Chemically-modified attapulgite-clay-based porous ceramic and preparation method thereof

A technology of porous ceramics and chemical modification, which is applied in the field of preparation of chemically modified attapulgite-based porous ceramics. It can solve the problems of porous ceramics such as limited performance, poor pore distribution uniformity, and no well-developed channels, so as to achieve good pore distribution uniformity, Excellent adsorption and complexation performance, widening the effect of application fields

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

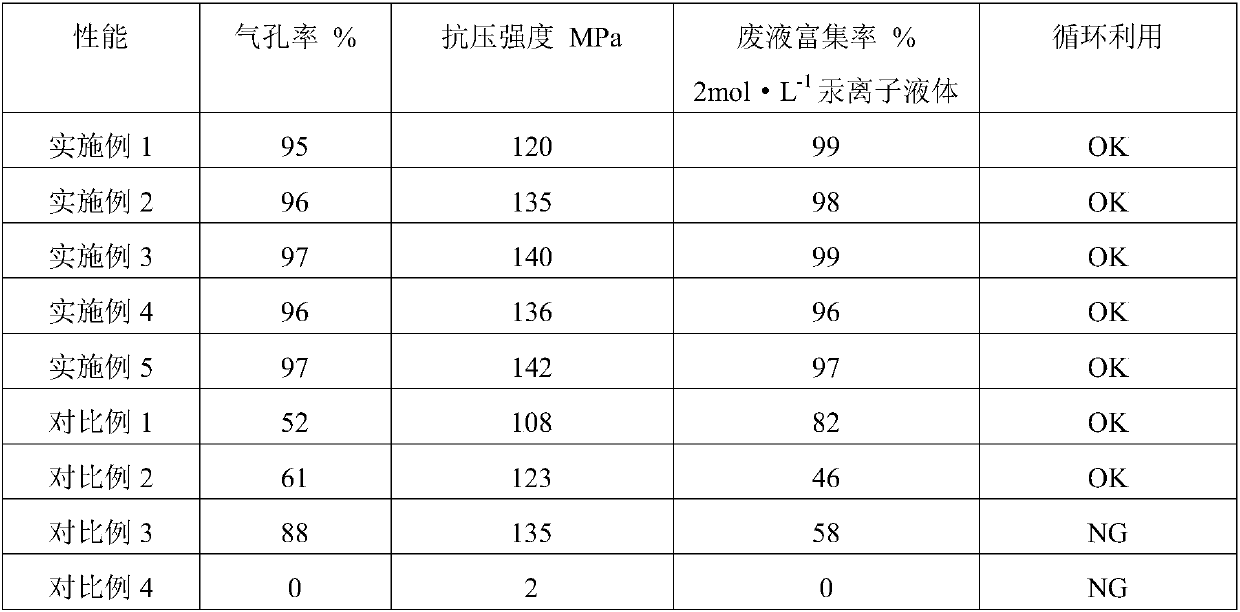

Examples

Embodiment 1

[0030] Step S11: Preparation of attapulgite-based porous ceramics

[0031] Process polyurethane organic foam into products first, add water to attapulgite to make slurry, then sizing the product, roll pressing, drying at 60°C, spraying slurry, and finally calcining at 500°C to obtain attapulgite Based porous ceramics, wherein the mass ratio of attapulgite to polyurethane organic foam and water is 1:0.05:0.2;

[0032] Step S12: Hydroxylation treatment of attapulgite-based porous ceramics

[0033] Immerse attapulgite-based porous ceramics in sodium hydroxide solution, stir at 20°C for 0.5 h, wash until the surface is neutral after reaction, and prepare hydroxylated attapulgite-based porous ceramics, wherein the concentration of sodium hydroxide solution is 0.5 mol / L, the mass ratio of attapulgite-based porous ceramics to sodium hydroxide is 0.05:1;

[0034] Step S13: Chemical modification of hydroxylated attapulgite-based porous ceramics

[0035] Add hydroxylated attapulgite-...

Embodiment 2

[0037] Step S21: Preparation of attapulgite-based porous ceramics

[0038] First process polyvinyl chloride organic foam into products, add water into attapulgite to make slurry, then sizing the product, roll pressing, drying at 120°C, spraying slurry, and finally calcining at 1500°C to obtain Attapulgite-based porous ceramics, wherein the mass ratio of attapulgite to polyvinyl chloride organic foam and water is 1:1:10;

[0039] Step S22: Hydroxylation treatment of attapulgite-based porous ceramics

[0040] Immerse attapulgite-based porous ceramics in potassium hydroxide solution, stir at 100°C for 24 hours, wash until the surface is neutral after reaction, and prepare hydroxylated attapulgite-based porous ceramics, wherein the concentration of potassium hydroxide solution is 20mol / L, the mass ratio of attapulgite-based porous ceramics to potassium hydroxide is 0.25:1;

[0041] Step S23: Chemical modification of hydroxylated attapulgite-based porous ceramics

[0042] Add h...

Embodiment 3

[0044] Step S31: Preparation of attapulgite-based porous ceramics

[0045] First process polystyrene organic foam into products, add water into attapulgite to make slurry, then sizing the product, roll pressing, drying at 100°C, spraying, and finally calcining at 1000°C to obtain Attapulgite-based porous ceramics, wherein the mass ratio of attapulgite to polystyrene organic foam and water is 1:0.5:5;

[0046] Step S32: Hydroxylation treatment of attapulgite-based porous ceramics

[0047] Immerse attapulgite-based porous ceramics in lithium hydroxide solution, stir at 80°C for 12 hours, wash until the surface becomes neutral after reaction, and obtain hydroxylated attapulgite-based porous ceramics, wherein the concentration of lithium hydroxide solution is 10mol / L, the mass ratio of attapulgite-based porous ceramics to lithium hydroxide is 0.2:1;

[0048] Step S33: Chemical modification of hydroxylated attapulgite-based porous ceramics

[0049] Add hydroxylated attapulgite-ba...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com