Method for recycling waste concrete

A technology for waste concrete and recycled concrete, applied in solid waste management, sustainable waste treatment, climate sustainability, etc., can solve problems such as the difficulty of concrete waste treatment, and achieve sustainable development, solve treatment difficulties, and save energy. The effect of waste removal and disposal costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

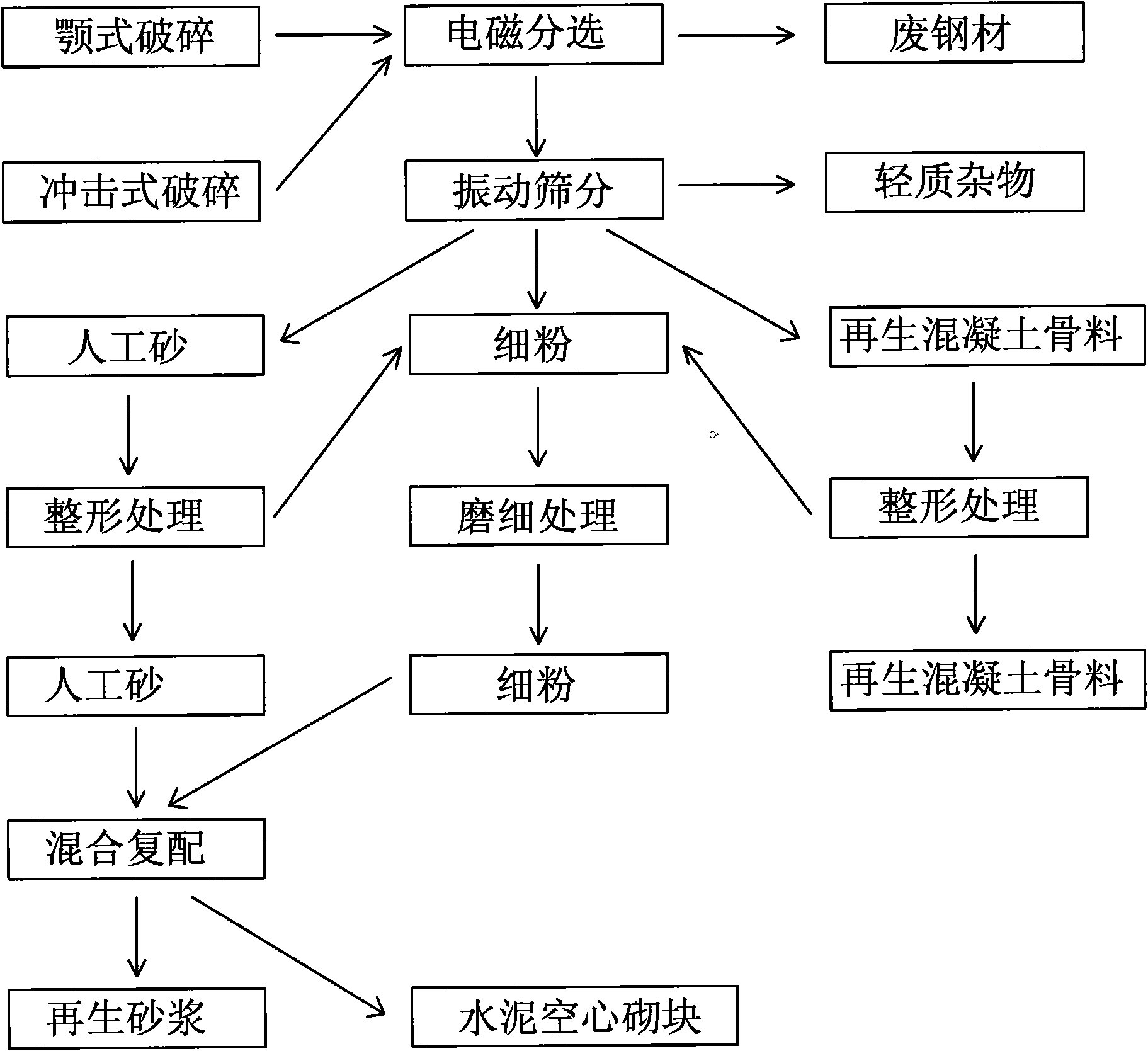

[0019] Such as figure 1 , a method for recycling waste concrete, comprising the following steps:

[0020] Step 1: The waste concrete containing scrap steel is crushed in the second stage by a jaw crusher and an impact crusher, and then the scrap steel is electromagnetically separated by a magnetic separator, and then light impurities are screened out by a vibrating screen to obtain regeneration Concrete aggregate, artificial sand and fine powder;

[0021] Step 2: Reshaping the recycled concrete aggregate and artificial sand obtained in Step 1 respectively in a mixing and shaping machine to prepare recycled concrete aggregate and artificial sand with good particle shape, and the recycled concrete aggregate and artificial sand after shaping treatment. The average particle size of the sand particles is distributed between 2 and 25 mm, and the bulk density of the recycled concrete aggregate after plastic treatment is 1.3 to 1.6 tons per cubic meter, and the particles have no obvi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com