Composite complexing agent and method of preparing lithium-ion power battery cathode precursor material

A technology of composite complexing agent and power battery, applied in battery electrodes, positive electrodes, secondary batteries, etc., can solve the problems of high control requirements of experimental conditions, threats to the health of operators, serious waste liquid treatment problems, etc. The effect of easy long-term storage, good surface particle morphology and high industrial value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

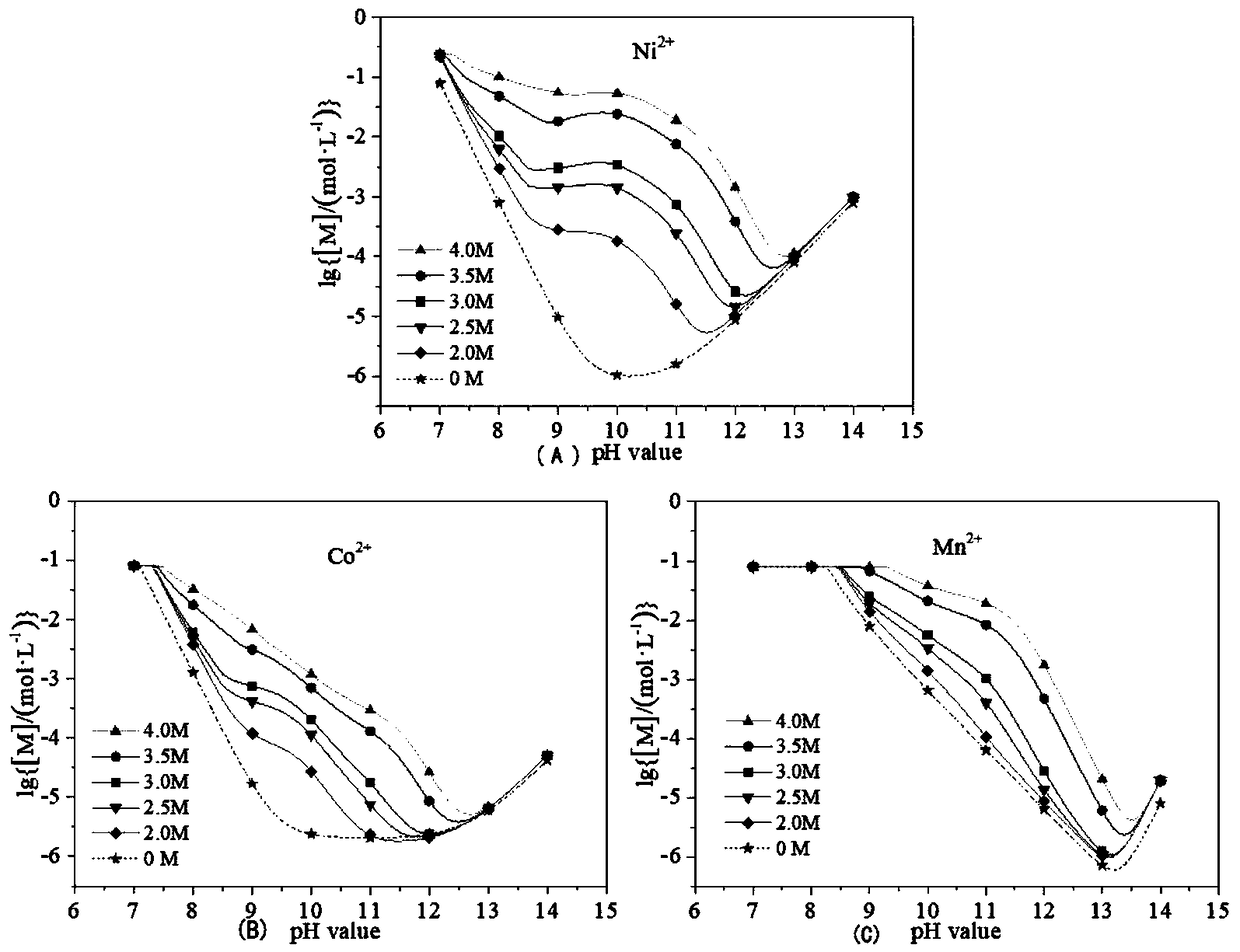

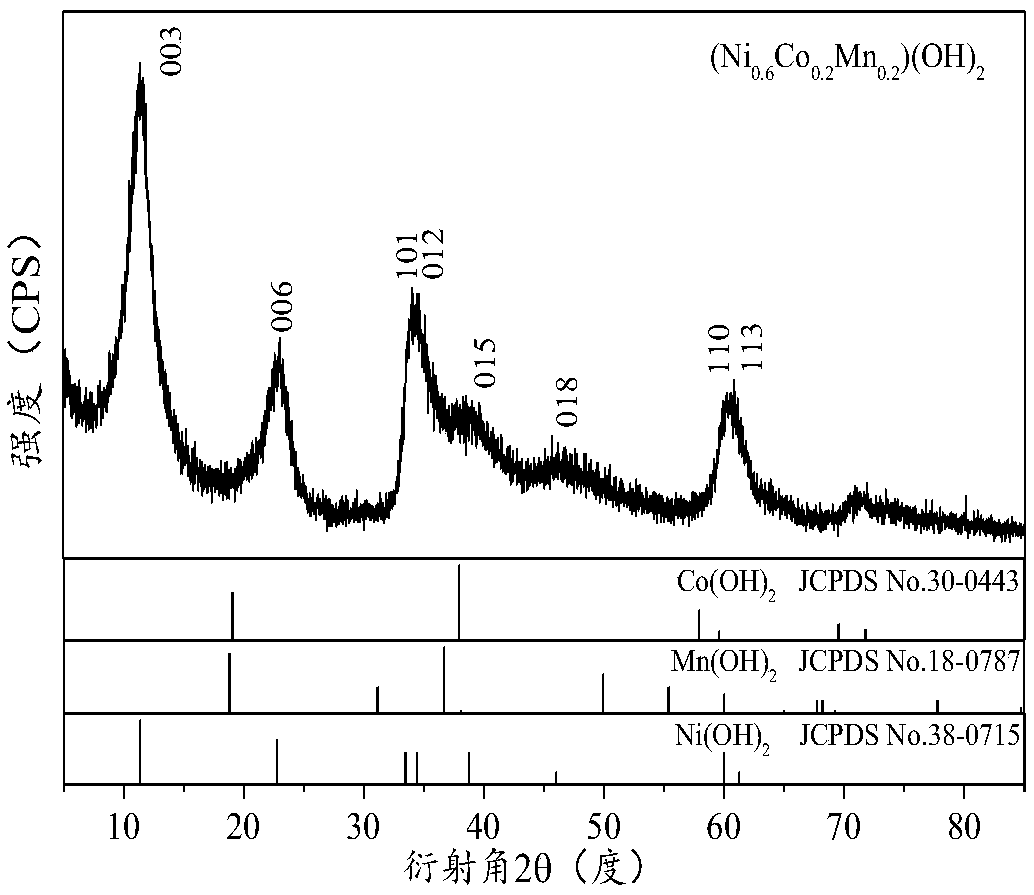

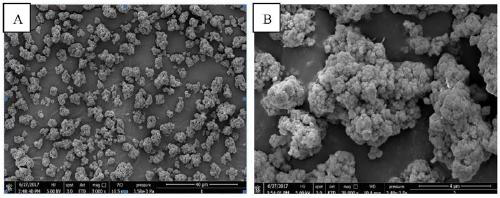

[0034] First prepare NiSO with a concentration of 4.0mol / L 4 ·6H 2 O, CoSO 4 ·7H 2 O, MnSO 4 ·H 2 O mixed solution in which the molar ratio of metal cations satisfies Ni 2+ :Co 2+ :Mn 2+ =6:2:2; prepare composite complexing agent solution (citrate 2.5mol / L, glutamate 0.5mol / L); preparation concentration is the sodium hydroxide solution of 4.0mol / L as precipitation agent; The sodium hydroxide solution is pumped into the reaction kettle, the temperature of the water bath is controlled at 60°C, the pH value is adjusted and controlled to be 11.5, and then the mixed solution of the metal cation solution and the complexing agent is pumped in, and the stirring speed is controlled at 800 rpm. After aging in a reactor at ℃ for 20 hours, deionized washing, and drying at 100℃, a tap density of 1.85g / cm was obtained. 3 of (Ni 0.6 mn 0.2 co 0.2 )(OH) 2 Precursor. Analysis of ICP components in the precursor showed that metal cations (Ni 2+ :Co 2+ :Mn 2+ ) The mol ratio basic...

Embodiment 2

