Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

242results about How to "Reduce demoulding time" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

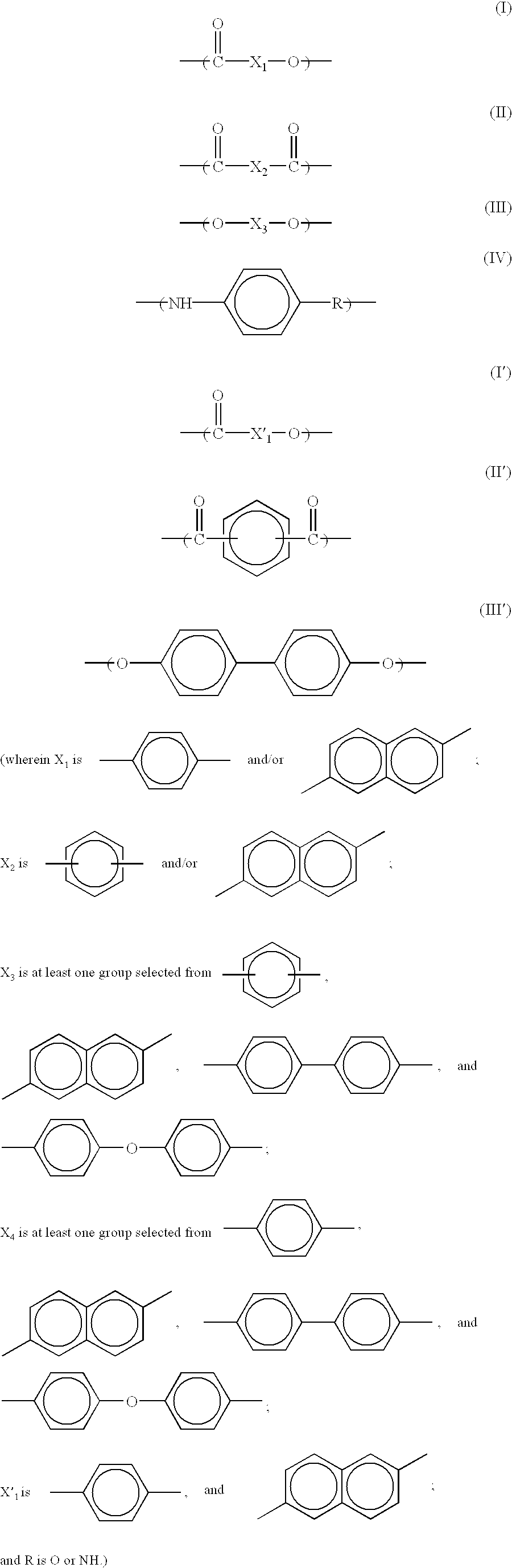

Liquid-crystalline polymer composition and molding method

InactiveUS20020190432A1Shorten molding timeImprove rigidityLiquid crystal compositionsPolyesterPolymer science

To provide liquid crystal polymer materials superior in shortening the molding time, which are suitable for connectors, electronic appliances, etc. That is, a liquid crystal polymer composition including (A) from 90 to 50% by weight of a liquid crystal polymer made of a specified aromatic polyester and (B) from 10 to 50% by weight of a liquid crystal polymer made of a specified aromatic polyester amide.

Owner:POLYPLASTICS CO LTD

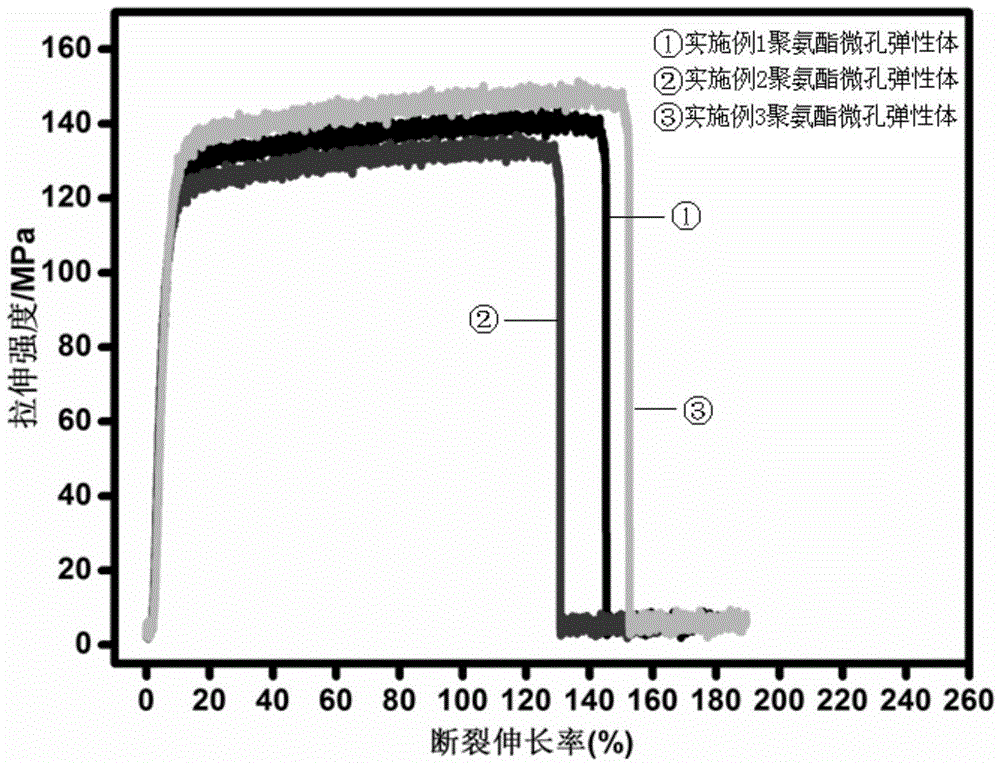

Highly-elastic urethane elastomer composition

ActiveCN101134843AImprove mechanical propertiesIncrease elasticityPolyurethane elastomerPolymer science

The present invention is one high elasticity polyurethane composition, which is one double component system comprising one pre-polymer component and one polymer component. The pre-polymer component is obtained through the reaction of diisocyanate and polyol and has NCO of 8-15 %, the diisocyanate is MDI and / or carbodiimide modified MDI, and the polyol is polytetramethylene ether polyol or polyoxetane ether polyol and has molecular weight of 1000-3000 and functionality of 2. The polymer component is prepared with the above said polyol, 1, 4-utanediol, catalyst and antiager. The pre-polymer component and the polymer component are mixed in the ratio of 1 to 1, and the mixture is poured, vulcanized and formed to obtain high elasticity polyurethane elastomer with excellent mechanical performance and high shock strength and resilience. The present invention is used mainly in producing roller for roller skates and scooter.

Owner:SHANDONG INOV POLYURETHANE

Yellowing-resistant transparent polyurethane elastomer combined material and using method thereof

ActiveCN101096408ALow costOvercome the disadvantage of poor yellowing resistancePolyurethane elastomerAlcohol

The invention provides a yellowed-resistance type transparent urethane elastomer combination material, wherein the polyatomic alcohol part comprises 3 functionality and 4000-6000 molecular weight polyether polyol, 2 functionality and 2000-4000 molecular weight polyether polyol, aromatic, chain expansion agent and accelerant; the prepolymer part (NCO%=12%-17%)is made by 1000-2000 molecular weight, 2 functionality polyether polyol and isophorone diisocyanate at 70-90Deg. The use method comprises the following steps: mixing prepolymer with polyatomic alcohol part according to 2:1-1:1 at 25Deg. C-40Deg. C, pouring; vulcanizing at 25Deg. C-70Deg. C. The product avoids the low yellowed resistance problem of the urethane elastomer product, which is used to manufacture the armoured glass, the neon sign board, the shoe sign and the nameplate of the household electrical appliance.

Owner:SHANDONG INOV POLYURETHANE

Polyurethane elastomer for automobile glass encapsulation and preparation method thereof

The invention discloses a polyurethane elastomer for automobile glass encapsulation and a preparation method thereof. The elastomer is prepared from isocyanate component A and polyhydric alcohols component B with a reaction injection moulding process, wherein the density is larger than 1000kg / cubic meter, and the index number of the isocyanate is 90 to 120, the component A is NCO-capped prepolymer with NCO % being 18 to 28 %, and is the reaction product of aromatic diisocyanate and polyhydric alcohols with low molecular weight; the component B comprises at least 60 percent of polyether polyol with the molecular weight of 1000 to 10000, 1 to 20 percent of arylamine, 0 to 20 percent of alcohol, and 0.2 to 0.5 percent of composite catalyst, and also comprises an antioxidant, a light stabilizer and color paste. The polyurethane elastomer of the invention has excellent mechanical capacity and moderate aging resistant performance, and is applicable to the glass encapsulation with various specifications, especially to the large, ultrathin or complex product.

Owner:南京汇科高分子材料有限公司

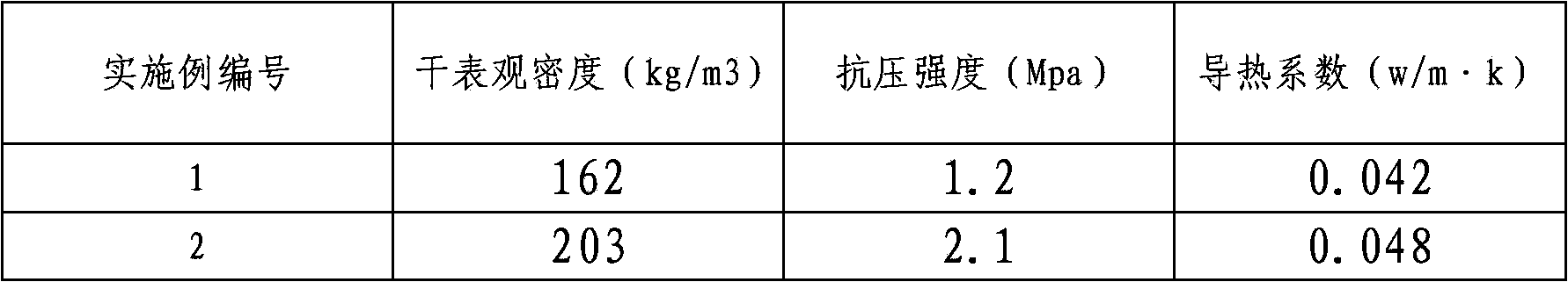

High-performance foam concrete insulation board and preparation method thereof

The invention belongs to the field of an external wall insulation material of a building, and particularly relates to a high-performance foam concrete insulation board and a preparation method thereof. The high-performance foam concrete insulation board is prepared from the following raw materials in parts by weight: 45-250 parts of cement, 10-125 parts of admixture, 6-30 parts of foaming agent, 40-130 parts of water, 0.8-5.5 parts of additive, and 2-11 parts of modifier in a mixed casting manner. The insulation board provided by the invention is light in weight, high in strength and excellent in waterproofness.

