Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

97 results about "Pharmaceutical waste" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

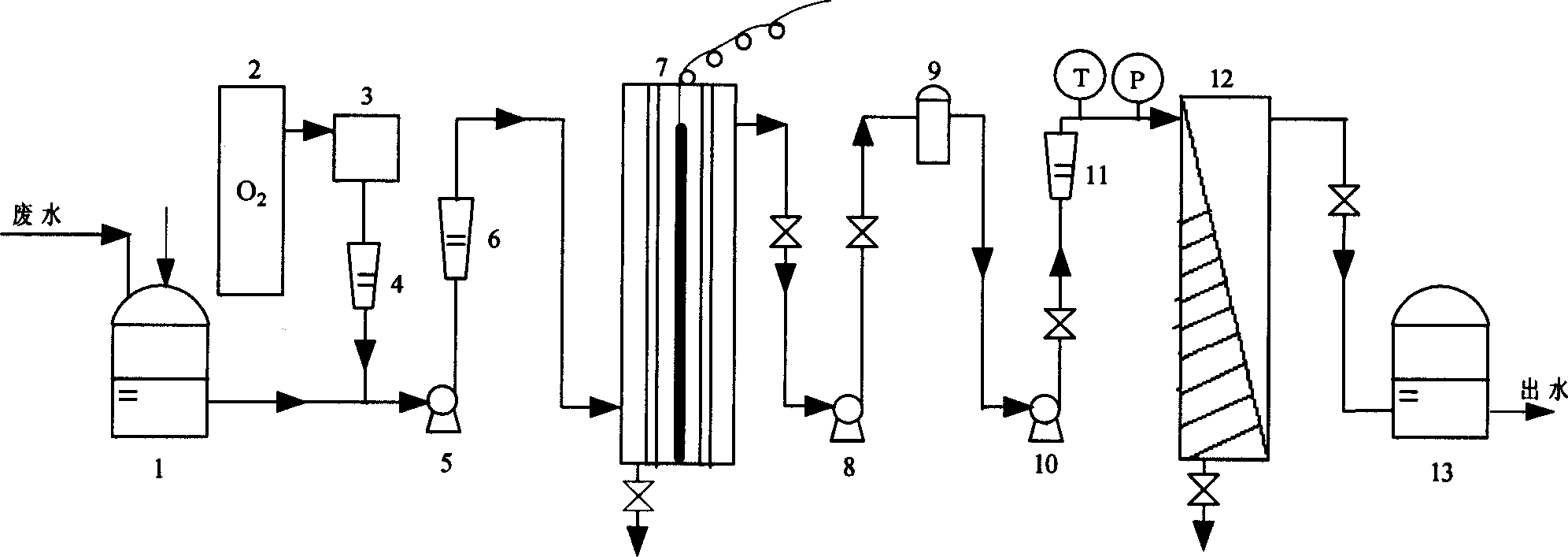

Photocatalytic oxidation reaction- membrane separation method for processing antibiotic industry waste water

InactiveCN1733624AEfficient removalRealize purification and reuseWater/sewage treatment by irradiationWater/sewage treatment bu osmosis/dialysisChlorine dioxideUltraviolet lights

The invention relates to a treatment method for antibiotic pharmaceutical waste water integrated with photocatalyst oxidation reaction and membrane separation. Wherein, taking flocculations, coarse filter and adjust pH value to the waste water putting the water into photocatalyst oxidation reactor with particle titania as catalyst, ultraviolet light as light source and ozone, hydrogen dioxide or chlorine dioxide as oxidizer; degradating organic in water; forcing the waste water into membrane separator to catch most inorganic salt and organic of 97% removal ratio and 98% desalinization ratio and satisfy the recycle standard. This method has high efficiency and the yielding water is colourless and clear.

Owner:TIANJIN UNIV

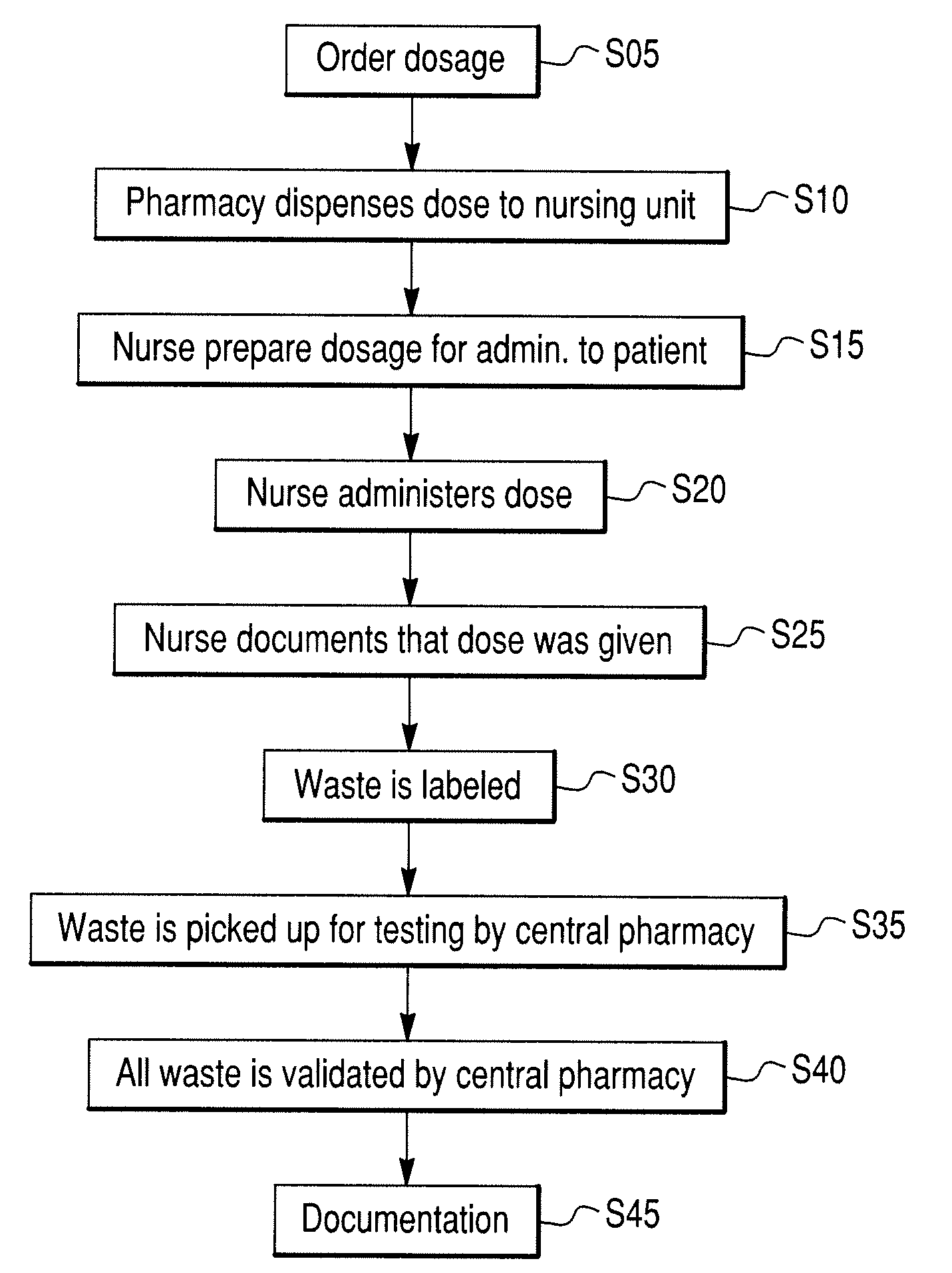

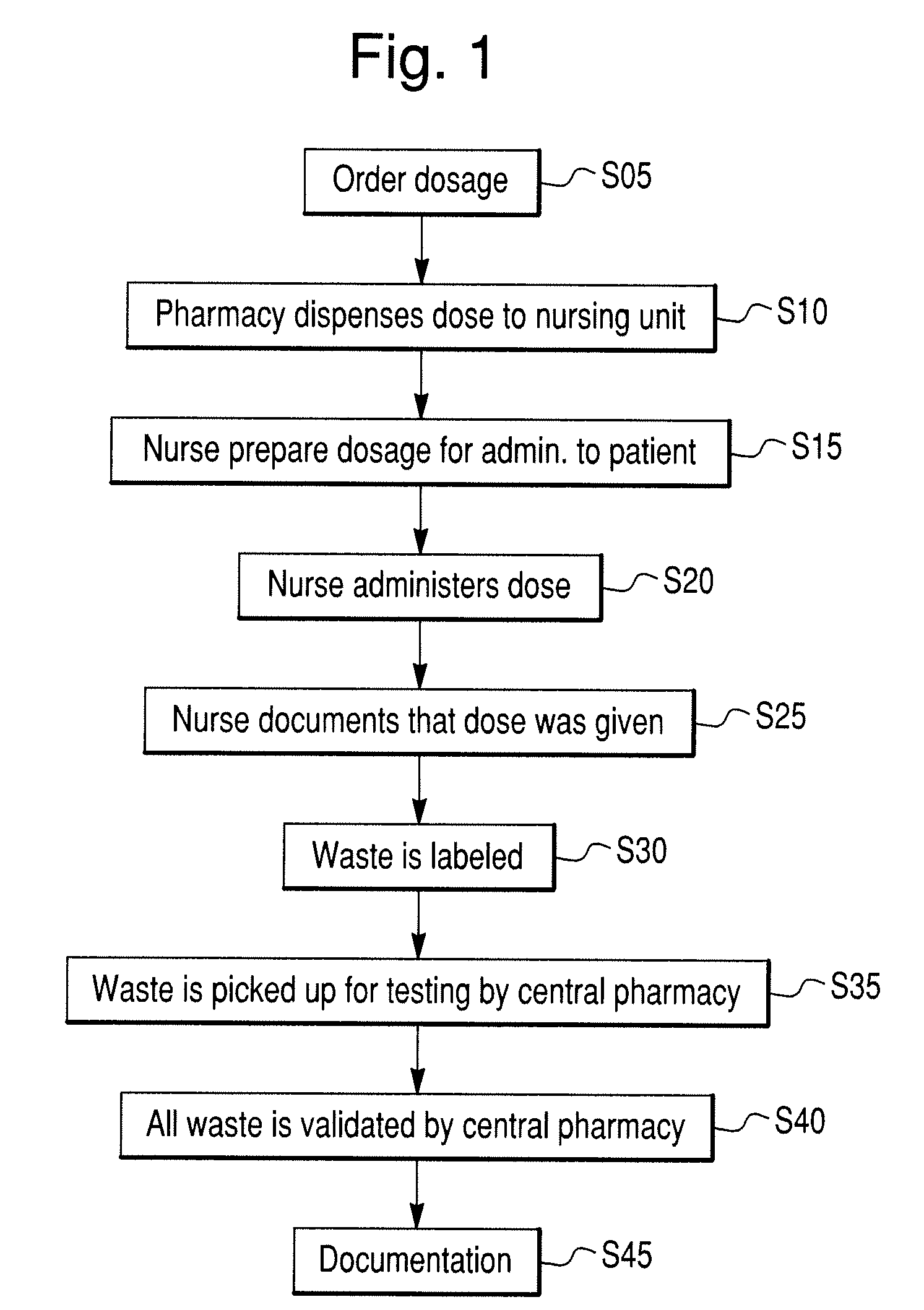

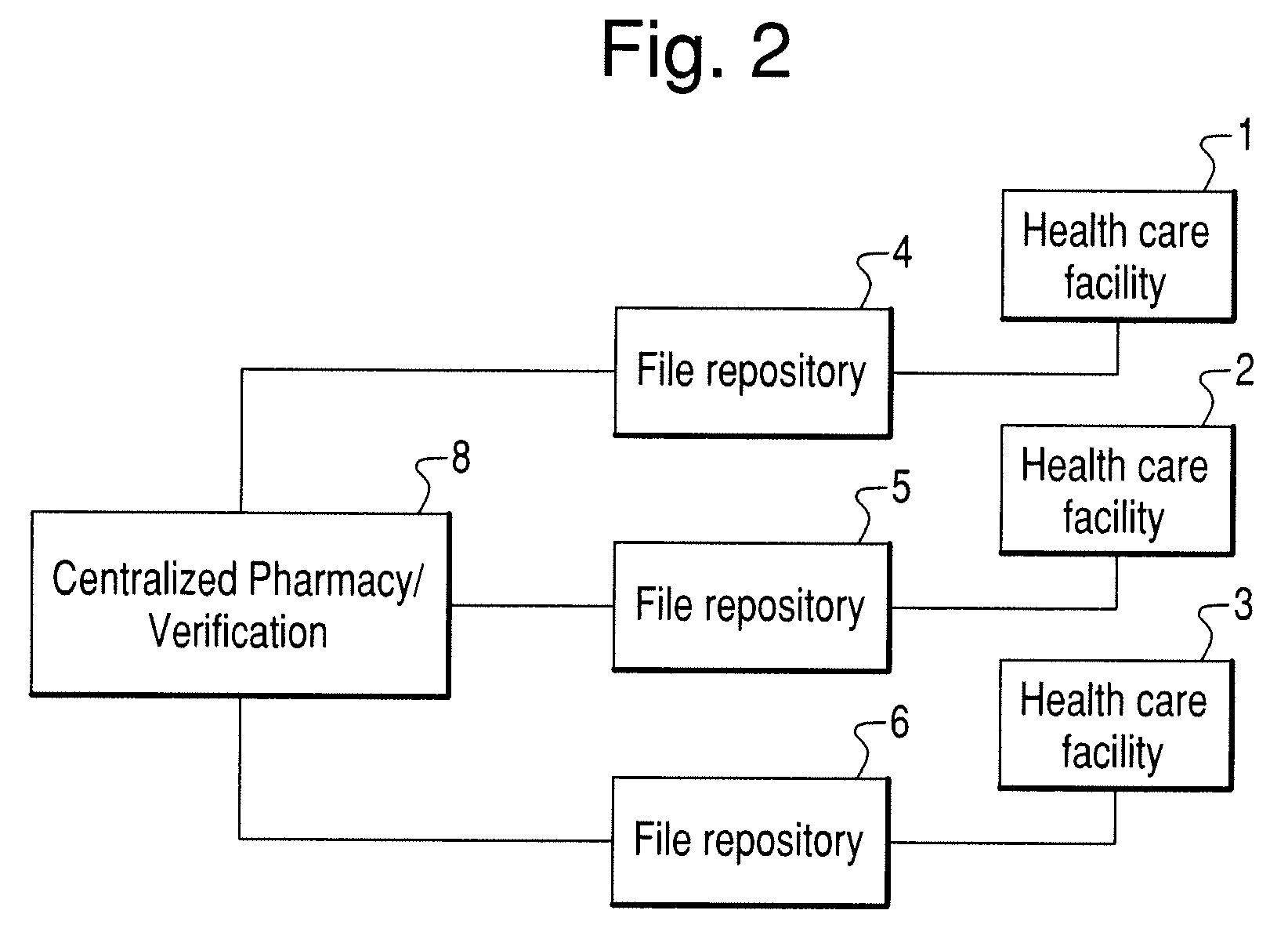

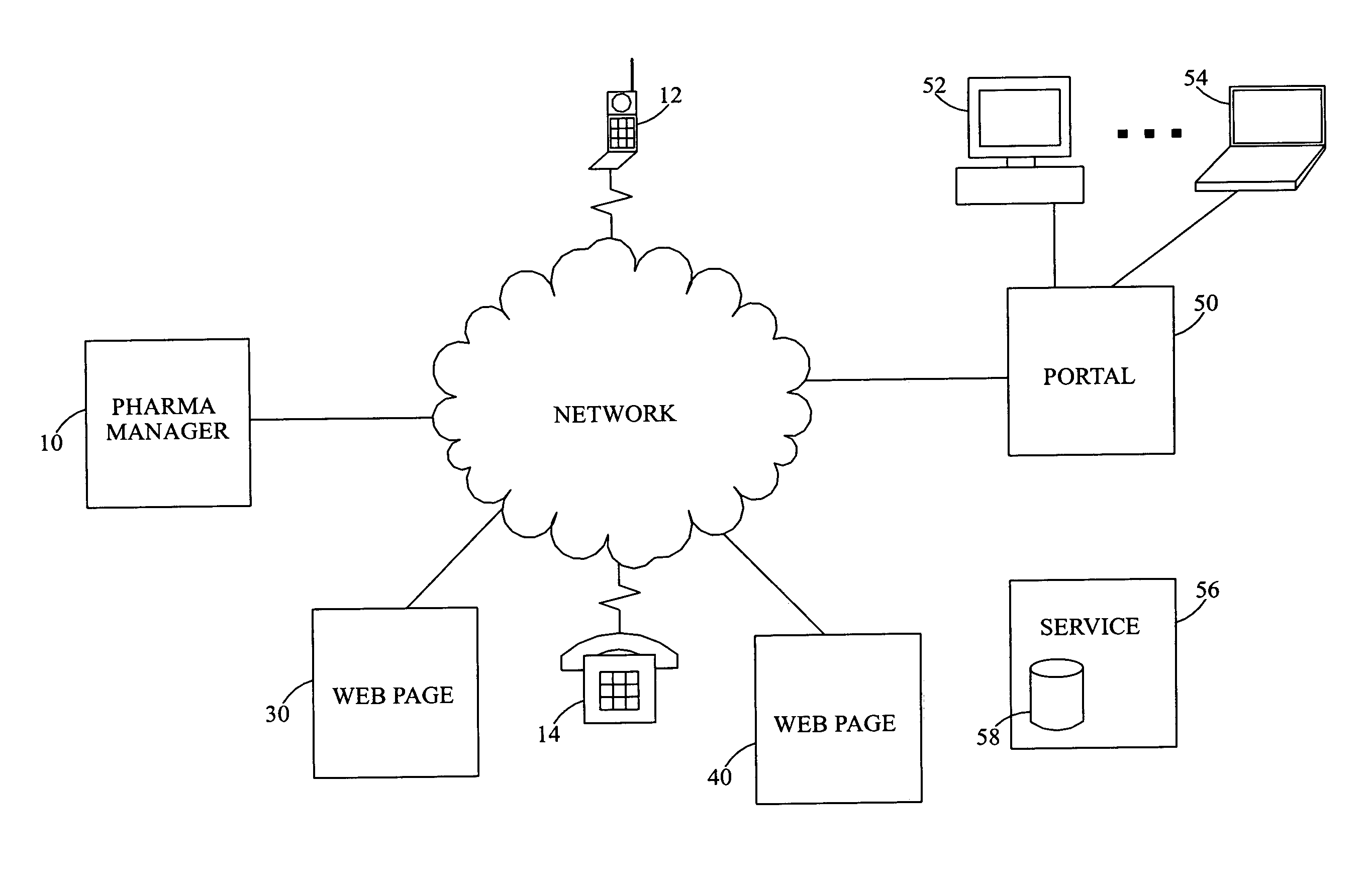

System and methods for detection and identification of chemical substances

InactiveUS20080319795A1Convenient verificationReduces risk of diversionData processing applicationsDrug and medicationsPharmacyControl substances

The invention provides a system and methods for centralized collection and verification of controlled substance / pharmaceutical waste. The invention provides a system and methods that replace the witness's co-signature with a process of centralized pharmacy controlled substance validation. In this process, the administering health care practitioner or nurse will give the medication to the patient and return the wasted portion of the dose to a secured storage area for a centralized pharmacy to pickup. The collected doses are then validated at the centralized pharmacy. Validation can include determining the composition, concentration, amount and type of drug.