[0044] Prepare NiSO with a concentration of 4.0mol / L 4 ·6H 2 O, CoSO 4 ·7H 2 O, MnSO 4 ·H 2 O mixed solution in which the molar ratio of metal cations satisfies Ni 2+ :Co 2+ :Mn 2+ =6:2:2; prepare composite complexing agent solution (citrate 2.0mol / L, glutamate 1.0mol / L) as buffer complexing agent solution; preparation concentration is the sodium hydroxide solution of 4.0mol / L As a precipitant; first pump sodium hydroxide solution into the reaction kettle, control the temperature of the water bath at 55°C, adjust and control the pH value to 12.0, then pump the mixed solution of metal cation solution and complex complexing agent, and control the stirring speed at 600 rpm After aging for 12 hours in a reactor at a temperature of 55°C, the reactant was deionized and washed to a pH of 7.0 to 7.5, and dried at 100°C to obtain (Ni 0.6 mn 0.2 co 0.2 )(OH) 2 Precursor. The prepared (Ni 0.6 mn 0.2 co 0.2 )(OH) 2 The precursor was mixed with a certain proportion of lithi...

Embodiment 3

[0046] Prepare NiSO with a concentration of 3.0mol / L 4 ·6H 2 O, CoSO 4 ·7H 2 O, MnSO 4 ·H 2 O mixed solution in which the molar ratio of metal cations satisfies Ni 2+ :Co 2+ :Mn 2+ =6:2:2; prepare compound complexing agent solution (citrate 1.0mol / L, glutamate 2.0mol / L) as buffer complexing agent solution; preparation concentration is 3.0mol / L sodium hydroxide solution As a precipitant; first pump sodium hydroxide solution into the reaction kettle, control the temperature of the water bath at 60°C, adjust and control the pH value to 12.0, then pump the mixed solution of metal cation solution and complex complexing agent, and control the stirring speed at 800 rpm / min, after aging for 24 hours in a reactor at a temperature of 50°C, the reactant was deionized and washed to a pH of 7.0 to 7.5, and dried at 100°C to obtain (Ni 0.6 mn 0.2 co 0.2 )(OH) 2 Precursor.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com