Adhesive and fiber board preparation method

An adhesive and cellulose technology, applied in the directions of adhesives, adhesive additives, cellulose adhesives, etc., can solve the problems such as the inability to increase the output value of the chemical pulp waste liquid, unfavorable sustainable development, and inability to increase the output value, etc. To achieve sustainable development, increase output value, and good economic effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

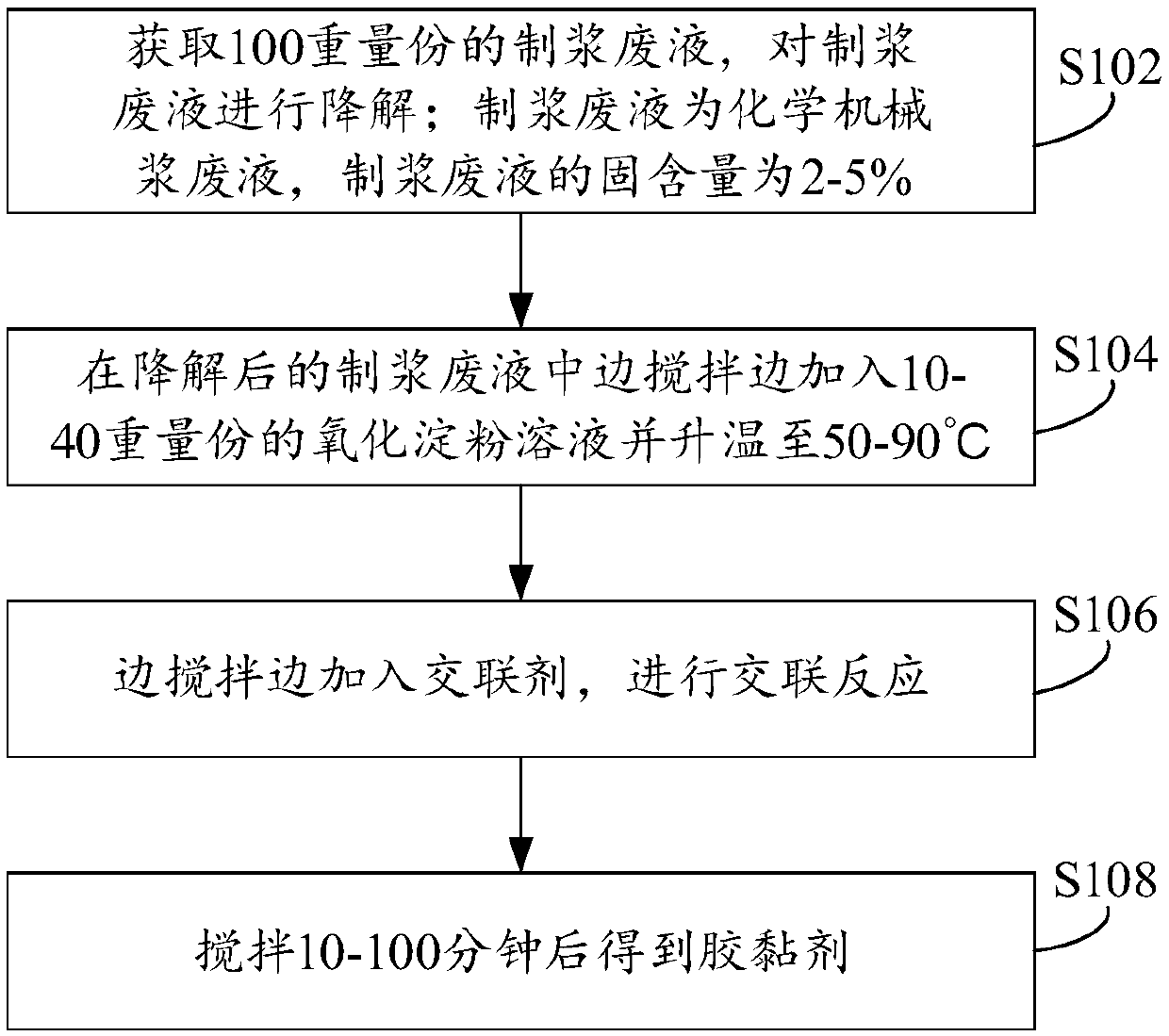

[0031] Embodiment 1 of the present invention provides a kind of adhesive preparation method, see figure 1 The flow chart of a kind of adhesive preparation method shown, comprises the steps:

