Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

638 results about "EMPTY CONTAINER" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

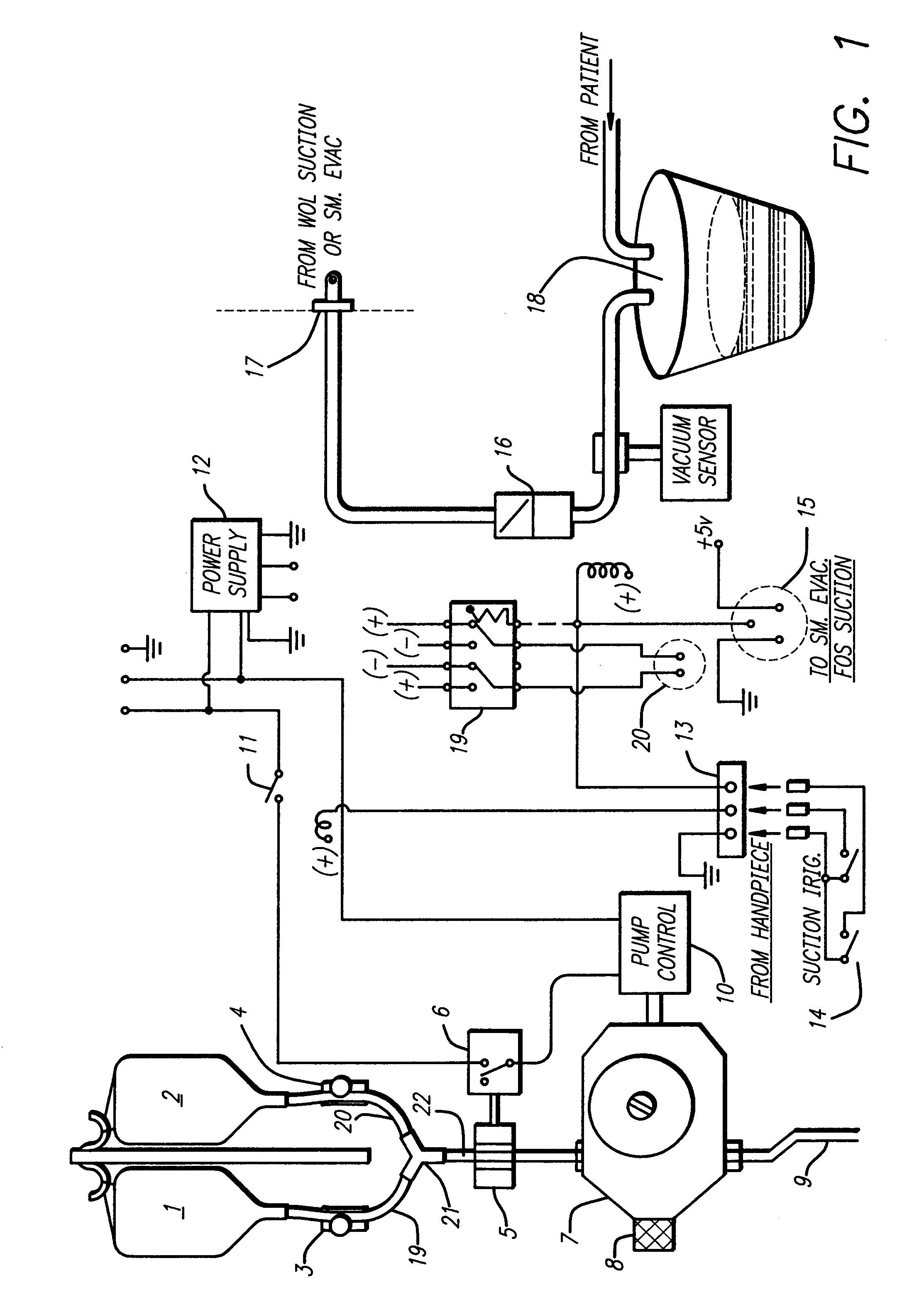

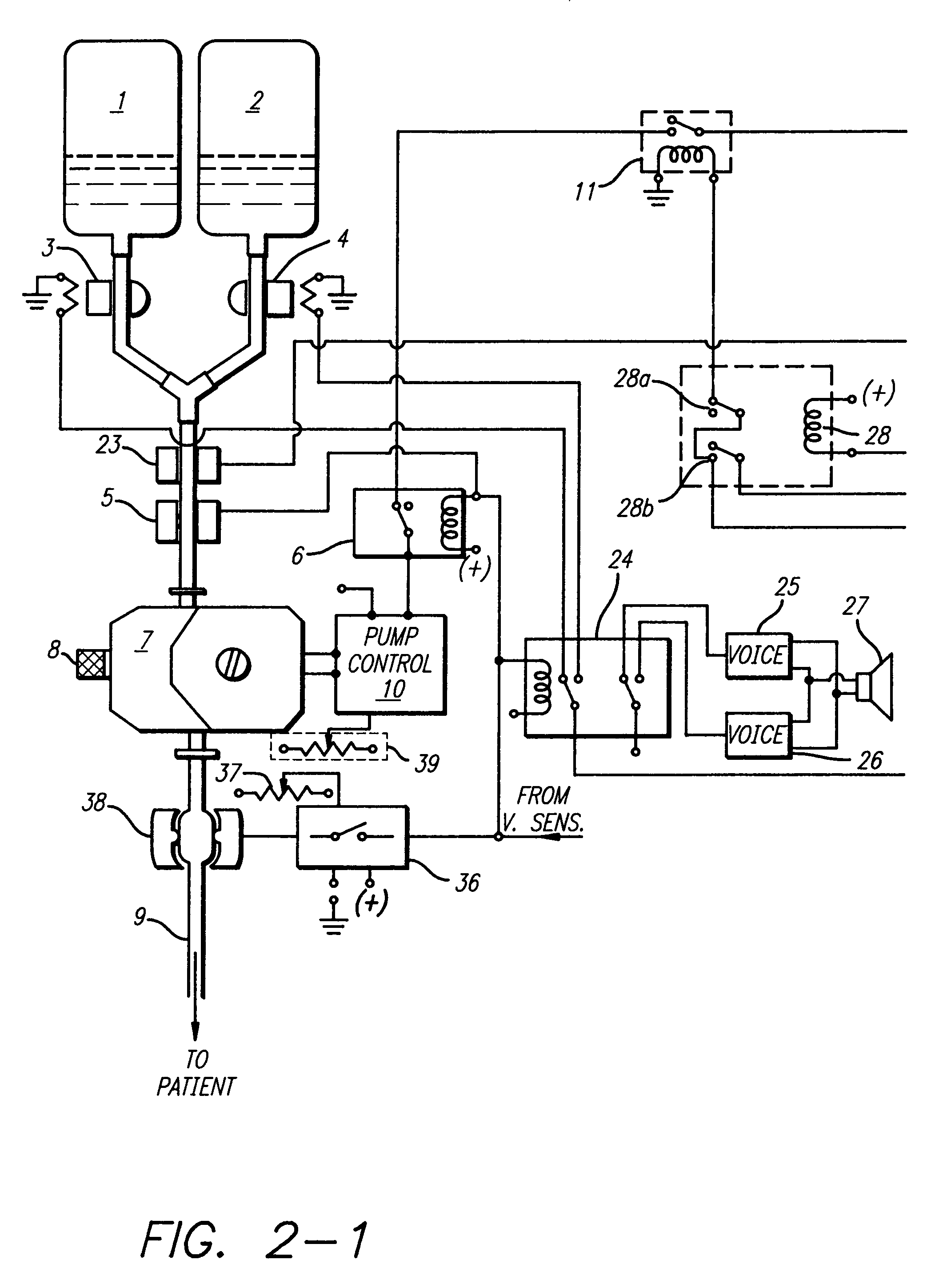

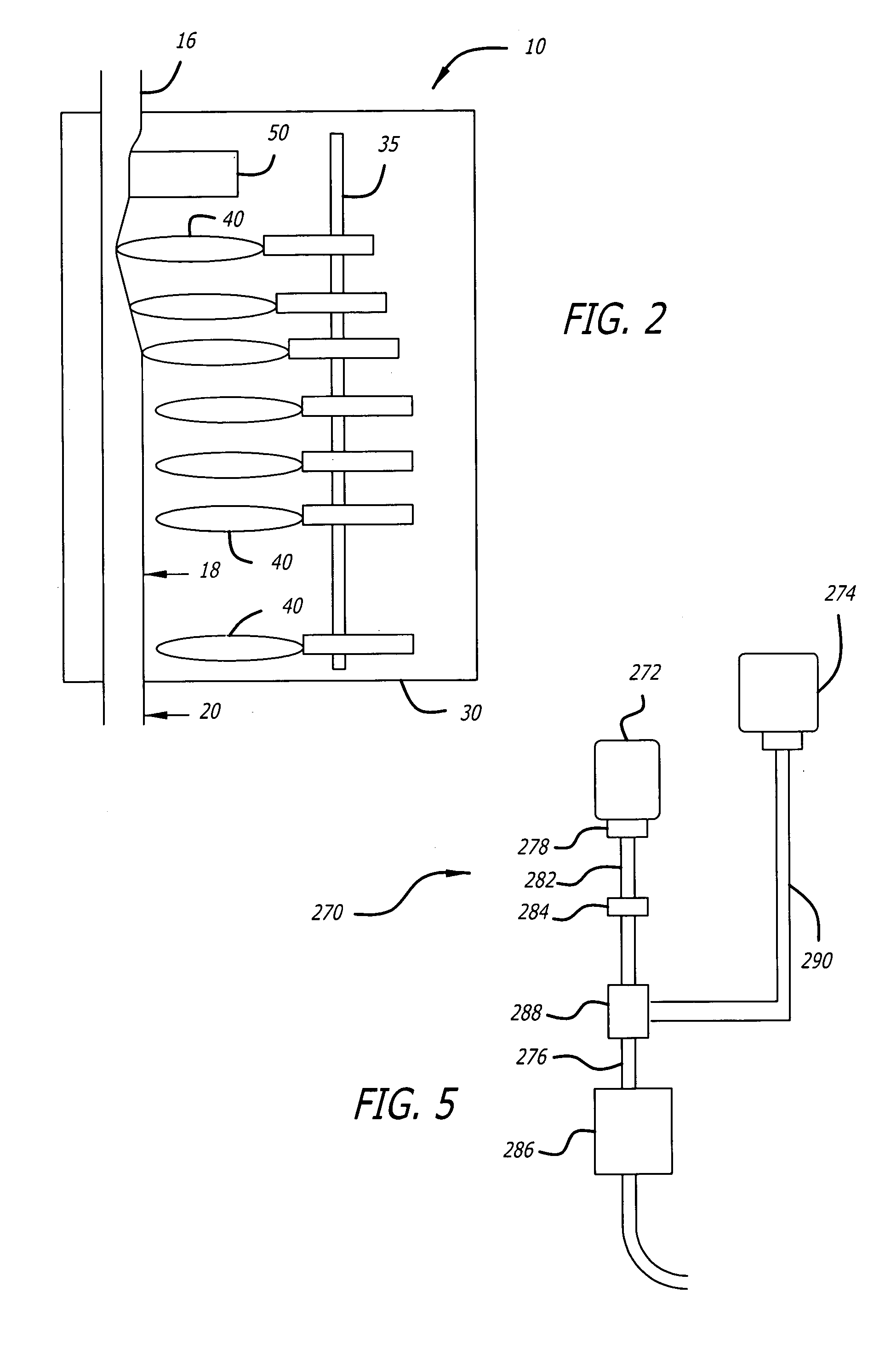

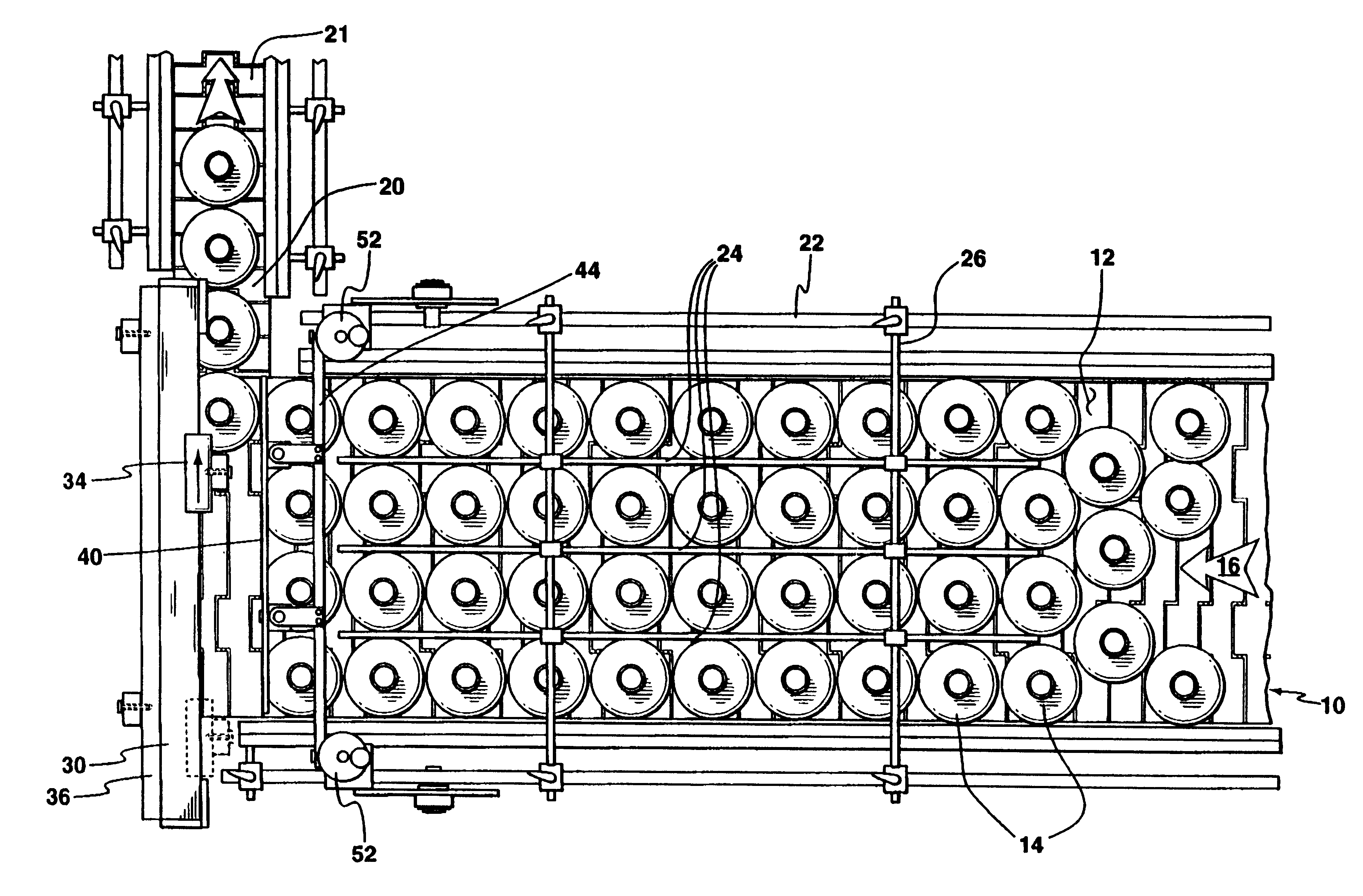

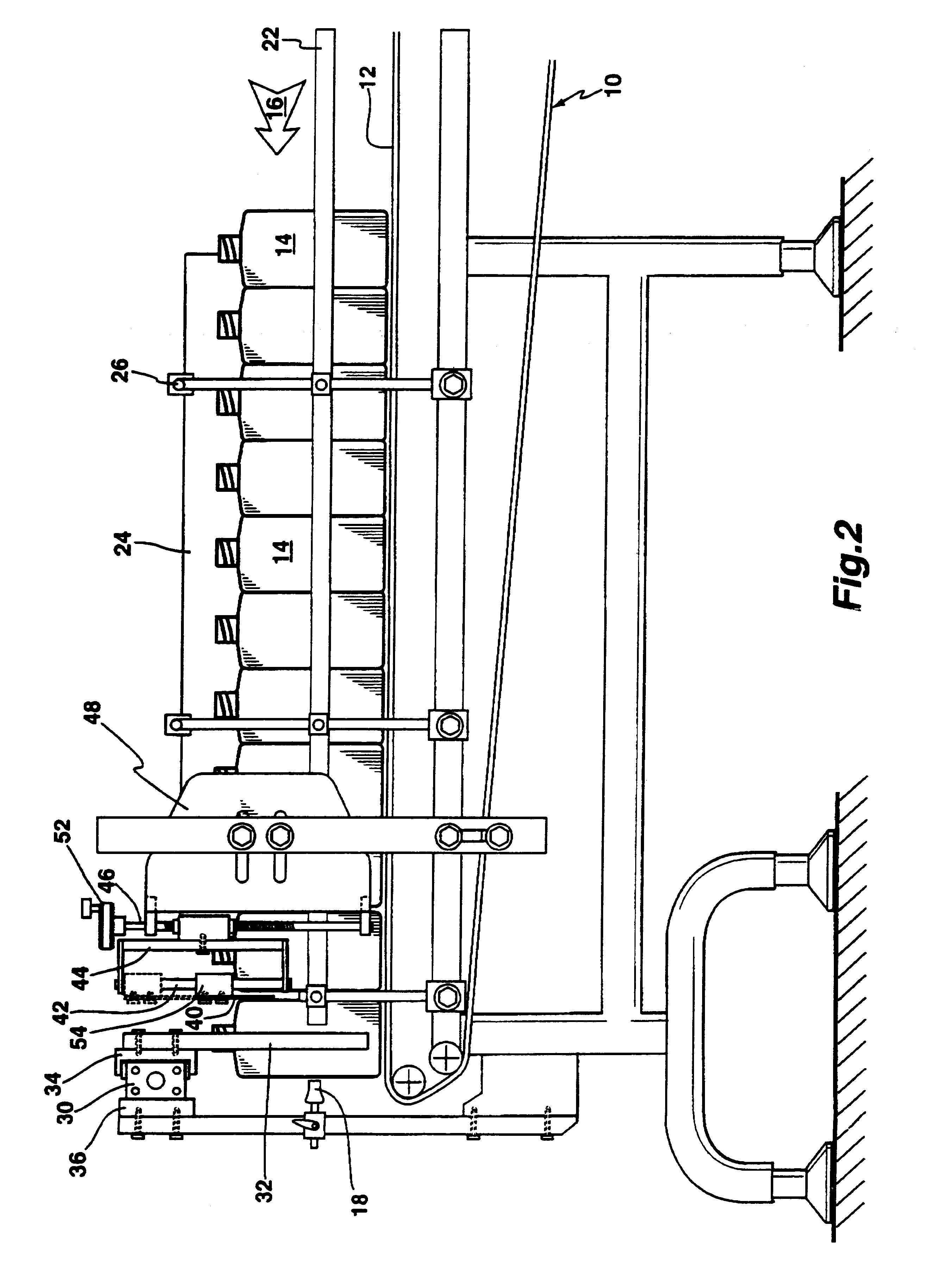

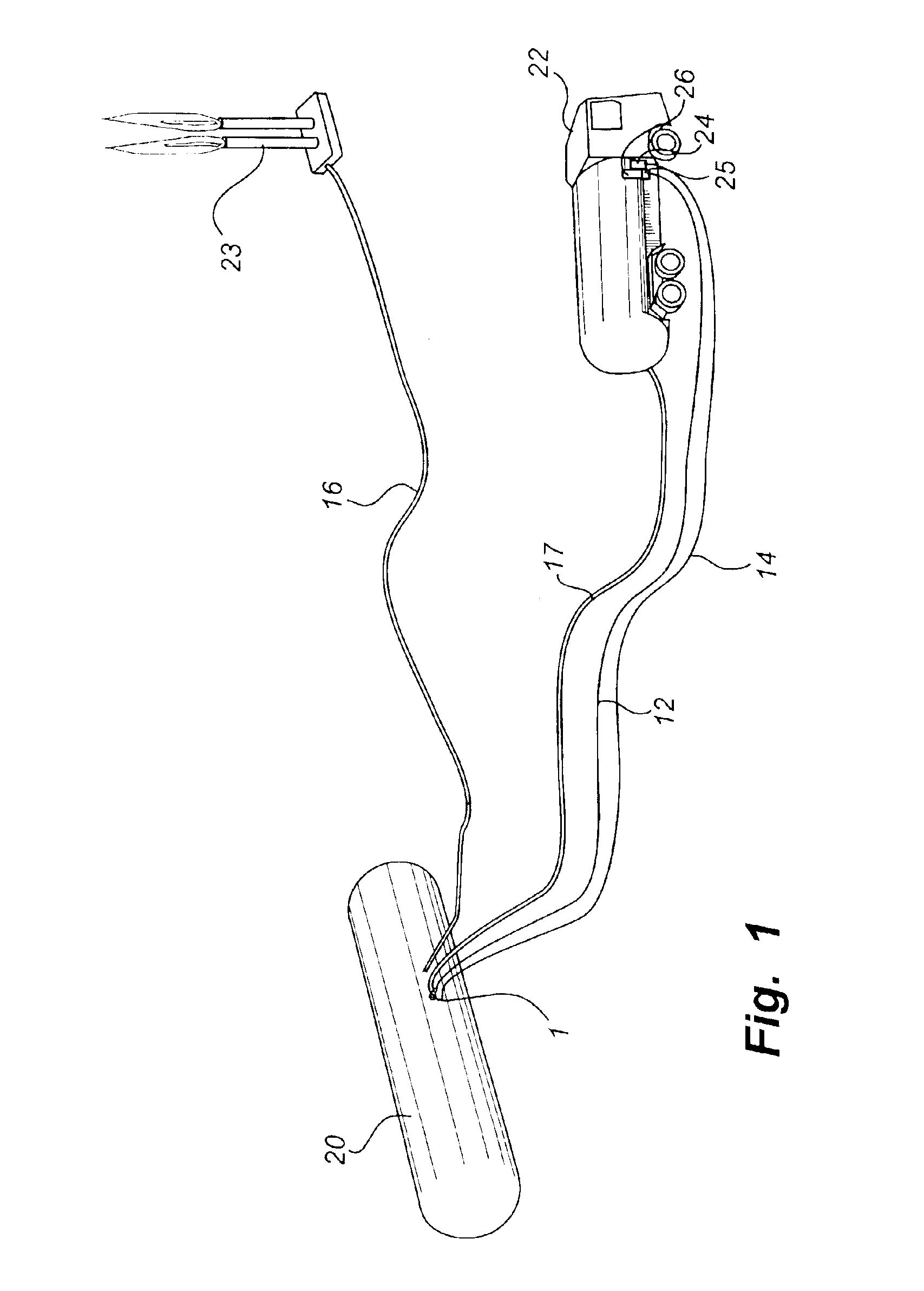

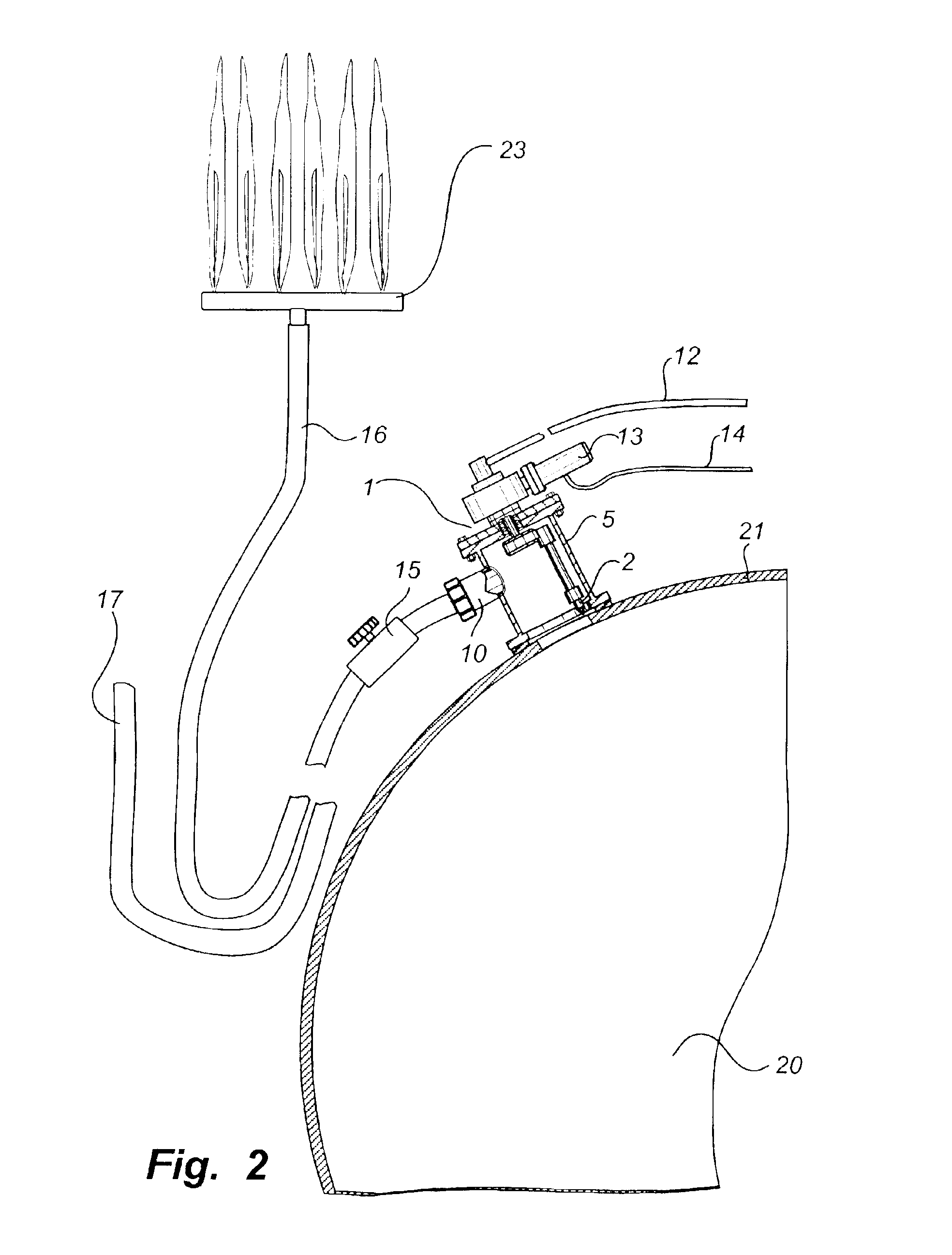

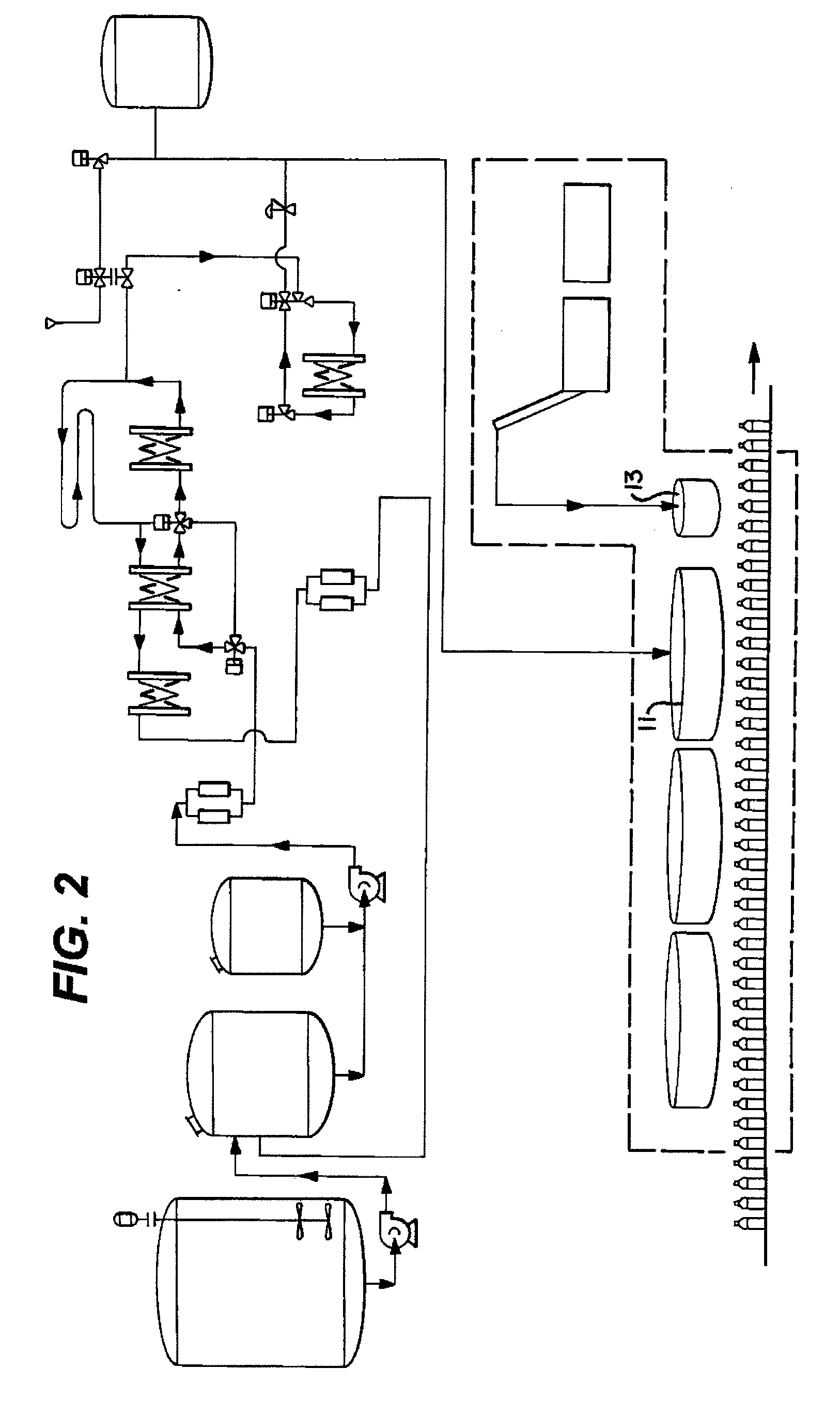

Automatic fluid control system for use in open and laparoscopic laser surgery and electrosurgery and method therefor

InactiveUS7083601B1Increase pressureImprove liquidityEnemata/irrigatorsChiropractic devicesAutomatic controlFluid control

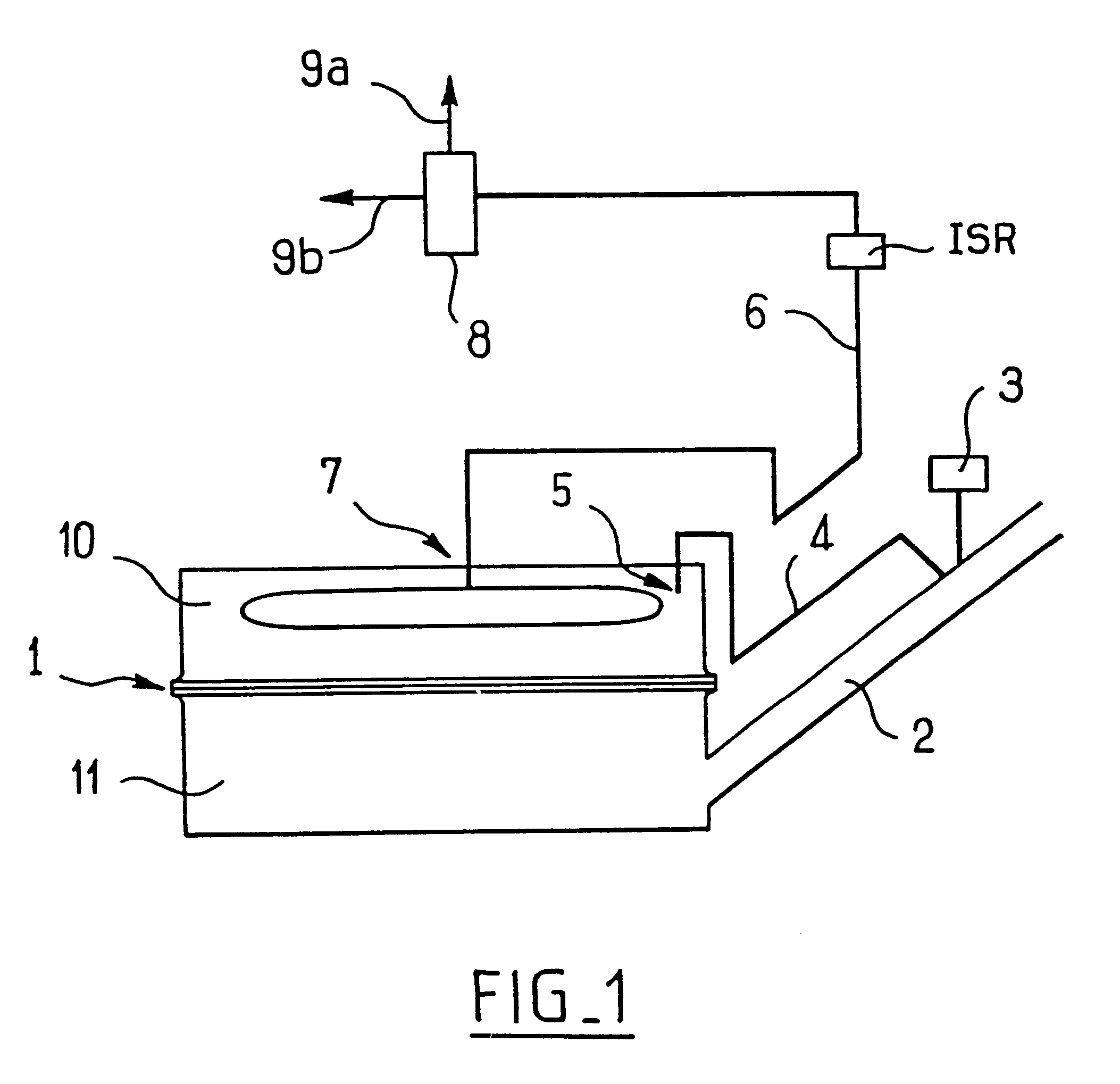

A manual and automatic fluid control system and method for use in open and laparoscopic laser surgery and electrosurgery is disclosed. The system includes a manual mode along with several automatic modes which can effectuate both suction and irrigation, either individually or simultaneously. In the various automatic modes, the suction and / or irrigation is automatically activated during activation of a medical apparatus for laser surgery or electrosurgery without requiring separate activation from the surgeon or operating room staff. Several safety features for monitoring the fluid control system are also incorporated within the system such as fluid sensors for detecting the absence of irrigation fluid, pressure sensors and vacuum systems for monitoring fluid pressure, fluid sensors for monitoring fluid volume, and warning signals for detecting empty containers. All of the safety features are designed to automatically deactivate suction and / or irrigation means contained within the fluid control system upon detection of unsafe levels. Finally, specially designed suction / irrigation hand pieces are disclosed for use in connection with the fluid control system.

