Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

152results about How to "Fast filling" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

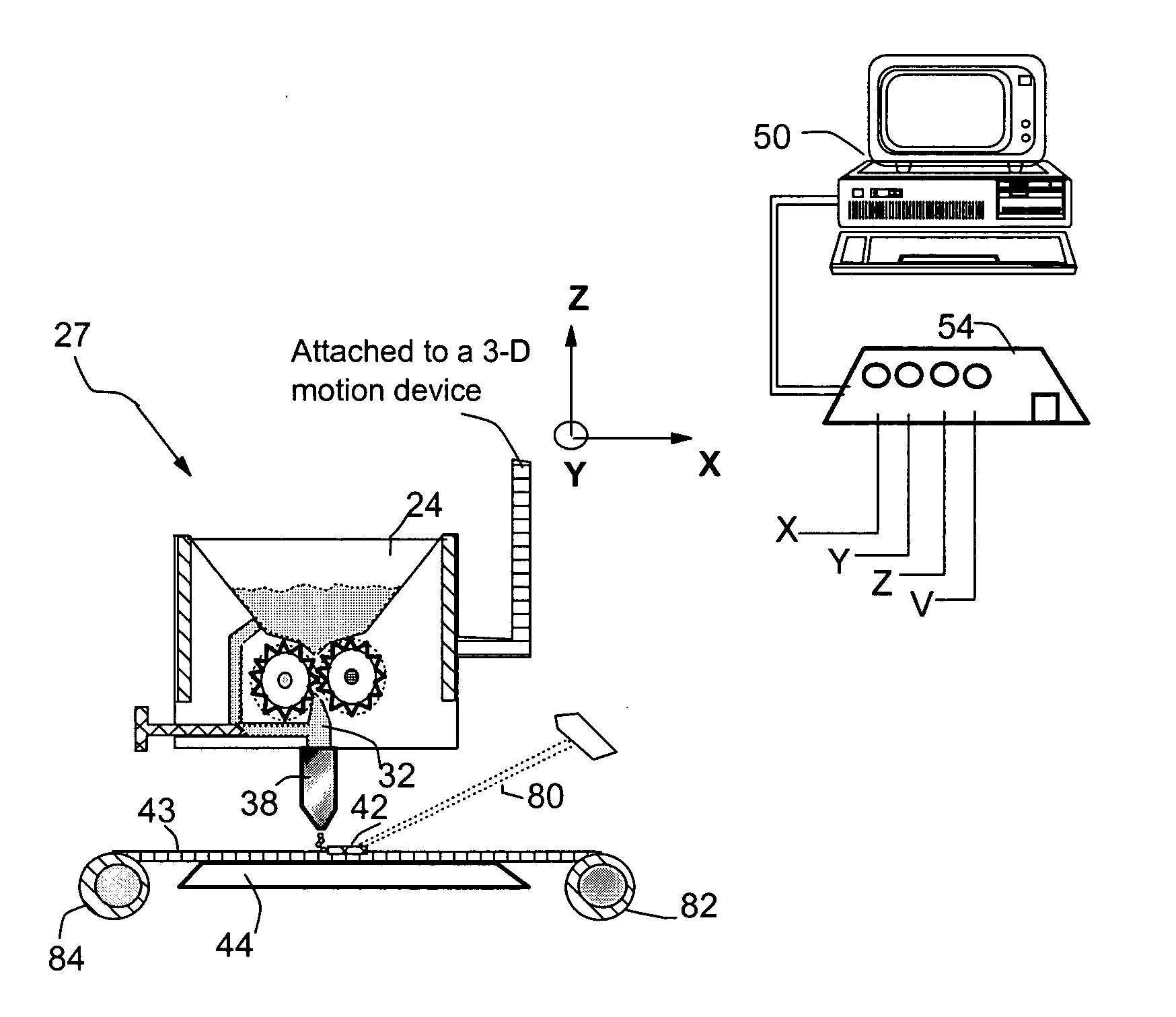

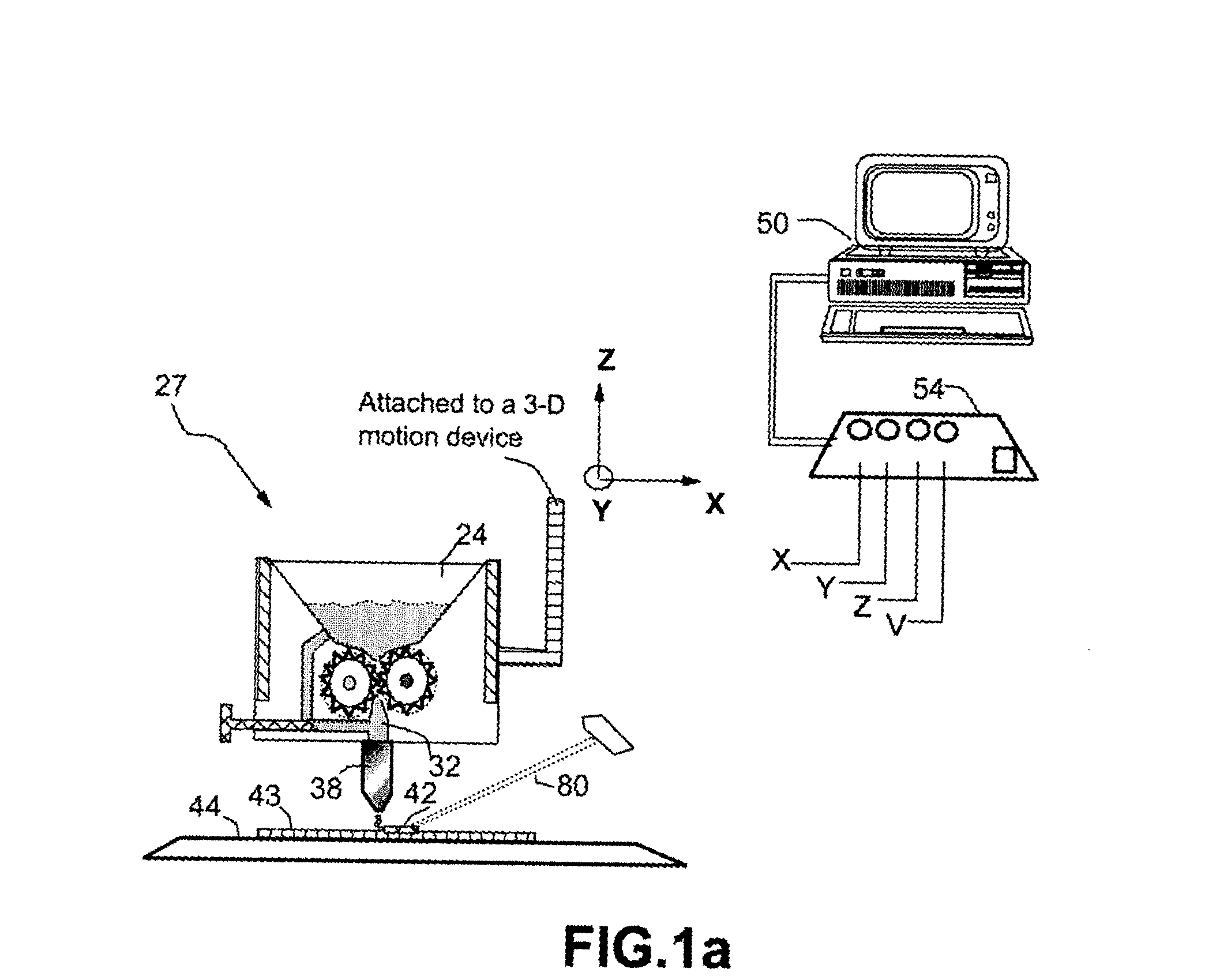

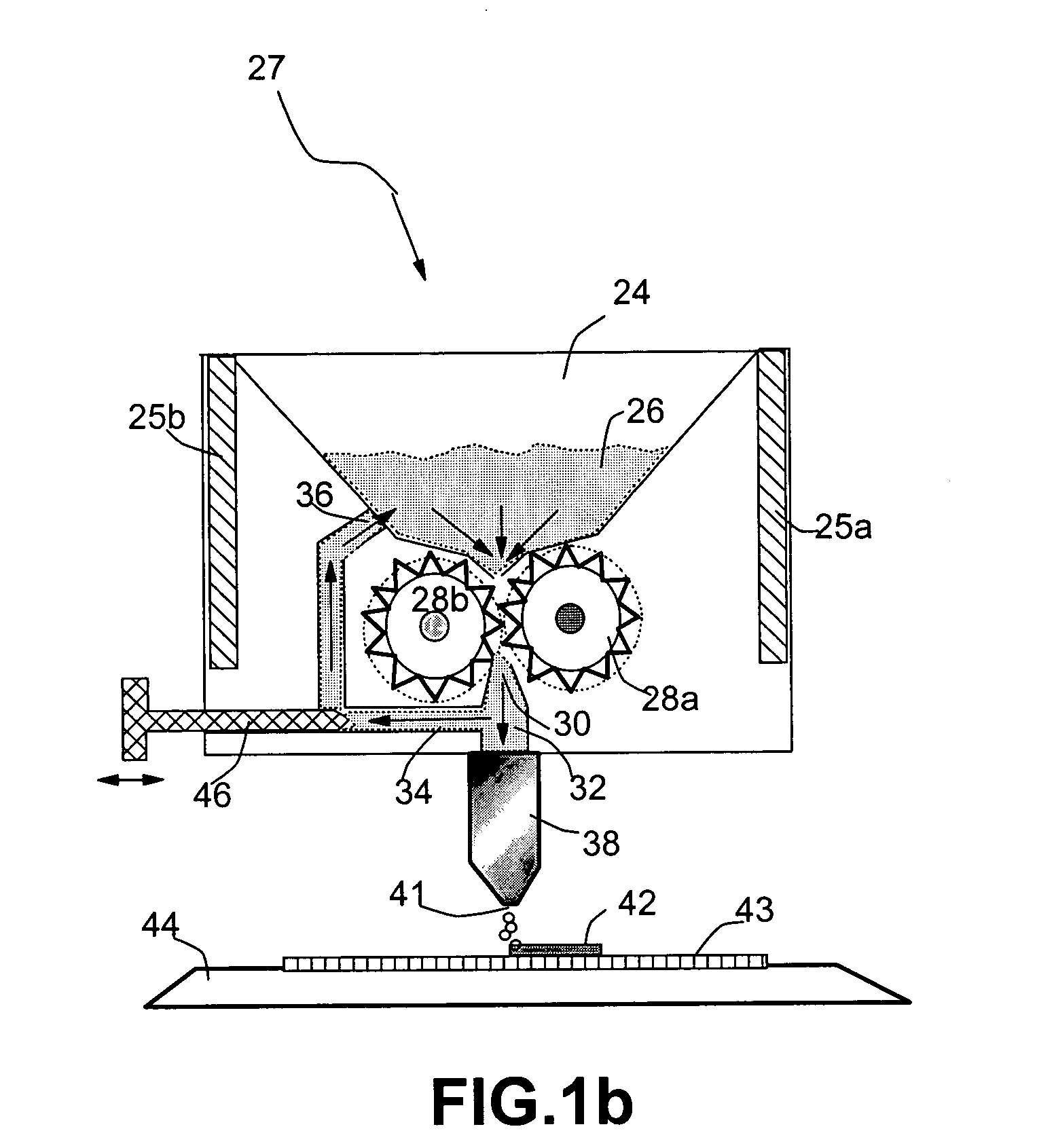

Direct write process and apparatus

ActiveUS20050015175A1Fast preparationIncrease back pressureRecording apparatusAdditive manufacturing apparatusDielectricControl signal

A direct write process and apparatus for fabricating a desired circuit component onto a substrate surface of a microelectronic device according to a computer-aided design (CAD). The process includes (a) providing a support member by which the device is supported while being fabricated; (b) providing a chamber for containing a precursor fluid material under a substantially constant pressure differential relative to the ambient pressure, with the precursor fluid material having a viscosity no less than 10 cps; (c) operating an inkjet-based dispensing head with a control valve or actuator for dispensing and depositing minute droplets of the precursor fluid material onto the substrate surface; (d) energy- or heat-treat the deposited precursor fluid material for converting it to the desired active or passive component; and (e) operating a machine controller for generating control signals in response to the CAD coordinates for controlling the position of the dispensing head relative to the support member in response to the control signals to control dispensing and depositing of the precursor material to form the desired component. The process is useful for depositing a wide range of component materials onto an electronic device, including conductor, resistor, capacitor, dielectric, inductor, antenna, solar cell electrode, battery electrode, interconnect, superconductor, sensor, and actuator element materials.

Owner:NANOTEK INSTR GRP LLC

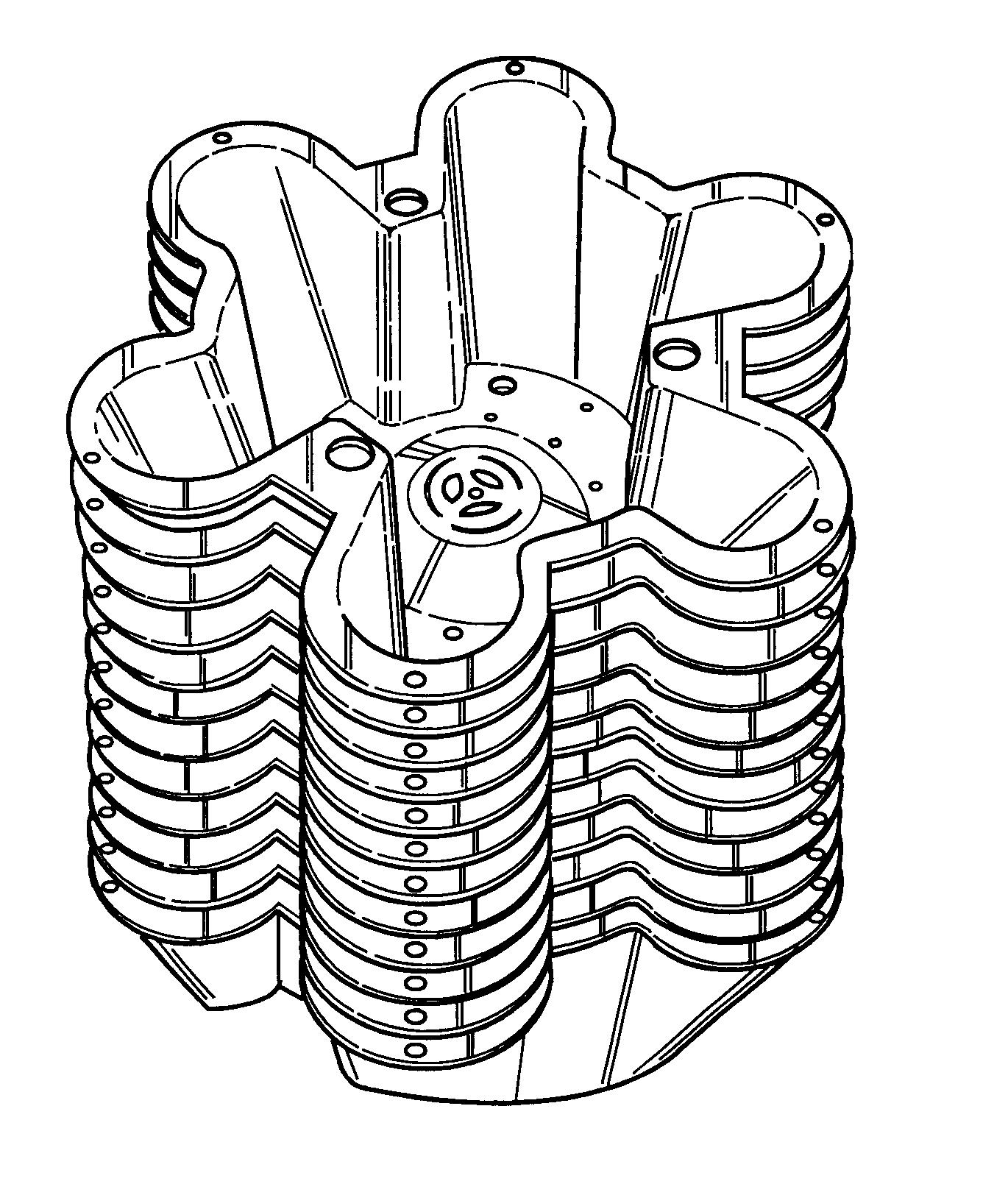

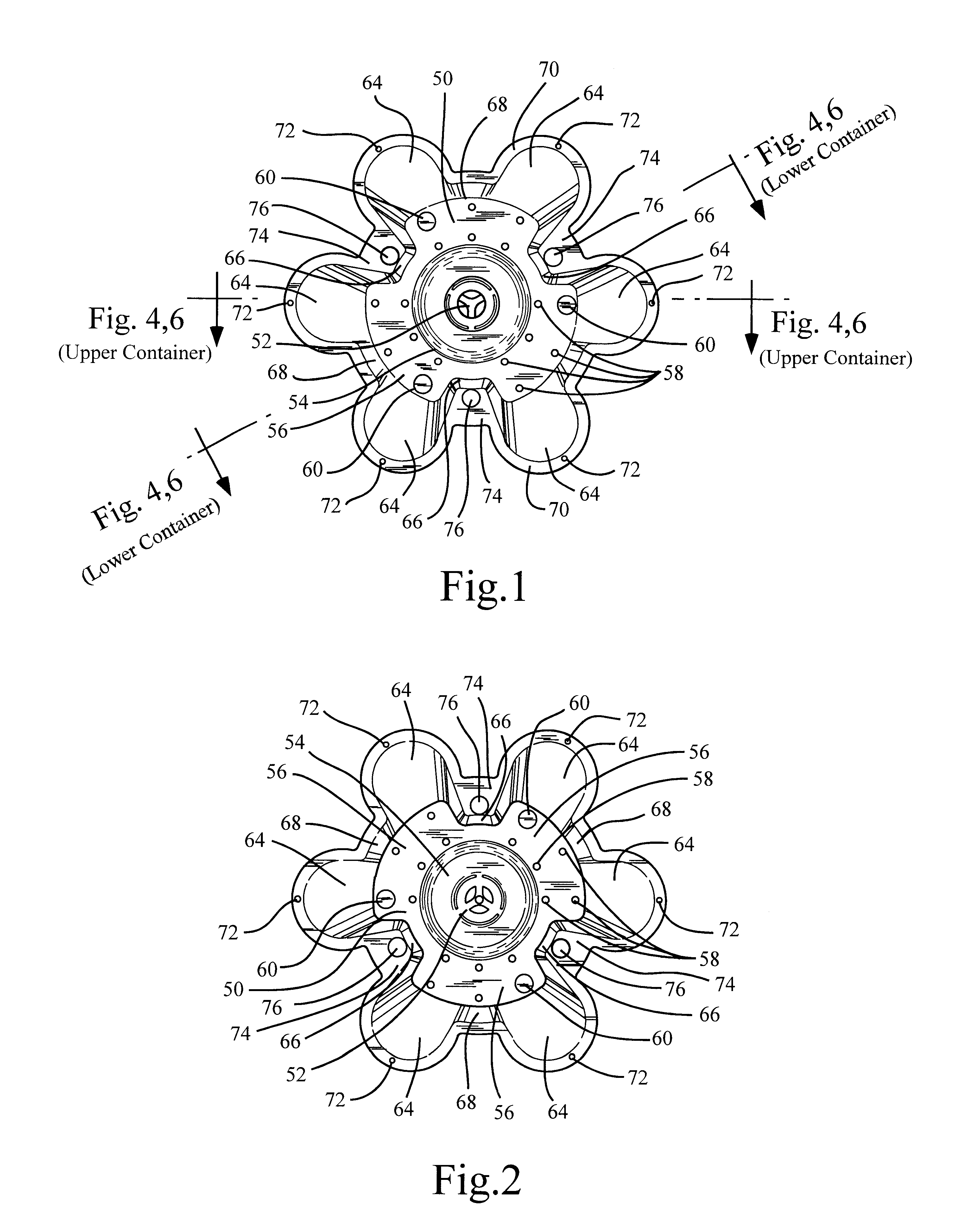

Intensive plant growing stacking container system

InactiveUS6612073B1Quickly and easily repeatedSmall sizeWatering devicesCultivating equipmentsEngineeringVertical array

A molded plant growing container system is easily stacked in a vertical array providing a self-supporting apparatus for intense horticulture. This apparatus increases crop yields over conventional growing methods. The containers nest within each other for ease of transport, are quickly and easily assembled, provide efficiency in installation and use of growing medium, increased numbers of plants in a given space, and are adaptable to a variety of irrigation methods.

Owner:MARKS & NOVA BALL MARKS TRUSTEES OR SUCCESSORTRUSTEE OF THE MARKS FAMILY TRUST UAD 5 13 05 ROBIN

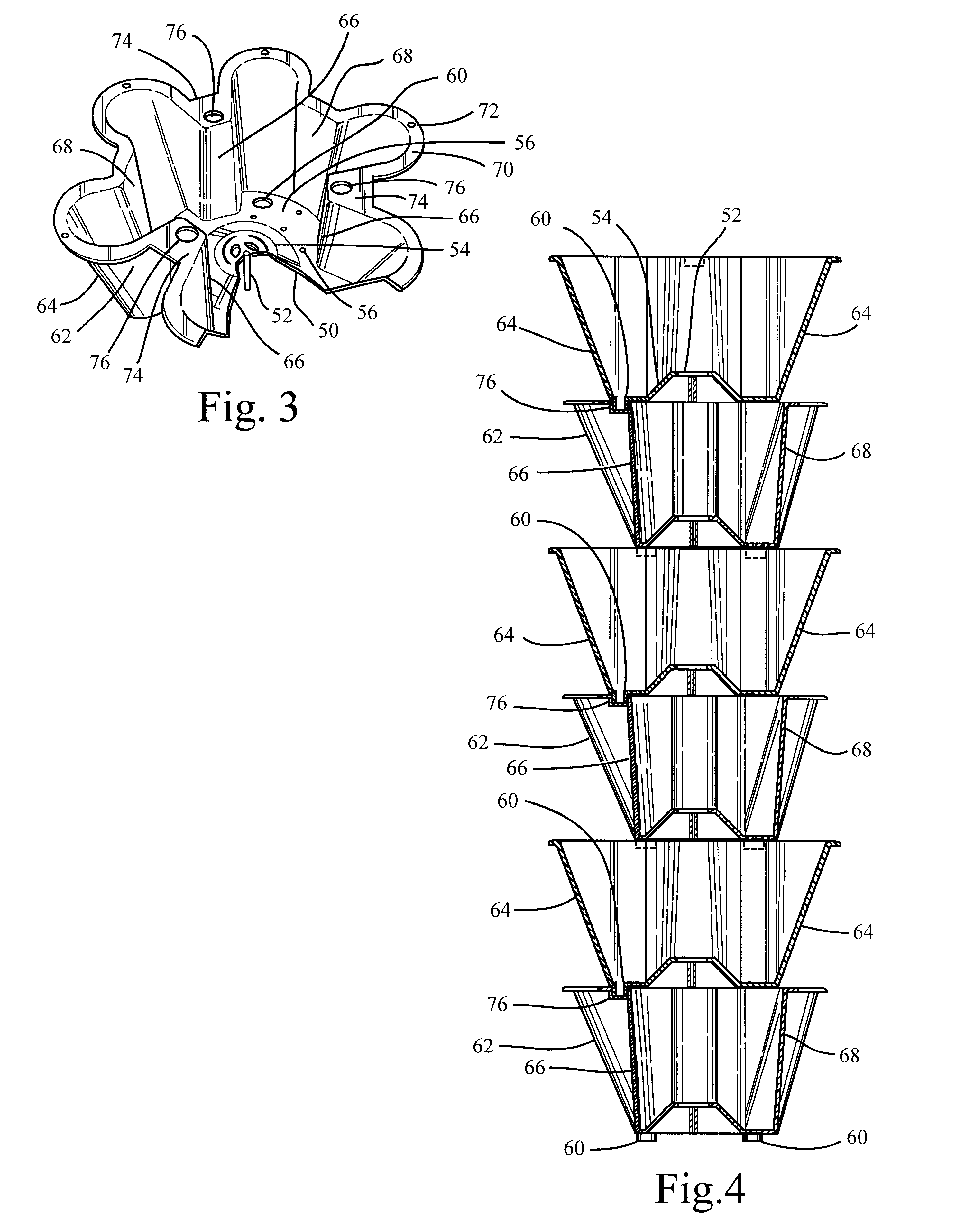

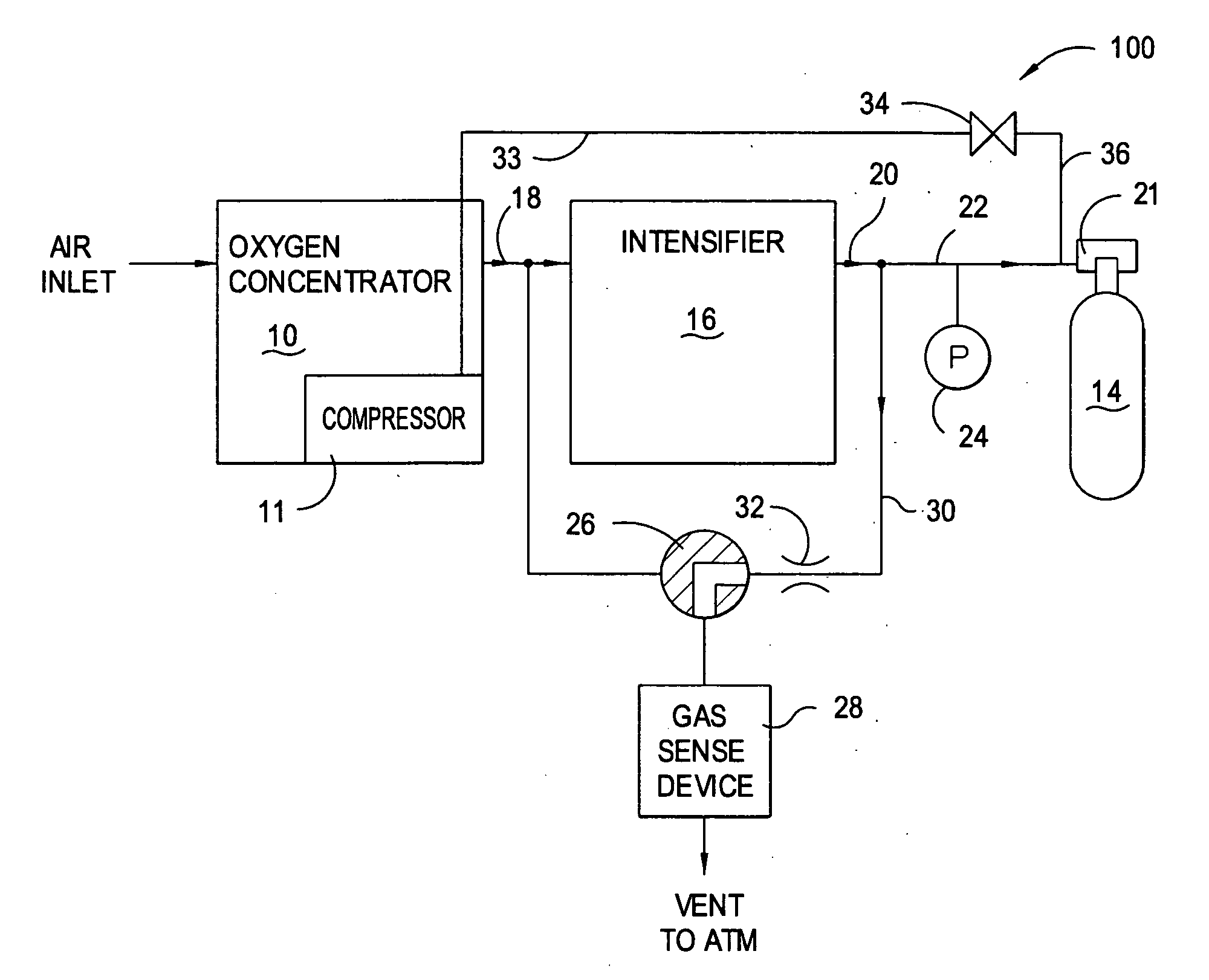

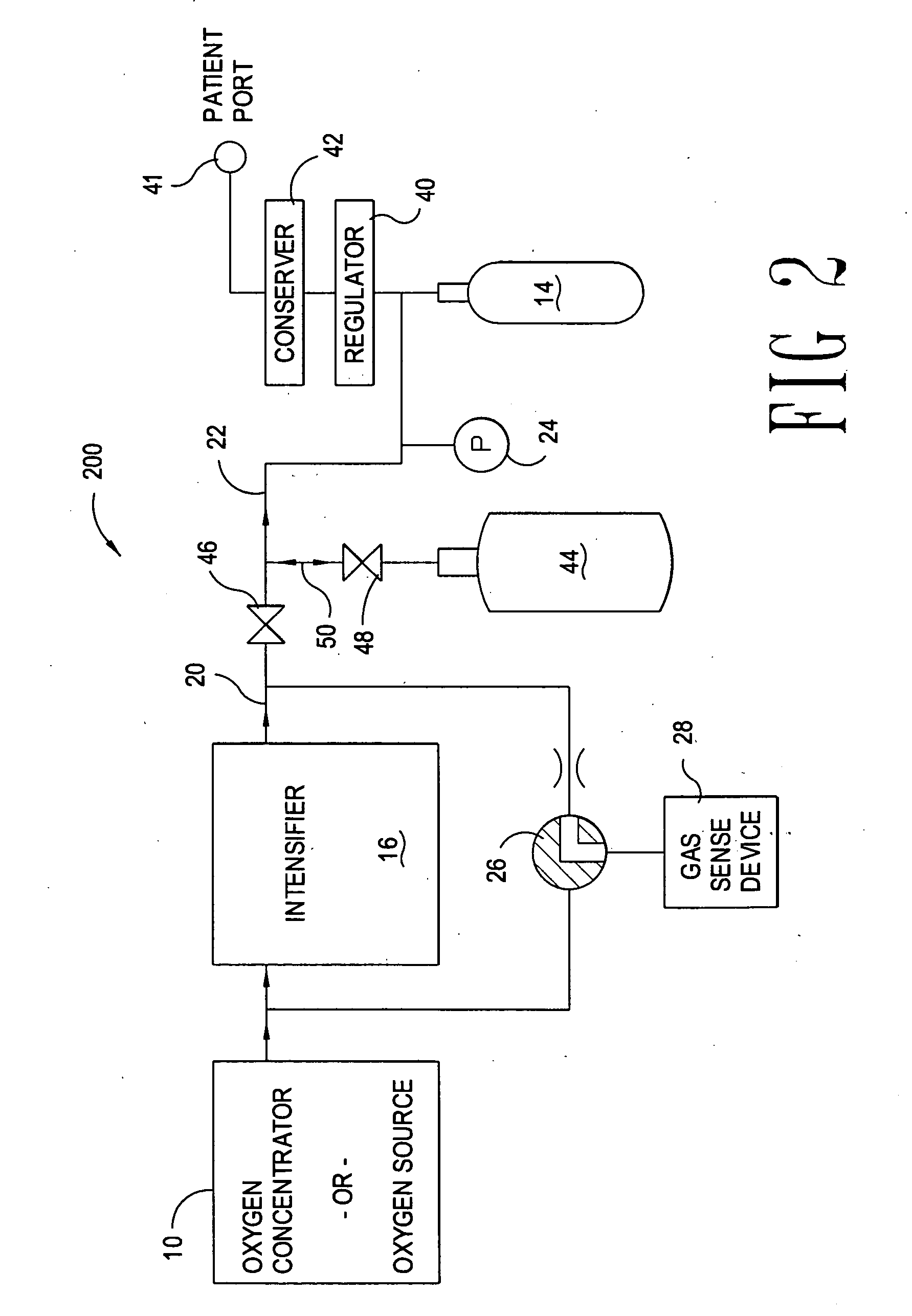

Method and system for delivery of therapeutic gas to a patient and for filling a cylinder

