Corrugated pipe filling master batch as well as preparation method and application thereof

A technology of filling masterbatch and bellows, which is applied in the field of bellows preparation, can solve the problem that HDPE bellows cannot have both impact resistance strength and high rigidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0064] In this embodiment, a kind of corrugated pipe filling masterbatch is prepared, and the specific process is as follows:

[0065] S1. Finely grind the defective glass products recovered from the glass fiber manufacturing enterprises to obtain glass powder with a particle size of about 10 μm;

[0066] S2. Put the glass powder obtained in step S1 in a high mixer, and stir at 100° C. for 1 hour to remove water;

[0067] S3. In the glass powder obtained in step S2, add KH550 accounting for 1% of the glass powder mass, continue to stir for 1 hour, stop stirring and cool to normal temperature to obtain modified glass powder;

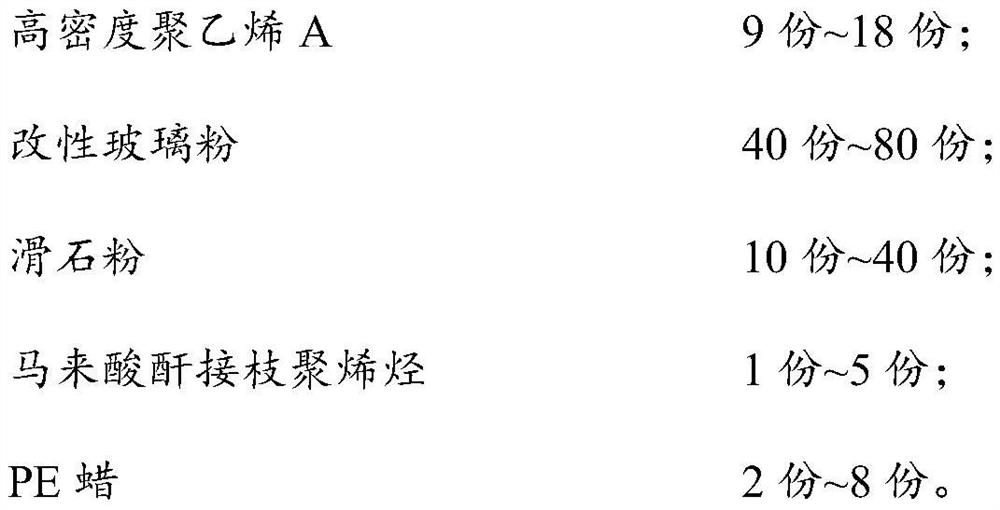

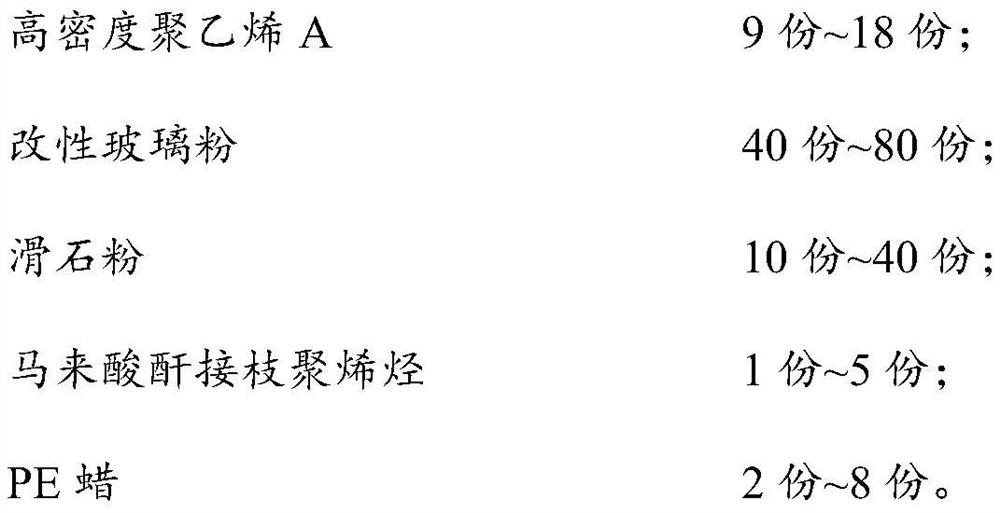

[0068] S4. According to the ratio shown in Table 1, after mixing modified glass powder, high-density polyethylene A, maleic anhydride grafted polyethylene, PE wax, antioxidant and lubricating stabilizer for 10 minutes, add talcum powder, and then continue to stir 10min;

[0069] S5. Extrude the mixed system obtained in step S4 at 140°C with a parallel c...

Embodiment 2

[0072] This example prepares a kind of corrugated pipe filling masterbatch, the specific difference with example 1 is:

[0073] The components are different, and the detailed ratio is shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| impact strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com