Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

151results about "Lignin adhesives" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Formaldehyde-Free Adhesives and Lignocellulosic Composites Made from the Adhesives

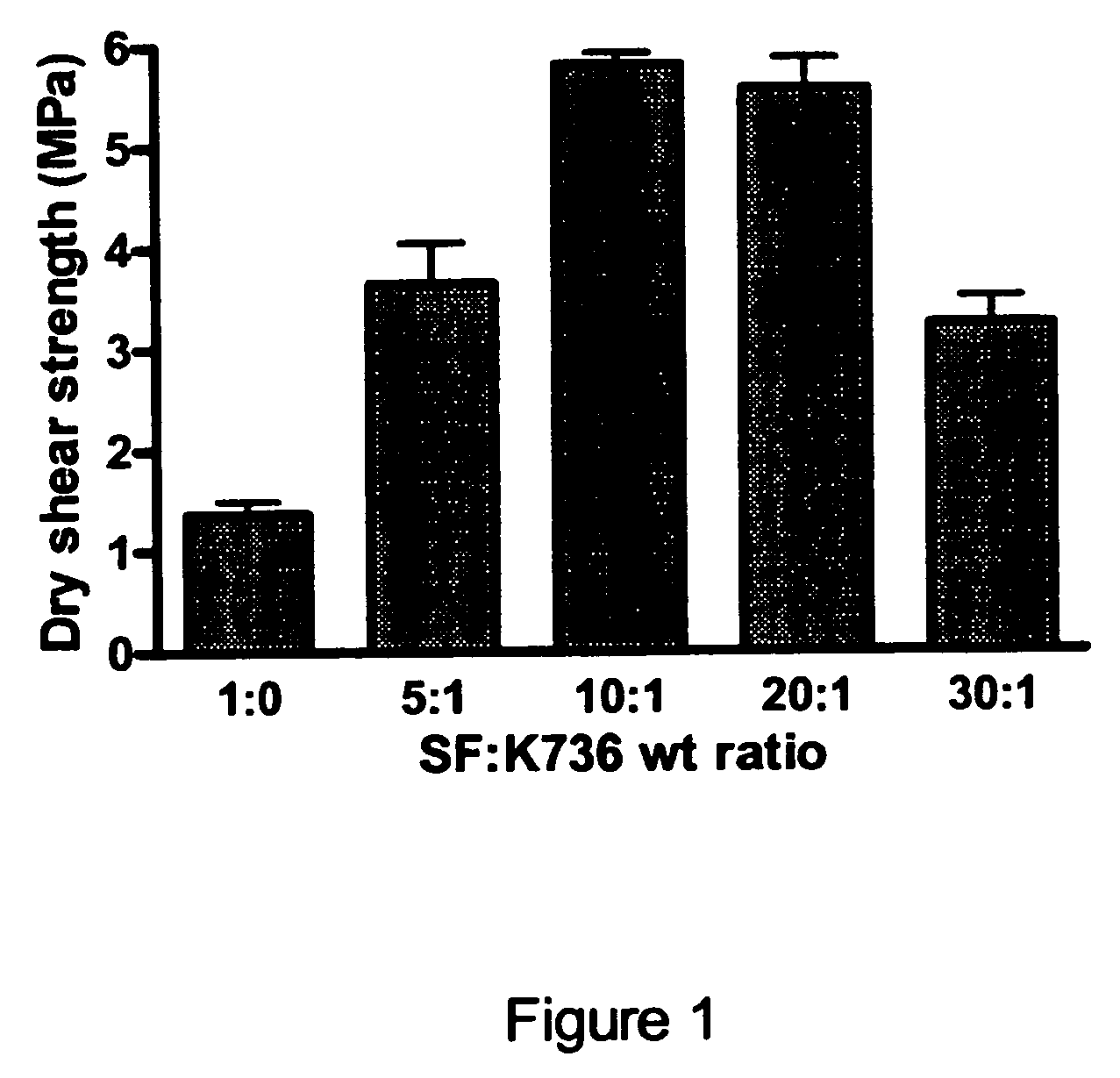

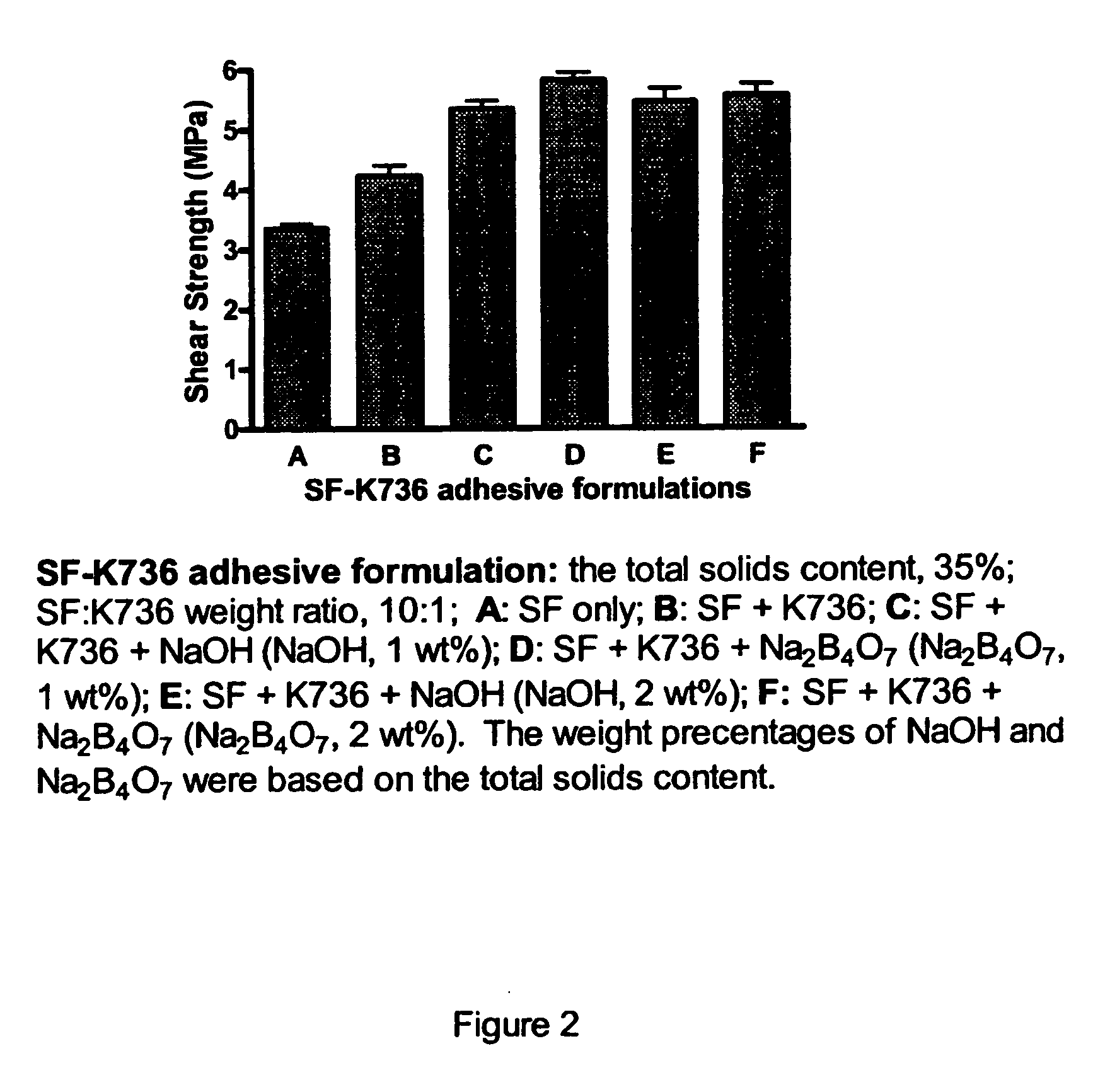

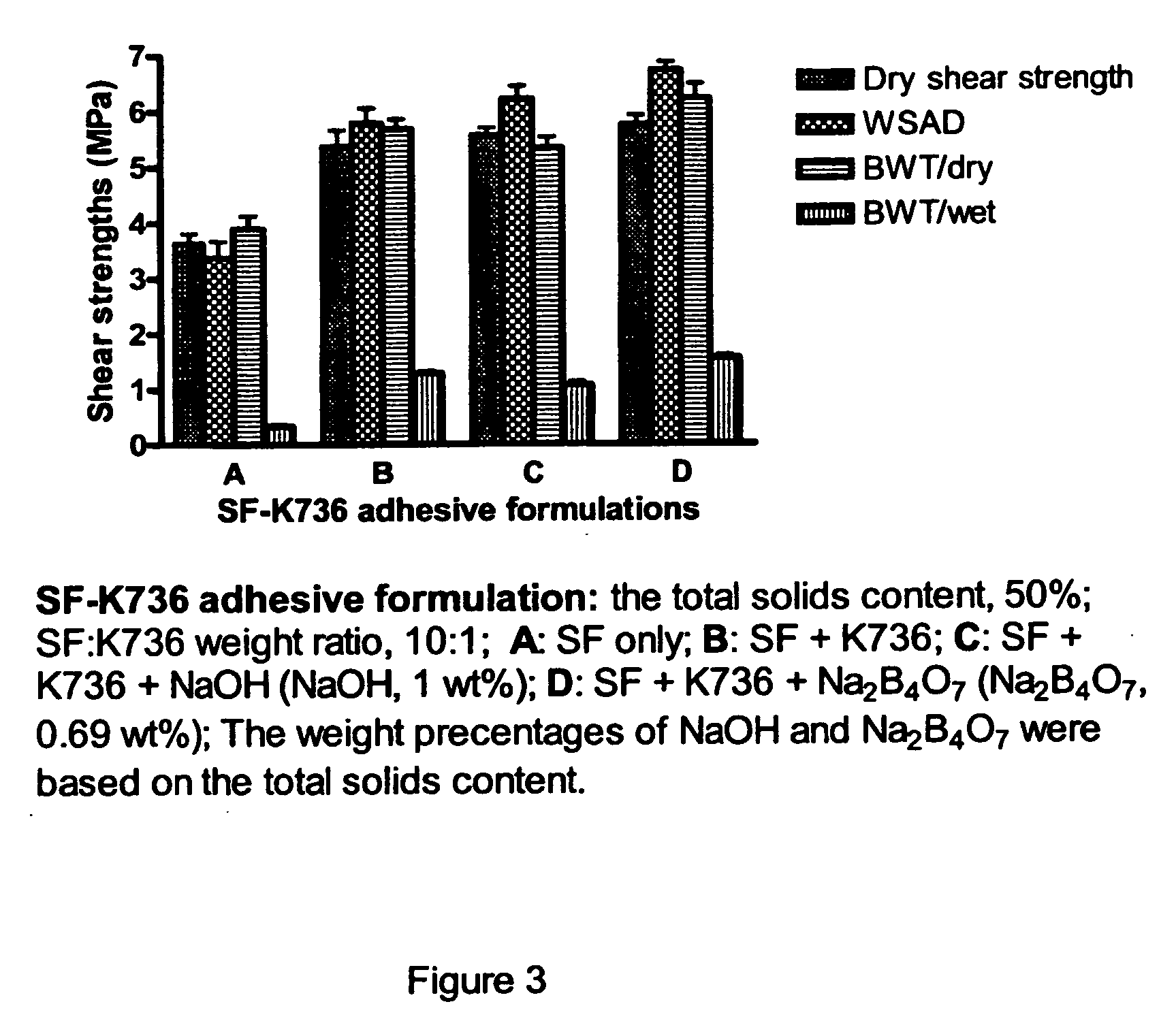

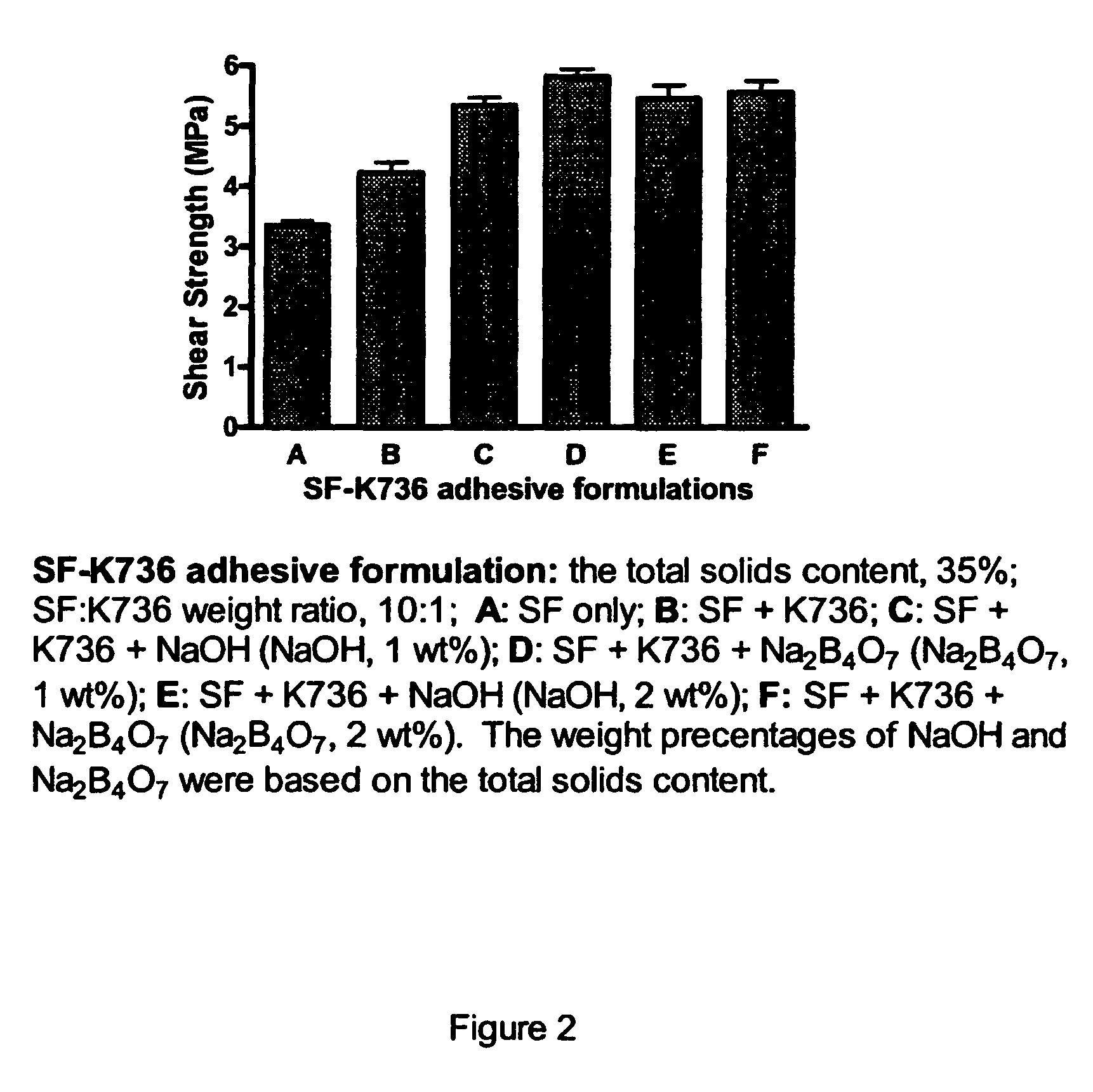

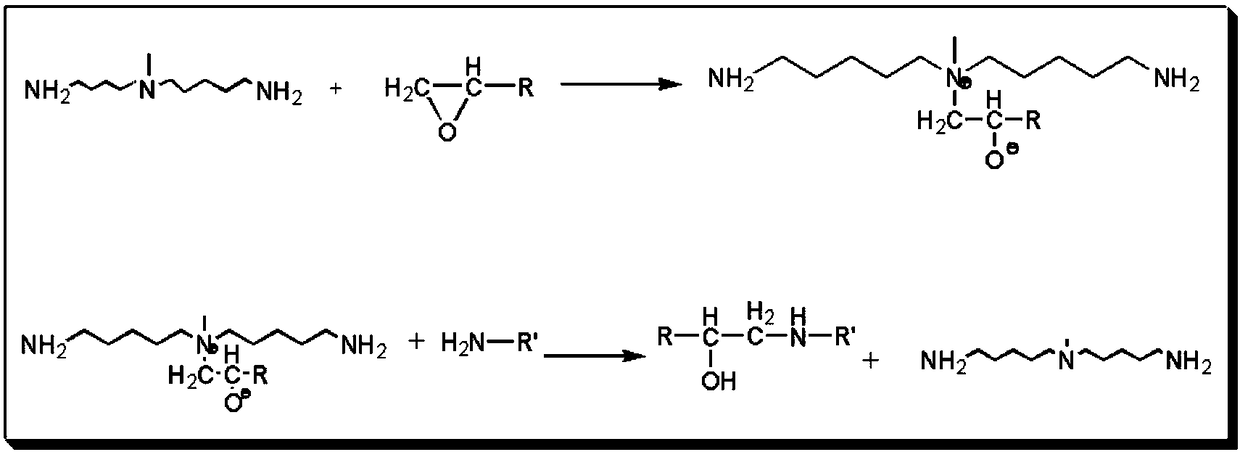

A first variant of an adhesive composition for making a lignocellulosic composite includes soy protein and / or lignin; at least one substantially formaldehyde-free curing agent that includes at least one amine, amide, imine, imide, or nitrogen-containing heterocyclic functional group that can react with at least one functional group of the soy protein; and at least one compound selected from a boron compound, a group IA oxide or hydroxide, or a group IIA oxide or hydroxide. A second variant of an adhesive composition includes a first component selected from soy protein and / or lignin; and at least one substantially formaldehyde-free curing agent selected from a reaction product of epichlorohydrin with ethylenediamine, a reaction product of epichlorohydrin with bis-hexamethylenetriamine, or a reaction product of epichlorohydrin with hexamethylenediamine.

Owner:THE STATE OF OREGON ACTING BY & THROUGH THE OREGON STATE BOARD OF HIGHER EDUCATION ON BEHALF OF OREGON STATE UNIV

Formaldehyde-free adhesives and lignocellulosic composites made from the adhesives

A first variant of an adhesive composition for making a lignocellulosic composite includes soy protein and / or lignin; at least one substantially formaldehyde-free curing agent that includes at least one amine, amide, imine, imide, or nitrogen-containing heterocyclic functional group that can react with at least one functional group of the soy protein; and at least one compound selected from a boron compound, a group IA oxide or hydroxide, or a group IIA oxide or hydroxide. A second variant of an adhesive composition includes a first component selected from soy protein and / or lignin; and at least one substantially formaldehyde-free curing agent selected from a reaction product of epichlorohydrin with ethylenediamine, a reaction product of epichlorohydrin with bis-hexamethylenetriamine, or a reaction product of epichlorohydrin with hexamethylenediamine.

Owner:THE STATE OF OREGON ACTING BY & THROUGH THE OREGON STATE BOARD OF HIGHER EDUCATION ON BEHALF OF OREGON STATE UNIV

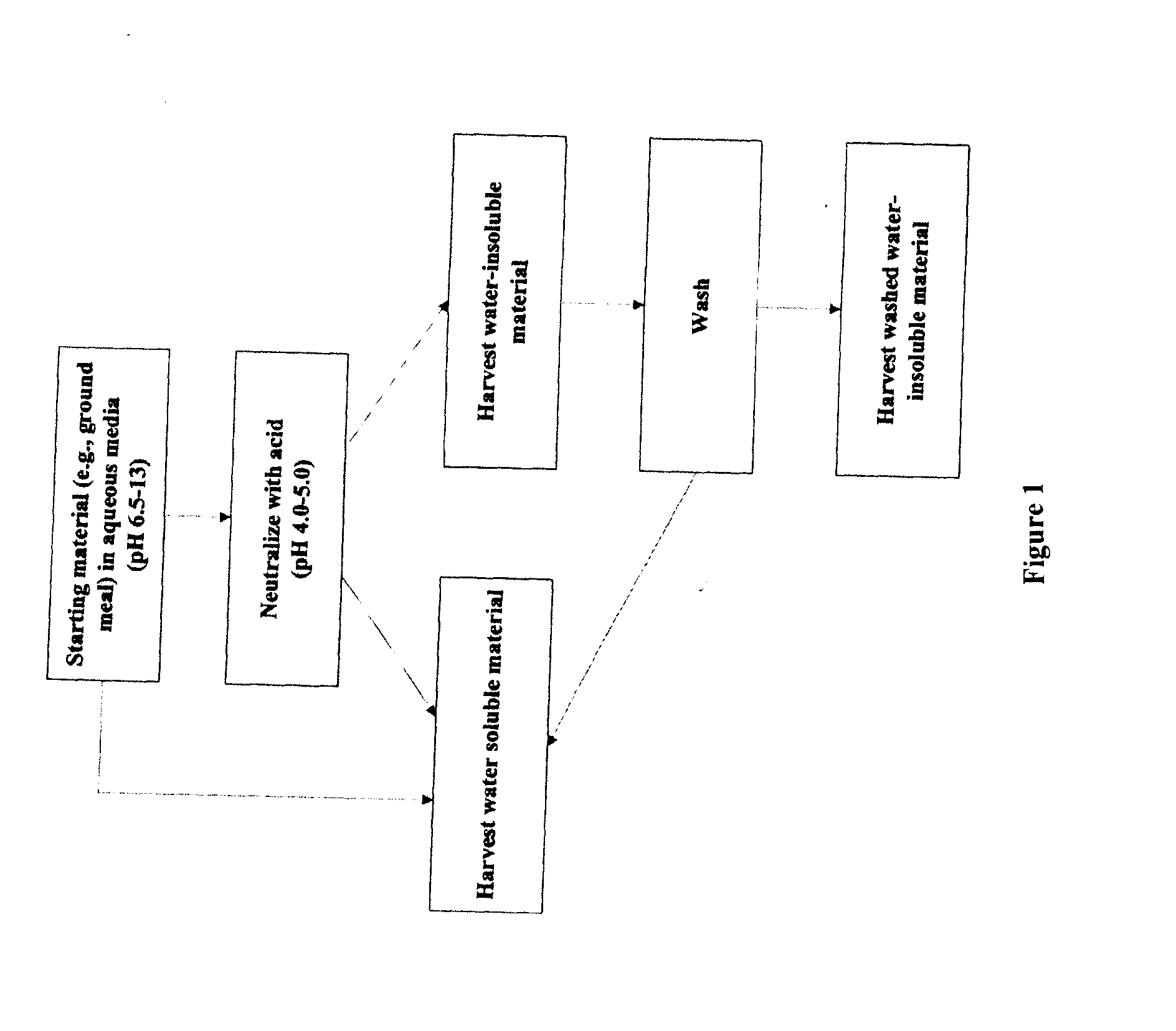

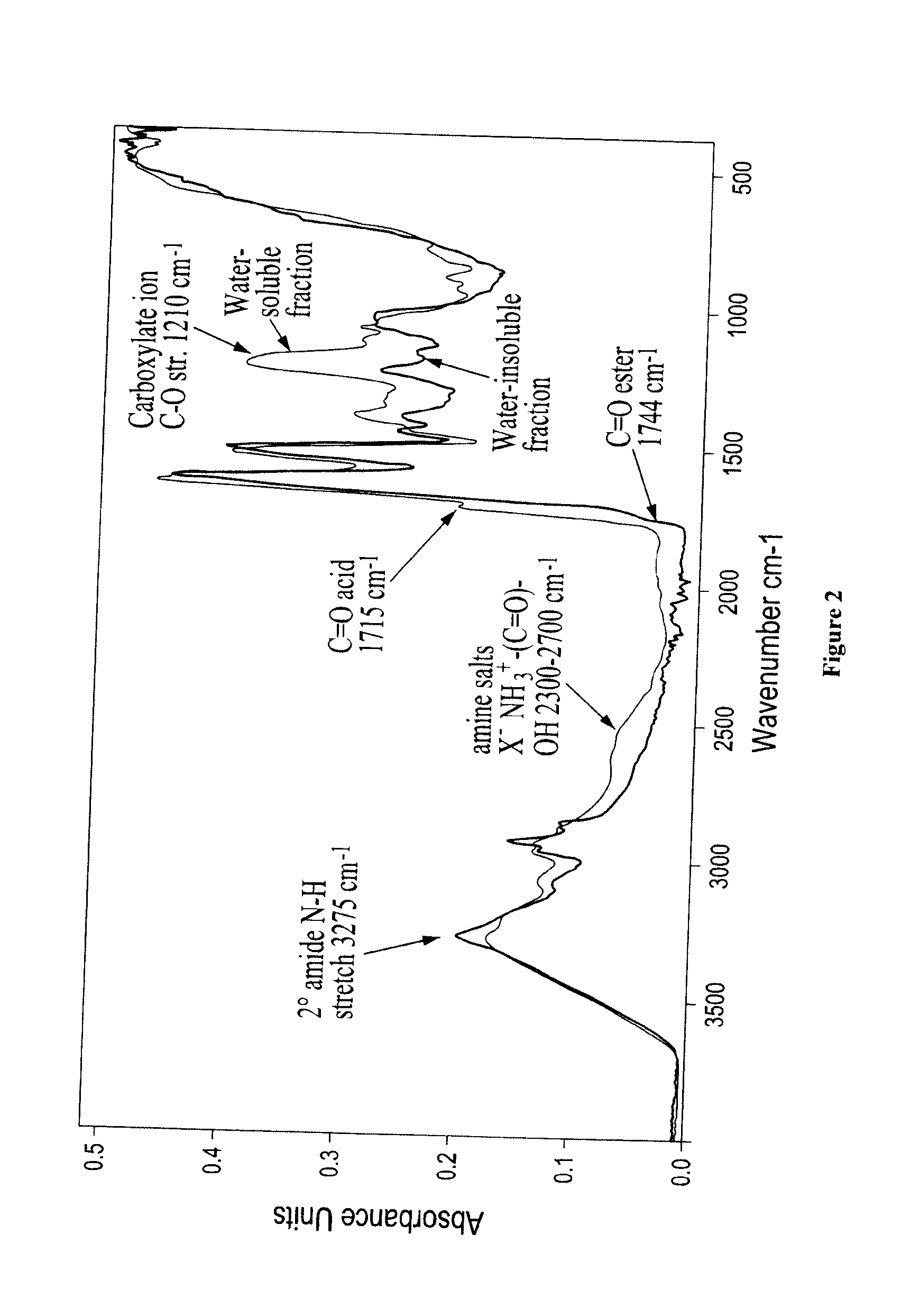

Protein-containing adhesives, and manufacture and use thereof

InactiveUS20130065012A1Optimizing performance propertyImprove water resistanceWood working apparatusGlass/slag layered productsAdhesiveBiomass