Owner:IC MEDICAL

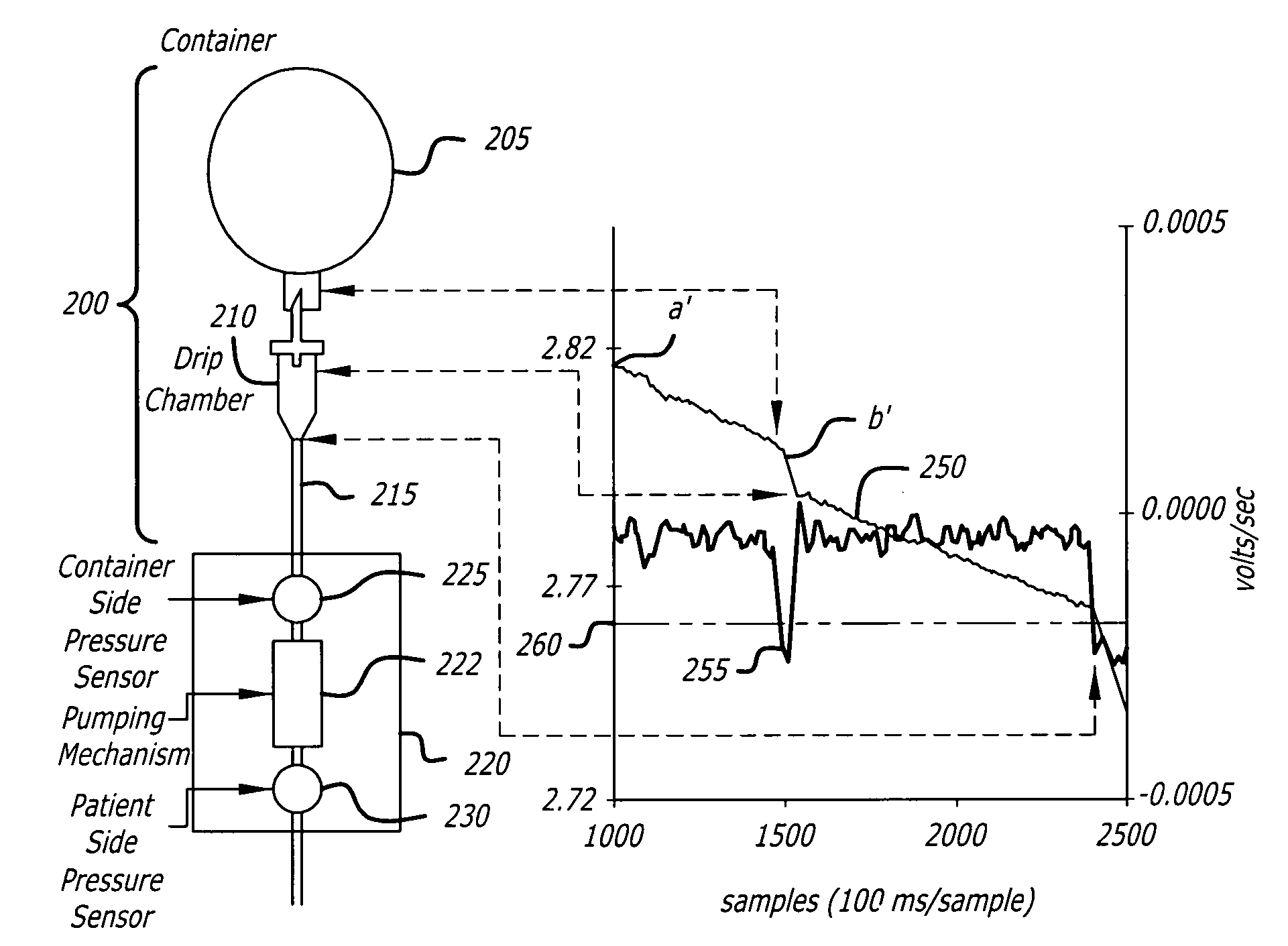

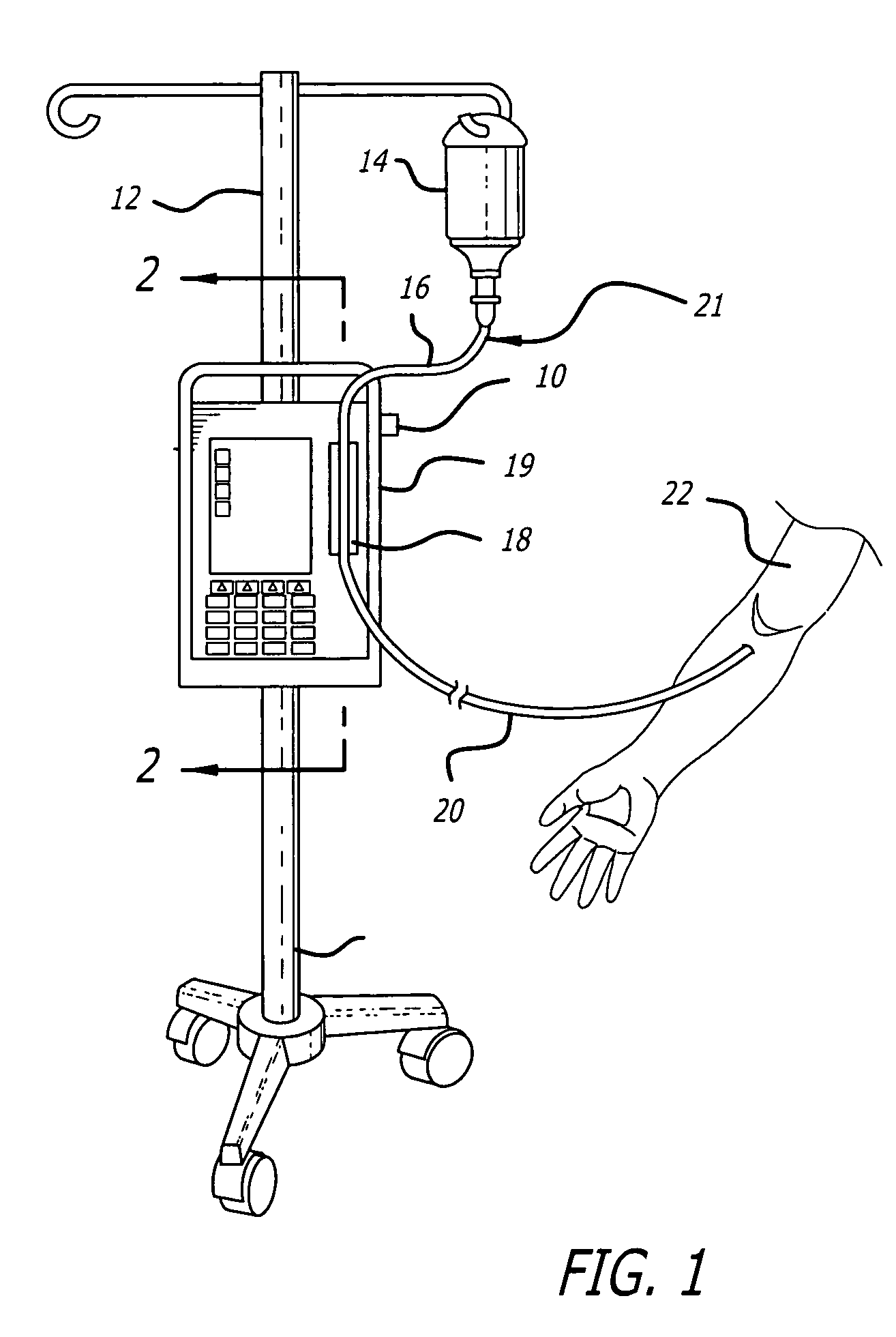

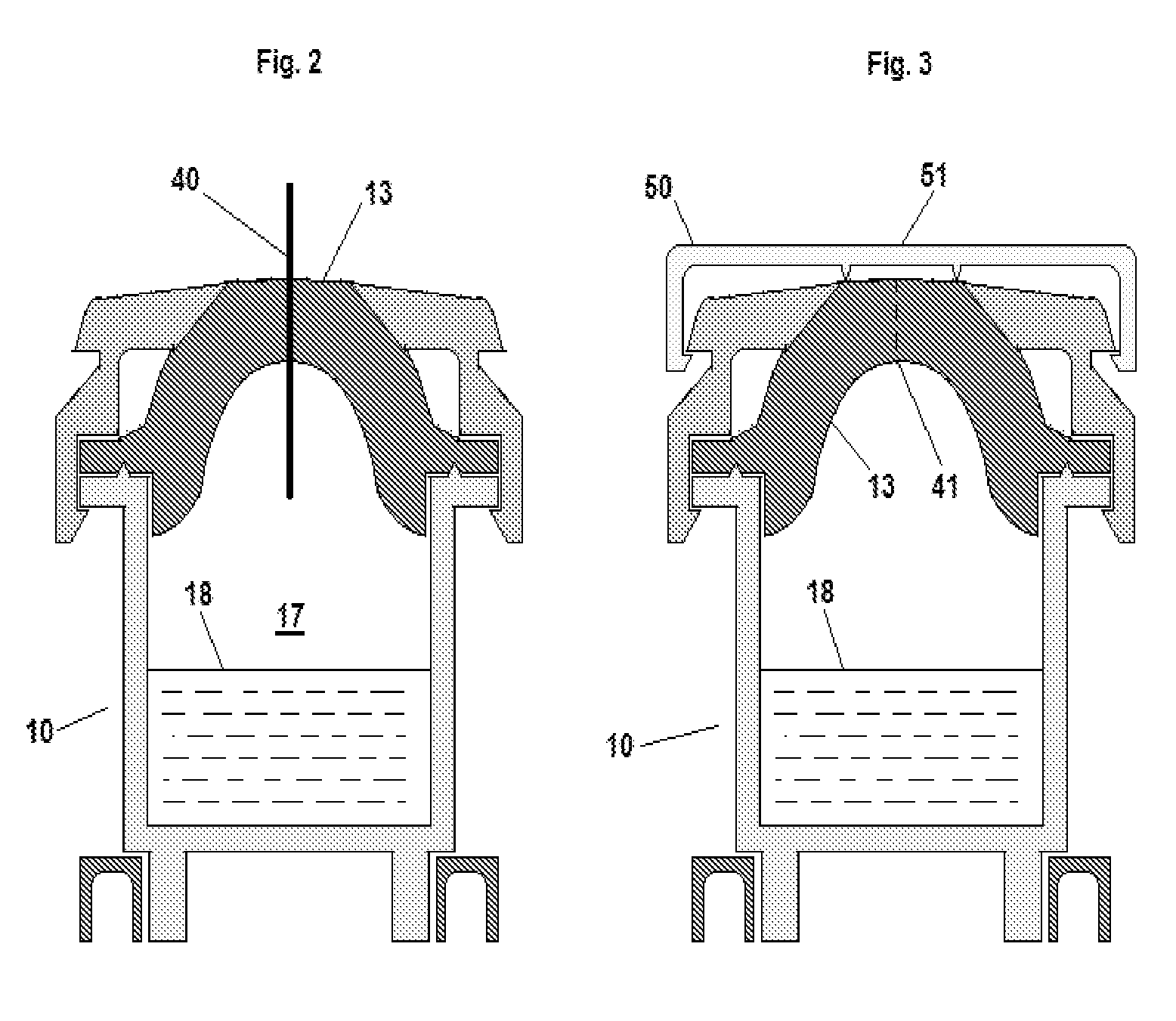

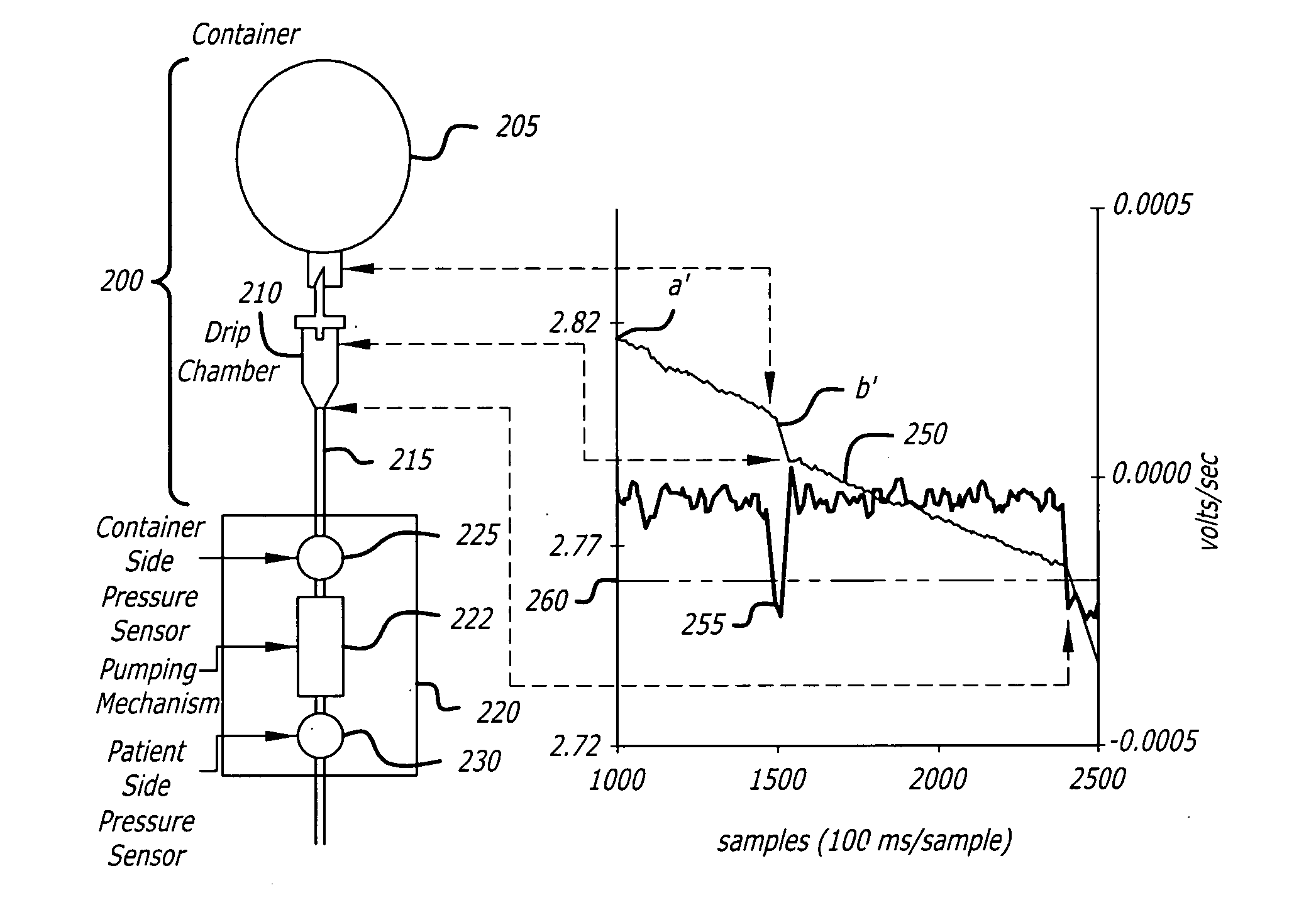

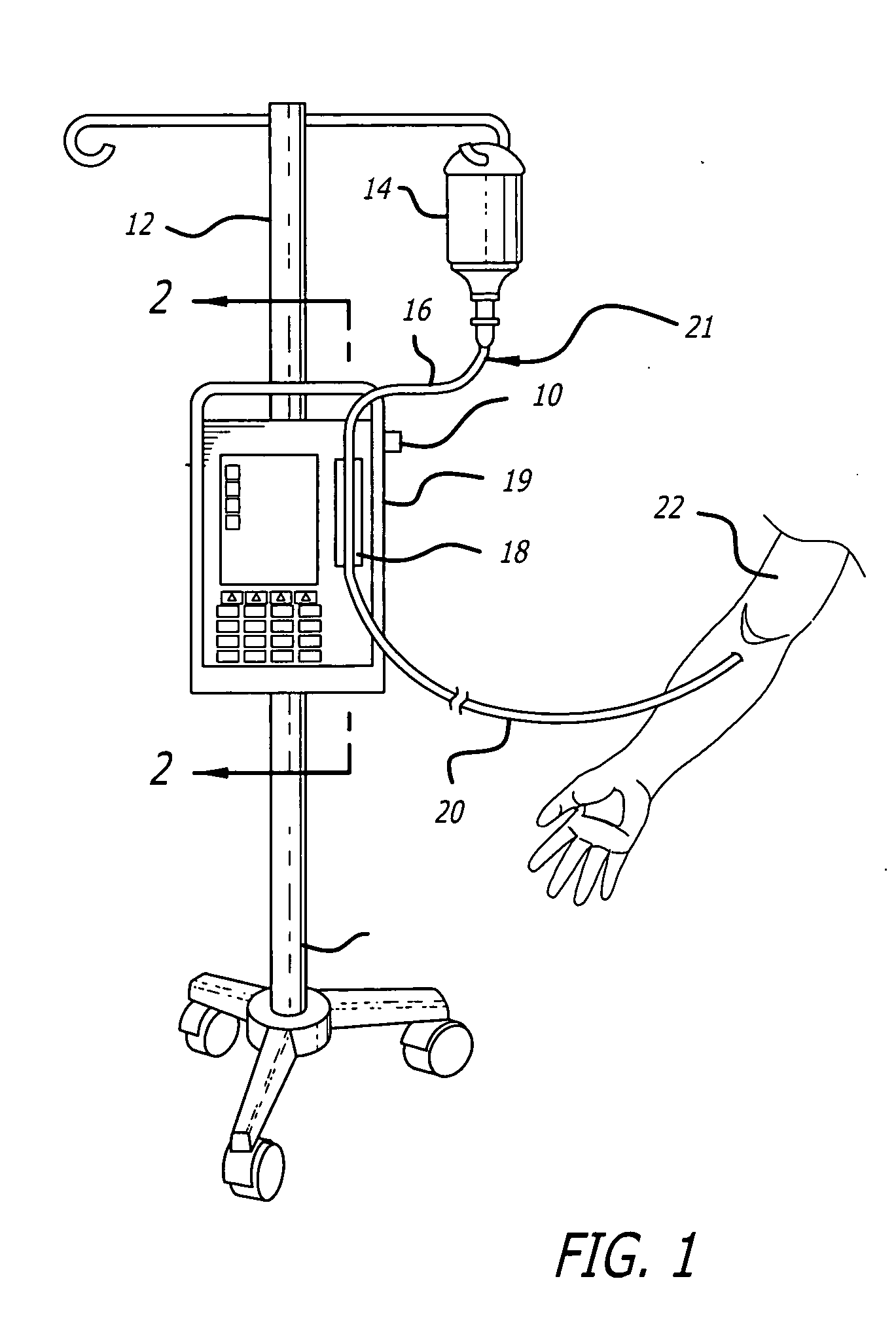

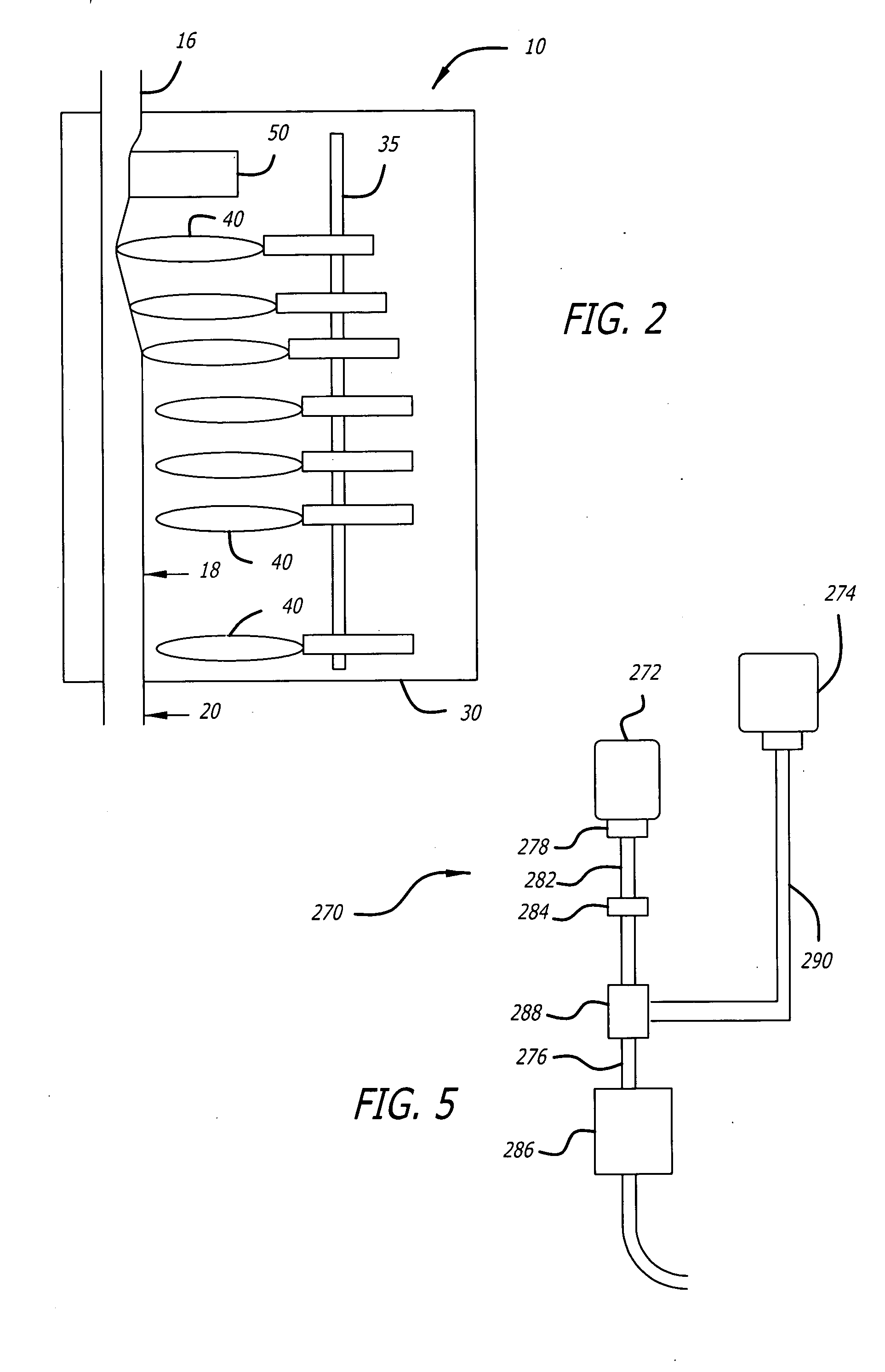

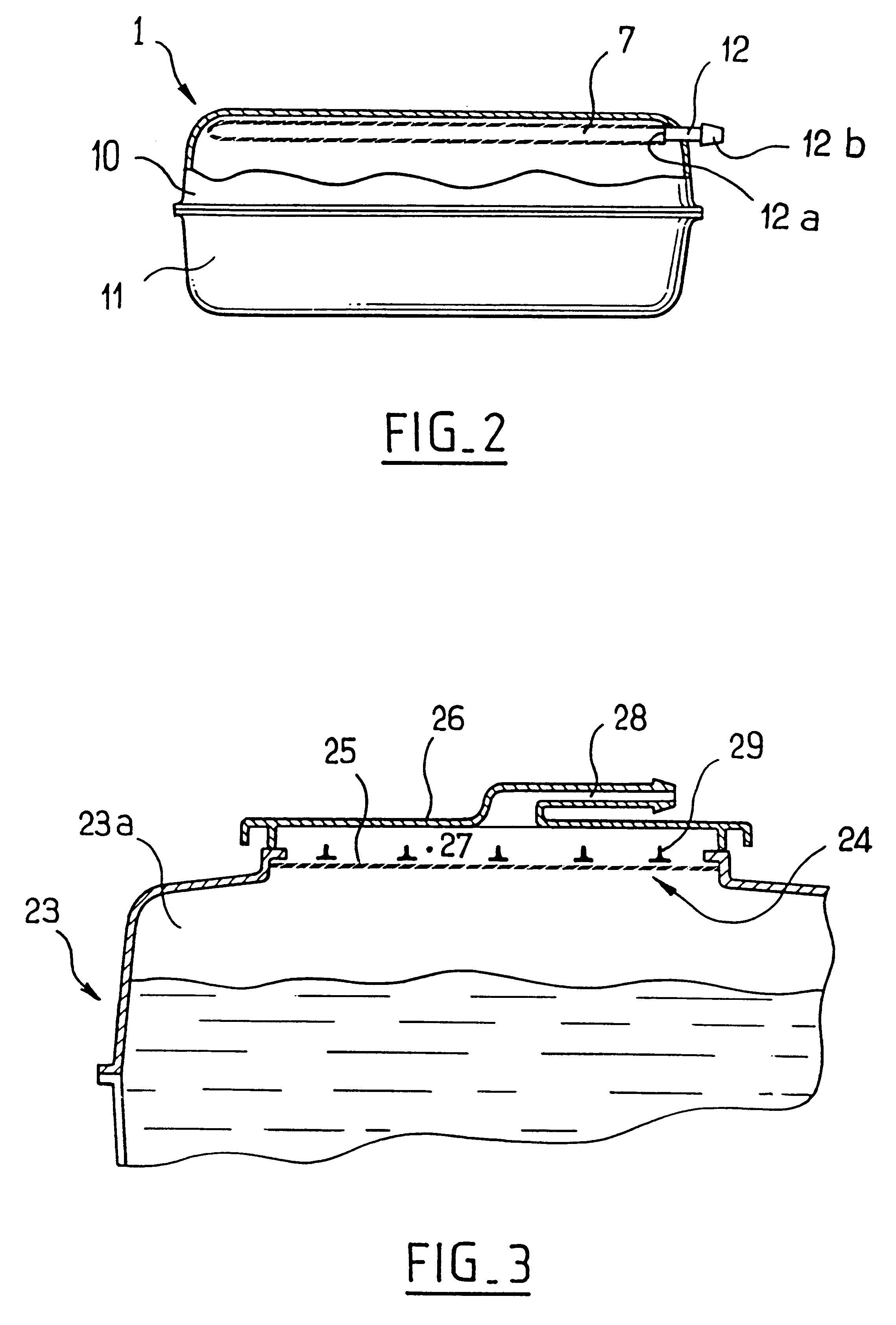

Empty container detection using container side pressure sensing

ActiveUS7206715B2Inflated body pressure measurementFluid pressure measurement by electric/magnetic elementsEngineeringInfusion pump

A system and method for monitoring changes in the pressure of a fluid line upstream of an infusion pump to determine when a fluid container has emptied, and to provide a signal indicating that the container needs replacement or replenishment. The difference between averaged pressures over separate time periods is monitored to determine when the fluid container is empty. The system and method are applicable to primary and secondary fluid container setups and can detect the point where the secondary has been emptied and the primary flow has resumed.

Owner:CAREFUSION 303 INC

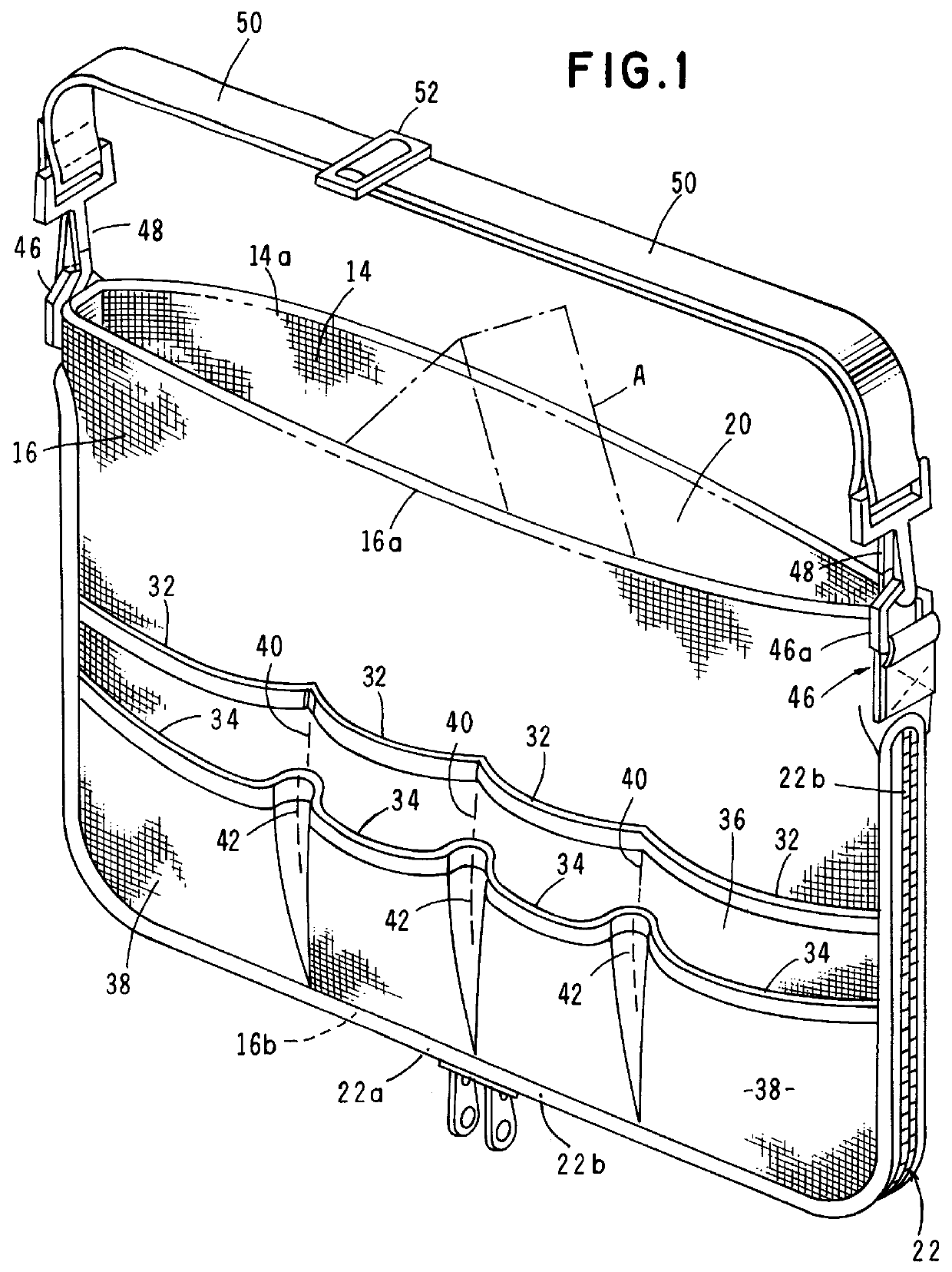

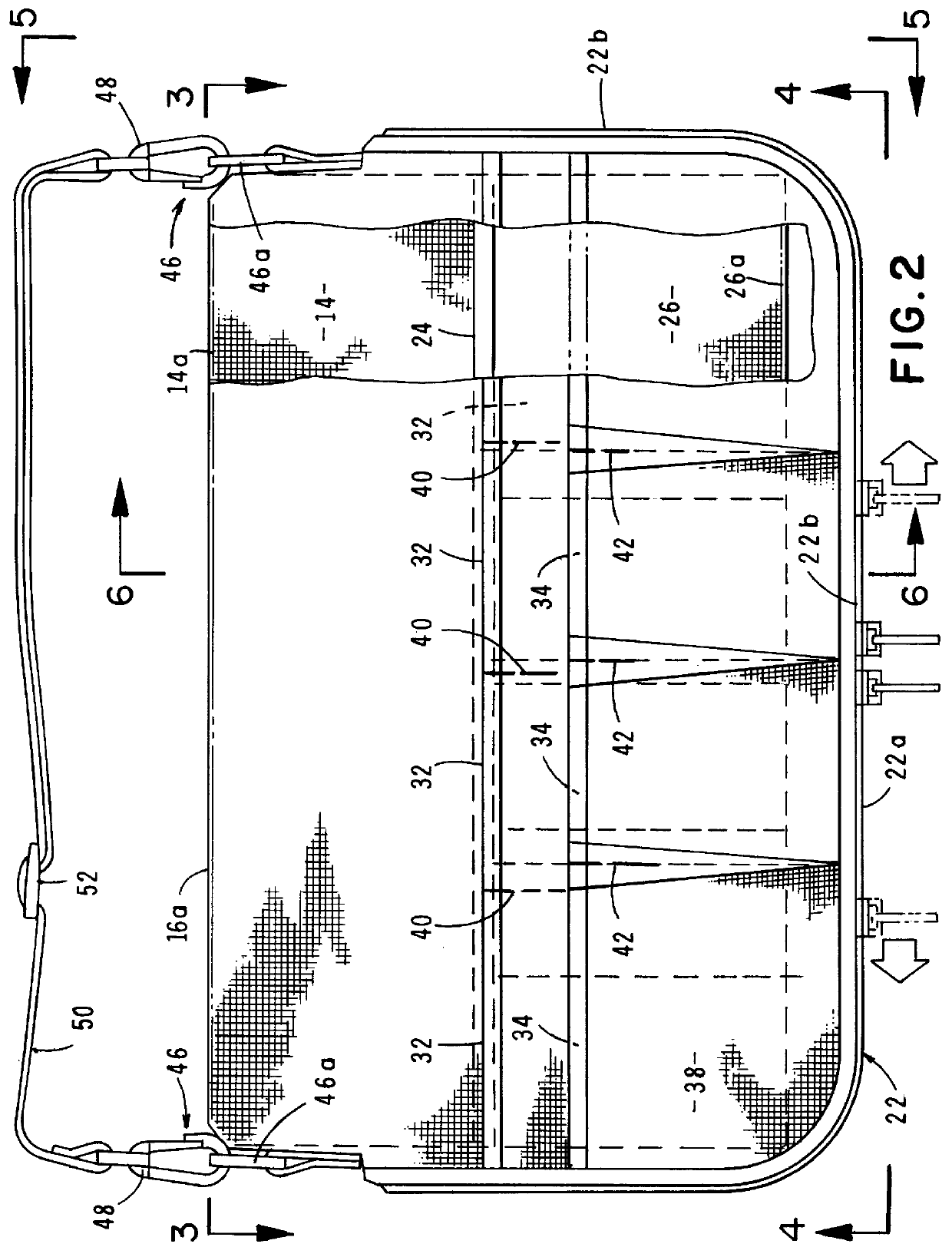

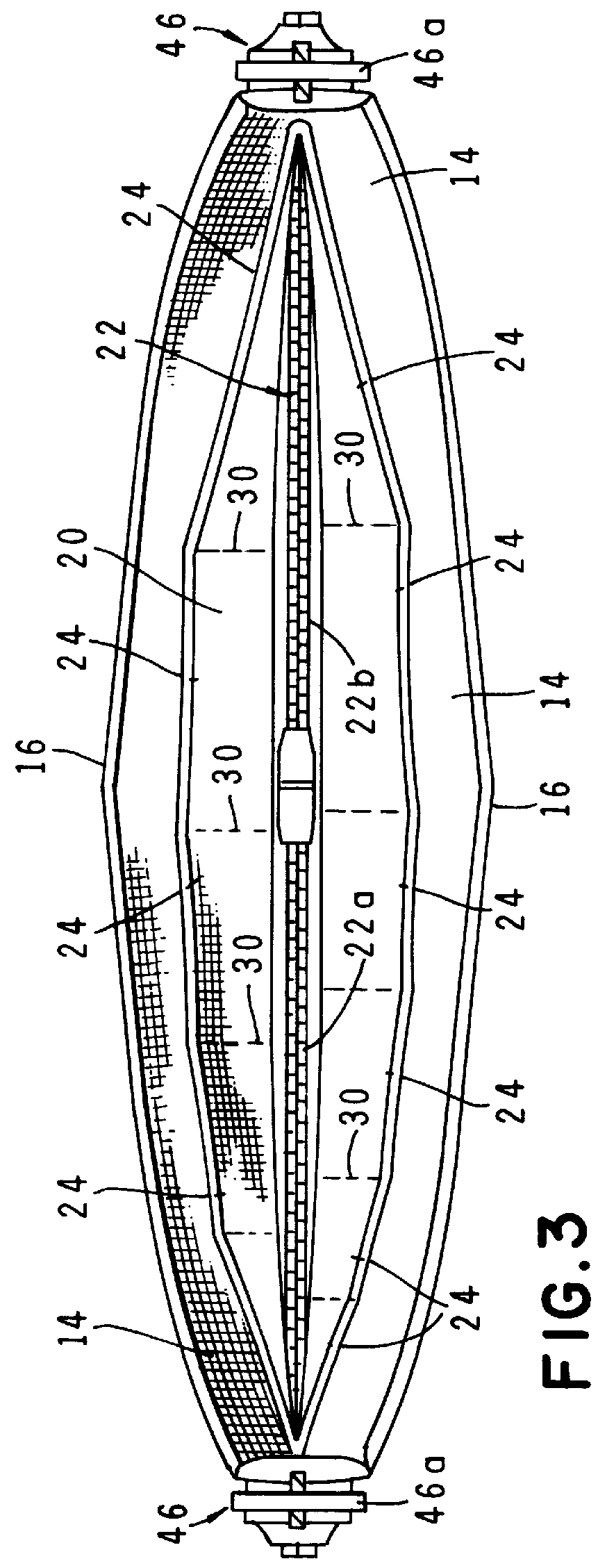

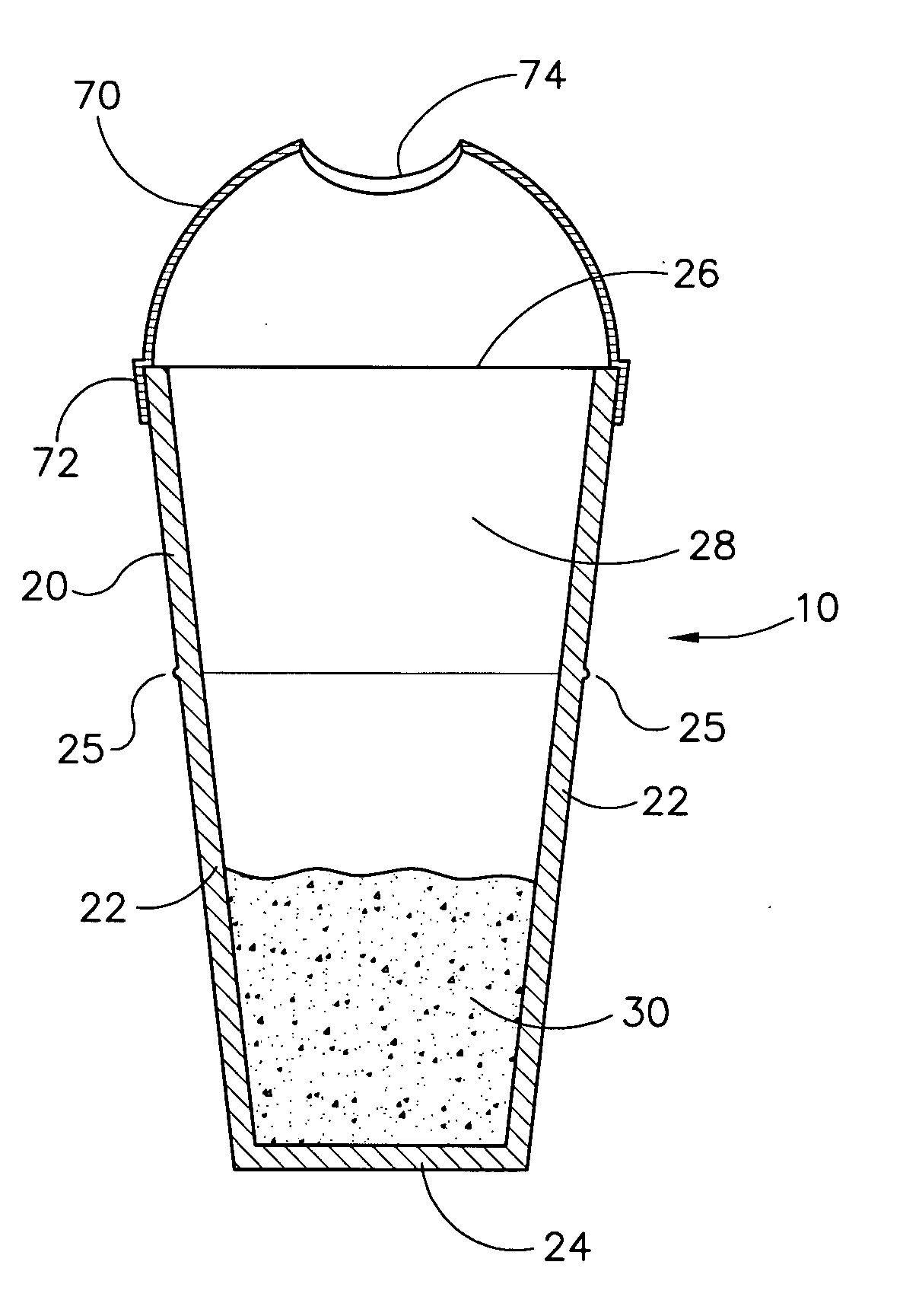

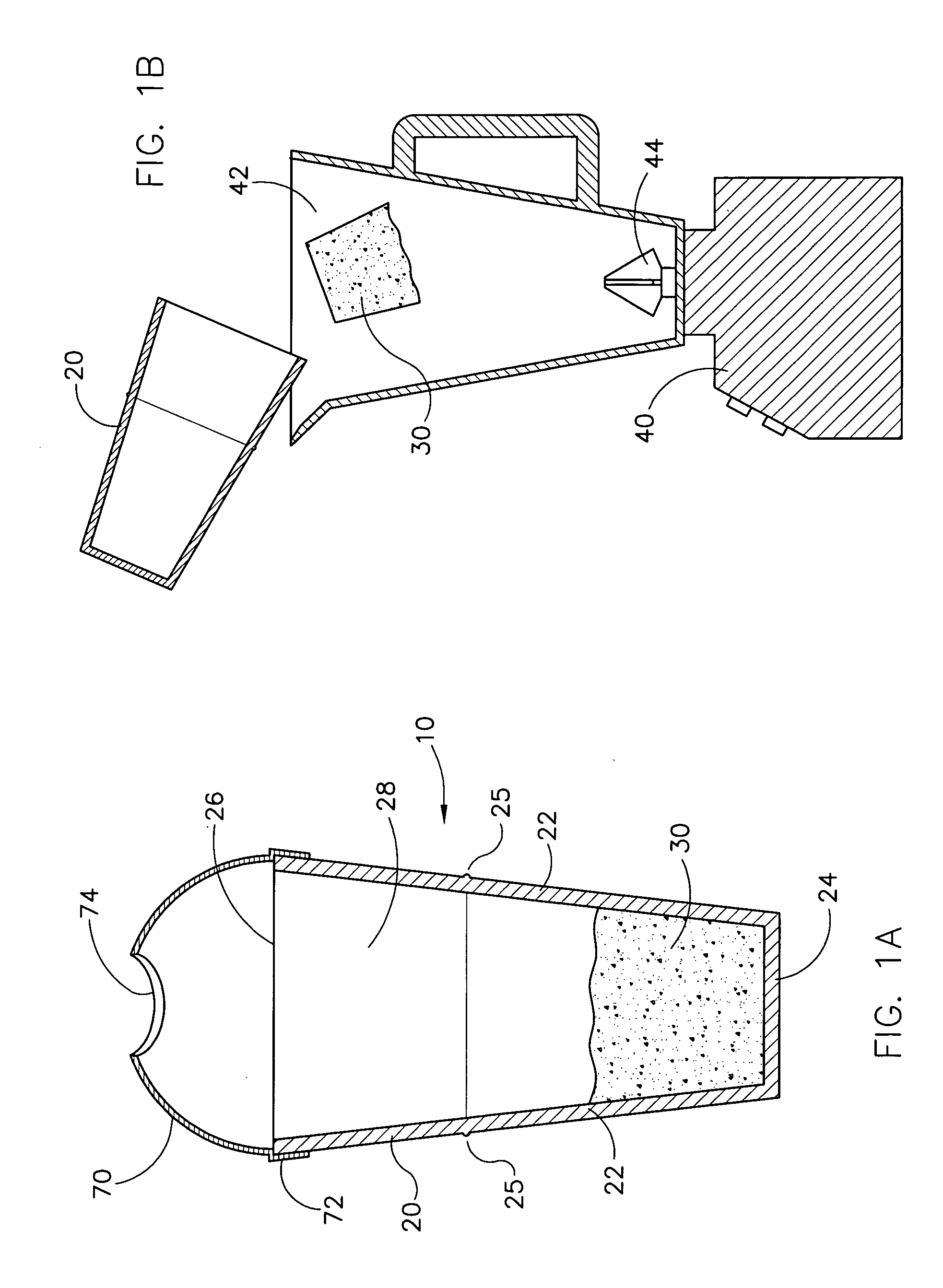

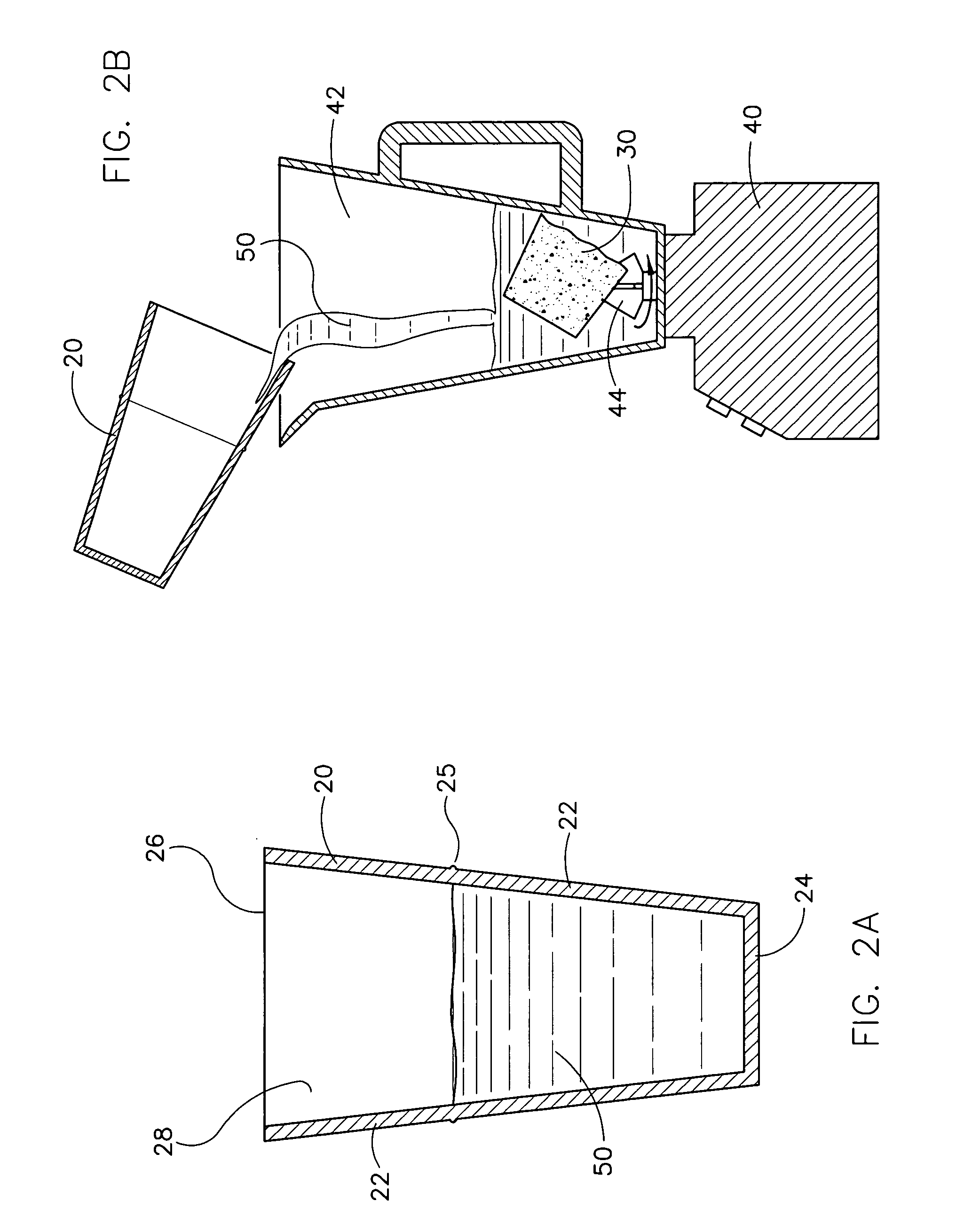

Article transport and organizer

An article transport and organizer which can conveniently be used either as a tote bag for transport and storage of small articles or alternatively can be used in connection with an empty container such as a five-gallon bucket for the transport and storage of larger articles as well as for the transport of smaller articles and tools. The apparatus includes a removable shoulder strap that can be used to conveniently transport the apparatus when it is being used as a tote bag. The inner and outer skirt-like walls of the apparatus are provided with a plurality of spaced-apart pockets which are adapted to receive and organize hand tools and other small articles. Easy-to-operate zipper mechanisms are provided for interconnecting together the lower margins of the outer skirt-like walls so as to convert the apparatus from a bucket organizer into a tote bag.