Owner:沈阳红姗石新型建材有限公司

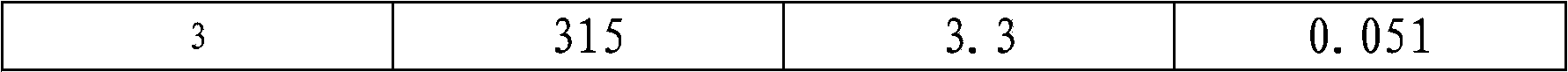

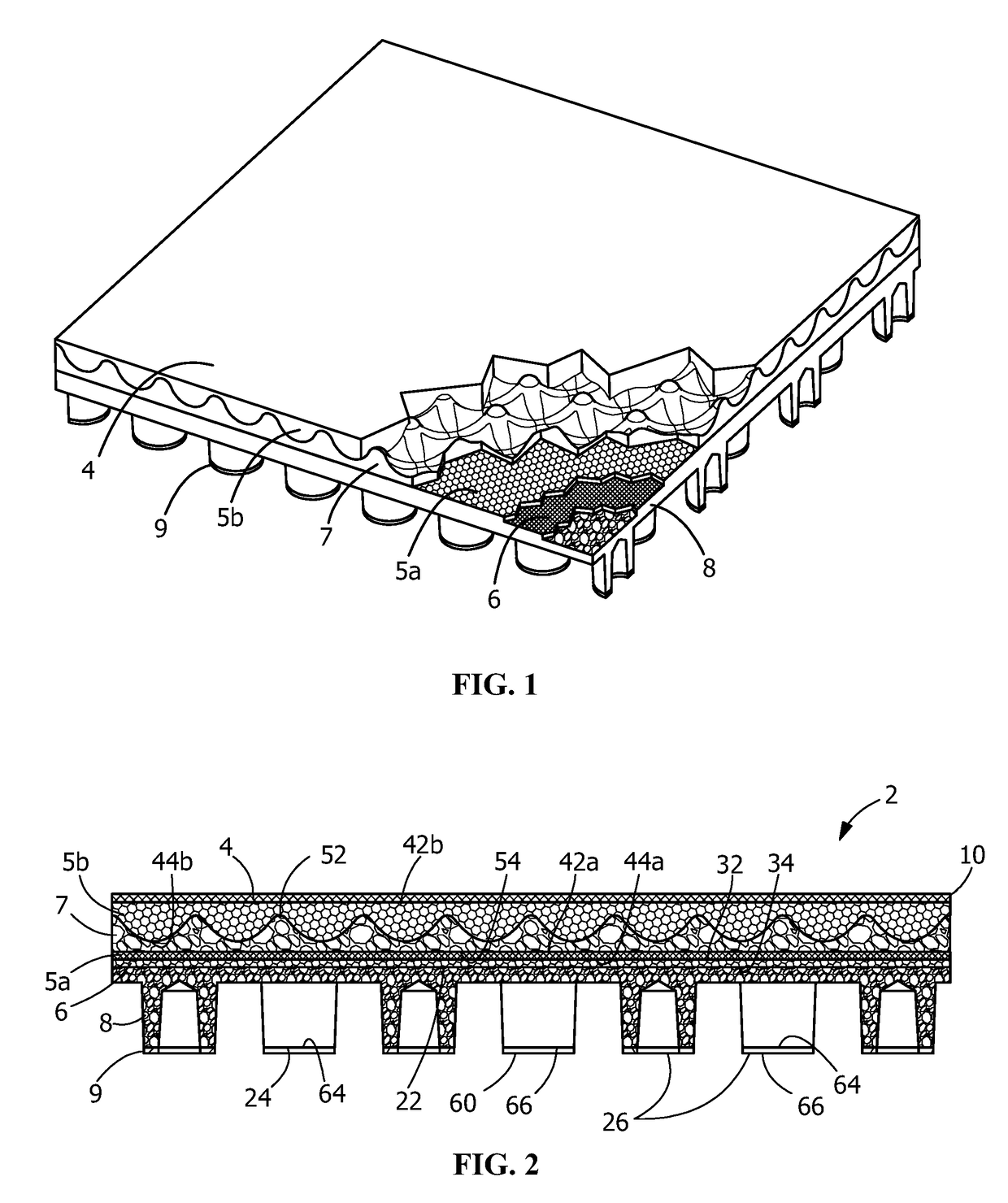

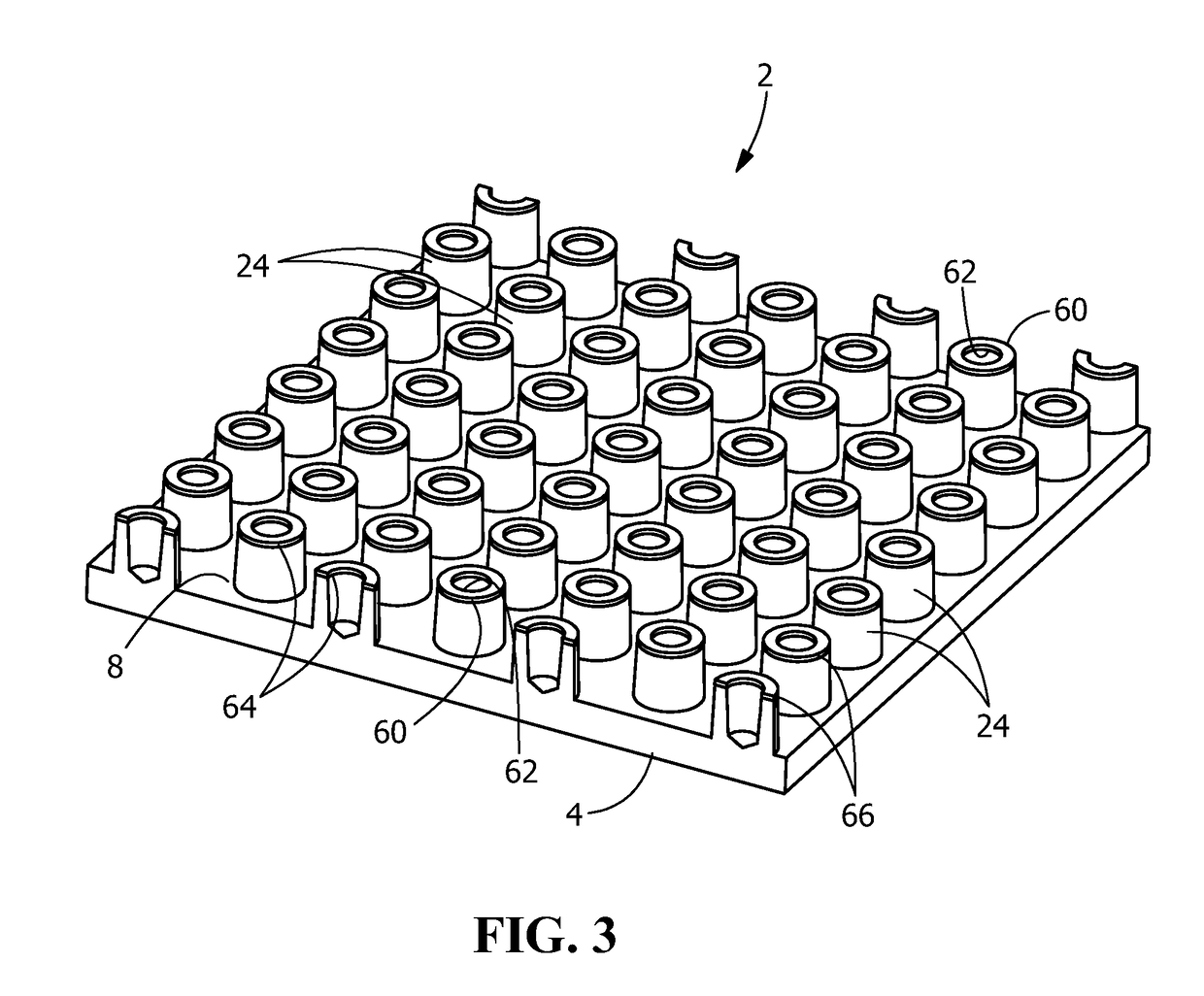

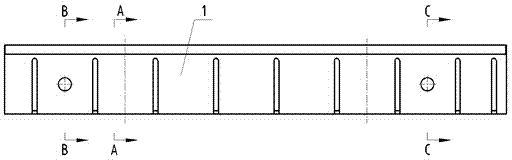

Floor tile with vibration and shock control

InactiveUS20180073254A1Lower natural frequencyReduce demoulding timeCovering/liningsConstructions elementsEnergy transferVibration control

A floor panel with shock and vibration control and method of manufacture. A first sound dampening layer is positioned between a top layer and a bottom layer of the floor panel. The first sound dampening layer has a series of hills and valleys and is made of material which provides a low natural frequency in response to a dynamic impact and transforms energy into heat in response to a high energy impact. The second sound dampening layer extends from the bottom layer in a direction away from the top layer. The second sound dampening layer is a plurality of preformed rings. The first sound dampening layer and the second sound dampening layer reduce the amount of energy transferred from the floor panel to a structure on which the floor panel is positioned.

Owner:REGUPOL AMERICA

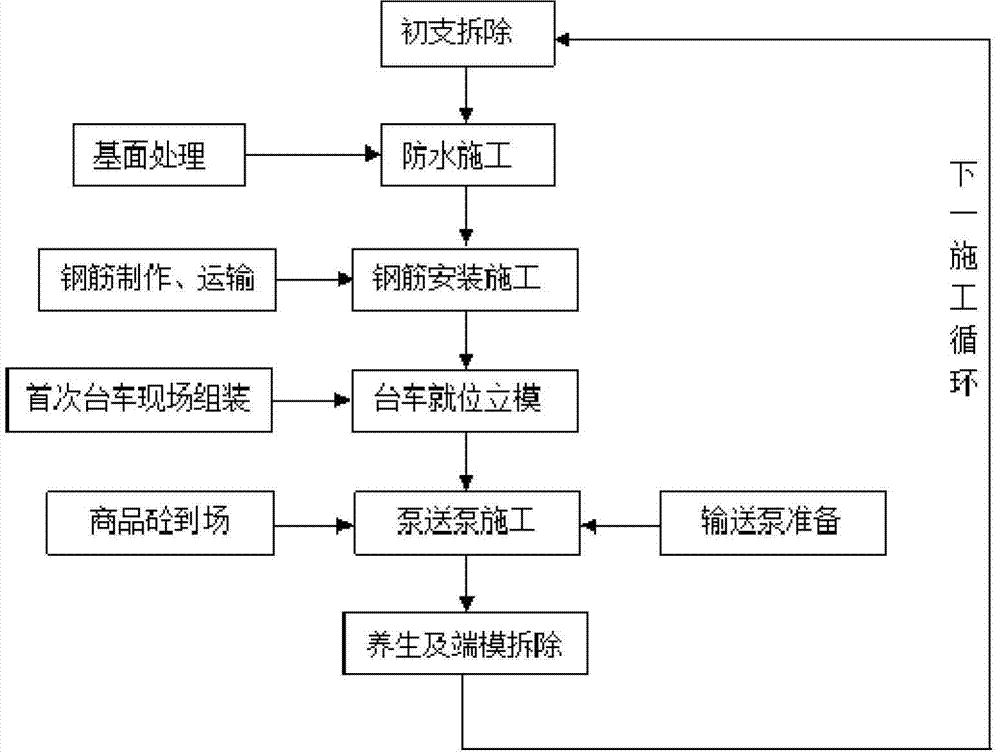

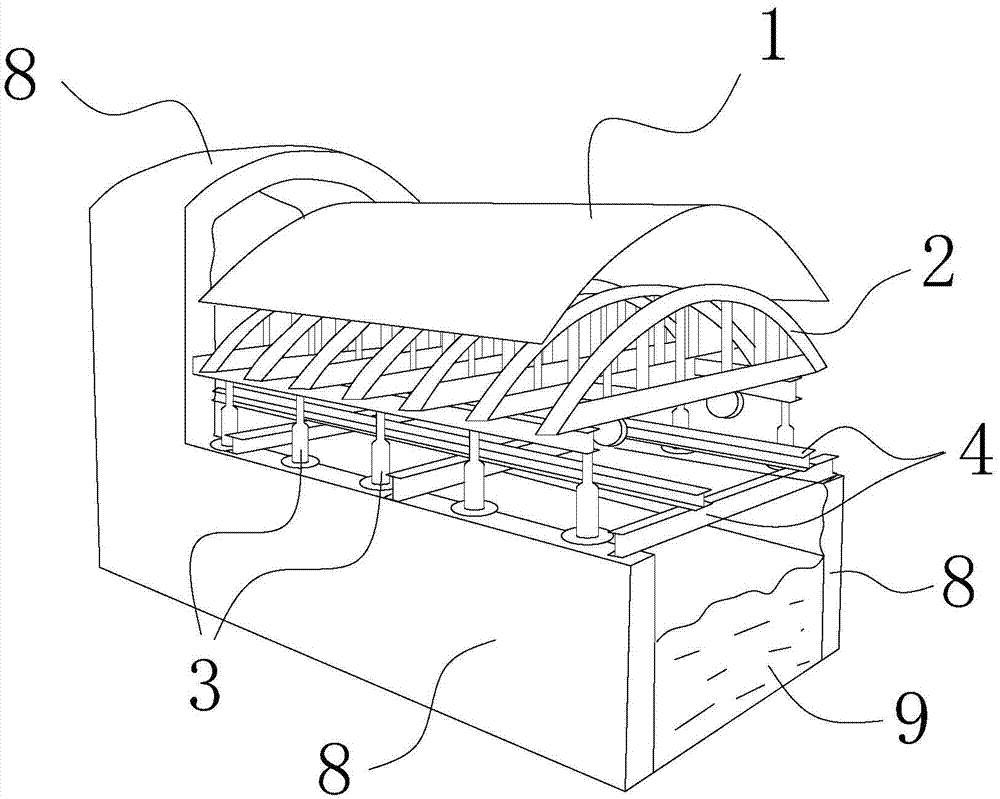

Lining construction method for suspension rail type trolley

ActiveCN103939114AFast constructionReduced demoulding timeUnderground chambersTunnel liningRebarBuilding construction

The invention discloses a lining construction method for a suspension rail type trolley. The method comprises the following steps that (1) a primary support is dismounted, 1 / 3 to 1 / 2 of the primary support of a pilot tunnel is dismounted to adapt to the height of the trolley, then the surface of the dismounted portion is leveled, and the dismounted portion of the primary support of the pilot tunnel is a side wall of the primary support of the pilot tunnel; (2) water preventing construction is carried out, and waterproof plates are arranged on the contact faces of a top longitudinal beam, a buckle arch primary support and a designed two-lining buckle arch; (3) steel bars are machined and mounted, and the pre-machined and formed steel bars are transported to an operating face, and are mounted according to design requirements; (4) the trolley is mounted in place, the trolley is lifted, a formwork is lifted to a design position, and concrete pouring is carried out. According to the lining construction method for the suspension rail type trolley, the two-lining buckle arch concrete construction formwork dismounting and shutting time is greatly shortened, the construction period is shortened, and the continuous construction performance is good. Labor cost for splicing and dismounting the formwork and a scaffold is greatly saved. Pouring precision and quality are improved.

Owner:CHINA RAILWAY ERJU 1ST ENG +1

Mould-less large-caliber PVC pipe dynamic molding method and device

ActiveCN103991221AReduce demoulding timeImprove molding efficiencyTubular articlesUltrasonic weldingSheet film

The invention discloses a mould-less large-caliber PVC pipe dynamic molding device and method. The device is mainly composed of an extruder, a film bracket, bracket rolls, a bracket motor, a heating box, a three-point circle setting instrument, rollers, pressure rollers, supporting rollers, a pipe support frame, a support frame motor, guide rollers, a guide roller motor, guide rails and an ultrasonic welding instrument, etc. The three-point circle setting instrument can be used for continuous molding, and the PVC pipe length is not restricted by a roller mould. Compared with existing PE large-caliber pipes, the PVC raw material is much cheaper than PE, thus greatly lowering the production cost. The device provided by the invention omits the large-caliber roller mould, thus being able to save demoulding time and improving the molding efficiency. Also, the ultrasonic welding temperature is precisely controlled, thus effectively avoiding the PVC degradation problem caused by a high melting welding temperature. And the welding is fast. The mould-less large-caliber PVC pipe dynamic molding method and device provided by the invention can be used for molding large-caliber PVC smooth wall round pipes and outer corrugated pipes simultaneously.

Owner:BEIJING UNIV OF CHEM TECH

Carbon-fiber-reinforced polyurethane foamed plastic and preparation method thereof

The invention relates to a carbon-fiber reinforced polyurethane foamed plastic which is characterized by comprising the following components: component A: 100 parts of polyether glycol, 5-15 parts of flame retardant, 7-15 parts of foaming agent, 1.5-2.5 parts of foam stabilizer, 5-15 parts of carbon fiber, 1.5-2.5 parts of catalyst, 0.01-0.15 part of water, and epoxy resin; and component B: 20-30 parts of isocyanate (crude MDI (methylenediphenyl diisocyanate)) of which the index is 100-105. The flame retardant is a mixture of aluminum hydroxide and TCPP (trichloropropylphosphate); the foaming agent is CFC-11 or pentane; the catalyst is a mixture of tertiary ammonium salt catalyst and organotin; and the foam stabilizer is organosilicon ketone. The preparation method comprises the following steps: mixing carbon fiber and epoxy resin, evenly mixing to form quasispheric carbon fibers, mixing the carbon fibers with the component A and the component B, and carrying out primary cast molding. The density of the polyurethane material is 0.49g.cm<-3>, the compression modulus is 550MPa, the impact strength is 1.5kJ.m<-2>, and the density, compression modulus, impact strength and other physical and chemical parameter reach the standard at the same time.

Owner:WUJIANG MINGFENG POLYURETHANE PROD

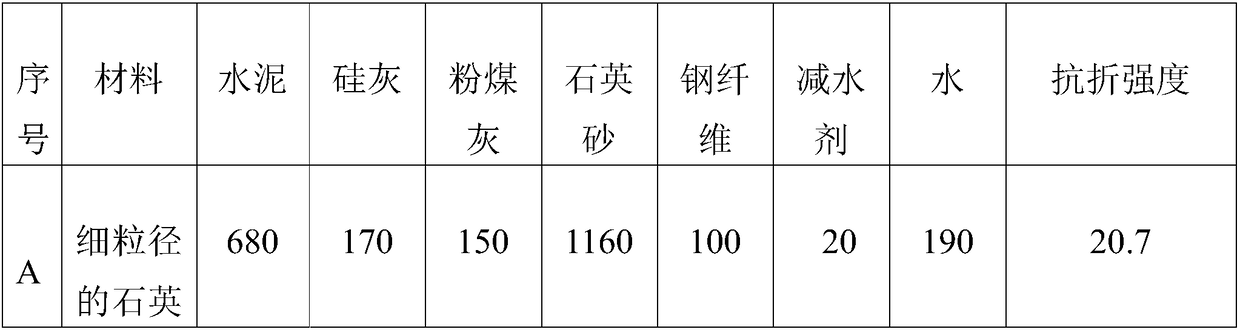

Active powder concrete and production technology for pouring fabricated component by active powder concrete

The invention belongs to the technical field of concrete, and discloses active powder concrete. The active powder concrete comprises the following components by mass which is metered by taking unit cubic concrete content as a reference: 660-710 kg of cement, 160-200 kg of silicon ash, 150-180 kg of fly ash, 1100-1160 kg of quartz sand, 100-120 kg of steel fiber, 18-22 kg of a water reducer, and 180-200 kg of water. The mass ratio of ultrafine particle size quartz sand to fine particle size quartz sand and middle particle size quartz sand is 15-25:65-75:5-15. The invention also discloses a production technology for pouring a fabricated component by the active powder concrete. Three particle size types of quartz sands (an integral particle size is fine) are employed, quartz sand grading is uniform and reasonable, the particles with different materials can be better and mutually coated and embedded, and the aggregate compactness is increased, the fluidity of the papered active powder concrete is better, and the fabricated component has good flexural intensity.

