Purification method for recovering dichloromethane from waste solvent

A technology of dichloromethane and a purification method is applied in the field of purification of recovering dichloromethane from pharmaceutical waste solvents or industrial waste liquids, and can solve problems such as environmental impact, difficulty in effective separation, and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

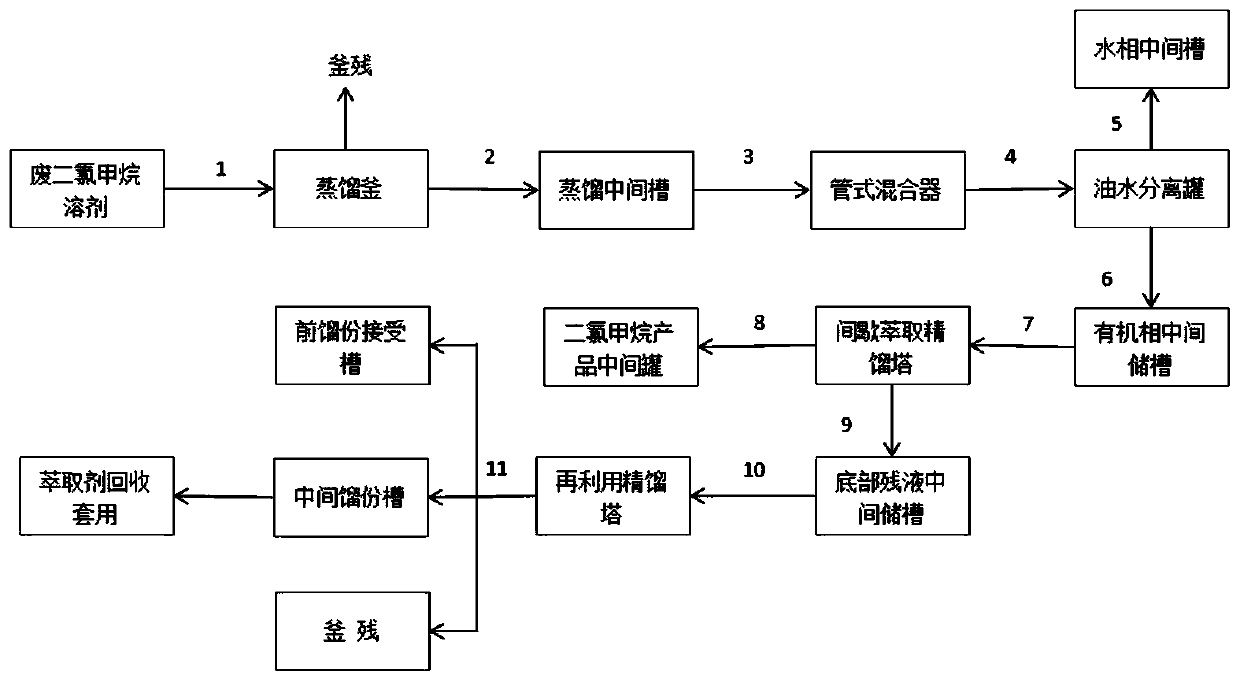

Image

Examples

Embodiment 1

[0021] The recovery, purification of methylene chloride in the pharmaceutical waste liquid of embodiment 1

[0022] Its process steps are as follows:

[0023] 1) Pump the barreled dichloromethane waste solvent (or waste liquid) collected from pharmaceutical companies into the distillation still (the still can be equipped with stirring, vacuuming, nitrogen, lye dripping, steam or electric heating temperature control system as required etc.), use acid or alkali to adjust the pH in the still to 7-10, then heat the still, the temperature in the still is controlled at 39-42°C, the light components are evaporated by heating and passed through the overhead condenser, and the condenser is a secondary condensation , circulating water and 7°C low-temperature water, the dichloromethane at the top distillate condenses and enters the intermediate collection tank (that is, the middle tank of the still), and the residue at the bottom of the still is removed for hazardous waste disposal. The...

Embodiment 2

[0031] The waste dichloromethane solvent collected from a pharmaceutical company consists of (w%): 70.30% dichloromethane, 6.29% methanol, 6.80% ethanol, 5.50% acetone, 4.54% EA, 3.14% toluene, and 1.15% water , the other about 2.28%, PH=4, the color of the waste liquid is yellowish brown.

[0032] The recovery and purification process is:

[0033] 1. Pump the waste liquid into a 5000L still (the still needs to be replaced three times with nitrogen), start stirring at 50 rpm and add liquid caustic soda to adjust the pH to 7-8, open the steam valve and turn on the condensed water in the still to heat up and distill at 45°C , The distillation time is 5h, and the collected fractions flow into the middle tank.

[0034] 2. Pump the dichloromethane in the middle tank into the pipeline mixer (here the pipeline mixer is 1m long and 80mm in diameter and adopts two sections connected in series.), add the sodium hydroxide aqueous solution of PH=9, mix well and send into Oil-water separ...

Embodiment 3

[0039] The waste dichloromethane solvent collected from a pharmaceutical company consists of (w%): 70.30% dichloromethane, 6.29% methanol, 6.80% ethanol, 5.50% acetone, 4.54% EA, 3.14% toluene, and 1.15% water , the other about 2.28%, PH=4, the color of the waste liquid is yellowish brown.

[0040] The recovery and purification process is:

[0041] 1. Pump the waste liquid into a 5000L still (the still needs to be replaced three times with nitrogen), start stirring at 50 rpm and add liquid caustic soda to adjust the pH to 8-10, open the steam valve and turn on the condensed water of the still to raise the temperature at 45°C Distillation, the distillation time is 5h, and the collected fractions flow into the middle tank.

[0042] 2. Pump the dichloromethane in the middle tank and the aqueous sodium hydroxide solution (according to the mass ratio of 1:0.1 to 0.3) into the pipeline mixer (here the pipeline mixer is 1m long and 80mm in diameter). Two sections connected in serie...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com