivate cold resistanceGrow fastTreatment using aerobic processesBacteriaMicroorganismCupriavidus

The invention relates to a heterotrophic nitrification-aerobic denitrification compound bacterial agent for low-temperature high ammonia-nitrogen removal and application. The compound bacterial agentis formed by compounding of 10-20% of cupriavidus SWA1, 5-20% of alcaligenes faecalis, 10-30% of acinetobacter and 20-50% of ochrobacterum TAC-2. The compound bacterial agent has advantages of high ammonia-nitrogen resistance, low-temperature resistance, heavy metal resistance and synchronous nitrification and denitrification; by synergistic effects of four microorganisms, efficient denitrification of high ammonia-nitrogen wastewater can be realized in an aerobic environment under low-temperature conditions.

Owner:CHONGQING UNIV OF TECH

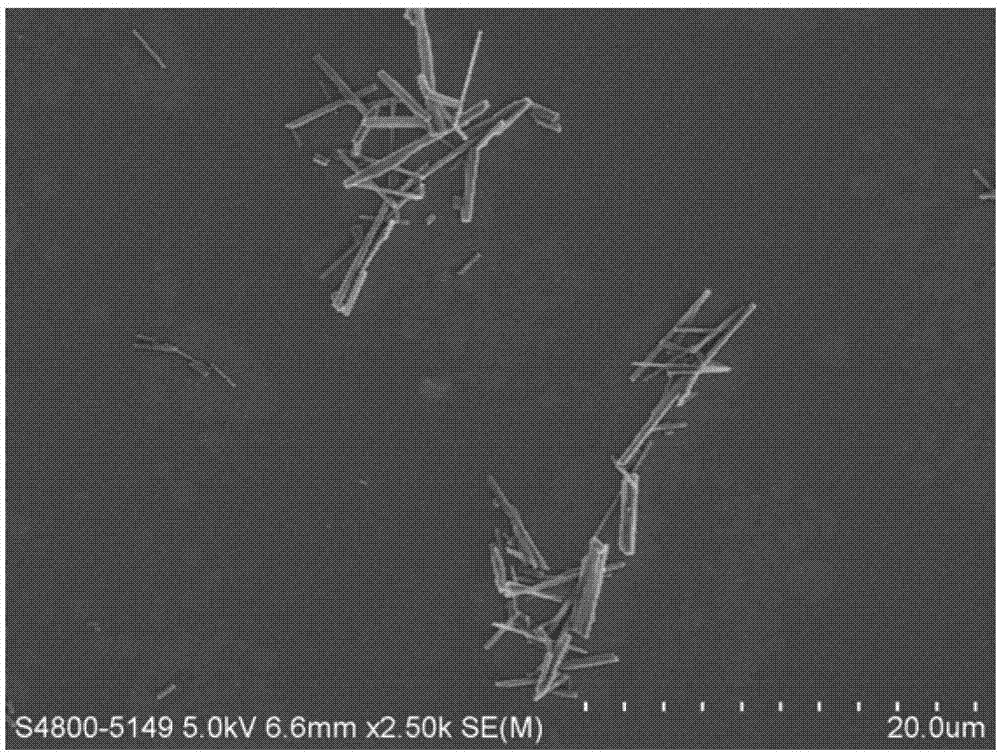

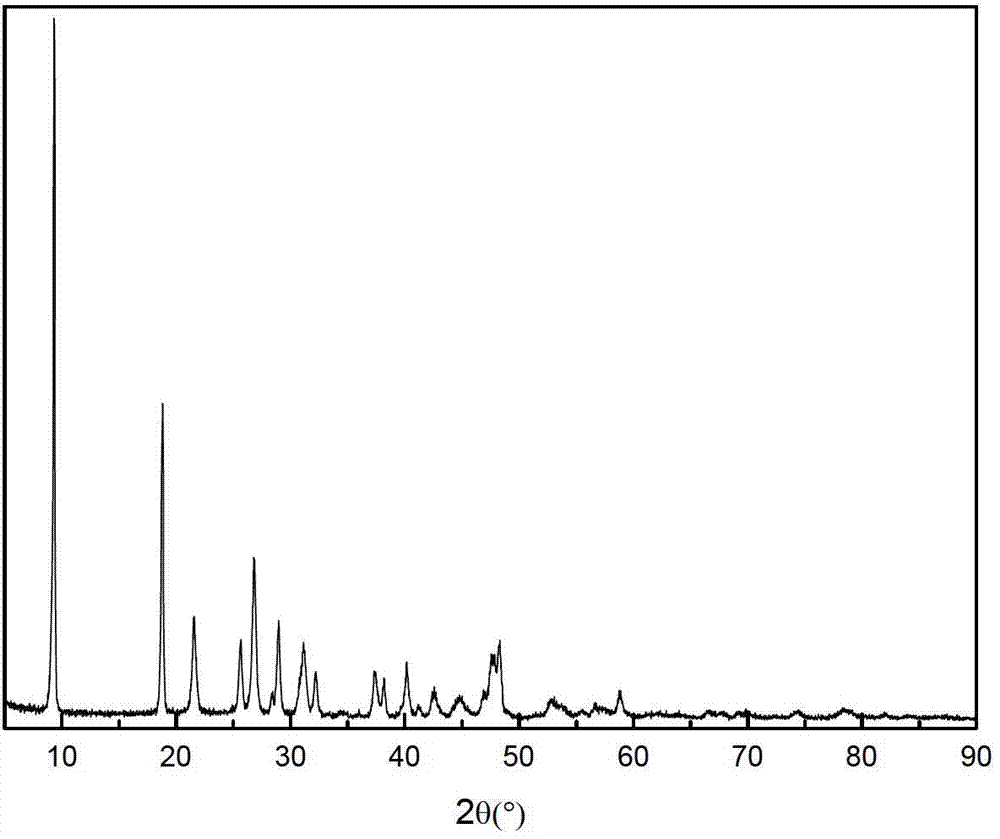

Production method and application of terephthalic metal slat whisker

ActiveCN103173845ASolve the vagariesSolve processingPolycrystalline material growthFrom normal temperature solutionsWastewaterWhiskers

The invention relates to a production method and application of a terephthalic metal slat whisker. The production method disclosed by the invention comprises the steps of: recycling crude terephthalic acid of which the purity is not smaller than 95% by an alkali peeling waste water treatment process; adding and dissolving crude terephthalic acid in a caustic soda solution as a raw material; adding a surface active agent after