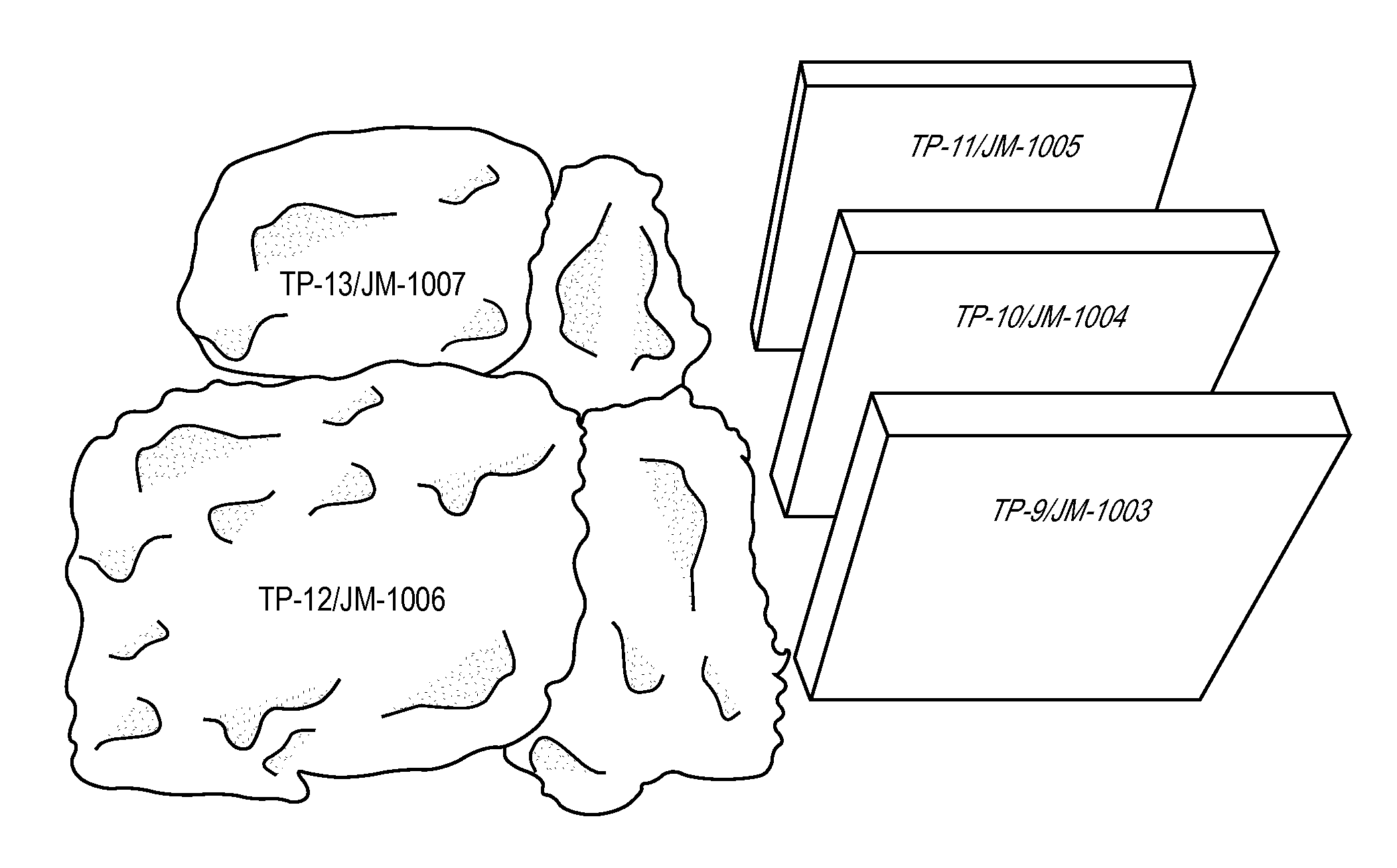

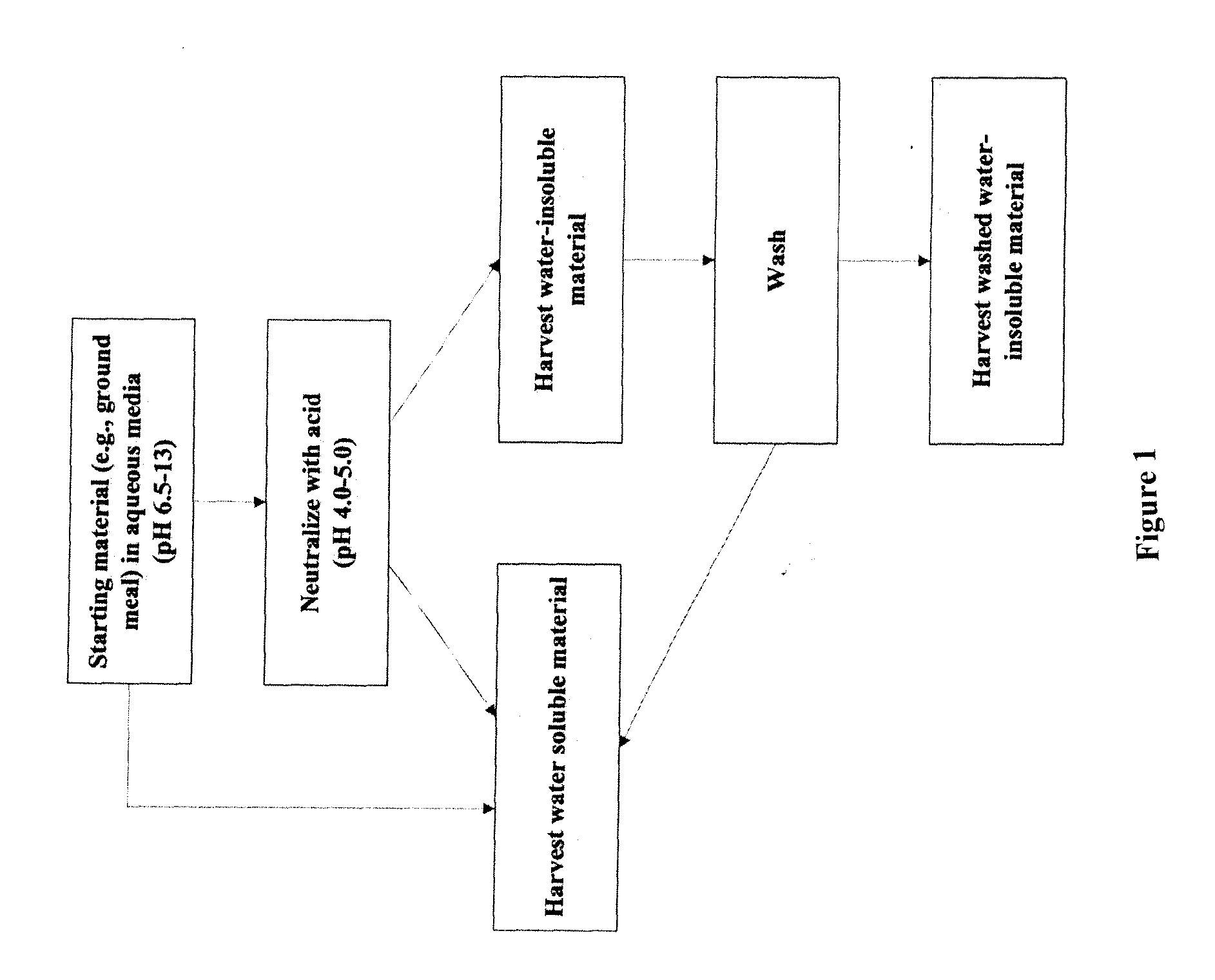

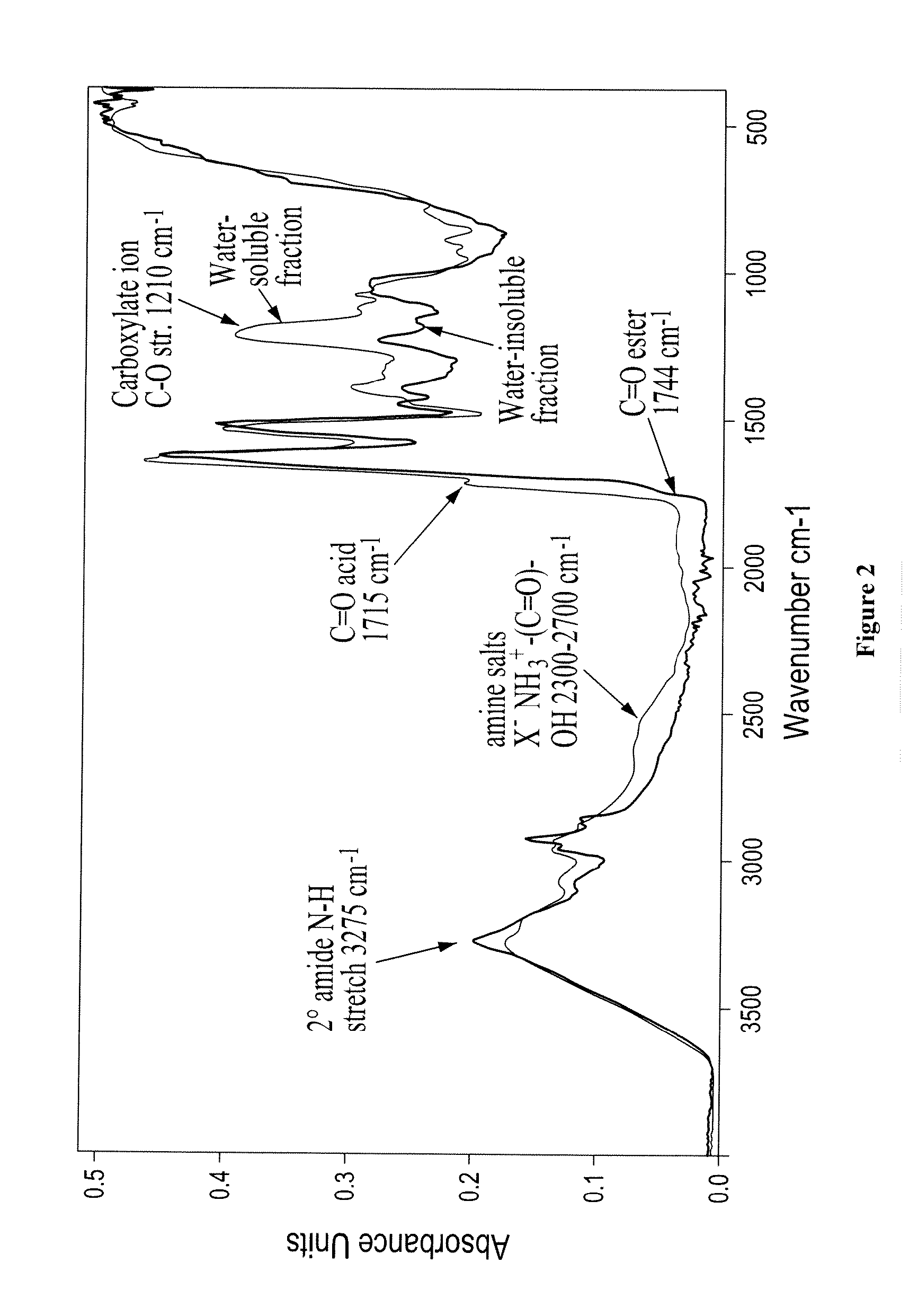

The invention provides protein adhesives and methods of making and using such adhesives. One type of protein adhesive described herein contains lignin and ground plant meal or an isolated polypeptide composition obtained from plant biomass. Other types of protein adhesives described herein contain a plant protein composition and either a hydroxyaromatic / aldehyde, urea / aldehyde, or amine / aldehyde component.

Owner:EVERTREE

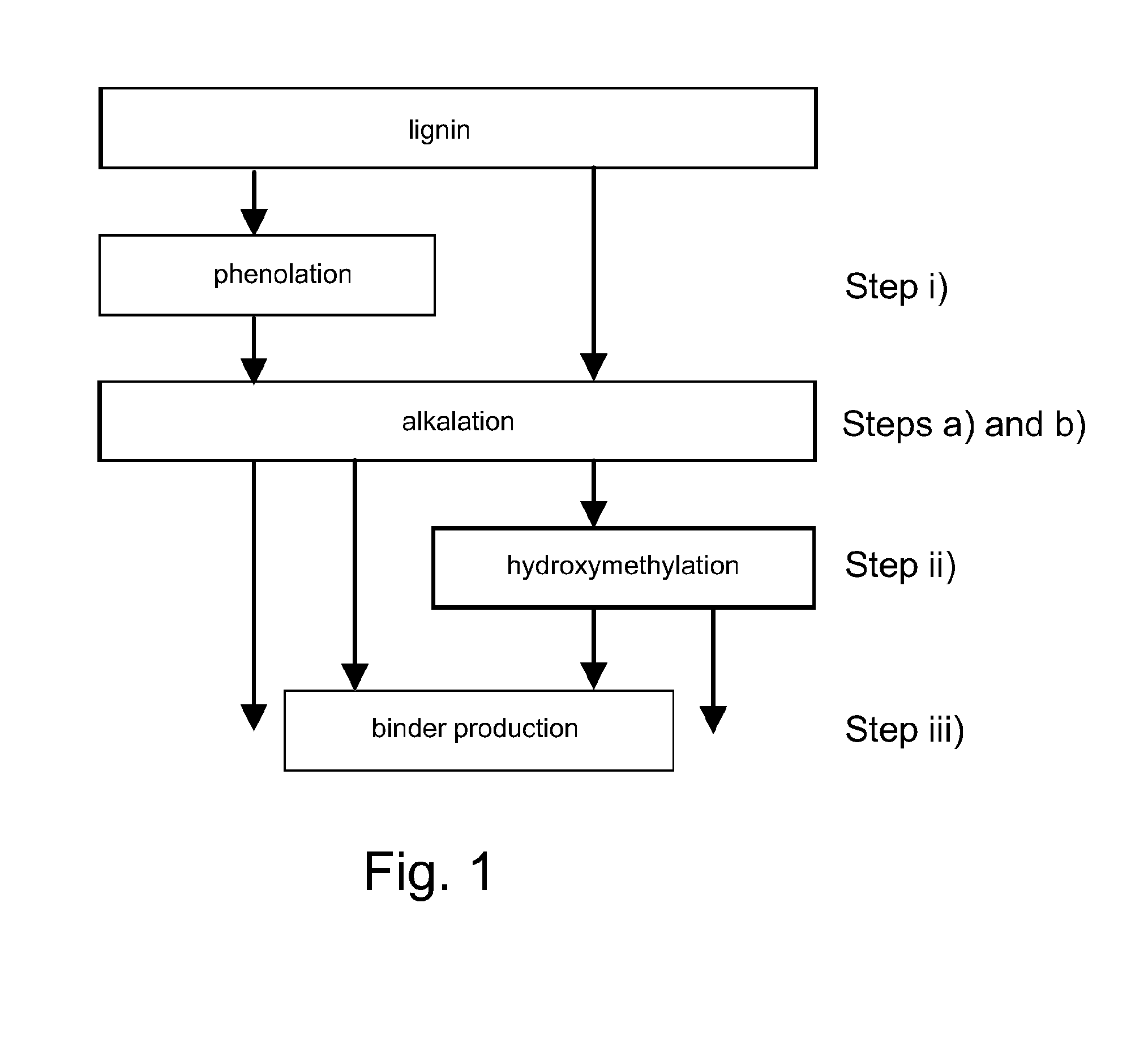

Method for increasing the reactivity of lignin

ActiveUS20140249271A1Improve responseIncrease the number ofAldehyde/ketone condensation polymer adhesivesLignin derivativesAlkali metalMetal

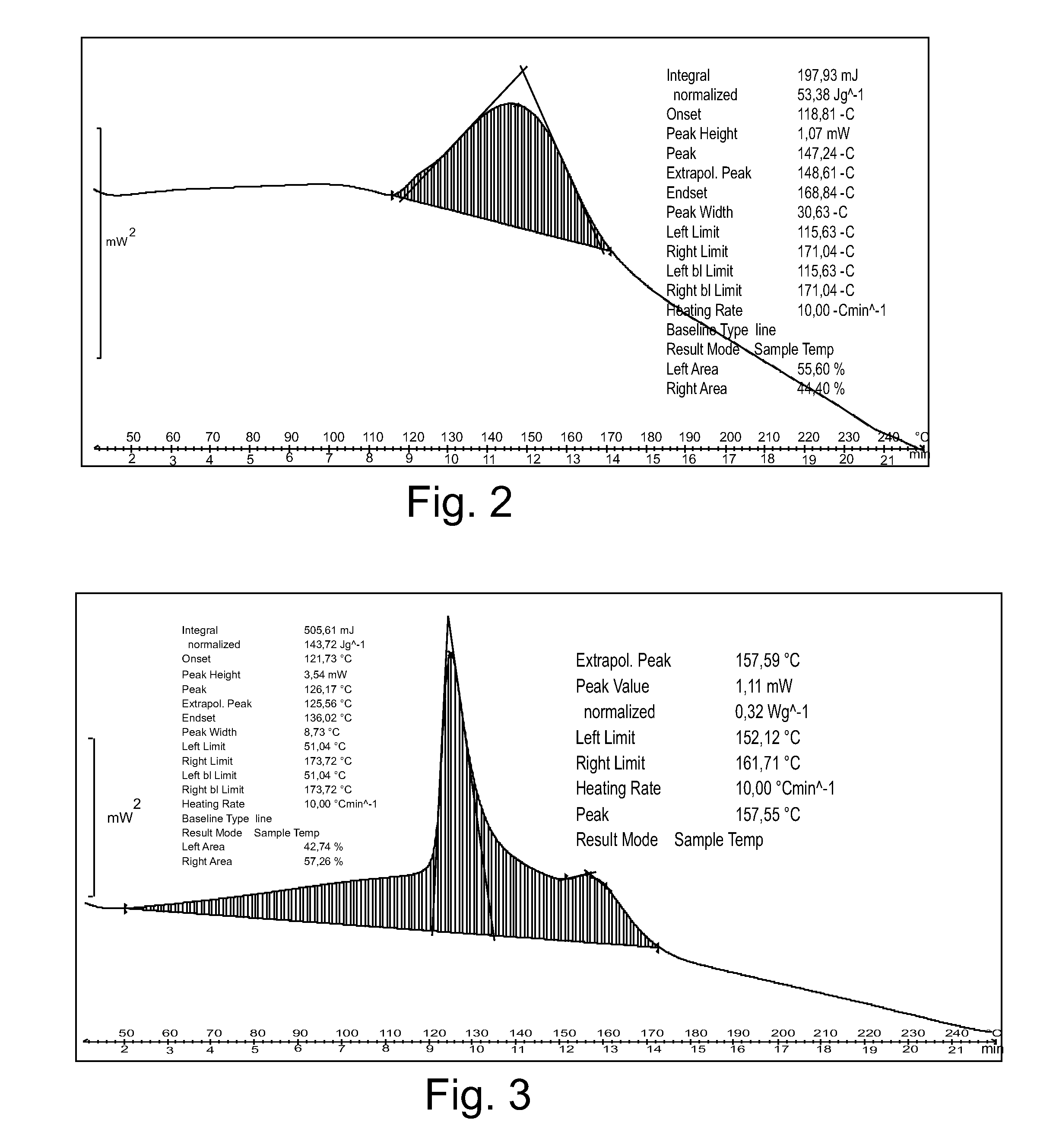

The present invention relates to a method for increasing the reactivity of lignin, wherein the method comprises the following steps: a) forming, under heating at a temperature of 30-70° C., an aqueous dispersion comprising alkali and lignin, wherein the alkali comprises a hydroxide of an alkali metal; and b) heating the dispersion formed in step a) at a temperature of 50-95° C. for producing alkalated lignin.

