Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

784 results about "Continuous fermentation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Continuous fermentation. Continuous Fermentation is a method of converting wort into beer in a continuous process, whereby wort is fed into one end of the process and beer is discharged at the other without recourse to holding the beer in a static holding vessel (batch fermentation).

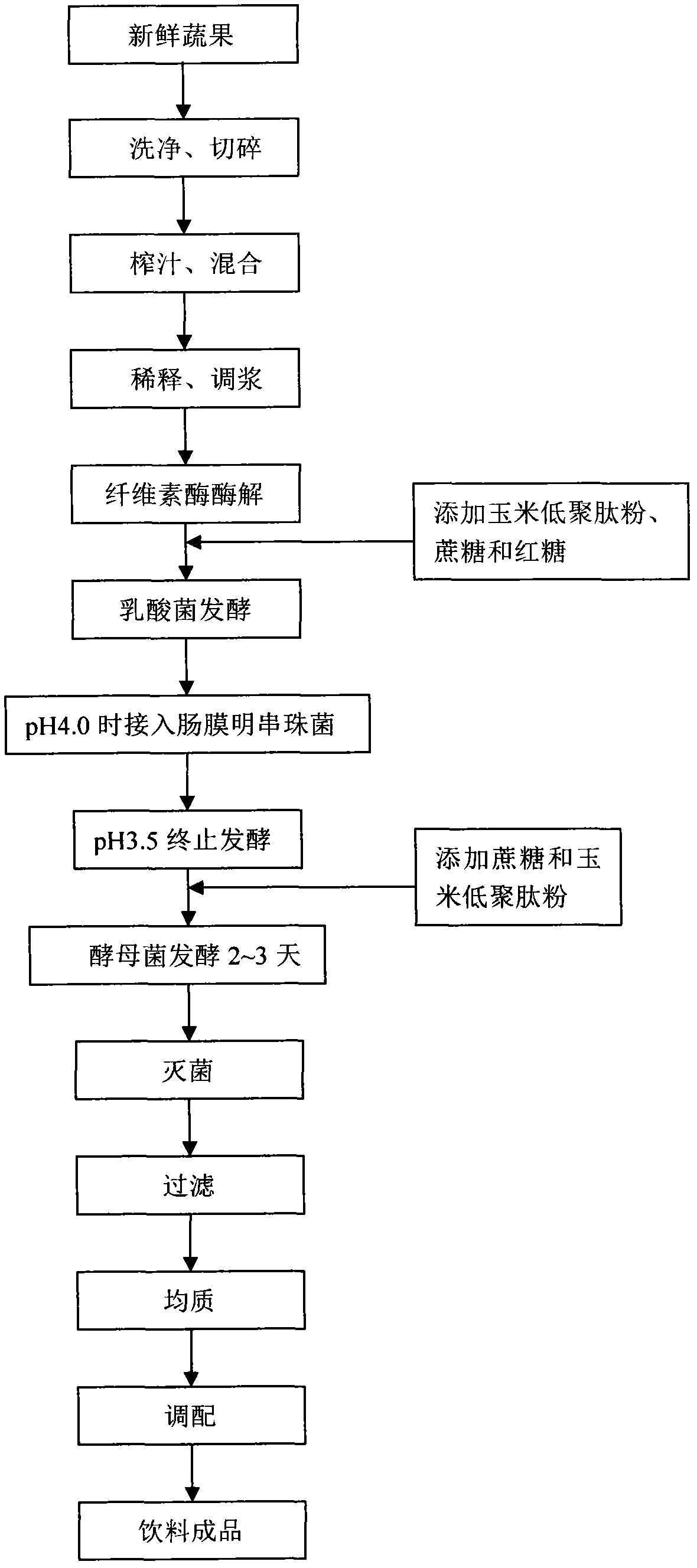

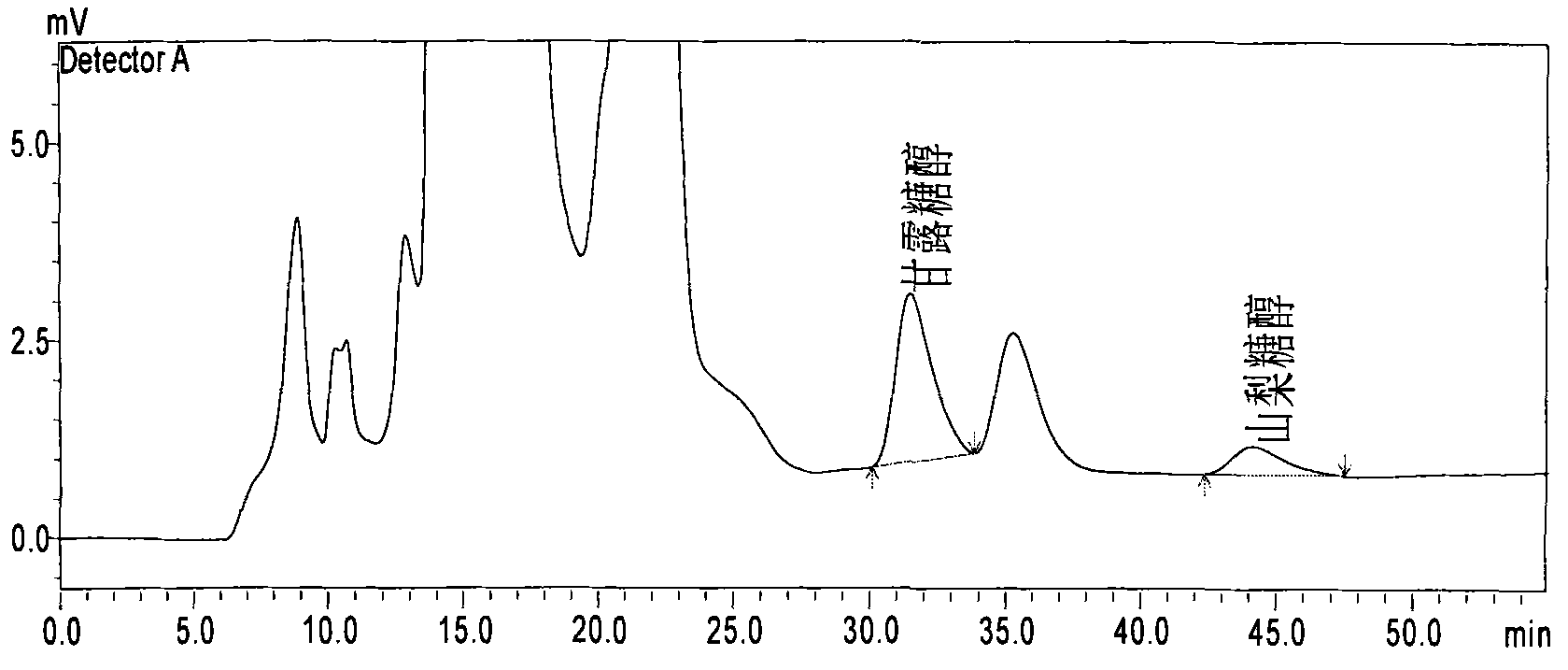

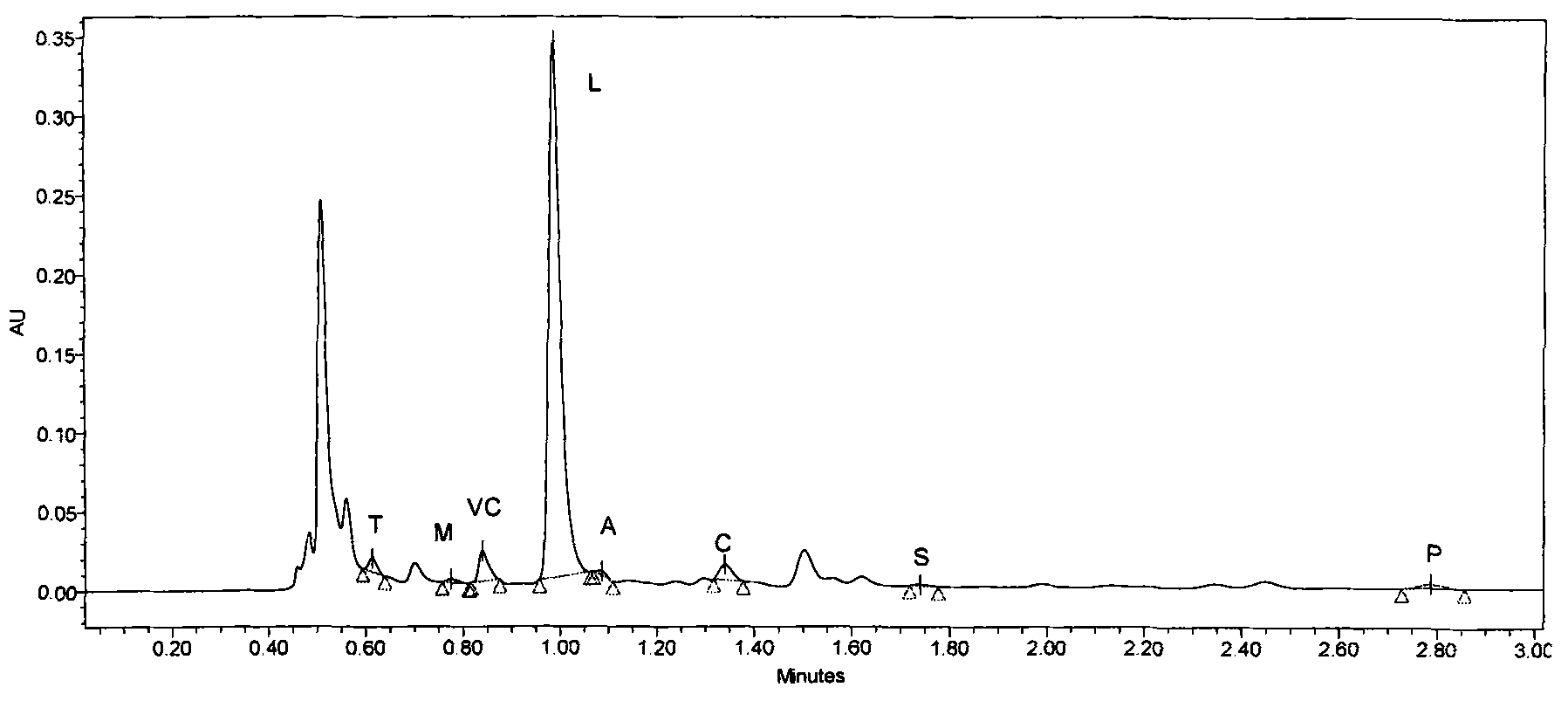

Natural vegetable and fruit fermented beverage

The invention discloses a preparation method of a novel vegetable and fruit fermented beverage. The preparation method comprises the steps of: firstly carrying out enzymolysis on mixed fresh juice of fresh vegetables and fruits after dilution and size mixing by adopting cellulase, fermenting by adopting a mixed lactic acid starter after adding sugar and corn oligopeptide as fermentation substrates and sterilizing, adding calcium carbonate when the pH reaches 4.0, and then inoculating leuconostoc mesenteroides for continuous fermentation; adding a feed supplement and sterilizing when the pH reaches 3.5, and then adding high-activity dry yeast for the fermentation for 2-3 days; and finally performing sterilization, centrifugation, homogenizing, blending, sterilizing and filling to obtain the novel vegetable and fruit fermented functional beverage. The enzymolysis is firstly carried out on a product by the cellulase, then lactic acid bacteria and saccharomycetes are utilized for the step-by-step fermentation of the mixed fresh juice of the fresh vegetables and fruits, and the corn oligopeptide is added to promote the growth and the metabolism of fermentation strains, so that the novel vegetable and fruit fermented beverage has clear composition of functional components, contains abundant oligopeptide, organic acids, reducing sugars, sugar alcohols and soluble dietary fiber, and integrates nutrition and health care, thus being a novel vegetable and fruit fermented beverage.

Owner:CHINA NAT RES INST OF FOOD & FERMENTATION IND CO LTD

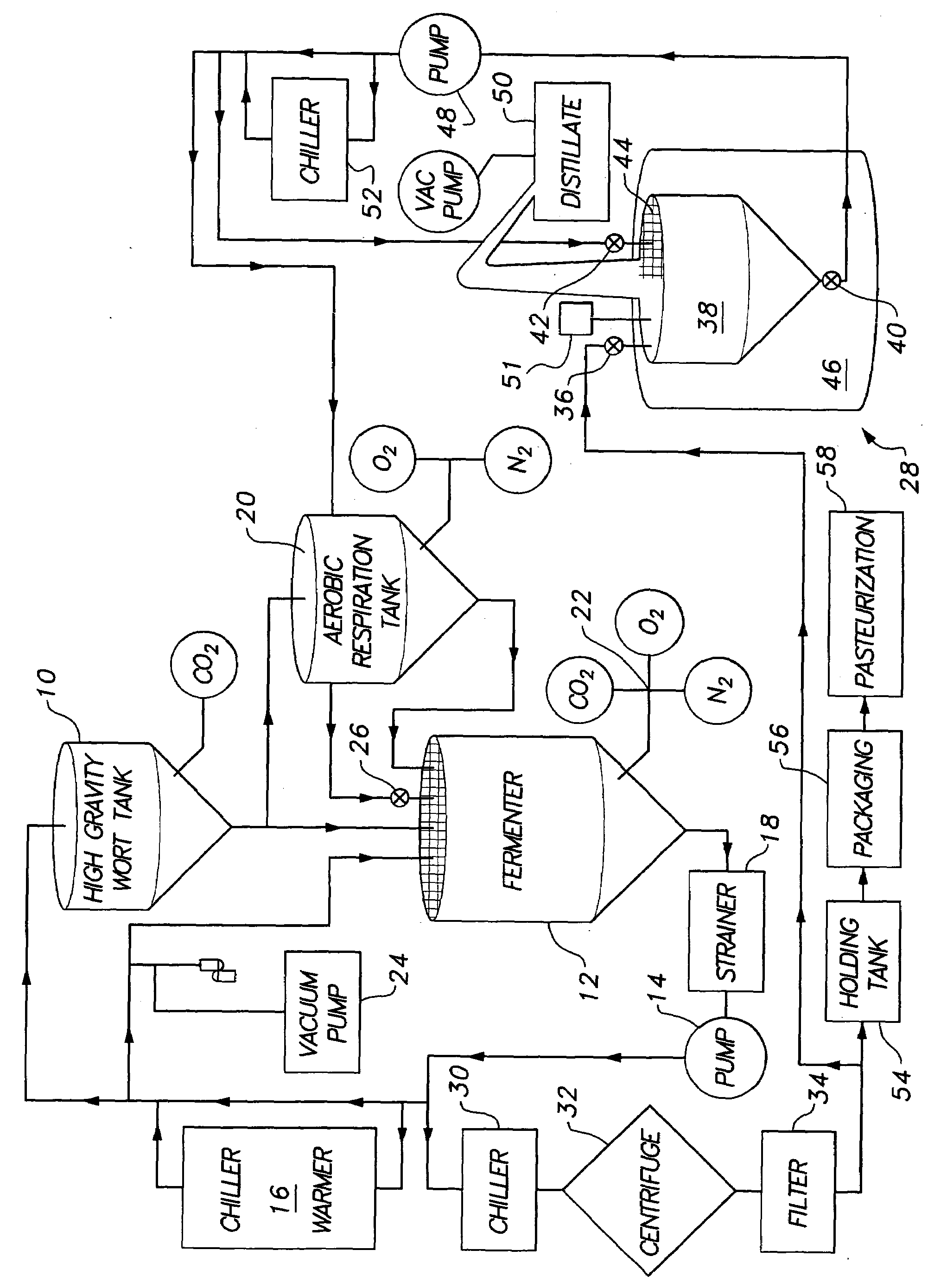

Method of making alcohol concentrate

ActiveUS20100047386A1Efficient extractionBeer fermentationWine preparationContinuous fermentationAlcohol

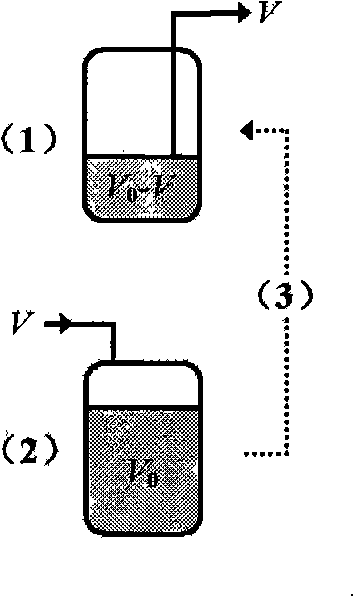

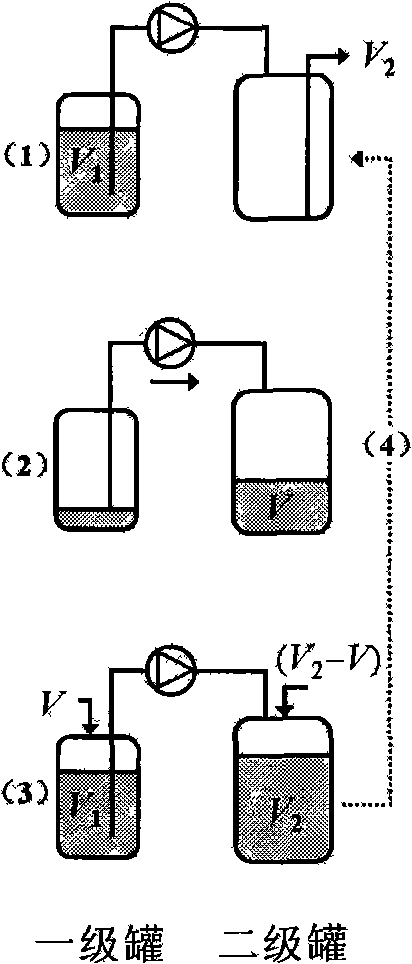

One embodiment of the present invention is method for making an alcohol concentrate using a nested batch fermentation process, wherein multiple rounds of wort fermentation, distillation and refortification, is described. The rounds are repeated until the desired concentration of fermented wort is obtained. Another embodiment of the present invention is a method for a continuous fermentation process, wherein portions of the fermentation are distilled and the remaining wort is returned to the active fermentation. This process is repeated until the desired concentration of the fermented wort is obtained. Yet another embodiment of the present invention is a method for extraction of hops compounds, wherein the distilled alcohol from the nested or continuous fermentation process is used.

Owner:SUSTAINABLE BEVERAGE TECH INC

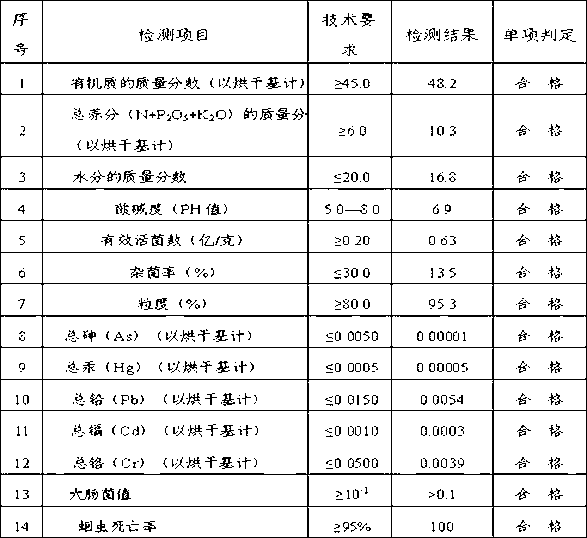

Production method for biological organic fertilizer

InactiveCN102951950ASimple production processEasy to operateBio-organic fraction processingOrganic fertiliser preparationPhosphatePotassium

The invention discloses a production method for a biological organic fertilizer which belongs to the field of manufacturing of composite fertilizers. The production method comprises the following steps: with pig manure, cow dung, chicken manure, sheep manure, vinasse, vinegar residue, cassava residue, furfural residue, uncontaminated river mud, corn straw, peanut straw, rape straw, a cottonseed cake, plant ash, a deodorant, a biological nitrogen fixation bacterium, a phosphate solubilizing bacterium, a potassium solubilizing bacterium, a nodule bacterium and a phosphorus activator used as raw materials, carrying out tank continuous fermentation to allow the raw materials become thoroughly decomposed; carrying out deodorizing and removing water; and carrying out granulation to obtain the granular biological organic fertilizer. The fertilizer has the following advantages: a complete range of nutrient elements, capacity of improving physical and chemical properties of soil and enhancing water retention, fertilizer retention and fertility supplying capacity of the soil, no corrosion and damage to roots and seedlings and capacity of substantially improving the quality of an agricultural product.