Owner:CDEX

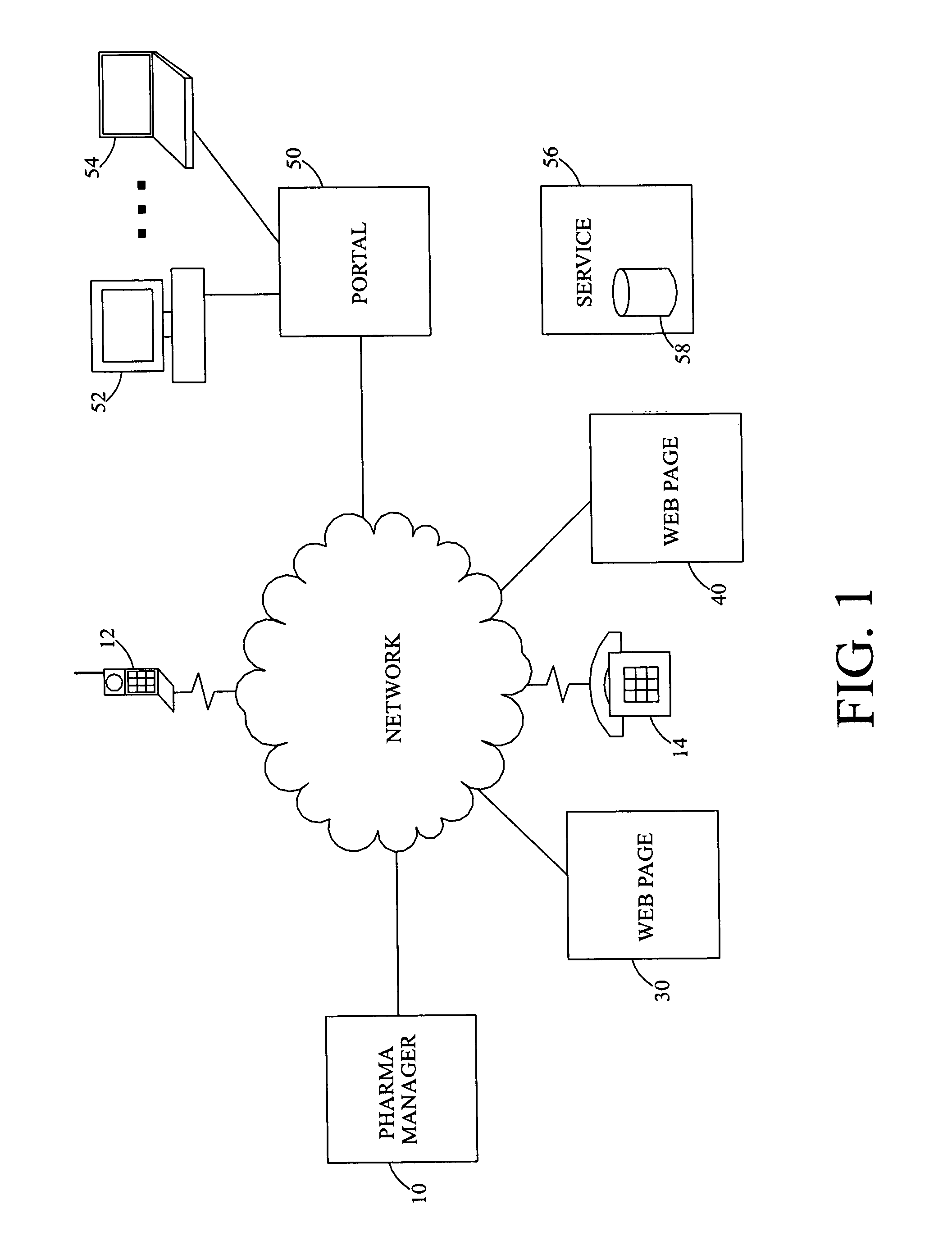

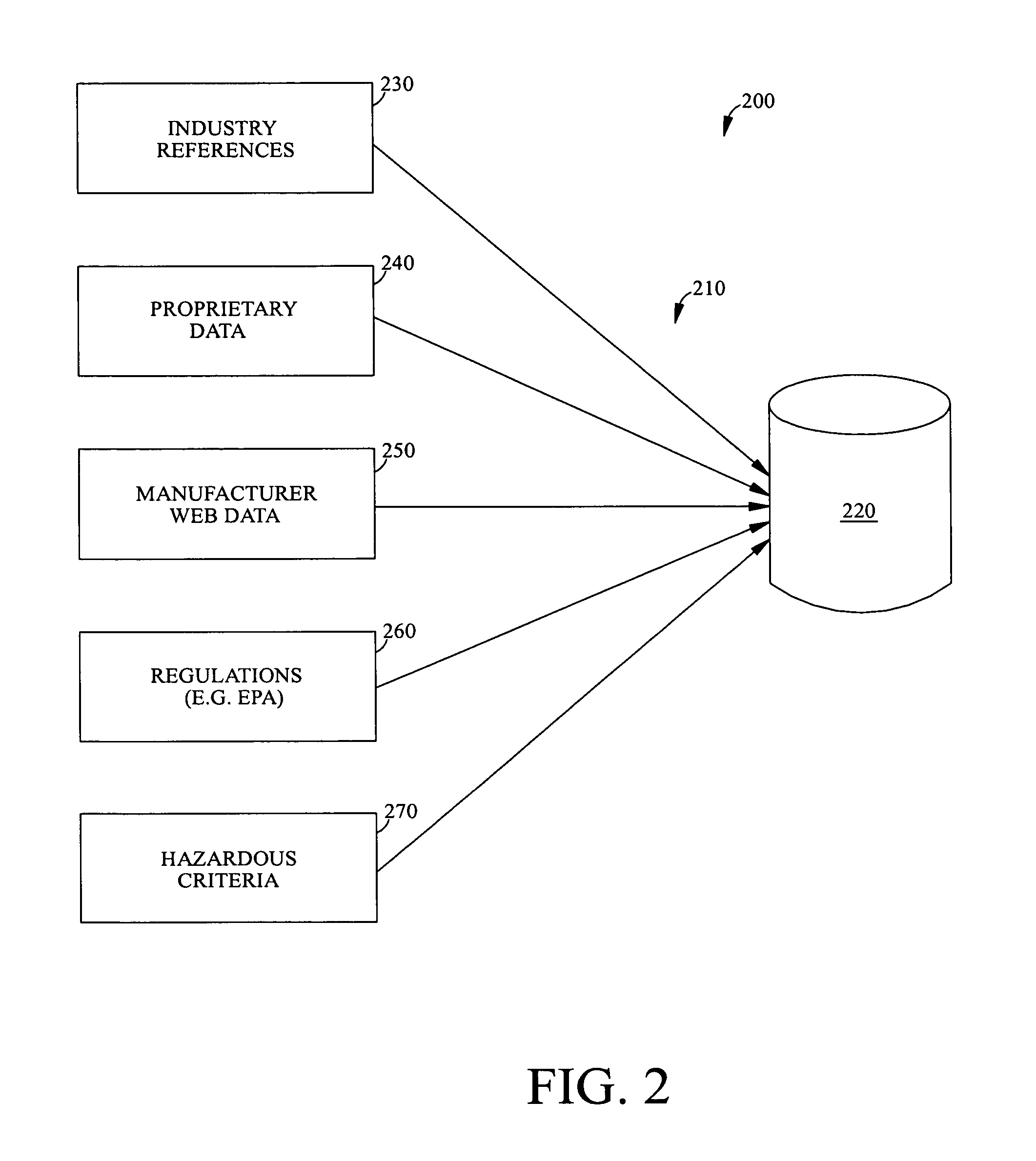

Pharmaceutical waste identification system

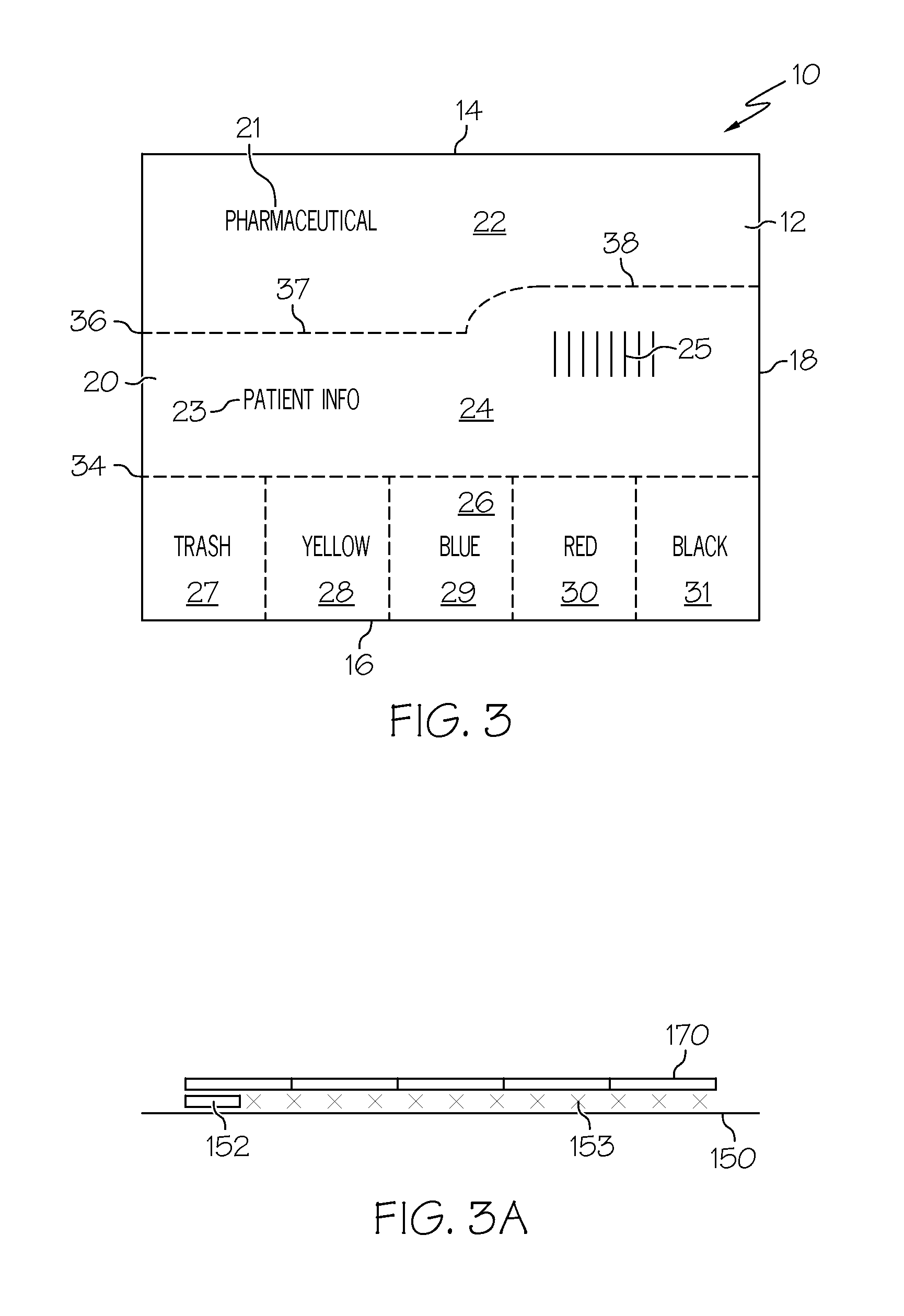

InactiveUS7366640B2Data processing applicationsDrug and medicationsIdentification systemPharmaceutical waste

A pharmaceutical waste identification system presents pharmaceutical waste information and, in response to a client entering a pharmaceutical name, the system provides a pharmaceutical waste disposal recommendation. This recommendation can include a labeling recommendation for a container for the pharmaceutical, a disposal recommendation for an empty container previously containing the pharmaceutical, and a disposal recommendation for the pharmaceutical.

Owner:WASTE MANAGEMENT NAT SERVICES INC

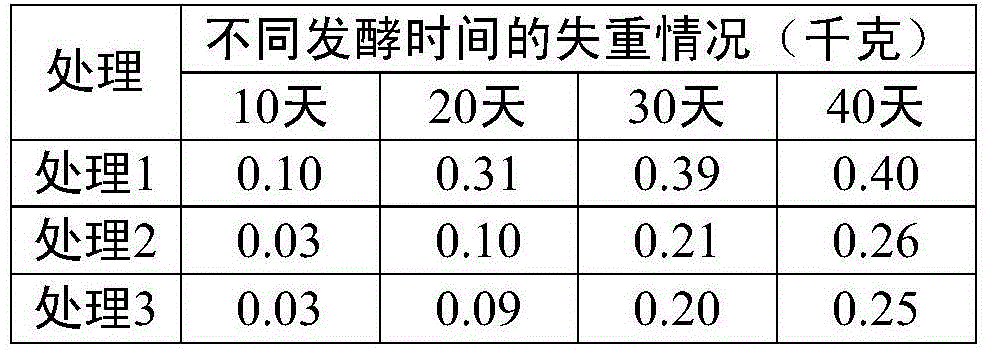

Multifunctional high efficient organic material decomposition agent and preparation method thereof

InactiveCN105733975APromote growthPrevent diseaseFungiBio-organic fraction processingDiseaseRoot growth

The invention discloses a multifunctional high efficient organic material decomposition agent and a preparation method thereof. The decomposition agent of the invention comprises composite original strains consisting of bacillus amyloliquefaciens, Aspergillus oryzae, Trichoderma viride, and Saccharomyces cerevisiae and an organic material carrier, and an inorganic carrier. Strains of the decomposition agent can be mutualistic, and have complementary advantages. The adaptation is wide, and a plurality of organic matter clastic enzymes can be produced by metabolism. The decomposition agent has high activity and can be used for fermentation and conversion of a plurality of organic materials such as livestock and poultry excrements, crop straws, city sludge, food waste, food processing and pharmaceutical waste residues, and has fast fermentation start, fast deodorization, low temperature resistance, and low moisture resistance. The fermentation period is shorter by 5-7 days than that in the same technology. Fermented and converted organic fertilizers have the obvious rhizosphere ecological regulation and control function, promote the root growth, and improve the root vitality. A plurality of soil borne diseases are prevented by improving the flora diversity, hyperparasitism and biological antagonism.

Owner:HEBEI ACADEMY OF AGRI & FORESTRY SCI INST OF GENETICS & PHYSIOLOGY

Pharmacy Waste Identification Labeling and Disposal System and Related Method of Using

InactiveUS20120173440A1Present inventionEffectively and permanently alterSustainable waste treatmentSurgical furniturePharmacyHandling system

The present invention is directed to a tag and labeling system that is used in connection with the disposal of pharmaceutical waste materials that are created in a health care treatment facility. The tag uses a RFID device with an alterable parameter in order to selectively actuate a disposal system to receive a particular type of waste material