Owner:湖北中力通新材料有限公司

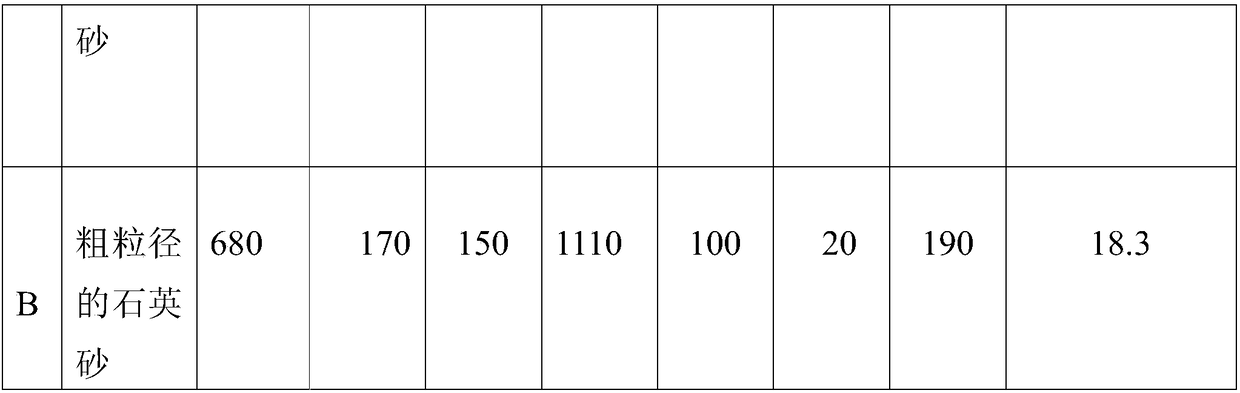

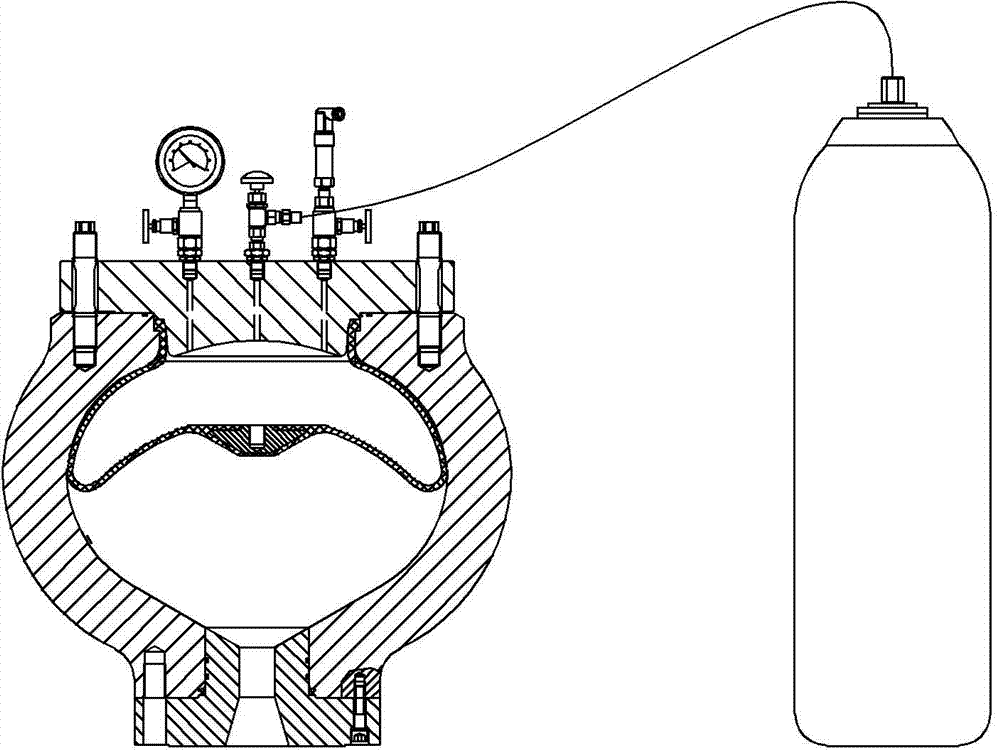

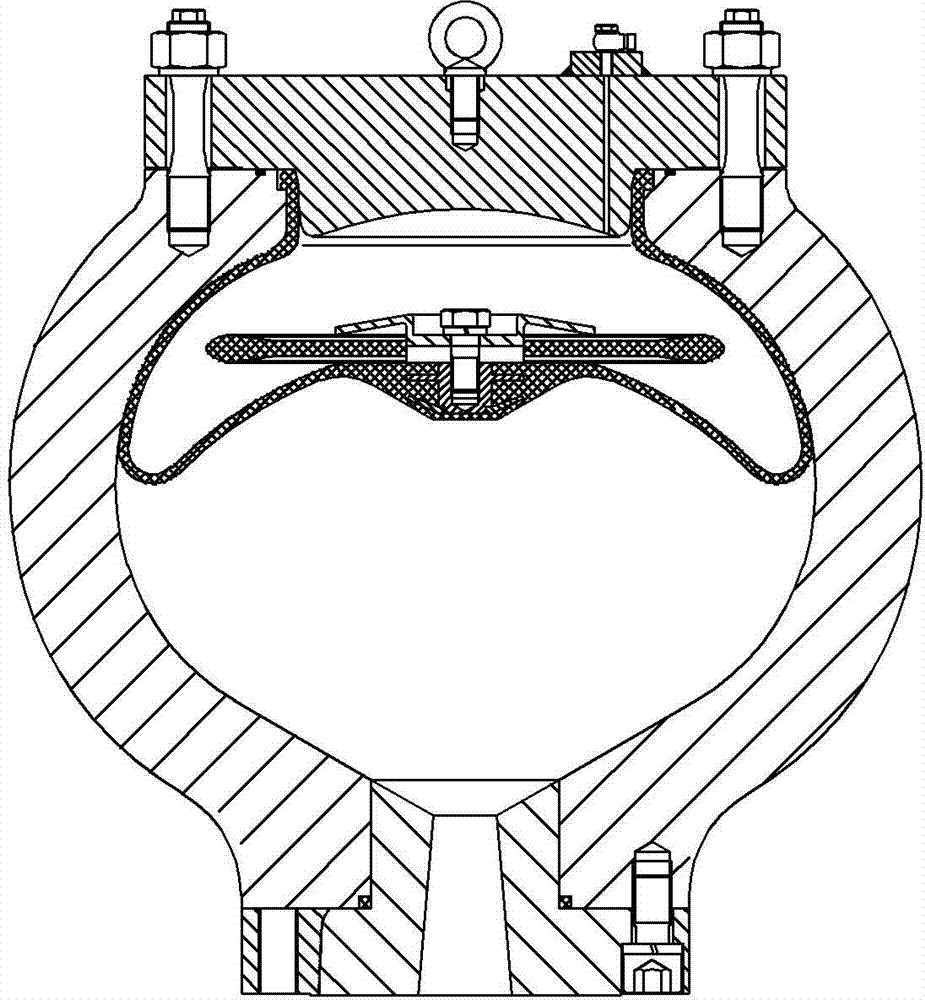

Air bag die and method for machining air bag by adopting same

The invention belongs to the technical field of dies, and in particular relates to an air bag die and a method for machining an air bag by adopting the air bag die. The invention provides an air bag die and method for machining the air bag, which not only can ensure air bag forming rate, and prolong the service life of the air bag, but also can improve the air bag production efficiency. The air bag die consists of a lower die, a middle die and an upper die, wherein a cone frustum-shaped bump is arranged in the middle of the lower die, and an air bag iron core adaptive to the shape of a depressed center at the top of the cone frustum-shaped bump is arranged at the center of the lower die; a middle core is arranged above the lower die, a cylindrical cavity with an upward opening is arranged in the middle of the middle core, and a through hole is arranged at the bottom of the cavity and internally provided with a connecting bolt; the middle die is positioned above the middle core, the upper part of the middle core penetrates through the center of the middle die, and a glue flowing channel is arranged on the outer edge of the lower die corresponding to the bottom of an outer arc surface of the middle core; and the upper die is positioned above the middle die, and a middle jacket is arranged between the inner side wall of the hollow center of the upper die and an annular bushing part at the upper part of the middle core.

Owner:NFC SHENYANG PUMP IND

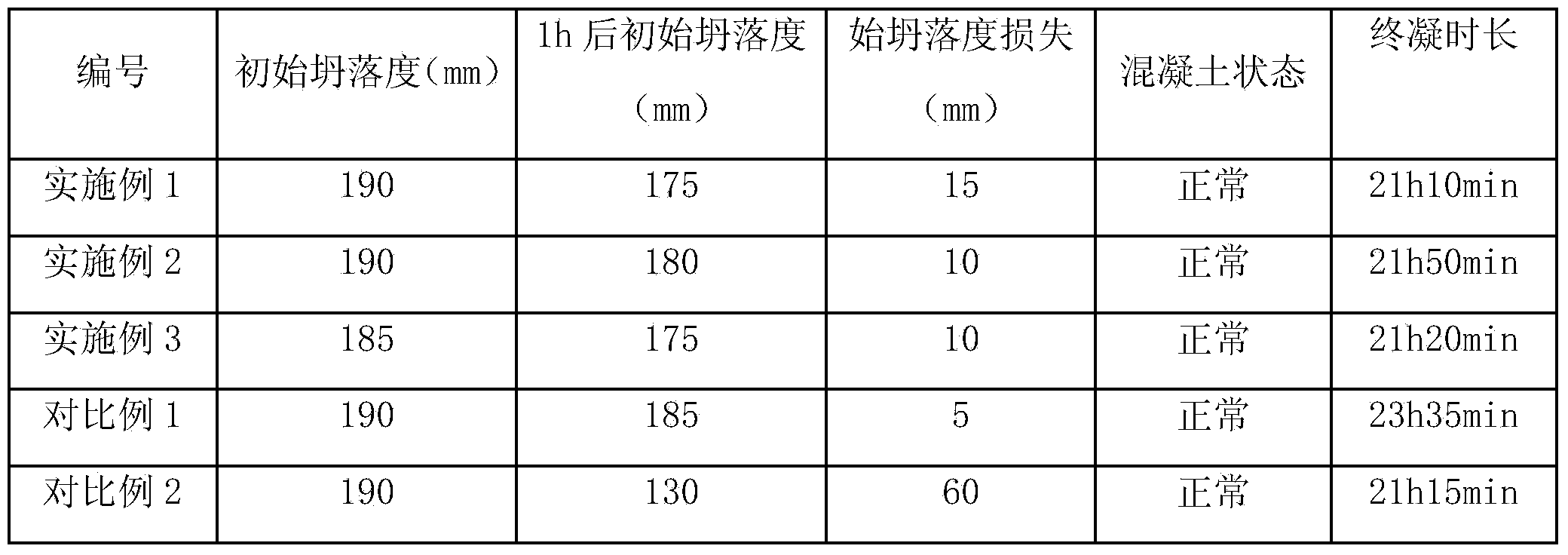

Composite early-strength type polycarboxylate superplasticizer as well as preparation method and application thereof

The invention relates to a composite early-strength type polycarboxylate superplasticizer as well as a preparation method and application thereof, belonging to the field of building materials. The technical problem to be solved by the invention is to provide the composite early-strength type polycarboxylate superplasticizer as well as the preparation method and application thereof. The composite early-strength type polycarboxylate superplasticizer is prepared from the following components in parts by weight: 20-50 parts of polycarboxylate superplasticizer, 2-5 parts of retarder, 30-75 parts of sodium thiosulfate, 3-10 parts of tri-isopropanolamine and 50-80 parts of water. Further, the invention also discloses the preparation method of the composite early-strength type polycarboxylate superplasticizer and the application of the composite early-strength type polycarboxylate superplasticizer in C15-C16 concrete. The composite early-strength type polycarboxylate superplasticizer disclosed by the invention has the advantages of excellent early-strength performance, relatively good compatibility among components, low alkali content, low shrinkage rate, low mixing amount and the like.