Owner:訾然

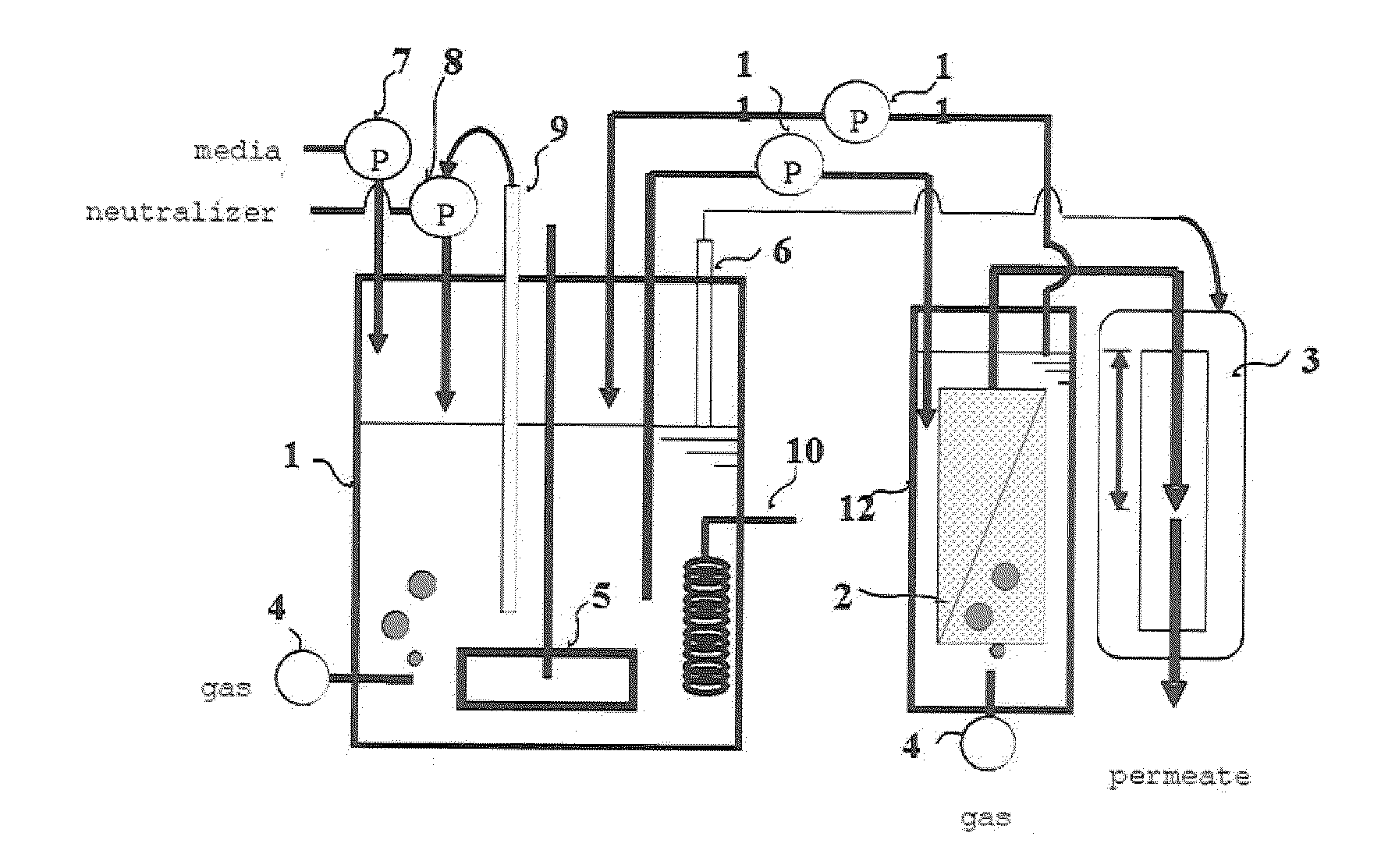

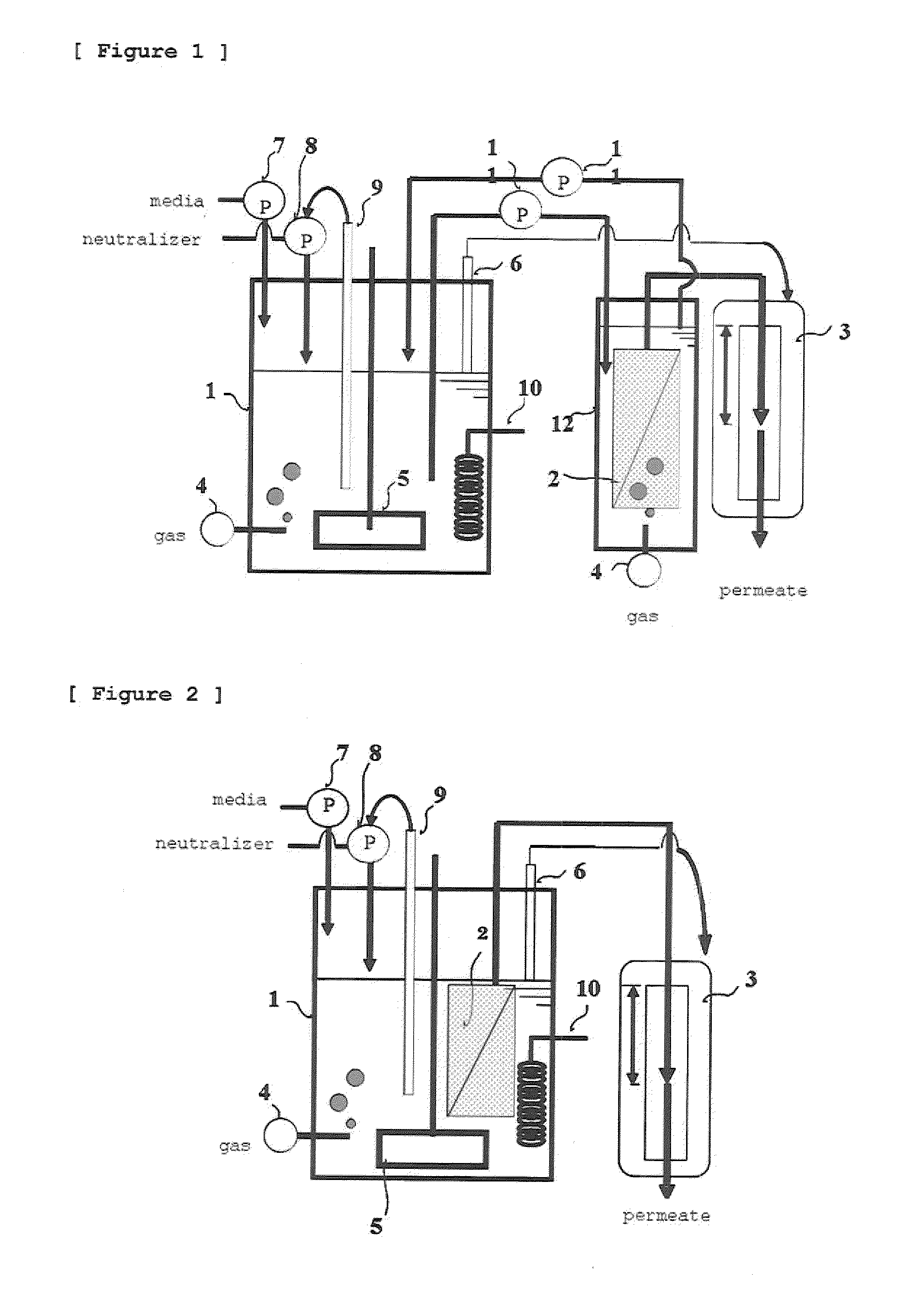

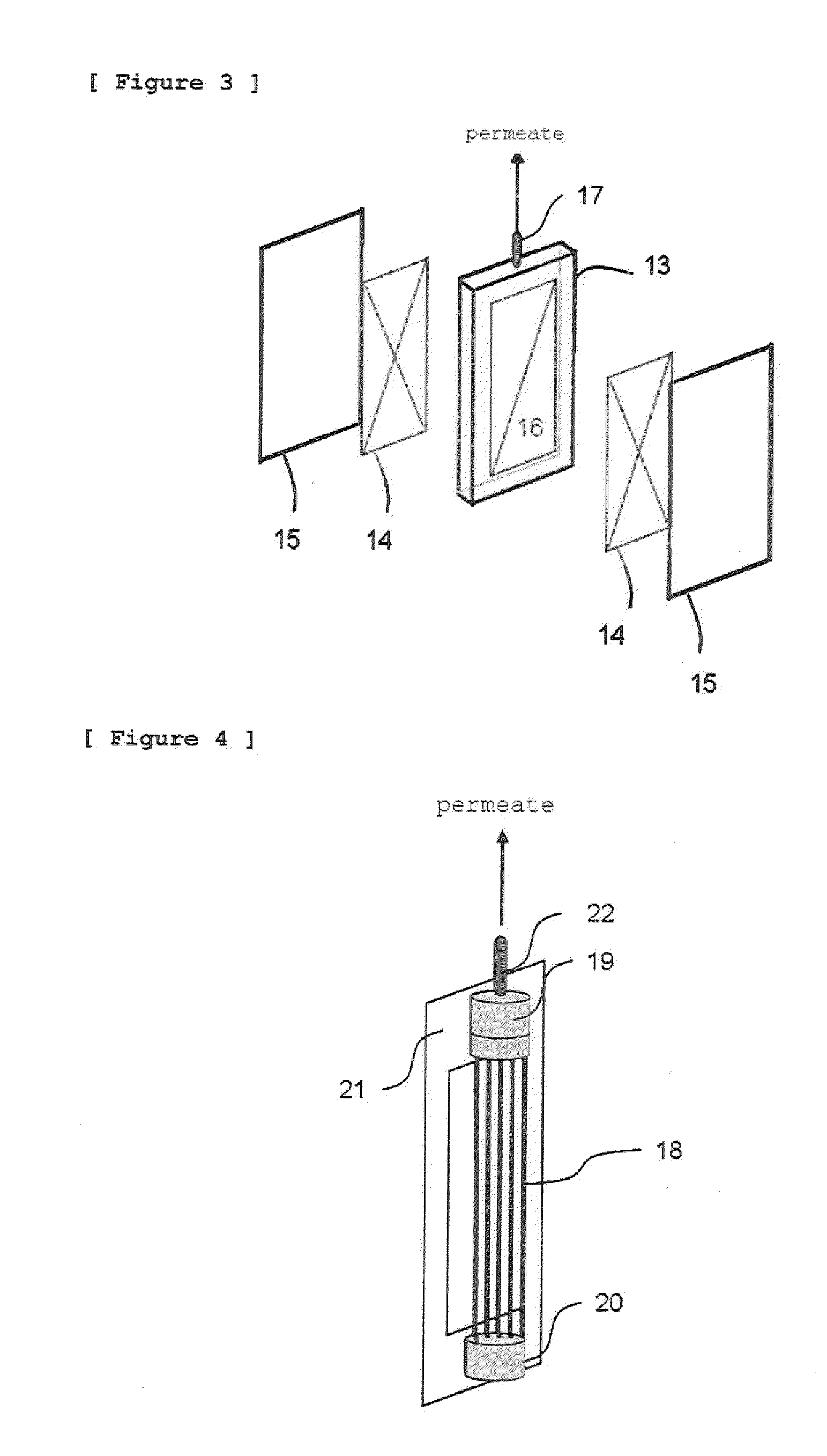

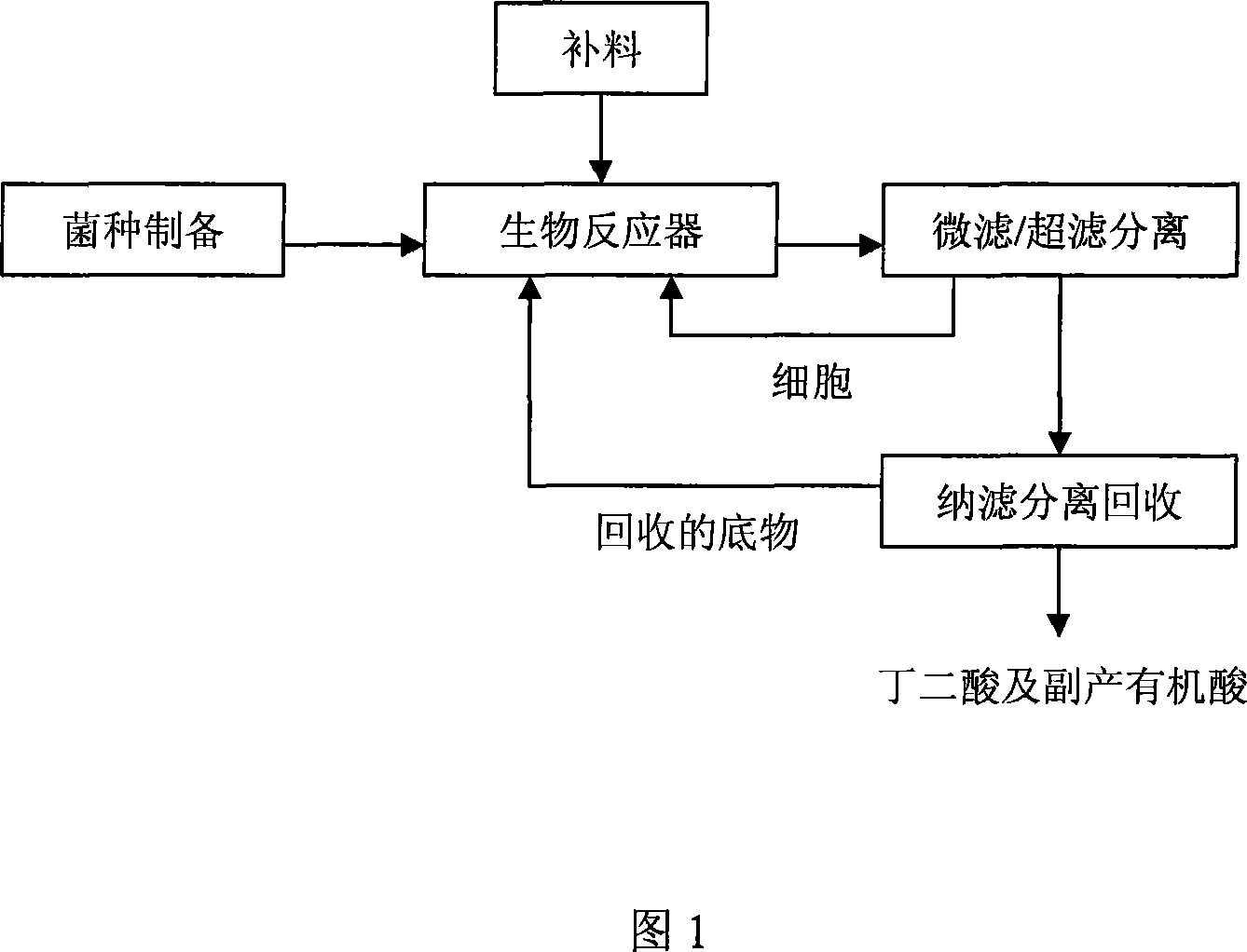

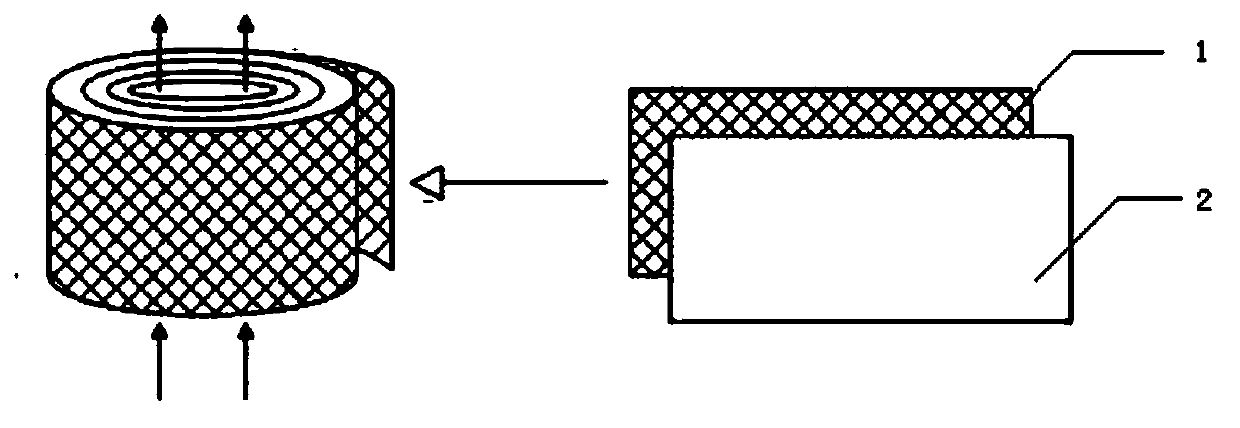

Method of producing chemical product and continuous fermentation apparatus

ActiveUS20090269812A1Bioreactor/fermenter combinationsBiological substance pretreatmentsContinuous fermentationMicroorganism

The invention provides a method of producing a chemical product through continuous fermentation which includes filtering a culture of a microorganism or cultured cells with a separation membrane to recover a product from a filtrate and simultaneously retaining a nonfiltered fluid in, or refluxing it to, the culture, and adding fermentation materials to the culture, wherein a porous membrane having an average pore size of 0.01 μm or more to less than 1 μm is used as the separation membrane and the filtration is conducted with a transmembrane pressure difference in the range of 0.1 to 20 kPa. According to this method, the fermentation productivity of the chemical product can be largely elevated at high stability and a low cost.

Owner:TORAY IND INC

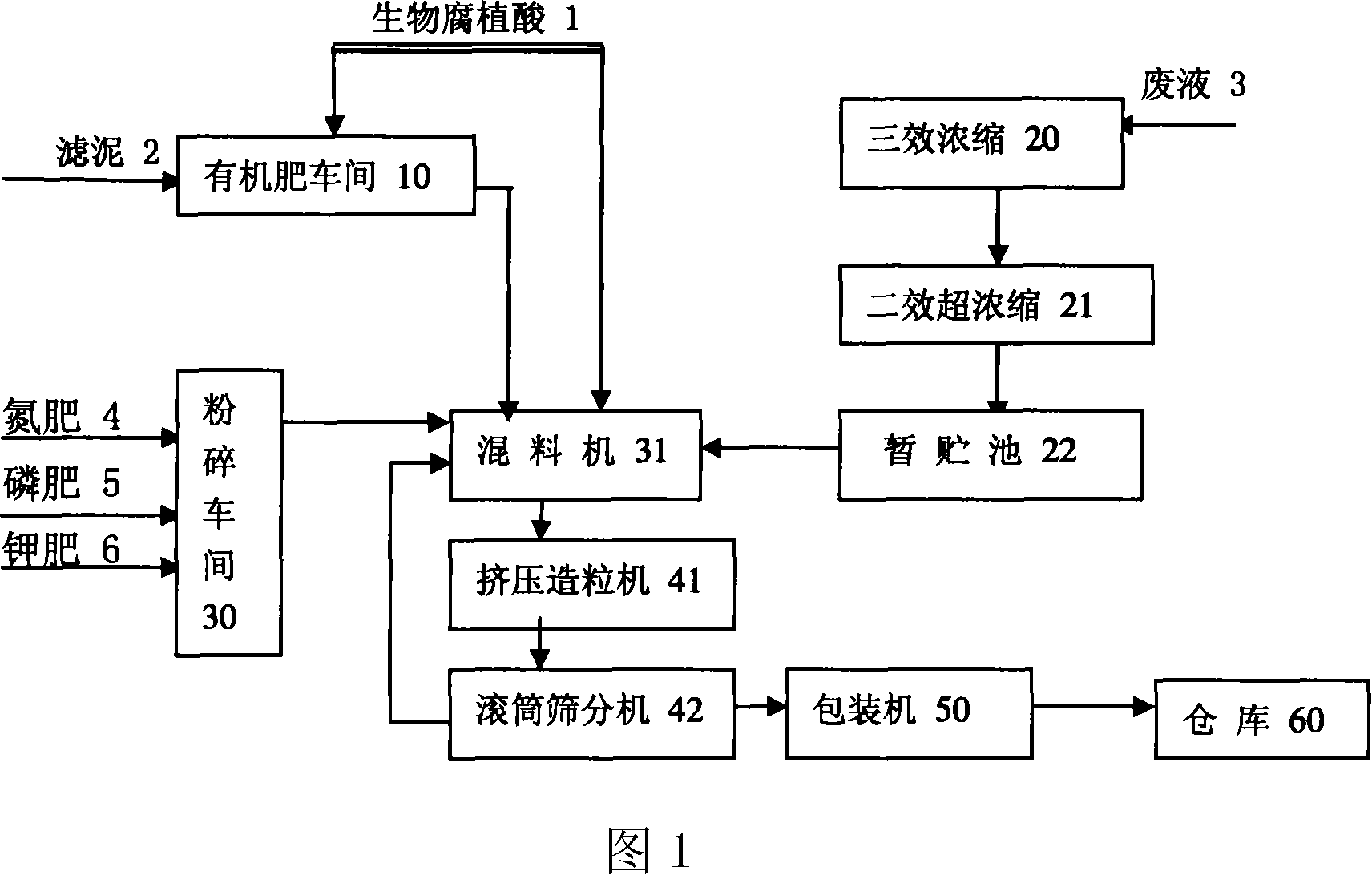

Method of manufacturing organic, inorganic compound fertilizer with molasses zymolysis waste liquor and lime sludge

InactiveCN101108779AImprove efficiencyLow efficiencyBio-organic fraction processingClimate change adaptationLiquid wasteContinuous fermentation

The invention provides a method producing the organic-inorganic compound fertilizer by the molasses fermentation waste liquor and the lime sludge, which relates to a method producing the fertilizer through fermentation and solves the problem of reclaiming and processing the molasses fermentation waste liquor continuously on a large scale. The method of the invention is that the biological humic acid with weight per cent of 0.4 per cent to 0.6 per cent and made by the bagasse is mixed with the lime sludge of 65 per cent to 68 per cent, bagasse powder of 10 per cent to 12 per cent, wheat bran of 1.5 per cent to 2.5 per cent and regulator of 16 per cent to 25 per cent to ferment fully and continuously in a shorter time. The fermented materials with water of 10 per cent to 12 per cent are gained after opening and drying and are crushed into the lime sludge organic fertilizer. The molasses fermentation waste liquor with water of 90 per cent is condensed to the hyperconcentration liquor with water of 26 per cent to 28 per cent by the three-effect forced circulating concentration system and then through the two-effect scraping and steaming hyperconcentration system. The hyperconcentration liquor of 30 per cent to 33 per cent and the biological humic acid of 9 per cent to 10 per cent are stirred and mixed uniformly based on the weight per cent and are added with the fertilizer of 32 per cent to 34 per cent and the lime sludge organic fertilizer of 25 per cent to 27 per cent to stir to produce the organic-inorganic compound fertilizer through dry extrusion and prilling.

