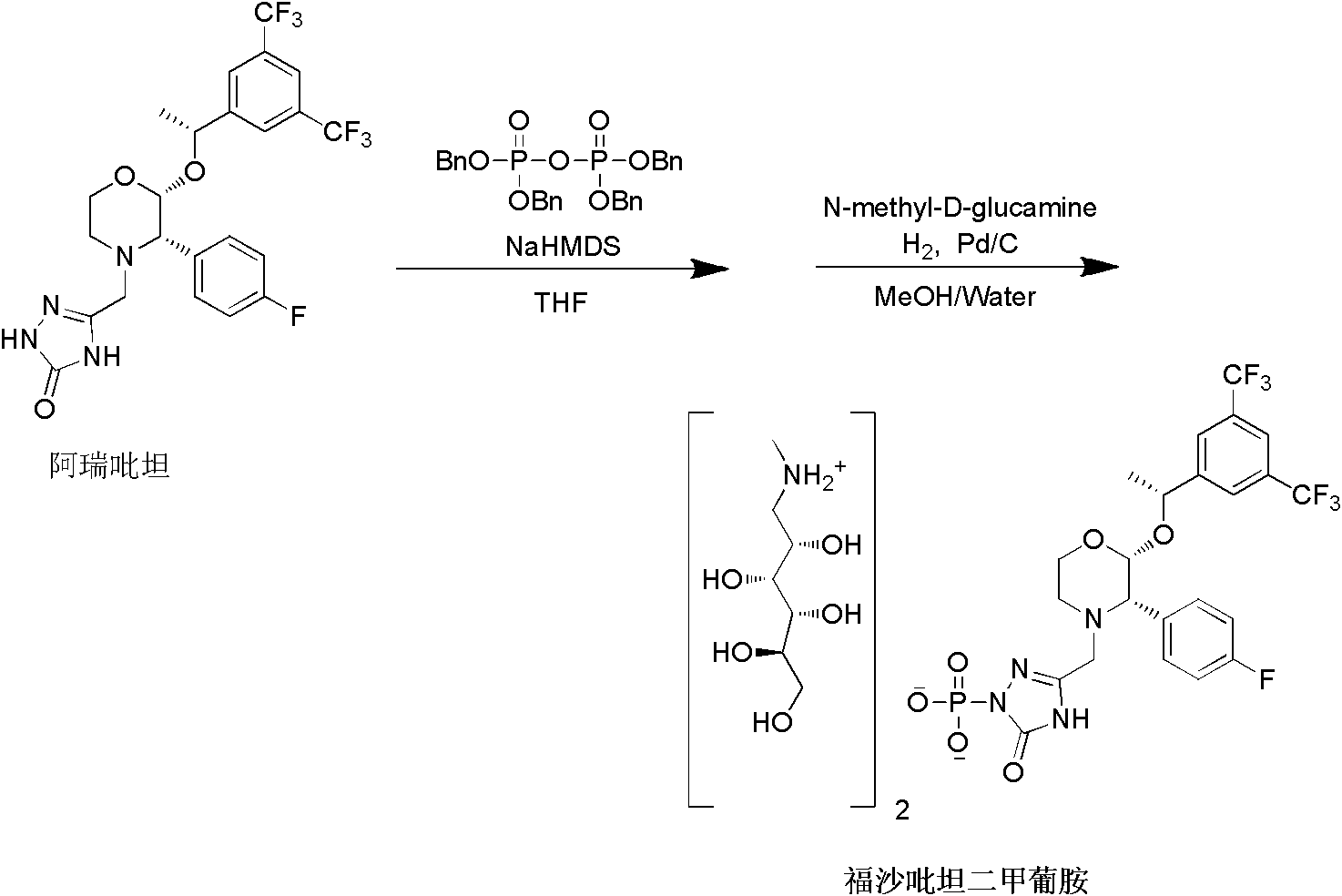

Preparation method for fosaprepitant dimeglumine

A technology of fosaprepitant dimeglumine and methanol, applied in the field of drug preparation, can solve the problems of long reaction time, high cost of industrial production, low yield, etc., and achieve the effects of simple operation, low cost and high yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

