Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

65results about How to "In line with the concept of green production" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

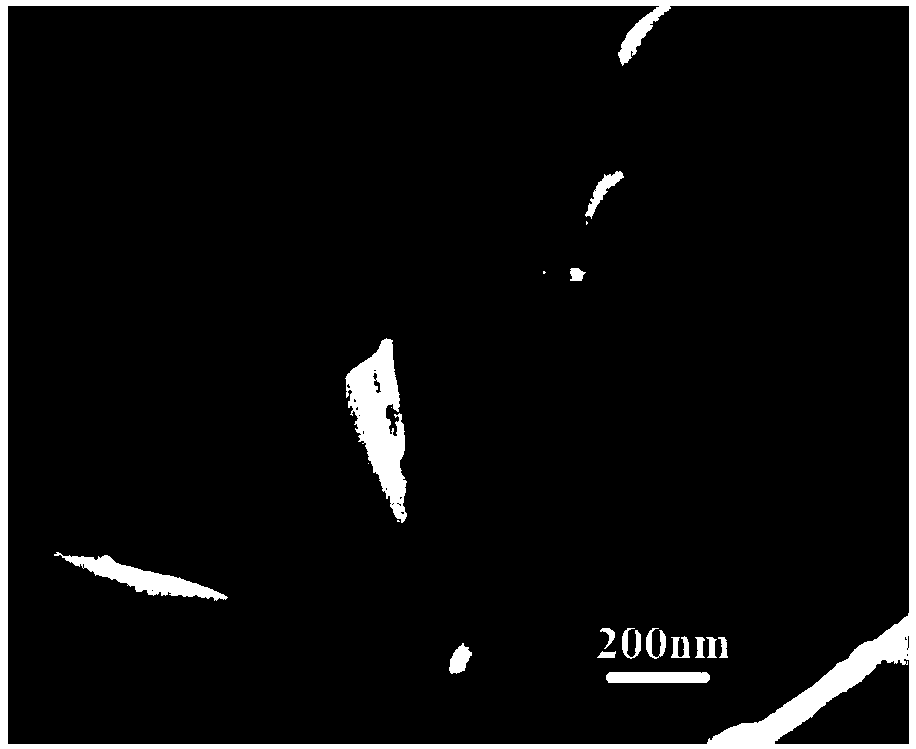

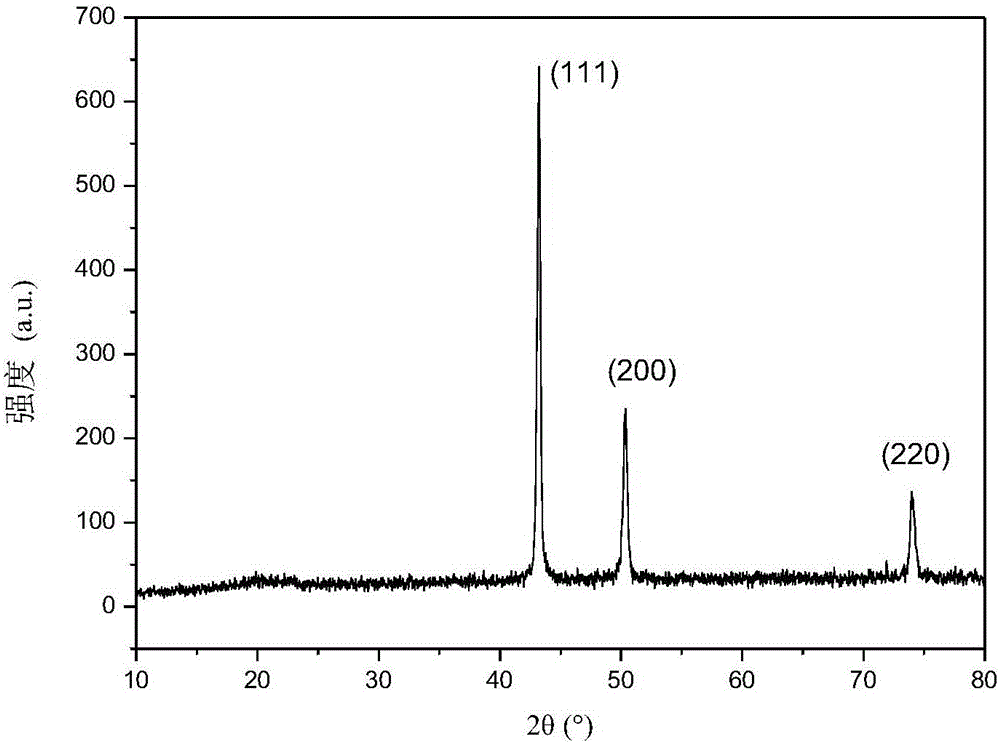

Preparation method of graded spherical cuprous oxide hollow nano particle

InactiveCN103466681ASimple reaction systemReduce manufacturing costMaterial nanotechnologyCopper oxides/halidesHydrazine compoundCopper salt

The invention discloses a preparation method of a graded spherical cuprous oxide hollow nano particle. The preparation method of the graded spherical cuprous oxide hollow nano particle is characterized by comprising the following steps of: (1) dissolving copper salt in water, (2) dropwise adding a mixed aqueous solution of hydrazine hydrate and acetate at 5-40 DEG C under a stirring condition, and (3) after dropwise adding, continuing stirring for 10-30min at 5-40 DEG C, centrifuging, washing with water, performing vacuum drying, and obtaining the graded spherical cuprous oxide hollow nano particle, wherein a molar concentration of Cu<2+> is 0.1-4mol / L, and a molar ratio of acetate (CH3COO<->) to hydrazine hydrate (N2H4) to copper salt (Cu<2+>) is (1-3):(0.5-4):1. According to the method, a reaction system is simple, raw materials are cheap and easy to obtain, and the method produces no hazardous waste, meets a green production concept, is simple in process route, easy and simple to operate, mild in reaction condition, short in reaction time and high in efficiency, and is suitable for mass production.

