Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

33results about How to "Reduce risk of defects" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

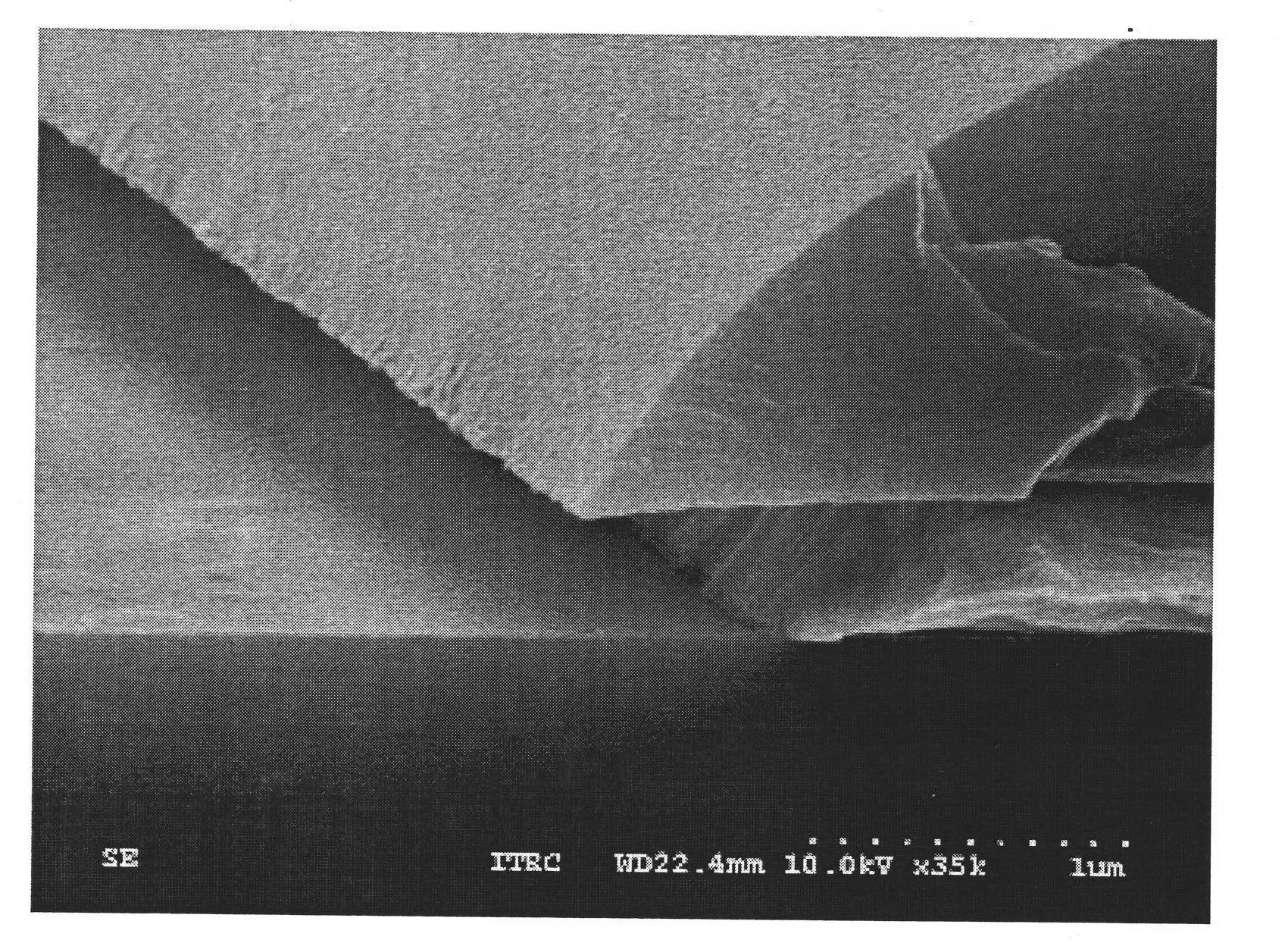

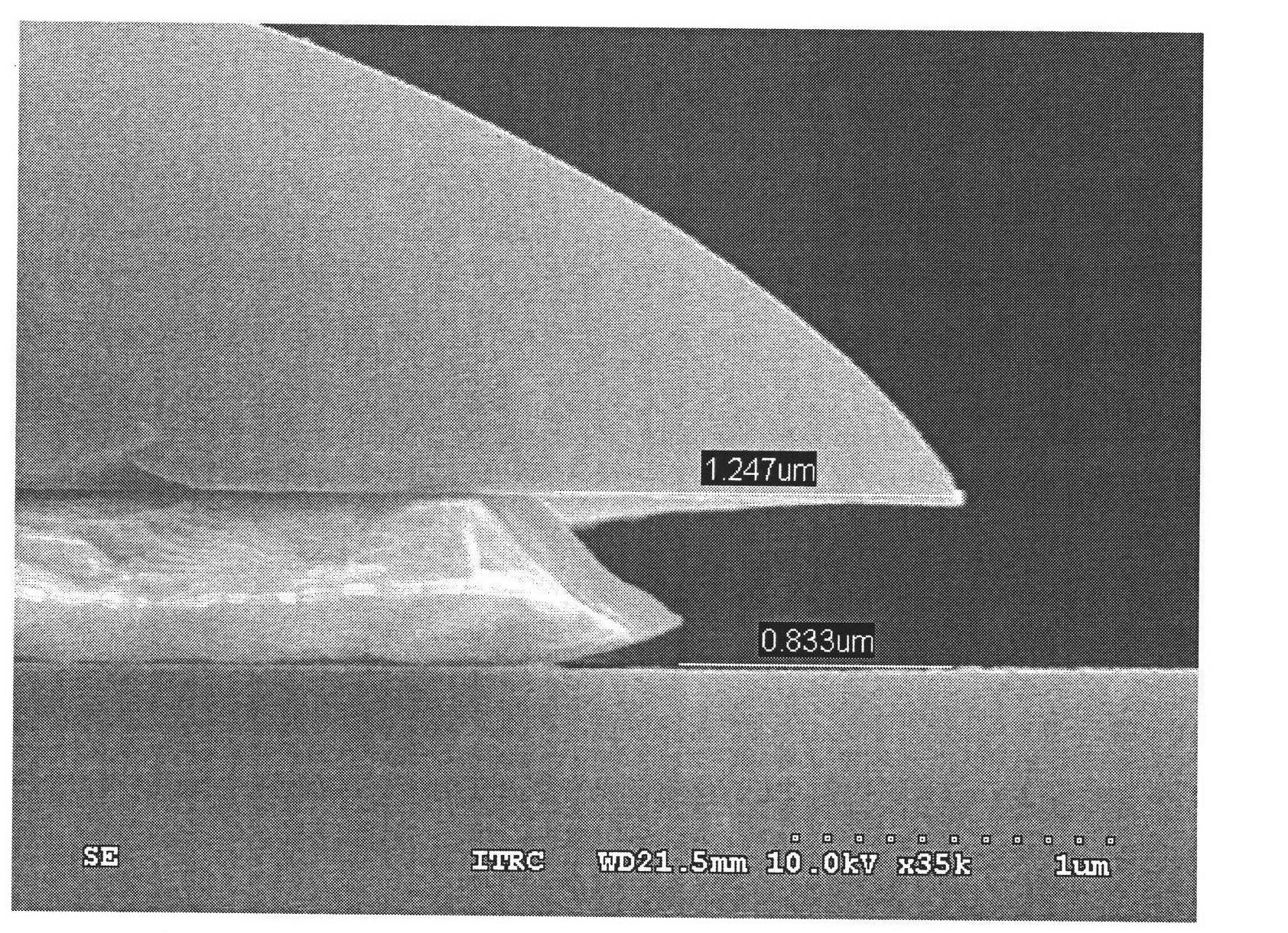

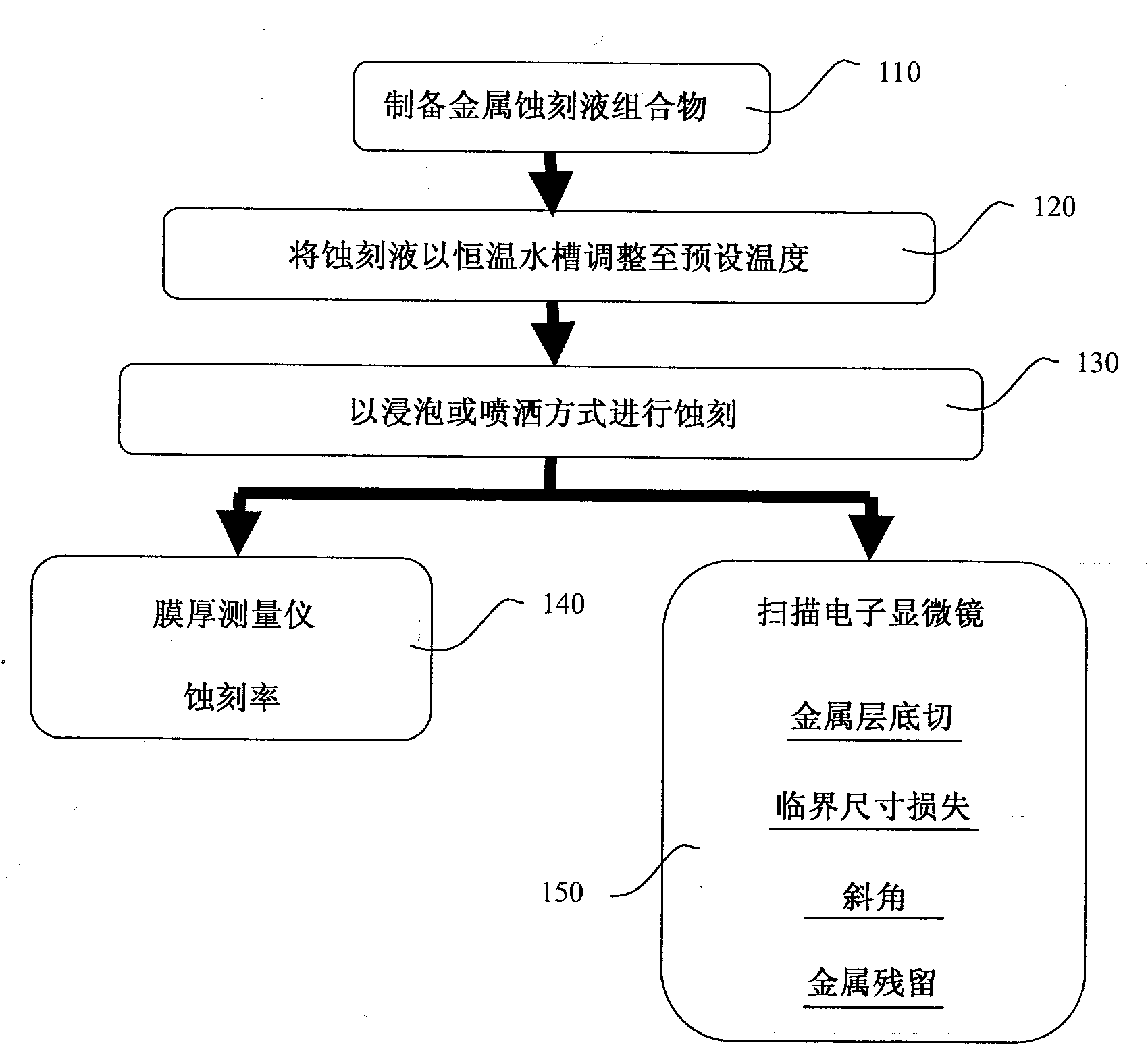

Metal etching liquid composition and etching method

The invention relates to a metal etching liquid composition and an etching method, and provides a metal etching liquid composition for etching copper, a copper alloy, molybdenum, a molybdenum alloy, a multilayer alloy containing the copper alloy and the molybdenum alloy, or copper / molybdenum multilayer metal. The metal etching liquid composition comprises the following components in percentage by weight: 6 to 30 percent of oxidant, 0.1 to 10 percent of chelating agent, 0.1 to 5 percent of nitrogen-containing compound, 0.2 to 10 percent of inorganic salt and the balance of water-based medium, wherein the inorganic salt comprises 0.1 to 5 weight percent of sulfate and 0.1 to 5 weight percent of phosphate.

Owner:PROSPERCHEM

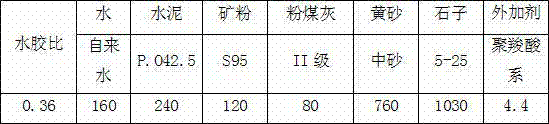

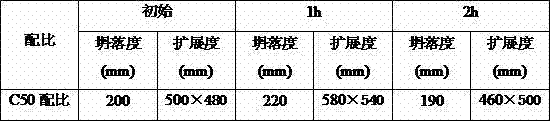

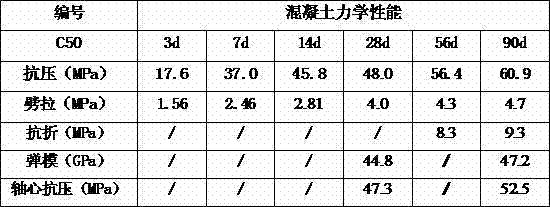

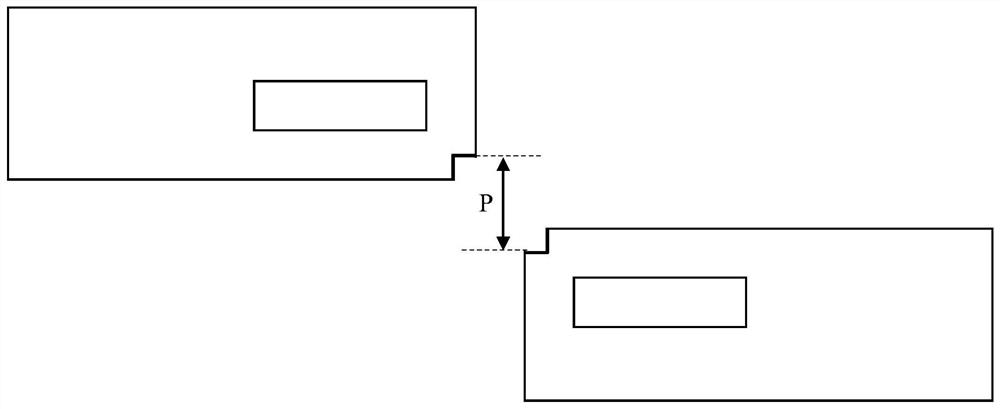

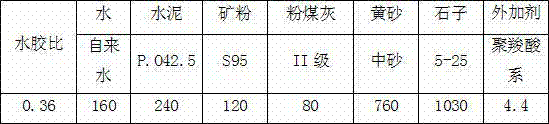

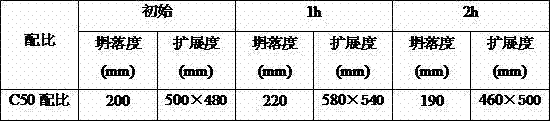

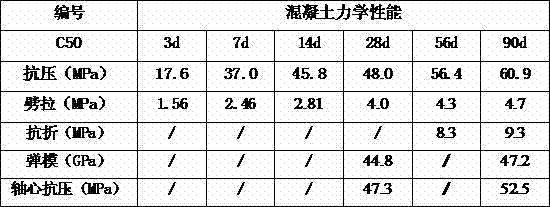

Concrete with ultra-large volume, high strength and low hydration heat

The invention relates to concrete with ultra-large volume, high strength and low hydration heat. The concrete comprises the following components in parts by weight (cube dosage kg / m3): 200-260 parts of cement, 100-160 parts of mineral powder, 80-100 parts of fly ash, 740-800 parts of fine aggregate, 1010-1050 parts of coarse aggregate, 4.0-5.0 parts of additive and 155-165 parts of water. The concrete with ultra-large volume, high strength and low hydration heat can be used to effectively reduce the hydration heat, greatly reduce the cracking risk of the large-volume concrete from the source and increase the engineering quality.

Owner:SHANGHAI CONSTR BUILDING MATERIALS TECH GRP CO LTD +5

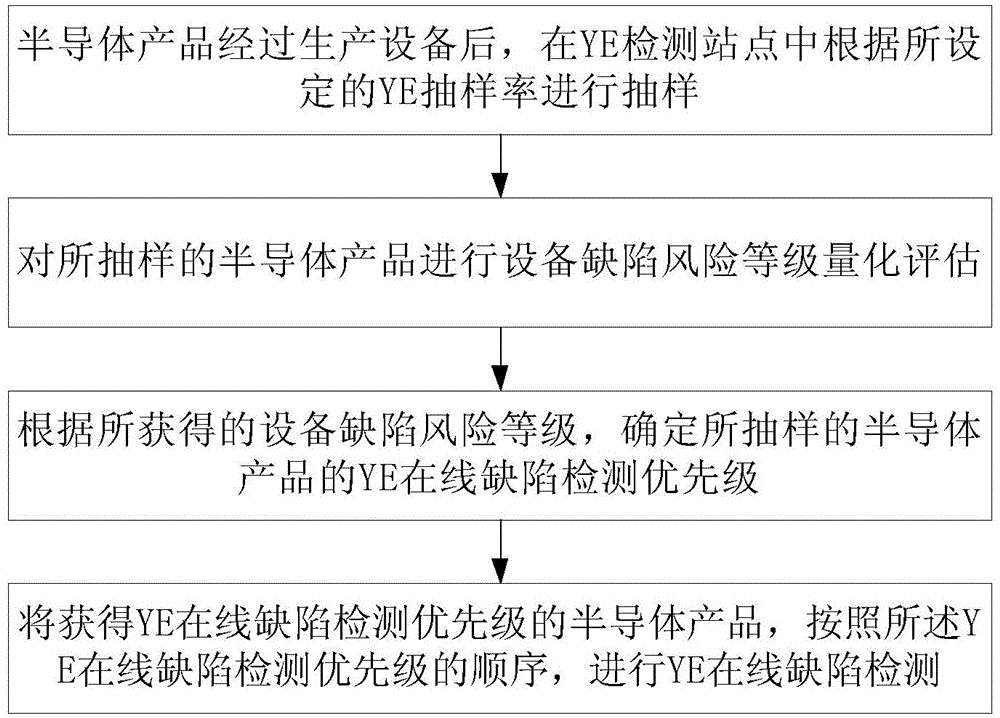

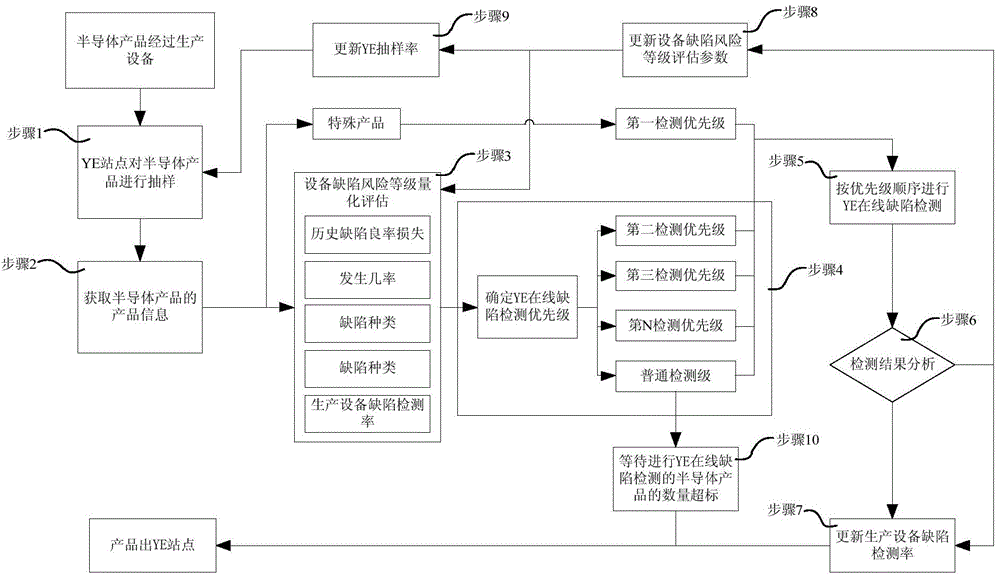

Yield enhancement (YE) on-line detection management and control method

ActiveCN104867840AImprove detection efficiencyReduce risk of defectsSemiconductor/solid-state device testing/measurementEquipment DefectsVia device

The present invention discloses a YE on-line detection management and control method. The method comprises the steps of sampling the semiconductor products passing the production equipment according to a set YE sampling rate, determining the equipment defect risk grade by an equipment defect risk grade quantification assessment means, deciding the YE on-line defect detection priorities of the sampled semiconductor products according to the equipment defect risk grade to carry out the subsequent equipment defect detection, then adjusting a YE sampling rate, the YE on-line defect detection priorities, an equipment defect risk grade quantification assessment parameter, a production equipment defect detection rate according to the good and bad equipment defect detection results. The YE on-line detection management and control method of the present invention optimizes the YE sampling rate, the YE on-line defect detection priorities, the equipment defect risk grade quantification assessment parameter and the production equipment defect detection rate in the YE on-line defect detection according to each time of detection result, thereby improving the detection efficiency of a YE on-line detection board, and reducing the defect risk of a production board.

Owner:SEMICON MFG INT (SHANGHAI) CORP

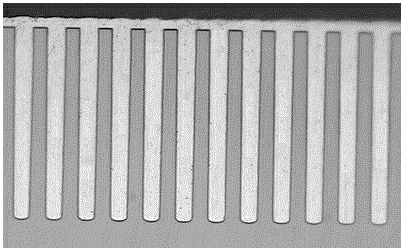

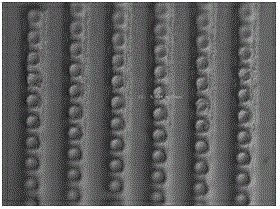

Additive B capable of controlling TSV deep hole copper plating crystallization and growth mode and application of additive B

The invention discloses an additive B capable of controlling the TSV deep hole copper plating crystallization and the growth mode and an application of the additive B. The additive B comprises, by weight, 1%-10% of one of polyethylene glycol and polyvinyl alcohol with the molecular weight being 200 to 20,000 or the mixture of polyethylene glycol and polyvinyl alcohol with different molecular weights, 0.01%-10% of an EO-PO-EO-quaternary ammonium compound, 0.1%-5% of a thioimidazole compound, 0.1%-10% of polyethylenimine and derivative thereof and the balance water. By means of the additive B, the TSV deep hole electroplating copper filling mode can be changed, the crystal habit of copper is changed, and thus defect-free micro protrusion filling along holes of TSV micro holes can be achieved; the copper crystallization shape and the hole opening growth mode are effectively controlled, the surface copper thickness is reduced, TSV deep hole opening micro protrusions are also reduced, hence, the subsequent CMP processing pressure is lightened, the subsequent processing cost is lowered, and the yield and the production efficiency are greatly improved.

