Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

245results about How to "Shorten injection time" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

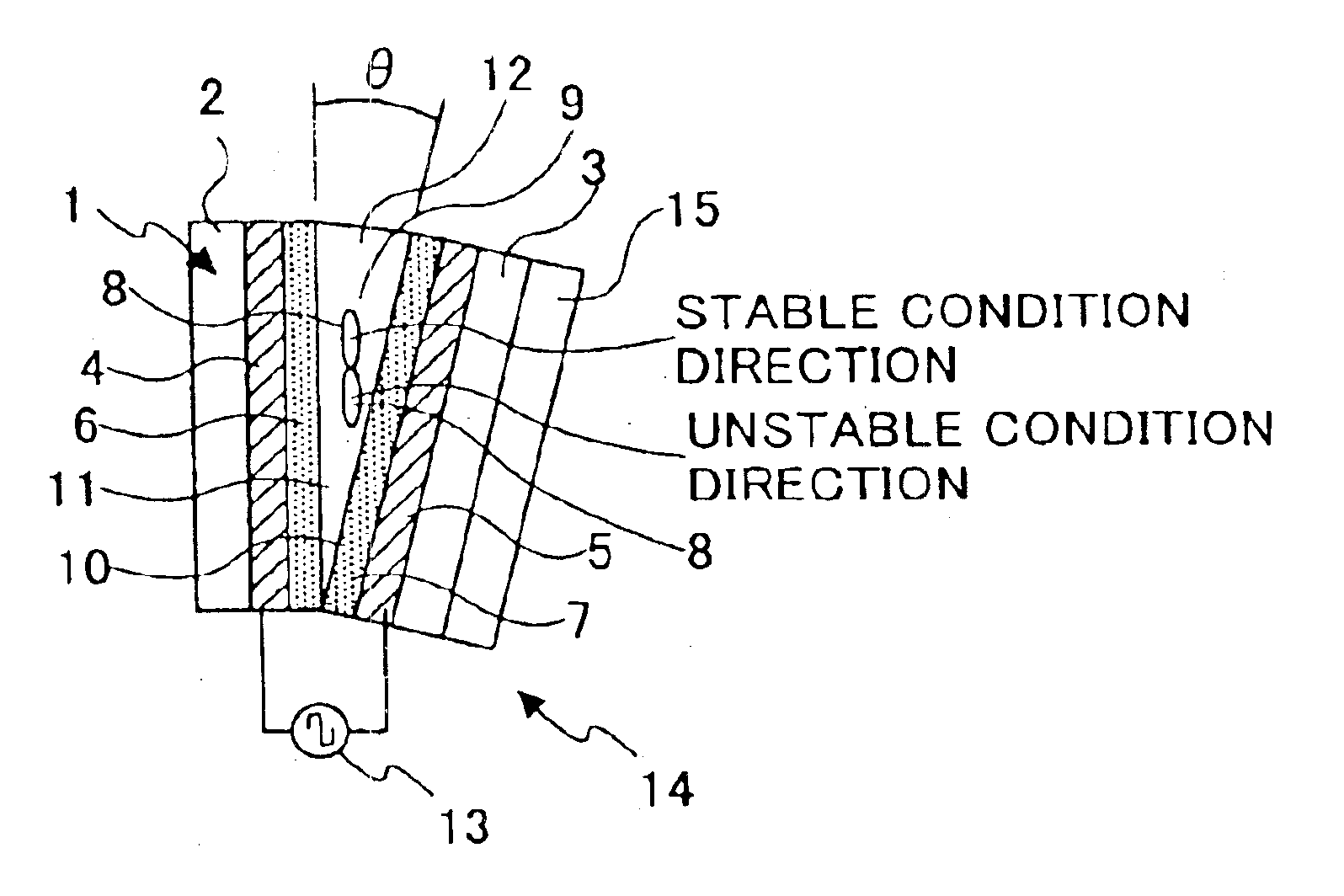

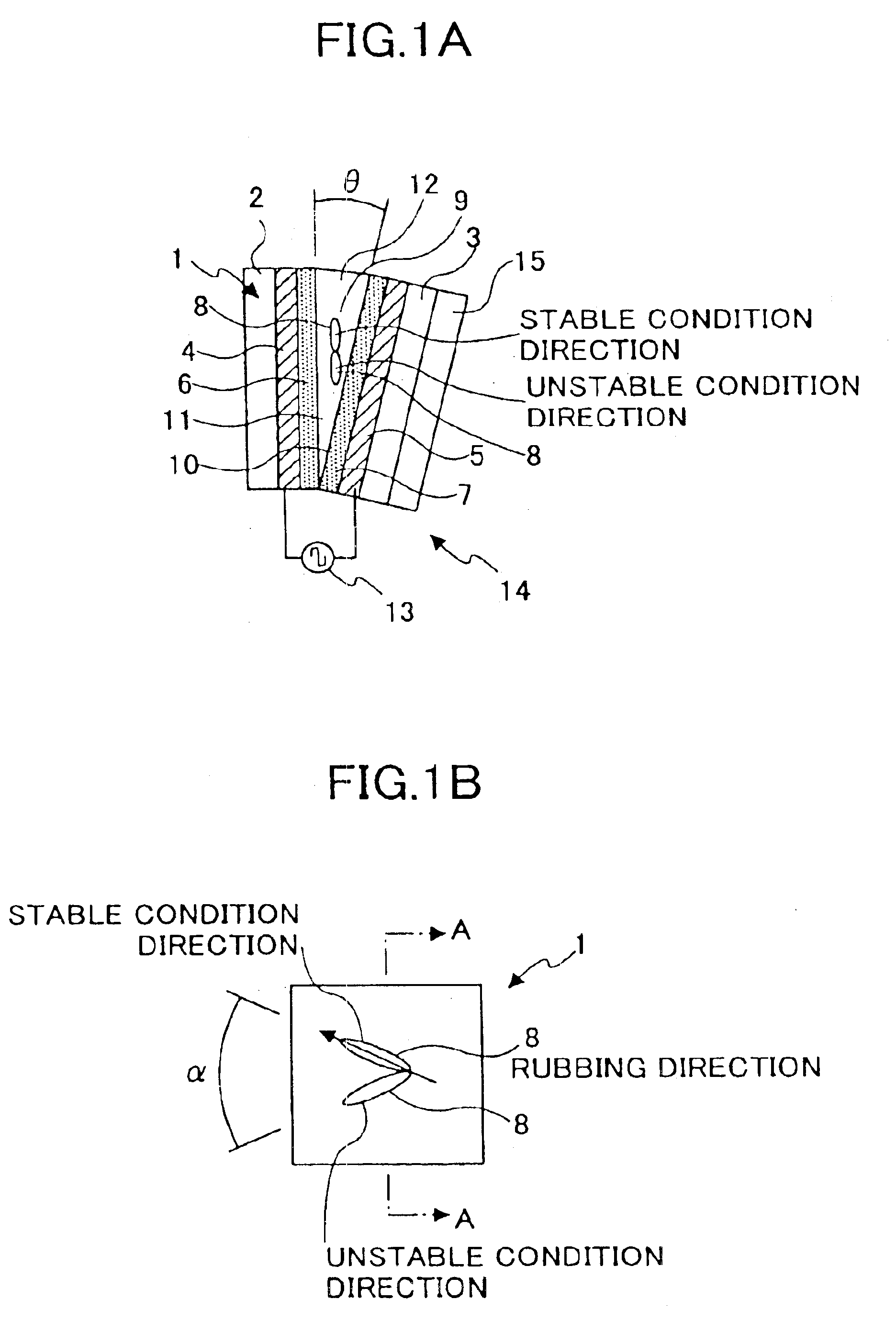

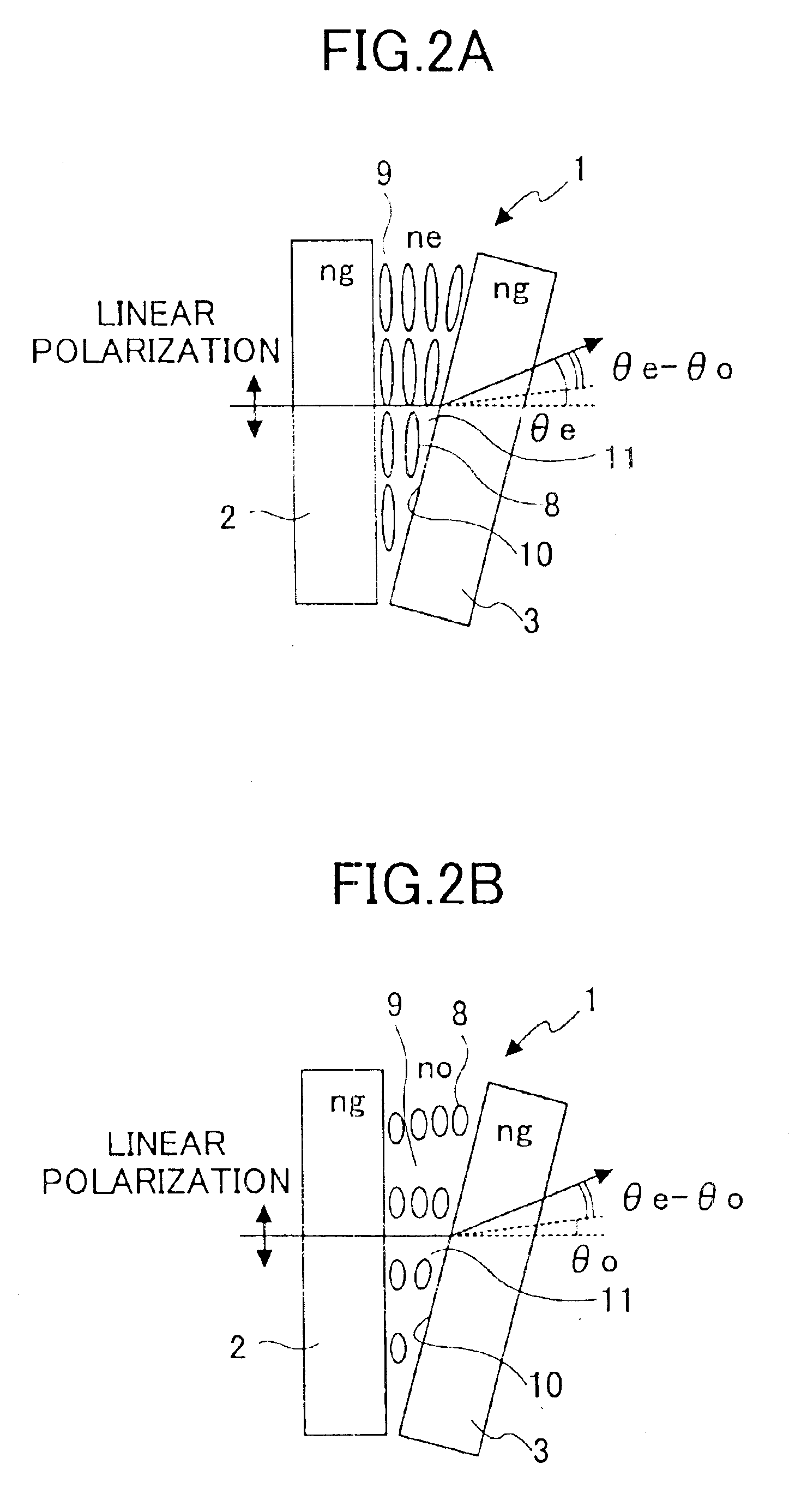

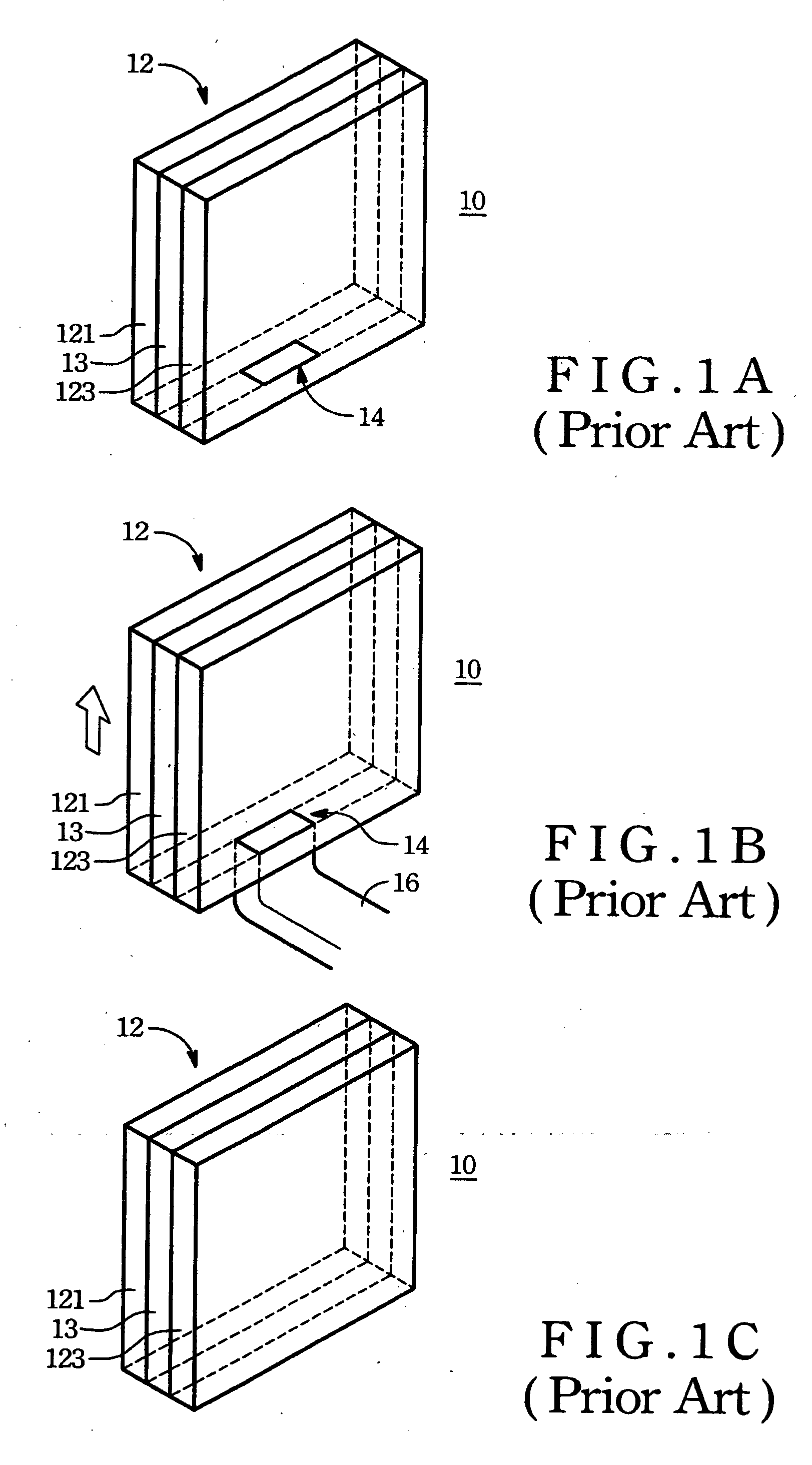

Optical path deflecting element, optical path deflecting apparatus, image displaying apparatus, optical element and manufacturing method thereof

InactiveUS6919982B2Reduce Optical NoiseReduce resolutionStatic indicating devicesNon-linear opticsElectrical polarityEngineering

An optical path deflecting element, an optical path deflecting apparatus, an image displaying apparatus, an optical writing apparatus, an optical interconnection apparatus, an optical element, and a fabrication method thereof. The optical path deflecting element includes a pair of transparent substrates, transparent electrode films on the substrates to which a voltage having an inverse polarity is selectively applied, an alignment layer in the inner sides of the substrates, and a liquid crystal layer formed of a chiral smectic C phase between the substrates via the alignment layer and homogeneously aligned by the alignment layer. The optical deflecting element can realize the uniformly-aligned liquid crystal layer more easily than a case in which the liquid crystal is aligned to become in a bistable condition. For this reason, it is possible to improve yield in the fabrication.