Owner:R D S IND

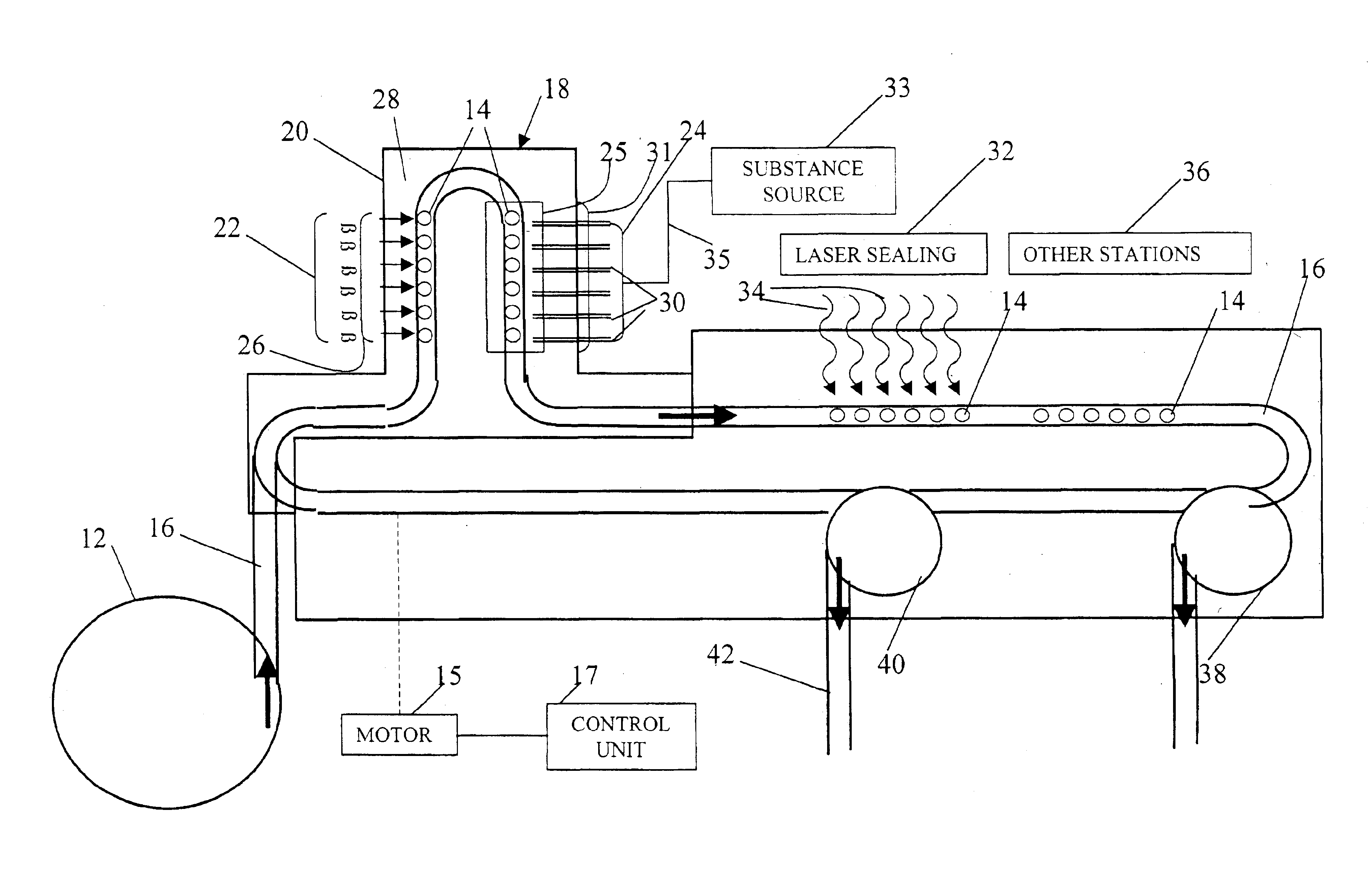

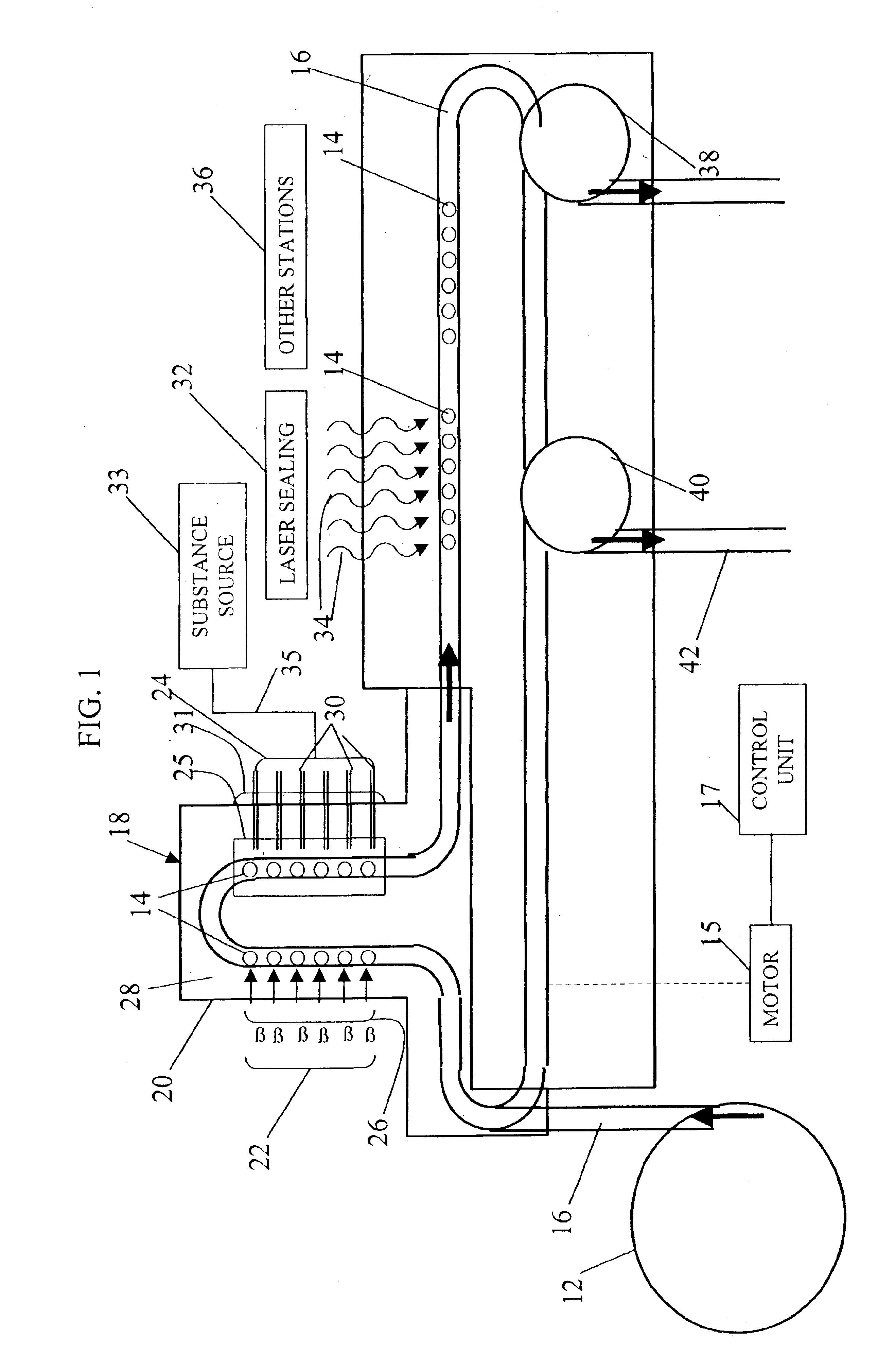

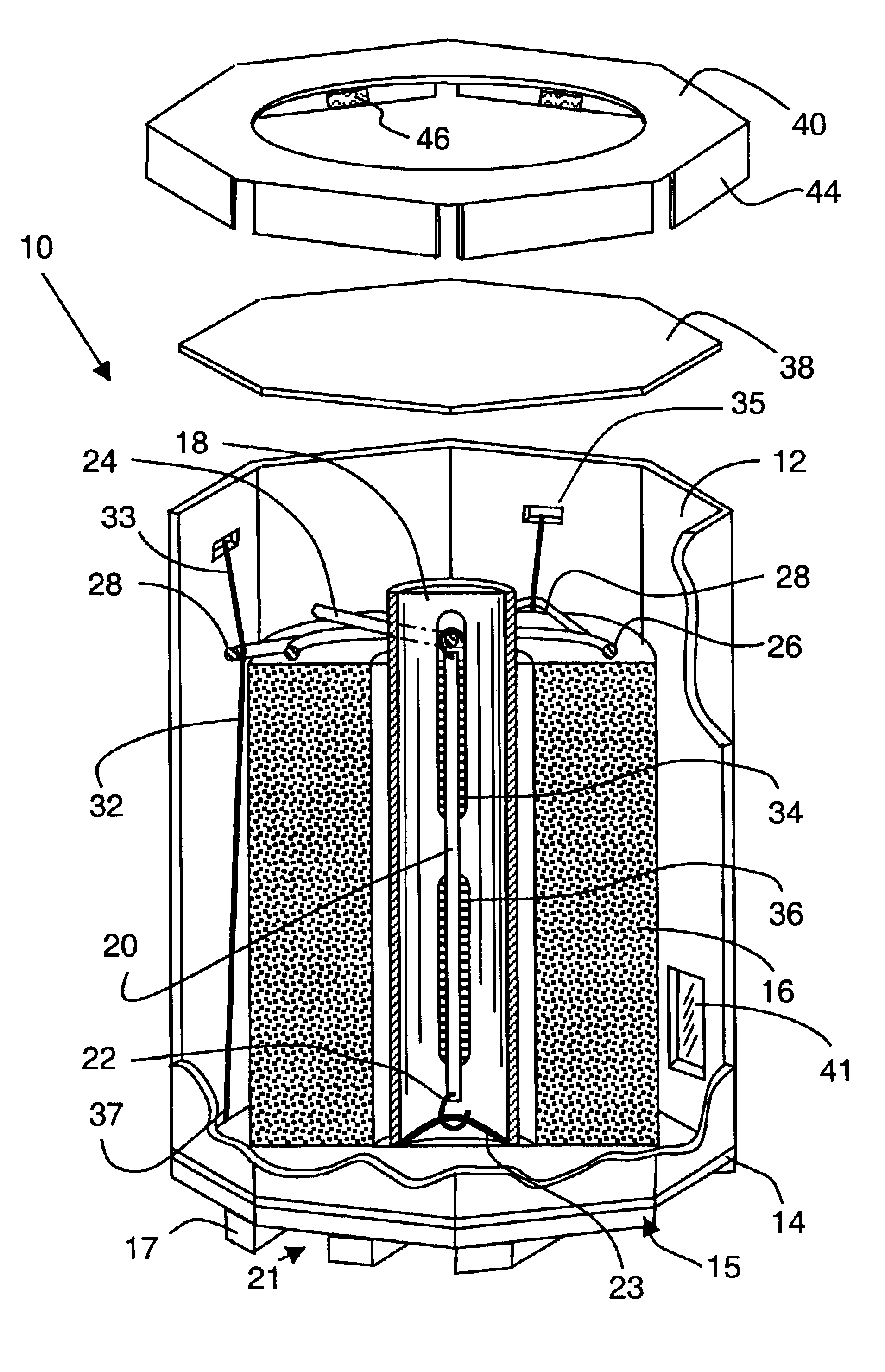

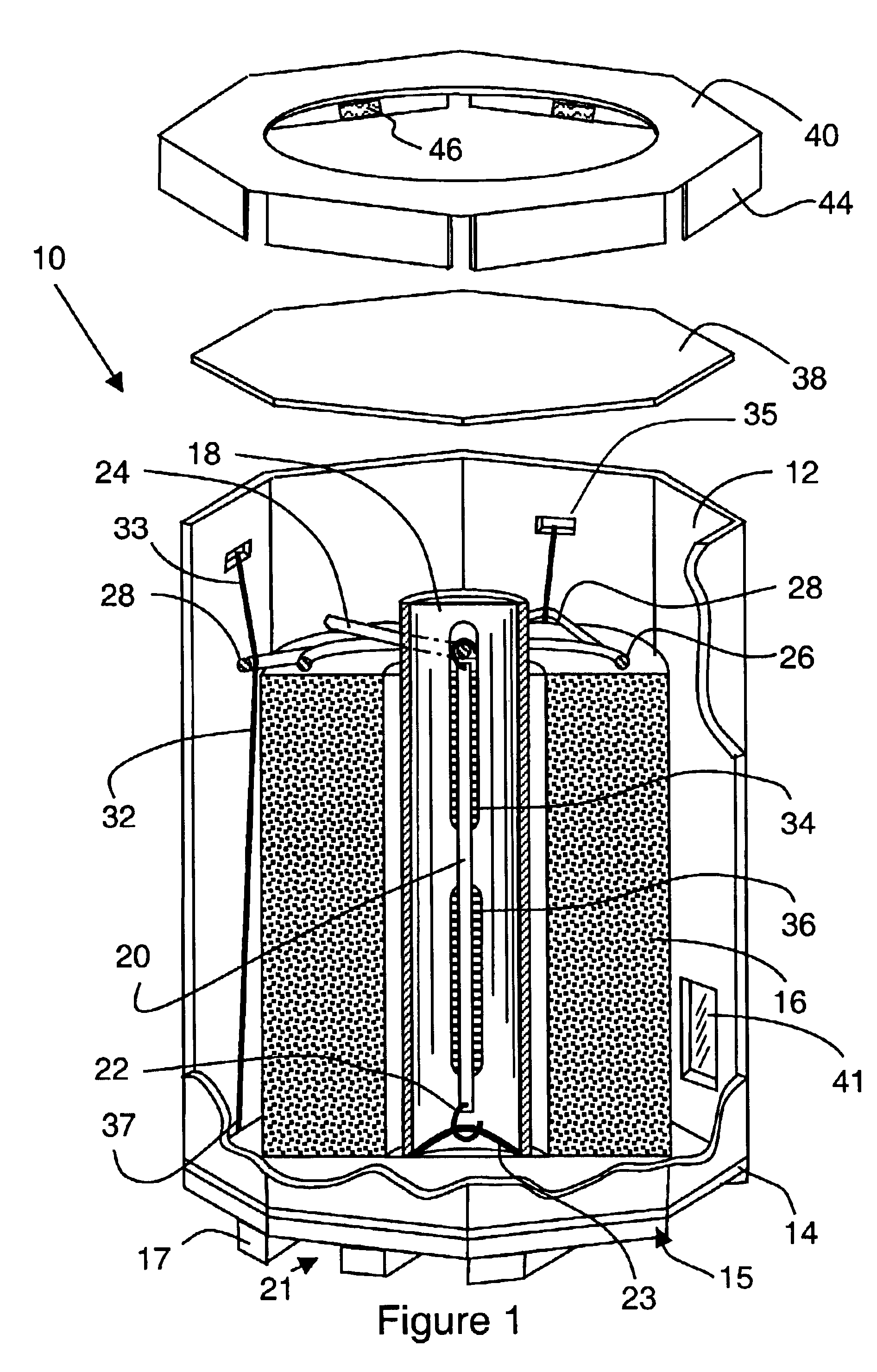

Sterile filling machine having needle filling station within e-beam chamber

InactiveUS6929040B2Obstruct passageEliminate the risk of contaminationLiquid fillingPackage sterilisationEngineeringSyringe needle

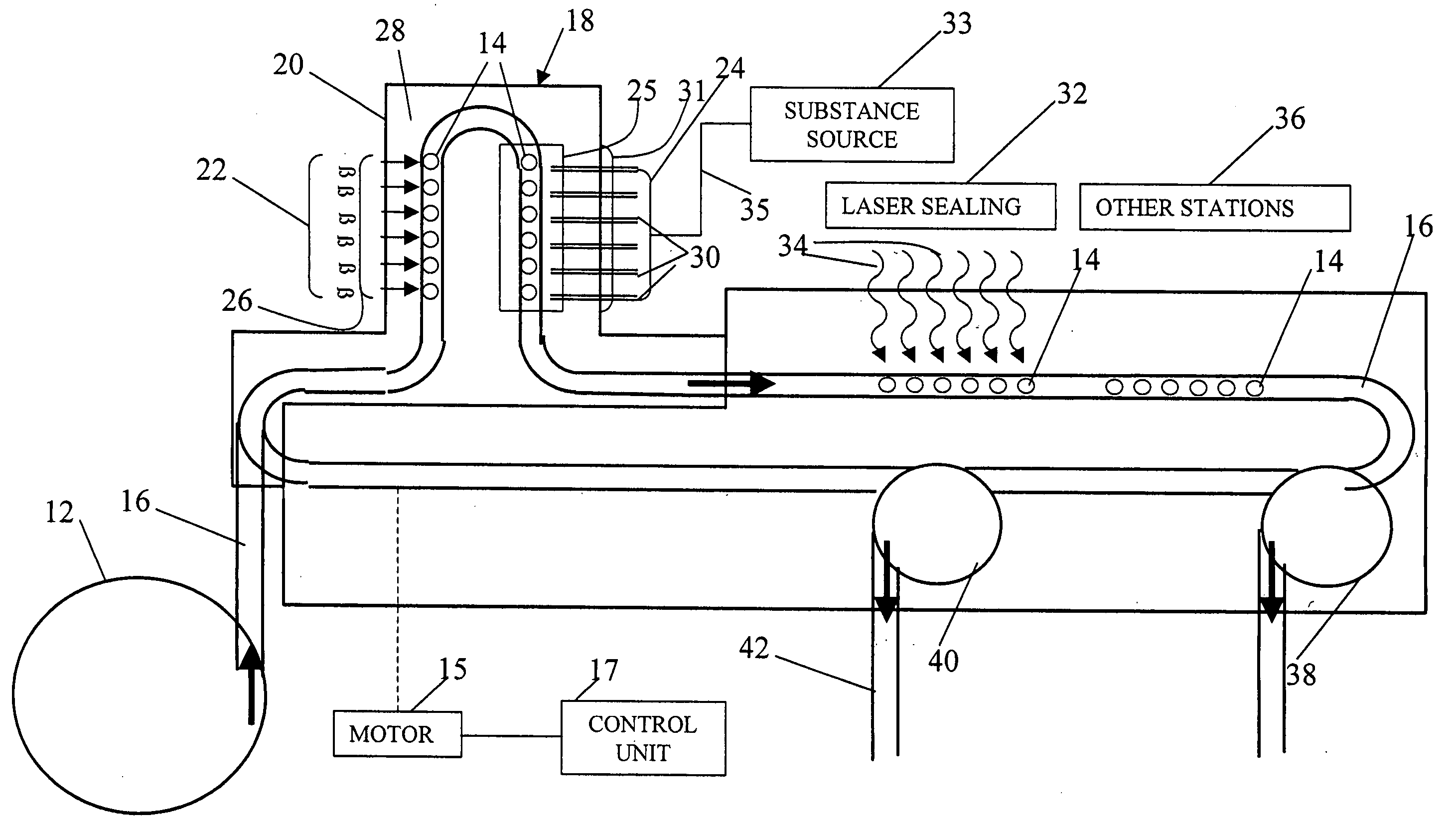

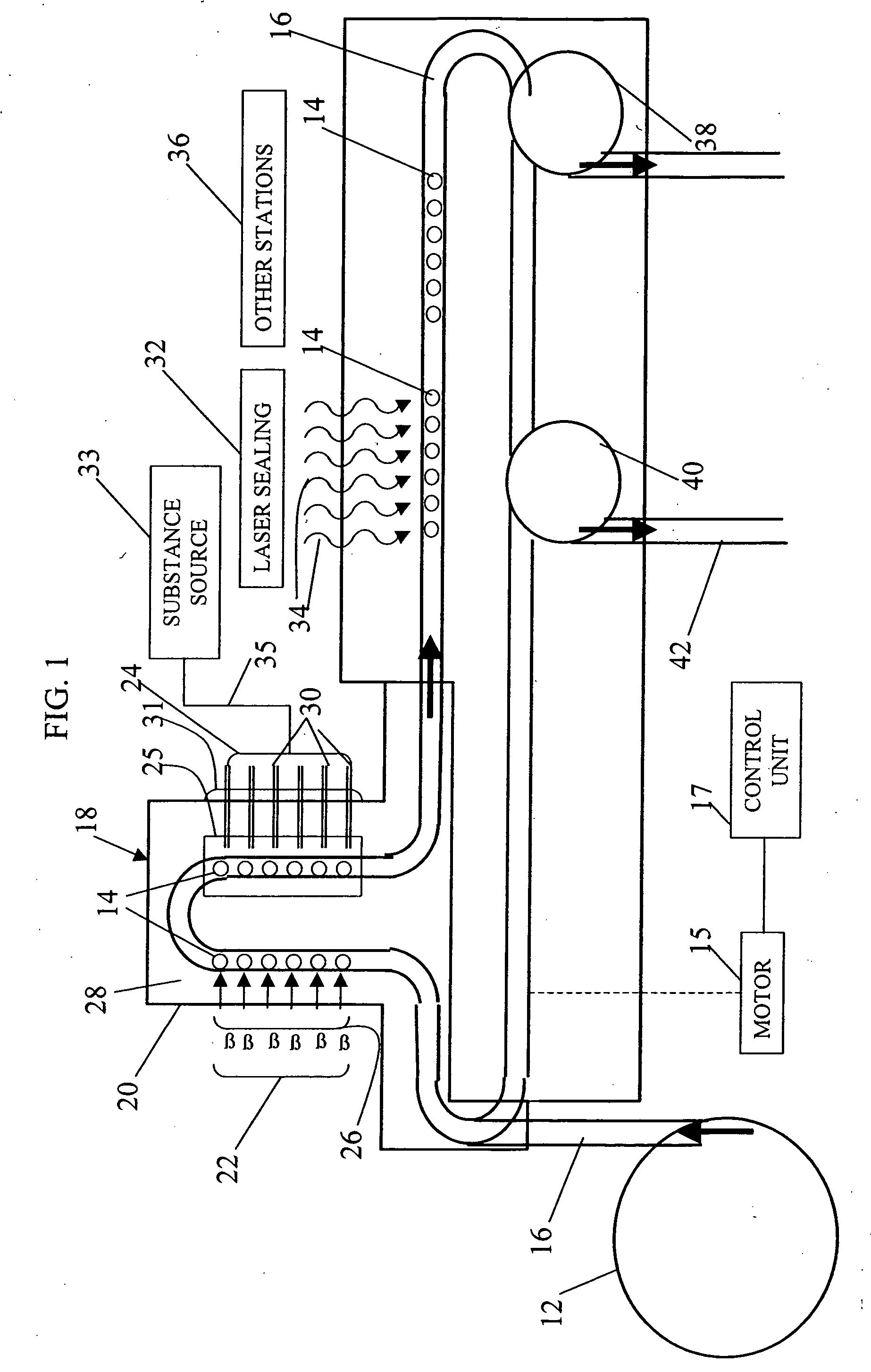

A sterile filling machine and related method are provided for sterile filling a container with a substance. The container includes a heat resealable stopper and a chamber for receiving the substance therein. The sealed, empty containers are subjected to radiation capable of penetrating through the stopper and chamber for sterilizing the container. The previously sterilized containers are then transported through an e-beam chamber, wherein an electron beam is directed onto a penetrable surface of the stopper to sterilize the penetrable surface. A needle is mounted within the e-beam chamber and moved into engagement with the stopper to pierce the sterilized penetrable surface of the stopper and inject the substance through the needle and into the chamber of the container. The needle is then withdrawn from the stopper and the filled container is transported outside of the e-beam chamber. Laser energy is then transmitted onto the penetrated surface of the stopper to fuse the stopper material and hermetically re-seal the stopper.

Owner:MEDINSTILL DEV

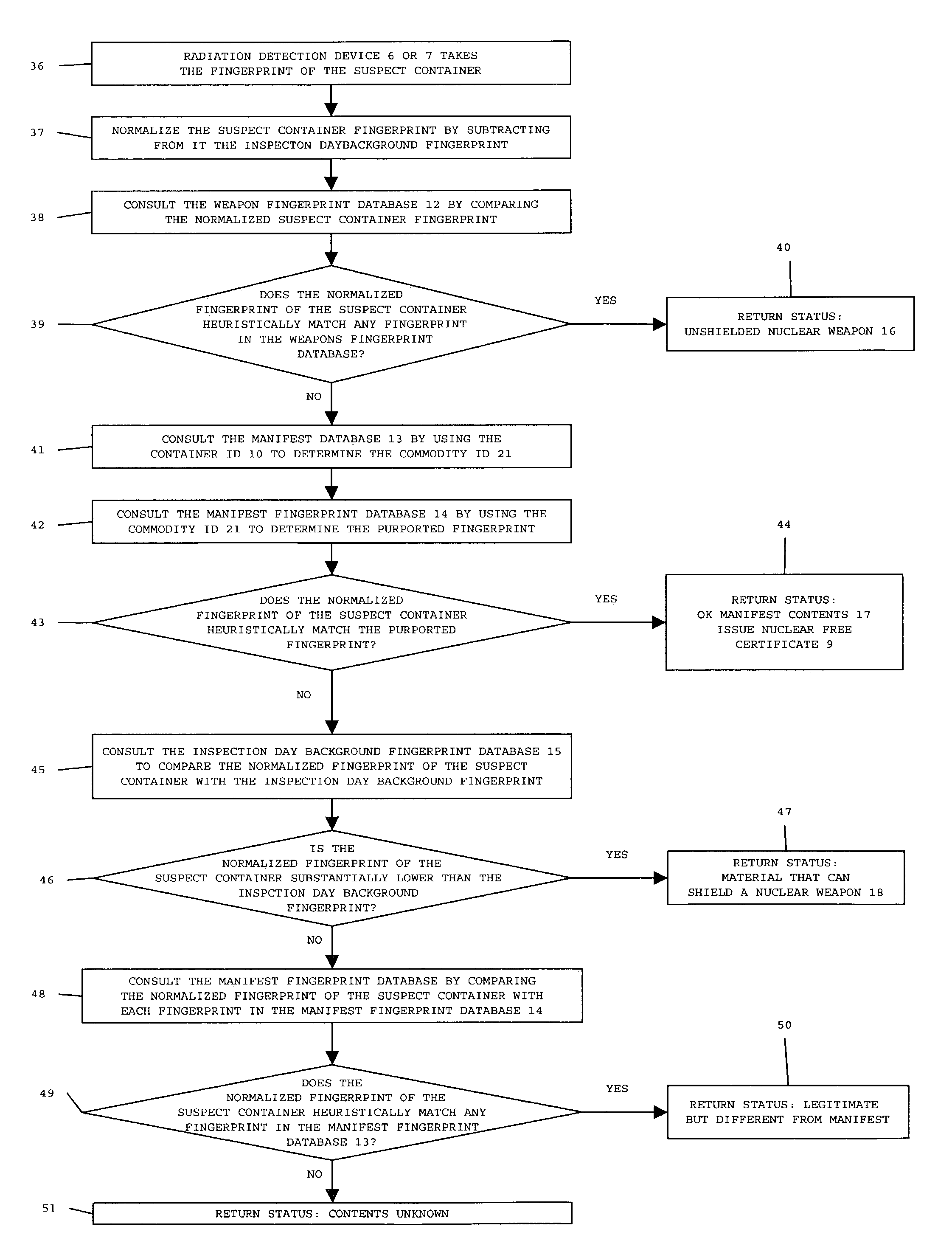

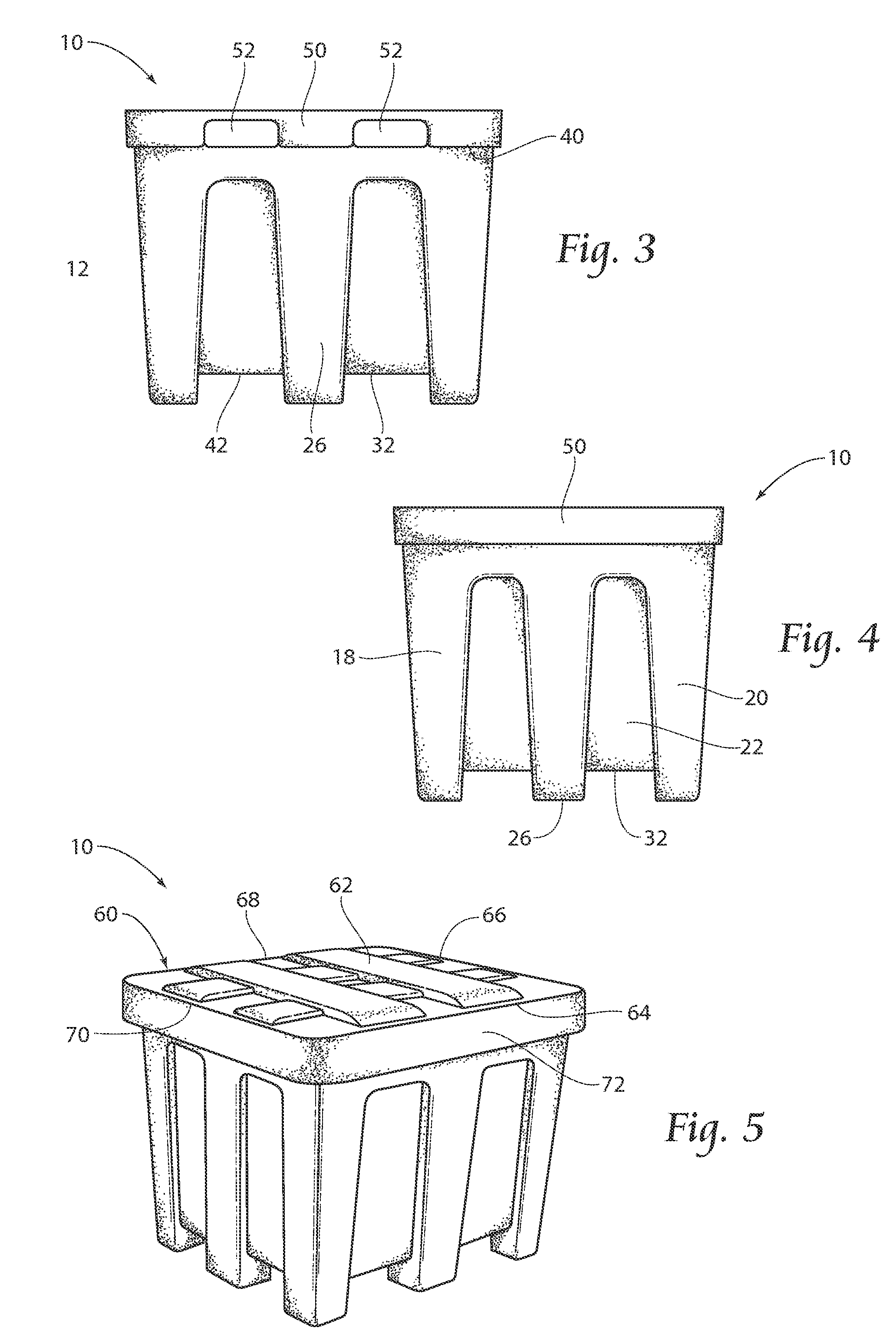

Apparatus and method for detecting radiation or radiation shielding in containers

InactiveUS7026944B2Inspection is accurateTrolley cranesX/gamma/cosmic radiation measurmentRadioactive agentEngineering

A computer program, database and method for the detection of fissile or radioactive material or radiation shielding material in a container works with detection devices brought into proximity to containers so that the presence of fissile or radioactive material, or shielding materials to conceal the presence of such fissile or radioactive materials, may be detected. A comparison may then be made of the output of the detector to a threshold to determine subsequent action regarding the shipping container. The threshold may be based on the output of known, dangerous radioactive materials, known legitimate contents or empty containers.