Owner:SHANGHAI SINYANG SEMICON MATERIALS

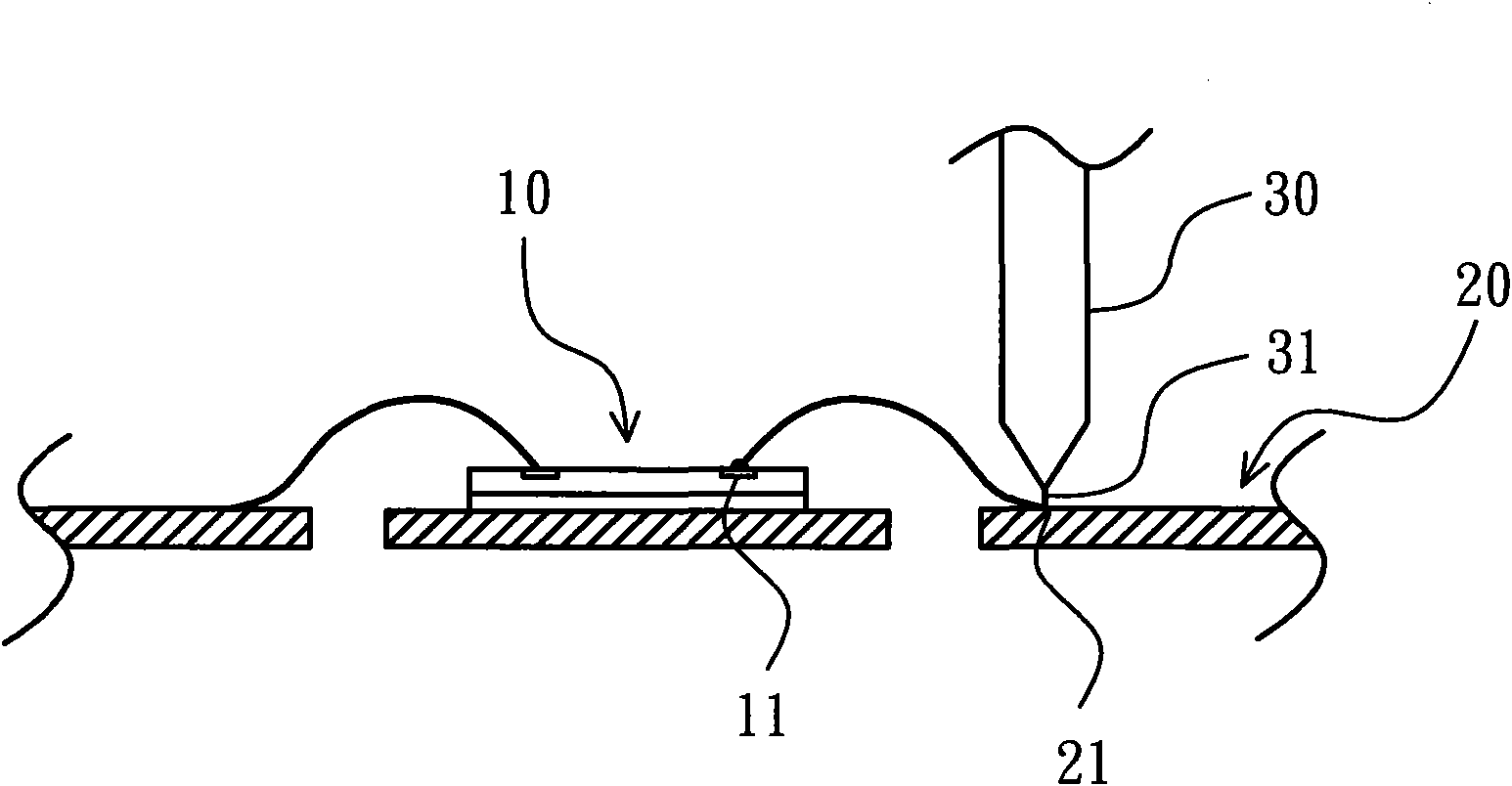

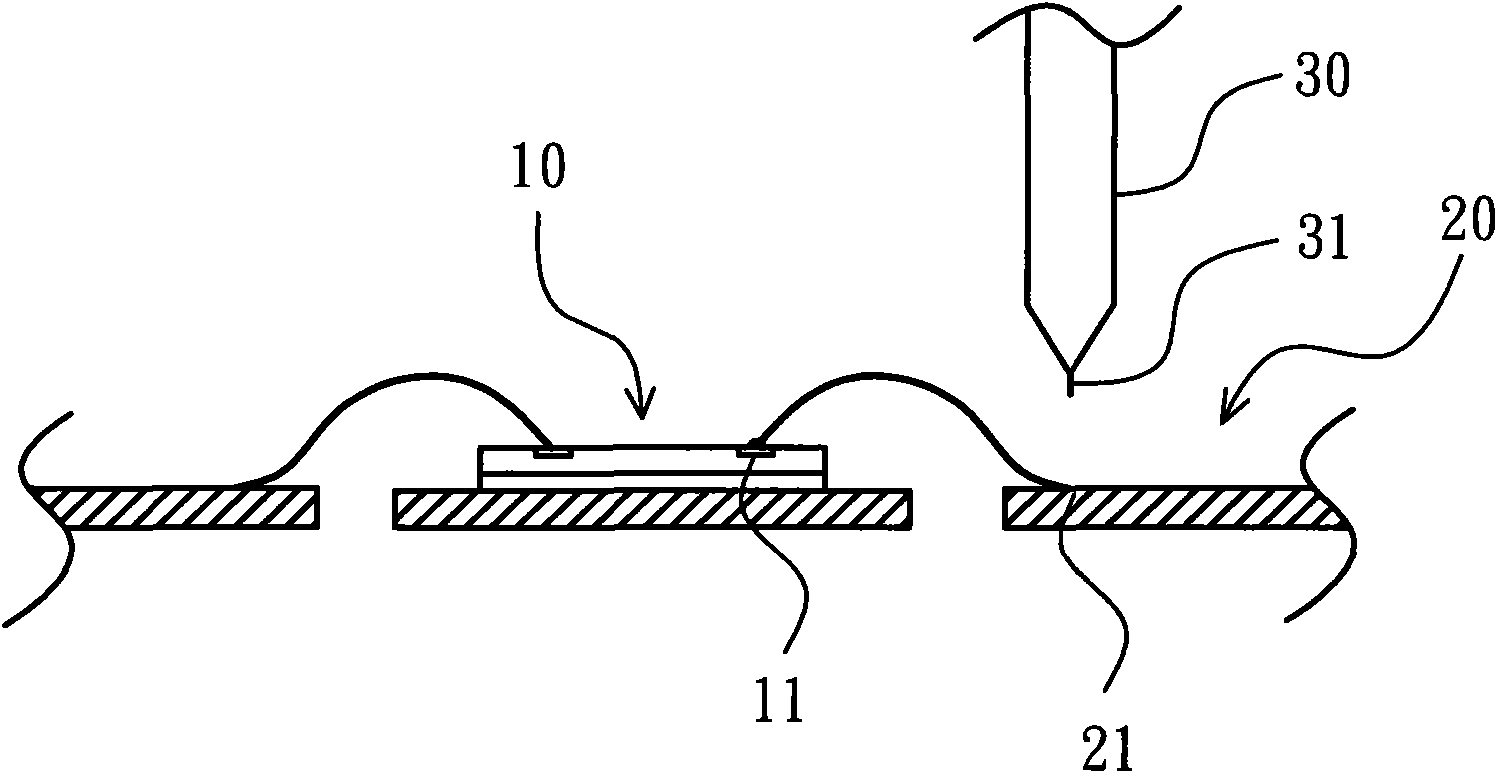

Pre-oxidation method of semiconductor packaging and routing surface and pre-oxidation layer structure thereof

InactiveCN101894770AImprove yield rateAvoid corrosionSemiconductor/solid-state device detailsSolid-state devicesSemiconductor packageEngineering

The invention discloses a pre-oxidation method of a semiconductor packaging and routing surface and a pre-oxidation layer structure thereof. The pre-oxidation method comprises the following steps of: providing a lead and a routing joint surface, wherein one end of the lead is welded and combined to the routing joint surface to form a routing and combining part; providing an oxidizing gas for the routing and combining part to ensure that a pre-oxidation layer is formed on the routing joint surface on the routing and combining part and / or the surface of the lead; and packaging the lead, the routing joint surface, the pre-oxidation layer and the routing and combining part by utilizing a sealing glue material. Because the routing joint surface and / or the surface of the lead have / has the pre-oxidation layer, when the packaging procedure is carried out, the pre-oxidation layer can prevent the lead and / or the routing joint surface from being corroded, so that the risk of generating oxidation defects in the packaging procedure can be reduced so as to improve the welding quality of the routing and combining part and effectively improve the yield of semiconductor packaging.

