Photolytic catalytic purification device and corresponding process for treating pharmaceutical waste gas

A technology of photolysis catalysis and purification device, applied in the direction of using liquid separating agent, chemical instruments and methods, dispersed particle filtration, etc., can solve the problem of excessive treatment cost and investment cost, low treatment rate of factory waste gas, and long biological treatment time. and other problems, to achieve the effect of fast deodorization rate, easy control of process flow and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

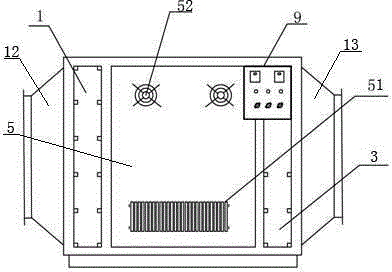

[0042] Example 1 A photocatalytic purification device for treating pharmaceutical waste gas

[0043] Such as figure 1 As shown, this embodiment is a photocatalytic exhaust gas purification device for treating pharmaceutical exhaust gas, including a box body 7 and a pre-filter system 1, a UV photolysis system 2, and a filter system that are arranged in the box body 7 and communicated in sequence. Exhaust system 5, rear deodorization system 3, and a control panel 9 is also provided on the side wall of the box body 7.

[0044] The pre-filter system 1 is provided with a first filter screen 10 , the first filter screen 10 is arranged at the air inlet 12 of the box body 7 , is fixed in the box body 7 , and extends along the width direction of the box body 7 .

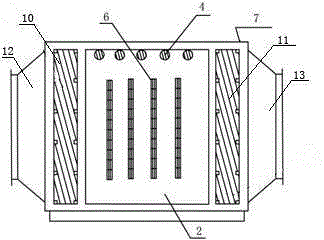

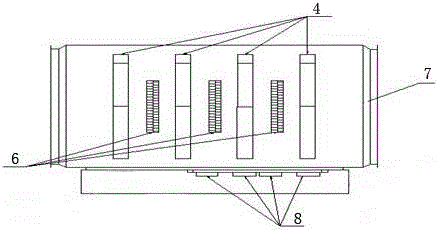

[0045] Such as figure 2 and image 3As shown, the UV photolysis system 2 is located in the middle of the box body 7 and includes an ultraviolet lamp 4 , a second filter screen 6 , and an electronic ballast 8 . A plura...

Embodiment 2

[0050] Example 2 A pharmaceutical waste gas treatment process

[0051] The pharmaceutical waste gas treatment process is carried out in the following steps:

[0052] ⑴The gas volume is 60000 m 3 After the exhaust gas per hour is preliminarily dedusted by a water film dust collector with a diameter of φ2.4×7.0m under a negative pressure of 0.03MPa, the gas A1 is obtained;

[0053] (2) Gas A1 enters the photocatalytic purification device for treating pharmaceutical waste gas provided in Example 1 through the water film dust collector, and enters the UV photolysis unit for 0.7s under the action of the component pre-filter unit to obtain gas B1;

[0054] (3) The gas B1 is drawn out by the negative pressure of the centrifugal induced draft fan, and sent into the chimney to meet the standard discharge.

[0055] The waste gas deodorization rate treated in this embodiment is 99.4%, the waste gas treatment capacity is large, the deodorization rate is fast, the dust residue is low, ...

Embodiment 3

[0056] Example 3 A pharmaceutical waste gas treatment process

[0057] The pharmaceutical waste gas treatment process is carried out in the following steps:

[0058] ⑴The gas volume is 21000 m 3 / h exhaust gas passes through the filter area of 378m 3 , processing capacity is 21000 m 3 After preliminary dust removal by the bag filter in / h, gas C1 is obtained;

[0059] (2) Gas C1 enters the photocatalytic purification device for treating pharmaceutical waste gas provided in Example 1 through the bag filter, and enters the UV photolysis unit for 0.7s under the action of the pre-filter unit of the component to obtain gas D1;

[0060] (3) The gas D1 is drawn out by the negative pressure of the centrifugal induced draft fan, and sent into the chimney to meet the standard discharge.

[0061] The waste gas deodorization rate treated in this embodiment is 99.3%, the waste gas treatment capacity is large, the deodorization rate is fast, the dust residue is low, the process flow...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com