Formaldehyde-free medium-high-density board capable of meeting deep facing requirements and manufacturing method of medium-high-density board

A high-density board and manufacturing method technology, applied in the field of wood processing, can solve the problems of inability to meet the needs of deep veneer processing, restrict application fields, and high surface hardness, and achieve the effects of increasing strength, expanding application fields, and improving surface hardness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

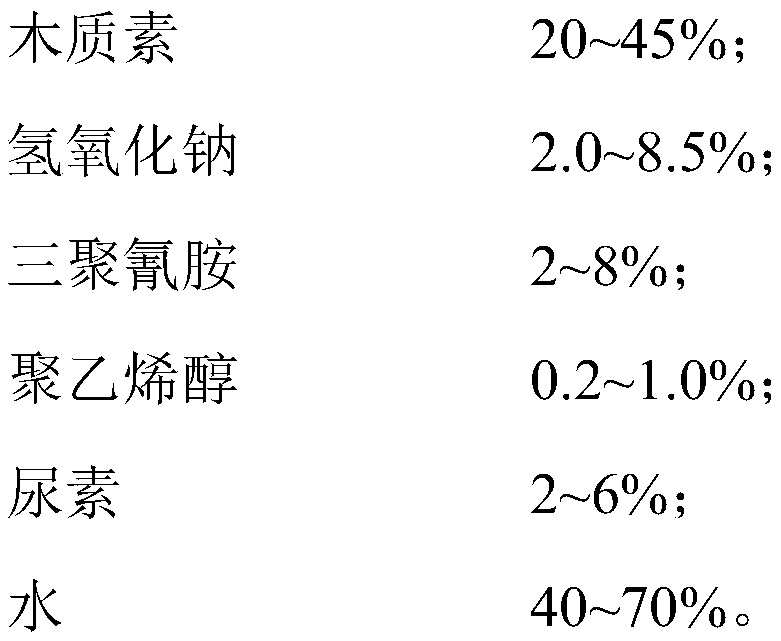

[0038] The preparation method of lignin glue is as follows: first use sodium hydroxide solution to dissolve lignin, reduce the viscosity of lignin lye by adding urea, then add melamine and then undergo a certain degree of polycondensation reaction with lignin at high temperature, and finally add the dissolved Polyvinyl alcohol aqueous solution can improve the initial viscosity of lignin glue.

[0039] The lignin glue of the embodiment of the present invention utilizes sodium hydroxide alkaline condition to dissolve lignin, polyvinyl alcohol improves the initial viscosity, urea reduces the viscosity of lignin, and melamine promotes the self-gluing of lignin under the action of high temperature to play the role of glue The effect of the agent. Formaldehyde is not added in the preparation process, and the product is aldehyde-free, and the lignin self-glued during high-temperature curing has high bonding strength and good water resistance.

[0040] As a preferred embodiment, the ...