Owner:VERITAINER ASSET HLDG LLC

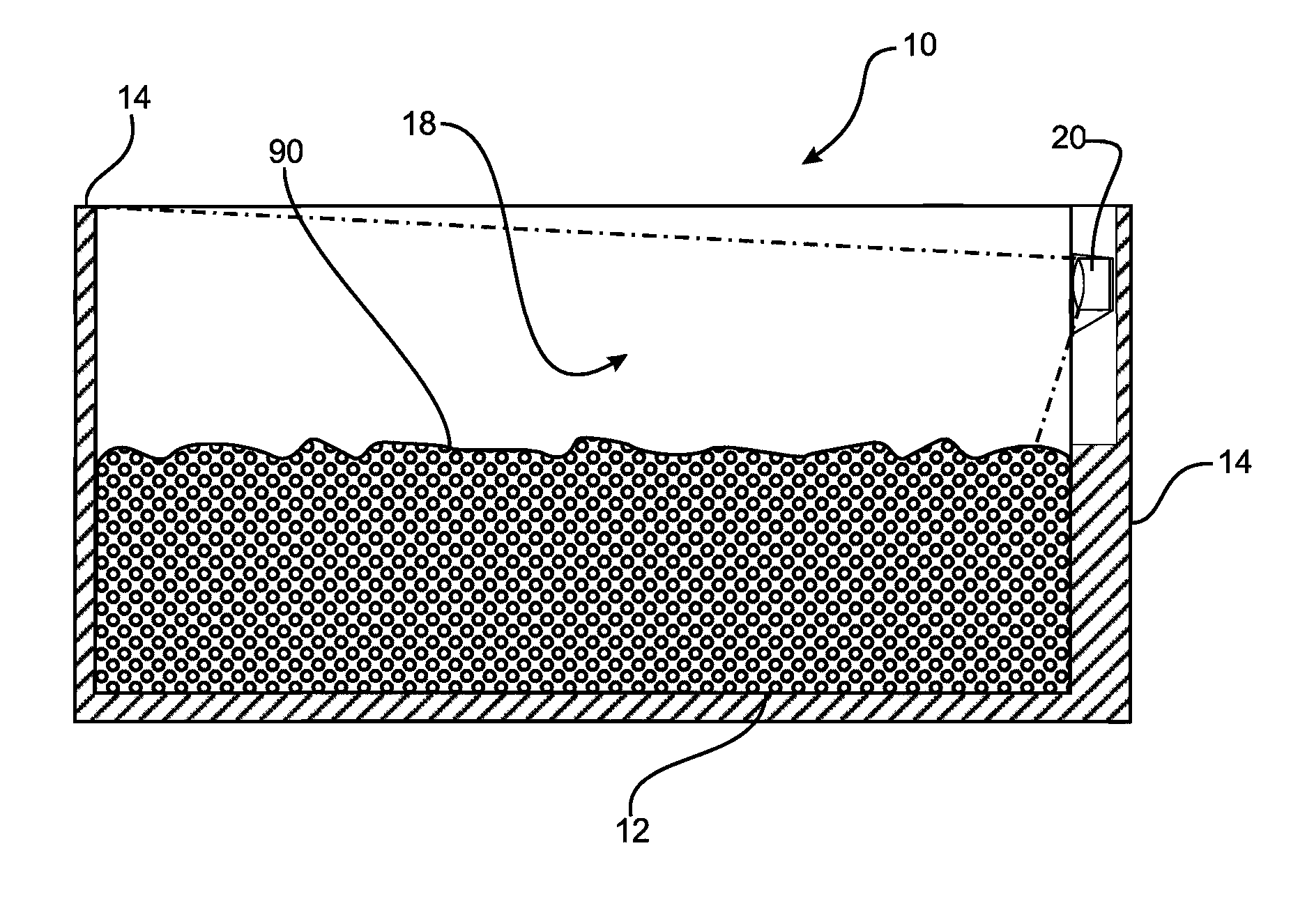

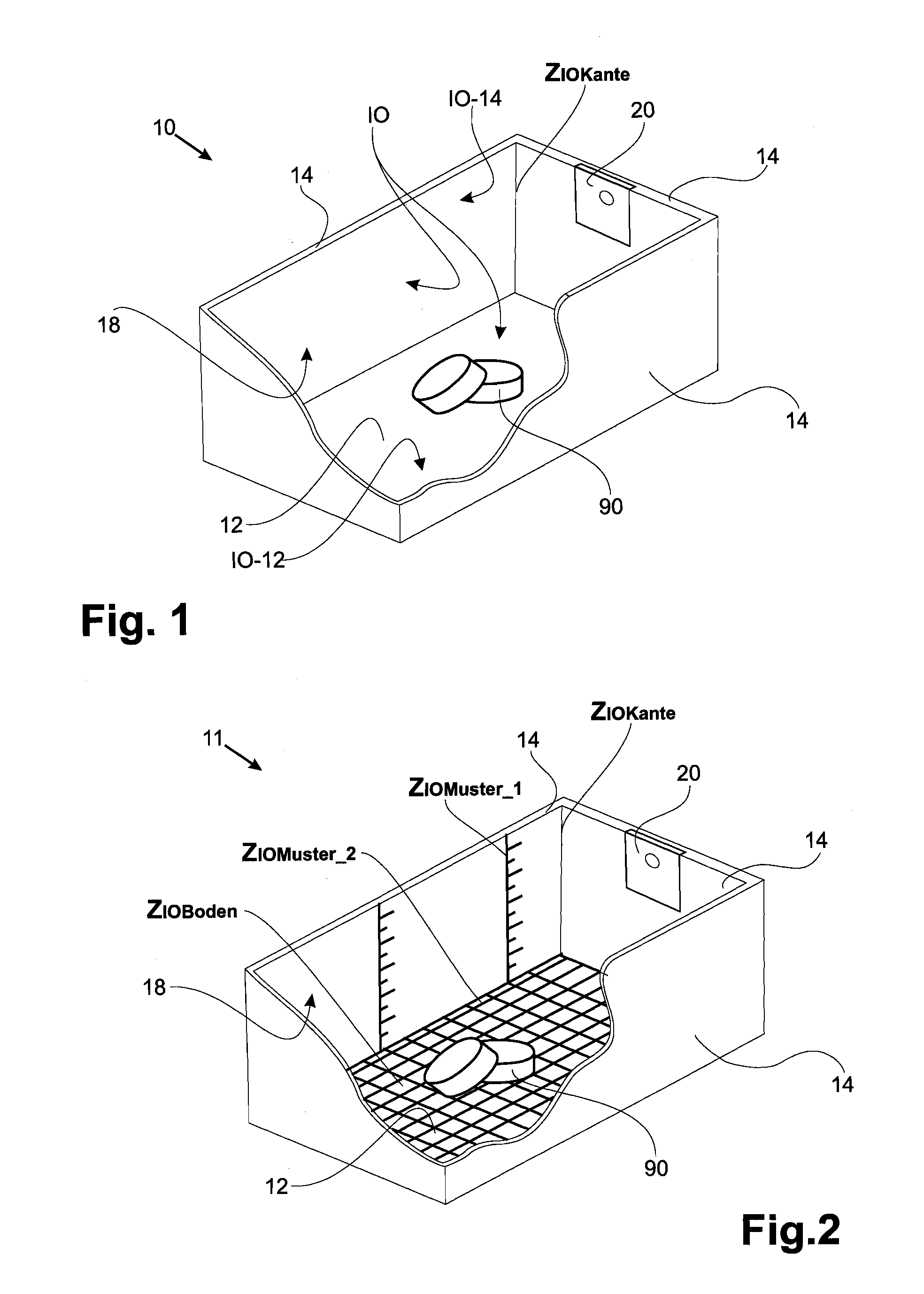

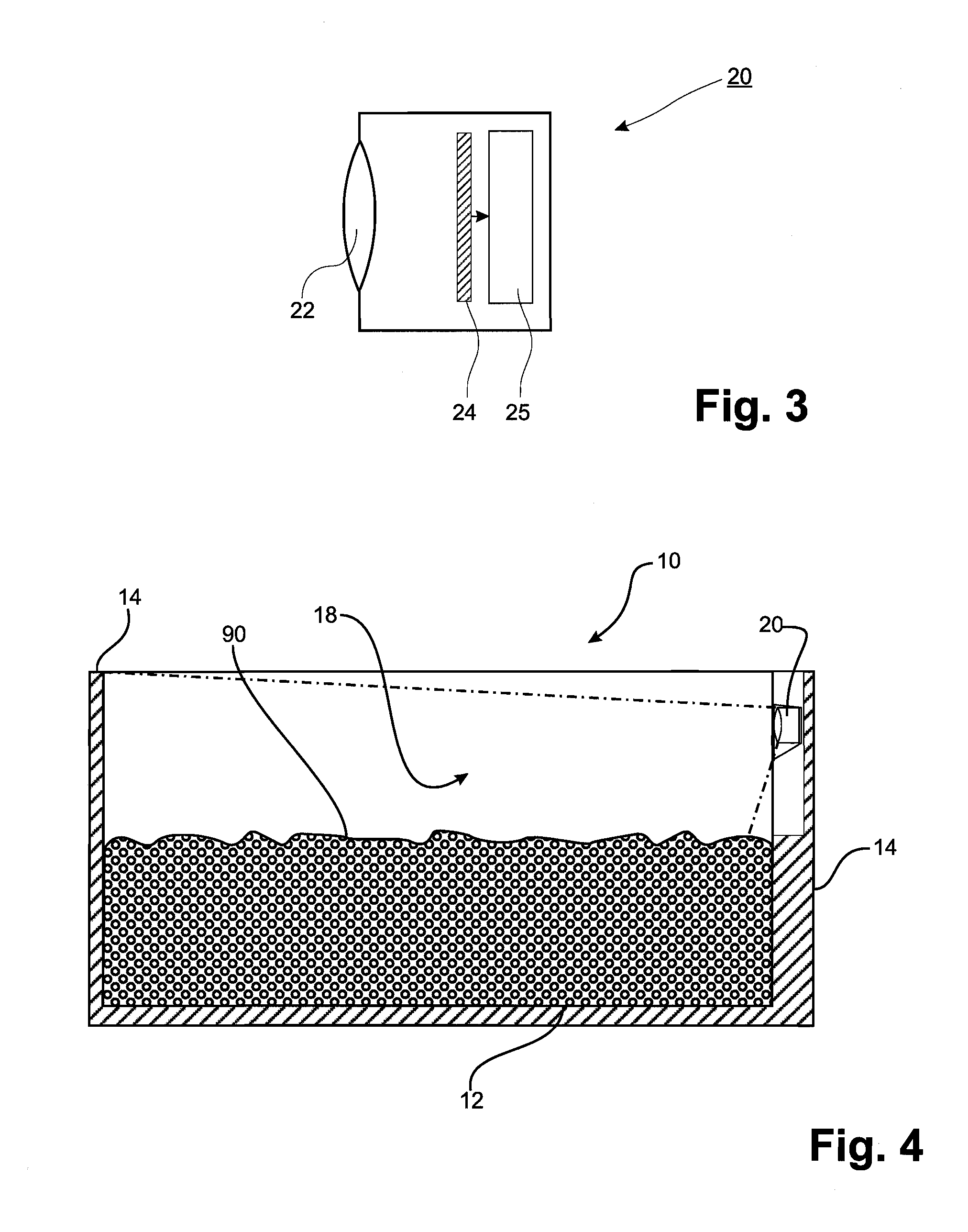

Method for dynamically detecting the fill level of a container, container therefor, and system for dynamically monitoring the fill level of a plurality of containers

InactiveUS20120314059A1Efficient detectionAccurate measurementImage enhancementImage analysisEMPTY CONTAINER

The application pertains to detecting the fill level of a container for transporting and / or storing objects. This is achieved by determining an estimate of the number of objects in the container with the aid of a value of the container volume occupied by the objects or the already emptied container volume, on the basis of an average object volume of one or of a predetermined number of the objects, as long as the container bottom is covered by objects situated in the container. When a predetermined portion of the container bottom is visible, the objects in the container are counted, by identifying the individual objects on the container bottom. In addition, a container that is particularly suitable for the proposed methods and a system with a plurality of such containers are proposed.

Owner:WUERTH IND SERVICE +1

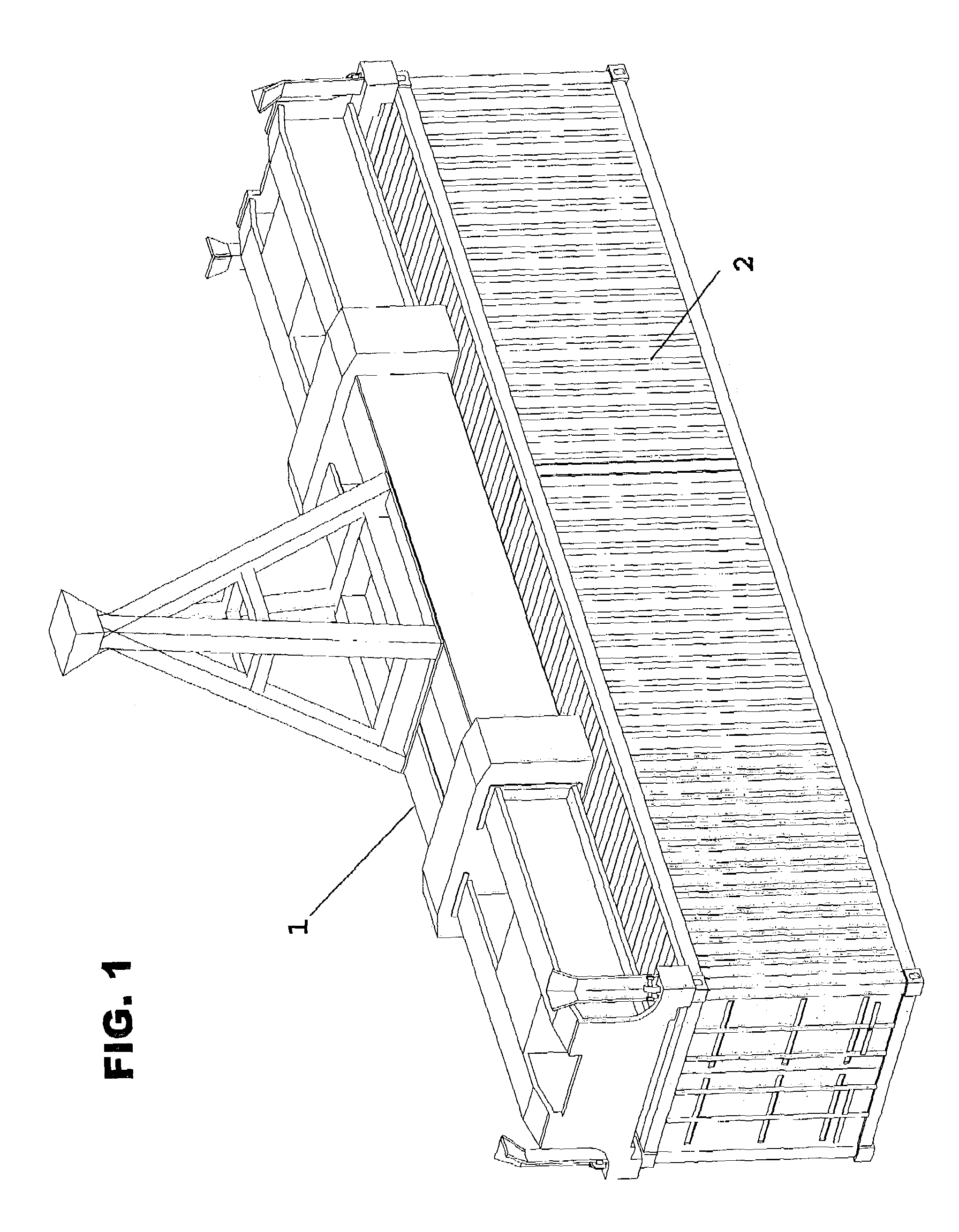

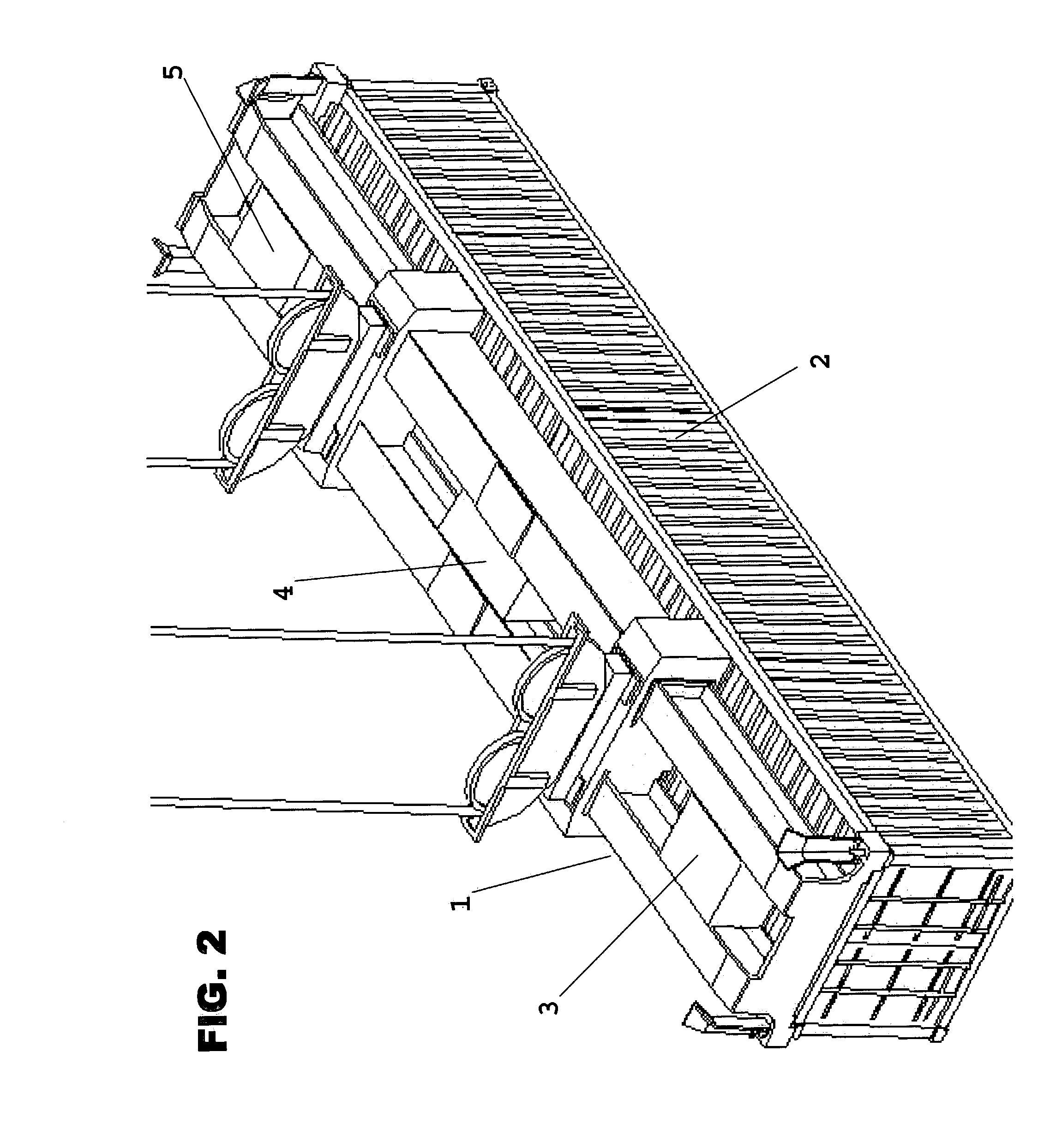

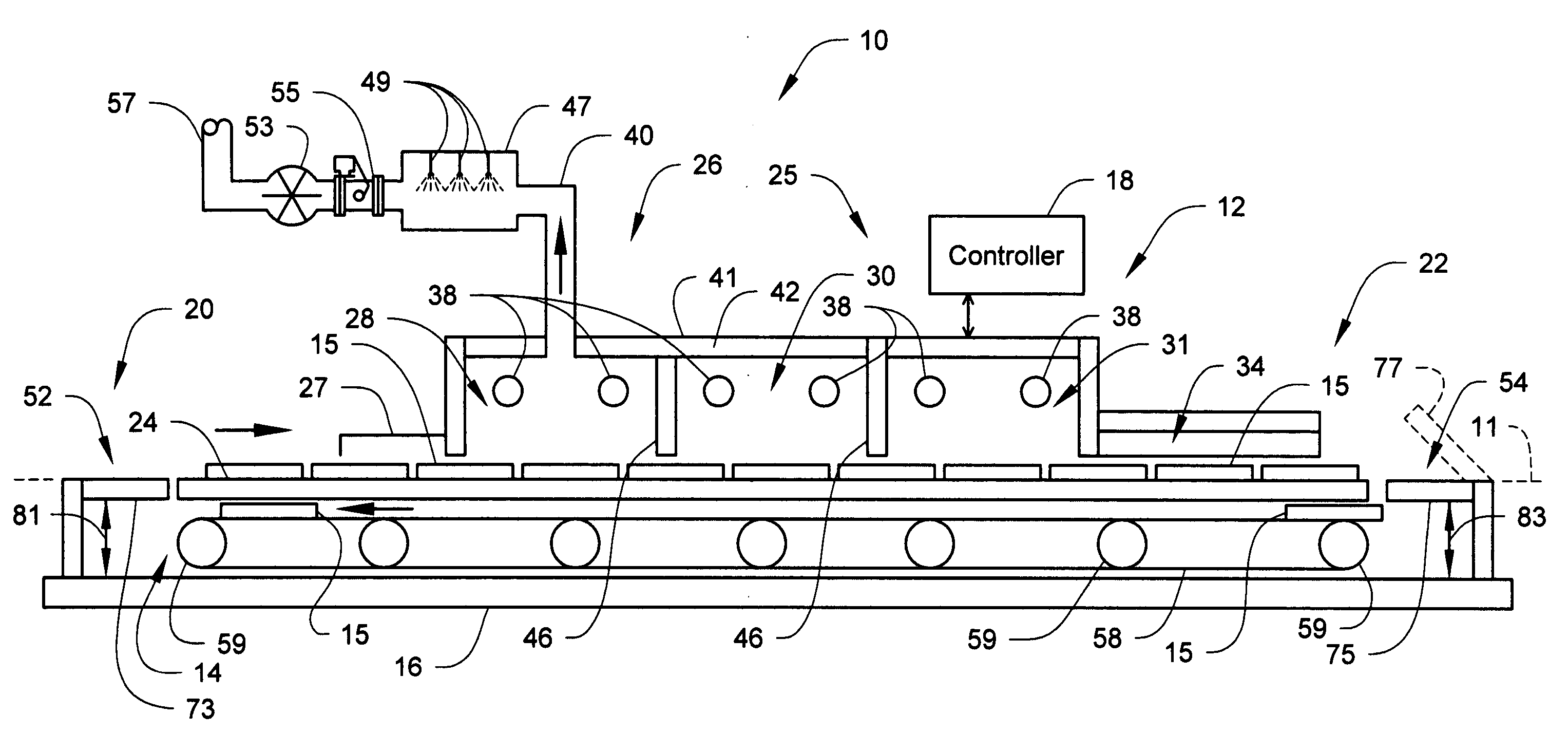

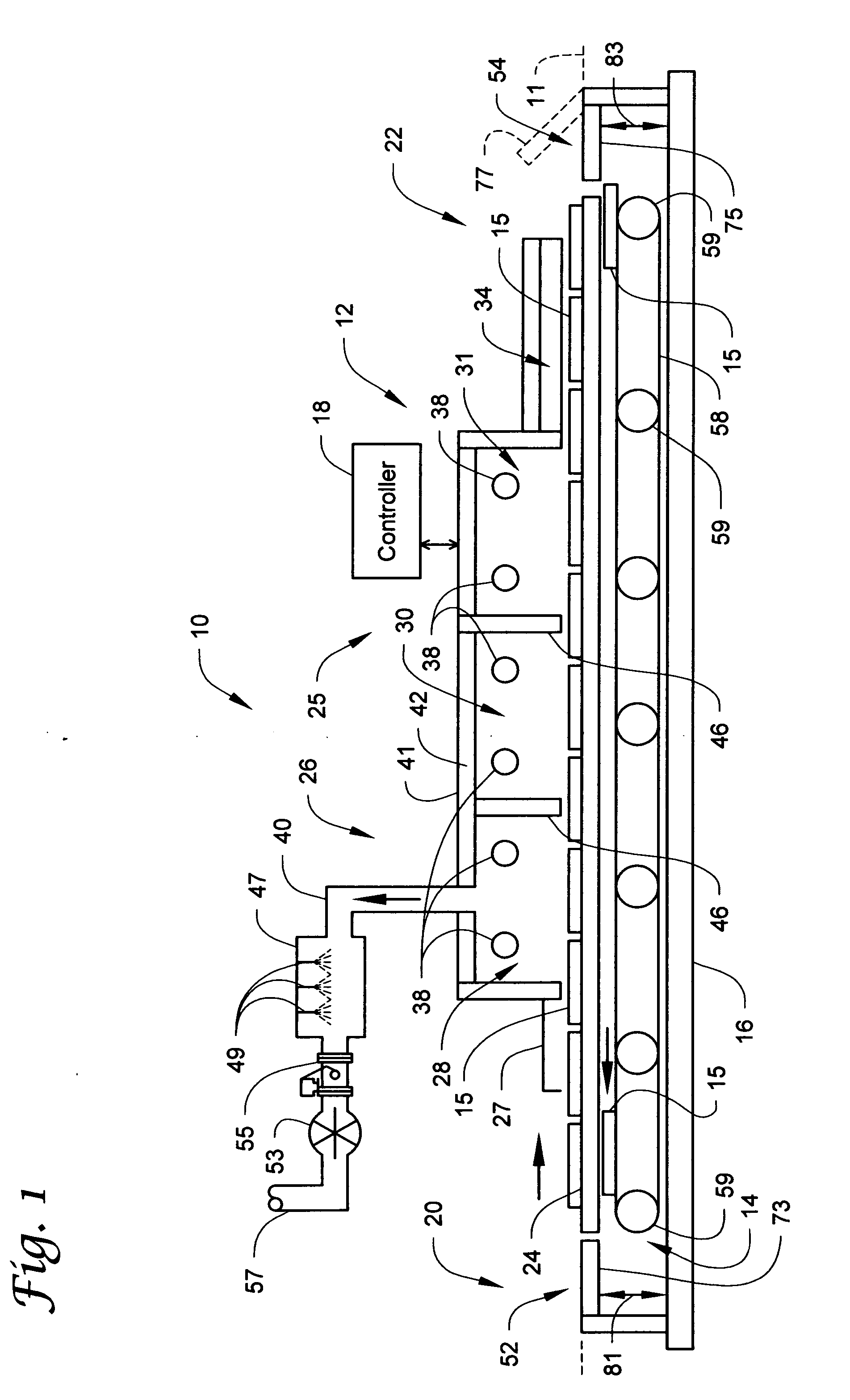

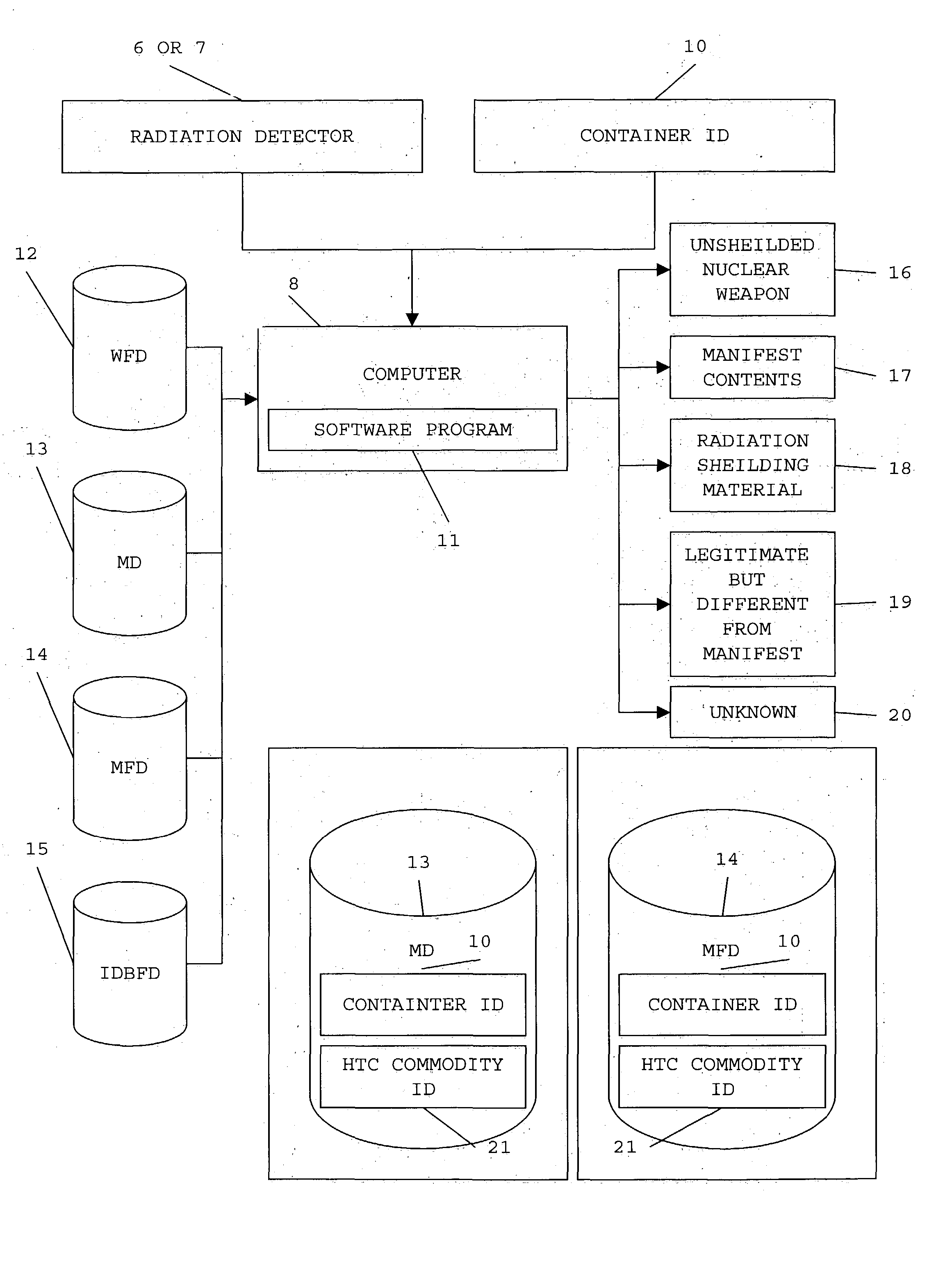

Linear hearth furnace system and methods regarding same

Systems and methods for use in processing raw material (e.g., iron bearing material) include a linear furnace apparatus extending along a longitudinal axis between a charging end and a discharging end (e.g., the linear furnace apparatus includes at least a furnace zone positioned along the longitudinal axis). Raw material is provided into one or more separate or separable containers (e.g., trays) at the charging end of the linear furnace apparatus. The separate or separable containers are moved through at least the furnace zone and to the discharging end where the processed material is discharged resulting in one or more empty containers. One or more of the empty containers are returned to the charging end of the linear furnace apparatus to receive further raw material.

Owner:NU IRON TECH LLC

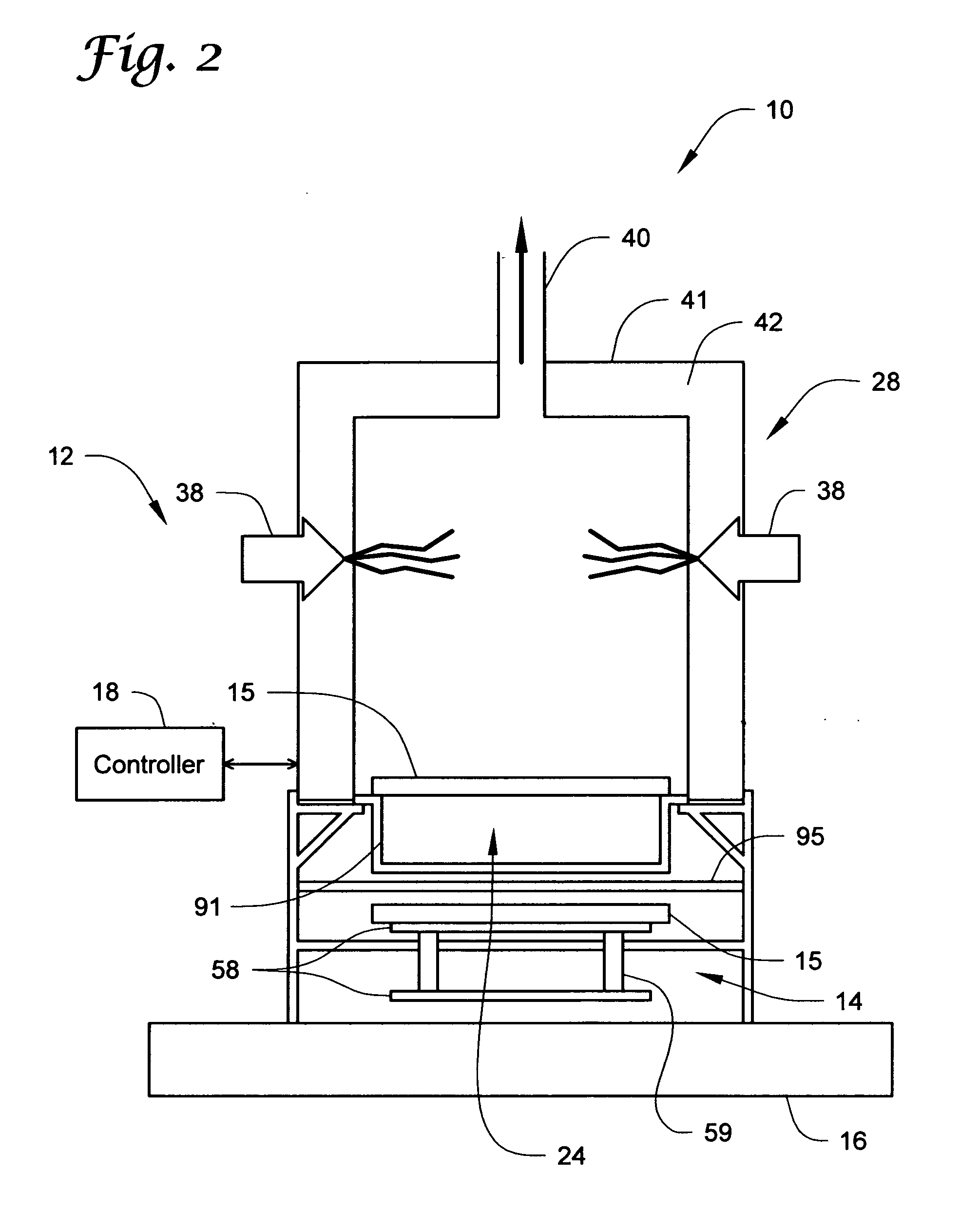

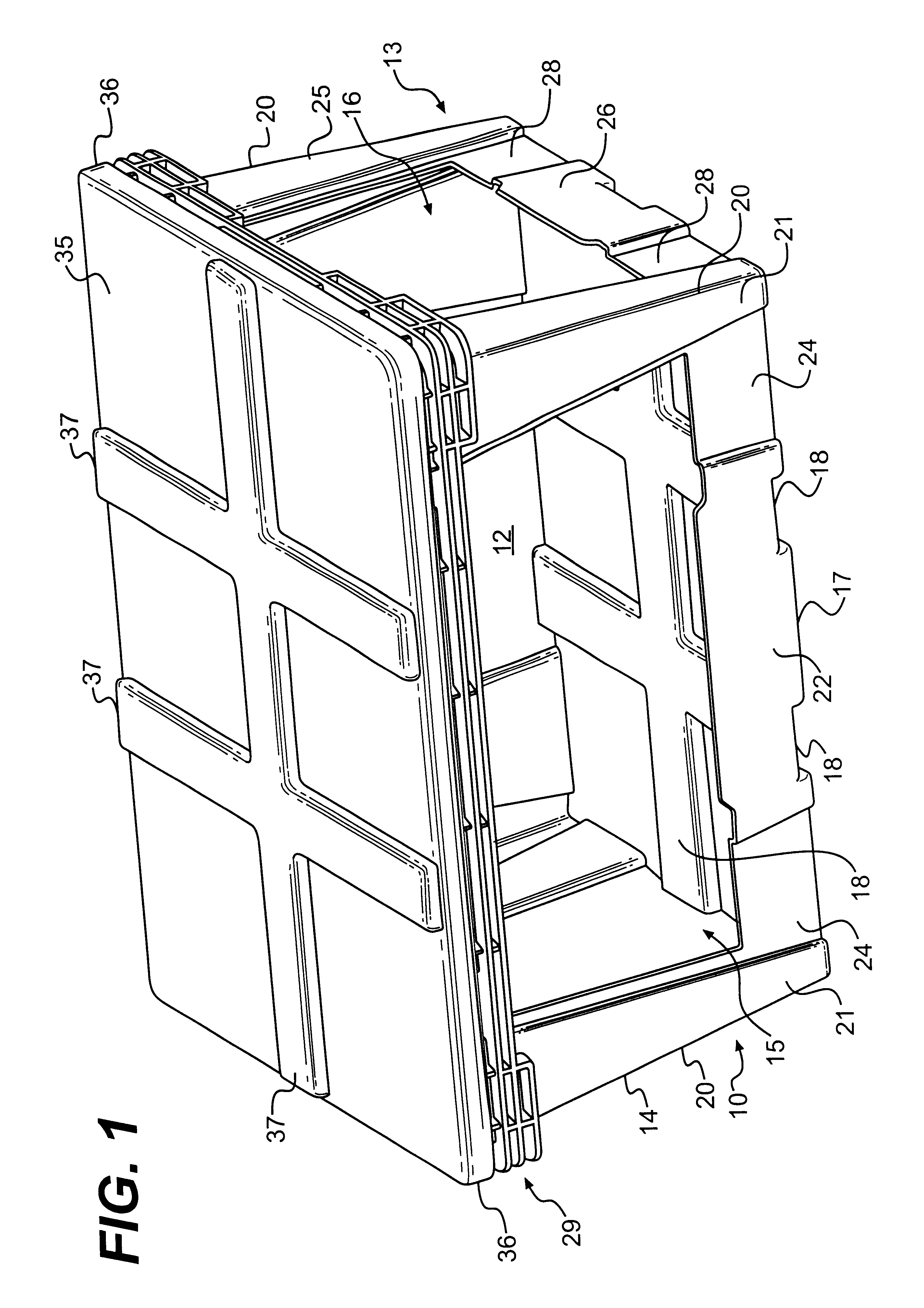

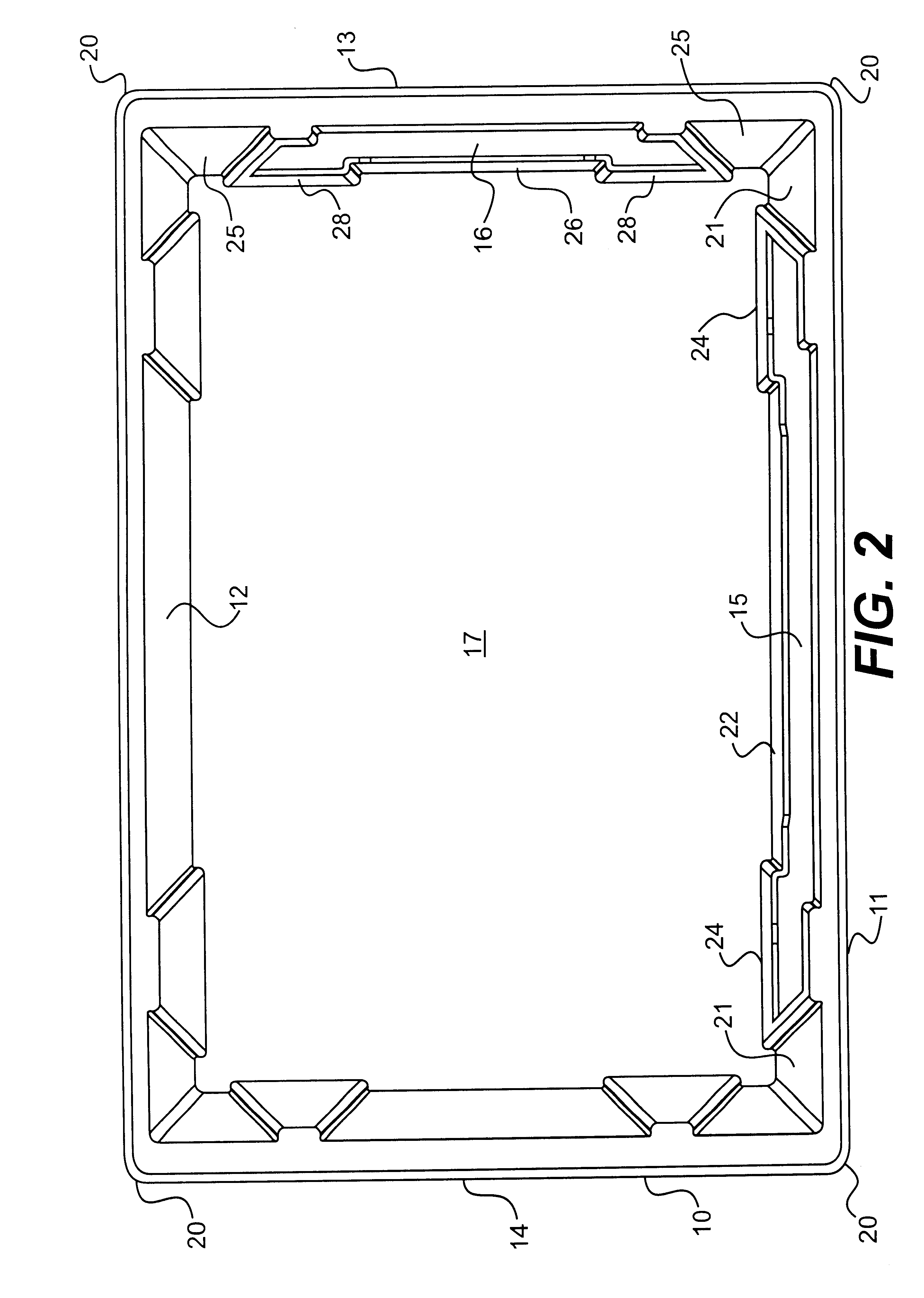

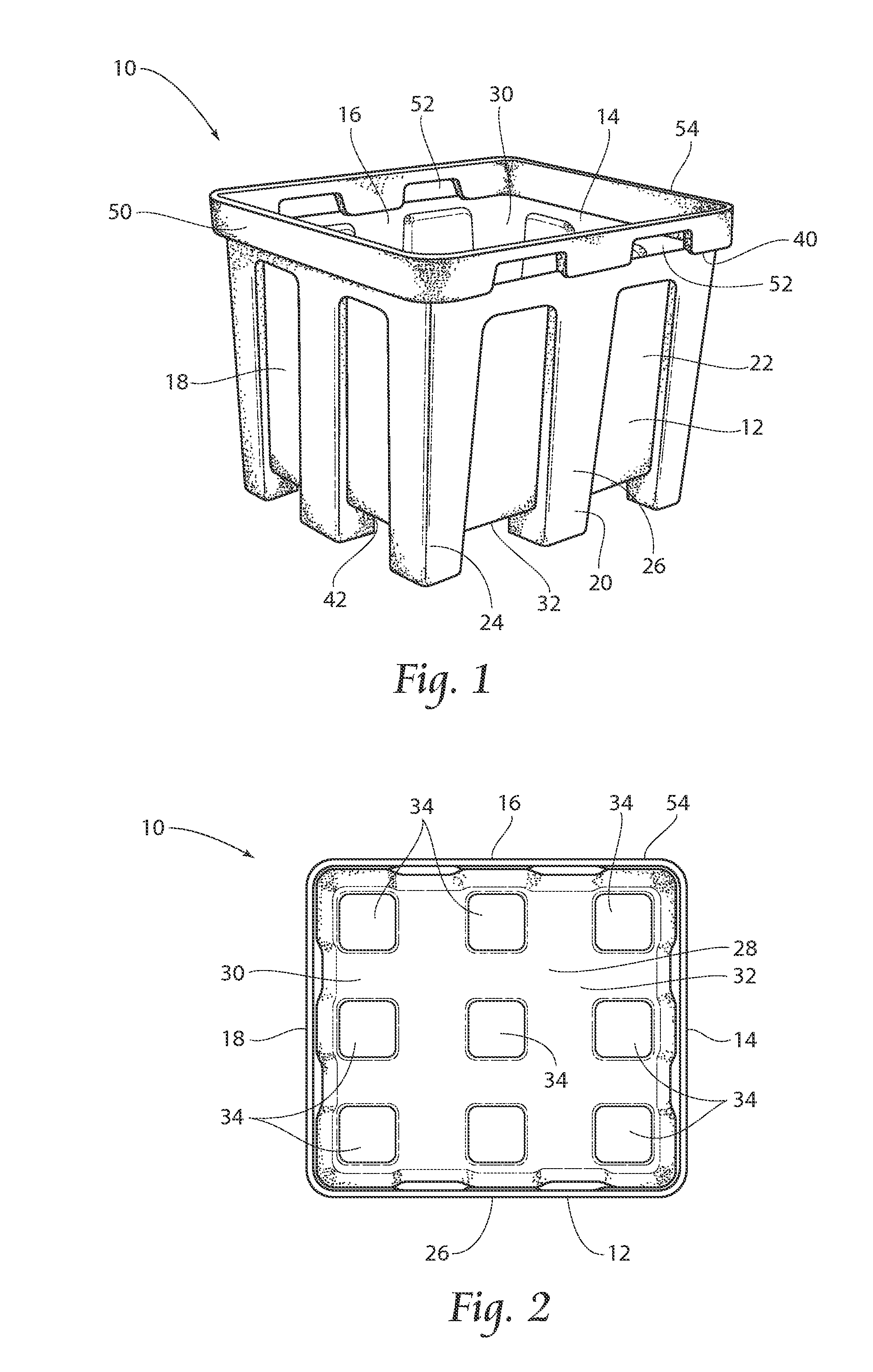

Nestable container with expendable closure panel covering access opening in container wall