Owner:CHINA 19TH METALLURGICAL CORP CHENGDU CONSTR +1

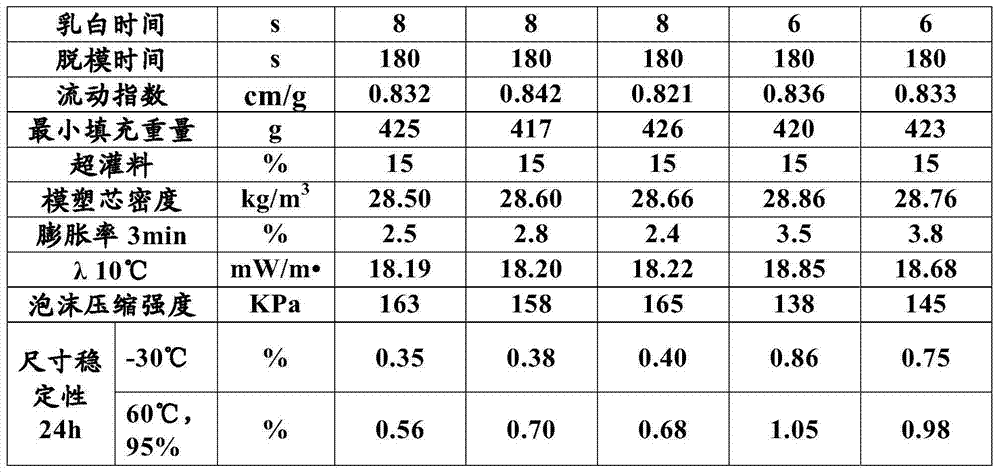

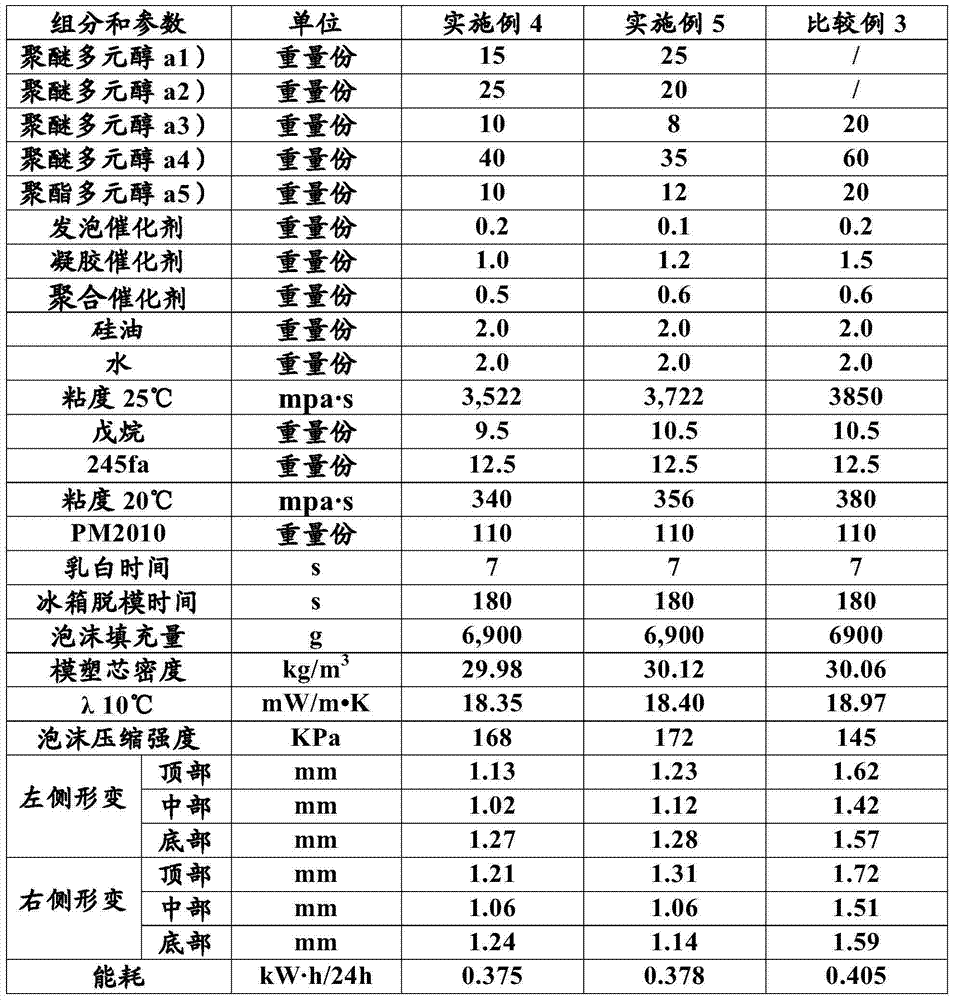

Polyalcohol composition, application thereof and rigid polyurethane foam prepared from polyalcohol composition

The invention relates to a polyalcohol composition containing the following components in parts by weight: 5-45 parts of polyether polyol (a1) formed by toluenediamine and oxyalkylene polymerization, 7-50 parts of polyether polyol (a2) formed by toluenediamine, triethanolamine and oxyalkylene polymerization, 3-25 parts of polyether polyol (a3) formed by glycerin and oxyalkylene polymerization, 15-65 parts of polyether polyol (a4) formed by saccharose and oxyalkylene polymerization and 3-20 parts of polyether polyol (a5), wherein the total weight part of the components from (a1) to (a5) is 100. The invention also relates to an application of the polyalcohol composition to the preparation of rigid polyurethane foam and rigid polyurethane foam prepared from the polyalcohol composition.

Owner:HEFEI MIDEA REFRIGERATOR CO LTD

Heat-insulation house for concrete curing in winter concrete construction

The invention relates to a heat-insulation house for concrete curing in winter concrete construction. The heat-insulation house comprises a frame, horizontal bracings, longitudinal bracings, hangers, supports, a heat-insulation layer and positioning strips, wherein the frame is arranged on the periphery of the heat-insulation house, the horizontal bracings and the longitudinal bracings are arranged in the frame at intervals respectively, the hangers are arranged at two ends of the longitudinal bracings which are arranged in the middle of the heat-insulation house, the frame of the heat-insulation house is integrally covered with the heat-insulation layer, and the positioning strips for fixing the heat-insulation layer are arranged on the longitudinal bracings. The heat-insulation house for concrete curing in winter concrete construction has the advantages that the heat-insulation house is firm and stable in structure and is overturned by wind difficultly; an external covering transparent plastic film heat-insulation layer is good in windproof and frost-resisting functions and good in light transmission performance, so that when indoor environment temperature is 0 DEG C in presence of sunshine, temperature inside the heat-insulation house can reach about 20 DEG C, and concrete curing and strength improvement are benefited; the heat-insulation house is simple in structure, reasonable in design, simple and convenient to produce, excellent in performance, economical, practical and quite remarkable in application effect.

Owner:TIANJIN NO 2 CONSTR ENG +1

Cast polyurethane elastomer composition for fashion model

The invention relates to a cast polyurethane elastomer composition for a fashion model. The composition has a two-component system, wherein a component A consists of trifunctional and tetrafunctional polypropylene oxide ether polyol with the molecular weight of 300 to 6,000, 3,3'-dichloro-4,4'-diaminodiphenylmethane (MOCA), a catalyst and other aids; a component B consists of isocyanate which is polymethylene polyphenyl polyisocyanate (PAPI), diphenylmethane diisocyanate-50 (MDI-50), carbodiimide modified MDI or a mixture thereof; and the component B and the component A are mixed at room temperature in a weight ratio of 100:(60-70) and the mixture is subjected to centrifugal casting molding to form a cast polyurethane elastomer with the shore D hardness of 70 to 80D and high mechanical property. The cast polyurethane elastomer composition is mainly used for producing the fashion model and other polyurethane sundries which have requirements on high strength and hardness.

Owner:SHANDONG INOV POLYURETHANE

Environment-friendly polyurethane elastomer

The invention discloses an environment-friendly polyurethane elastomer, which has a bi-component system. A prepolymer component containing 15.2 to 17 percent of NCO is prepared by reacting diisocyanate with polyatomic alcohol, wherein the diisocyanate is diphenylmethane diisocyanate (MDI), MDI modified by carbonized diimine, or a mixture thereof, and the polyatomic alcohol is polyoxypropylene polyatomic alcohol with the number-average molar mass of 2,000-4,000; and a polymer component is prepared from polyoxypropylene polyatomic alcohol with the number-average molar mass of 3,000-6,000, 1,4-butylene glycol, a catalyst and an antiaging agent. The prepolymer component and the polymer component are mixed in a weight ratio of 1:1, and the mixture is cast, and vulcanized and molded to form the environment-friendly polyurethane elastomer; and the environment-friendly polyurethane elastomer has excellent environmental friendliness and mechanical properties.

Owner:SHANDONG INOV POLYURETHANE

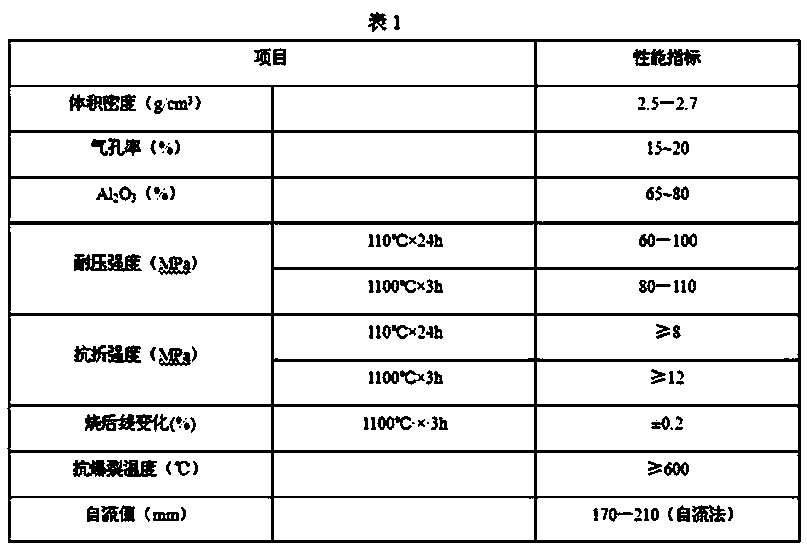

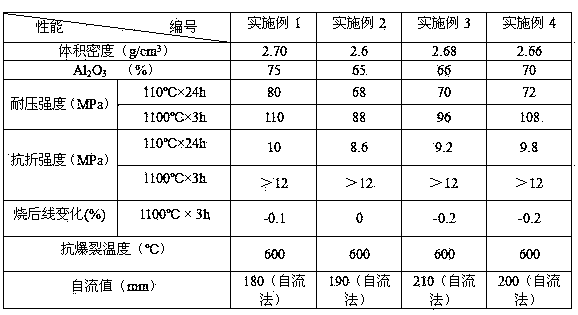

Early strength anti-detonation fireproof self-flow material

The invention belongs to the technical field of refractory materials, and particularly discloses an early strength anti-detonation fireproof self-flow material. The material comprises the following raw materials: alumina or flint clay, pyrophyllite, silicon carbide, alumina based alpha-Al2O3 micropowder, SiO2 micropowder and the like. Aluminate cement serves as a binding agent, and a composite additive and an antidetonator are added. The self-flow material has the advantages of early strength, high strength, detonation resistance, shortened demold time, rapid baking and the like, and has good resistance to high temperature.

