Preparation method of spherical calcium-based CO2 adsorbent

A technology of CO2 and adsorbent, which is applied in the field of preparation of spherical calcium-based CO2 adsorbent, can solve the problems of increased cost and unfavorable industrial application, and achieve the effect of complete shape, simple method and stable performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

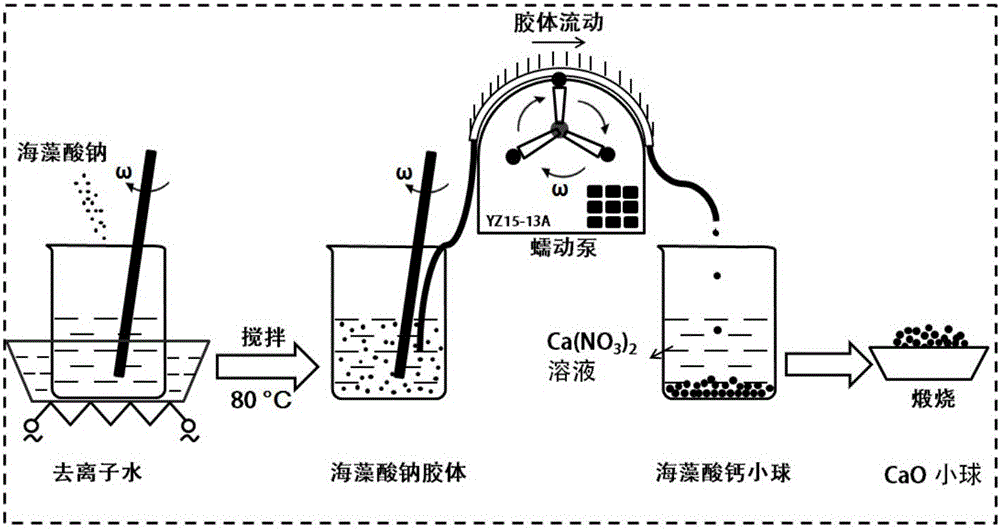

[0037] The invention provides a spherical calcium-based CO 2 The preparation method of adsorbent comprises the following steps:

[0038] (1) Based on 1 part by weight of sodium alginate, add 1 part of sodium alginate, 0.05 to 0.2 parts of inert load, and 0.5 to 5 parts of pore-forming agent in 1 part to 1000 parts of water , heated at room temperature or 30°C to 100°C with water to make it evenly mixed to obtain a colloidal solution;

[0039] (2) Through a peristaltic pump or a syringe, drop the colloidal solution into a calcium salt solution with a mass fraction greater than or equal to 1% at a speed of 1ml / min to 15ml / min to obtain spherical calcium alginate; the particle size of the spherical calcium alginate It is mainly related to the concentration of the colloidal solution. The higher the concentration of the colloidal solution, the larger the droplet of the colloidal solution is due to the intermolecular force of the sodium alginate molecules, so the particle size of t...

Embodiment 1

[0044] (1) Add 2 g of sodium alginate to 100 g of deionized water, heat at 80° C. and stir to form a sodium alginate colloid;

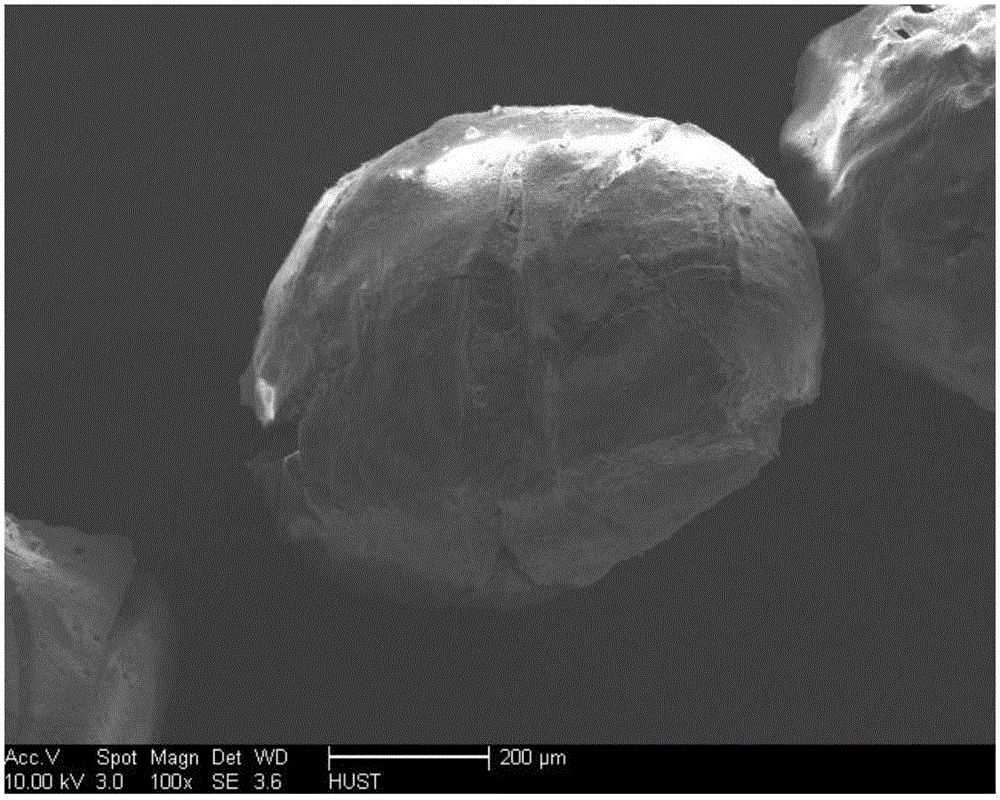

[0045] (2) Drop the formed sodium alginate colloid into a calcium nitrate solution with a mass concentration of 20% at a rate of 8 ml / min through a peristaltic pump to form a spherical calcium alginate precipitate with a diameter of about 3 mm;

[0046] (3) Spherical calcium alginate was calcined at 850°C for 30 minutes in an air atmosphere to obtain the desired spherical calcium-based CO 2 Adsorbent.

Embodiment 2

[0048] (1) Mix 2 g of sodium alginate powder and 2 g of cellulose powder with a particle size of less than 300 μm, then add 100 g of deionized water, heat at 80° C. and stir to form a sodium alginate colloid containing cellulose;

[0049] (2) drop the formed sodium alginate colloid into a calcium nitrate solution with a mass concentration of 20% at a rate of 8ml / min through a peristaltic pump to form a spherical calcium alginate precipitate with a diameter of about 3mm;

[0050] (3) Spherical calcium alginate was calcined at 850°C for 30 minutes in an air atmosphere to obtain the required spherical calcium-based CO 2 Adsorbent.

[0051] In addition, the parameters of Example 3-Example 10 are specifically shown in Table 1, and the parameters not listed in the table are the same as those of Example 1.

[0052]

[0053]

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com