regulating the pH value; stirring the mixed solution uniformly, then adding a dissolvable calcium salt, stirring and ageing, thereby obtaining the terephthalic metal slat whisker. The terephthalic metal slat whisker can be used as an active filler of rubber, and the addition of the whisker can greatly improve the mechanical properties of a rubber plastic material.

Owner:常州市五洲环保科技有限公司

Method for producing high-efficiency washing soap powder by using sewer oil or swill oil

InactiveCN1603396ASolve processingSolve the use problemDetergent powders/flakes/sheetsSoap detergent compositionsOil and greasePowder method

The invention discloses a kind of use ditch oil or slops incompatible highly effective washes clothes with the soap powder method, including the ditch oil or slops the incompatible pretreatment, the ditch oil or slops the incompatible acidification, the ditch oil or slops the incompatible saponification, the saponified fluid synergize, bestows on the shape, makes grain, is dry and so on the step. The invention method, both reduced the ditch oil either slops incompatibly and has stopped up the derelict land ditch oil to the environment pollution from the source or slops incompatible two edible, has guaranteed people's health, moreover also provides the sufficient raw material supply for the fat chemistry, simultaneously this method also has the soap powder decontamination strength which the production cost low, makes to be strong, not injurying also the non- pollution characteristic, has the better application promotion value.