Owner:ASE ASSEMBLY & TEST SHANGHAI

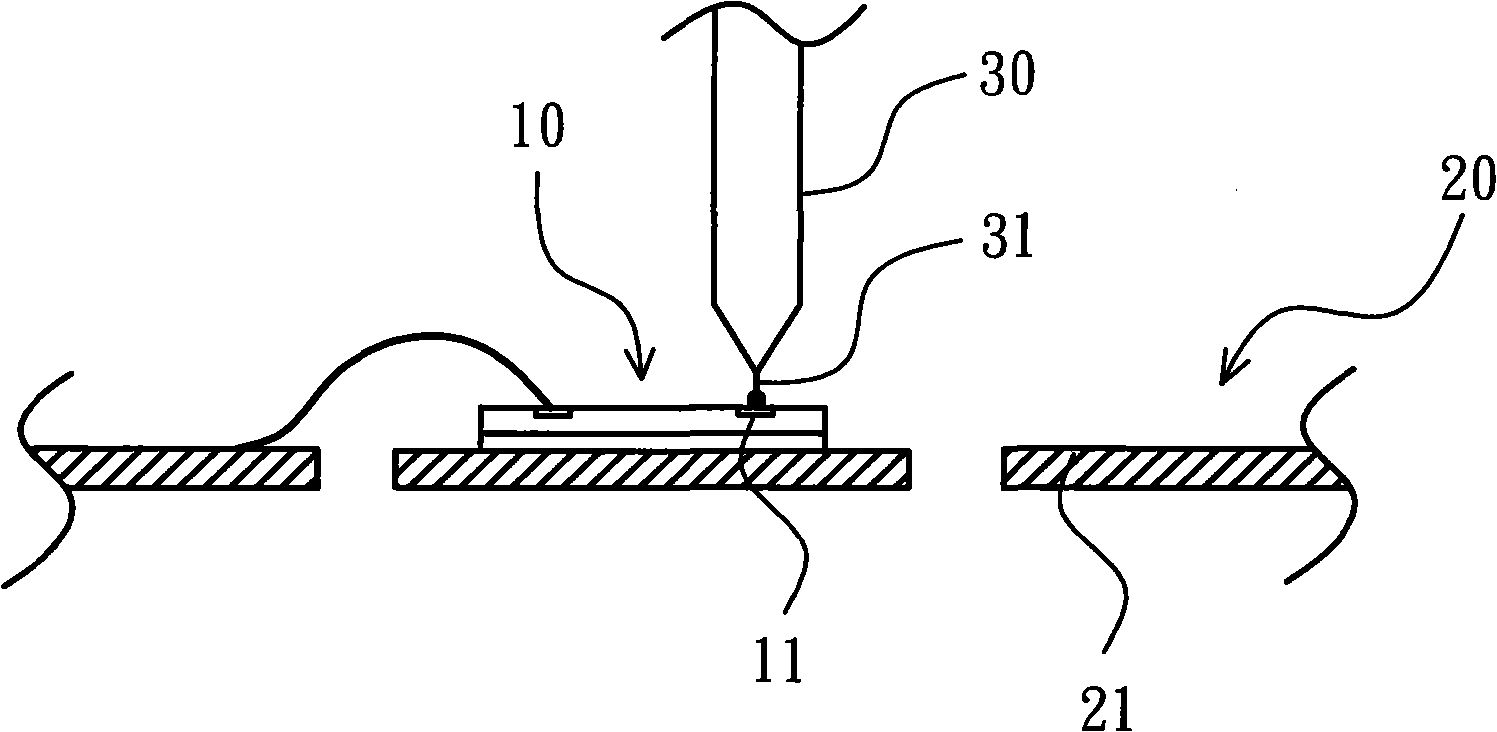

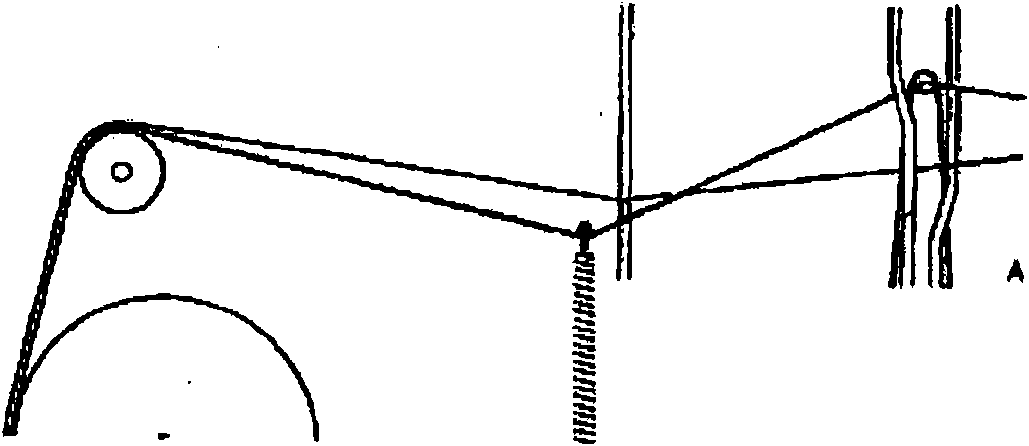

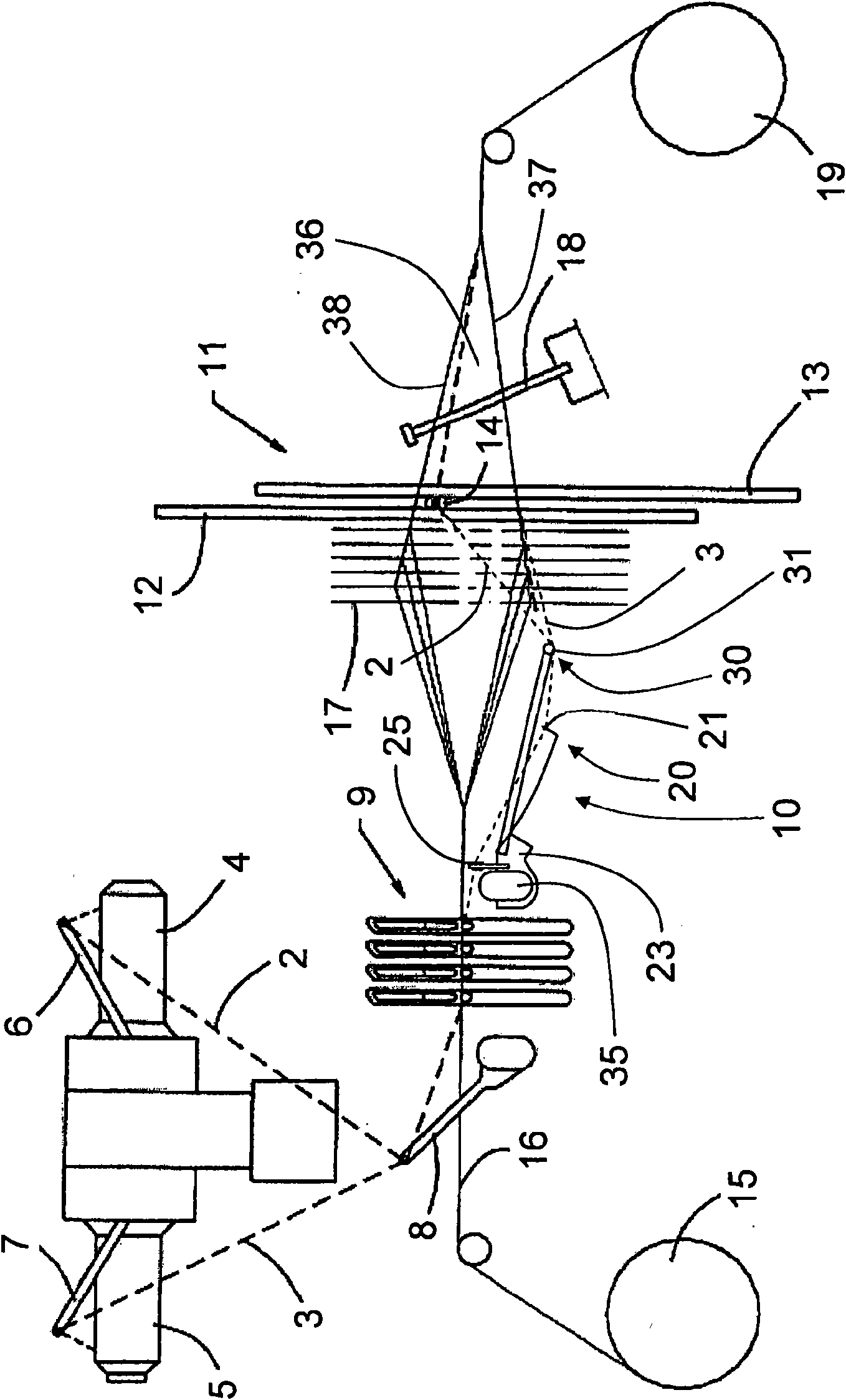

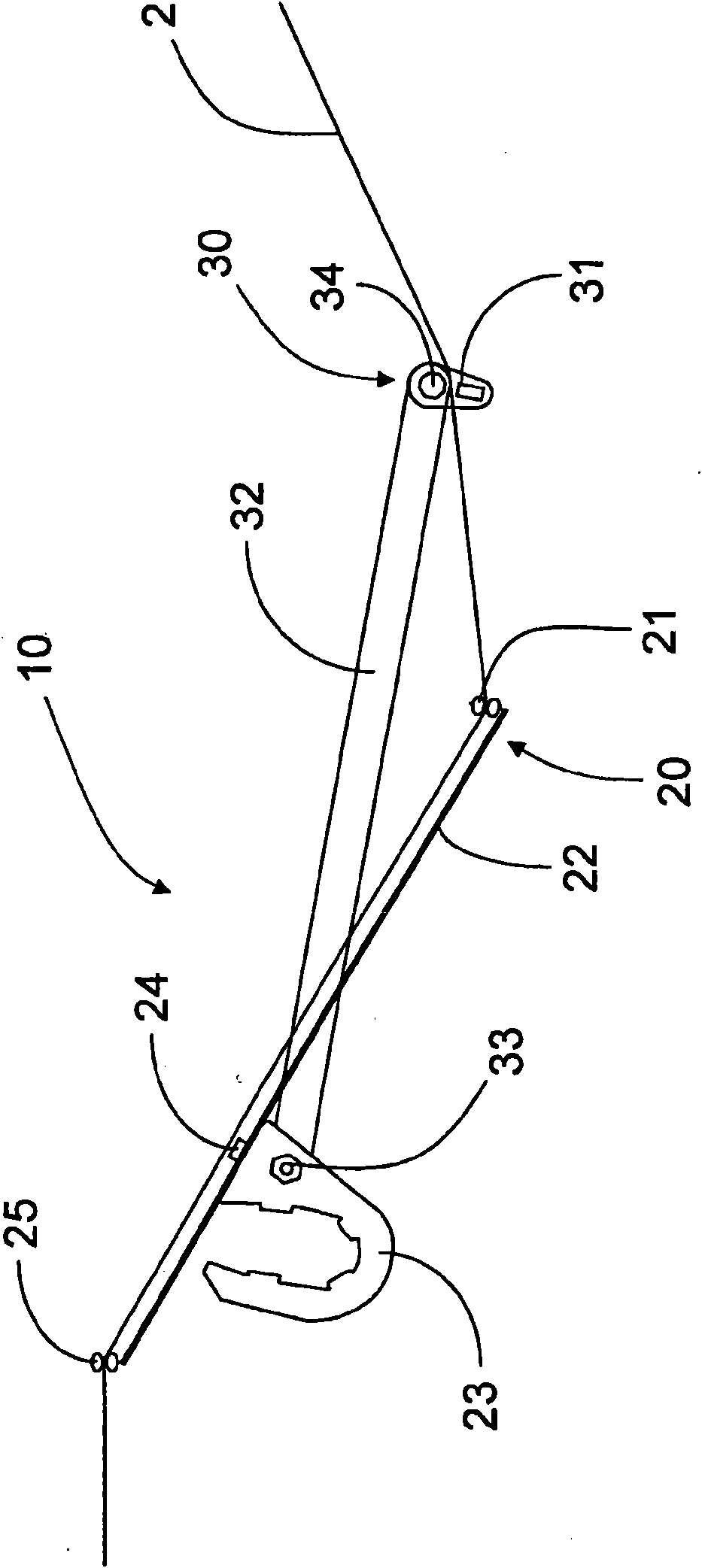

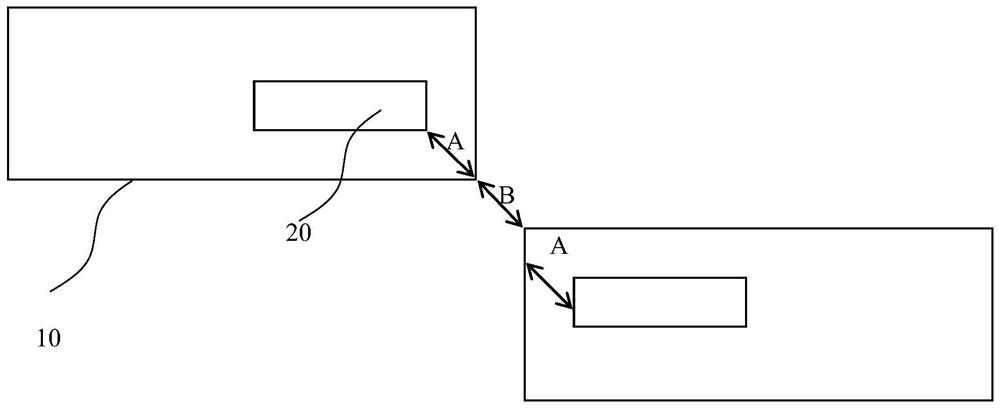

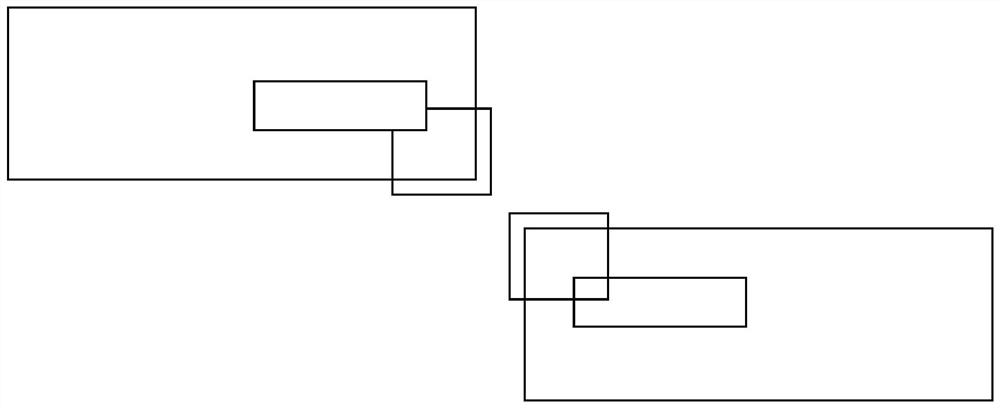

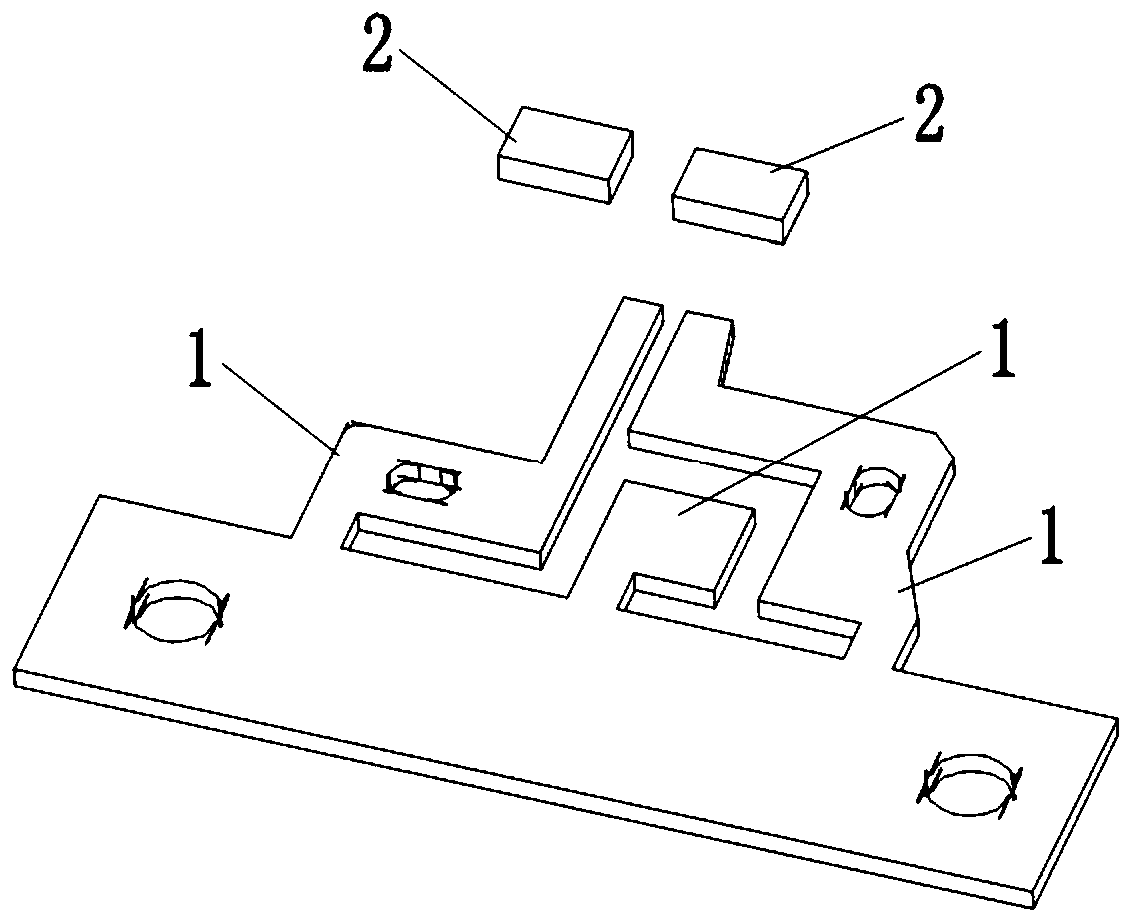

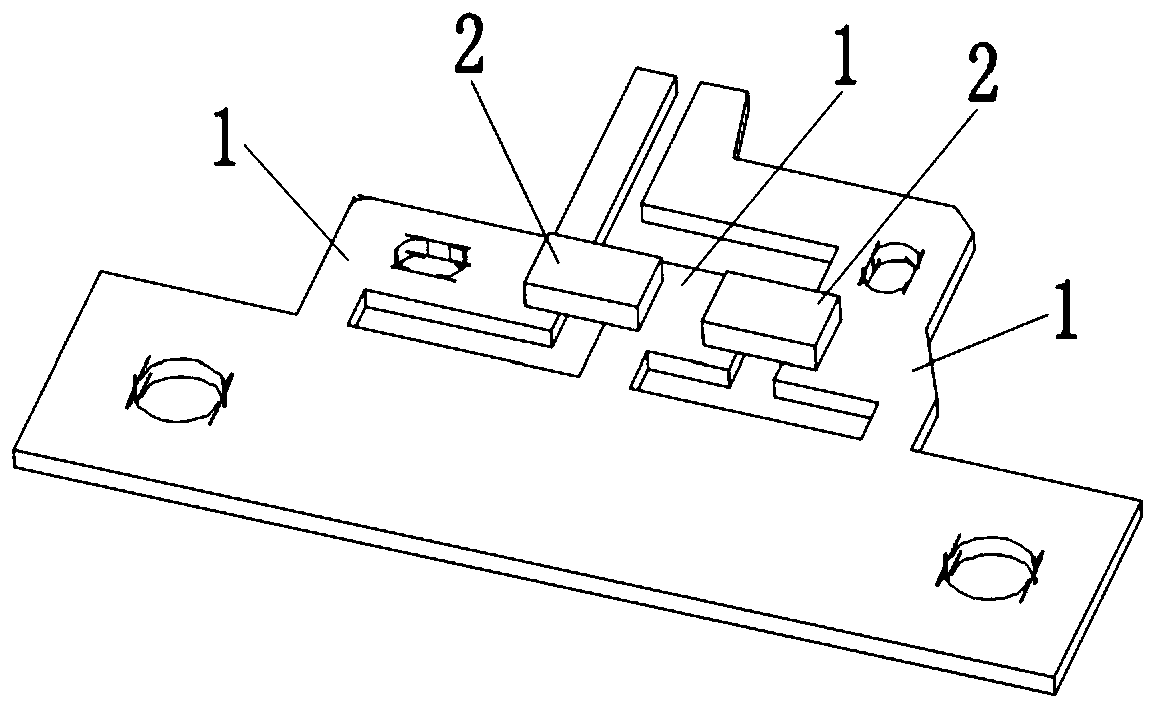

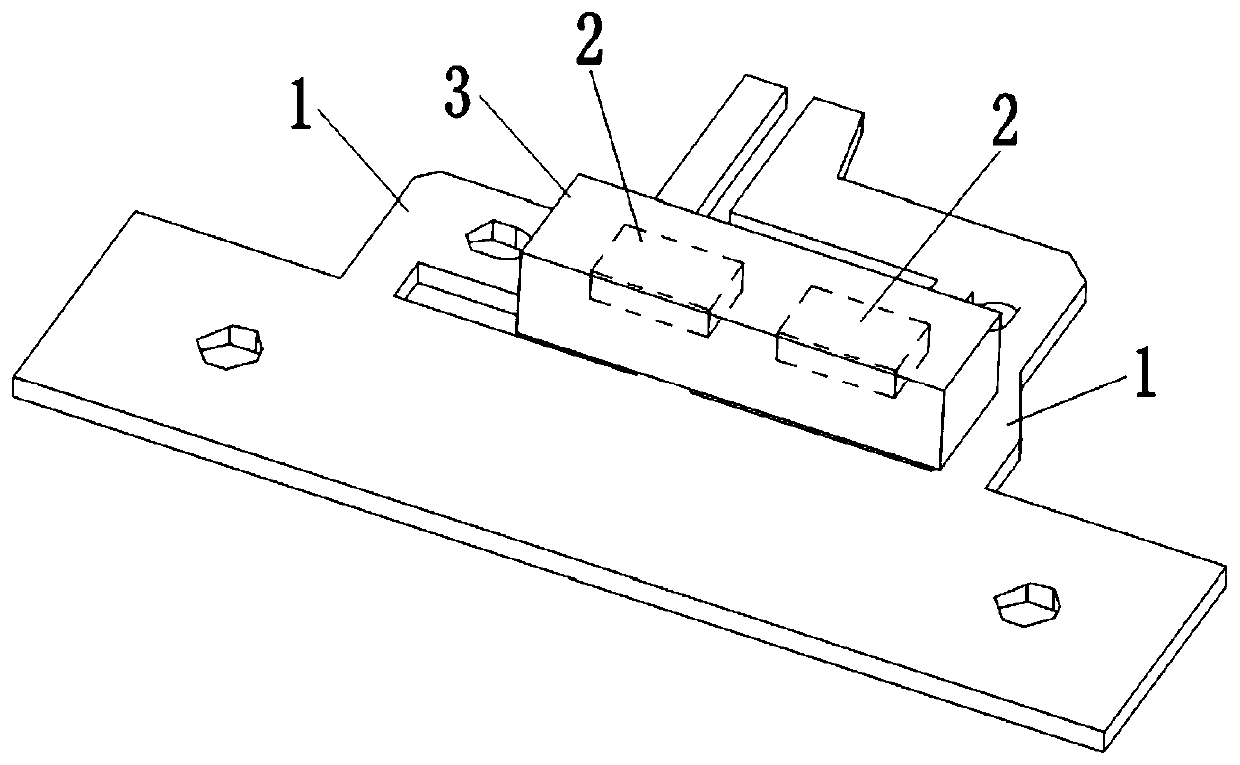

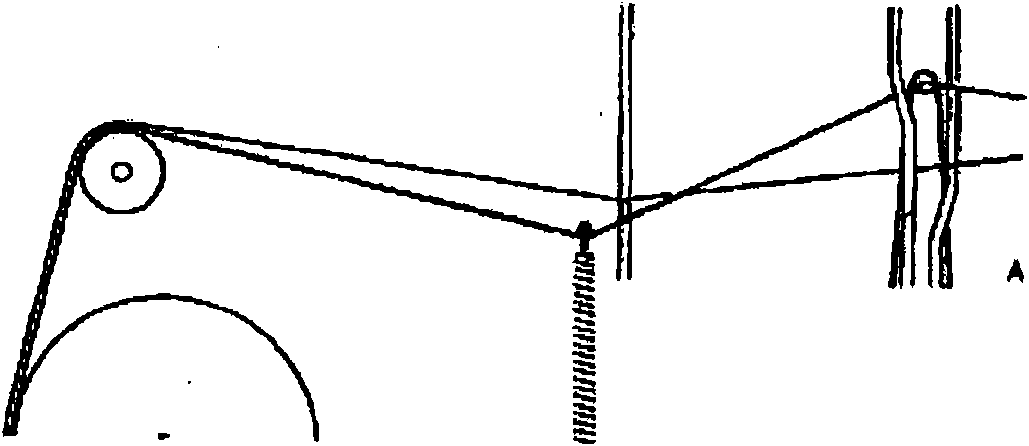

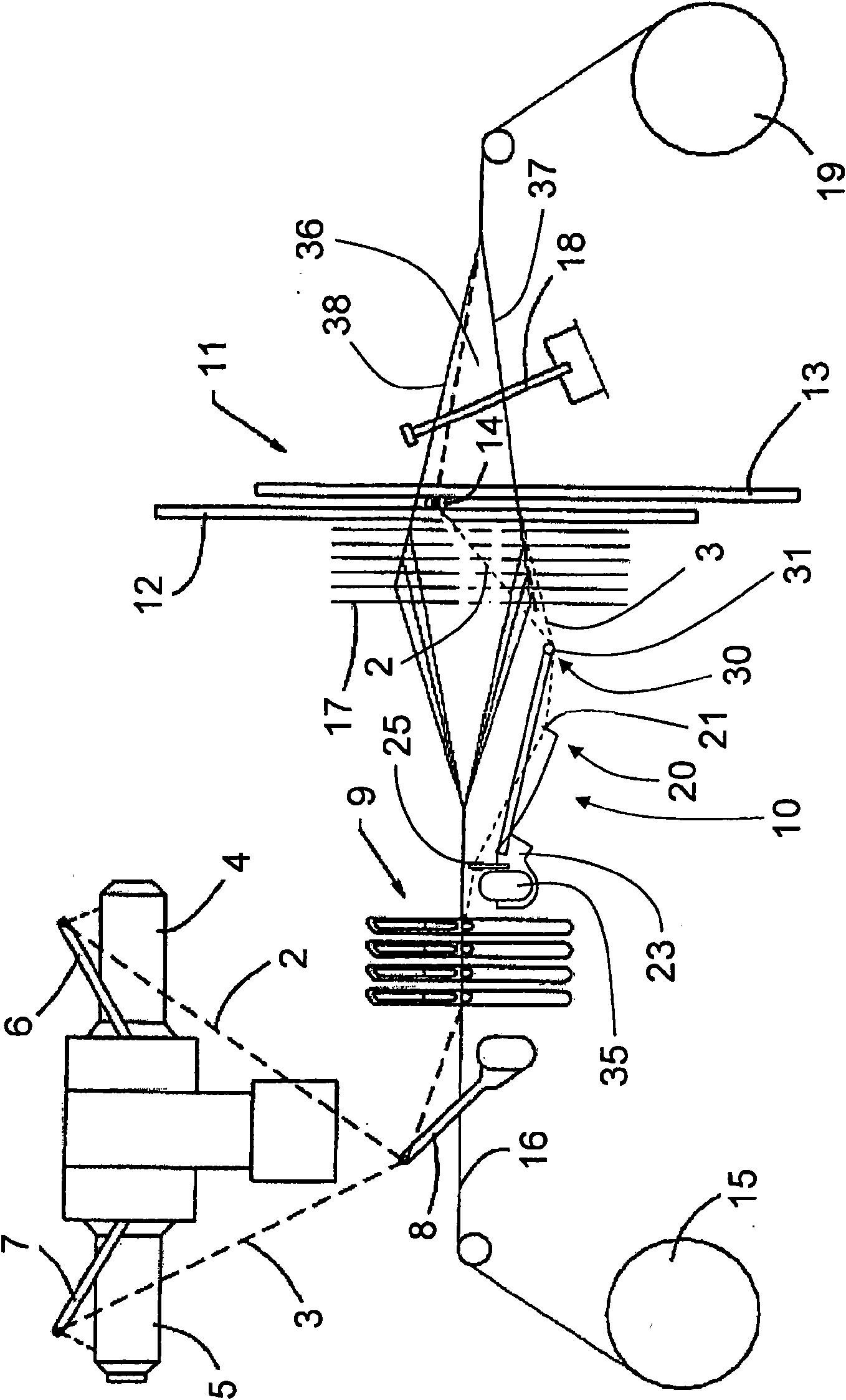

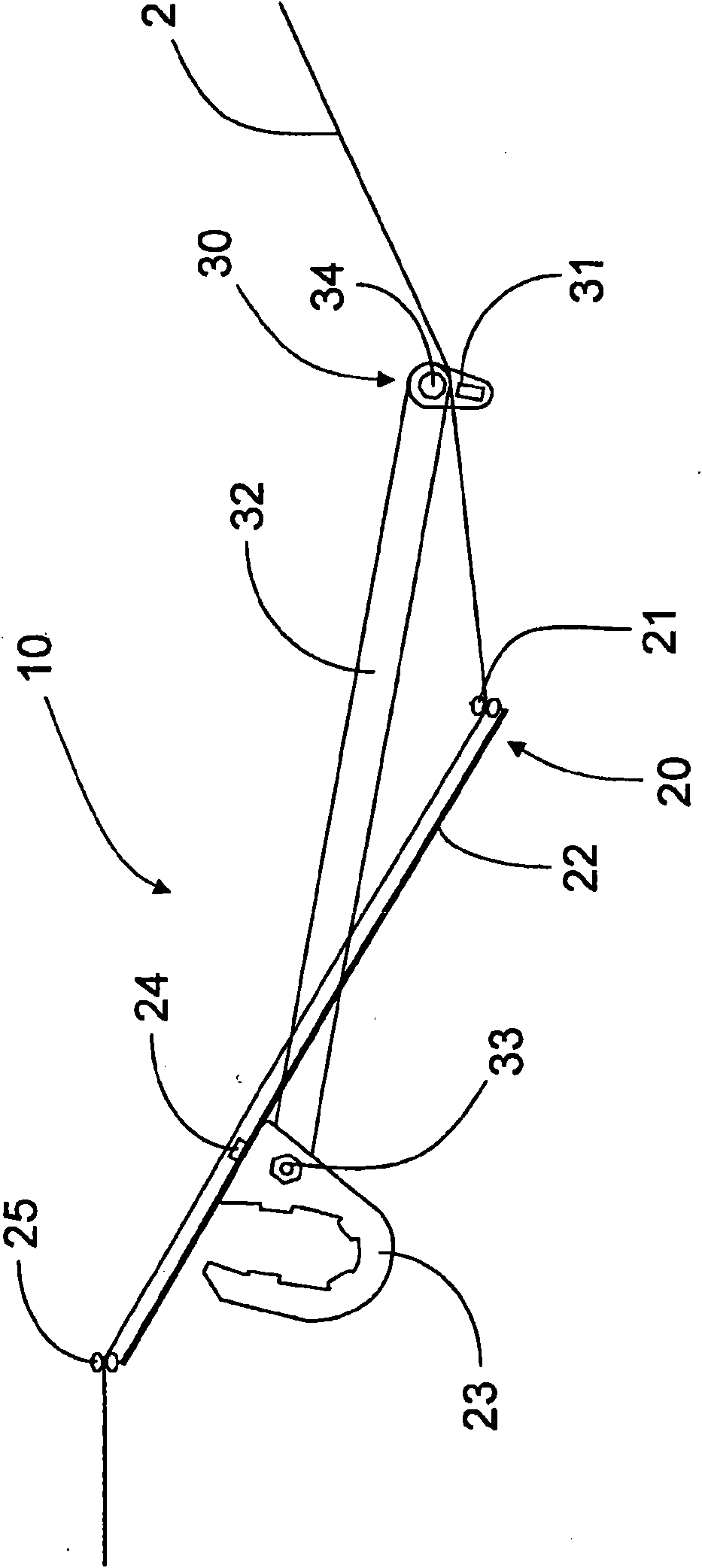

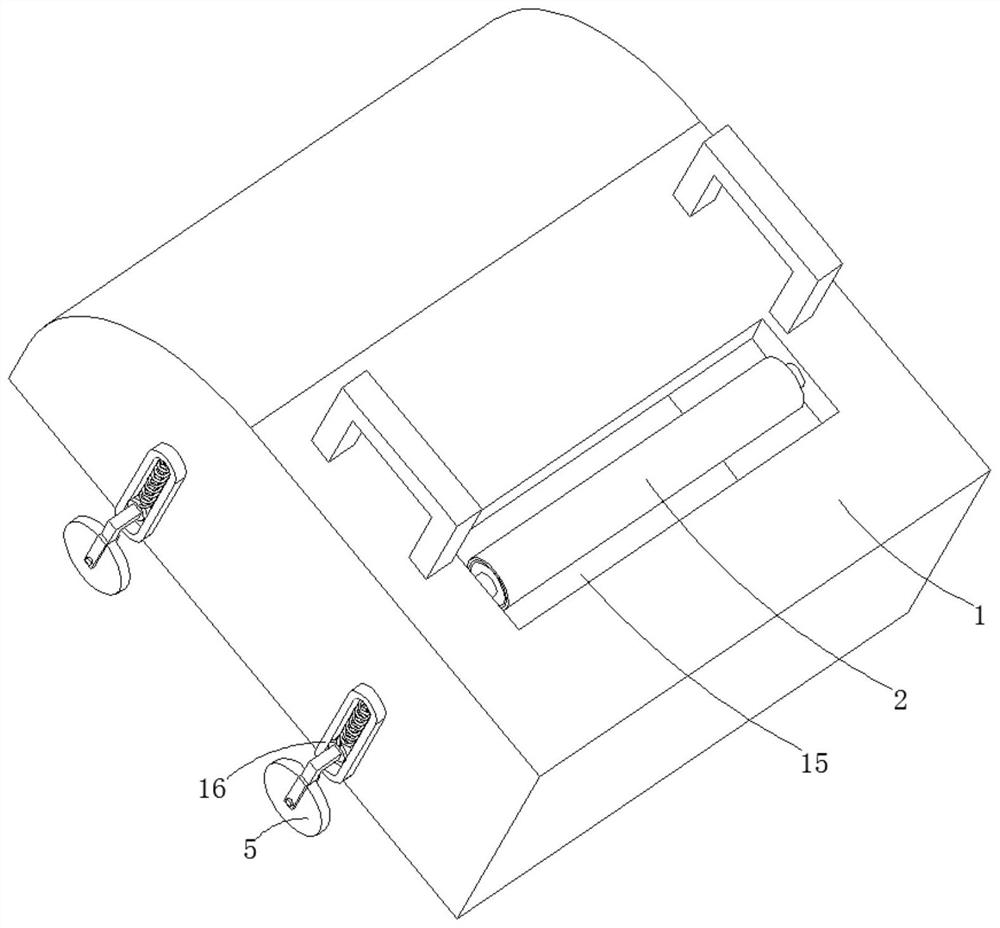

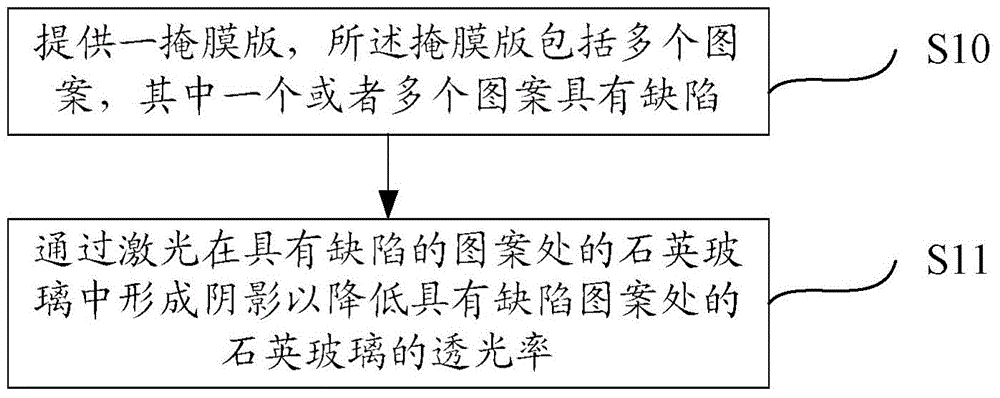

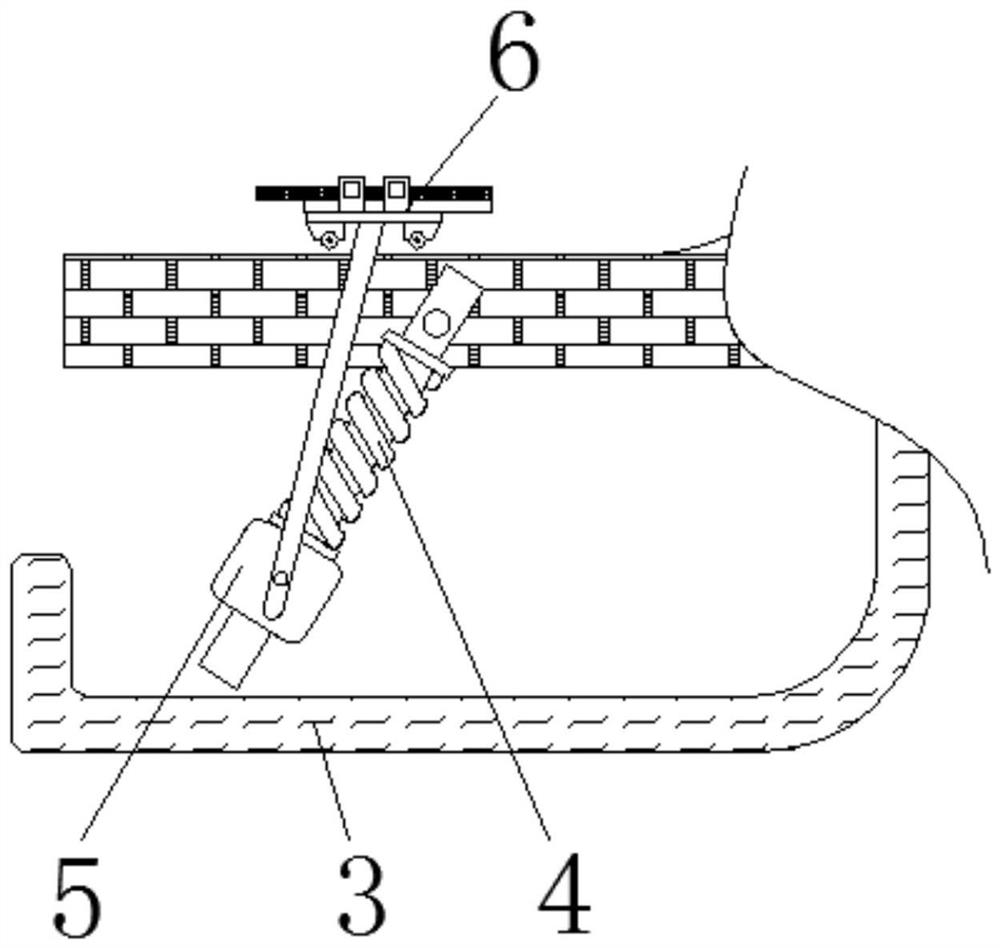

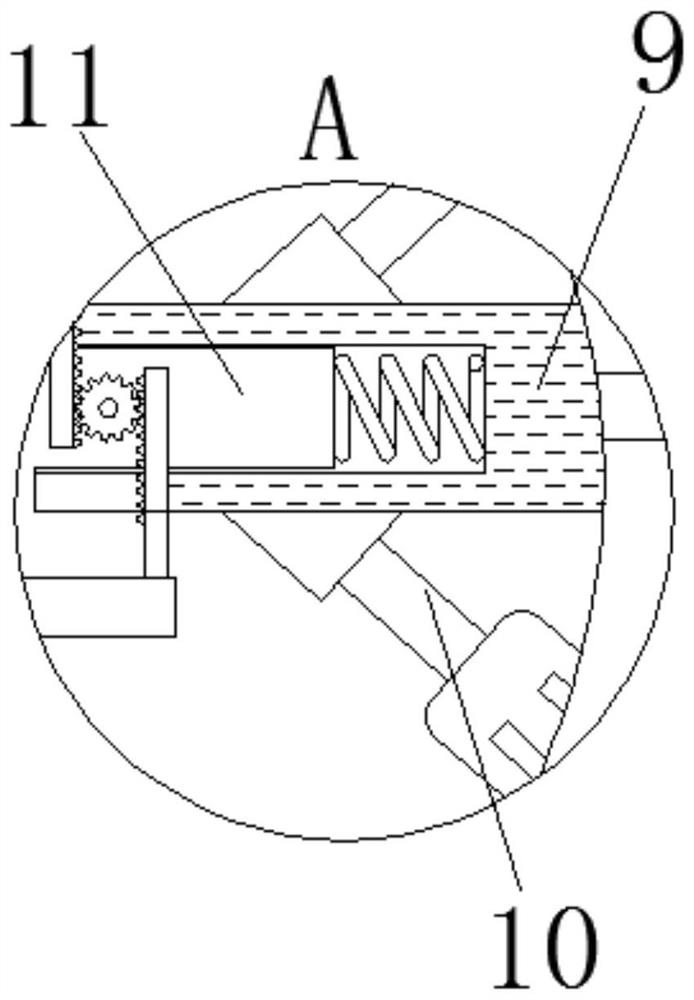

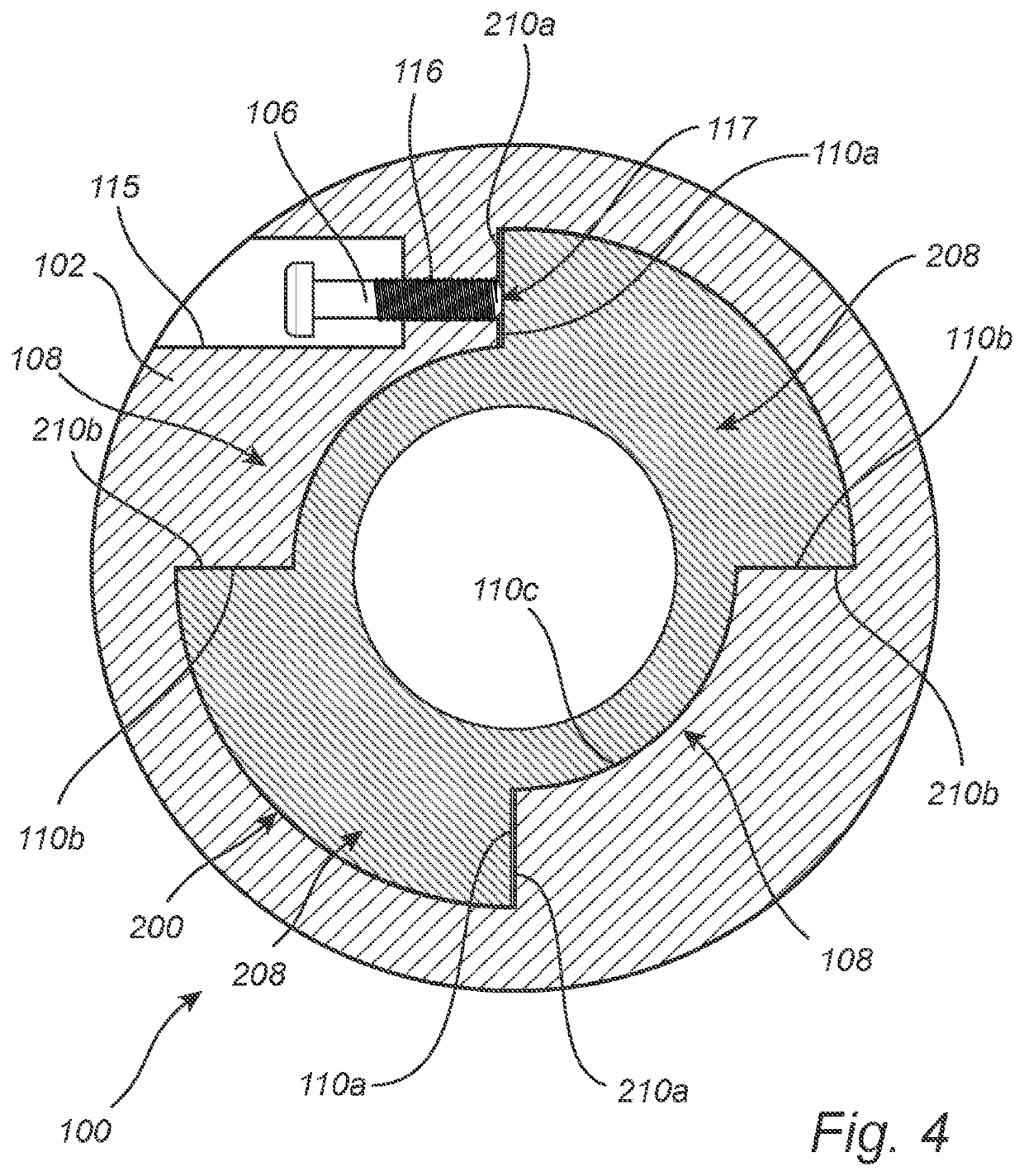

Device for the tensioning of a leno thread for a doup heddle device for a weaving machine

A device (10) for the tensioning of a leno thread (2, 3) for a doup heddle device (11) can be positioned in proximity to the doup heddle device (11 ), wherein the device (10) comprises for at least one leno thread (2, 3) a resiliency mounted thread guide (20) which forms a bending point (21) for the leno thread (2, 3), wherein the device (10) also comprises a fixedly mountable thread guide (30) which forms a bending point (31) for the leno thread (2, 3) which in use is positioned in proximity to the doup heddle device (11). A weaving machine which comprises a device (10).