Owner:HENAN NORMAL UNIV

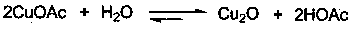

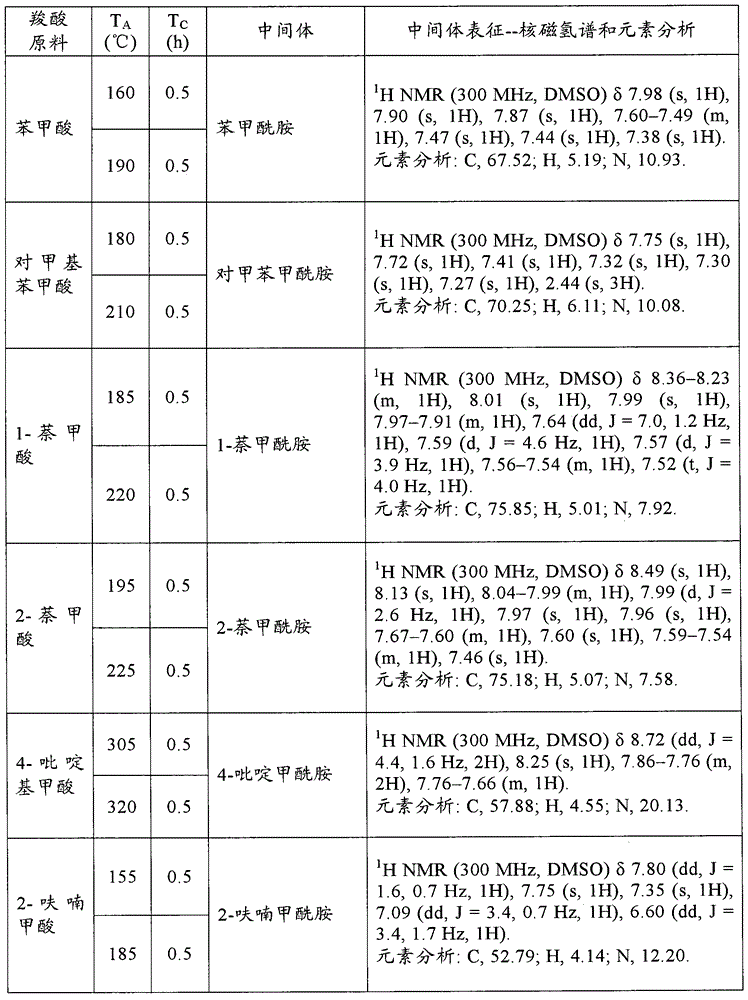

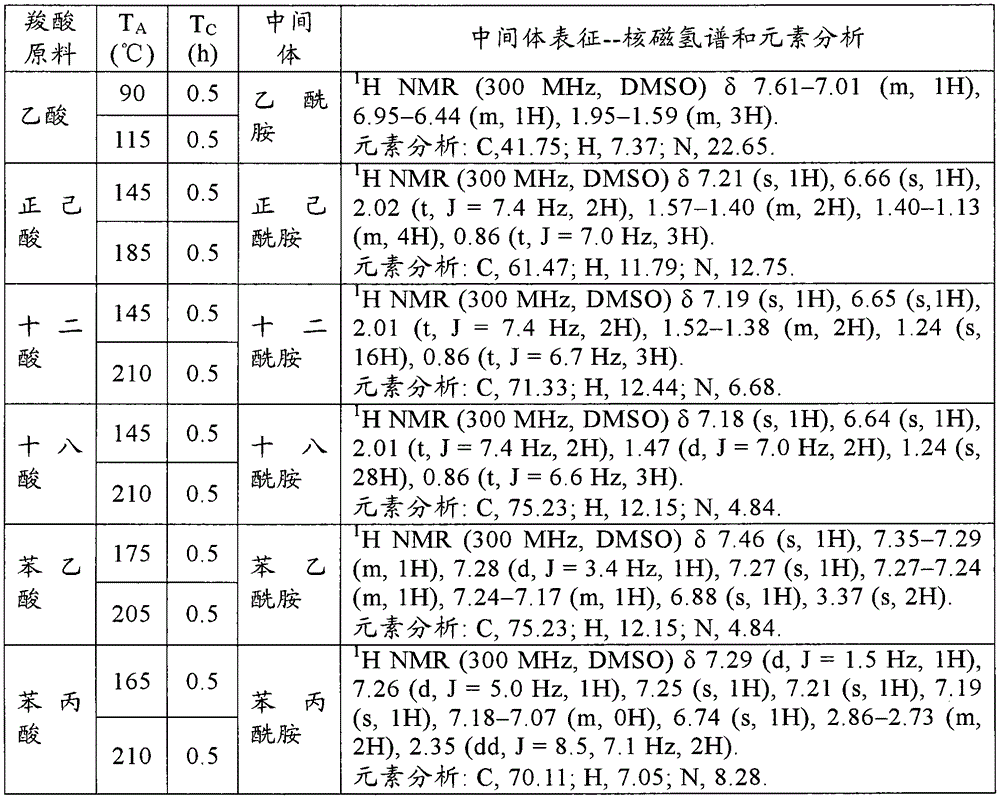

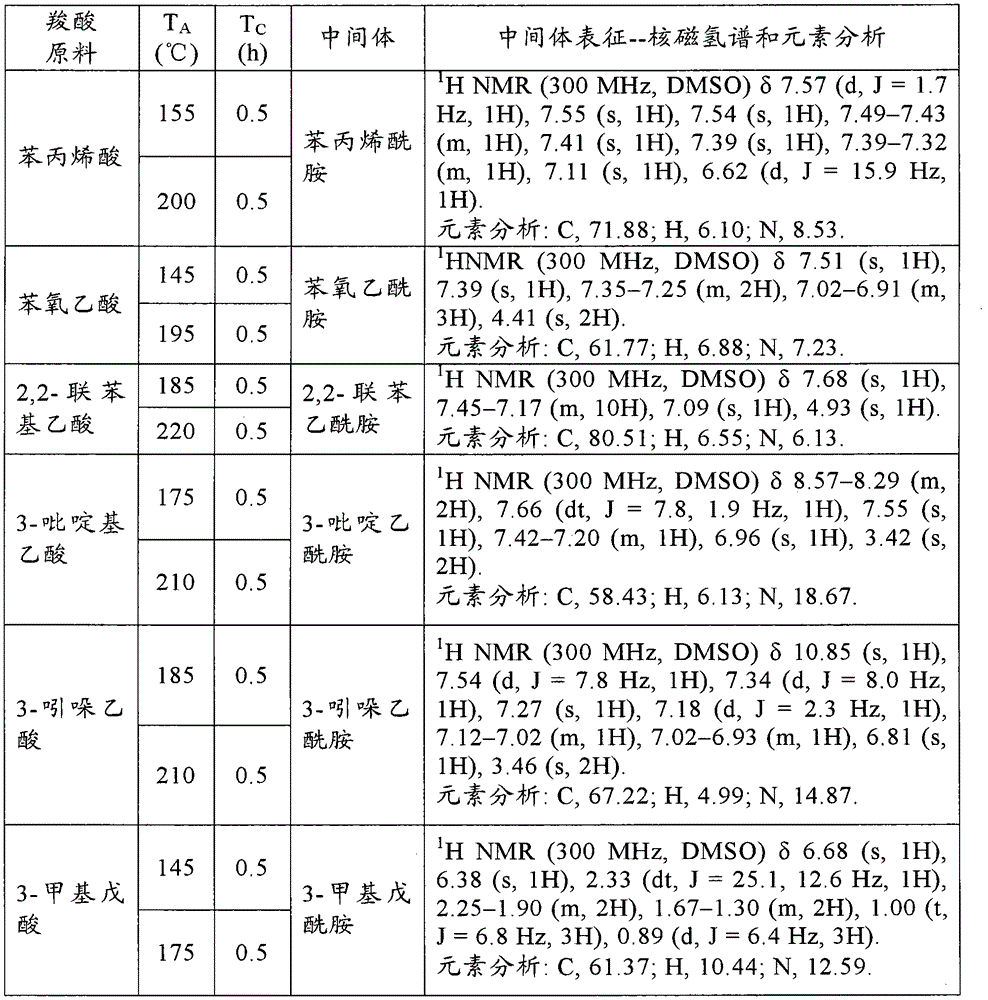

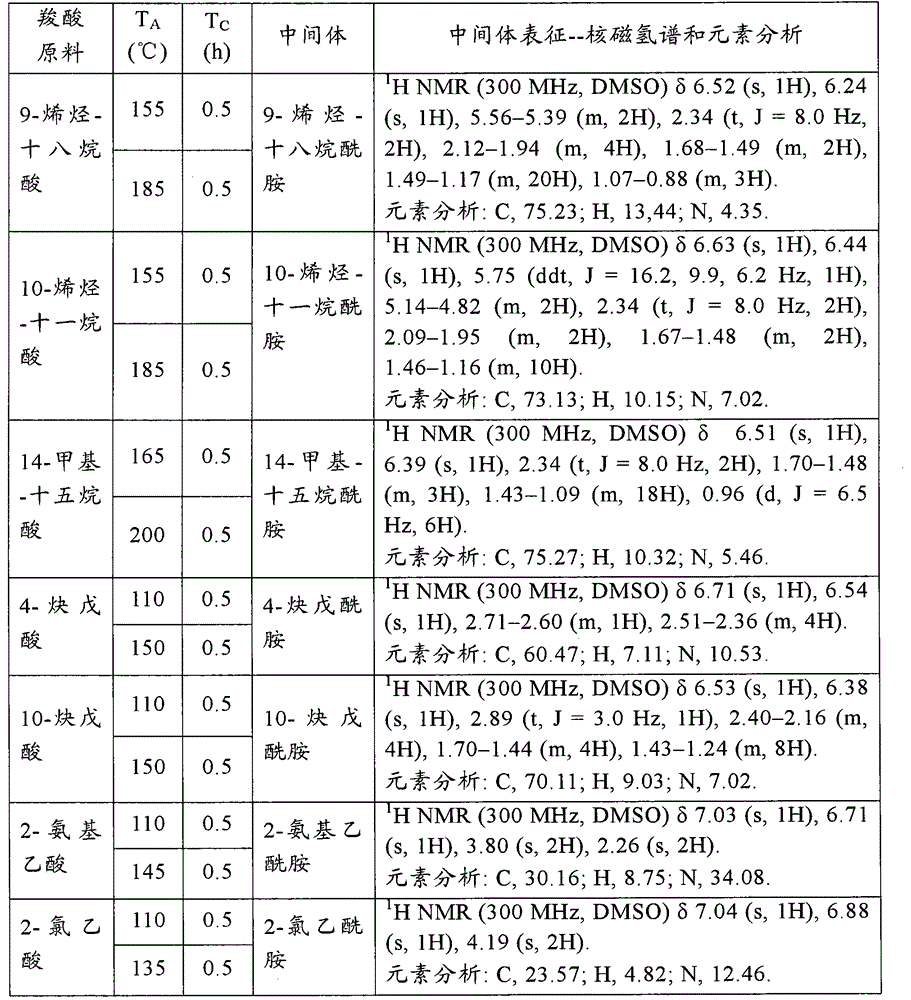

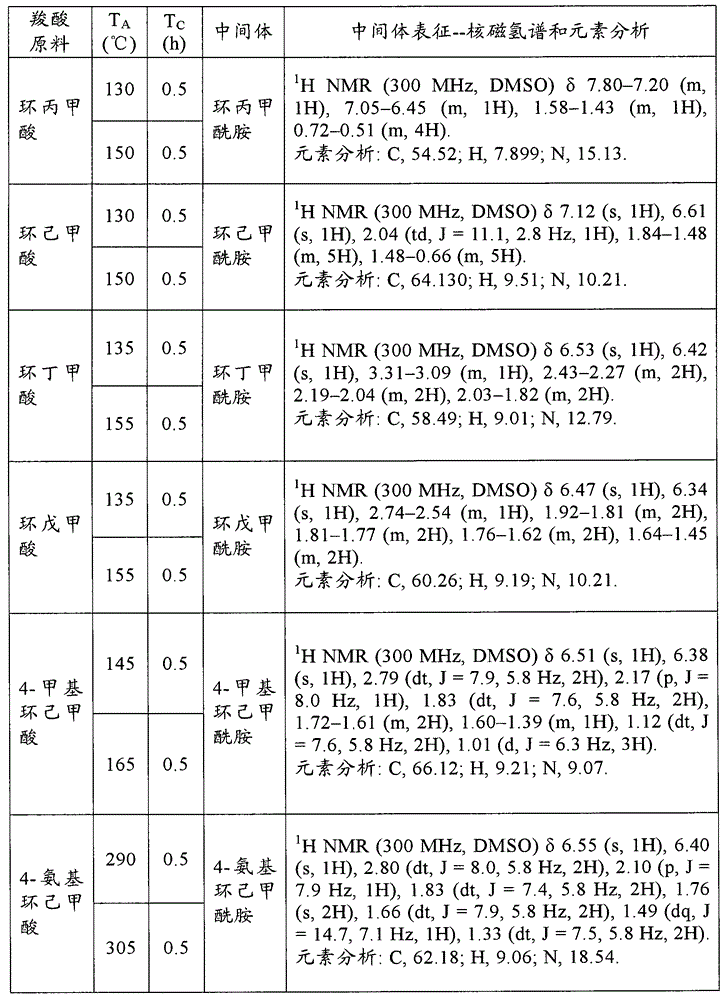

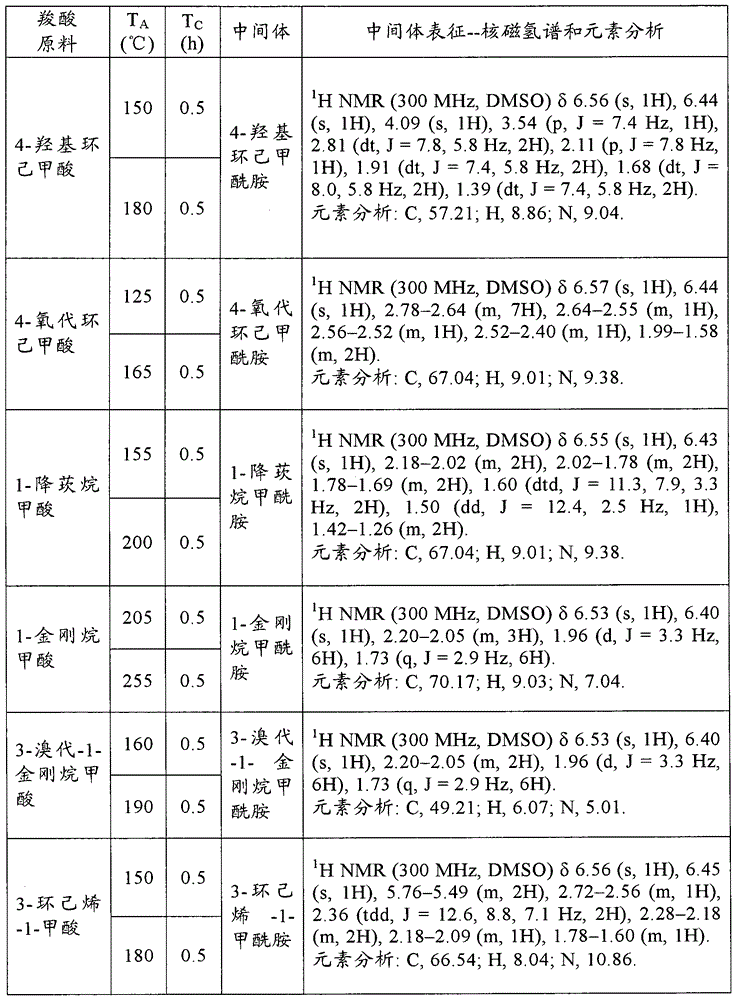

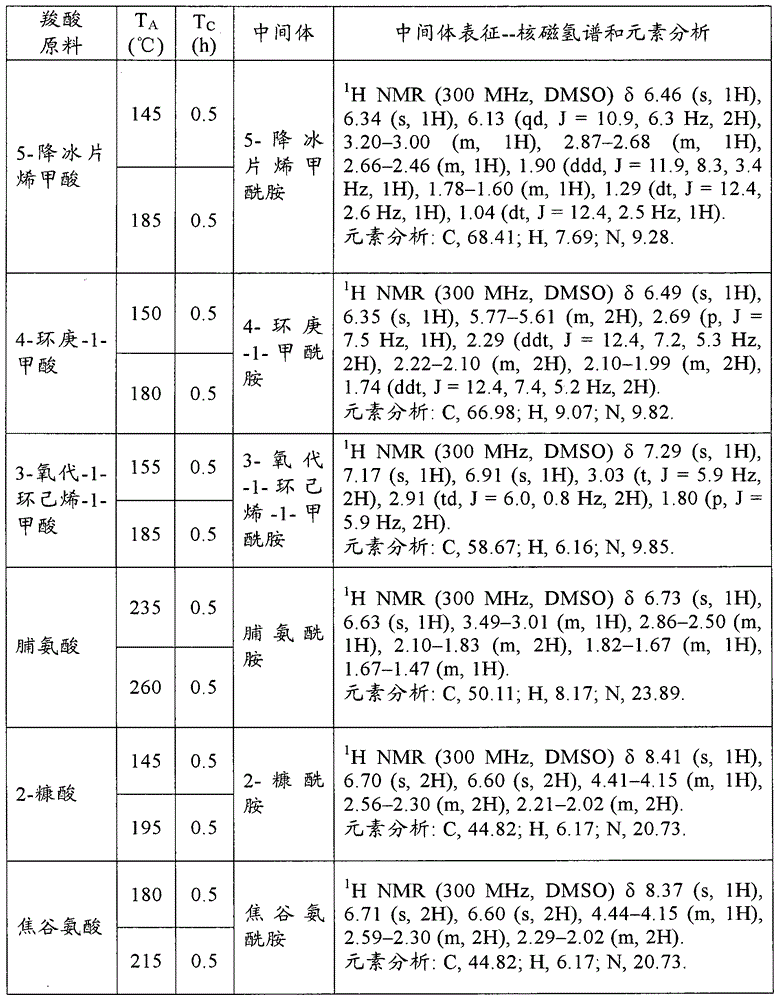

Manufacturing method of nitrile and corresponding amine thereof

ActiveCN104557357AReduce dosageIncrease profitOrganic compound preparationPreparation by carboxylic acid amide dehydrationAmmoniaNH3 compound

The invention relates to a manufacturing method of nitrile. Compared with the prior art, the manufacturing method has the characteristics of significantly reduced using amount of an ammonia source, low environmental pressure, low energy consumption, low production cost, high purity and yield of a nitrile product and the like, and nitrile with a more complex structure can be obtained. The invention also relates to a method for manufacturing corresponding amine from nitrile.

Owner:SINOPEC YANGZI PETROCHEM +1

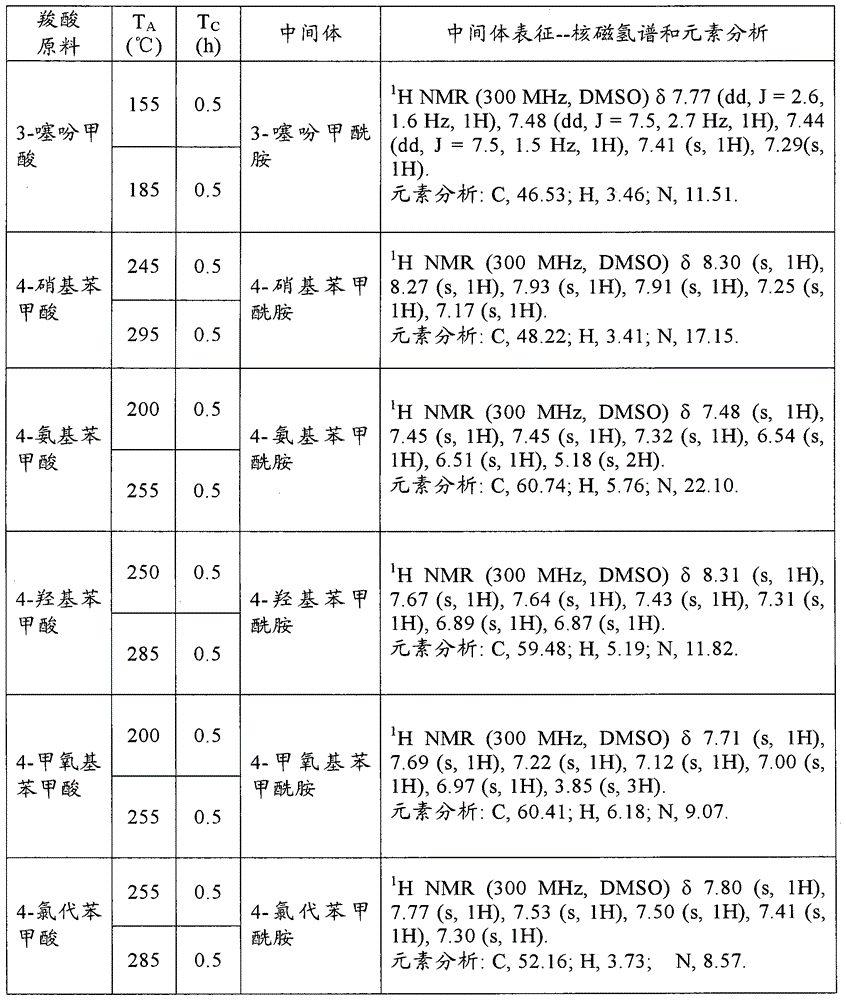

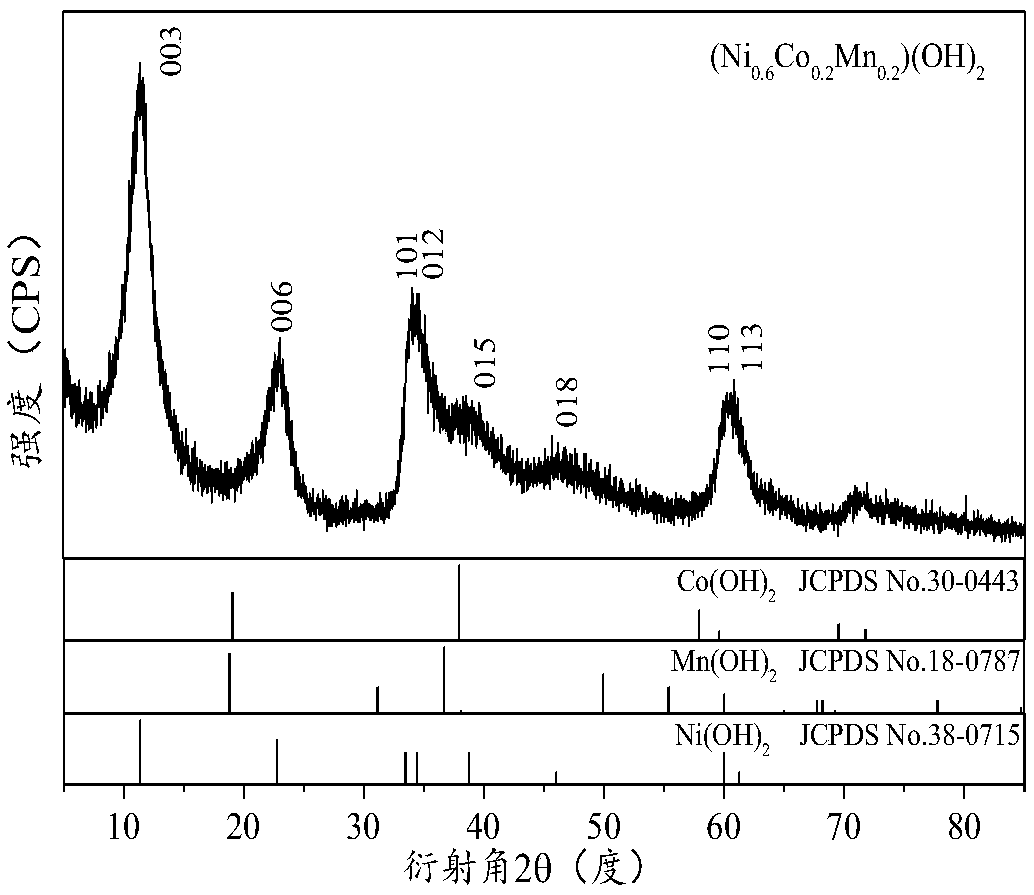

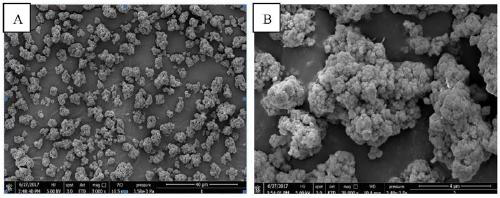

Composite complexing agent and method of preparing lithium-ion power battery cathode precursor material

ActiveCN109081384AGood complexation performanceSlow down reactionSecondary cellsPositive electrodesHeavy metalsNickel

The invention discloses a composite complexing agent and a method of preparing a lithium-ion power battery cathode precursor material, and belongs to the technical field of lithium-ion cathode materials. The two green organic salts, citrates and glutamates (or glycinates), are combined into the novel composite complexing agent to adjust and control pH value and temperature of a reaction system. Settling reaction level herein is more thorough; the reaction process is milder; settling conversion efficiency is high; the low-cost green production of nickel-rich cathode material precursor (Ni0.6Mn0.2Co0.2)(OH)2 is achieved. The precursor prepared herein has uniform particle morphology; both optimization of the co-precipitating technique and precise control of organic salt complexing agent concentration help greatly reduce the environmental pollution due to reaction wastewater and heavy metal ions, true green production is achieved, and high industrial value is provided.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

Manufacturing method of nitrile and corresponding amine thereof

ActiveCN104557610AReduce dosageIncrease profitThiol preparationOrganic compound preparationAmmoniaNH3 compound

The invention relates to a manufacturing method of nitrile. Compared with the prior art, the manufacturing method has the characteristics of significantly reduced using amount of an ammonia source, low environmental pressure, low energy consumption, low production cost, high purity and yield of a nitrile product and the like, and nitrile with a more complex structure can be obtained. The invention also relates to a method for manufacturing corresponding amine from nitrile.

Owner:CHINA PETROLEUM & CHEM CORP +1

Manufacturing method of nitrile and corresponding amine thereof

ActiveCN104557356AReduce dosageIncrease profitOrganic compound preparationPreparation by carboxylic acid amide dehydrationProcess engineeringEnergy consumption

The invention relates to a manufacturing method of nitrile. Compared with the prior art, the manufacturing method has the characteristics of significantly reduced using amount of an ammonia source, low environmental pressure, low energy consumption, low production cost, high purity and yield of a nitrile product and the like, and nitrile with a more complex structure can be obtained. The invention also relates to a method for manufacturing corresponding amine from nitrile.