InactiveUS20040079359A1Overcome deficienciesReadily apparentRespiratorsVessel mounting detailsGas cylinderEngineering

A system for filling a portable cylinder with therapeutic gas, and providing therapeutic gas to a patient. Therapeutic gas delivery to a patient may be through a conserver, or may be in a continuous mode. Some embodiments of the invention may test the contents of the portable cylinder prior to filling. The specification also discloses a silent mode of operation where therapeutic gas is provided from the system by means of internal and / or external cylinders.

Owner:RESPIRONICS +1

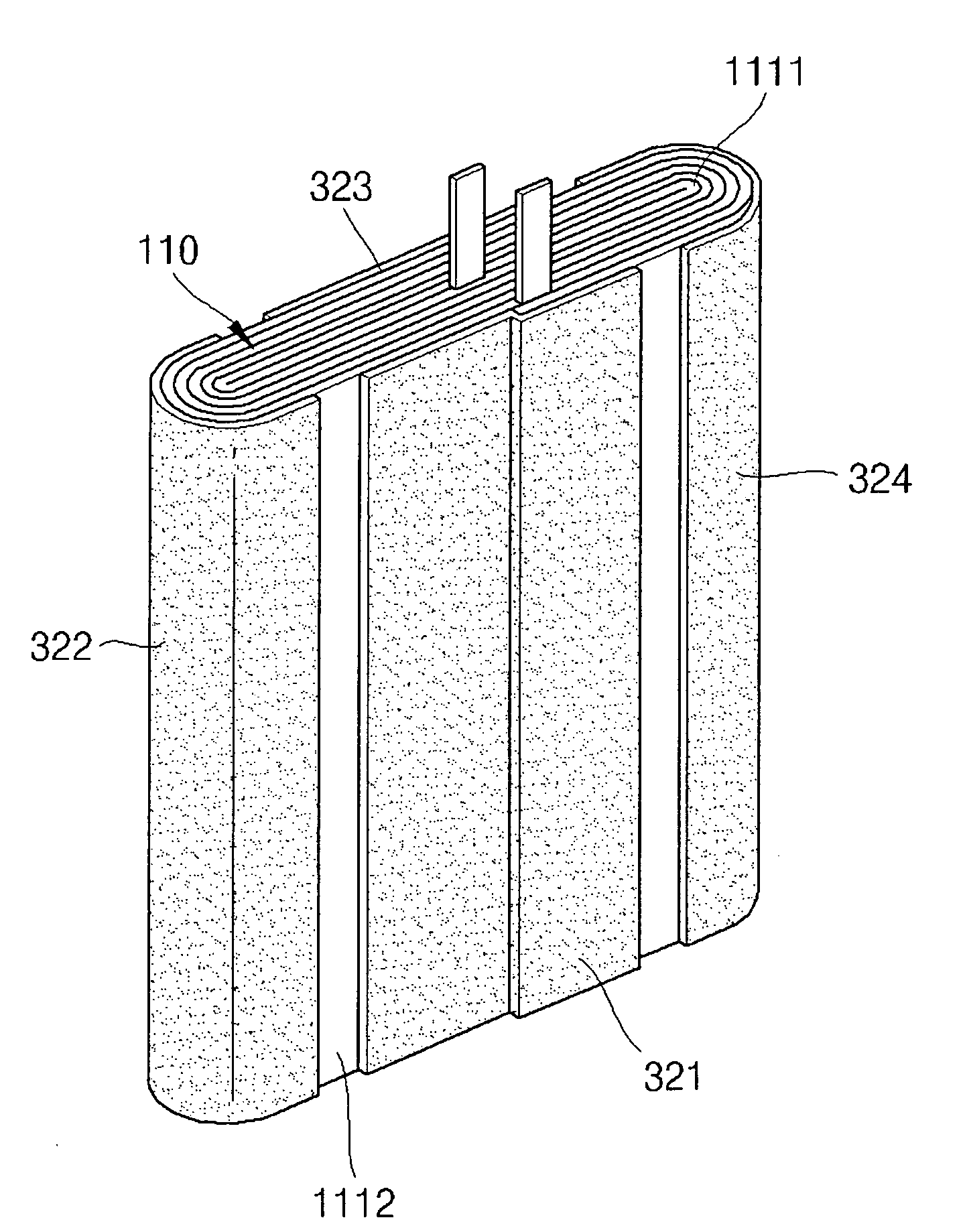

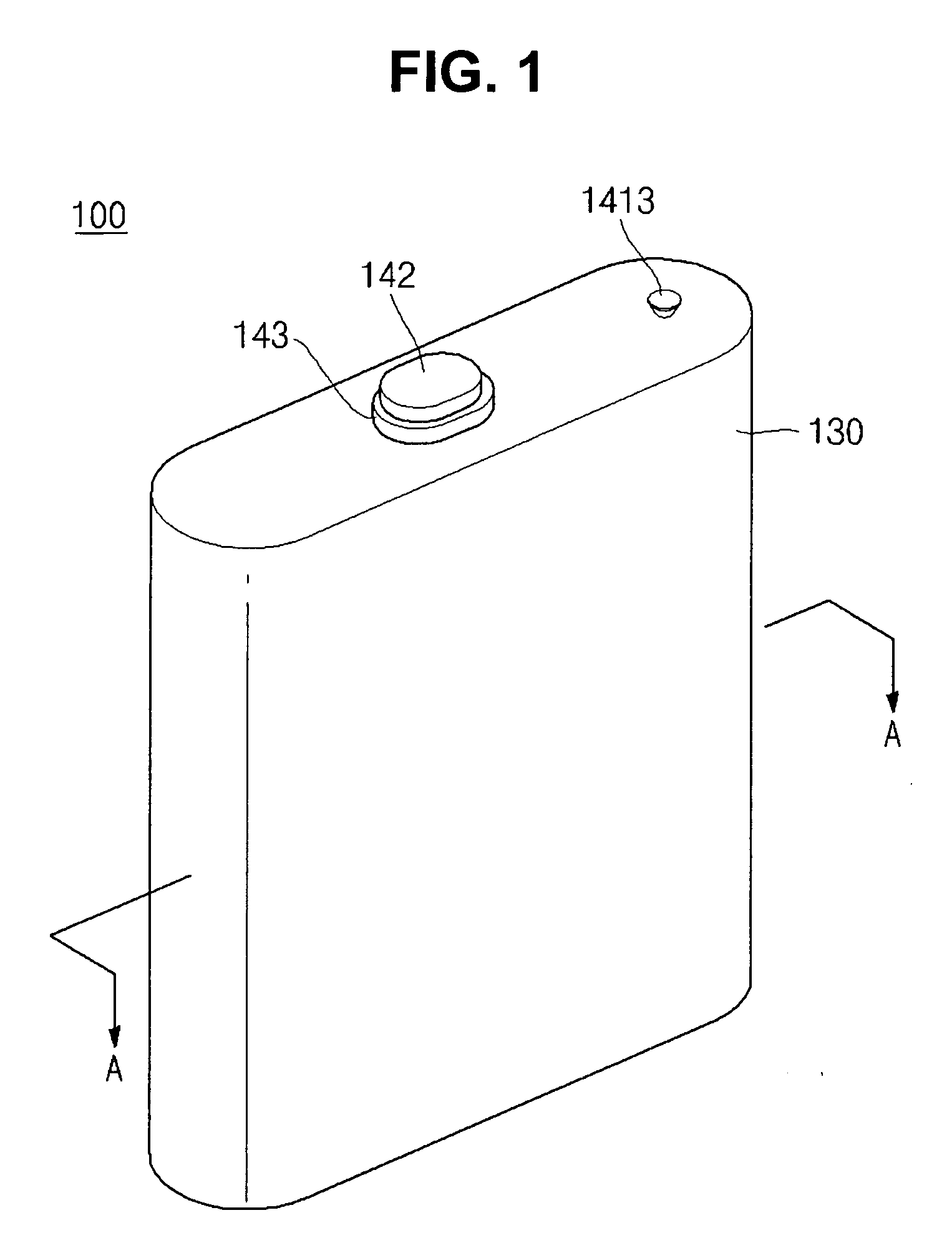

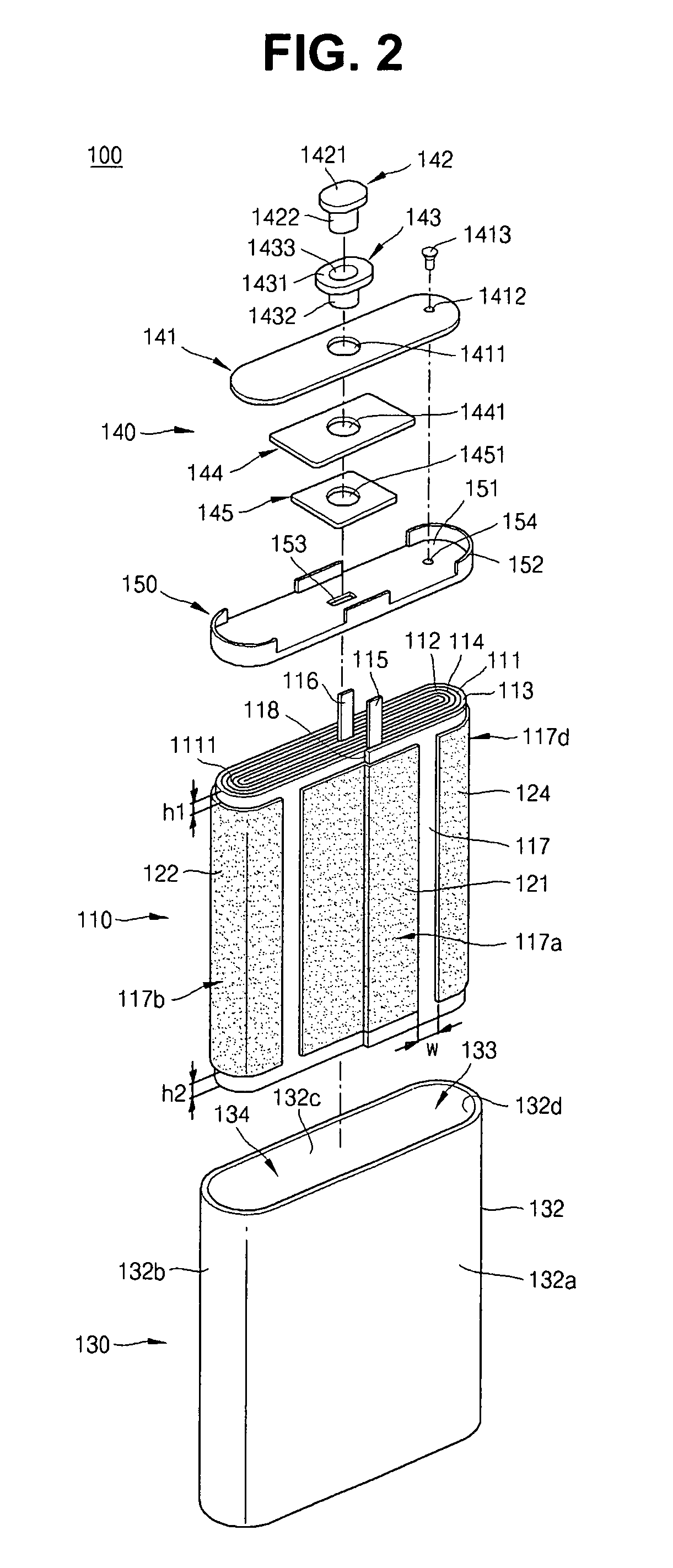

Secondary battery

InactiveUS20100035132A1Shape can not be easilyIncrease heat radiationFinal product manufactureCell electrodesBiomedical engineeringElectrode

A secondary battery includes an electrode assembly in which a first electrode plate, a separator, and a second electrode assembly are sequentially stacked forming a stack and is wound about one edge of the stack, and a plurality of finishing tapes attached to the outer surface of the electrode assembly and spaced apart from each other along the winding direction of the electrode assembly.