Owner:RICOH KK

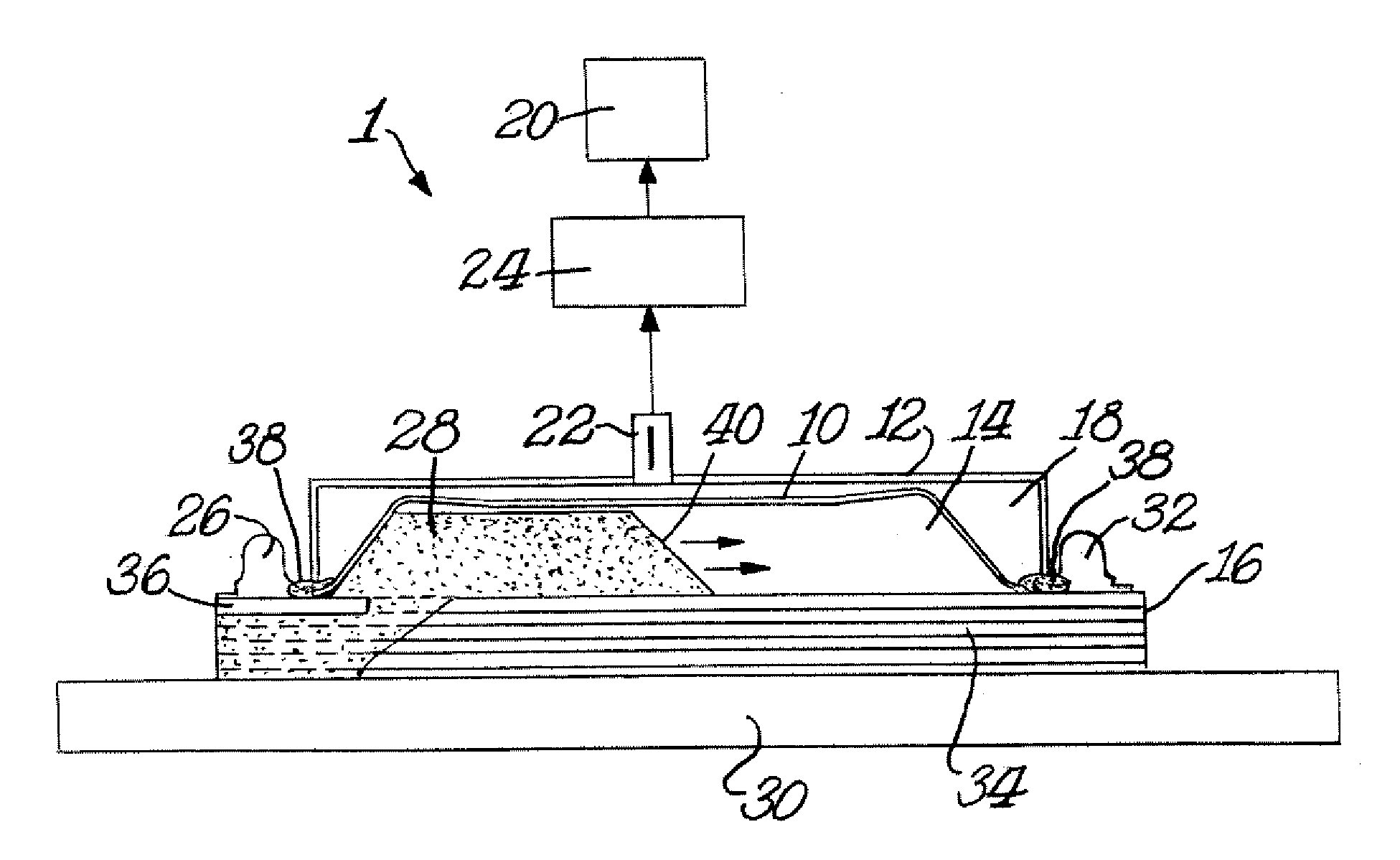

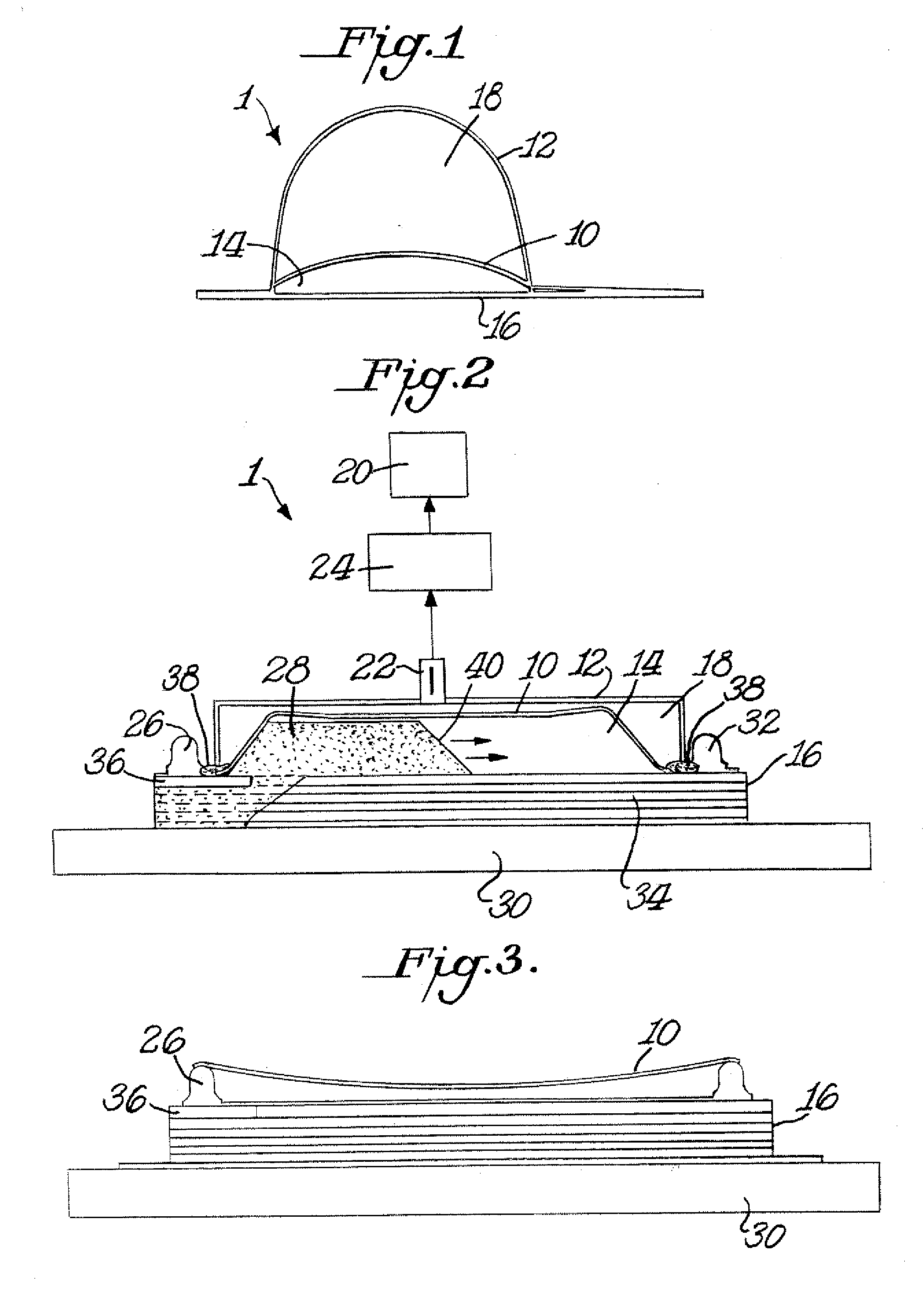

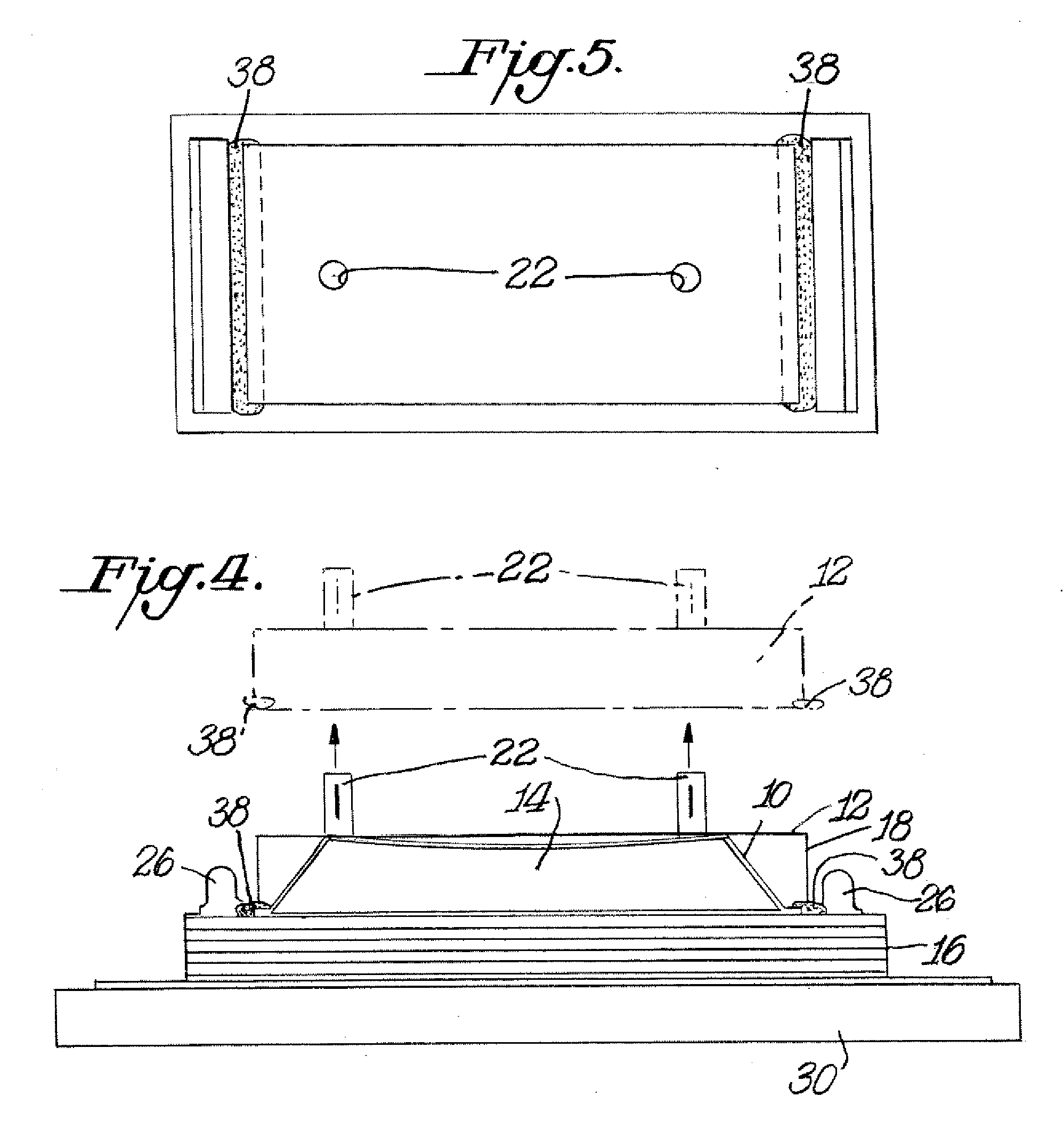

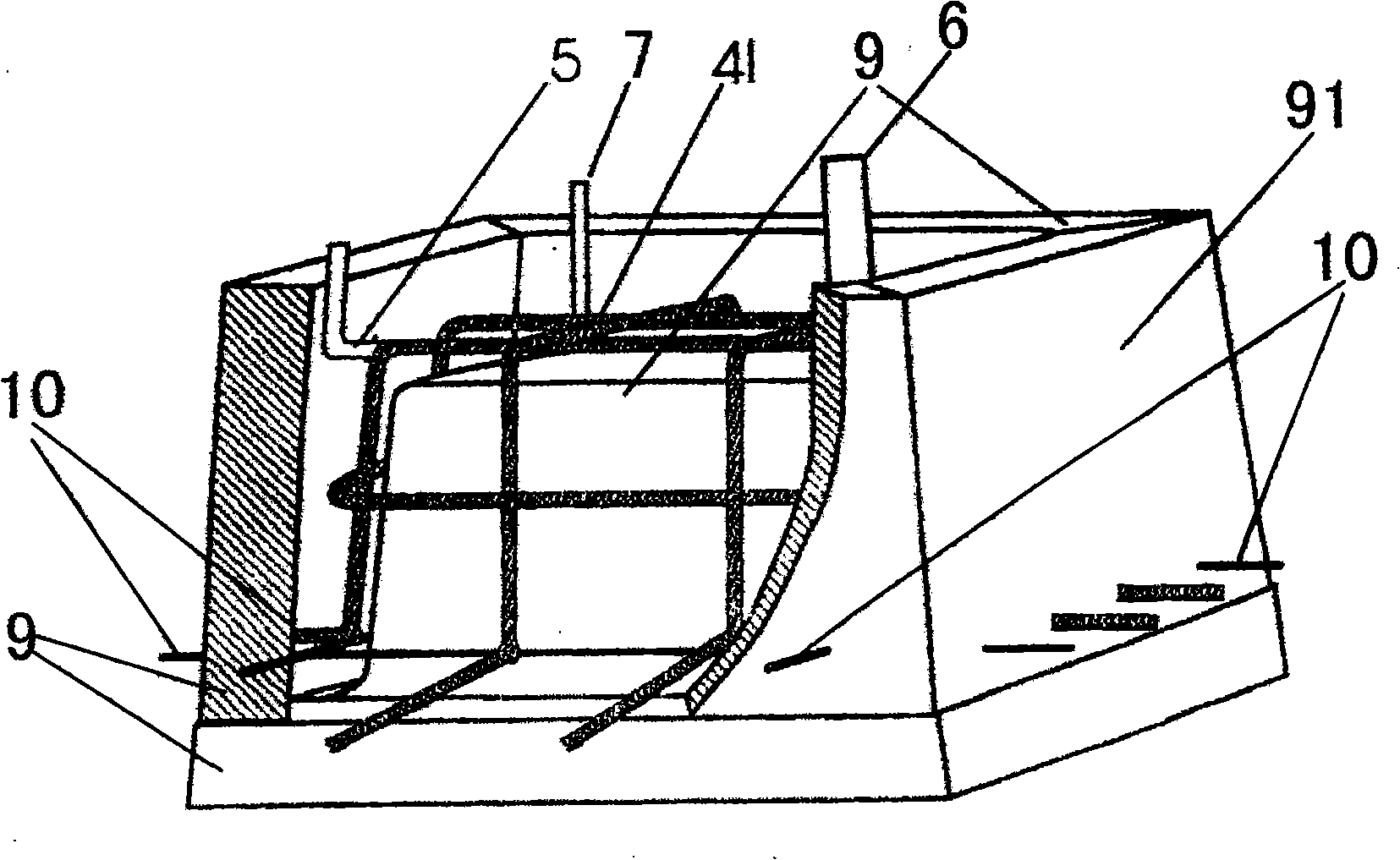

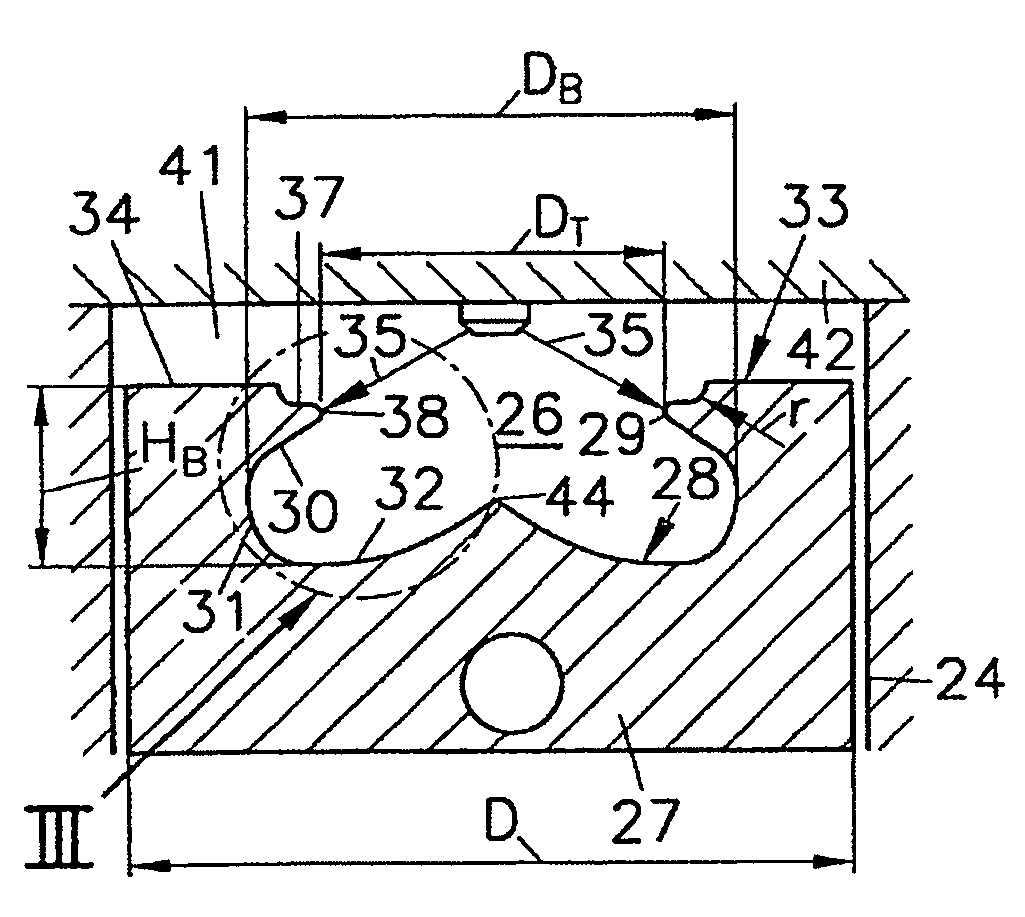

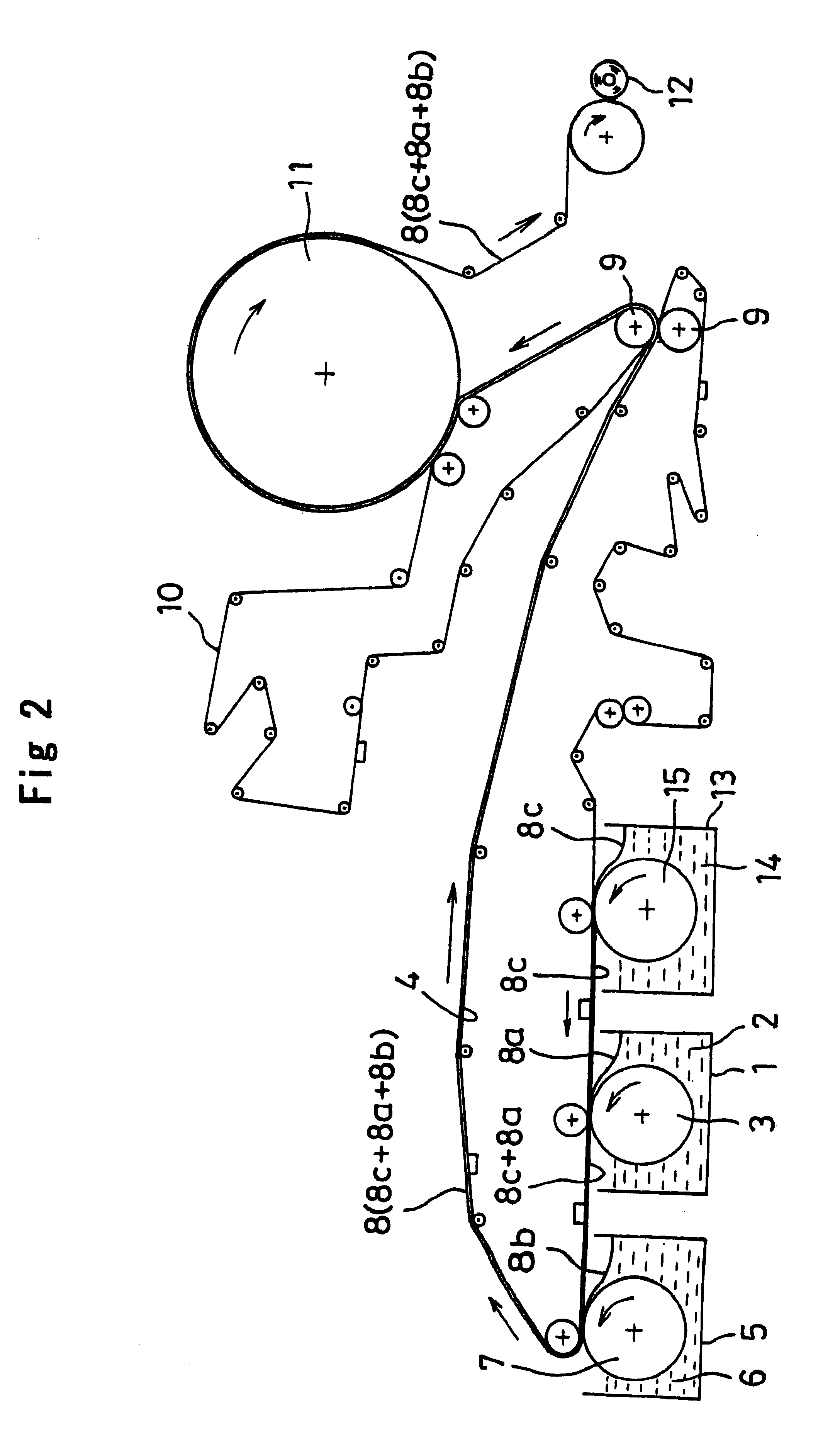

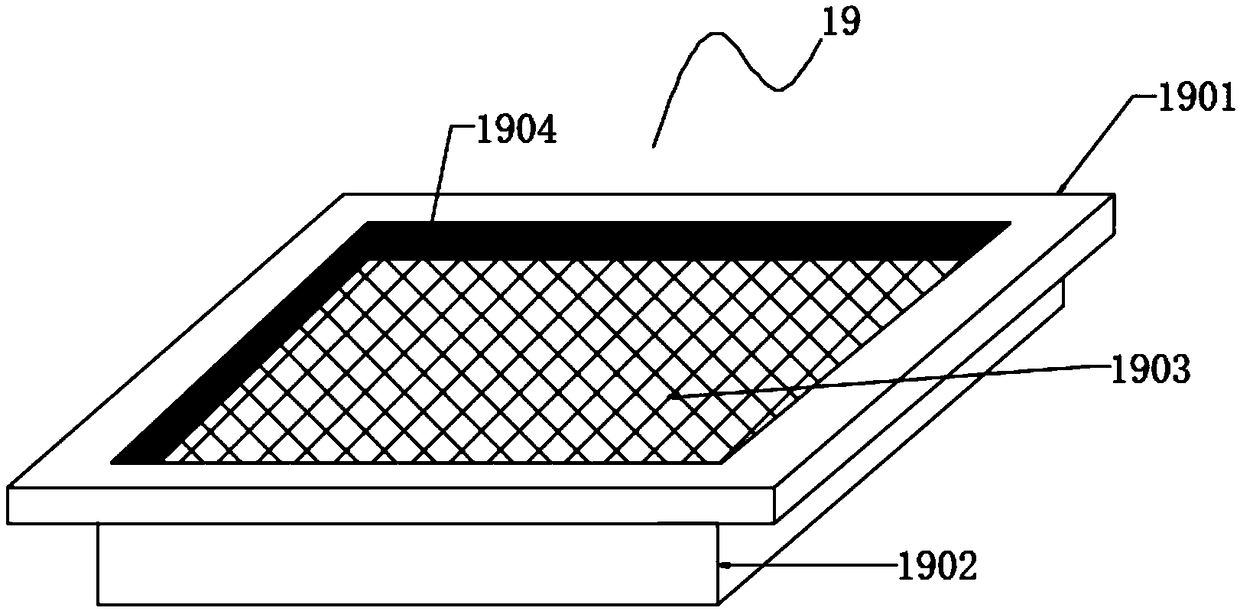

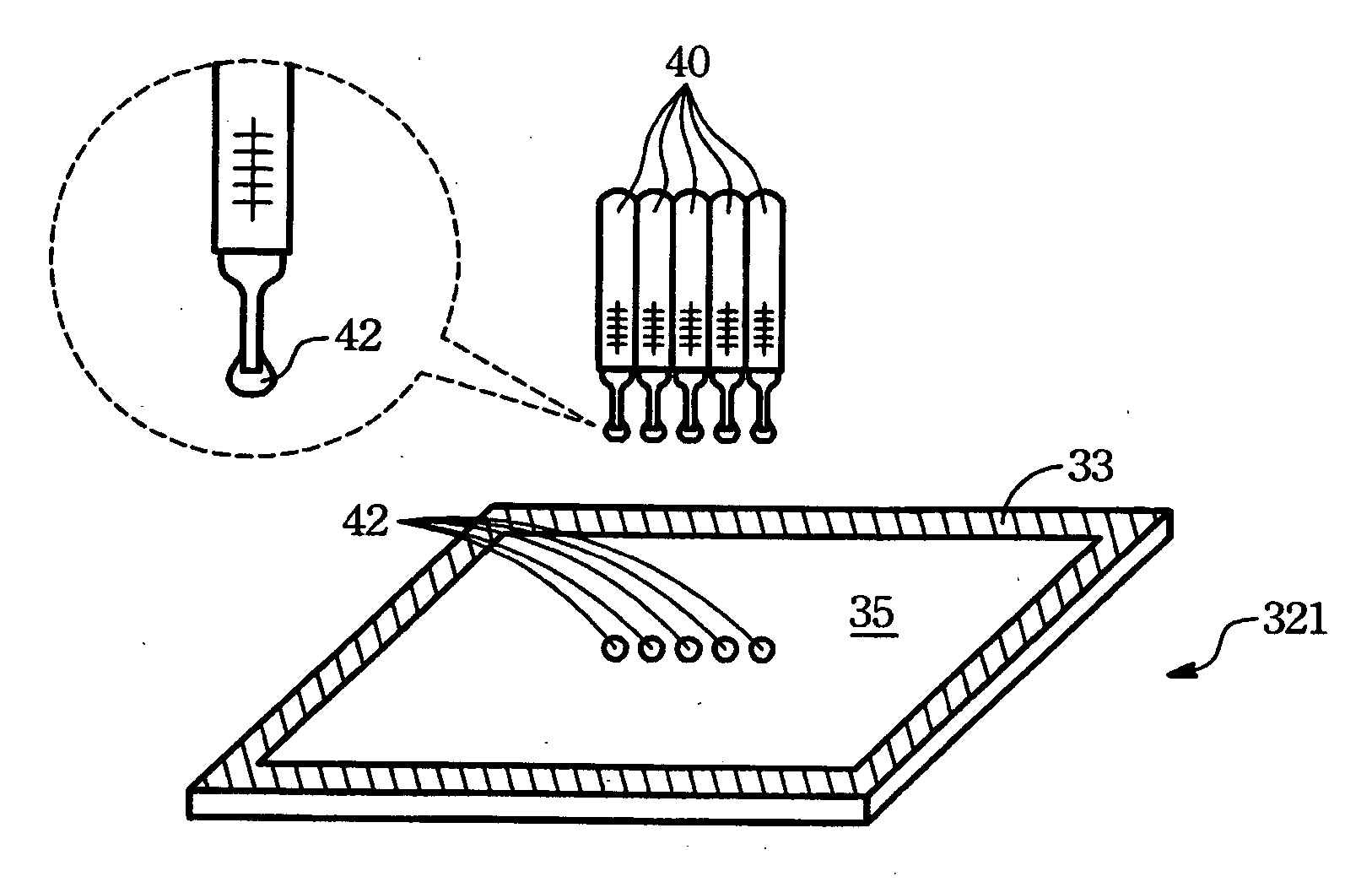

