Hyperdispersant, and preparation method and application method thereof

A technology of hyperdispersant and silane coupling agent, which is applied in chemical instruments and methods, transportation and packaging, dyeing polymer organic compound treatment, etc. It can solve the problems of weak dispersion ability of dispersant and achieve short cycle and easy The effect of industrial promotion and super dispersing ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

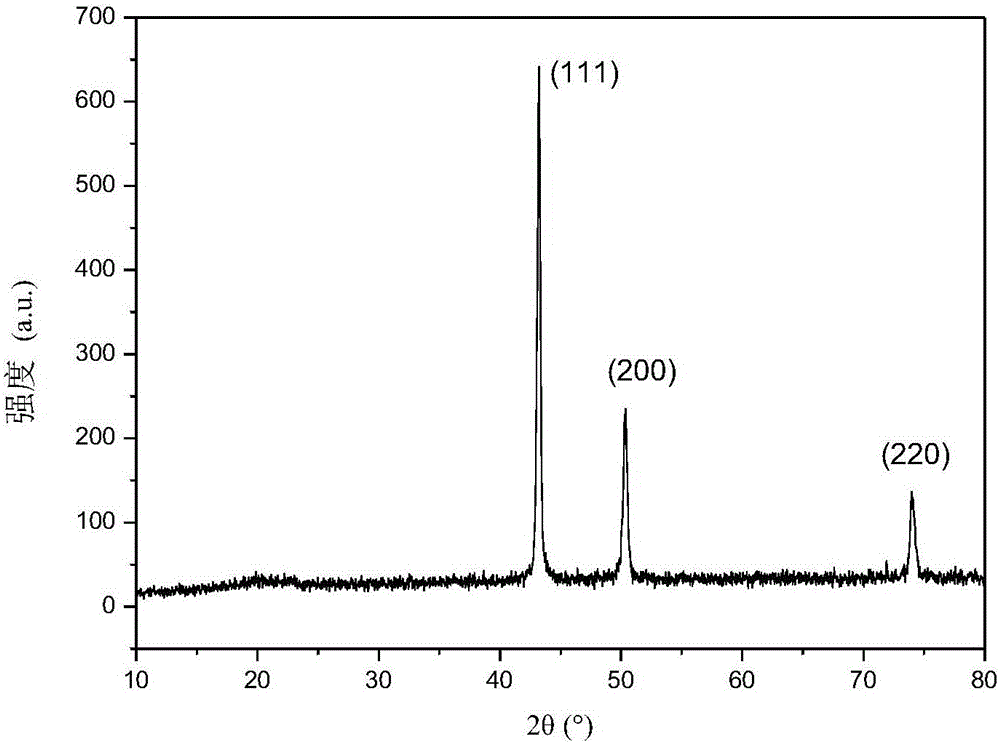

Method used

Image

Examples

Embodiment 1

[0035] (1) Mix 1 mol of silane coupling agent KH-570, 0.5 mol of acrylic acid, 1 mol of styrene, 0.03 mol of azobisisobutyronitrile and 0.01 mol of isopropanol to obtain solution A;

[0036] (2) Place the container containing the toluene solution in a water bath at 70°C and heat it under N 2 Protect the environment and stir at 500 rpm, add the solution A obtained in step (1) dropwise in 40ml of toluene solution within 2 hours (dropping at a constant speed), and keep warm for 4 hours after the dropping is completed;

[0037] Filter the product after heat preservation with a filter paper with a pore size of 30-50 μm under reduced pressure. Specifically, select a round filter paper with a slightly smaller inner diameter than the Buchner funnel and spread it on the bottom of the funnel, wet it with acetone, and turn on the suction device to make the filter paper close to the bottom of the funnel. at the bottom of the funnel;

[0038] Wash the filtered product with absolute ethano...

Embodiment 2

[0044]Prepare hyperdispersant and modified nano-copper powder according to the method described in Example 1, the difference is that in step (1), 1mol silane coupling agent KH-570, 1mol acrylic acid, 1mol styrene, 0.03 mol azobisisobutyronitrile and 0.013 mol isopropanol were mixed to obtain solution A.