Owner:UPM-KYMMENE OYJ

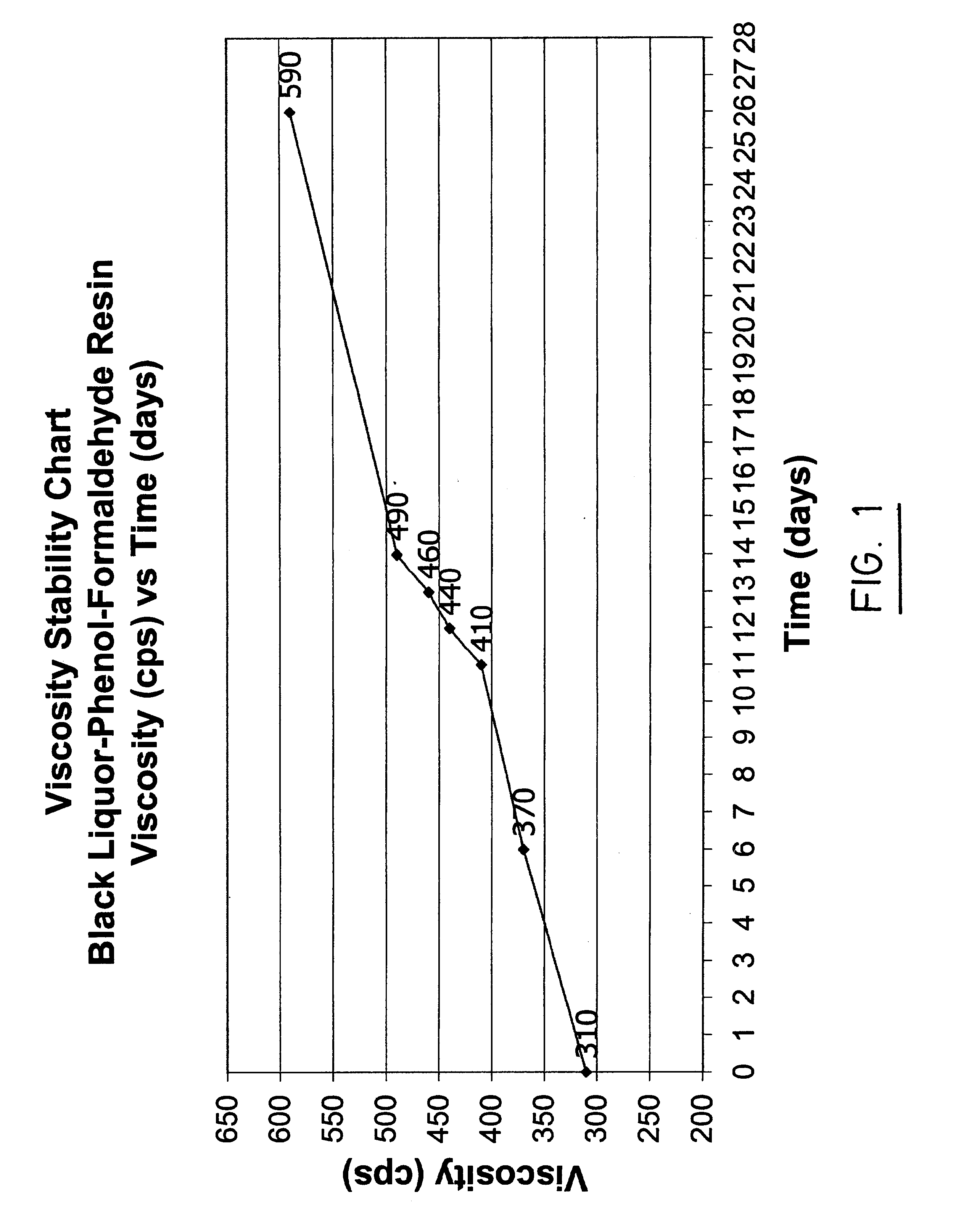

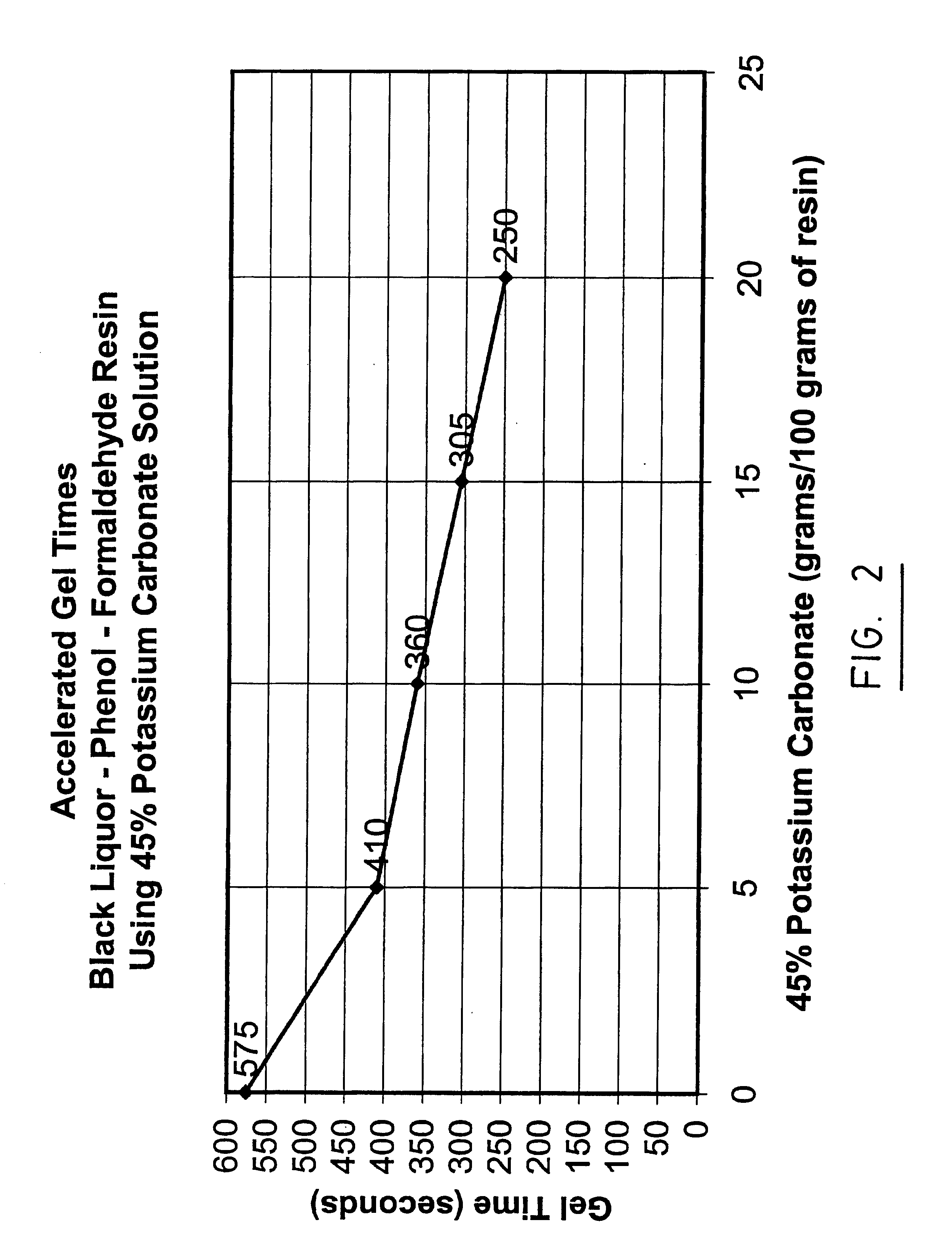

Process for preparing a black liquor-phenol formaldehyde thermoset resin

Owner:CASCADES CANADA INC

Process for preparing a black liquor-phenol formaldehyde thermoset resin

Disclosed is a process for preparing phenol-formaldehyde thermoset resin that can contain up to 80% by weight a black liquor, preferably a sodium carbonate black liquor. Black liquor are by-products extracted from pulping process, which normally contain lignosulfonates, kraft lignin or sodium carbonate lignin as well as salts, depending on the process that is used. The use of such a black liquor permits to obtain a stable copolymerized phenol-formaldehyde thermoset resin. In the process, the black liquor is first mixed with phenol in the pressure of a base. Then, formaldehyde is added together with a base in two successive steps. The obtained thermoset resin has bonding properties that meet or exceed the CSA and ASTM requirements for the engineered forest products, such as wafer boards or oriented strand boards at pressing cycles of 16 mm per second or less.

Owner:CASCADES CANADA INC

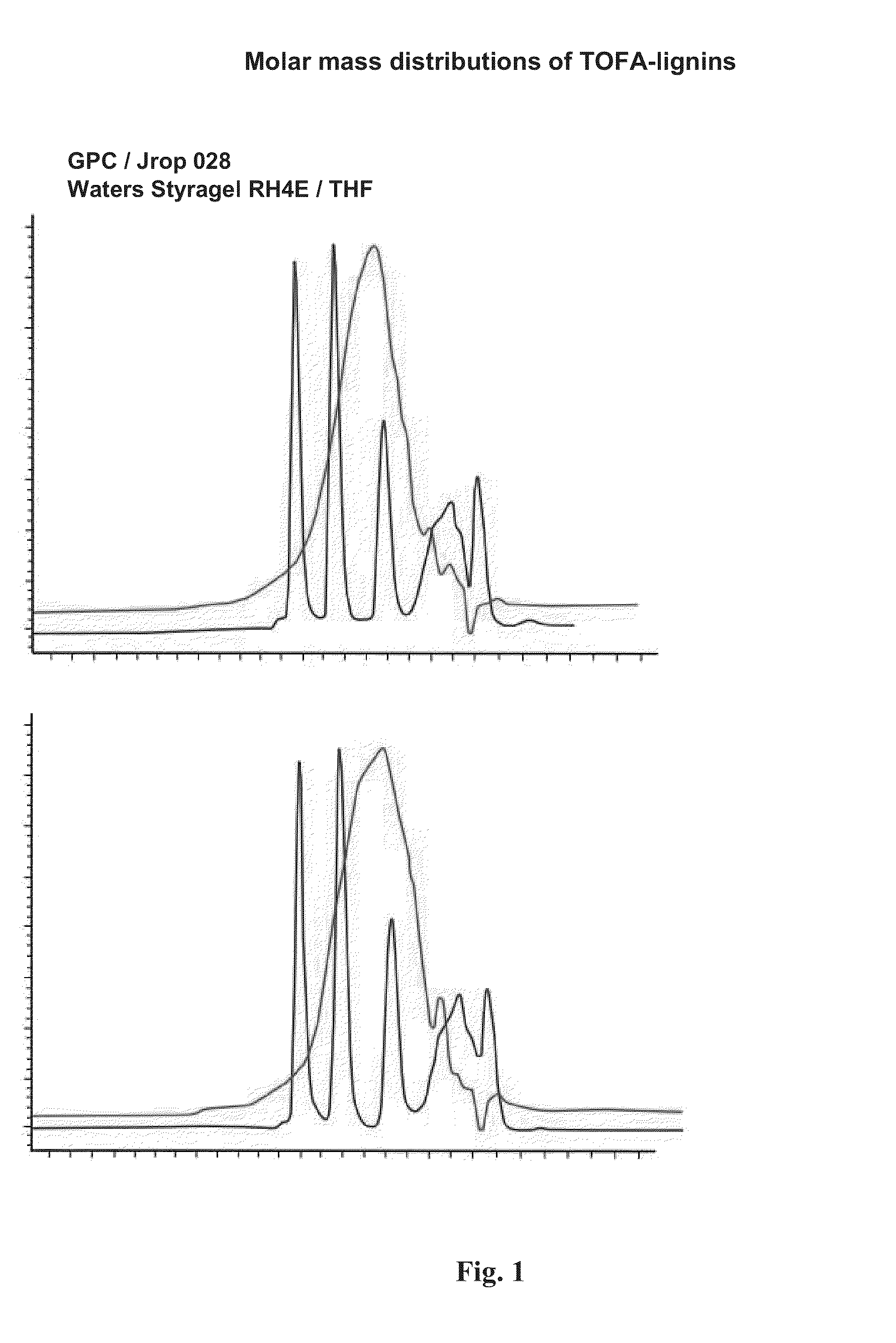

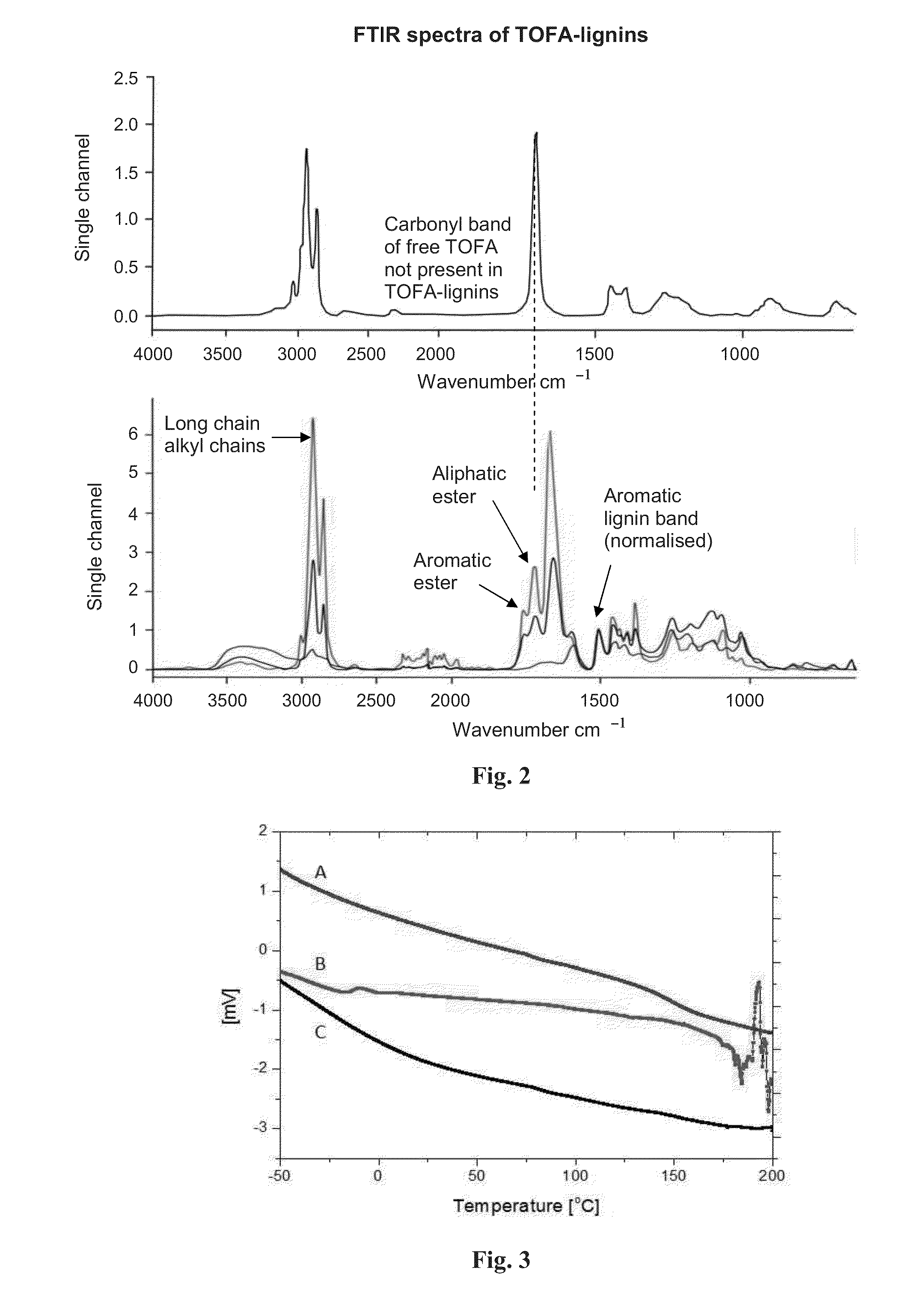

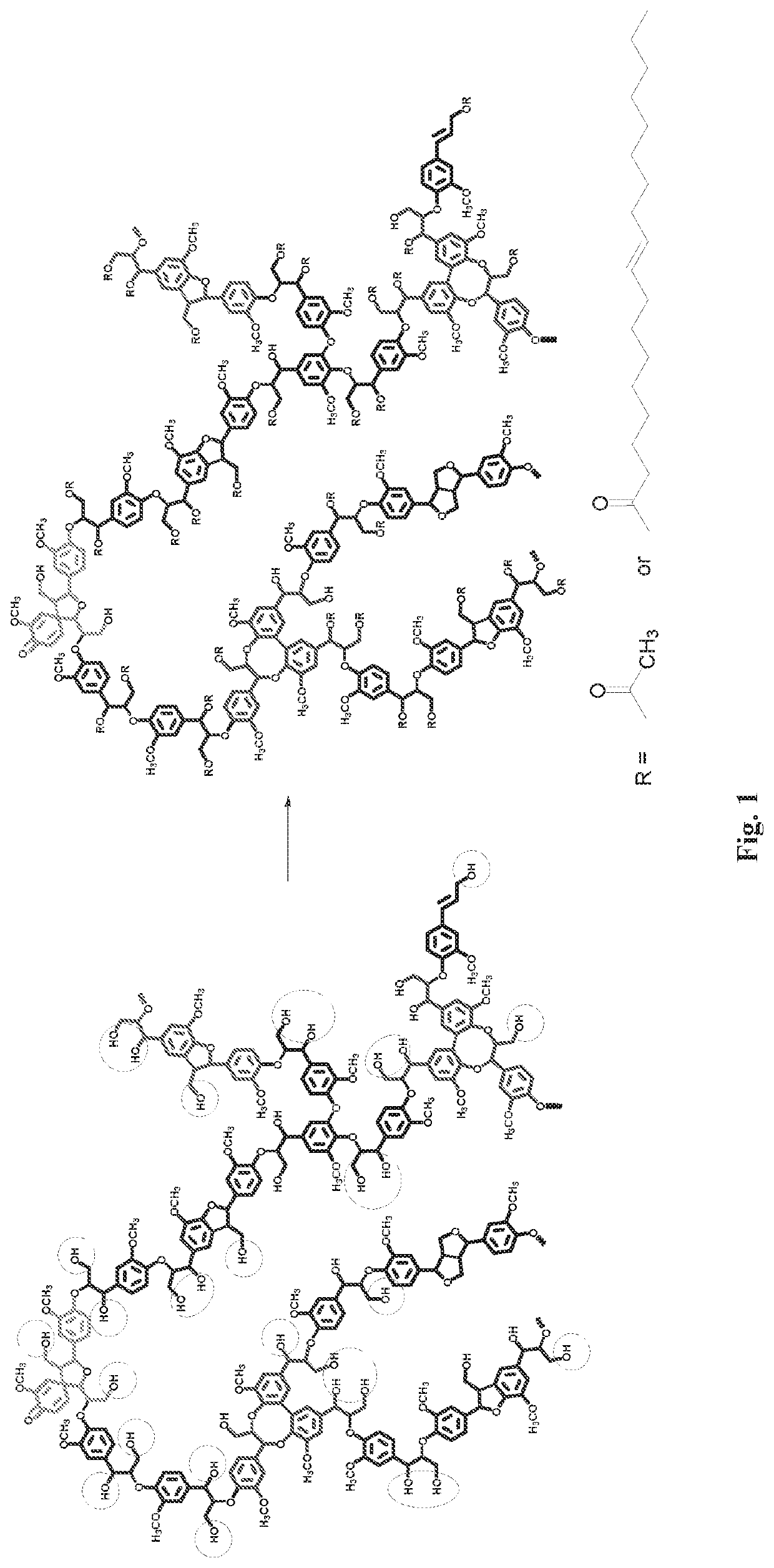

Functionalized lignin and method of producing the same

ActiveUS20140243511A1Improve barrier propertiesMedium barrier propertyNon-fibrous pulp additionLignin derivativesFiberPaperboard