Owner:CHINA PETROLEUM & CHEM CORP +1

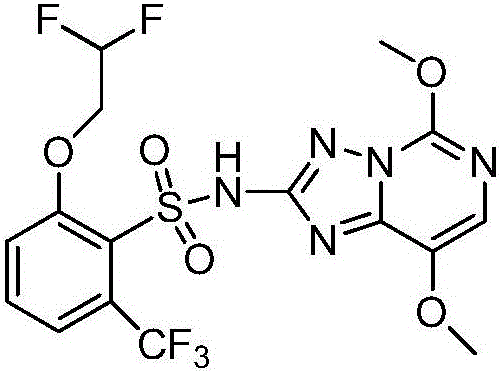

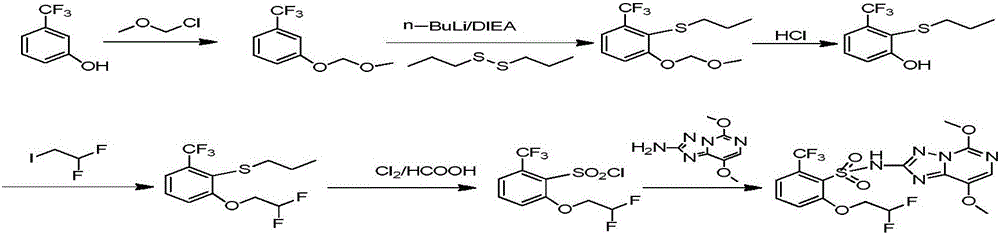

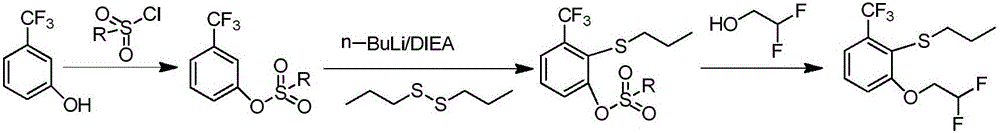

Method for preparing penoxsulam intermediate

InactiveCN106518738AGood reaction selectivityThe synthetic route is safe and environmentally friendlySulfide preparationBulk chemical productionTrifluoromethylPyrimidine

The invention discloses a method for preparing a penoxsulam intermediate. The method comprises the following steps: taking m-trifluoromethylphenol as a raw material, under effect of organic base, protecting hydroxyl of m-trifluoromethylphenol with allyl chlorocarbonate to obtain an intermediate 1-(allyloxy carbonyl oxygen)-3-fluoroform)benzene, then under effect of n-butyllithium, performing a thiolation reaction to obtain an intermediate 1-allyloxy carbonyl oxygen-2-propythio-3-benzotrifluoride, removing a protective group to obtain 2-propythio-3-trifluoromehtyl phenol, then performing chlorine oxidation to obtain 2-(2,2-difluoroethoxy)-6-trifluoromethylbenzenesulfonyl chloride, directly conducting condensation with 2-amino-5,8-dimethoxy[1,2,4] triazol[1,5-c]pyrimidine to obtain penoxsulam. In penoxsulam synthesis, usage of a raw material strong acid is avoided, reaction selectivity is good, the synthesis route is safe and environmentally friendly, material amount is greatly used, the overall yield exceeds the current technology, waste water amount is reduced, and the method accords with an environmentally-friendly production idea.

Owner:天津市津绿宝农药制造有限公司

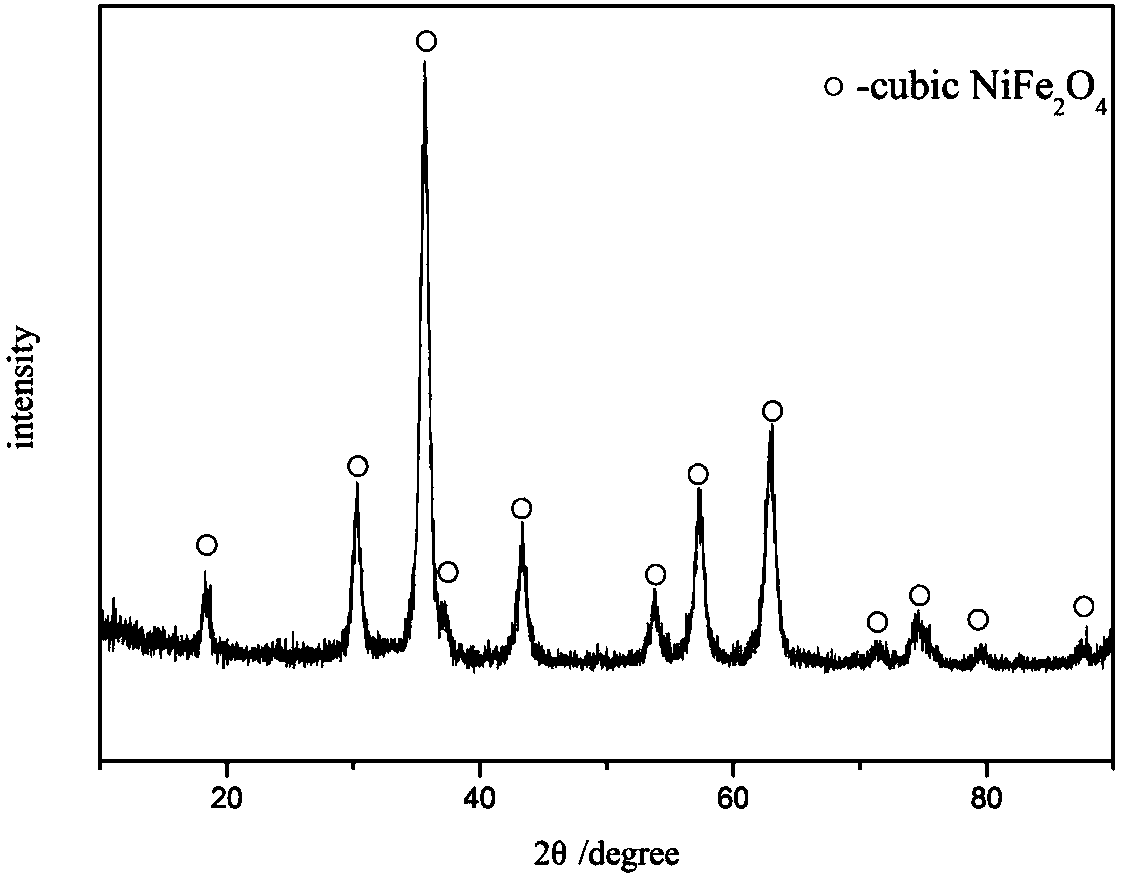

Nickel ferrite nanosheet as well as preparation method and application thereof

The invention provides a nickel ferrite nanosheet as well as a preparation method and application thereof. The preparation method comprises the following steps: S1, adding ferric salt and nickel saltto water, uniformly mixing; S2, adding a precipitator to solution obtained in the step S1, uniformly mixing; S3, performing hydrothermal reaction on solution obtained in the step S2, purifying a product to obtain a nickel ferrite precursor; and S4, performing high temperature thermal treatment on the nickel ferrite precursor obtained in the step S3 to obtain the nickel ferrite nanosheet. The provided preparation method is safe and stable, pollution-free, easy to obtain raw materials, easy to operate, simple in equipment, and higher in yield, and the prepared nickel ferrite nanosheet is largerin dimension, a sheet layer is thinner, and the appearance is integrated, so the nickel ferrite nanosheet has an extensive application prospect in electromagnetic materials, catalysts and catalyst carriers.

Owner:SHANDONG UNIV

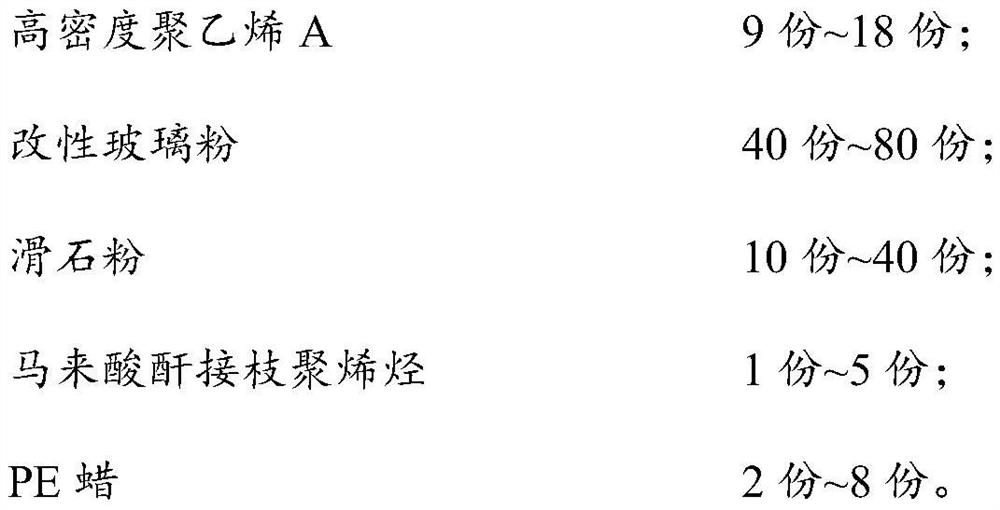

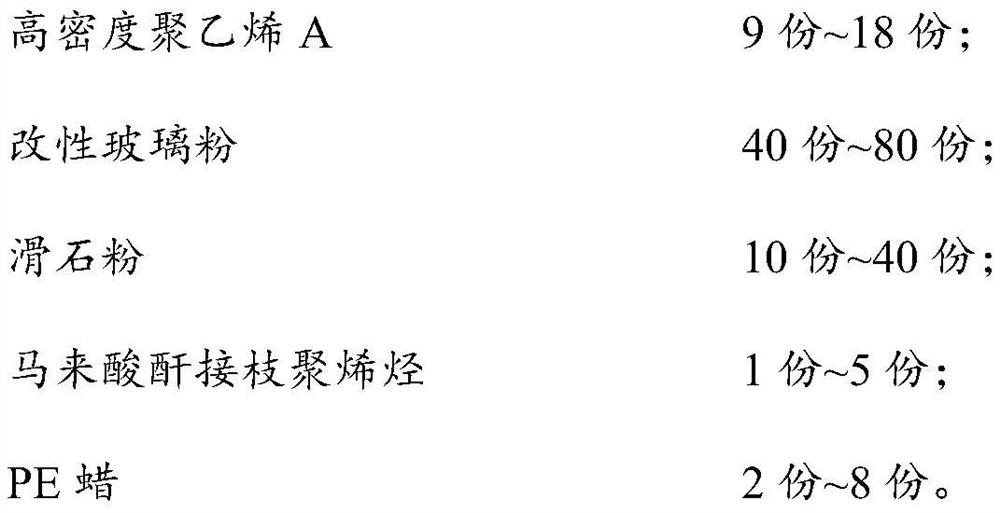

Corrugated pipe filling master batch as well as preparation method and application thereof

The invention discloses a corrugated pipe filling master batch as well as a preparation method and application thereof, and belongs to the technical field of corrugated pipe preparation. The corrugated pipe filling master batch comprises the following components: high-density polyethylene, modified glass powder, talcum powder, maleic anhydride grafted polyolefin and PE wax. The main filler adopted by the invention is modified glass powder, and the price of the filler is equivalent to that of calcium carbonate powder and is lower than that of talcum powder, so that the corrugated pipe filling master batch provided by the invention is relatively low in raw material price; and compared with calcium carbonate powder or talcum powder, the filler can be mined without destroying the environment, waste glass can be recycled, and the green production concept is met.

Owner:长沙争明新材料有限公司

Technology for preparing quick-setting agent by utilizing industrial waste phosphoric acid

InactiveCN108483965AGood quick setting effectShorten the setting timeChemical treatmentAluminium hydroxide

The invention discloses a technology for preparing a quick-setting agent by utilizing industrial waste phosphoric acid. The technology adopts the following raw materials in parts by weight: 50-200 parts of deionized water, 50-200 parts of aluminum hydroxide, 80-150 parts of industrial waste phosphoric acid, 20-50 parts of hydrofluoric acid, 5-15 parts of boric acid, 15-50 parts of triethanolamine,and 200-350 parts of aluminum sulfate hydrate. The technology directly utilizes waste phosphoric acid without any physical or chemical treatment, belongs to the hazardous wastes reuse, not only accords with the country's concept of promoting green production conformed with, but also reduces the cost of waste liquid disposal of enterprises, can also realize recycling of wastes and generate incomefor the enterprises to get three results with one action, and is suitable for promotion.

