Light-weight partition wall board blended with pharmaceutical waste salt residues and preparation method of light-weight partition wall board

A lightweight partition board and waste salt slag technology, applied in solid waste management, sustainable waste treatment, climate sustainability, etc., can solve the problems of long maintenance cycle, affecting product quality, affecting the production continuity of mold turnover, etc. , to improve production efficiency, eliminate adverse effects, and shorten the mold turnover cycle.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] A lightweight partition wall board mixed with pharmaceutical waste salt slag is made of the following raw materials in parts by weight: 200 parts of Portland cement, 35 parts of pharmaceutical waste salt slag, 80 parts of fly ash, 20 parts of sand, melamine It is 1 part of water reducer, 1 part of sodium lauryl sulfate, 0.01 part of vegetable protein foaming agent, 0.5 part of carbide slag, 5 parts of polyphenylene particles, and 35 parts of water.

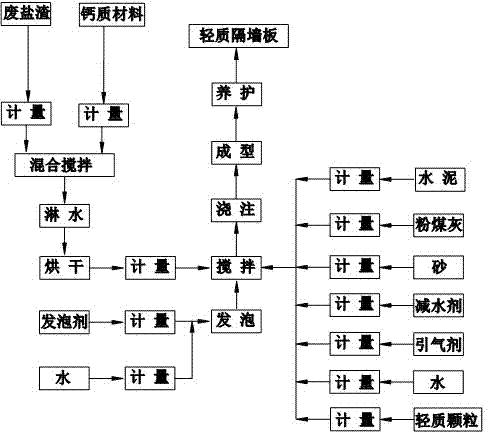

[0042] The preparation method of the lightweight partition wall board mixed with pharmaceutical waste salt slag is as follows: Weigh each raw material according to the weight part, first take the pharmaceutical waste salt slag and calcium material in the measured ratio, mix and stir in the reaction kettle, and carry out water mist Spraying and recovery of ammonia gas, ammonia gas recovery into the recovery device, the water consumption accounts for 3% of the total water consumption; then the mixture of pharmaceutical waste s...

Embodiment 2

[0045] A lightweight partition wall board mixed with pharmaceutical waste salt slag is made of the following raw materials in parts by weight: 250 parts of rapid hardening sulphoaluminate cement, 10 parts of pharmaceutical waste salt slag, 100 parts of fly ash, 45 parts of sand 0.5 parts of polycarboxylate superplasticizer, 3 parts of sodium α-olefin sulfonate, 0.03 parts of animal protein foaming agent, 0.35 parts of ash calcium powder, 400 parts of ceramsite, and 20 parts of water.

[0046] The preparation method of the lightweight partition wall board mixed with pharmaceutical waste salt slag is as follows: Weigh each raw material according to the weight part, first take the pharmaceutical waste salt slag and calcium material in the measured ratio, mix and stir in the reaction kettle, and carry out water mist Spraying and ammonia gas recovery, the ammonia gas is recycled into the recovery device, and the water consumption accounts for 1% of the total water consumption; then ...

Embodiment 3

[0049]A lightweight partition wall board mixed with pharmaceutical waste salt slag is made of the following raw materials in parts by weight: 300 parts of Portland cement, 50 parts of pharmaceutical waste salt slag, 50 parts of fly ash, 70 parts of sand, naphthalene It is 5 parts of water reducer, 2 parts of fatty alcohol polyoxyethylene ether sodium sulfate, 0.05 part of animal protein foaming agent, 1 part of quicklime powder, 300 parts of vitrified microbeads, and 50 parts of water.

[0050] The preparation method of the lightweight partition wall board mixed with pharmaceutical waste salt slag is as follows: Weigh each raw material according to the weight part, first take the pharmaceutical waste salt slag and calcium material in the measured ratio, mix and stir in the reaction kettle, and carry out water mist Spraying and recovery of ammonia gas, ammonia gas recovery into the recovery device, the water consumption accounts for 5% of the total water consumption; then the mi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com