Owner:PICANOL SUZHOU IND PARK TEXTILE MACHINERY

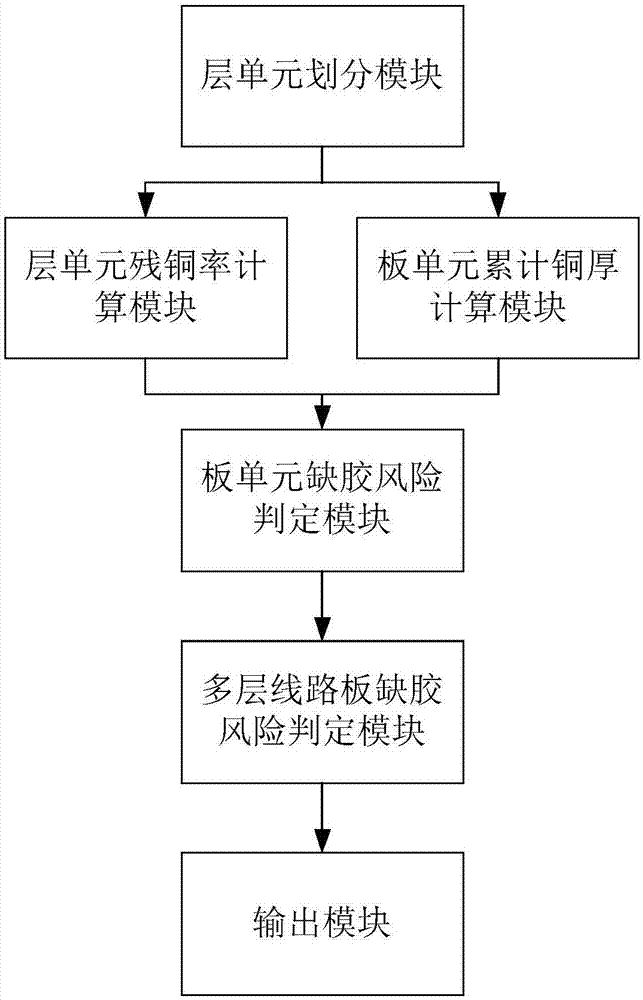

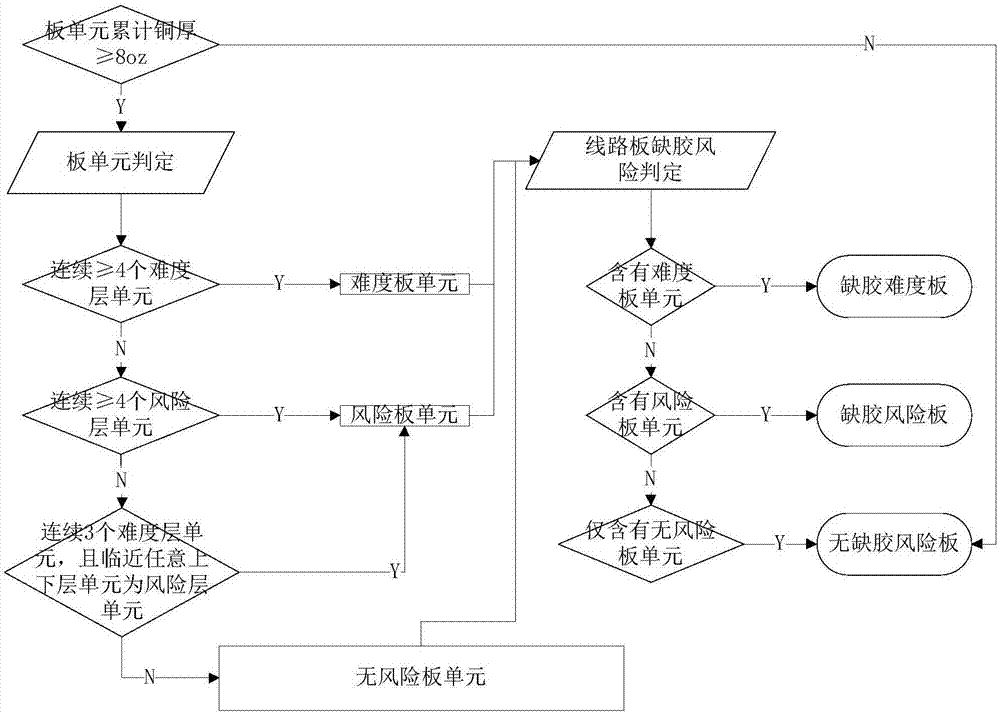

Automatic identification early-warning system for no-copper area of multilayer circuit board

ActiveCN108008288AAccurate predictionReduce risk of defectsPrinted circuit testingEarly warning systemCountermeasure

The invention discloses an automatic identification early-warning system for a no-copper area of a multilayer circuit board. The system comprises a layer unit dividing module, a layer unit copper remaining rate calculating module, a board unit accumulated copper thickness calculating module, a board unit glue shortage risk determining module and an output module. The automatic identification early-warning system has advantages of performing more accurate pre-estimation on a glue shortage risk of the circuit board, grading defect conditions so as to take corresponding measures, and greatly reducing the glue shortage risk in a printed circuit board pressing process.

Owner:DALIAN CHONGDA CIRCUIT

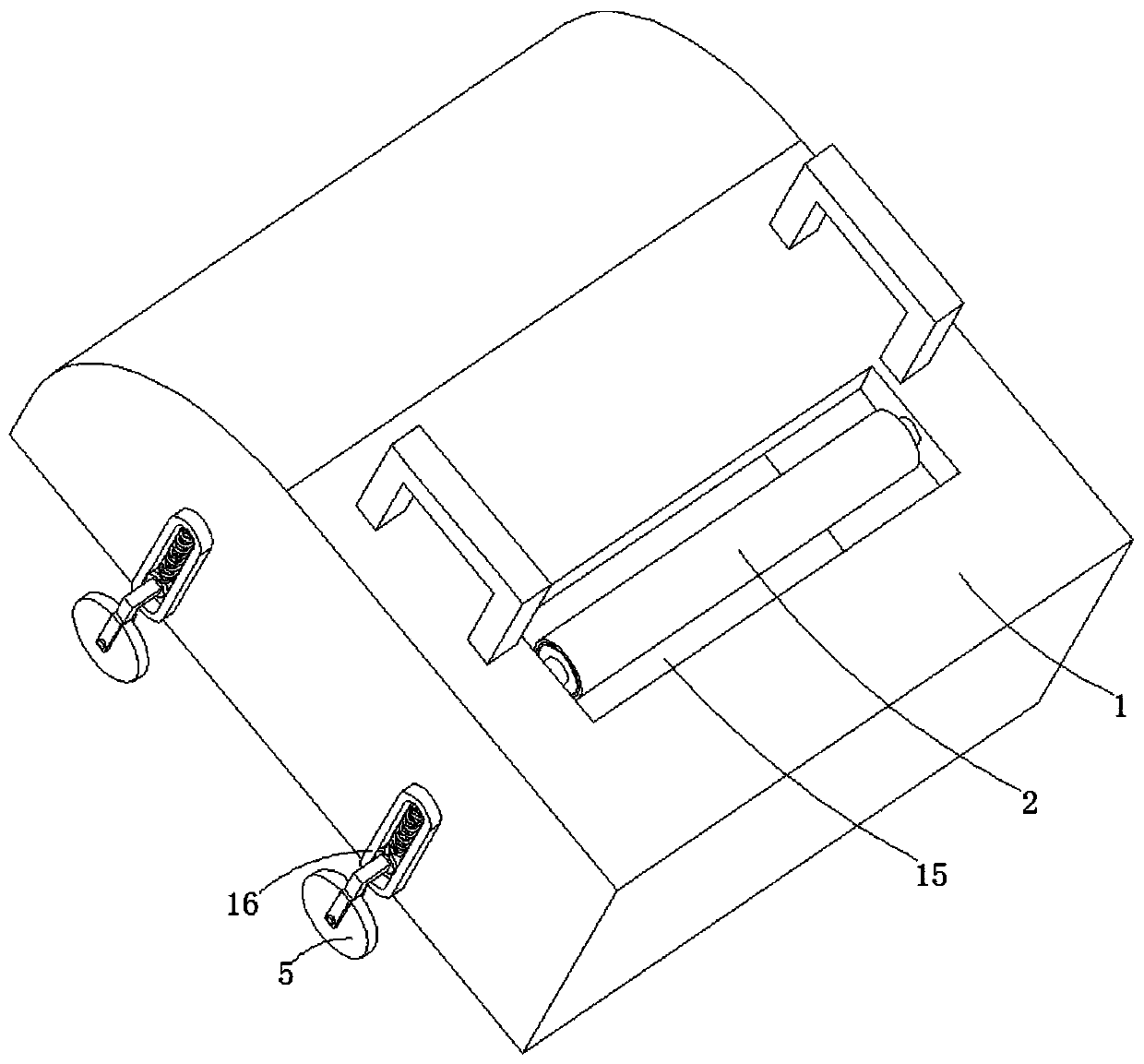

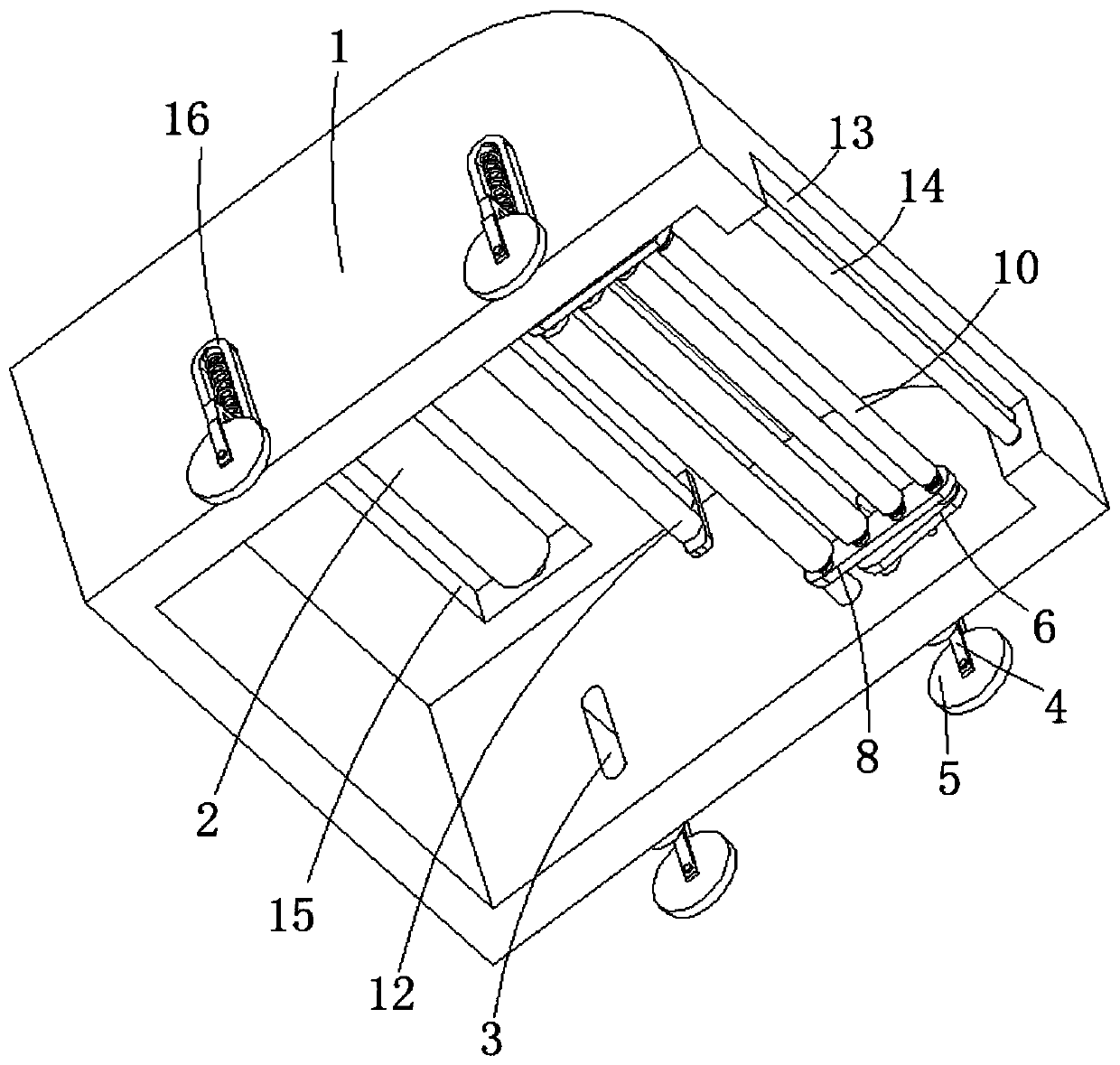

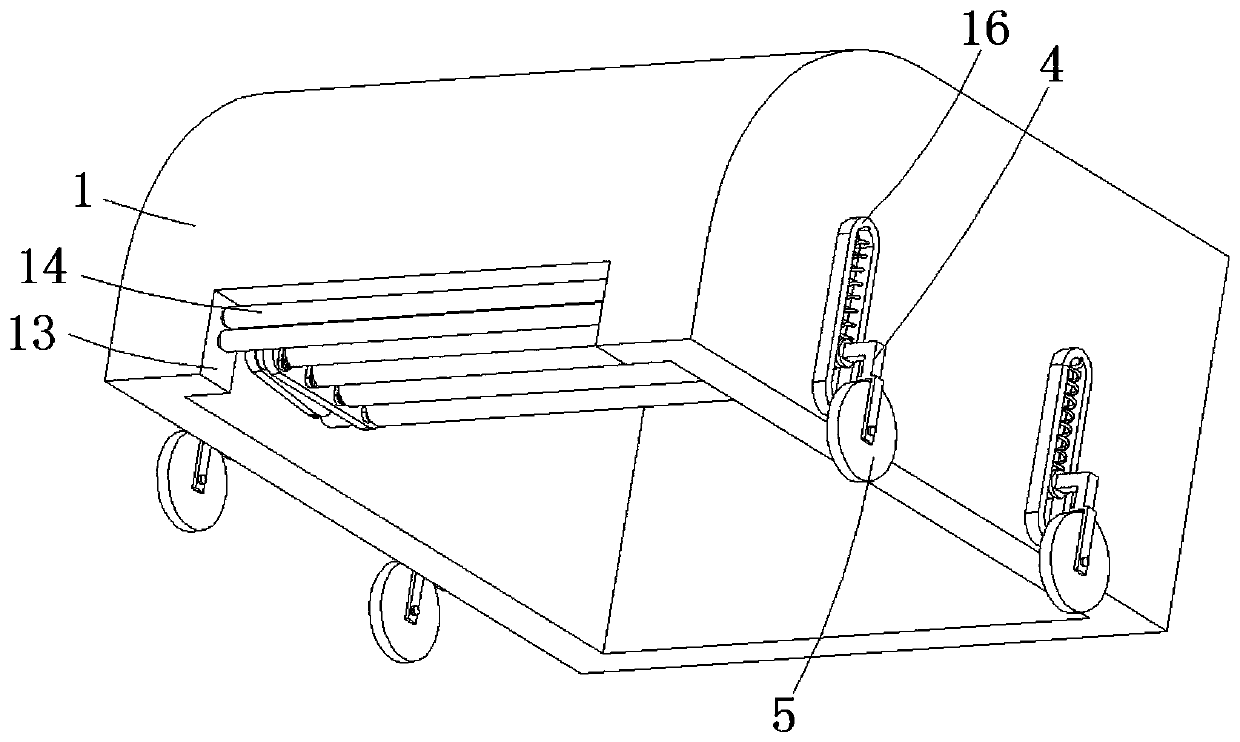

Sunglasses lens coating equipment

ActiveCN112501574AReduce duplicationImprove space utilizationVacuum evaporation coatingSputtering coatingControl systemEngineering

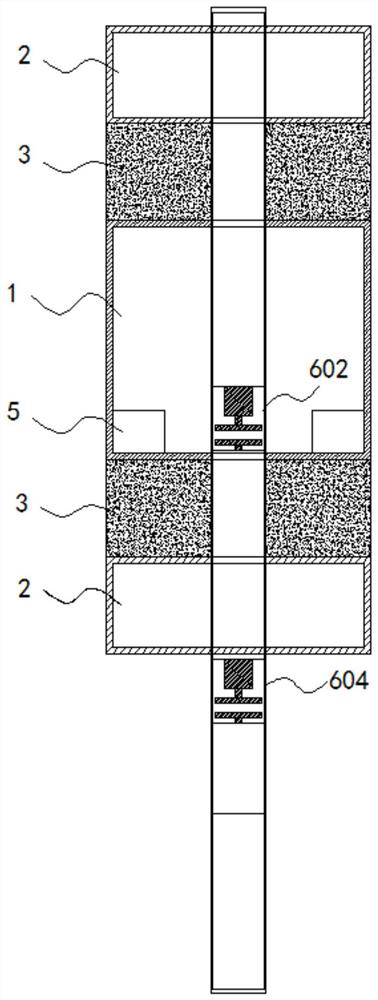

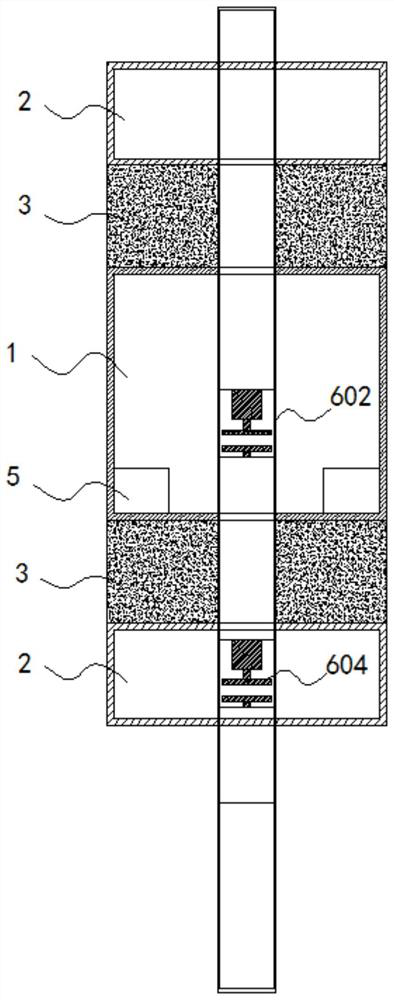

The invention discloses sunglass lens coating equipment. The sunglass lens coating equipment comprises a coating cavity, a vacuum system, a heating system, film material excitation systems, film layerthickness control systems and axis components, wherein buffer cavities are formed in the two side parts of the coating cavity correspondingly, and shuttling channels penetrate through separation parts and the buffer cavities; the axis components are arranged in the shuttling channels in a sleeved mode, and the axis components are sequentially provided with sealing sections, first mounting sections, middle sections, second mounting sections and sealing sections; and substrates are arranged on the mounting sections, the relative position relation of two mounting sections is utilized, and different processes can be complete on two substrates at the same time in the same time period and do not conflict with each other. According to the sunglass lens coating equipment, the space utilization rate of the coating cavity is effectively improved, and the repeated vacuumizing and vacuum losing times of the coating cavity are reduced; and the design of the buffer cavities ensures that the substrates are subjected to pretreatment and annealing treatment processes, so that the time required for heating the substrates in the coating cavity is shortened, and the risk of defects caused by severe environmental change after the substrates are withdrawn from the coating cavity after the coating operation is completed is reduced.

Owner:DONGXING HUAHONG OPTICAL TECH

Optical proximity effect correction method and correction system

ActiveCN110456617AReduce defects during photolithographyImprove pass ratePhotomechanical exposure apparatusMicrolithography exposure apparatusComputer sciencePhotoresist

The invention discloses a model-based optical proximity effect correction method, which includes the following steps: simulating a pattern on a current mask to form a photoresist contour based on a model; determining the edge placement error according to the position relationship between the photoresist contour and the corresponding sides of a target pattern; screening out opposite sides satisfying preset correction conditions; calculating the pre-movement amount and actual movement amount of the opposite sides; correcting the actual movement amount of the opposite sides screened out; and repeating the steps above until there are no opposite sides in the layout which satisfy the preset correction conditions. The invention also discloses a model-based optical proximity effect correction system. The optical proximity effect correction method / correction system of the invention can reduce the risk of product defects and improve the qualification rate of products by properly increasing theamount of movement of one of opposite sides about to move in the same direction in the future in advance during same-order iteration of optical proximity effect correction.

Owner:SHANGHAI HUALI INTEGRATED CIRCUTE MFG CO LTD

Wall cloth attaching device capable of preventing wrinkles

Owner:河南省同宇建筑工程有限公司

Copper-titanium corrosive liquid for integrated circuit and production process of copper-titanium corrosive liquid

The invention discloses a copper-titanium corrosive liquid for an integrated circuit, and belongs to the technical field of microelectronic chemical reagents. The copper-titanium corrosive liquid comprises, by mass, 10-19% of sulfuric acid, 5-8% of nitric acid, 28-33% of acetic acid, 2-5% of potassium persulfate, 2-4% of hydrogen peroxide, 0.05-0.1% of adsorbent and the balance pure water. The invention also discloses a production process of the corrosive liquid. The corrosion liquid is uniform in corrosion to a copper-titanium composite metal layer and stable in performance, due to the fact that the adsorbent is added, the corrosive liquid can be purified, the generation of waste corrosive liquid is reduced, the service life of the corrosive liquid is prolonged, the corrosive liquid does not contain fluorine, a silicon base material, silicon nitride and non-crystalline silicon cannot be corroded, meanwhile, the product yield, safety and environmental friendliness are considered, the risk of defects after reworking is reduced, and the production process can be widely applied to the fields of the preparation of integrated circuit industry, flat panel displays, color filters, touch panels, organic light-emitting diodes and the like.

Owner:JIANGYIN RUNMA ELECTRONICS MATERIAL

Optical proximity correction method for corner-to-corner structure in layout

PendingCN114077155AReduces the risk of shrinkage or even sheddingGuaranteed accuracyOriginals for photomechanical treatmentEngineeringMechanical engineering

The invention discloses an optical proximity correction method for a corner-to-corner structure in a layout. The optical proximity correction method comprises the following steps: S1, finding out an original pattern of an ion implantation layer photoetching layout, wherein the original graph is a graph of a corner-to-corner structure; S2, cutting off a corner at each of the original corners of the original graph, and obtaining a corner part with a notch; S3, on the basis of the pattern in the step S2, carrying out the correction processing to obtain a target pattern structure, wherein notches are formed in the corners of the target pattern, and protrusions are formed on the two adjacent corner edges of the corners of the target pattern; S4, performing model-based adjacent optical effect correction on the target graph to obtain a simulated photoresist contour line.

Owner:SHANGHAI HUALI INTEGRATED CIRCUTE MFG CO LTD

Concrete with ultra-large volume, high strength and low hydration heat

The invention relates to concrete with ultra-large volume, high strength and low hydration heat. The concrete comprises the following components in parts by weight (cube dosage kg / m3): 200-260 parts of cement, 100-160 parts of mineral powder, 80-100 parts of fly ash, 740-800 parts of fine aggregate, 1010-1050 parts of coarse aggregate, 4.0-5.0 parts of additive and 155-165 parts of water. The concrete with ultra-large volume, high strength and low hydration heat can be used to effectively reduce the hydration heat, greatly reduce the cracking risk of the large-volume concrete from the source and increase the engineering quality.