Owner:萧县沃德化工科技有限公司 +1

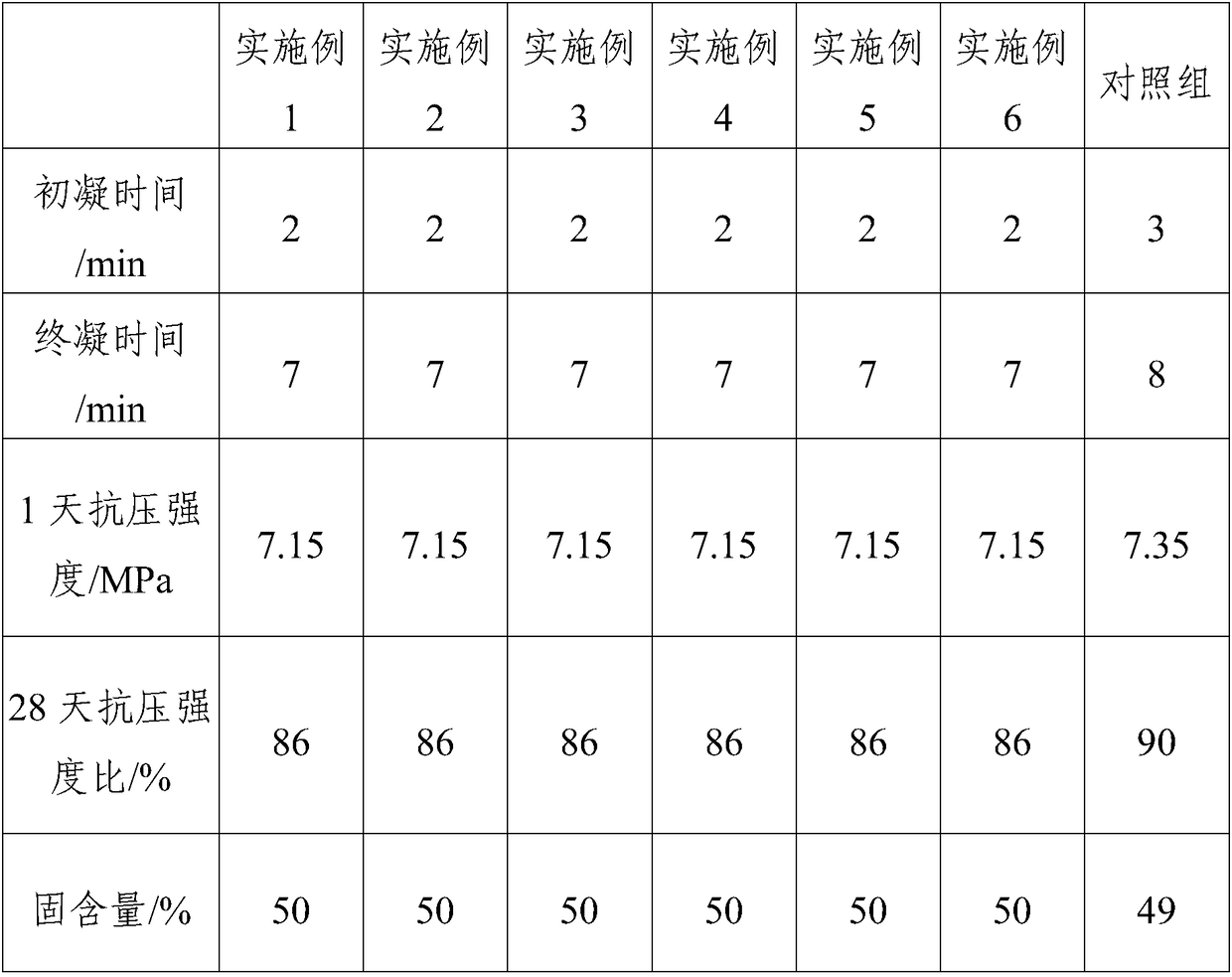

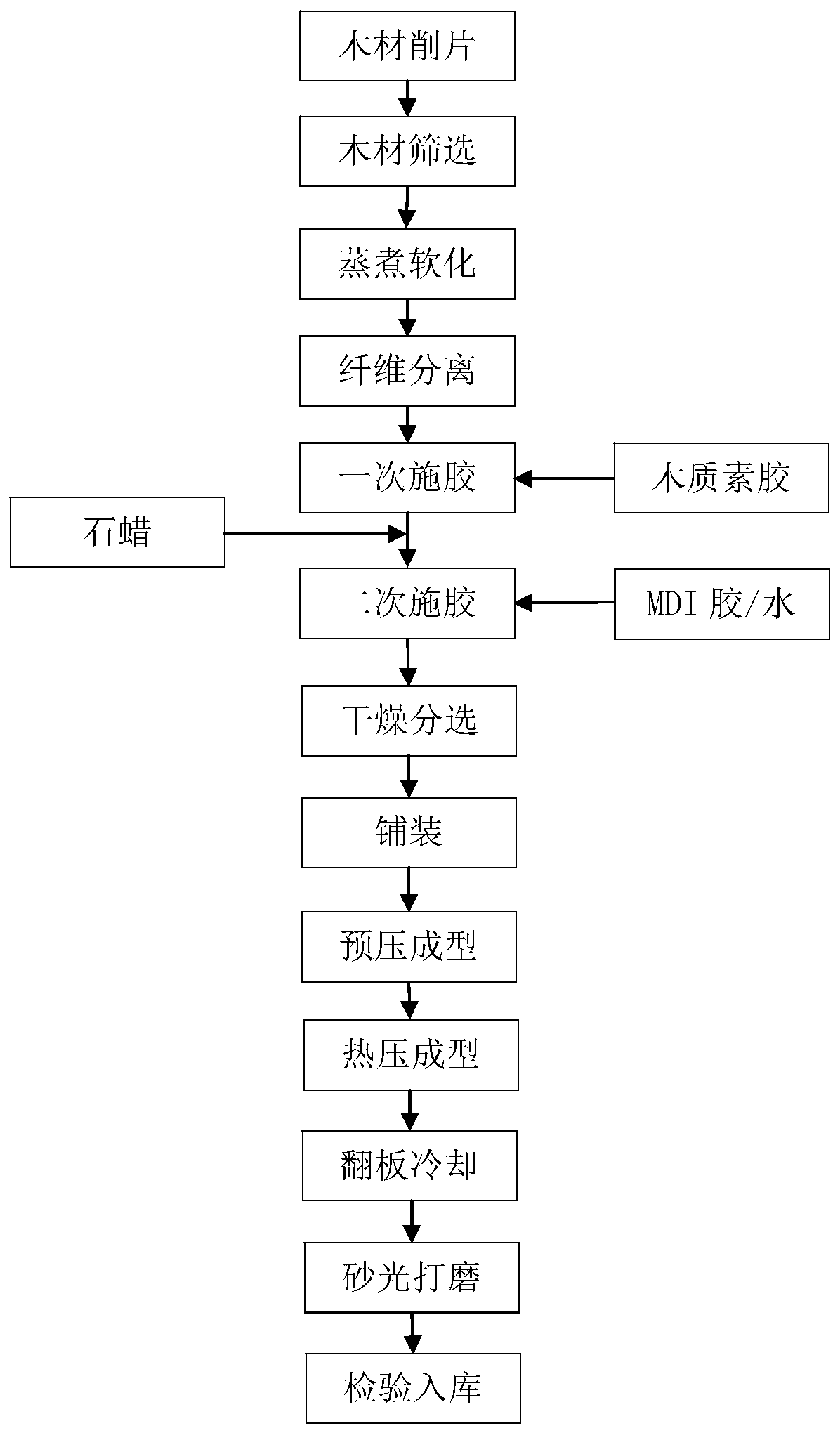

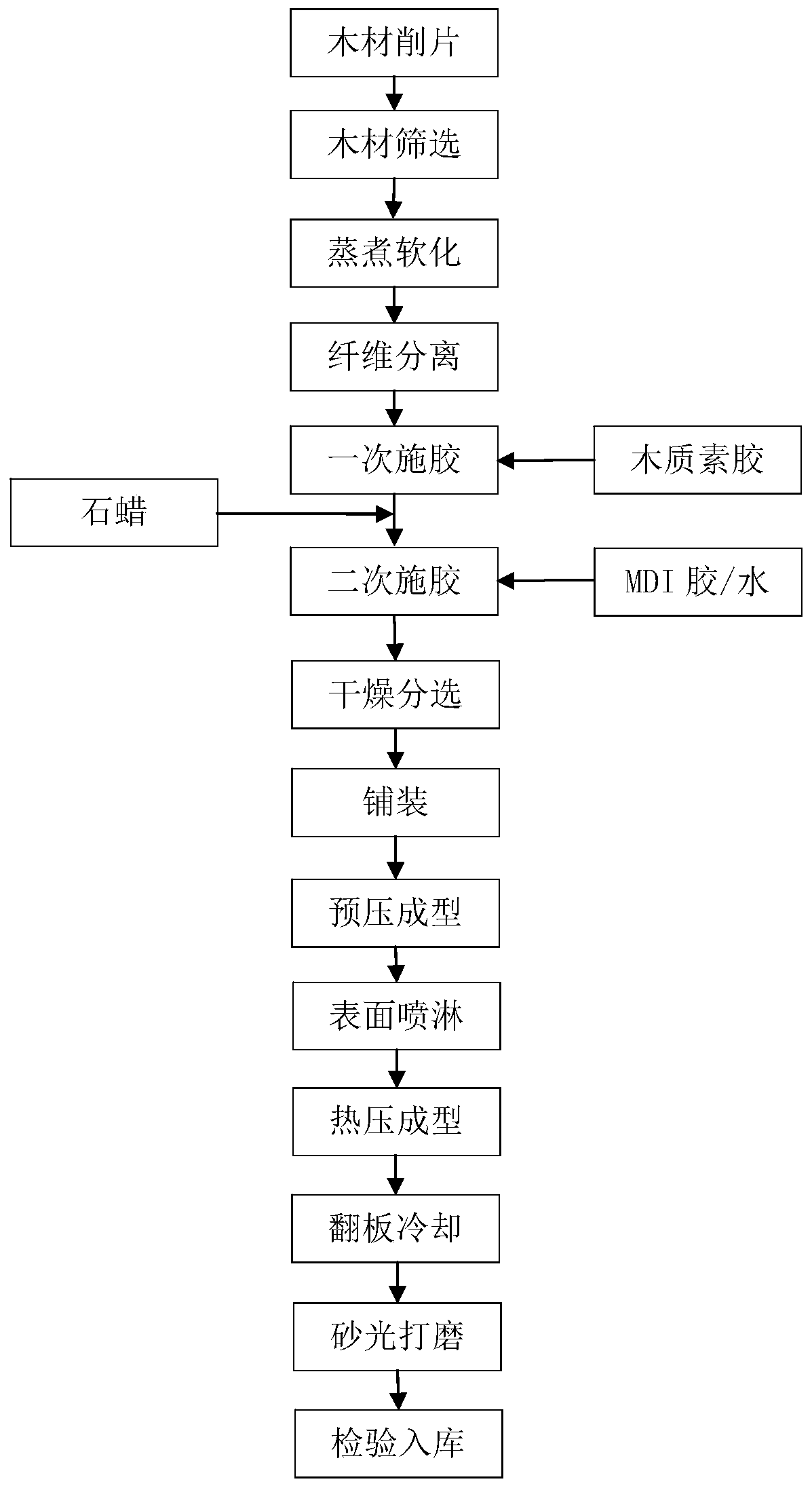

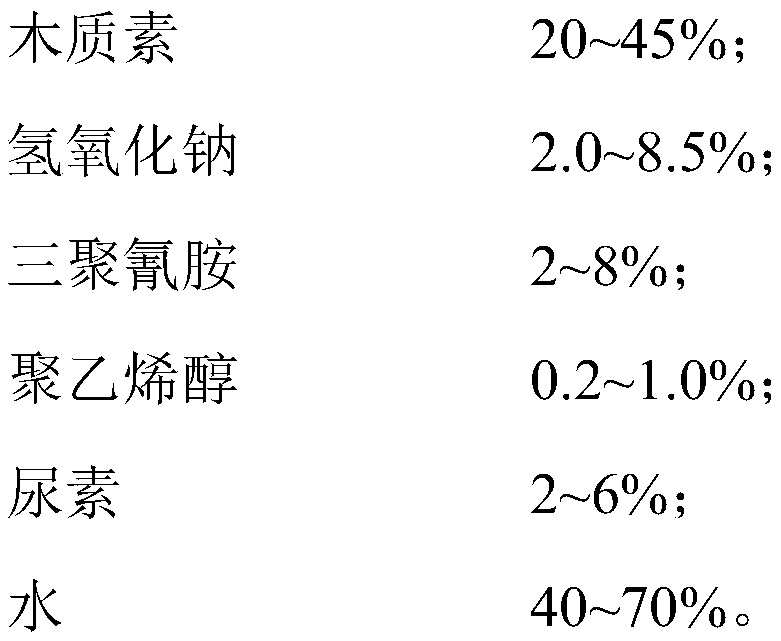

Formaldehyde-free medium-high-density board capable of meeting deep facing requirements and manufacturing method of medium-high-density board

ActiveCN110281341AImprove permeabilityMildew proofPolyureas/polyurethane adhesivesFlat articlesFiberHigh density

The invention relates to a formaldehyde-free medium-high-density board capable of meeting deep facing requirements and a manufacturing method of the medium-high-density board. The medium-high-density board comprises the following steps of wood chipping, screening, cooking and softening, fiber separating, gluing, drying and sorting, paving, pre-pressing, hot pressing, cooling, sanding, and inspection and warehousing. The gluing comprises two steps of gluing, and specifically comprises the steps of carrying out primary gluing by using lignin glue, carrying out waterproof treatment, and then carrying out secondary gluing by using MDI glue. According to the manufacturing method, a biomass adhesive and a formaldehyde-free adhesive are adopted, a curing agent, an anti-mildew agent and the like are not added, by virtue of a two-time gluing method, formaldehyde pollution is completely eradicated from a source, and formaldehyde-free production and formaldehyde-free products are realized; and the gluing process is controlled in sequence and glue types and proportion are controlled, so that the surface hardness of the products can be improved, and the final products can be subjected to deep facing so as to achieve 2-8 millimeters.