Embodiment 1

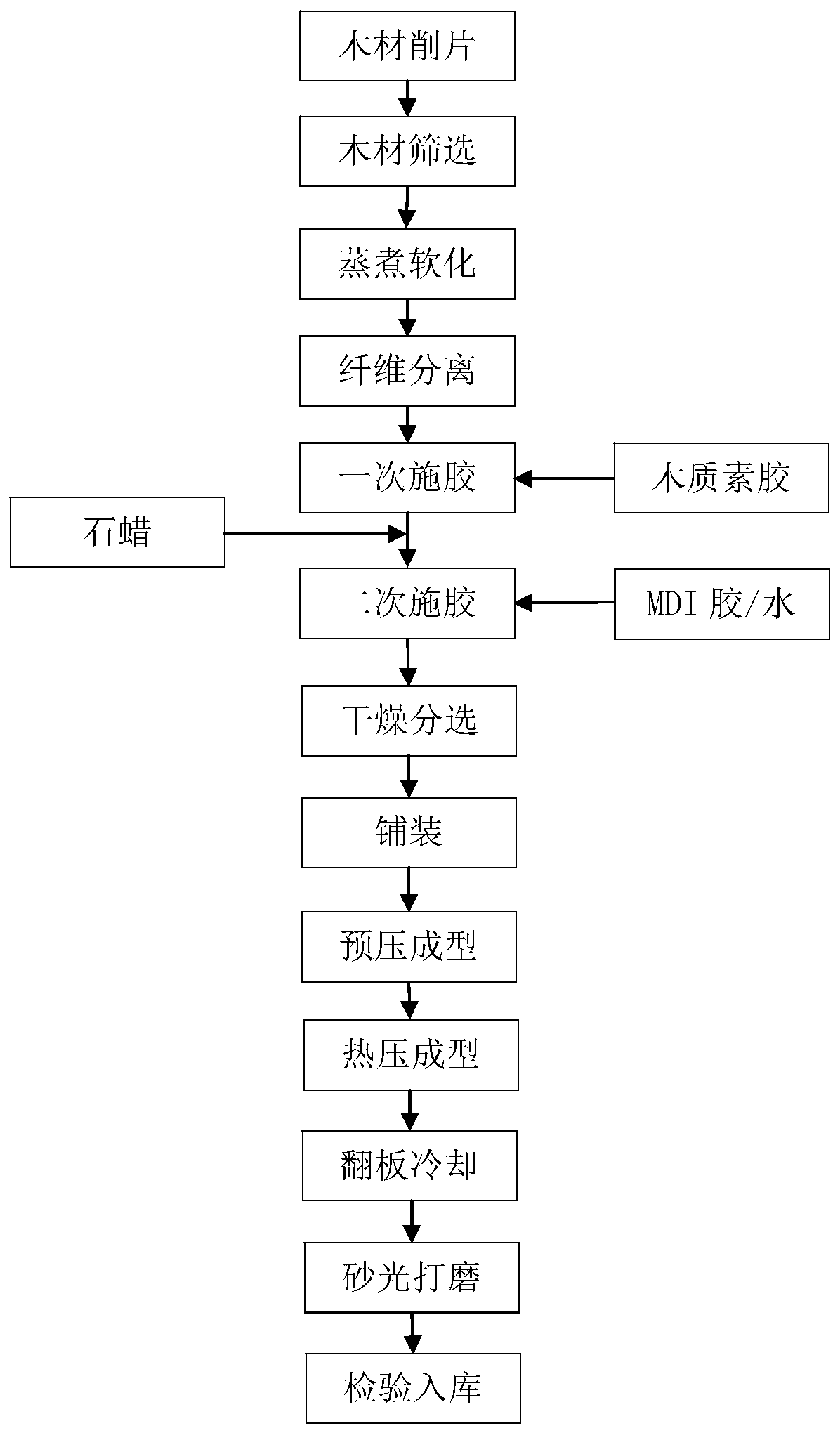

[0058] A method for manufacturing formaldehyde-free deep-decorated medium and high-density boards, specifically comprising the following steps:

[0059] (1) wood chipping: wood raw material eucalyptus is chipped into wood chips that meet the production scale;

[0060] (2) Timber screening: screen the chipped wood chips, remove the debris, and separate the oversized wood chips for further crushing;

[0061] (3) Cooking and softening: After screening, wood chips of moderate size are softened by cooking, the cooking pressure is 0.85MPa, and the cooking time is 3.5min;

[0062] (4) Fiber separation: put the wood chips into the thermal grinder, mechanically separate the fibers, the thermal grinding temperature is 157 ° C, and the pressure is 0.8 MPa;

[0063] (5) One-time sizing: one-time sizing of fibers, the glue applied is lignin glue, and the amount of sizing is 68kg / m 3 , the lignin glue used is self-made lignin glue, and its composition is lignin, sodium hydroxide, melamine...