Owner:越百年创新肥业(海南)有限公司

Starter Cultures and Fermentation Method

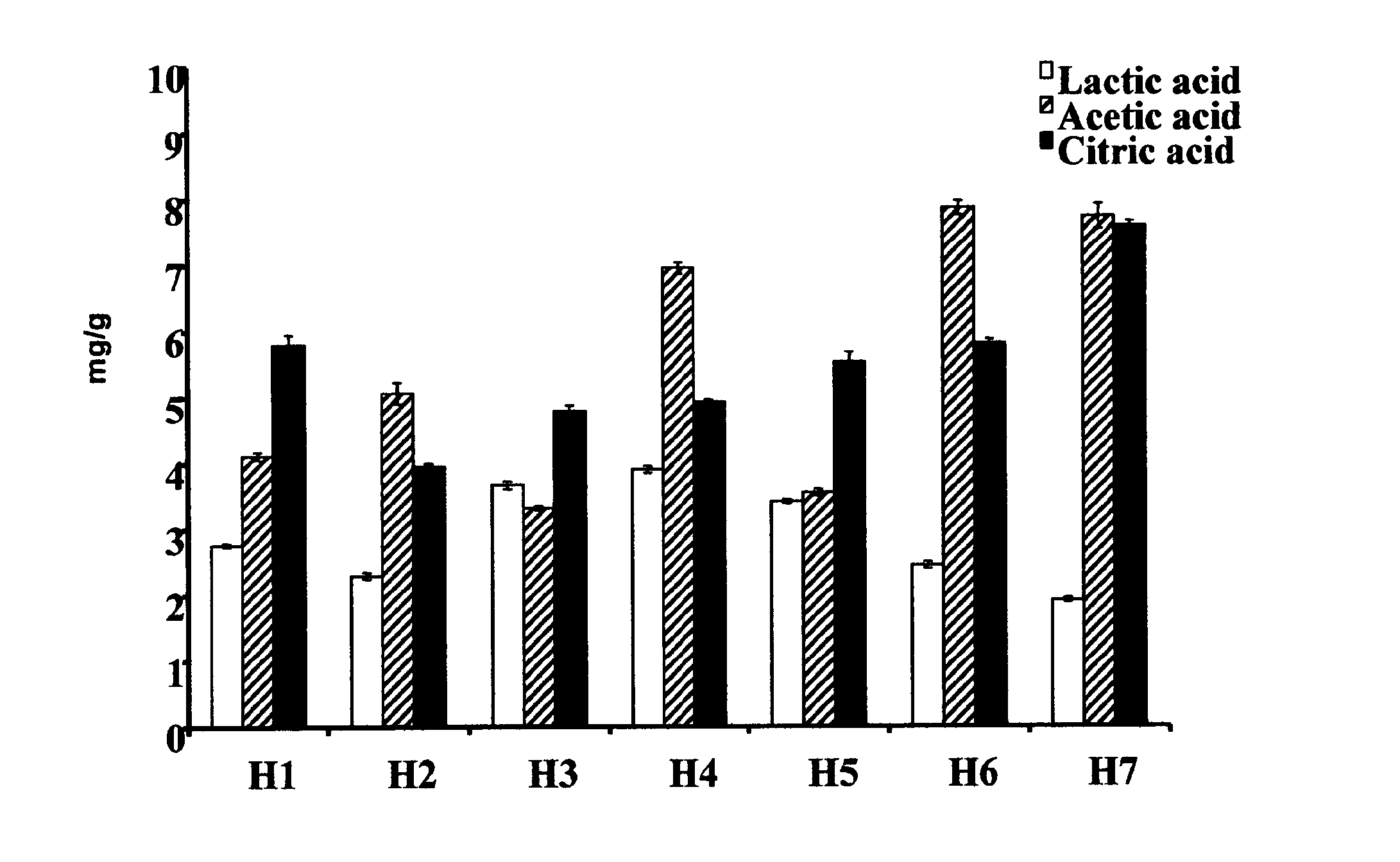

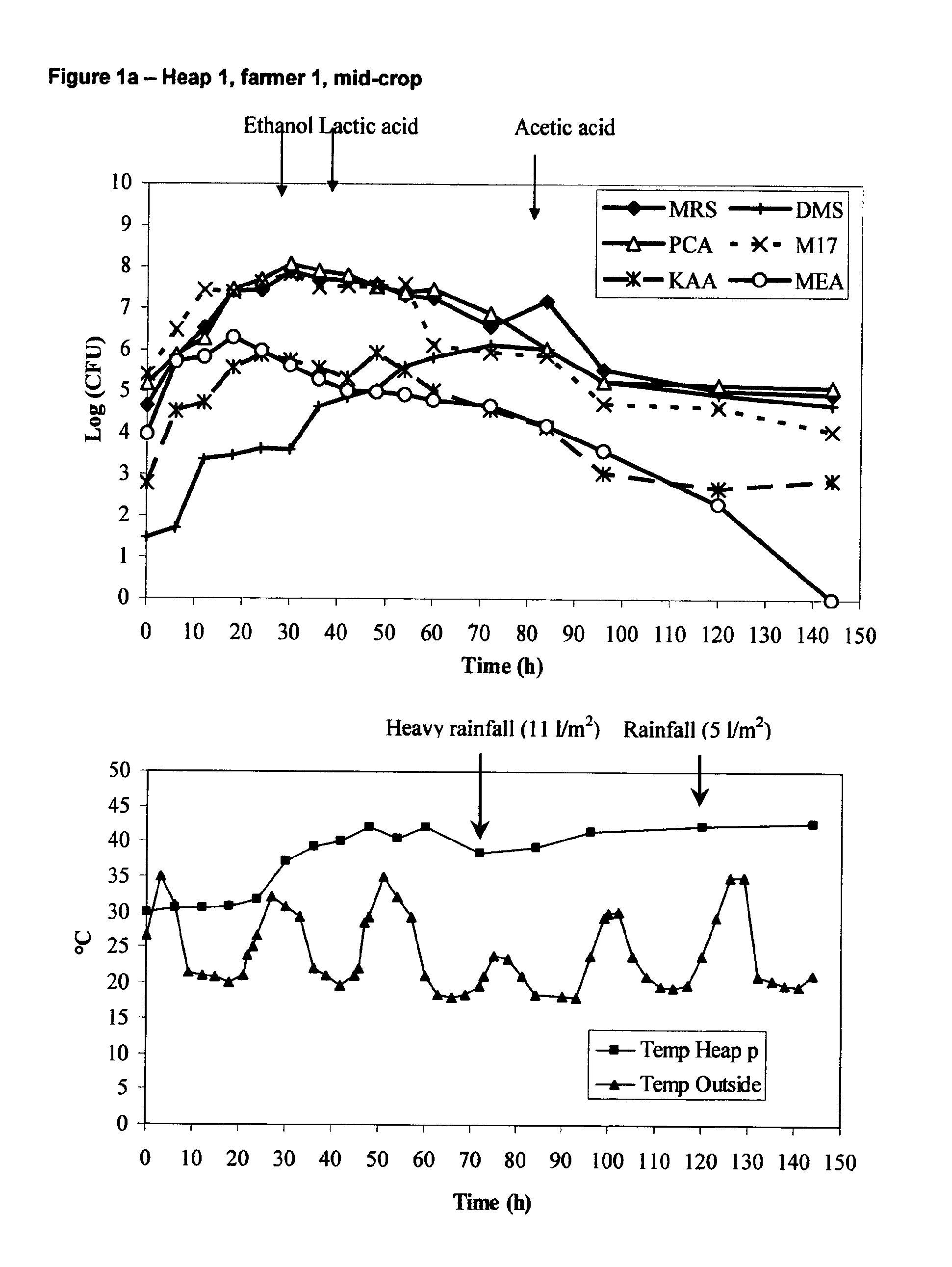

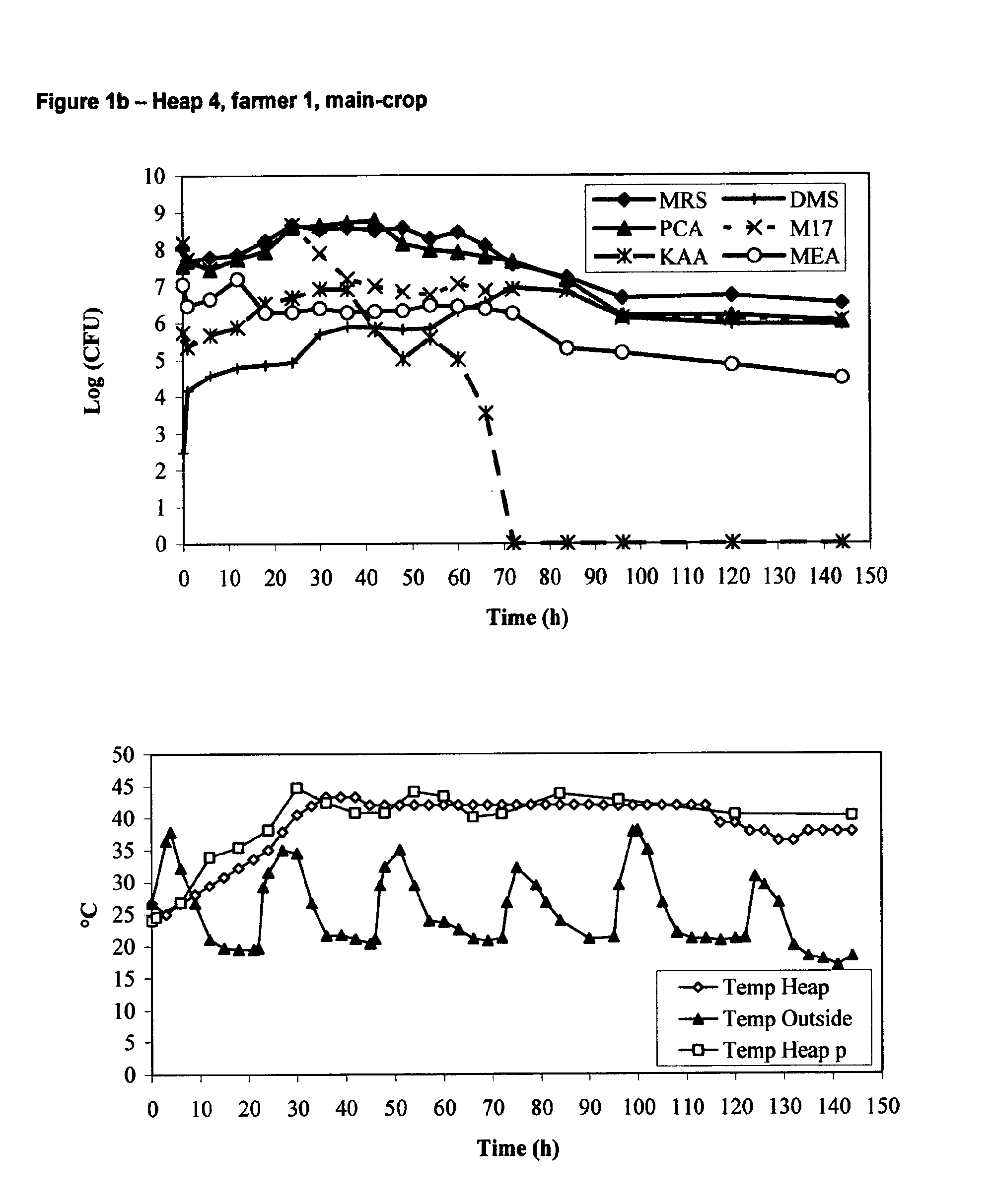

A method for regulating fermentation of organic material, such as cocoa beans and pulp is disclosed. The method includes adding at least one strain of lactic acid bacteria and / or acetic acid bacteria to the organic material. Optionally, at least one strain of yeast is added. Bacterial strains and compositions, useful in the described method, are also disclosed. The use of the described starter cultures and compositions permits faster fermentation, fermentations with targeted population dynamics and succession of microorganisms, and fermentations with targeted levels of both desirable and undesirable metabolites.

Owner:BARRY CALLEBAUT +1

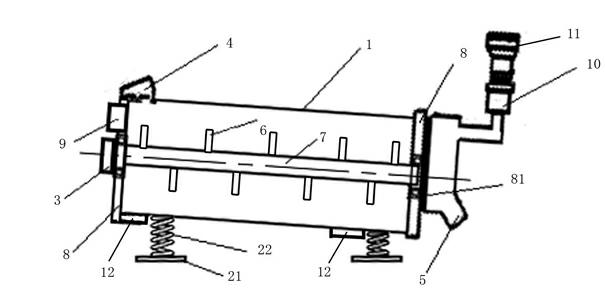

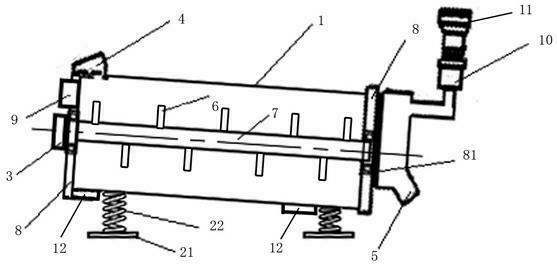

Stationary type organic material fermentation machine and fermentation technology thereof

InactiveCN102674921AGood effectHigh yieldBio-organic fraction processingAnimal corpse fertilisersContinuous fermentationMotor drive

The invention relates to a stationary type organic fertilizer fermentation machine. The stationary type organic fertilizer fermentation machine comprises a substrate, a fermenter, a motor, an electric cabinet, an air purifier and microwave electromagnetic heaters; the two ends of the fermenter are fixedly erected on the substrate; the motor is electrically connected with the electric cabinet; a rotating shaft is arranged on the motor; the rotating shaft is a hollow pipeline and is provided with an air outlet; the rotating shaft is penetrated through the middle part of the fermenter; a plurality of blades which are forwards slantwise are extended on the rotating shaft; the motor drives the rotating shaft to rotate so that the blades fixed on the rotating shaft drive organic materials to synchronously rotate along with the blades and push the organic materials forward from the front end to the back end; the air purifier is positioned at the upper part of the back end of the fermenter; and the two microwave electromagnetic heaters are respectively arranged at the two ends of the bottom of the outer wall of the fermenter. The stationary type organic fertilizer fermentation machine realizes the continuous fermentation of organic fertilizers, is high-efficiency and energy-saving, has strong practical applicability, strong adaptability and more complete functions and can be matched with the traditional bacterial agents. The stationary type organic fertilizer fermentation machine can adapt to multiple raw materials and the mixture of raw materials with different moisture contents as well as multiple climatic environments.