Vacuum assisted resin transfer molding techniques with flow flooding chamber

InactiveUS20070063393A1Short injection timeLabor savingLaminationLamination apparatusMechanical engineeringVacuum assisted resin transfer molding

Vacuum assisted resin transfer molding techniques are improved by mounting a rigid external shell on top of a vacuum bag. The shell is sealed around the vacuum bag so that a vacuum is created between the shell and the vacuum bag, the vacuum causes the vacuum bag to be freely stretched and lifted away from the preform to create a flow flooding chamber which provides a flow channel on the top face of the preform to accelerate the resin flow and reduce the injection time.

Owner:UNIVERSITY OF DELAWARE

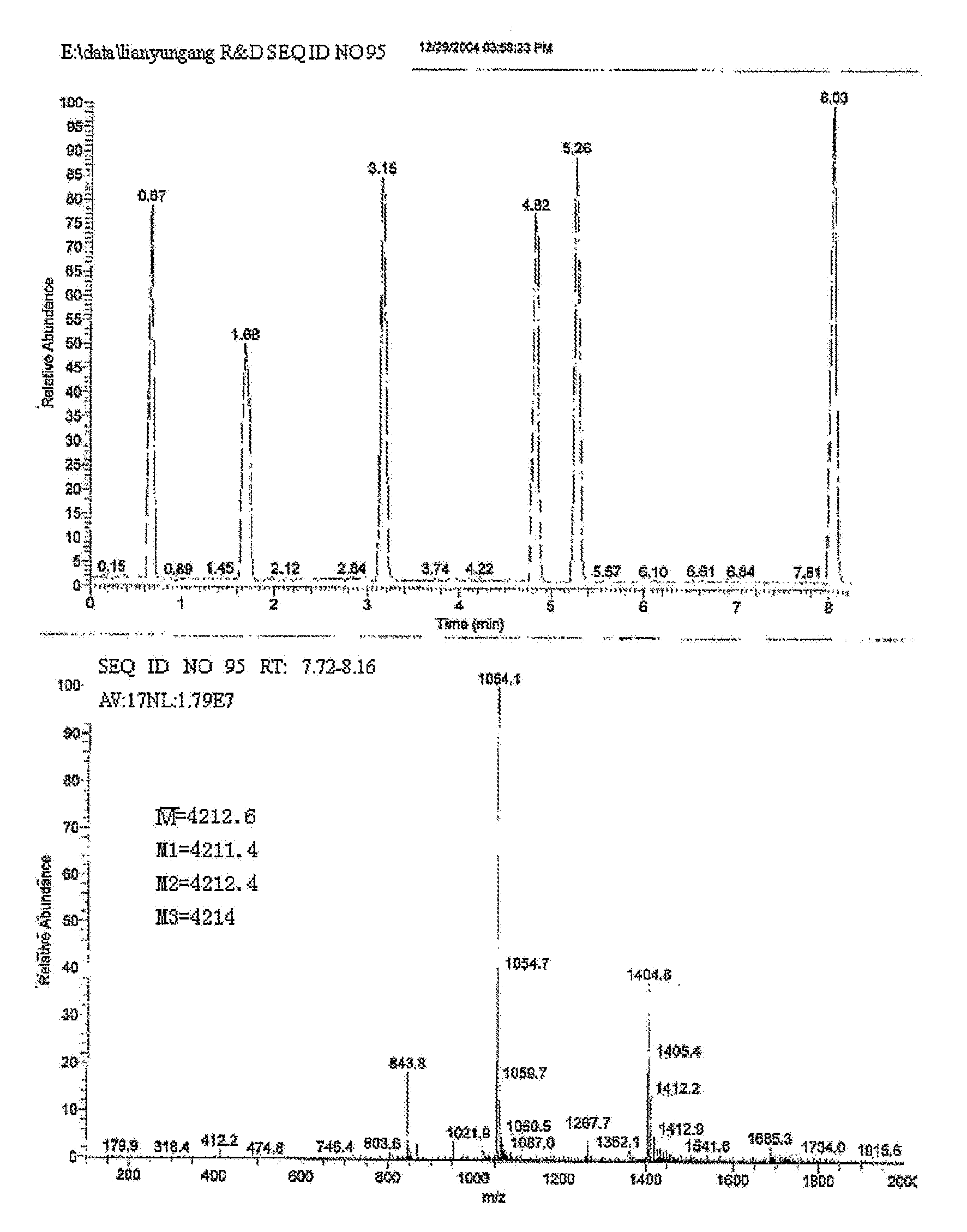

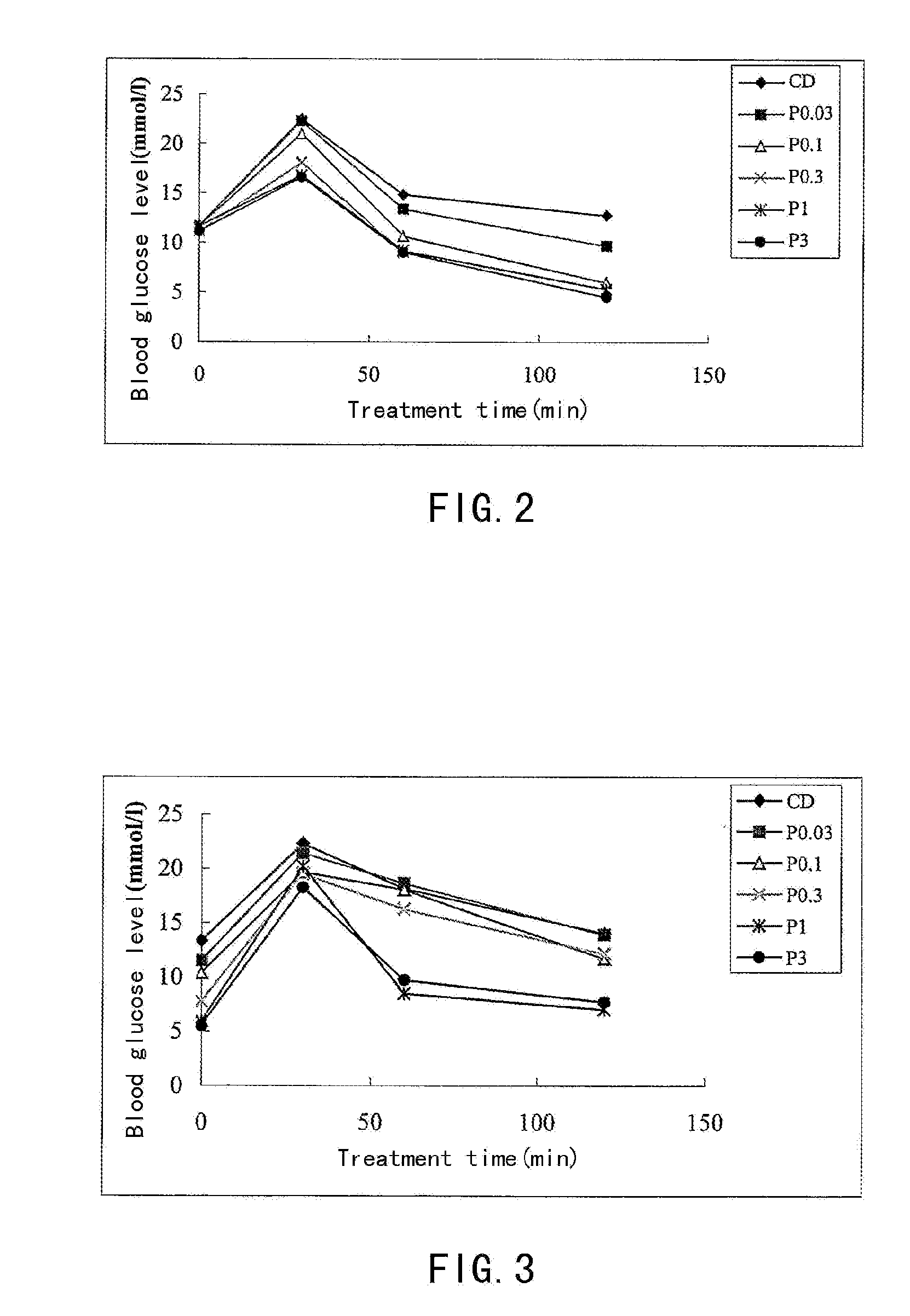

Modified Exedins and Uses Thereof

ActiveUS20100009904A1Long retention timeProlonged actionAntibacterial agentsPeptide/protein ingredientsPolyethylene glycolAgonist

Novel exendins with modifications at one or more of following positions: 2, 14, 27 or 28 and polyethylene glycol derivatives thereof are provided. These compounds are useful in treating type 2 diabetes as GLP-1 receptor agonists.