Owner:SAMSUNG SDI CO LTD

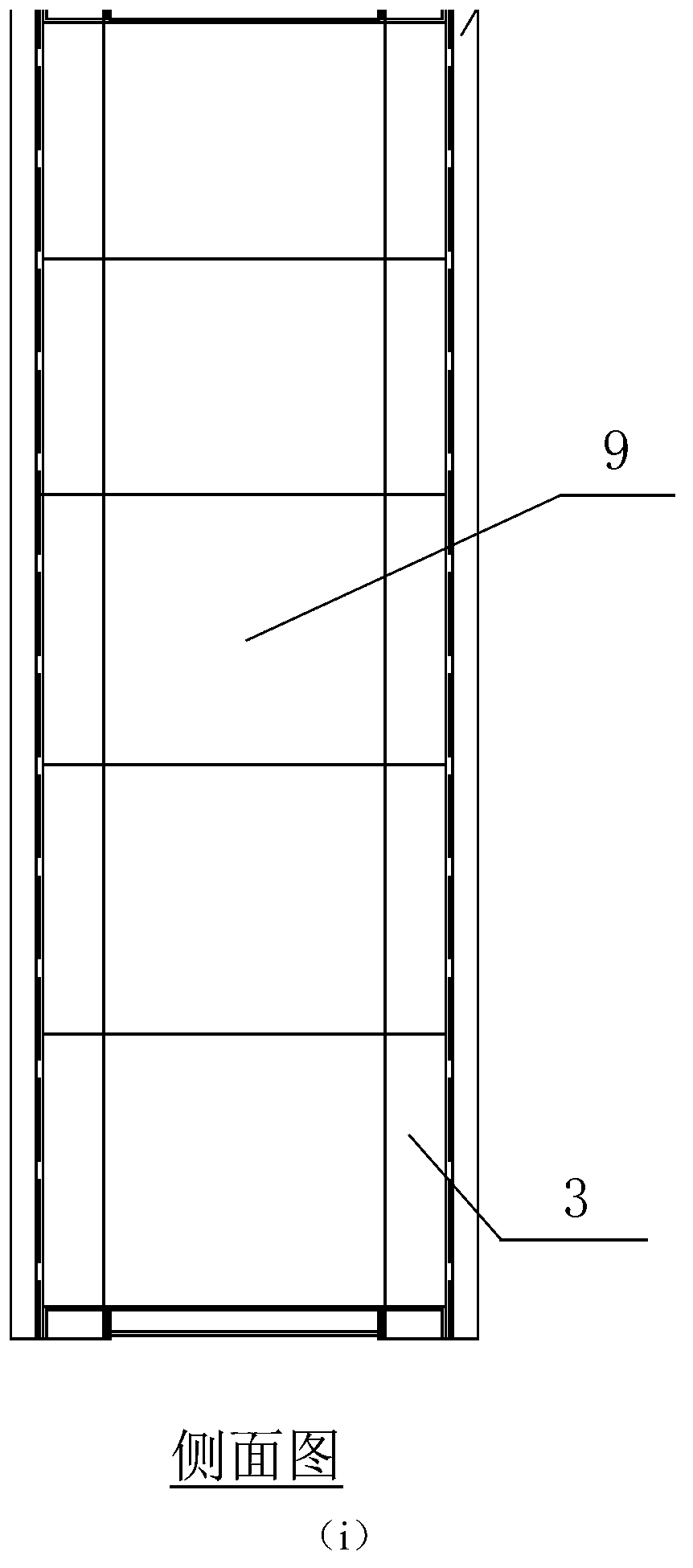

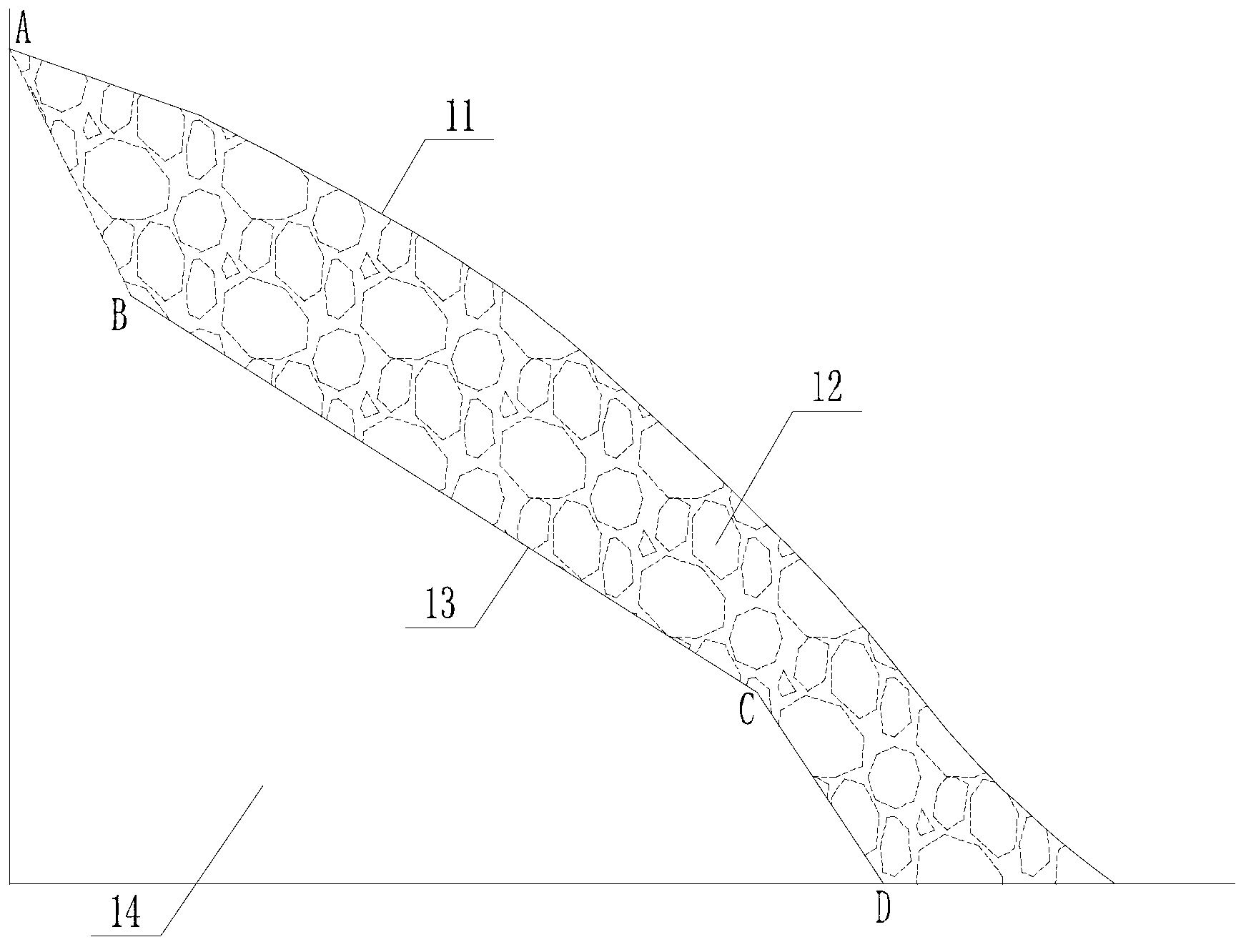

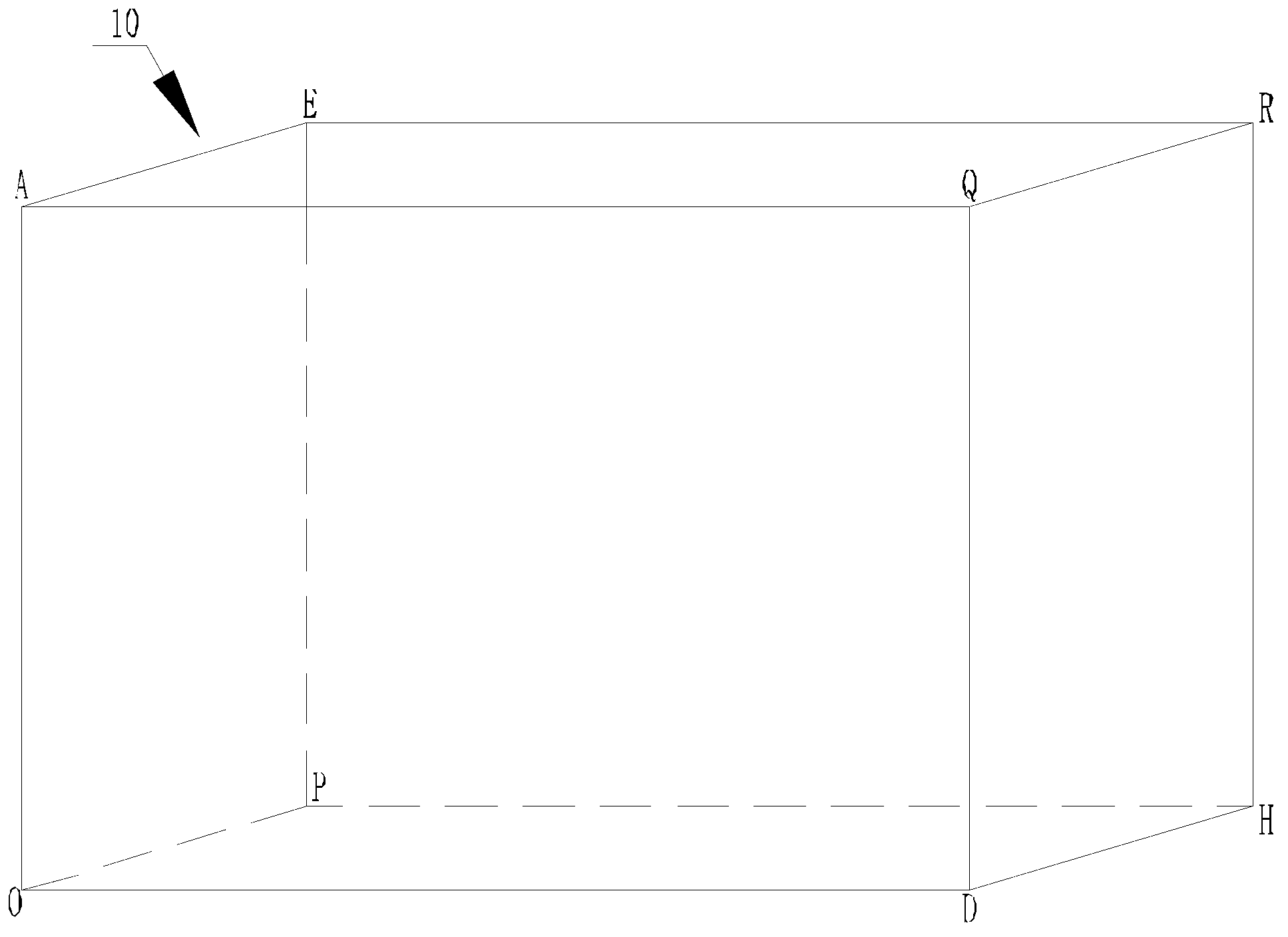

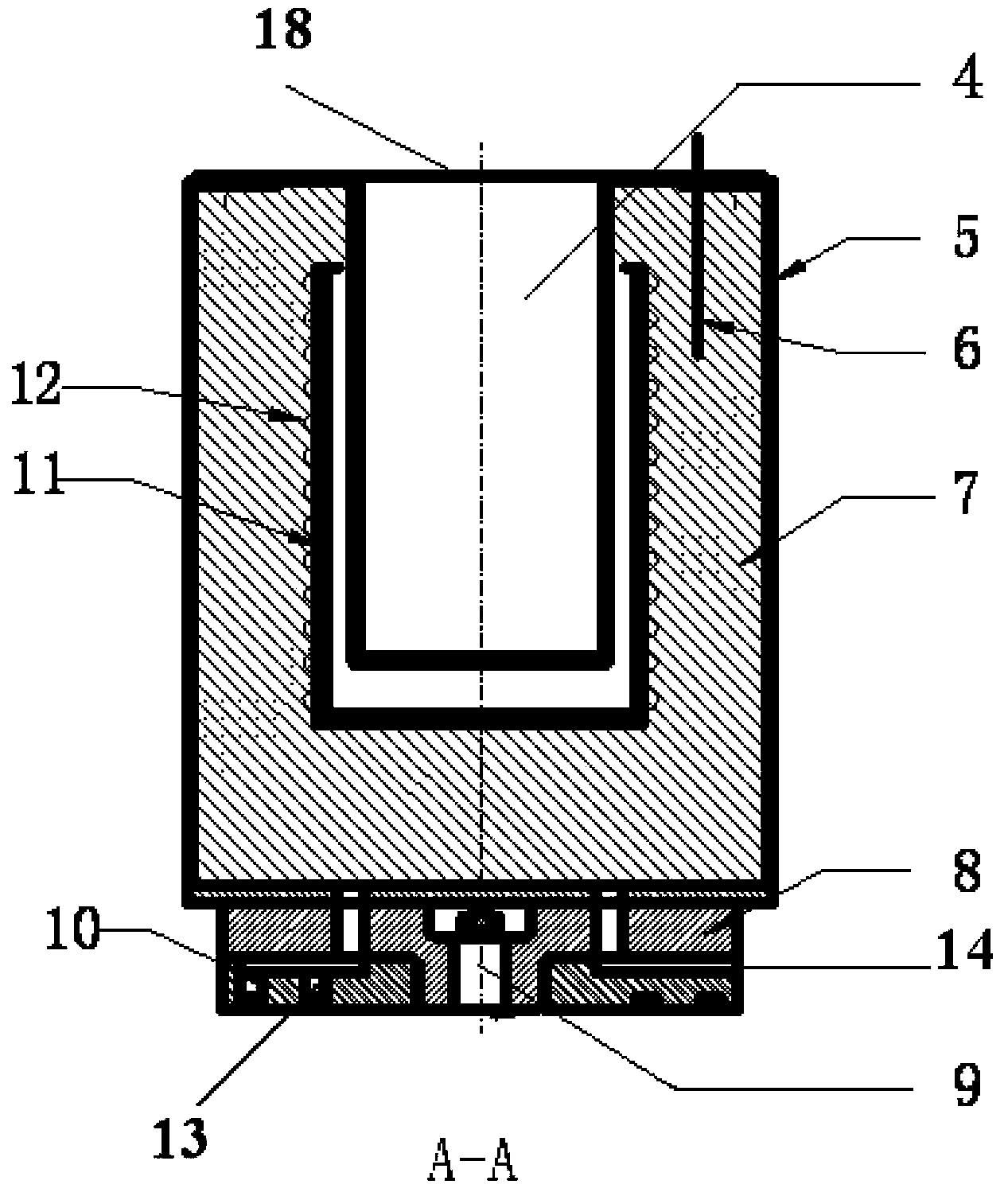

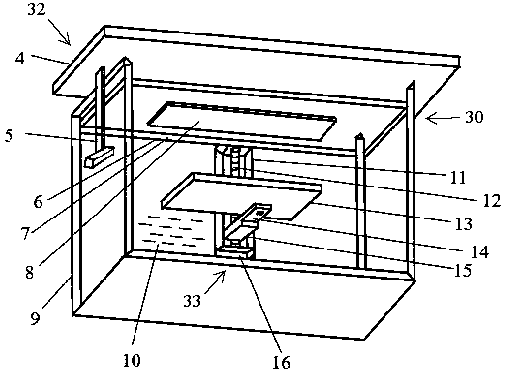

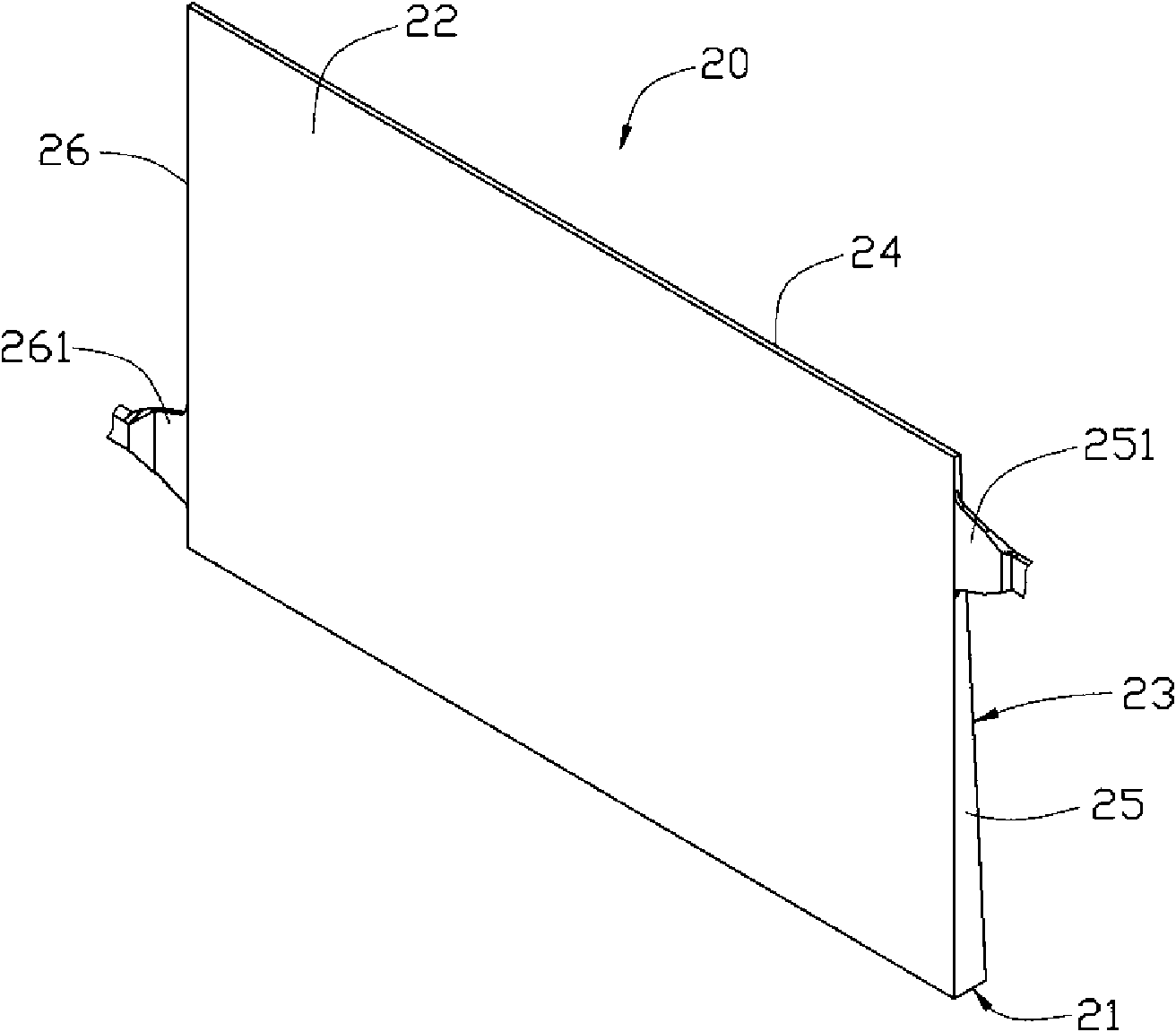

Geotechnical engineering landslide model test box

InactiveCN103308663AReduce loadingSave manpower and moneyEarth material testingInterior spaceModel material

The invention relates to a geotechnical engineering landslide model test box which overcomes the defects that the landslide model test wastes time and energy in the prior art. The geotechnical engineering landslide model test box comprises a box body, wherein the box body is basically a cuboid; an inclined plane is arranged on the inner sides of the two opposite side faces with the maximum areas of the cuboid; the inclined plane is perpendicular to the two side faces, and divides an inner space of the cuboid into an upper part and a lower part; and the shape of the inclined plane is similar to that of a slide face simulated by a geotechnical engineering landslide model test. According to the geotechnical engineering landslide model test box, the inclined plane is arranged in the test box, and divides the inner space of the box body into the upper part and the lower part, namely a part above the inclined plane and a part below the inclined plane; the shape of the inclined plane is similar to that of the slide face simulated by the geotechnical engineering landslide model test; when the geotechnical engineering landslide model test is performed, the part below the inclined plane does not need to be filled with a model material; and therefore, the filling quantity of the model material is reduced greatly, and manpower and financial resources are saved.

Owner:SOUTHWEST JIAOTONG UNIV

Fine particle tissue hydraulic fill for injection and preparation method thereof

ActiveCN101366978AImprove biocompatibilityFast fillingProsthesisGranulation tissueBiocompatibility Testing

The invention discloses an injectable filling material of particle tissues, wherein particulate acellular bio-derived materials are mixed with drug-containing release microspheres, after the filling material is evenly mixed with a gel solution before use, the filling material is injected into a recipient site, an operator can arbitrarily model the particle tissue before gel is solidified according to the condition of the recipient site so as to achieve a satisfactory cosmetic effect. The particle tissue material which can be moulded rapidly is implanted in the body to fill defective soft tissues and promote wound healing. Compared with the prior art, the injectable filling material of the particle tissues has high biocompatibility, and is capable of rapid arbitrarily modeling and rapid filling the defect of tissue organs, and can promote fibroblast ingrowth, the formation of new capillary, generation of granulation tissue and wound healing. The injectable filling material of the particle tissues has the following clinical functions that the injectable filling material can be used as a filler of defective soft tissues which is used for repairing body depression deformity; for filling wrinkles or ruga of skins; and for demands of cosmetic surgeries, such as soft tissue arthroplasty and so on.

Owner:SHAANXI RUISHENG BIOTECH

Method for filling cavity in Kinect depth image in real time

ActiveCN104299220AIntegrity guaranteedImprove integrityImage enhancementImage analysisColor imageBackground image

Disclosed in the invention is a method for filling a cavity in a Kinect depth image in real time. The method comprises the following steps: step 1, obtaining a color image of a shooting scene and a corresponding depth image by using a Kinect camera and determining a foreground image position and a background image position by using an operating-period Gauss average method and a background differencing method; step 2, constructing a deepest image by using a Kinect depth image and filling a cavity in the deepest image; step 3, replacing the pixel of the deepest image with a background pixel of the depth image, thereby realizing cavity filling of the depth image background; and step 4, with the foreground image position obtained by the step 1, marking the cavity existed in the foreground position of the Kinect depth image and filling the marked cavity in real time. According to the invention, the object edge in the depth video with the filled cavity becomes stable; and the no flicker phenomenon occurs in the depth video. Meanwhile, the cavity filling speed in the depth image and the image stability can be improved effectively.

Owner:SHANGHAI UNIV +1

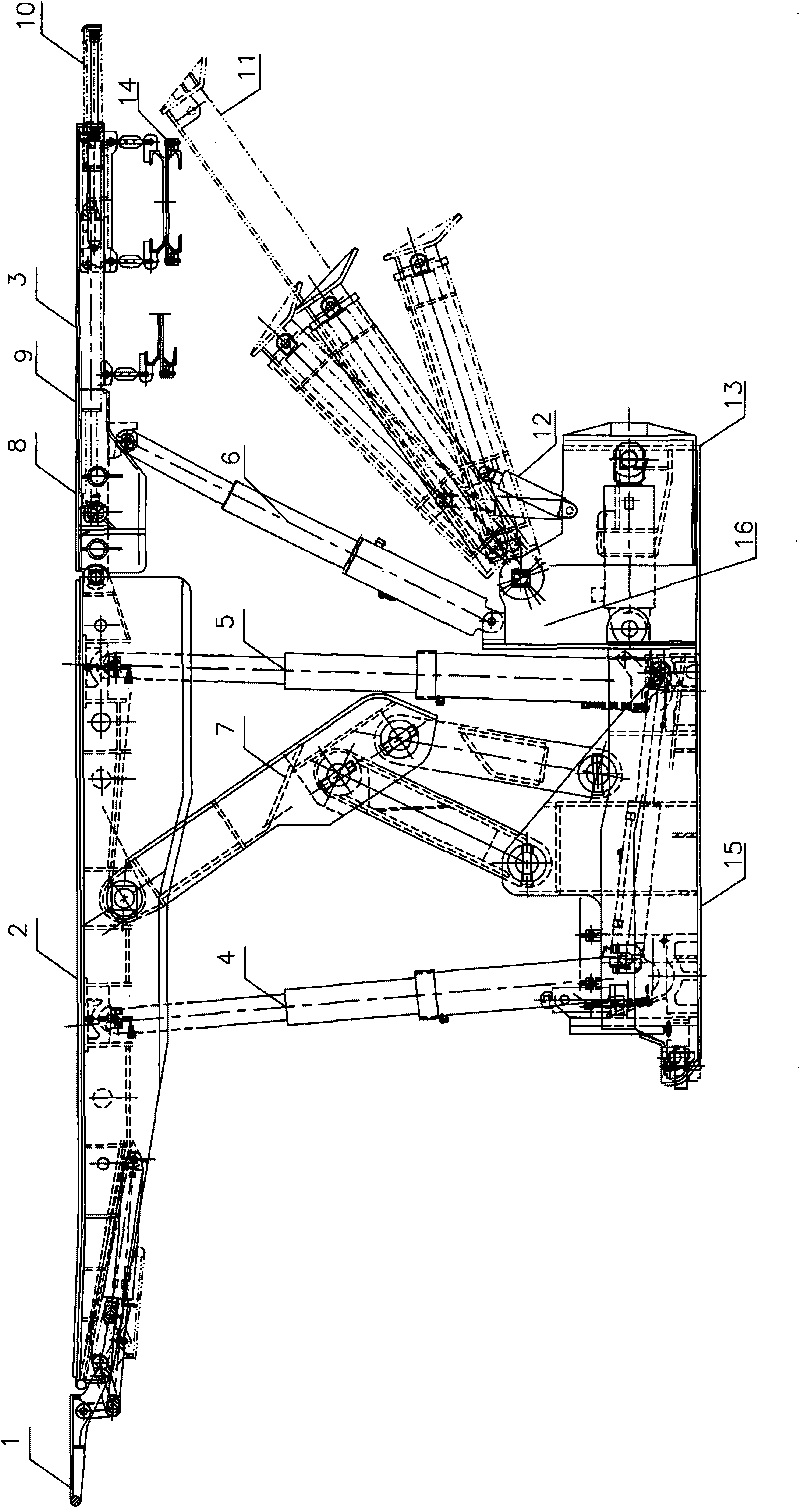

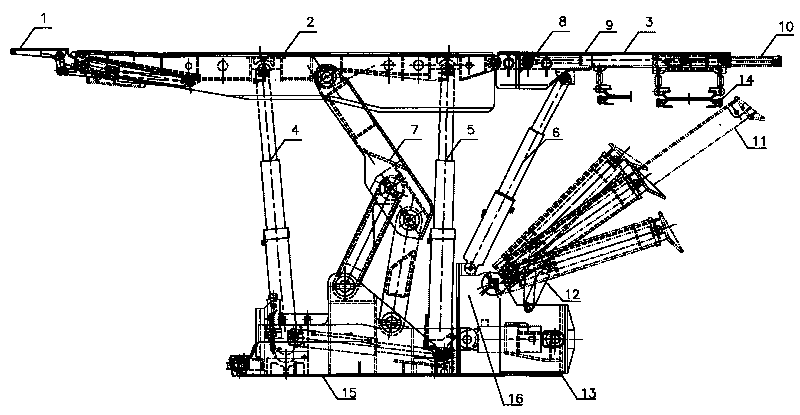

Hexastyle supporting type coal mining and filling hydraulic bracket

InactiveCN101725365ARealize fillingAchieve compactionMaterial fill-upMine roof supportsEngineeringWork space

The invention relates to a hexastyle supporting type coal mining and filling hydraulic bracket which comprises a telescopic girder, a front top girder, a rear top girder, a front upright post, a middle upright post, a rear upright post, a four bar mechanism, a middle upper part compaction mechanism, a height-regulating jack, a lower box type compaction mechanism, a slide way, a pulling jack, a rear-inserting type top protection device, a filling and mining conveyer and a base, wherein the front top girder is supported through the front upright post and the middle upright post and maintains the balance through the four bar mechanism; the rear top girder is mutually hinged with the front top girder and supported through the rear upright post, bears the pressure of a top plate, controls the deflection of the top plate before filling and can overhang the filling and mining conveyer to realize filling solid fillers in a goaf; and the rear top girder is provided with the slide way and can maintain a working space for normal mining of a working surface, realize the full filling of the goaf and meanwhile compact the fillers by clean mining within a high range. The hexastyle supporting type coal mining and filling hydraulic bracket has compact structure, strong supporting force, convenient operation and good filling effect on the goaf and can adapt to the filling and the mining under a complicated geological condition.

Owner:CHINA UNIV OF MINING & TECH

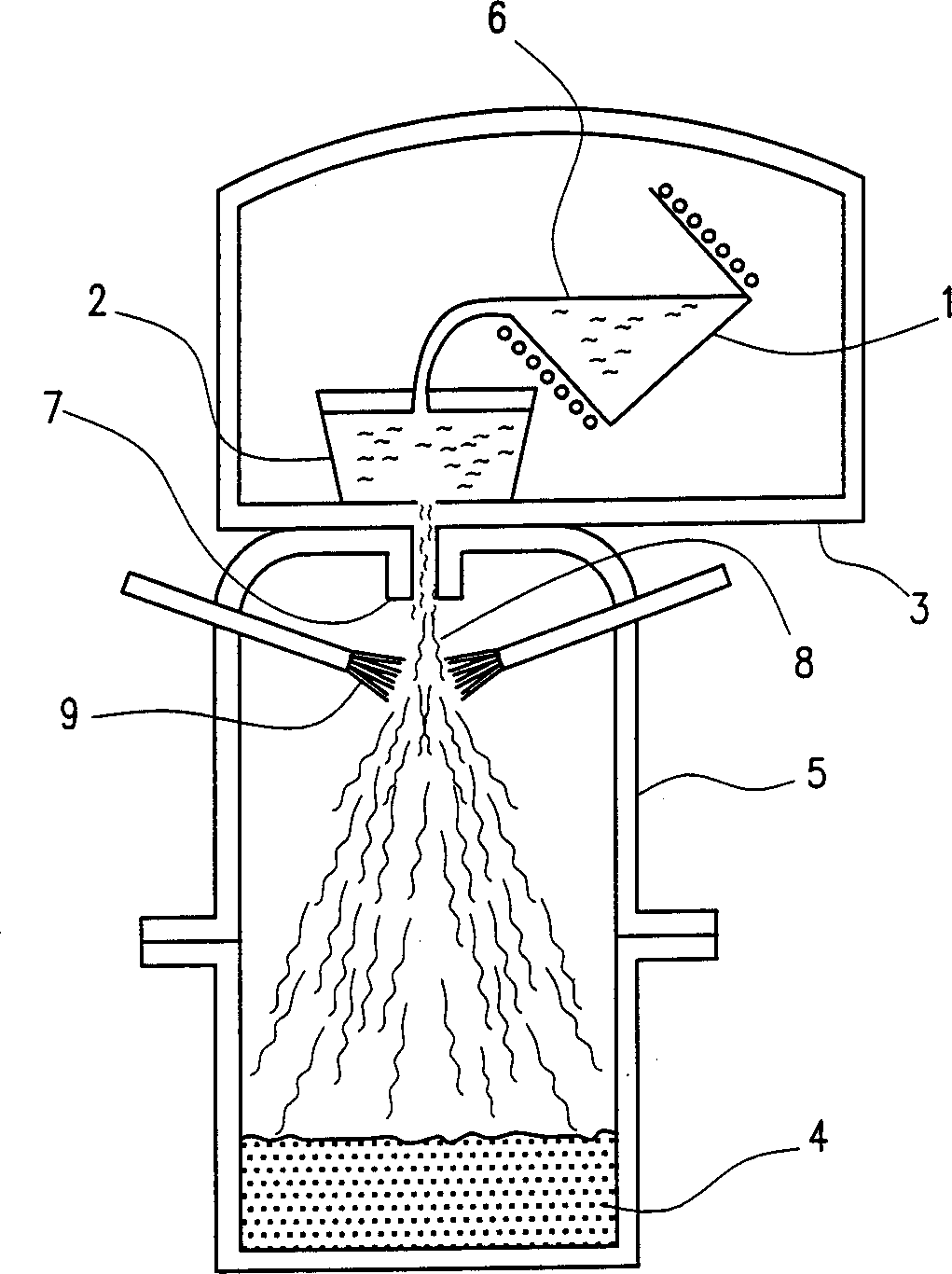

Vacuum-induction centrifugal casting device and titanium alloy casting method

The invention discloses a vacuum-induction centrifugal casting device comprising a furnace body, wherein the upper end of the furnace body is provided with a furnace cover, a smelting cavity and a centrifugal casting cavity are symmetrically arranged in the furnace body, a smelting device is arranged in the smelting cavity, a centrifugal heating and casting device is arranged in the centrifugal casting cavity, and an overturning space for the smelting device is respectively arranged between the upper parts of the smelting cavity and the centrifugal casting cavity and the furnace cover. The invention further discloses a titanium alloy casting method by utilizing the vacuum-induction centrifugal casting device, wherein the titanium alloy casting method comprises the following steps that after titanium alloy is molten into liquid metal in a crucible, the crucible is overturned so that the liquid metal flows into a rotating casting liner, and a heating and heat-insulating device is further mounted outside the casting liner, finally a thin-wall titanium alloy casting is obtained. The vacuum-induction centrifugal casting device disclosed by the invention can cast flawless-surface thin-wall metal components.