Owner:广州万吉生物科技有限公司

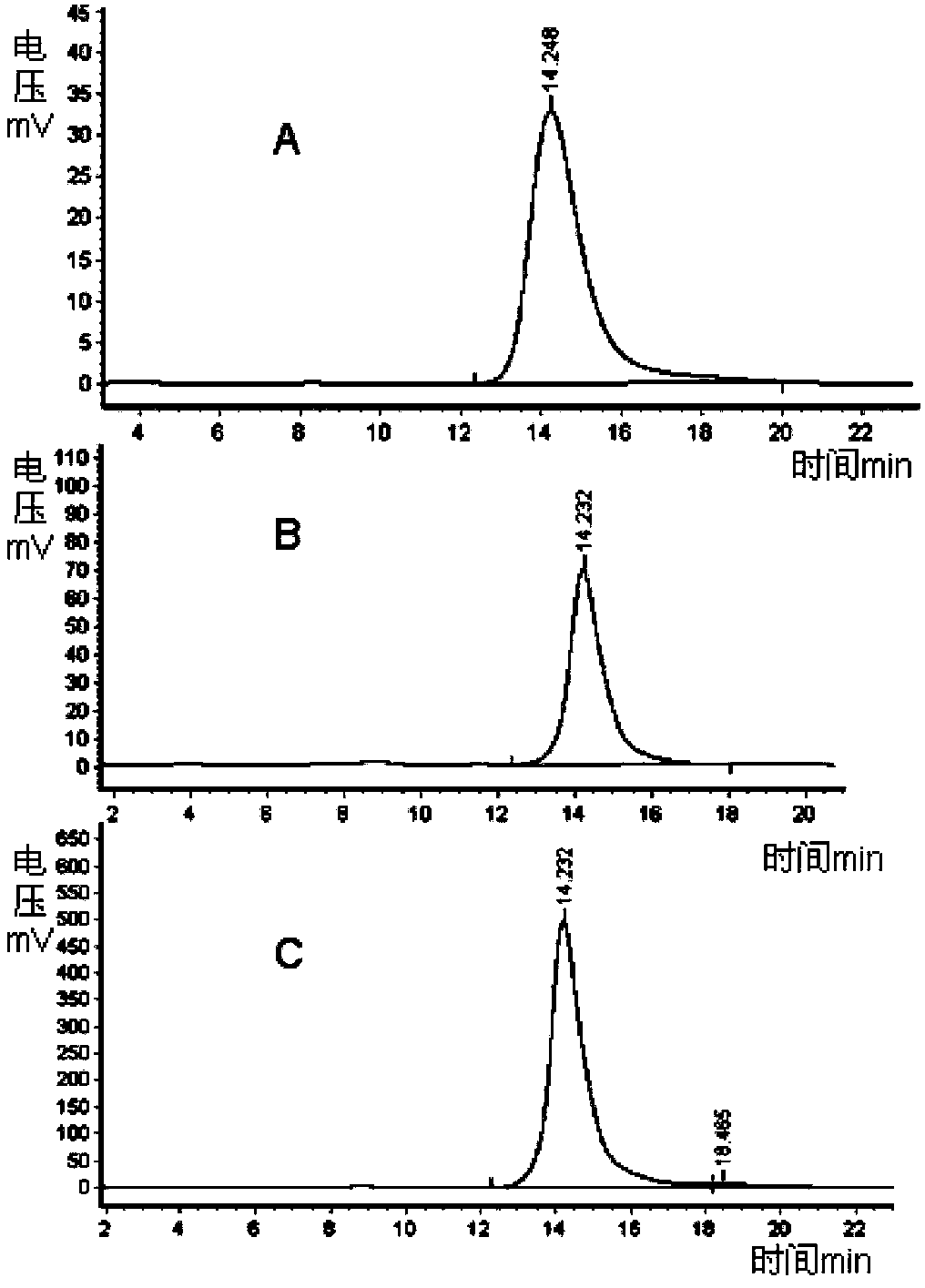

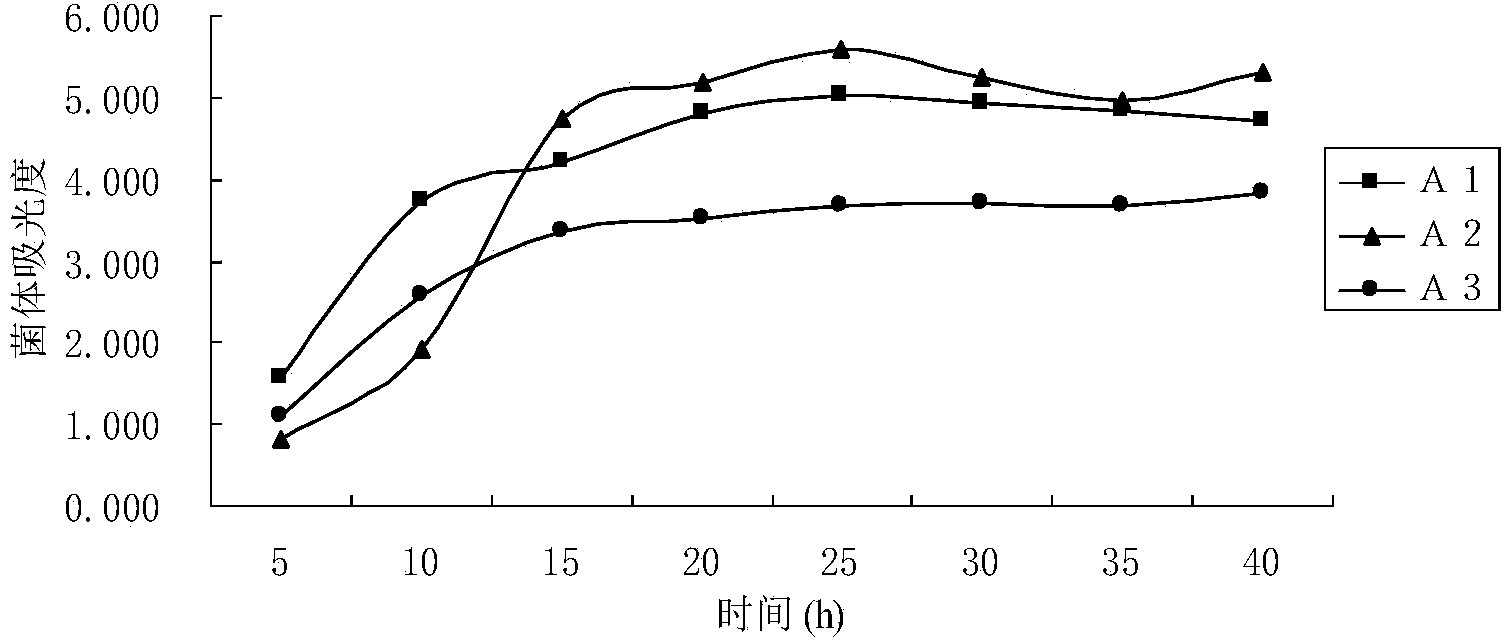

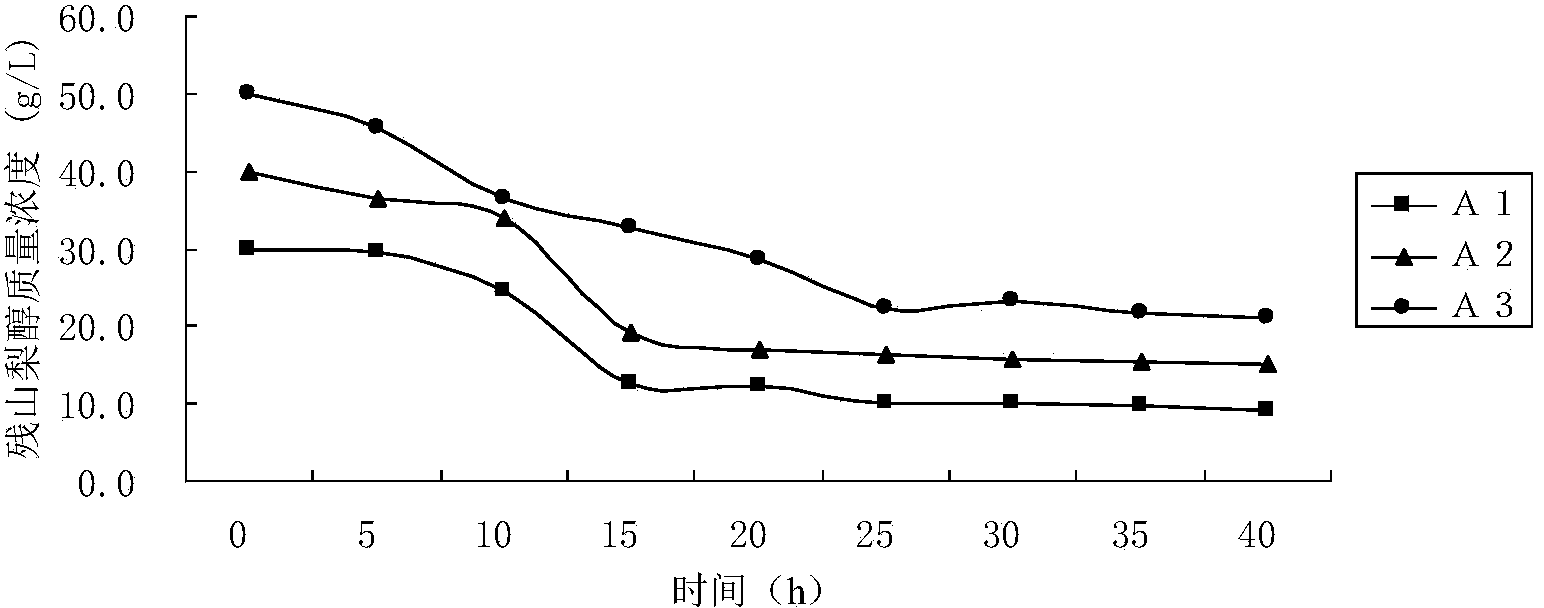

Yarrowia lipolytica strain and method thereof for synthesizing erythritol

ActiveCN103374534AHigh ability to synthesize erythritolImprove conversion rateFungiMicroorganism based processesContinuous fermentationInorganic salts

The invention discloses a yarrowia lipolytica strain and a method thereof for synthesizing erythritol. The yarrowia lipolytica strain is yarrowia lipolytica BLC13 CGMCC NO. 7326. The method for synthesizing the erythritol by the yarrowia lipolytica strain comprises the following steps of: taking a carbon source with an initial fermentation concentration of 100-400g / L, a nitrogen source with an initial fermentation concentration of 2-35g / L and inorganic salt as raw materials, treating for 30 minutes at 80-90 DEG C, cooling down and subsequently inoculating the yarrowia lipolytica strain, carrying out continuous fermentation or in-batch fed-batch fermentation under an aerobic condition, and after the fermentation is accomplished, purifying the erythritol from a fermentation liquid. The yarrowia lipolytica strain disclosed by the invention is used for synthesizing the erythritol from glucose, the conversion rate is high, and the Chinese erythritol standard is met.

Owner:SHANGHAI JIAO TONG UNIV +1

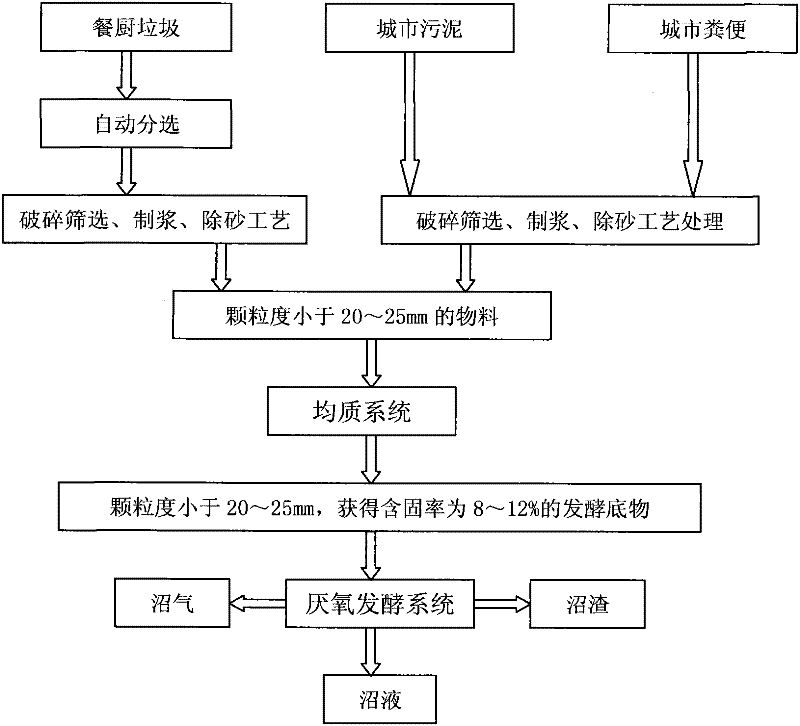

A method for preparing biogas from kitchen waste, urban sludge and urban excrement

InactiveCN102286541AFully fermentedOvercoming the deficiency of high energy consumption in high temperature fermentationWaste based fuelFermentationParticulatesFeces

A method for preparing biogas by joint anaerobic fermentation of food waste, urban sludge and urban excrement, comprising the following steps: (1) pretreatment system: food waste, urban sludge and urban excrement undergo a pretreatment process to obtain granules (2) homogeneous system: the materials processed in step (1) enter the homogenizing tank one after another, mix evenly and degrade part of the suspended matter, so that the particle size of the solid material is less than 20-25mm, and obtain Fermentation substrate with a solid content rate of 8 to 12%; (3) anaerobic fermentation system: the fermentation substrate treated in step (2) is transported to an anaerobic fermentation tank by a pump and adopts a continuous fermentation process and a mesophilic anaerobic fermentation The anaerobic fermentation method combined with jet stirring produces biogas, biogas residue and biogas slurry. The combined anaerobic fermentation preparation method of the present invention has the effects of complete material fermentation and high gas production rate.

Owner:ZHONGCHENG HONGTIAN BEIJING ENVIRONMENT TECH DEV

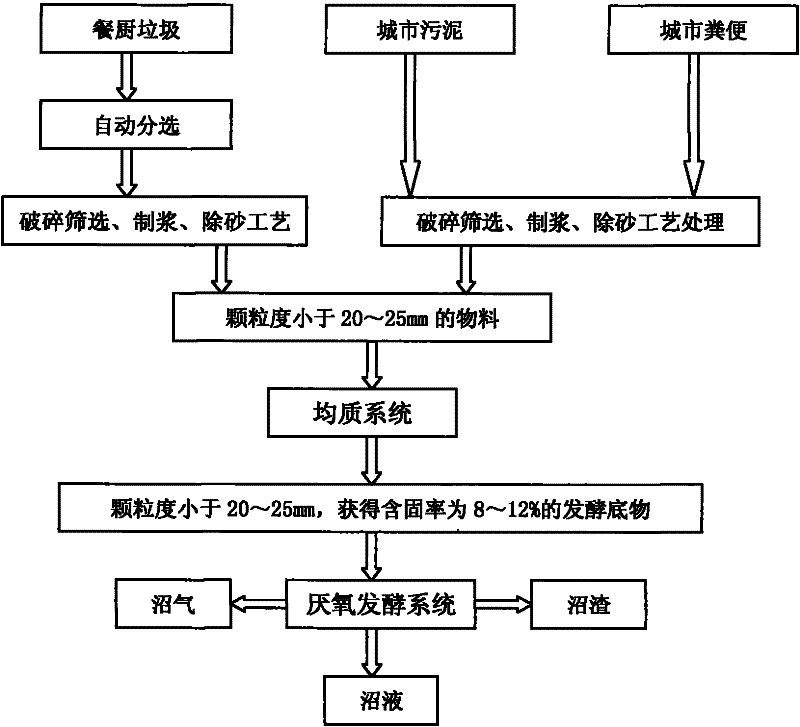

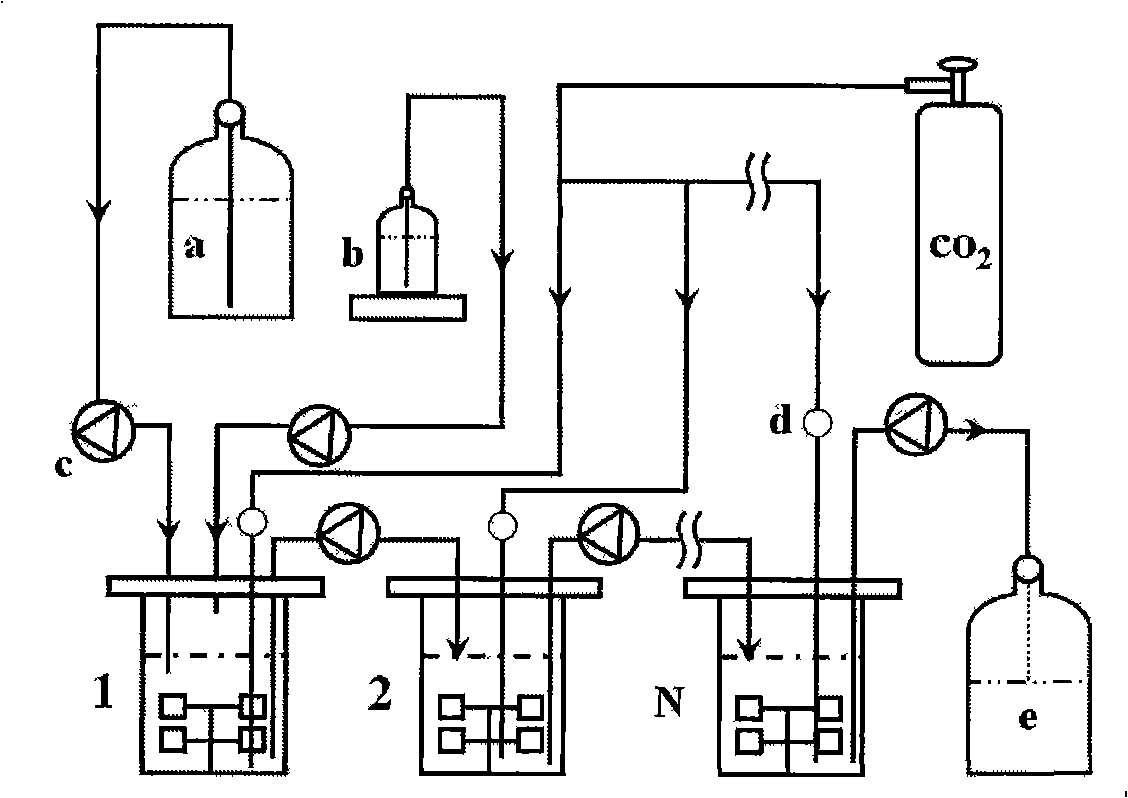

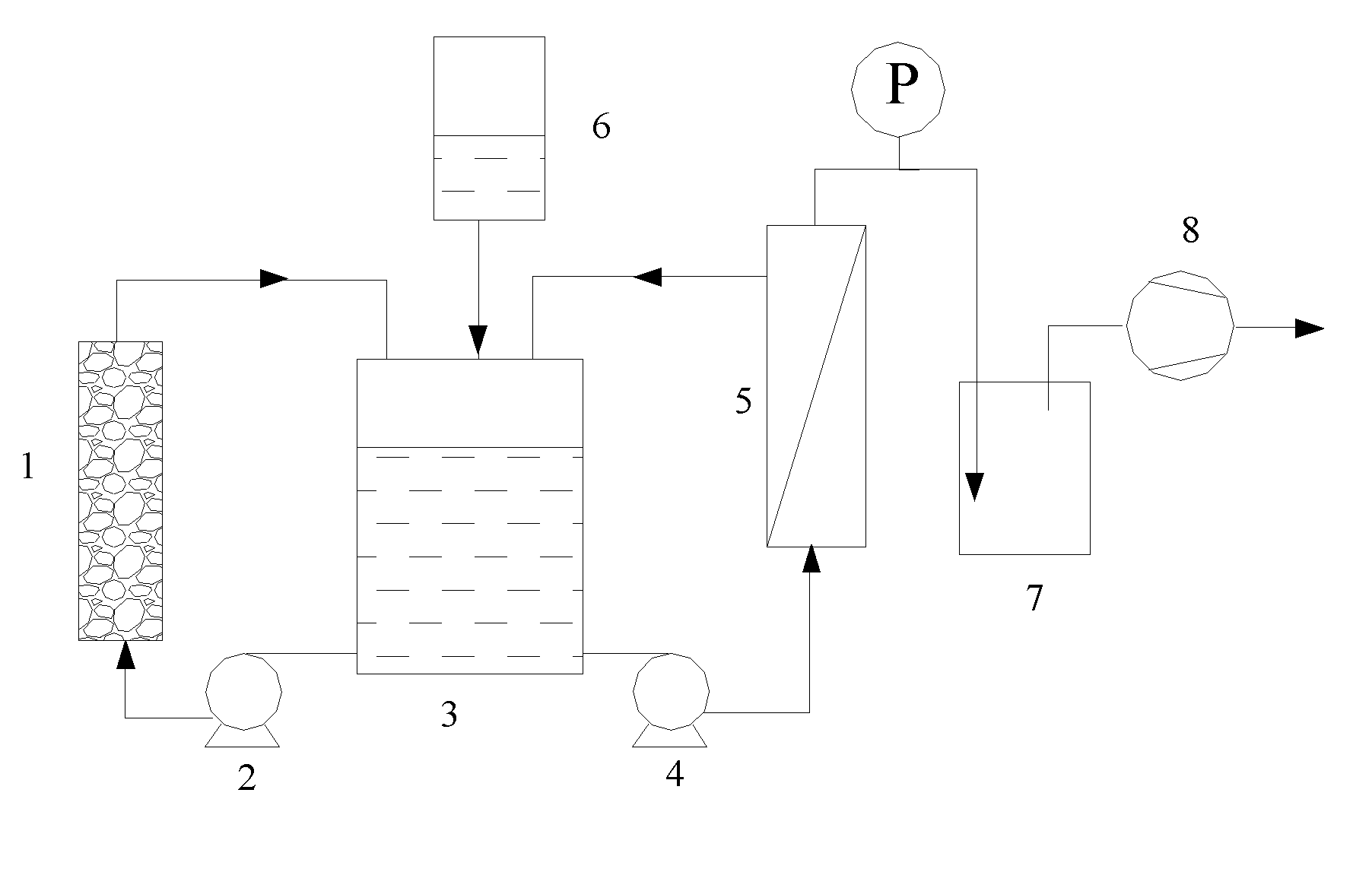

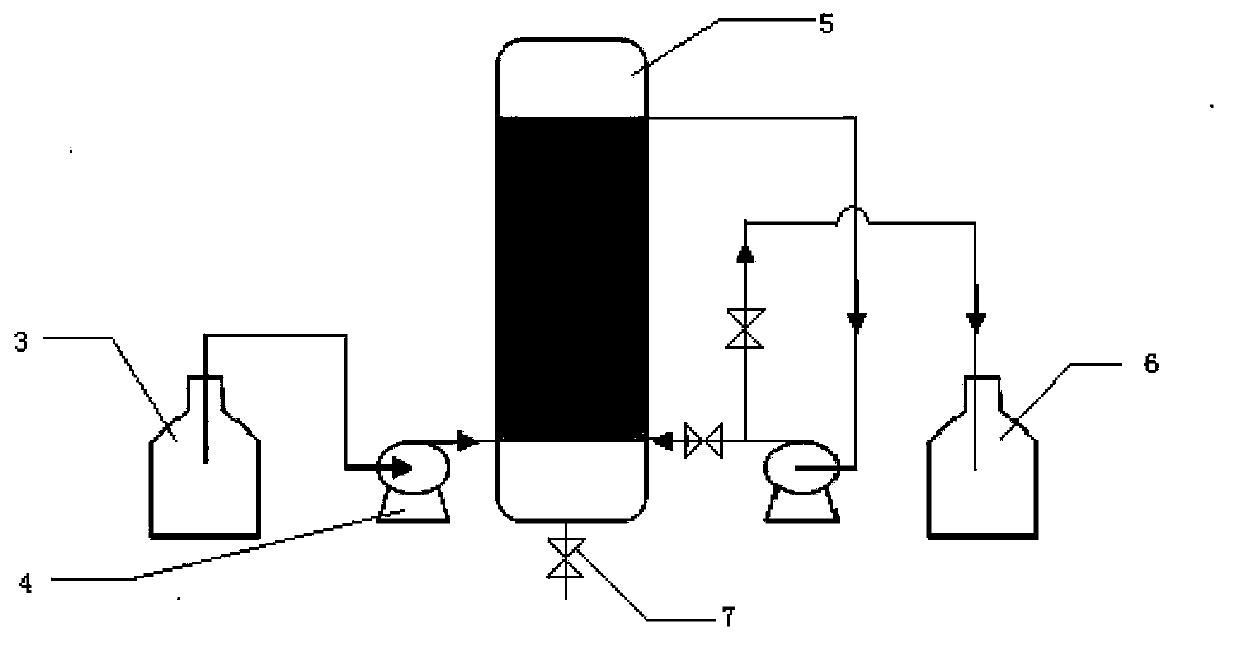

Method for preparing succinic acid by coupling fermentation and film separation unit

InactiveCN101215583AAchieve separationAchieve enrichmentMicroorganism based processesFermentationContinuous fermentationMetabolite

The invention discloses a process for preparing succinic acid through coupling fermentation and membrane separation units, the process for preparation comprises following steps: firstly, inoculating fermentation seeds of bacteria strains which produce the succinic acid into a fermentation tank to culture, then, coupling microfiltration or ultrafiltration membrane separation units with the fermentation tank to realize semi-continuously or continuously preparing the succinic acid with fermentation, separating out part of fermentation liquor, releasing from the control of metabolites, returning somatic cells and components which are cut off by the membrane separation units back into the fermentation tank and continuingly fermenting, continuingly using substrate which is not consumed in the fermentation liquor which is nanofiltrated, reclaimed, and separated to ferment, and simultaneously adding the fermentation culture medium to keep the volume of the fermentation liquor in the fermentation tank constant. The invention not only can release from the control of the metabolites and increase the production strength of the succinic acid, but also uses reducing sugar which is not consumed in the liquor which is nanofiltrated, reclaimed, and separated, simultaneously concentration is available, the technical condition is moderate, environmental pollution is little, which is easy to control automatically and has wide social and economic benefits.

