Concrete with ultra-large volume, high strength and low hydration heat

A low heat of hydration, concrete technology, applied in the field of building materials, can solve the problems of reduced physical and mechanical properties of concrete, reduced concrete life, easy penetration of corrosive media, etc., achieve obvious pouring effect, improve the ability to resist cracking, and reduce hydration Effect of Heat and Heat Release Rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

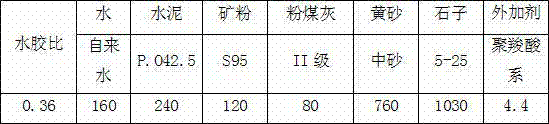

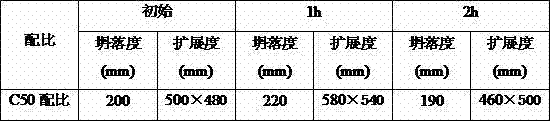

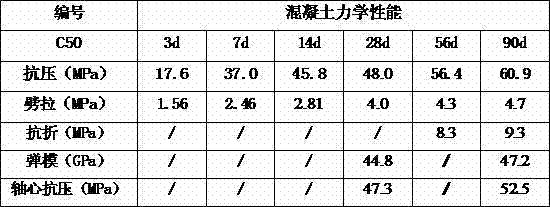

Method used

Image

Examples

Embodiment Construction

[0023] Below we will further elaborate on the ultra-large volume, high strength and low heat of hydration concrete of the present invention in conjunction with specific examples, and strive to understand the present invention more clearly from the aspects of theoretical design and practical application, but this cannot be used to limit the present invention. protection scope of the invention.

[0024] The control of cracks in super-large concrete is a systematic project. The selection and preparation of cementitious materials for mass concrete, concrete production and pouring construction, and maintenance will all affect the quality of the final concrete project. However, the heat of hydration of cementitious materials is the most important reference parameter for the design of mass concrete temperature crack control, and it is also the source of controlling the cracking of super-volume concrete. After a large number of small tests, multiple pilot tests and a simulation test,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hydration enthalpy | aaaaa | aaaaa |

| hydration enthalpy | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com