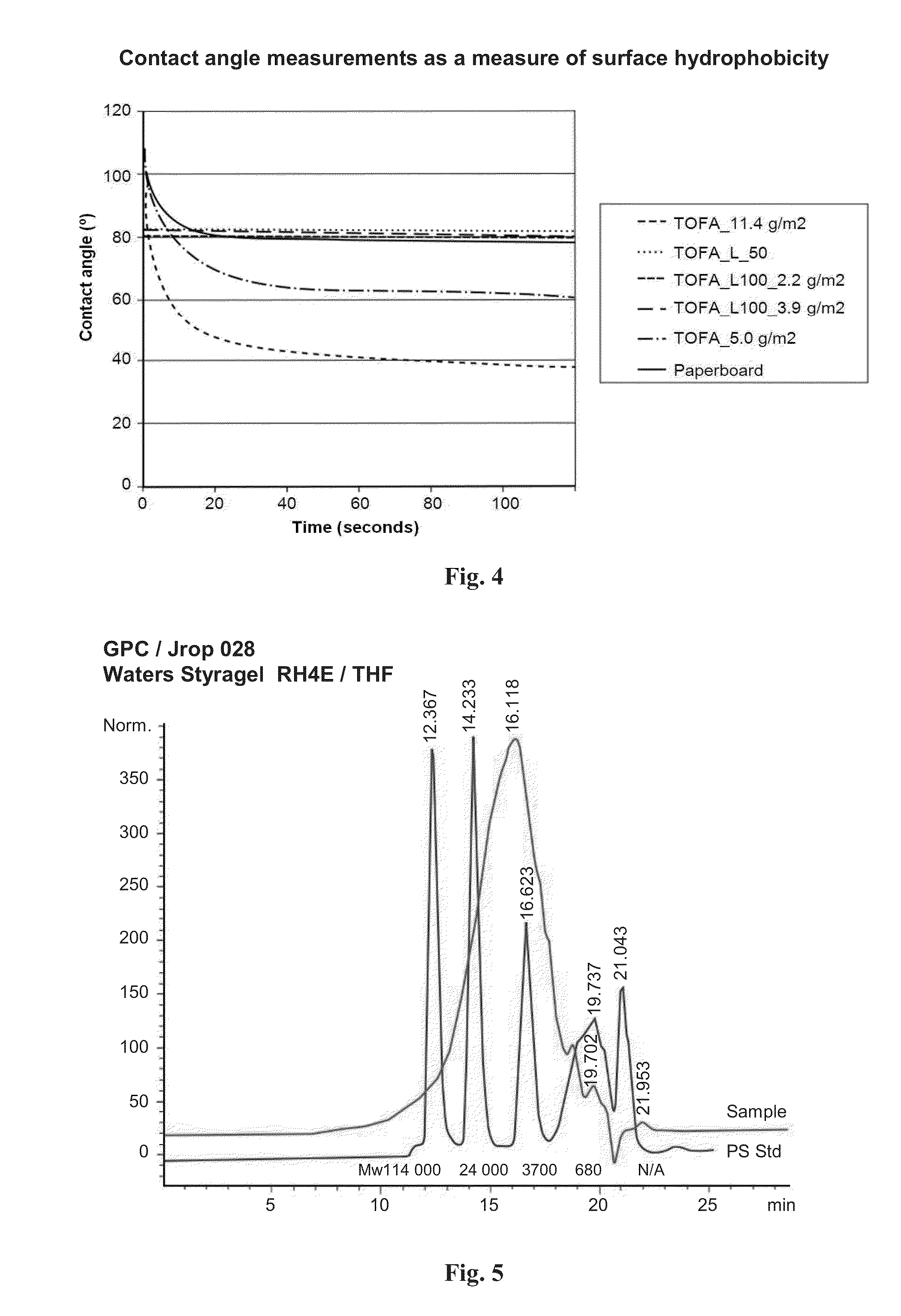

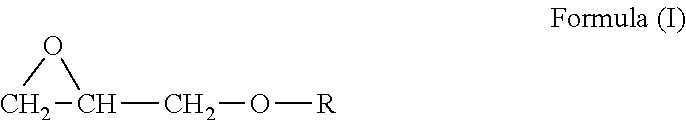

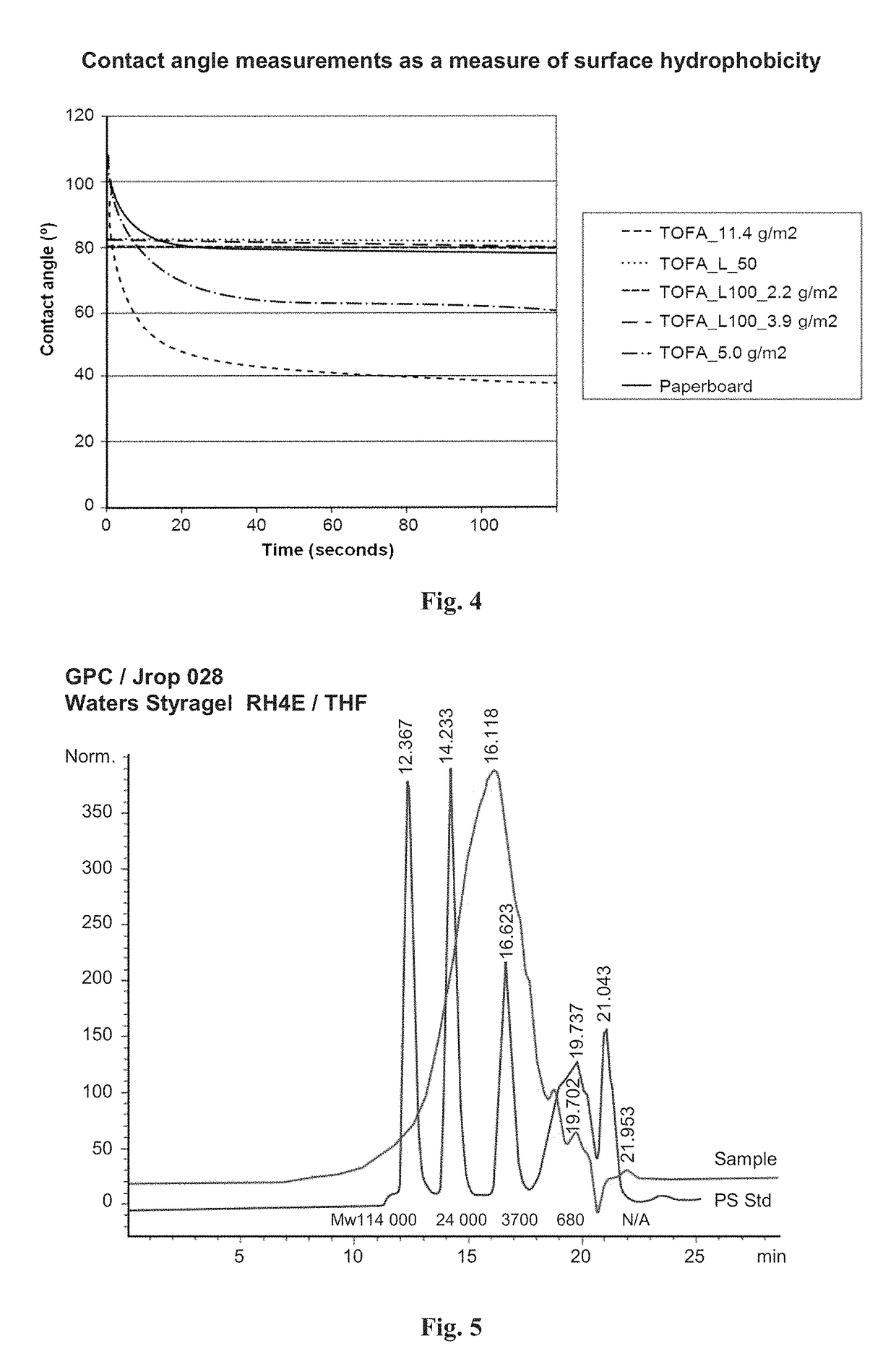

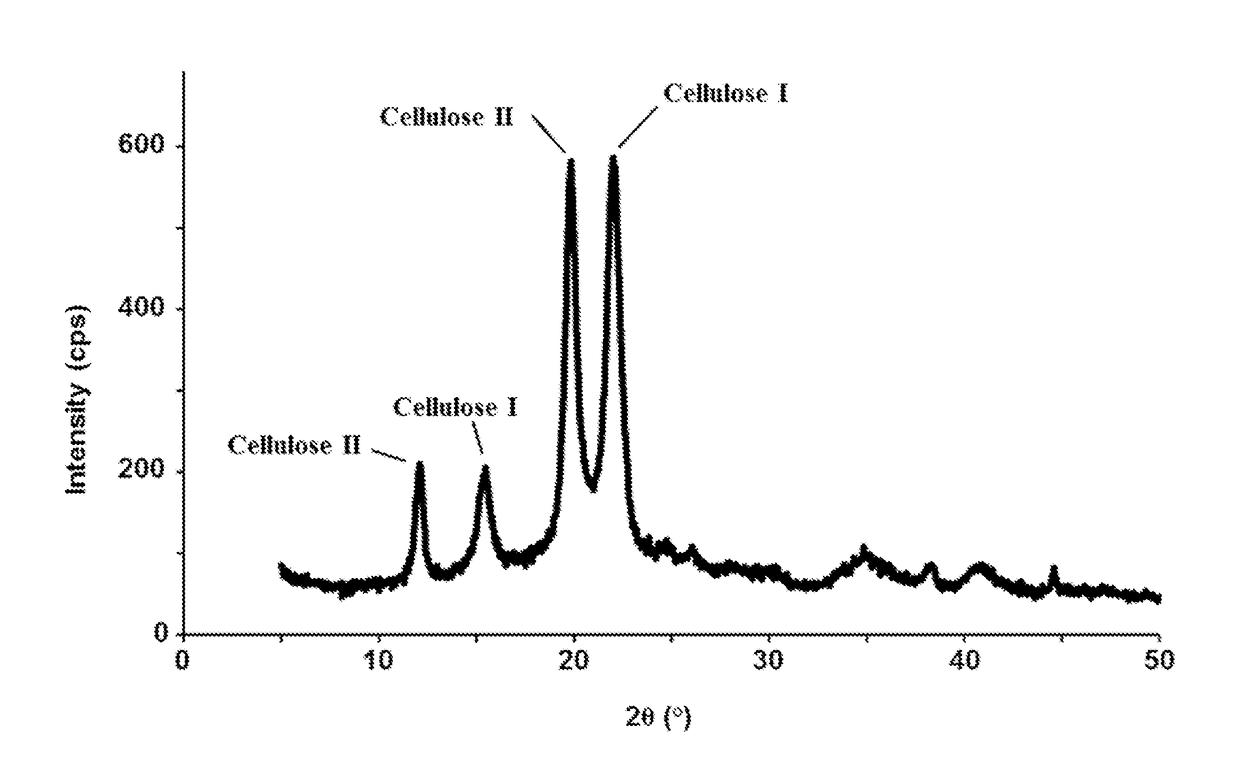

In this study, commercially available softwood lignin was esterified with tall oil fatty acid (TOFA) and tested as barrier material in fiber-based packaging material. The modified lignin samples were applied with a bar coater forming an even coating on the paperboard substrate. A significant decrease in WVTR and OTR value was observed for paperboard coated with the modified lignin as well as pure TOFA used as a reference. In contrast to the TOFA coating, the modified lignin coatings exhibited a high and stable contact angle. The coating material did not affect the tensile strength of the paperboard. According to the results, the demonstration of the conversion of lignin into a value added product has been shown. Furthermore, the novel coating material shows promising properties for the development as sustainable barrier material in fiber-based packaging material to replace oil-placed barriers.

Owner:TEKNOLOGIAN TUTKIMUSKESKUS VTT

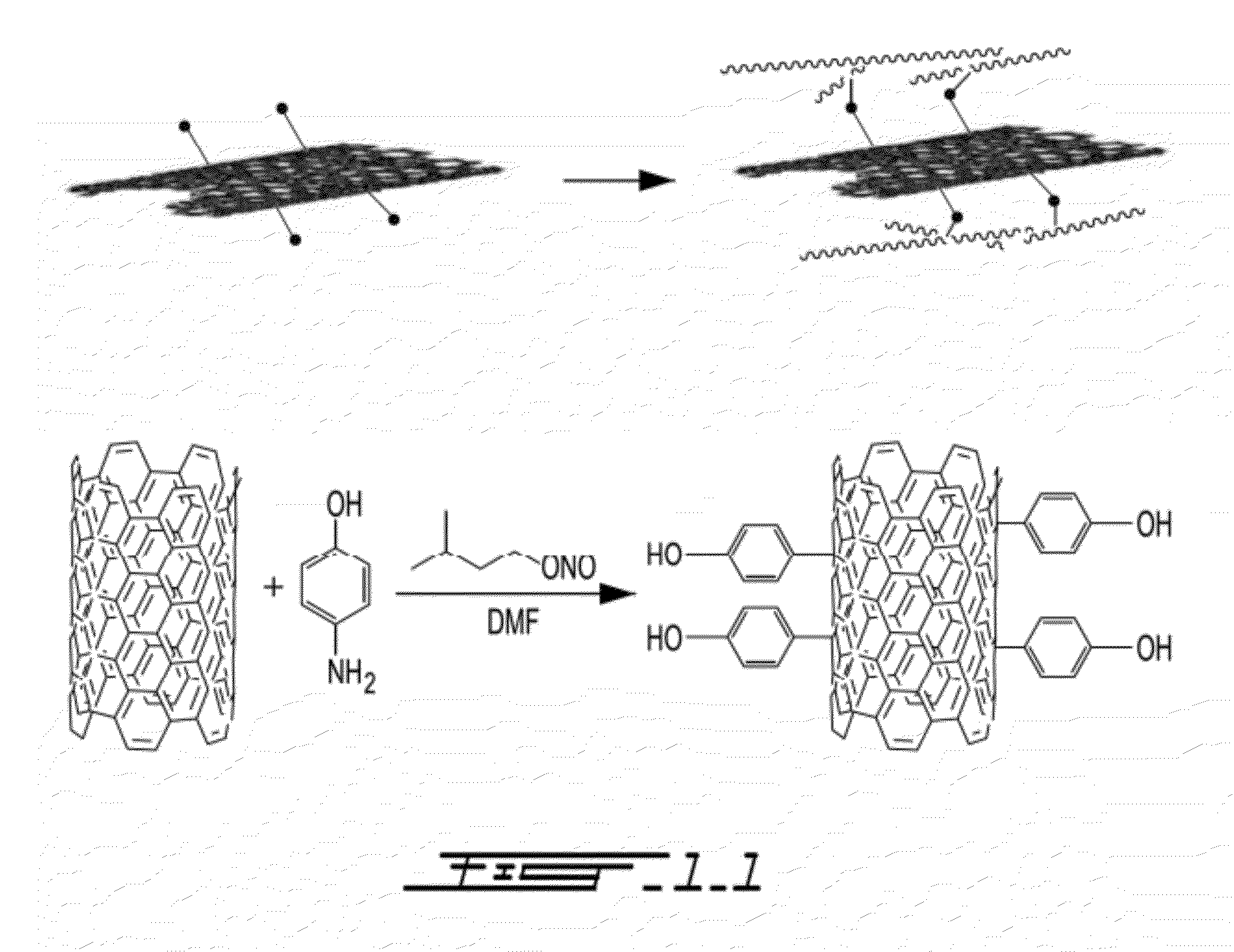

Modified polyphenol binder compositions and methods for making and using same

ActiveUS20140094562A1Simple compositionOrganic chemistryPlastic/resin/waxes insulatorsPolyphenolUnsaturated monomer

Modified polyphenol binder compositions and methods for making and using same are provided. In at least one specific embodiment, the binder composition can include at least one unsaturated monomer and at least one polyphenolic compound. The polyphenolic compound can include a lignin, a tannin, a novolac resin, a modified phenol formaldehyde resin, bis-phenol A, humic acid, or any mixture thereof.

Owner:GEORGIA PACIFIC CHEM LLC

A method for increasing the reactivity of lignin

ActiveUS20160237194A1Improve responseIncrease the number ofWood working apparatusAldehyde/ketone condensation polymer adhesivesAlkali metalMetal

The present invention relates to a method for increasing the reactivity of lignin, wherein the method comprises the following steps: a) forming, under heating at a temperature of 71-94° C., an aqueous dispersion comprising alkali and lignin, wherein the alkali comprises a hydroxide of an alkali metal; and b) heating the dispersion formed in step a) at a temperature of 50-95° C. for producing alkalated lignin.

Owner:UPM-KYMMENE OYJ

Cellulose nanocrystals - thermoset resin systems, applications thereof and articles made therefrom

InactiveUS20160002462A1Enhanced interactionAldehyde/ketone condensation polymer adhesivesLignin adhesivesPolymer scienceAdhesive

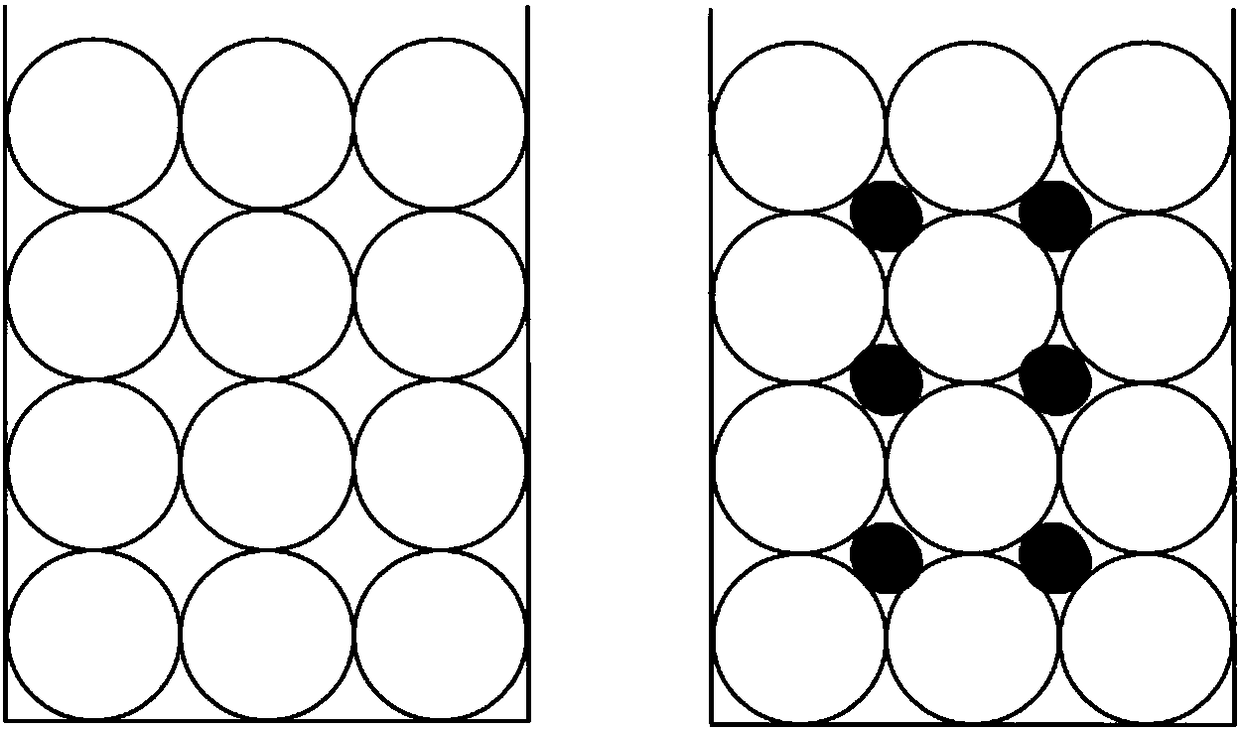

The present describes wood adhesives reinforced with cellulose nanocrystals (CNC), in liquid and powder forms in which resin system are a phenol-formaldehyde polymer and / or lignin-phenol-formaldehyde polymer and polymeric methylene diphenyl diisocyanate (pMDI), and a method of making this polymer in liquid and powder from and the composite products that can be produced therefrom.

Owner:FPINNOVATIONS INC

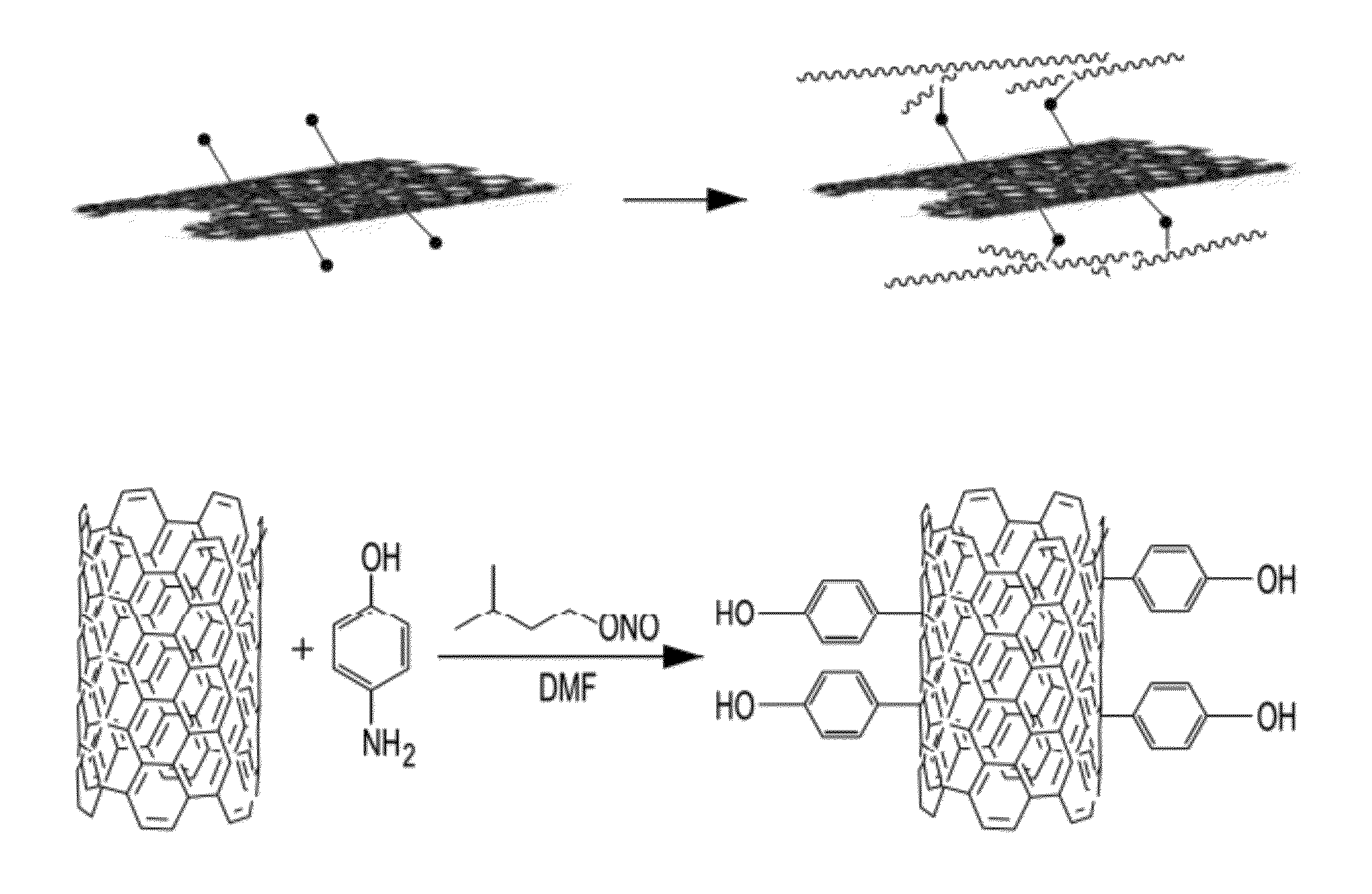

Phenol-formaldehyde polymer with carbon nanotubes, a method of producing same, and products derived therefrom

InactiveUS20120041146A1Material nanotechnologyAldehyde/ketone condensation polymer adhesivesCellulosePolymer science

The present invention provides methods to functionalize and solubilize WCNT with a phenolic polymer such as a lignin or a PF resin followed by in-situ integration of this functionalized CNT in the presence of formaldehyde and phenol and / or lignin to generate either CNT-reinforced phenol-formaldehyde polymer or CNT-reinforced lignin-phenol-formaldehyde polymer in either liquid or powder form suitable as an adhesive in the manufacture of a lignocellulosic composite material such as OSB and plywood.

