Preparation method of graded spherical cuprous oxide hollow nano particle

A cuprous oxide and hollow nano technology is applied in the field of preparation of graded spherical cuprous oxide hollow nanoparticles, which can solve the problems of unsuitability for large-scale production, small preparation amount, low solubility and the like, and achieves short reaction time, simple operation, mild response

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

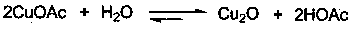

Method used

Image

Examples

Embodiment 1

[0023] Take 0.1mol / LCuCl 2 Add 100ml of aqueous solution into the reaction flask, add dropwise 20ml of mixed aqueous solution containing 0.005mol hydrazine hydrate and 0.01molNaOAc at 5°C and a stirring speed of 250-500r / min, and control the dropping time at 10-15min; Stir for 10 min, centrifuge, wash with water, place it in a vacuum drying oven, and dry at 40°C to obtain red hierarchical spherical cuprous oxide hollow nanoparticles.

Embodiment 2

[0025] Take 0.5mol / LCuCl 2 Add 20ml of aqueous solution into the reaction flask, add 20ml of mixed aqueous solution containing 0.01mol hydrazine hydrate and 0.01mol NaOAc dropwise at 15°C and a stirring speed of 500-1000r / min, and control the dropping time at 10-15min; after adding, continue Stir for 10 min, centrifuge, wash with water, place it in a vacuum drying oven, and dry at 50° C. to obtain red hierarchical spherical cuprous oxide hollow nanoparticles. figure 1 The XRD spectrum of the prepared hierarchical spherical cuprous oxide hollow nanoparticles is shown. By comparing with the standard spectrum, it can be seen that the prepared product is cuprous oxide. figure 2 The SEM spectrum of the prepared hierarchical spherical cuprous oxide hollow nanoparticles is shown, and the spherical structure of cuprous oxide can be seen from the accompanying drawings, image 3 The TEM spectrum of the prepared hierarchical spherical cuprous oxide hollow nanoparticles is shown. It can...

Embodiment 3

[0027] Take 1mol / LCuCl 2 Add 10ml of aqueous solution into the reaction flask, add dropwise 20ml of mixed aqueous solution containing 0.02mol hydrazine hydrate and 0.01molNaOAc at 25°C and a stirring speed of 1000-1500r / min, and control the dropping time at 15-20min; Stir for 20 minutes, centrifuge, wash with water, place it in a vacuum drying oven, and dry at 60°C to obtain red hierarchical spherical cuprous oxide hollow nanoparticles. Figure 4 The TEM spectrum of the prepared hierarchical spherical cuprous oxide hollow nanoparticles is shown, and it can be seen from the accompanying drawings that the cuprous oxide has a hierarchical structure.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com