Owner:AVERY DENNISON CORP

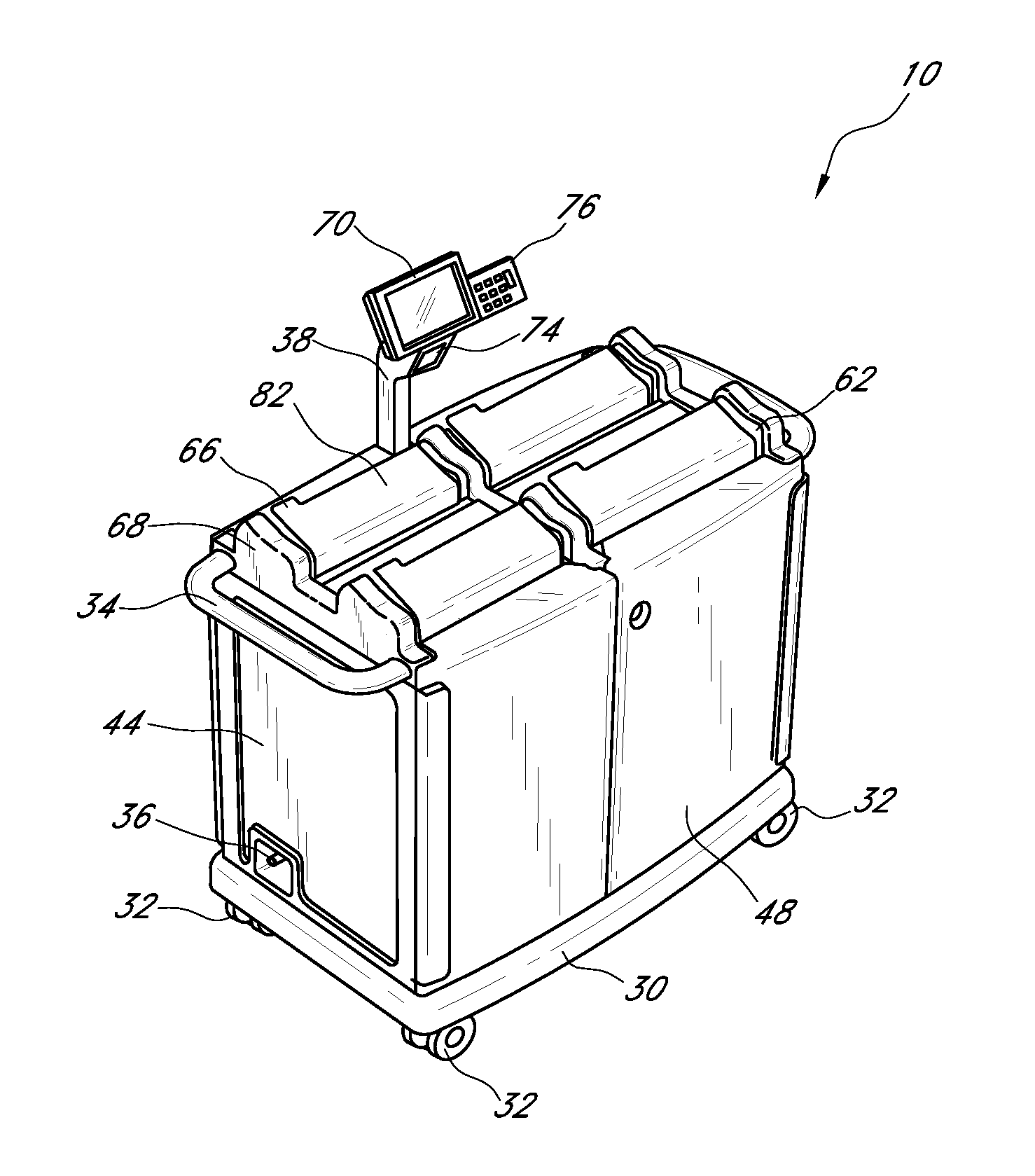

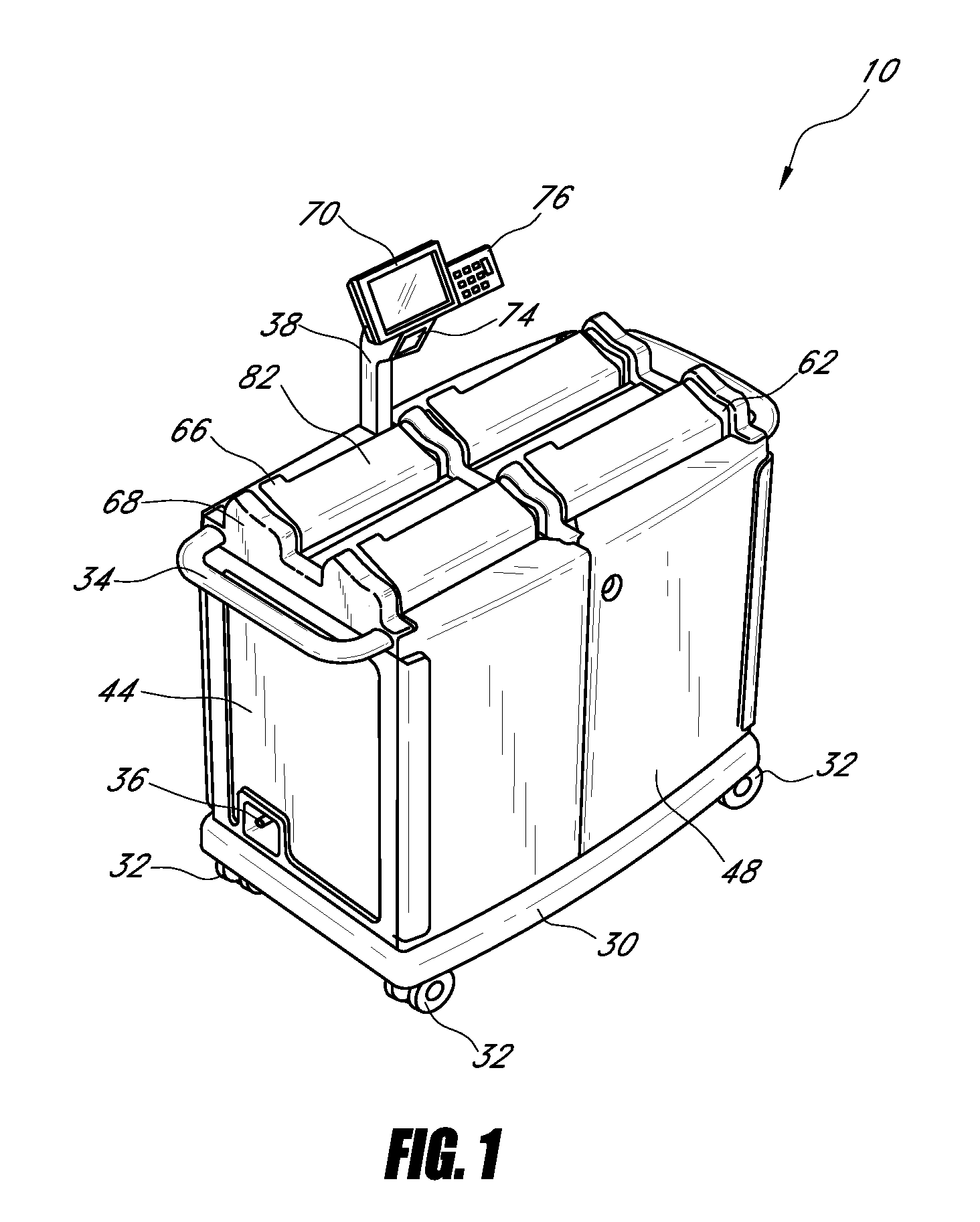

Systems and methods for disposing narcotic and other regulated waste

InactiveUS20130325727A1Efficiently and effectively track and sortAvoid mixingSustainable waste treatmentSurgical furnitureMedical wasteControl substances

A system for disposing of medical waste is generally configured to sort waste items into a plurality of containers according to applicable rules and regulations governing the handling and / or disposal of such items. In some embodiments, a system comprises sorting stations each of which houses a number of disposable containers. Each station can identify an item of waste, determine the most appropriate container for the item, and facilitate disposal of the item in the appropriate container. In some embodiments, a container or receptacle is configured to receive waste that comprises a controlled substance (e.g., a narcotic, other CII pharmaceutical waste, etc.). Such controlled waste can be discarded into the container or receptacle directly or indirectly (e.g., by placing the waste in a cup or other enclosure).

Owner:CAREFUSION 303 INC

Advanced treatment process for fermented pharmaceutical waste water

InactiveCN102358651AImprove processing efficiencyImprove reuse rateWater/sewage treatment bu osmosis/dialysisMultistage water/sewage treatmentChemical treatmentUltrafiltration

The invention belongs to the technical field of waste water treatment, particularly relates to an advanced treatment process for fermented pharmaceutical waste water, which comprises the following steps: placing the pharmaceutical waste water after being subject to bio-chemical treatment into a Fenton reactor to perform oxidation treatment, and performing coagulating precipitation, ultra-filtration and reverse osmosis. The advanced treatment process for the fermented pharmaceutical waste water overcomes the shortcoming that limitation of potential of hydrogen (pH) in a Fenton method needs to be adjusted in the waste water treatment of biopharmaceutical industry, operation is simple, waste water treatment efficiency and reuse rate are high, and operating cost is low.

Owner:ZHENGZHOU UNIV

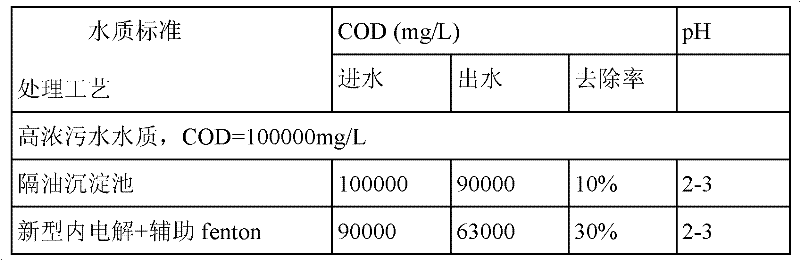

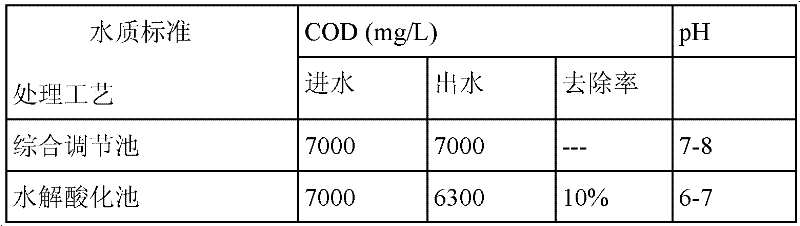

Combination type treatment method for pharmaceutical waste water

InactiveCN102336502AEfficient removalGuaranteed treatment effectMultistage water/sewage treatmentWater/sewage treatment by neutralisationHigh concentrationWater quality

The invention discloses a combination type treatment method for pharmaceutical waste water, which belongs to the technical field of water treatment. The method comprises the following steps of: first, improving the biodegradability of high concentration of waste water by adopting an efficient pretreatment technology, and finally removing a main pollutant COD (Chemical Oxygen Demand) in the waste water until reaching the standards. The invention has the advantages of stable running, flexible operation, convenience for maintenance, and strong impact resistance capability and strain capability for the variation of water inlet quantity and water quality.

Owner:WUXI TONGYUAN ENVIRONMENTAL PROTECTION TECHNG

Treatment method of pharmaceutical chemical industry park hybrid waste water

InactiveCN101254993AHigh speed processingEasy to handleBiological treatment apparatusTreatment with aerobic and anaerobic processesChemical industryHigh concentration

The invention discloses a method for processing mixed waste water in a pharmaceutical chemical industry park, and belongs to the water processing field. The method comprises the following steps: after regulation of water quantity and water quality is performed to the mixed waste water in the pharmaceutical chemical industry park, the mixed waste water flows into a hydrolytic tank, the hydrolytic tank is filled with suspension type filling material inside, and an up-flow type water distribution method is adopted; the water outlet of the hydrolytic tank enters into an anaerobic tank, the anaerobic tank also adopts an up-flow type water distributing method; the water outlet of the anaerobic tank enters into a moving bed biofilm reactor, suspended filling is added into the moving bed biofilm reactor, and an aeration device is arranged on the bottom of the tank; the water outlet of the moving bed biofilm reactor enters into a biological aerated filter through adopting the form of sprinkling at upper part, and ceramic filling is added into the biological aerated filter; the water outlet of the biological aerated filter enters into a sedimentation tank and a coagulation reaction tank for deposition in sequence. According to the characteristics of high concentration and complex component of the organic matter of the mixed waste water in the pharmaceutical chemical industry park, the invention can perform rapid and highly efficient treatment at a proper time, the water outlet can meet the latest pharmaceutical waste water discharge standard of the state, and the COD is less than 100 mg / L.