Owner:BEIJING FORESTRY UNIVERSITY +2

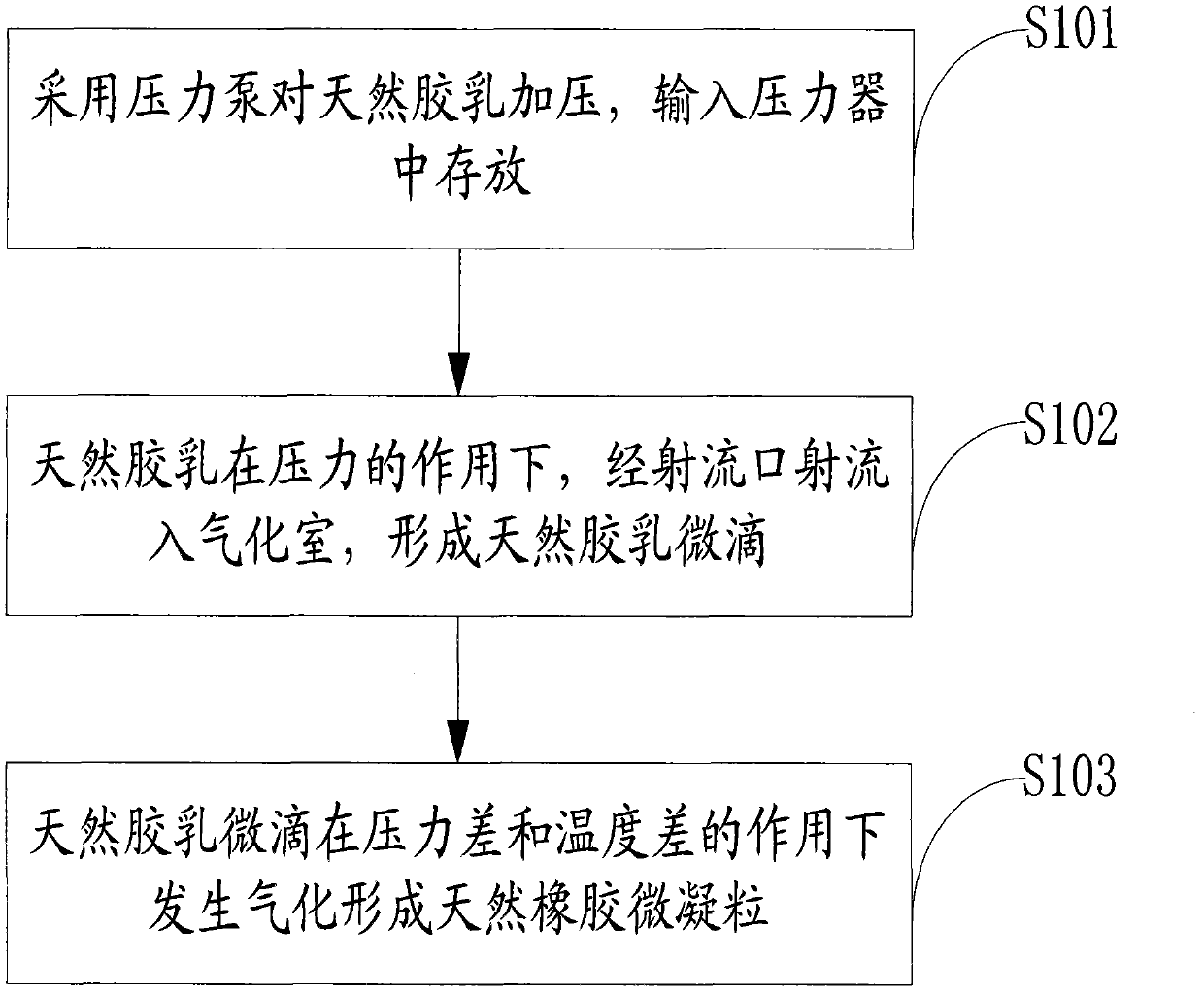

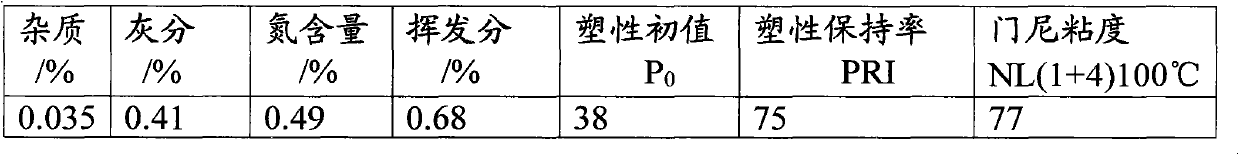

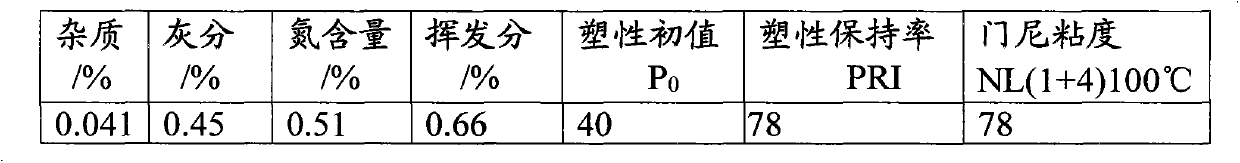

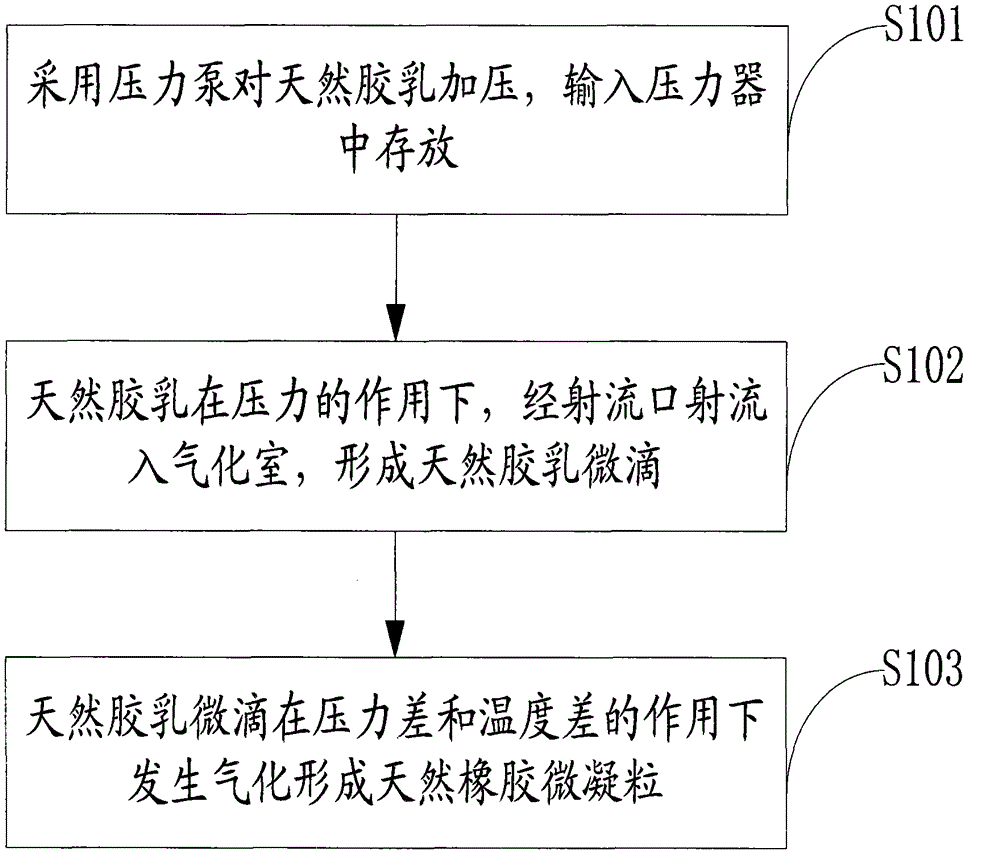

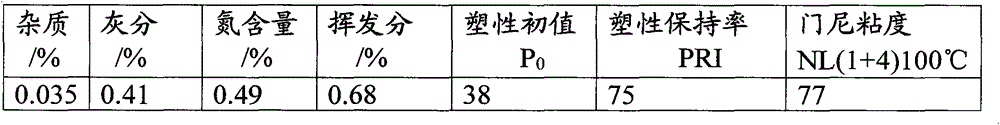

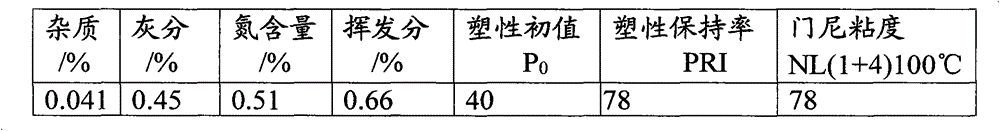

Natural latex jet-flow solidification method

The invention discloses a natural latex jet-flow solidification method which comprises the following steps of: pressurizing the natural latex by using a pressure pump, putting the natural latex into a pressure instrument to be stored up, jetting the natural latex into a gasifying chamber through a jet-flow port under the action of pressure, so as to form natural latex microdroplets; and gasifying the natural latex microdroplets under the action of pressure difference and temperature difference so as to form natural latex solidified grains. The natural latex jet-flow solidification method provided by the invention overcomes the defects that the acid solidification in the conventional production is high in production cost, long in production period, large in environmental pollution and large in body damage to operators, the production cost is greatly lowered, the application and the emission of harmful pollutants are reduced, the production period is shortened, and at the same time the production profits of enterprises are increased, so that the natural latex jet-flow solidification method is non-pollution environment-friendly production, meets the environment-friendly production concept which is proposed by China, and has wide application prospect in future.

Owner:HAINAN UNIVERSITY

Hyperdispersant, and preparation method and application method thereof

ActiveCN105778573AGood dispersionEasy to operateTransportation and packagingMixingWater bathsProcess equipment

The invention provides a hyperdispersant, and a preparation method and an application method thereof. The preparation method includes mixing silane coupling agent KH-570 with styrene (St), acroleic acid (AA), azodiisobutyronitrile (AIBN) and isopropanol to obtain a solution A, adding the solution A into a methylbenzene solution drop by drop while stirring under the N2 protection environment, heating the methylbenzene solution in water bath at the temperature of 70-90 DEG C, insulating heat for 4-6 hours after dropwise addition, and filtering, washing and drying a product to obtain the hyperdispersant. The hyperdispersant has the advantages that inorganic nano-particles can be well dispersed in lubricating oil; technological operation is simple, cost is low, cycle is short, special process equipment is not needed, and easiness in industrial popularization is realized; the composite hyperdispersant is poisonless and harmless and is in conformity with the green production idea.

Owner:江苏妙润新材料科技有限公司

Method for producing DHA by fermentation of schizochytrium limacinum

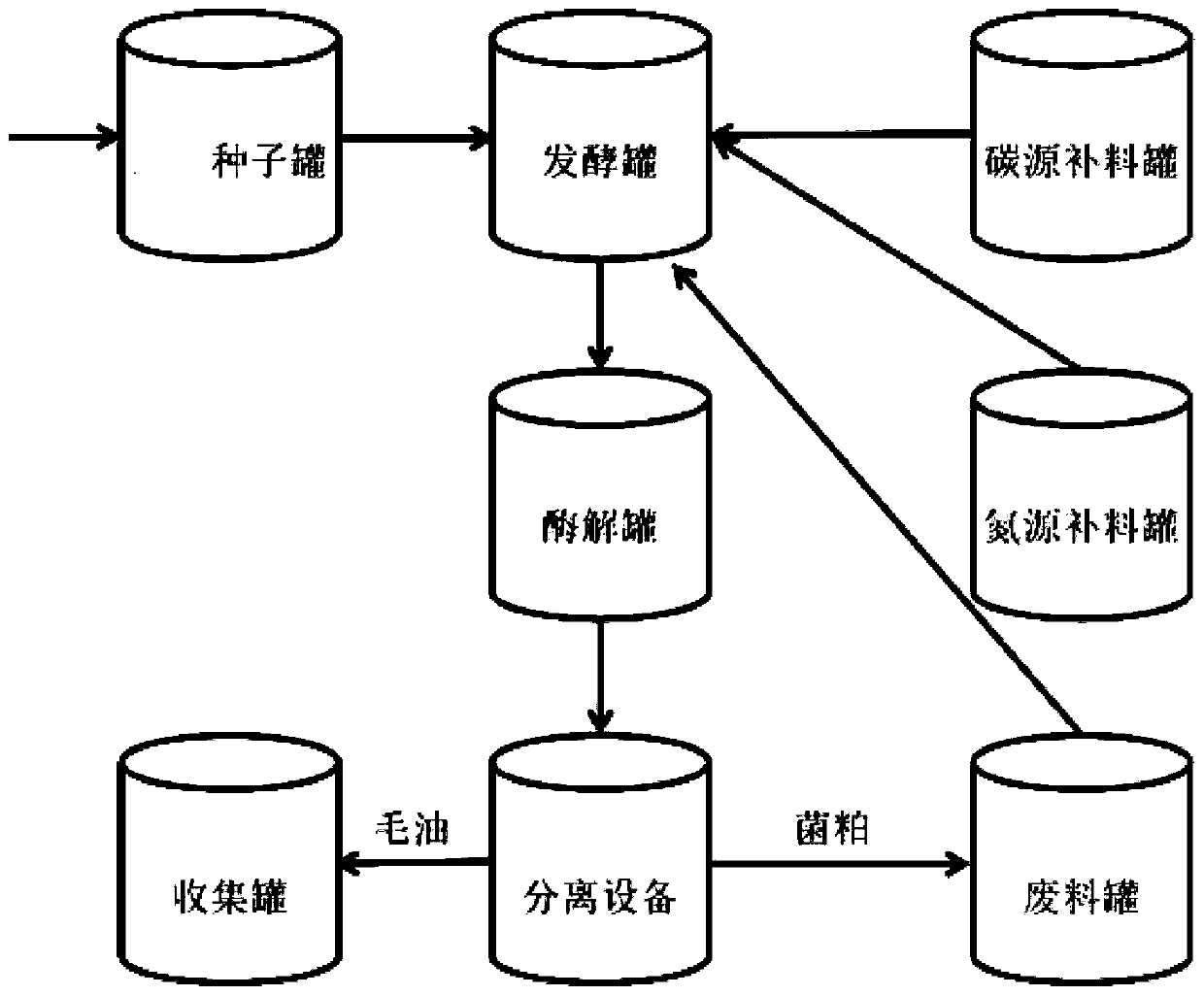

InactiveCN111378699AGuaranteed outputKeep productiveFungiMicroorganism based processesNutritionFermentation broth

The invention provides a method for producing DHA by fermentation of schizochytrium limacinum. The method comprises the following steps: (1) activating the schizochytrium limacinum, and carrying out expanding culture and fermenting so as to obtain a fermentation liquor; (2) partially discharging the fermentation liquor into an enzymolysis tank for enzymolysis, transferring an obtained enzymolysisliquid to separation equipment, extracting crude DHA oil, and recovering schizochytrium limacinum meal for subsequent usage; and (3) supplementing a part of culture medium components and recovered schizochytrium limacinum meal for subsequent usage into the residual fermentation liquor, continuing fermentation, and repeating the step (2) until a fermentation period is finished. According to the fermentation method provided by the invention, the schizochytrium limacinum meal is used as a nutrient substance for cyclic utilization, so nutrition can be provided for microorganisms, and the production activity of the microorganisms is maintained; the production efficiency of traditional semi-continuous fermentation can be improved; meanwhile, the bacterial contamination risk can be reduced; the DHA production cost of the schizochytrium limacinum can be reduced; the concept of green production can be met; and environmental protection can be easily achieved.

Owner:CABIO BIOTECH WUHAN CO LTD

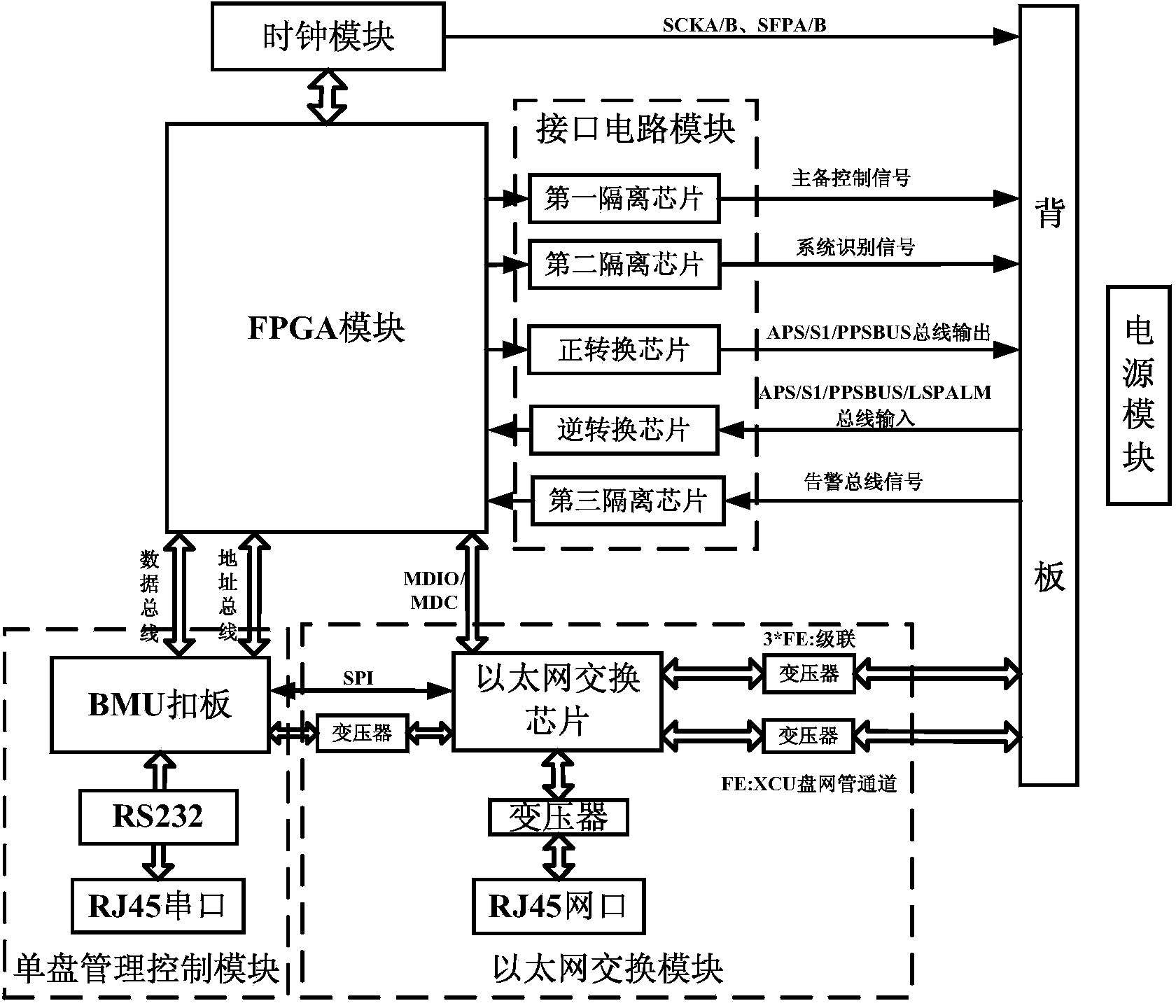

Automated test equipment and automated test method for L3 circuit panels

ActiveCN104253720AAutomatic monitoring of working statusImprove accuracyData switching networksComputer moduleNetwork management

The invention discloses automated test equipment and an automated test method for L3 circuit panels, which relate to the field of function and performance testing of circuit panels of communication equipment. The automated test equipment comprises a test sub-rack, a network management platform and an integrated instrument; an automated test unit is arranged in the test sub-rack, and comprises a power module, a clock module, a field programmable gate array (FPGA) module, an individual panel management and control module, an Ethernet switch module and an interface circuit module; the power module is connected with the clock module, the FPGA module, the interface circuit module, the individual panel management and control module and the Ethernet switch module; the FPGA module is connected with the clock module, the interface circuit module, the individual panel management and control module and the Ethernet switch module; the individual panel management and control module is connected with the Ethernet switch module. The test equipment not only has high testing accuracy and testing efficiency, but also occupies less testing environment resources, can reduce the building cost and shorten the building process, and is convenient to use by people.

Owner:FENGHUO COMM SCI & TECH CO LTD

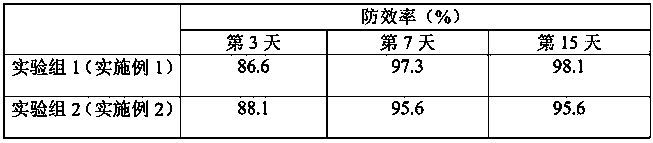

Biological pesticide for preventing Apple scar skin viroid and preparation method of biological pesticide

The invention discloses biological pesticide for preventing Apple scar skin viroid and a preparation method of the biological pesticide, and belongs to the field of pesticide. The biological pesticidefor preventing Apple scar skin viroid is prepared from the following raw materials: in parts by weight, 2-5 parts of zinc sulfate, 3-7 parts of boric acid, 5-10 parts of glycerin, 10-15 parts of cyanuric acid, 20-30 parts of triethylamine, 25-35 parts of tetrahydrofuran, 7-12 parts of liquid bromine, 2-7 parts of chlorine, 25-35 parts of ethyl acetate, 30-40 parts of deionized water, 30-40 partsof a saturated salt solution, 10-20 parts of anhydrous sodium sulfate, 3-5 parts of Zhongshengmycin, 5-7 parts of nekal, 5-7 parts of naphthalene sulfonate formaldehyde condensate, 10-14 parts of talcpowder and 15-20 parts of kaolin. The biological pesticide for preventing Apple scar skin viroid has a strong inhibitory effect on plant viruses and harmful bacteria, and especially has a good prevention effect on Apple scar skin viroid, and since zinc, boron and other trace elements are contained in the biological pesticide for preventing Apple scar skin viroid, the growth and development of apples can be promoted.

Owner:赵泉泉

Single-layer double-sided heat transfer printing process for polyester blankets

InactiveCN110117915ABroaden the field of printing and dyeingPlay a protective effectTransfer printing processDyeing processWater usePolyester

The invention discloses a single-layer double-sided heat transfer printing process for polyester blankets. The printing process includes the steps of 1), pretreatment; 2), double-sided printing; 3), over-hydrolyzed untwisting ; 4), drying; 5), brushing; 6), aftertreatment; 7), production of finished products. In the printing process, the single-layer double-sided magnetic rod printing technology of traditional polyester blankets is innovated, good permeability of blanket fiber in the printing process with a heat transfer printing machine is achieved, and the printing process is simple, clear and time saving and labor saving; continuous washing and fixing of high-temperature evaporated flowers using over-hydrolyzed untwisting instead of traditional magnetic bar printing machines greatly reduces the amount of water used and can guarantee the untwisting degree of the blanket fiber, functions in energy saving and no sewage treatment are imperceptibly achieved, and the concept of green environmental protection production is met; most importantly, the effect of printing is quite realistic and can be matched with digital printing heat transfer printing paper, traditional heat transfer printing paper can be used as well, and a wide market prospect is achieved.