Embodiment 2

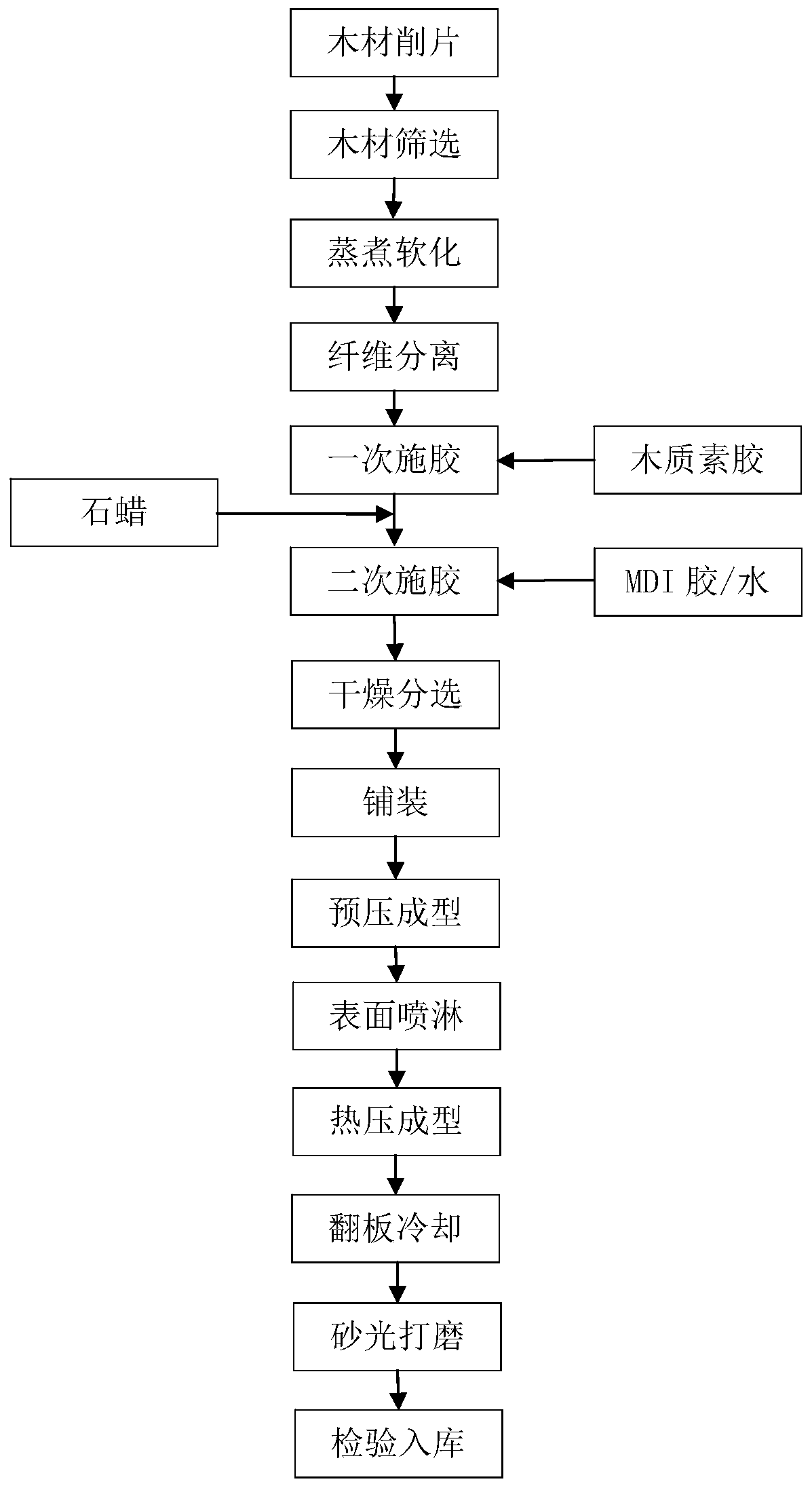

[0074] A method for manufacturing formaldehyde-free deep-decorated medium and high-density boards, specifically comprising the following steps:

[0075] (1) Wood shavings: the wood raw material poplar is cut into wood chips that meet the production scale;

[0076] (2) Timber screening: screen the chipped wood chips, remove the debris, and separate the oversized wood chips for further crushing;

[0077](3) Cooking and softening: After screening, wood chips of moderate size are softened by cooking, the cooking pressure is 0.81MPa, and the cooking time is 4.0min;

[0078] (4) Fiber separation: put the wood chips into the thermal grinder, mechanically separate the fibers, the thermal grinding temperature is 156°C, and the pressure is 0.84MPa;

[0079] (5) One-time sizing: one-time sizing of fibers, the glue applied is lignin glue, and the amount of sizing is 79kg / m 3 , the lignin glue used is self-made lignin glue, its composition is lignin, sodium hydroxide, melamine, polyvinyl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com