Owner:盛金英

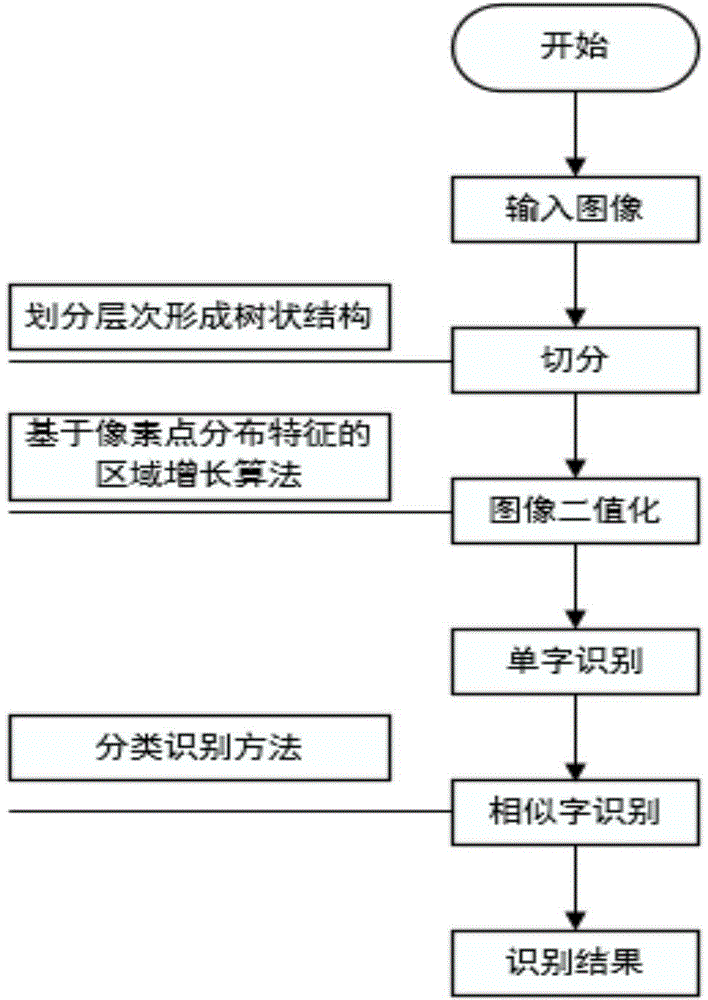

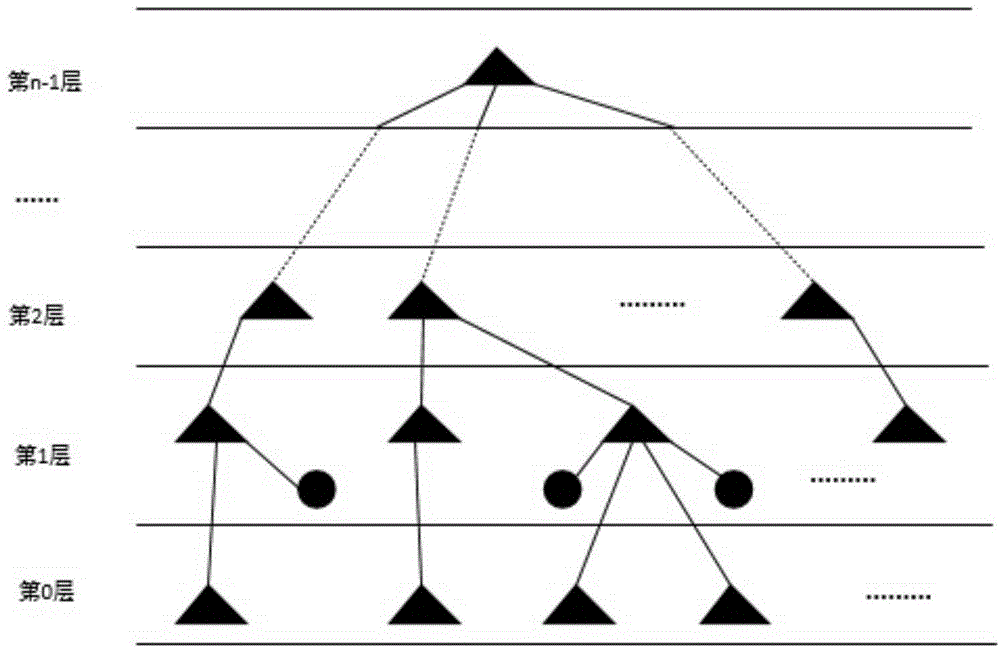

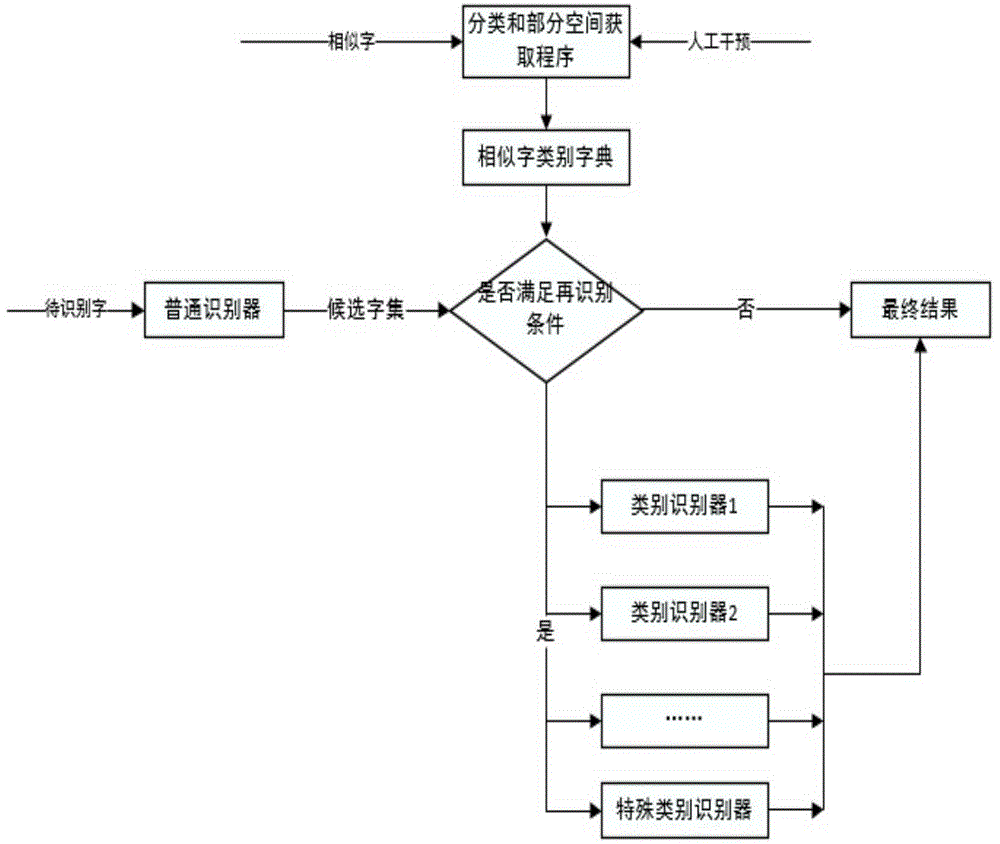

Chinese character recognition method based on optical character recognition technology

InactiveCN104156706AEasy to identifyImprove recognition efficiencyCharacter and pattern recognitionInformation processingText recognition

The present invention discloses a Chinese character recognition method based on an optical character recognition technology. For an inputted gray scale text image, a cutting result is obtained by a hierarchical structure cutting method based on a connected region, then the binaryzation and denoising operations are carried out on the image by a region-growing algorithm based on the pixel distribution characteristics to obtain a to-be-recognized character, and then the to-be-recognized character is sent to a general single character recognizer to recognize to thereby obtain a candidate character set, and finally, a final recognition result is obtained by a similar character classification and recognition method. Compared with the prior art, the Chinese character recognition method based on the optical character recognition technology of the present invention enables the character recognition accuracy and efficiency to be improved effectively, enables the text information to be inputted to a computer at a high speed, solves the conflict between the low-speed information input and the high speed information processing, and enables the onerous keyboard recording work to be simplified.