Owner:SHANGHAI CONSTR BUILDING MATERIALS TECH GRP CO LTD +5

Electronic element, plastic coating technology of microswitch with resistor and microswitch with resistor

InactiveCN111571922AImprove quality stabilityImprove vibration resistanceElectric switchesEngineeringResistor

The invention discloses an electronic element, a plastic coating technology of a microswitch with a resistor and the microswitch with the resistor. According to the plastic coating technology, plasticcoating production is performed for the electronic element in a sequential low-temperature low-pressure and high-temperature high-pressure injection molding plastic coating mode, wherein low-temperature low-pressure plastic coating is performed in advance for protection so that the internal structure of the electronic element can be effectively kept stable in the plastic coating process, the phenomena of displacement, falling and the like in the subsequent assembly process are prevented, and then high-temperature high-pressure plastic coating is carried out to improve the vibration resistance, impact resistance and waterproof capability of the electronic element; based on the plastic coating technology, in the production of the microswitch with the resistor, the microswitch with the resistor with good vibration resistance, impact resistance and waterproofness can be produced, the resistor is protected through low-temperature low-pressure plastic coating in advance, the resistor can beeffectively prevented from displacement, falling off and the like in the subsequent assembly process, the internal structure of the microswitch with the resistor can be effectively kept stable, and the product quality stability is greatly improved.

Owner:仝达产品开发(惠州)有限公司

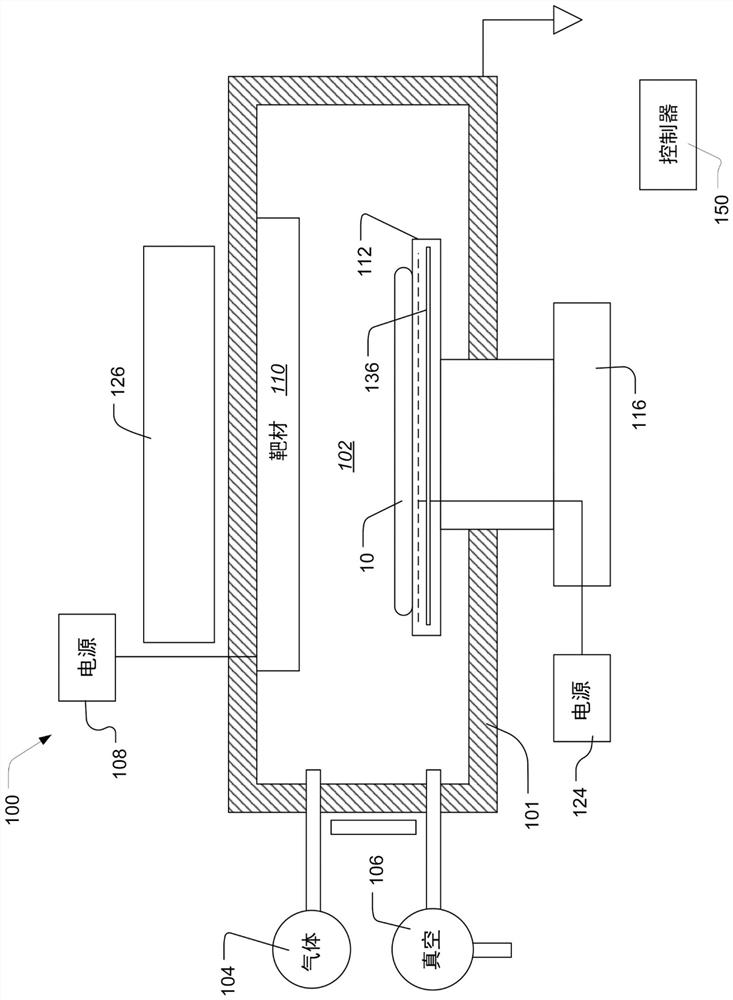

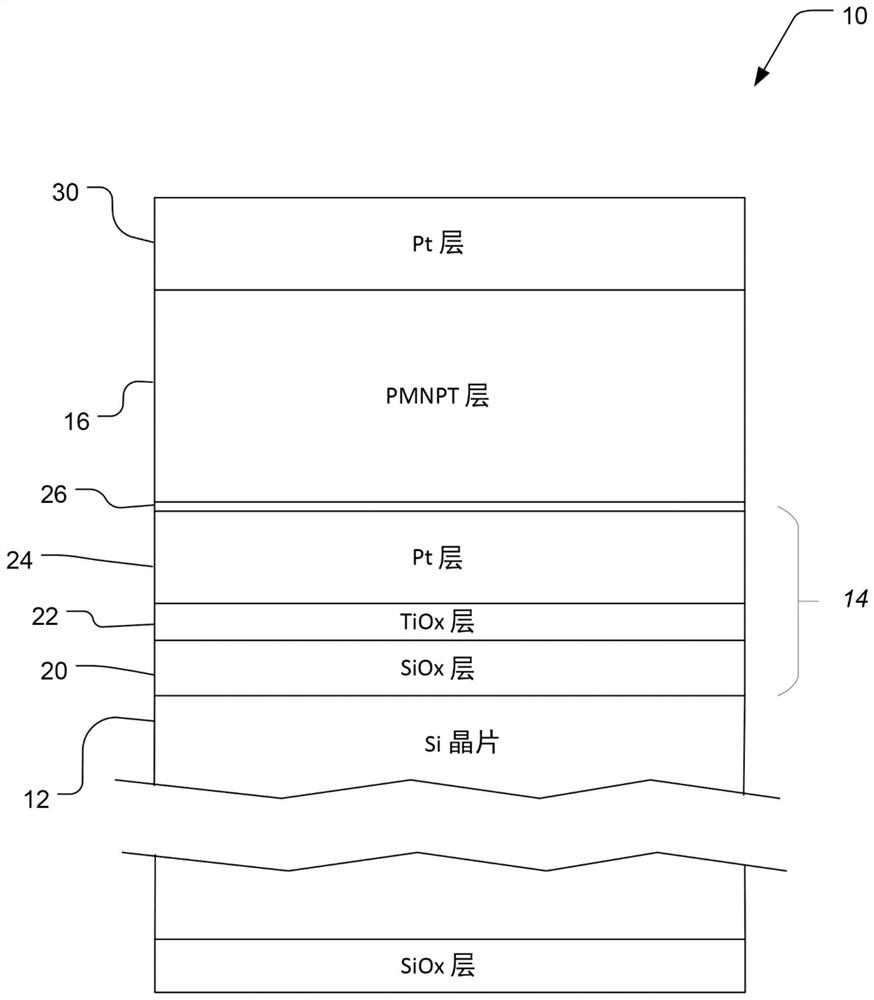

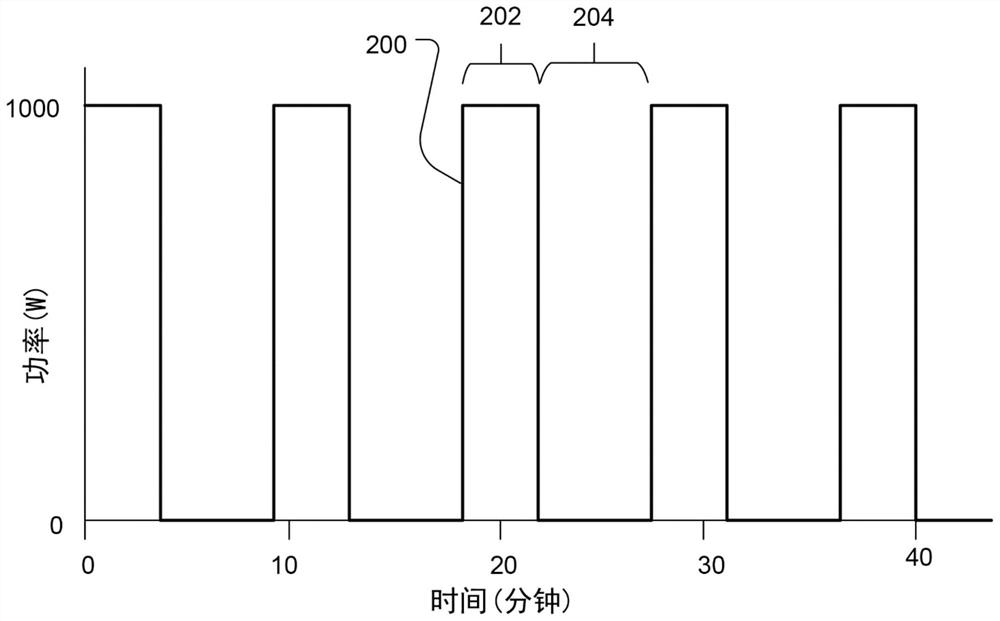

Physical vapor deposition of piezoelectric films

PendingCN112853286AAvoid damageExtended downtimeVacuum evaporation coatingSputtering coatingPlasma depositionPiezoelectric membrane

The invention relates to a method for manufacturing a piezoelectric layer. The method comprises: depositing a piezoelectric material of a first crystalline phase onto a substrate by physical vapor deposition while maintaining the substrate at a temperature below 400 DEG C; and thermally annealing the substrate at a temperature above 500 DEG C to convert the piezoelectric material into a second crystalline phase. The physical vapor deposition comprises sputtering from a target in a plasma deposition chamber.

Owner:APPLIED MATERIALS INC

Device for the tensioning of a leno thread for a doup heddle device for a weaving machine

ActiveCN102084047BReduce tensionAvoid damageLeno shedding mechanismFilament handlingStructural engineeringMechanical engineering

A device (10) for the tensioning of a leno thread (2, 3) for a doup heddle device (11) which can be positioned in proximity to the doup heddle device (11 ), wherein the device (10) comprises for at least one leno thread (2, 3) a resiliency mounted thread guide (20) which forms a bending point (21) for the leno thread (2, 3), wherein the device (10) also comprises a fixedly mountable thread guide (30) which forms a bending point (31) for the leno thread (2, 3) which in use is positioned in proximity to the doup heddle device (11). A weaving machine which comprises a device (10).

