Cu-doped hydrotalcite-based photocatalytic material as well as preparation method and application thereof

A photocatalytic material and technology of catalytic material, applied in the field of photocatalyst, can solve the problems of low energy utilization rate, low surface adsorption rate, waste, etc., achieve strong photochemical stability, improve photocatalytic performance, and solve the effect of difficult recovery

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-3

[0026] 1) Prepare Cu(NO) whose molar ratios of copper, magnesium and aluminum are 1:2:1, 1.5:1.5:1 and 2:1:1 3 ) 2 , Mg(NO 3 ) 2 ·6H 2 O and Al (NO 3 ) 3 ·9H 2 A solution of O in 200mL each;

[0027] 2) Preparation of NaOH:Na 2 CO 3 Three 200mL portions of 2:1 B solution;

[0028] 3) Using the double-drop co-precipitation method, pour the solution A in step 1) and the solution B in step 2) into six constant pressure dropping funnels, respectively, and place them in three wells with 100 mL of deionized water respectively. Put the three-necked round-bottomed flask on the magnetic stirrer at both ends of the round-bottomed flask, and keep the pH value between 9.5 and 10.0. After the dropwise addition, continue stirring for 30 minutes to obtain a blue gelatinous precipitate, which is placed in the Crystallized at 60 °C for 24 h in an oven, then washed with water, filtered, dried, crushed, and passed through a 100-mesh sieve to obtain blue powders, which are respectively ...

Embodiment 4

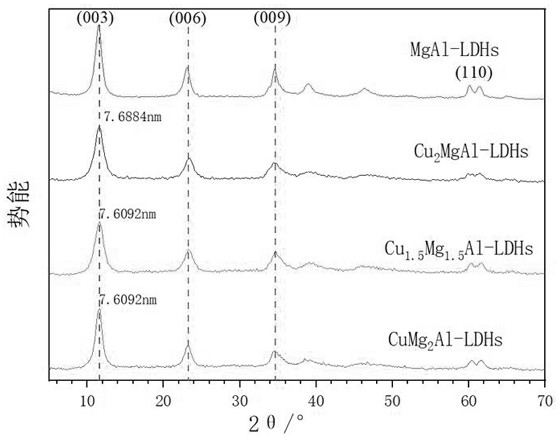

[0030] Shimadzu XRD-6000 X-ray powder diffractometer was used, and the characterization parameters were set as follows: Cu target, K α ray, λ is 0.1542 nm, the angle range is 5°~80°, and the crystal structures of the samples from Example 1 to Example 3 are determined. from figure 1 It can be seen from the XRD spectrum that the baseline is stable, the characteristic peak of (003) crystal plane is narrow and sharp, and the diffraction peaks of (003), (006), (009), (110) unique to hydrotalcite are all clear and not accompanied by impurity peaks, which indicates that the prepared material has high crystallinity and good regularity. figure 1 The 2θ corresponding to (003), (006), and (009) are: 11.4°, 23.52°, and 34.8°, respectively. According to the Bragg formula (nλ=2dsinθ), the layer spacing of Example 1-Example 3 is calculated to be 7.6092 , 7.6092, 7.6884, where Cu 2 The interlayer spacing of MgAl-LDHs is about 7.6884 nm. Comparing the interlayer spacing of the three sample...

Embodiment 5

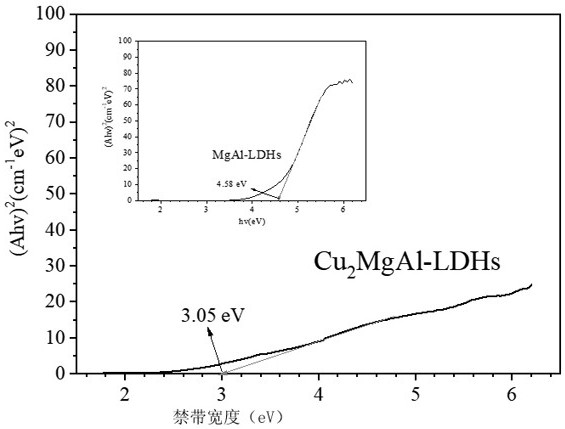

[0032] Get each 2000mg of the photocatalytic material prepared by the method of Example 1-3, scan the wavelength range of 200~800nm in an ultraviolet-visible spectrophotometer (2550 type, Shimadzu), and measure the diffuse reflection spectrum of hydrotalcite, such as figure 2As shown, in the visible light region, the three CuMgAl-LDHs have a certain degree of absorption in the 560-700 nm band, and are effective in the visible light region. According to the simplified Kubelka-Munk formula E=1240 / λeV, Cu 1 Mg 2 Al-LDHs, Cu 1.5 Mg 1.5 Al-LDHs, Cu 2 The forbidden band widths of MgAl-LDHs are: 3.21eV, 3.13eV, 3.05eV, Cu 2 MgAl-LDHs has a lower band gap than the other two samples, and the wavelength range of the required excitation light source is large.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com