Owner:XI'AN POLYTECHNIC UNIVERSITY

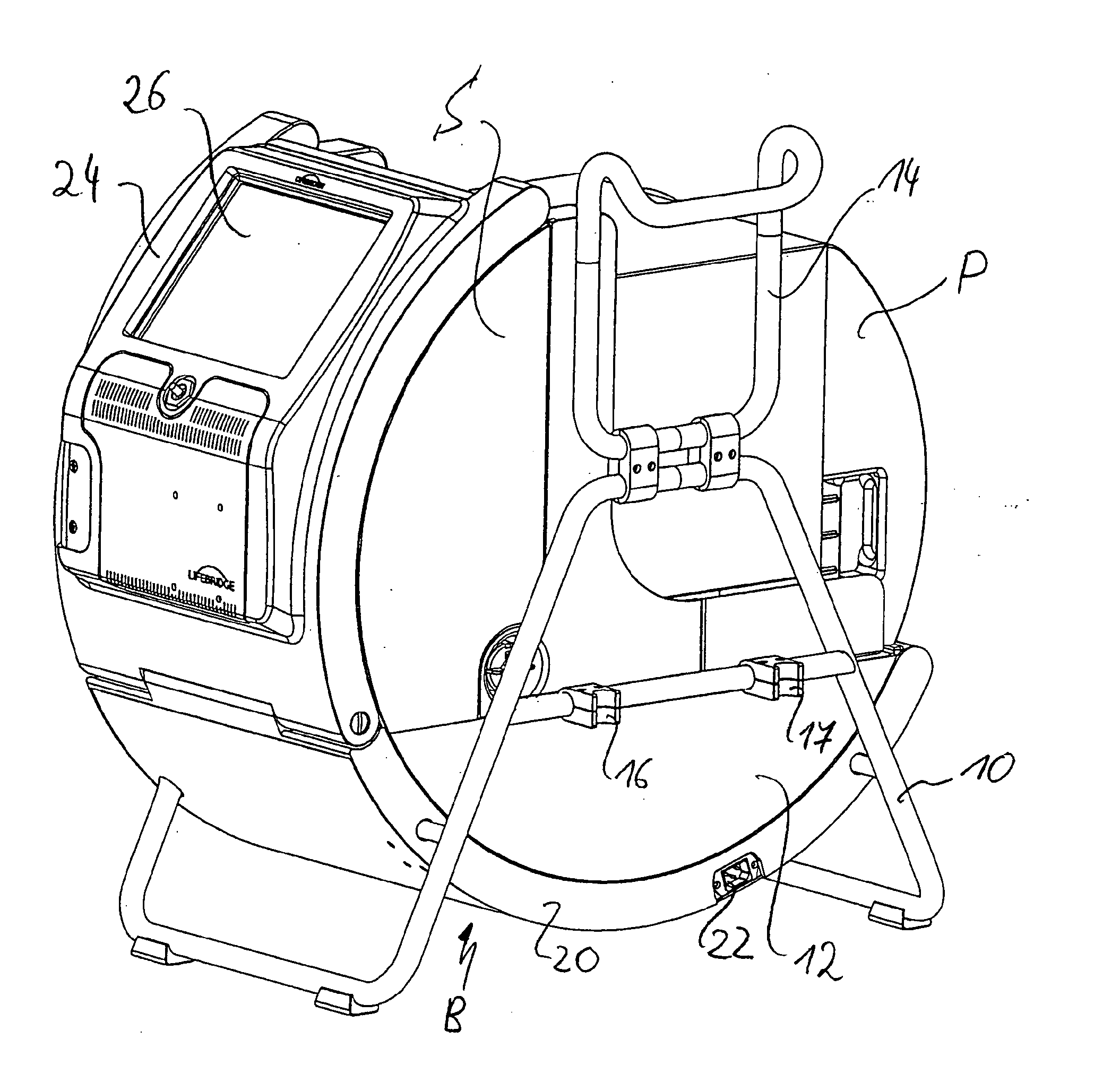

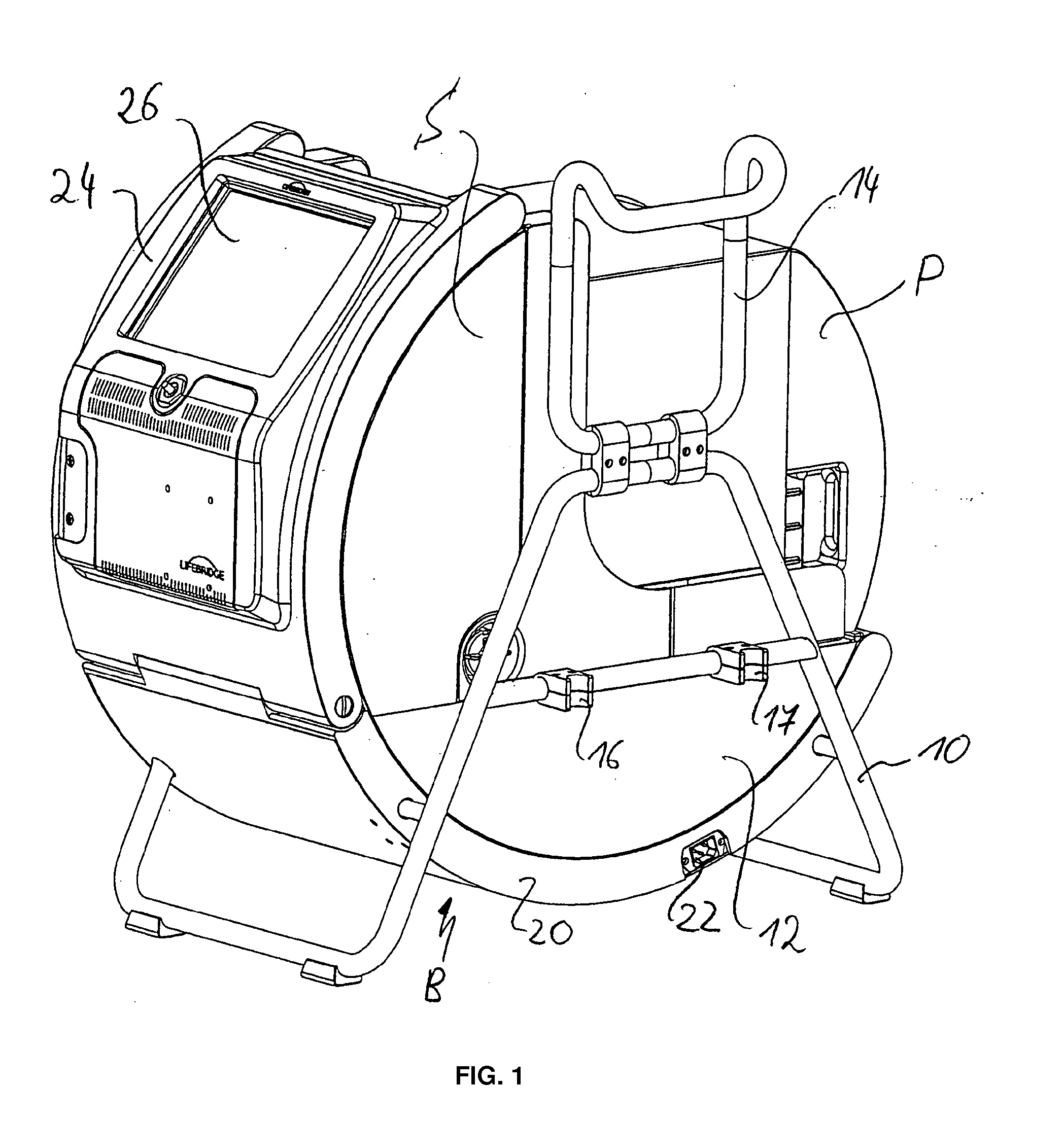

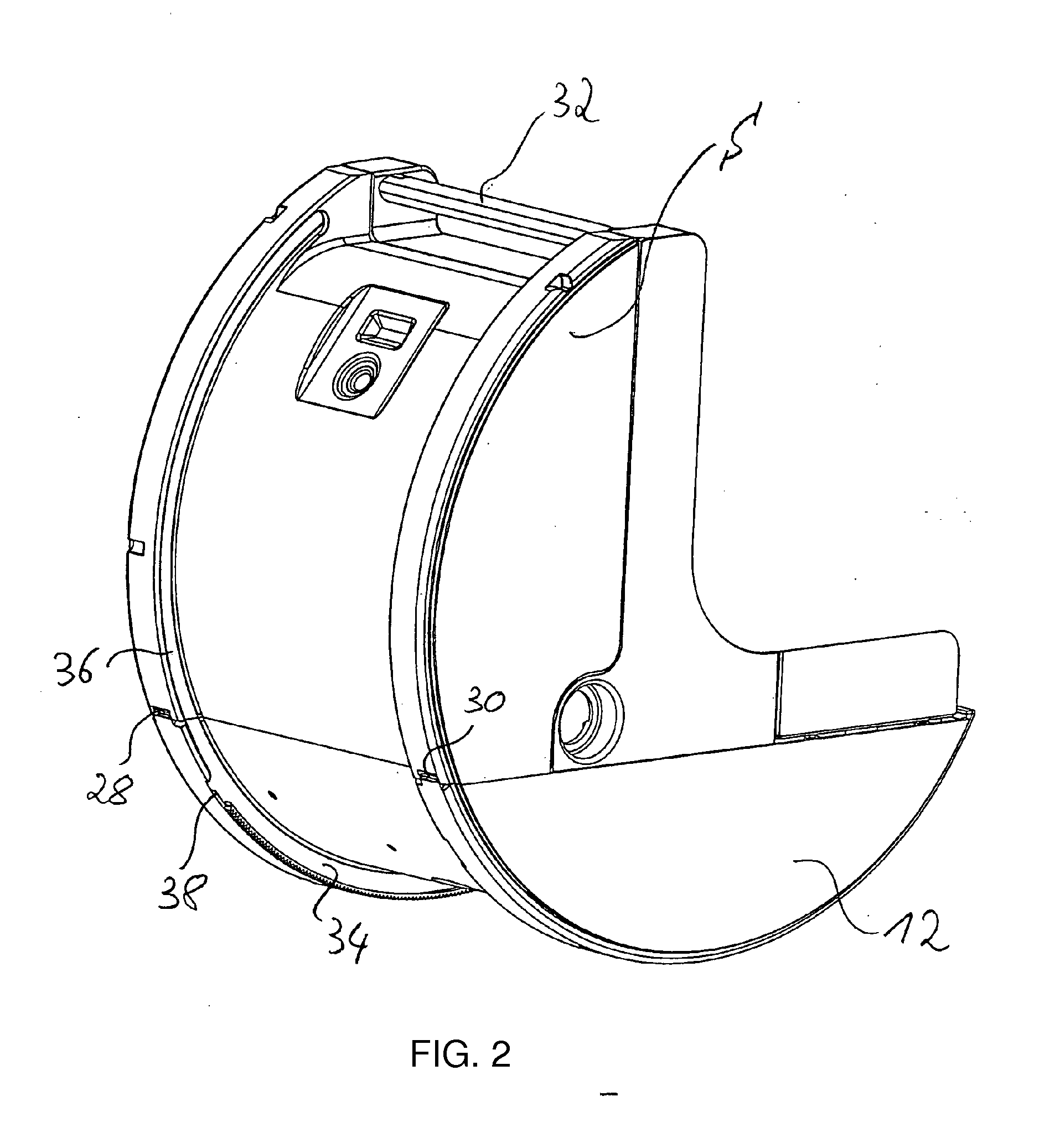

Cardiopulmonary Apparatus And Methods For Preserving Life

InactiveUS20110208107A1Rapid and safe transitionMaintaining the life of a patientRespiratorsOperating means/releasing devices for valvesPhases of clinical researchIntensive care medicine

Apparatus and methods for providing extracorporeal blood circulation and oxygenation control include seven-stage de-airing of blood to provide automated cardiopulmonary replacement to sustain patient life during a medical procedure comprising repairing or replacing the heart valve in a patient.

Owner:ZOLL LIFEBRIDGE

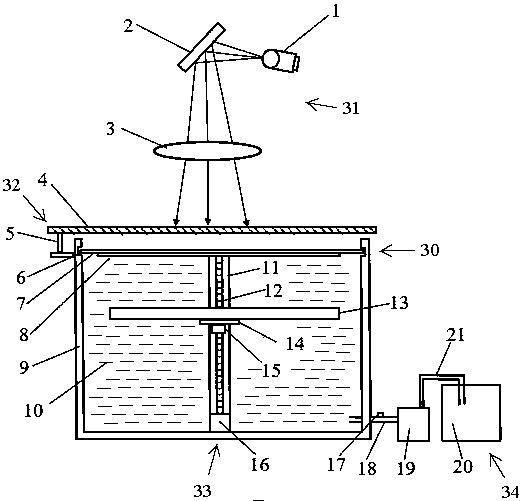

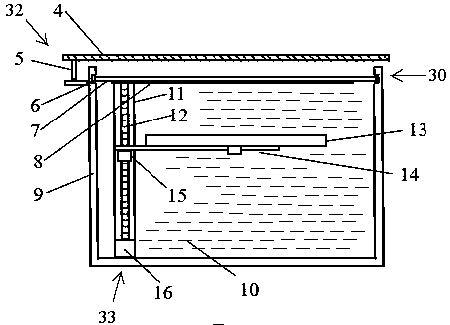

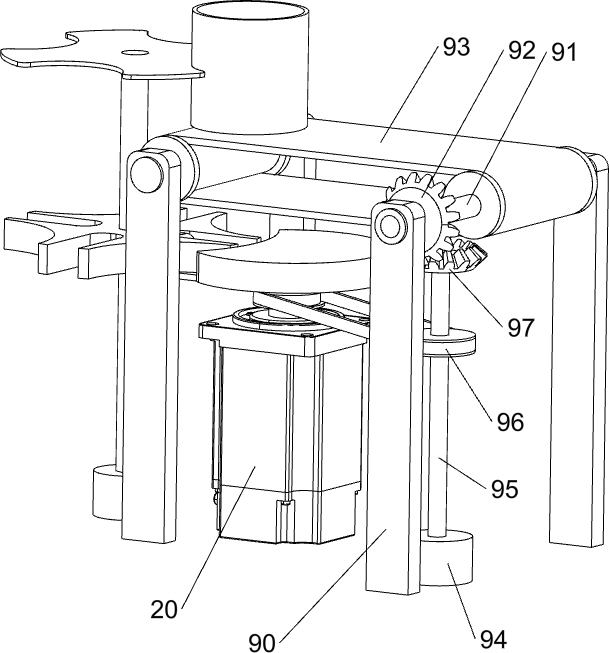

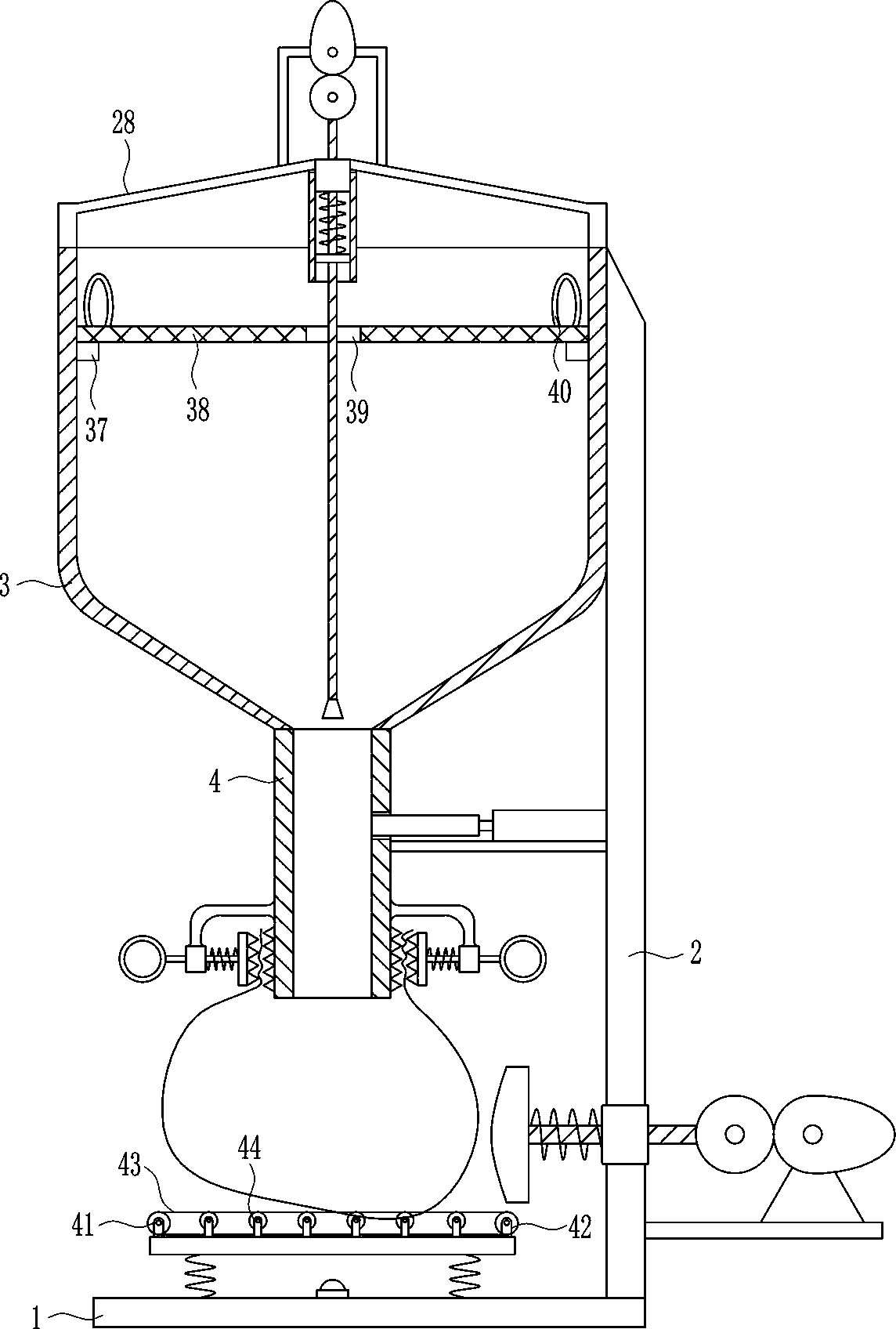

Sealing booster-type slurry pool device for overhead light source 3D printer

ActiveCN107627601AImprove adaptabilityGuaranteed dark storageManufacturing enclosures3D object support structuresSurface layerSlurry

The invention relates to a sealing booster-type slurry pool device for an overhead light source 3D printer. The sealing booster-type slurry pool device comprises a main slurry pool, a light source mechanism, a transparent sealing mechanism, a lifting mechanism, a sample platform and a booster filling mechanism, wherein the main slurry pool is filled with liquid slurry for light solidification, thelight source mechanism is installed above the device, the transparent sealing mechanism is installed on the top of the main slurry pool, the lifting mechanism is installed in the main slurry pool, the sample platform is installed on the lifting mechanism, and the booster filling mechanism is connected with the main slurry pool. According to the sealing booster-type slurry pool device, the heightcontrol over slurry in the slurry pool can be guaranteed, the coating step of the surface layer of the slurry after light solidification is omitted, the printing time is shortened, the defects of level fluctuation and uniformity in coating of a traditional scraper type spreading structure are overcome, the influence of the slurry flowability on a slurry filling process is reduced, the working efficiency is improved, and the printed layer thickness accuracy is increased.

Owner:SHANGHAI INST OF CERAMIC CHEM & TECH CHINESE ACAD OF SCI

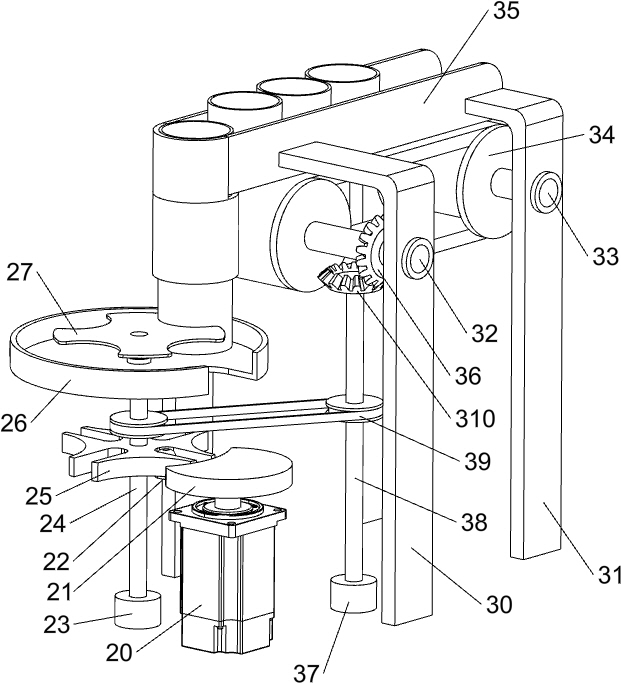

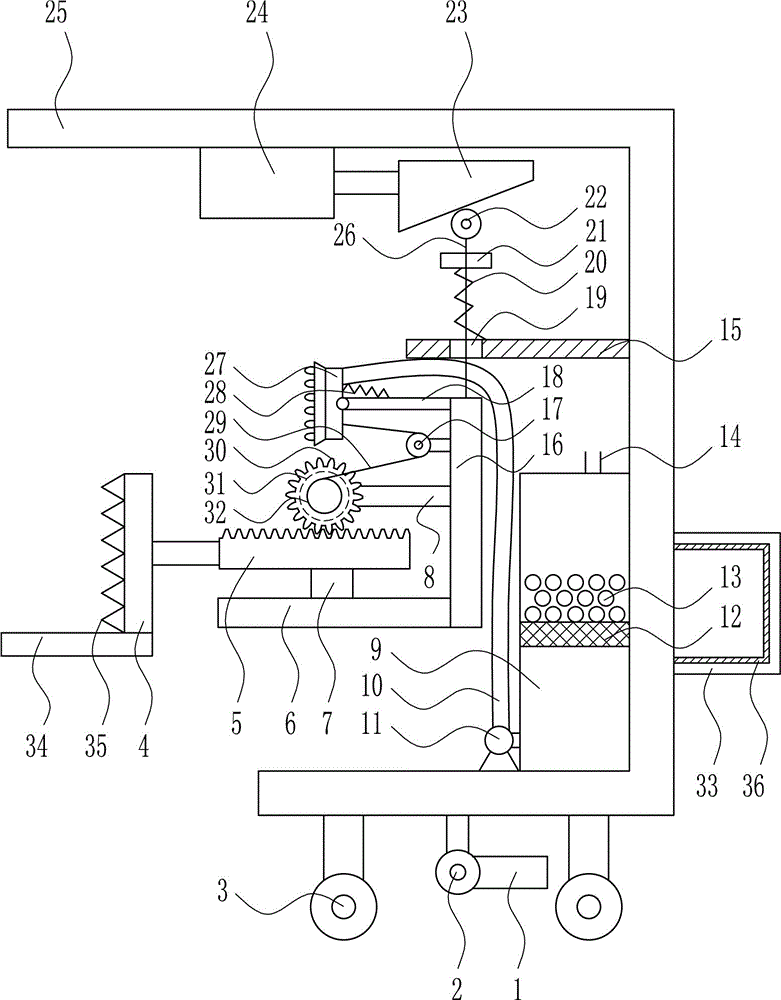

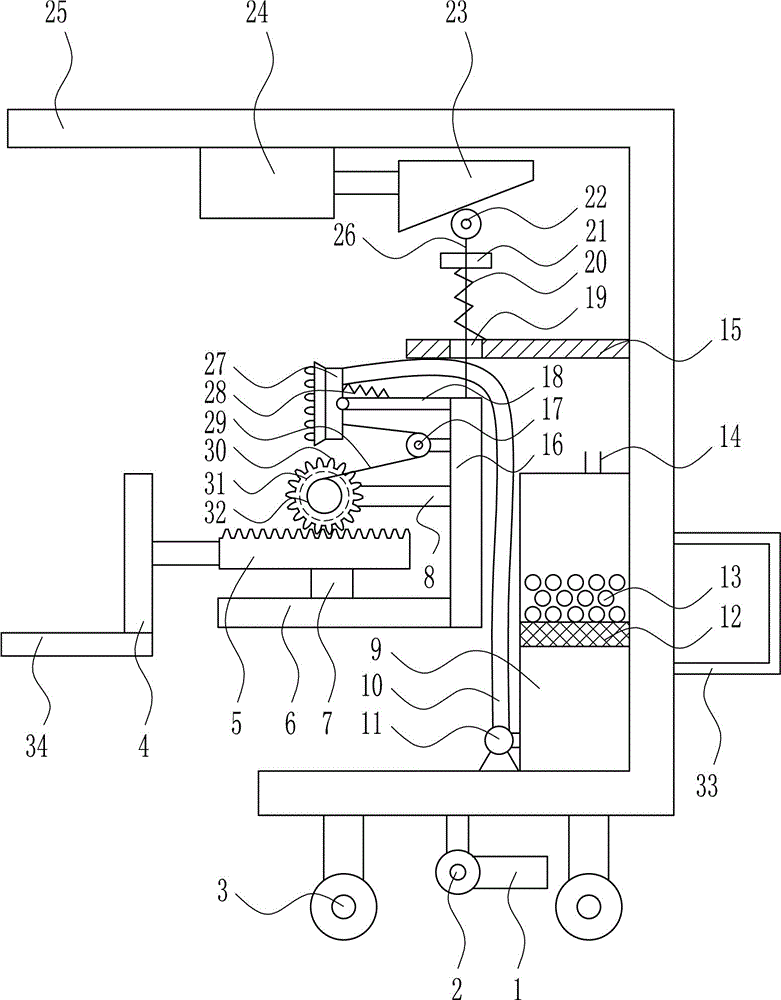

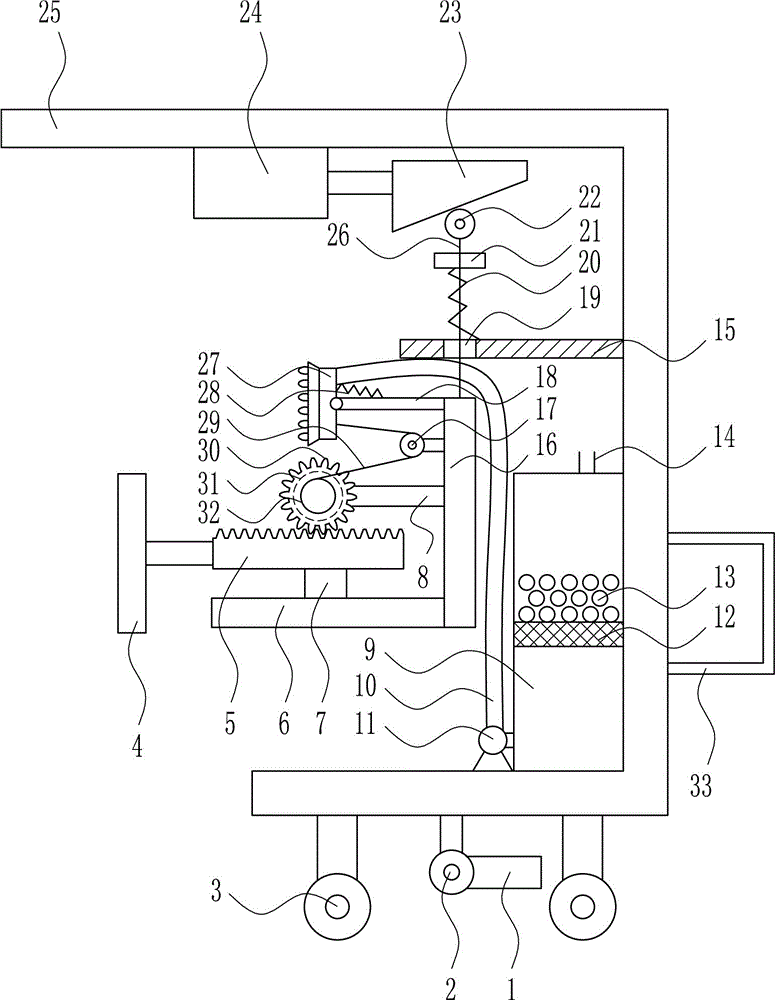

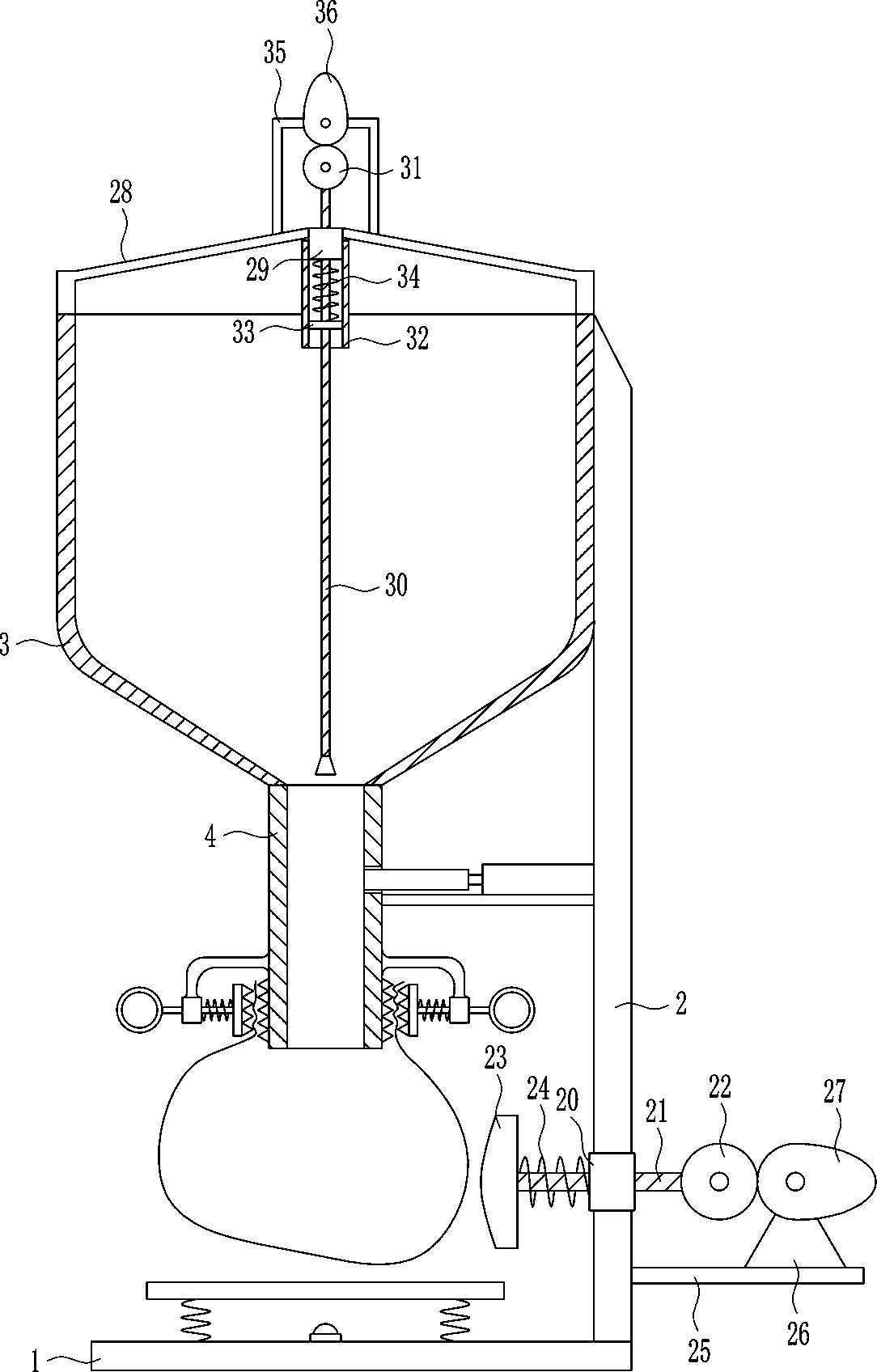

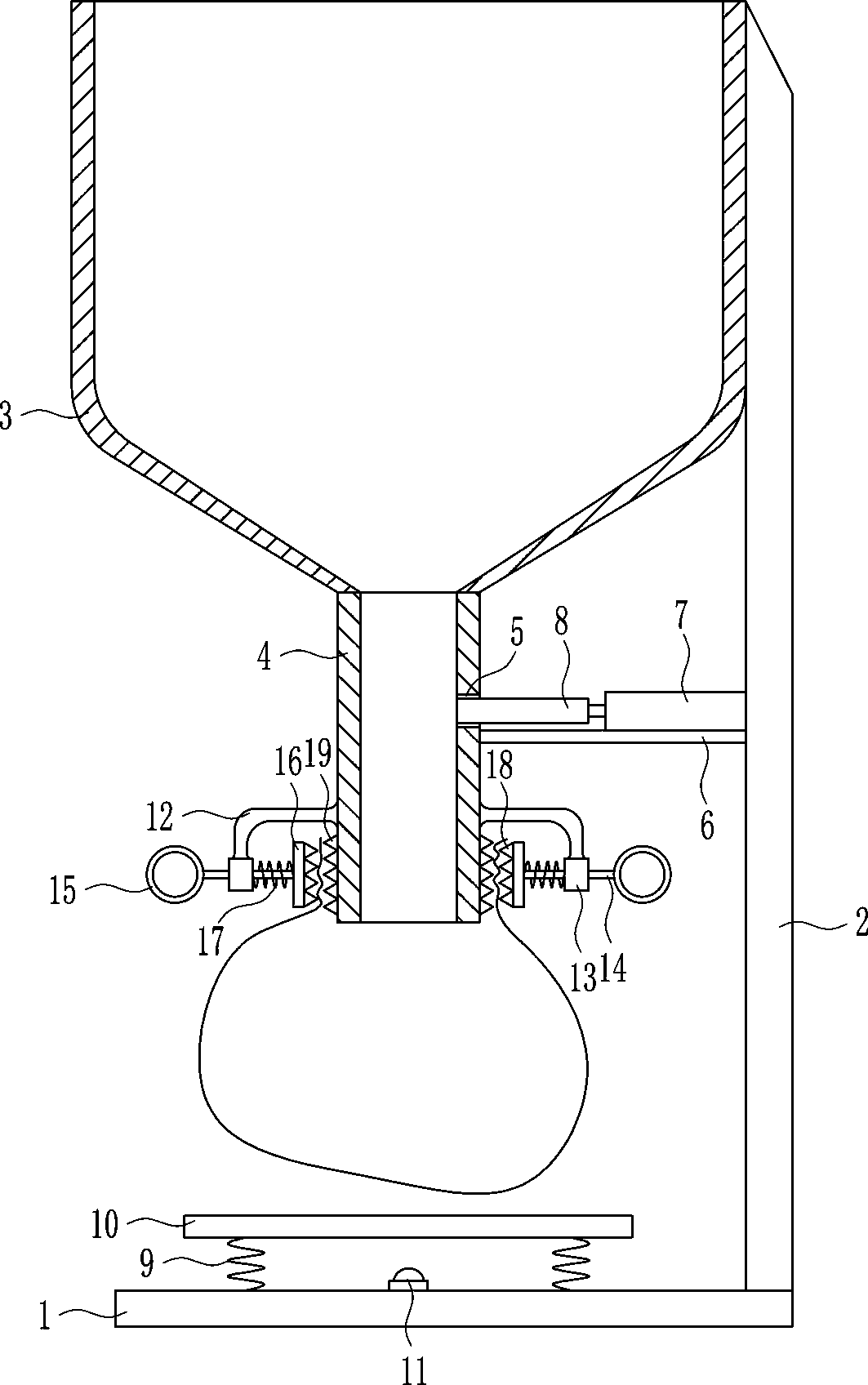

Equipment for automatic filling of canned industrial butter

The invention relates to filling equipment, in particular to equipment for automatic filling of canned industrial butter. The technical problem to be solved by the invention is to provide the equipment for automatic filling of the canned industrial butter, the equipment can quickly achieve filling of the butter and can conduct capping on cans filled with the butter while filling of the butter is carried out. The equipment for automatic filling of the canned industrial butter comprises a bottom plate used for installing the whole device, a rotating mechanism which is arranged at the left frontside of the upper portion of the bottom plate, a discharging mechanism which is arranged at the right rear side of the upper portion of the bottom plate and a material box which is arranged at the left rear side of the upper portion of the bottom plate. The equipment achieves the effects that quick filling of the butter can be achieved; meanwhile, the cans filled with the butter can be capped while filling of the butter is carried out; and the empty cans on a rotary round box are moved to the position below a discharging pipe by rotating a driving disc, so that the effect of being high in butter filling speed is achieved.