Owner:江苏康尼纺织品有限公司

Method for preparing ethanol by adding Mn (II) salt for promoting simultaneous saccharification and fermentation of straw

InactiveCN103436588AHigh activityImprove final yieldBiofuelsMicroorganism based processesChemistryFermentation broth

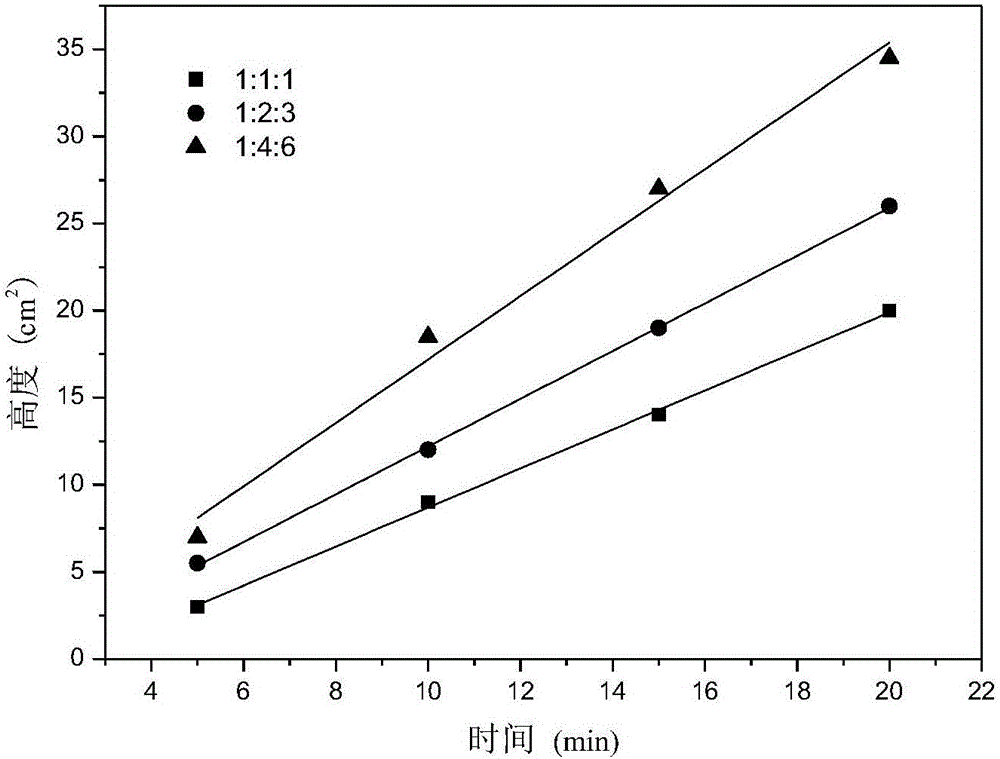

The invention provides a method for preparing ethanol by adding Mn (II) salt for promoting simultaneous saccharification and fermentation of straw. The method comprises the steps of: after grinding and sieving straw stalks, selecting glycol as a liquefier, carrying out liquefaction pretreatment under the catalysis action of concentrated sulfuric acid, and carrying out washing and suction filtration to obtain a fermentation substrate; selecting pachysolen tannophilus and saccharomyces cerevisiae as fermentation microorganisms, respectively taking the two types of yeast after slant culture and activating in a YEPD (Yeast Extract Peptone Dextrose) liquid culture medium, loading a culture medium mixed liquor by using a hemocytometer, determining the yeast concentration through microscopic counting, and diluting to suitable concentration; respectively adding the fermentation substrate, a MnSO4 solution, cellulase and the diluted yeast mixed liquor into a fermentation tank, and after adjusting to a suitable solid-liquid mass ratio by using sterile water, carrying out simultaneous saccharification and fermentation under the condition of constant temperature; finally determining the ethanol concentration in fermentation liquor by using a spectrophotometric method, and calculating to obtain the final yield of the ethanol. According to the method, the related raw materials are wide in sources, and the method is convenient to operate, and can be used for reducing the dosage of the cellulase so as to lower the process cost and starting biochemical reaction at low temperatures, thus providing a new train of thought for a production process in the field.

Owner:CHONGQING UNIV

Acrylic hyperdispersing agent and preparation method thereof

InactiveCN104693338AThe synthesis and preparation process is simpleLow costTransportation and packagingMixingReaction temperatureDistilled water

The invention relates to an acrylic hyperdispersing agent and a preparation method thereof. The preparation method comprises the following steps: adding 40-60 parts of acrylic acid, 20-30 parts of ethyl acrylic acid, 10-30 parts of (methyl) butyl acrylate, 0.8-1.2 parts of maleic anhydride, 0.8-1.2 parts of initiator, 0.2-0.7 part of chain-transfer agent and 20-50 parts of NaOH used as reaction raw materials into a reaction kettle which is previously filled with 150 parts of distilled water, adding an initiator and a chain-transfer agent, stirring at 400-650 r / min to react at 85 DEG C below for 4-6 hours, and cooling to 30-50 DEG C; and adding NaOH into the cooled reaction solution, and reacting for 0.8-1.5 hours to obtain the hyperdispersing agent finished product. The preparation method has the advantages of short production cycle and low cost. The hyperdispersing agent has the advantages of superhigh dispersing power, no toxicity and no harm, and conforms to the concept on green production.

Owner:HAO YU ADDITION AGENT

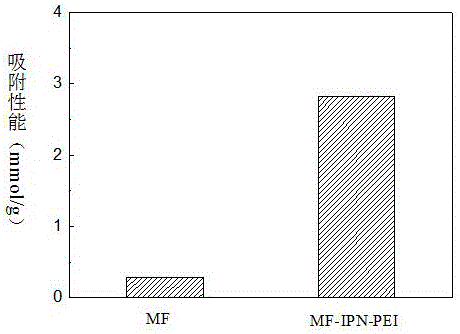

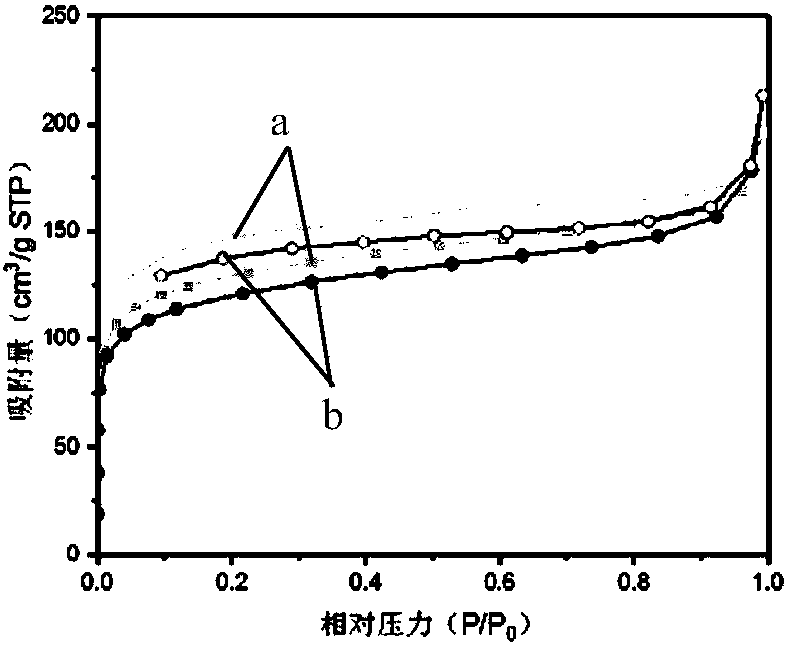

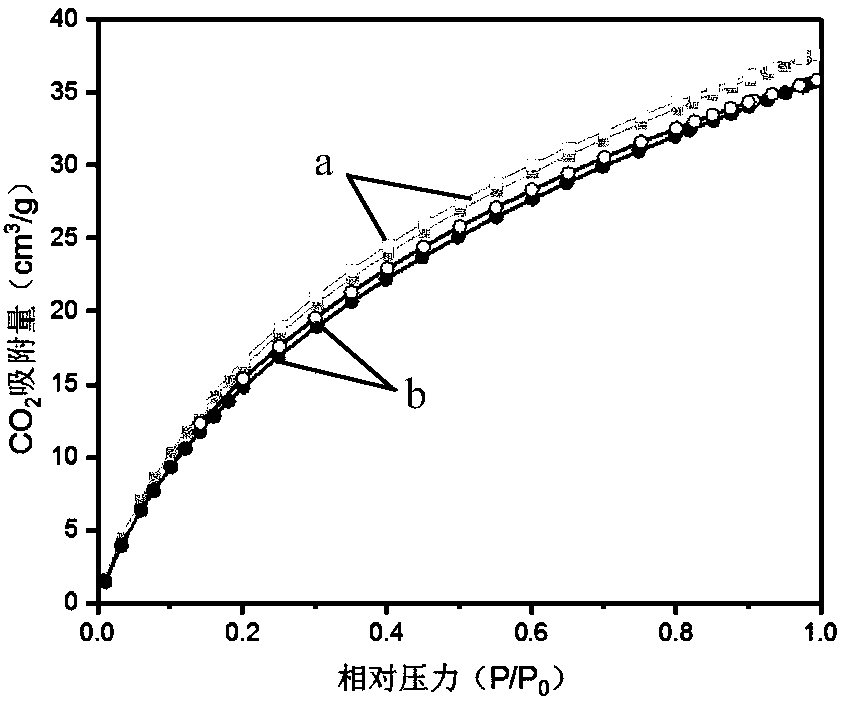

Solid amine interpenetrating network porous amino resin and its preparation method and use

ActiveCN106064082AImprove adsorption capacityNothing producedGas treatmentOther chemical processesToxic gasSolvent based

The invention discloses solid amine interpenetrating network porous amino resin and its preparation method and use. The preparation method comprises uniquely introducing polyacrylic acid into porous amino resin so that interpenetrating network porous amino resin is obtained and carrying out further amination treatment to obtain the solid amine interpenetrating network porous amino resin for physical and chemical combined adsorption of CO2 so that an adsorption amount is substantially improved. In preparation of the interpenetrating network porous amino resin, the preparation method is free of a pore forming agent, a catalyst and an initiator and realizes interpenetrating network porous amino resin preparation through direct solvent-based thermopolymerization at a low temperature. The product has strong stability, can be simply and easily prepared, can be massively produced, does not produce odor and toxic gas, can be post-treated simply and can satisfy green production requirements. Through use of acrylic acid, the product greatly improves swelling properties than those of the porous amino resin, can be fast swelled directly through water, can improve an amination reagent grafting amount and can realize physical and chemical combined high efficiency adsorption of CO2.

Owner:SUN YAT SEN UNIV

Coal asphalt porous polymer prepared through heteropolyacid catalysis as well as preparation method and application thereof

InactiveCN108517051AMild production conditionsIncrease productivityOther chemical processesDispersed particle separationPolymer scienceDimethoxymethane

The invention provides a coal asphalt porous polymer prepared through heteropolyacid catalysis as well as a preparation method and application thereof, and relates to the coal asphalt porous polymer.The coal asphalt porous polymer prepared through heteropolyacid catalysis is prepared from the following raw materials according to the mass ratio: 1 part of substrate raw material, 3 parts of crosslinking agent and 9.47 parts of catalyst. The solid asphalt is firstly dissolved into purified 1,2-dichloroethane; then, dimethoxymethane is added; after the uniform heating, heteropolyacid subjected toheat treatment is added to obtain a mixed solution; the asphalt porous polymer is prepared; the obtained asphalt porous polymer is firstly cleaned by methanol; cleaning filter liquid is collected; then, products are extracted; after the drying, the coal asphalt porous polymer is obtained. The coal asphalt porous polymer can be applied to adsorption such as gas adsorption and storage. The reactionconditions are mild; the green and environment-friendly effects are achieved; the catalyst can be repeatedly used for many times; the cost is very low. The equipment investment can be greatly reduced; the process technology difficulty is reduced; the process production efficiency is improved.

Owner:XIAMEN UNIV

Kiwi fruit wine residue biscuits and preparation method thereof

InactiveCN105532827AFull of nutritionRich in nutrientsDough treatmentBakery productsVegetable oilAdditive ingredient

The invention discloses kiwi fruit wine residue biscuits. The kiwi fruit wine residue biscuits are prepared from, by weight, 30-45 parts of wheat flour, 10-15 parts of corn starch, 20-40 parts of kiwi fruit wine residues, 5-10 parts of wheat dietary fiber, 5-10 parts of dried Chinese yam, 20-25 parts of vegetable oil, 25-30 parts of rock candy, 0.3-0.8 part of baking soda powder, 0.2-0.4 part of salt and 6-13 parts of water. The kiwi fruit wine residue biscuits have rich nutritional ingredients, integrate nutritional ingredients of the Chinese yam and the wheat dietary fiber and are suitable for middle-aged and aged people, young and middle-aged white-collar workers and adolescents. In addition, the preparation method of the kiwi fruit wine residue biscuits is simple, easy to operate and suitable for large-scale production.