[0045] In step (2), the container containing toluene is placed in a 70°C water bath to heat, solution A is added dropwise to the toluene solution within 2 hours, and after 4 hours of heat preservation, it is filtered, washed and dried to obtain a hyperdispersant, which is then gel permeated The number average molecular weight of the hyperdispersant measured by spectroscopy is 6000-6500.

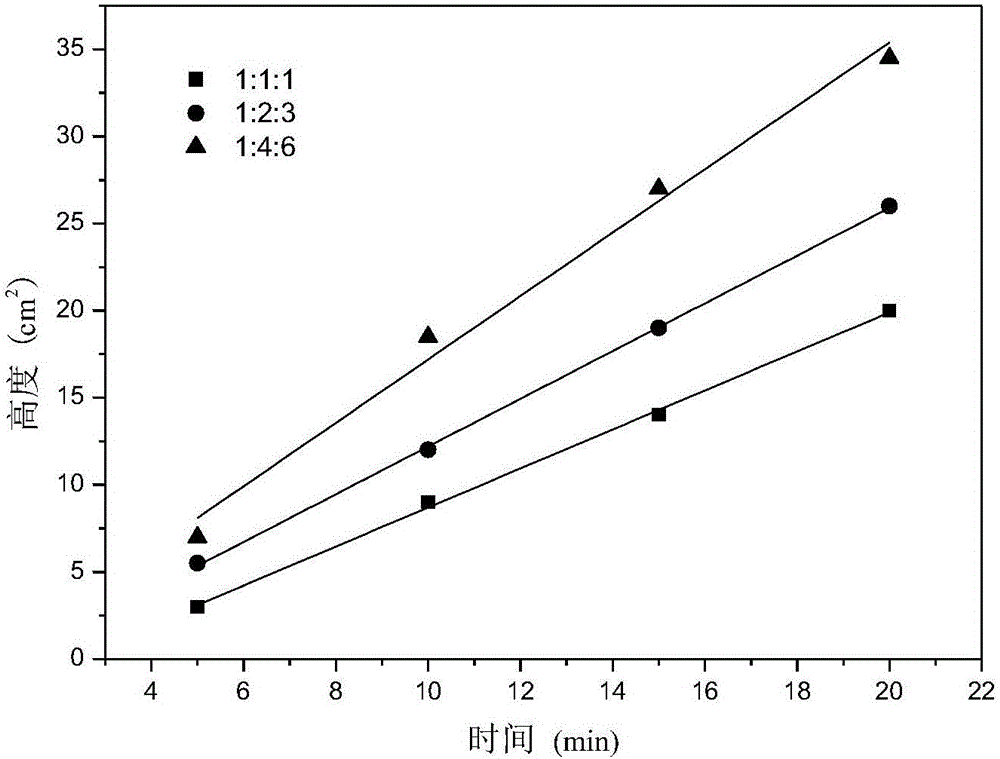

[0046] In step (3), 1g of nano-copper powder and 0.06g, 0.08g, 0.1g of hyperdispersant were placed in 40ml of toluene solution, ultrasonically dispersed at 100-120W for 0.5h, and then heated in a water bath at 70°C, 400-600 Stirring for 3 hours at rpm; filtering, washing and drying the prod...

Embodiment 3

[0048] Prepare hyperdispersant and modified nano-copper powder according to the method described in Example 1, the difference is that in step (1), 1mol silane coupling agent KH-570, 3mol acrylic acid, 2mol styrene, 0.06 mol azobisisobutyronitrile and 0.02 mol isopropanol were mixed to obtain solution A.

[0049] In step (2), the container containing toluene was heated in a water bath at 80°C, solution A was added dropwise to the toluene solution within 3 hours, and after 5 hours of heat preservation, it was filtered, washed and dried to obtain a hyperdispersant. The number average molecular weight of the hyperdispersant measured by gel permeation spectrometry is 6000-6500.

[0050] In step (3), put 1g of nano-copper powder and 0.06g, 0.08g, 0.1g of hyperdispersant into 50ml of toluene solution, ultrasonically disperse at 100-120W for 1h, then heat in a water bath at 80°C, 400-600 rpm Stir for 4 hours at 1 / min; filter, wash and dry the product to obtain surface-modified nano-c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com