InactiveUS6253948B1Easy to useEasy to changeLarge containersRemovable lids/coversFace sheetEMPTY CONTAINER

Owner:BUCKHORN

Novel Process

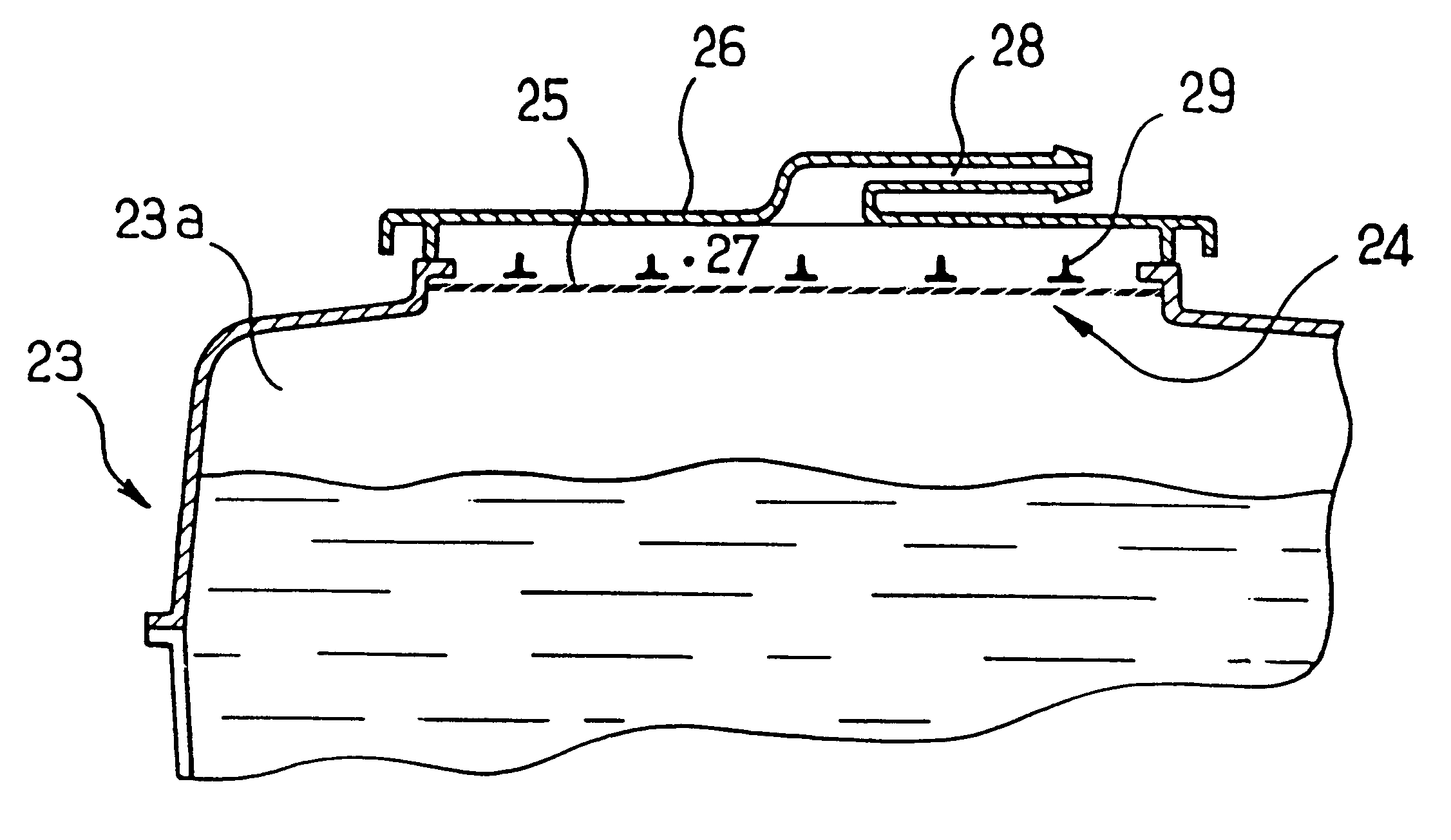

A process for reducing the oxygen concentration in a container prior to filling the container with a liquid by passing a hollow filling needle through a puncturable part of the container wall, in which the empty container is enclosed within an envelope which is less permeable to oxygen than the container wall. The process is suitable for use with vials having a puncturable closure.

Owner:ASEPTIC TECH

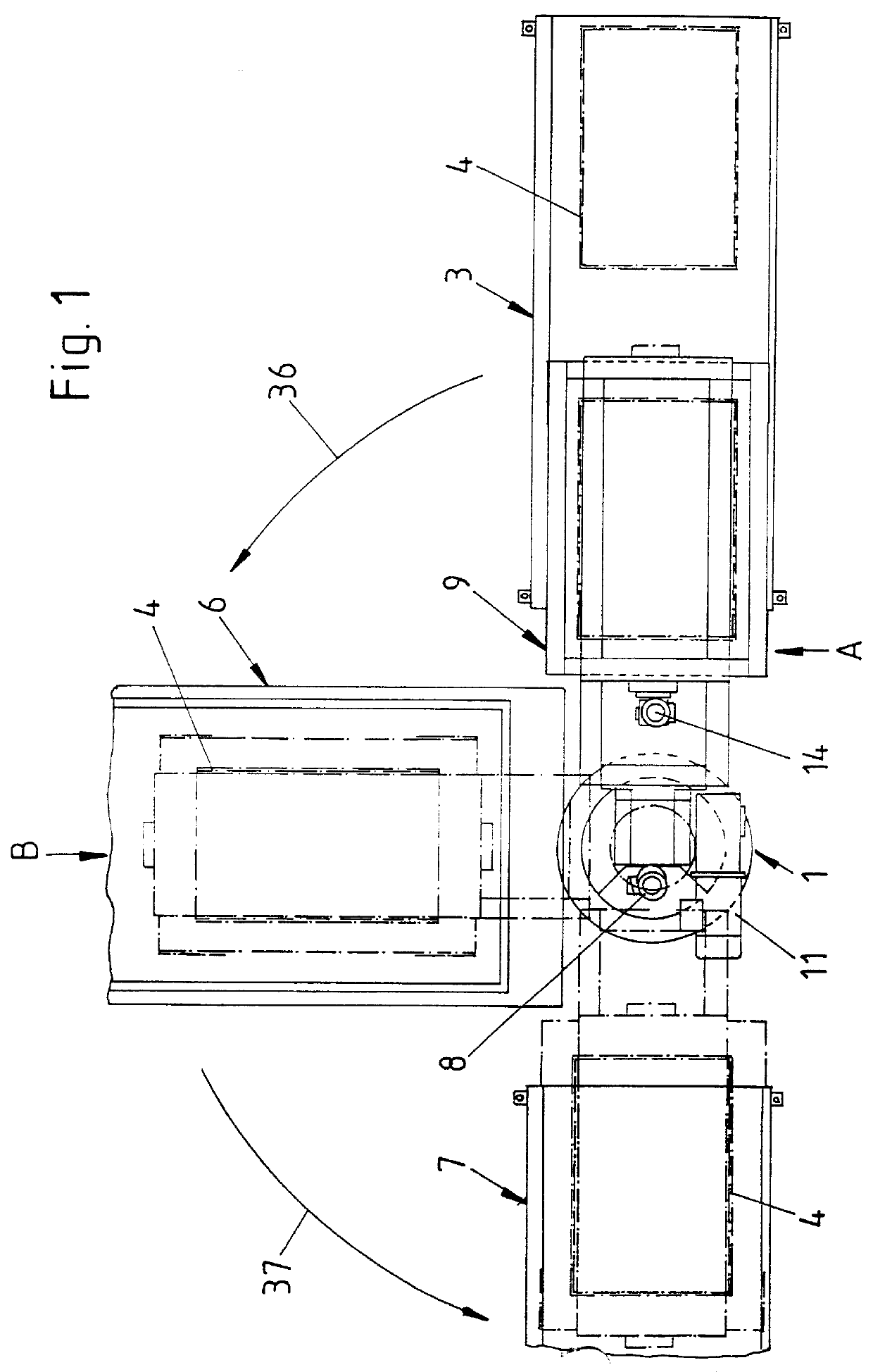

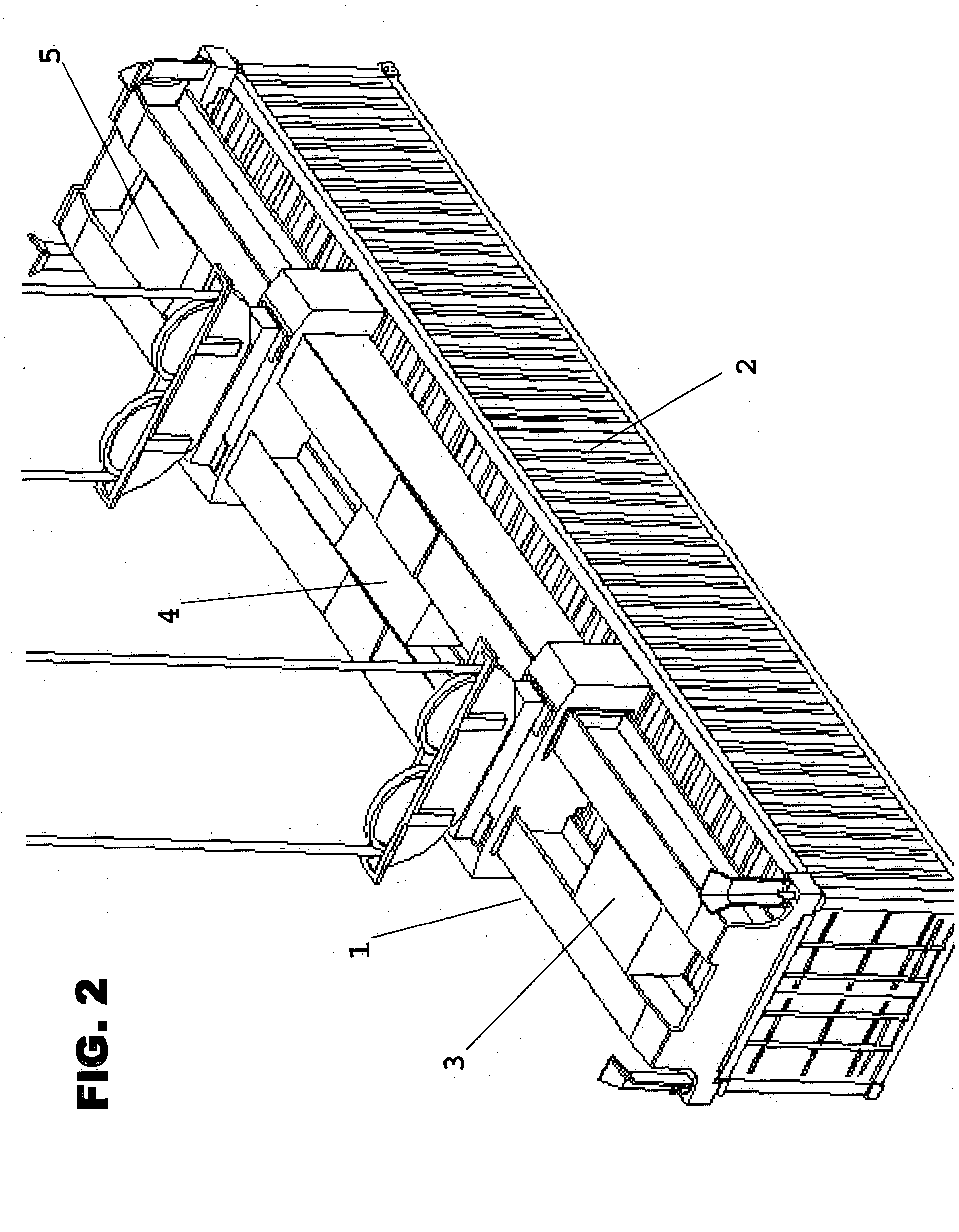

Method and apparatus for feeding containers in serial order on a conveyor belt

System for feeding empty containers on a conveyor belt, namely for packaging installations, such as bottling plants. The system for feeding containers comprises a supporting surface having dimensions sufficient to accommodate a multitude of empty containers placed side by side. This supporting surface continuously moves the containers against an abutment wall. The movement of the supporting surface causes empty containers to agglomerate against the abutment wall. A pushing device is provided to selectively push out from the containers agglomeration a number of containers over a secondary conveyor belt that will lead those containers to successive processing stations, such as a filling station, capping station, labeling station etc. The pushing device is mounted relative to the supporting surface such that it moves generally parallel to the abutment wall. The movement of the pushing device pushes out of the agglomeration a row of containers that are maintained in a serial order during this movement by the abutment wall on one hand and the rest of the empty containers on the other hand.

Owner:NOVA PACKAGING SYST

Empty container detection using container side pressure sensing

ActiveUS20050145009A1Inflated body pressure measurementFluid pressure measurement by electric/magnetic elementsEngineeringMean pressure

A system and method for monitoring changes in the pressure of a fluid line upstream of an infusion pump to determine when a fluid container has emptied, and to provide a signal indicating that the container needs replacement or replenishment. The difference between averaged pressures over separate time periods is monitored to determine when the fluid container is empty. The system and method are applicable to primary and secondary fluid container setups and can detect the point where the secondary has been emptied and the primary flow has resumed.

Owner:CAREFUSION 303 INC

Container and retaining device for packaging and unwinding coiled welding wire

InactiveUS6857521B2Reduce packaging costsAvoid transportContainers for annular articlesFilament handlingCardboardEngineering

Owner:PLASTICOS & ALAMBRES

Fuel tank equipped with a gas evacuating system

The invention relates to a fuel tank comprising a vessel for containing fuel and a system for evacuating the gases contained in the vessel. The system has a passage putting the inside of the vessel into communication with the outside of the vessel, and the passage is closed by a membrane suitable for allowing air and fuel vapor to pass therethrough while preventing liquid fuel from passing therethrough. The membrane is situated inside the vessel and it extends over the major portion of the top wall of the vessel.

Owner:CO PLASTIC OMNIUM

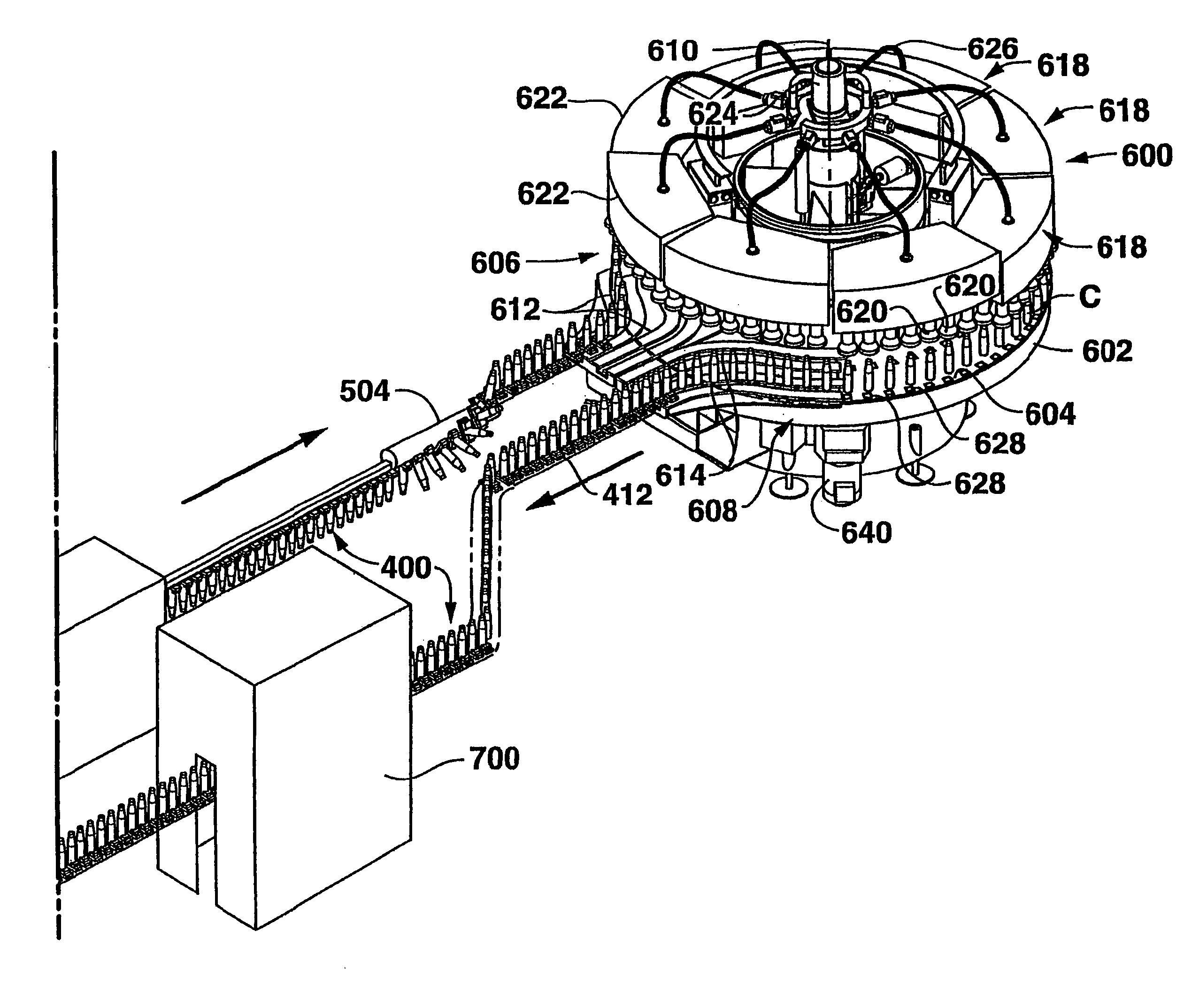

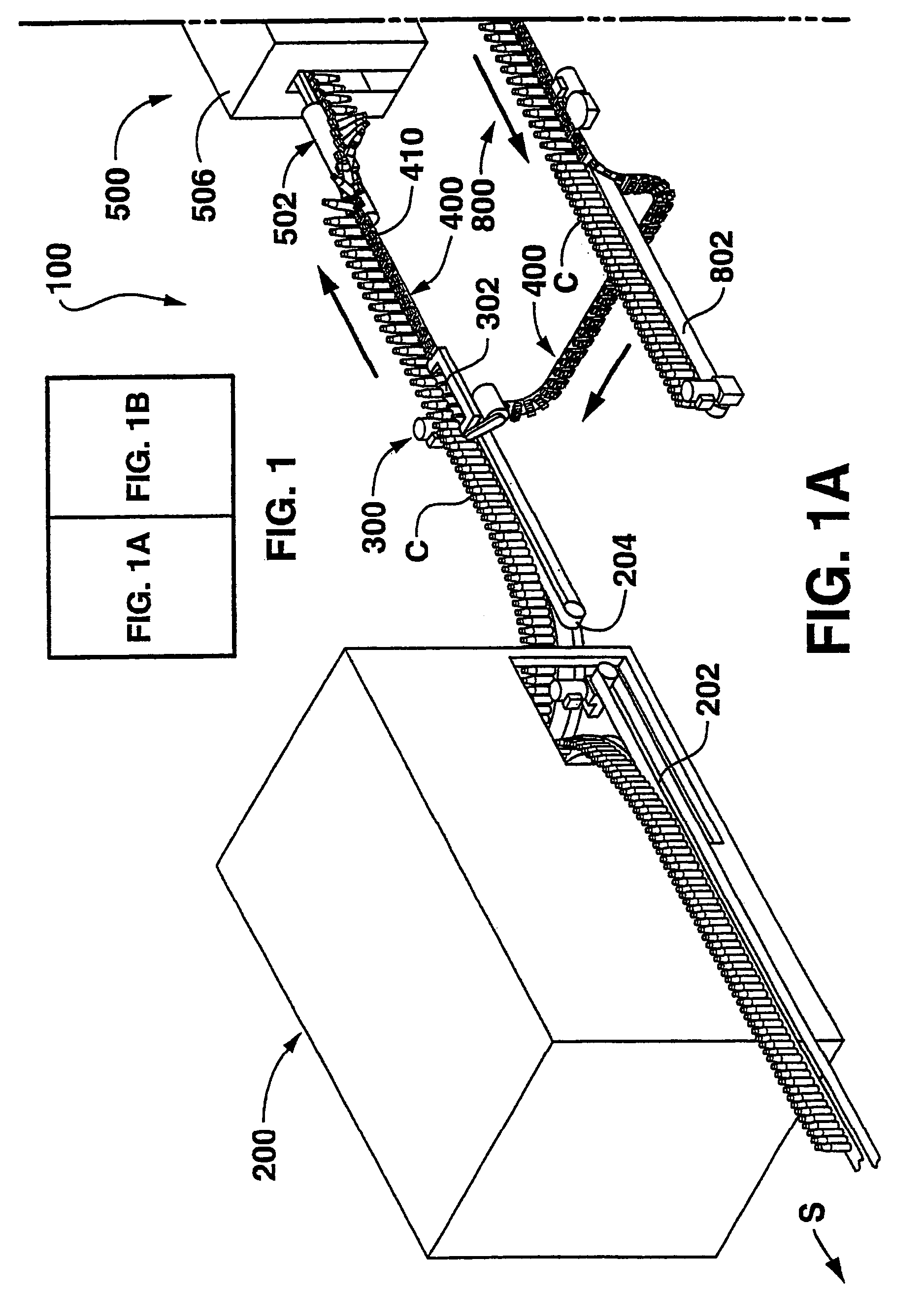

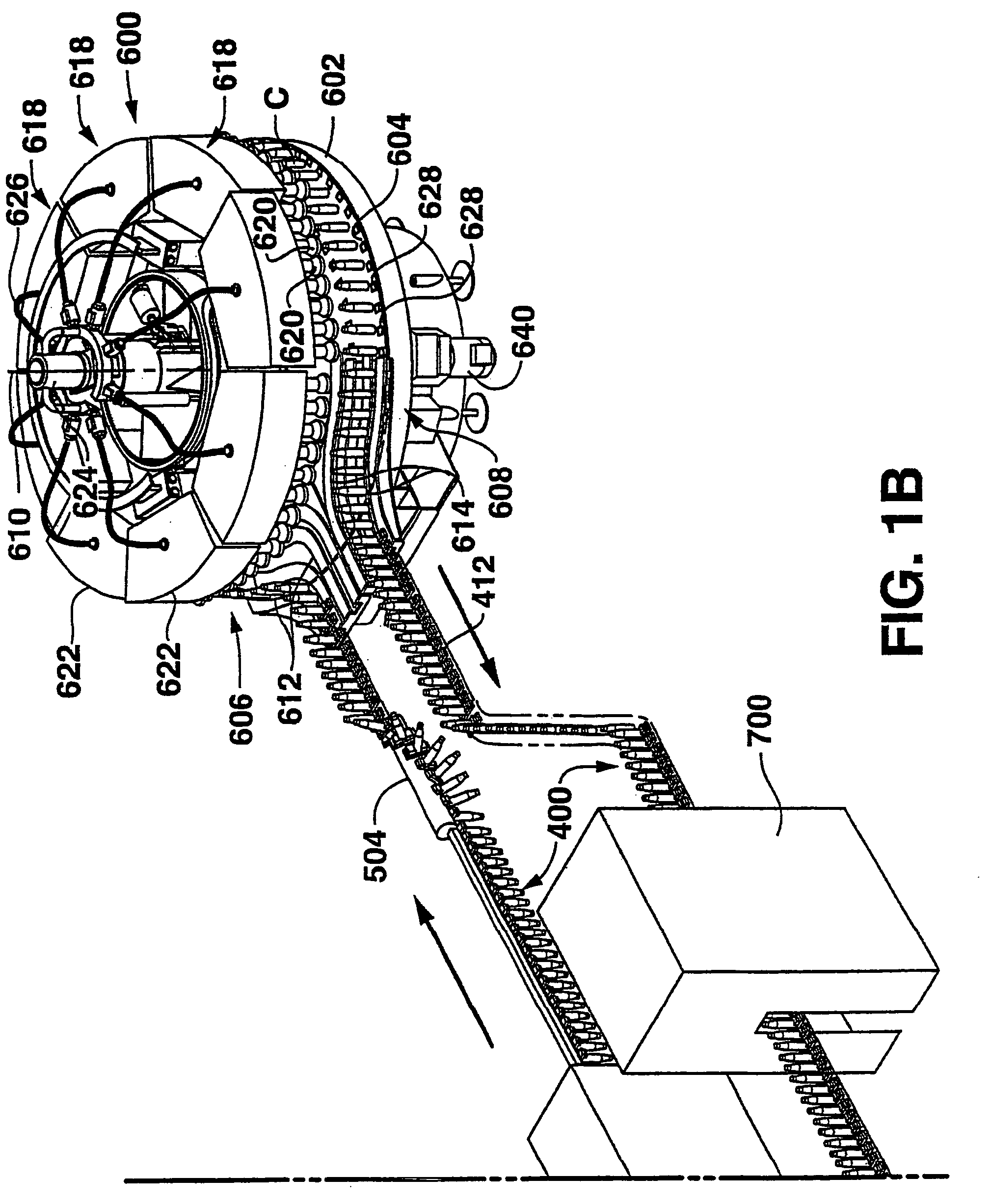

Rotary filling machine and related components, and related method

A rotary filling machine is disclosed for filling containers, the machine including a rotating platform rotatable relative to a vertical rotating axis through a filling zone, and a conveyor configured to convey empty containers to be filled to the rotating platform for filling and to convey filled containers from the rotating platform. Various aspects and designs of the above elements are disclosed, as well as a related method.