Owner:北京华电天益信息科技有限公司

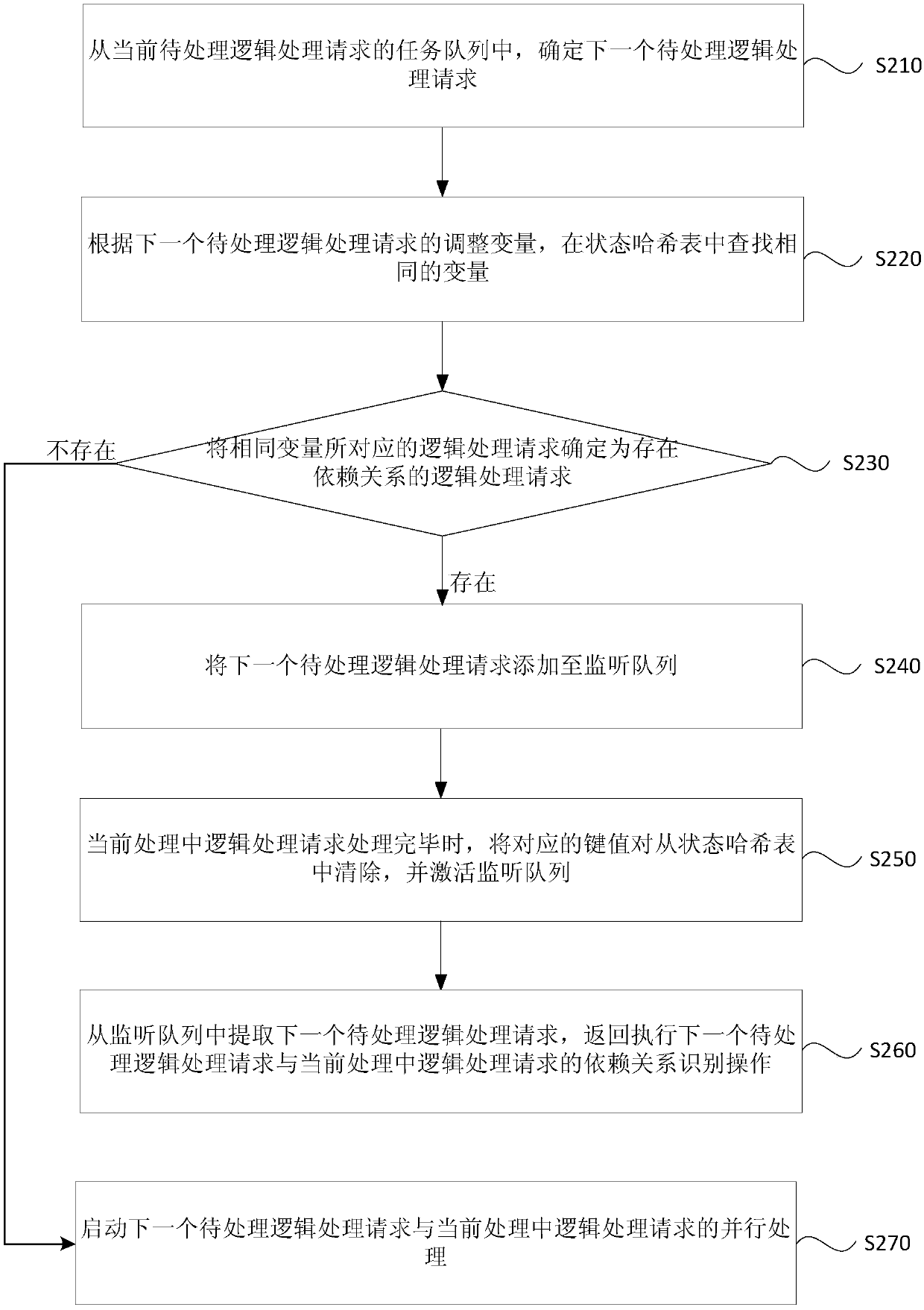

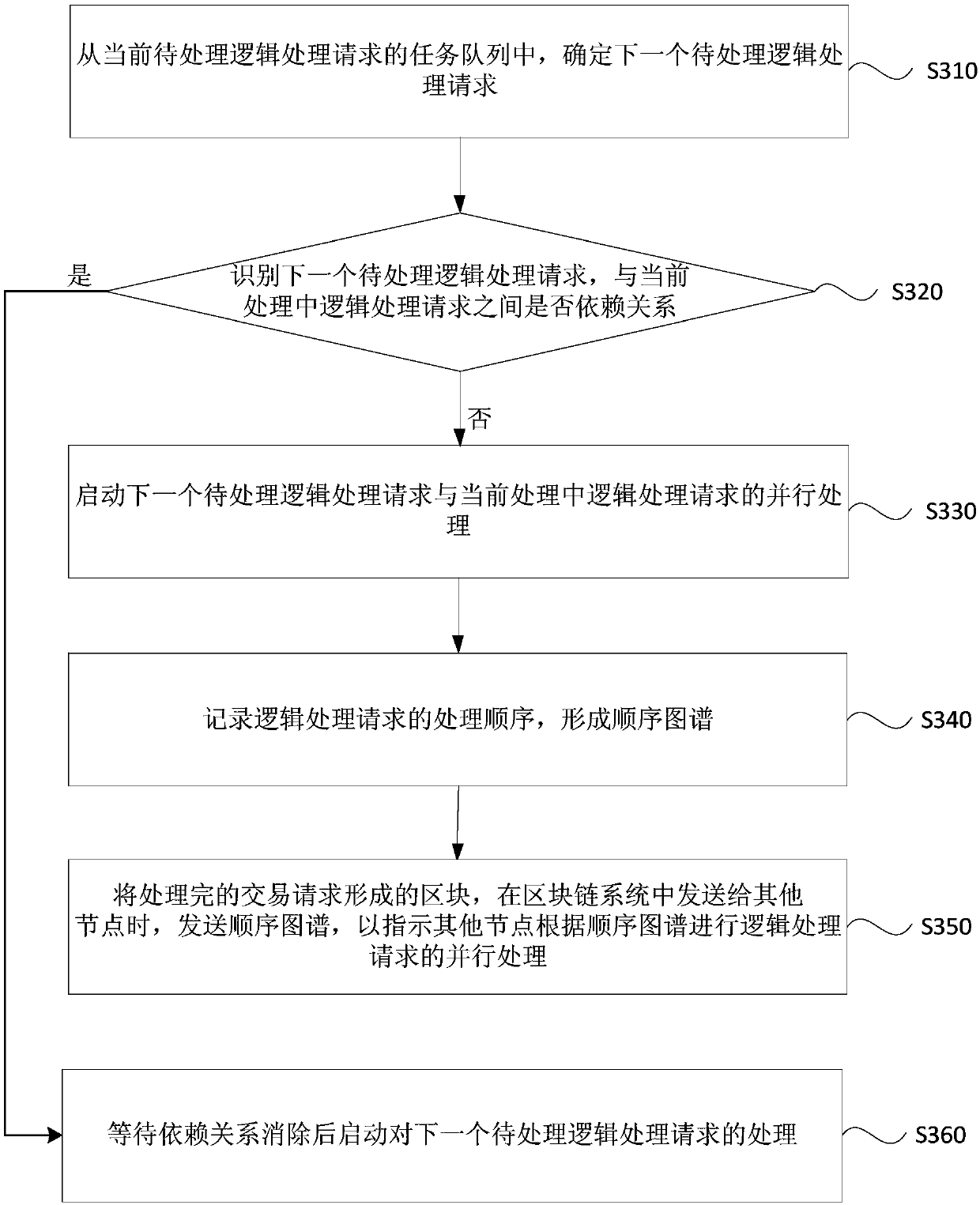

Block chain data parallel processing method and device, equipment and storage medium

ActiveCN108681565AImplement parallel processingSolve processingFinanceSpecial data processing applicationsParallel processingBlockchain

An embodiment of the invention provides a block chain data parallel processing method and device, equipment and a storage medium. The method comprises the following steps: determining a next logical processing request to be processed from a task queue of current logical processing requests to be processed; identifying a dependency relationship between the next logical processing request to be processed and the current logical processing request being processed; if there is no dependency relationship, starting parallel processing of the next logical processing request to be processed and the current logical processing request being processed; and if there is a dependency relationship, starting the processing of the next logical processing request to be processed after the dependency relationship is eliminated. The embodiment of the invention realizes the parallel processing of part of the logic processing requests while taking into account the dependency relationship of the logic processing requests, and improves the processing efficiency.

Owner:BAIDU ONLINE NETWORK TECH (BEIJIBG) CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com