Owner:PICANOL SUZHOU IND PARK TEXTILE MACHINERY

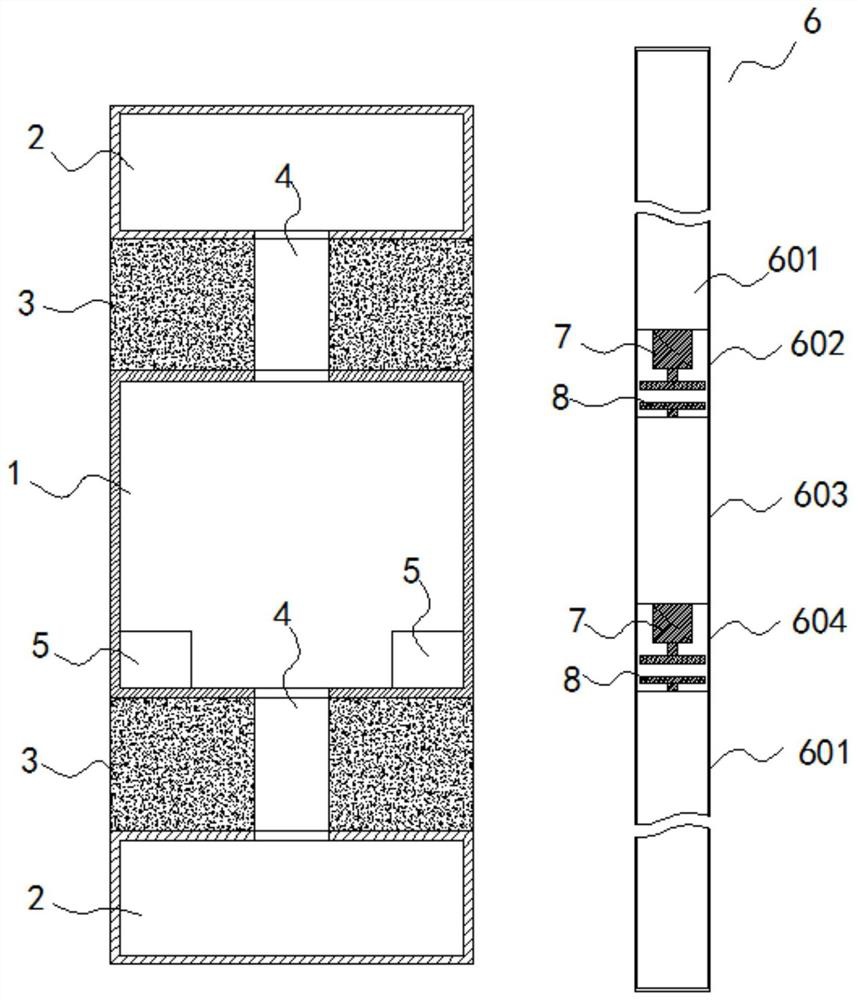

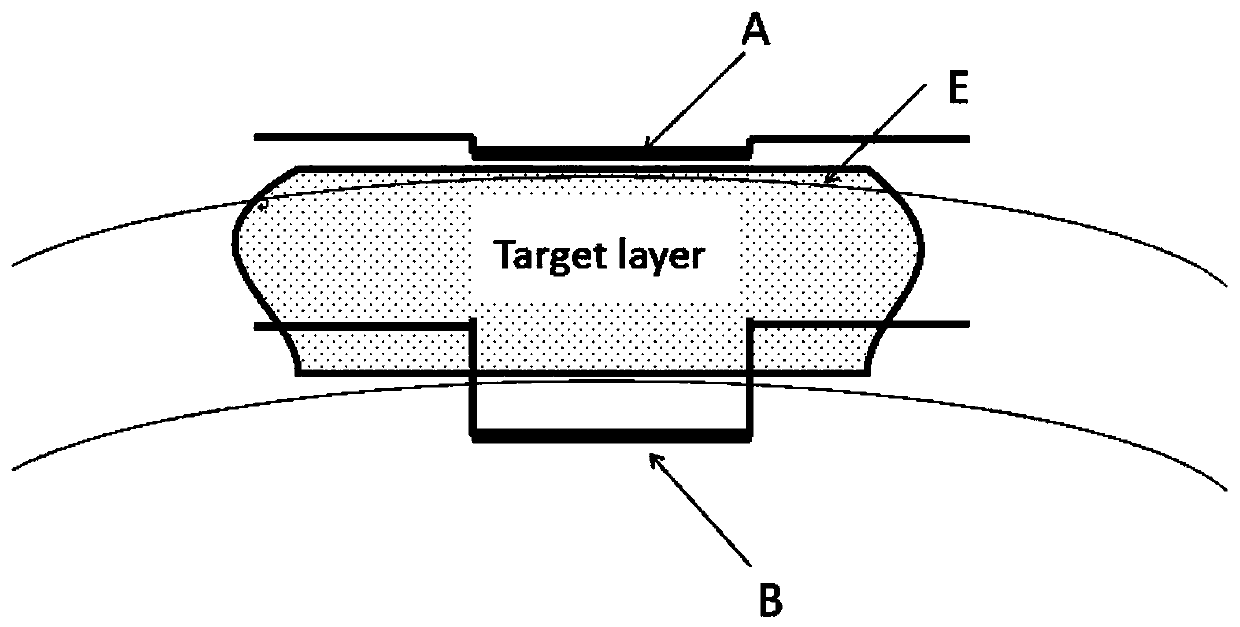

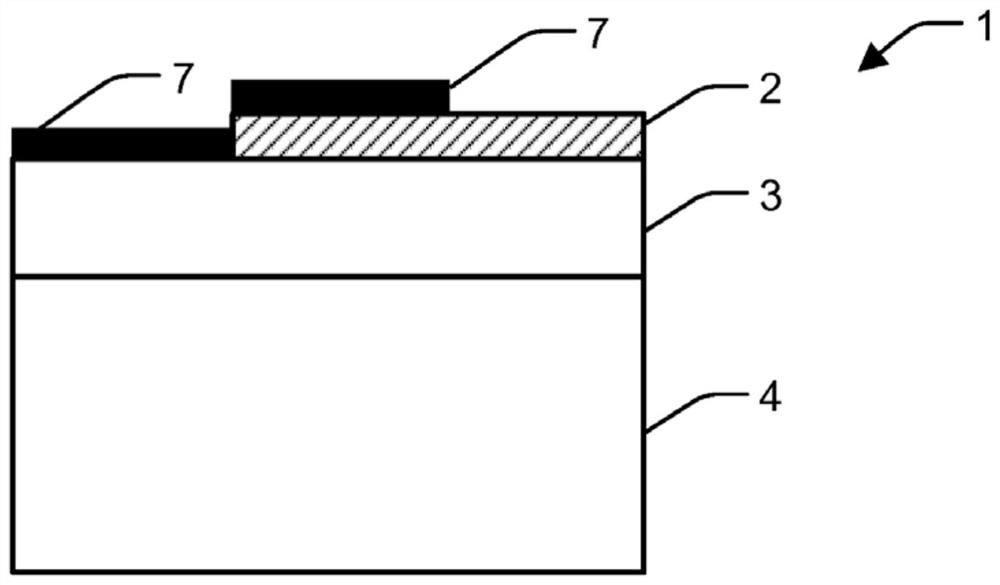

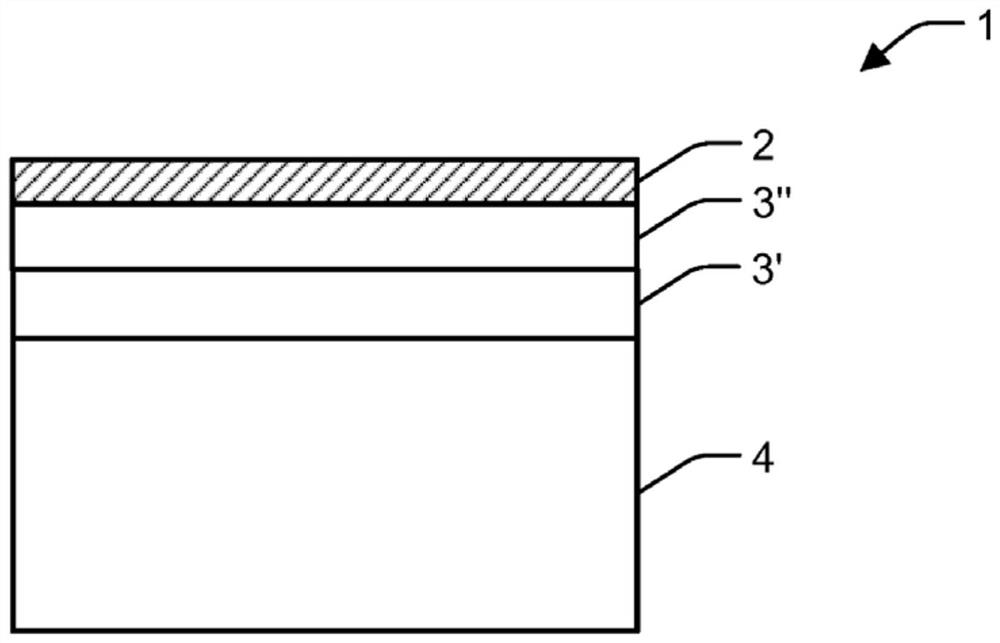

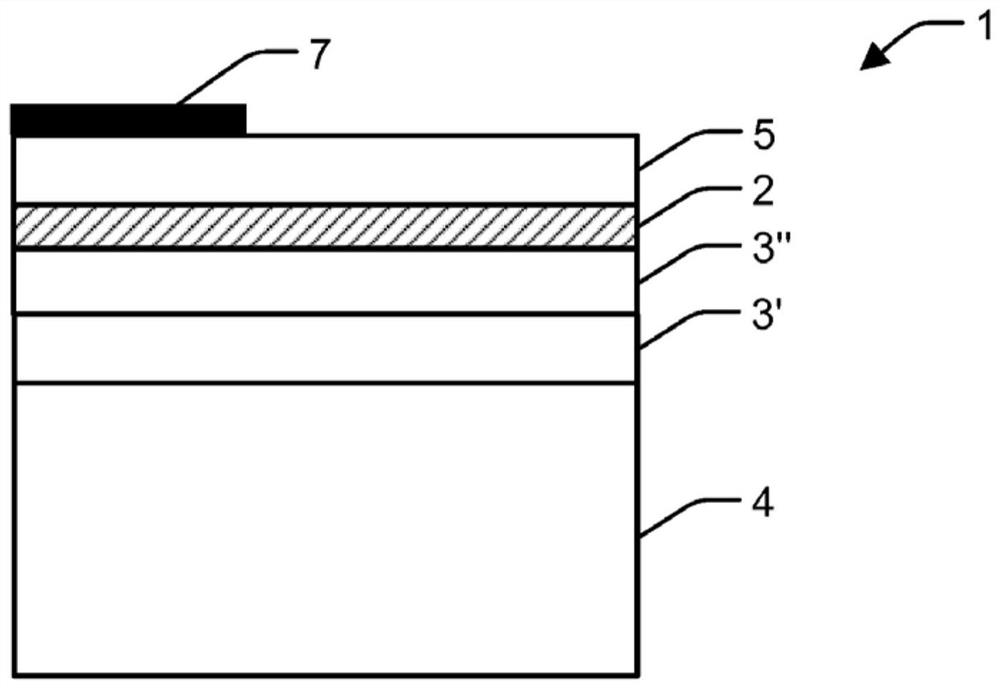

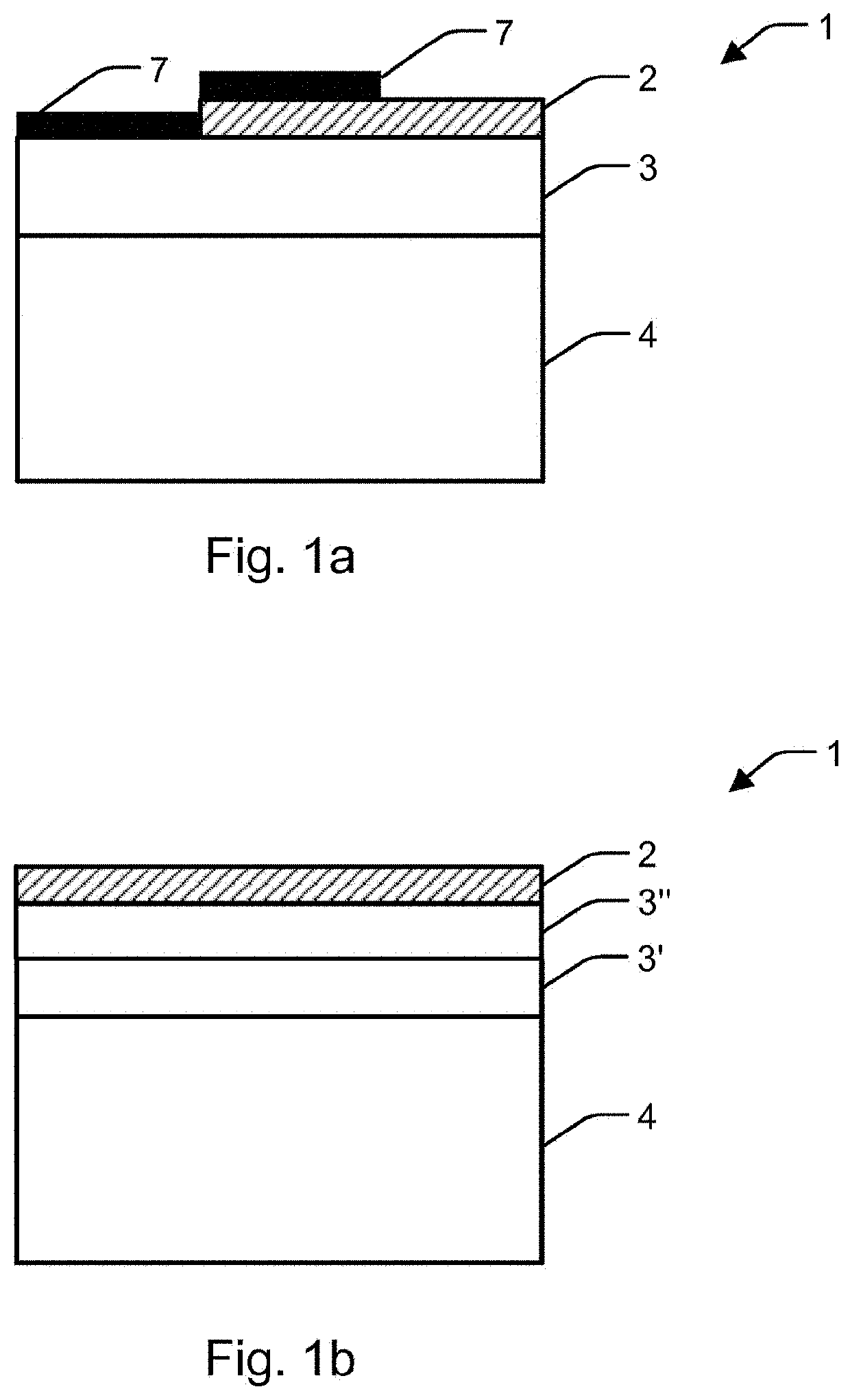

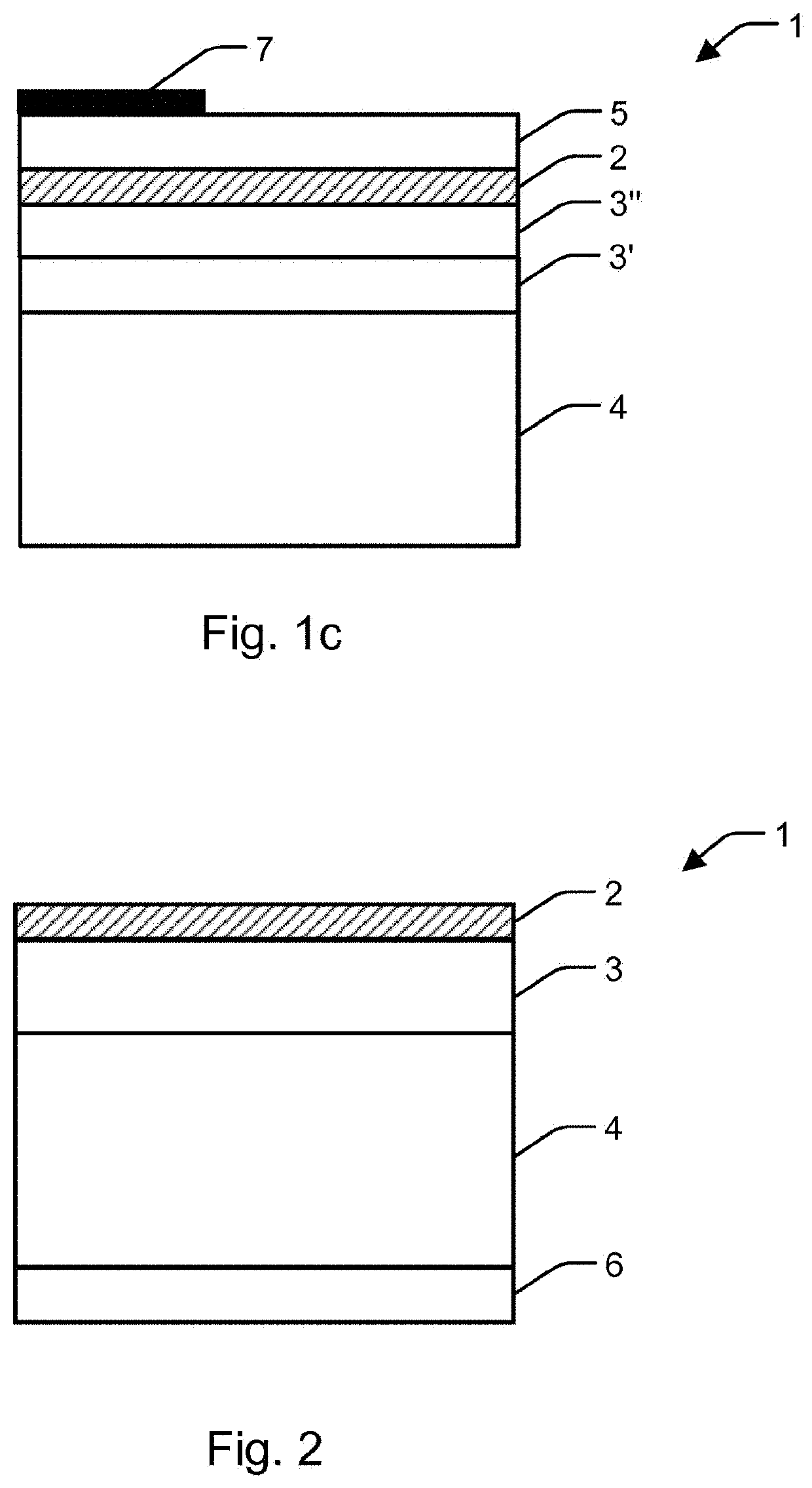

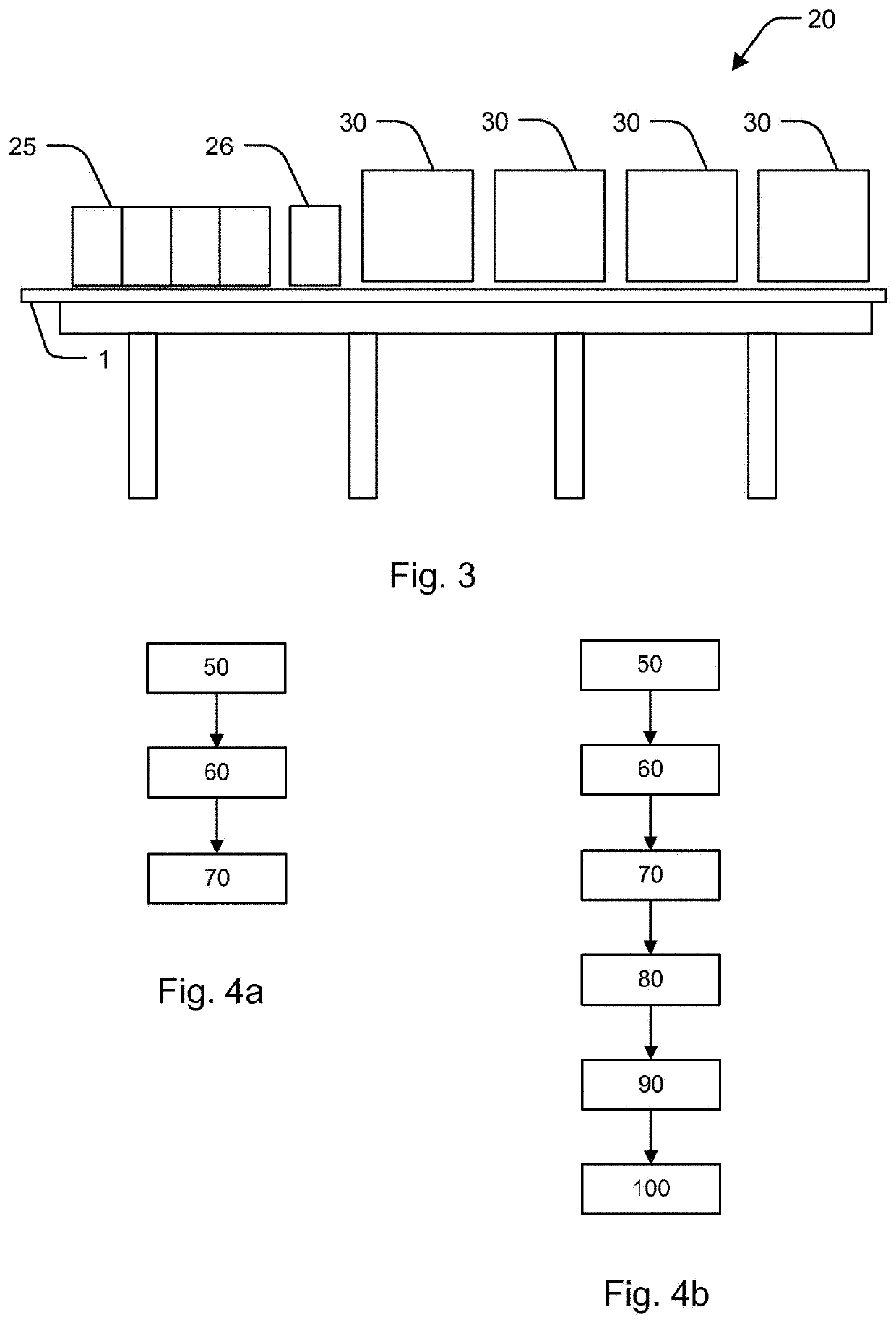

A laminated packaging material for liquid food products, a method for making the same, a method for printing on the same and a package made from the same

ActiveCN112638656AReduce the temperatureReduce risk of defectsLamination ancillary operationsDuplicating/marking methodsCellulosePaperboard

A laminated packaging material (1) for liquid food products comprising, a core layer (4) of paper or paperboard or other cellulose-based material, a laminate portion (3) being arranged on a first side of the core layer (4), a dark colored flexographic ink composition (2) printed onto the free surface of the laminate portion (3), the dark colored ink composition comprises color bases mixed at a ratio such that a total energy absorption by the dark colored flexographic ink composition (2), when provided on the laminated packaging material (1), is below 80%, such as below 70% in an emission spectra from a tungsten light source in the region 250-2500 nm at a temperature of 3000 K, the dark colored flexographic ink composition (2) has a color space lightness value L* <= 25, and a color space difference ([delta]E2000) equal to or lower than 6, with respect to a specified black reference composition.

Owner:TETRA LAVAL HLDG & FINANCE SA

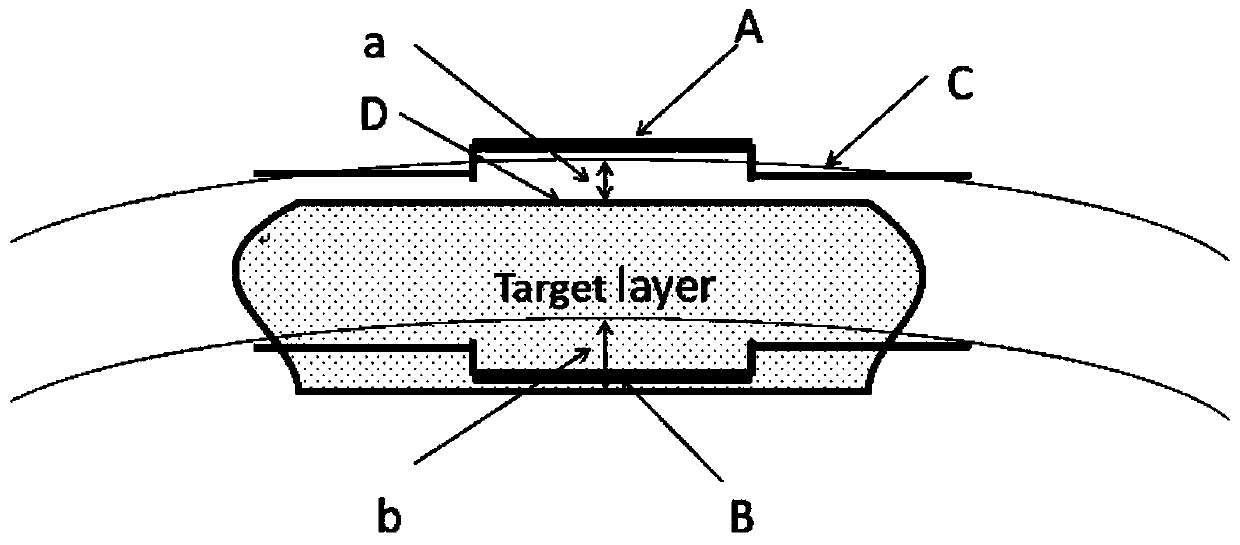

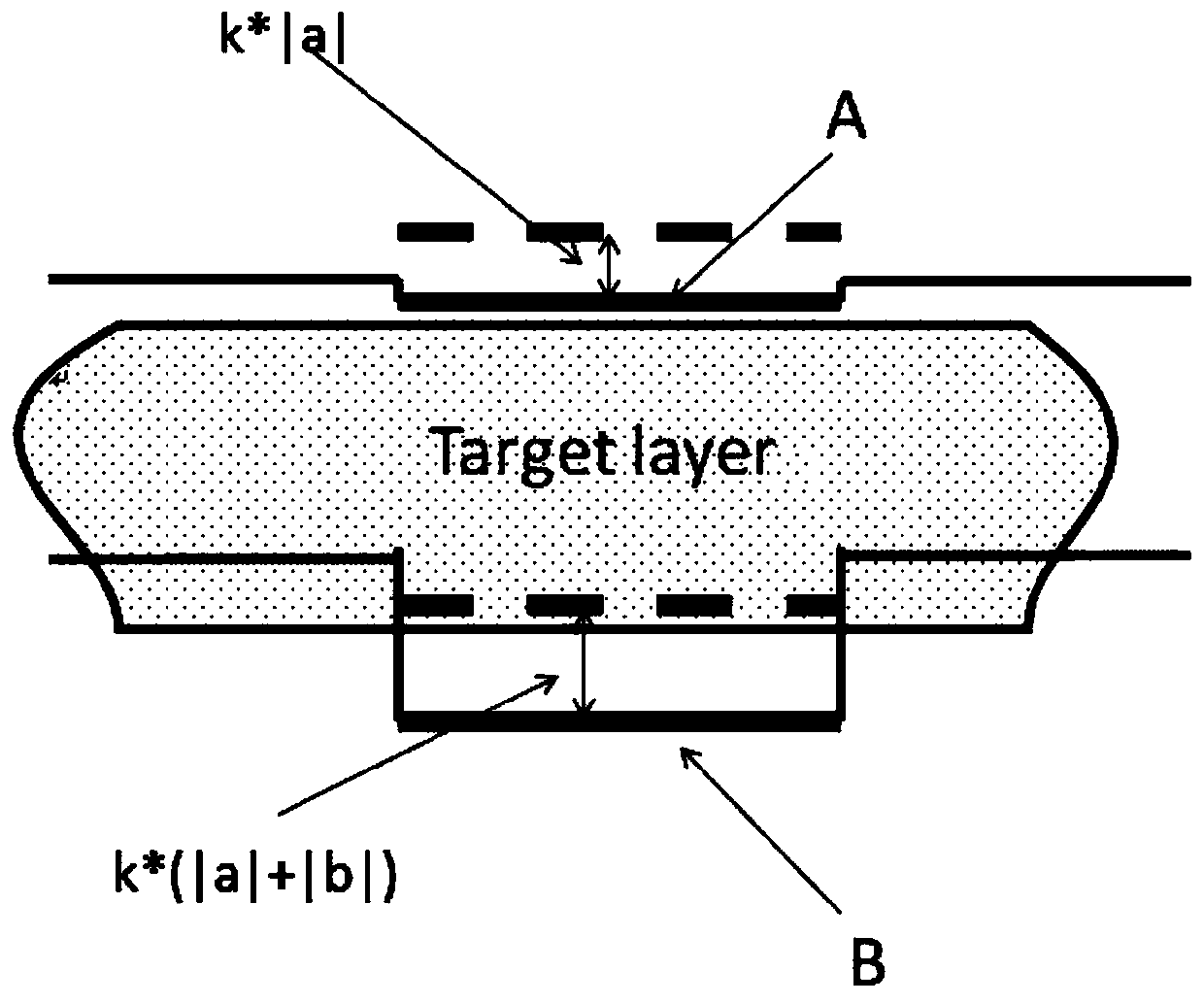

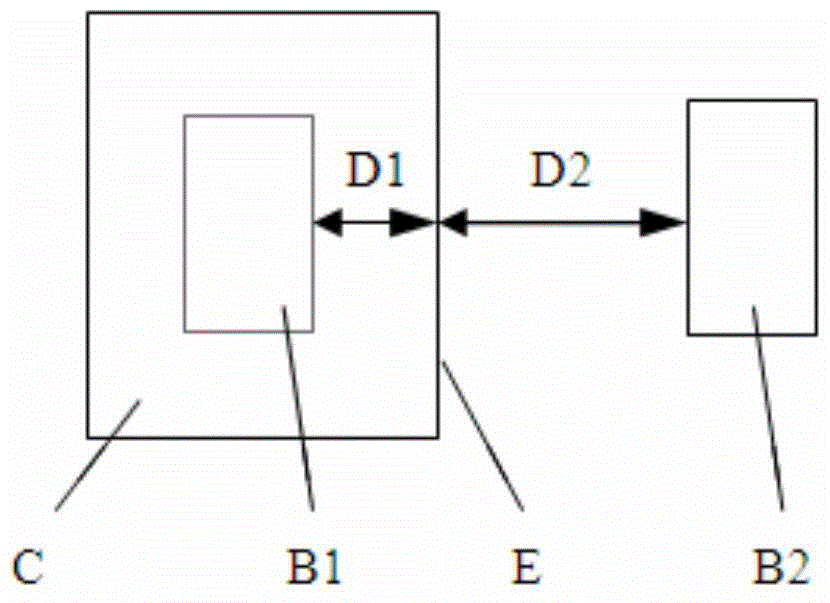

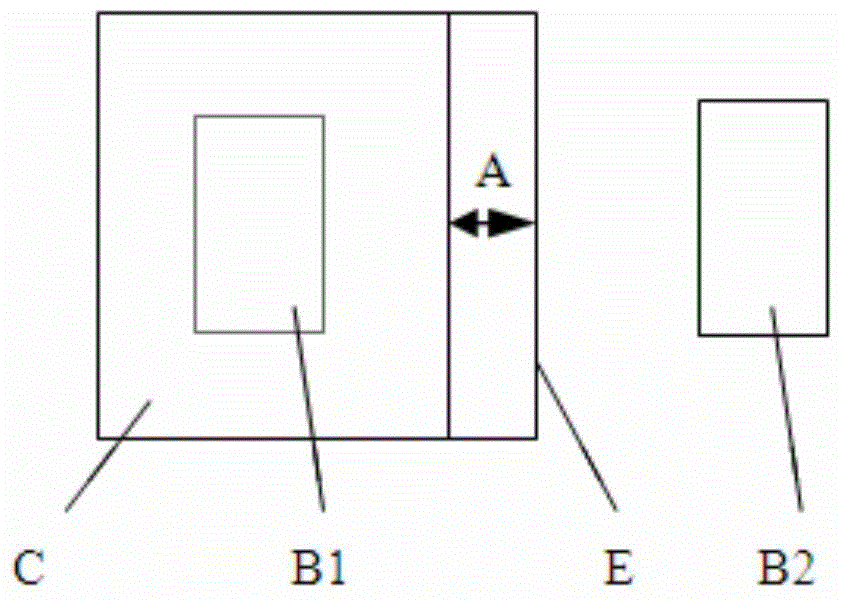

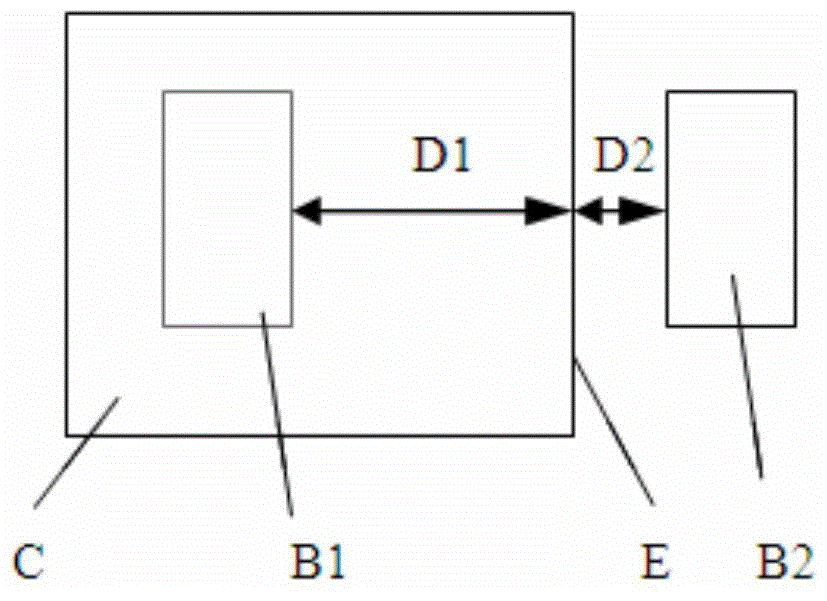

A layout processing method for improving photolithography process window

ActiveCN104460250BPerformance is not affectedImprove pass ratePhotomechanical treatmentLithography processDistance space

The invention discloses a layout treatment method for adding a photoetching process window. The layout treatment method comprises the following steps: providing a photoetching layout pattern with a shallow ion-implanted layer; finding a pattern boundary falling in a shallow groove insulation area from the photoetching layout pattern, wherein the distance from the pattern boundary to a first front layer pattern positioned in a photoresist open area is a first dimension, and the distance from the pattern boundary to a second front layer pattern positioned in a photoresist coverage area is a second dimension; and if the value of the first dimension is less than the value of the second dimension, moving the pattern boundary towards the direction of the second front layer pattern by a distance A1, if not, moving the pattern boundary towards the direction of the first front layer pattern by a distance A2, wherein the value of the A1 is less than the value of the second dimension, and the value of the A2 is less than the value of the first dimension. The layout treatment method disclosed by the invention can achieve the effect of adding the photoetching process window by utilizing the surplus distance space of a shallow ion-implanted layer layout, and can not influence parts because the ion implantation in the shallow groove insulation area is ineffective, and thus the risk of causing defects due to pattern distortion is effectively reduced and the finished product qualification rate is increased.

Owner:SHANGHAI HUALI MICROELECTRONICS CORP

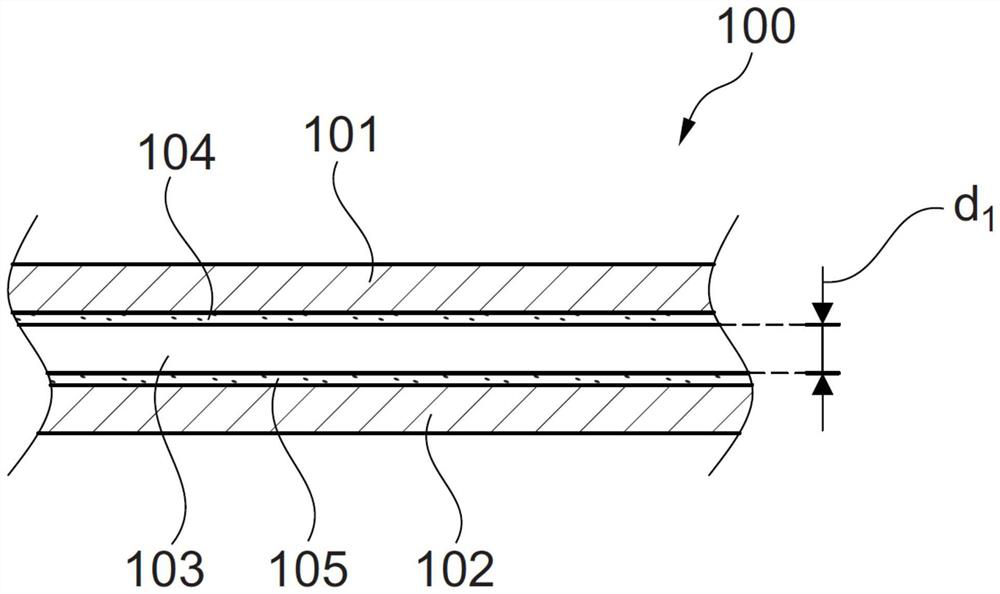

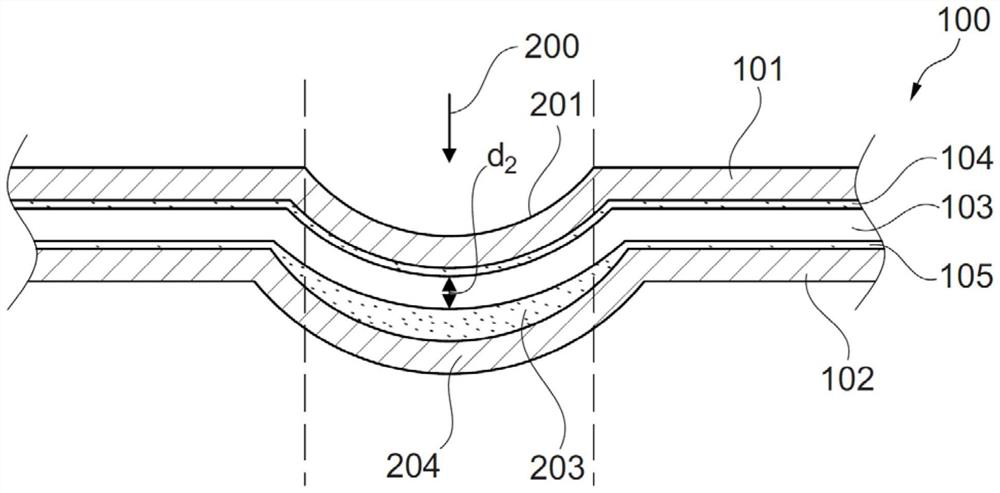

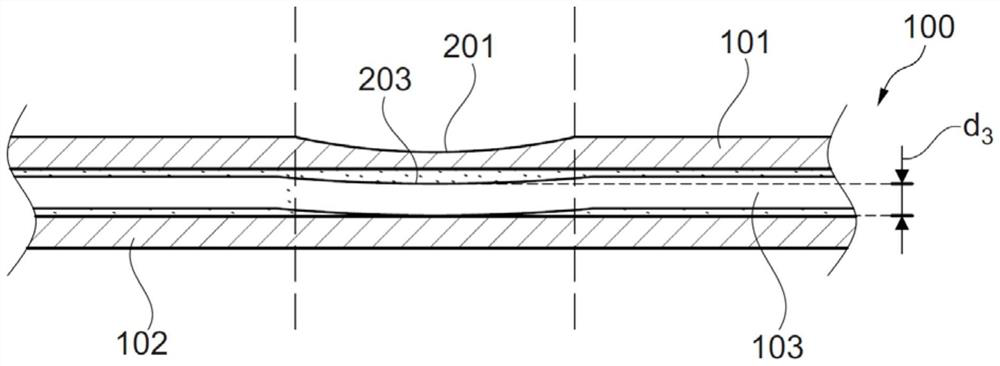

Elastic interlayer assembly

InactiveCN112406200AReduce risk of defectsGuaranteed deformationSynthetic resin layered productsVehicle componentsShear stiffnessPhysics

The invention relates to an interlayer assembly (100) having a first cover layer (101), a second cover layer (102) and a core layer (103). Because the core layer (103) is arranged between the first cover layer (101) and the second cover layer (102), the first cover layer (101), the core layer (103) and the second cover layer (102) form an interlayer structure. The core layer (103) has a shear stiffness greater than 5 MPa. The core layer (103) is configured to be recoverable such that at least 95% of the original thickness of the core layer (103) is recoverable when the thickness of the core layer (103) is reduced by 20% of the original thickness due to the compressive force.

