Combination type treatment method for pharmaceutical waste water

A technology for chemical and pharmaceutical wastewater and a treatment method, applied in the field of water treatment, can solve problems such as large differences in operating costs, and achieve the effects of reducing subsequent treatment load, stable operation, and small capital investment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

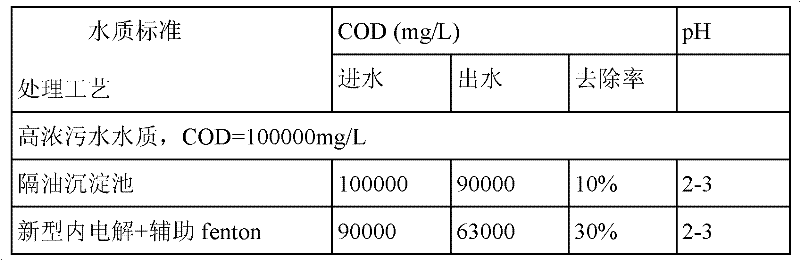

[0049] Embodiment 1: the pretreatment method of high-concentration wastewater

[0050] 1) Grease trap treatment unit: remove water-insoluble organic solvents;

[0051] 2) Regulating tank processing unit: adjust PH to 2-3, control hydraulic retention time;

[0052] 3) New internal electrolysis and auxiliary fenton treatment unit: the pH of the influent is 2-3, the residence time is 2-4h, and the dosage of fenton is 1000-2000mg / l for hydrogen peroxide.

[0053] Among them, the new internal electrolysis and auxiliary fenton processing unit refers to:

[0054] Internal electrolysis technology is currently an ideal process for treating high-concentration organic wastewater, also known as internal electrolysis. It uses the internal electrolytic material filled in the wastewater to generate a 1.2V potential difference to electrolyze the wastewater to achieve the purpose of degrading organic pollutants without electricity. The internal electrolysis materials used in the traditional...

Embodiment 2

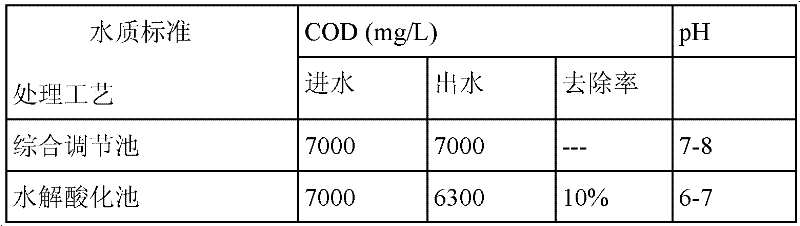

[0058] Embodiment 2: further treatment of waste water

[0059] 1) ABR acidification pool: the effective residence time is 16-24h (depending on the water quality), the main feature is to use its own hydraulic deflection for stirring, without additional mechanical stirring;

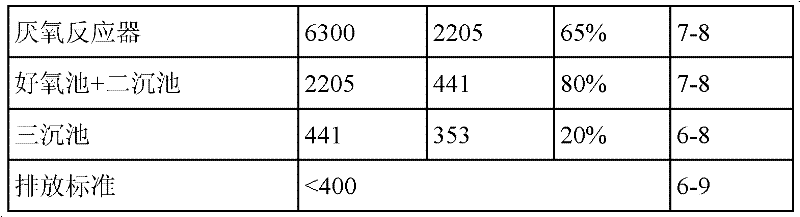

[0060] 2) Anaerobic treatment unit: In the anaerobic reactor, the organic matter in the degraded wastewater is biogas, and the volume load is 3-5kgCOD / (m 3 d);

[0061] 3) MBBR and activated sludge treatment unit: the front section adopts mud membrane MBBR for high load section, the rear section adopts activated sludge method for low load section, high load MBBR section, volume load 2.5-4kgCOD / (m 3 d), the filler used is mesh filler (size 10*10*10mm), low-load activated sludge section, volume load 1.5kgCOD / (m 3 d), sludge concentration 3-3.5gMLSS / L;

[0062] 4) Terminal physical and chemical treatment unit: a sedimentation tank is used to remove the suspended sludge entrained in the biochemical effluent,...

Embodiment 3

[0070] Embodiment 3: preferred treatment process

[0071] The preferred wastewater treatment steps are as follows:

[0072] 1) Grease separation tank treatment unit: The grease separation sedimentation tank divides chemical and pharmaceutical wastewater into high-concentration wastewater and low-concentration wastewater. The high-concentration wastewater is first treated with a grease separation sedimentation tank to remove harmful substances that can be precipitated such as chloroform and lighter than water. organic solvents, low-concentration waste water directly leads to the grid / water collection well of step 6);

[0073] 2) Wastewater adjustment pool: store high-concentration wastewater in the high-concentration wastewater adjustment pool, adjust the pH value to 2-3, and stay for 48 hours;

[0074] 3) New internal electrolysis and auxiliary fenton treatment unit: use iron-carbon contained filler to partially degrade organic matter under electrochemical action, the pH of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com