Owner:NANJING UNIV

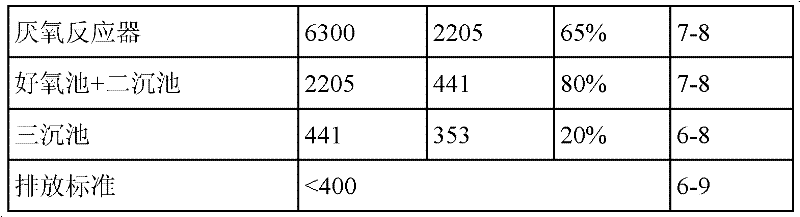

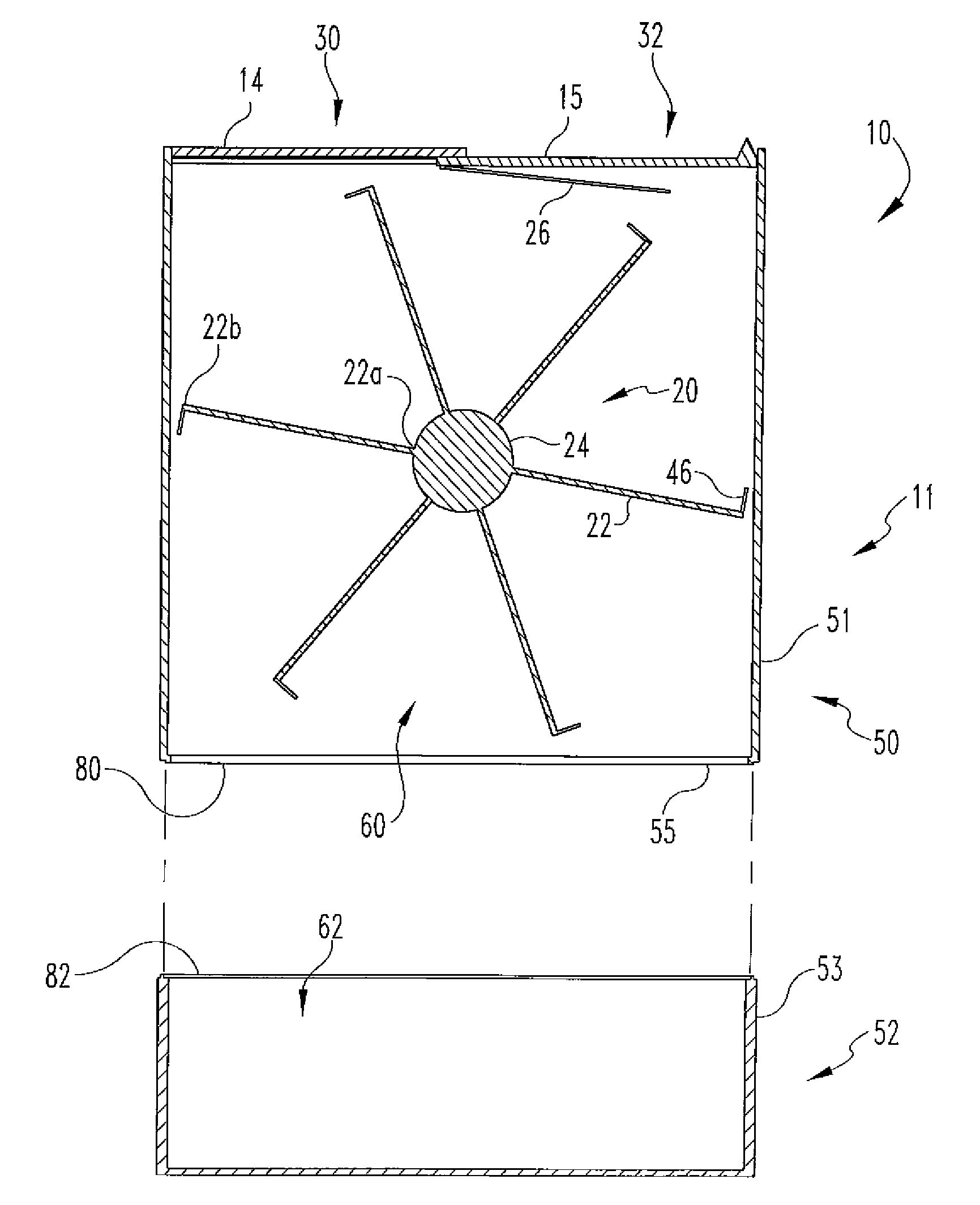

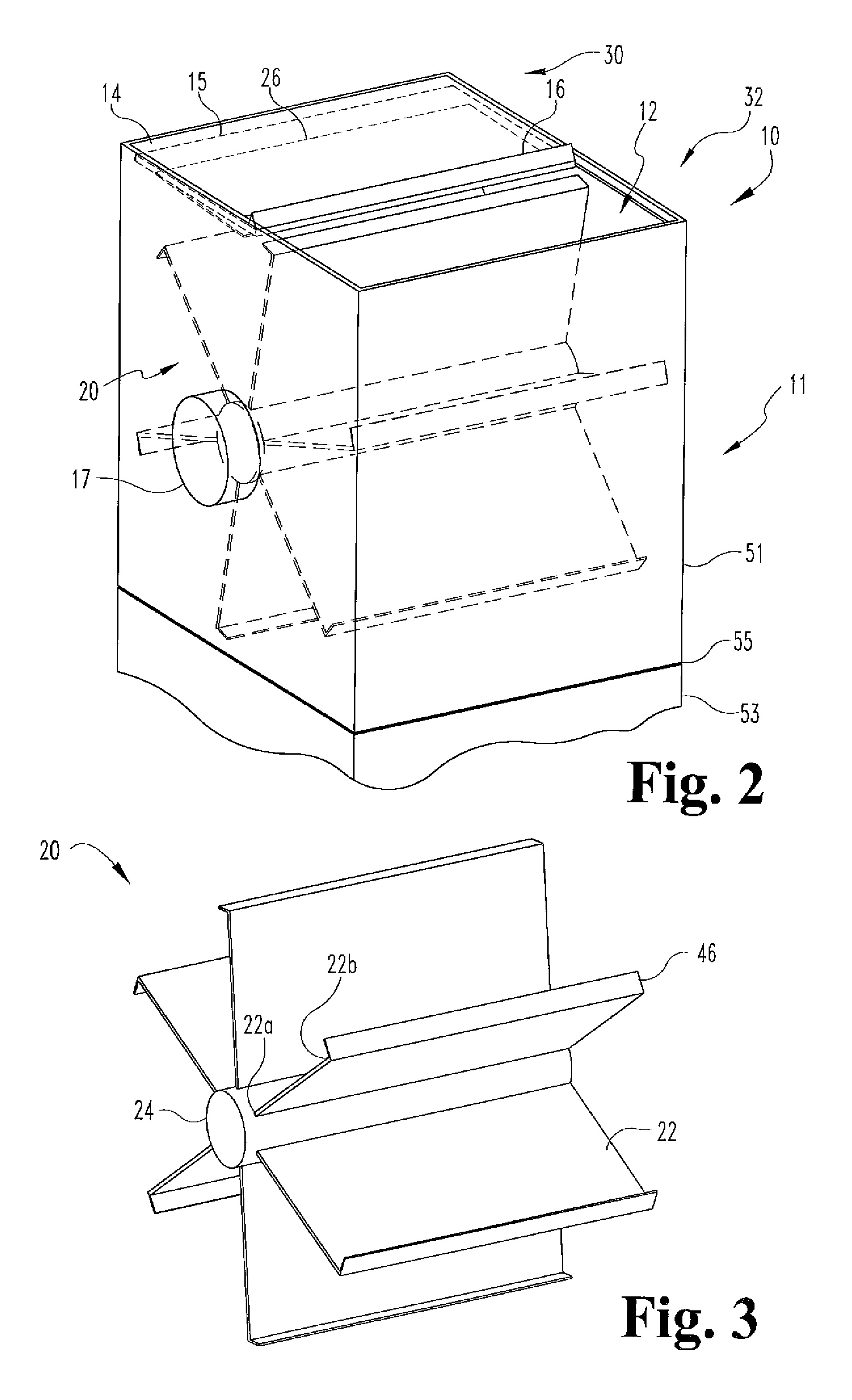

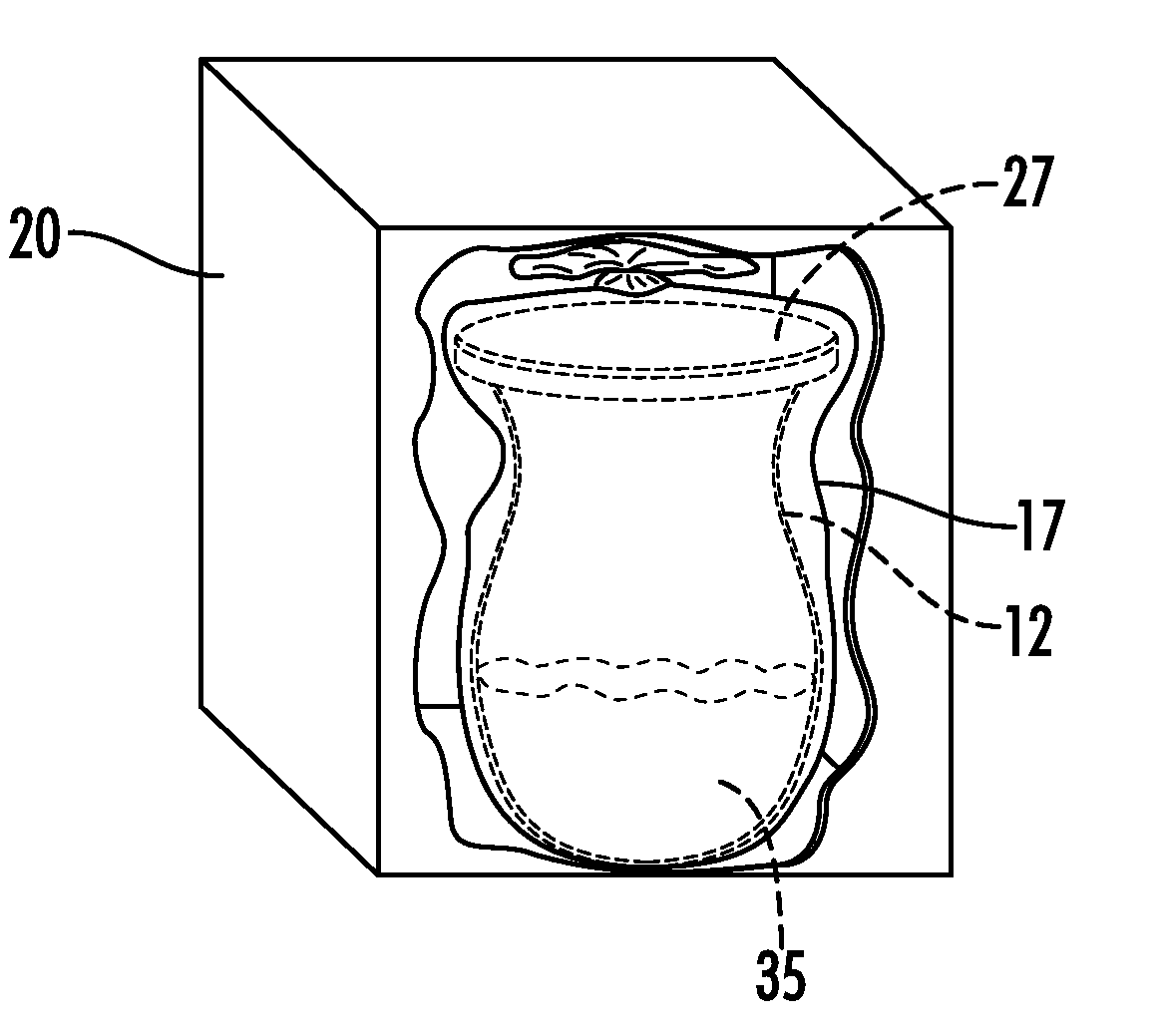

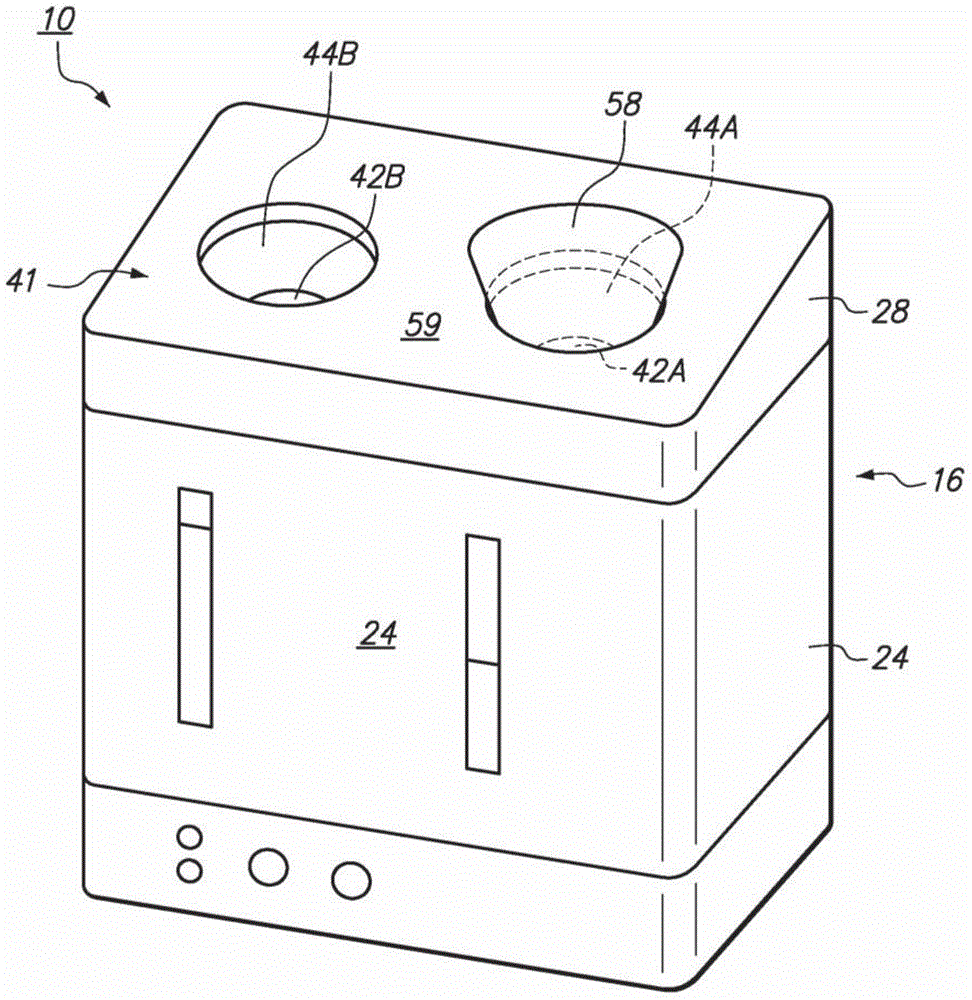

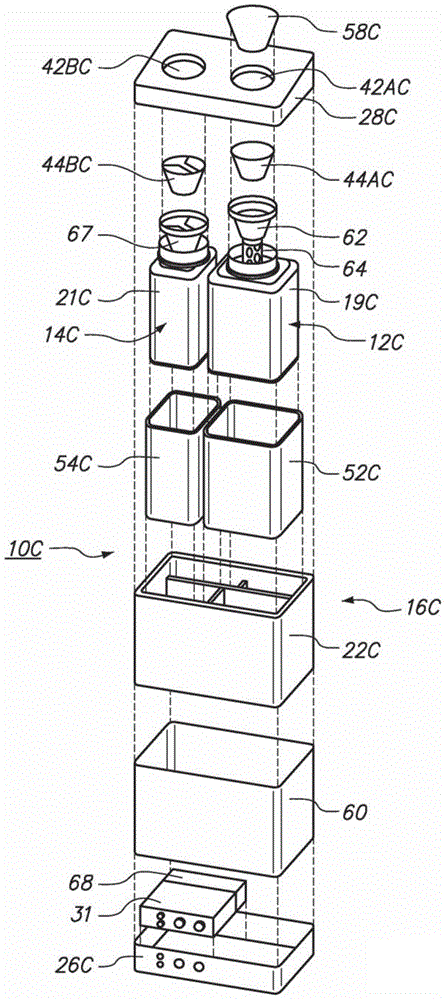

Pharmaceutical waste container system

InactiveUS20090294312A1Avoid accessSurgical furnitureDispensing apparatusPharmaceutical wasteInternal rotation

A pharmaceutical waste disposal device comprises an upper portion adapted for receiving pharmaceutical waste and a lower portion adapted for collecting the pharmaceutical waste, the lower portion being selectively and removably engagable with the upper portion. The upper portion includes a housing surrounding an internal rotating wheel and a lid slideably engaged with the housing. Additionally, the rotating wheel includes collection areas adapted for collecting pharmaceutical waste placed in the upper portion. The lid includes a lower pivoting flap adapted for contacting and rotating the wheel upon closing the lid to transfer the pharmaceutical waste to the lower portion. Further, the rotating wheel is sized and positioned within the housing in a manner to substantially prevent access to the pharmaceutical waste collected in the lower portion.

Owner:HITSON TAMARA

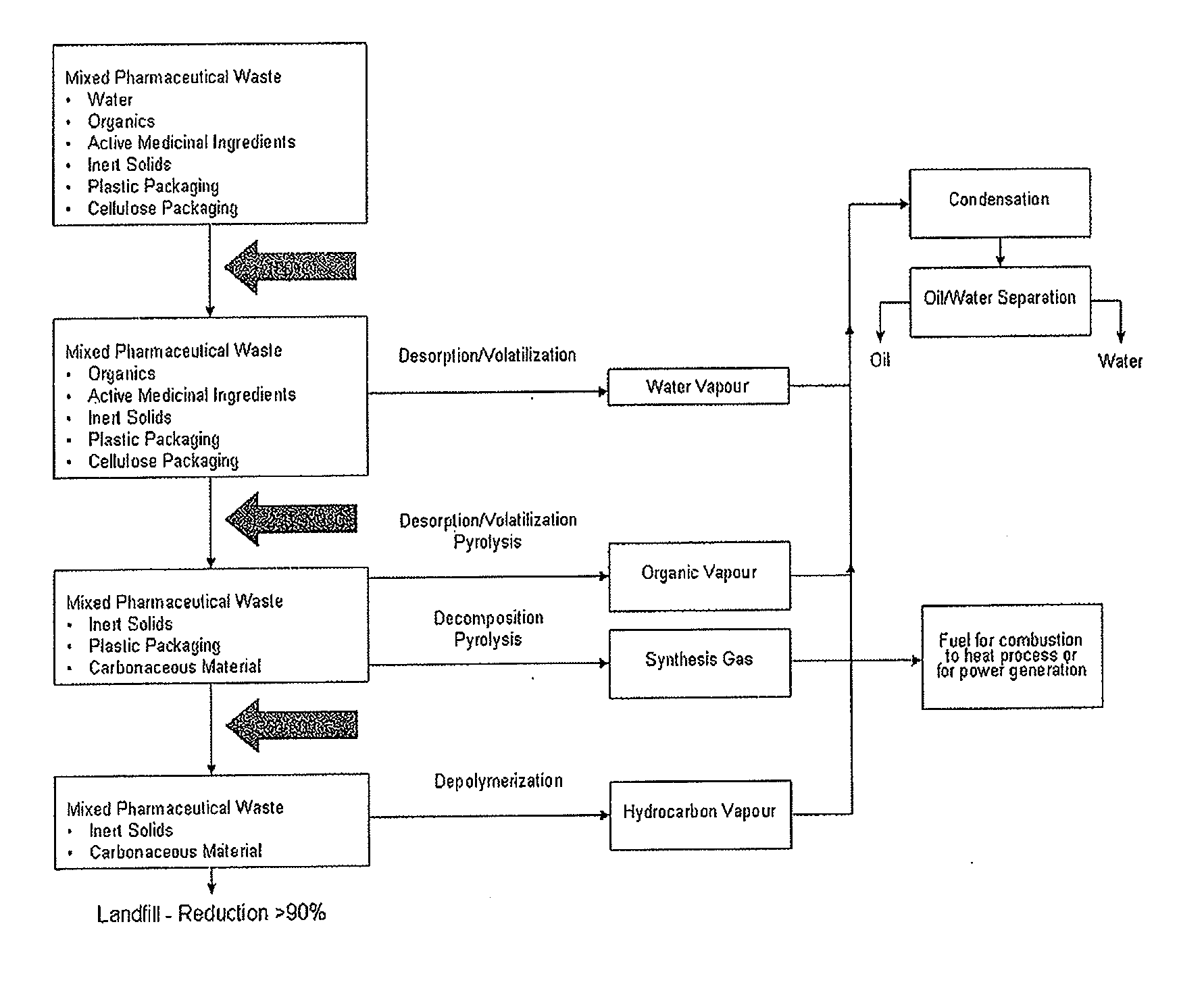

Process for the Thermal Treatment of Pharmaceutical Waste Material

InactiveUS20080179257A1Reduce healingLower the volumeSolid waste disposalTransportation and packagingSyngasAdditive ingredient

There is provided a process for the thermal treatment of waste materials, particularly pharmaceutical waste materials. The process comprises placing the waste material into a chamber and increasing the temperature inside the chamber in three stages. At a first stage, water in the material is desorbed as water vapor. At a second stage, organic ingredients in the material are desorbed and decomposed producing condensable organic vapor and non-condensable synthesis gas. And at a third stage, polymer-based components of the material are depolymerized and decomposed producing condensable hydrocarbon vapor. The non-condensable synthesis gas produced can be used as heating source for the process.