Owner:JIANGSU HANSOH PHARMA CO LTD

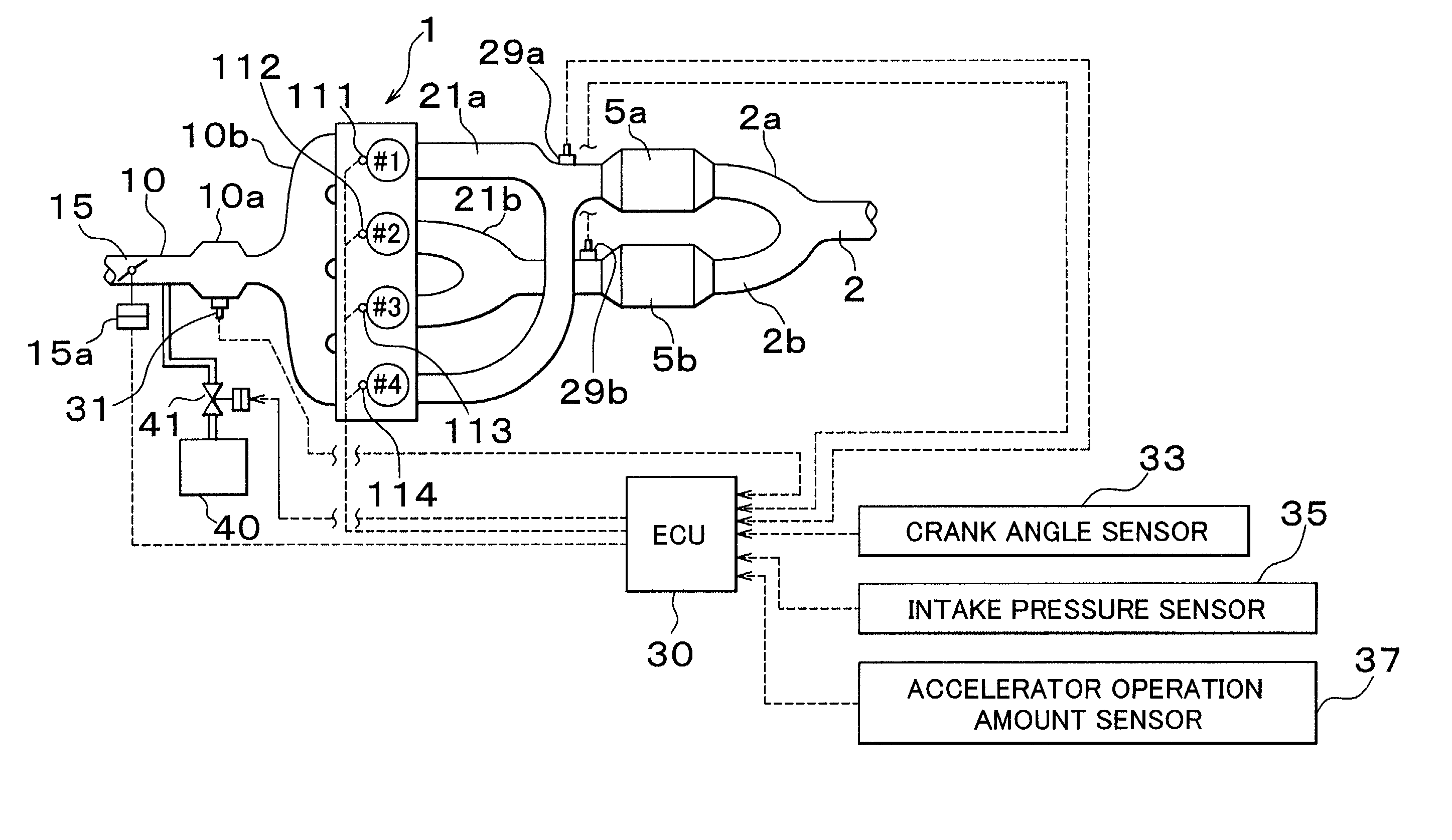

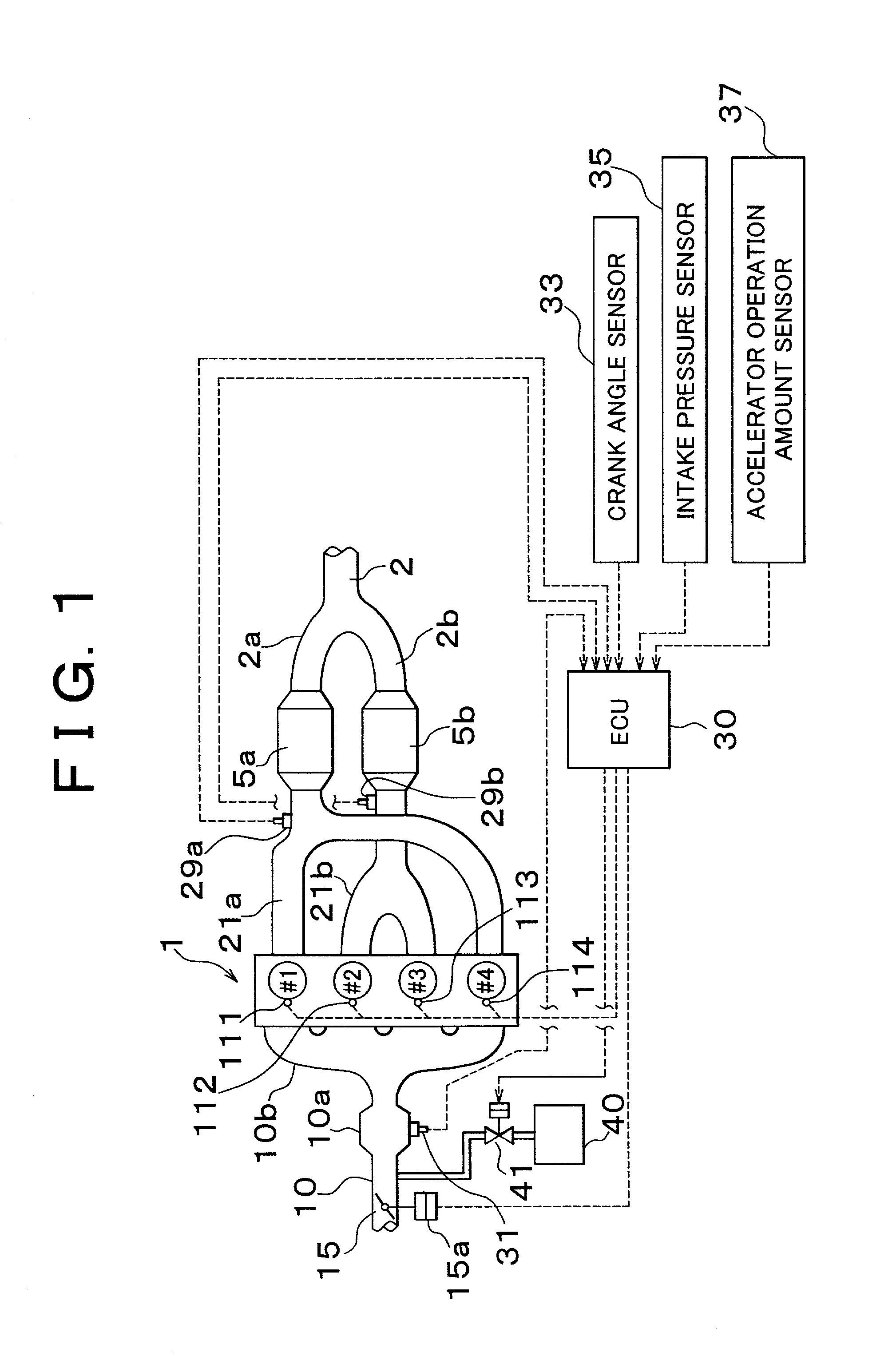

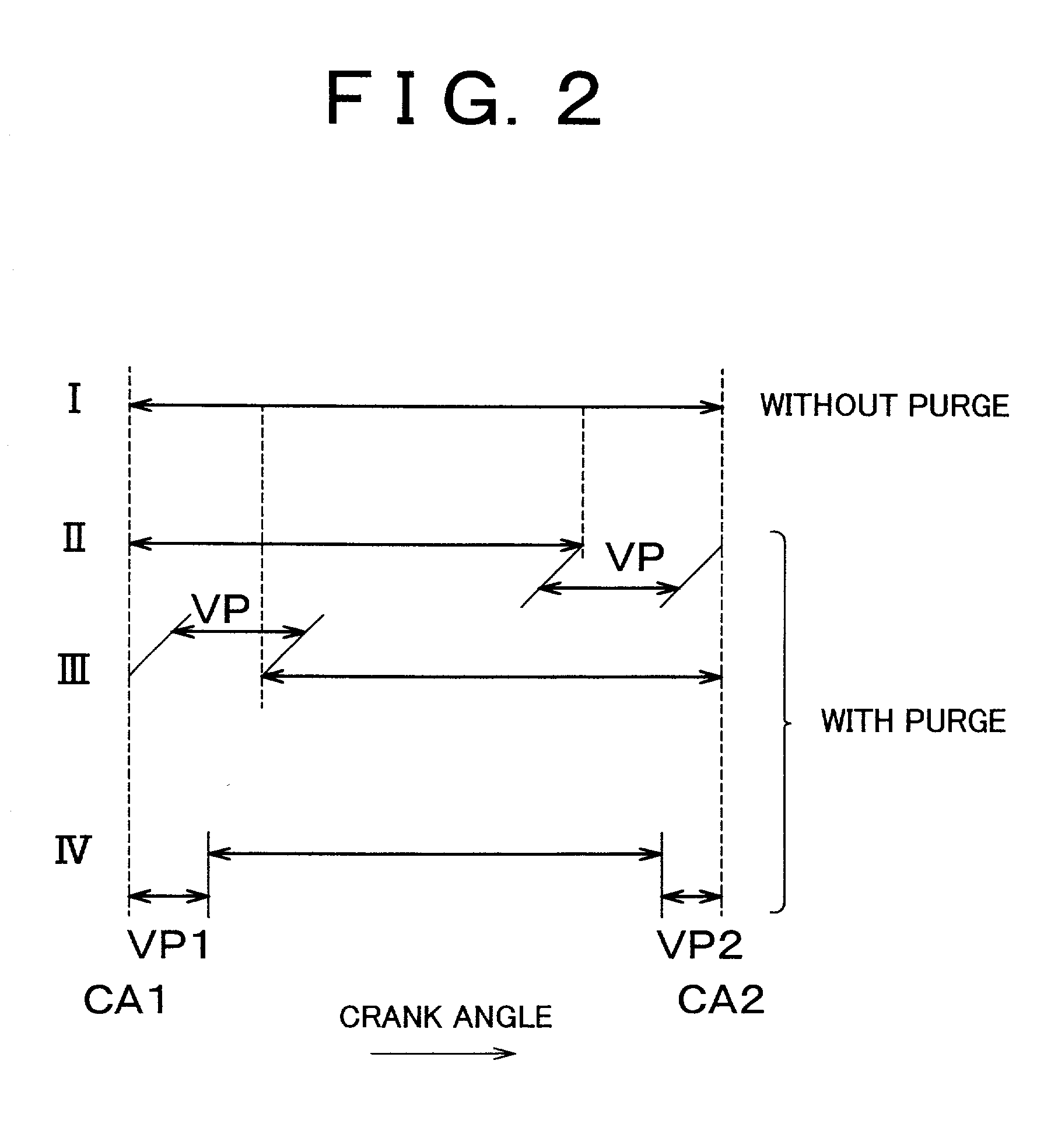

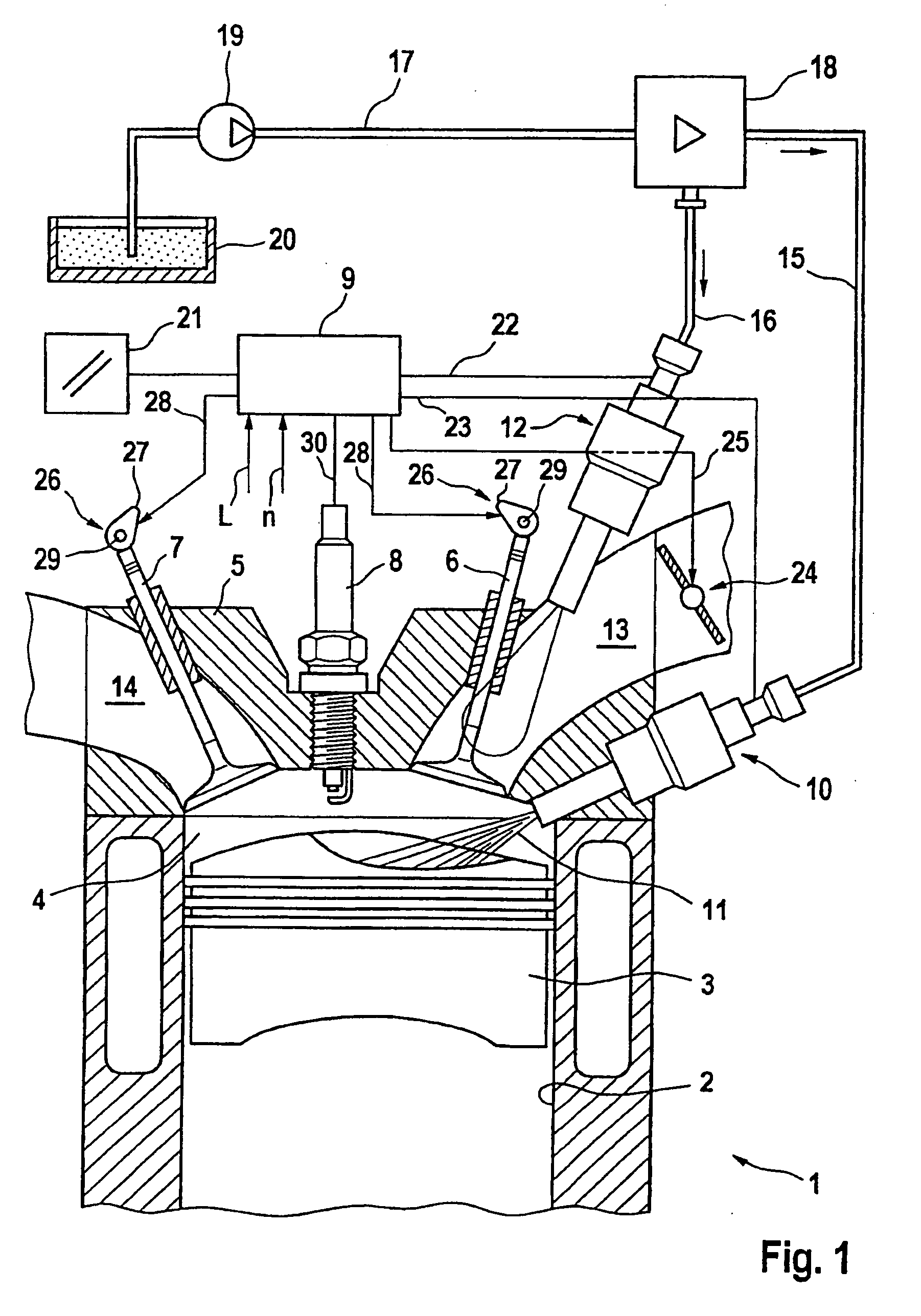

Fuel injection control apparatus and method of direct fuel injection-type spark ignition engine

InactiveUS20020029768A1Accurate detectionShorten injection timeElectrical controlInternal combustion piston enginesOxygenFuel vapor

Fuel vapor is introduced into an intake passage of a direct fuel injection type engine by a fuel vapor purge apparatus. The intake passage is provided with an intake oxygen concentration sensor for detecting the amount of fuel vapor in intake air. An ECU corrects the amount of fuel injection from each direct fuel injection valve in accordance with the amount of fuel vapor detected, and changes the fuel injection starting timing and the fuel injection ending timing in accordance with the amount of fuel vapor.