Owner:郑州瑞泰耐火科技有限公司

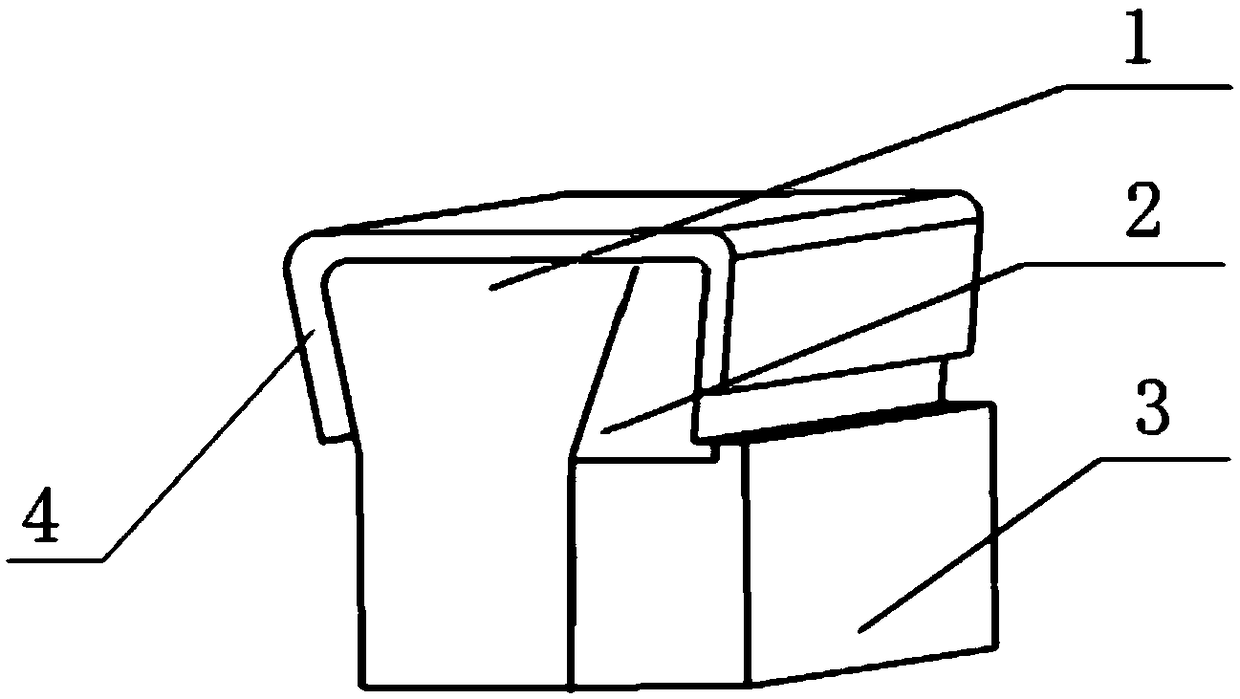

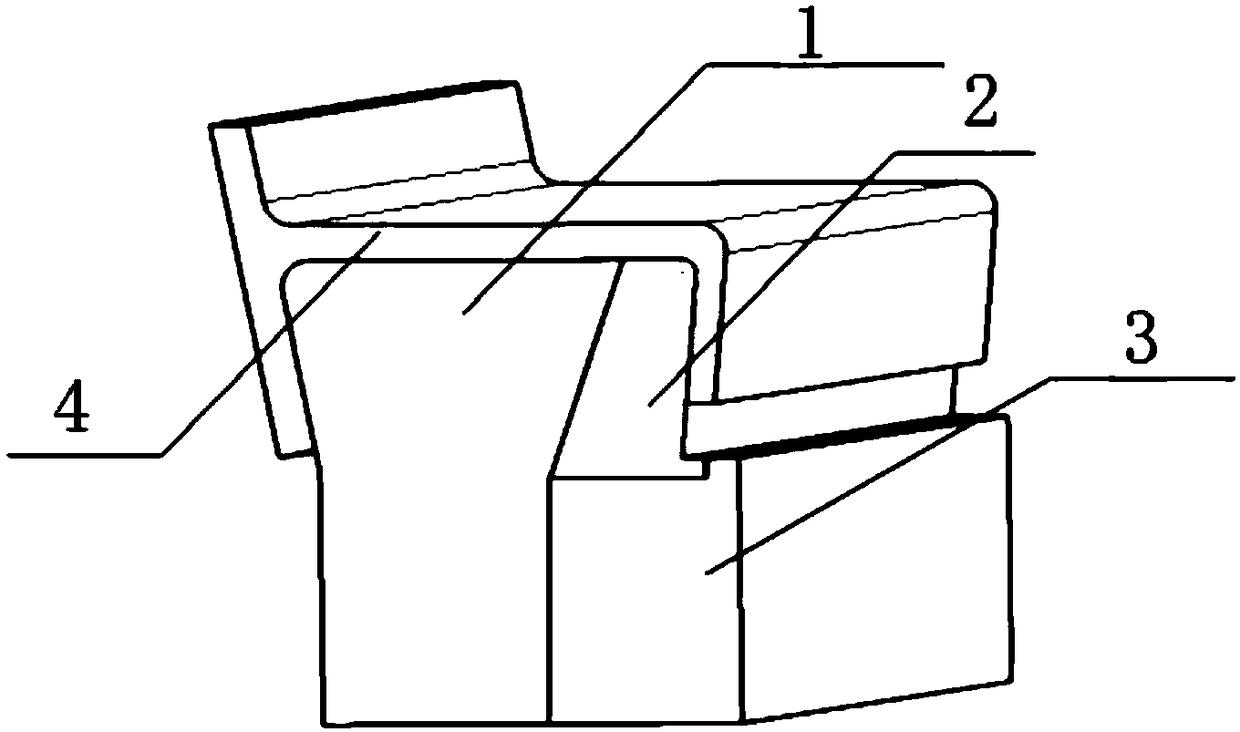

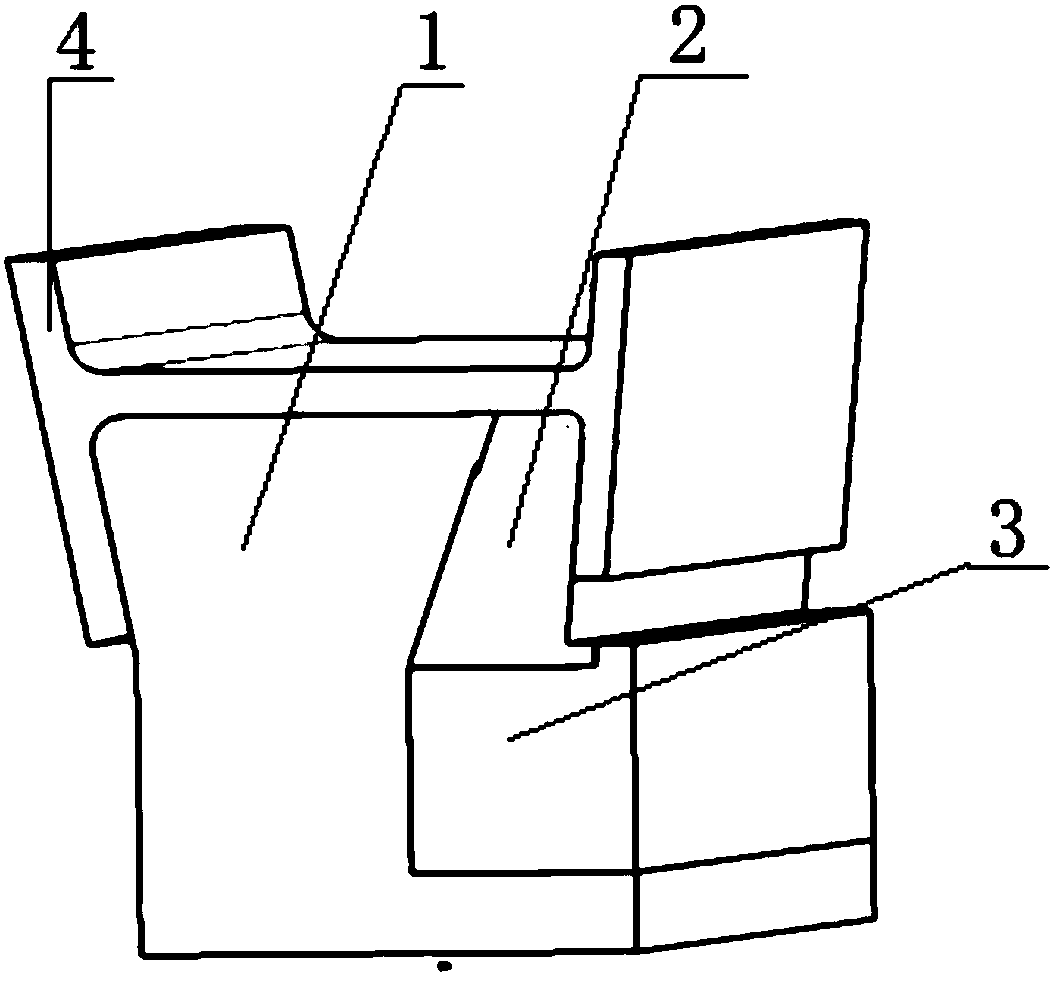

Enclosed composite member forming tool and application method thereof

ActiveCN108568974AReduce manufacturing costExtended service lifeDomestic articlesDamage repairEngineering

The invention belongs to the technical field of composite member forming and relates to an enclosed composite member forming tool and an application method thereof. The invention is intended to overcome the defect that separate forming tooling for traditional enclosed composite members uses a great amount of positioning pins and fastening bolts; the enclosed composite member forming tool depends on base positioning and fully avoids the use of positioning fasteners, such as positioning pins and bolts, such that manufacture cost of the tool is greatly reduced, and tool manufacture cycle is shortened. A demolding process has no need for removal of bolts and positioning pins, demolding time is greatly shortened, the technical requirement on the demolding process is lowered, and production efficiency is improved. The enclosed composite member forming tool has good positioning simplicity, has very low damage repair rate, and has greatly extended service life.