Owner:NAT RES COUNCIL OF CANADA +1

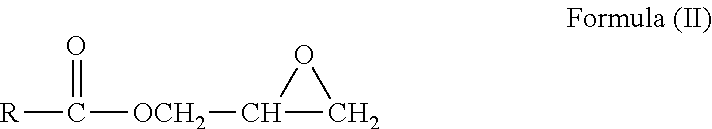

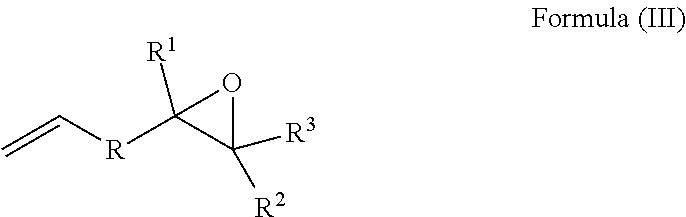

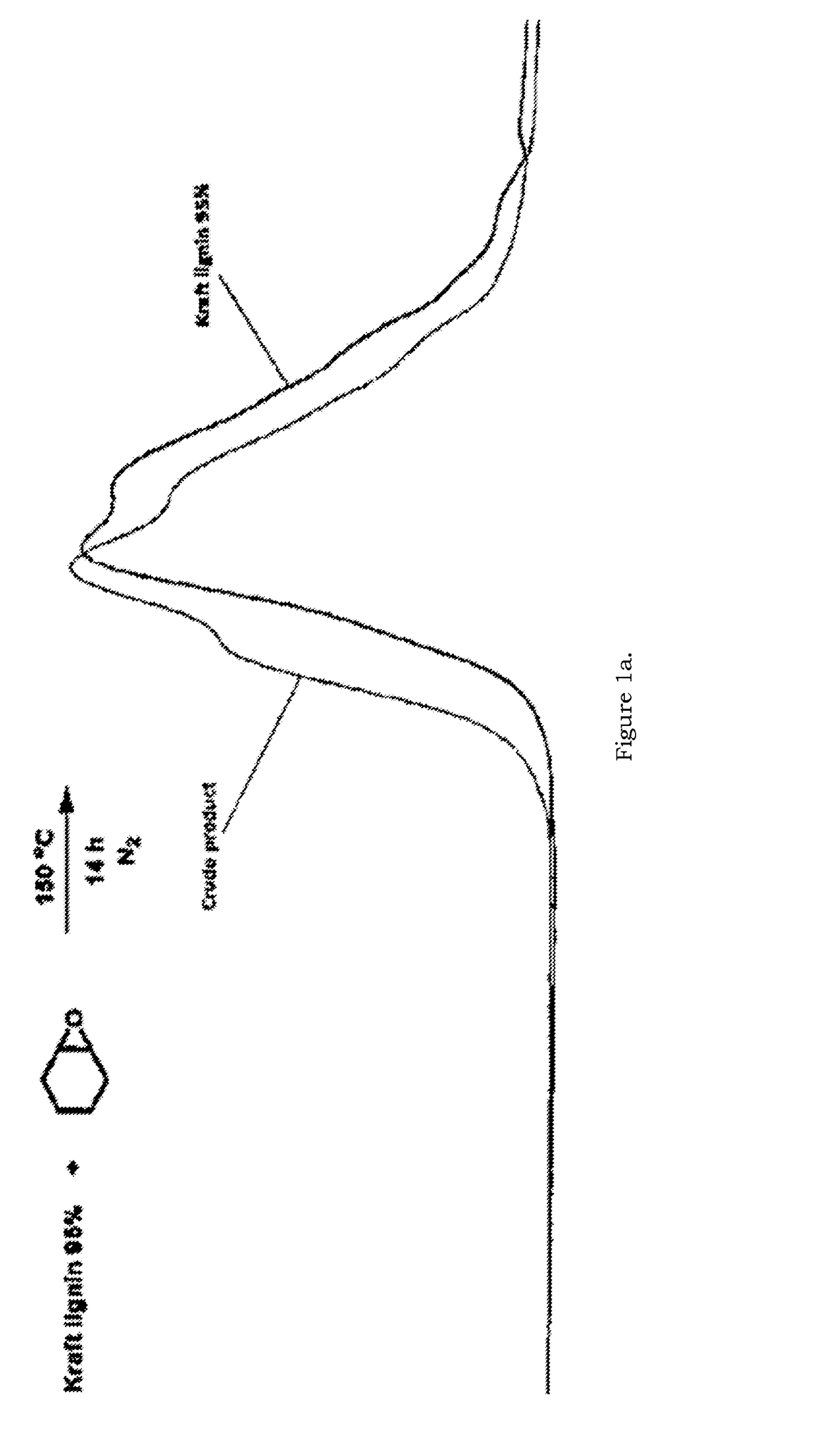

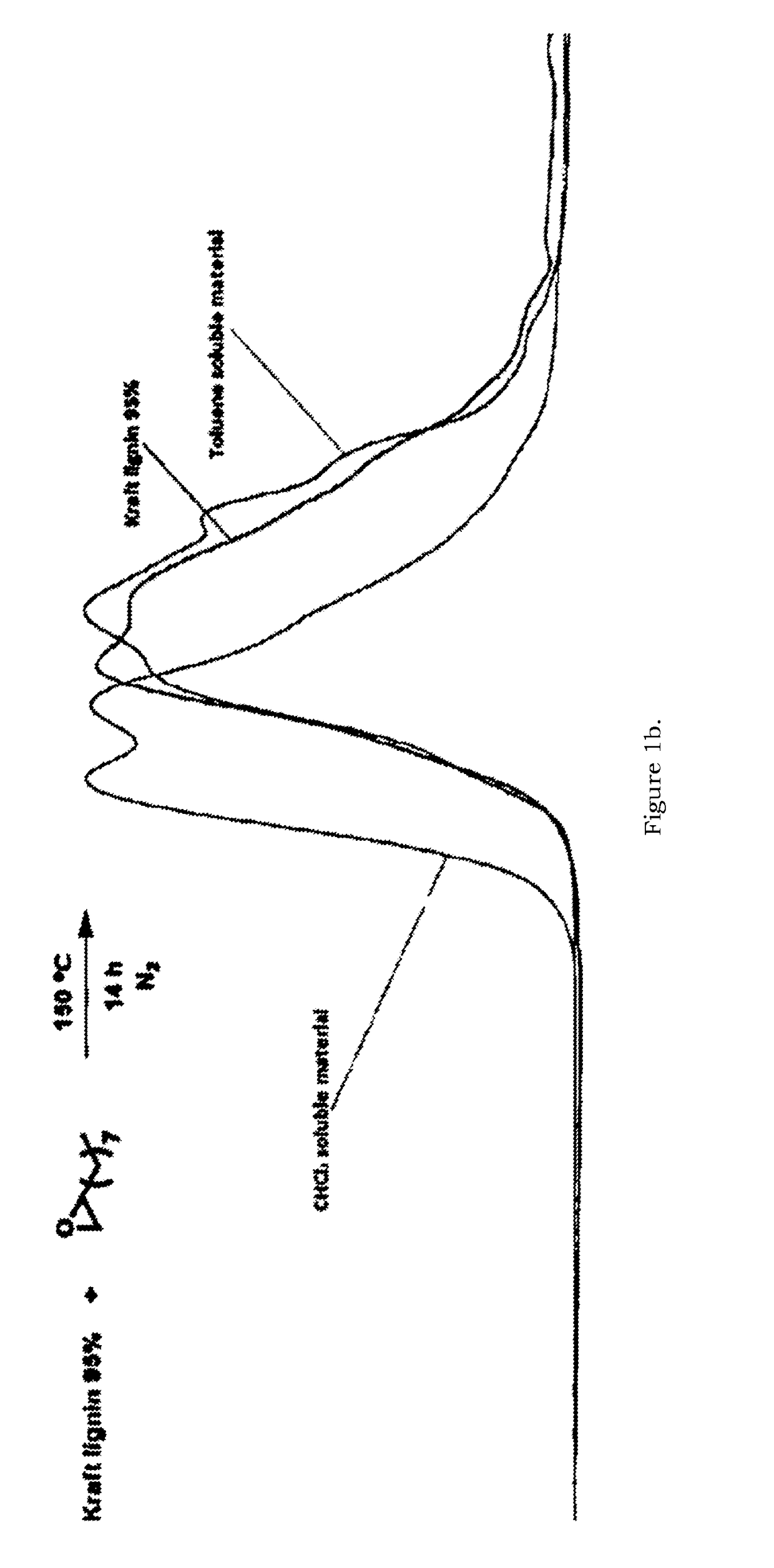

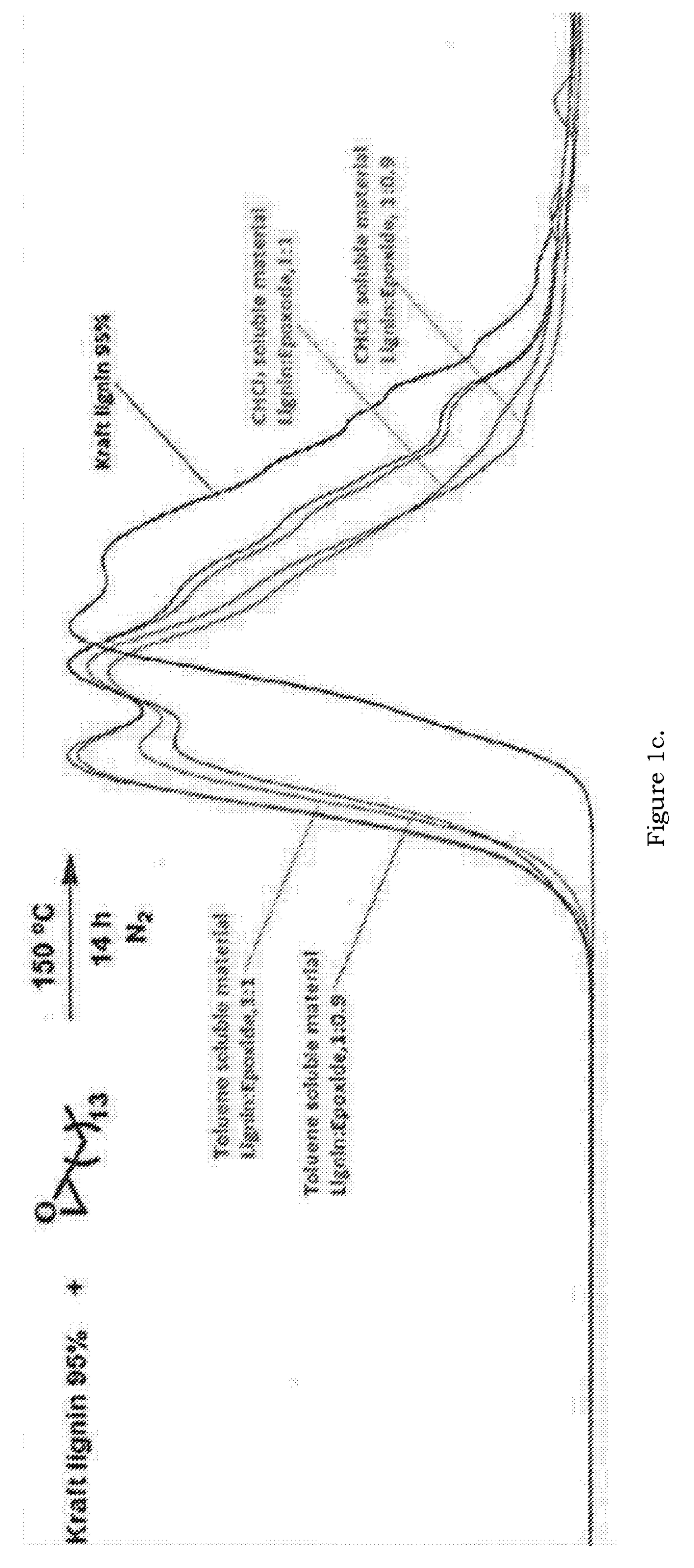

A composition comprising lignin and epoxy compound for coating and method for the manufacturing thereof and use thereof

The present invention relates to a composition for coating, in particular a composition comprising lignin and one or more epoxy-group containing compounds, and methods for the manufacturing thereof and uses thereof. The present invention also relates to products obtainable by said methods and uses thereof.

Owner:STORA ENSO OYJ

Adhesives containing a resin, a kraft lignin, and a surfactant and methods for making and using same

InactiveUS20160096985A1Improve methodGood viscosity stabilityAldehyde/ketone condensation polymer adhesivesLignin adhesivesAdhesiveKraft paper

Adhesives containing an aldehyde-based resin, a kraft lignin, and a surfactant and methods for making and using same are provided. In one or more embodiments, the adhesive can include an aldehyde-based resin; a kraft lignin; a surfactant; an alkaline compound; and water. The adhesive can have a viscosity of about 500 cP to about 5,000 cP, at a temperature of about 25° C. In one example, the adhesive can include about 20 wt % to about 40 wt % of the aldehyde-based resin, about 1 wt % to about 15 wt % of the kraft lignin, about 0.05 wt % to about 2 wt % of the surfactant, about 0.5 wt % to about 10 wt % of the alkaline compound, and about 45 wt % to about 70 wt % of water, where all weight percent values are based on a combined weight of the aldehyde-based resin, the kraft lignin, the surfactant, the alkaline compound, and the water.

Owner:GEORGIA PACIFIC CHEM LLC

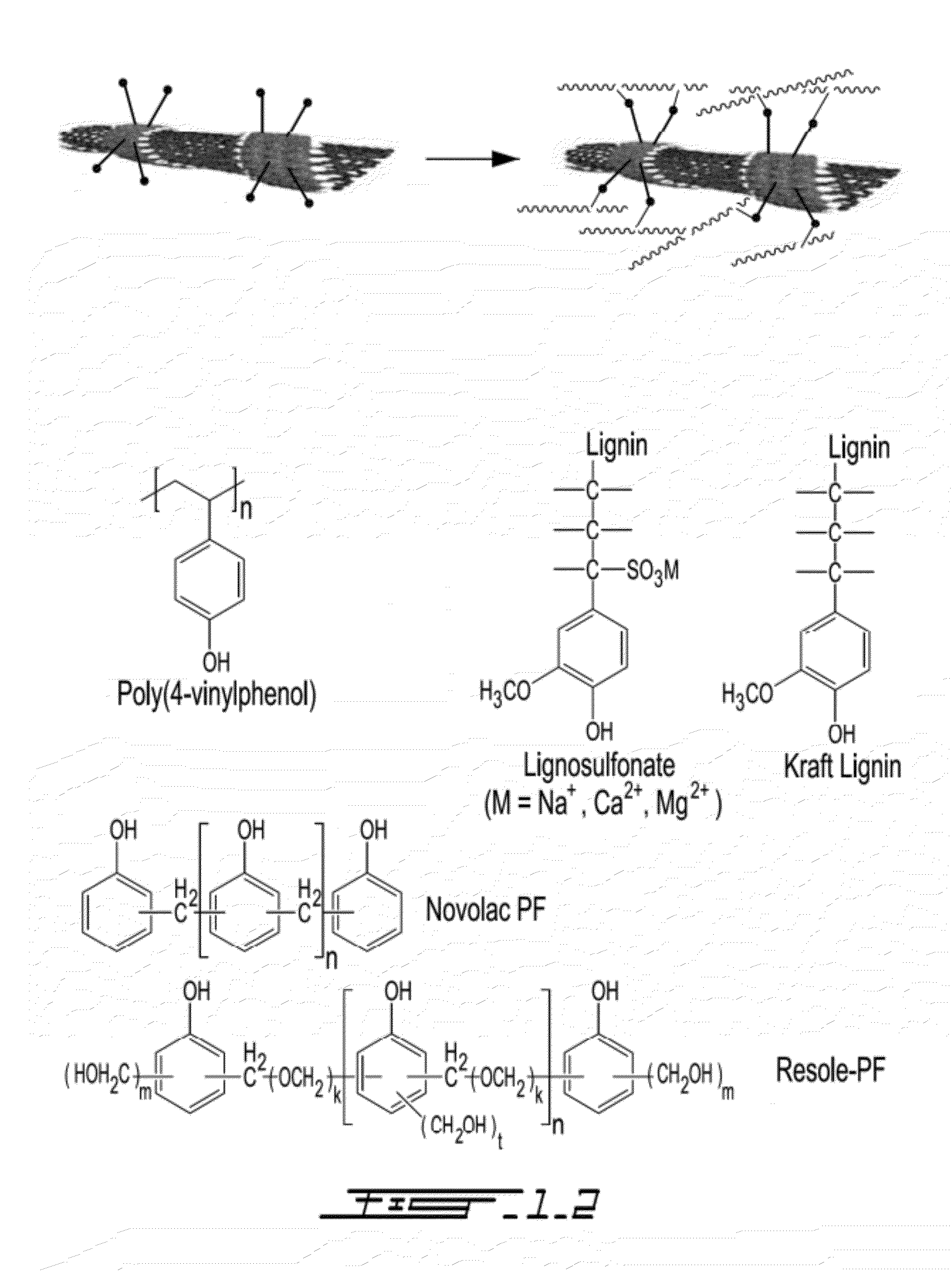

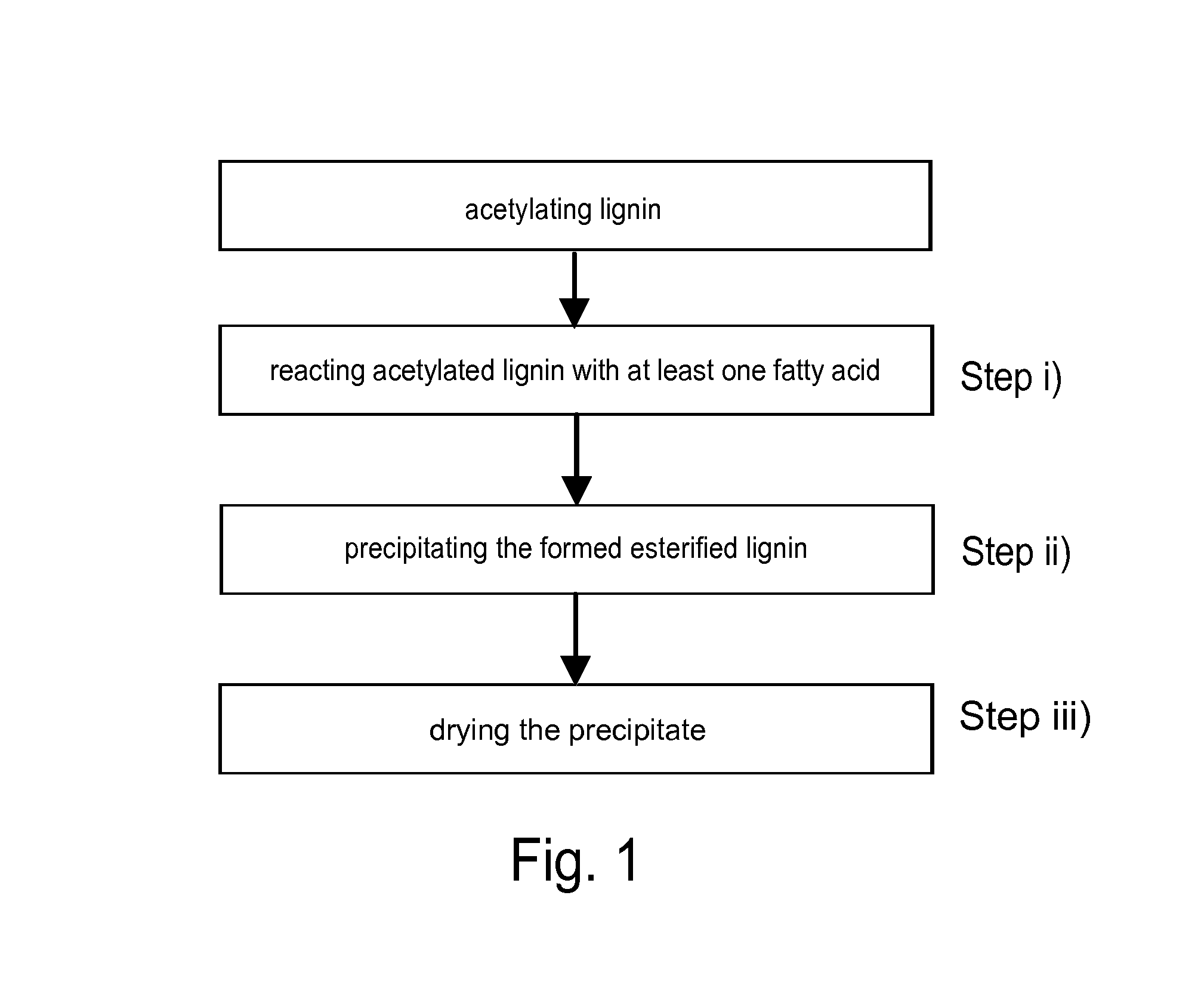

Method for esterifying lignin with at least one fatty acid

InactiveUS20150232497A1Reduce probabilityReduce rateLignin derivativesLignin adhesivesAcetic acidAcetylation

The present invention relates to a method for producing lignin esterified with at least one fatty acid, wherein the method includes the following steps: (i) reacting acetylated lignin with at least one fatty acid under the influence of heating and distilling at least part of the acetic acid formed during the reaction away from the reaction mixture, wherein per each mole of acetyl groups present in the lignin an excess molar amount of at least one fatty acid is used; and (ii) recovering lignin esterified with at least one fatty acid formed in step (i).

Owner:UPM-KYMMENE OYJ

Binder compositions comprising lignin derivatives

The present disclosure provides a binder composition comprising a diisocyanate and a derivative of native lignin. The derivative of native lignin is treated such that it is characterized by the aliphatic hydroxy content. The binder may be used in an adhesive system comprising: a. a resin comprising at least about 30% by weight of phenol-formaldehyde resin and at least about 30% by weight of derivative of native lignin; and b. an isocyanate based binder.

Owner:SUZANO CANADA INC

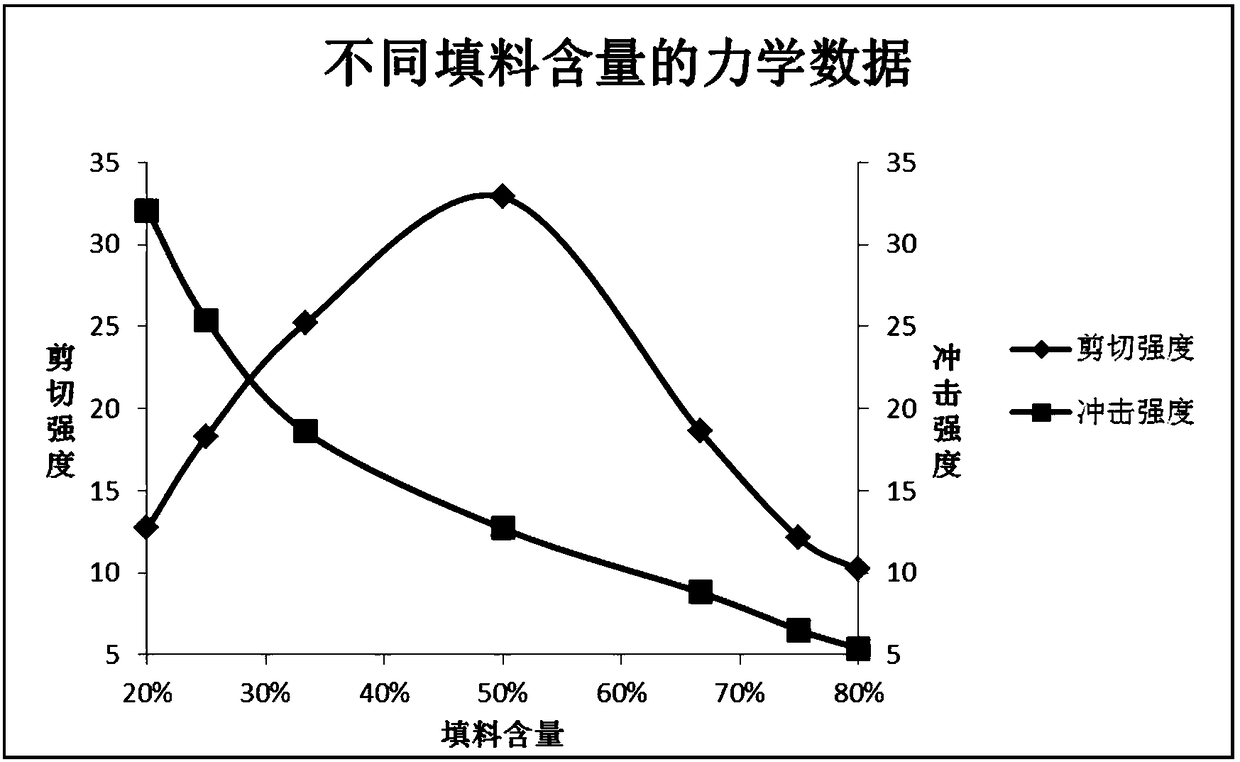

High-filling high toughness epoxy stone adhesive and preparation method thereof

ActiveCN108192547AAvoid internal stressFast curingNon-macromolecular adhesive additivesLignin adhesivesAdhesiveEconomic benefits

The invention discloses a high-filling and high-toughness epoxy stone adhesive and a preparation method thereof. The adhesive is prepared from a component A and a component B, wherein the weight ratioof the component A to the component B is (1 to 3) to 1; the component A is prepared from the following components in parts by weight: 30 to 50 parts of epoxy resin, 1 to 5 parts of a bifunctional reactive diluent and 100 to 150 parts of composite filler; the component B is prepared from the following components in parts by weight: 15 to 40 parts of self-catalyzed toughness curing agent compound and 50 to 200 parts of the composite filler. Compared with the prior art, the high-filling and high-toughness epoxy stone adhesive disclosed by the invention has the characteristics of large filling ratio, high strength, good toughness, excellent thixotropy, stable storage and considerable economic benefits; the preparation method of the high-filling and high-toughness epoxy stone adhesive has theadvantages of low requirements on equipment, simple operation and suitability for industrial production.

Owner:WUHAN KEDA MARBLE PROTECTIVE MATERIALS

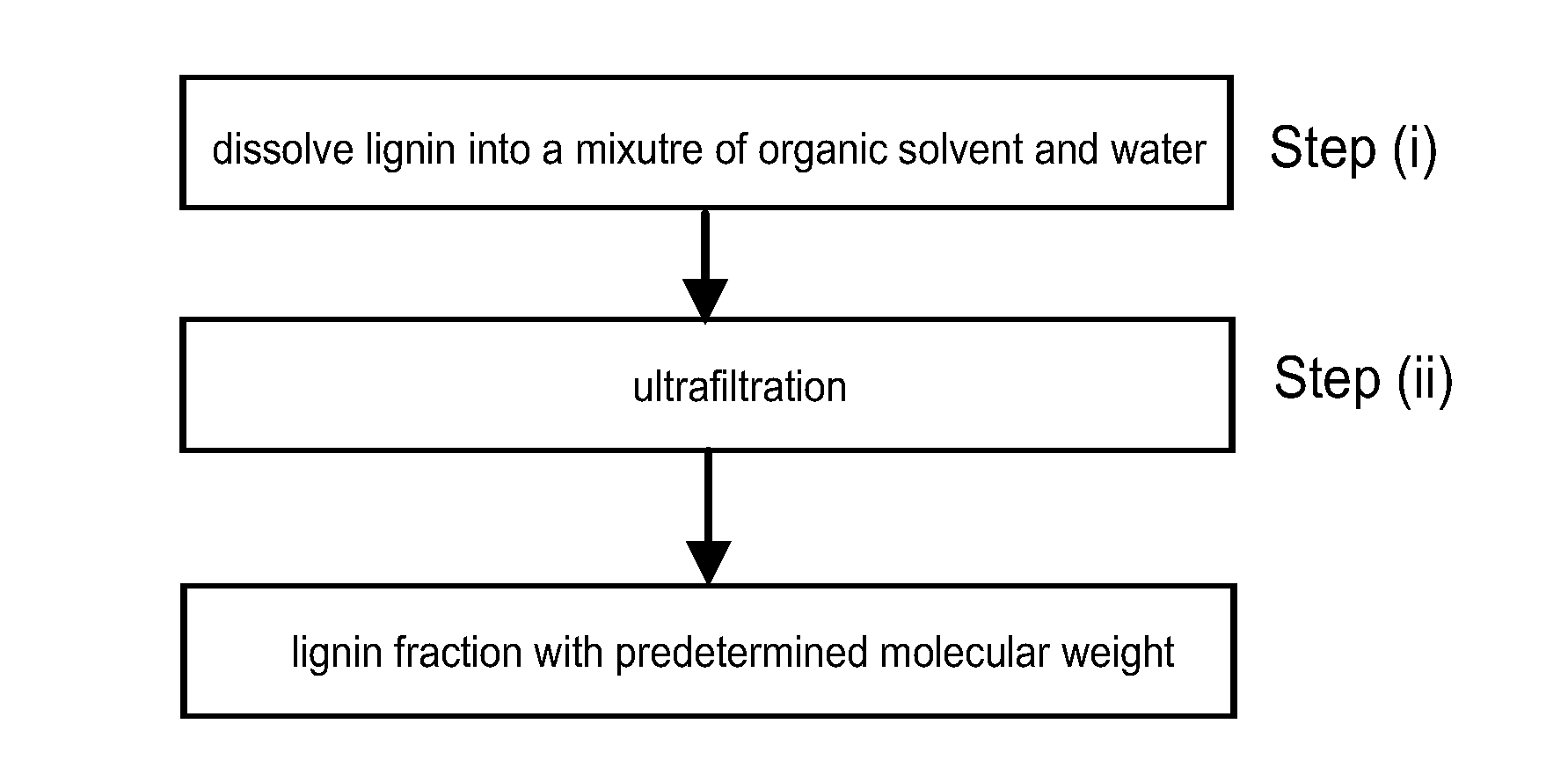

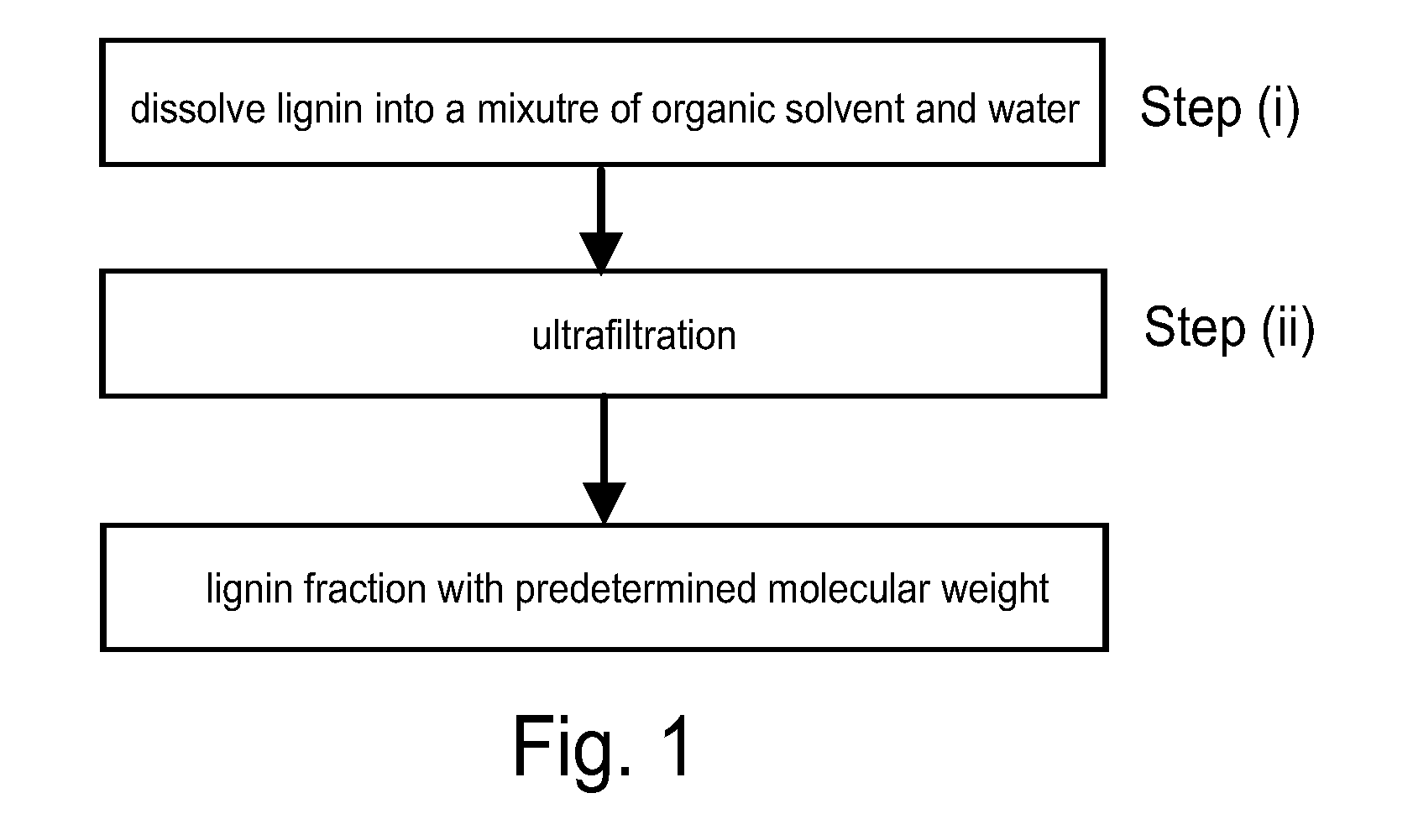

Method for fractionating lignin

ActiveUS20150183813A1Good effectLignin derivativesFibre chemical featuresFiltration membraneOrganosolv

The present invention relates to a method for fractionating lignin, wherein the method comprises the following steps: (i) dissolving lignin into a mixture containing organic solvent and water; and (ii) ultrafiltrating the mixture formed in step (i) through one or more filtration membranes for producing a predetermined number of lignin fractions, wherein each fraction contains lignin with a molecular weight within a predetermined range. The present invention further relates to a lignin fraction and to the uses thereof.

