A laminated packaging material for liquid food products, a method for making the same, a method for printing on the same and a package made from the same

A technology for packaging materials, liquid food, applied in the field of laminated packaging materials containing ink compositions, capable of solving the problems of different, imperfect alignment, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

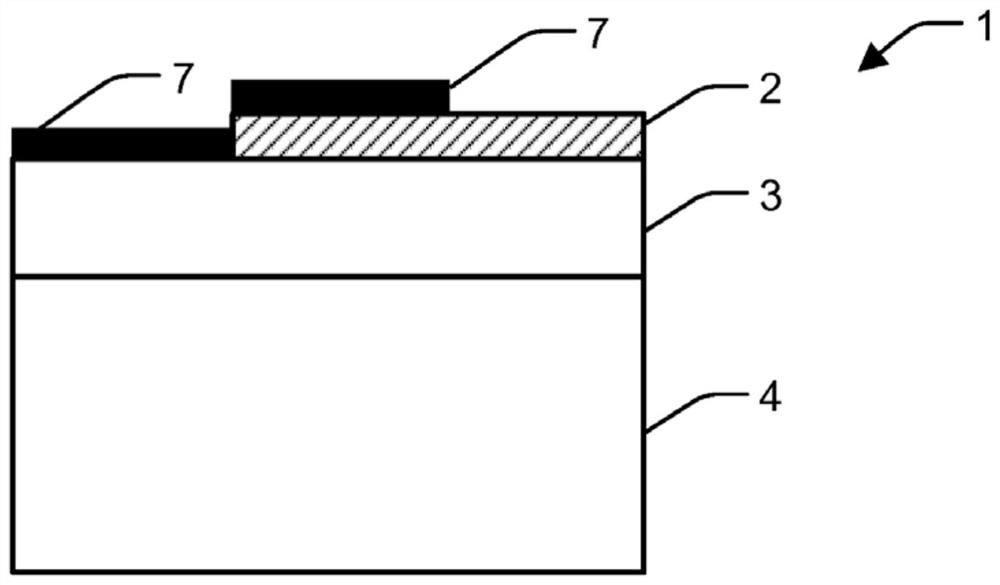

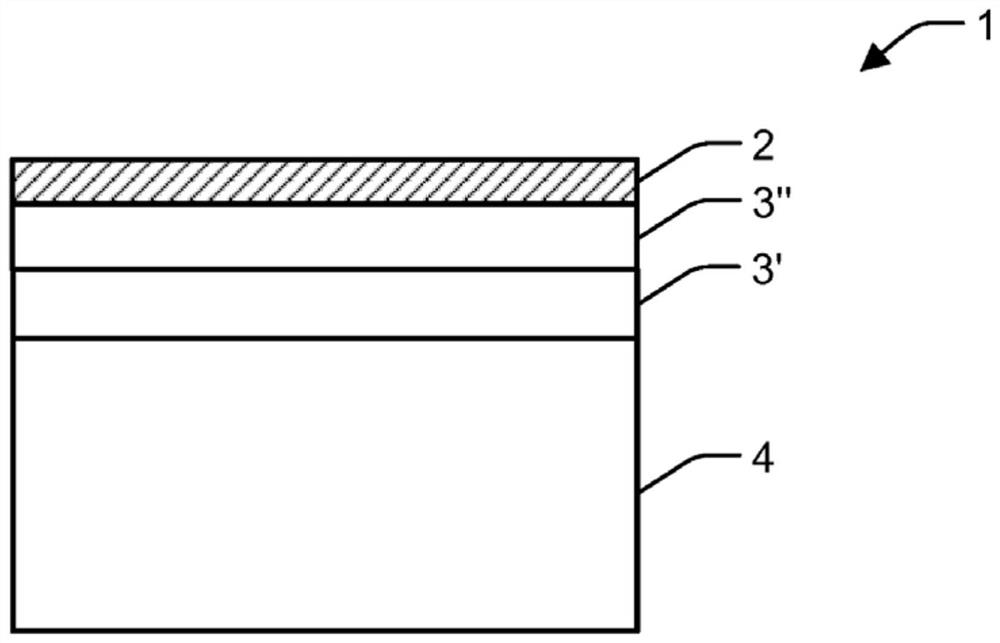

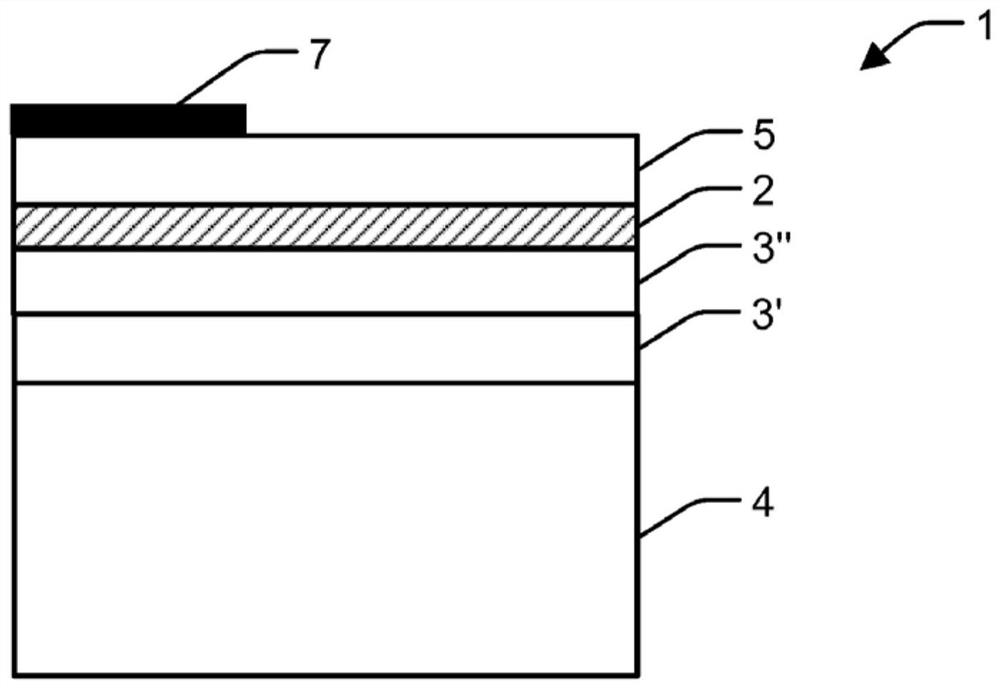

[0036] refer to Figure 1a , shows an example of a laminated packaging material 1 for liquid food. The laminated packaging material 1 comprises a core layer 4 of paper or cardboard or other cellulose based material having a first side and a second side. The second side is located on the side opposite to the first side of the core layer 4 of paper or cardboard or other cellulose-based material, thereby constituting the inner side of the laminated packaging material 1 which is directed towards the package made of the laminated packaging material 1 inside the container 10. The laminated packaging material 1 further comprises a laminated portion 3 arranged on the first side of the core layer 4 , which is directed towards the outside of the package 10 made of the laminated packaging material 1 . A dark ink composition 2 is printed onto the free surface of the laminate 3 . The dark ink composition 2 thus at least partially covers the free surface with the printed pattern. Dark i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com