Owner:ILLINOIS TOOL WORKS INC

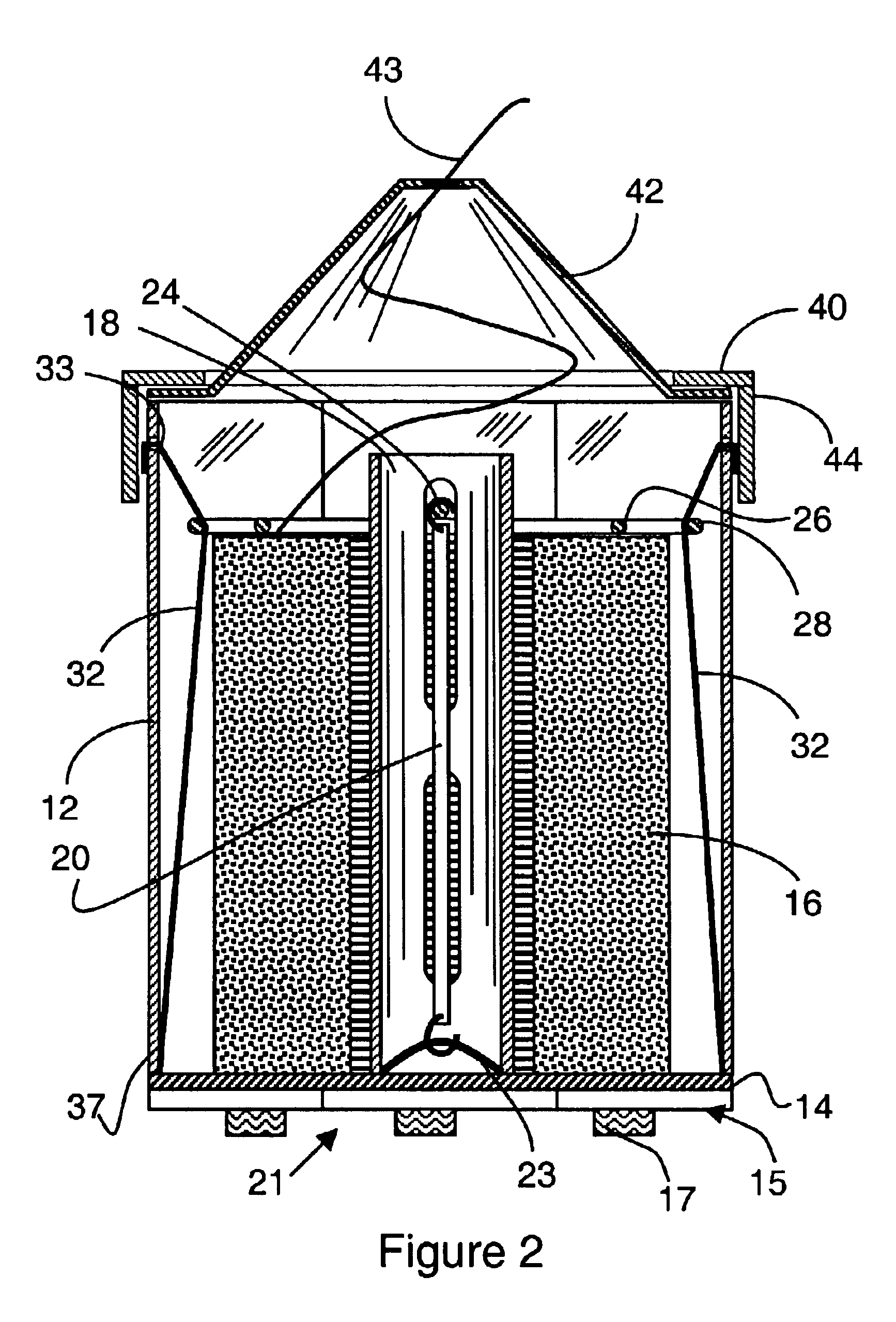

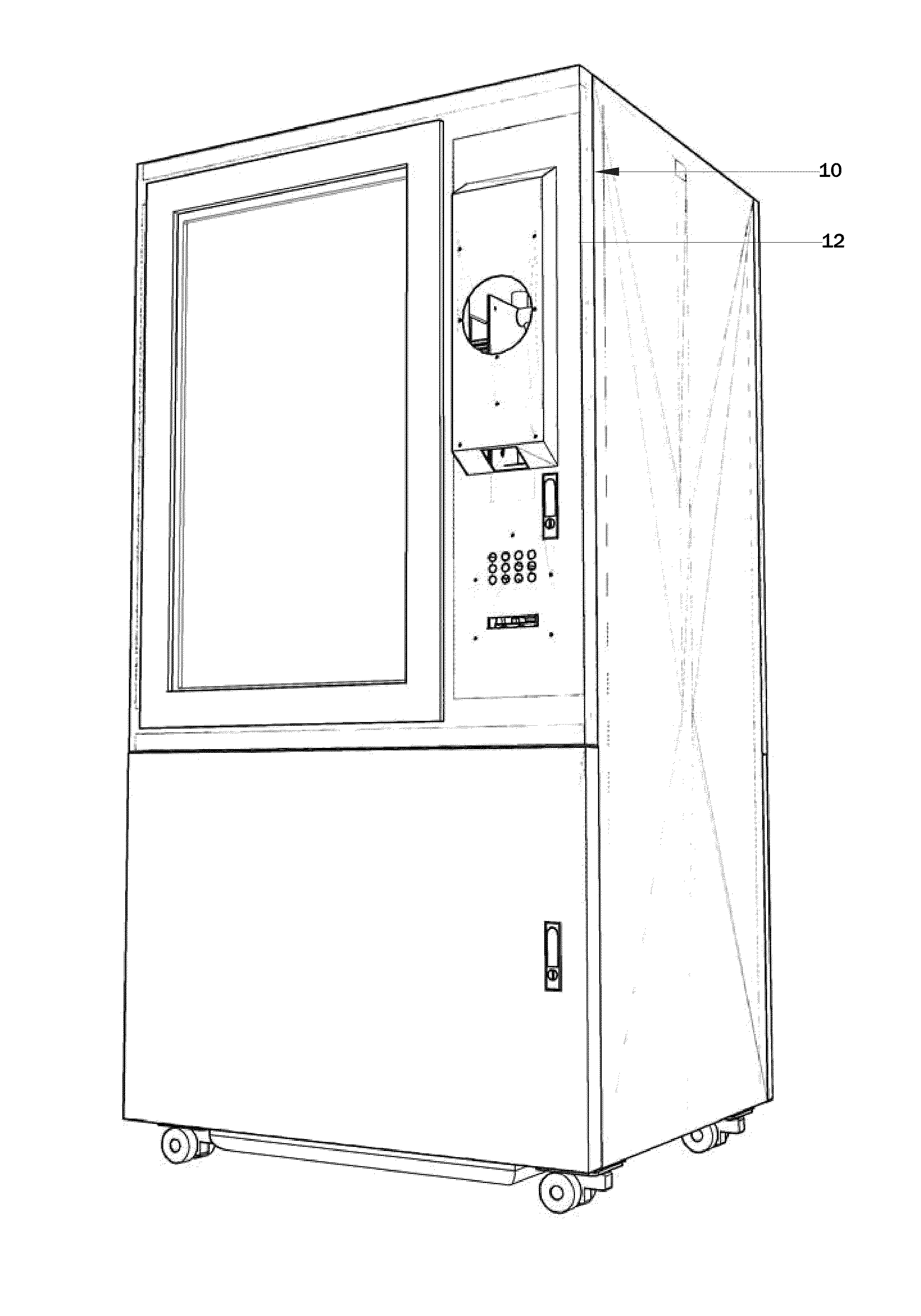

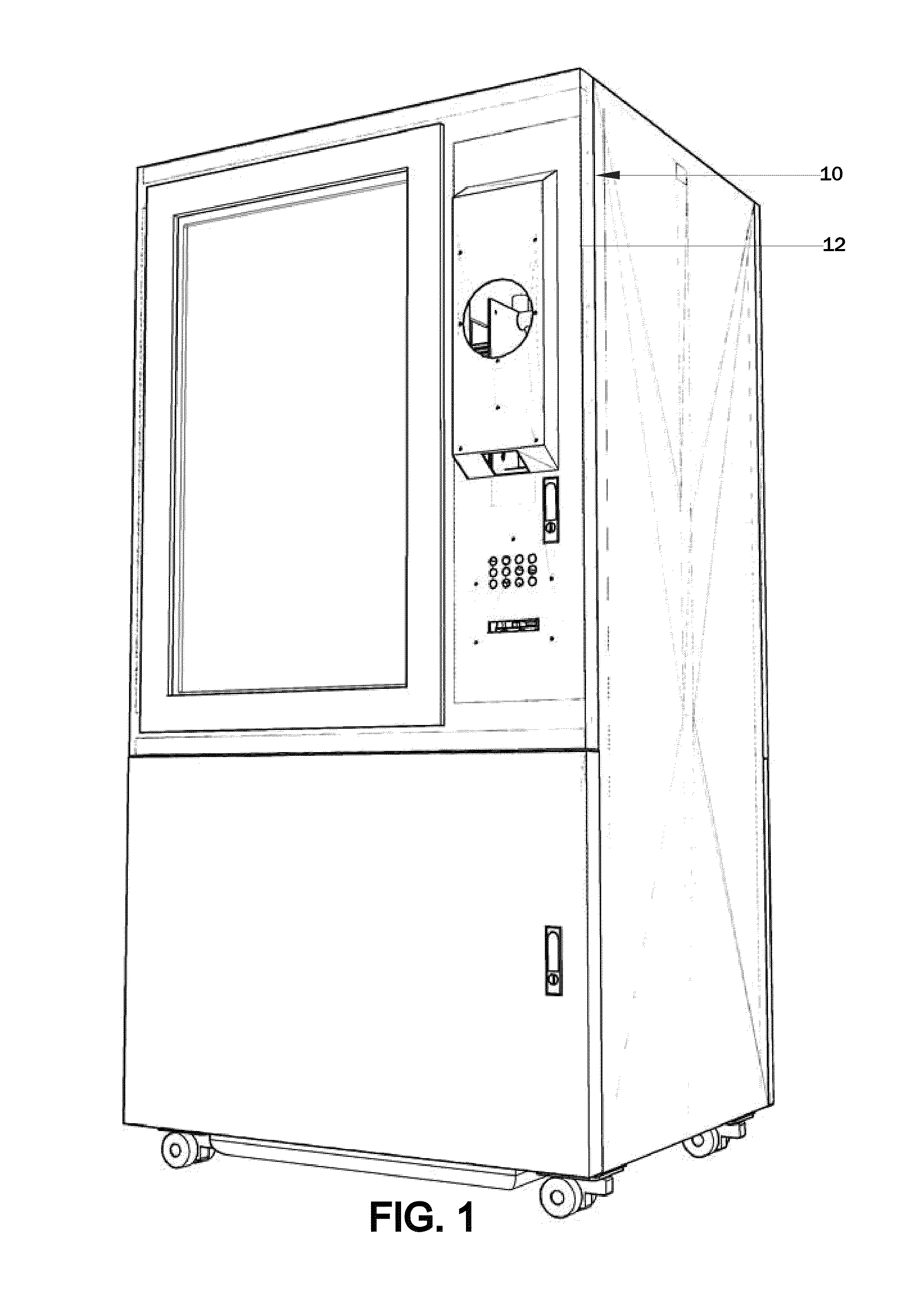

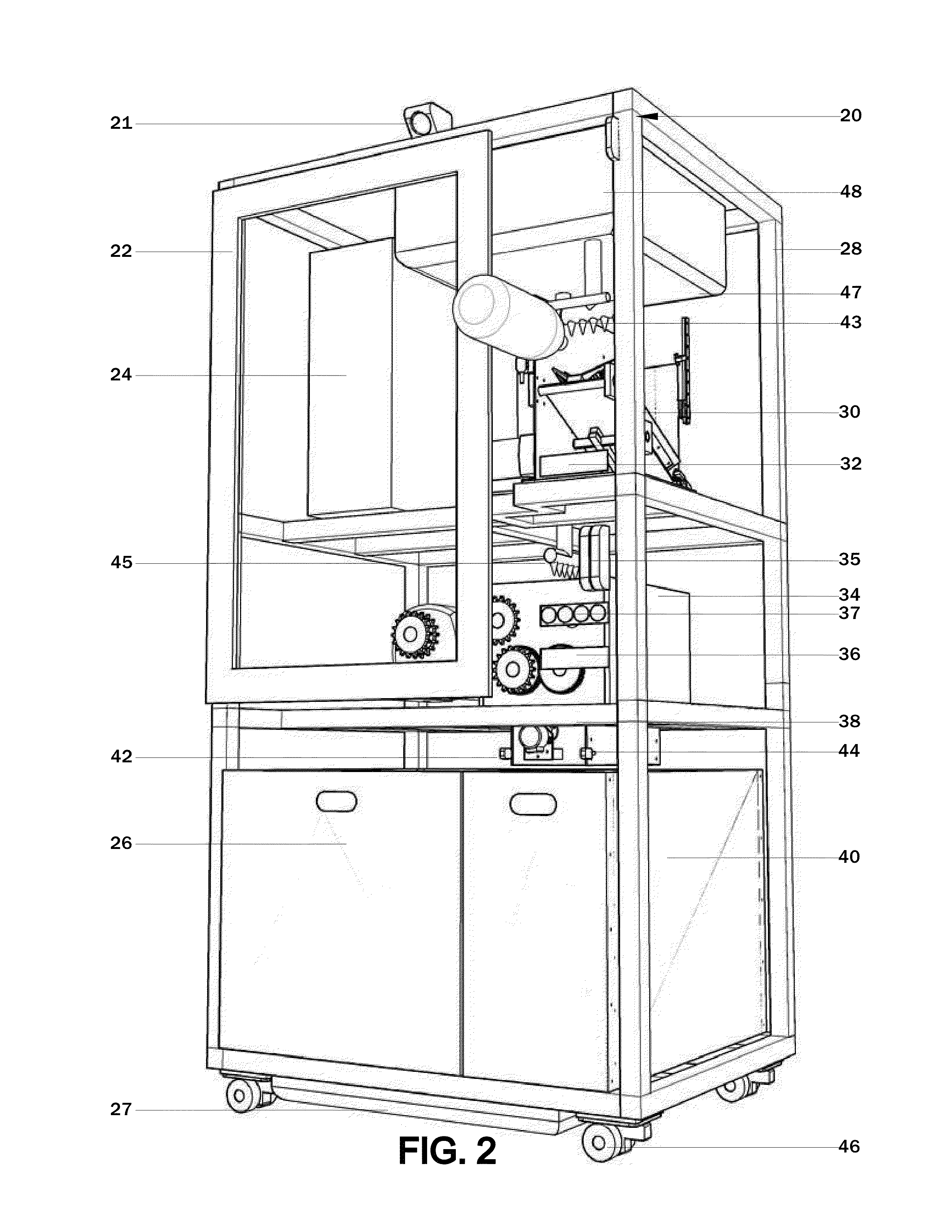

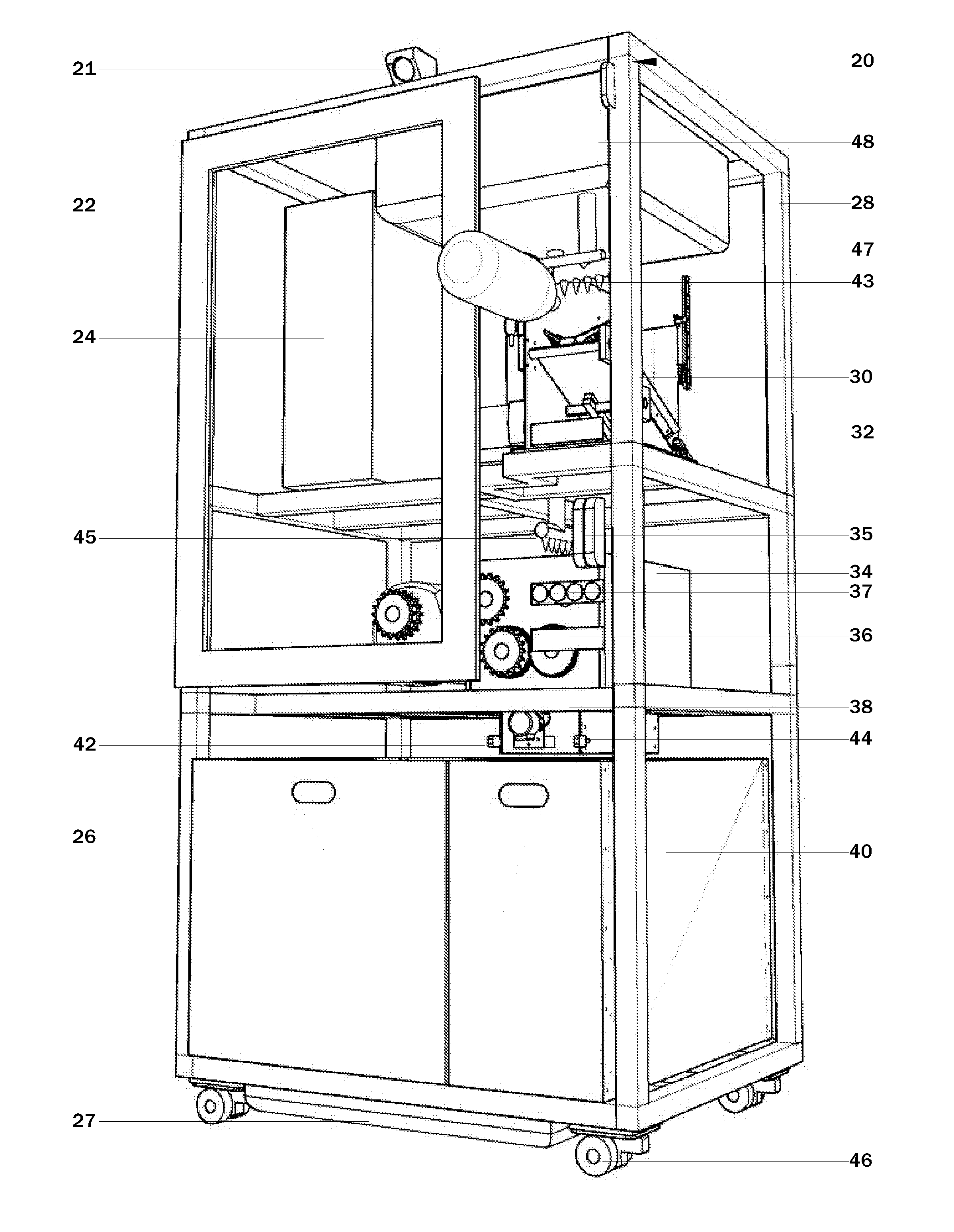

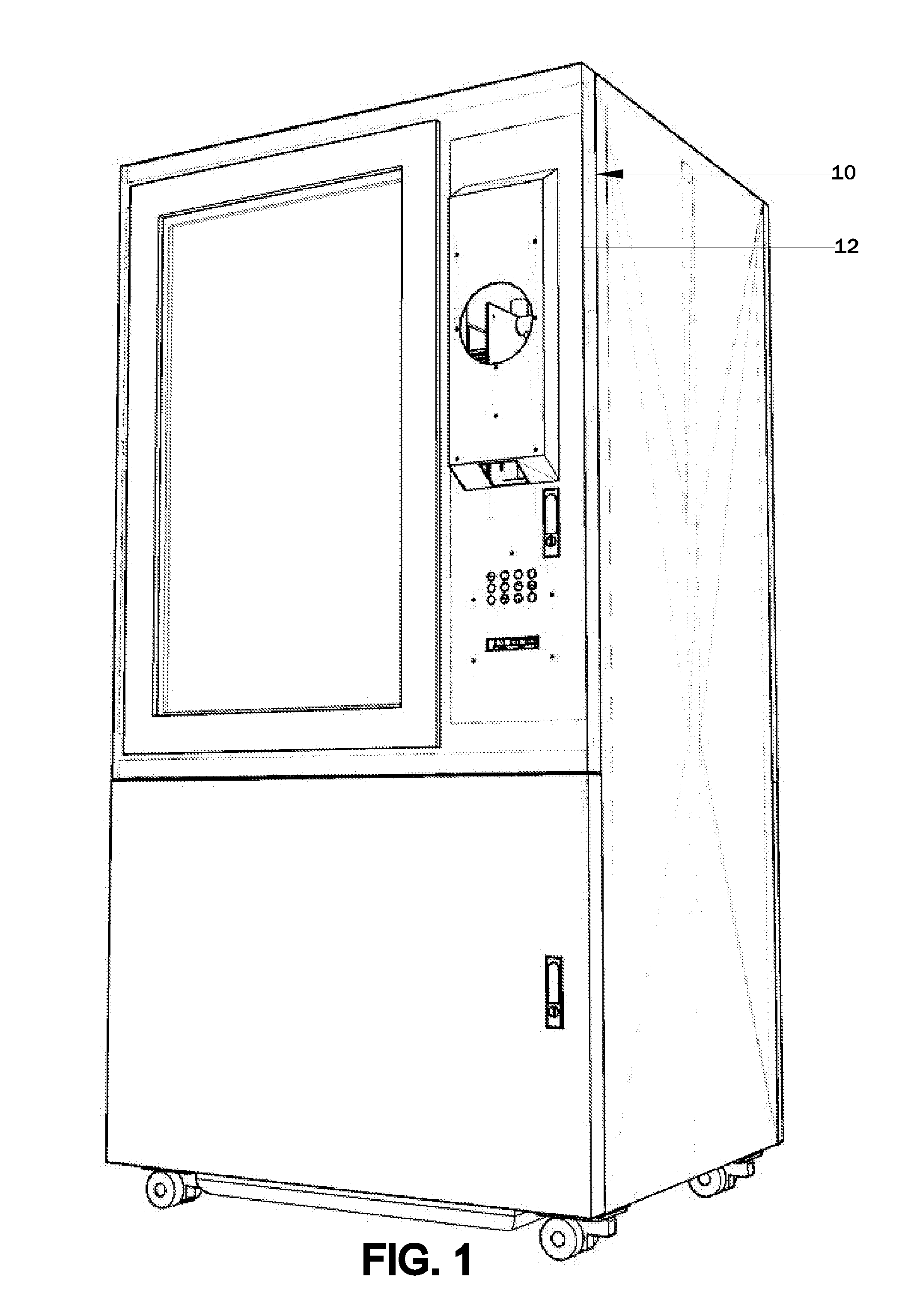

Reverse vending machine

ActiveUS8851265B2Continuous operationDigital data processing detailsCeramic shaping apparatusBarcodeEngineering

The present invention is a reverse vending machine which accepts non-metallic and metallic beverage containers for processing. The beverage containers are inserted by the user into an intake chute, where they are then compacted, sorted, and deposited in storage bins contained in the machine. A number of additional functions are provided by the reverse vending machine, including a self cleaning system, a video screen for displaying information to users, a bar code scanner for scanning bar codes, a user ID reader, and a coupon printer for issuing coupons to users. All transaction information is processed by a computer and stored electronically. The invention automatically returns non-empty containers and containers with unacceptable or unreadable bar codes to the user. The user is also provided warning messages when the storage bins are nearly full, or when a container is jammed in the machine.

Owner:RECYCLETECH

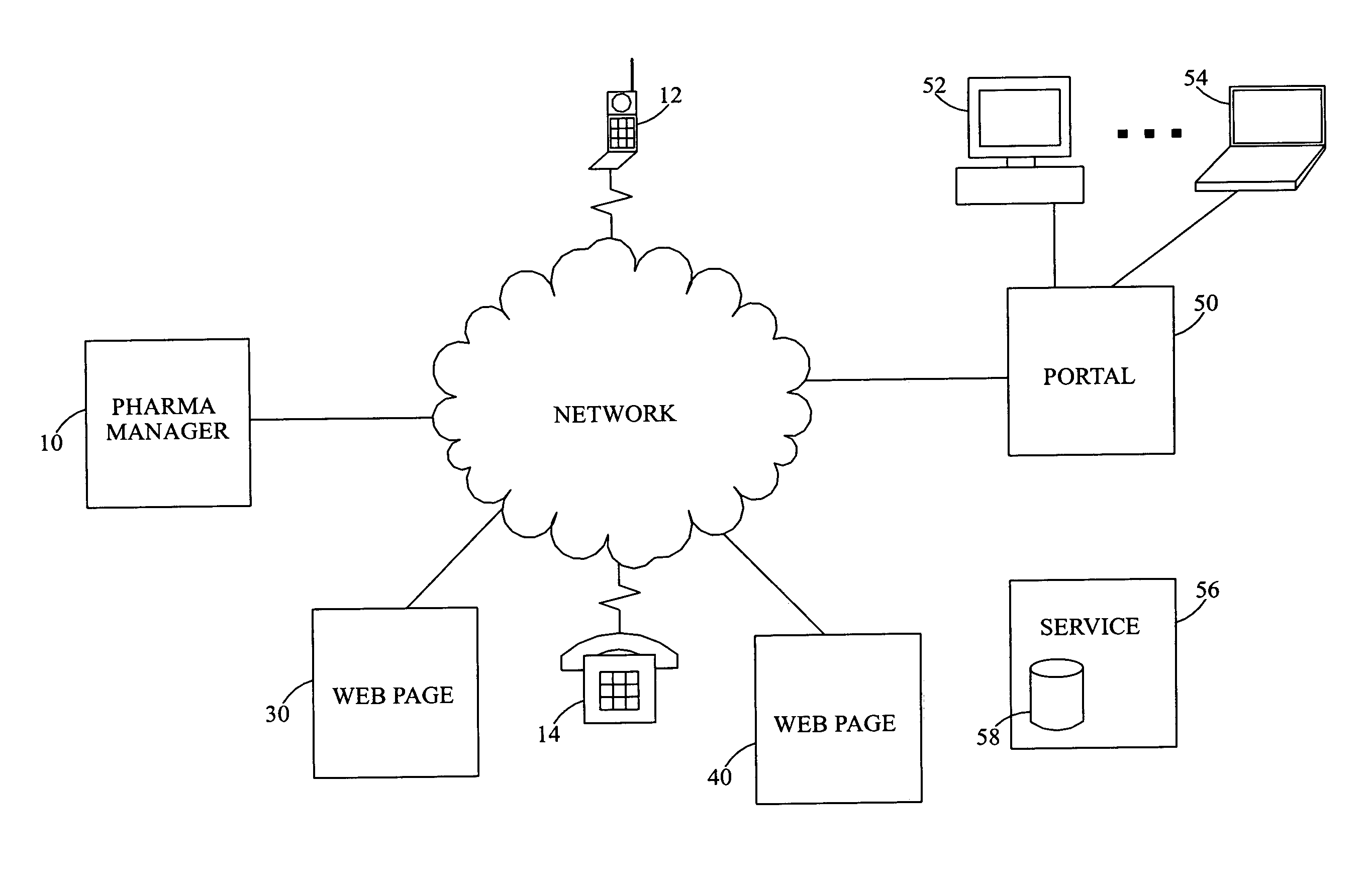

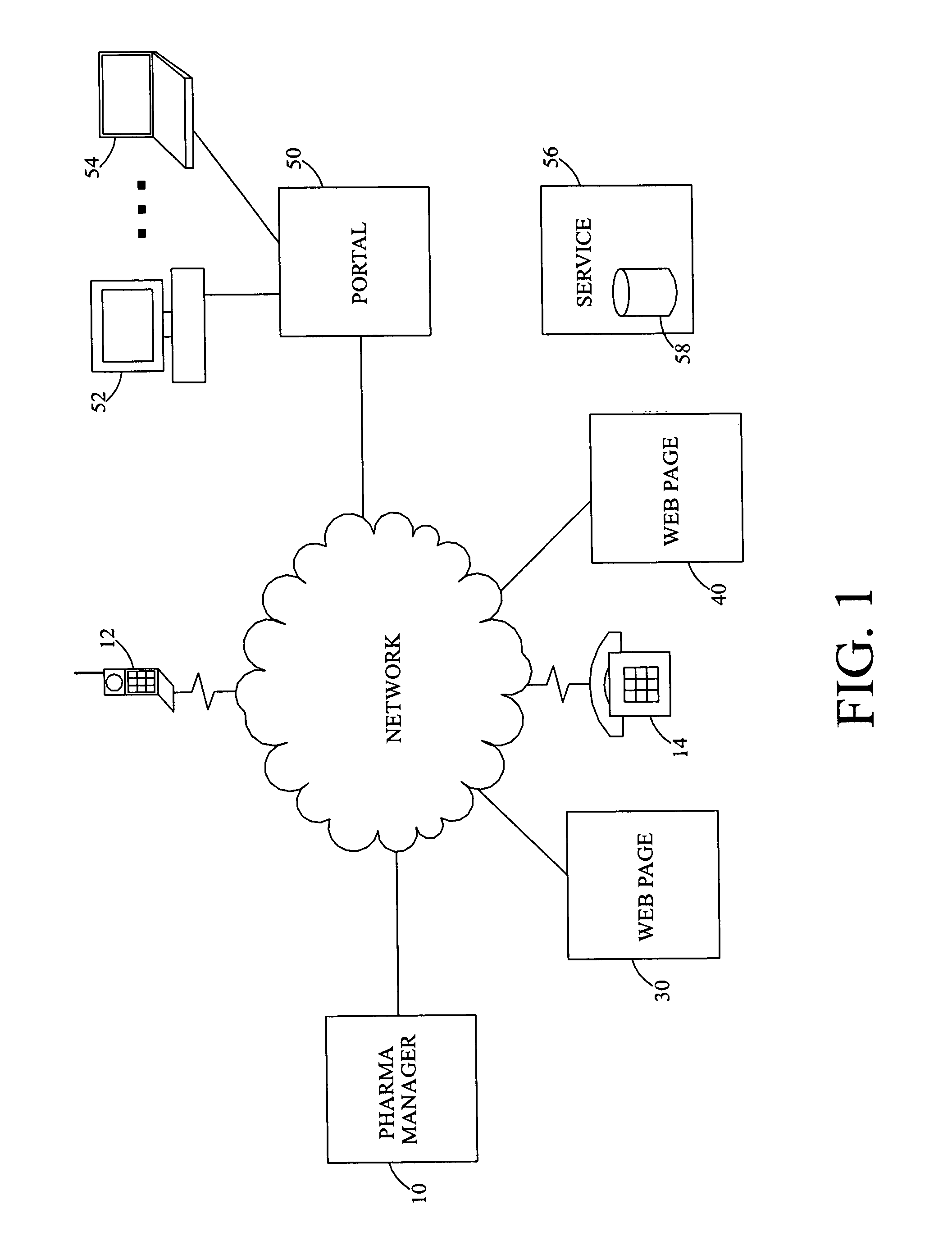

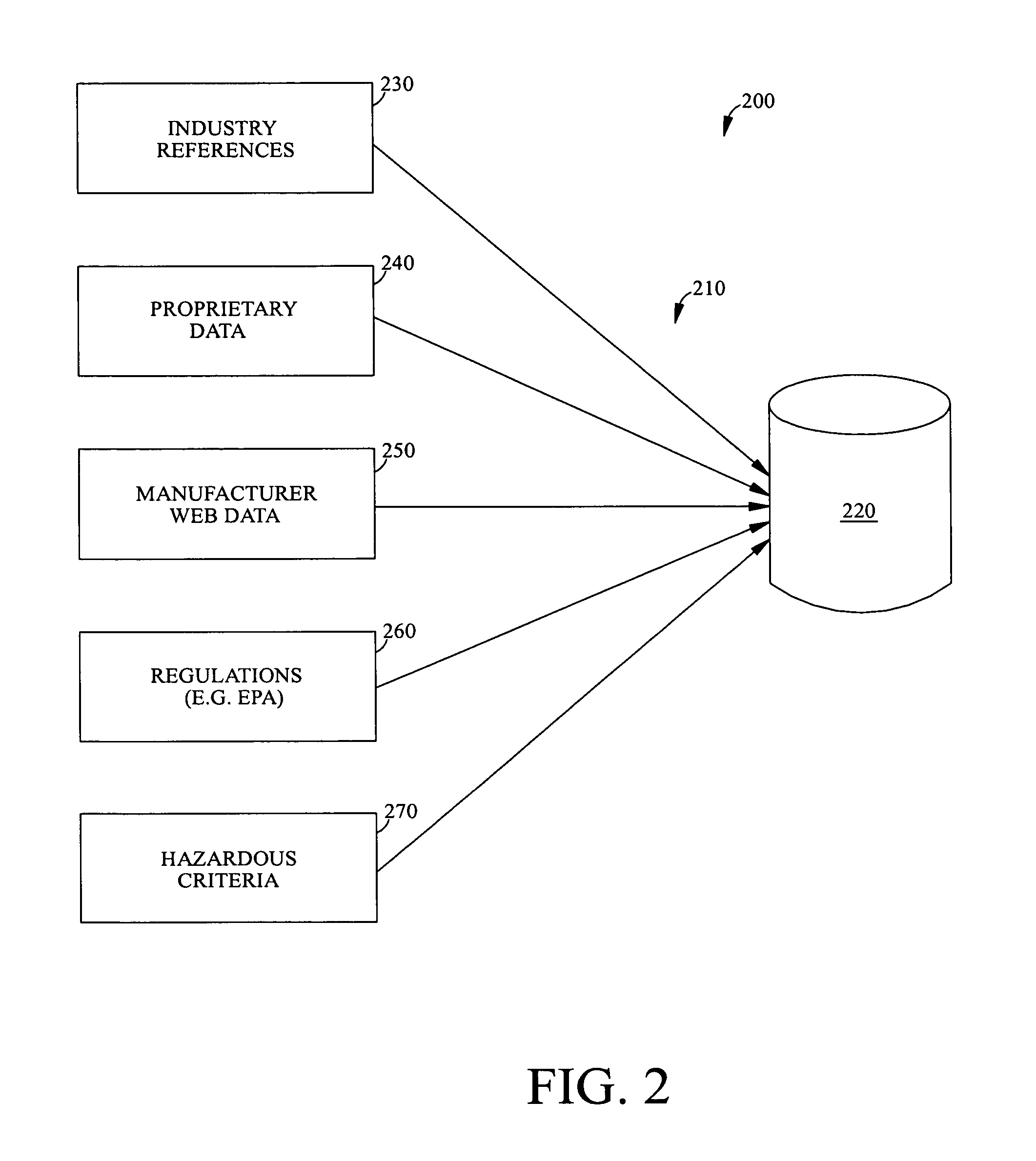

Pharmaceutical waste identification system

InactiveUS7366640B2Data processing applicationsDrug and medicationsIdentification systemPharmaceutical waste

A pharmaceutical waste identification system presents pharmaceutical waste information and, in response to a client entering a pharmaceutical name, the system provides a pharmaceutical waste disposal recommendation. This recommendation can include a labeling recommendation for a container for the pharmaceutical, a disposal recommendation for an empty container previously containing the pharmaceutical, and a disposal recommendation for the pharmaceutical.

Owner:WASTE MANAGEMENT NAT SERVICES INC

Reverse Vending Machine

ActiveUS20120173014A1Continuous operationAcutation objectsDigital data processing detailsBarcodeEngineering

The present invention is a reverse vending machine which accepts non-metallic and metallic beverage containers for processing. The beverage containers are inserted by the user into an intake chute, where they are then compacted, sorted, and deposited in storage bins contained in the machine. A number of additional functions are provided by the reverse vending machine, including a self cleaning system, a video screen for displaying information to users, a bar code scanner for scanning bar codes, a user ID reader, and a coupon printer for issuing coupons to users. All transaction information is processed by a computer and stored electronically. The invention automatically returns non-empty containers and containers with unacceptable or unreadable bar codes to the user. The user is also provided warning messages when the storage bins are nearly full, or when a container is jammed in the machine.

Owner:RECYCLETECH

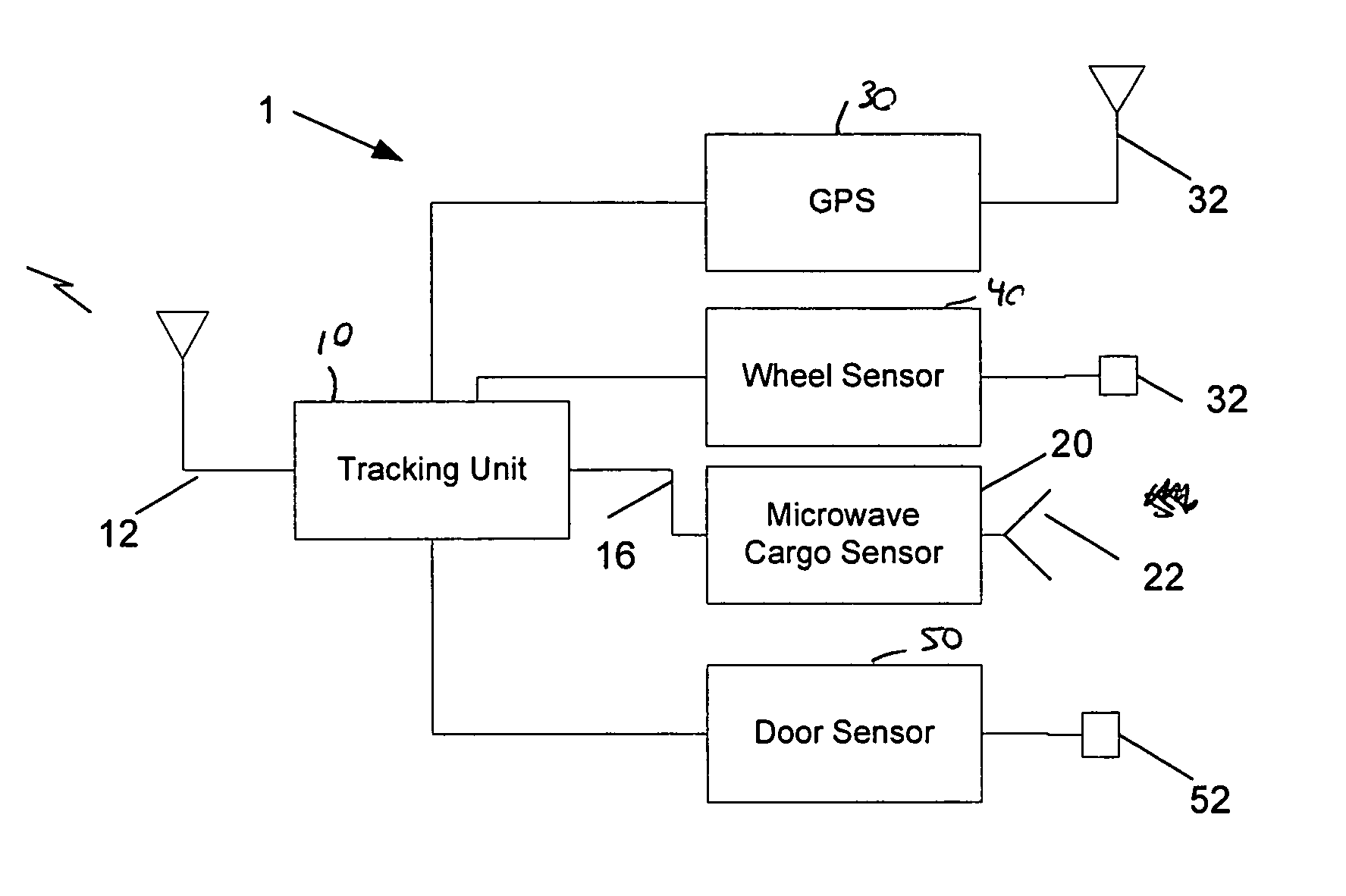

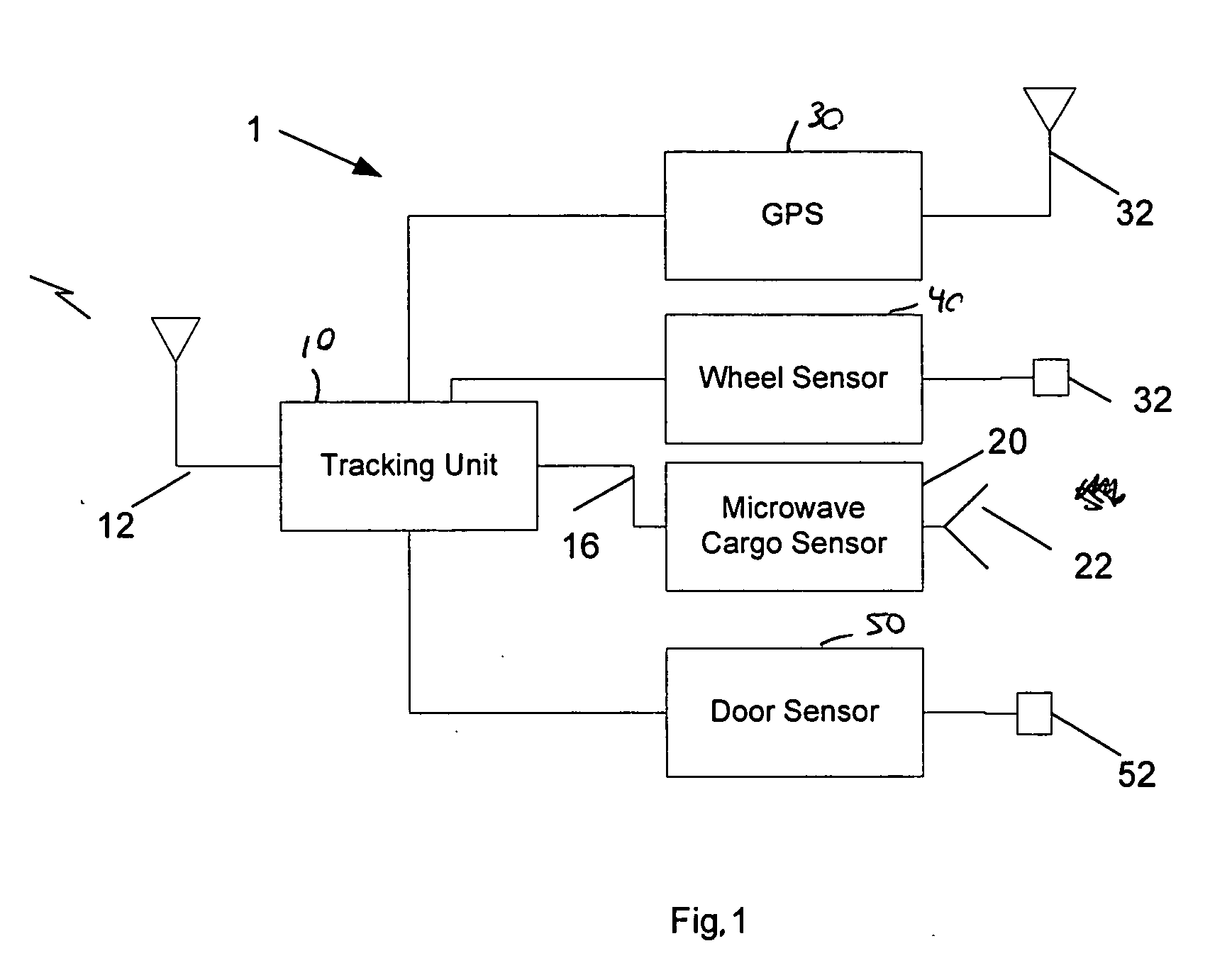

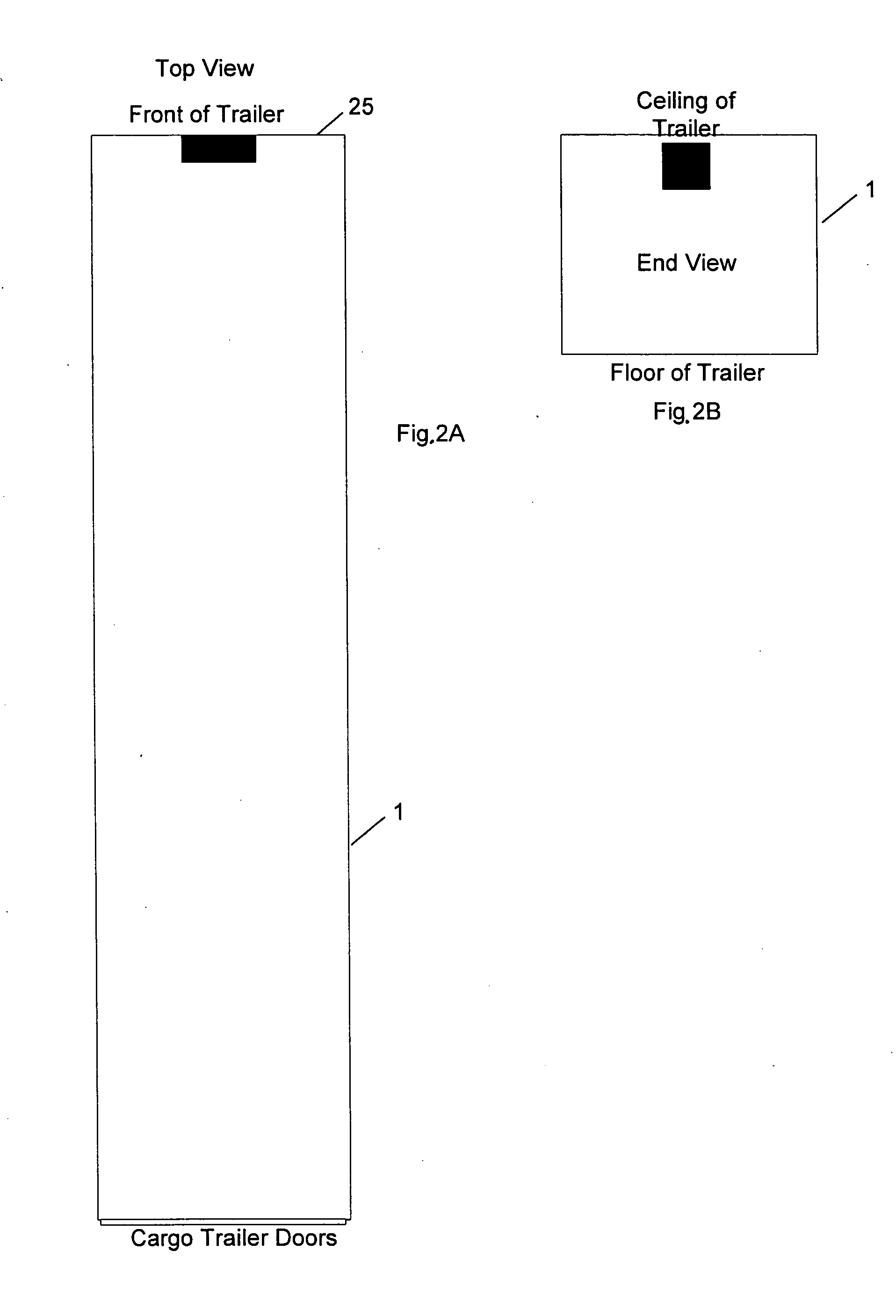

Detecting cargo status and load activity

InactiveUS20070040677A1Improve power efficiencyReduce the temperatureLogisticsBurglar alarm by hand-portable articles removalRadio frequency energyEngineering

A cargo detection unit that detect the status of cargo and loading activity within a container. The device transmits microwave radio frequency energy pulses and detects reflections from cargo. Similar to the operation of a radar, the reflected pulses are then analyzed to determine (a) the presence of cargo, such as by comparing the reflected pulses against stored empty containers signature signals and / or (b) detecting a Doppler effect, as caused by loading and / or unloading cargo from the container. The device may use standard radar signal processing techniques, i.e., a digital signal processor, to generate and analyze the reflected pulses cargo status. Activity reports can be forwarded to a cargo tracking unit such as one that uses a wireless mobile telephone communication network to report cargo status to a central location.