Owner:UPM-KYMMENE OYJ

Novel waterproof wood material adhesive and preparation method thereof

InactiveCN105647451AStable water expansion coefficientHydrophilicProtein adhesivesPolyureas/polyurethane adhesivesEpoxyPolyurethane adhesive

The invention discloses a novel waterproof wood material adhesive and a preparation method thereof. Sodium carboxymethylcellulose or carboxymethylcellulose or carboxymethyl starch accounting for 0.3-0.8% is added to the adhesive. The adhesive is urea resin adhesive, waterborne polyurethane adhesive, acrylic ester adhesive, epoxy resin adhesive, isocyanate adhesive, phenolic resin adhesive, soy-based adhesive, starch adhesive, lignin adhesive, tannin adhesive and the like. Liquid sodium carboxymethylcellulose and carboxymethylcellulose can be directly added to the adhesive; powdery sodium carboxymethylcellulose, carboxymethylcellulose and carboxymethyl starch are added together with the last batch of solid raw materials in the production process. The waterproof wood material adhesive is high in bonding strength, good in waterproofing performance and low in cost; when the adhesive is used for manufacturing fiberboards or plywood, the water absorption expansion coefficient of panels is kept between 0.5 mm and 0.8 mm, the waterproofing performance is improved, the bonding strength is improved, and the adhesive is particularly suitable for manufacturing fiberboards.

Owner:上海齐驭实业有限公司

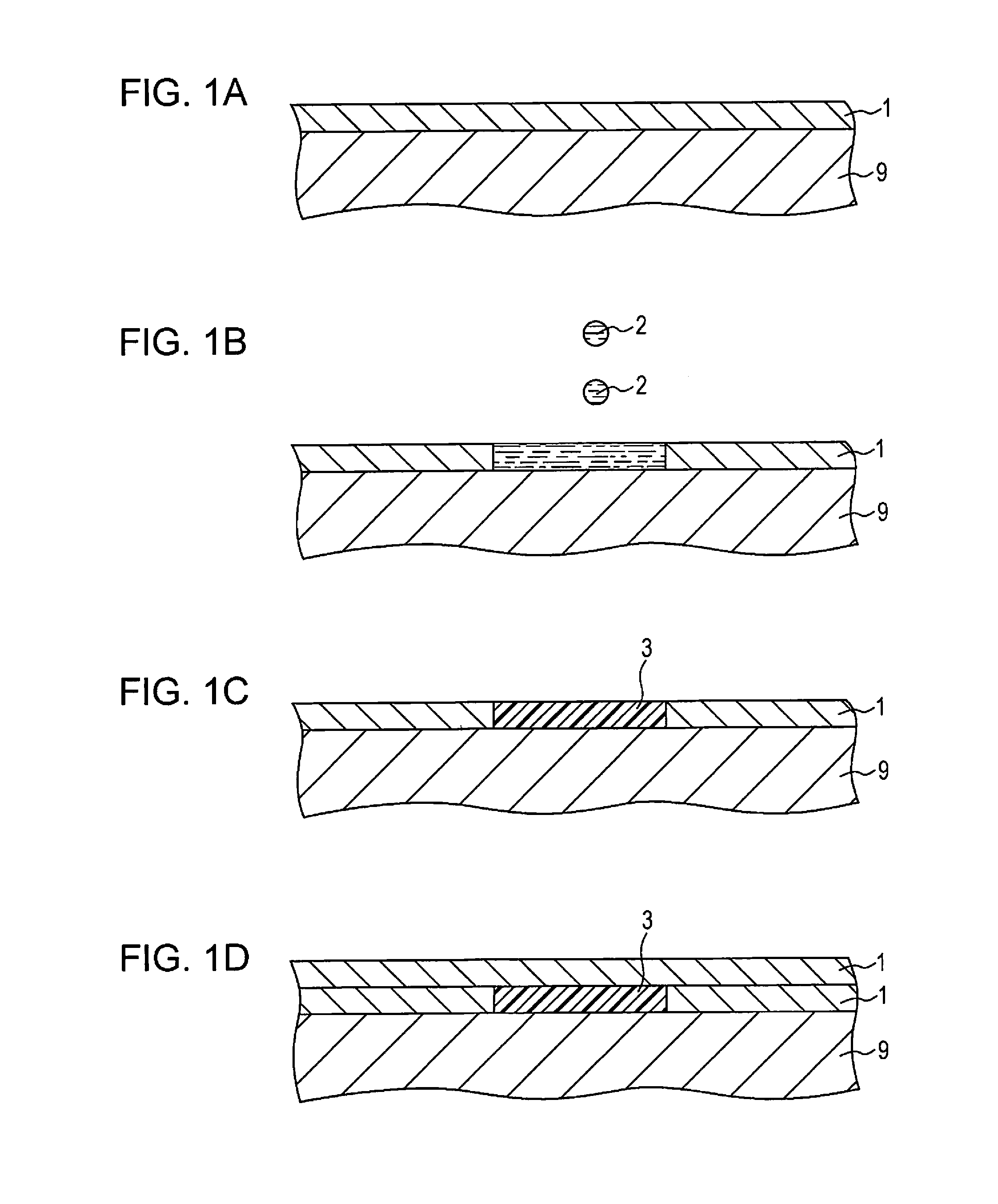

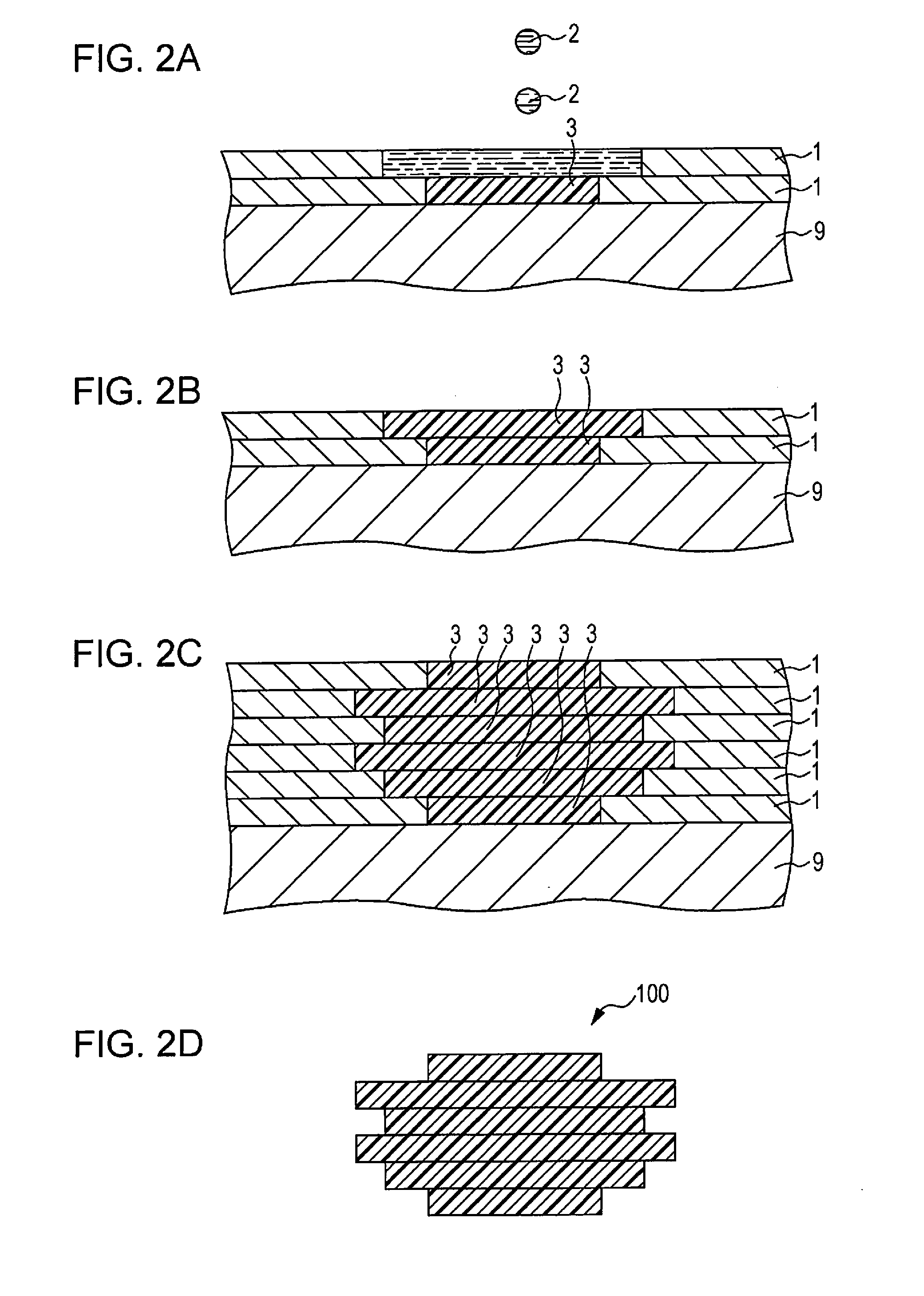

Method of manufacturing three-dimensional structure, three-dimensional structure, and three-dimension formation composition

InactiveUS20160001506A1Efficient preparationNon-fibrous pulp additionAdditive manufacturing apparatusWater solubleSolvent

There is provided a method of manufacturing a three-dimensional structure, in which the three-dimensional structure is manufactured by laminating a layer, the method including: forming the layer using a three-dimension formation composition containing particles, a binding resin, and a solvent; applying a binding solution containing a binder to the layer; and removing the particles, which are not bound by the binder, using a removing solution after repeating the forming of the layer and the applying of the binding solution, in which, in the removing of the unbound particles, the binding resin has a water-soluble functional group whose pKa in water is less than the pH of the removing solution.

Owner:SEIKO EPSON CORP

Adhesive

ActiveUS20160333240A1Promote denaturisationPromote solubilisationAgar-agar adhesivesStarch adhesivesLignanPolyphenol

An aqueous adhesive composition and a process for preparing such compositions are disclosed. The composition comprises macromolecular complex comprising (A) a first component comprising (i) a framework element and (ii) a polyphenol, and (B) second component comprising a polypeptide, oligopeptide, amino acid, or polyamine. The framework element comprises (a) a polypeptide, oligopeptide, amino acid, or polyamine, (b) a polysaccharide, oligosaccharide, or monosaccharide, or a saccharide conjugate, or (c) a lignin, a lignan or a lignin conjugate. The polyphenol comprises a tannin, a tannic acid, a flavonoid, or a poly-resorcinol. An adhesive precursor composition comprising the first component is also disclosed.