Owner:莱因哈德哈菲琳娜

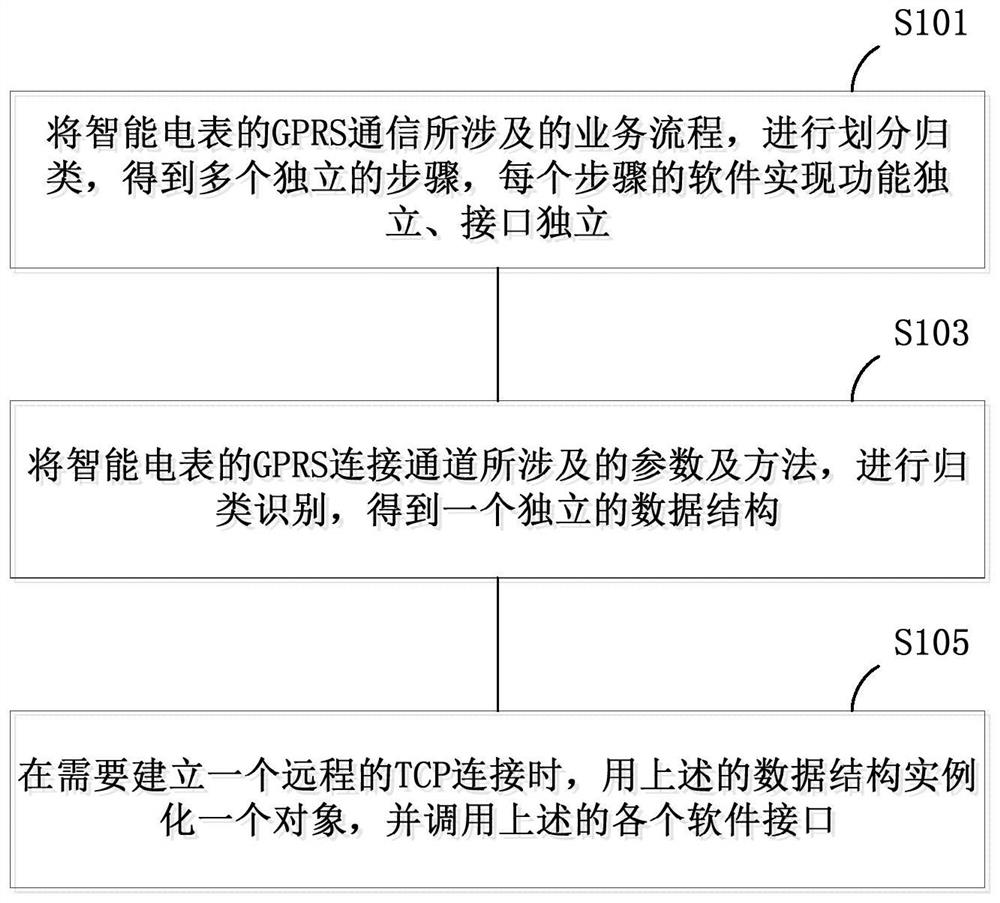

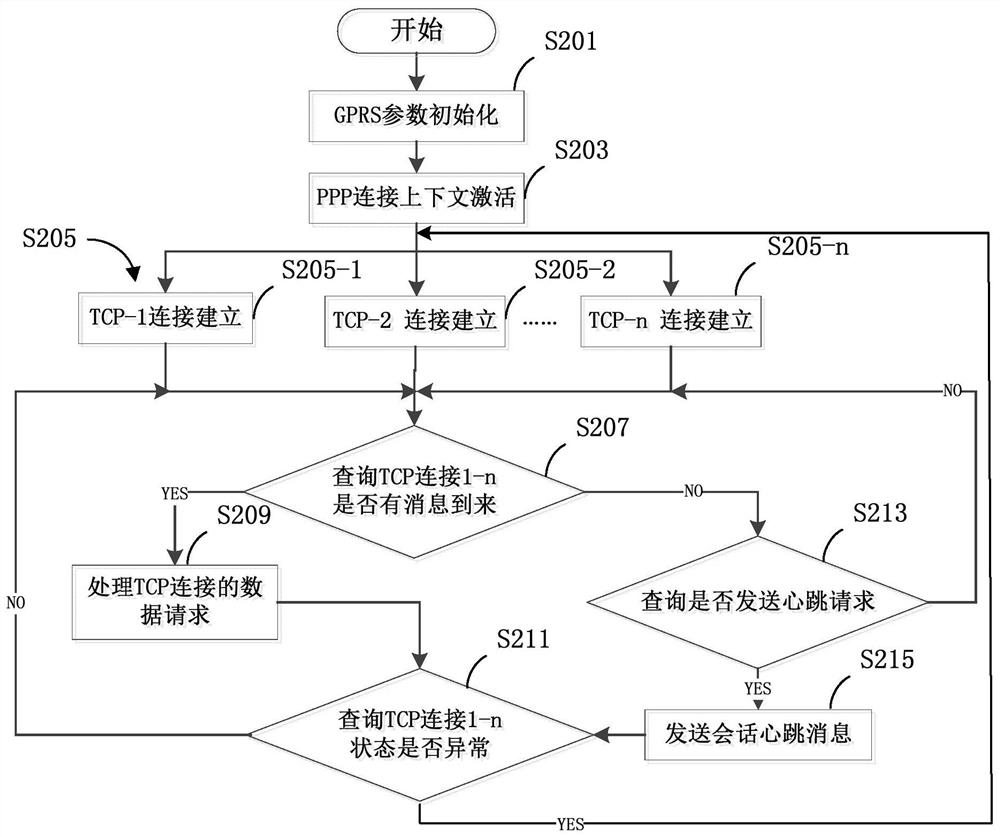

Software design method for gprs multi-channel communication of smart electric meter

A software design method for GPRS multi-channel communication of a smart meter, comprising: dividing and classifying the business processes involved in the GPRS communication of the smart meter to obtain a plurality of independent steps, and the software of each step realizes independent functions and interfaces. Independent; classify and identify the parameters and methods involved in the GPRS connection channel of the smart meter to obtain an independent data structure; and when a remote TCP connection needs to be established, use the above data structure to instantiate an object, and Call each of the above software interfaces. The invention can improve the portability of software, reduce the workload of secondary development, and reduce the risk of software defects.

Owner:SHENZHEN KAIFA TECH (CHENGDU) CO LTD

Wall cloth attaching device

InactiveCN112706558AEvenly attachedAchieve flat attachmentPaperhangingStructural engineeringMechanical engineering

Owner:南京奥新可工程科技有限公司

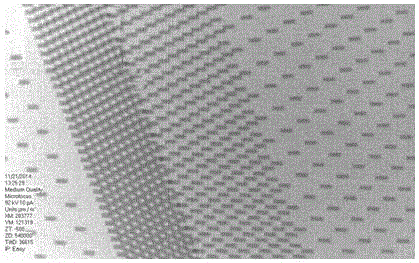

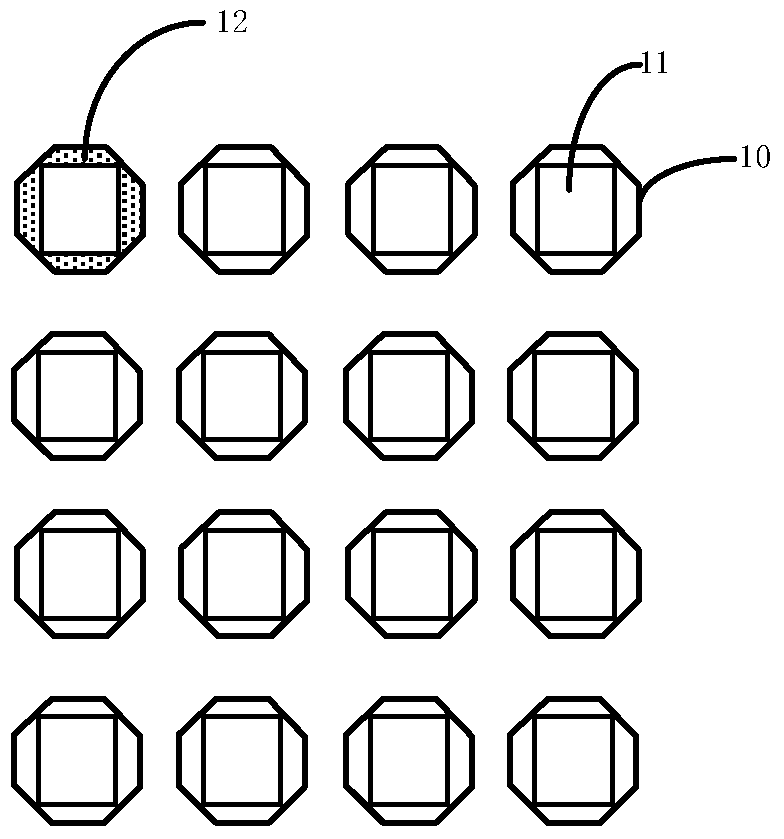

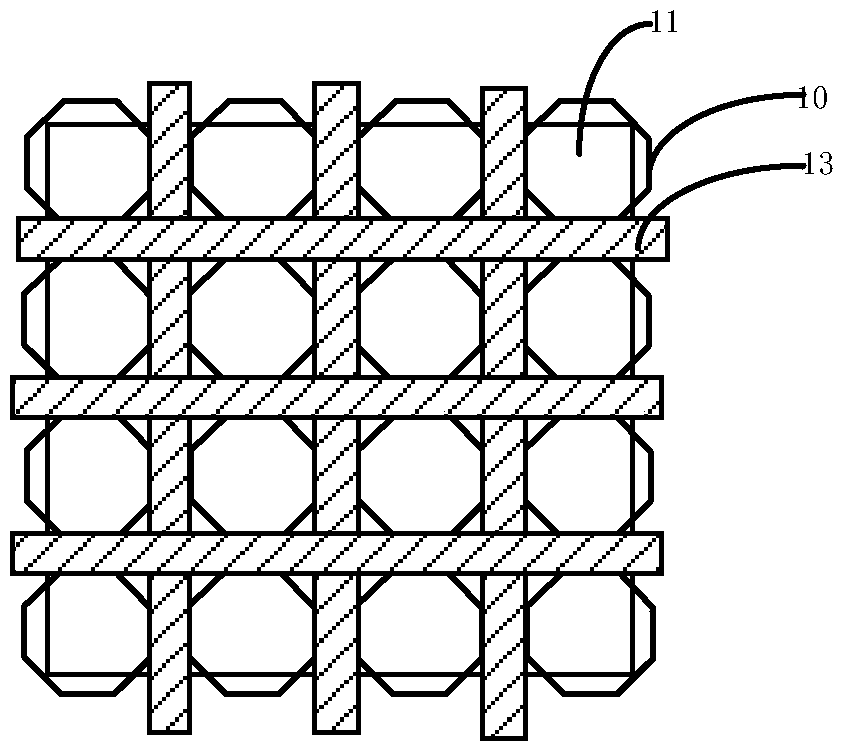

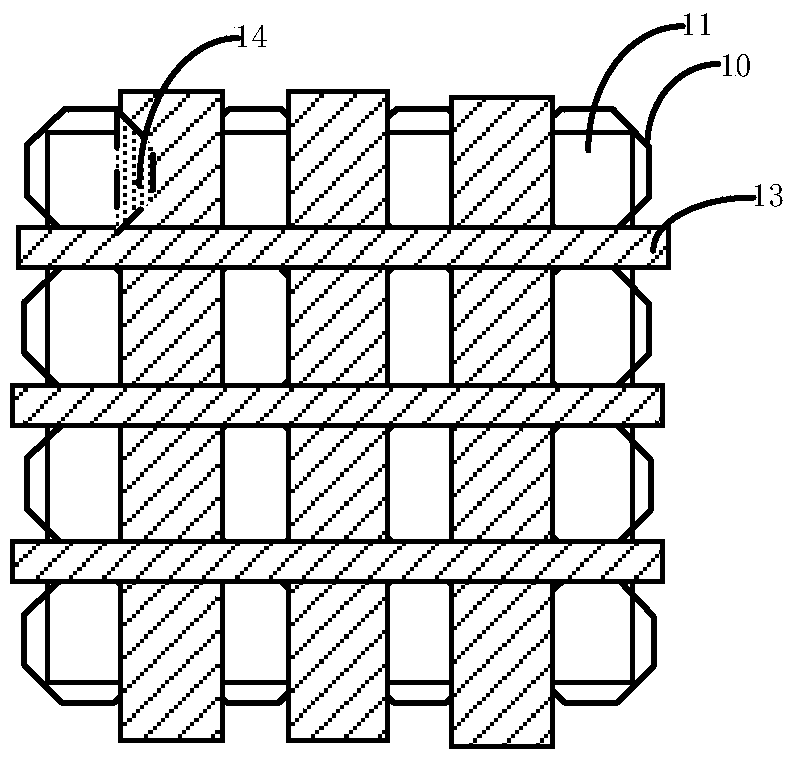

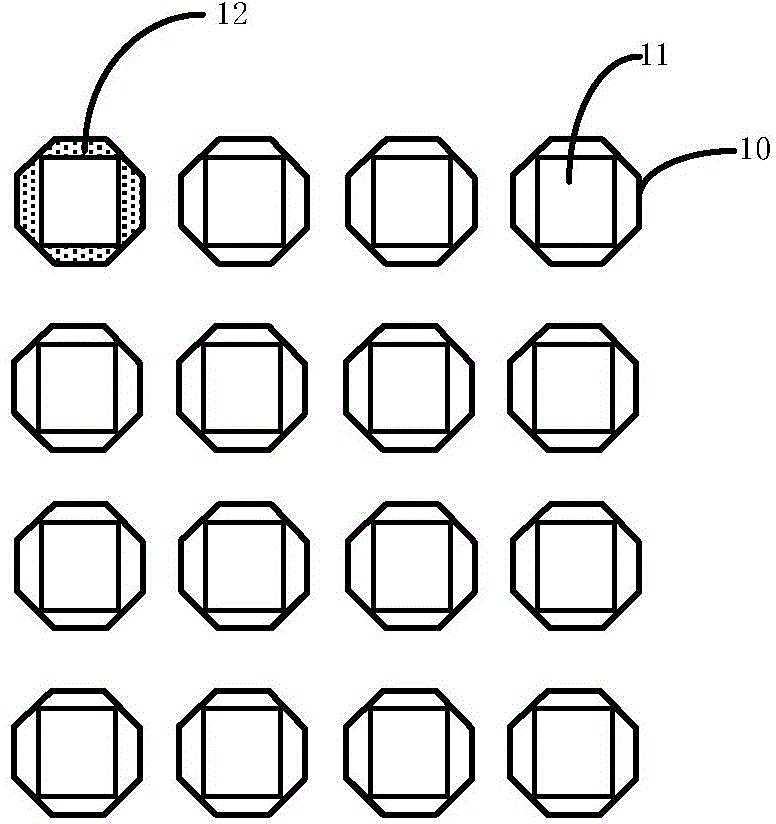

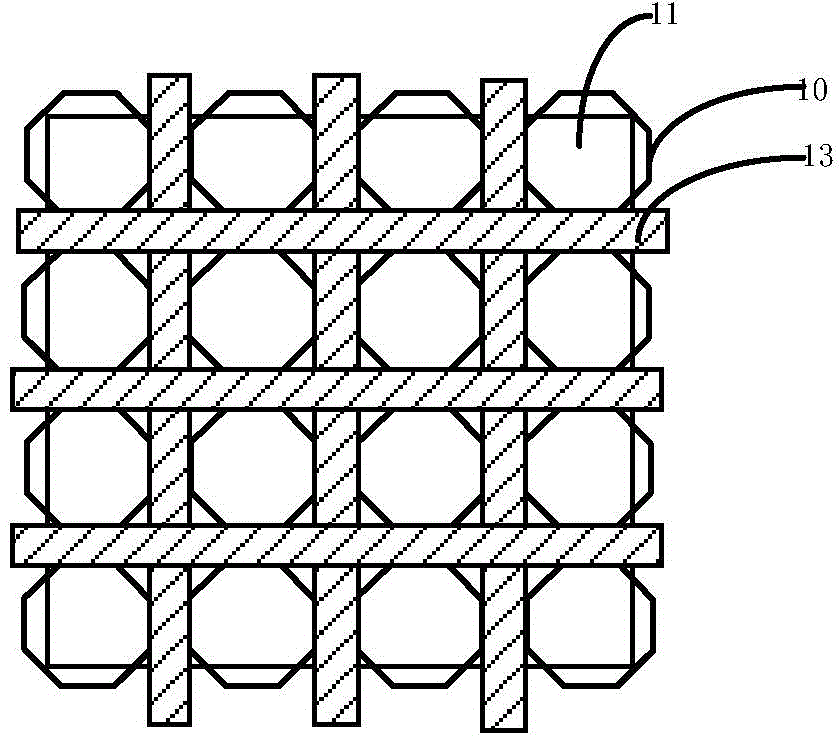

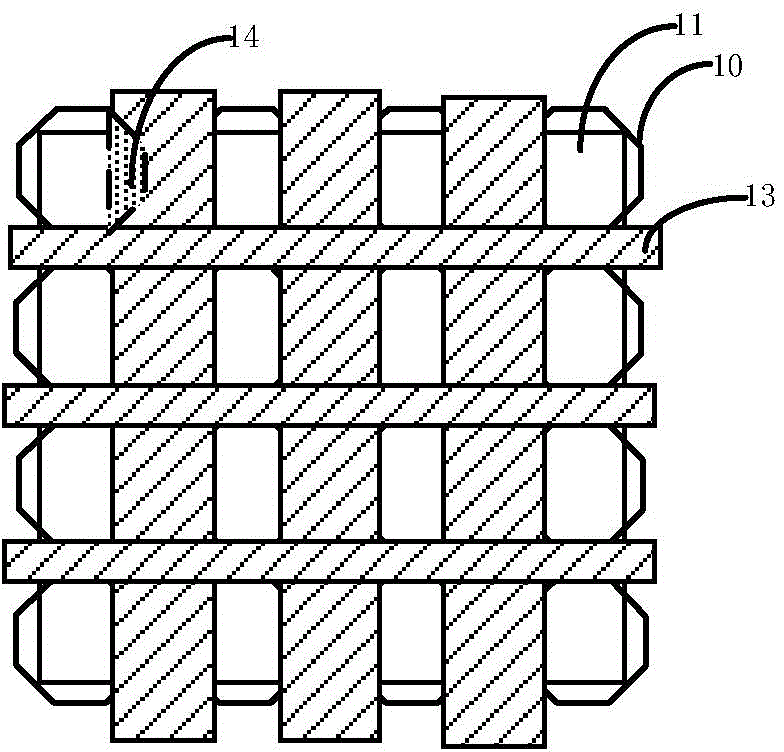

A detection structure and detection method of a photomask

ActiveCN104914664BExpand the detection areaReduce defectsOriginals for photomechanical treatmentAnnular arrayComputer science

The invention relates to a photomask detection structure and a detection method thereof. The method comprises the following steps: a)providing a photomask, wherein the photomask has a chromium crystal rings array composed of mutual-isolated chromium crystal rings; b)determining a scope of an inspection area in the photomask, arranging a horizontal frame and a vertical frame at most external side in the chromium crystal ring array in the inspection area, setting as a non-inspection area; c)setting a first non-inspection area array in the photomask, covering the horizontal frame and the vertical frame in the chromium crystal ring array to form the non-inspection areal; d)arranging a second non-inspection area array in the photomask, covering a beveling frame of the chromium crystal ring in the chromium crystal ring array to form the non-inspection area. The method can ensure the largest detection area and the smallest which can be obtained, defect existence risk is reduced, and the obtained accurate detection result is more accurate.

Owner:SEMICON MFG INT (SHANGHAI) CORP

Photomask detection structure and detection method thereof

ActiveCN104914664AExpand the detection areaReduce defectsOriginals for photomechanical treatmentComputer scienceAnnular array

The invention relates to a photomask detection structure and a detection method thereof. The method comprises the following steps: a)providing a photomask, wherein the photomask has a chromium crystal rings array composed of mutual-isolated chromium crystal rings; b)determining a scope of an inspection area in the photomask, arranging a horizontal frame and a vertical frame at most external side in the chromium crystal ring array in the inspection area, setting as a non-inspection area; c)setting a first non-inspection area array in the photomask, covering the horizontal frame and the vertical frame in the chromium crystal ring array to form the non-inspection areal; d)arranging a second non-inspection area array in the photomask, covering a beveling frame of the chromium crystal ring in the chromium crystal ring array to form the non-inspection area. The method can ensure the largest detection area and the smallest which can be obtained, defect existence risk is reduced, and the obtained accurate detection result is more accurate.

Owner:SEMICON MFG INT (SHANGHAI) CORP

A laminated packaging material for liquid food products, a method for making the same, a method for printing on the same and a package made from the same

PendingUS20210245949A1Reduce risk of defectsOvercome limitationsLamination ancillary operationsDuplicating/marking methodsCellulosePaperboard

A laminated packaging material for liquid food products comprising, a core layer of paper or paperboard or other cellulose-based material, a laminate portion being arranged on a first side of the core layer, a dark colored flexographic ink composition printed onto the free surface of the laminate portion, the dark colored ink composition comprises color bases mixed at a ratio such that a total energy absorption by the dark colored flexographic ink composition, when provided on the laminated packaging material, is below 80%, such as below 70% in an emission spectra from a tungsten light source in the region 250-2500 nm at a temperature of 3000 K, the dark colored flexographic ink composition has a color space lightness value L*≤25, and a color space difference equal to or lower than 6, with respect to a specified black reference composition.

Owner:TETRA LAVAL HLDG & FINANCE SA

Thermal insulation water-based paint capable of being constructed at low temperature and preparation method thereof

PendingCN114163886ALow thermal conductivityReduce risk of defectsCoatingsCelluloseThermal insulation

The invention relates to the technical field of water-based paint, in particular to heat-preservation water-based paint capable of being constructed at low temperature and a preparation method of the heat-preservation water-based paint. The heat-preservation water-based paint is prepared from the following raw materials in percentage by weight: 0.2 to 0.6 percent of dispersing agent, 0.1 to 0.4 percent of hydroxyethyl cellulose, 0.1 to 0.4 percent of defoaming agent, 0.2 to 0.5 percent of wetting leveling agent, 1 to 4 percent of anti-freezing agent, 0.8 to 2 percent of coalescing agent, 14 to 18 percent of titanium dioxide, 0.4 to 1.2 percent of fumed silica, 0.7 to 1.7 percent of sericite, 4 to 7 percent of nano coated ceramic microbeads, 1.5 to 6 percent of expanded perlite, 7 to 13 percent of floating beads, 6 to 12 percent of aerogel, 0.3 to 0.7 percent of thickening agent, 0.05 to 0.25 percent of mildew preventive and the balance of water. The coating is prepared from the following components in percentage by weight: 0.05-0.25% of a light stabilizer, 0.2-0.6% of an ultraviolet light absorber, 1.5-4% of a silane coupling agent, 9-14% of deionized water and the balance of hydroxyl acrylic emulsion. The thermal-insulation water-based paint has the advantage that the thermal-insulation water-based paint can be constructed at a low temperature.

Owner:北京安连科技股份有限公司

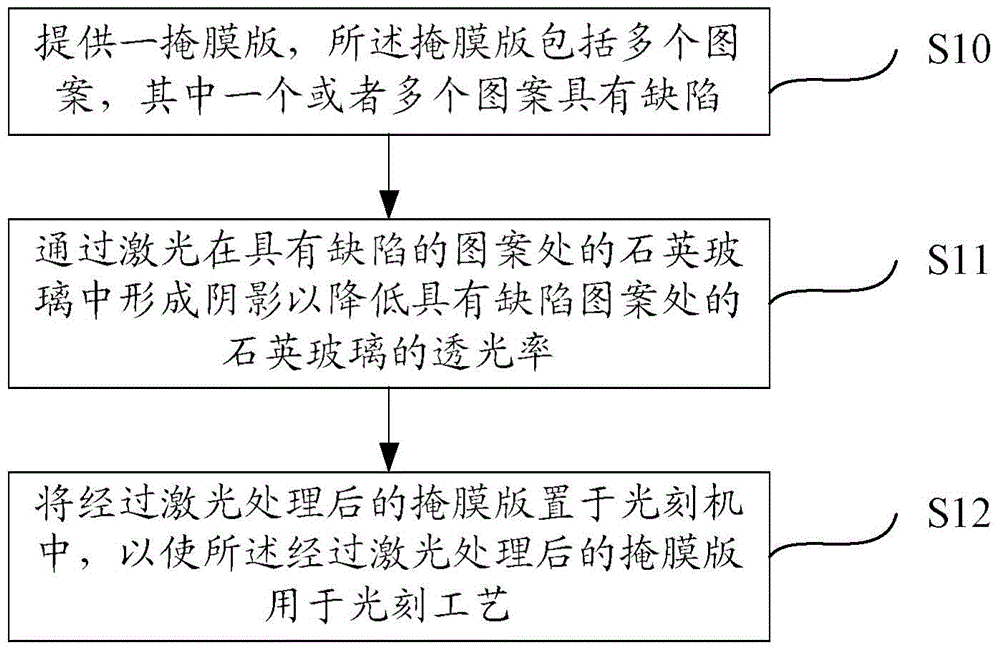

Post-processing method and use method of mask having defect pattern

InactiveCN104898370AReduce light transmittanceReduce risk of defectsOriginals for photomechanical treatmentTransmittanceEngineering

The invention provides a post-processing method of a mask having a defect pattern; a shadow is formed in quartz glass at a position having a defect pattern by a laser so as to reduce the light transmittance of the position having the defect pattern, in the process of using the mask having the defect pattern for exposure, the defect pattern is avoided from being formed on a wafer, a risk of defect generation of the wafer after a photolithography technology is reduced, and a mask having the defect is reused, so as to avoid the problems of high manufacturing costs brought by repairing the mask having the defect or re-manufacturing a mask, namely reduce the manufacturing costs; and at the same time, the production yield is improved.