Owner:AVIC BASIC TECH RES INST

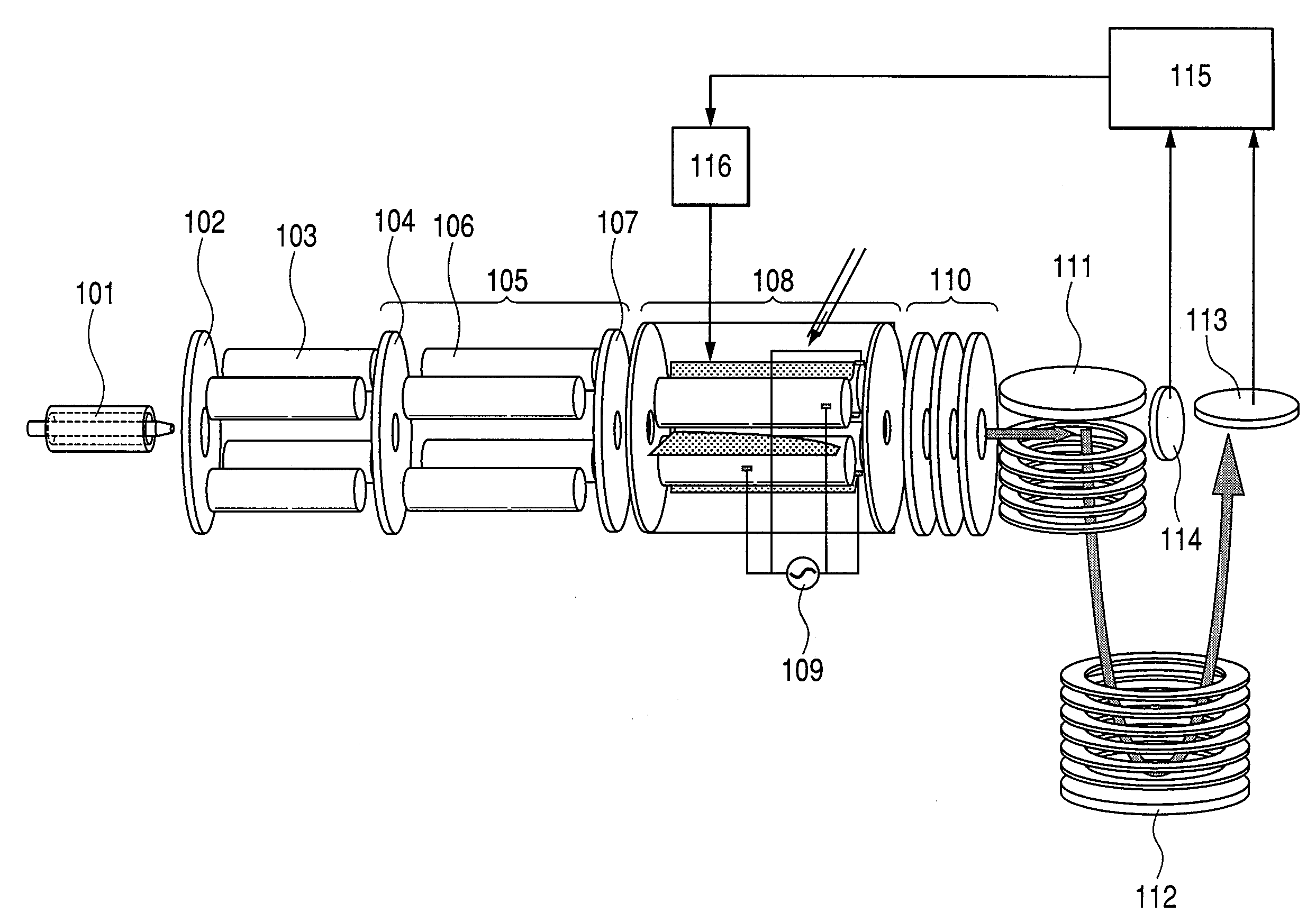

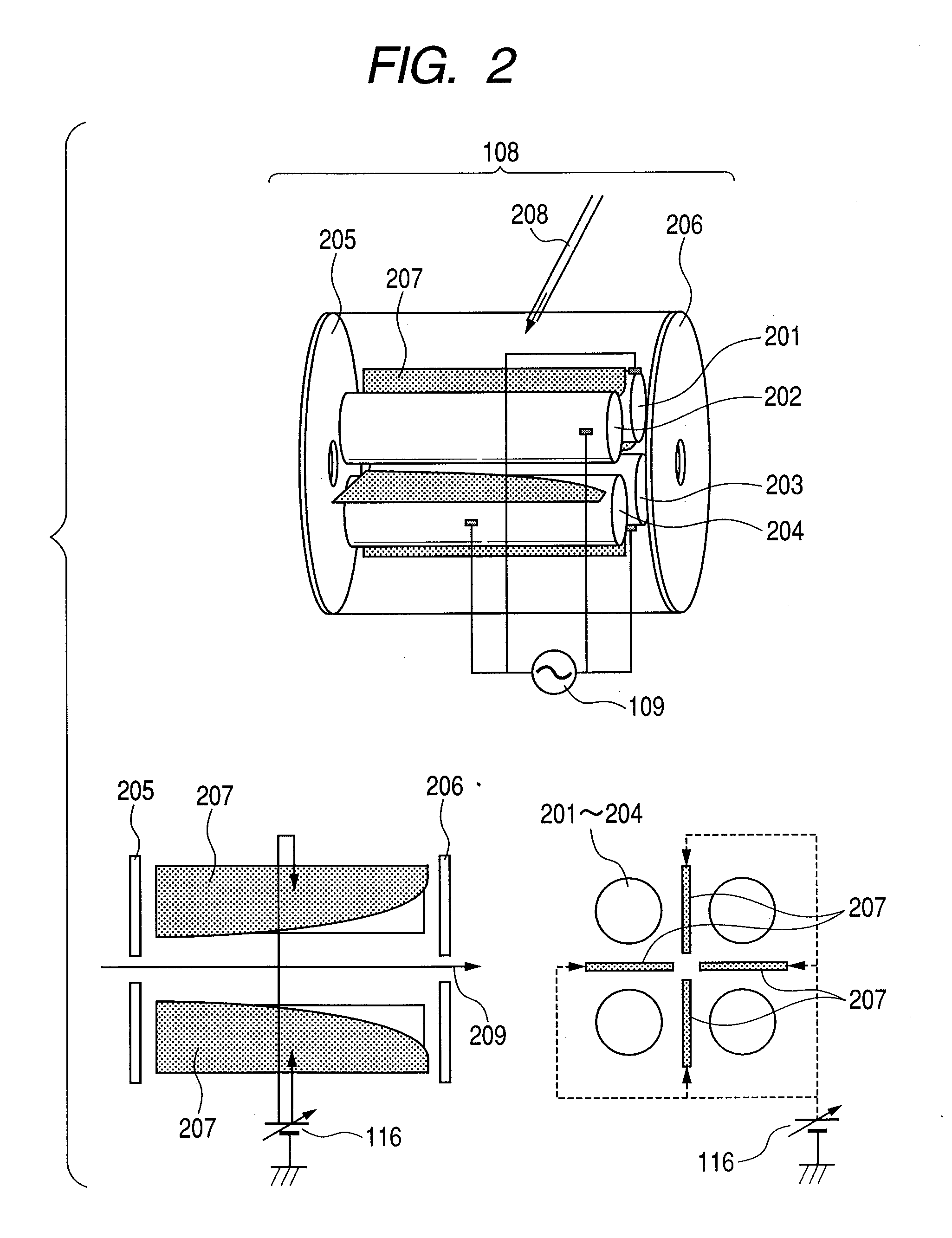

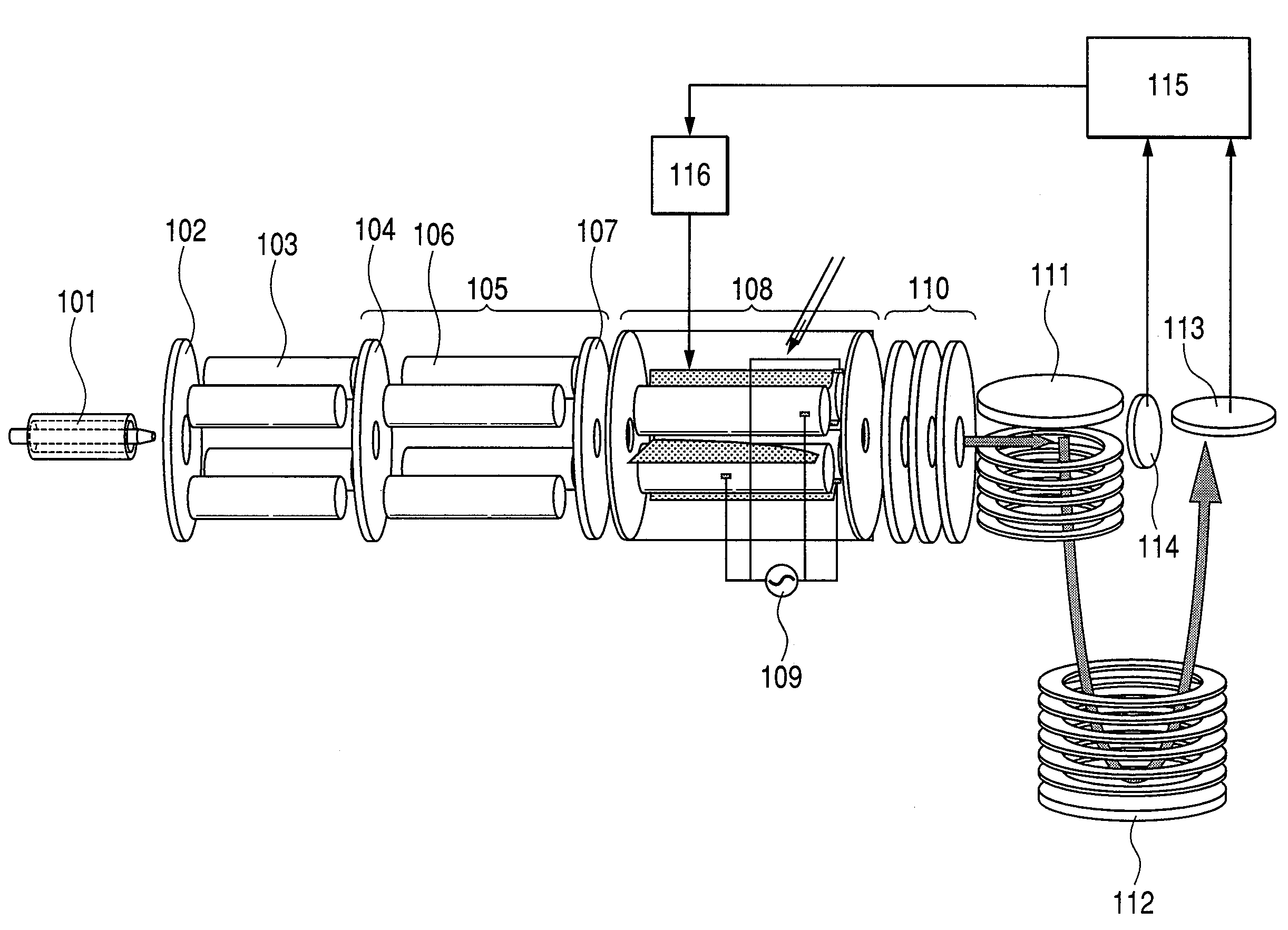

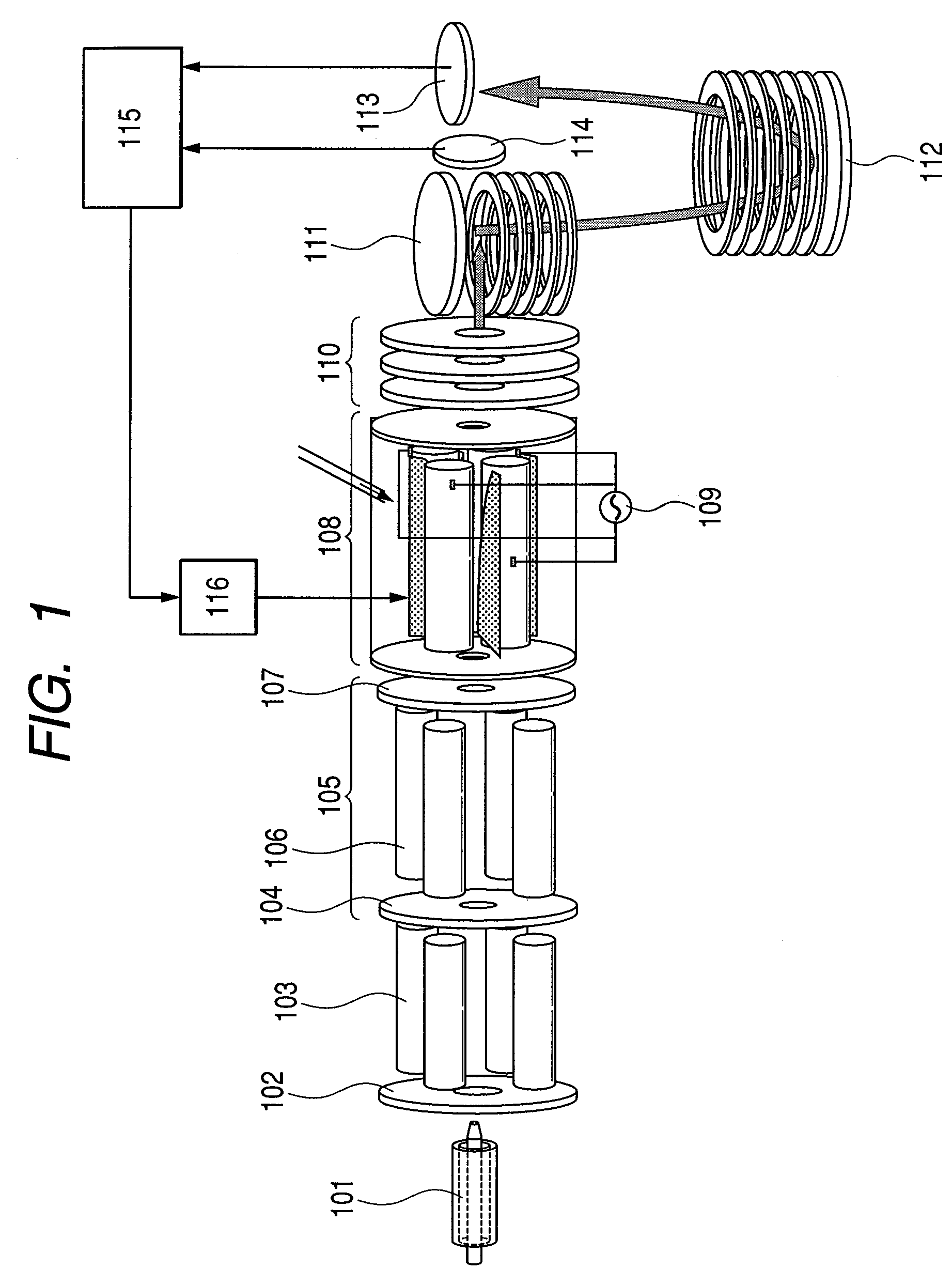

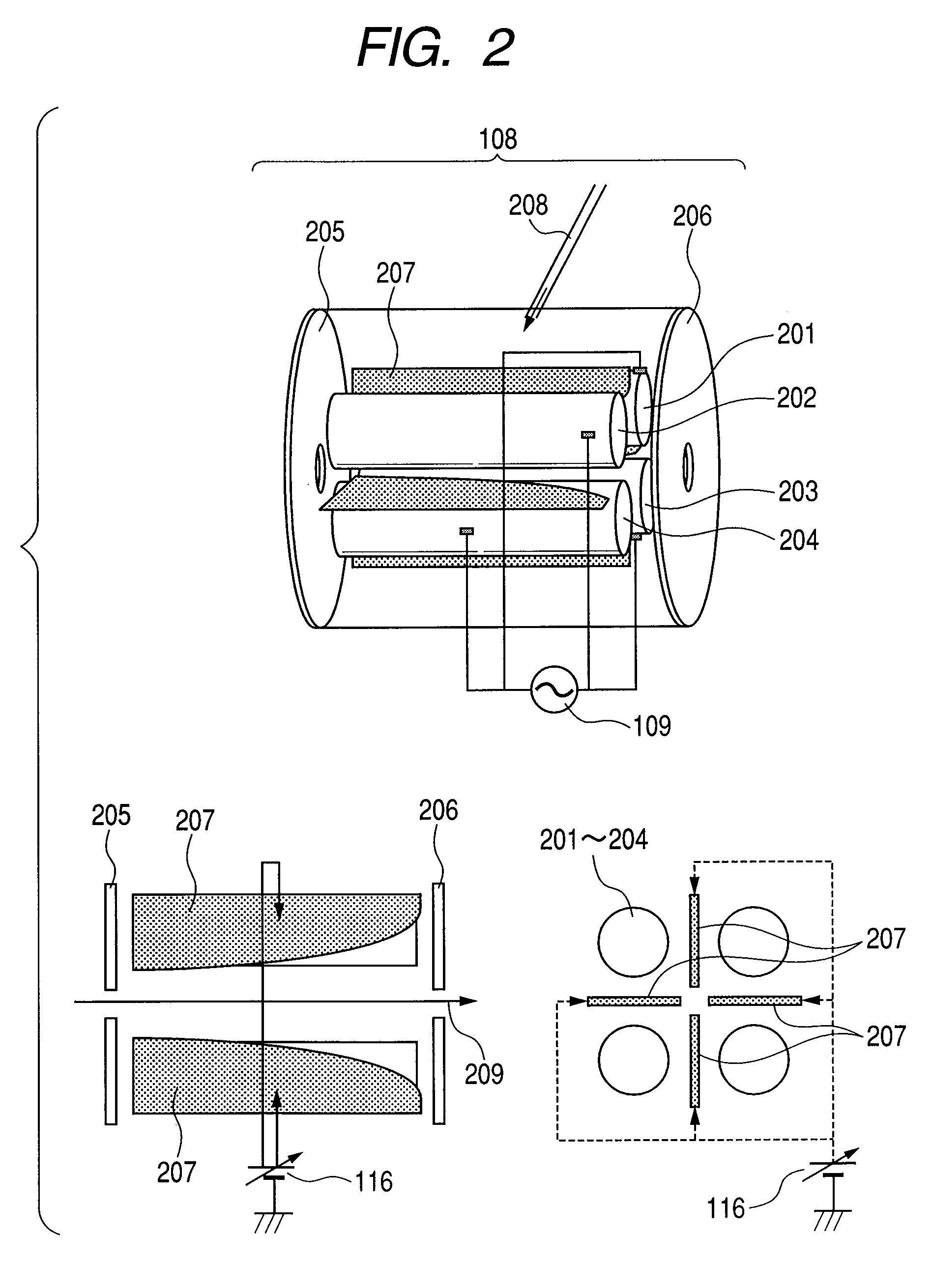

Mass spectrometer

ActiveUS20090020695A1Lengthen time distributionImprove utilization efficiencyIsotope separationSpectrometer combinationsAuxiliary electrodeConfusion

A mass spectrometer includes a linear multipole electrode, an auxiliary electrode that applies a DC potential on the center axis of the linear multipole electrode, and a DC power supply that supplies a DC power to the auxiliary electrode. The DC potential slope formed on the center axis of the multipole electrode is changed according to the measuring condition. The ejection time of ions can be adjusted optimally by adjusting the potential slope so as to satisfy the measuring condition. If the ejection time of ions is shortened, confusion of different ion information items that might otherwise occur on a spectrum can be avoided. If the ejection time of ions is lengthened, detection limit exceeding can be avoided and ions can be measured efficiently, thereby highly efficient ion measurements are always assured.

Owner:HITACHI HIGH-TECH CORP

Filled low-temperature modulation wax for precision casting and preparation method thereof

InactiveCN104610762AImprove thermal stabilityGood dimensional stabilityFoundry mouldsFoundry coresMicrocrystalline waxGray level

The invention discloses filled low-temperature modulation wax for precision casting and a preparation method thereof. The wax comprises components in parts by weight as follows: 31-33 parts of microcrystalline wax, 1.5-2.5 parts of polyethylene wax, 27-29 parts of rosin resin, 3-5 parts of an ethylene-vinyl acetate copolymer, 4-6 parts of an alpha-olefin polymer, 0.8-1.2 parts of stearic acid and 25-30 parts of filler. The modulation wax prepared with the formula and the preparation method can have the advantages of high size stability, high strength, low gray level and easiness in demolding and can be applied to production of supreme precision castings.

Owner:青岛新诺科铸造材料科技有限公司

Mass spectrometer

ActiveUS8044349B2Shorten injection timeShorten the timeIsotope separationSpectrometer combinationsMass analyzerAuxiliary electrode

A mass spectrometer includes a linear multipole electrode, an auxiliary electrode that applies a DC potential on the center axis of the linear multipole electrode, and a DC power supply that supplies a DC power to the auxiliary electrode. The DC potential slope formed on the center axis of the multipole electrode is changed according to the measuring condition. The ejection time of ions can be adjusted optimally by adjusting the potential slope so as to satisfy the measuring condition. If the ejection time of ions is shortened, confusion of different ion information items that might otherwise occur on a spectrum can be avoided. If the ejection time of ions is lengthened, detection limit exceeding can be avoided and ions can be measured efficiently, thereby highly efficient ion measurements are always assured.

Owner:HITACHI HIGH-TECH CORP

Shell preparation method for investment casting

ActiveCN108746496AEffective identification of stress concentration locationsEffectively identify the easy-to-deform position of the investment patternFoundry mouldsFoundry coresInvestment castingMold filling

The invention relates to a shell preparation method for investment casting. The shell preparation method comprises the steps of stiffener determining, reinforced investment pattern module preparation,shell preparation, stiffener removal, investment pattern removal and shell roasting. According to a casting piece structure, the investment pattern stress situation and mold filling solidification process computer simulation, the position of a stiffener is determined, and the investment pattern and the shell are prevented from deformation advantageously and are supported. By removing the stiffener, a hole channel and a demolding opening are formed in the investment pattern, the shell can be separated from the investment pattern without being turned over, and the surface quality of an inner cavity of the shell is improved.

Owner:BAIMTEC MATERIAL CO LTD

Polyurethane raw material special for cosmetic powder puff

InactiveCN108715629AOvercome unfriendlinessRebound fastPackaging toiletriesPackaging cosmeticsFirming agentUltimate tensile strength

The invention discloses a polyurethane raw material special for a cosmetic powder puff. The polyurethane raw material special for the cosmetic powder puff comprises a polyurethane prepolymer and a curing agent. Meanwhile, the invention further provides a special production process for producing the cosmetic powder puff by using the polyurethane raw material. According to the polyurethane raw material special for the cosmetic powder puff, the traditional foaming mode of directly using isocyanate is adjusted into the mode of using prepolymer foaming, a mode of using water as a main component ofthe curing agent, and foaming is conducted in a mode of adding fillers, so that no friendliness of latex serving as a raw material is overcome, a mode for producing hydrophilic makeup cotton by takingthe polyurethane as the raw material is created, and the makeup cotton is hydrophilic and skin-friendly in hand feeling; furthermore, a brand new foaming process is used for the special raw material,the common foaming machine can be used for rapidly foaming, and the demolding time can be shortened to 2 to 3 minutes, so that the foam hole structure is more exquisite, and the product has skin-friendly hand feeling, is flexible and rebounded rapidly and meets the requirements of female consumers. The polyurethane raw material special for the cosmetic powder puff has the following characteristics: the product has high water-absorbing rate; the strength and the resilience maintaining rate are high after the product is wetted.

Owner:滁州市赢聚高分子材料有限公司

Polyether urethane material, method for preparing same and application of polyether urethane material

ActiveCN105566625AStrong low temperature performanceStrong water resistancePolyurethane elastomerOrganic solvent

The invention provides a polyether urethane material. A method for preparing the polyether urethane material includes carrying out room-temperature reaction on polyhydric alcohol of initiators and alkylene oxide A in organic solvents under catalytic actions of alkali A for 1-30 h to obtain systems A; adding alkylene oxide B and metal sulfate into the systems A and carrying out room-temperature reaction on the alkylene oxide B, the metal sulfate and the systems A for 1-40 h to obtain systems B; adding alkylene oxide C and alkali B into the systems B, carrying out room-temperature reaction on the alkylene oxide C, the alkali B and the systems B for 1-60 h to obtain reaction mixtures and carrying out after-treatment on the reaction mixtures to obtain a finished product. The polyether urethane material and the method have the advantages that the polyether urethane material can be used for preparing polyurethane cellular elastomers which are used as shoe sole materials; the polyether urethane material is high in low-temperature performance, hydrolysis resistance and mildew resistance, the reaction time and the mold release time can be shortened when the polyether urethane material is used for preparing the polyurethane cellular elastomers, and the physical performance of the product can be improved.

Owner:薛立新

Construction method for duplicating soft mould and installing building granitic plaster floriation member

The invention discloses a construction method for duplicating a soft mould and installing a building granitic plaster floriation member. The construction method comprises the following steps of: A. information preservation, B.. preparation of a soft mould: a. imitating an unpainted clay idol; b. duplicating an outer mould by using gypsum; c. taking out the unpainted clay idol; d. pouring an inner gypsum mould; e. demoulding f. repairing the inner mould; g. baking; h. coating silicon rubber; and i. demoulding; preparation of a floriation member: a. analyzing materials; b. proportioning materials; c. placing and installing a framework; d. pouring; e. demoulding; f. brushing with water; g. repairing; h. brushing with water; and i. maintaining; D installation; and E. coating of protective liquid. According to the method, chemical materials are used for making the soft mould, so that the cost of the soft mould is lower than that of other moulds, and the soft mould can be reused for multiple times; and by virtue of the elasticity of the soft mould, the demoulding time can be shortened greatly, the surface of the member can be cleaned timely, and the demoulding is more convenient since the demoulding difficulties of conventional moulds are overcome according to the three-dimensional characteristics (such as petal and relief shapes) of the floriation member.