Owner:PHASE SEPARATION SOLUTIONS

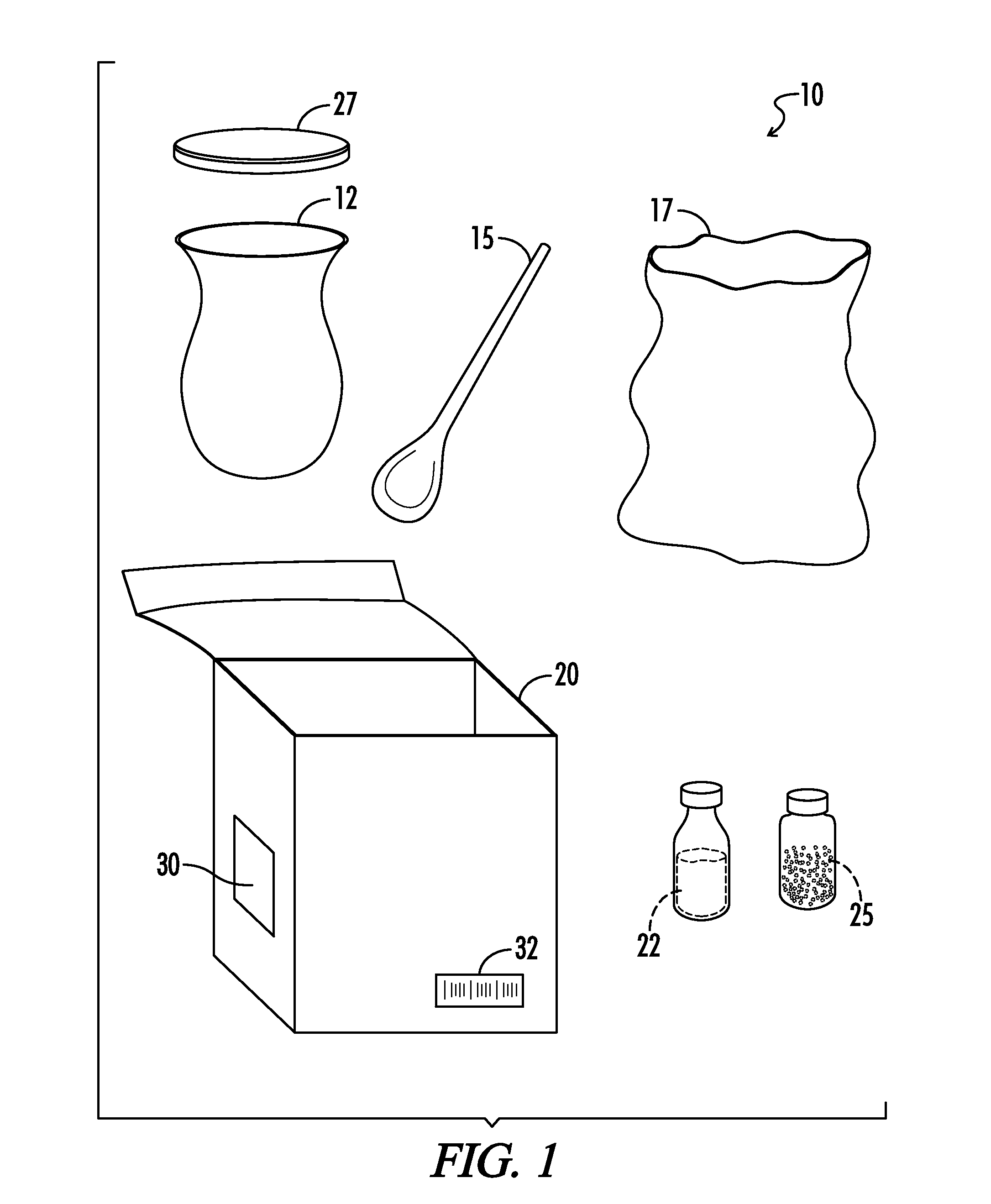

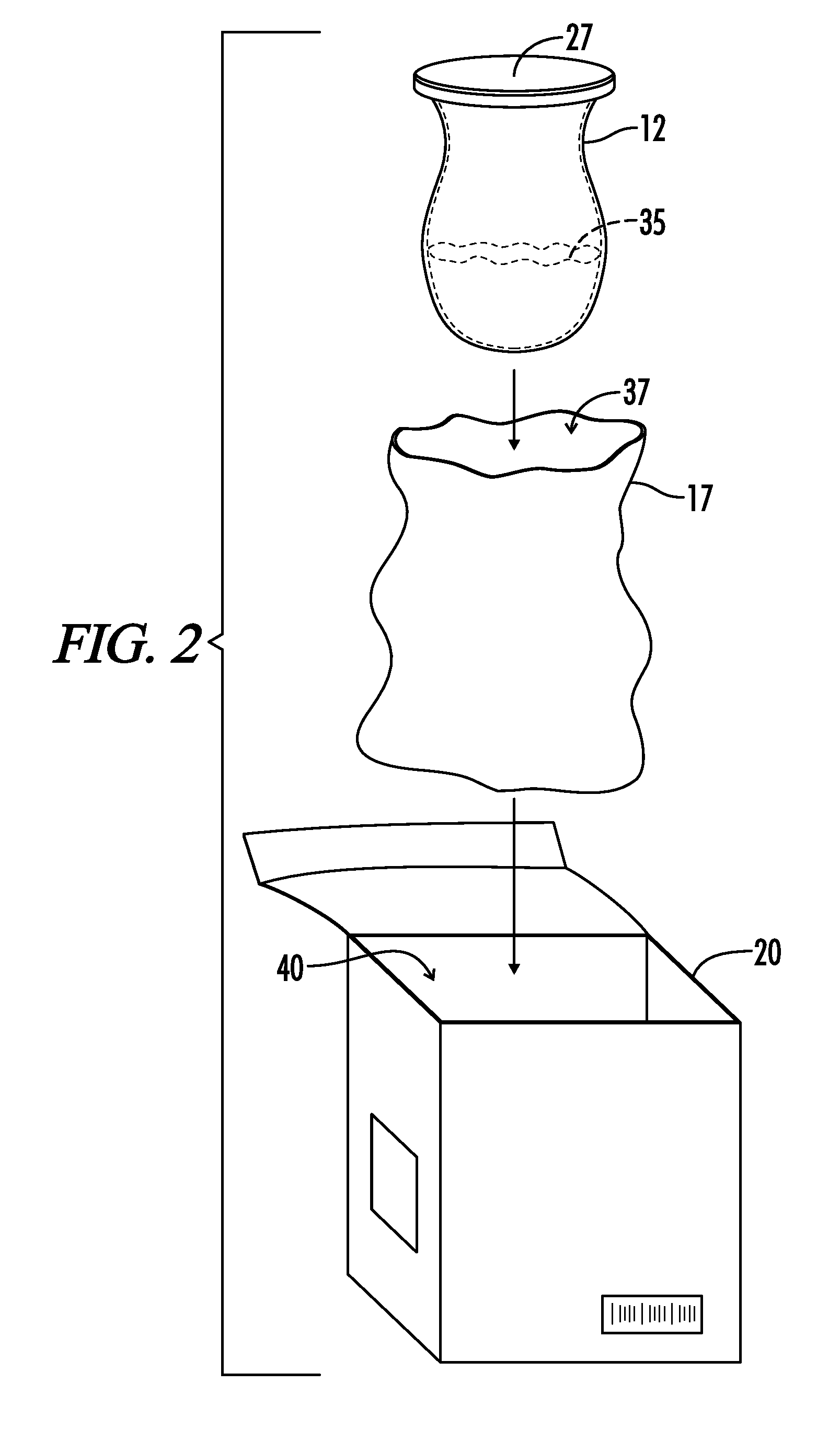

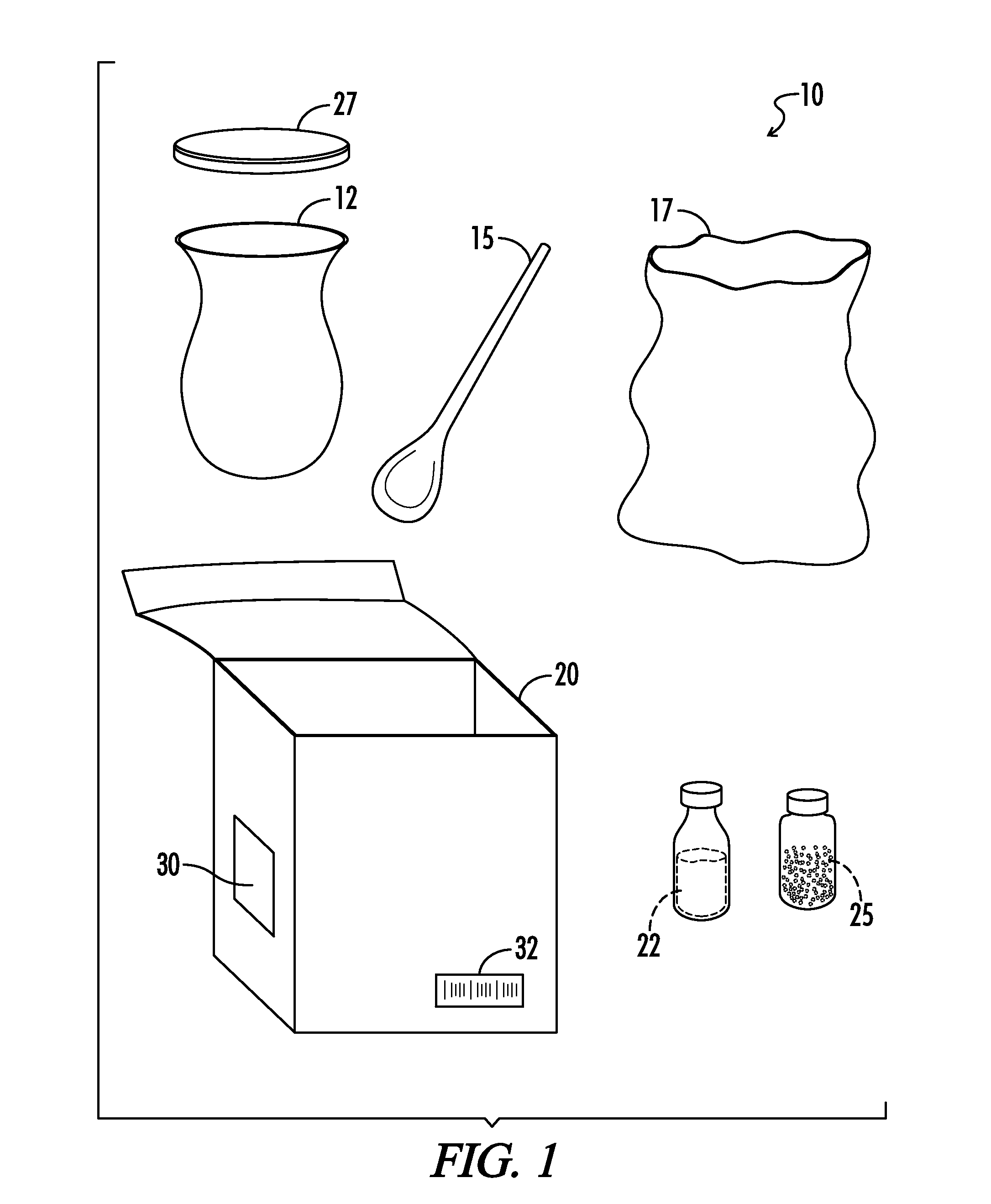

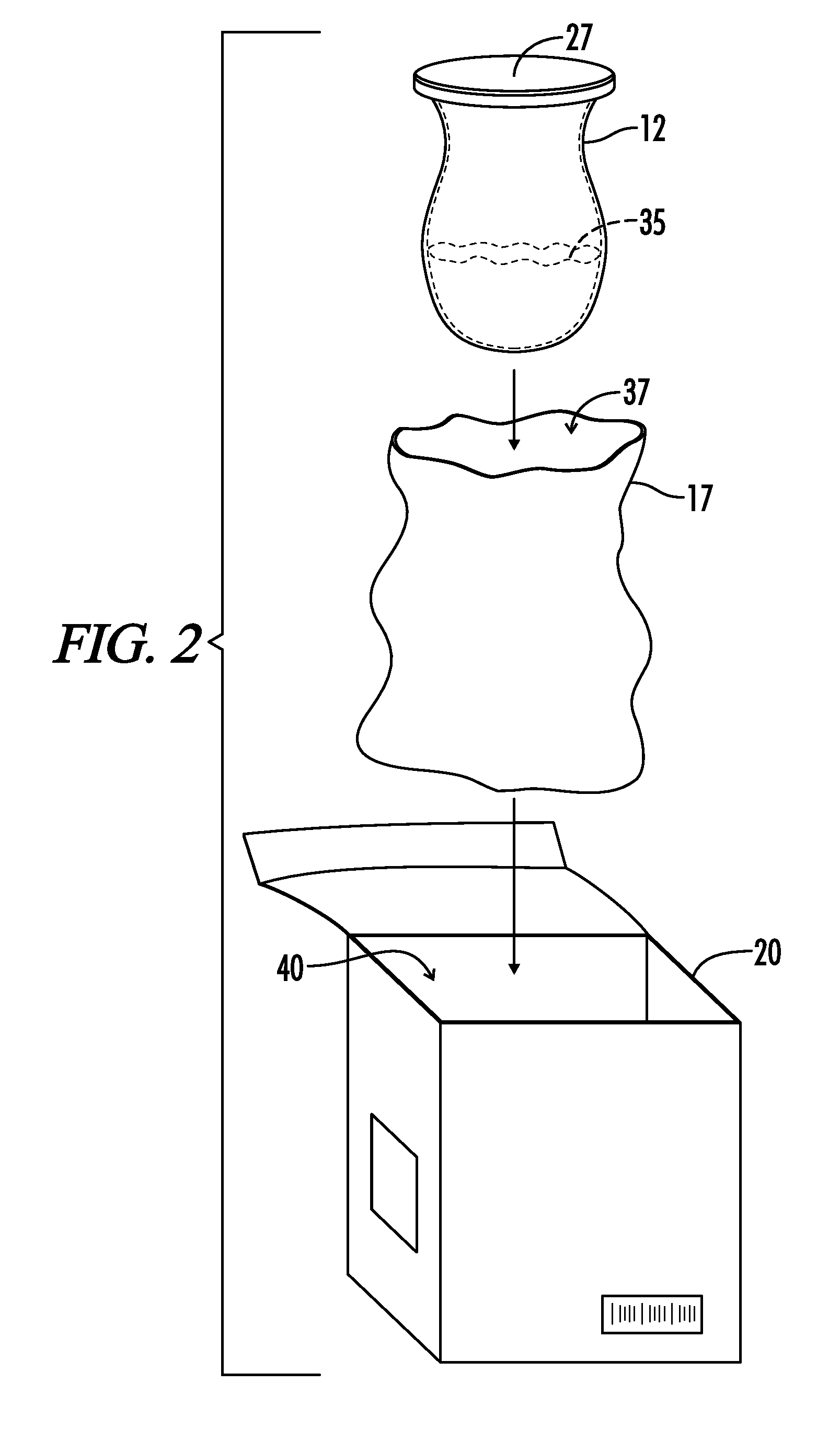

System and method for treatment and disposal of pharmaceutical waste

InactiveUS20120323061A1Solid waste disposalRefuse receptaclesEnvironmental engineeringAcid substances

An exemplary system for treatment and disposal of pharmaceutical waste comprises a sealable pail, a stirring device, a sealable bag, a container, an acidic substance, and a denaturant. The sealable pail receives the pharmaceutical waste and the acidic substance. The acidic substance dissolves the pharmaceutical waste, and the stirring device stirs the acidic substance to ensure that the pharmaceutical waste is completely dissolved. The denaturant is added to the dissolved pharmaceutical waste and renders the dissolved pharmaceutical waste safe for transport. The treated pharmaceutical waste is sealed within the sealable pail, and the sealable bag receives the sealed pail and is sealed. The sealed bag is then placed in the container for transport to a disposal facility.

Owner:STALONS DONALD R

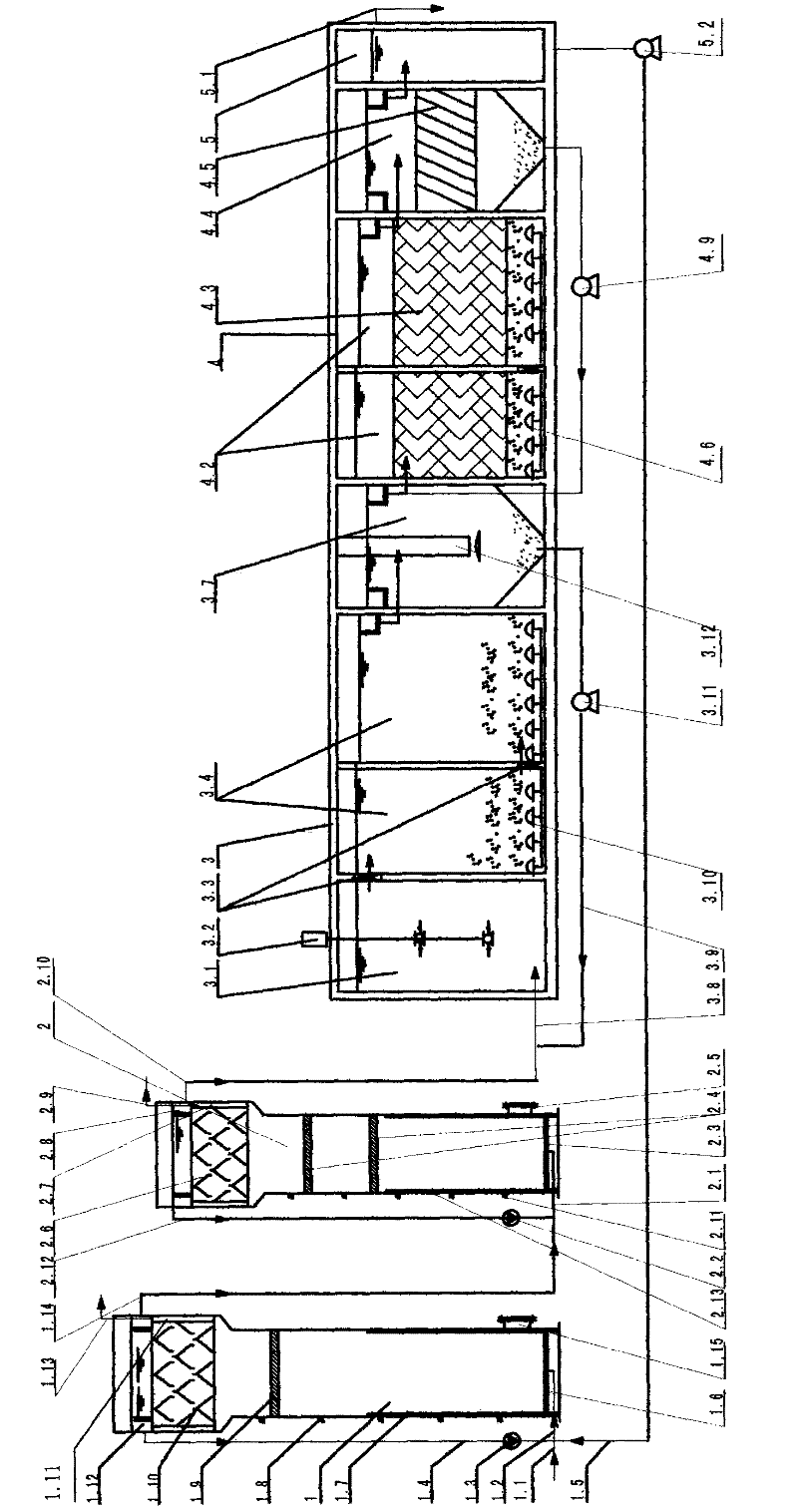

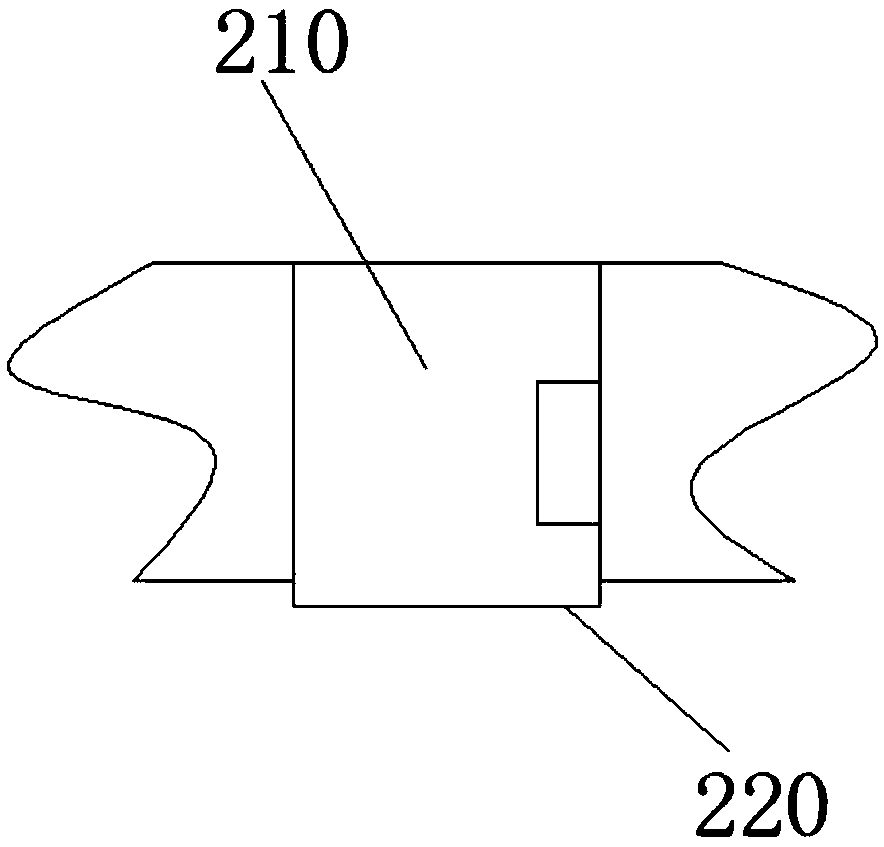

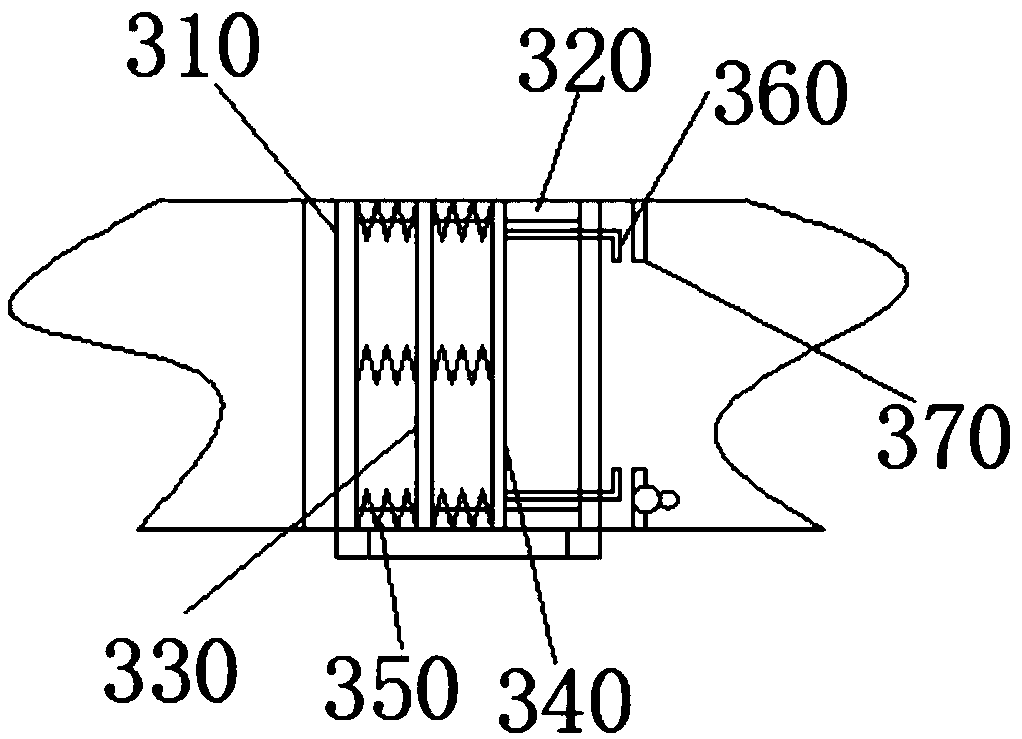

Device and method for treating pharmaceutical waste water through synchronous biological denitrification and devulcanization and autotrophic biological denitrification

InactiveCN102351366AReduce dosePrevent overacidificationMultistage water/sewage treatmentWater treatmentAutotroph

The invention relates to a device and a method for treating pharmaceutical waste water through synchronous biological denitrification and devulcanization and autotrophic biological denitrification. The device is provided with a synchronous denitrification and devulcanization pool, an anaerobic methane generation pool, a partial nitrosification pool, an autotrophic biological denitrification pool and a water outlet pool. The method comprises the steps that: 1) anaerobic digested sludge is added to the synchronous denitrification and devulcanization pool; 2) outlet water of the synchronous denitrification and devulcanization pool enters the anaerobic methane generation pool; 3) outlet water of the anaerobic methane generation pool enters the partial nitrosification pool; 4) outlet water of the partial nitrosification pool enters the autotrophic biological denitrification pool through a middle settling pool; and 5) mixed liquid in the autotrophic biological denitrification pool flows into the water outlet pool after the sludge and water separation in a final setting pool. Through the cooperative action of the synchronous biological denitrification and devulcanization, anaerobic methane generation and autotrophic biological denitrification processes, the deep treatment of the pharmaceutical waste water is realized, and the method and the device are suitable for the standard reaching treatment and the regeneration of the pharmaceutical waste water. The device structure and the operation method are perfect, the energy is saved, the cost is low, the waste water treatment effect is good, and the efficiency is high.

Owner:BEIJING TANSI ENVIRONMENTAL PROTECTION TECHCO

Environmental protection material with insect expelling and purifying functions, and manufacturing method and application thereof

InactiveCN104693830AEasy to handleHas the function of repelling insects and purifyingCoatingsFiberEngineering

The invention relates to an environmental protection material with insect expelling and purifying functions, and a manufacturing method and an application thereof, and belongs to the field of the environmental protection material. The environmental protection material comprises the following components in percentage by mass: 10-15% of plant fiber, 30-40% of traditional Chinese medicine residue, 28-35% of glue and 18-25% of additive. The environmental protection material has the following beneficial effects: the raw materials of the environmental protection material are agricultural wastes and pharmaceutical wastes, the processing problem of the agricultural wastes is solved, and the processing problem of the pharmaceutical wastes is solved at the same time, the corruptible is transformed into mysterious life, the earth is protected and the environment is purified.

Owner:杨国桢 +2

A high-efficiency organic waste water degrading method

ActiveCN106946314APromote circulationImprove utilization efficiencyWater/sewage treatment by irradiationWater/sewage treatment by oxidationSludgeHydroxy compound

A high-efficiency organic waste water degrading method is disclosed. The method includes steps of adding a complexing agent after all ferrous ions are oxidized into ferric ions on the basis of a traditional Fenton reaction; and after a complexing reaction, adding hydrogen peroxide to allow a Fenton-like reaction between the hydrogen peroxide and an iron complex compound under ultraviolet radiation to occur so as to continuously generate hydroxyl radicals. According to the method, through combination of the traditional Fenton reaction and the Fenton-like reaction of the iron complex compound and ferric ions, the reaction pH range is wide, the application range is wide, the total iron amount of the reactions is less than the iron adding amount in the traditional Fenton reaction, iron ion cyclic effects are superior to those of the traditional Fenton reaction, the utilization rate is high, the amount of sludge is low, operation is simple, degradation effects are good, the cost is low and operation is convenient. The method can be used for treating pharmaceutical waste water, pesticide waste water, printing and dyeing waste water, and the like. The waste water COD removing rate after treatment can be 89% or above. The method has a good application prospect.