Owner:广西富勒星科技有限责任公司

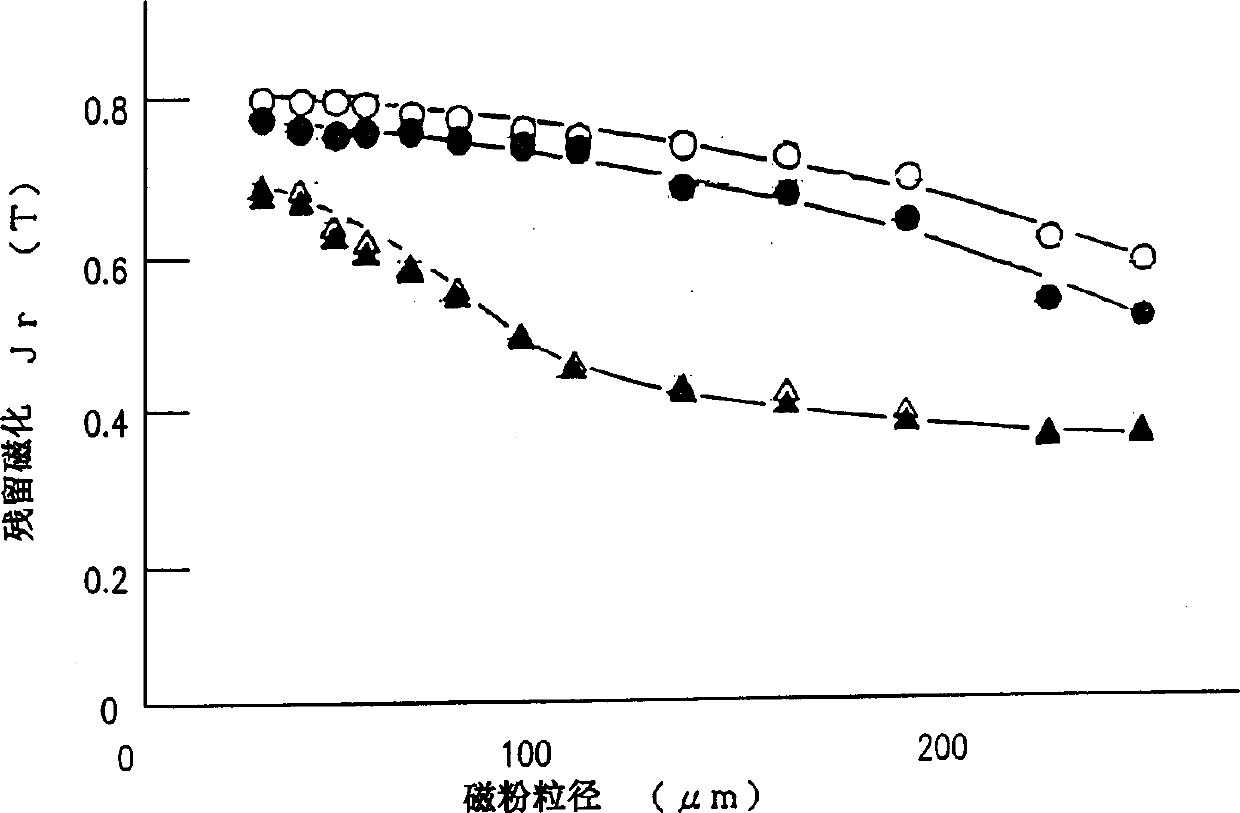

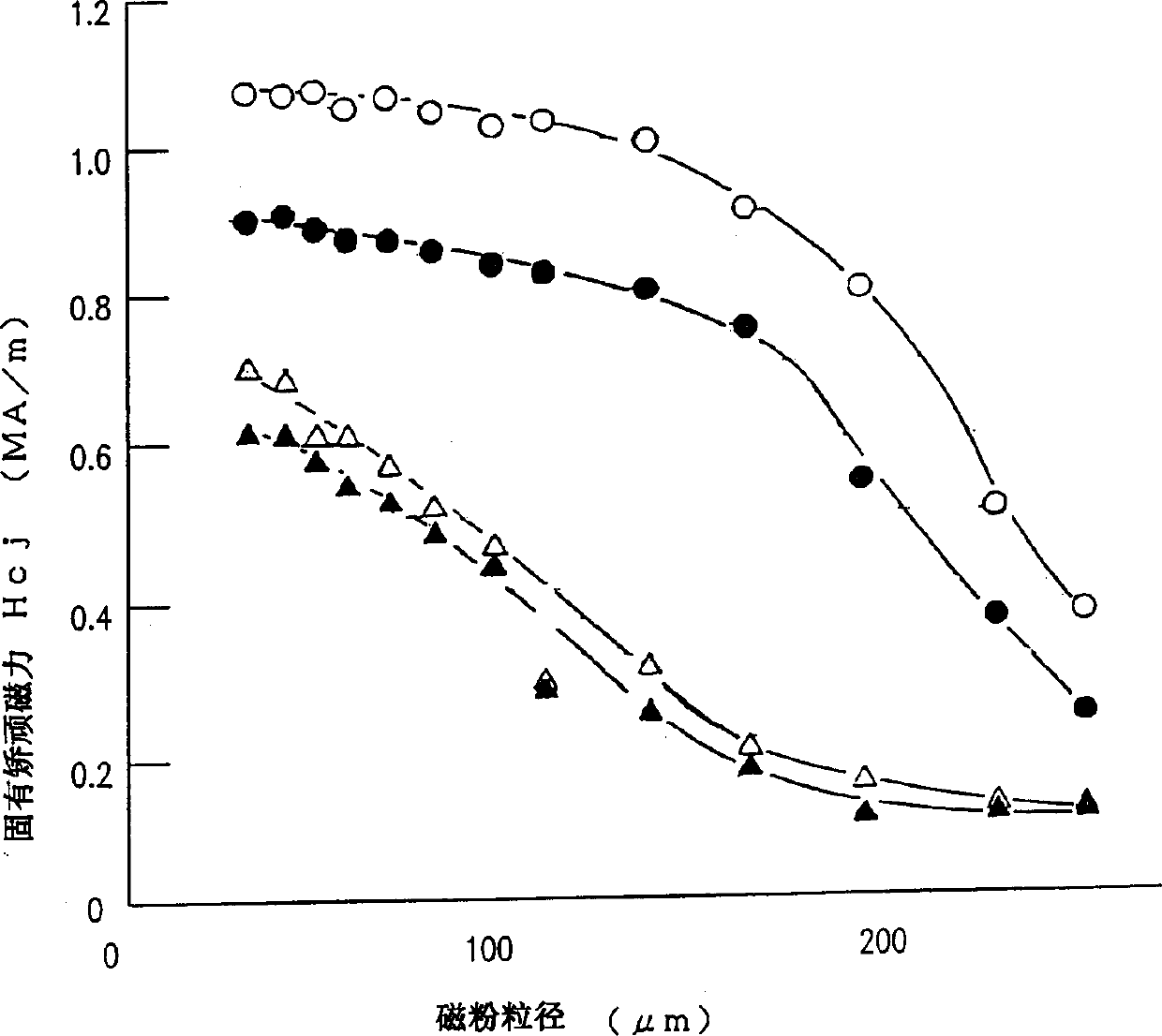

Magnetic alloy powder for permanent magnet and mfg. method thereof

InactiveCN1360316AImprove cooling effectImprove liquidityInorganic material magnetismRare-earth elementNon oxidative

To mass-produce alloyed rare-earth magnetic powder having high coercive force by using the gas atomization method. Spherical powder is formed by spraying molten alloyed pig iron containing R (R is at least one kind of rare-earth elements including Y.) of >=20 wt.% and <=40 wt.%, T (T is a transition metal including Fe as the main component.) of >=60 wt.% and <=79 wt.%, and Q (Q is an element including B (boron) and C (carbon)) of >=0.5 wt.% and <=2.0 wt.%, in the non-oxidative atmosphere, and the shape of particles of the powder is substantially spherical. After that, the spherical powder is heat-treated at a temperature of >=500 deg.C and <=800 deg.C.

Owner:SUMITOMO SPECIAL METAL CO LTD

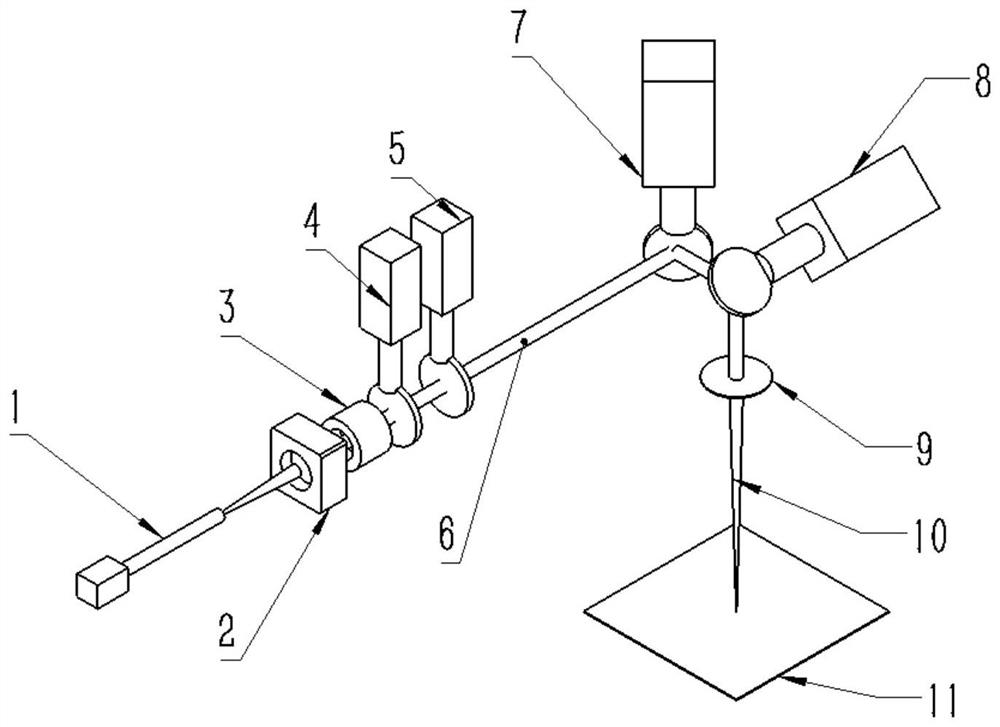

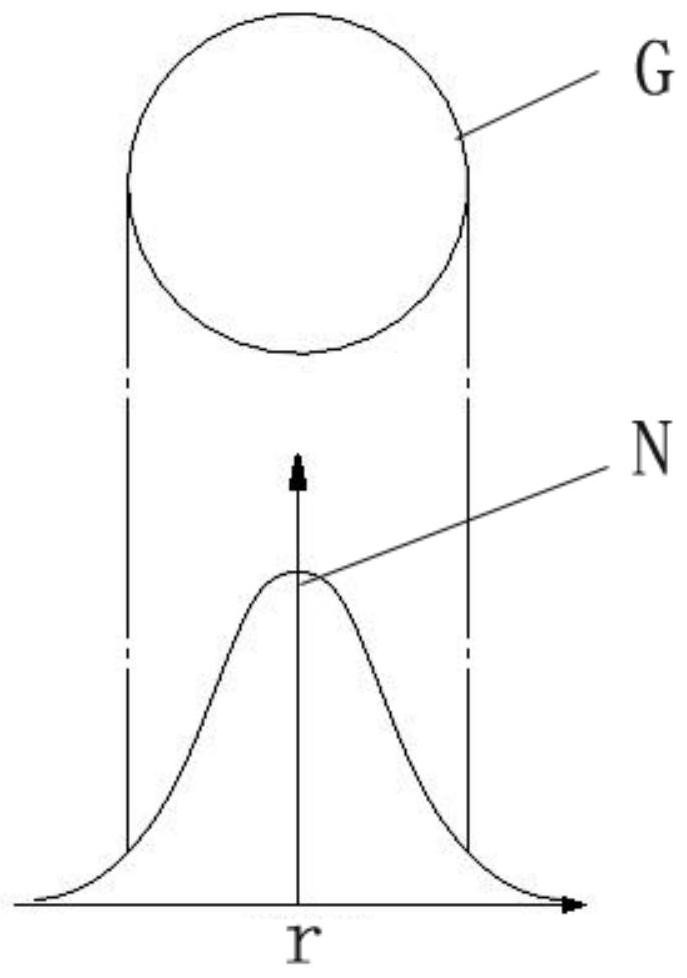

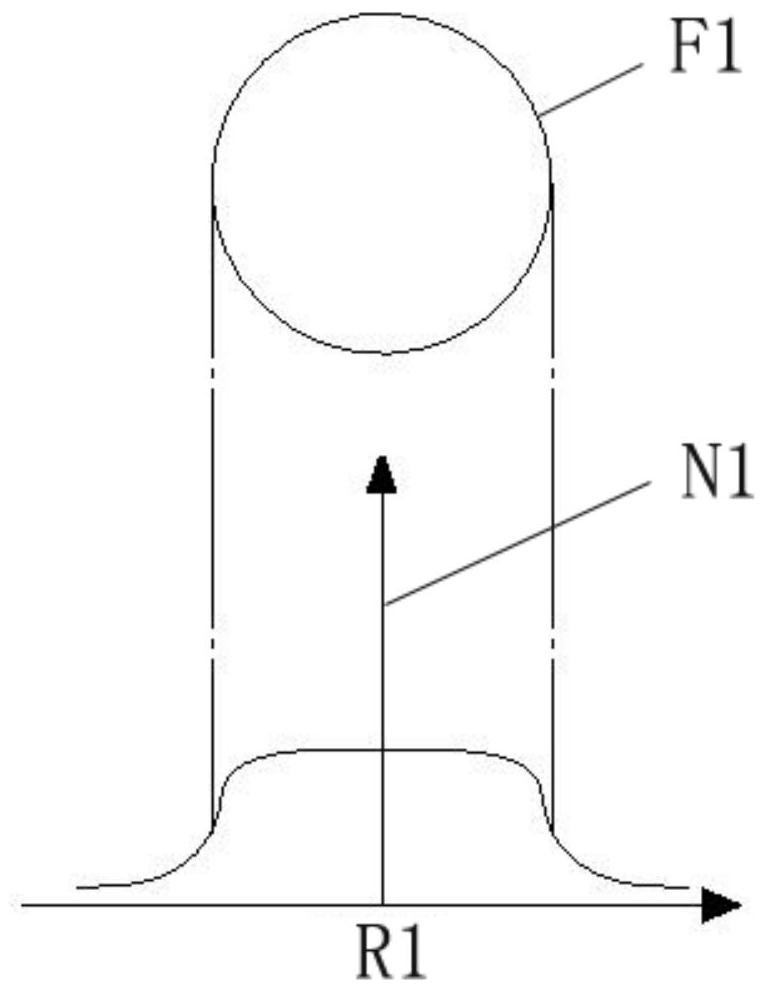

Beam shaping system for metal SLM printing

ActiveCN111796429AAuto switchMeeting Research Application NeedsAdditive manufacturing apparatusIncreasing energy efficiencyLight spotFacula

The invention provides a light beam shaping system for metal SLM printing. The system comprises a laser, and a collimator, a zoom beam expander, a beam shaping mechanism, a galvanometer system and a working platform which are sequentially arranged in the propagation direction of laser beams emitted by the laser. A laser beam emitted by the laser is transmitted through an optical fiber to the collimator with an optical fiber interface for collimation, and the spot size is adjusted through the zoom beam expander to meet the incident spot size requirement of the beam shaping mechanism, the incident spots are shaped through a beam homogenizer or a beam shaper and then converted into flat-topped spots, the flat-topped spots are focused through the galvanometer system to form gathered spots, andthen the gathered spots reach the working surface to machine the metal powder. According to the system, light beam energy is redistributed to obtain circular, rectangular and oval flat-topped light spots or flat-topped light spots of specific shapes are customized according to requirements, metal printing defects can be effectively reduced through shaping of the system, and meanwhile, efficient printing can be conducted by introducing a high-power laser system in cooperation with large-size light spots.

Owner:GUANGXI UNIV

Preparation method of nickel-polytetrafluoroethylene coating

ActiveCN103225098AHigh temperature resistantReduce coefficient of frictionElectrolytic coatingsPolyvinyl chlorideSilica gel

The invention relates to the technical field of electroplating, and particularly relates to a preparation method of a nickel-polytetrafluoroethylene coating. According to the invention, nickel is combined with polytetrafluoroethylene, a fluorinated ethylene-propylene copolymer, a perfluoroalkoxy copolymer and other assistants to be used as an electroplating solution and used for electroplating under certain conditions. The invention can be widely applied to various base materials such as steel, copper alloys, wrought aluminum, cast iron, stainless steel and the like, and can be also perfectly used on various injection molding materials except pure rubber, such as silica gel, TPO0, PVC (polyvinyl chloride) and the like. The coating is favorable in wear resistance and non-corrosibility, has weldability and hardenability, and causes no negative effect on the surfaces of other molds.

Owner:模德模具(东莞)有限公司

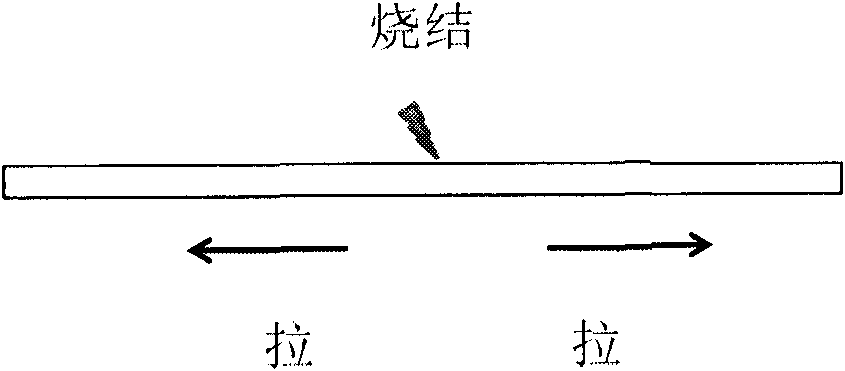

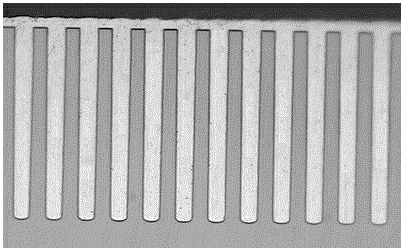

Nanospray capillary high pressure liquid chromatographic column and its preparation method

InactiveCN102243220AImprove resolution efficiencySmall back pressureGlass making apparatusComponent separationChemistryChromatography column

The invention belongs to the field of analytical chemistry. More specifically, the invention discloses a nanospray capillary high pressure liquid chromatographic column and its preparation method. The preparation method of the liquid chromatographic hollow column comprises three steps of: filling a polyimide-coated quartz capillary with a large-grained material which can be melted and solidified, removing the polyimide coating outside the capillary and drawing the capillary chromatographic column. The particle size of the meltable and solidifiable large-grained material in the chromatographic column is 10-15 microns, and a hollow gap can be formed after the large-grained material is heated and melted; in comparison with regular chromatographic columns, the chromatographic column provided by the invention has advantages of small back pressure on the tip as well as fast flow velocity and fast column-filling speed under the same pressure; when separating samples, the column has relatively small back pressure and high flow velocity. Therefore, a longer chromatographic column can be used on a regular liquid chromatogram under the same pressure so as to effectively raise the resolution and target protein identification efficiency of the chromatographic column.

Owner:徐平

Rapid foundation pit soil filling device applied to construction sites

ActiveCN106638747AIncreased fill speedFalling smoothlySoil-shifting machines/dredgersEngineeringBuilding construction

The invention relates to a soil filling device and particularly relates to a rapid foundation pit soil filling device applied to construction sites. In order to solve the technical problem of providing a rapid foundation pit soil filling device applied to construction sites with high soil filling speed, the invention provides such a rapid foundation pit soil filling device applied to construction sites. The rapid foundation pit soil filling device comprises a friction block, an electric wheel, trolley wheels, a pushing plate, a rack, a sliding rail, a sliding block, a connection rod, a purification box, a flexible pipe, an air suction pump, a filter screen, an air outlet pipe and a guide plate, wherein the electric wheel is arranged between the trolley wheels at the bottom of a pushing trolley; the friction block is arranged on the electric wheel; a handle is arranged on the right side of the pushing trolley; the guide plate and the purification box are arranged on the inner right wall of the pushing trolley; the guide plate is located above the purification box; the bottom of the purification box is connected with the inner bottom of the pushing trolley; a guide hole is formed in the guide plate. The rapid foundation pit soil filling device achieves the effects of high pit filling speed, simple structure and simplicity in operation.

Owner:江苏晟功筑工有限公司

Air pump and opening and closing structure of air valve thereof

InactiveCN102606496AEasy to operateSimple structurePump componentsPump installationsImpellerAir pump

The invention discloses an air pump which comprises a shell, an air valve and an air blasting device. The shell is provided with an accommodating cavity, a first air port and a second air port, wherein the air blasting device is pivoted in the accommodating cavity; the lower end of the air blasting device is connected with the air valve which comprises a rotary shell, a motor, an impeller and an air chamber; a first air guide groove and a second air guide groove are arranged at the lower end of the air blasting device; the upper ends of the first air guide groove and the second air guide groove are respectively communicated with an air inlet end and an air outlet end of the impeller; the lower ends of the first air guide groove and the second air guide groove are alternately communicated with the second air port; and a drive positioning mechanism is arranged between the shell and the rotary shell, and the drive positioning mechanism comprises a plurality of limiting grooves at different heights, a pushing slope surface positioned between two adjacent limiting grooves, a convex column and an elastic element. Therefore, when being rotated, the air blasting device can switch the first air guide groove and the second air guide groove and enable the first air guide groove and the second air guide groove to be alternately communicated with the second air port, and the second air port is opened or closed at the same time, therefore, the operation is convenient, and the structure is simple and compact.