Owner:NANJING UNIV OF TECH

Method and device for improved fermentation process

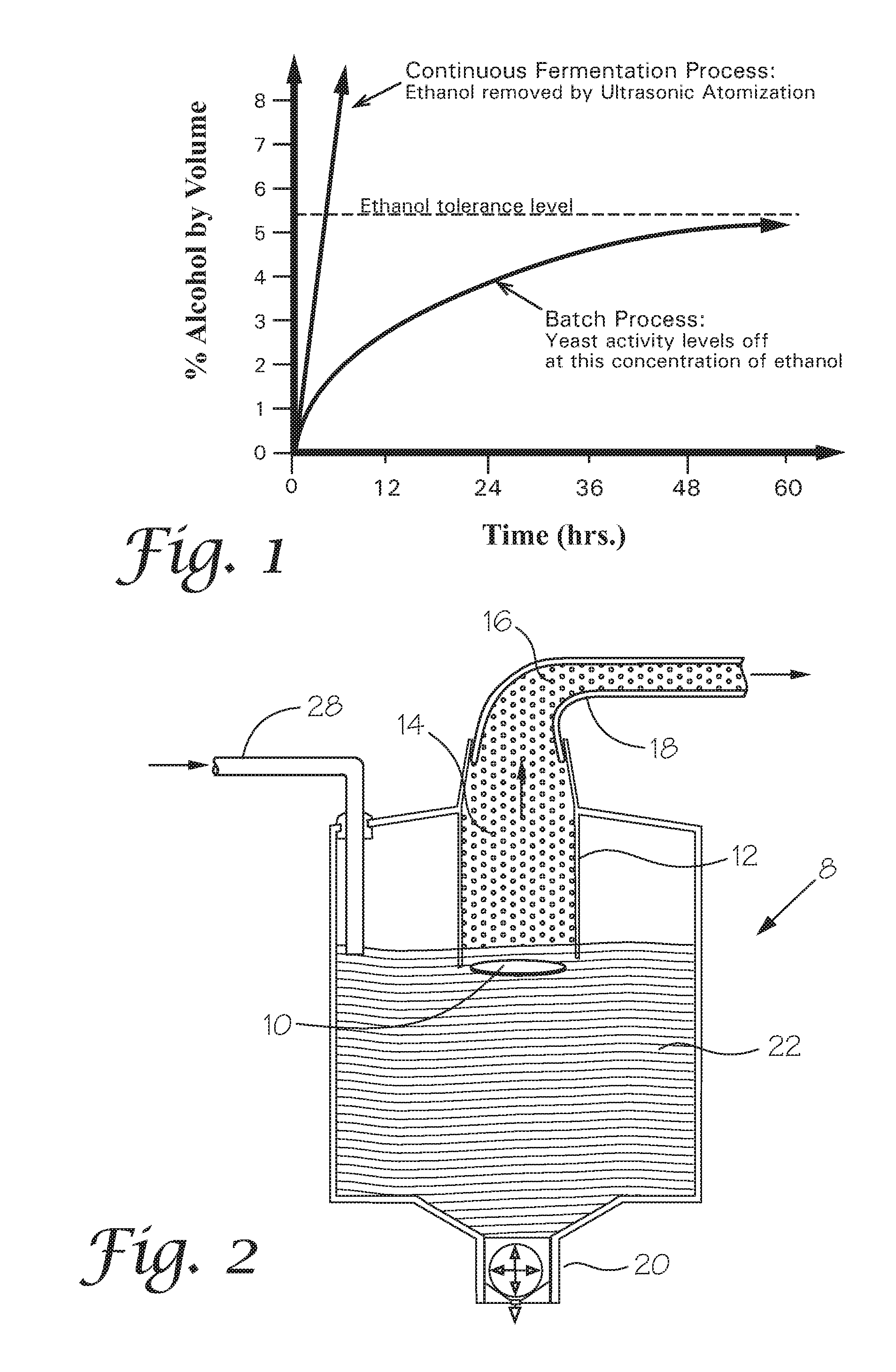

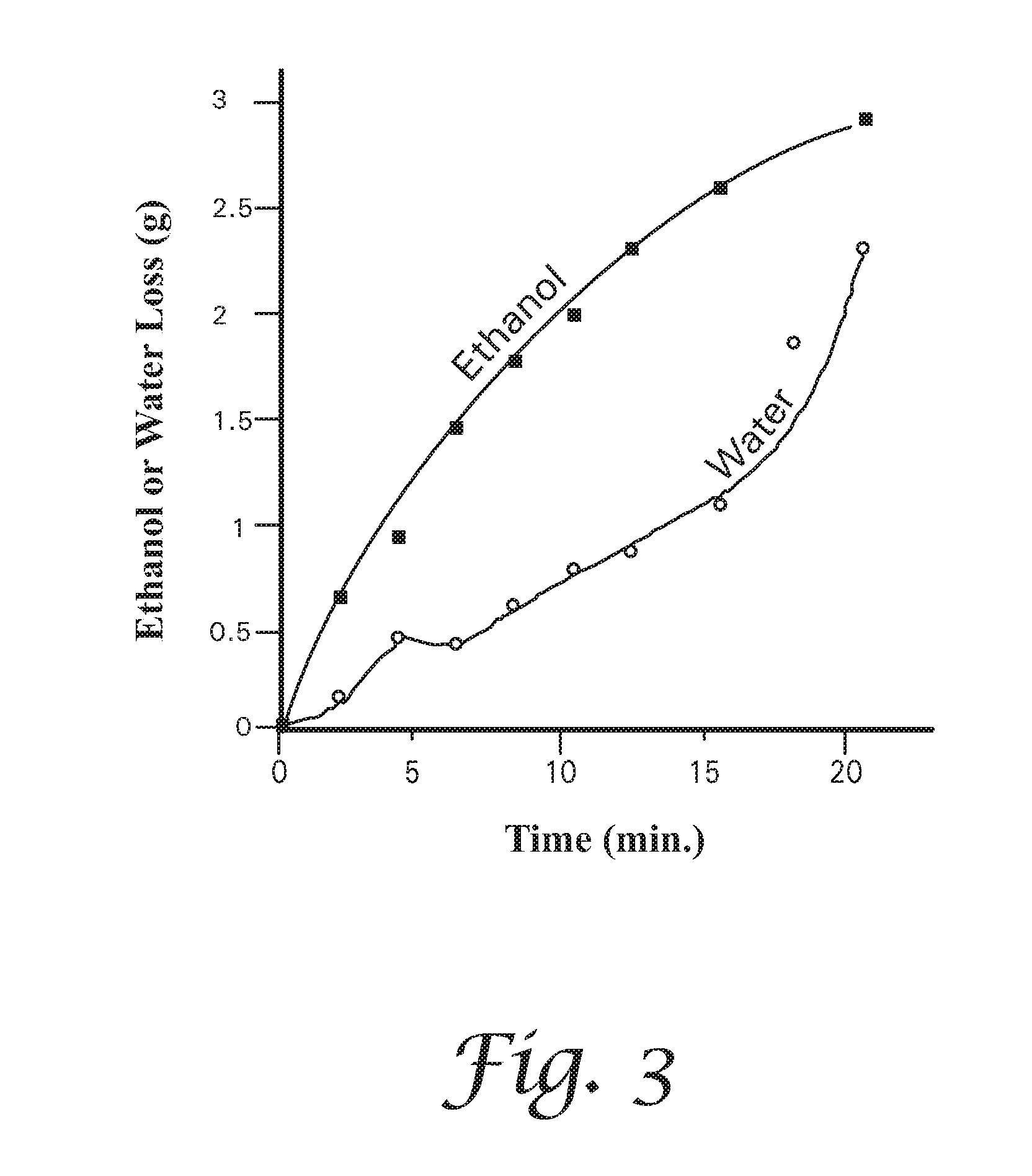

InactiveUS20070193874A1Prevents exceeding ethanol toleranceSpeed up the processFermented solutions distillation/rectificationBiofuelsContinuous fermentationDistillation

An improved method and device is accomplished for ethanol production using an in-line extraction of ethanol by ultrasonic atomization, thereby removing the effect of the ethanol inhibition factor that adversely affects the rate and yield. The in-line removal of ethanol as it is formed increases the fermentation rate, improves the yield and uses 20-25% of the energy required as compared to thermal distillation processes currently used. The improved method makes sure that ultrasonic vibration does not deactivate enzymes to any significant level. The elimination of the effect of the ethanol inhibition factor allows for a continuous fermentation process as opposed to the costly, time-consuming repeated batch processes.

Owner:ADIGA KAYYANI C +1

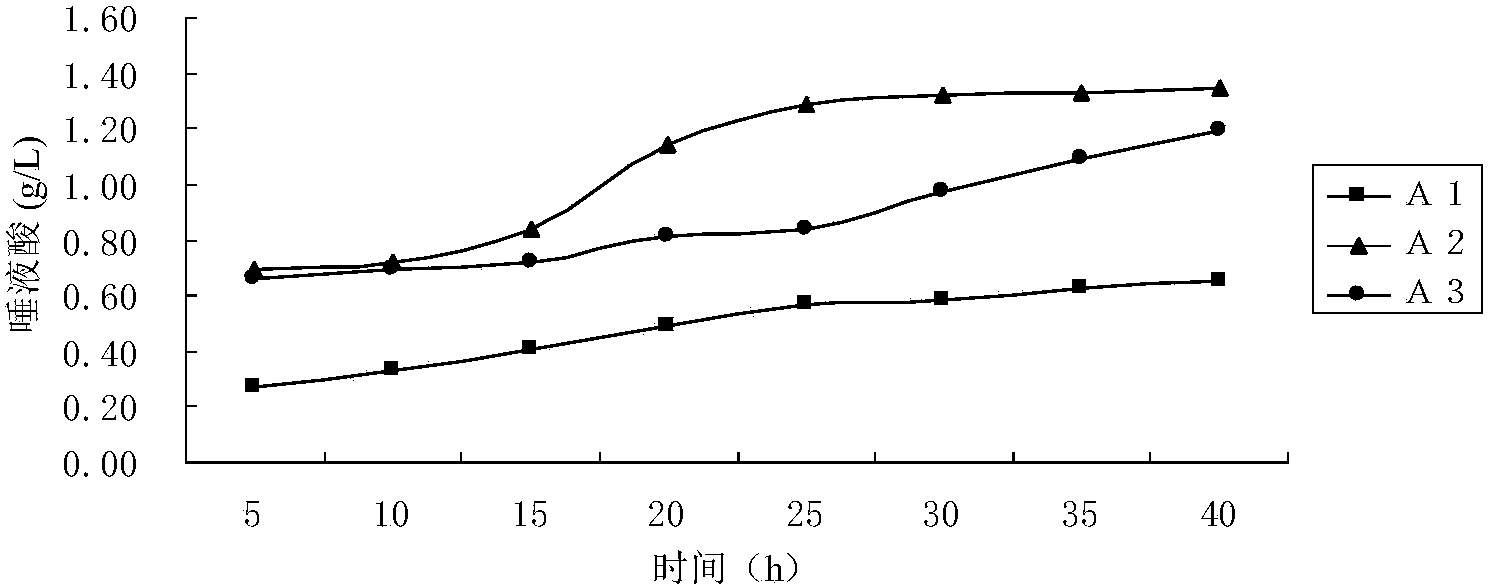

Fermentation production method of sialic acid

The invention discloses a fermentation production method of sialic acid and belongs to the technical field of bioengineering. The method comprises the following steps: adding a seed liquid into a fermentation tank containing a sterilizing fermentation culture medium; continuously fermenting to produce fermentation liquid containing polysialic acid in a way of replenishing feeding liquid and a hydrogen dioxide solution; then carrying out centrifugal separation, ethanol precipitation and filtration to obtain refined polysialic acid; then, carrying out acidolysis and crystallization on the polysialic acid; and finally, washing and freeze-drying to obtain sialic acid powder. The output of the polysialic acid produced by the method provided by the invention can reach 12.96g / L, the already reported maximum content of the polysialic acid is improved by 87.28%, the hydrolysis rate of polysialic acid is 95%, the content of purified sialic acid reaches 10.01g / L and the purity reaches 94.80%. The method is suitable for industrial promotion and application.