Owner:GENERAL ELECTRIC CO

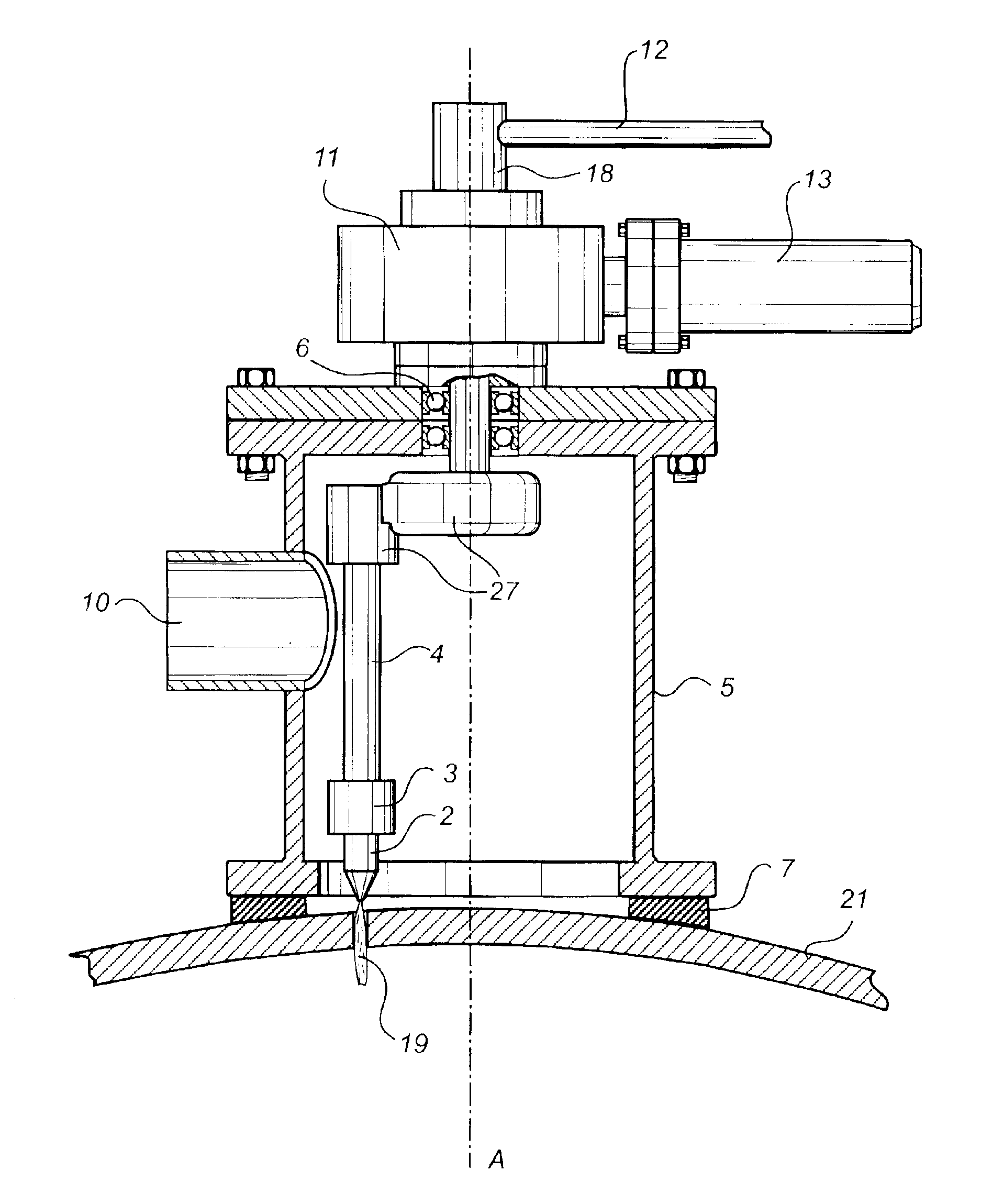

Hole cutting tool and method

InactiveUS6908372B2Risk minimizationTight powerfulAbrasive machine appurtenancesMetal working apparatusAbutmentEngineering

A tool and a method for cutting holes in a container wall such as in a tank, a cistern, a pipeline, a vehicle, a ship, a production like or the like that contains inflammable, explosive, or other hazardous gasses, and liquids. The tool includes means for pressurising a cutting medium and discharging said medium via a nozzle. The nozzle is arranged in an enclosing cover including a scalable safety outlet for evacuation of the container contents. The cover has means of sealed-off abutment against the container wall concerned in the area in which hole cutting is to be performed. The nozzle is arranged to be directed towards the container wall in such a way that in use the cutting medium is discharged in the form of a jet impinging against the container wall with sufficient force to cut through said wall.

Owner:COLT CUT SYST SVENSKA

Combined preparation and apparatus for use with a food blender and method for making preparation

InactiveUS20060003059A1Easy to useMeat/fish preservationKitchen equipmentSemi-solid foodIngested food

Owner:TABORA BURT

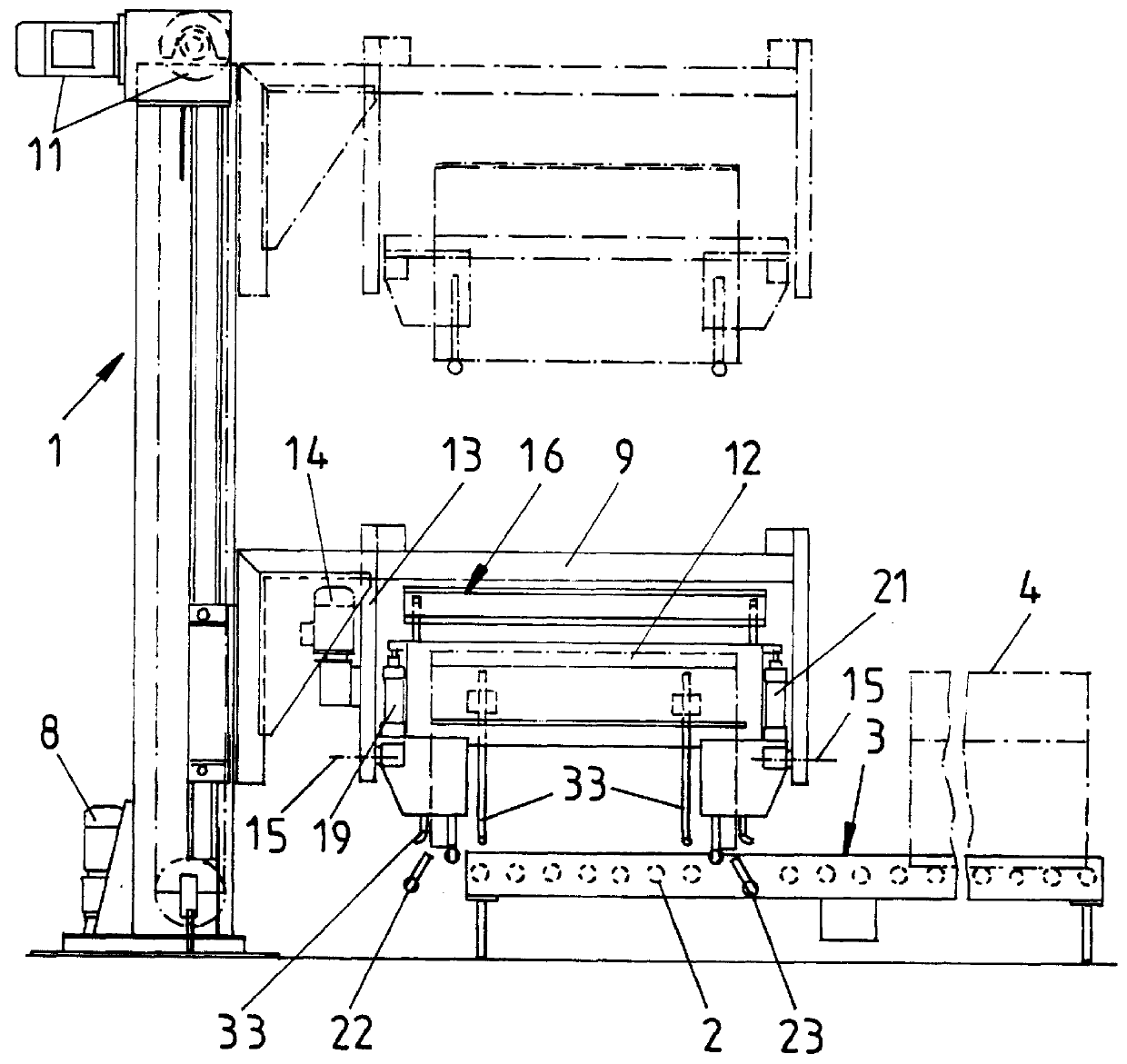

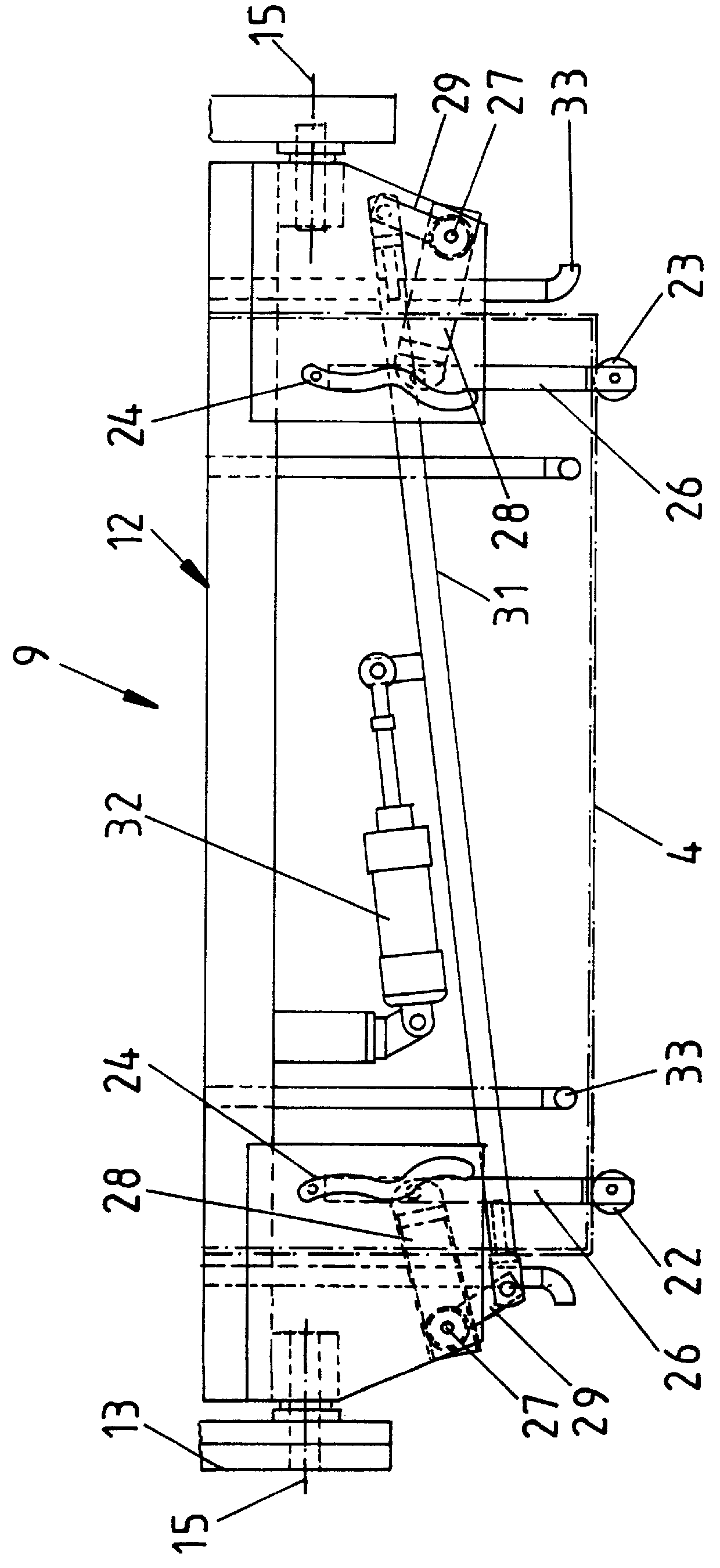

Method of and apparatus for emptying containers for flowable materials such as comminuted tobacco leaves

The contents of successive containers for comminuted tobacco leaves are transferred onto or into a receiver (such as a belt conveyor) at a transfer station where an indexible upright manipulator carries a lifter and an evacuating device including a tilting unit. Successive containers, delivered to the transfer station by a roller conveyor or the like, are lifted by the lifter off the conveyor and the manipulator is thereupon indexed to deliver the lifted container to a location above the receiver. The tilting unit is thereupon caused to tilt the container to thus transfer, by gravity flow, the contents of the container onto an openable intercepting device at a level between the tilter and the receiver. The intercepting device is thereupon opened to permit the intercepted material to descend onto or into the receiver. The manipulator is thereupon indexed to move the emptied container to a position above a further conveyor serving to transport empty containers away from the transfer station. The multi-stage transfer of particulate material from a container above the receiver onto or into the receiver reduces the generation of dust and the likelihood of undesirable comminution of such material.

Owner:HAUNI MASCHINENBAU AG

Automatic empty container return machine equipped with self-cleaning arrangement

InactiveUS6575290B2Problems due to cramped space are eliminatedOptimal and efficient cleaningCleaningHollow article cleaningProcess engineeringIndustrial engineering

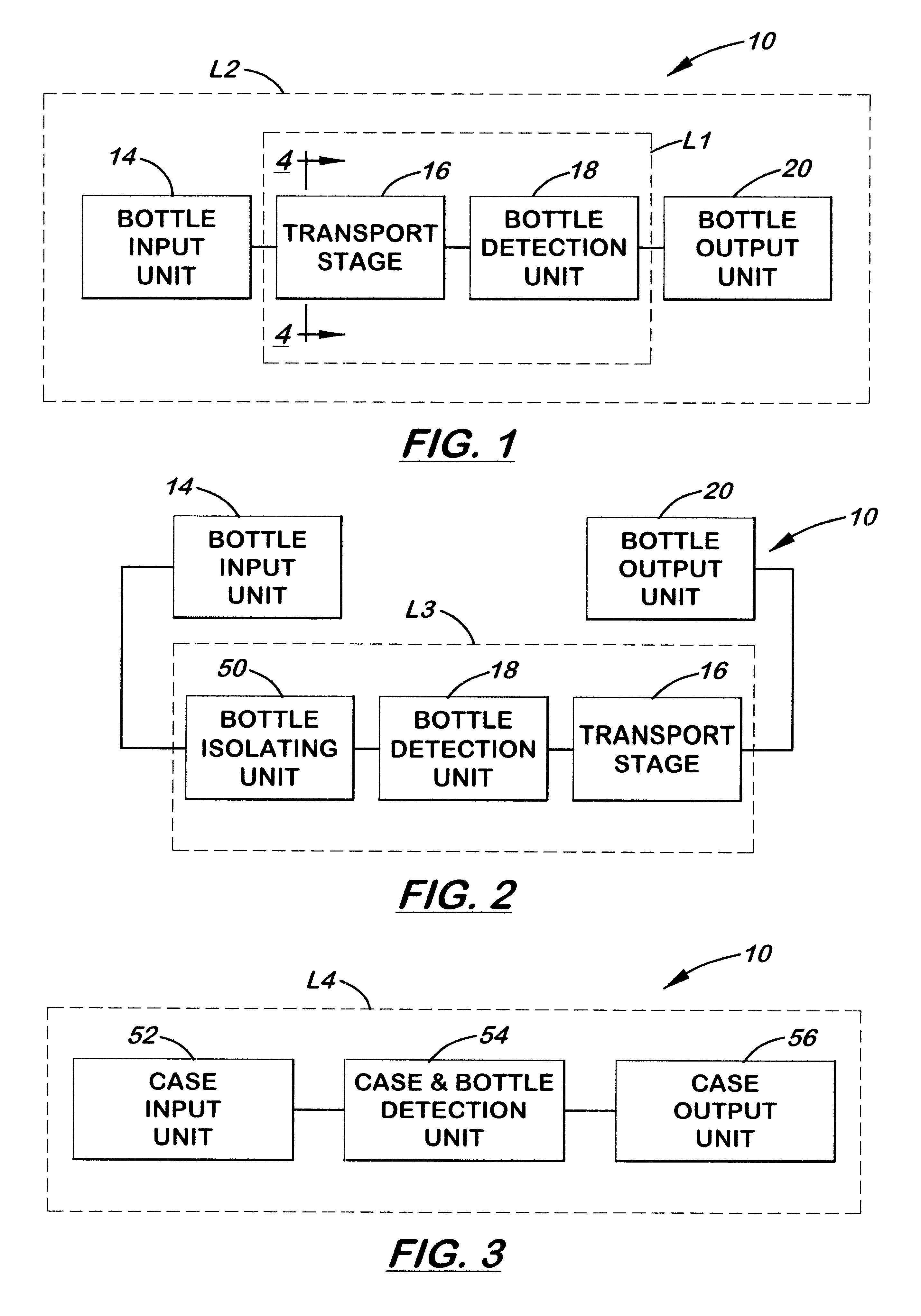

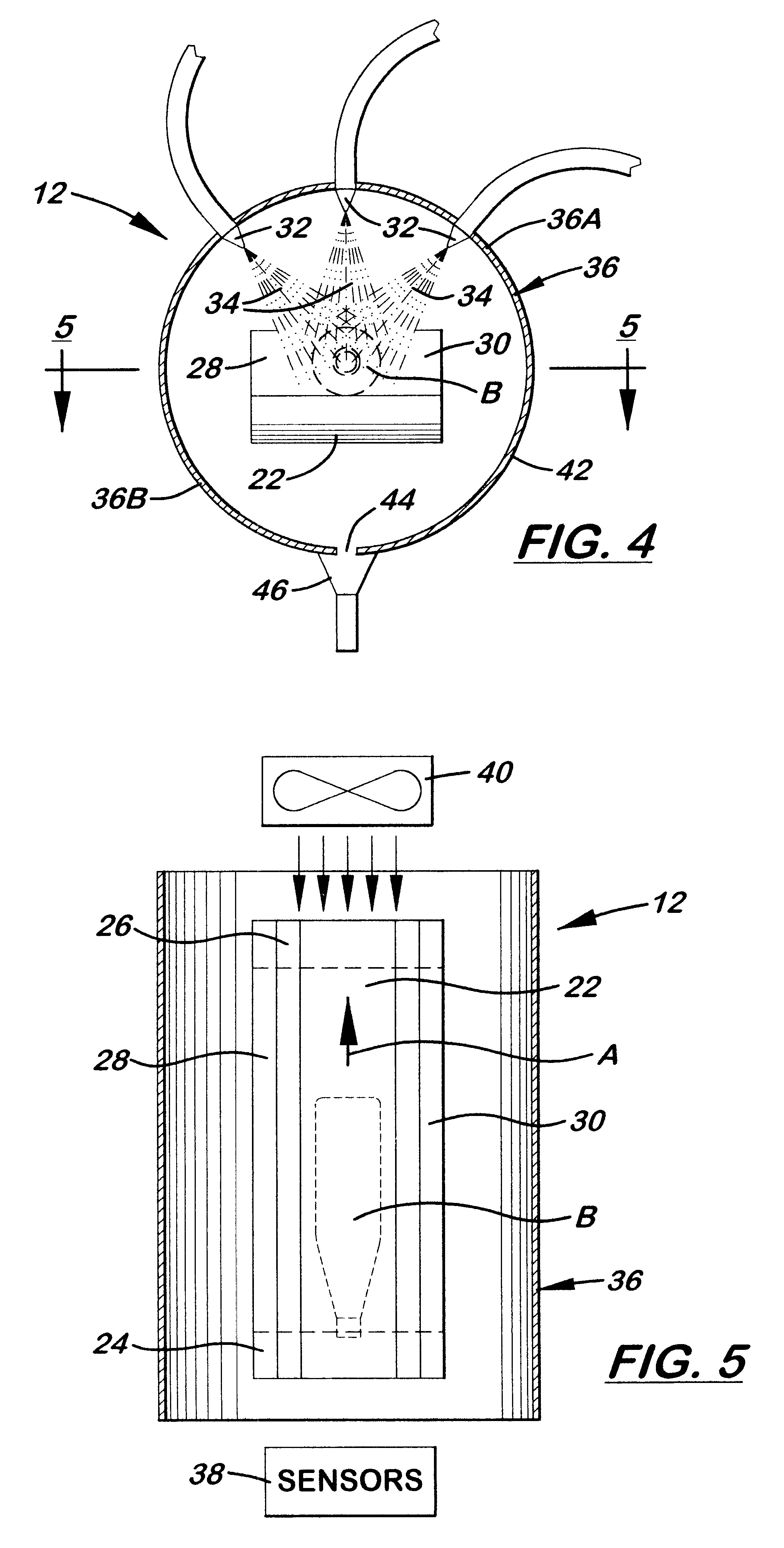

An automatic empty container return machine includes a detection unit operable for identifying whether or not an empty container is of a predetermined category, an input unit located upstream of the detection unit for receiving empty containers to supply the empty containers to the detection unit, an output unit located downstream of the detection unit for receiving empty containers that have been identified by the detection unit as being of the predetermined category, a transport stage having a conveyor for transporting empty containers from the input unit through the detection unit to the output unit, and a self-cleaning arrangement having components integrated with at least one of the input unit, detection unit, output unit and transport stage and being operable at selected times to clean surfaces thereof that are preselected to be cleaned.

Owner:WINCOR NIXDORF INT

Sterile filling machine having needle filling station within E-Beam chamber

InactiveUS20050173020A1Eliminate the risk of contaminationObstruct passageLiquid fillingPackage sterilisationBiomedical engineeringElectron

A sterile filling machine and related method are provided for sterile filling a container with a substance. The container includes a heat resealable stopper and a chamber for receiving the substance therein. The sealed, empty containers are subjected to radiation capable of penetrating through the stopper and chamber for sterilizing the container. The previously sterilized containers are then transported through an e-beam chamber, wherein an electron beam is directed onto a penetrable surface of the stopper to sterilize the penetrable surface. A needle is mounted within the e-beam chamber and moved into engagement with the stopper to pierce the sterilized penetrable surface of the stopper and inject the substance through the needle and into the chamber of the container. The needle is then withdrawn from the stopper and the filled container is transported outside of the e-beam chamber. Laser energy is then transmitted onto the penetrated surface of the stopper to fuse the stopper material and hermetically re-seal the stopper.

Owner:MEDICAL INSTILL TECH

Method for filling containers with piece goods

Owner:ROBERT BOSCH GMBH

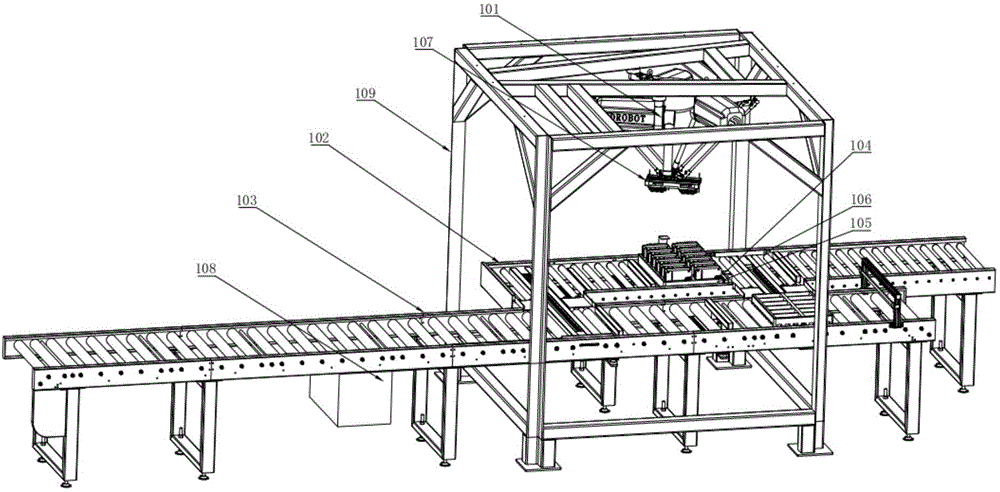

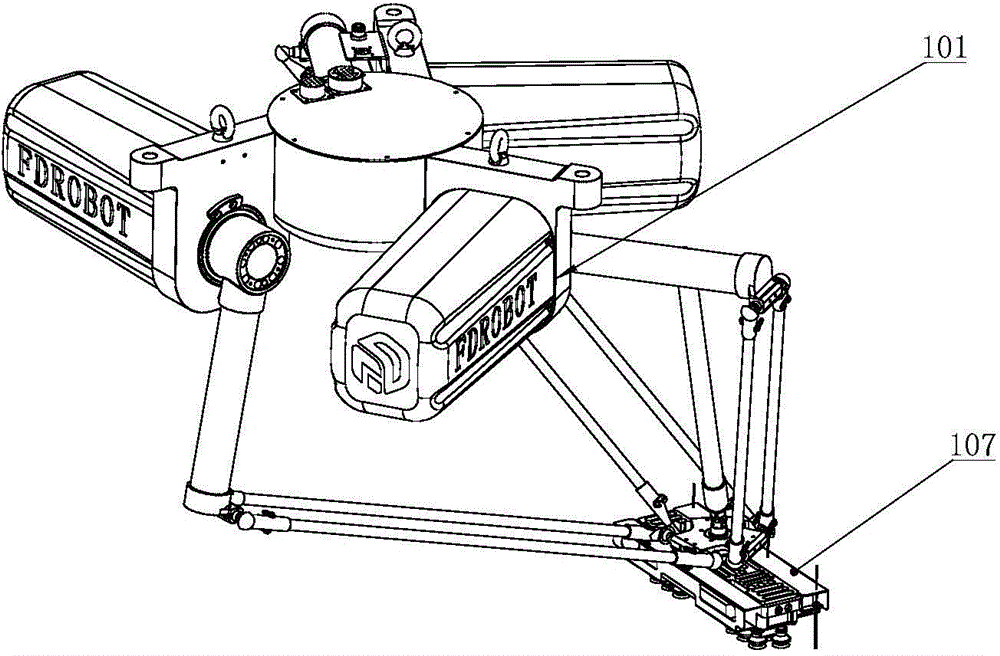

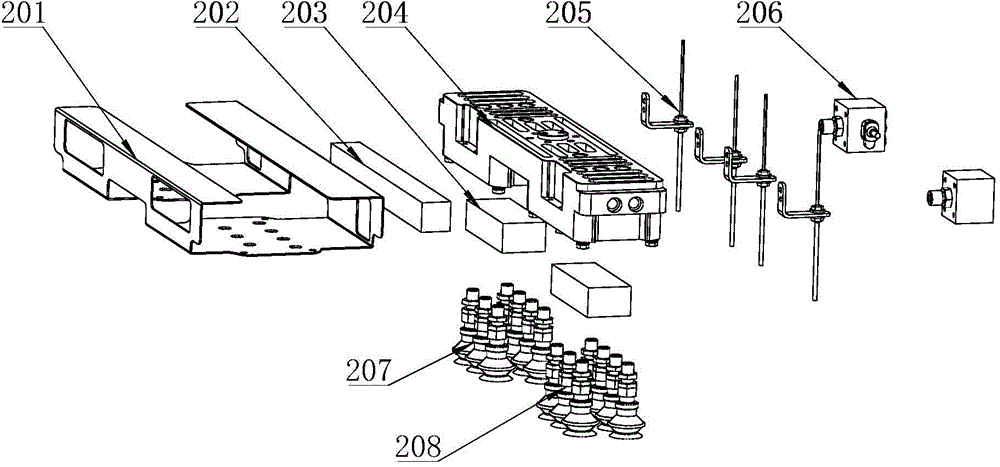

Automatic sorting system for electric energy meters, and method

The present invention discloses an automatic sorting system of electric energy meters, which comprises a full carton conveying line, an empty carton conveying line, a control system, a robot, a carton blocking device, a carton clamping device, a carton removing device, an intelligent claw, and a rack, wherein the robot, the carton blocking device, the carton clamping device, the carton removing device, the intelligent claw and the rack are respectively connected with the control system, the intelligent claw scans the loading-into-carton state of the electric energy meter in the carton and uploads to the control system, and the control system determines the sorting position according to the electric energy meter position information and the loading-into-carton state of the electric energy meter. The present invention provides the automatic sorting system integrating the detecting and the grabbing, wherein the robot is adopted to perform automatic sorting so as to reduces the labor intensity of the worker, the intelligent claw carried on the robot terminal end integrates the detecting and the grabbing so as to reduce the cost and increase the production efficiency and the equipment utilization rate, the automatic sorting system achieves the functions of the automatic sorting of the electric energy meter and the automatic removing of the empty carton, and the loading-into-carton position information and the forward and reverse loading-into-carton information of the electric energy meter can be automatically recognized so as to increase the grabbing efficiency and the grabbing reliability of the electric energy meter.

Owner:STATE GRID CHONGQING ELECTRIC POWER CO ELECTRIC POWER RES INST +1

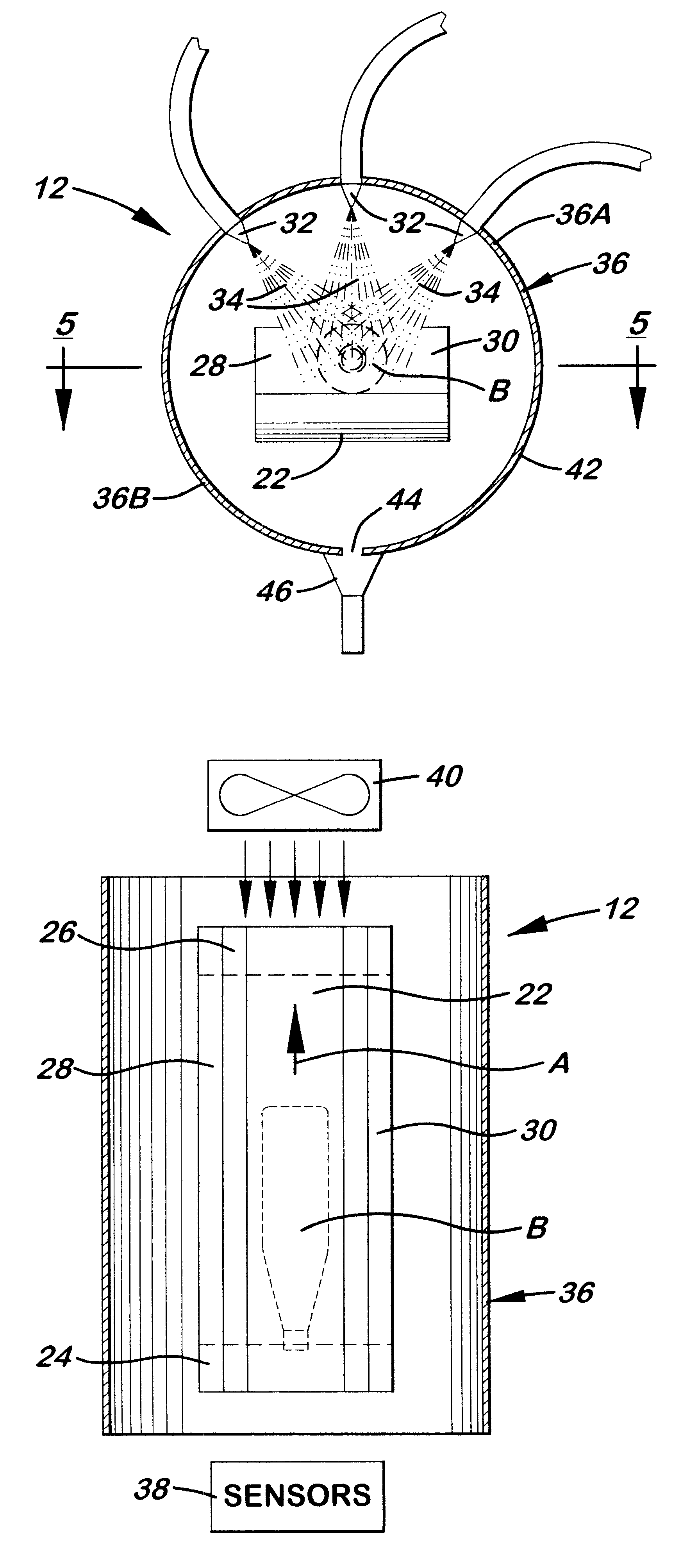

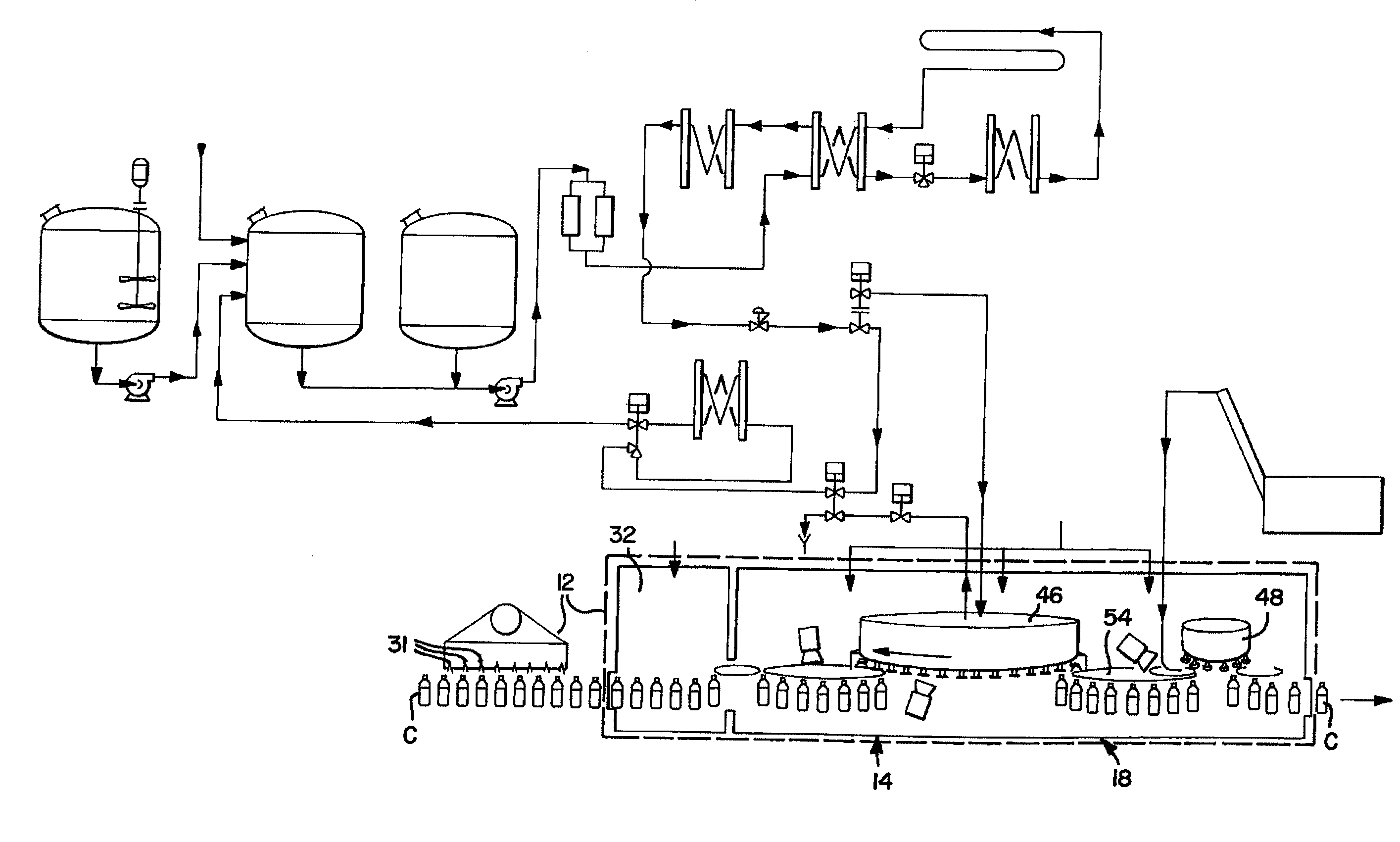

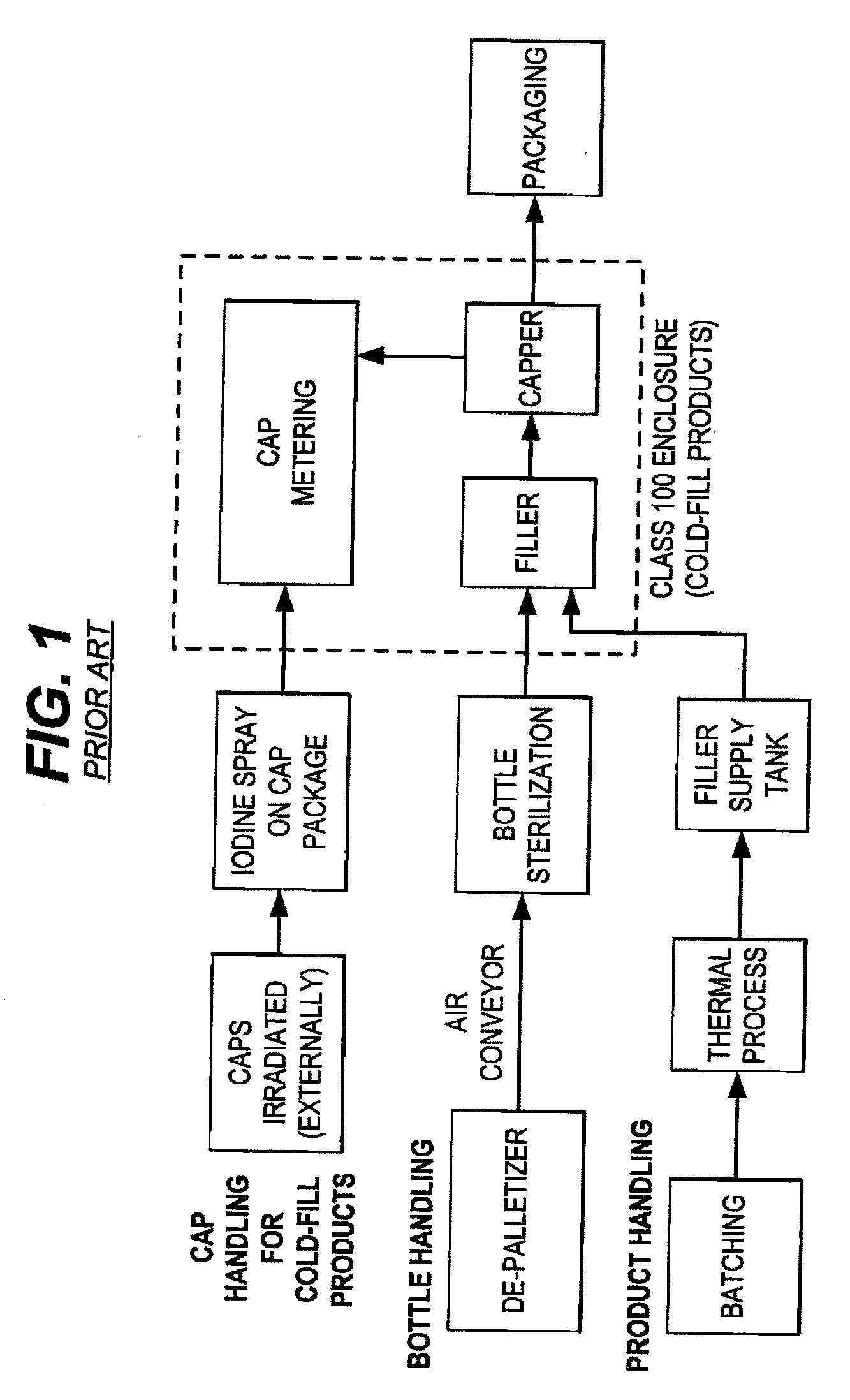

Active sterilization zone for container filling

InactiveUS20090013645A1Maintain a sterile environmentLiquid fillingSynchronising machinesEngineeringEMPTY CONTAINER