Owner:NEW ZEALAND FOREST RES INST

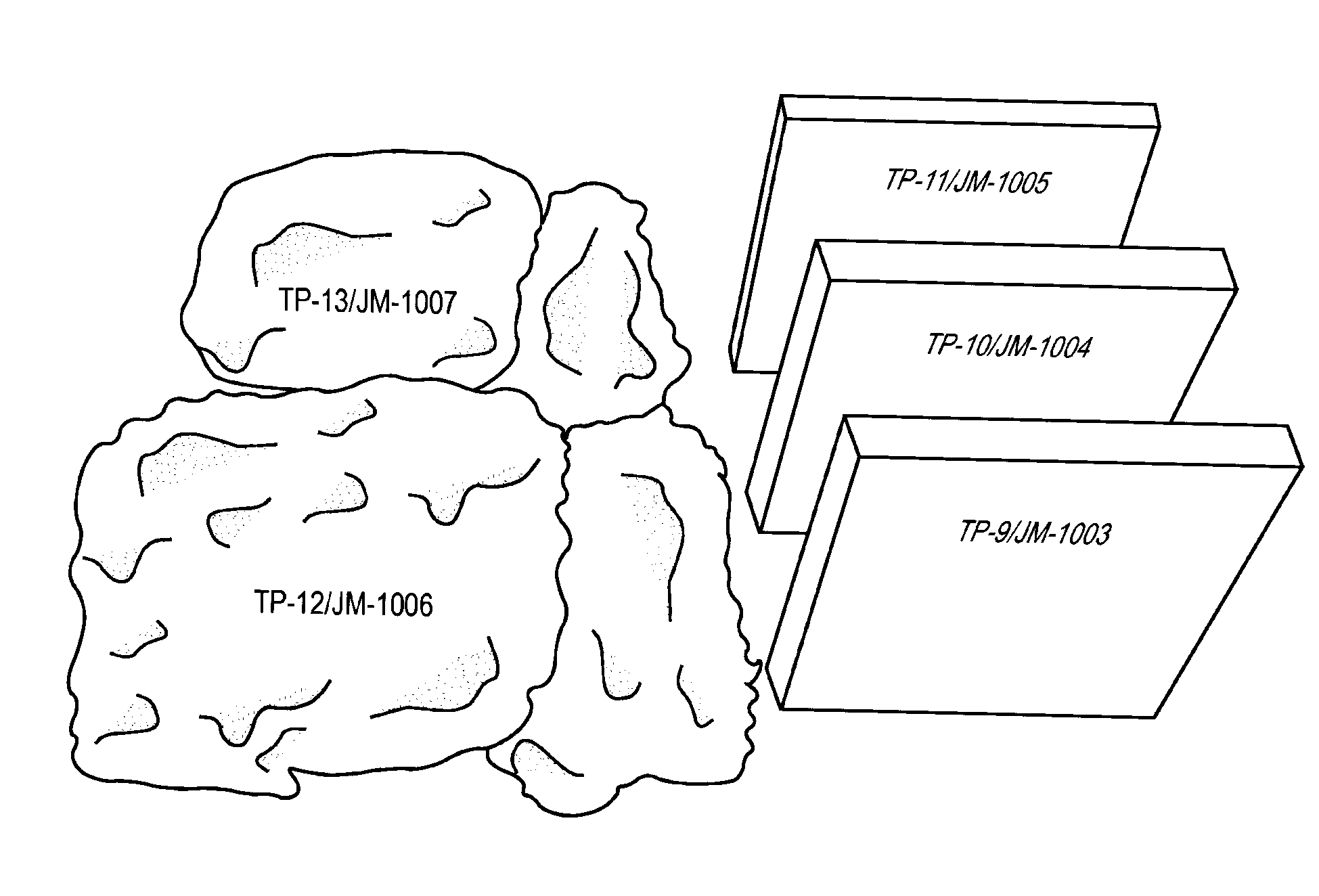

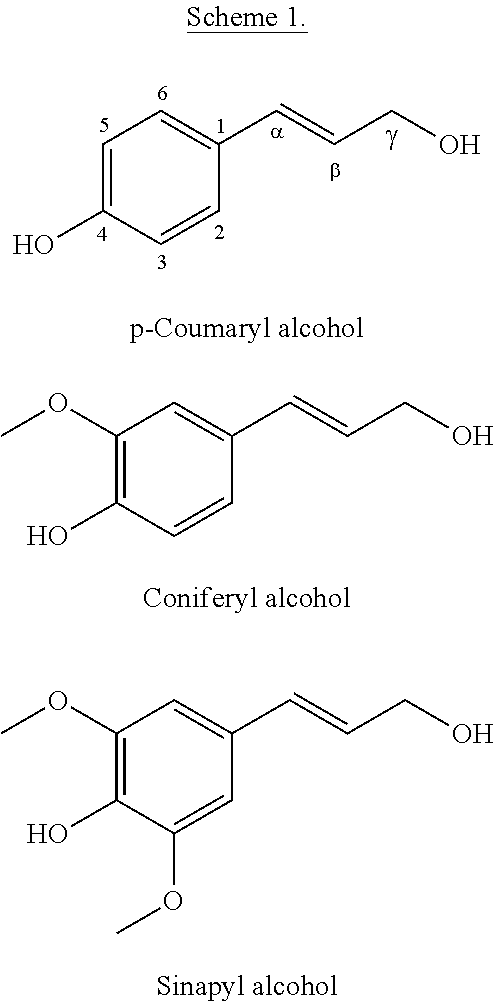

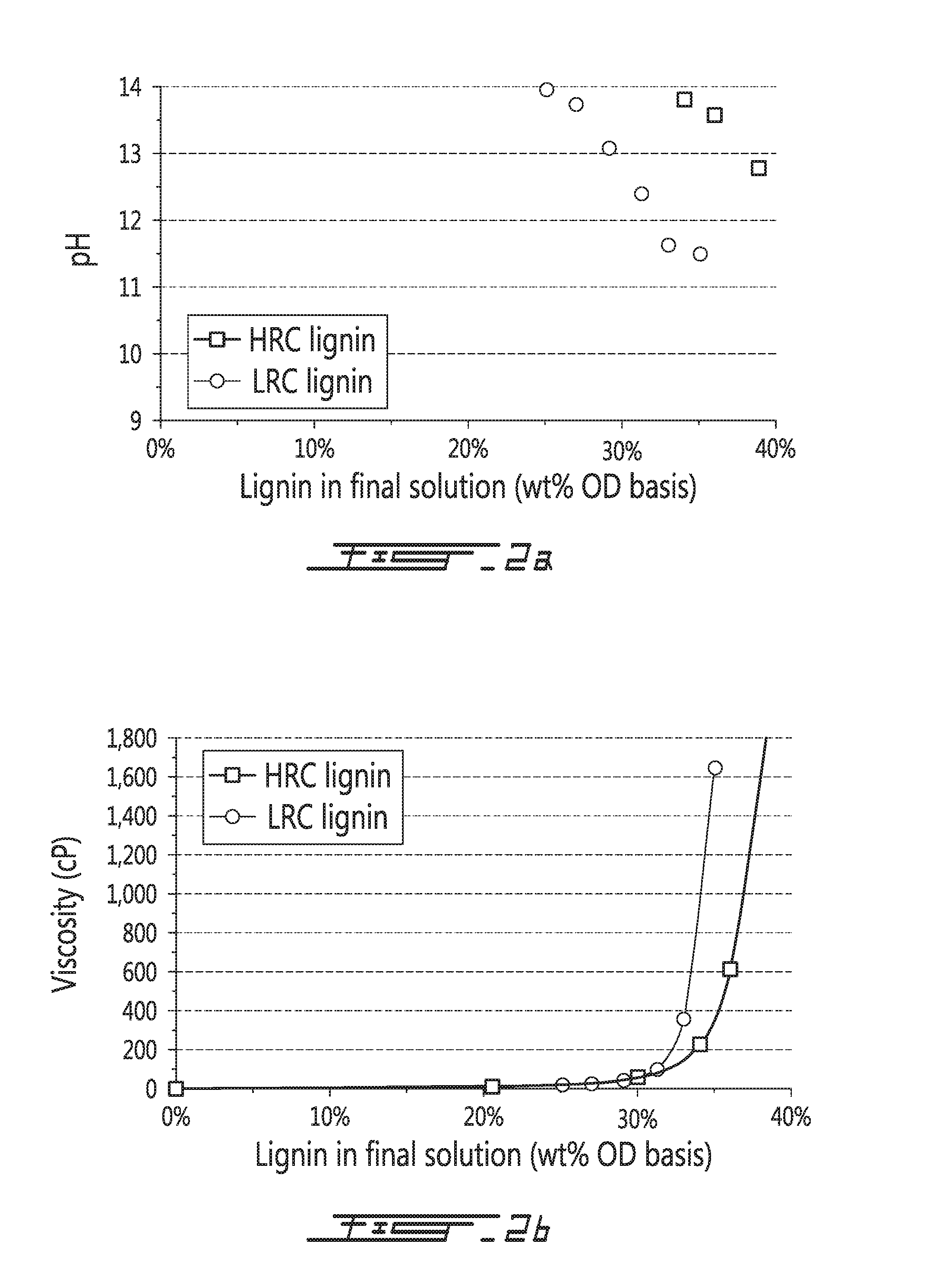

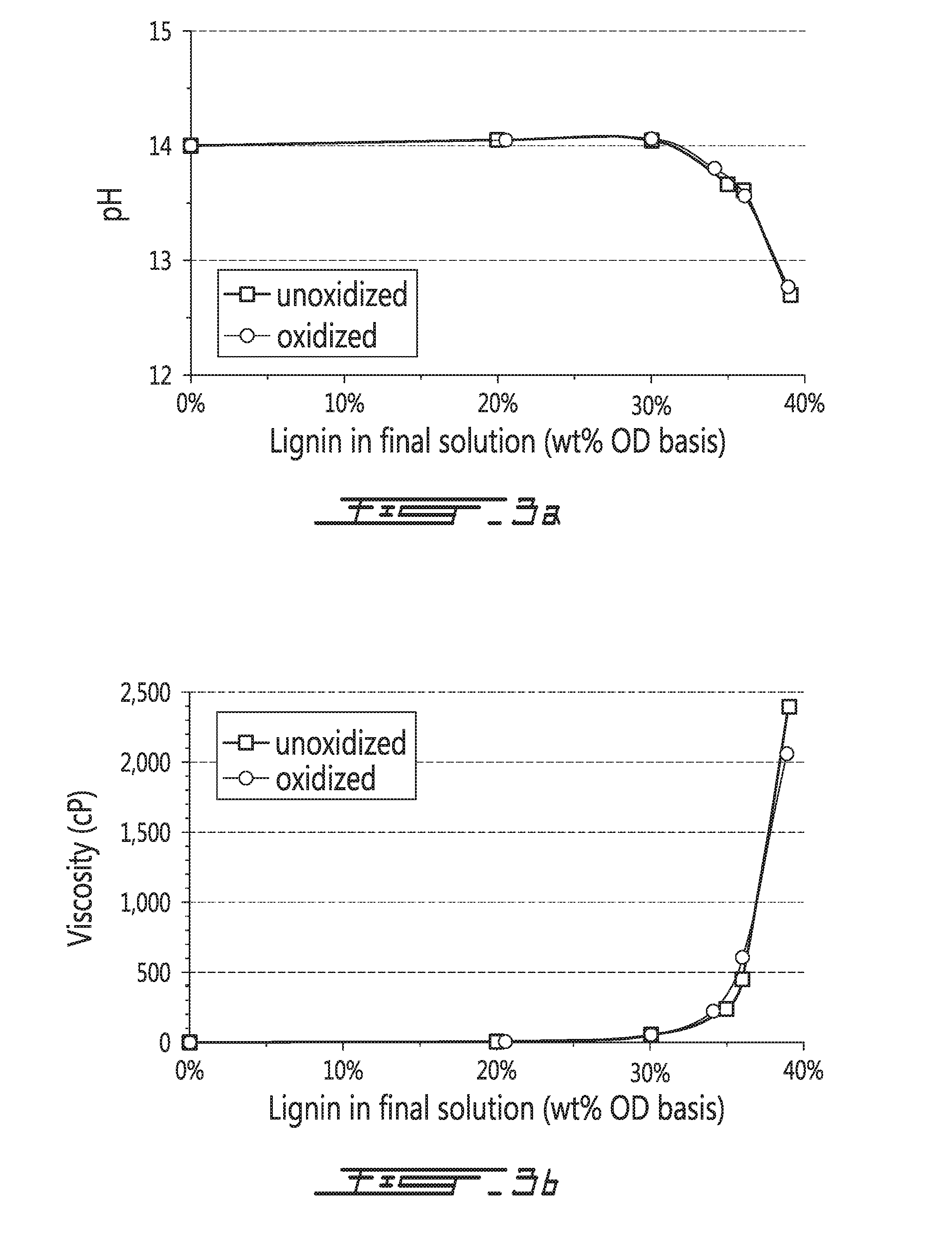

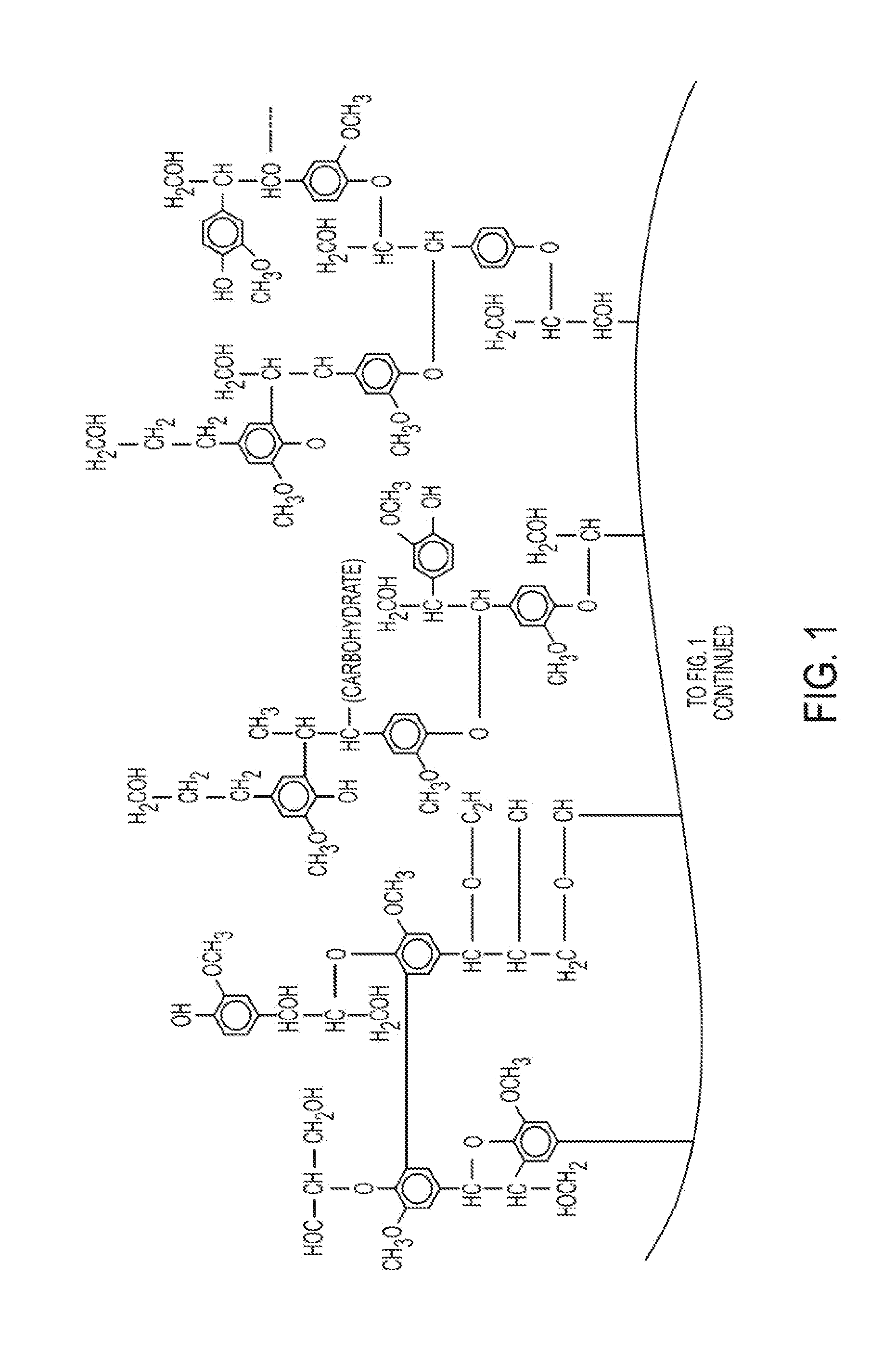

High residual content (HRC) kraft/soda lignin as an ingredient in wood adhesives

ActiveUS20160304757A1Aldehyde/ketone condensation polymer adhesivesLignin adhesivesBlack liquorAdhesive

Most processes currently being proposed and / or used for the production of lignin from kraft or soda black liquors are capable of producing two main types of lignin: high residual content (HRC) lignin and low residual content (LRC) lignin. Surprisingly, it was discovered that HRC lignin, is a suitable ingredient in alkaline adhesives, particularly wood adhesives of the phenolic type (e.g. resole resins). This biomaterial is environmentally green and remarkably low cost, which makes it an industrially viable material to be used as a novel and major ingredient in phenolic adhesives for the manufacture of exterior grade plywood, laminated veneer lumber, oriented strand board (OSB) and other wood products—this was successfully demonstrated in a number of laboratory experiments as well as several different mill trials. The composition, preparation and application of such wood adhesives are hereby disclosed.

Owner:FPINNOVATIONS INC

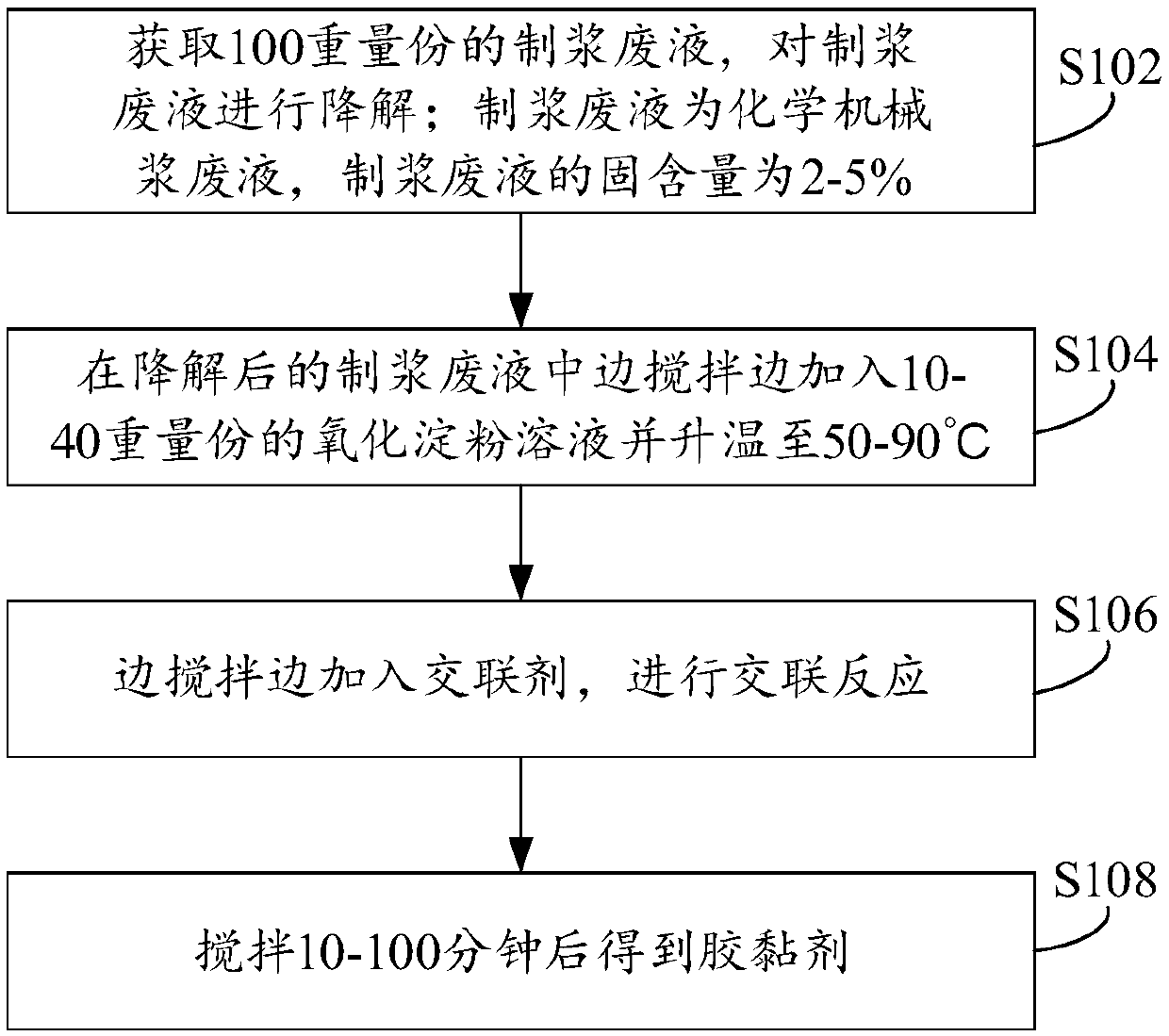

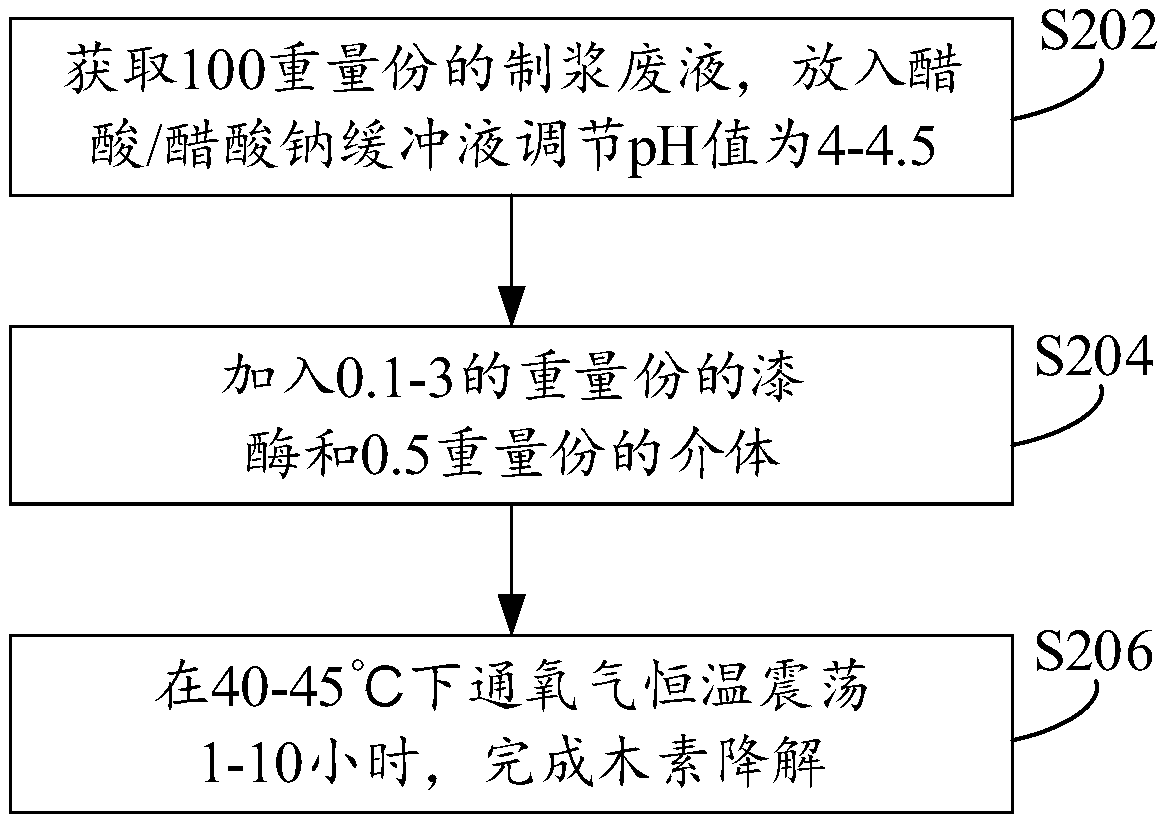

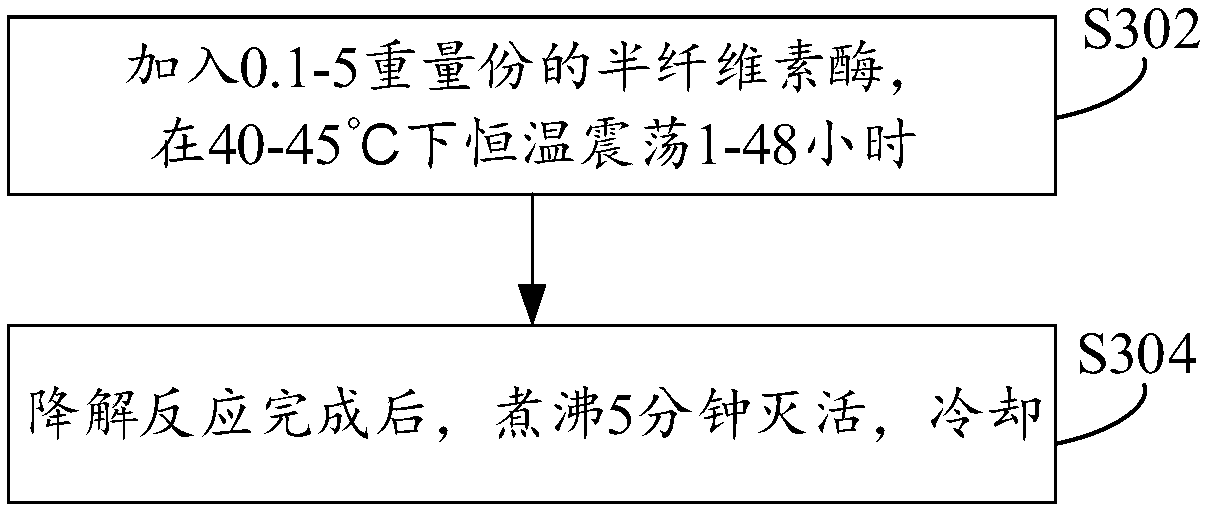

Adhesive and fiber board preparation method

InactiveCN109517579AAvoid pollutionHigh outputHemicellulose adhesivesStarch derivtive adhesivesCross-linkFiber

The invention provides an adhesive and a fiber board preparation method, relating to the technical field of waste liquid treatment. The adhesive is prepared by the following steps: fetching 100 partsof pulping waste liquid, and degrading the pulping waste liquid, wherein the pulping waste liquid is chemical mechanical slurry waste liquid, and the solid content of the pulping waste liquid is 2%-5%; adding 10-40 parts of an oxidized starch solution into the degraded pulping waste liquid while stirring, and heating to 50-90 DEG C; and adding a cross-linking agent while stirring, so as to generate cross-linking reaction; and stirring for 10-100 minutes, so as to obtain the adhesive. The pulping waste liquid is degraded, the oxidized starch solution is added while stirring after the degradation, the mixed solution is heated, the cross-linking agent is added to generate the cross-linking reaction, and then the adhesive can be obtained, so that the environmental pollution is avoided, chemical-mechanical pulp waste liquid is comprehensively utilized, the production value is increased, the economical efficiency is good, and the sustainable development can be realized.

Owner:丰禾新材(北京)技术有限公司

Ether functionalized lignin for fuel production

ActiveUS20170298192A1Reduce the amount of solutionPrevent disproportionationCatalytic crackingBiofuelsEtherSolvent

Owner:REN FUEL K2B

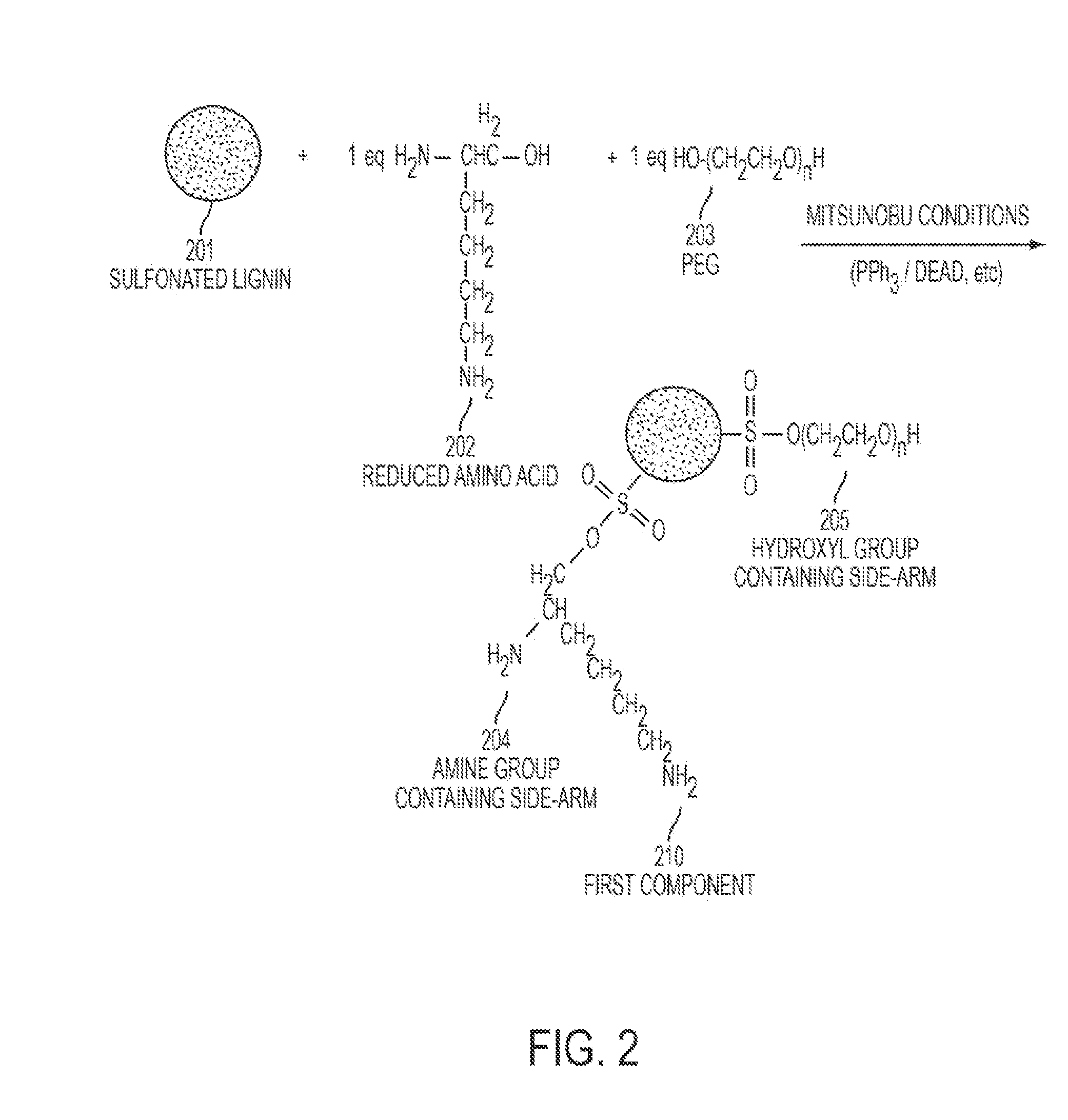

Tailorable lignosulfonate carbonate adhesives

A two component adhesive system is described. The first component of the system is made from a sulfonated lignin having at least one amine group containing side arm and at least one hydroxyl group containing side arm. The second component of the system is made from a sulfonated lignin having at least one chloroformate group containing side arm.

Owner:EMPIRE TECH DEV LLC

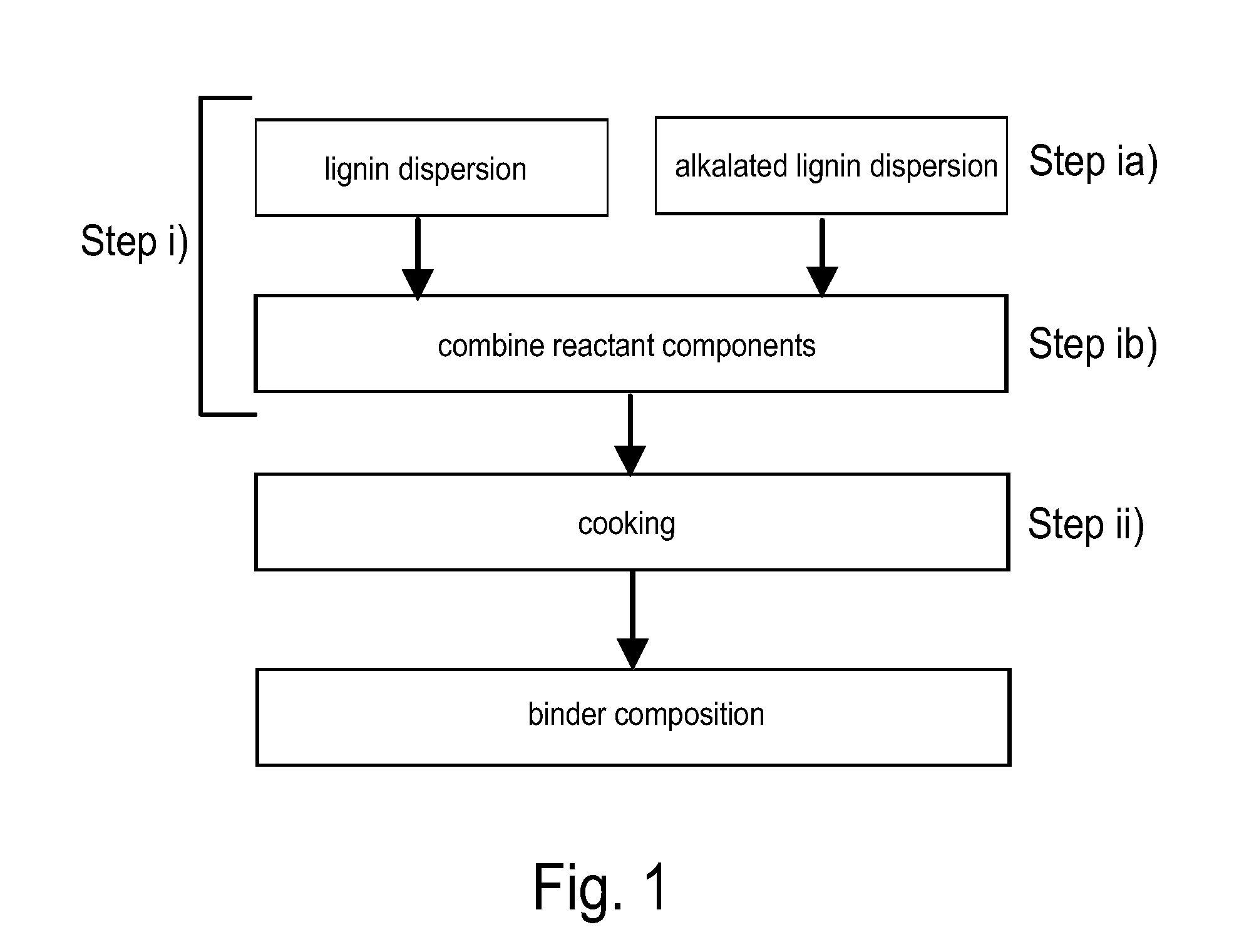

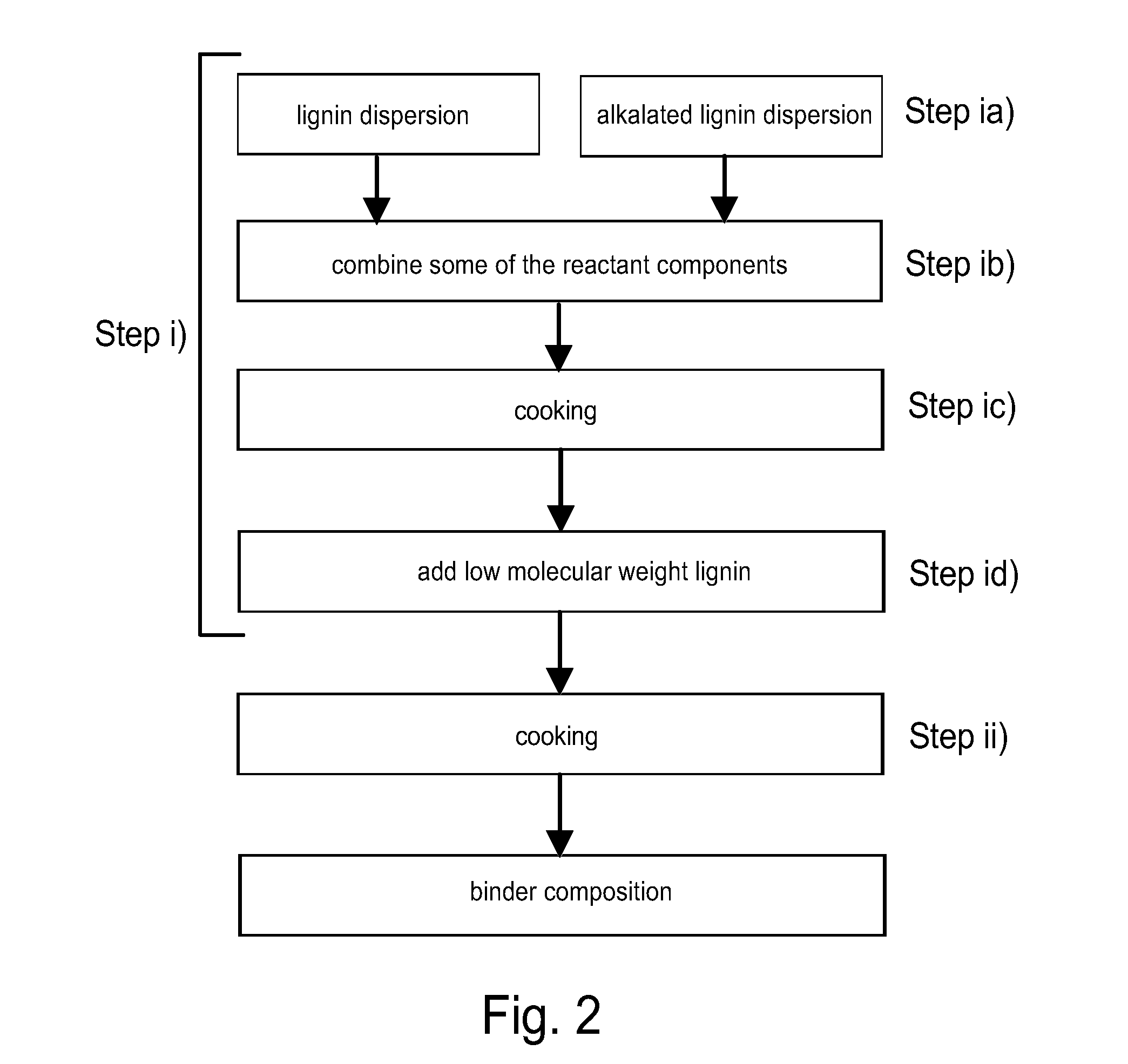

Use of low molecular weight lignin together with lignin for the production of a phenol-formaldehyde binder composition