Owner:WUHAN CONSTR ENG

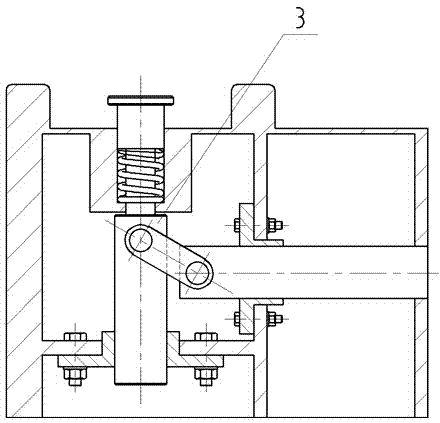

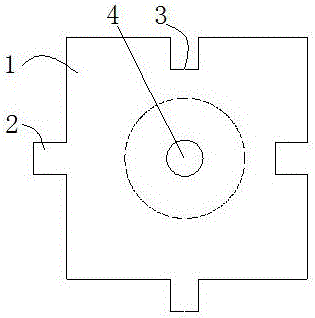

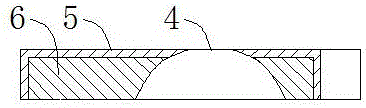

Concrete magnetic side form with form removal device

InactiveCN104328907AAvoid breakingImprove product qualityForming/stuttering elementsForm treatmentArchitectural engineeringPrecast concrete

The invention discloses a concrete magnetic side form with a form removal device, and the concrete magnetic side form is applied to the field of modern construction industry. The concrete magnetic side form consists of a side form body, a magnetic unit and the form removal device, wherein the magnetic unit and the form removal device are fixedly arranged in the side form body, the concrete magnetic side form can be fixedly arranged on a template tray, and the form removal device consists of a mandril cap, a spring, a vertical mandril, an intermediate connecting rod, a horizontal push rod, a push rod guide sleeve, a push rod pin shaft, a mandril pin shaft and a mandril guide sleeve. The horizontal push rod of the form removal device can be ejected out from the interior of the magnetic side form, and directly acts on a precast concrete component, the serious mold damage caused by form removal through dragging and beating is avoided, the precast concrete component damage caused by the form removal is avoided, the product quality of the precast concrete component is improved by virtue of the magnetic side form, meanwhile the form removal is convenient, automatic form removal of a manipulator is realized, the form removal time is effectively shortened, the labor efficiency of the form removal is improved, and the labor intensity of the form removal operation is lowered.

Owner:NORTHERN HEAVY IND GRP CO LTD

Surface treatment method of wood female mold body of electric arc spraying mold

ActiveCN108499829AFlat surfaceAvoid damageLiquid surface applicatorsPolyurea/polyurethane coatingsEpoxyBinding force

The invention discloses a surface treatment method of a wood female mold body of an electric arc spraying mold. An epoxy resin glue solution is sprayed on the surface of the mold in advance, then a layer of polyurethane protection film with good temperature resistance is sprayed on the surface of an epoxy resin layer, and a layer of release agent is sprayed between the polyurethane and the epoxy resin layer to reduce the binding force between the polyurethane and epoxy resin. The surface of the mold treated through the surface treatment method is smooth and clean; after electric arc spraying is completed, the demolding efficiency is high, 70-95% of the demolding time can be saved, and the production efficiency is improved; and damage to the surface of the wood female mold body is small, thus the wood female mold body can be reused, and the cost is saved advantageously.

Owner:NAT INST CORP OF ADDITIVE MFG XIAN

Multifunctional concrete form book-pad

The invention provides a multifunctional concrete formwork underlay, and is characterized in that the underlay is formed by a drainage exhaust layer and a filter layer, wherein the surface of the drainage exhaust layer is provided with grids or grazing, and the filter layer is an earthwork fabric layer with certain porosity and permeability. The drainage exhaust layer is a drainage body with a three-dimensional porous structure; the dimension of pores of the drainage body is determined by the pouring requirement of concrete; the thickness of the drainage body is between 1.5 and 2.0mm; each grid can be of a quadrangular shape or a hexagonal shape with a side length of between 0.3 and 0.5mm; and the filter layer can be the earthwork fabric layer. The earthwork fabric layer adopts a spunbonded continuous yarn earthwork fabric; the pore diameter and the permeability of the earthwork fabric layer are determined by the pouring requirement of the concrete; the pore diameter of the earthwork fabric layer is generally of between 0.15 and 0.20mm; and the permeability coefficient of the earthwork fabric layer is generally Kx10<-3>cm / s. The multifunctional concrete formwork underlay can automatically drain water, exhaust steam and perform maintenance, thereby improving the strength and compactness of the surface layer of the concrete; moreover, construction is convenient, formwork removal time is shortened, the turnover rate of the formwork is increased, and the cost is reduced.

Owner:NANJING HYDRAULIC RES INST THE MINISTRY OF WATER RESOURCES THE MINIST

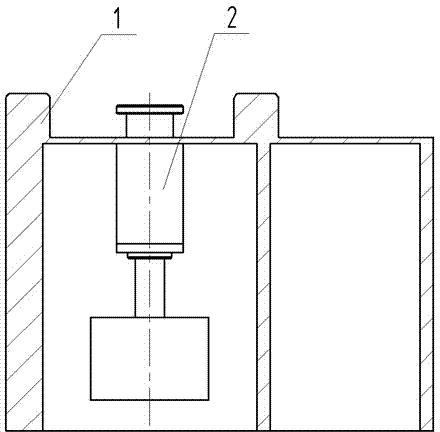

Method for forming cushions

ActiveUS20130020016A1Reduce demoulding timeIncrease productivityStuffed mattressesSpring mattressesEngineeringCushion