Owner:NORTHEAST AGRICULTURAL UNIVERSITY

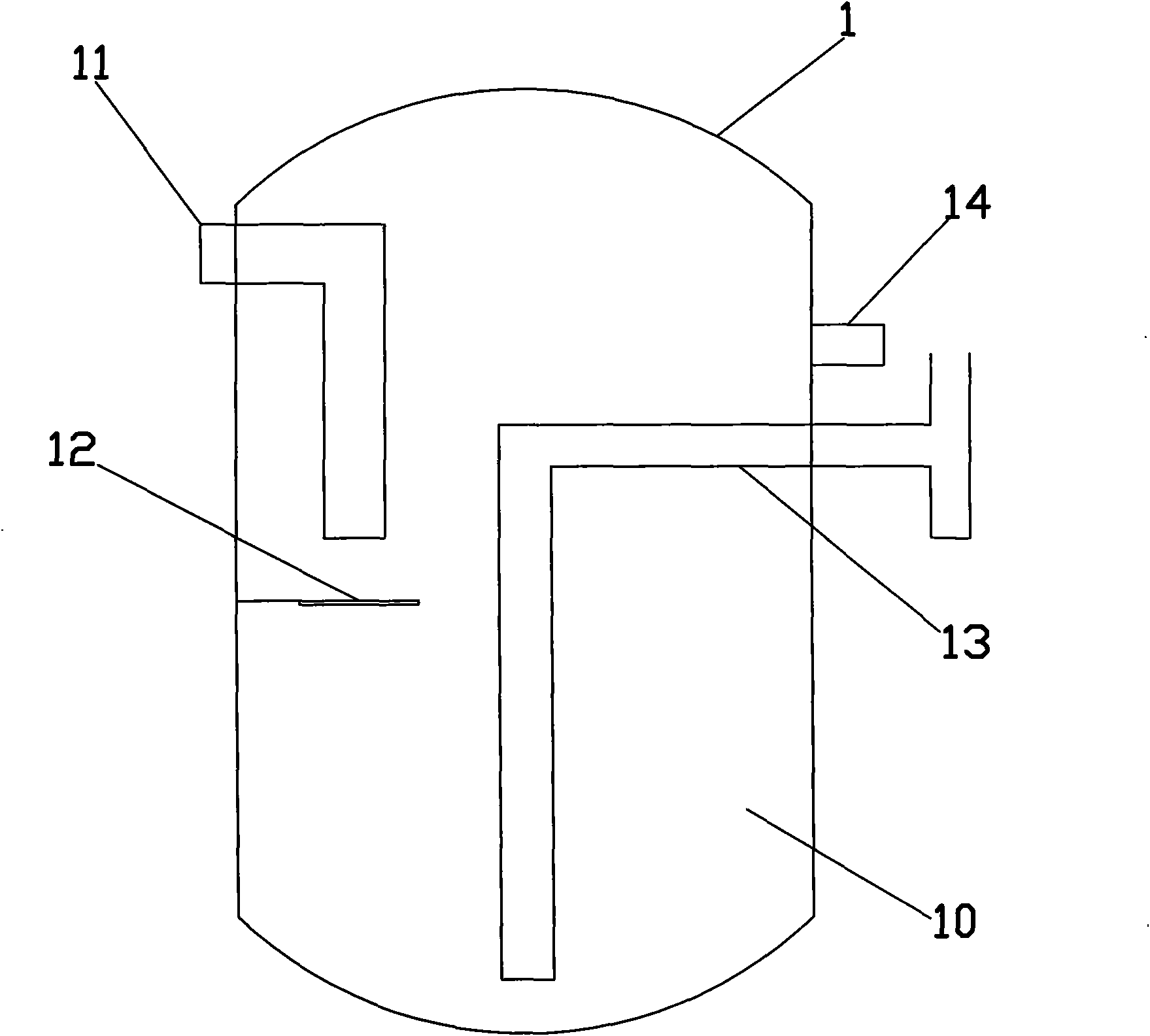

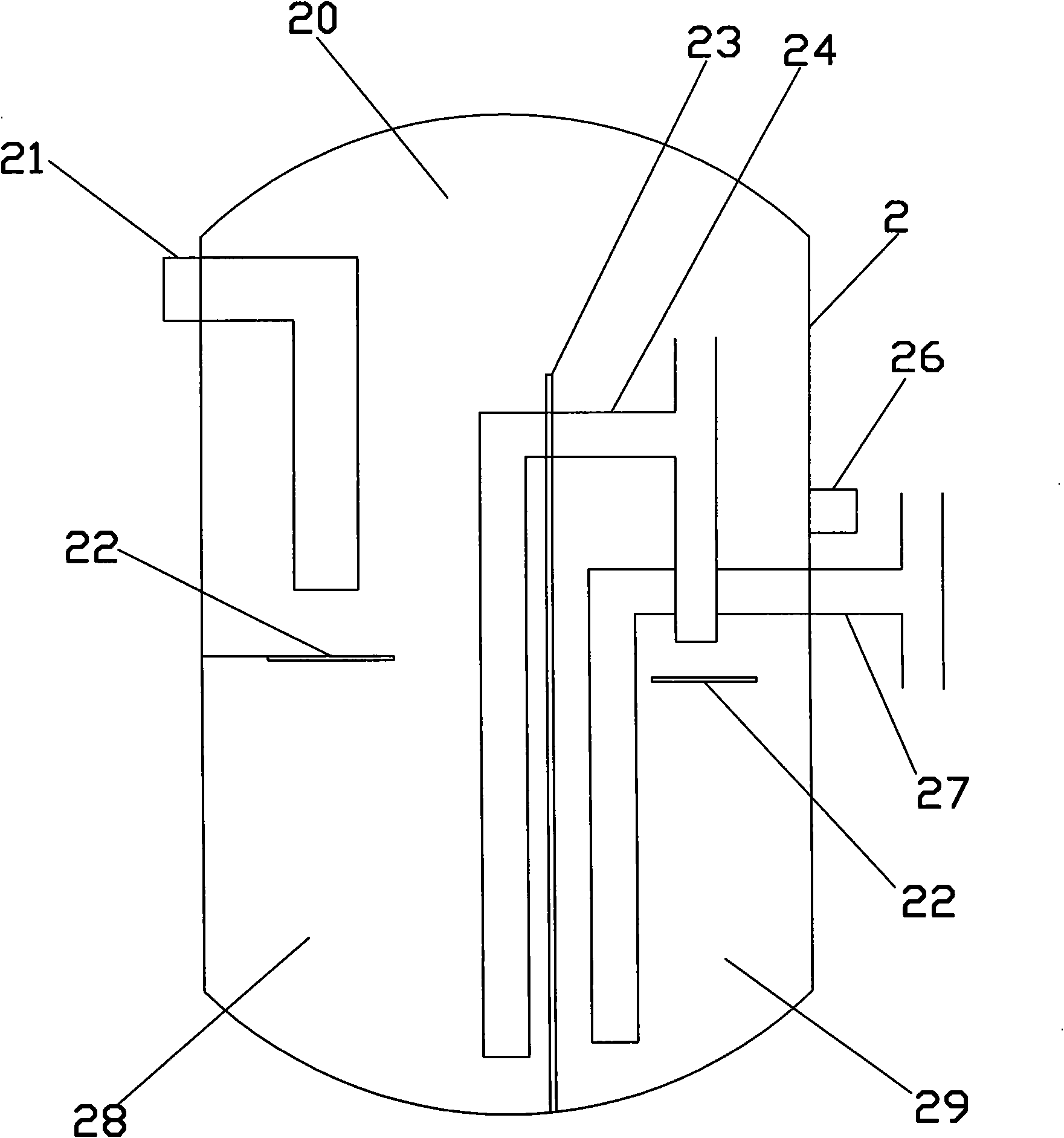

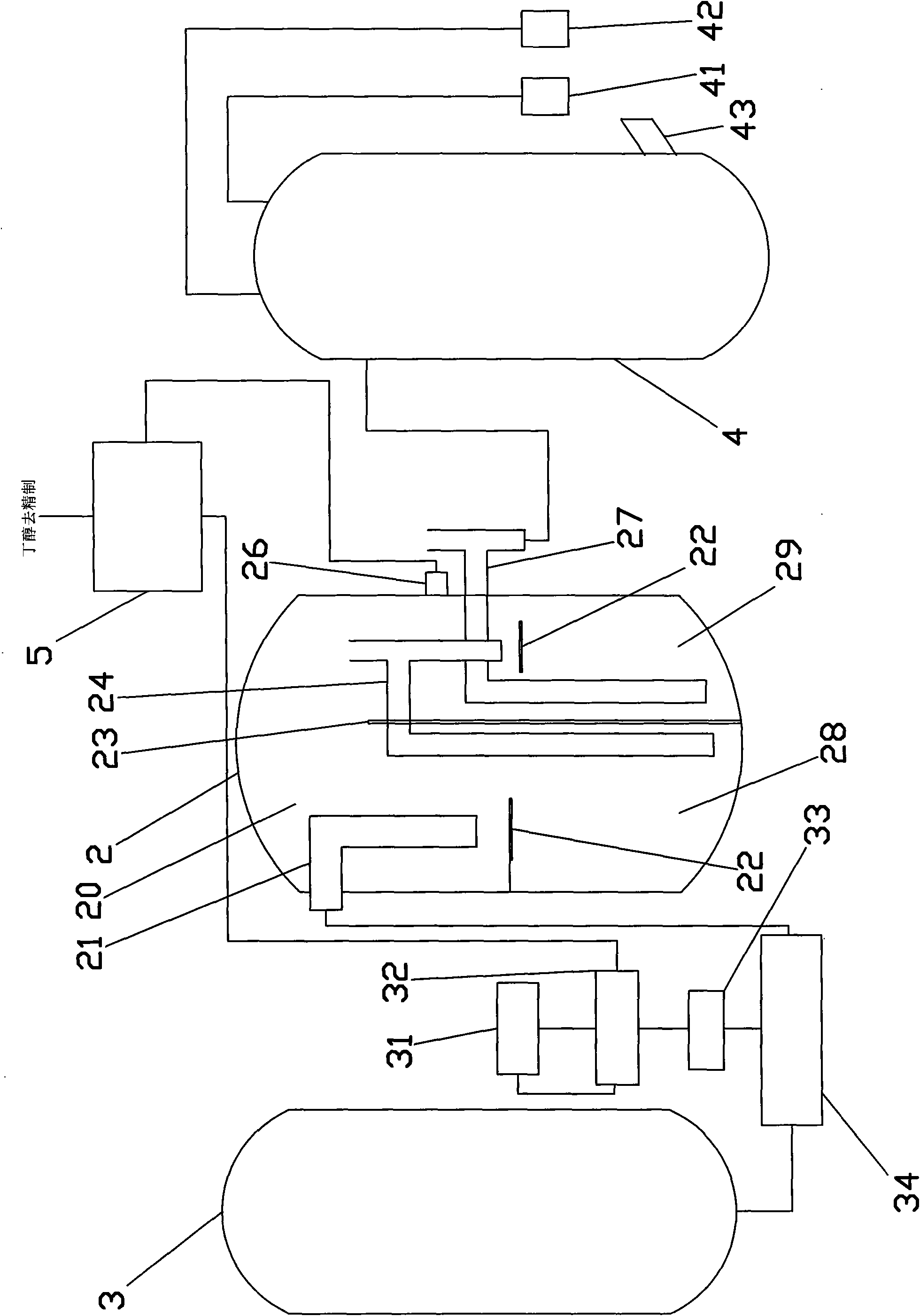

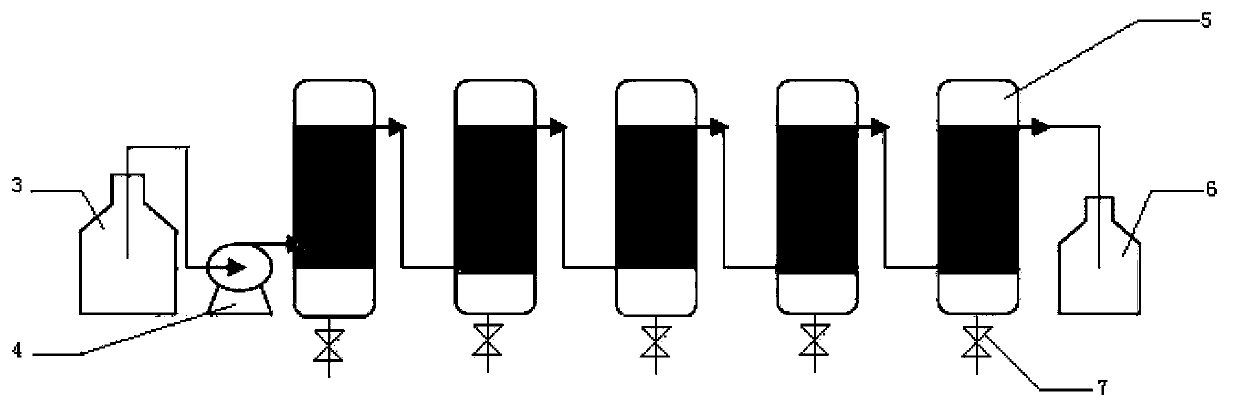

Method and device for producing biological butanol by continuous extraction and fermentation

InactiveCN101787378AAchieve separationIncrease productionOrganic compound preparationHydroxy compound preparationContinuous fermentationWastewater

The invention belongs to the technical field of producing biological butanol by fermentation, which relates to a method and a device for producing the biological butanol by extracting and fermenting starch substances and sugar substances. The method comprises the following steps: discharging fermented liquor from a last fermentation tank; then feeding the fermented liquor into a next fermentation tank for continuous fermentation; adding an extracting agent to be mixed for extracting butanol in the bulking tank and conveying process of feeding the fermented liquor from the last fermentation tank to the next fermentation tank; extracting and separating the butanol generated by the fermented liquor with the extracting agent; and feeding the fermented liquor separated from a mixture of the extracting agent and the butanol into the next fermentation tank for fermentation. The invention realizes the method and the device for producing the biological butanol by the continuous extraction and fermentation. The biological butanol can be produced by a method for continuously adding the extracting agent, continuously separating the biological butanol and continuously supplementing original fermented liquor. The invention can improve the yield of the biological butanol by 3 times to maximum extent, save one second of steam, reduce the discharge of over 60 percent of wastewater and bring considerable economic benefits to enterprises for producing the biological butanol.

Owner:王建设

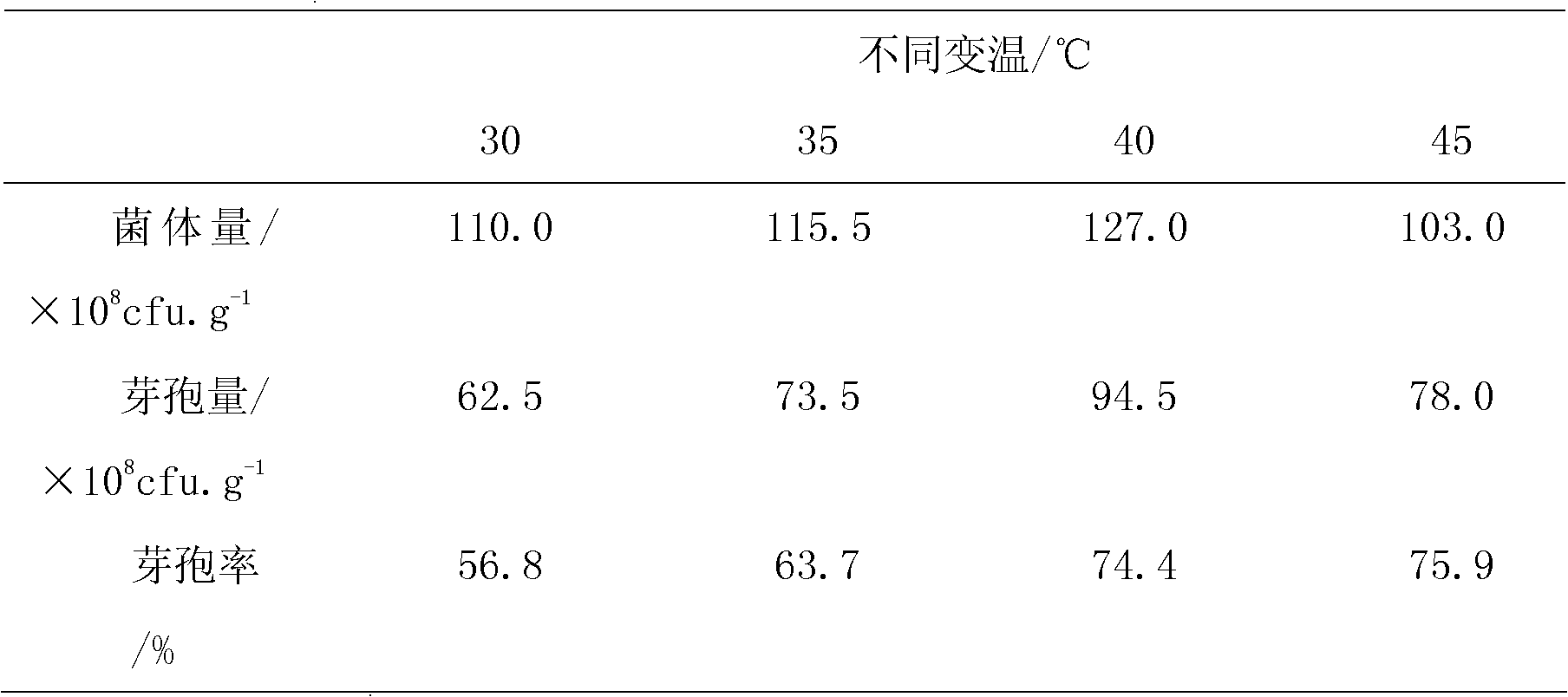

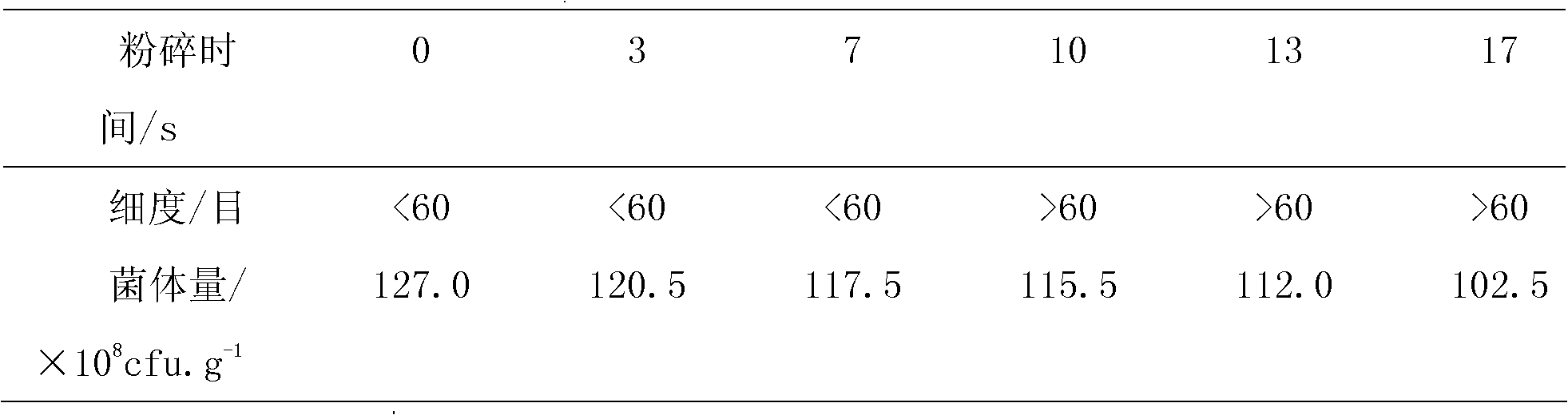

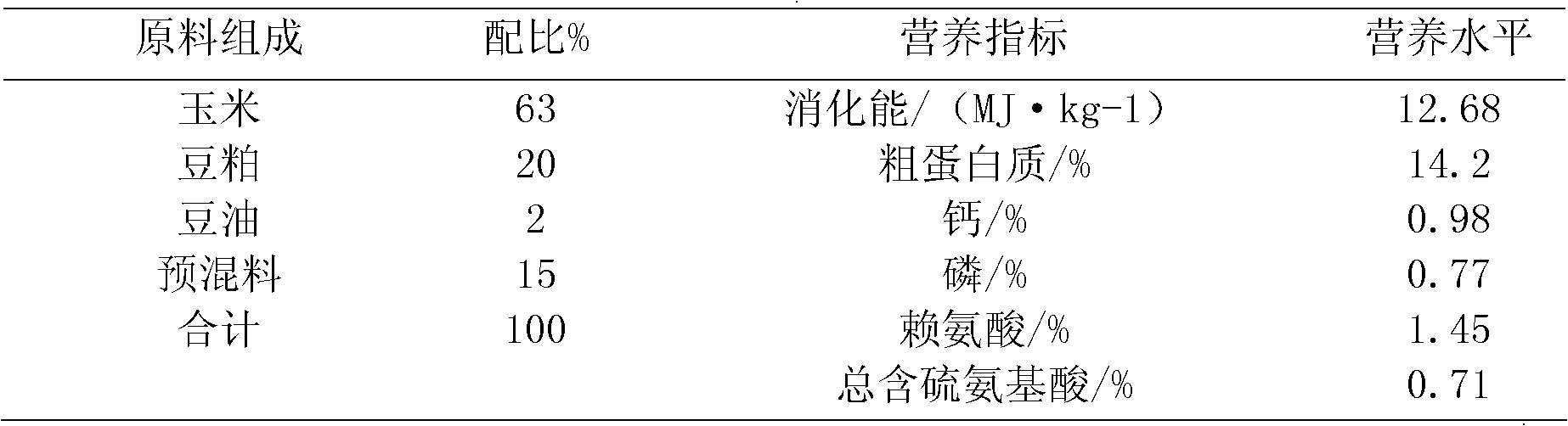

High-density fermenting method of bacillus coagulans for livestock and poultry, as well as preparation prepared by method and application thereof

ActiveCN102505003AIncrease the amount of bacteriaHigh spore rateBacteriaMicroorganism based processesSporeContinuous fermentation

The invention discloses a high-density fermenting method of bacillus coagulans for livestock and poultry, as well as a preparation prepared by the method and application thereof. The strain collection number of the bacillus coagulans is CICC (China Center of Industrial Culture Collection) No.20138. The method comprises the following steps: performing liquid fermentation on the bacillus coagulans;performing solid alternating temperature continuous fermentation; ventilating in later phase of solid fermentation; continuing fermenting and drying, and preparing a bacillus coagulans preparation initial product after the drying is completed; further crushing and screening to obtain a high-density bacillus coagulans preparation final product, wherein the number of strains of the final product is115.5*10<8>cfu.g<-1>, and the spore rate is 77.2%. The product has the effects of increasing the weight and preventing diarrhea of piglet, and the application adding concentration is 0.05wt%. The number of strain preparation is far higher than that of similar strain preparations (20*10<8>cfu.g<-1>) in the market, so that the preparation has wide market competitively in the livestock and poultry breeding industry.

Owner:HUNAN INST OF MICROBIOLOGY

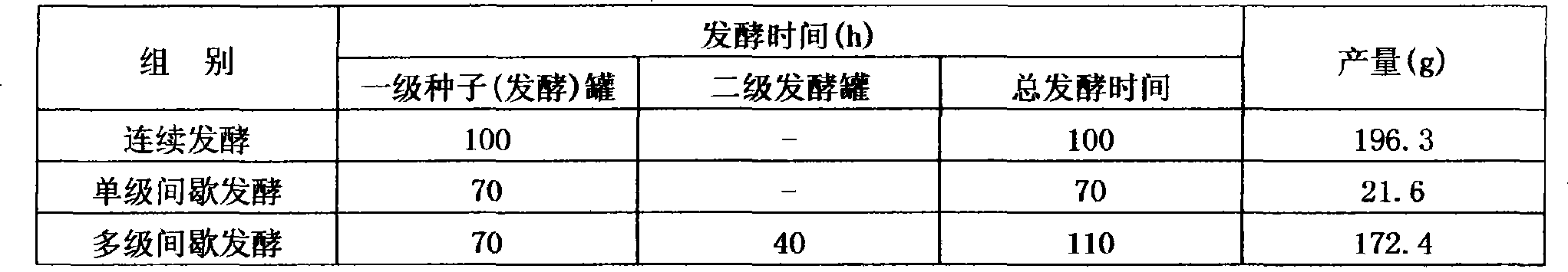

Method for producing amber acid by continuous fermentation or semi-continuous fermentation

InactiveCN101302546AIncrease production intensityLess investmentBacteriaMicroorganism based processesBatch fermentationSweet sorghum

The invention discloses a method for producing butane diacid through continuous fermentation or semi-continuous fermentation, which belongs to the bioengineering technical field. The invention provides application of Actinobacillus succinogenes in the method for continuously or semi-continuously preparing the butane diacid by utilizing carbohydrate raw materials such as cane molasses, corn starch syrup, Jerusalem artichoke hydrolysis syrup, sweet sorghum straw syrup, and lignocellulose hydrolysis syrup and so on. The method utilizes multi-step continuous fermentation or two-step semi-continuous fermentation, which can improve germ concentration and cell activity and can obtain high butane diacid output and high butane diacid production intensity; the method is easy to realize automatic and continuous operation; compared with batch fermentation, the method can save non-fermentation time such as repeated tank cleaning, sterilization and so on, so the production efficiency can be greatly improved; the semi-continuous fermentation for producing the butane diacid is easier to control fermentation parameters than the continuous fermentation, has high sugar utilization rate, target product yield and target product output, has simple and easy equipment and operation, and is suitable for industrialized production.

Owner:JIANGNAN UNIV

Method for preparing ethanol by one-step fermentation after ion liquid stage treatments from native cellulose material

InactiveCN101298620AAchieve full utilizationReduce accumulationBiofuelsMicroorganism based processesHigh concentrationNatural fiber

The invention relates to a method that prepares ethanol through the grading processing with ionic liquids and one-step zymolysis and utilizes a raw material of native cellulose. The raw material of native cellulose is orderly processed by the ionic liquids A and B so as to respectively remove hemicellulose and lignin, and the obtained cellulose is used as a substrate so as to be further fermented to prepare the ethanol; the ionic liquid A is an acid or alkalic ionic liquid, the ionic liquid B is a halogenated-imidazole-like ionic liquid. The method utilizes the ionic liquids to implement the grading processing of the raw material of native cellulose, removes the substances of the hemicellulose and the lignin that are harmful to the zymolysis production of the ethanol, uses the substances for other purposes, and only utilizes the cellulose as the substrate so as to implement the ethanol zymolysis, thus realizing complete utilization of the raw material of native cellulose. Simultaneously the method can avoid adsorption of the hemicellulose and the lignin by cellulose enzyme and improve the activity of the cellulose enzyme; the accumulation of the substances that are not fermented in a reactor is reduced, and the method can realize continuous zymolysis in a long time, has high input concentration, recycles yeast and cellulose enzyme, has high concentration of recycled ethanol, and saves water.

Owner:HENAN UNIV OF SCI & TECH

Method of producing protein feed by liquid-solid two-step fermentation method

InactiveCN105010758APromote growthFast fermentationFood processingAnimal feeding stuff[Candida] apicolaBacilli

The invention discloses a method of producing a protein feed by a liquid-solid two-step fermentation method. The method comprises the following steps: performing liquid culture on corynebacterium glutamicum, candida utilis, bacillus subtilis, lactobacillus plantarum and aspergillus oryzae so as to obtain corynebacterium glutamicum fermentation liquor, candida utilis fermentation liquor, bacillus subtilis fermentation liquor, lactobacillus plantarum fermentation liquor and aspergillus oryzae fermentation liquor; mixing the corynebacterium glutamicum fermentation liquor, the candida utilis fermentation liquor, the bacillus subtilis fermentation liquor, the lactobacillus plantarum fermentation liquor and the aspergillus oryzae fermentation liquor so as to obtain mixed bacterium liquor; loading raw materials of soybean meal, cluster bean meal, cottonseed meal and the like into an explosion vat for performing steam explosion; after steam explosion, mixing materials, the mixed bacterium liquor and molasses in proportion, and adding an enzyme preparation so as to obtain mixed materials; conveying the mixed materials into a special modularized solid-state biological raw material continuous fermentation device for enzymolysis and fermentation, and drying the fermented materials so as to obtain the protein feed. According to the method disclosed by the invention, the modularized automatic fermentation device is adopted, the materials after explosion, the fermented bacterium liquor and the enzyme preparation are mixed, then the mixed materials are loaded into the automatic fermentation device for enzymolysis and biological fermentation, so that requirements for automatic temperature control, automatic dampness control and automatic ventilation control are met, the bioconversion rate is high, the fermentation period is short, the consumption is low, the cost is low, and mechanized and large-scale production requirements can be met.

Owner:河南双成生物科技有限公司

Kiwi fruit enzyme and preparation method thereof

InactiveCN105962343ASolve technical problems that are difficult to retainGuaranteed stabilityFood ingredient functionsPectinaseActinidia

The invention discloses a preparation method of kiwi fruit enzyme with high anti-oxidation activity. A formula is characterized in that fresh kiwi fruits are adopted as raw materials, fruit skin is reserved for pulping after washing and deburring the kiwi fruits, and enzymolysis is carried out on kiwi fruit pulp by adding a composite enzyme preparation (which is prepared from pectinase, cellulose, hemicellulase, protease and diastase), so that the juice yield and the production efficiency are improved; then, a multi-strain symbiotic fermentation technology and a grading inoculation process are adopted, and fermentation and ageing are carried out on a product by sequentially adding saccharomycetes, acetic acid bacteria and lactic acid bacteria; finally, the purpose of removing bacteria is achieved through the technologies of kieselguhr filter, membrane filter and the like, so that continuous fermentation of the product is ended, the stability of the shelf life is ensured, and meanwhile, the activity of active ingredients and enzyme is maximum kept. The enzyme prepared through the preparation method has the characteristics of high anti-oxidation activity, richness in enzymes and high enzyme activity; the appearance is clear and transparent, the flavor is sour, sweet and gentle, and the fruity fragrance is elegant.

