Metakaolin concrete for oversized structure and mixing proportion designing method

A technology of metakaolin and concrete, applied in the direction of ratio control, instrumentation, non-electric variable control, etc., can solve the problems of structural impermeability, integrity, durability, even unfavorable bearing capacity, harmful cracks, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

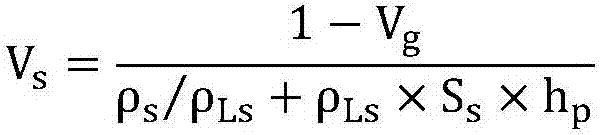

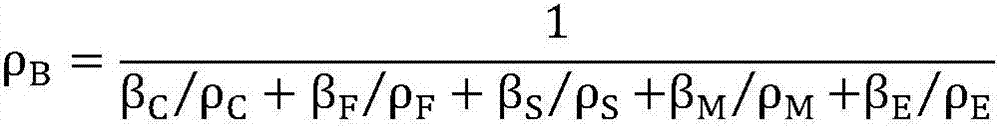

[0073] The C30 metakaolin concrete used for ultra-large volume structures is composed of crushed stone, high-quality machine-made sand, P·O42.5 cement, II-class fly ash, S75 slag powder, metakaolin, I-type UEA expansion agent, polypropylene fiber, retarding Type polycarboxylate superplasticizer and water are mixed according to a certain ratio. The mass ratio of each component of unilateral concrete is as follows: crushed stone 1025kg, high-quality machine-made sand 839kg, P·O42.5 cement 213kg, grade II powder Coal ash 37kg, S75 slag powder 74kg, metakaolin 22kg, Type I UEA expansion agent 22kg, polypropylene fiber 0.6kg, retarded polycarboxylate superplasticizer 6.26kg, water 176kg. The mix ratio design of concrete is carried out in the following steps: (1) Determine the volume of crushed stone (V g ) and mass (m g ), m g =V g ×ρ g =0.3782×2710=1025kg. (2) Determine the volume of fine machine-made sand (V s ) and mass (m s ), m s =V s ×ρ s =0.3108×2700=839kg. (3...

example 2

[0075] The C35 metakaolin concrete used for super-large volume structures is composed of crushed stone, high-quality machine-made sand, P O42.5 cement, class II fly ash, S75 slag powder, metakaolin, type I UEA expansion agent, polypropylene fiber, retarding Type polycarboxylate superplasticizer and water are mixed according to a certain ratio. The mass ratio of each component of unilateral concrete is as follows: crushed stone 1031kg, high-quality machine-made sand 830kg, P·O42.5 cement 233kg, grade II powder Coal ash 40kg, S75 slag powder 80kg, metakaolin 24kg, type I UEA expansion agent 24kg, polypropylene fiber 0.9kg, retarded polycarboxylate superplasticizer 7.22kg, water 172kg. The mix ratio design of concrete is carried out in the following steps: (1) Determine the volume of crushed stone (V g ) and mass (m g ), m g =V g ×ρ g =0.3763×2740=1031kg. (2) Determine the volume of fine machine-made sand (V s ) and mass (m s ), m s =V s ×ρ s =0.3061×2710=830kg. (3...

example 3

[0077] The C40 metakaolin concrete used for super-large volume structures is composed of crushed stone, high-quality machine-made sand, P O42.5 cement, class II fly ash, S75 slag powder, metakaolin, type I UEA expansion agent, polypropylene fiber, retarding Type polycarboxylate superplasticizer and water are mixed according to a certain ratio. The mass ratio of each component of unilateral concrete is as follows: crushed stone 1016kg, high-quality machine-made sand 825kg, P·O42.5 cement 267kg, grade II powder 42kg of coal ash, 64kg of S75 slag powder, 25kg of metakaolin, 25kg of type I UEA expansion agent, 0.9kg of polypropylene fiber, 7.61kg of retarded polycarboxylate superplasticizer, and 168kg of water. The mix ratio design of concrete is carried out in the following steps: (1) Determine the volume of crushed stone (V g ) and mass (m g ), m g =V g ×ρ g =0.3764×2700=1016kg. (2) Determine the volume of fine machine-made sand (V s ) and mass (m s ), m s =V s ×ρ ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| aspect ratio | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com