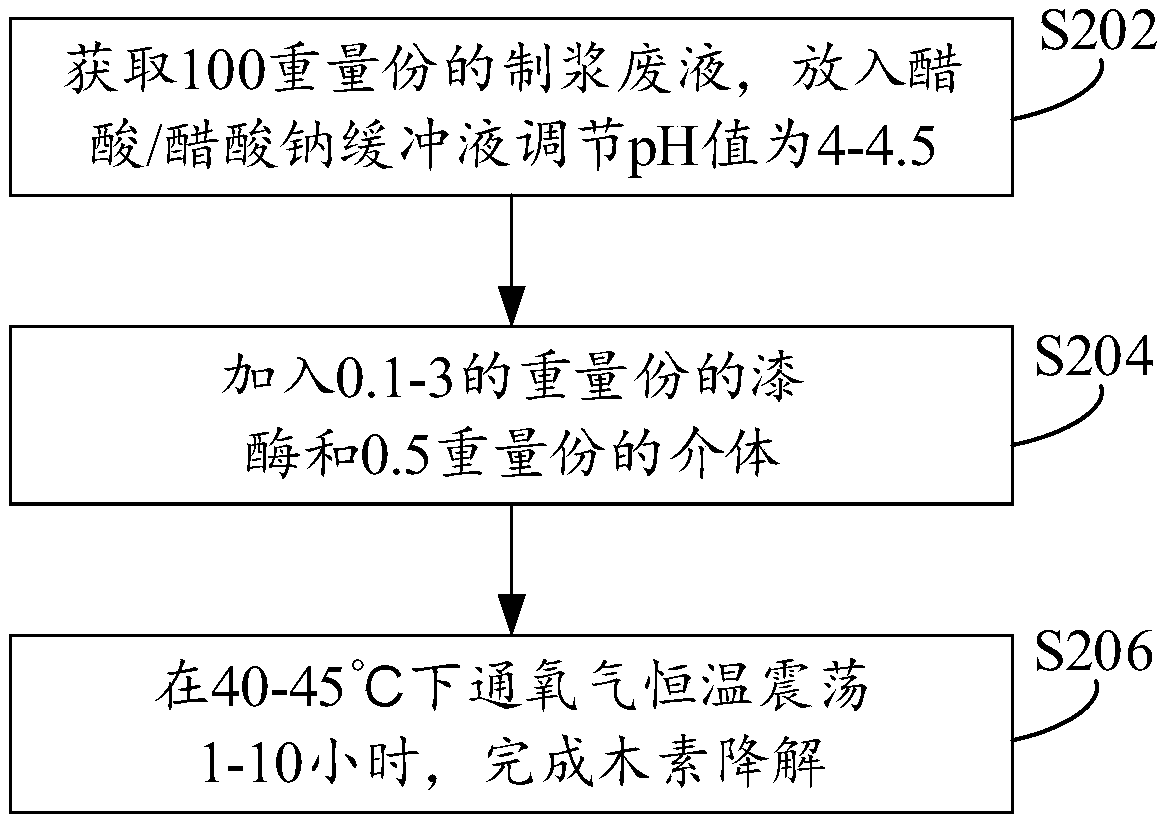

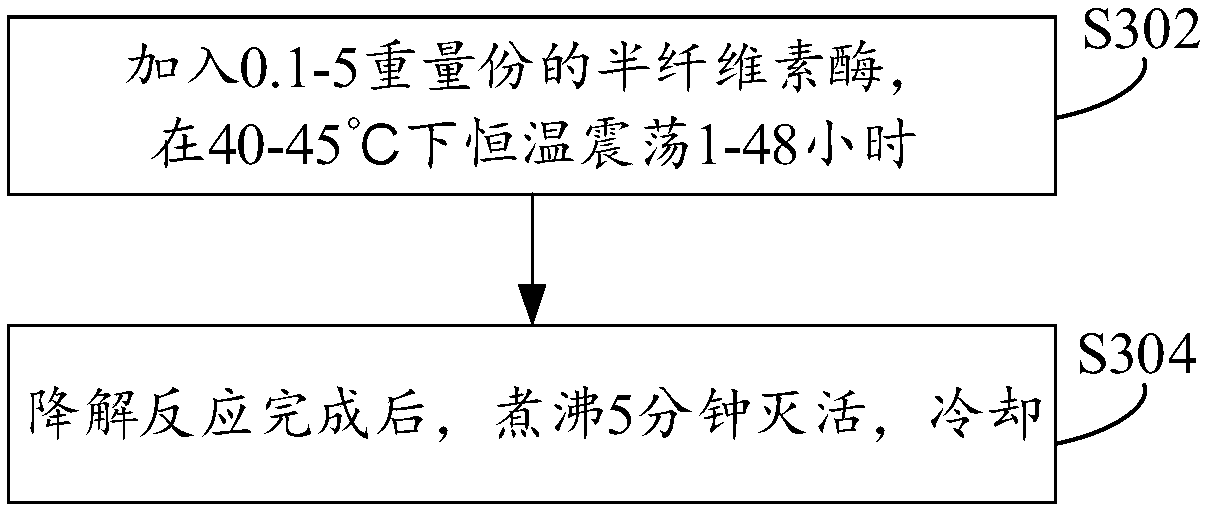

[0032] Step S102, obtaining 100 parts by weight of pulping waste liquid, and degrading the pulping waste liquid; the pulping waste liquid is chemical mechanical pulp waste liquid, and the solid content of the pulping waste liquid is 2-5%.

[0033] Pulping waste liquid is chemical mechanical pulp waste liquid, chemical mechanical pulping, using chemical pretreatment and mechanical grinding post-treatment pulping method. Light pretreatment (soaking or cooking) is carried out first with chemicals to remove part of the hemicellulose in the wood chips, and the lignin is less or not leached out, but the intercellular layer is softened. Afterwards, it is post-treated by a disc refiner to grind and soften the wood chips (or grass chips) to separate the fibers into pulp. This pulp is chemical mec...

Embodiment 2

[0076] Embodiment 2 of the present invention provides a kind of fiberboard preparation method, see Figure 4 A flow chart of a fiberboard preparation method shown, comprising the steps:

[0077] Step S402, obtaining 1-99% by weight of solid waste, 10-30% of waste paper pulp, 10-50% of poplar fiber, 2-5% of paraffin wax, and 8%-15% of the first aspect and its The adhesive prepared by the adhesive preparation method provided in one of the possible embodiments.

[0078] Solid waste includes bark, sawdust, lime soil, bagasse, grass clippings, pulp residue, a small amount of white mud, pulping sludge (primary sludge, secondary sludge, deinking sludge), etc. Timber refers to forest harvesting residues, such as branches, tips, small diameter timber, etc.; and wood processing residues, such as board edges, shavings, sawdust, etc. Waste paper pulp is not only the raw material for fiberboard, but also forms hydrogen bonds with other raw materials during the forming process of fiberboa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com