Biomass supercritical and subcritical combined continuous type pretreatment and hydrolysis equipment and method

A supercritical and subcritical technology, used in the preparation of sugar derivatives, sugar derivatives, sugar derivatives, etc., can solve the problem of high energy consumption, batch pretreatment and hydrolysis operations are not continuous, and the scale of equipment is difficult to scale up, etc. problem, to achieve the effect of no product inhibition, overcoming the large amount of catalyst and rapid reaction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

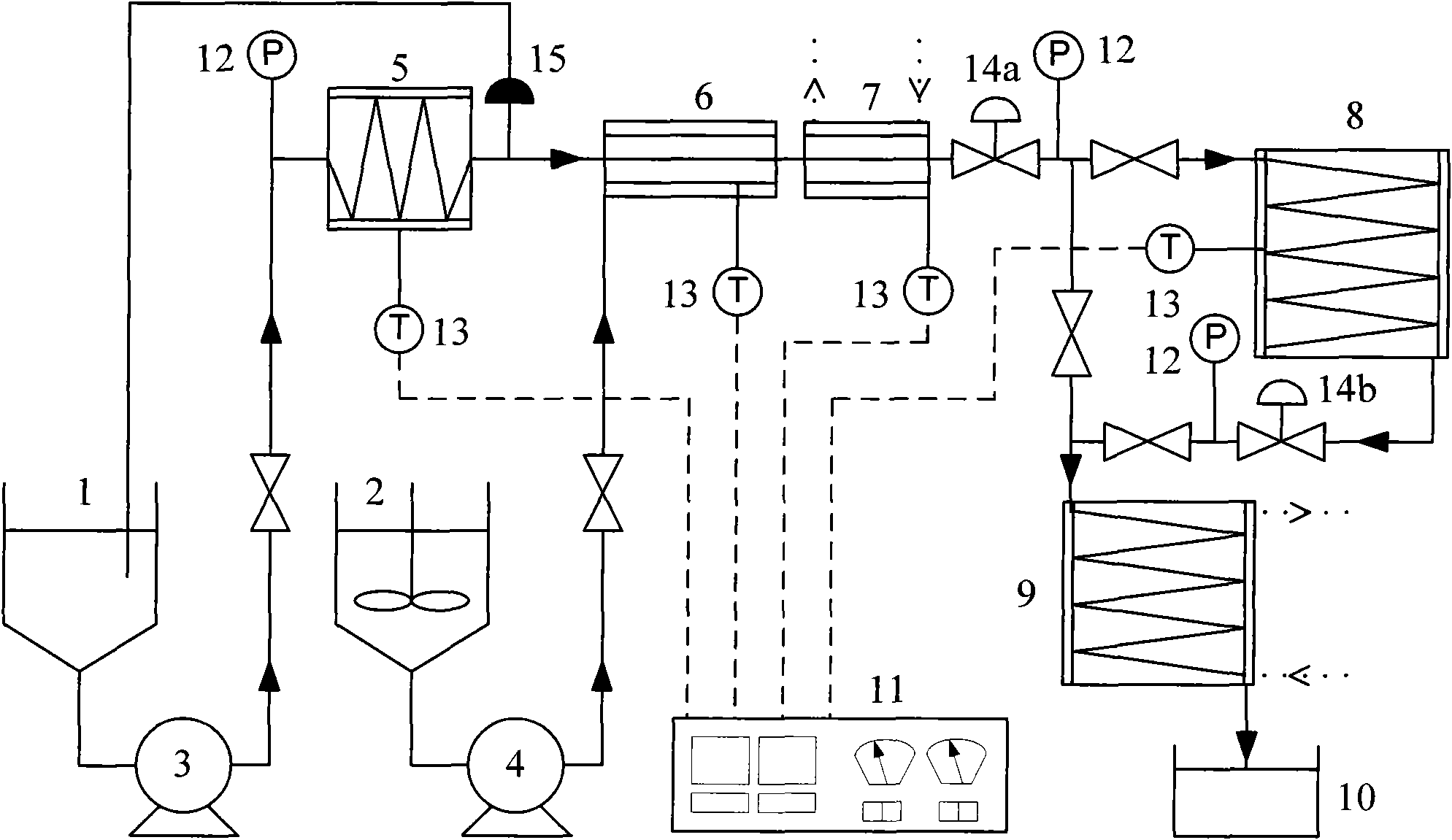

[0022] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

[0023] figure 1 It is a schematic diagram of the structural principle and method flow chart of the supercritical subcritical combined continuous pretreatment and hydrolysis equipment of the present invention. The equipment includes a water storage tank 1, a stirring storage tank 2, a preheating system 5, a supercritical reaction system 6, a primary cooling system 7, a subcritical reaction system 8, a final cooling system 9, a product collection system 10 and electronic A temperature control system 11, the water storage tank 1 is connected to the inlet of the preheating system 5 through a pipeline through a high-pressure water inlet pump 3, and the outlet of the preheating system 5 is connected to the inlet of the supercritical reaction system 6 through a tee; The storage tank 2 is connected to the inlet of the supercritical reaction ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com