Owner:东莞市鹏科电子科技有限公司

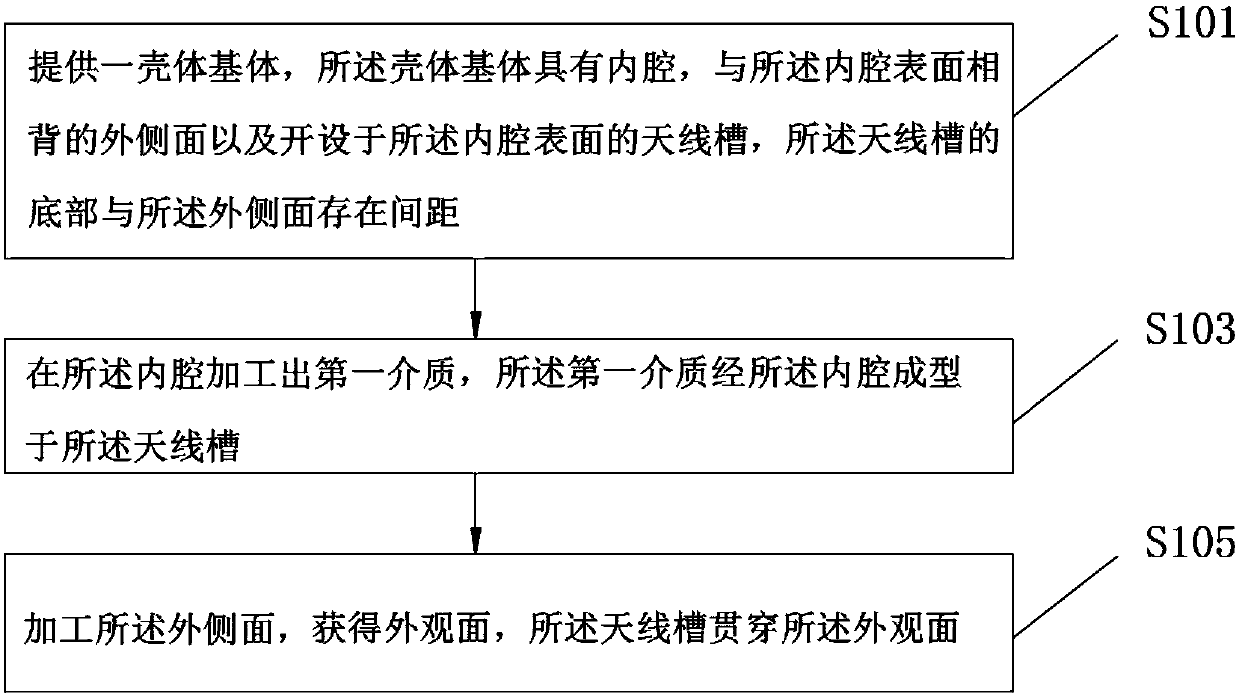

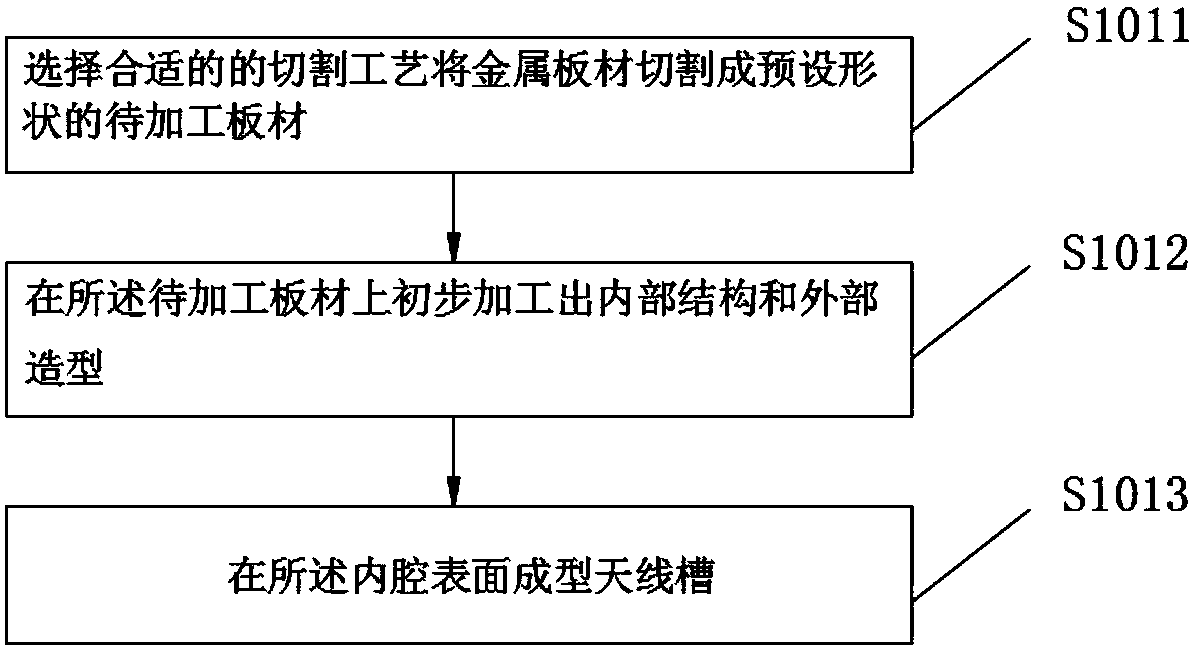

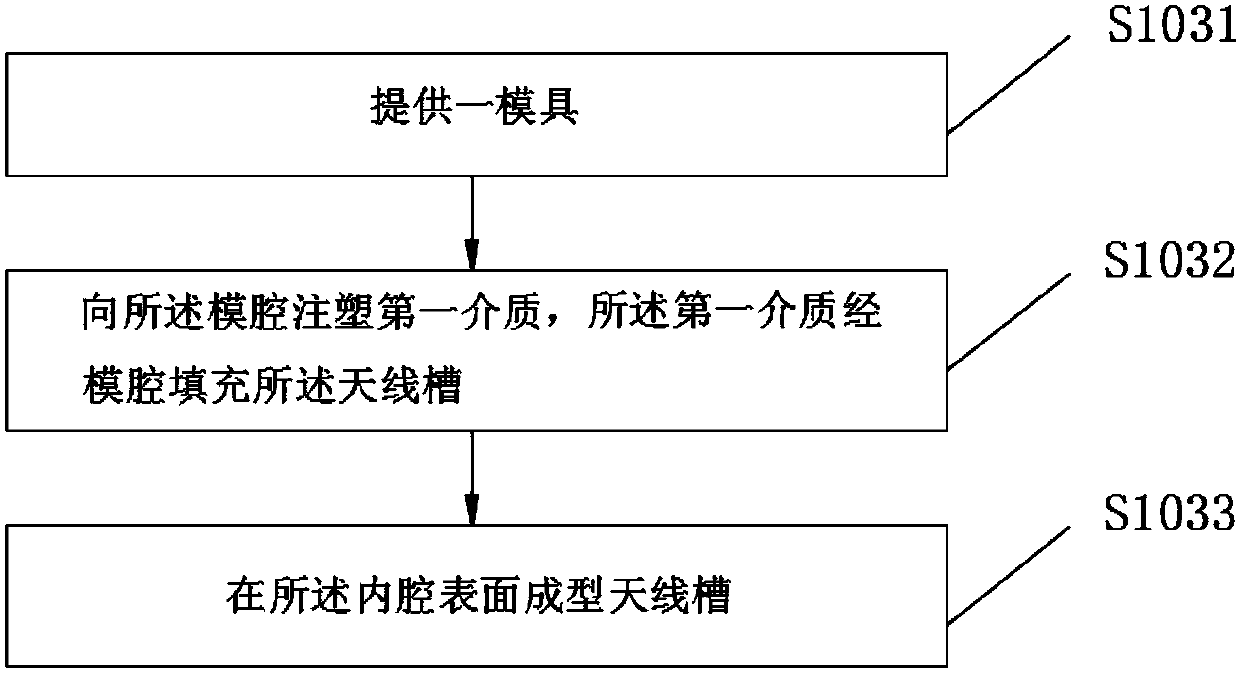

Shell and manufacturing method thereof and mobile terminal

Owner:GUANGDONG OPPO MOBILE TELECOMM CORP LTD

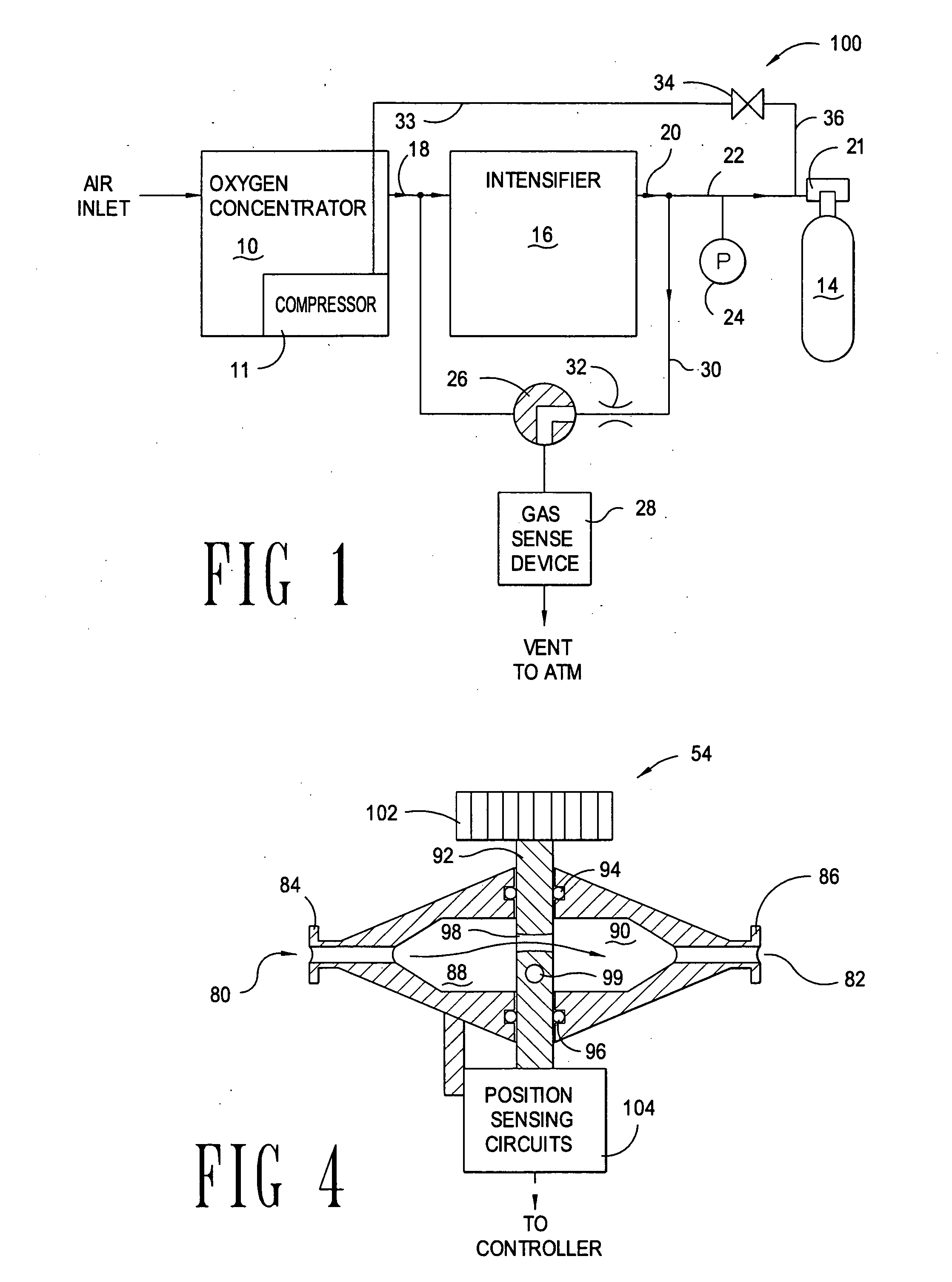

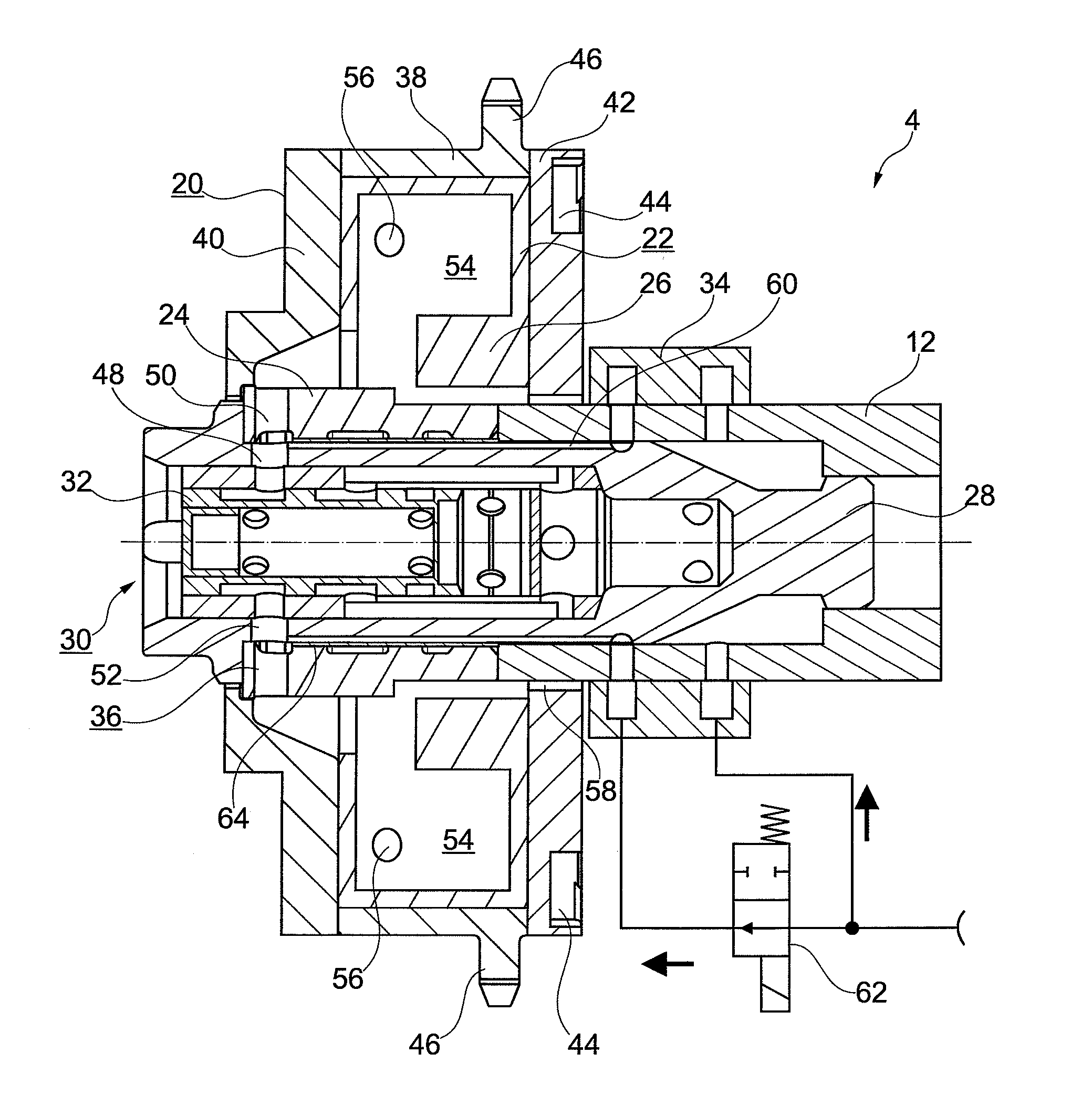

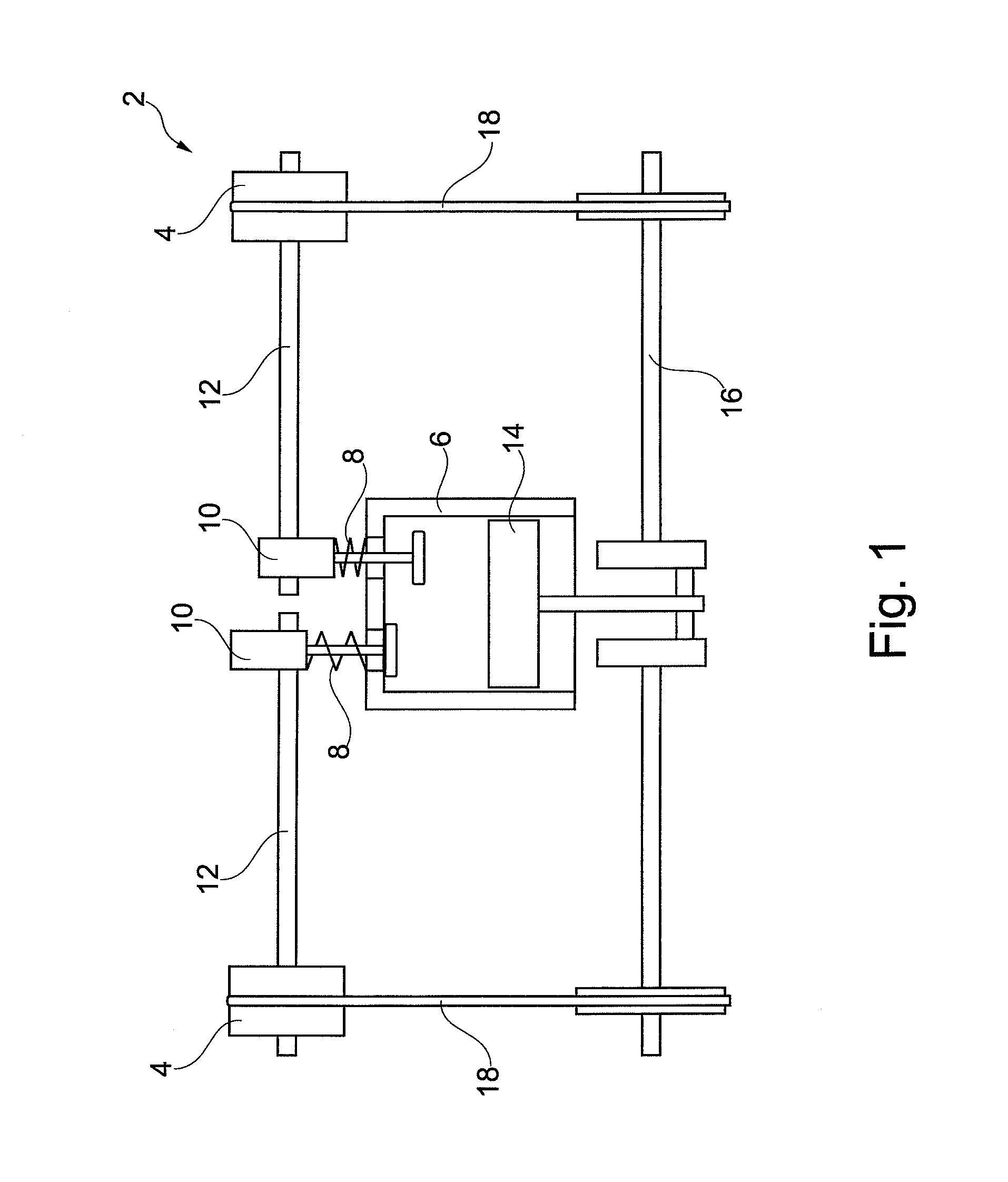

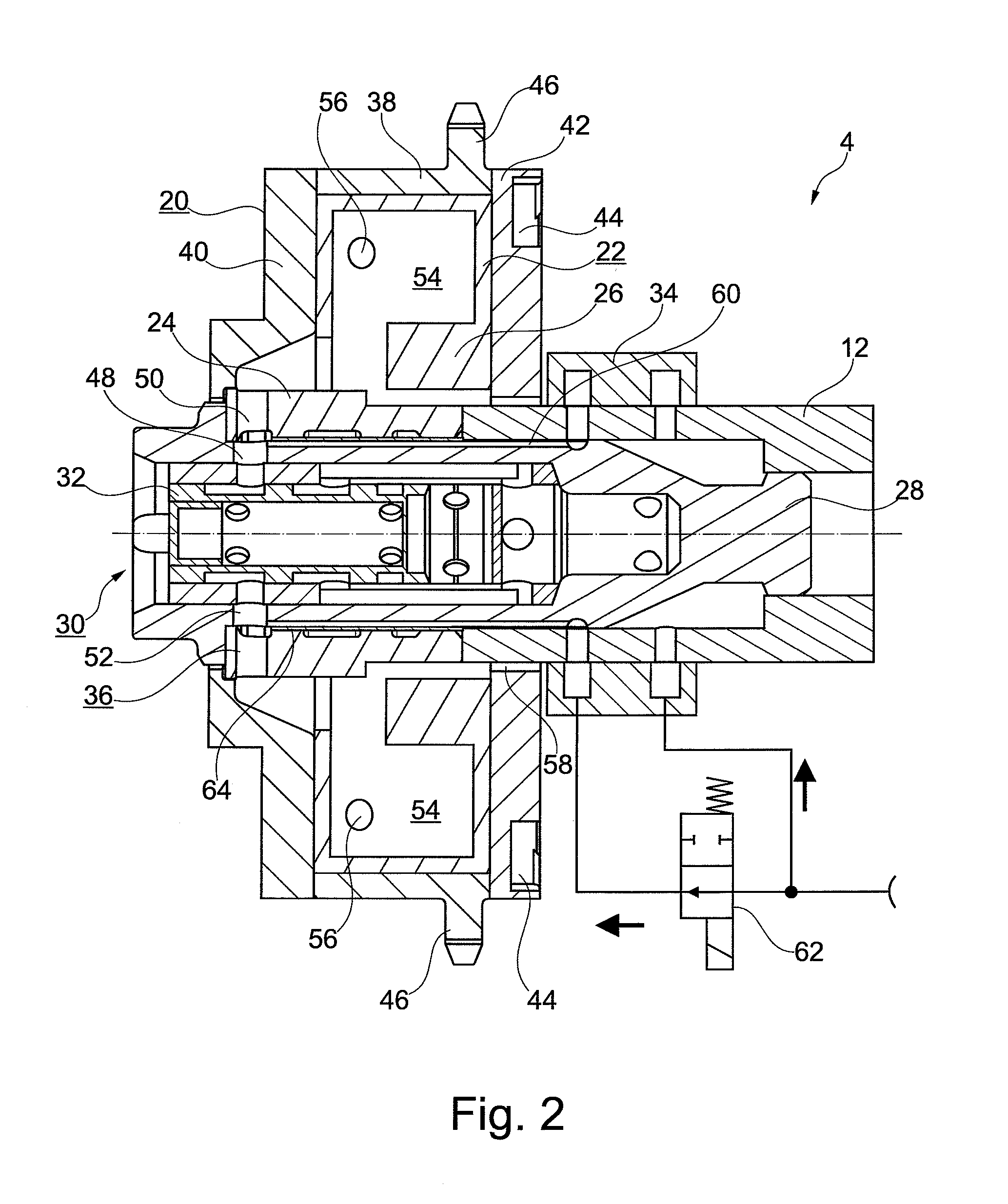

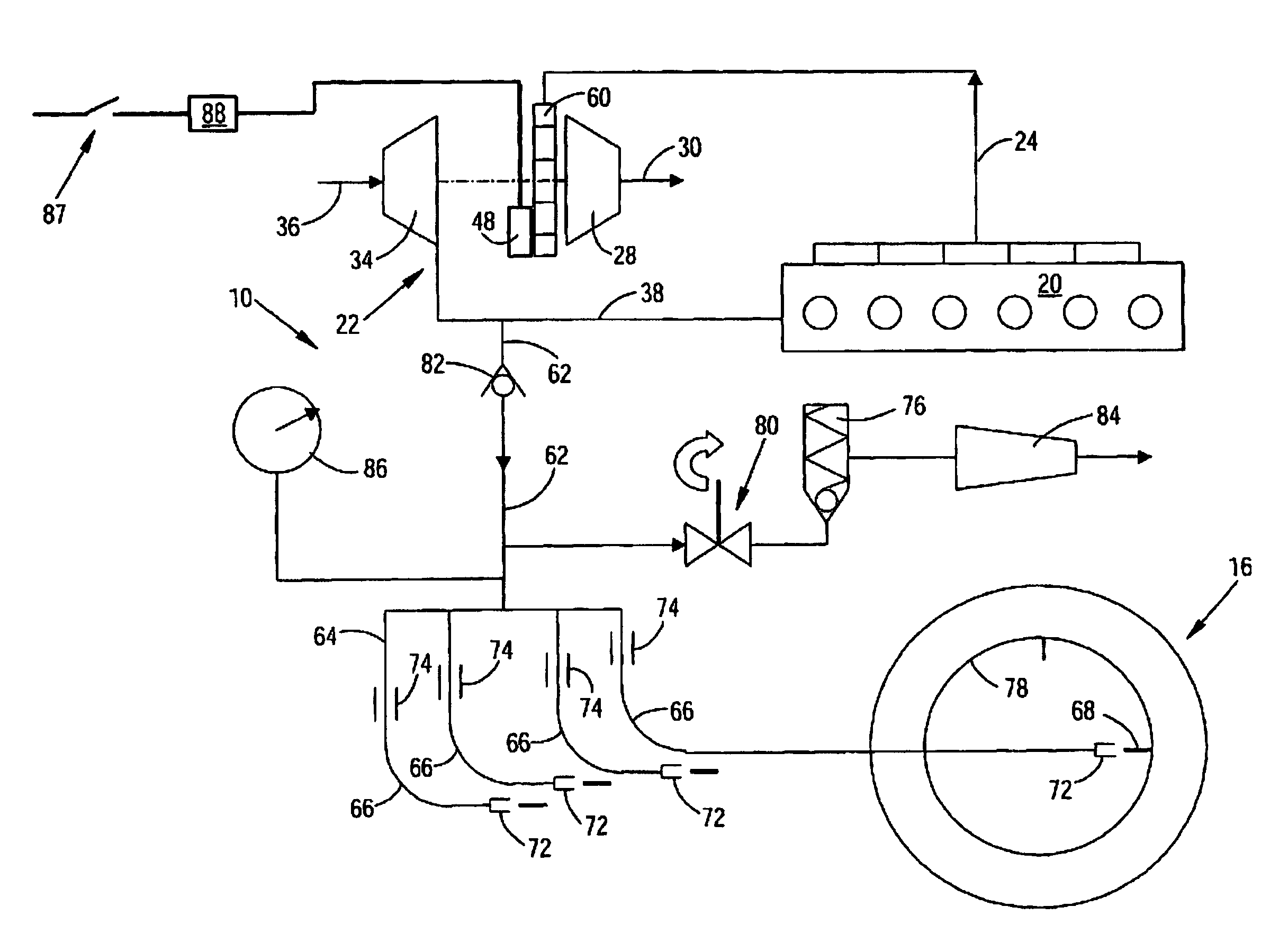

Filling of a volume accumulator in a camshaft adjuster

InactiveUS20130199475A1Fast fillingReduces high dynamic loadingCheck valvesEqualizing valvesFuel tankControl engineering

A directional valve (30) for controlling a hydraulic oil flow from a pressure port (34) via working chambers of a camshaft adjuster (4) to a tank port (58). The directional valve (30) includes an accumulator port (36) for conducting at least a part of the hydraulic oil flowing out of a working chamber into a volume accumulator (54) before said hydraulic oil flows out into the tank port (58), and the accumulator port (36) is connected via a passage (60) to the pressure port (34).