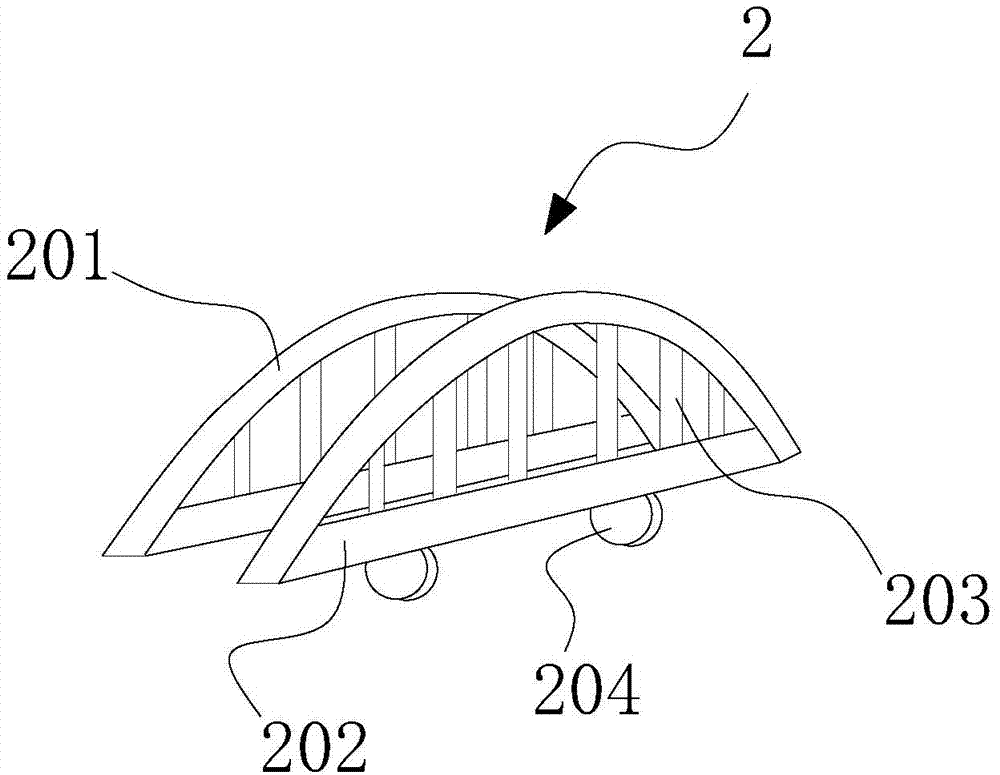

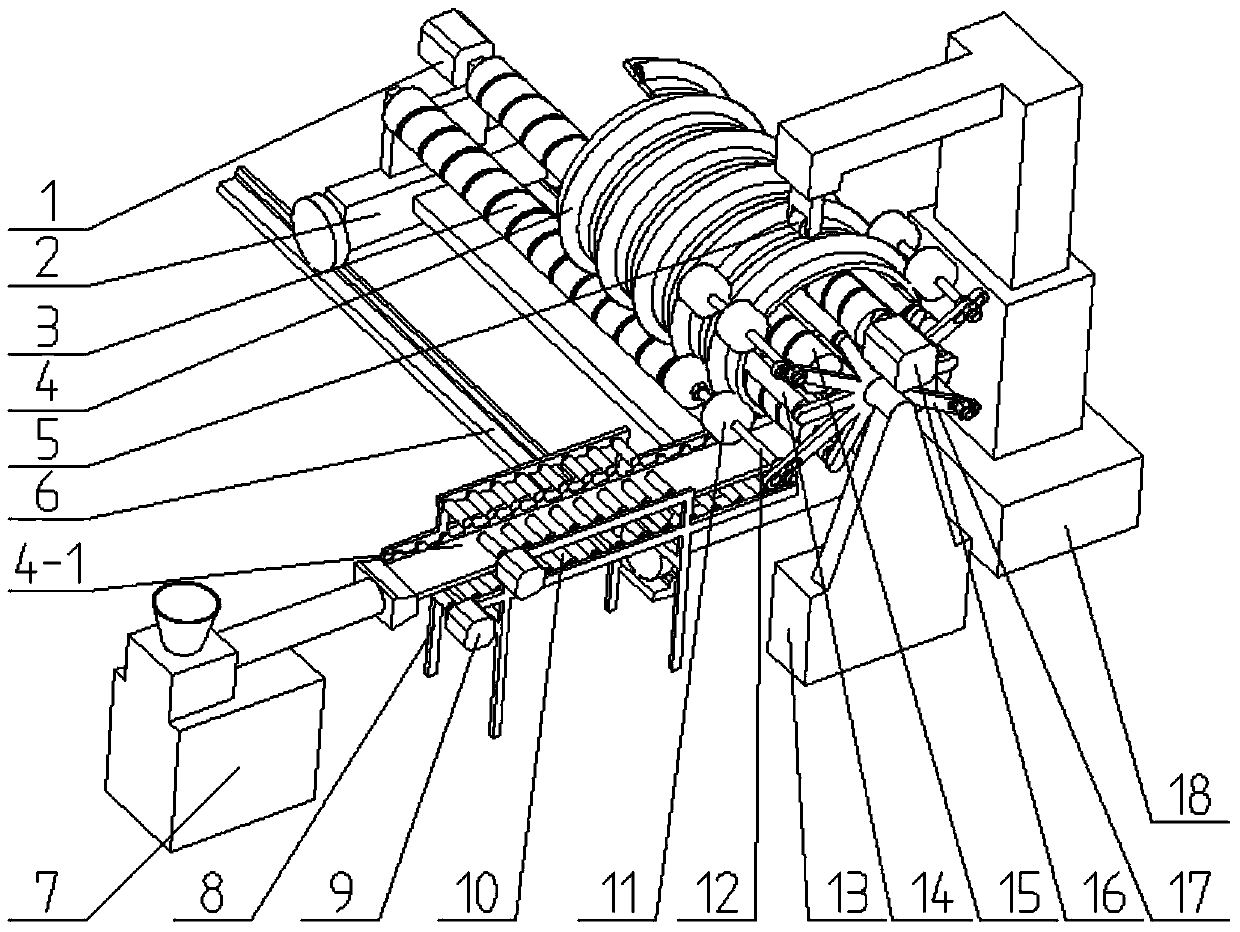

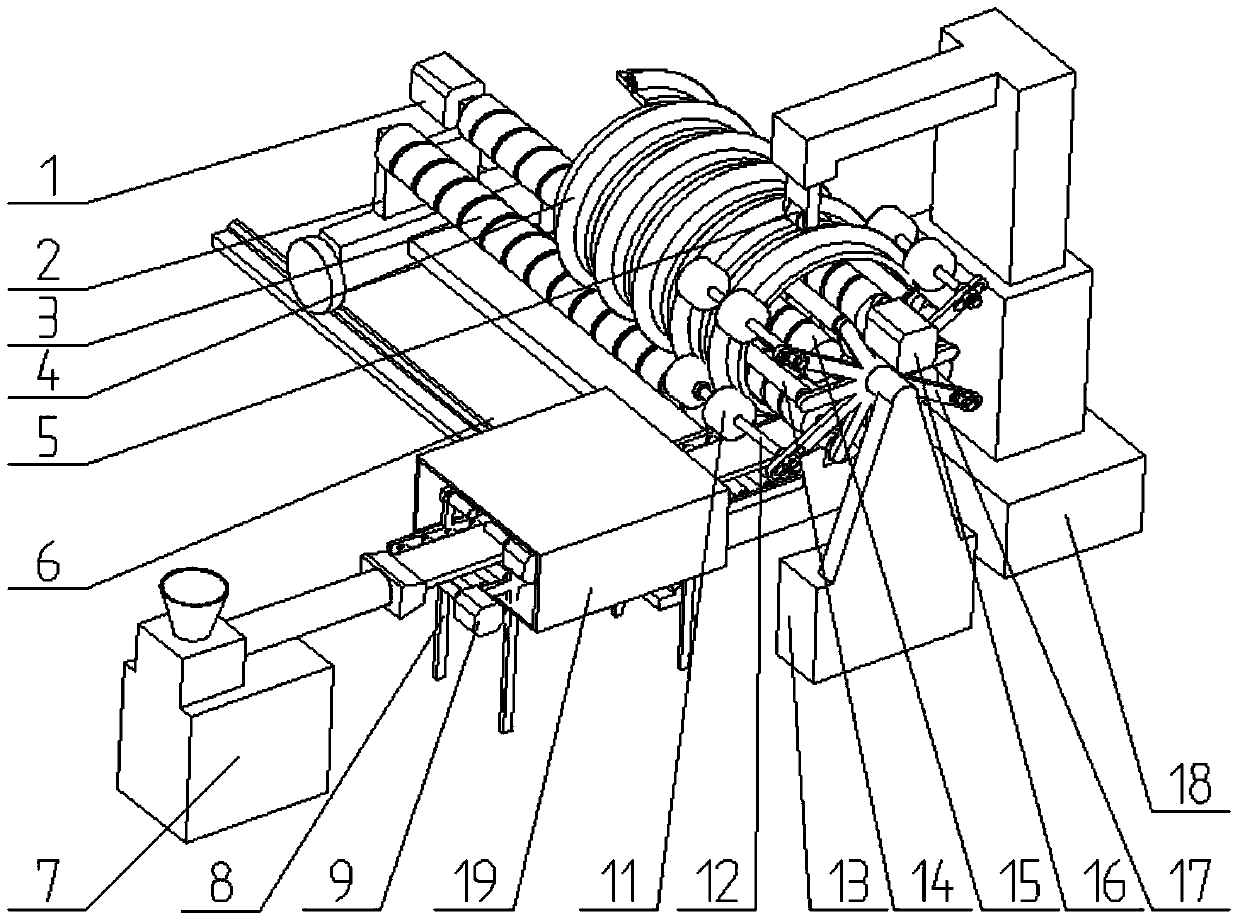

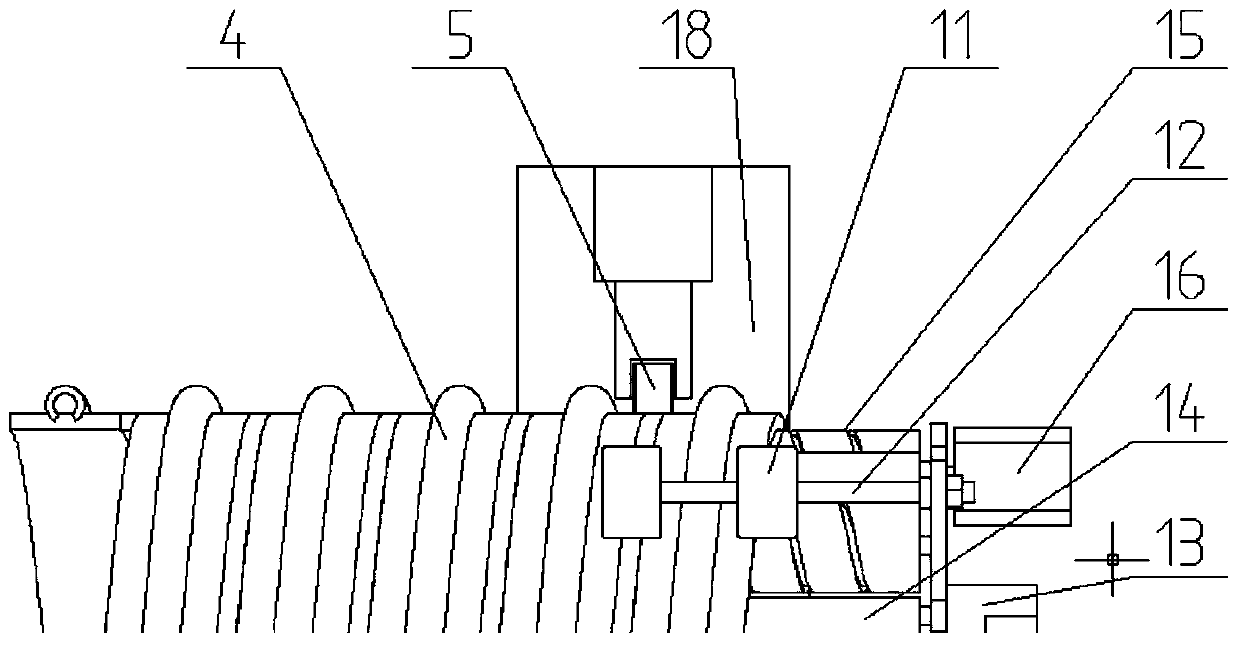

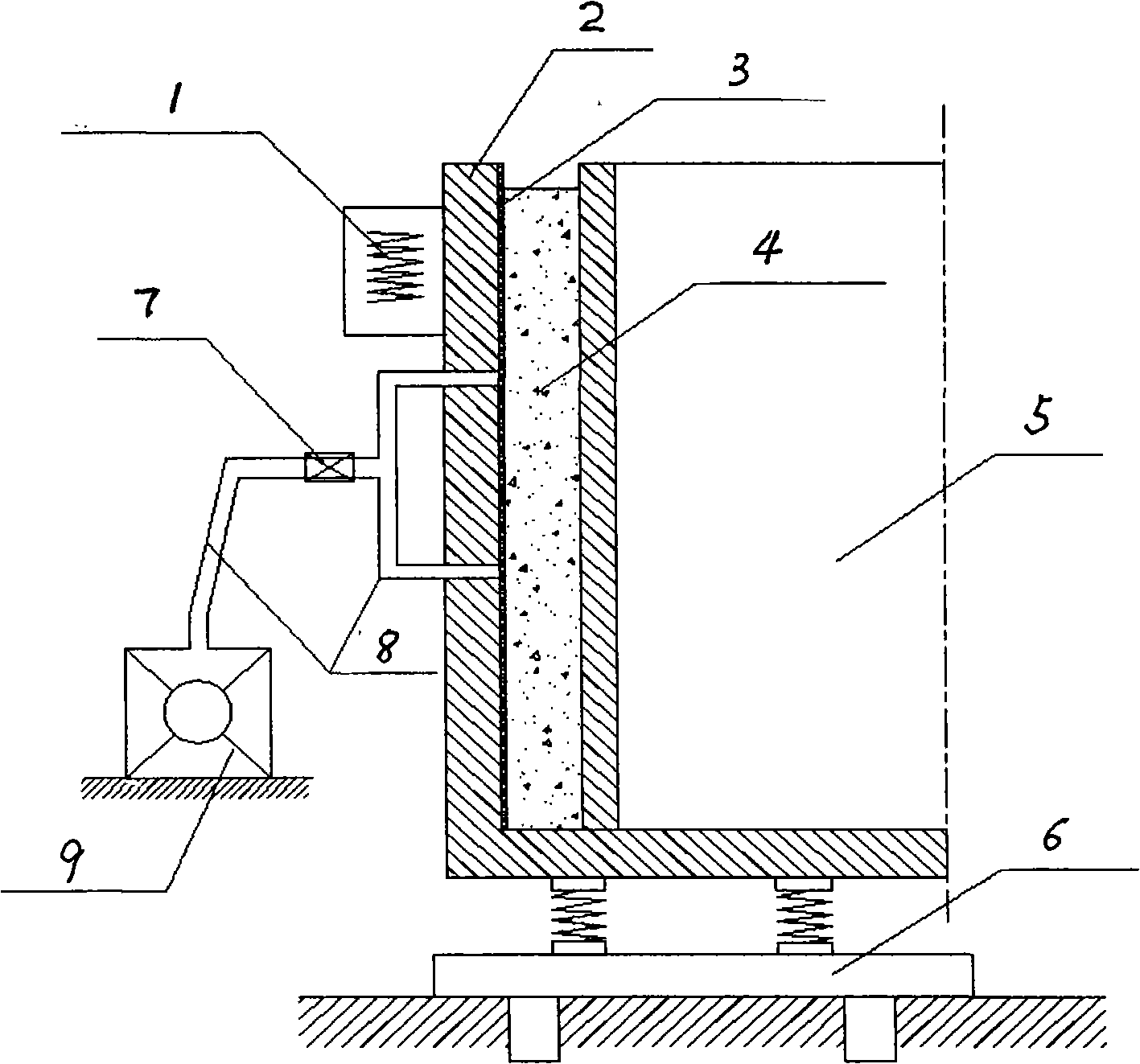

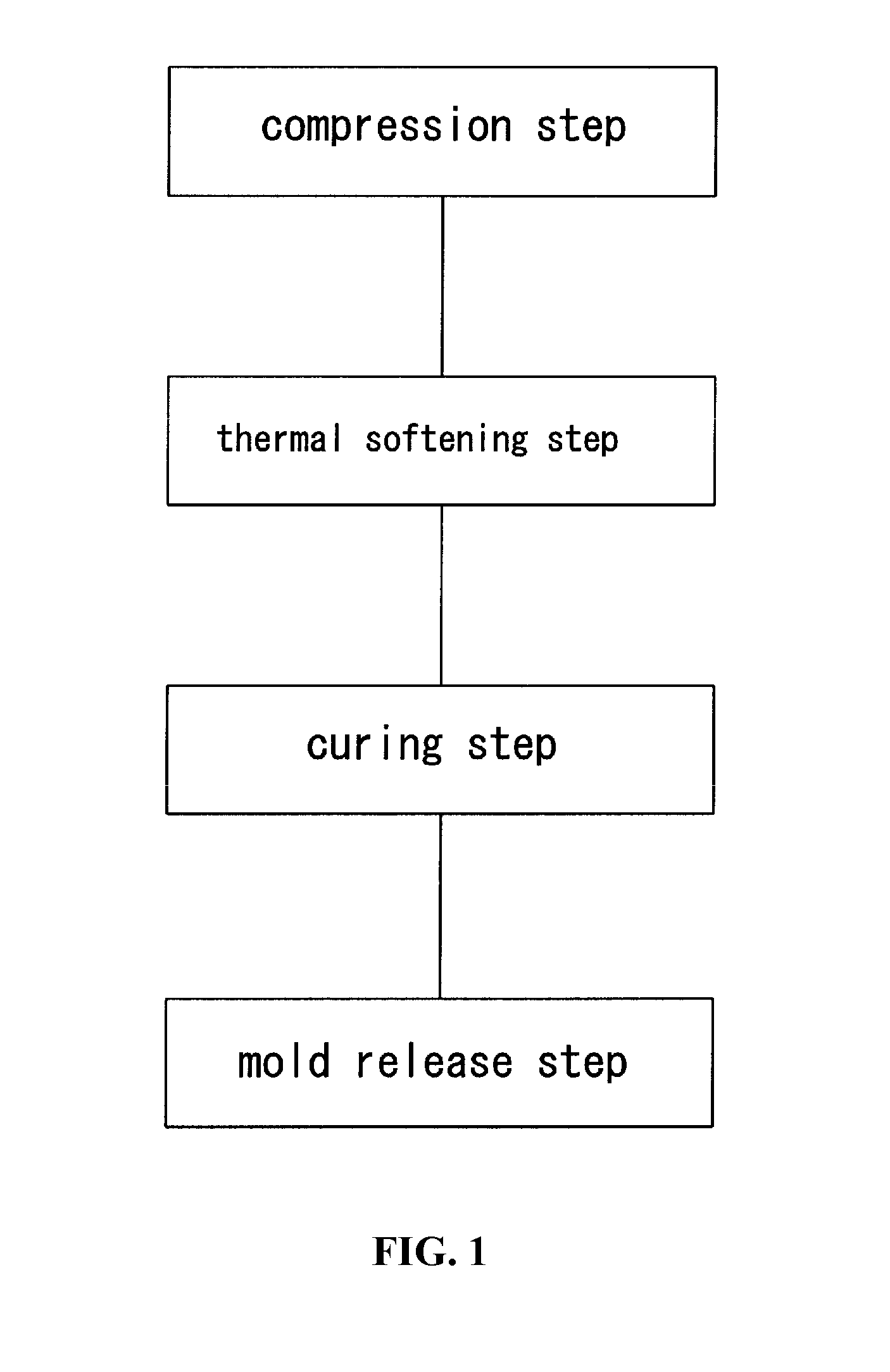

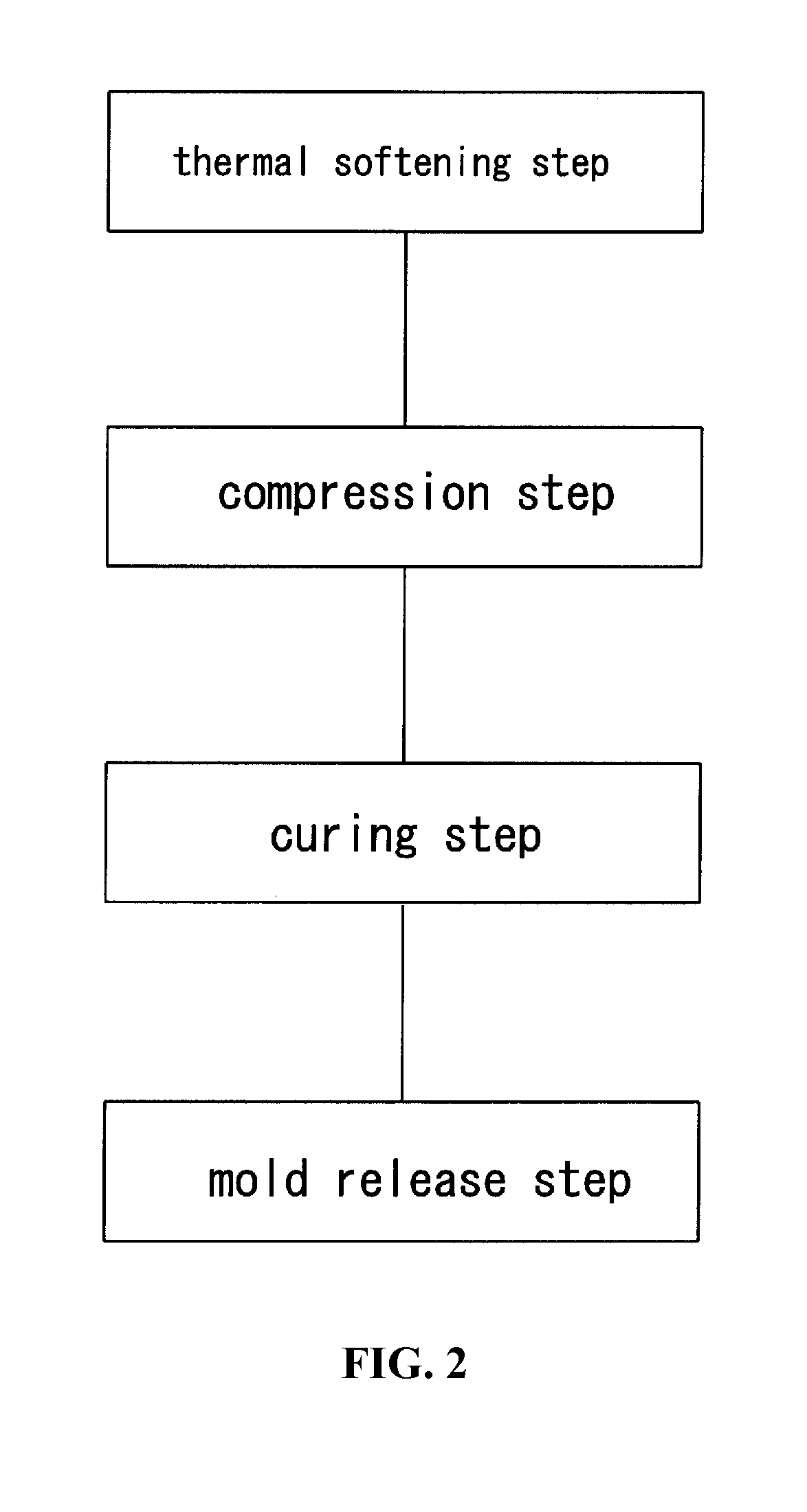

A method for forming cushions including the following four steps: (1) a compression step in which the structure (2) is compressed in a mold (3); (2) a thermal softening step in which the structure (2) is thermally softened by means of a heating medium; (3) a curing step in which the structure (2) directly undergoes forced cooling in a cooling medium, and is then cured; and (4) a mold release step in which the structure (2) is released from the mold (3).

Owner:C ENG CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com