Owner:SOUTHEAST UNIV

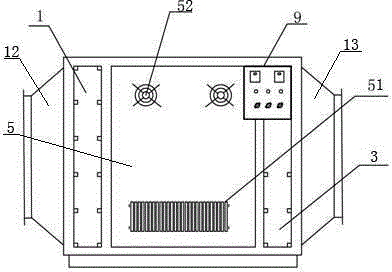

Photolytic catalytic purification device and corresponding process for treating pharmaceutical waste gas

InactiveCN103816782ASimple structureImprove applicabilityDispersed particle filtrationUsing liquid separation agentUltraviolet lightsDust control

The invention discloses a photolytic catalytic purification device for treating pharmaceutical waste gas, which comprises a box, and a front filter system, a UV photolysis system with UV lamp tubes and a rear deodorization system which are communicated in sequence with the interior of the box, wherein second filter screens are arranged between the UV lamp tubes; the UV lamp tubes are connected with electronic ballasts through wires. The photolytic catalytic purification device is simple in structure, high in applicability and low in operation cost, generates no noise, occupies a small area, and saves space. The invention further discloses a corresponding process for treating pharmaceutical waste gas. After being subjected to dust removal by a dust remover and conversion by the photolytic catalytic purification device, the waste gas is discharged by a centrifugal induced draft fan, and pollutants such as volatile organic compounds (VOC), hydrogen sulfide, ammonia gas and thiol can be removed; the deodorization rate is greater than or equal to 99.2%, the waste gas treatment capacity is high, the deodorization speed is high, the process flow is simple and easy to control, and the production cost is low. The device and the process are suitable for treating waste gas generated in antibiotics product manufacturing shops and by the industries of catering, food processing, machining, paint spraying, papermaking and the like.

Owner:河北欧美环境工程有限公司

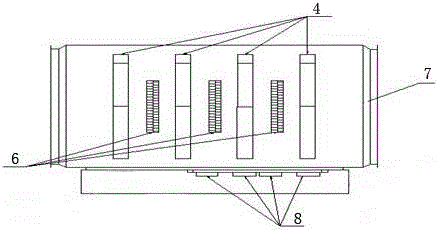

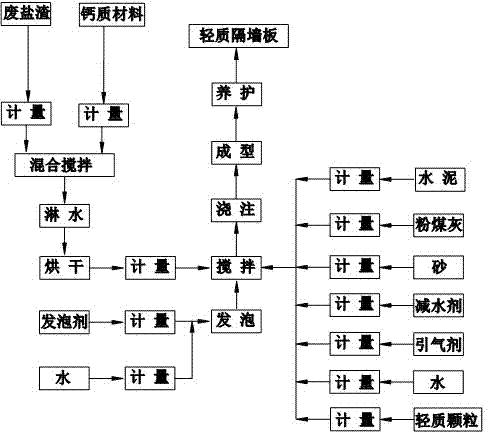

Light-weight partition wall board blended with pharmaceutical waste salt residues and preparation method of light-weight partition wall board

ActiveCN103896535APlay a composite early strength effectShorten turnaround timeSolid waste managementCalcium in biologyFoaming agent

The invention discloses a light-weight partition wall board blended with pharmaceutical waste salt residues and a preparation method of the light-weight partition wall board. The light-weight partition wall board is prepared from cement, the pharmaceutical waste salt residues, coal ash, sand, a water reducing agent, an air entraining agent, a foaming agent, calcareous materials, light-weight particles and water. The preparation method comprises the following steps: mixing and stirring the pharmaceutical waste salt residues and the calcareous materials according to a stoichiometric ratio in a reaction kettle and carrying out water mist spraying; drying a mixed material of the pharmaceutical waste salt residues and the calcareous materials; mixing the foaming agent and the water according to the stoichiometric ratio and preparing physical foams by utilizing a foam generator; mixing the mixed material of the pharmaceutical waste salt residues and the calcareous materials, the cement, the coal ash, the sand, the water reducing agent, the air entraining agent and the light-weight particles according to the stoichiometric ratio and stirring by adding the water and the physical foams so as to obtain a homogeneous material slurry; and injecting the homogeneous material slurry into a molding die and demolding, thereby obtaining the light-weight partition wall board. According to the method, the pharmaceutical waste salt residues are fully utilized, so that the pharmaceutical waste salt residues have a coagulating function and an early age strengthening function during a production process, thereby not only improving the early age strength of the board material and shortening the cycle period of the molding die but also realizing environmental friendliness and waste utilization so as to decrease the cost.

Owner:JIANGSU NIGAO SCI & TECH +1

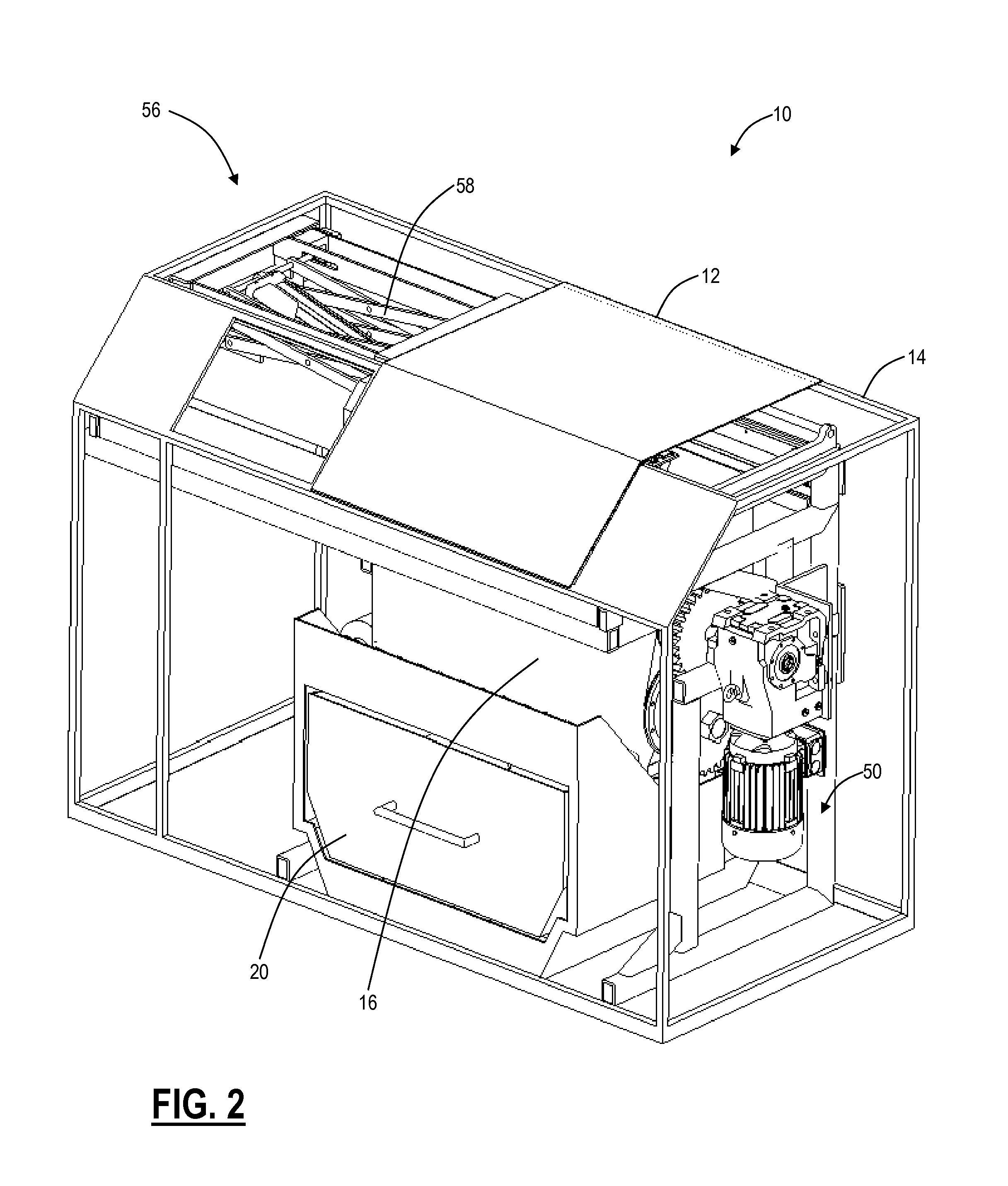

Batch processing device for pharmaceutical wastes

InactiveCN108479933AImprove crushing effectAchieve reactivityDispersed particle filtrationSolid waste disposalBatch processingEngineering

The invention discloses a batch processing device for pharmaceutical wastes. The batch processing device comprises a machine box. The machine box is internally provided with a smashing cavity, a backflow cavity and a sterilizing cavity. A purifying box is mounted on the back side of the machine box. A feeding hopper is arranged at the top end of the smashing cavity. Grinding gears are mounted in an inner cavity of the feeding hopper. Moving base plates are mounted at the bottom end of the feeding hopper. The moving base plates are divided into two parts and are in an arc shape. The bottom endsof the moving base plates are connected with the bottom end of the feeding hopper through moving shafts. Fixed insections are arranged on the inner walls of the moving base plates. The fixed insections and insections on the surfaces of the grinding gears are arrayed in a staggered mode. Fixing seats are arranged under the moving base plates. A plurality of squeezing springs are arranged between the moving base plates and the fixing seats for connection. According to the batch processing device for the pharmaceutical wastes, the moving base plates can have a squeezing effect on materials whilemoving within a small range, so that the smashing effect of the materials is enhanced, and meanwhile blocking is avoided during feeding.

Owner:张荷友

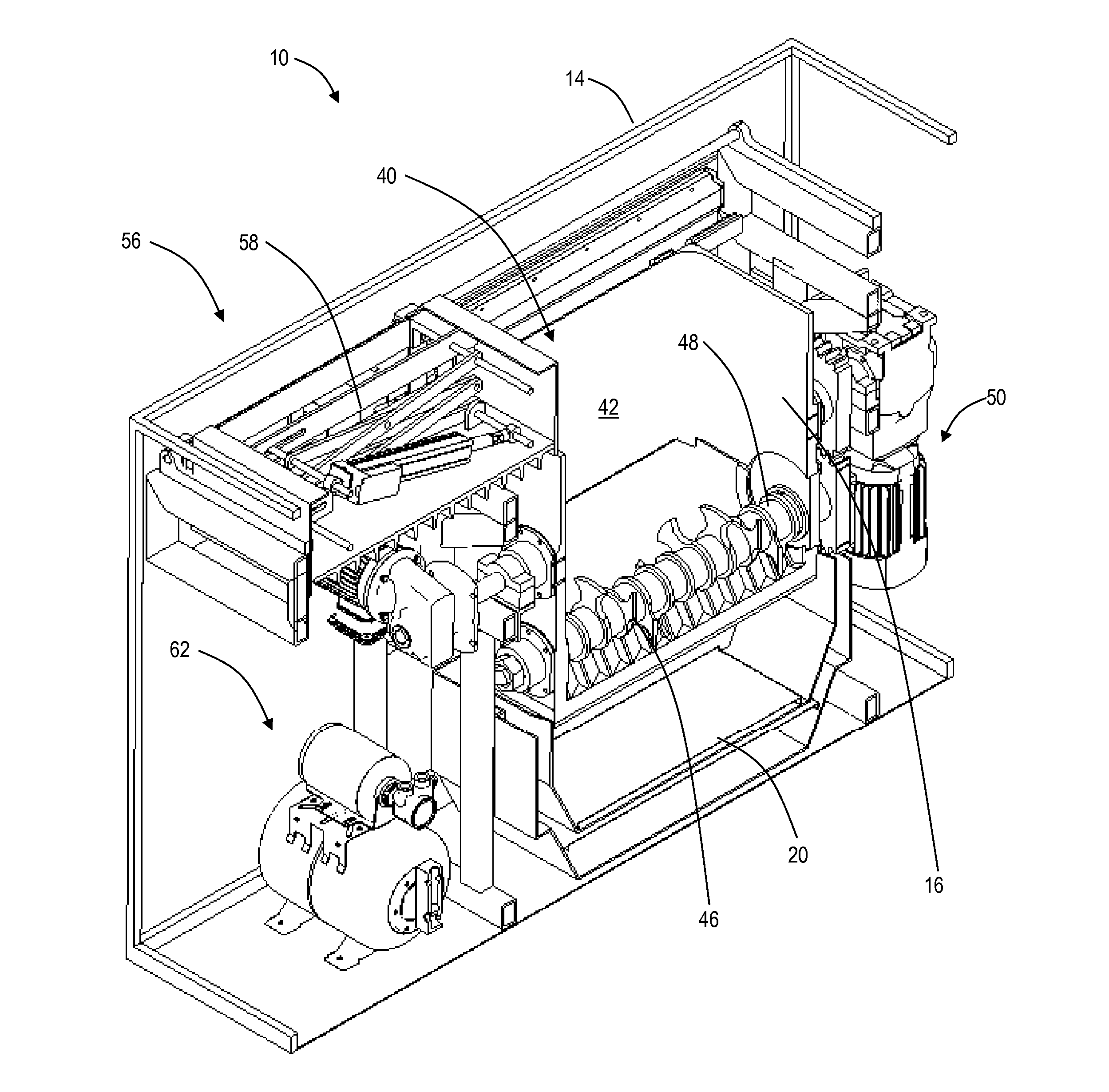

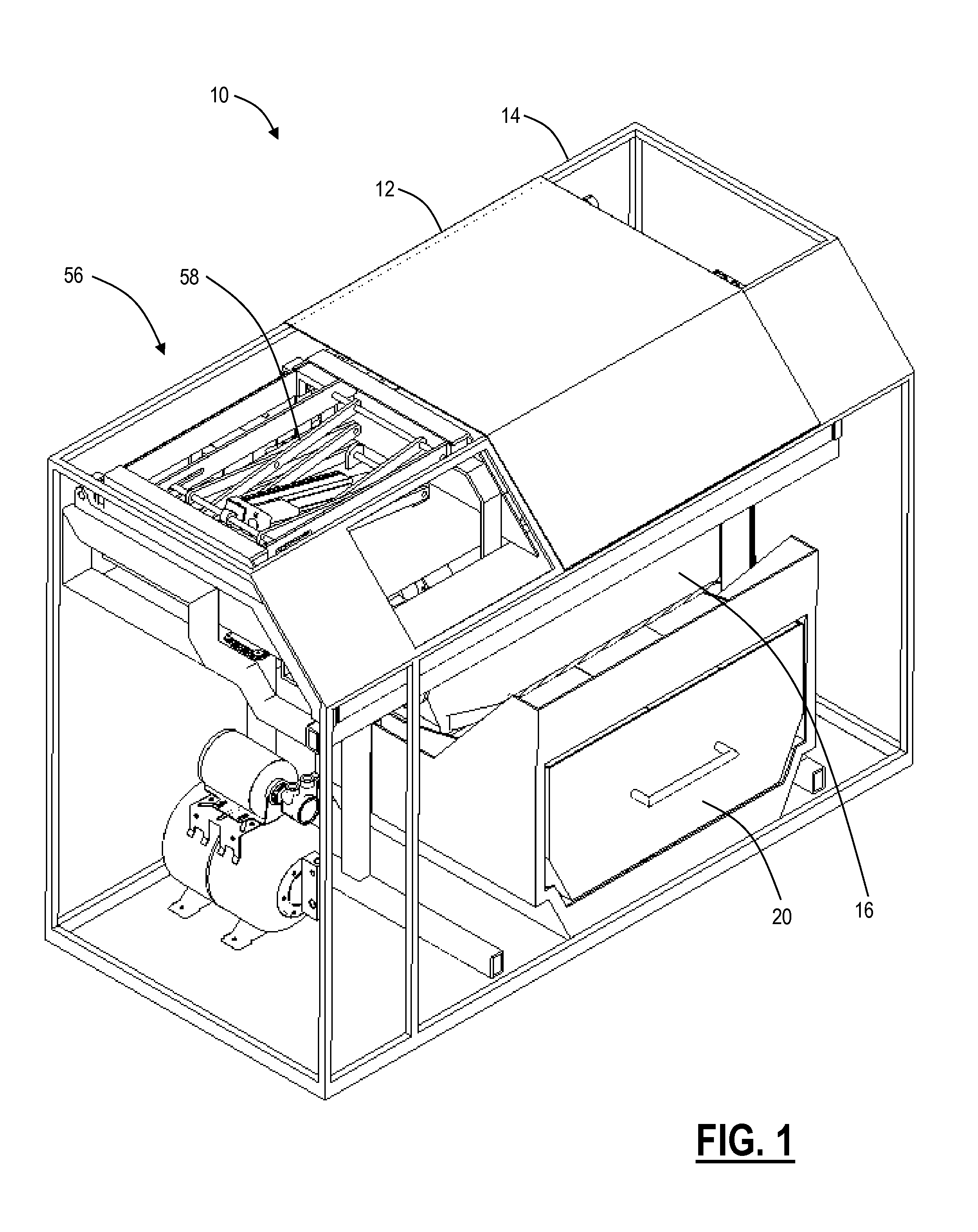

Biomedical and pharmaceutical waste sterilizing systems and methods

A biomedical and pharmaceutical waste sterilization system includes a vessel comprising a treatment chamber, wherein the vessel is disposed in an open frame for support thereof and the vessel comprises an opening on a top side configured to receive biomedical waste and a shredding system to treat the biomedical waste; and a chemical loading system configured to receive liquid ozone for introduction into the treatment chamber prior to and during a treatment cycle for the biomedical waste.