Owner:成都兴食尚食品研发设计中心(有限合伙)

Method for continuously producing biological butanol by fermentation, separation and coupling of static bed

InactiveCN101979615AReduce pollutionExtended operating timeMicroorganism based processesFermentationContinuous fermentationContinuous use

The invention discloses a method for continuously producing biological butanol by fermentation, separation and coupling of a static bed. The method comprises the following steps of: filling a modified immobilized medium into the static bed, and circularly connecting in series with a bioreactor; incubating a butanol producing strain into the bioreactor, culturing the butanol producing strain in a fermentation medium, circulating fermentation liquor between the static bed and the bioreactor, and gradually absorbing free thallus cells into the static bed; pumping the fermentation liquor into a pervaporation membrane module for separation when the concentration of the butanol in the bioreactor is between 3 and 7g / L, collecting penetrating fluid, and returning liquid intercepted by a membrane to the bioreactor for continuous use; meanwhile, adding the fermentation medium into the midstream of the bioreactor, and continuously fermenting to produce the butanol. The method obviously weakens the pollution of the pervaporation membrane existing in the process of in situ separation and coupling, prolongs the operation time and service life of the membrane, eliminates butanol product inhibition in a fermentation process, and realizes the high-efficient and continuous production of the biological butanol.

Owner:NANJING UNIV OF TECH

Preparation of gold needle mushroom polysaccharide

ActiveCN101372701AProlong fermentation timeIncrease productionFungiMicroorganism based processesContinuous fermentationAlcohol

The invention relates to a method for preparing flammulina velutipes polysaccharide with simple operation and low equipment investment, which comprises the following process procedures: activating a slant strain, shaking culture of seeds, submerged fermentation in liquid, continuous fermentation, separation by an ultrafiltration membrane, condensation and alcohol precipitation. The method for preparing the flammulina velutipes polysaccharide has the advantages of continuous fermentation in a fermenter, prolonging the fermentation time, simplifying the operation flow and improving the polysaccharide yield.

Owner:JIANGSU HENGRUI ZELANG BIO ENG CO LTD

Flower planting nutrient soil and production method thereof

InactiveCN102863265ARealize harmless treatmentHarm reductionBio-organic fraction processingOrganic fertiliser preparationFlowering seasonDecomposition

The invention relates to a flower planting nutrient soil and a production method thereof. The method comprises the steps of 1) mixing municipal domestic sludge, food waste residues and yeast liquid waste according to the proportion of (75-85):(15-25):(0.5-1.5), and stirring uniformly; 2), adding a certain amount of active microorganisms into raw materials in the step 1), and conducting continuous fermentation for 15-18 days; 3), placing the raw materials after fermentation into a decomposition bin until the temperature is lowered to the room temperature, and obtaining the flower planting nutrient soil; and detecting N, P and K of the decomposed nutrient soil and the content of organic matters and adjusting the nutrient soil by adding a large amount of elements such as N, P and K. According to the production method of the flower planting nutrient soil, the sources of the raw materials are rich, the production period is short, the cost is low, and the produced flower planting nutrient soil is nutritious and capable of improving the survival of plantlets, prolonging the flower season and improving the quality of the flower.

Owner:GUANGDONG SHENGYIN FLOWER & HORTICULTURE CO LTD

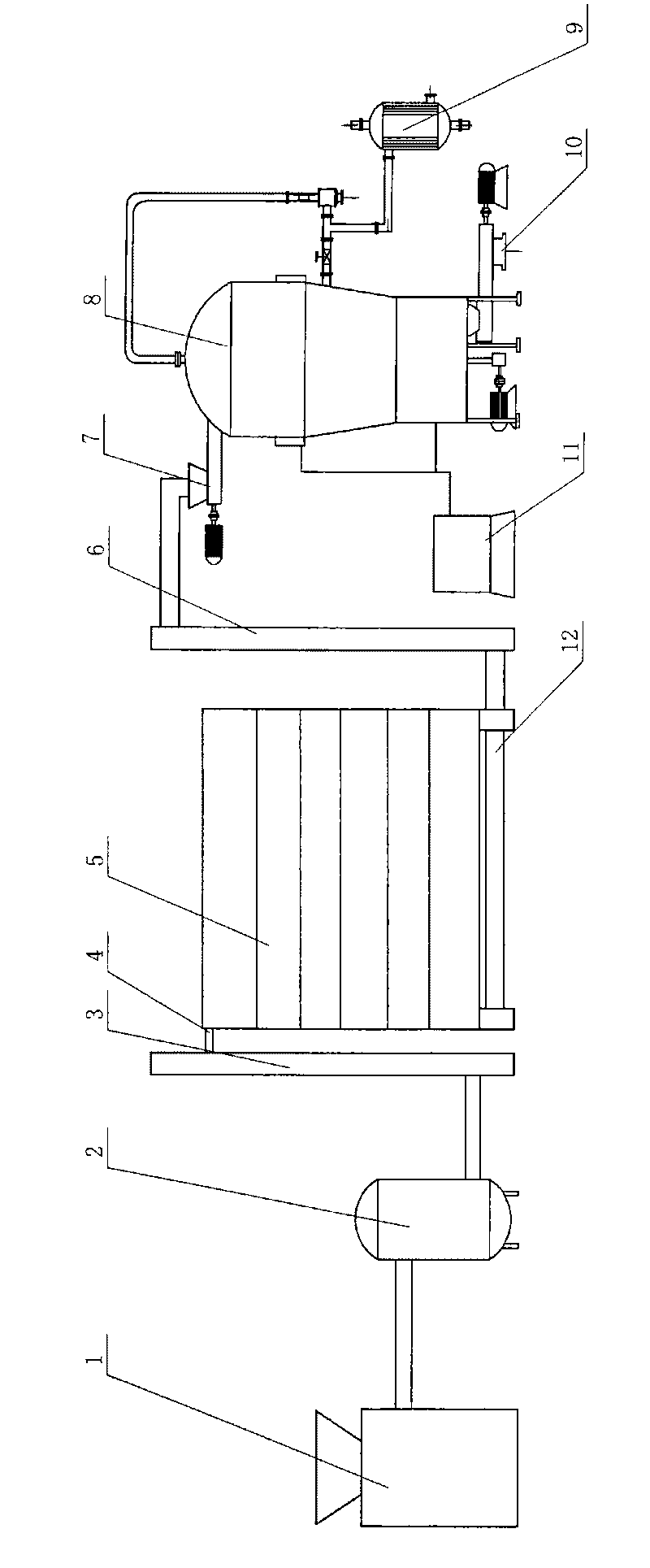

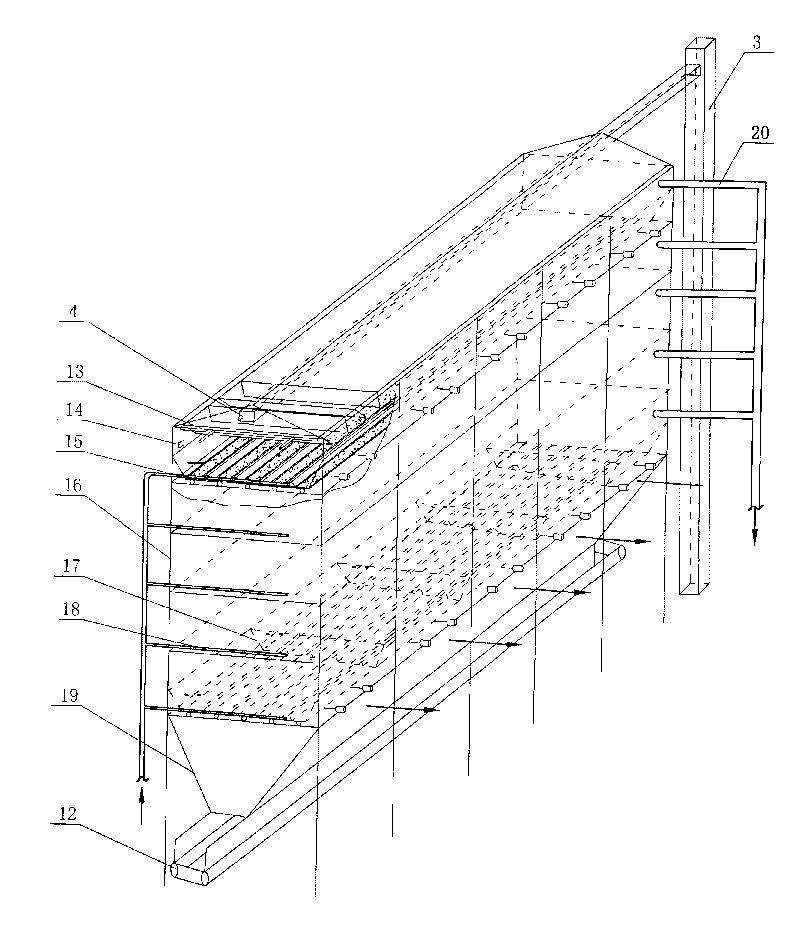

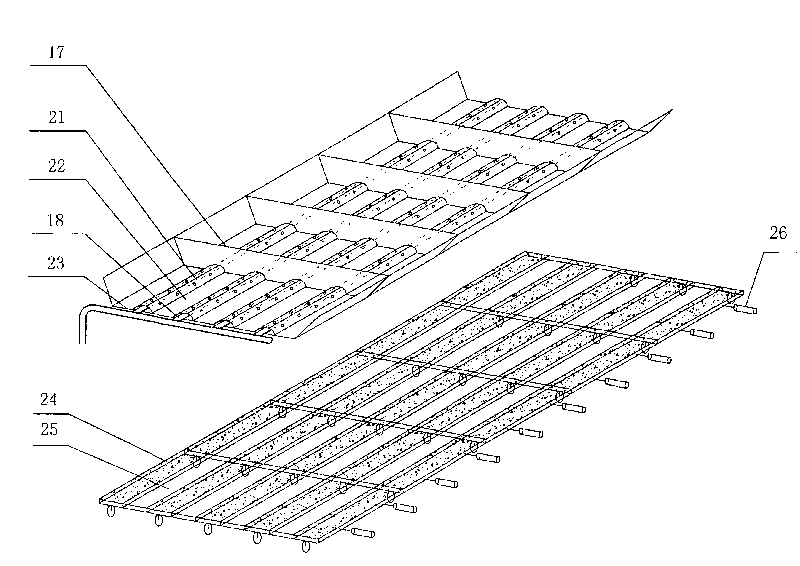

Process and system for producing ethanol through solid-state continuous fermentation and distillation of sorgo straws

ActiveCN101724661AUniform and complete fermentationHigh yieldBioreactor/fermenter combinationsBiological substance pretreatmentsDifferential pressureDistillation

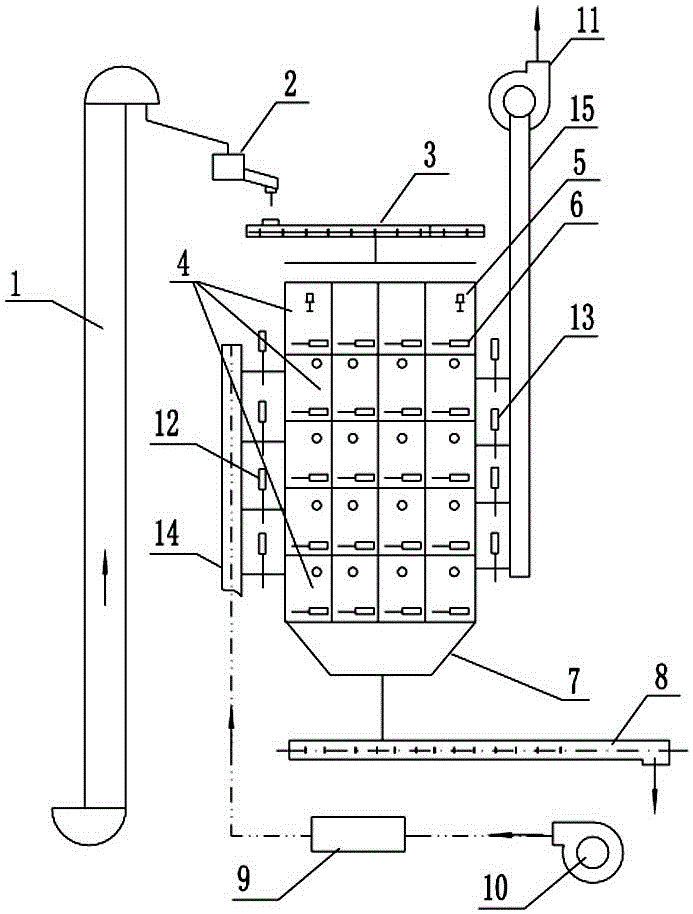

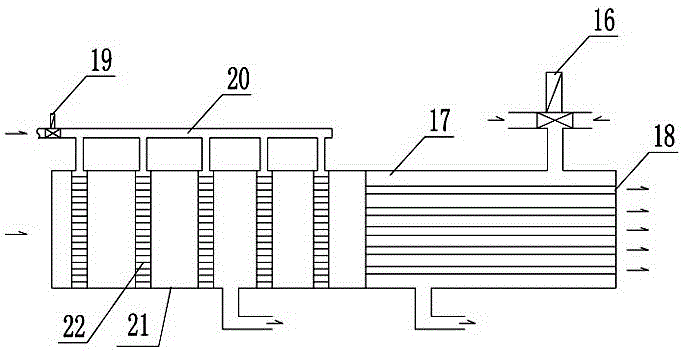

The invention relates to a process and a system for producing ethanol through solid-state continuous fermentation and distillation of sorgo straws, wherein the process comprises a raw material pulverizing and preprocessing step, a strain adding step, a solid-state fermentation step and a solid-state distillation step; the solid-state fermentation step is continuously finished in a multilayer multisection solid-state continuous fermentation device, and the solid-state distillation step is continuously finished in a multilayer differential pressure type solid-state continuous distillation device, thereby radically overcoming the abuse that the past solid-state fermentation and distillation processes can not continuously produce, realizing continuous, mass and automated production and processing, greatly improving the production efficiency of preparing the fuel ethanol from the sorgo straws, and achieving the purposes for lowering the production cost, improving the yield and improving the economic benefit; an adopted continuous production system device is particularly suitable for industrialized large-scale production, thereby promoting the generalization and the application of a biological energy source technology.

Owner:天津实发中科百奥工业生物技术有限公司 +1

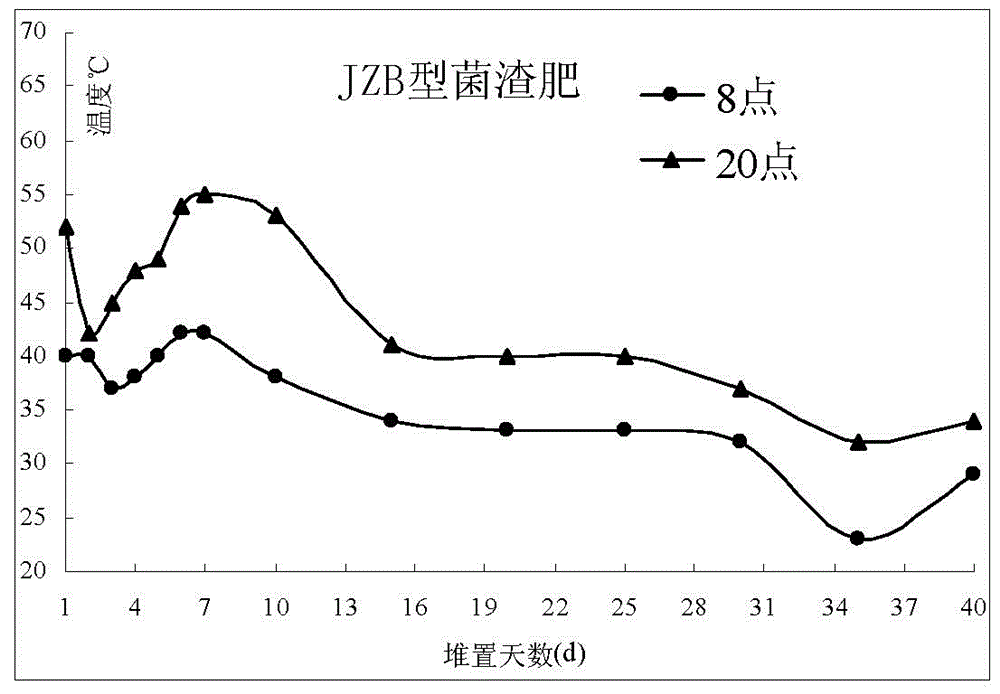

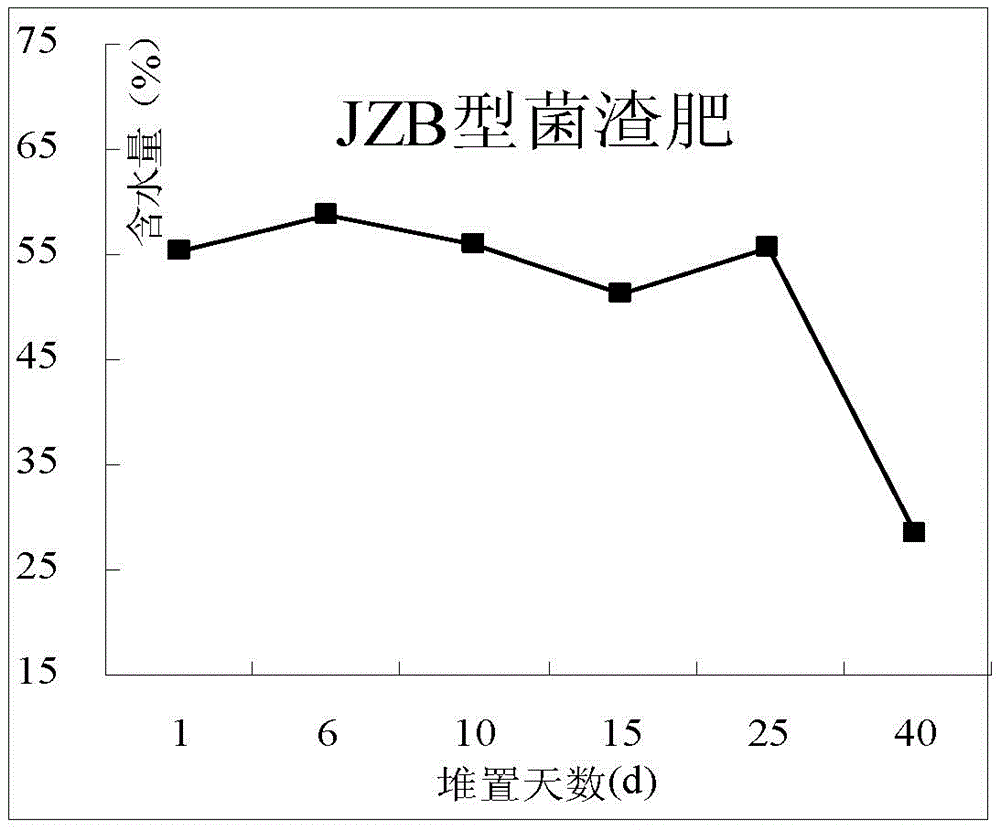

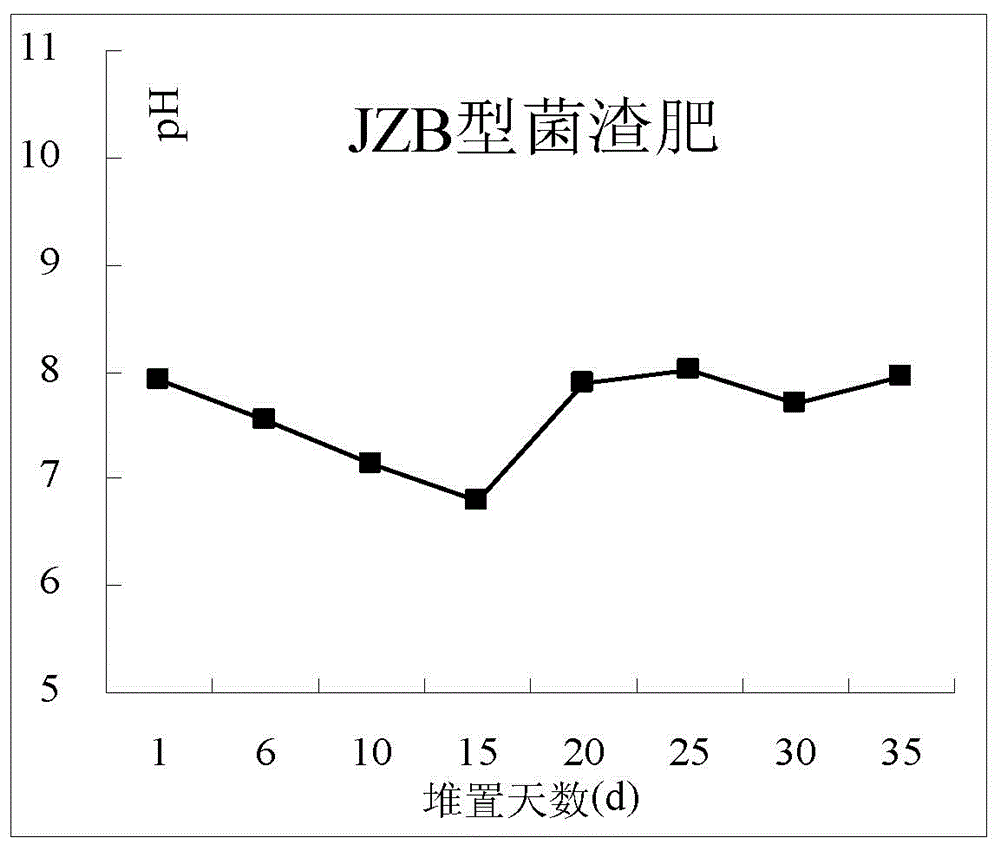

Production method of mushroom dreg and cow dung composite organic fertilizer

ActiveCN104788151ATake advantage ofNo pollution in the processBio-organic fraction processingOrganic fertiliser preparationContinuous fermentationEdible mushroom

Owner:INST OF PLANT NUTITUION & RESOURCE ENVIRONMENT HENAN ACADEMY OF AGRI SCI

Active organic bacterial manure and preparation method thereof

ActiveCN103011961AReduce pollutionChanged organic matter content is lowBio-organic fraction processingOrganic fertiliser preparationContinuous fermentationCrop cultivation

The invention discloses an active organic bacterial manure and a preparation method thereof. The active organic bacterial manure is prepared by the following steps of: performing one-time continuous fermentation, granulation, drying and screening on plant ash, industrial and agricultural wastes enriched with organic matters, and an inorganic fertilizer which are used as raw materials and inoculating bacteria subjected to breeding from the raw materials above. According to the active organic bacterial manure, the industrial and agricultural wastes enriched with the organic matters can be greatly consumed, and the environmental pollution is reduced; in the process of crop cultivation and urban greening, the problems of soil hardening, gradual fertilizer efficiency reduction and environmental pollution which are caused by that fertilizers are used year by year are solved; and a new fertilizer source is supplied to the agricultural production.