Owner:SCHAEFFLER TECH AG & CO KG

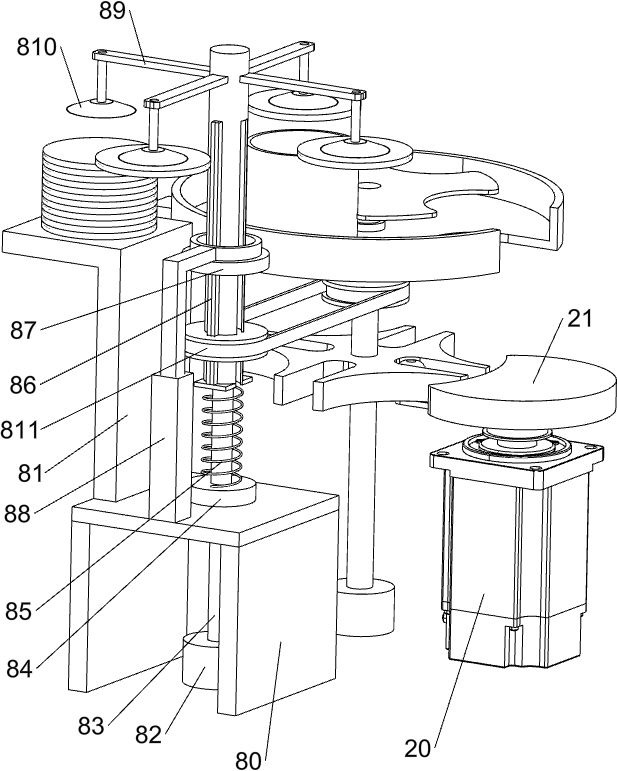

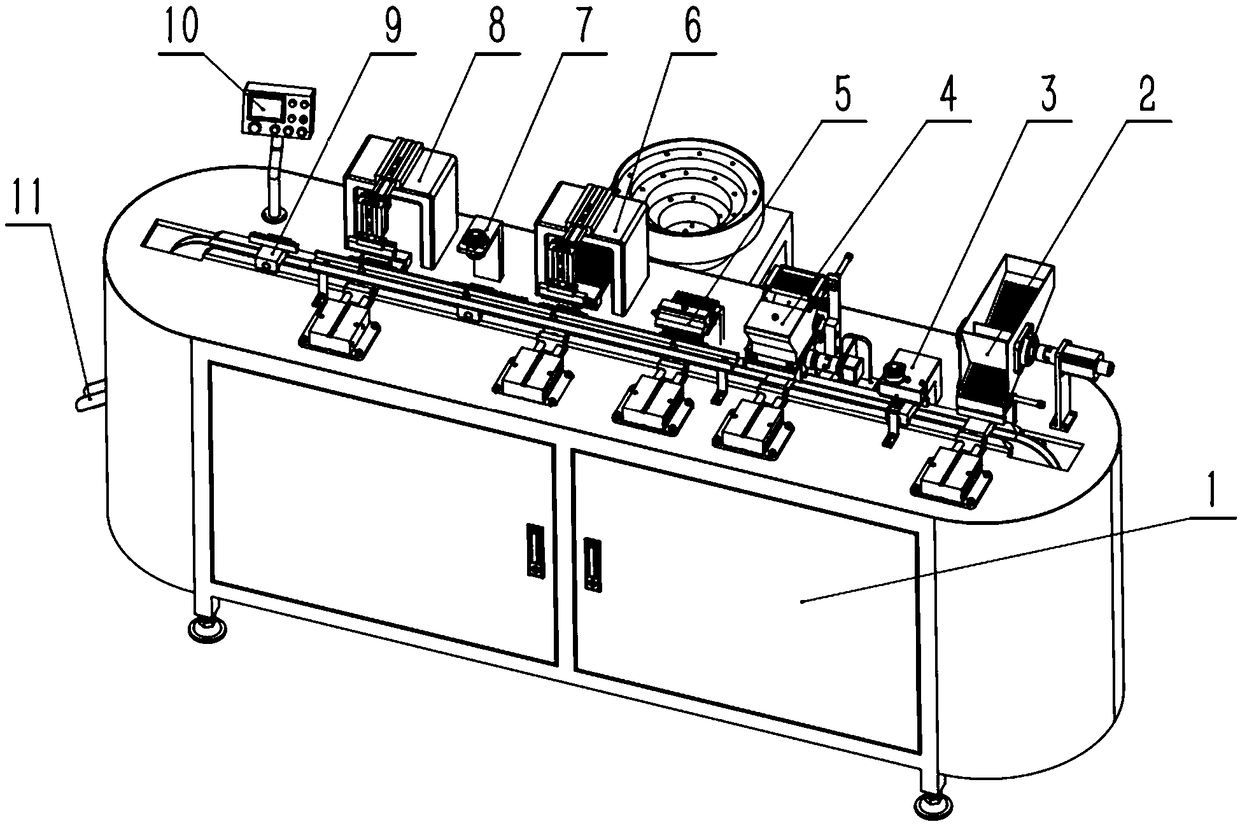

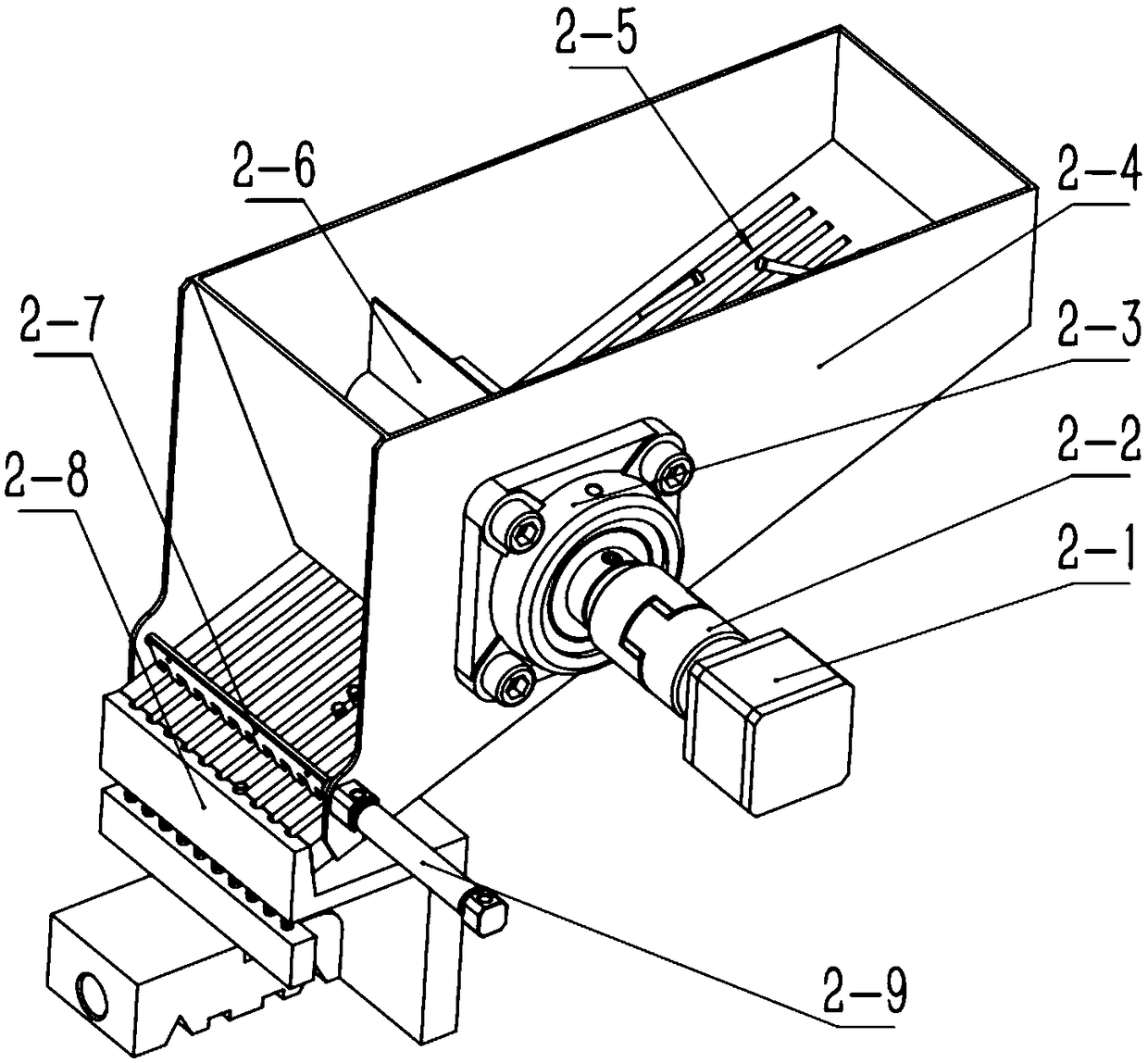

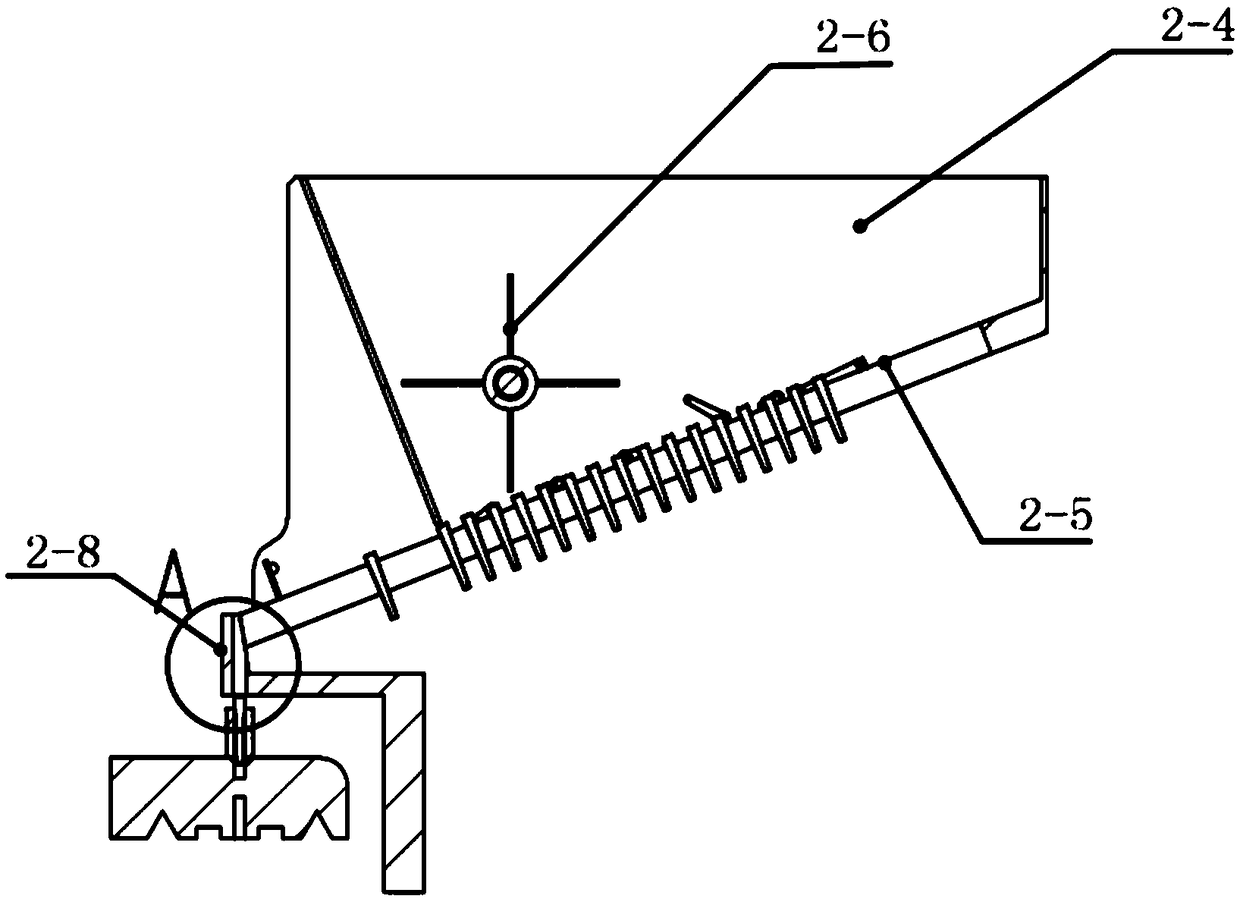

Multifunctional full-automatic pellet filling machine

PendingCN108945618AImprove quality and efficiencyImprove filling efficiencyPackaging automatic controlSolid materialImage detectionEngineering

The invention relates to a multifunctional full-automatic pellet filling machine, and belongs to the field of automatic filling / packaging machinery. The multifunctional full-automatic pellet filling machine is mainly composed of a bottle arranging mechanism, a bottle alignment and checking mechanism, a pellet filling mechanism, a pellet supplementing mechanism, a cover arranging and cover feedingmechanism, a sampling and defective product removing mechanism, an image detection mechanism and a transmission and positioning mechanism. According to the multifunctional full-automatic pellet filling machine, a plurality of batches of disordered pellet bottles are orderly arranged on a bottle fixing tool of the transmission and positioning mechanism by utilizing the bottle arranging mechanism, the plurality of batches of pellet bottles which are arranged orderly are moved sequentially to pass through the bottle alignment and checking mechanism through the transmission and positioning mechanism, the pellet bottles are guaranteed to be well arranged on the bottle fixing tool, a certain number of pellets are automatically filled through the pellet filling mechanism, bottle covers are installed in place through the cover arranging and cover feeding mechanism, the sampling and defective product removing mechanism is used for regular and quantitative sampling according to an instruction and defective product removing in real time; and the pellets can be filled automatically and precisely, the pellet supplementing mechanism is arranged, so that sampling can be conducted regularly and quantitatively, the defective product removing can also be conducted, manual operation is not needed in the whole process, and therefore filling quality and filling efficiency are greatly improved.

Owner:成都创合丰生物科技有限公司

Additive B capable of controlling TSV deep hole copper plating crystallization and growth mode and application of additive B

The invention discloses an additive B capable of controlling the TSV deep hole copper plating crystallization and the growth mode and an application of the additive B. The additive B comprises, by weight, 1%-10% of one of polyethylene glycol and polyvinyl alcohol with the molecular weight being 200 to 20,000 or the mixture of polyethylene glycol and polyvinyl alcohol with different molecular weights, 0.01%-10% of an EO-PO-EO-quaternary ammonium compound, 0.1%-5% of a thioimidazole compound, 0.1%-10% of polyethylenimine and derivative thereof and the balance water. By means of the additive B, the TSV deep hole electroplating copper filling mode can be changed, the crystal habit of copper is changed, and thus defect-free micro protrusion filling along holes of TSV micro holes can be achieved; the copper crystallization shape and the hole opening growth mode are effectively controlled, the surface copper thickness is reduced, TSV deep hole opening micro protrusions are also reduced, hence, the subsequent CMP processing pressure is lightened, the subsequent processing cost is lowered, and the yield and the production efficiency are greatly improved.

Owner:SHANGHAI SINYANG SEMICON MATERIALS

Sand filling device for flood control sandbags used in geological disasters

The invention relates to a sandbag filling sand device, in particular to a sandbag filling sand device for flood control of geological disasters. The invention provides a sandbag filling sand device for flood control of geological hazards, which can improve filling speed, save time and labor, and has high safety. A sand bag filling device for flood control of geological disaster comprises a bottomplate, a support plate, a storage box, a feeding pipe, a horizontal plate, an air cylinder, a baffle plate, a first spring, a pressure plate, a contact switch, a first connecting rod, a first guide sleeve, etc. A support plate is arrange on that right side of the top of the bottom plate, a storage tank is arranged on the upper part of the left side of the support plate, a blanking pipe is arrangein the middle of the bottom of the storage tank, and an opening is arranged on the upper part of the right wall of the blanking pipe. The first toothed plate and the second toothed plate of the invention can be matched to fix the sandbag on the blanking pipe, so that the sandbag does not need to be manually stretched, and the blanking pipe can make the sand fill the sandbag, so that the filling speed can be improved, the time and labor can be saved, and the safety is high.

Owner:余富斌

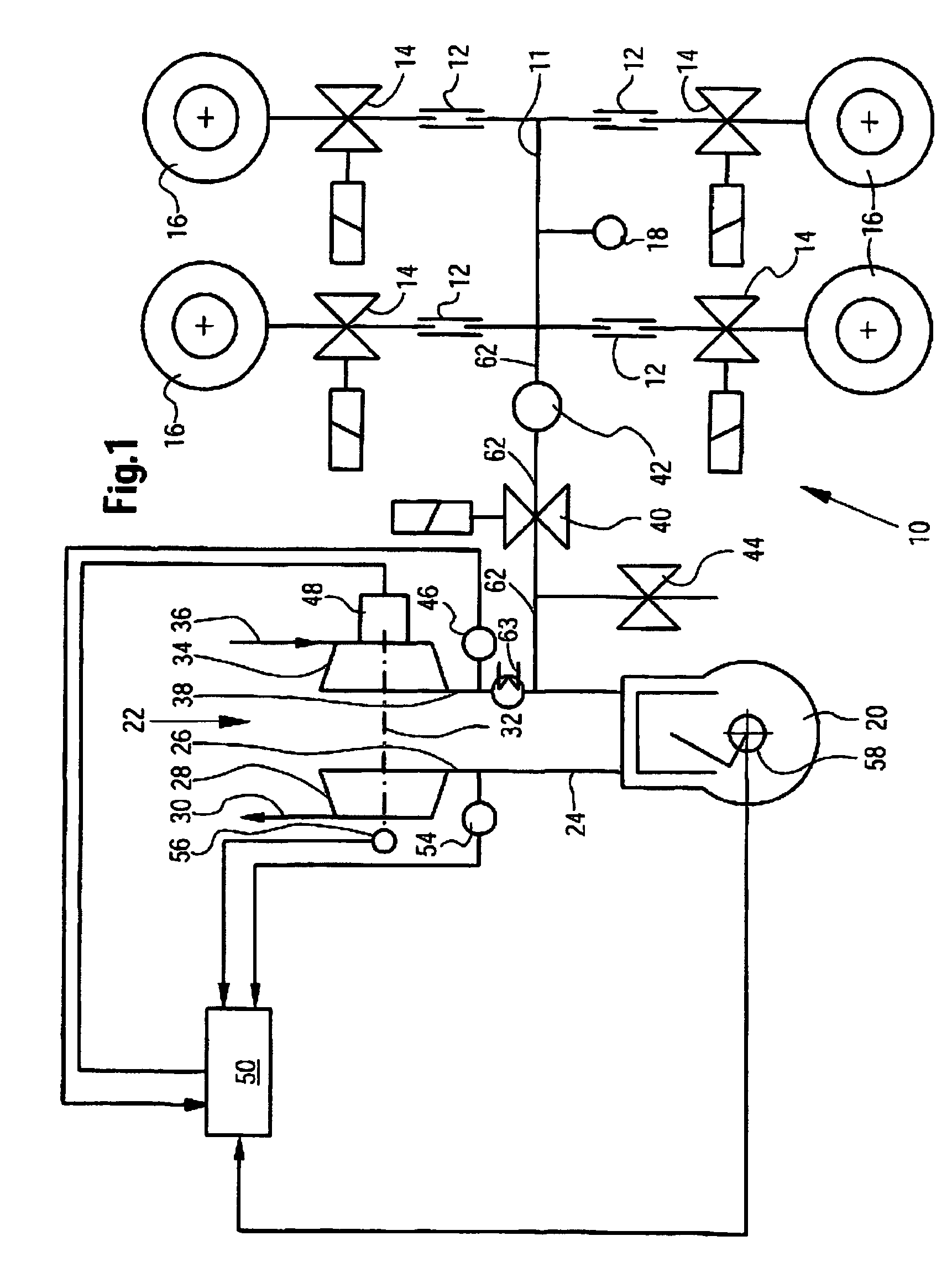

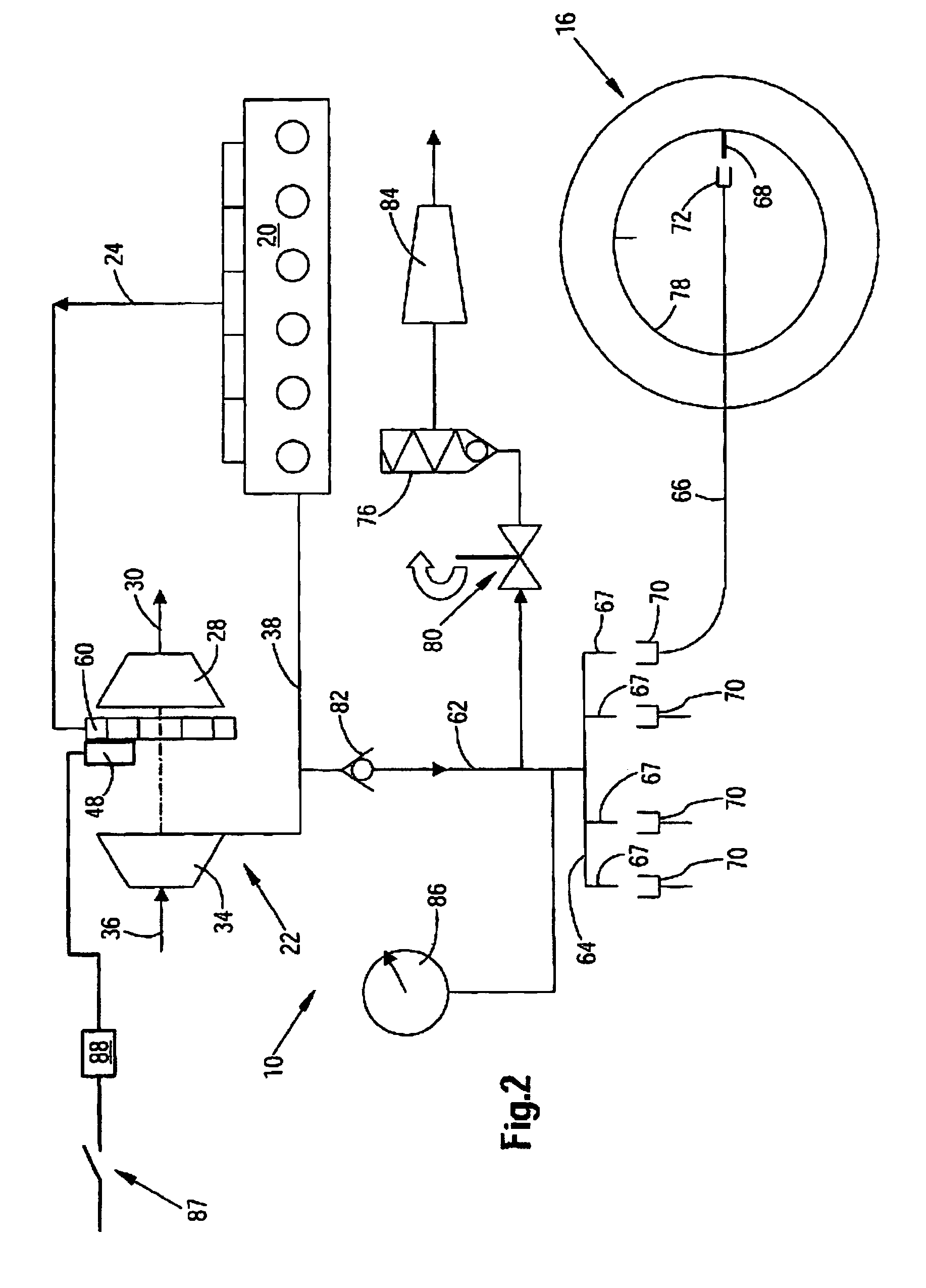

Tire pressure regulating system

InactiveUS7555903B2Fast fillingFast emptyingInternal combustion piston enginesElectric propulsion mountingTurbochargerHigh pressure

The invention relates to a system for regulating the pressure of tires mounted on a vehicle. The vehicle has an engine with a turbocharger which is a compressed air source for the pressure regulating system. The turbocharger has a variable geometry in order to supply a sufficiently high pressure.

Owner:DEERE & CO

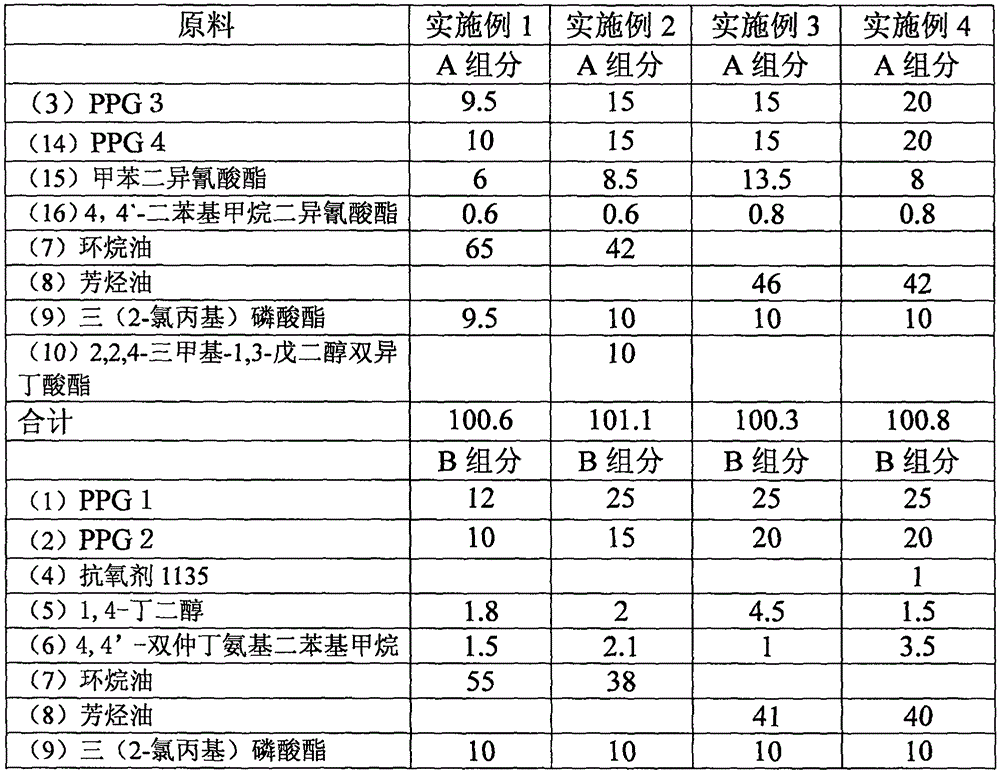

Low cost polyurethane material for safe tyre internal filling and using method thereof

The invention discloses a low cost polyurethane material for safe tyre internal filling and a using method thereof, and the low cost polyurethane material comprises components A and B, the component A comprises, by weight, 5%-15% of diisocyanate, 15%-40% of a polyether polyol a and 50%-75% of a diluent; and the component B includes, by weight, 20%-47.5% of a polyether polyol b, 1%-5% of a chain extender, 1%-5% of a crosslinking agent, 50%-75% of the diluent, 0.3%-1.0% of a catalyst and 0-2% of an antioxidant. The polyether polyol a is selected from a polypropylene oxide ether polyol with the functionality of 2 or 3 and the molecular weight of 2000-5000, the polyether polyol b is selected from a polypropylene oxide ether polyol with the functionality of 2 or 3 and the molecular weight of 4000-8000, the diluent is selected from naphthenic oil, aromatic hydrocarbon oil, tris(clorisopropyl) phosphate and 2,2,4-trimethyl-1,3-pentanediol diisobutyrate. The material is low in raw liquid viscosity and low in cost, and after mixing, operable time is long, and filling speed is fast.

Owner:LIMING RES INST OF CHEM IND

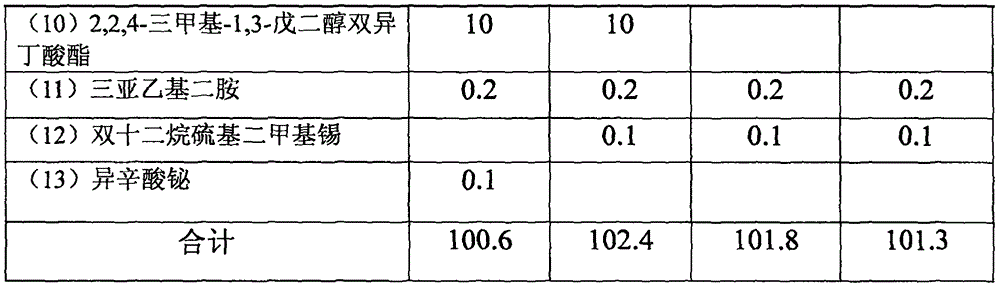

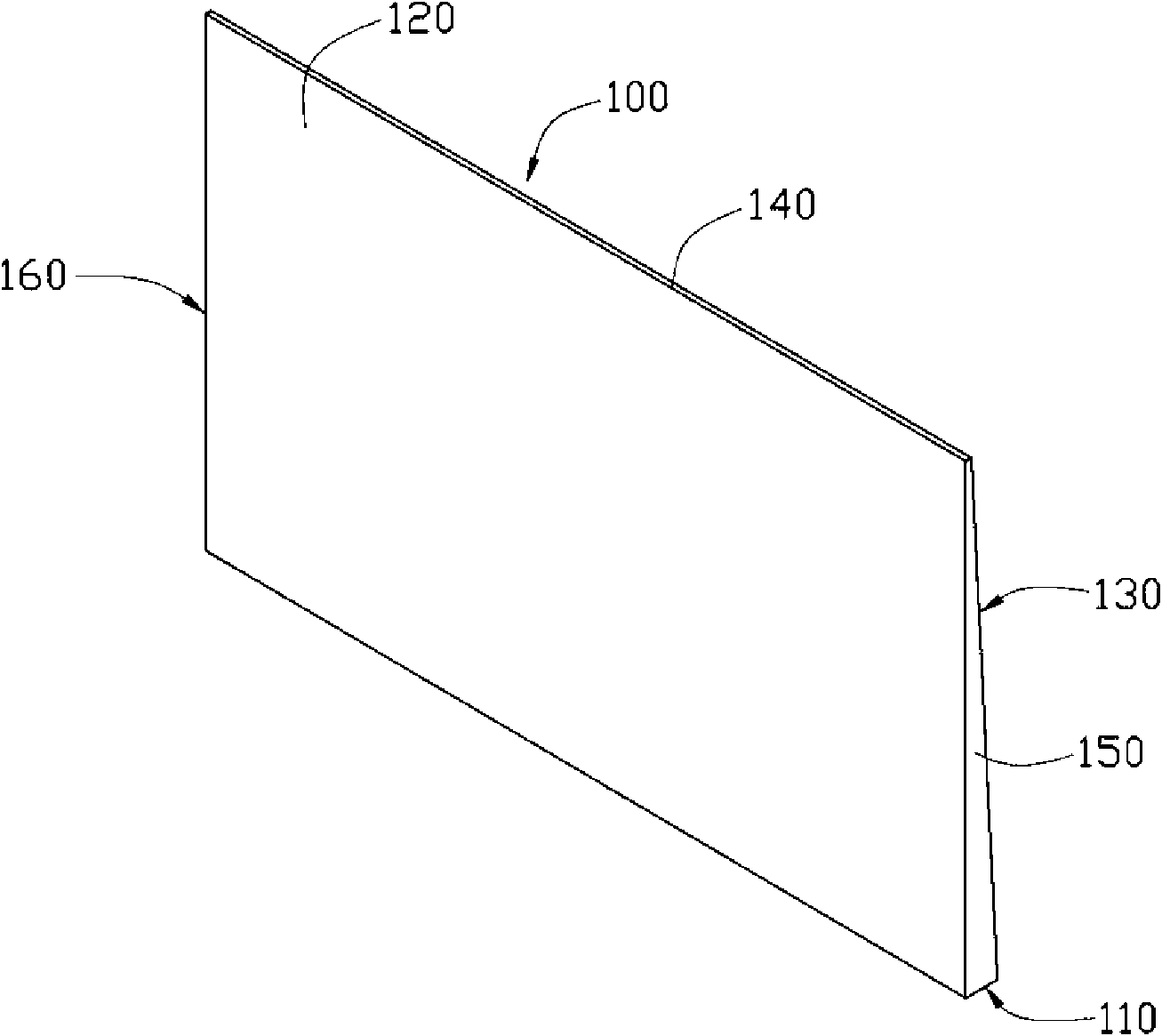

Injection molding device

InactiveCN101885222AShorten the timeUniform stressOptical articlesOptical light guidesLight guideOptoelectronics

The invention relates to an injection molding device, which comprises a molding chamber. The molding chamber is used for manufacturing a wedge-shaped light guide plate which comprises a light incoming surface, a light outgoing surface connected with the light incoming surface, a first side face opposite to the light incoming surface, two second side faces connected with and opposite to the light incoming surface, and a bottom surface opposite to the light outgoing surface; the width of the second side faces is reduced gradually from the light incoming surface to the first side face; the molding chamber is provided with a first inner wall corresponding to the light incoming surface, a second inner wall corresponding to the light outgoing surface, a third inner wall corresponding to the bottom surface, a fourth inner wall corresponding to the first side face, and two fifth inner walls corresponding to the two second side faces; at least one of the fifth inner walls is provided with a first sprue and a second sprue which are used for filling the molding material for the light guide plate; and the distance between the position of the first sprue and the first inner wall is less than that between the position of the second sprue and the second inner wall.