Owner:SEMICON MFG INT (SHANGHAI) CORP

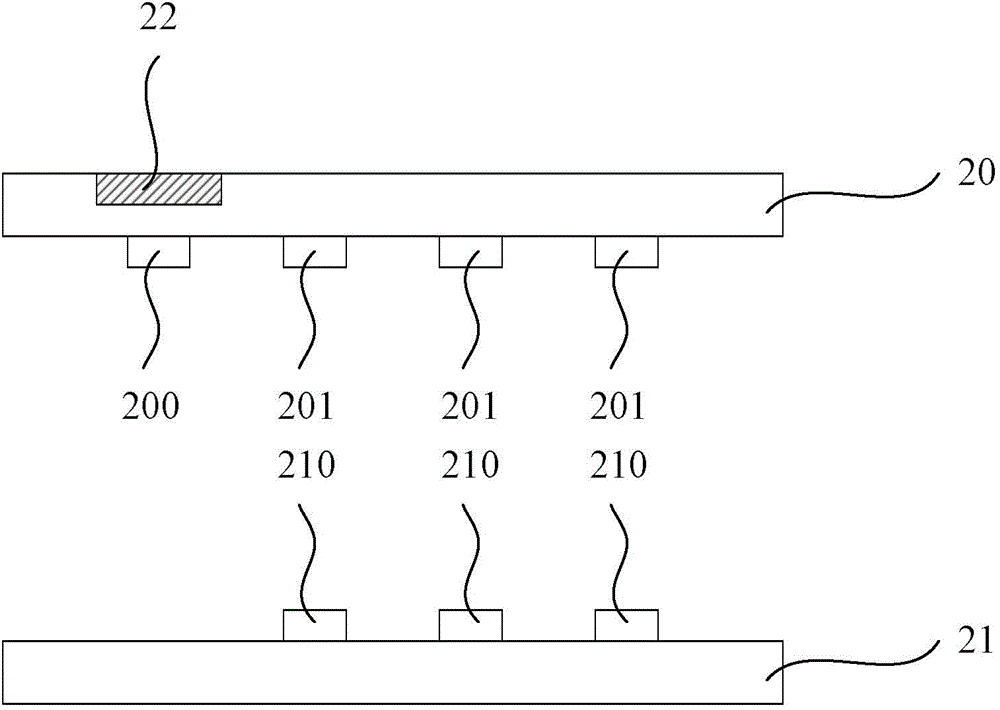

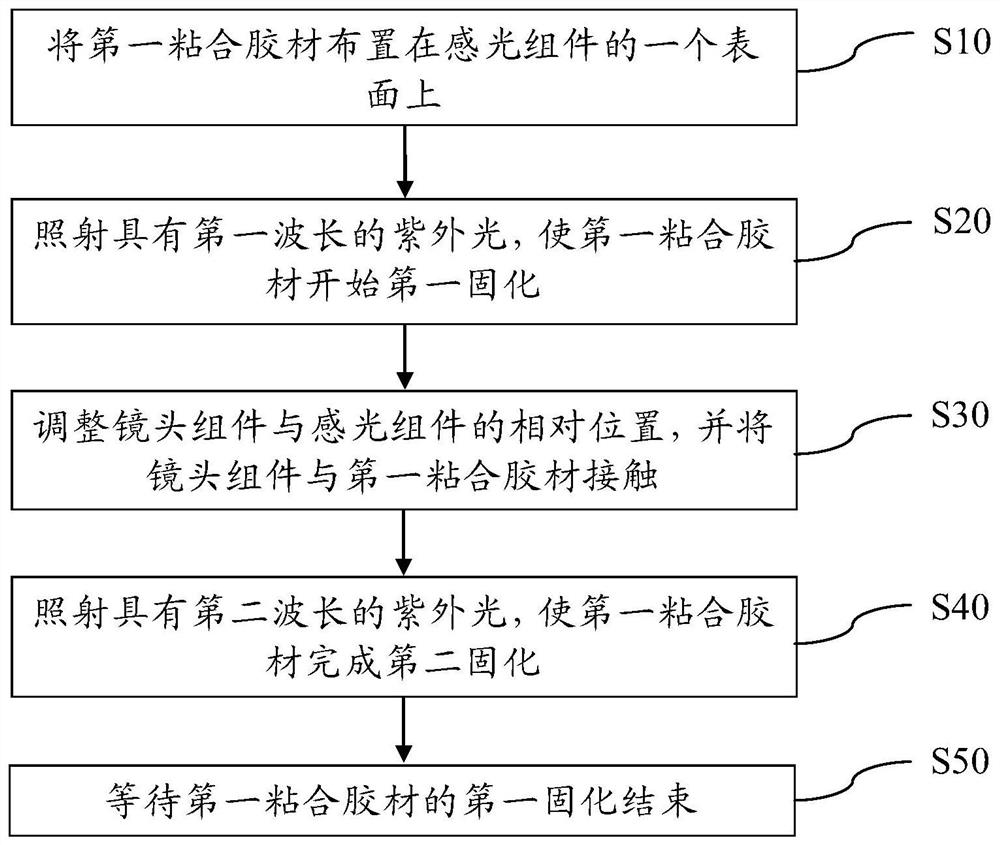

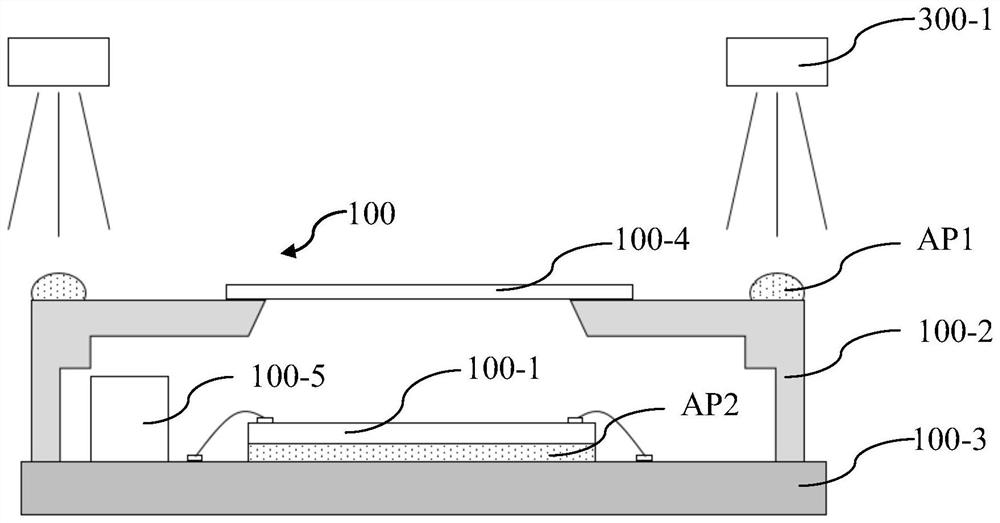

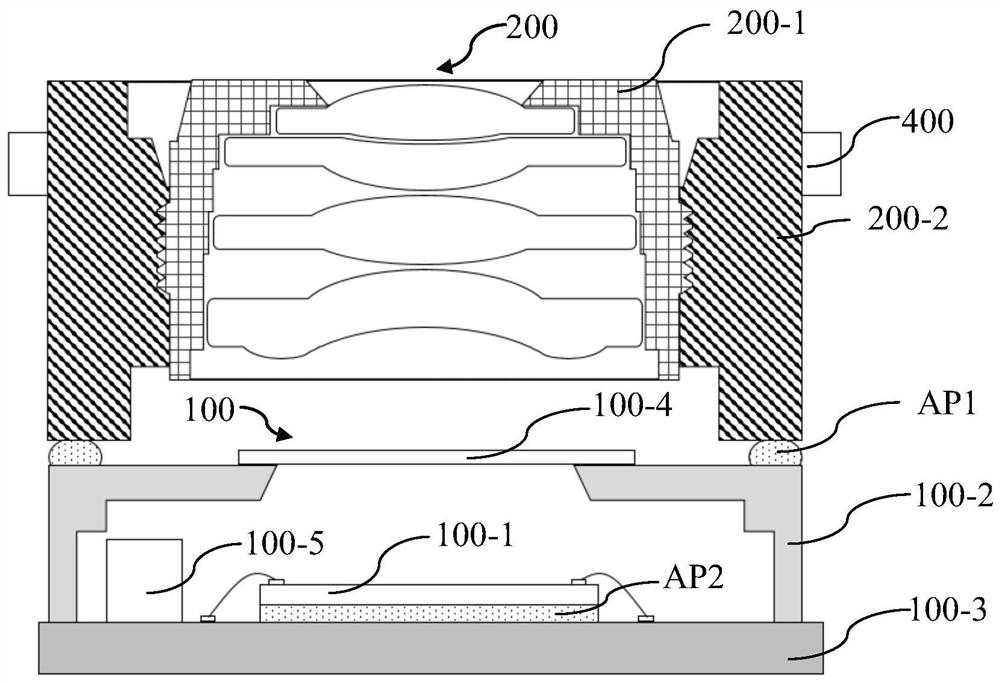

Camera module and assembly method for camera module

ActiveCN113784017APrevent or reduce heat bendingPrevent or reduce image quality degradationTelevision system detailsColor television detailsPhoto irradiationUltraviolet lights

The invention relates to a camera module and an assembly method thereof. The camera module comprises a photosensitive component with a photosensitive chip and a lens component. The method comprises the following steps: arranging a first adhesive material on one surface of the photosensitive component; irradiating the first adhesive material by using ultraviolet light with a first wavelength to start first curing of the first adhesive material; during the first curing period of the first adhesive material, adjusting the relative position of the lens assembly and the photosensitive assembly, enabling the lens assembly to be in contact with the first adhesive material, and irradiating the first adhesive material by ultraviolet light with a second wavelength, so that second curing of the first adhesive material is completed, wherein in the second curing step, the first adhesive material is partially cured, and the second wavelength is different from the first wavelength; and waiting for the completion of the first curing of the first adhesive material.

Owner:NINGBO SUNNY OPOTECH CO LTD

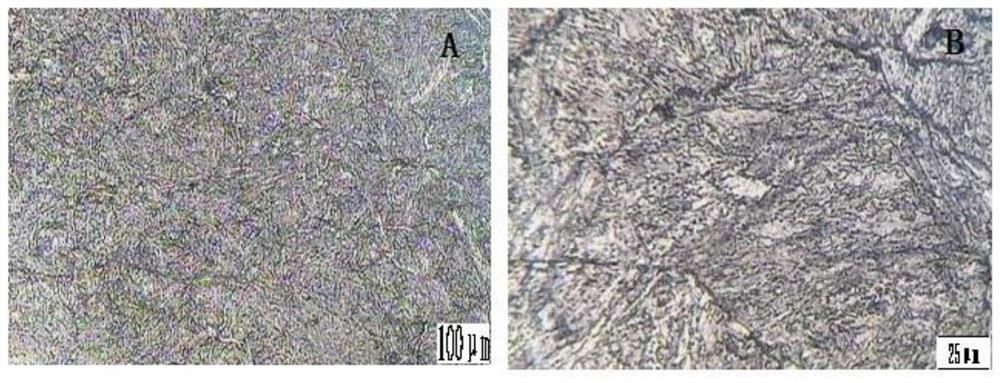

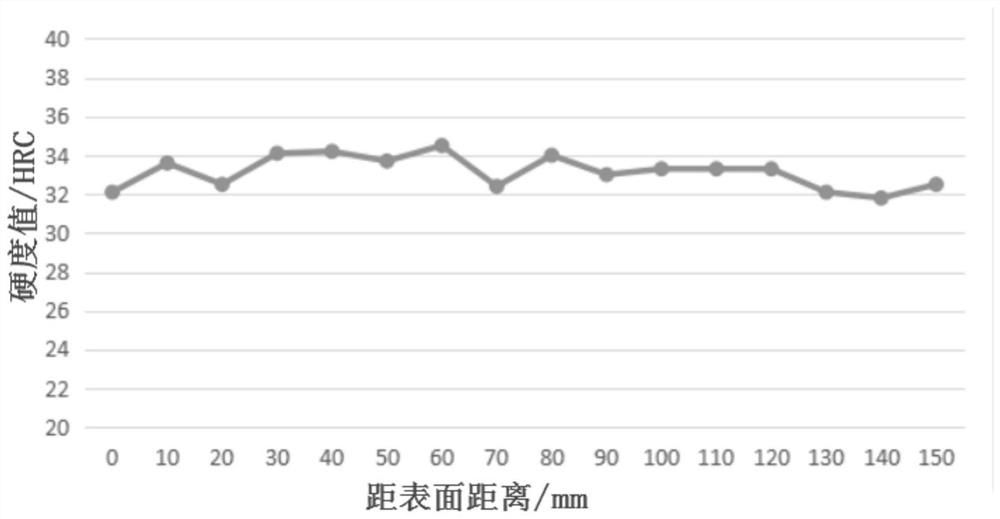

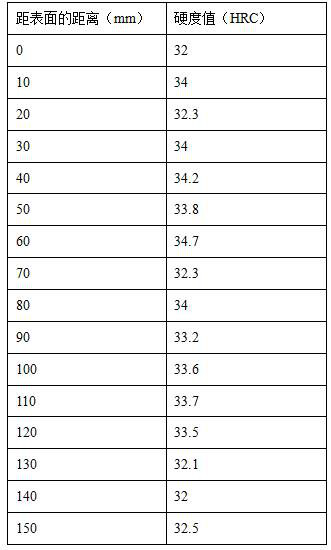

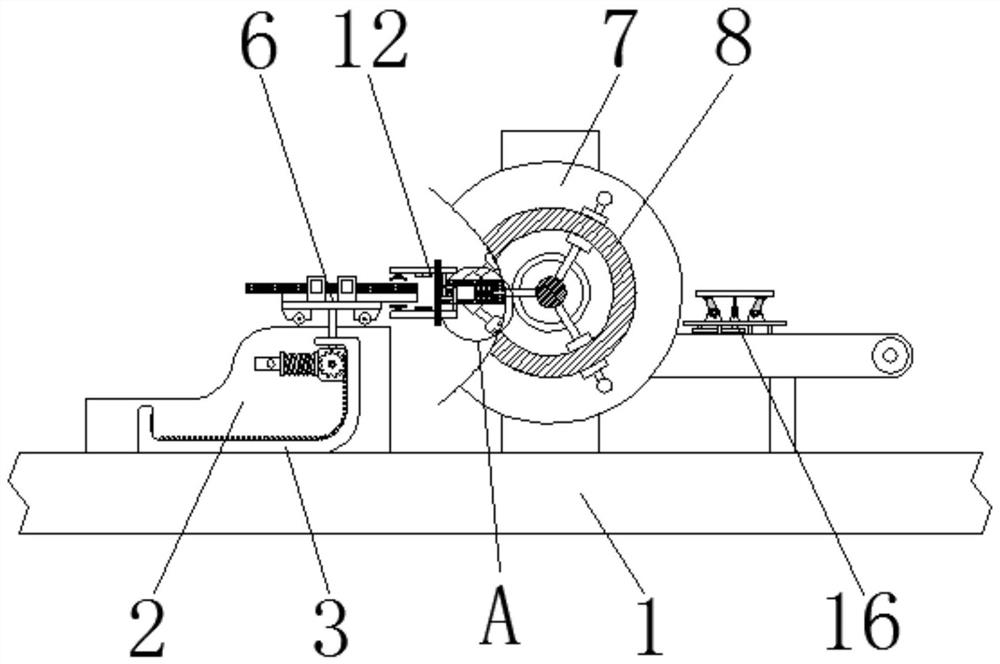

A kind of pre-hardened mold steel replacing 45 mold steel and its preparation method

Owner:浙江德得贸易有限公司

Mobile phone display screen turn-over processing and carrying device

InactiveCN112429503AGuaranteed machining accuracyReduce rigid contactConveyor partsMechanical conveyorsRobot handStructural engineering

The invention relates to the technical field of mobile phone manufacturing, and discloses a mobile phone display screen turn-over processing and carrying device. The device comprises a base, a carrying-in seat is arranged at the upper end of the left side of the base, a carrying-in rail is arranged in the carrying-in seat, a control rod is arranged above the carrying-in rail, and a cooperating block is arranged at the free end of the control rod. A carrying-in trolley is movably connected to the upper end of the cooperating block, a turn-over seat is arranged on the right side of the carrying-in seat, an index wheel is arranged on the front side of the turn-over seat, a butt joint support is arranged at the position, right facing the carrying-in trolley, of the rear portion of the index wheel, push rods are arranged on the upper side and the lower side of the butt joint support, and a movable core is arranged in the butt joint support. According to the mobile phone display screen turn-over processing and carrying device, clamping jaws rotate to the right side along with the butt joint support under control of the index wheel, turning over is completed, meanwhile, adjustable supports arranged at the upper end of a carrying-out rotary table are used in cooperation, and carrying out is completed; and due to the fact that the speed of the rotary turn-over manner is far larger thanthat of mechanical arm control operation, efficiency can be effectively improved in production, and cost is saved.

Owner:南京静燕家居有限公司

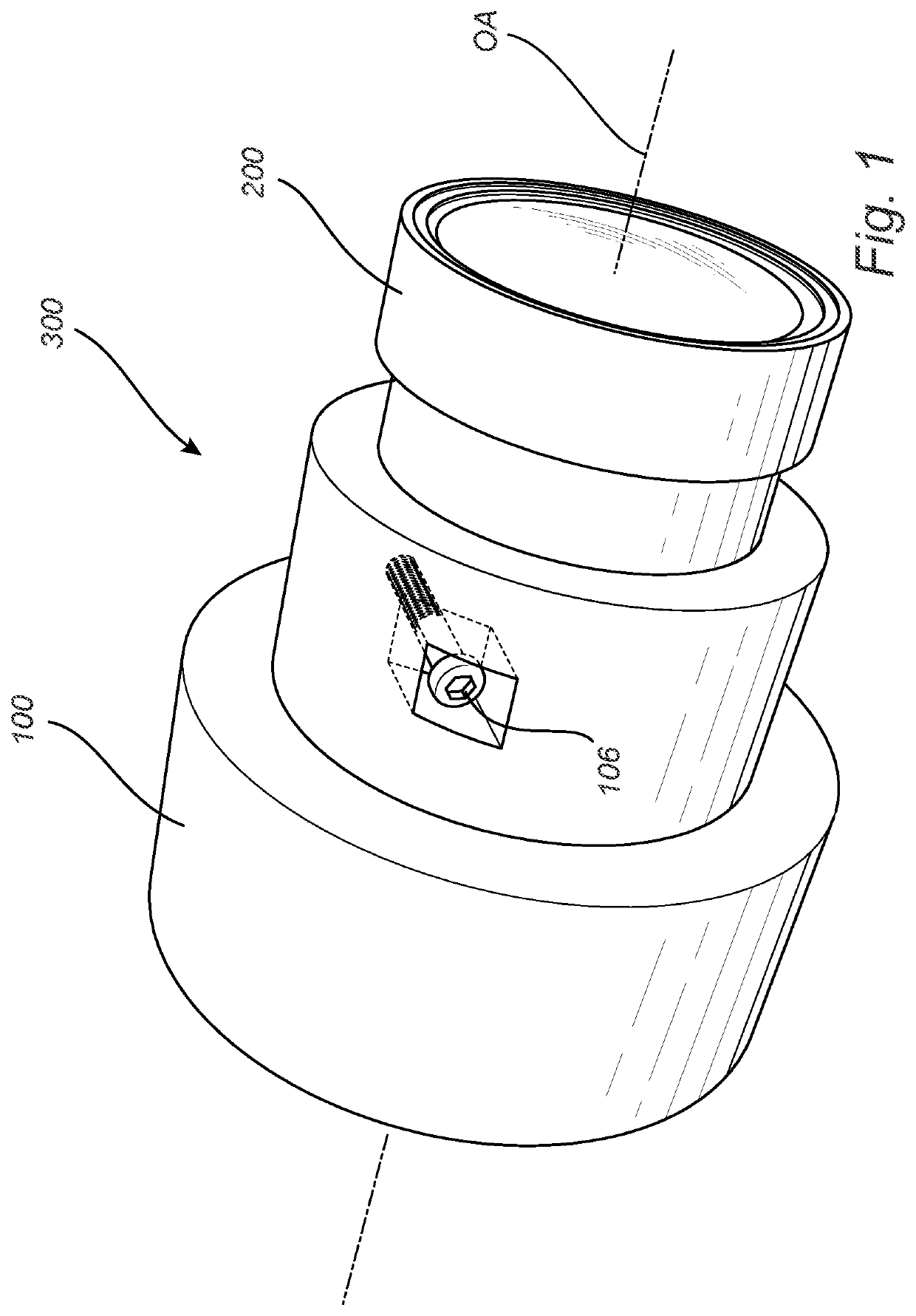

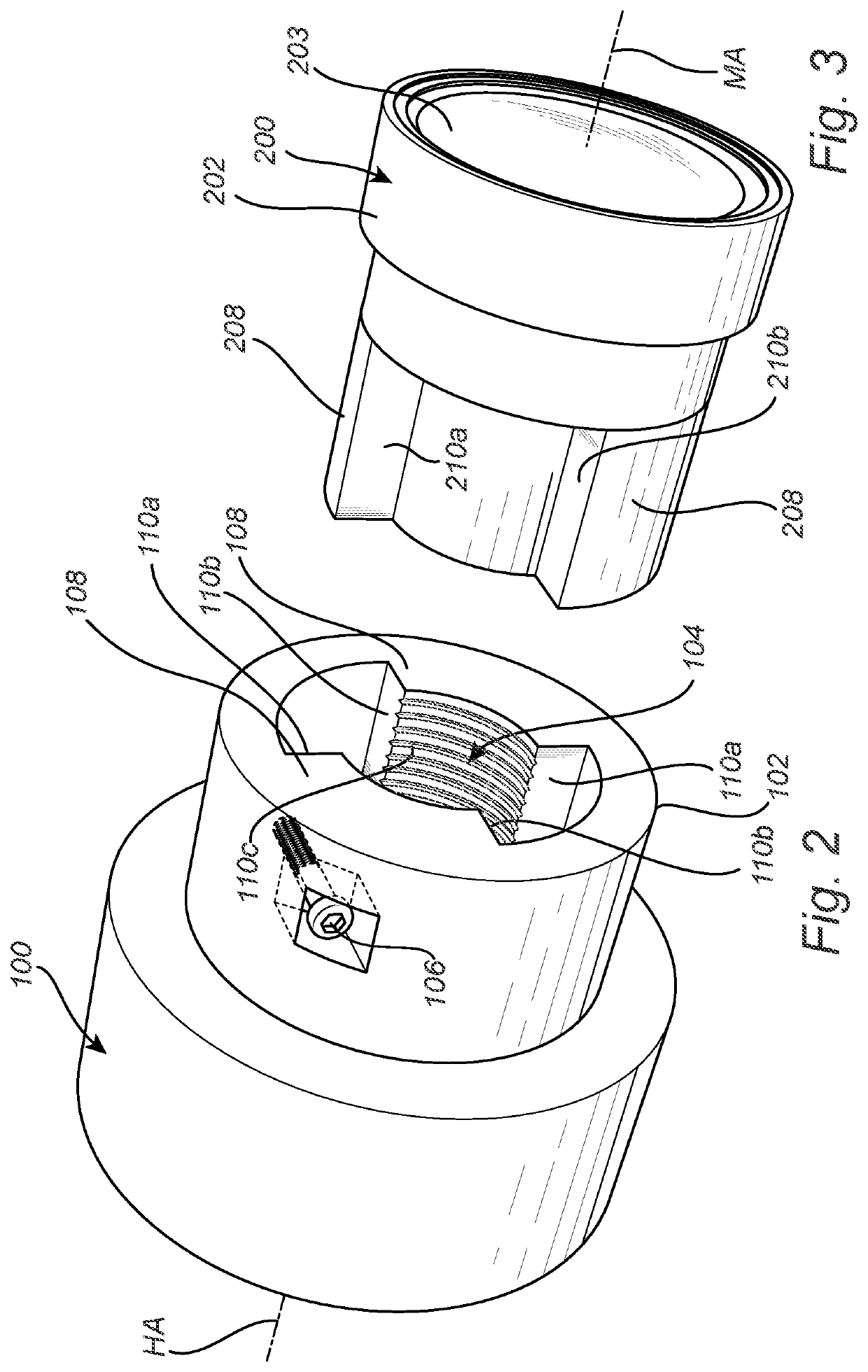

Lens holder, lens member, lens arrangement and camera device comprising such a lens arrangement

ActiveUS11022777B2Improved arrangementImprove positionMountingsCamera body detailsOphthalmologyOptometry

A lens arrangement of a camera device includes a lens holder and a lens member, the lens member being slidingly received by the cavity by axial insertion of the lens member into the cavity such that the longitudinal lens holder axis coincides with the longitudinal lens member axis, wherein a locking force is applied by the locking member in a direction from the first lens holder surface section, the locking force being perpendicular to the plane, wherein the lens holder protrusion and the lens member protrusion are such aligned that the locking force applied by the locking member in the direction from the first lens holder surface section is applied to the first lens member surface section. The second lens member surface section engage the second lens holder surface section in response to the locking force applied to the first lens member surface section.

Owner:AXIS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com