Owner:NANYANG NORMAL UNIV

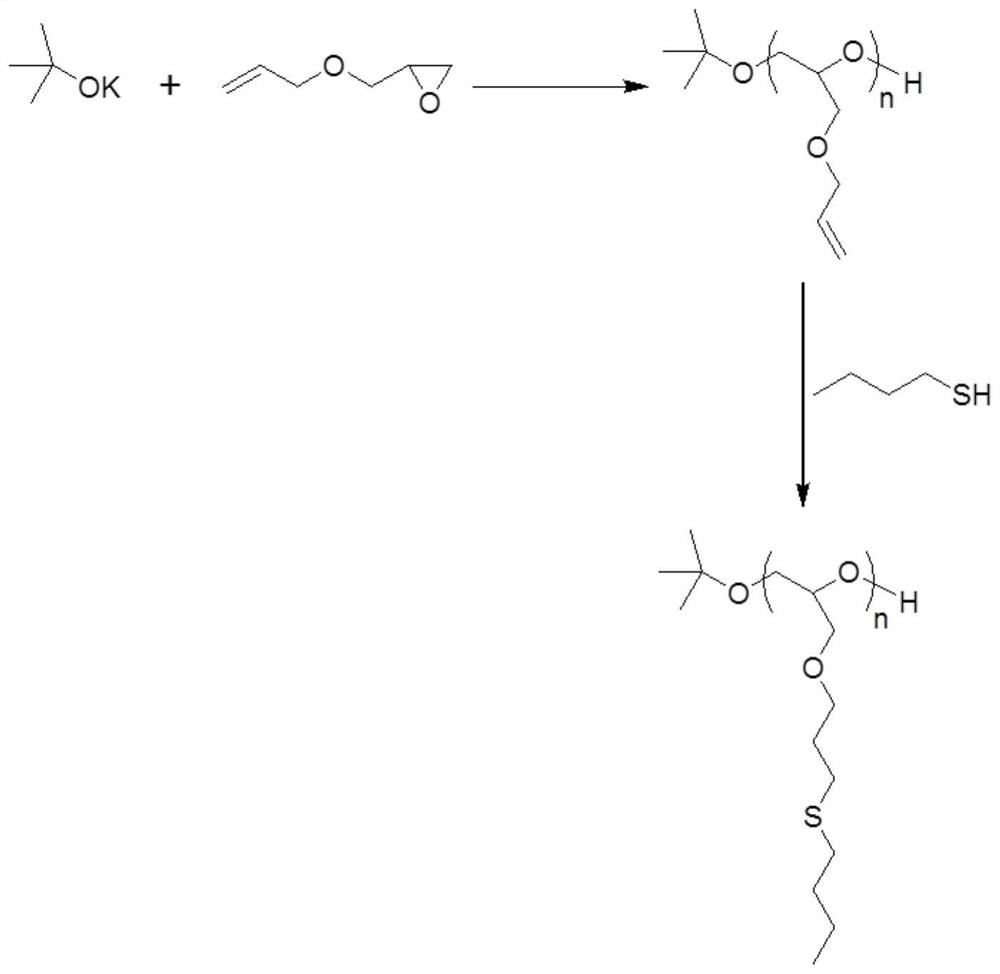

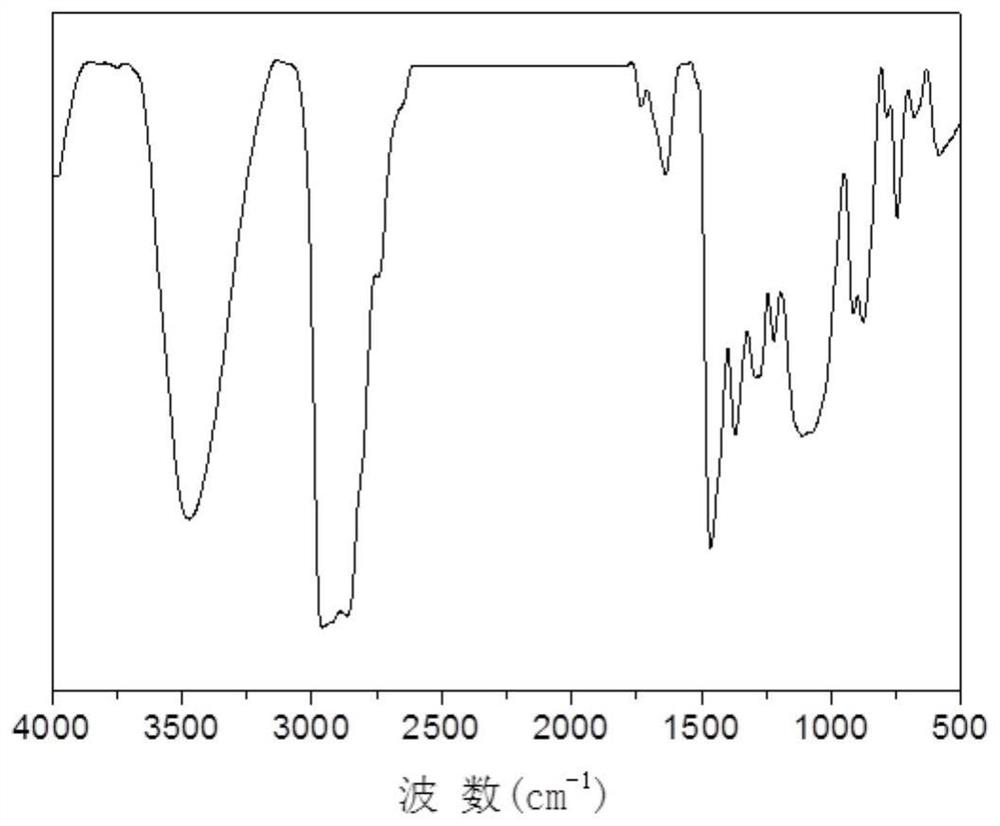

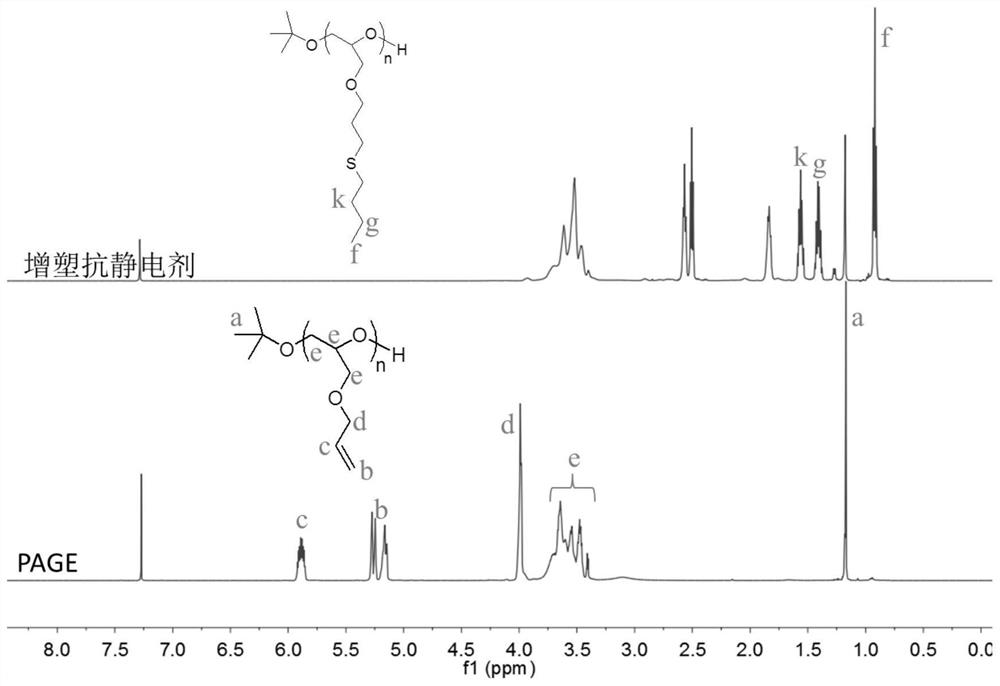

Polyvinyl chloride plasticizing antistatic agent and preparation method thereof

The invention relates to a polyvinyl chloride plasticizing antistatic agent and a preparation method thereof. The preparation method comprises the following steps: dissolving potassium tert-butoxide and allyl glycidyl ether in an anhydrous solvent; polymerizing the solution for 2-24 hours at the temperature of 40-80 DEG C; then adding an acidic material into the system to terminate the polymerization reaction, performing filtering to remove the precipitate, and removing the organic solvent by using a rotary evaporator to obtain a polyallyl glycidyl ether intermediate product; and 2, dissolving the intermediate product PAGE, n-butyl mercaptan and a photocatalyst in an organic solvent, placing the solution at room temperature, irradiating the solution with blue light for 0.5-2 hours to complete a reaction, dialyzing the solution in ethanol to remove unreacted n-butyl mercaptan, the solvent and the catalyst after the reaction is finished, and removing the ethanol by rotary evaporation to obtain the novel polyvinyl chloride plasticizing antistatic agent. According to the invention, the technological process in the actual processing process can be reduced, the addition cost of the additive is saved, and the composite function of the additive is realized.

Owner:SHAANXI UNIV OF SCI & TECH

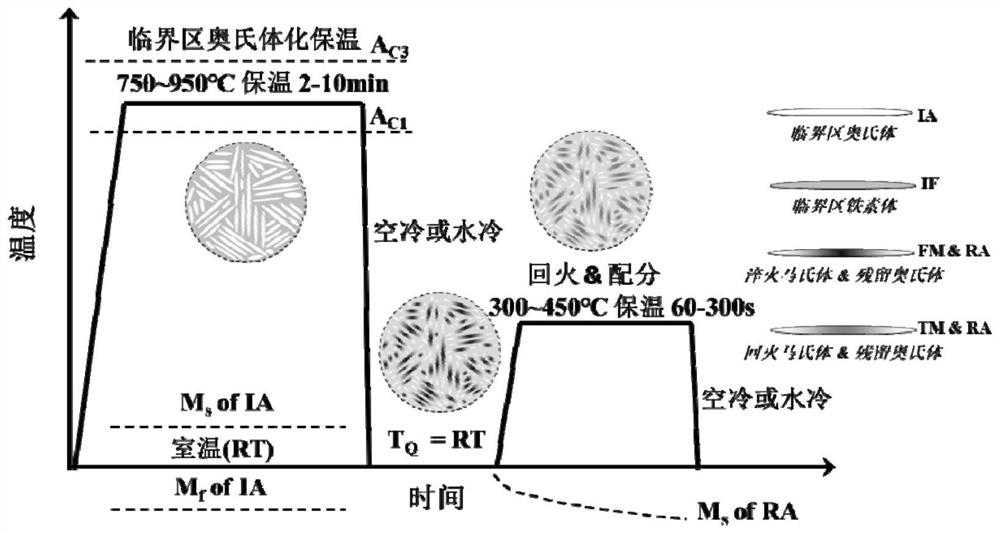

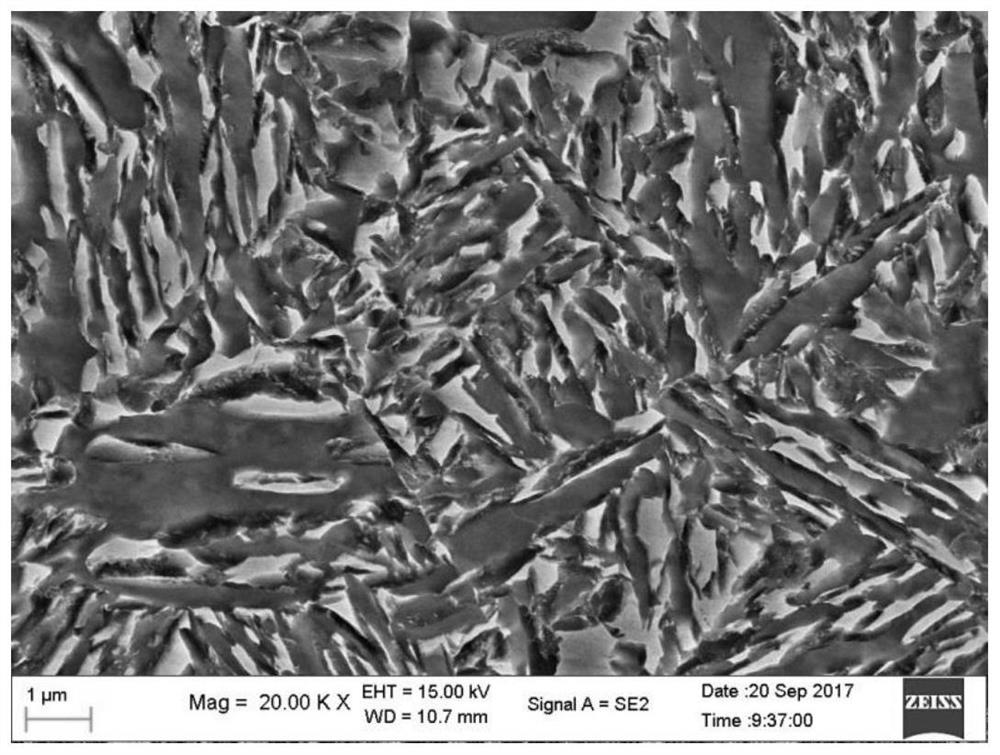

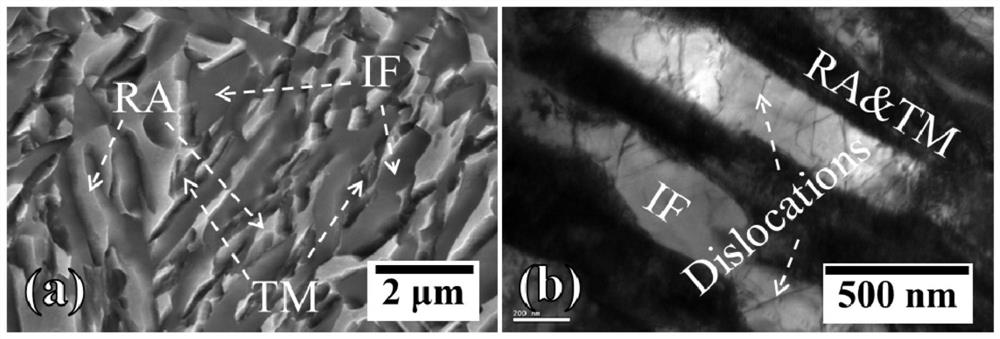

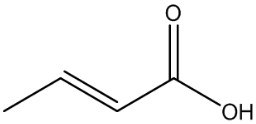

A kind of medium manganese ultra-high strength steel and preparation method thereof

The invention discloses middle-manganese ultrahigh-strength steel and a preparation method thereof. The chemical components of the steel comprise, by mass, 0.20%-0.45% of C, 3.0%-6.0% of Mn, 1.0%-4.0%of Si, 0.5%-3.0% of Al, smaller than or equal to 0.01% of P, smaller than or equal to 0.02% of S, 0%-0.05% of Nb, 0%-0.05% of V, 0%-0.05% of Ti and the balance Fe and unavoidable impurities, whereinthe content of Al and Si is larger than or equal to 1.5% and smaller than or equal to 5.5%, and the content of Nb, V and Ti is larger than or equal to 0% and smaller than or equal to 0.05%. When the middle-manganese ultrahigh-strength steel is prepared, a quenching and tempering technology is adopted, the temperature is lowered to the room temperature RT through air cooling or water cooling by adjusting the critical zone austenization TIA temperature, and then the carbon distribution substep is completed through tempering treatment. According to the middle-manganese ultrahigh-strength steel and the preparation method thereof, the technology is simple, the tensile strength of the prepared middle-manganese ultrahigh-strength steel can reach 1,150-1,950 MPa, and the highest product of strength and elongation can reach 40 GPa.% or above.