Owner:STOKLEY VAN CAMP INC

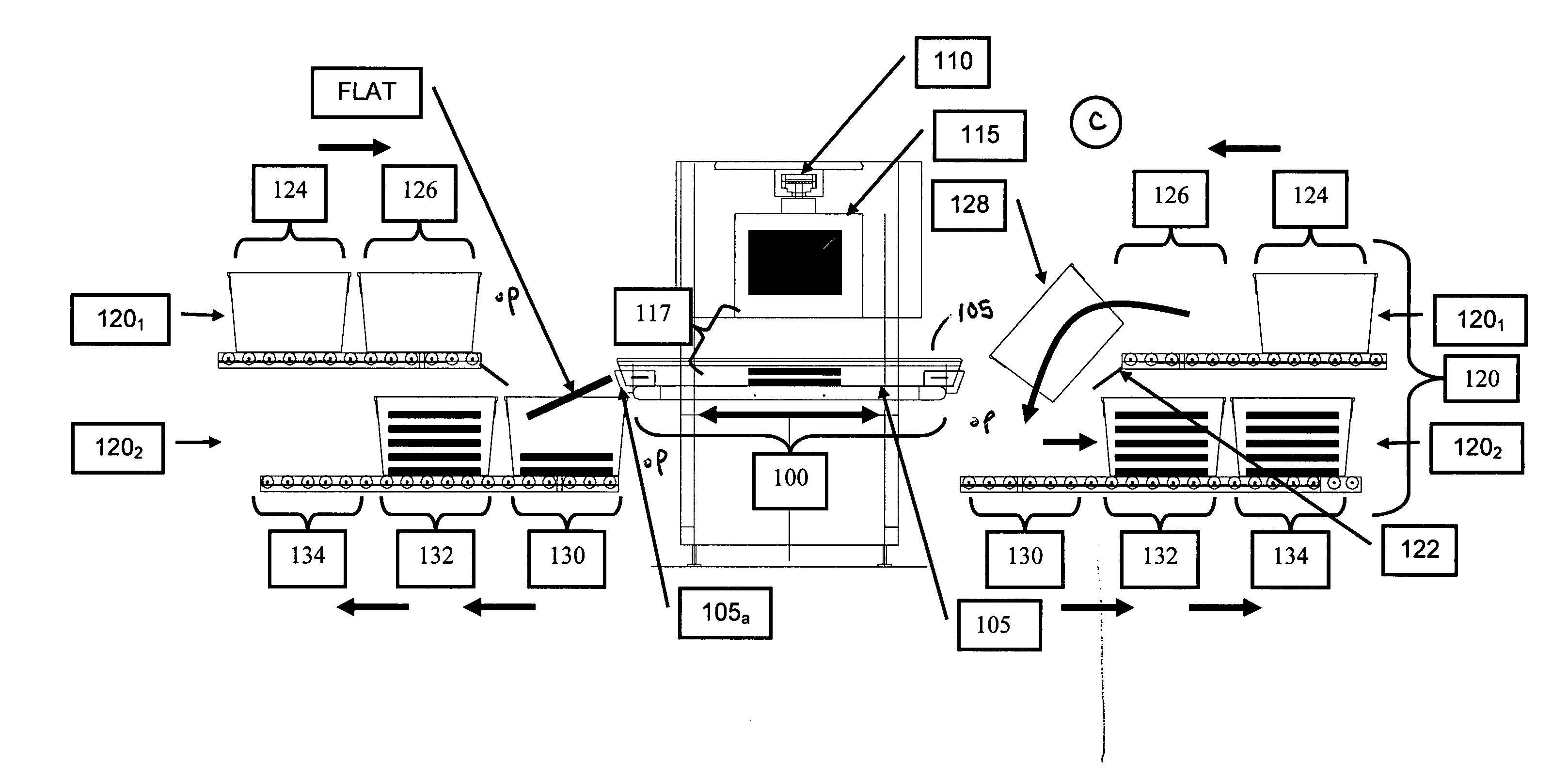

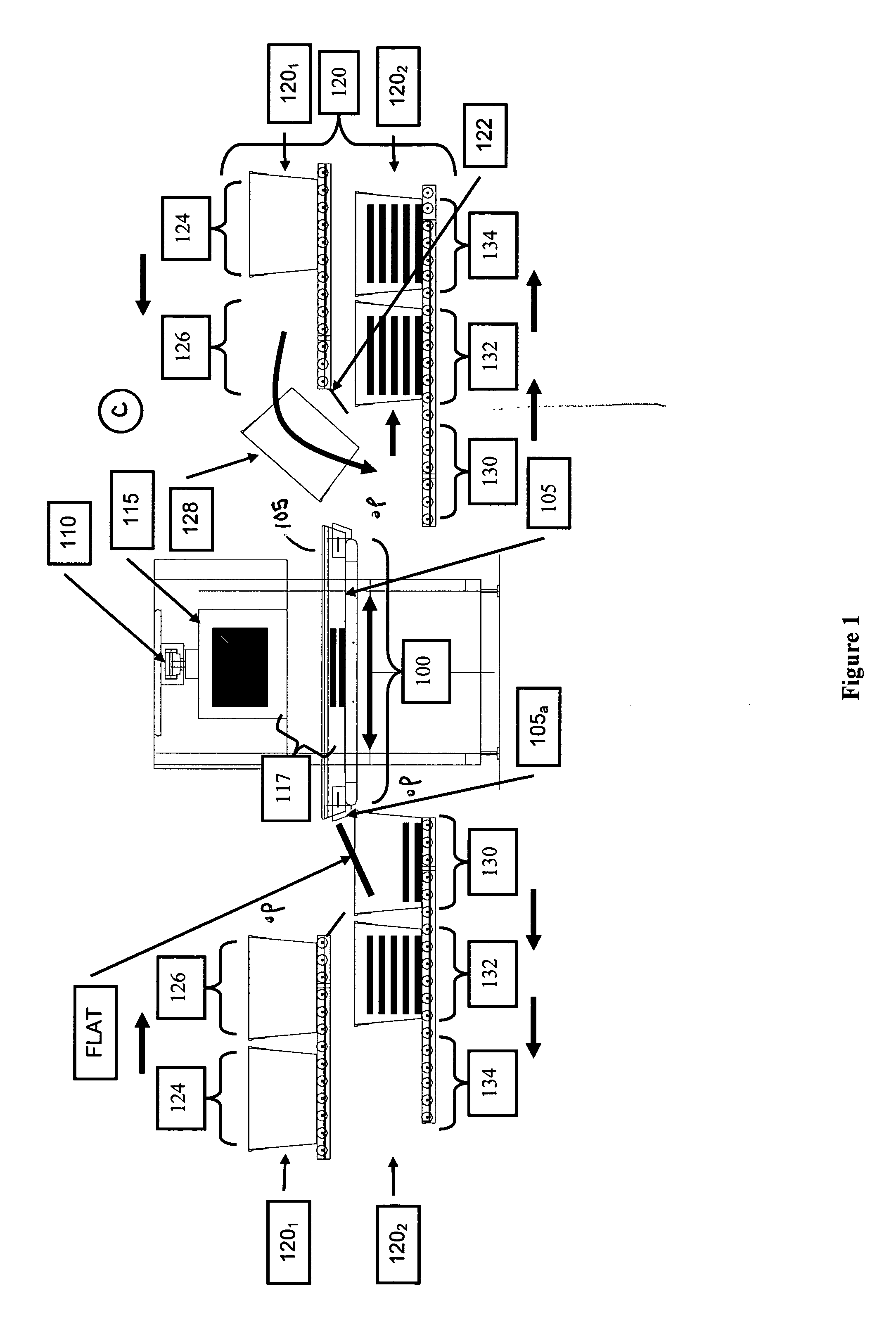

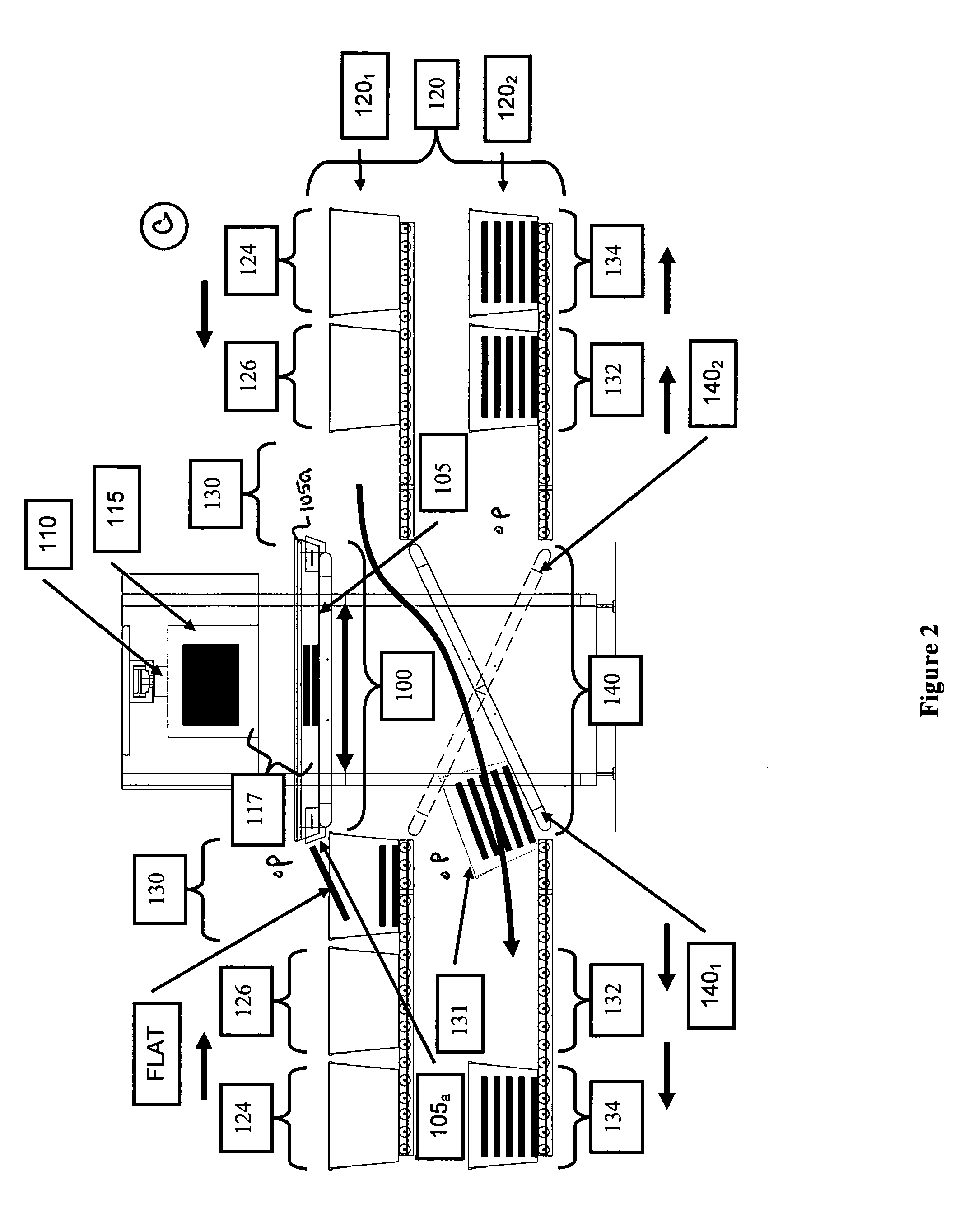

Bi-directional sort mechanism and method of use

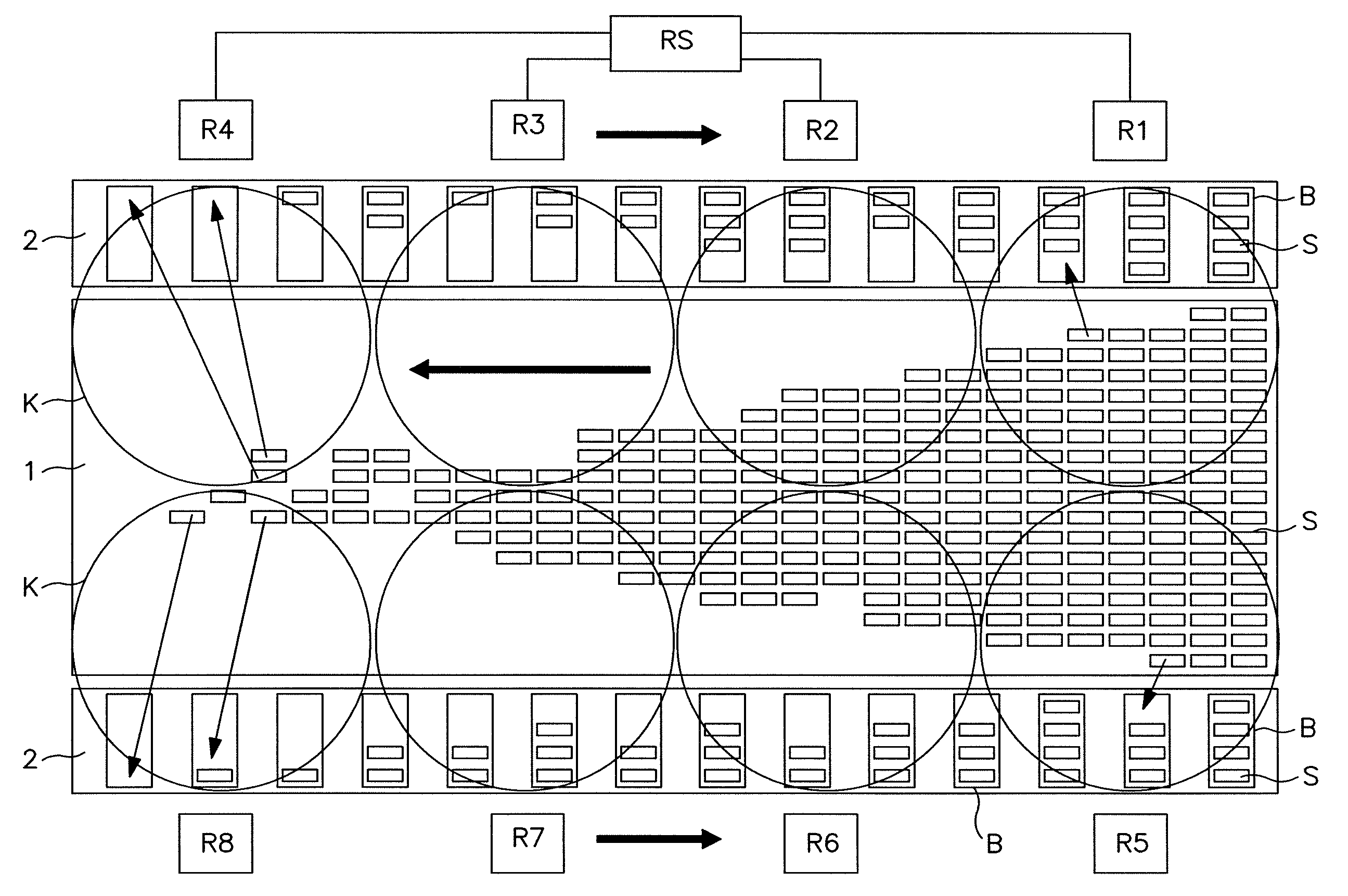

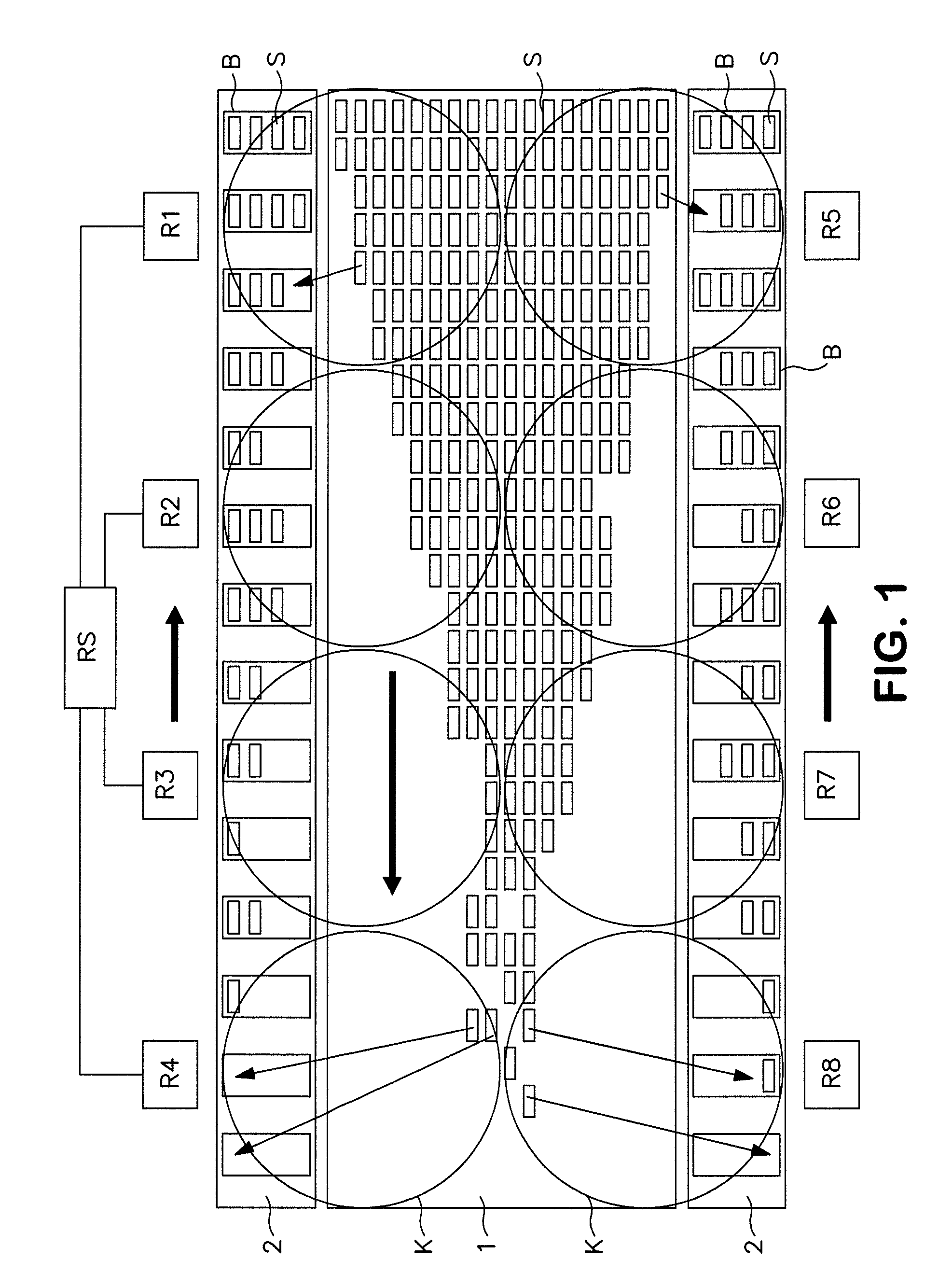

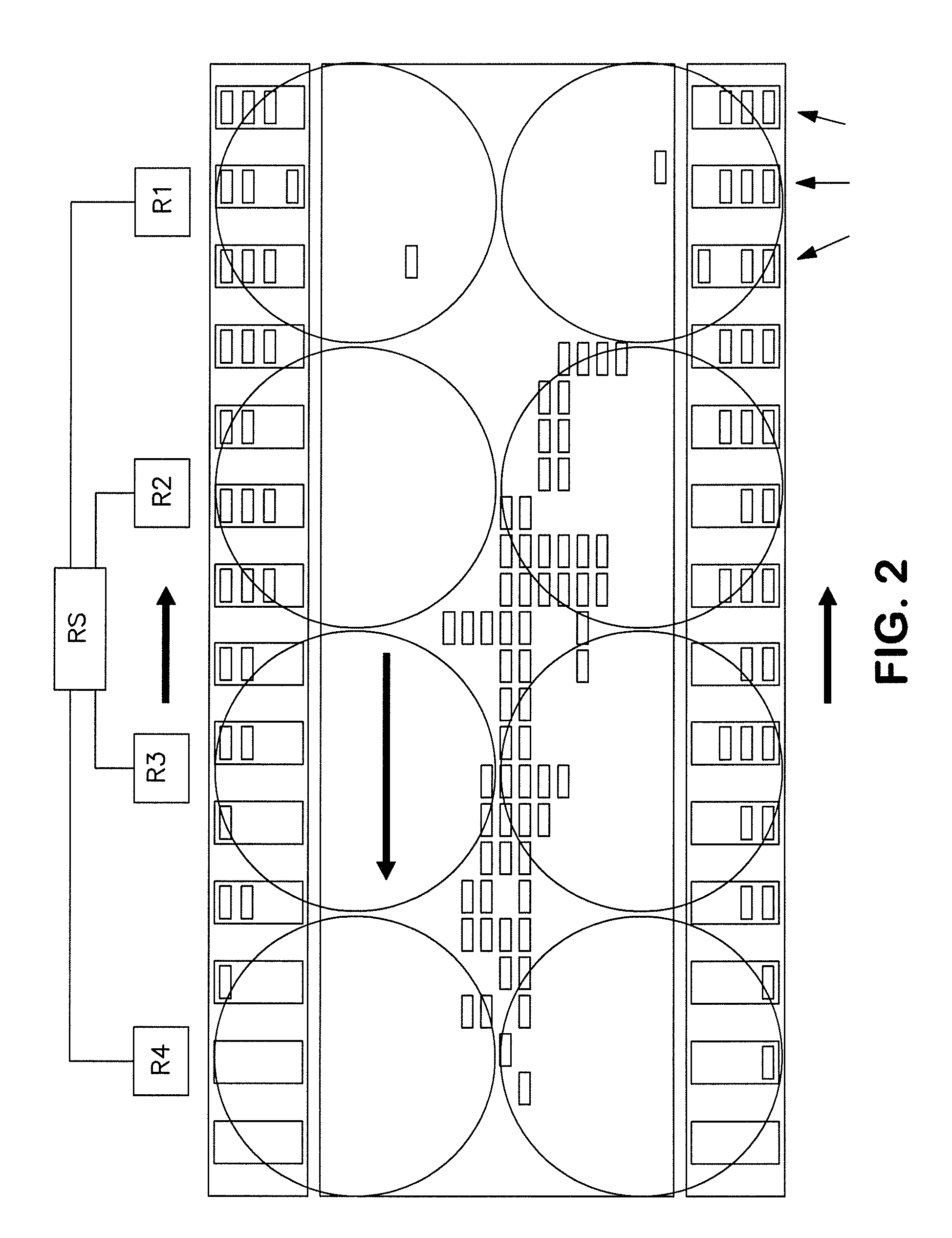

An apparatus and method for stacking product in a container. The apparatus comprises a bi-directional conveying system configured to transport product to either end thereof. A container handling system is positioned proximate the bi-directional conveying system. The container handling system is configured to move empty containers proximate the ends of the bi-directional conveying system for sorting and / or sequencing of product therein and containers with product therein away from the bi-directional conveying system.

Owner:LOCKHEED MARTIN CORP

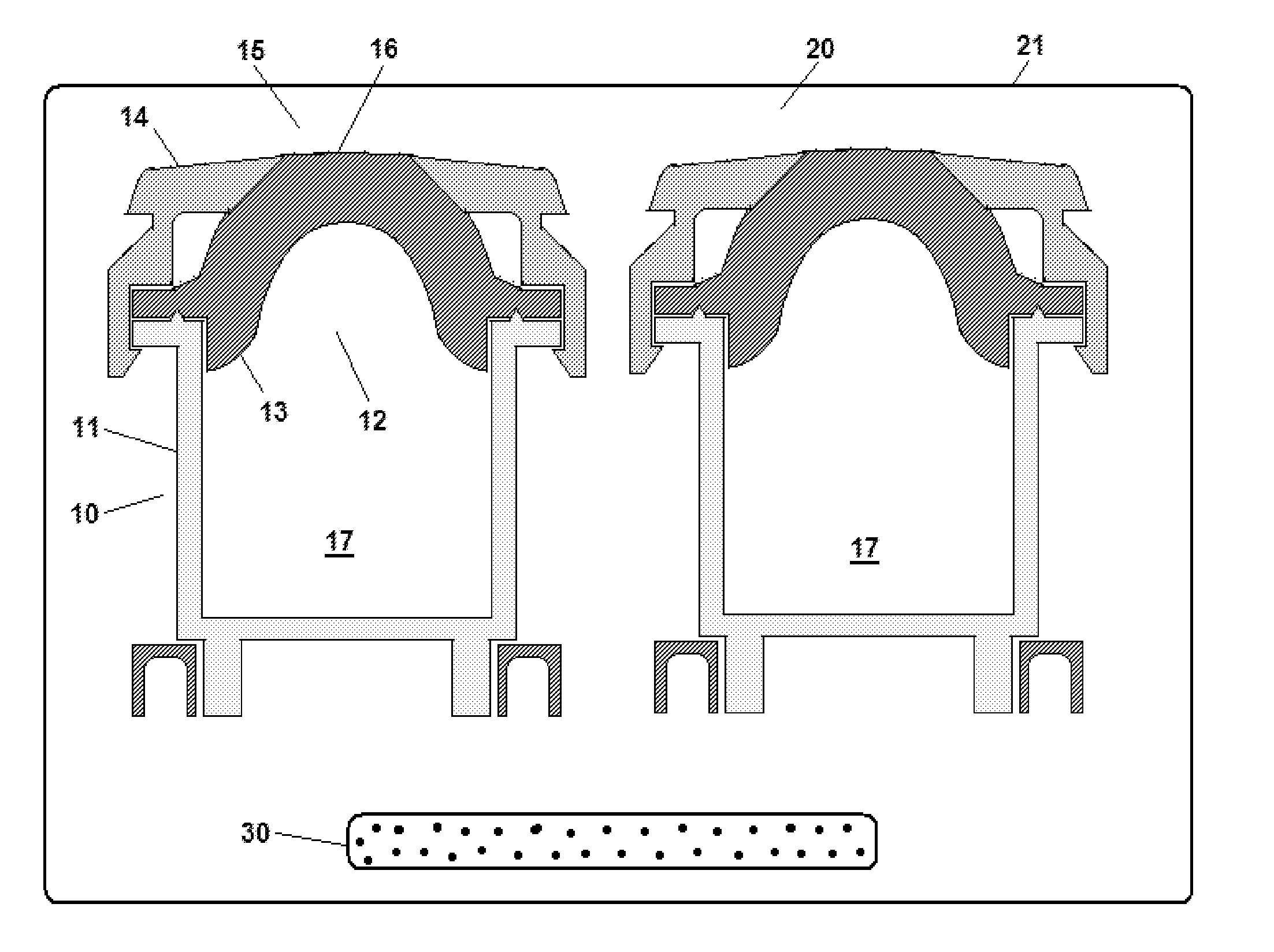

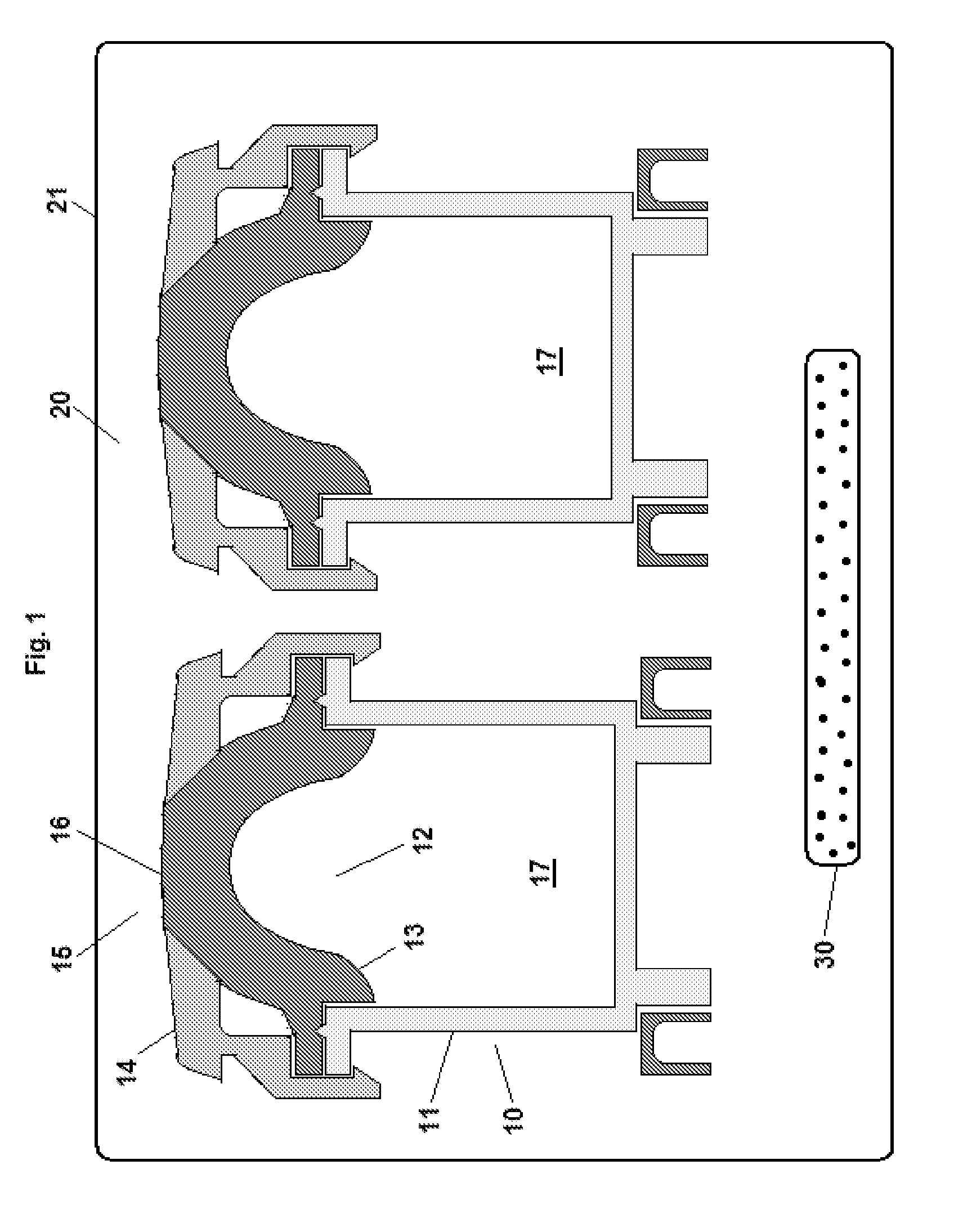

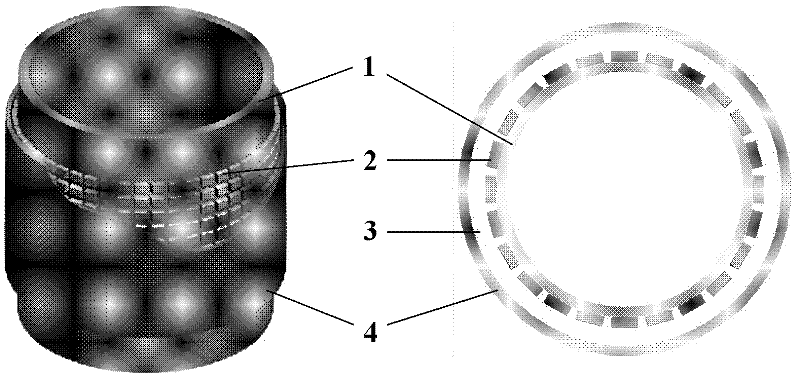

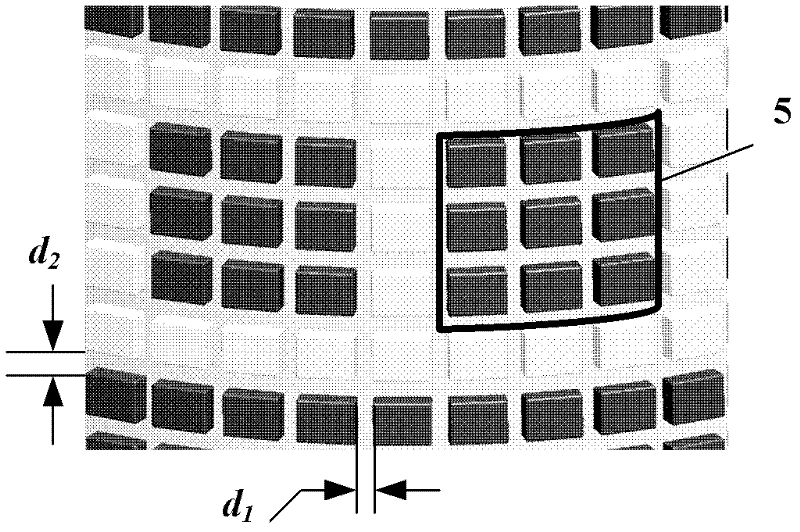

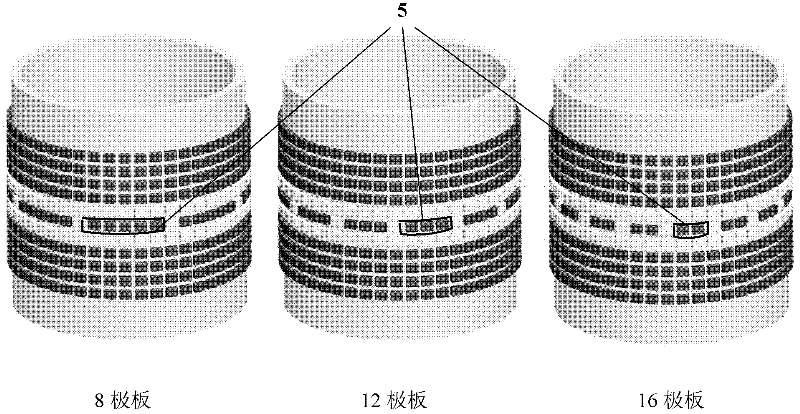

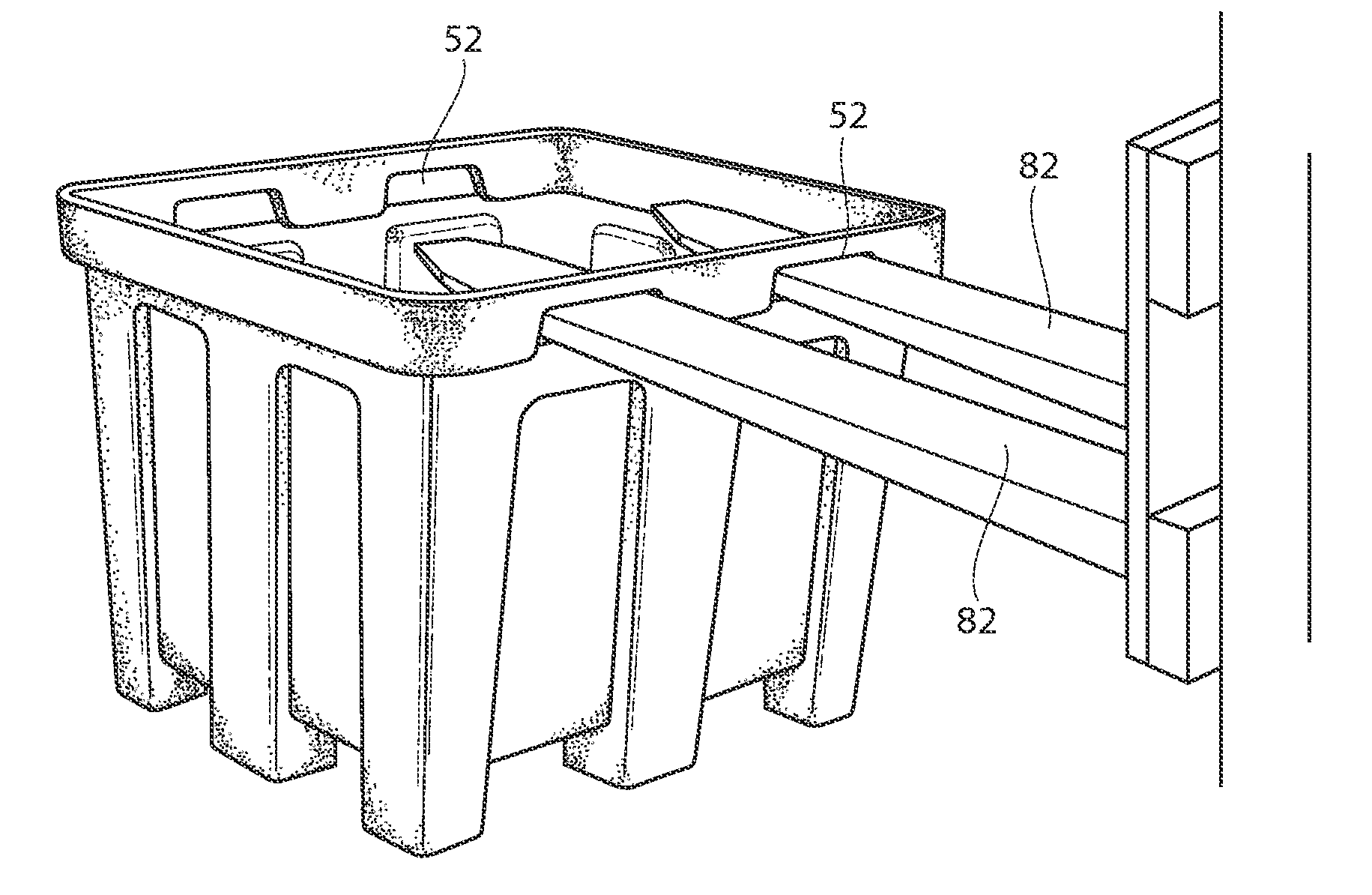

A multi-array adaptive capacitance tomography sensor device

InactiveCN102297884AImprove axial spatial measurement resolutionIncrease flexibilityMaterial capacitanceTomographySelf adaptive

A multi-array adaptive capacitance tomography sensor device belongs to the detection field. Including an empty insulating container, a multi-array electrode plate, an insulating layer and a shielding layer; the outer surface of the empty insulating container is fixedly connected with a multi-array electrode plate, and the outer layer of the multi-array electrode plate is an insulating layer and a shielding layer; the multi-array electrode plate It consists of multiple annular plate groups arranged at equal intervals along the axial direction from top to bottom, and each annular plate group is composed of multiple uniformly distributed unit plates; through the physical on-off control of the unit plates, Composite plates of different sizes can be formed. When the non-metallic mixture to be measured is placed in any position of the container, the position of the object to be tested is judged by the layer-by-layer detection of the multi-array adaptive ECT sensor, and the number of measuring plates, geometric dimensions, and axial shielding are selected according to the actual measurement requirements. And other parameters, so that the sensor always maintains a good measurement effect.

Owner:BEIJING UNIV OF TECH

Structure and process for recycling containers

A container for use in handling recyclable paper products is disclosed. The container has an open top and includes a plurality of openings formed near its upper edges for receiving fork lift truck tines. A method of nesting empty containers is also disclosed.

Owner:RUBICON CARTS

Apparatus and method for detecting radiation or radiation shielding in containers

InactiveUS20060007006A1Inspection is accuratePhotometryMaterial analysis by optical meansRadioactive agentEngineering

A computer program, database and method for the detection of fissile or radioactive material or radiation shielding material in a container works with detection devices brought into proximity to containers so that the presence of fissile or radioactive material, or shielding materials to conceal the presence of such fissile or radioactive materials, may be detected. A comparison may then be made of the output of the detector to a threshold to determine subsequent action regarding the shipping container. The threshold may be based on the output of known, dangerous radioactive materials, known legitimate contents or empty containers.

Owner:VERITAINER ASSET HLDG LLC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com