ActiveUS20150087781A1Improve the level ofDesired propertyAdhesive processesSynthetic resin layered productsPolymer sciencePtru catalyst

The present invention relates to a method for producing a binder composition, wherein the method comprises the following steps: (i) forming an aqueous composition comprising reactant components including lignin molecules of 11-60 lignin units, lignin molecules of 1-10 lignin units, polymerizable substance and crosslinking agent in the presence of a catalyst; and (ii) cooking the composition at a temperature of 60-95° C. for polymerizing the reactant components until a binder composition with a predetermined viscosity value is formed.

Owner:UPM-KYMMENE OYJ

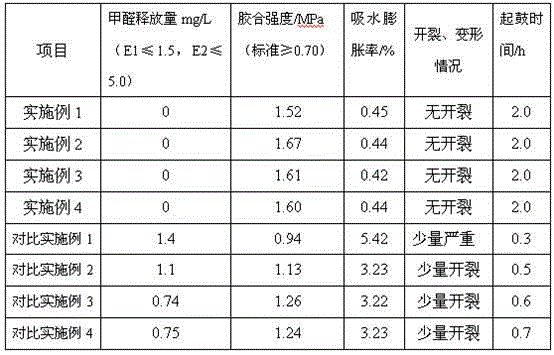

Method for producing clamp plate through lignin adhesives

ActiveCN104441105AReduce formaldehydeLow priceNon-macromolecular adhesive additivesPolyureas/polyurethane adhesivesAdhesiveSingle plate

The invention discloses a method for producing a clamp plate through lignin adhesives. The clamp plate is formed by bonding at least three layers of single plates through the lignin adhesives. The method comprises the specific steps that single plate sorting, gluing, prepressing, hot pressing, stacking maintenance and aluminum oxide abrasion paper pasting are carried out; according to the prepressing condition, temperature ranges from 95 DEG C to 100 DEG C, pressure ranges from 0.5 Kpa to 0.8 Kpa, and time ranges from 0.5 min / mm to 0.8 min / mm; according to the hot pressing condition, temperature ranges from 140 DEG C to 150 DEG C, pressure ranges from 0.5 Kpa to 1 Kpa, and time ranges from 0.5 min / mm to 0.8 min / mm; according to the specific method of stacking maintenance, bonded clamp plates are erected through battens layer by layer, and the battens on the upper layers and the lower layers are arranged in the shape like a Chinese character 'jing'. The manufactured clamp plate has the good dampproof performance, and is not likely to bulge or deform when encountered water and affected by damp. The cost of the adhesives used per square meter is low, and good application and popularization value is achieved.

Owner:莫明鑫

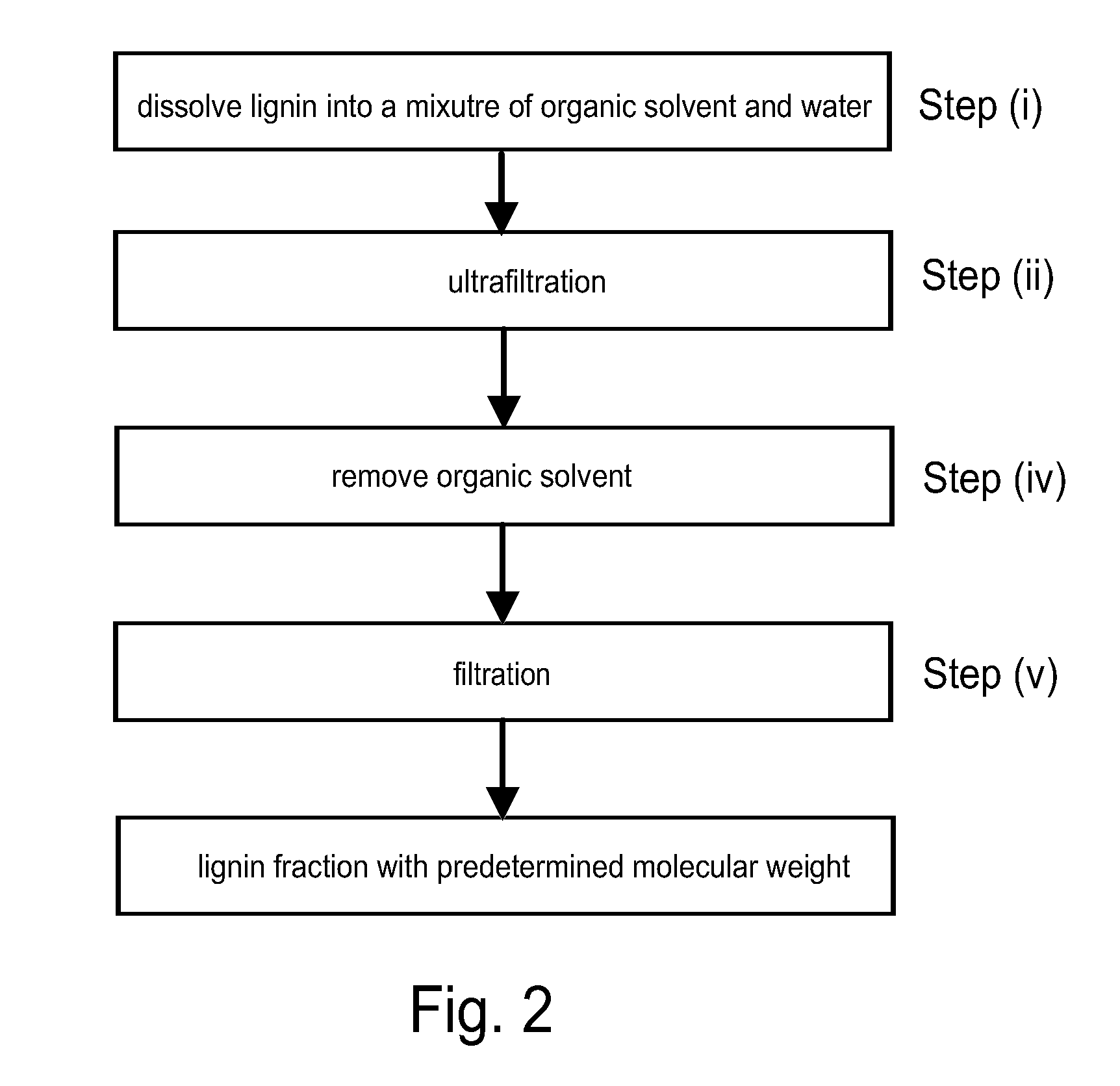

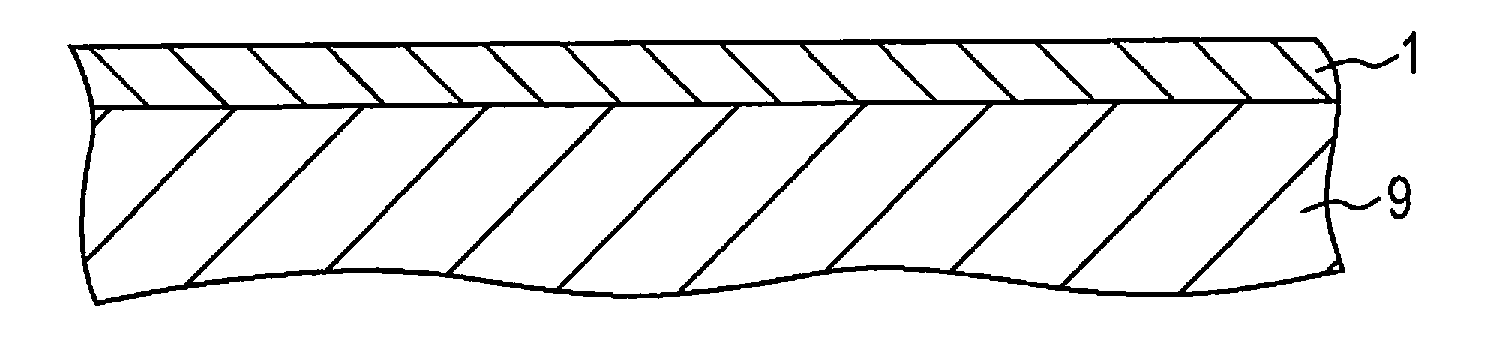

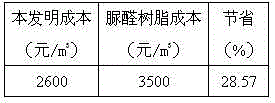

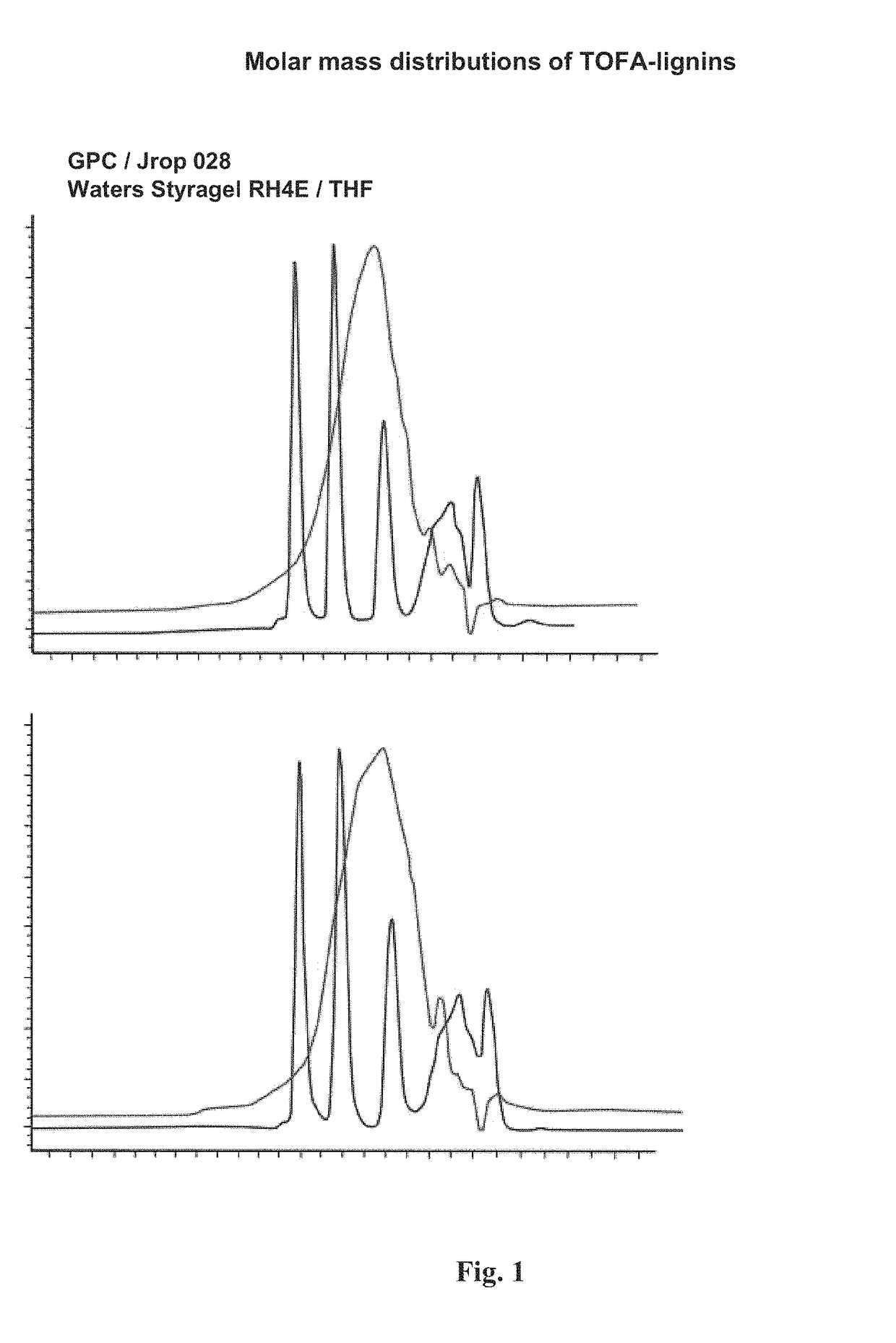

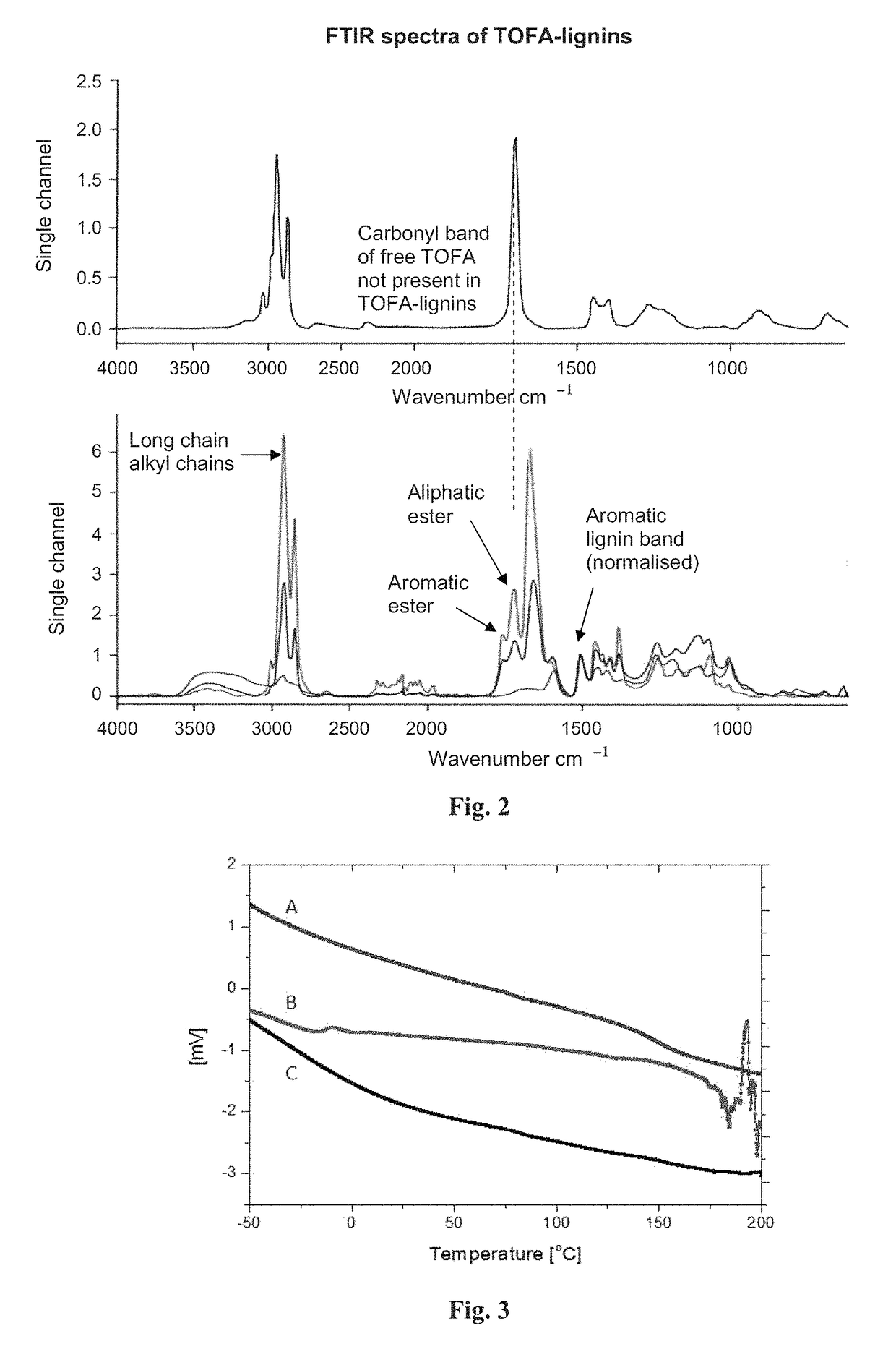

Functionalized lignin and method of producing the same

ActiveUS9902815B2Medium barrier propertyImprove barrier propertiesNon-fibrous pulp additionPaper/cardboardFiberPaperboard

In this study, commercially available softwood lignin was esterified with tall oil fatty acid (TOFA) and tested as barrier material in fiber-based packaging material. The modified lignin samples were applied with a bar coater forming an even coating on the paperboard substrate. A significant decrease in WVTR and OTR value was observed for paperboard coated with the modified lignin as well as pure TOFA used as a reference. In contrast to the TOFA coating, the modified lignin coatings exhibited a high and stable contact angle. The coating material did not affect the tensile strength of the paperboard. According to the results, the demonstration of the conversion of lignin into a value added product has been shown. Furthermore, the novel coating material shows promising properties for the development as sustainable barrier material in fiber-based packaging material to replace oil-placed barriers.

Owner:TEKNOLOGIAN TUTKIMUSKESKUS VTT

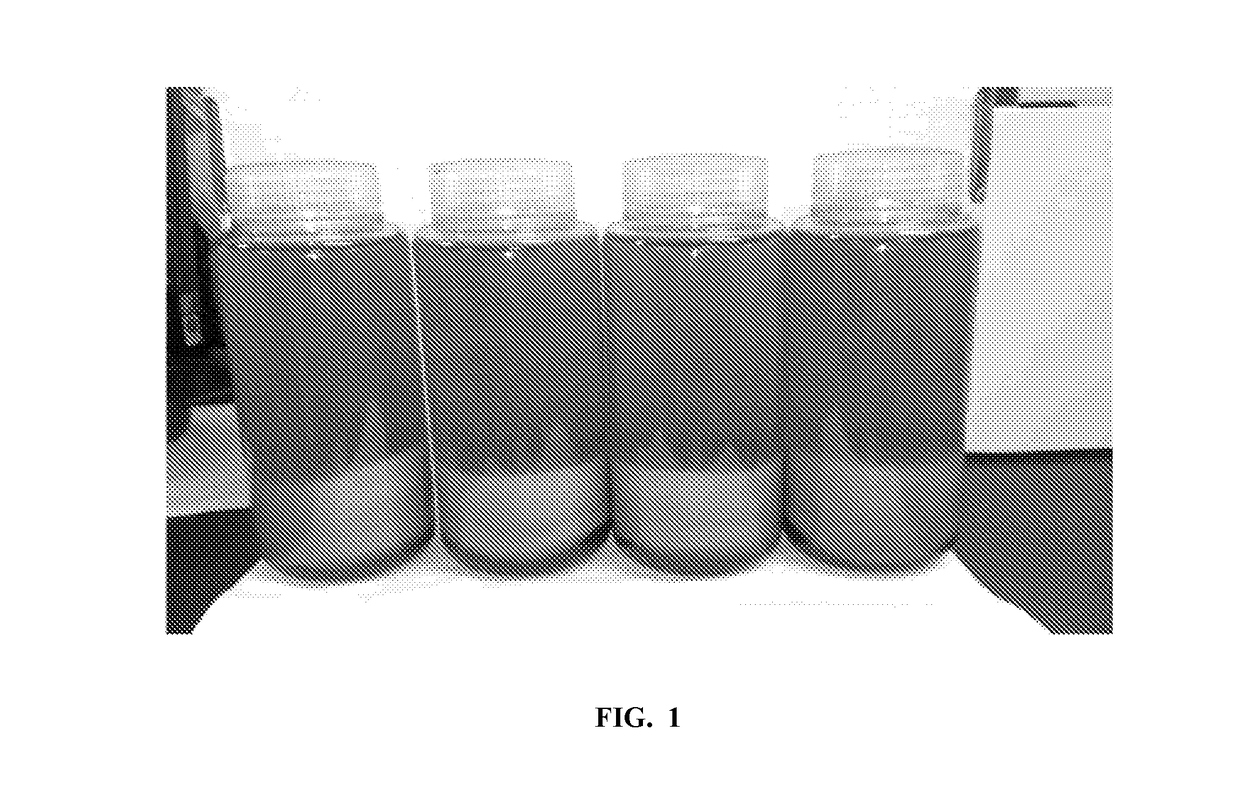

Cellulose-containing compositions and methods of making same

ActiveUS20170275385A1Non-macromolecular adhesive additivesPolyureas/polyurethane adhesivesCelluloseChemistry

Cellulose-containing compositions and method of making same are disclosed. The compositions comprise a cellulose product comprising a type-I cellulose, a type-II cellulose, amorphous cellulose, or a combination thereof. Further, methods are disclosed for making these compositions and for further hydrolyzing these compositions. Additionally, uses for the cellulose-containing compositions are disclosed.

Owner:RENMATIX INC

Biobased hot-melt adhesive including lignin as a component

InactiveUS20190338168A1Eliminate the problemNon-macromolecular adhesive additivesMacromolecular adhesive additivesPlasticizerHot melt

The present invention relates to an adhesive mixture, containing one or more cohesive polymers, one or more tackifiers and optionally one or more separate plasticizer, wherein at least one tackifier is selected from lignin or derivatized lignin. The invention also relates to the use of lignin or derivatized lignin as adhesion promoting components in particularly hot-melt or pressure-sensitive adhesives

Owner:TEKNOLOGIAN TUTKIMUSKESKUS VTT

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com