Owner:HONG FU JIN PRECISION IND (SHENZHEN) CO LTD +1

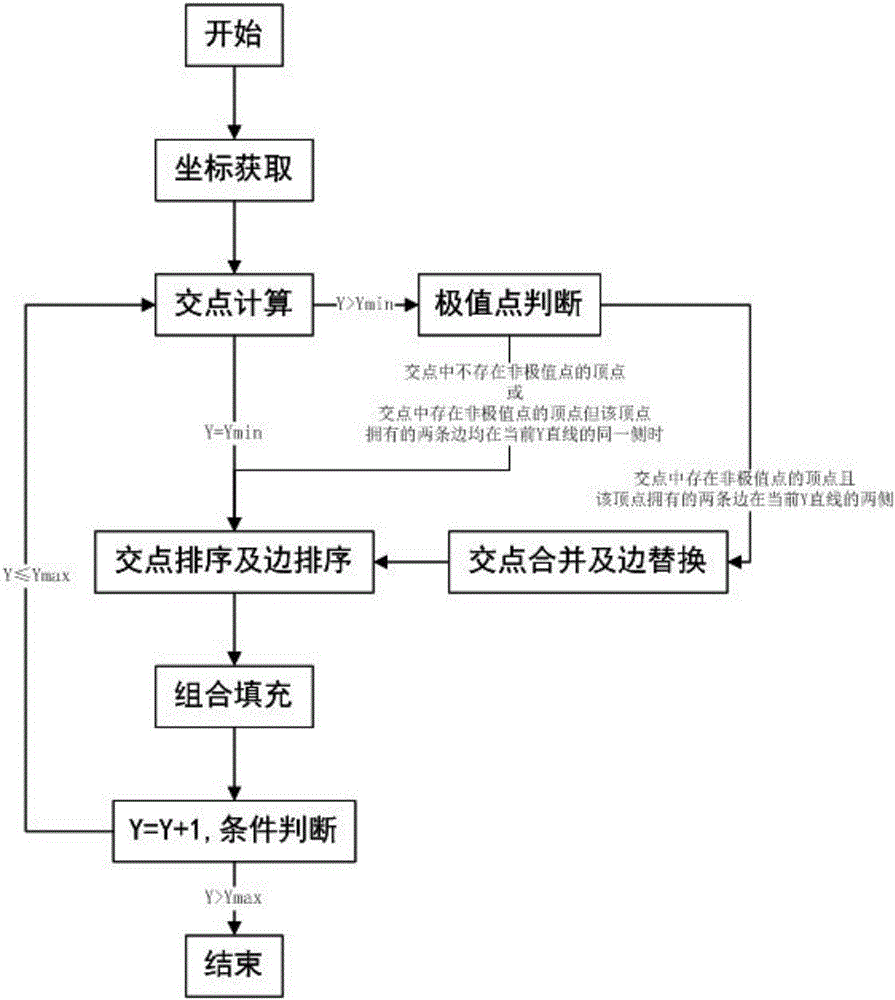

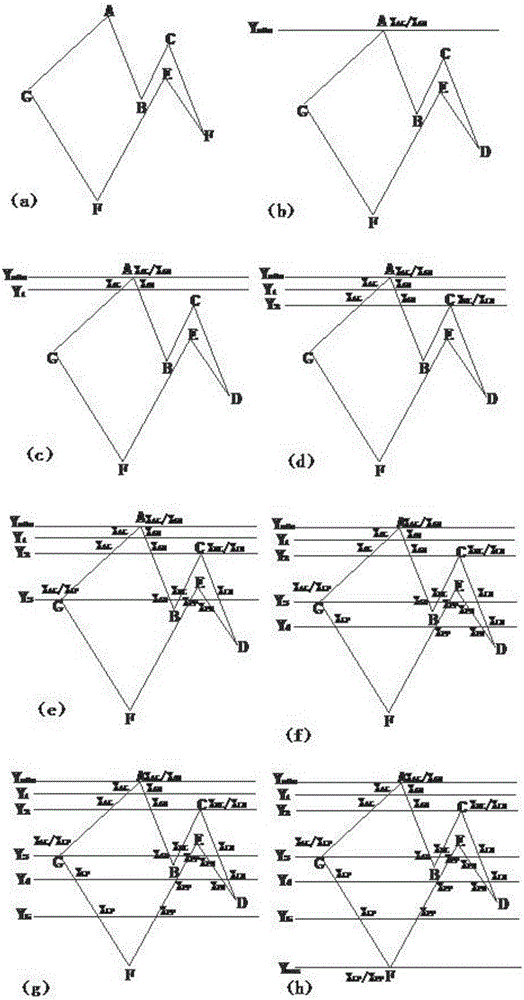

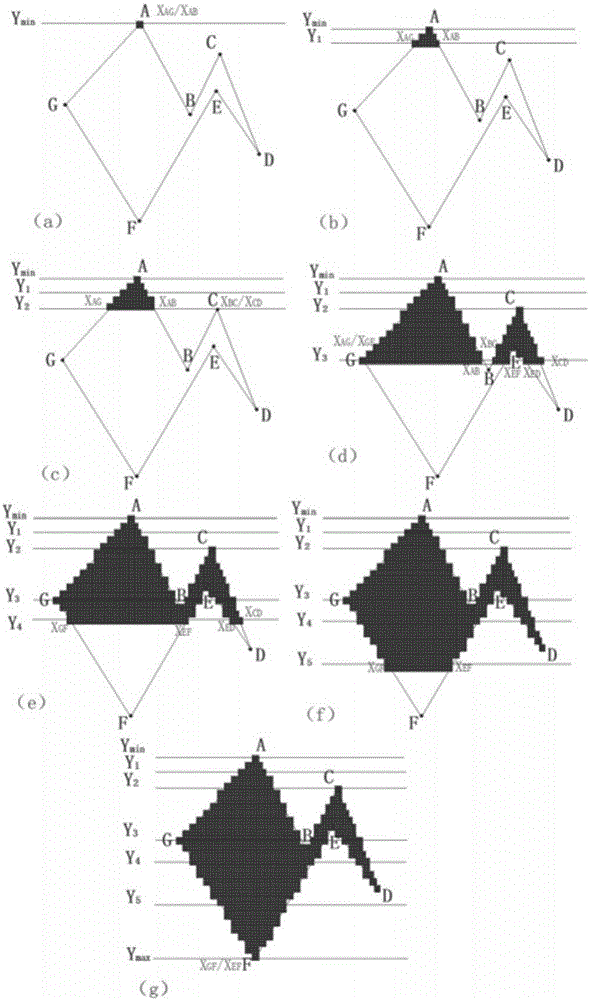

Method for filling non self-intersecting polygon in FPGA

InactiveCN106651993ASave time and costReduce the amount of sorting operationsProcessor architectures/configurationFilling planer surface with attributesAlgorithmIntersection of a polyhedron with a line

The present invention discloses a method for filling a non self-intersectig polygon in a FPGA. The filling method comprises the steps of coordination acquisition, intersection point calculation, intersection point ranking and edge ranking, combination filling, and condition determining. Compared with the existing algorithms, the method has a simple filling process and has high filling speed. Particularly, in the ranking algorithm in the filling method, a simplified ranking method is adopted according to change of the number of the intersection points, so that the ranking calculation amount of the intersection points in filling is greatly reduced, and the filling speed is improved remarkably.

Owner:ADVANCED DIGITAL SCREEN SYST INC

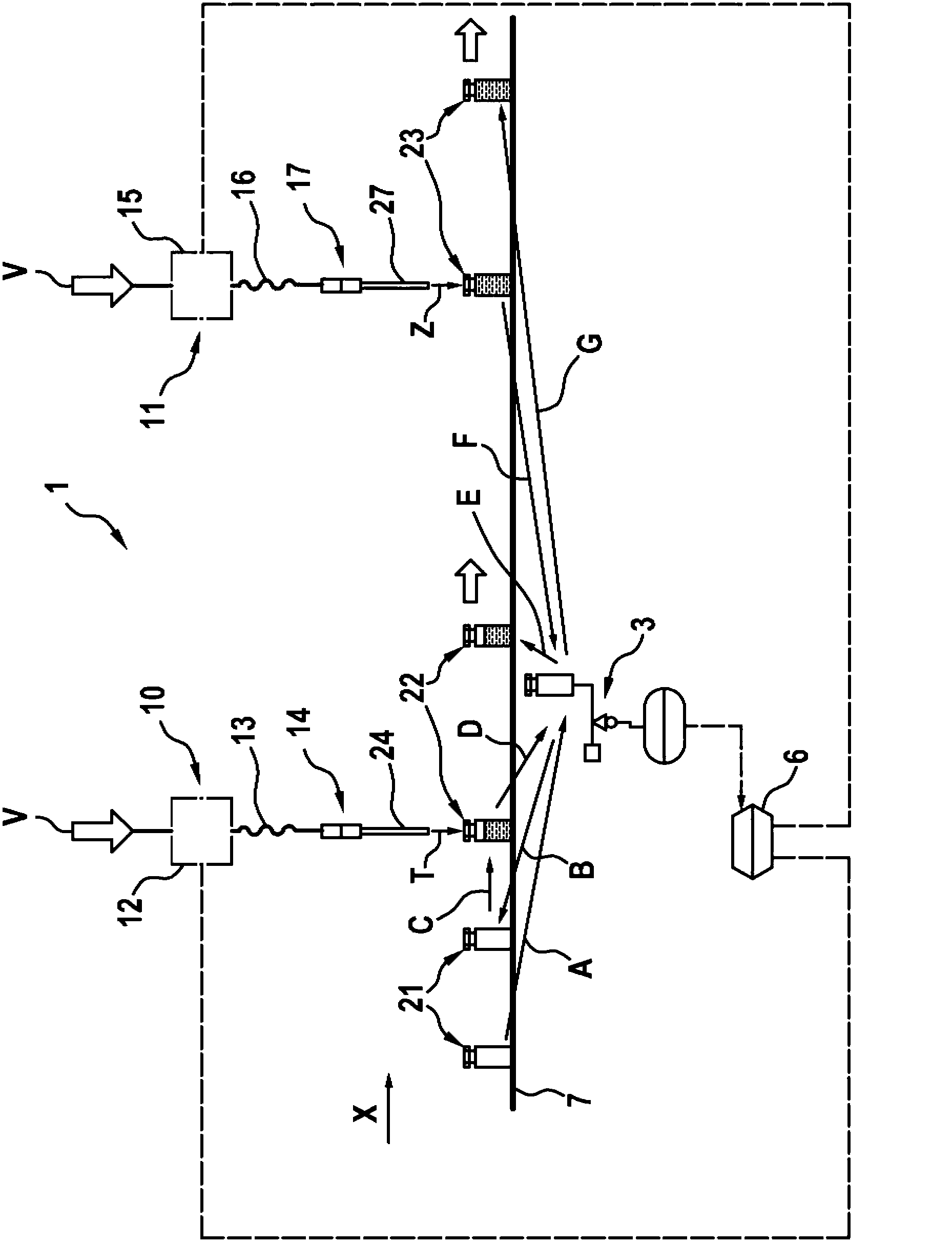

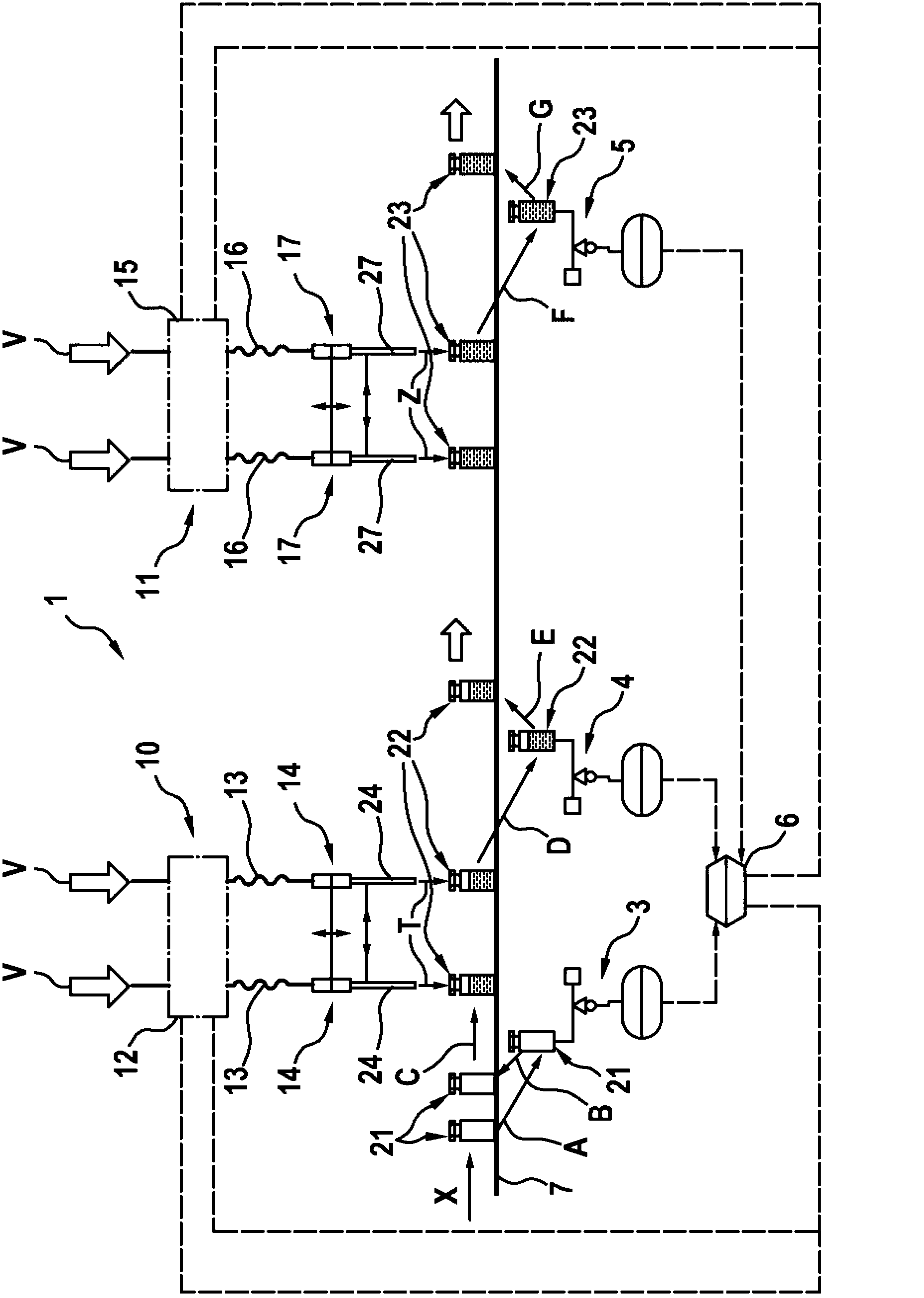

Filling device for filling a container

InactiveCN103189276AImprove productivityEnsuring process safetyLiquid materialEngineeringPartial filling

The invention relates to a filling device for filling a container, in particular with a pharmaceutical liquid, comprising a first filling unit (10), which carries out a partial filling of the container and only partially fills the container, a second filling unit (11), which carries out final filling of the container and completely fills the container, at least one scale (3), which weighs the empty container (21), the partially filled container (22) and the completely filled container (23), and a control unit (6), which is connected to the first filling unit (10), the second filling unit (11) and the scale (3) and is designed to control the first and second filling units (10, 11) on the basis of the values of the weighing processes determined by the scale (3).

Owner:ROBERT BOSCH GMBH

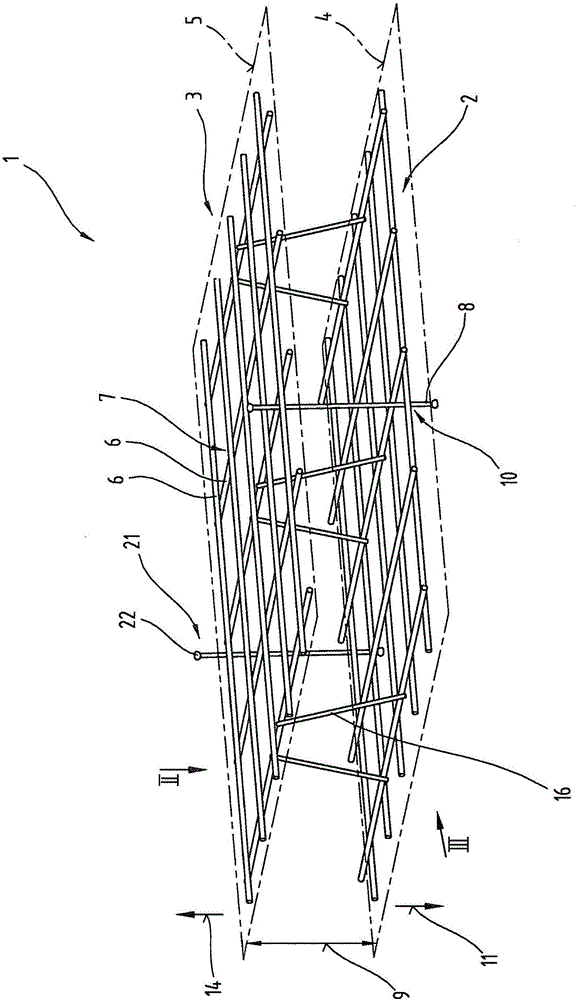

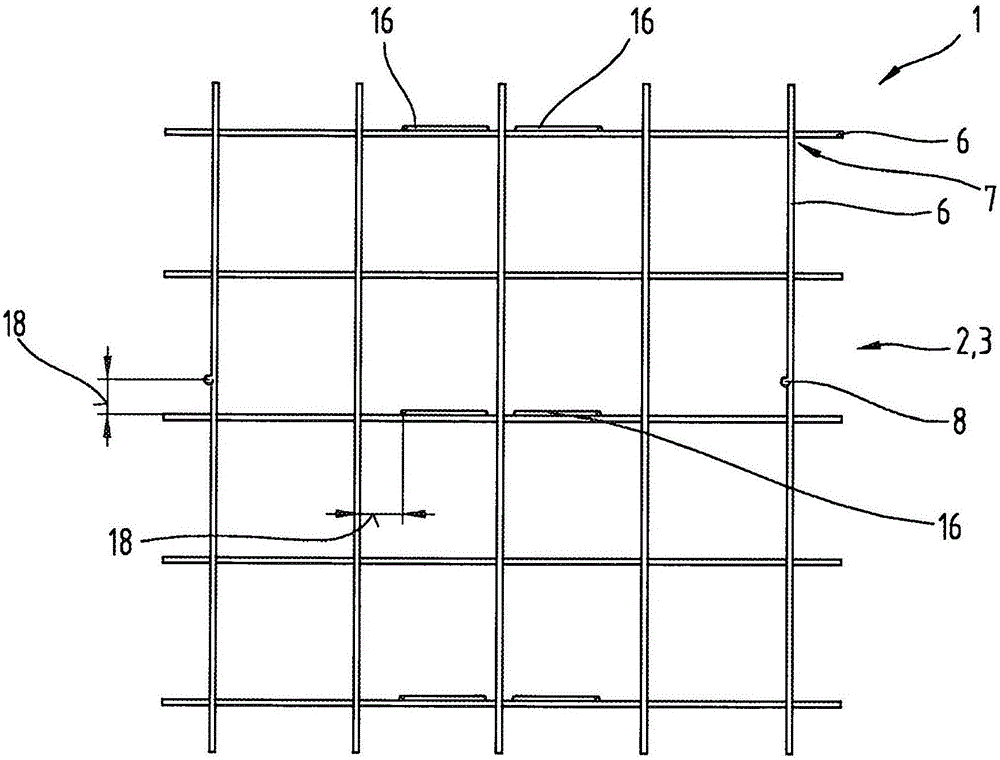

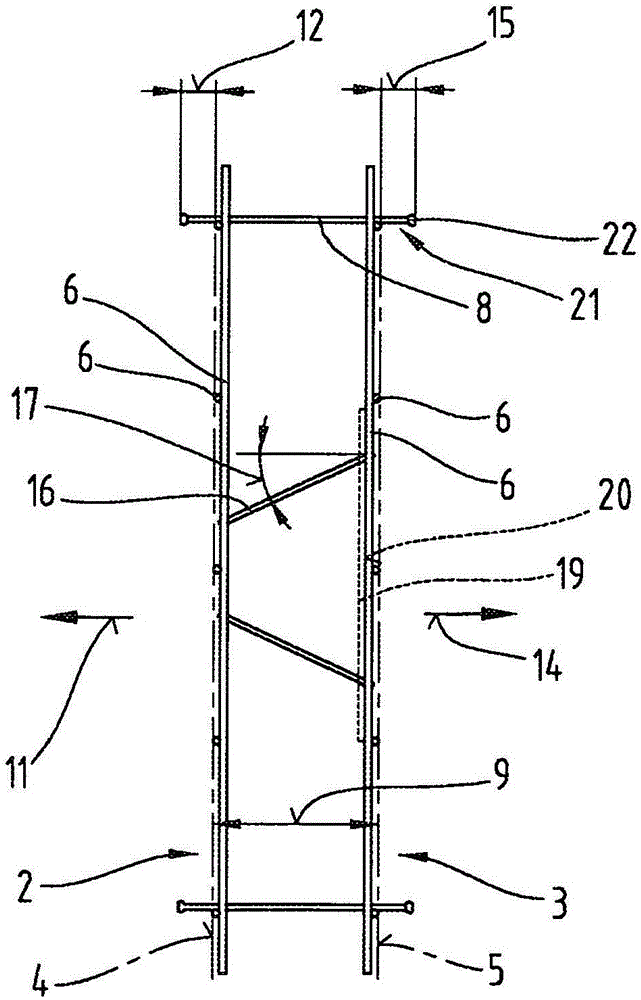

Reinforcing element and method for producing a reinforcing element

InactiveCN106794596AReduce weightEasy to manufactureConstruction materialWallsElectrical resistance and conductanceDouble wall

The invention relates to a reinforcing element (1), comprising a first reinforcing mat (2) and a second reinforcing mat (3) having metal mat rods (6), which are welded at angles to each other at junction points (7), which reinforcing mats (2, 3) are held spaced apart from each other at a normal distance (9) by rod-shaped spacers (8) with respect to the first mat plane (4) and the second mat plane (5) of the reinforcing mats. The spacers (8) are metal and are permanently connected to individual mat rods (6) of the first reinforcing mat (2) and of the second reinforcing mat (3) by welding connections (10), preferably resistance welding connections, wherein at least individual spacers (8) protrude outward at least beyond the first mat plane (4) of the first reinforcing mat (2) in a direction (11) pointing away from the second reinforcing mat (3) by a first protrusion length. The invention further relates to a double wall equipped with the reinforcing element and to methods for producing the reinforcing element and the double wall.

Owner:胡贝特拉佩斯托费尔

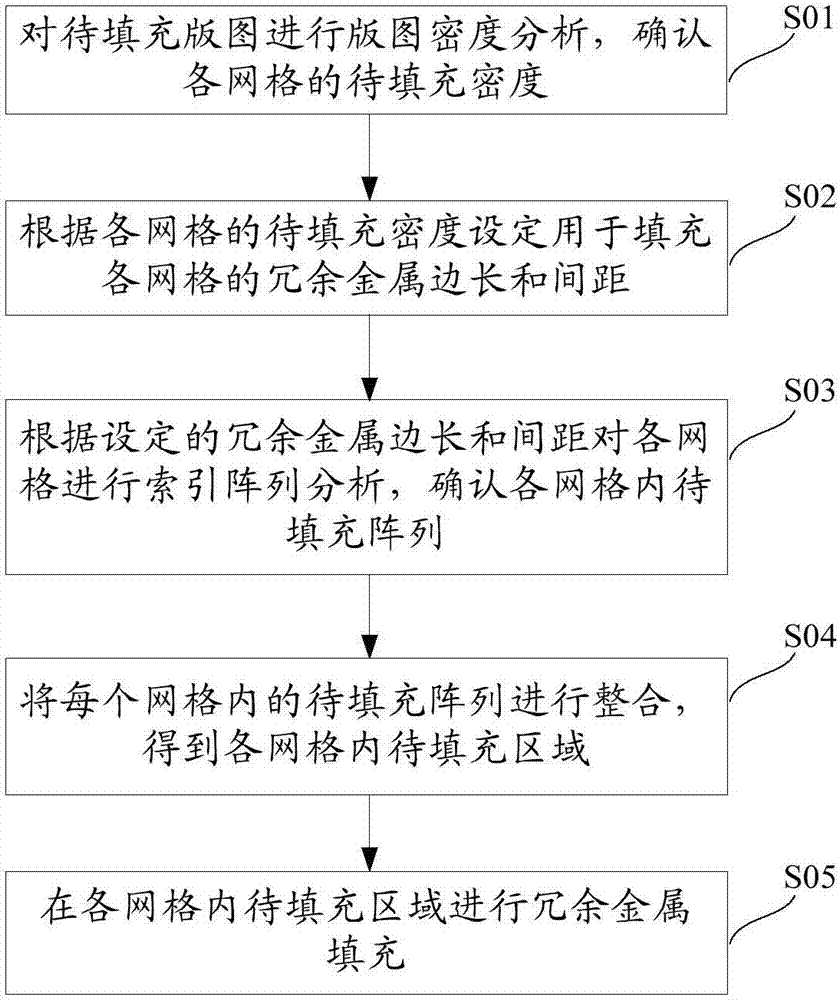

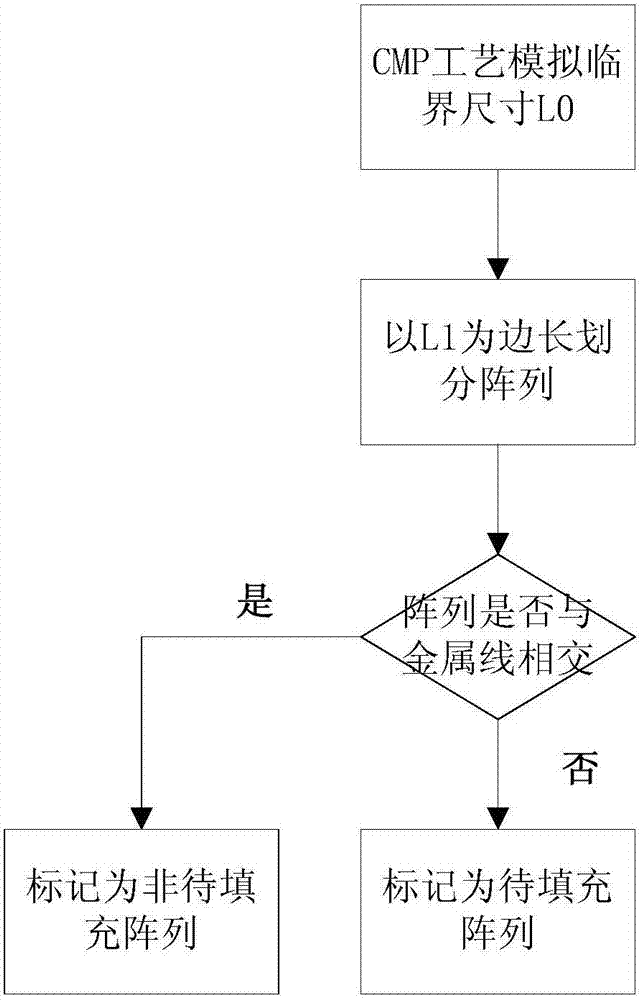

Dummy fill method and system

ActiveCN107153719AFast fillAvoid the phenomenon of missing fillingDesign optimisation/simulationSpecial data processing applicationsStructural engineeringMechanical engineering

The invention provides a dummy fill method and system. The method includes the steps that layout density analysis is conducted on a to-be-filled layout, and the fill density of grids is determined; the side length and spacing of dummy metal for filling the grids are set according to the fill density of the grids; index array analysis is conducted on the grids according to the set side length and spacing of the dummy metal, and to-be-filled arrays in the grids are determined; the to-be-filled arrays in the grids are integrated to obtain to-be-filled areas in the grids; dummy fill is conducted on the to-be-filled areas in the grids. Due to the fact that index array analysis is conducted on the grids according to the set side length and spacing of the dummy metal and the to-be-filled arrays are integrated to obtain the to-be-filled areas, dummy fill can be rapidly completed without fill omission.

Owner:INST OF MICROELECTRONICS CHINESE ACAD OF SCI

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com