Active powder concrete and production technology for pouring fabricated component by active powder concrete

A reactive powder and concrete technology, applied in the field of concrete, can solve the problems of difficult to meet the requirements of mechanical properties, easy to produce cracks, difficult to guarantee product quality, etc., and achieve the effect of improving the utilization rate of molds, reducing viscosity, and uniform and reasonable grading.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

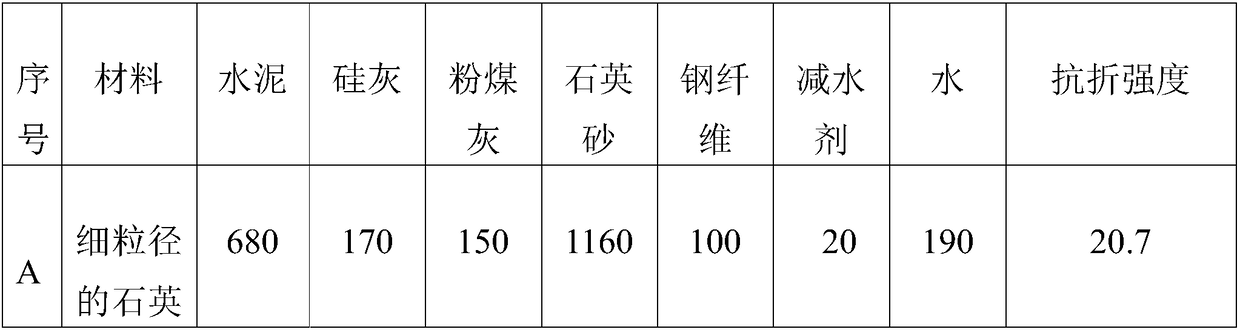

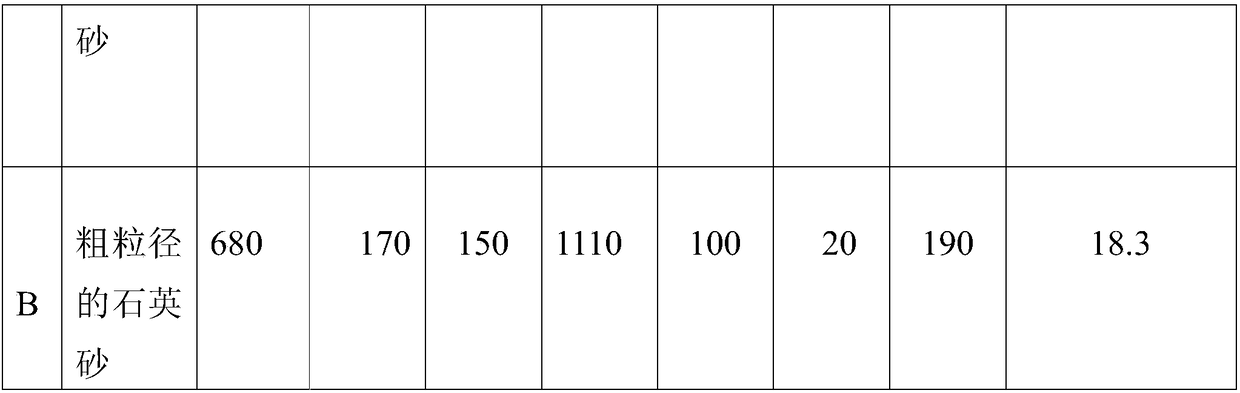

[0028] This embodiment provides a kind of reactive powder concrete, the mass of each component in unit cubic concrete content is: cement 680kg, silica fume 170kg, fly ash 150kg, quartz sand 1160kg, steel fiber 100kg, water reducer 20kg, water 190kg. Wherein, the diameter of the steel fiber is 0.18-0.22 mm, and the length of the steel fiber is 12-16 mm; the water reducing agent is a polycarboxylate water reducing agent with a water reducing rate greater than 30%.

[0029] Among them, the quartz sand is quartz sand with three particle sizes, namely: ultra-fine quartz sand with a particle size of 0.08mm-0.16mm, fine-grained quartz sand with a particle size of 0.17mm-0.315mm, and quartz sand with a particle size of The mass ratio of 0.316-0.63mm medium-sized quartz sand, ultra-fine-sized quartz sand, fine-sized quartz sand and medium-sized quartz sand is 15-25:65-75:5-15.

[0030] The reactive powder concrete of the present invention increases the consumption of quartz sand, and ...

Embodiment 2

[0046] This embodiment provides a kind of active powder concrete, the quality of each component in terms of unit cubic concrete content is: cement 700kg, silica fume 195kg, fly ash 165kg, quartz sand 1100kg, steel fiber 115kg, water reducer 22kg, water 185kg. Wherein, the diameter of the steel fiber is 0.18-0.22 mm, and the length of the steel fiber is 12-16 mm; the water reducing agent is a polycarboxylate water reducing agent with a water reducing rate greater than 30%.

[0047] Among them, the quartz sand is quartz sand with three particle sizes, namely: ultra-fine quartz sand with a particle size of 0.08mm-0.16mm, fine-grained quartz sand with a particle size of 0.17mm-0.315mm, and quartz sand with a particle size of The mass ratio of 0.316-0.63mm medium-sized quartz sand, ultra-fine-sized quartz sand, fine-sized quartz sand and medium-sized quartz sand is 15-25:65-75:5-15.

[0048] The reactive powder concrete of the present invention increases the consumption of quartz ...

Embodiment 3

[0060] This embodiment provides a kind of active powder concrete, the quality of each component in terms of unit cubic concrete content is: cement 660kg, silica fume 160kg, fly ash 180kg, quartz sand 1130kg, steel fiber 110kg, water reducer 18kg, water 195kg. Wherein, the diameter of the steel fiber is 0.18-0.22 mm, and the length of the steel fiber is 12-16 mm; the water reducing agent is a polycarboxylate water reducing agent with a water reducing rate greater than 30%.

[0061] Among them, the quartz sand is quartz sand with three particle sizes, namely: ultra-fine quartz sand with a particle size of 0.08mm-0.16mm, fine-grained quartz sand with a particle size of 0.17mm-0.315mm, and quartz sand with a particle size of The mass ratio of 0.316-0.63mm medium-sized quartz sand, ultra-fine-sized quartz sand, fine-sized quartz sand and medium-sized quartz sand is 15-25:65-75:5-15.

[0062] The reactive powder concrete of the present invention increases the consumption of quartz ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com