Owner:UNIV OF SCI & TECH BEIJING

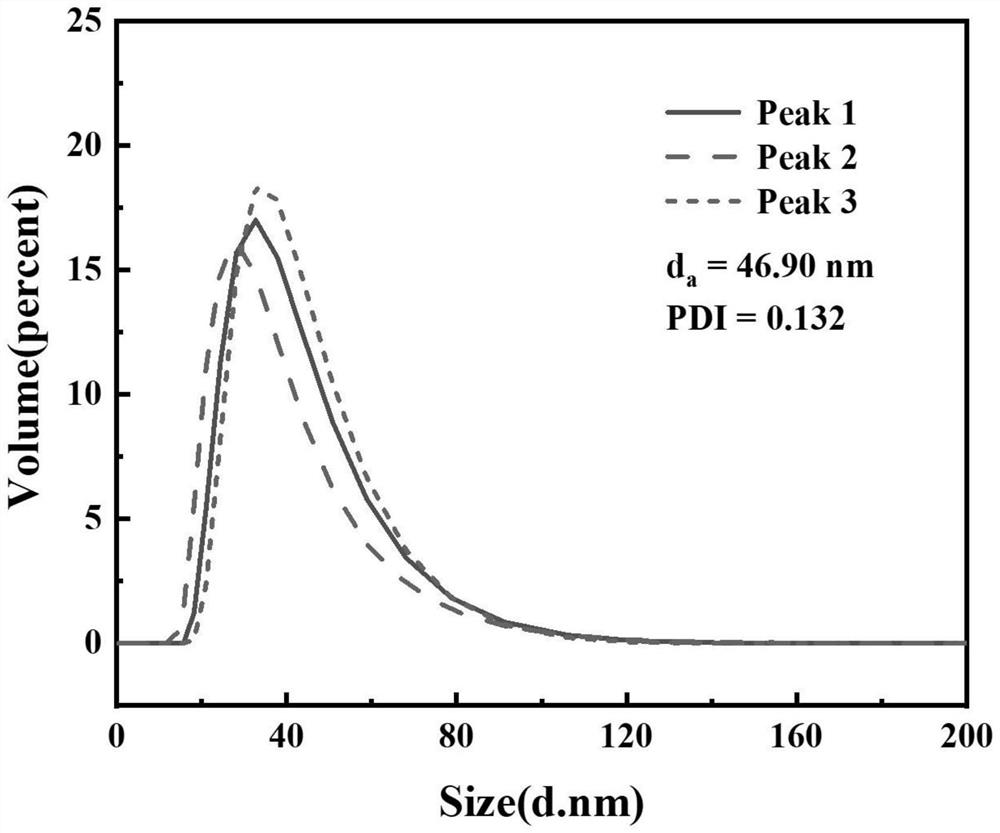

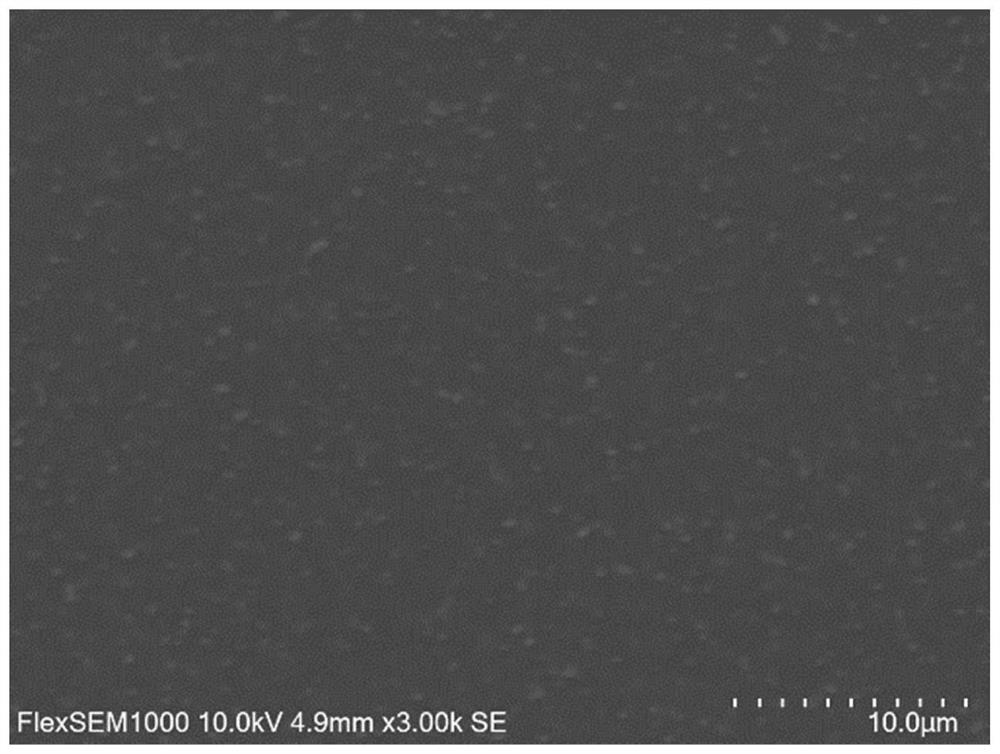

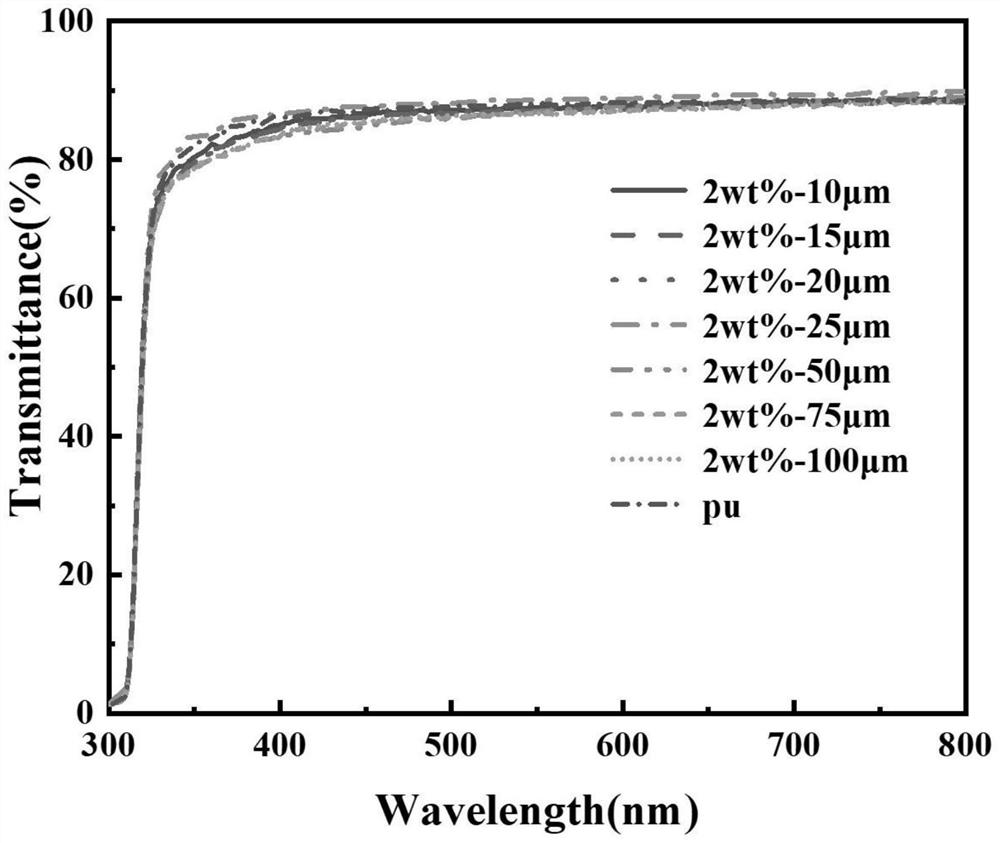

High-transparency antibacterial coating as well as preparation method and application thereof

PendingCN114806371ASimple processSimple equipmentAntifouling/underwater paintsPaints with biocidesPositive gram bacteriaResin matrix

The invention discloses a high-transparency antibacterial coating as well as a preparation method and application thereof. The high-transparency antibacterial coating is coated on the surface of a base material. The antibacterial coating comprises a resin matrix and a nano inorganic antibacterial agent. The invention further provides a preparation method of the antibacterial coating. The prepared coating is high in light transmittance in a visible region, good in stability and excellent and lasting in antibacterial performance on gram-negative bacteria and gram-positive bacteria, the preparation process is simple, complex instruments and equipment are not needed, the coating can be coated on the surfaces of various transparent base materials only through simple spraying, blade coating, spin coating and other modes, and the application range is wide. Meanwhile, production cost is low, and the application range is wide.

Owner:SHANGHAI UNIV

A kind of jet coagulation method of natural rubber latex

The invention discloses a natural latex jet-flow solidification method which comprises the following steps of: pressurizing the natural latex by using a pressure pump, putting the natural latex into a pressure instrument to be stored up, jetting the natural latex into a gasifying chamber through a jet-flow port under the action of pressure, so as to form natural latex microdroplets; and gasifying the natural latex microdroplets under the action of pressure difference and temperature difference so as to form natural latex solidified grains. The natural latex jet-flow solidification method provided by the invention overcomes the defects that the acid solidification in the conventional production is high in production cost, long in production period, large in environmental pollution and large in body damage to operators, the production cost is greatly lowered, the application and the emission of harmful pollutants are reduced, the production period is shortened, and at the same time the production profits of enterprises are increased, so that the natural latex jet-flow solidification method is non-pollution environment-friendly production, meets the environment-friendly production concept which is proposed by China, and has wide application prospect in future.

Owner:HAINAN UNIV

Environment-friendly plush fabric dyeing method and residual color paste treatment technology thereof

InactiveCN109355834AHigh uniformity of color brightnessImproved performance of the finished productHeating/cooling textile fabricsLiquid/gas/vapor removalColour fastnessDye absorption

The invention discloses an environment-friendly plush fabric dyeing method and a residual color paste treatment technology thereof. The technology comprises the following steps that 1, a white gray fabric of a plush fabric is pretreated; 2, a high-temperature dye is prepared into color paste and poured into a rolling groove of a padder; 3, the pretreated white grey cloth is guided into the rollinggroove in the padder through a cloth guide roller at the front end of the padder for quick hunger type high-permeability dye absorption to complete dyeing, and the dyed fabric and the residual colorpaste are obtained; 4, drying and primary color development are carried out; 5, drying and high-temperature color development are performed; 6, the fabric is discharged; 7, the fabric is rinsed and softened; 8, shaping is carried out; 9, post-treatment is performed; 10, a finished product is manufactured. The fabric dyed through the method is uniform in color, free of color difference, bright andgood in finished product, and the liquid rate when the padder is used for padding the gray fabric is controlled to be 35-50% so that color development can be fully achieved during color development, the color is bright, and the color fastness is quite good.

Owner:江苏康尼纺织品有限公司

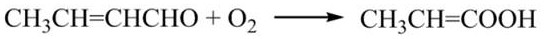

Production method of high-yield transbutylene-2-acid

ActiveCN114315557AHigh catalytic activityImprove catalytic selectivityOrganic compound preparationChemical recyclingButenePtru catalyst

The invention relates to the technical field of butenoic acid preparation, and provides a production method of high-yield transbutylene-2-acid. The method comprises the following steps: mixing butene-2-aldehyde, a solvent and a silver-loaded catalyst under an oxygen condition, and carrying out a catalytic oxidation reaction to obtain transbutene-2-acid; the solvent is an acetate solvent, and the carrier of the supported silver catalyst is ZrO2 and / or TiO2. The silver-loaded catalyst adopted by the invention has relatively high catalytic activity and selectivity, can be used for efficiently and continuously preparing the transbutene-2-acid, and is high in product yield, high in proportion of the transbutene-2-acid in the product, stable in activity and long in service life; the solvent adopted by the invention is low in toxicity and meets the green chemical requirements. Results of the embodiment show that when the transbutene-2-acid is prepared by adopting the method disclosed by the invention, the conversion rate of the butene-2-aldehyde is more than 95%, the selectivity of the butene-2-acid is more than 89%, and the proportion of the transbutene-2-acid in the product is more than 96%.

Owner:北京弗莱明科技有限公司 +2

Austempering heat treatment method of high bending property austempered ductile cast iron (ADI)

The invention discloses an austempering heat treatment method of high bending property austempered ductile cast iron (ADI). The austempering heat treatment method comprises the following steps: austenitizing ductile cast iron at the temperature of 860-900 DEG C, and immediately quenching the austenitized ductile cast iron in a quenching water-based suspension medium for 1-5s, wherein the flow rate of a water-based suspension is kept to be 0.2-0.6m / s in the quenching process; then, keeping isothermality for 5-600min at the temperature of 200-300 DEG C; and finally, air cooling to room temperature. Through the heat treatment method, the ADI after heat treatment is still a mixed matrix of speculate bainitic ferrite (BF) and retained austenite (AR), the rigidity of the ADI reaches HRC 53.8, the bending strength reaches 1565.6MPa, and the deflection reaches 2.1mm.

Owner:YANGZHOU UNIV

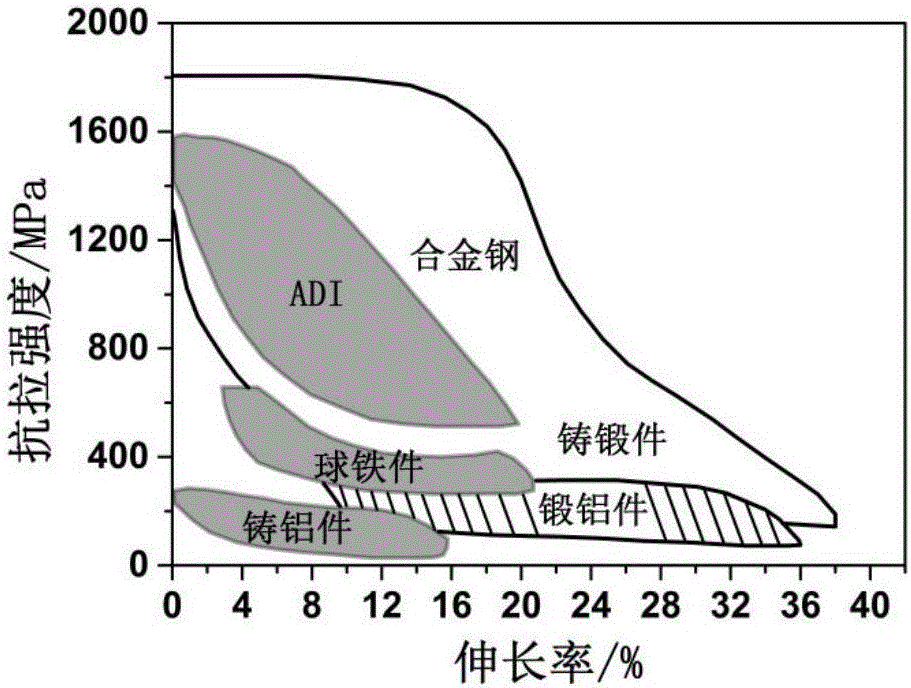

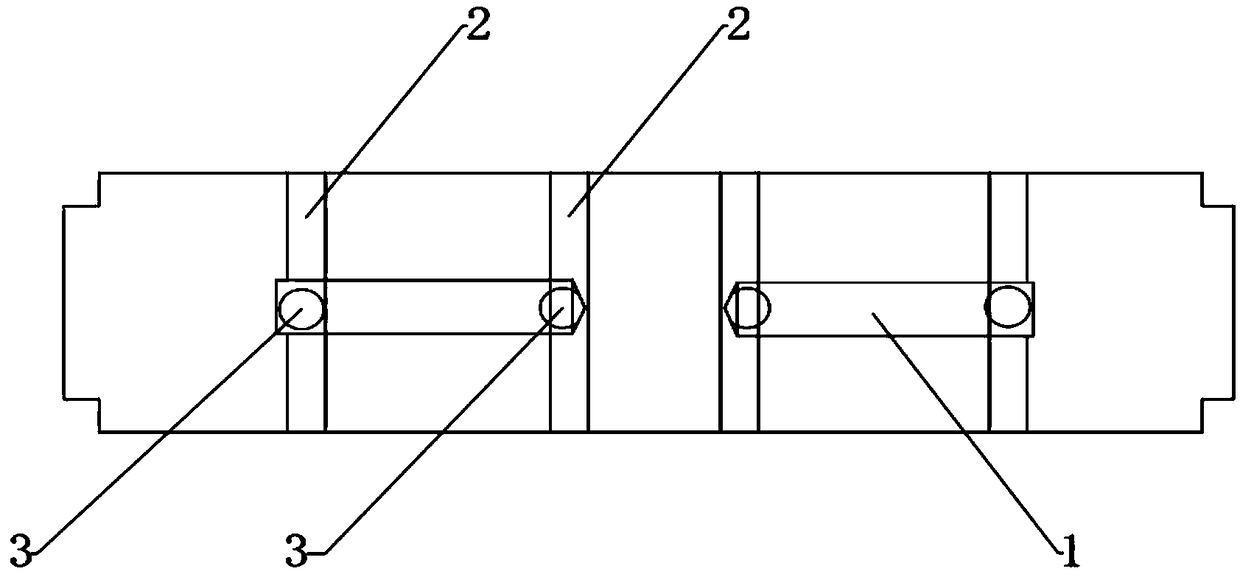

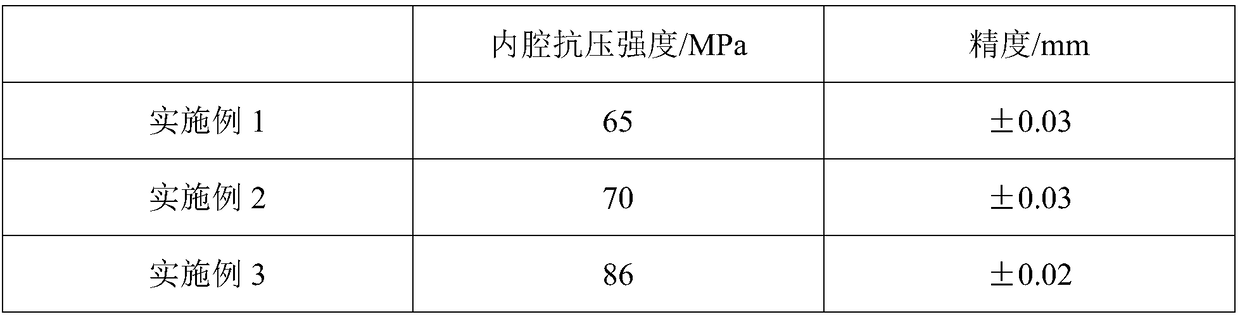

Ceramic component with cavity structure and preparing method of ceramic component

InactiveCN109227886AShort process cycleSimple methodCeramic shaping mandrelsCeramic shaping coresSintering

The invention discloses a preparing method of a ceramic component with a cavity structure. The method includes the steps of preparing a soluble core according to the cavity structure, preparing injection feed, placing the soluble core in a mold for injection molding, soaking the soluble core in a dissolving solution so that the dissolving solution and the soluble core can react, removing the soluble core to obtain a blank, and conducting drying and sintering. Accordingly, the invention further discloses the ceramic component with the cavity structure. The ceramic component is prepared throughthe preparing method. The method is simple, efficiency is high, the ceramic component can be produced on a large scale, and the prepared ceramic component is high in precision, high in strength and attractive in appearance.

Owner:广东金刚新材料有限公司 +1

Intumescent water-based fireproof coating

The invention discloses an intumescent water-based fireproof coating. The intumescent water-based fireproof coating comprises the following raw materials in parts by weight: 10 to 20 parts of propylene glycol, 20 to 30 parts of inorganic bentonite, 40 to 50 parts of ammonium polyphosphate, 25 to 35 parts of melamine, 15 to 35 parts of pentaerythritol, 30 to 40 parts of chlorinated paraffin, 10 to20 parts of nanoscale titanium dioxide, 25 to 35 parts of hydroxyethyl cellulose, 10 to 20 parts of a water reducing agent and 40 to 50 parts of ettringite powder. Compared with other treatment processes, the fireproof coating is prepared from a fireproof coating original material composed of propylene glycol, inorganic bentonite, ammonium polyphosphate, melamine, pentaerythritol, chlorinated paraffin, nanoscale titanium dioxide and hydroxyethyl cellulose. Meanwhile, a water reducing agent and ettringite powder are used as mixed components of the expanding agent, the raw materials are uniformly mixed, particles in the raw materials are ground to the maximum extent, the raw materials are odorless and do not pollute the external environment, the concept of green production is met, meanwhile,the uniformly ground and mixed coating is smooth in spraying performance, the attractiveness of a sprayed product is improved, and the using effect of the coating is improved.

Owner:百氏高涂料(苏州)有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com