Owner:ENVIRONTEK WORLDWIDE LLC

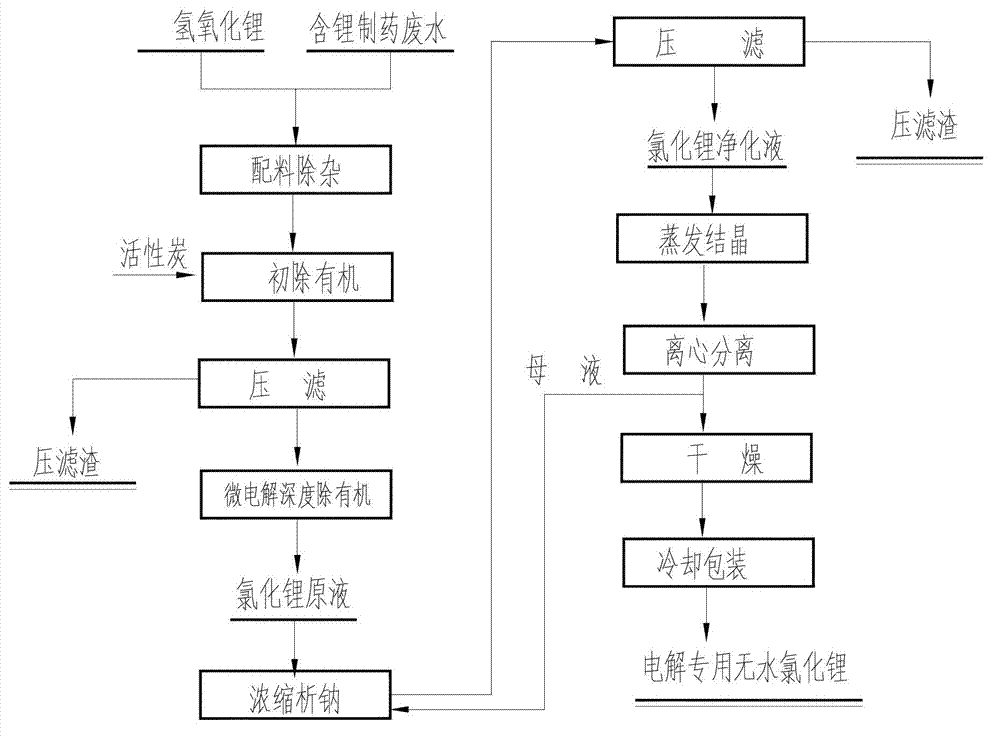

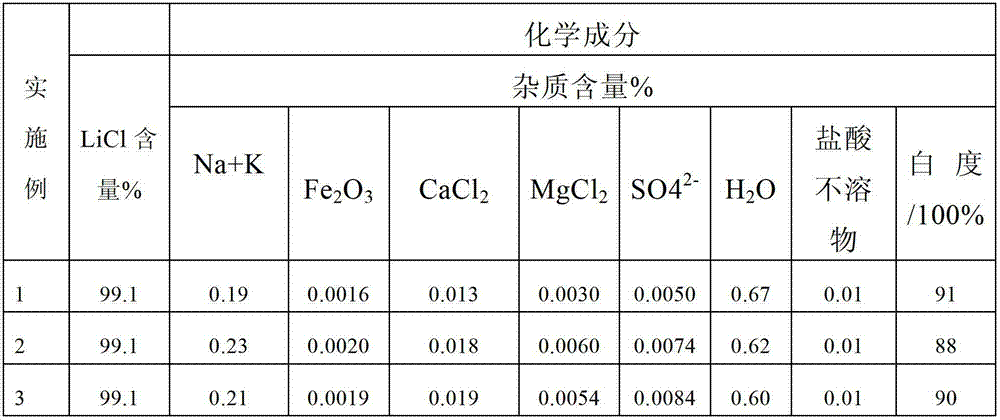

Method for producing anhydrous lithium chloride special for electrolyzing by using lithium recovered from lithium-containing pharmaceutical waste water

The invention discloses a method for producing anhydrous lithium chloride special for electrolyzing lithium by using lithium recovered from lithium-containing pharmaceutical waste water. The method comprises the following steps of: (a) preparing materials and removing impurities; (b) initially removing organic matters; (c) performing microelectrolysis and deeply removing the organic matters; (d) concentrating to separate sodium out; (e) evaporating and crystallizing; (f) performing centrifugal separation; (g) drying; and (h) cooling and packaging. By the method, the anhydrous lithium chloride special for producing and electrolyzing the lithium can be directly obtained by using the lithium recovered from the lithium-containing pharmaceutical waste water, so that the product impurity is more than 99 percent, the content of the sodium is less than 0.25 percent, and the whiteness of the products is high.

Owner:FENGXIN GANFENG LITHIUM

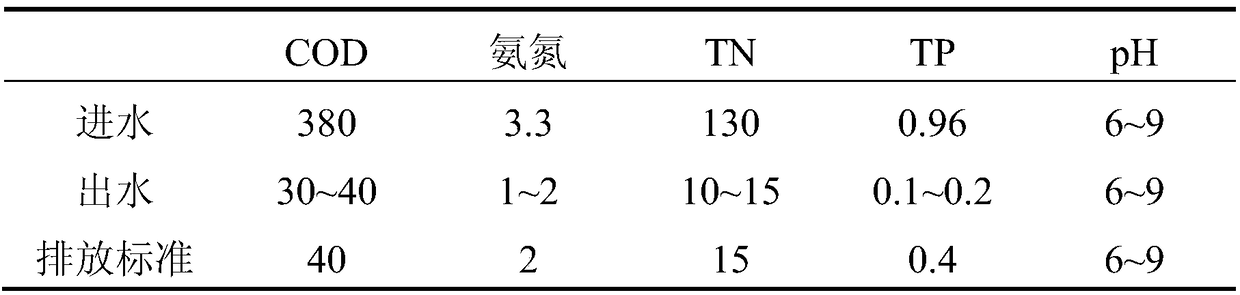

Deep treatment process and equipment of pharmaceutical waste water being stricter than class-A standards

InactiveCN108275835AImprove biodegradabilityGood removal effectWater contaminantsTreatment involving filtrationBiological filterOxidation pond

The invention belongs to the field of deep treatment of waste water and particularly relates to a deep treatment process and equipment of pharmaceutical waste water being stricter than class-A standards. The deep treatment equipment of the pharmaceutical waste water being stricter than class-A standards comprises an adjusting pond, a first-stage coagulating precipitation pond, a first-stage ozoneoxidation pond, a stabilizing pond, a hydrolytic acidification pond, an aerobic MBBR (Moving Bed Biofilm Reactor) pond, a secondary precipitation pond, a denitrifying biological filter, an aeration biological filter, a second-stage coagulating precipitation pond, a sand filter, a second-stage ozone oxidation pond and a disinfecting pond. The deep treatment process and equipment of the pharmaceutical waste water being stricter than the class-A standards has the advantages that according to the characteristics of complex components, high chromaticity, large toxicity and extremely poor biodegradability and the like of discharged water from a sewage treatment station of a pharmaceutical factory, physical and chemical processes, an advanced oxidation technology and a biological technology are reasonably combined and applied, and after treatment, the discharged water can meet the requirements of class-A local discharge standards.

Owner:CCCC TIANJIN ECO ENVIRONMENTAL PROTECTION DESIGN & RES INST CO LTD

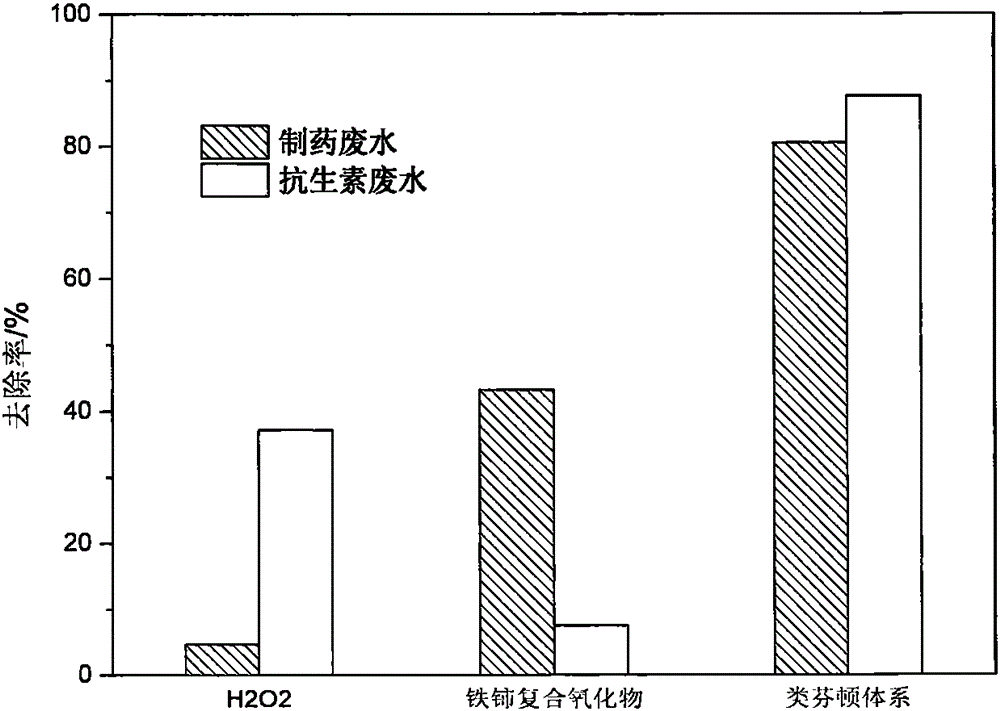

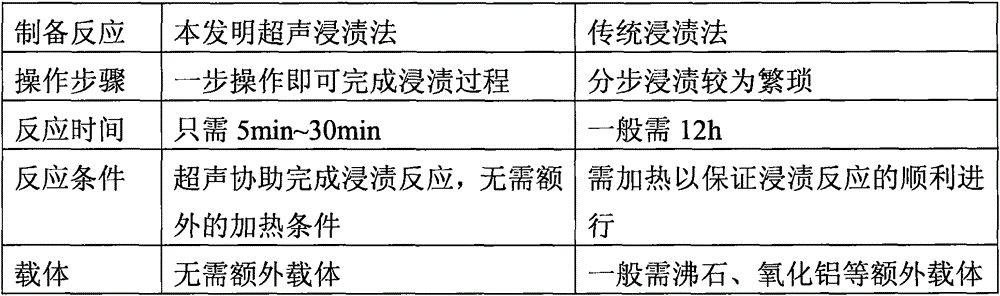

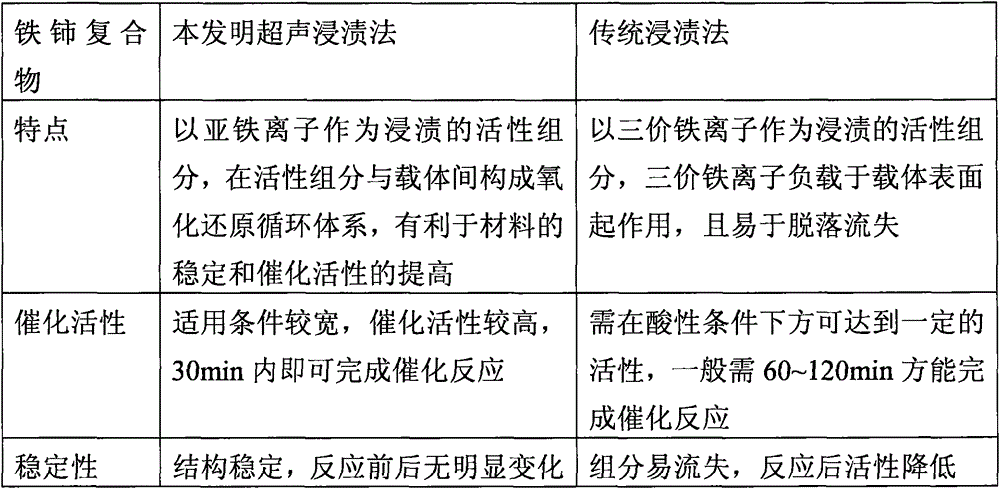

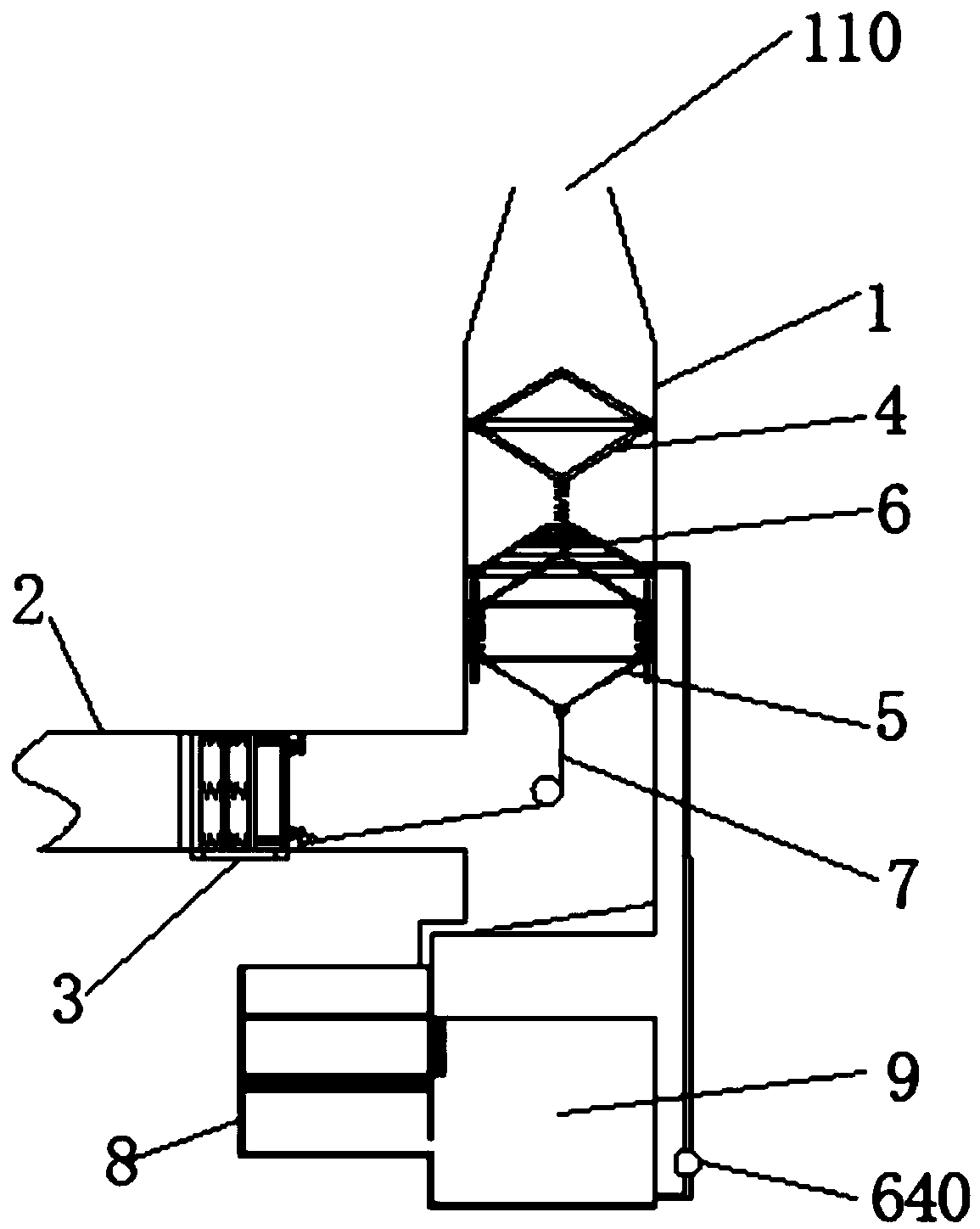

Method for preparing iron and cerium compound by means of ultrasonic infiltration and application of method in fenton-like water treatment

InactiveCN105251499AEasy to operateShort impregnation reaction timeWater contaminantsCatalyst activation/preparationCeriumPrecipitation

The invention discloses a method for preparing an iron and cerium compound oxide by means of ultrasonic infiltration and application of the method in fenton-like water treatment. The method for preparing the iron and cerium compound oxide by means of ultrasonic infiltration comprises the following steps that after cerium metal salt is dissolved in water, an alkaline aqueous solution is added for precipitation reaction, precipitation obtained after the reaction is completed is dried and ground, and cerium dioxide powder is obtained after natural cooling to the room temperature is conducted; after iron metal salt is dissolved in water, the cerium dioxide powder is added for ultrasonic infiltration, precipitation obtained after the reaction is completed is filtered and calcined, natural cooling to the room temperature is conducted, and the iron and cerium compound oxide is obtained. The iron and cerium compound oxide prepared through the ultrasonic infiltration method is simple in structure, higher in activity, the preparation method is simple in operation step and short in reaction time, the reaction condition is easy to control, and practical application value is achieved. After a catalytic reaction is conducted for 20 min in a fenton-like water treatment system, the removal effects on pharmaceutical waste water and antibiotic waste water can reach 81% and 87% respectively.

Owner:RENMIN UNIVERSITY OF CHINA

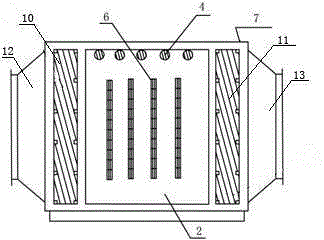

Pharmaceutical waste gas treatment device

ActiveCN108786288AReasonable structural designImprove purification effectGas treatmentDispersed particle filtrationInlet channelFiltration

The invention provides a specific technical scheme of a pharmaceutical waste gas treatment device, and is characterized in that the pharmaceutical waste gas treatment device comprises a device body, agas inlet channel, a first dust removal device, an activated carbon filter device, a second dust removal device, a spraying device, a vibration connection device, a filter box and a liquid storage tank. The pharmaceutical waste gas treatment device is reasonable in structure design. The first dust removal device and the second dust removal device are used for step-by-step filtration, and the filtration efficiency is improved; both a third filter screen and a fourth filter screen are conical, the contact area between waste gas and the filter screens is increased, and then the filtration efficiency is increased; the spraying device is combined with the second dust removal device, harmful organic gas in waste gas can be effectively absorbed, and the purification effect of the waste gas is improved; the vibration connection device makes a spraying liquid fall back and filter quickly, and the purification efficiency of the waste gas is increased; the upper part of the spraying device is equipped with the activated carbon filter device, the gas purification effect is further increased, and pollution of the pharmaceutical waste gas to air and environment is avoided.

Owner:天津鼎拓恒远知识产权服务有限公司

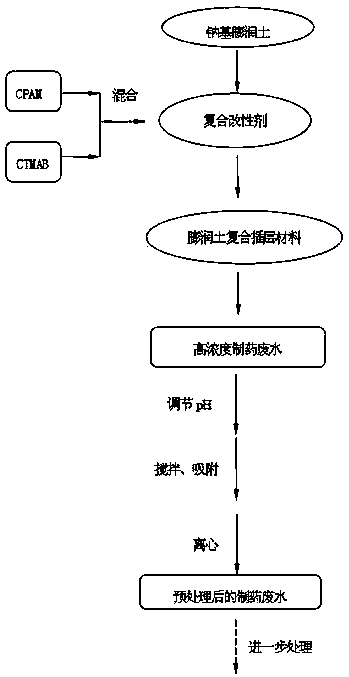

Method for pretreating high-concentration pharmaceutical wastewater by using bentonite composite intercalation material

InactiveCN103466743ASimple processLow technical requirementsOther chemical processesWater/sewage treatment by sorptionHigh concentrationWater baths

The invention relates to a method for pretreating high-concentration pharmaceutical wastewater by using a bentonite composite intercalation material, and relates to a method for treating the pharmaceutical wastewater. The method comprises the following steps: firstly preparing CTMAB / CPAM (Cetyl Trimethyl Ammonium Bromide / Cationic Polyacrylamide) composite modified liquid: dissolving 2 millimole of CTMAB and 0.03 grams of CPAM into 100 millilitres of distilled water, and stirring under the condition of a water bath at 40 DEG C for 20 minutes; preparing the bentonite composite intercalation material: adding 6 grams of sodium bentonite to 100 millilitres of the CTMAB / CPAM composite modified liquid; adding the bentonite composite intercalation material to the pharmaceutical waste with higher organic content, wherein the highest removal ratio of the bentonite composite intercalation material on COD (Chemical Oxygen Demand) can achieve 78.39%, the adsorption capacity is 3334 mg / g, and pretreatment effect is achieved. The bentonite composite intercalation material prepared by utilizing the sodium bentonite as a raw material and CTMAB / CPAM as a composite modifying agent is greatly enlarged in specific area and interlayer spacing and greatly enhanced in adsorption property.