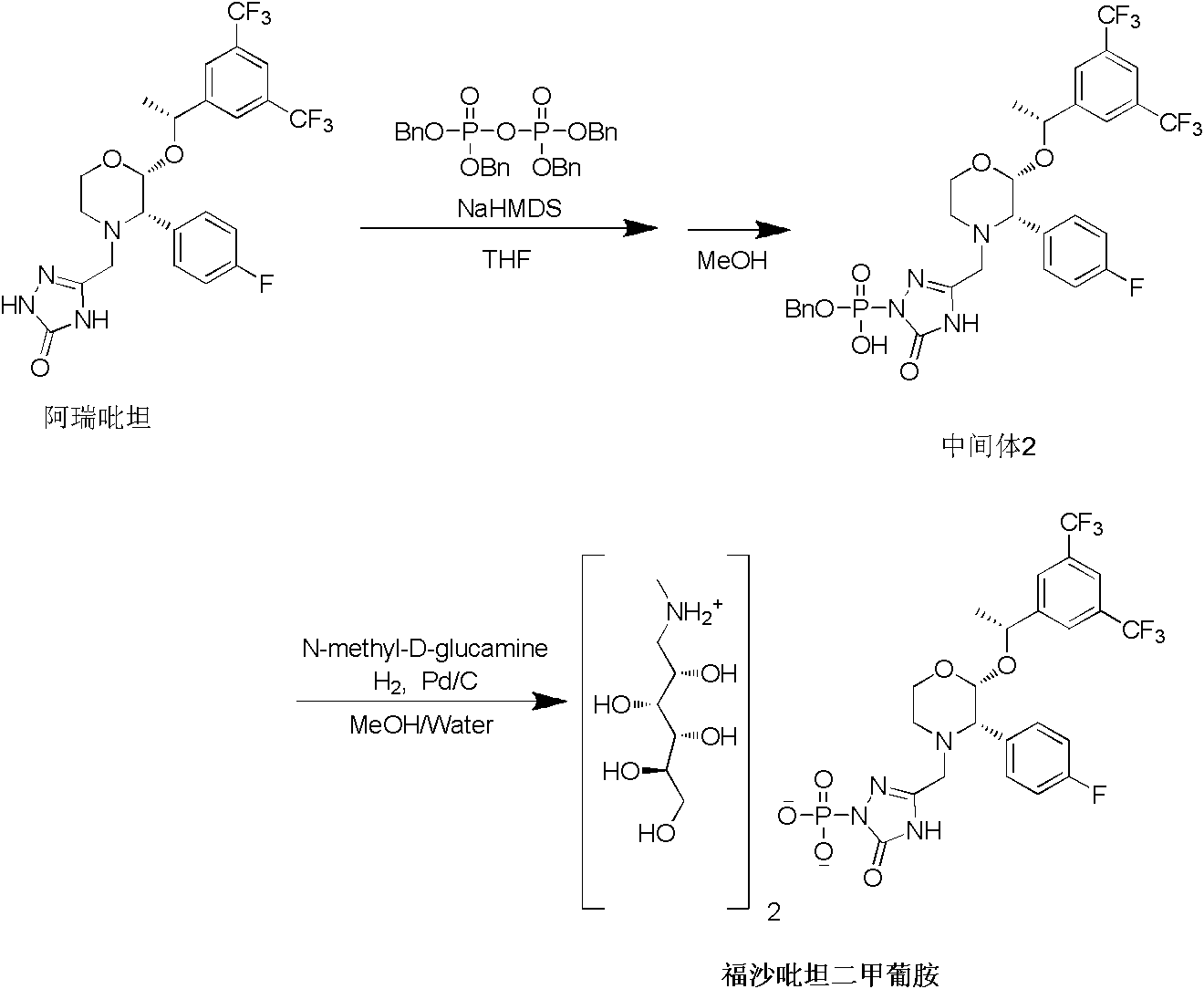

[0029] Embodiment 2 prepares mono-O-phenyl phosphate

[0030]

[0031] In a 500mL single-necked flask, add methanol (150mL) to dissolve 40g of bis-O-phenyl phosphate in Example 1, raise the temperature to 45°C, and react for 4h. A large amount of white precipitate precipitates, which is tracked by TLC until the bis-O-phenyl The base phosphoric acid ester reacted completely, stopped the reaction, and filtered to obtain a white solid, which was mono-O-phenyl phosphoric acid ester (25.1 g, total yield of Examples 1 and 2: 95%). Purity > 98%;

[0032] 1 H NMR (DMSO-d6, 500MHz, ppm) δ7.86(s, 1H), 7.52(brs, 2H), 7.34~7.29(m, 7H), 7.08(t, J=8.5, 2H), 5.01~4.94 (m, 2H), 4.36(s, 1H), 4.13(t, J=15.0, 2H), 3.63(s, 1H), 3.54(d, J=20.0, 2H), 3.17(s, 1H), 2.82 (t, J=15.0, 2H), 1.43 (d, J=6.6, 3H). ESI-MS 705.1 (M+H, 100%).

Embodiment 3

[0033] Embodiment 3 prepares fosaprepitant dimeglumine

[0034]

[0035] In a 2L catalytic hydrogenation reactor, add 2.0g 10% Pd / C, at 0.4MPa, at room temperature (28°C), hydrogenate for 0.5h, then add the mono-O-phenyl phosphate (20.0 g, 28.4mmol), N-methyl-D-glumine (11.1g, 56.9mmol), methanol (200mL), water (10mL), make its solid dissolve completely; ), hydrogenation reaction 4h, TLC analysis, raw material reaction is complete, stop reaction. Diatomaceous earth was used to filter out Pd / C, methanol (400 mL) was used to wash diatomaceous earth, the filtrate was dried over anhydrous sodium sulfate, filtered, and the filtrate was concentrated in vacuo at 35°C to obtain the crude product fosaprepitant dimeglumine. The crude product was completely dissolved in methanol (100 mL), quickly dropped into isopropanol (600 mL), and a large amount of white precipitate was precipitated, which was filtered with air isolation to obtain a white filter cake, which was dried under reduce...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com