Owner:SHANDONG SUPER AGRI SCI & TECH

Method for production of ethanol by continuous fermentation of immobilized yeast cells

The invention provides a method for production of ethanol by continuous fermentation of immobilized yeast cells, and the method comprises the following steps: (1) a fiber material is attached to a support frame, and is filled into a bioreactor; (2) yeast cells are immobilized in the fiber material in the bioreactor; (3) a fermentation medium is added into the bioreactor to begin ethanol fermentation; (4) when glucose in the fermentation medium is consumed, a fermentation liquid flows out of the bioreactor, the ethanol is collected, the fermentation medium is added, and then the step (4) is repeated. The method uses the fiber material for immobilization of the yeast cells for continuous fermentation to produce the ethanol, the fiber material as an immobilization material is stably in property, non-toxic, and good in adsorption and mass transfer effects, can be repeatedly used, is easy to achieve continuous production of the ethanol, and in a continuous fermentation process can greatly improve the ethanol yield.

Owner:NANJING HIGH TECH UNIV BIOLOGICAL TECH RES INST CO LTD

High-yield arginine deiminase bacterial strain and method for producing L-citrulline by same

ActiveCN102703339AHigh acid productionStable traitsBacteriaMicroorganism based processesContinuous fermentationMicrobiology

The invention discloses a high-yield arginine deiminase bacterial strain and a method for producing L-citrulline by the same. The high-yield arginine deiminase bacterial strain of the invention is streptococcus faecalis BM-2 CGMCC No.4990. After small-scale fermentation of the bacterial strain in a 30-L fermentation tank, the L-citrulline yield is up to 98 g / L, which is increased by 50% when compared with the L-citrulline yield of the original strain; after continuous fermentation for 5 batches, the L-citrulline yield of the bacterial strain is stable, and the L-citrulline yield level is obviously higher than that of reported bacterial strains; and the bacterial strain of the invention has important industrial production application value.

Owner:山东恩贝生物工程有限公司

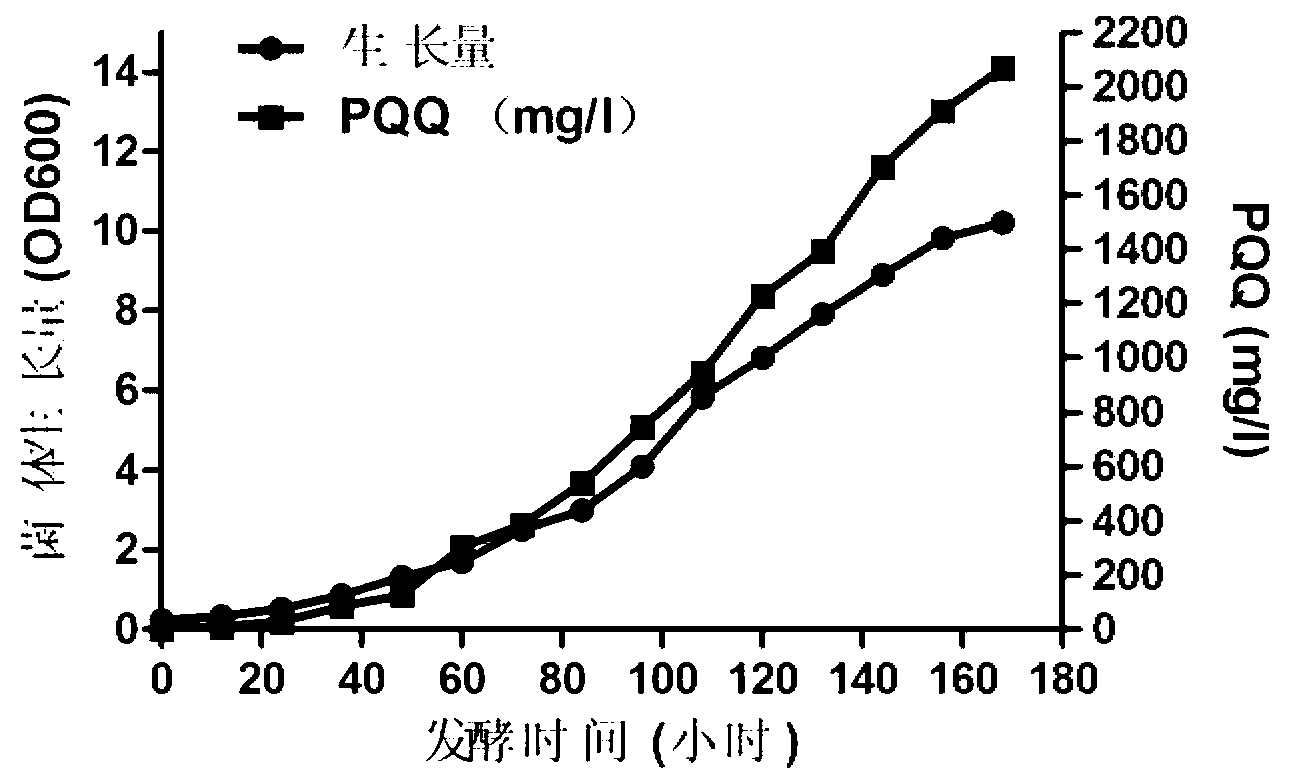

Method for producing pyrroloquinoline quinine through microbial fermentation and fermentation medium used in same

ActiveCN103224965AEfficient synthesisLow costMicroorganism based processesFermentationAutomatic controlAmmonium sulfate

The invention discloses a method for producing pyrroloquinoline quinine through microbial fermentation and a fermentation medium used in the method for producing the pyrroloquinoline quinine through the microbial fermentation. An oxygen control fermentation culture method is used for culturing methylotrophic bacteria, a carbon source contained in the fermentation medium is methyl alcohol, and a nitrogen source contained in the fermentation medium is ammonium sulfate, a dissolved oxygen level is controlled by stages to be 30%-50% of saturated dissolved oxygen in the fermentation process, pH is controlled to be 5.5-6.0 through fed-batch, the fed-batch is achieved through a pH-nitrogen source joint control technology, the methylotrophic bacteria are cultured for six days in a 7.5L fermentation tank, and eventually the cell density (OD 600) exceeds 10, yield of PQQ reaches 2g / L, and production intensity of the PQQ is 333.33mg / L / day. The method for producing the pyrroloquinoline quinine through the microbial fermentation is simple in operation, automatic control and continuous fermentation can be achieved easily, and a solid foundation for industrially producing the pyrroloquinoline quinine through the methylotrophic bacteria is laid.

Owner:INST OF BIOENG ACAD OF MILITARY MEDICAL SCI OF THE CHINESE

Biological organic fertilizer containing medium trace element chelates of humic acid

InactiveCN102951936ASimple production processEasy to operateBio-organic fraction processingOrganic fertiliser preparationTrichoderma sp.Phosphate

The invention discloses a production method for a biological organic fertilizer containing medium trace element chelates of humic acid. The biological organic fertilizer belongs to the field of manufacturing of composite fertilizers. The production method comprises the following steps: with pig manure, human feces, cow dung, rabbit manure, vinasse, cassava residue, leftovers in production of monosodium glutamate, trench mud, corn straw, soybean straw, vetch straw, a rapeseed cake, a tea seed cake, a deodorant, a biological nitrogen fixation bacterium, a phosphate solubilizing bacterium, a potassium solubilizing bacterium, a nodule bacterium, actinomyces, a silicate bacterium, trichoderma sp., microzyme, a photosynthetic bacterium, calcium humate, zinc humate, magnesium humate, iron humate, copper humate, and manganese humate used as raw materials, carrying out tank continuous fermentation to allow the raw materials become thoroughly decomposed; carrying out deodorizing and removing water; and carrying out granulation to obtain the granular biological organic fertilizer containing medium trace element chelates of humic acid. The fertilizer has a complete range of nutrient elements and can fully satisfy needs of a crop for a fertilizer during growth.

Owner:訾然

Organic fertilizer fermentation method

InactiveCN104261918AReduce the impact of unfavorable factorsAchieve harmlessBio-organic fraction processingClimate change adaptationMicroorganismContinuous fermentation

The invention discloses an organic fertilizer fermentation method which adopts pool type aerobic continuous fermentation. The method specifically comprises the following steps: A, uniformly mixing solid organic wastes, a microbial fermentation bacterial agent and auxiliary materials in proportion to obtain a fermentation raw material, wherein the solid organic wastes, the microbial fermentation bacterial agent and the auxiliary materials are in a ratio of (70-75) to (29.99-24.99) to 0.01, so that the carbon nitrogen ratio in the fermentation raw material is (25-30) to 1; B, carrying out primary aerobic fermentation not less than 7 days on the fermentation raw material at the temperature not lower than 55 DEG C to obtain a primary fermentation product; C, carrying out secondary fermentation on the primary fermentation product at normal temperature to obtain a secondary fermentation product within 10-15 days; and D, drying the secondary fermentation product to obtain an organic fertilizer. By using fresh chicken manure as a main fermentation raw material, the organic fertilizer fermentation method disclosed by the invention achieves the purposes of harmless treatment, recycling treatment and reducing treatment.

Owner:QINGHAI LVJIE SPECIAL BREED AQUATICS

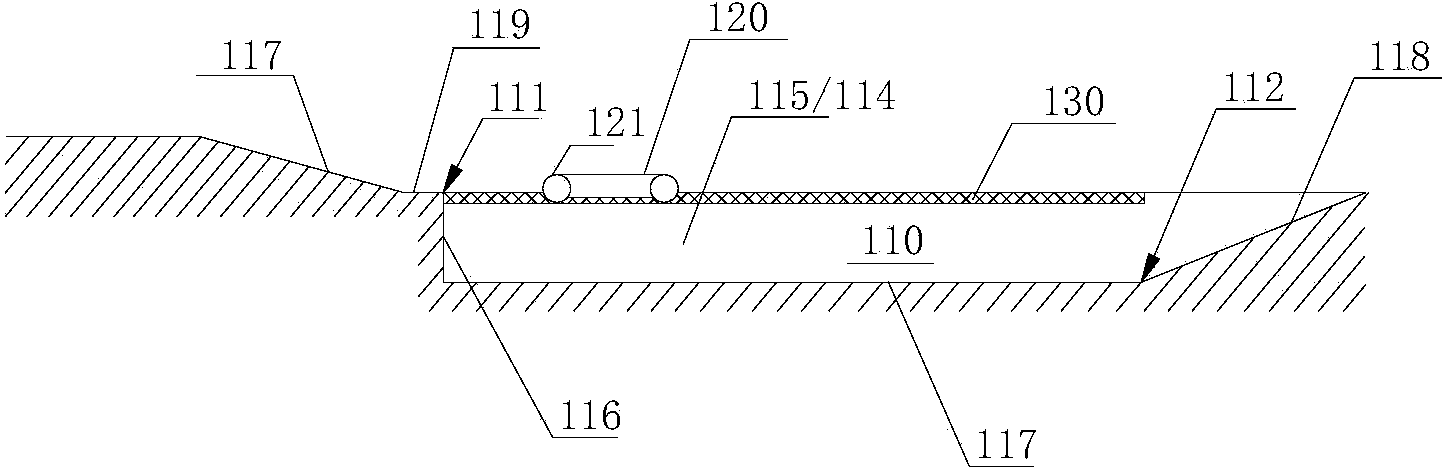

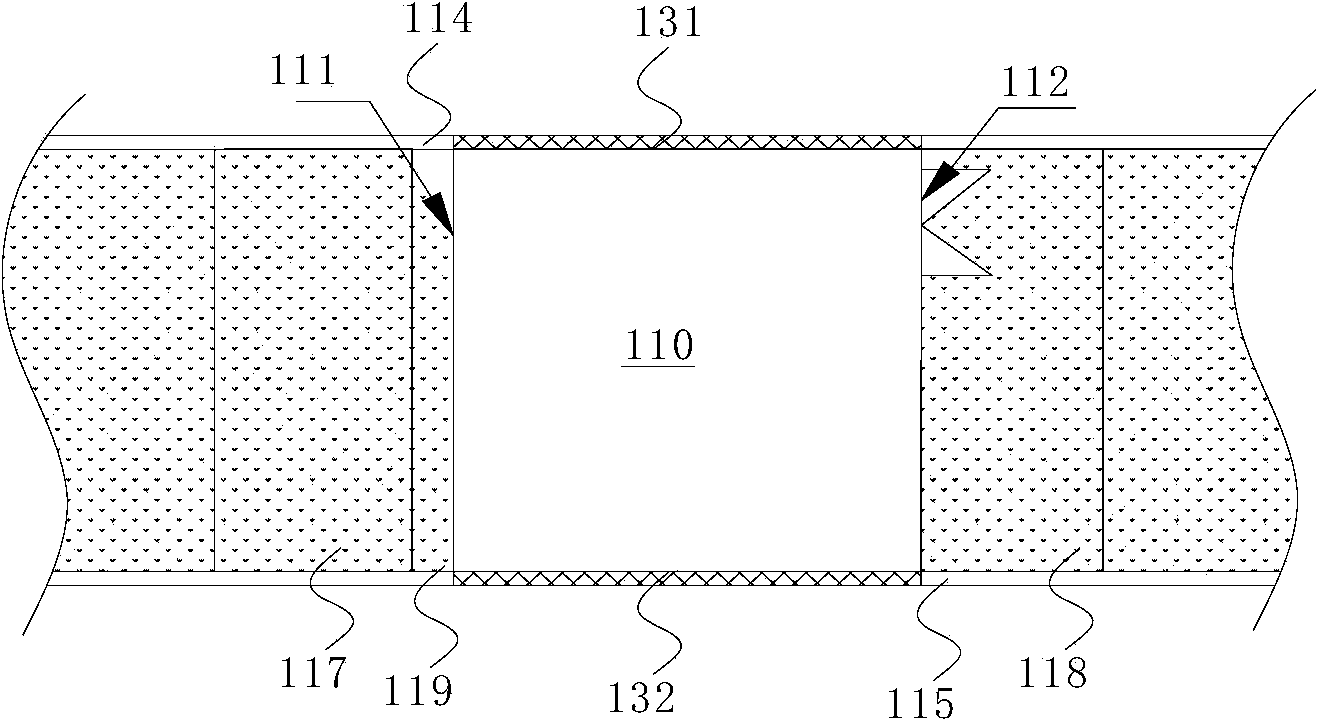

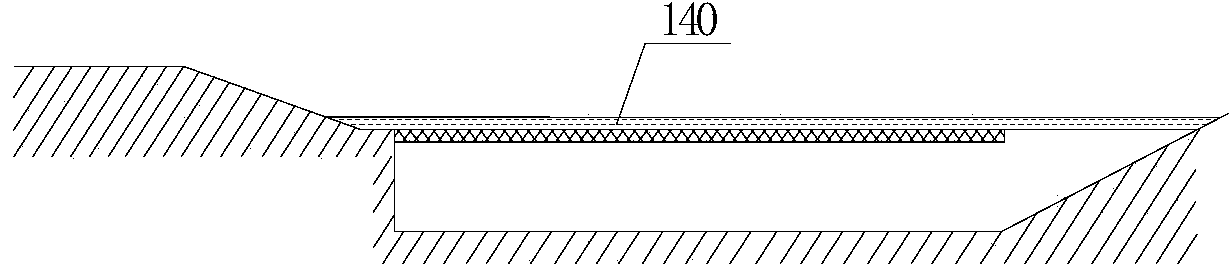

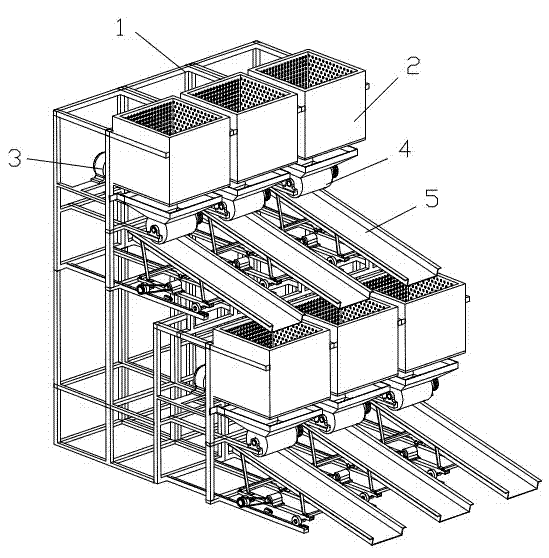

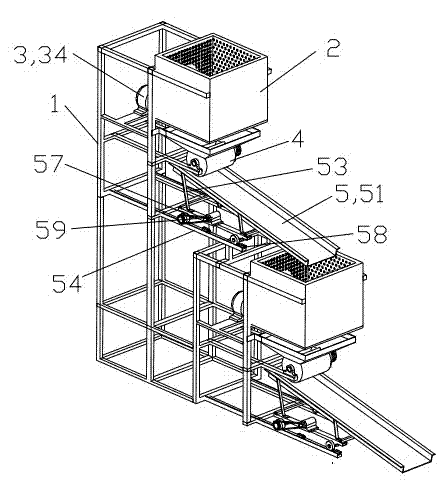

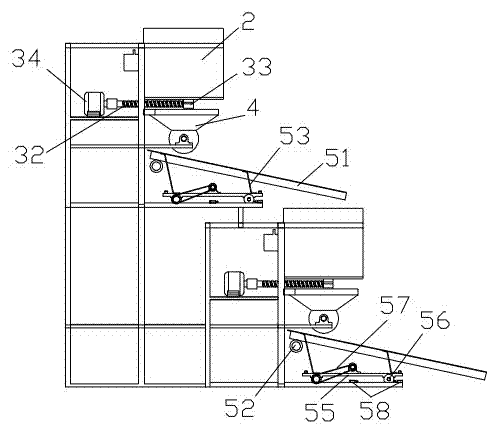

Stair-stepping tea continuous-fermentation device

ActiveCN103070257AImprove automationEasy to assemblePre-extraction tea treatmentContinuous fermentationAgricultural engineering

The invention discloses a stair-stepping tea continuous-fermentation device. The stair-stepping tea continuous-fermentation device at least comprises a fermentation group. The fermentation group comprises a frame and at least two fermentation units. The at least two fermentation units are stepwise arranged from top to bottom. Each one of the at least two fermentation units comprises a fermentation tank, a discharge device, a scattering device and a conveyer device. The fermentation tank is provided with an air chamber communicated with an inner cavity of the fermentation tank. A bottom cover is arranged at the bottom of the fermentation tank. The air chamber is annular. The top and the bottom of the air chamber are sealed. A side of the air chamber is provided with a ventilation pipe communicated with an external ventilation device. An atomizing nozzle is arranged in the ventilation pipe. A temperature sensor and an oxygen concentration sensor are arranged in the inner cavity of the fermentation tank. Through the fermentation tank having two or more layers and through a cycle flow of primary fermentation, scattering and secondary fermentation, fermentation is more uniform and thorough. Through the air chamber having an annular structure, air convection ventilation is formed in the air chamber so that uniform fermentation is realized. Uniformity and consistency of quality of black tea fermented by the stair-stepping tea continuous-fermentation device are guaranteed.

Owner:TEA RES INST CHINESE ACAD OF AGRI SCI

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com