Owner:SHENYANG INSTITUTE OF CHEMICAL TECHNOLOGY

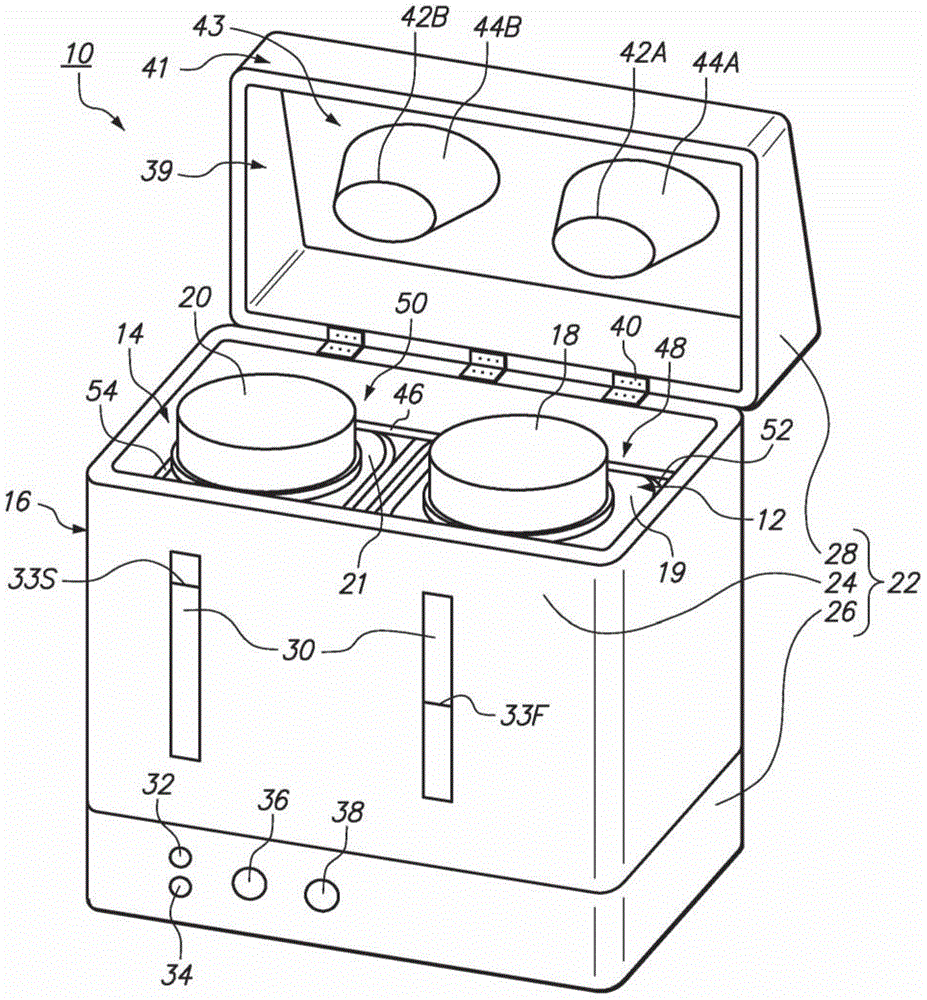

Pharmaceutical waste disposal assembly

A pharmaceutical waste disposal assembly (10) for disposing of raw pharmaceutical waste comprises a first receiver body (19) and a first reaction agent (287). The first receiver body (19) receives the pharmaceutical waste. The first receiver body (19) includes a receiver bottom (283), The first reaction agent (287) is positioned within the first receiver body (19) and spaced apart from the receiver bottom (283), The pharmaceutical waste reacts with the first reaction agent (287) to change the pharmaceutical waste in one of a chemical and physical manner so that the pharmaceutical waste is unrecoverable. The first receiver body (19) can receive fluid pharmaceutical waste and / or solid pharmaceutical waste. The first reaction agent (287) may include one or more of a denaturant, an emetic and a bittering agent. For example, the first reaction agent (287) may include one or more of quinine, ipecac and denatonium benzoate.

Owner:STRYKER CORP

Method for treatment and disposal of pharmaceutical waste

An exemplary system for treatment and disposal of pharmaceutical waste comprises a sealable pail, a stirring device, a sealable bag, a container, an acidic substance, and a denaturant. The sealable pail receives the pharmaceutical waste and the acidic substance. The acidic substance dissolves the pharmaceutical waste, and the stirring device stirs the acidic substance to ensure that the pharmaceutical waste is completely dissolved. The denaturant is added to the dissolved pharmaceutical waste and renders the dissolved pharmaceutical waste safe for transport. The treated pharmaceutical waste is sealed within the sealable pail, and the sealable bag receives the sealed pail and is sealed. The sealed bag is then placed in the container for transport to a disposal facility.

Owner:STALONS DONALD R

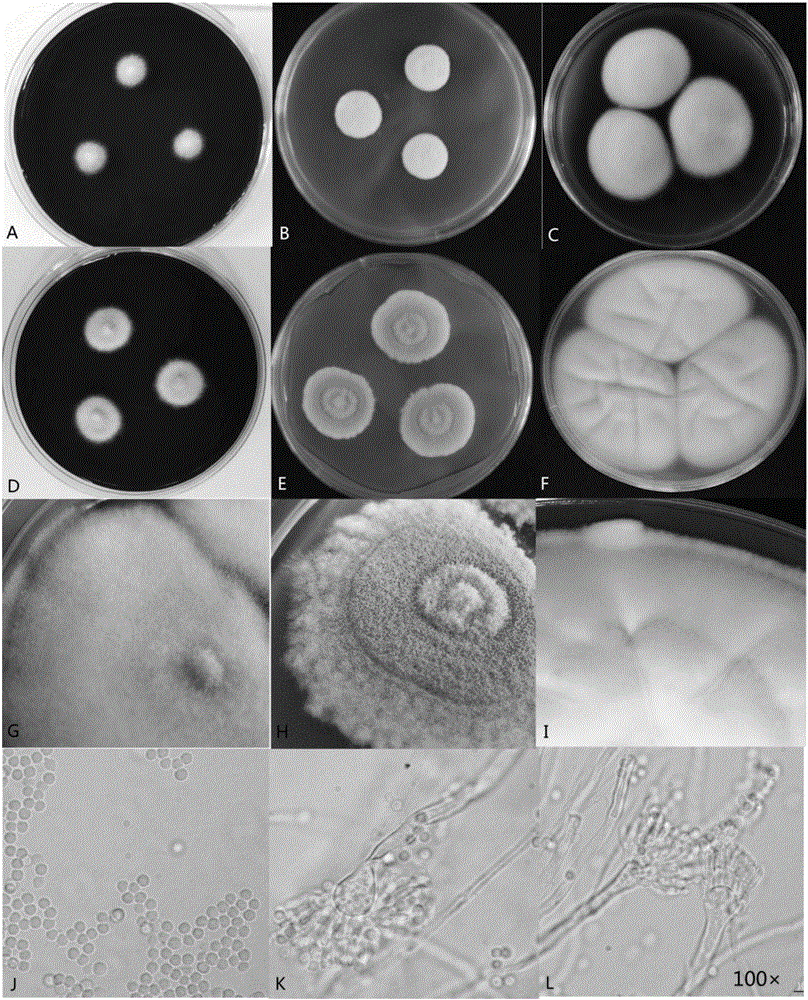

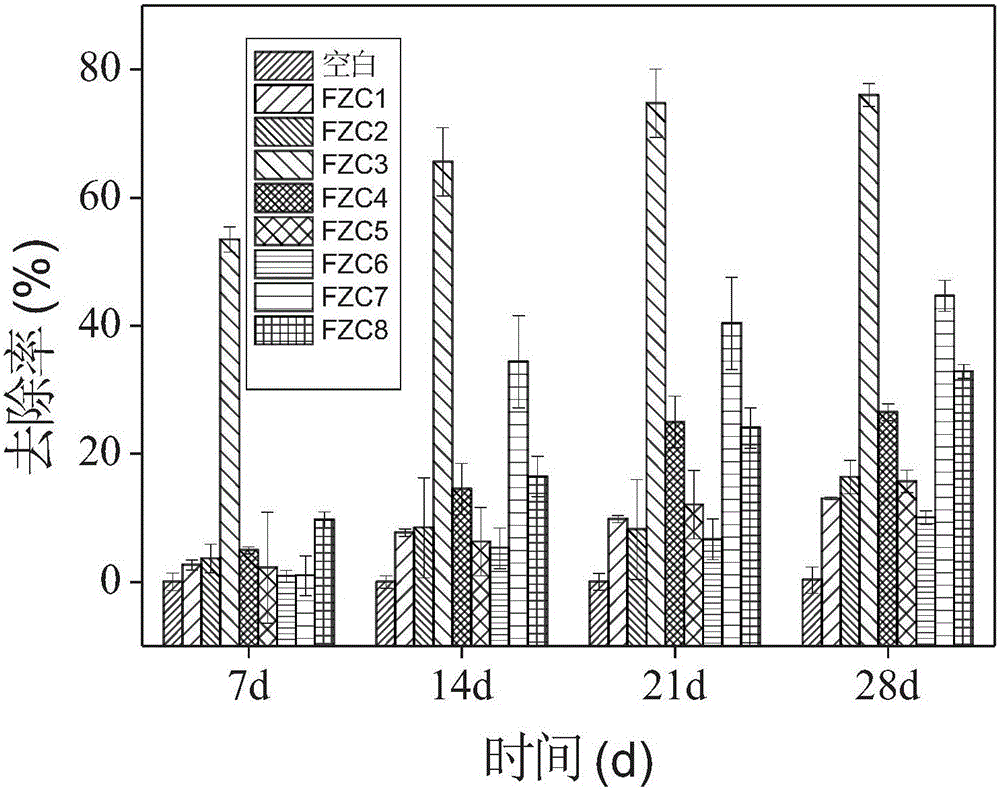

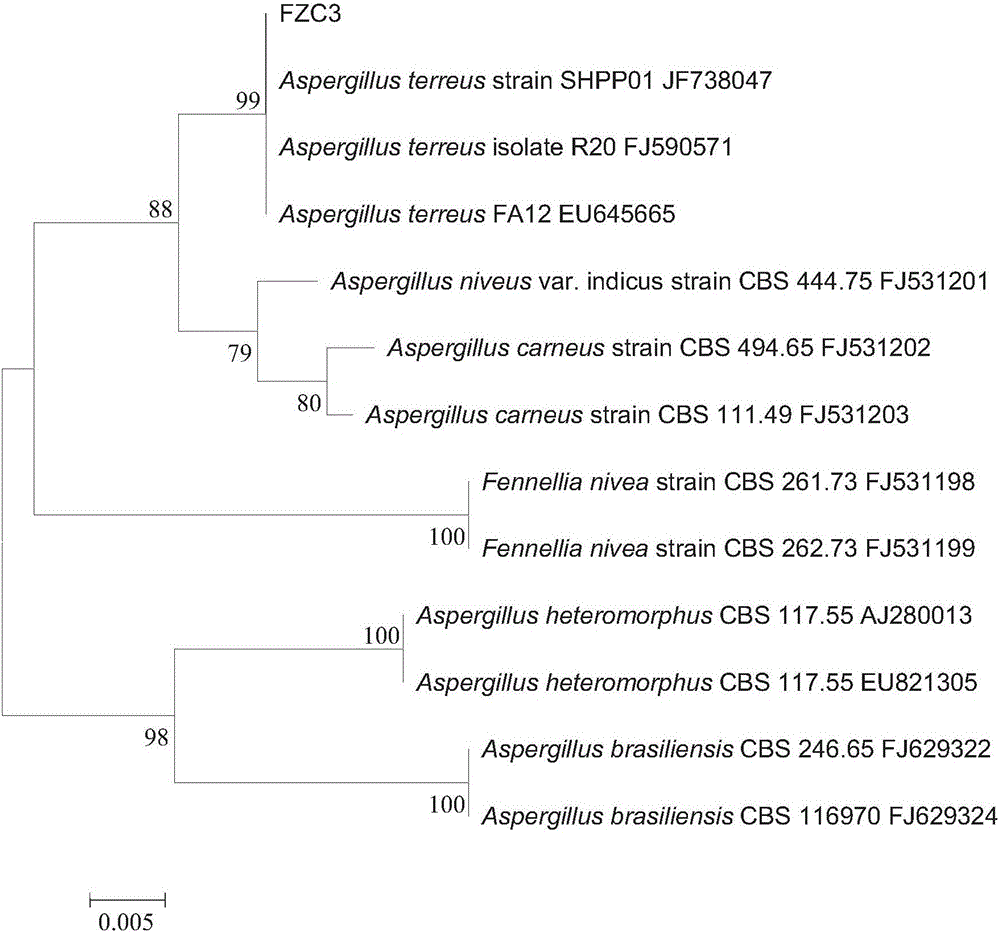

Gentamicin degradation fungus and application thereof

A fungus (Aspergillus terreus FZC3) with the preservation number of CGMCC No.12072 can be applied to grade gentamycin, and the fungus is inoculated to a system containing gentamycin and is cultured to realize degradation of gentamycin. The fungus is cultured to remove gentamycin in environment, and can be used to process pharmaceutical wastes in order to reduce harms of gentamycin to environment, humans and animals.

Owner:INST OF AGRI RESOURCES & REGIONAL PLANNING CHINESE ACADEMY OF AGRI SCI +1

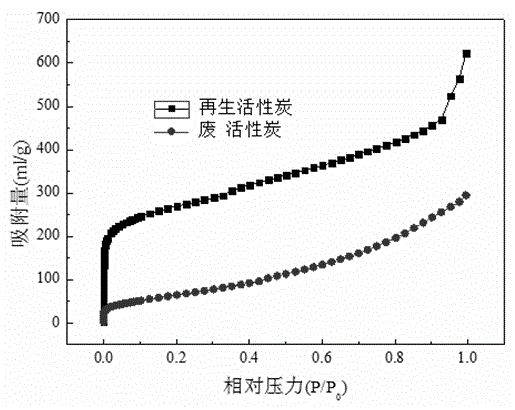

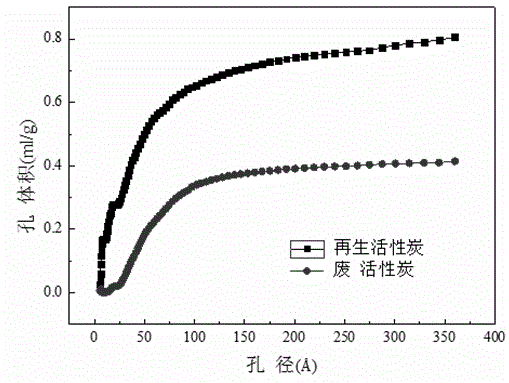

Method for acquiring activated regenerated paracetamol pharmaceutical waste activated carbon through microwave heating

InactiveCN104148039ANo pollution in the processRestore adsorption capacityOther chemical processesCombustible gas purificationActivated carbonMicrowave oven

The invention relates to a method for acquiring activated regenerated paracetamol pharmaceutical waste activated carbon through microwave heating and belongs to the technical field of resource recycling. The method for acquiring paracetamol pharmaceutical waste activated carbon through microwave heating comprises the following specific steps: paracetamol pharmaceutical waste activated carbon is placed in a microwave oven with power ranging from 0 to 40kW; the temperature rises to 500-700 DEG C at the heating rate of 145-175 DEG C / min and heat preservation is performed for 8-10 min; and the microwave heated paracetamol pharmaceutical waste activated carbon is dried for 24-48 h at the temperature ranging from 105 to 115 DEG C and then is cooled to acquire activated regenerated paracetamol pharmaceutical waste activated carbon. The method works without the use of protective gas, thereby simplifying the test process and operation, consuming less energy and producing no pollution. The activated regenerated activated carbon is characterized in that the absorption property is restored, the specific surface area reaches 1000 m<2> / g above, the total pore volume ranges from 0.95 ml / g to 1.10 ml / g, and the activating regeneration yield exceeds 90%.

Owner:KUNMING UNIV OF SCI & TECH

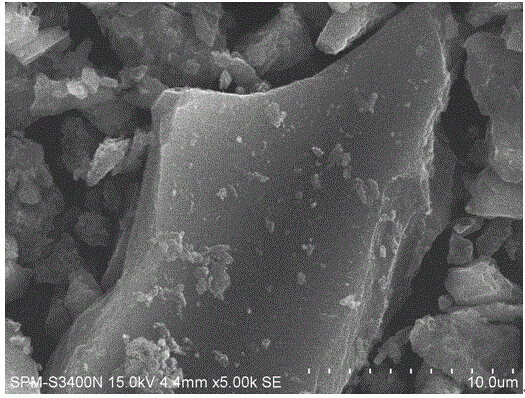

Purification method for recovering dichloromethane from waste solvent

ActiveCN109928861ASuitable for recyclingHalogenated hydrocarbon separation/purificationLiquid wastePurification methods

The invention discloses a purification method for recovering dichloromethane from a pharmaceutical waste solvent. The method comprises the following steps: 1) adjusting the pH value of the waste dichloromethane solvent to 7-10 by using an acid and / or an alkali, and carrying out heating distillation or / and decolorizing; 2) collecting the obtained fraction dichloromethane, adding an alkali solution,carrying out a reaction, and standing the obtained reaction to carry out layering; 3) removing the obtained upper aqueous phase, taking the obtained lower dichloromethane organic phase, extracting the lower dichloromethane organic phase with ethylene glycol, and rectifying the obtained extract; and 4) collecting a fraction at a temperature of 60-85 DEG C to obtain purified dichloromethane. The method is suitable for the recovery purification of the dichloromethane waste liquid with the complex components in the pharmaceutical industry, and the obtained dichloromethane reaches national standards. The method facilitates environment protection, and reduces the production cost.

Owner:XINZHONGTIAN ENVIRONMENTAL PROTECTION

Method for recycling pyridine from pharmaceutical waste liquid

InactiveCN104402804ADoes not affect separation performanceSimple processOrganic chemistryLiquid wastePotassium fluoride

The invention relates to a method for recycling pyridine from a pharmaceutical waste liquid and belongs to the field of recycling method of wastes. The method for recycling pyridine from the pharmaceutical waste liquid comprises following steps: (1) filtering and pre-treating the pharmaceutical waste liquid; (2) mixing a potassium fluoride solution having a certain concentration with the pre-treated pharmaceutical waste liquid according to a certain mass proportion to obtain a mixture; (3) feeding the mixture to a layering device and allowing the mixture to stand for three hours for layering; (4) feeding a water-enriched phase after layering to an evaporator with steam at 140 DEG C being fed; and (5) recycling concentrated strong salt water back to the layering device for recycling. In the method recycling pyridine from a pharmaceutical waste liquid, the pyridine can be recycled from the pharmaceutical waste liquid through common rectification and a salt-adding phase-separating method are employed. When a mass ratio of the potassium fluoride solution being 60% in concentration and a material composed of 50% of the pyridine and 50% of water is 2.0, purity of the pyridine in an organic phase can reach 92.60%. A separation performance of a potassium fluoride weak solution in the water phase is not influenced after being recycled through the evaporator. The method is simple in process, is convenient to operate and is low in cost.

Owner:SHAANXI HUALU CHEM ENVIRONMENTAL PROTECTION

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com