Owner:TOYOTA JIDOSHA KK

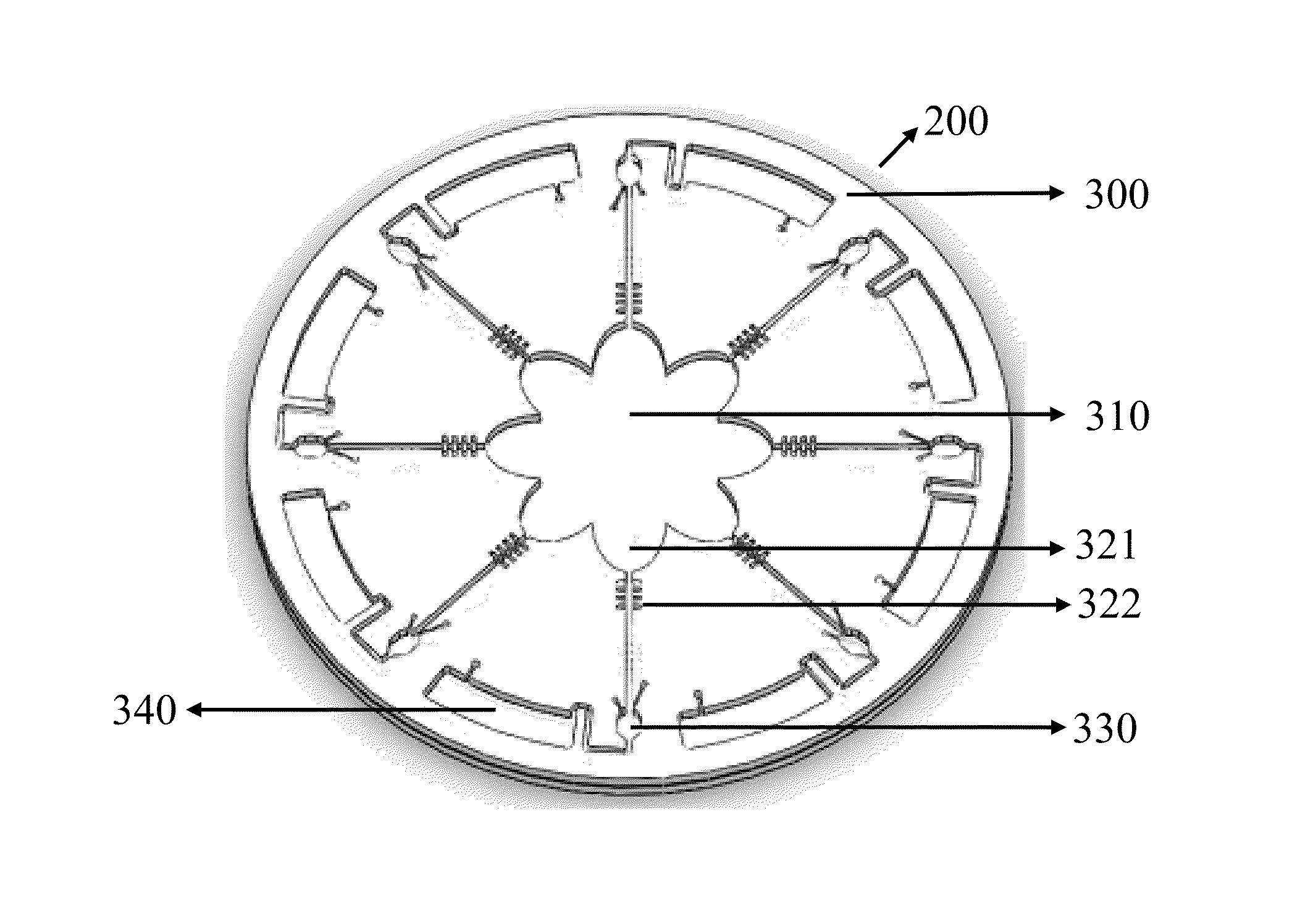

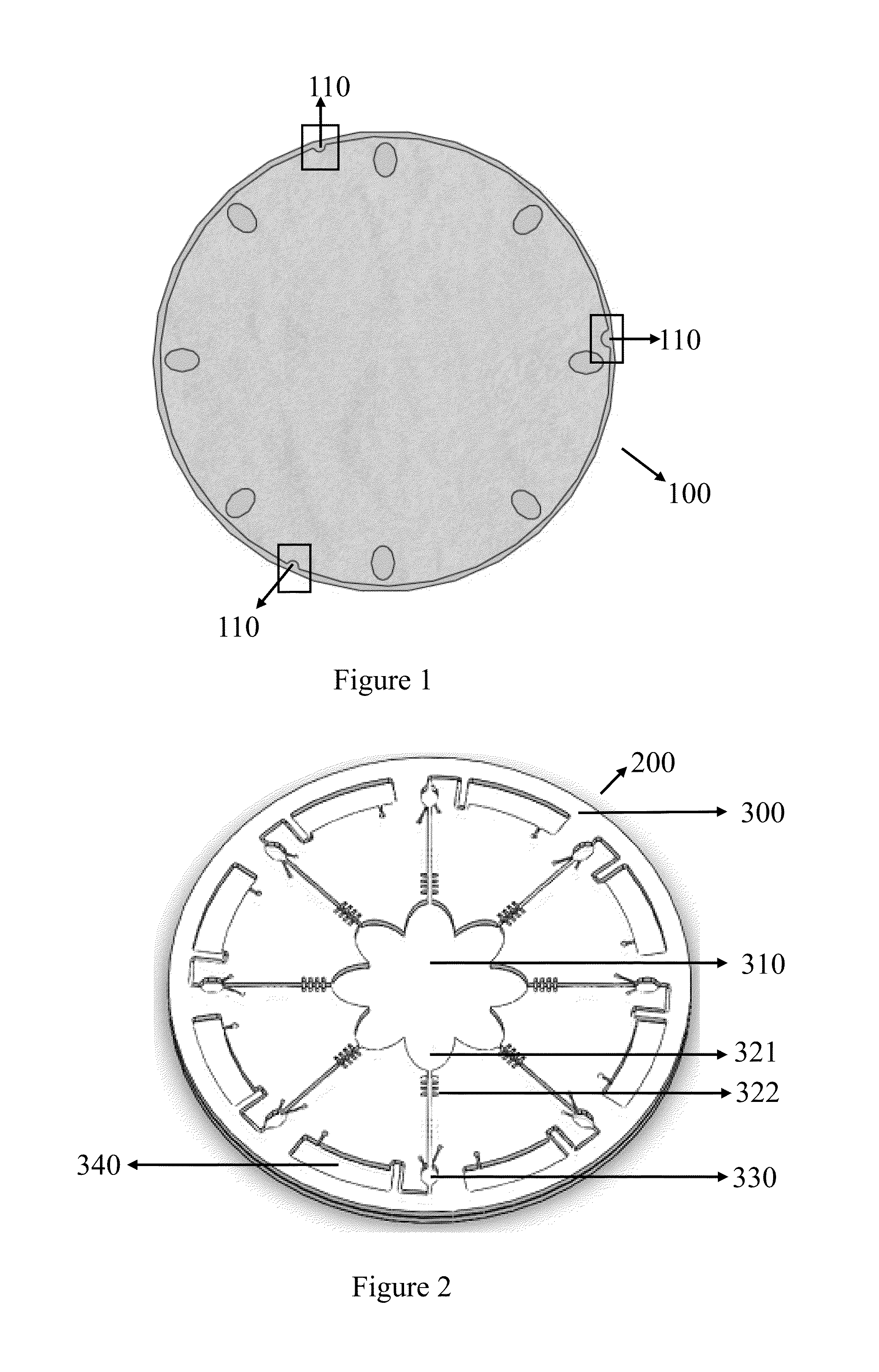

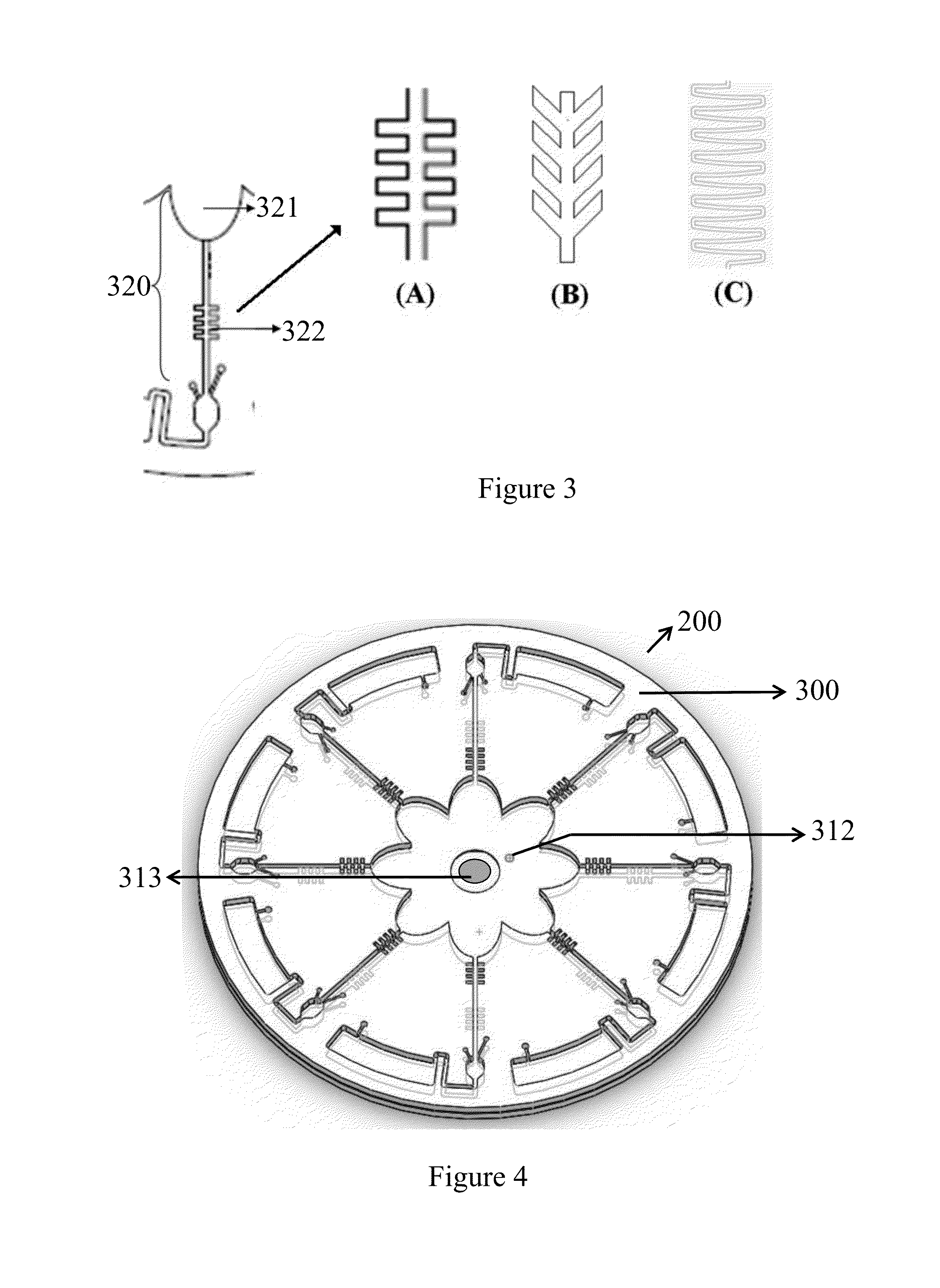

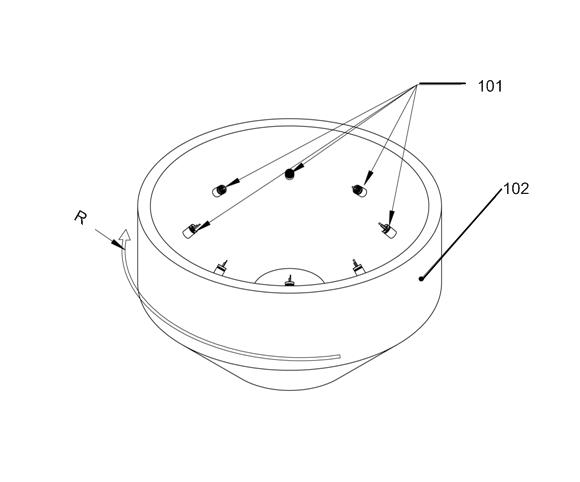

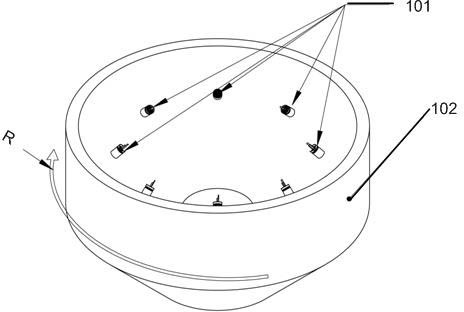

Apparatus and Methodology to Carry Out Biochemical Testing on a Centrifugal Platform Using Flow Splitting Technique

ActiveUS20140038209A1ContaminationIncrease speedBioreactor/fermenter combinationsBiological substance pretreatmentsBiochemical engineeringReagent

The invention provides an apparatus and methodology to carry out biochemical testing on a centrifugal platform using flow splitting technique. In conventional biochemical testing, reagents need to be loaded individually into each reservoir. By using the flow splitting technique in this invention, one reagent only need to be loaded once, then, it can be evenly distributed into each reaction chambers in single or multiple layers format. The invention greatly reduces the required manpower when large numbers of assays are integrated on one platform. Because of the invention, many medical examinations can be performed efficiently, thus reduce the waste of manpower, time and cost.

Owner:ZHEJIANG PUSHKANG BIOTECHNOLOGY CO LTD

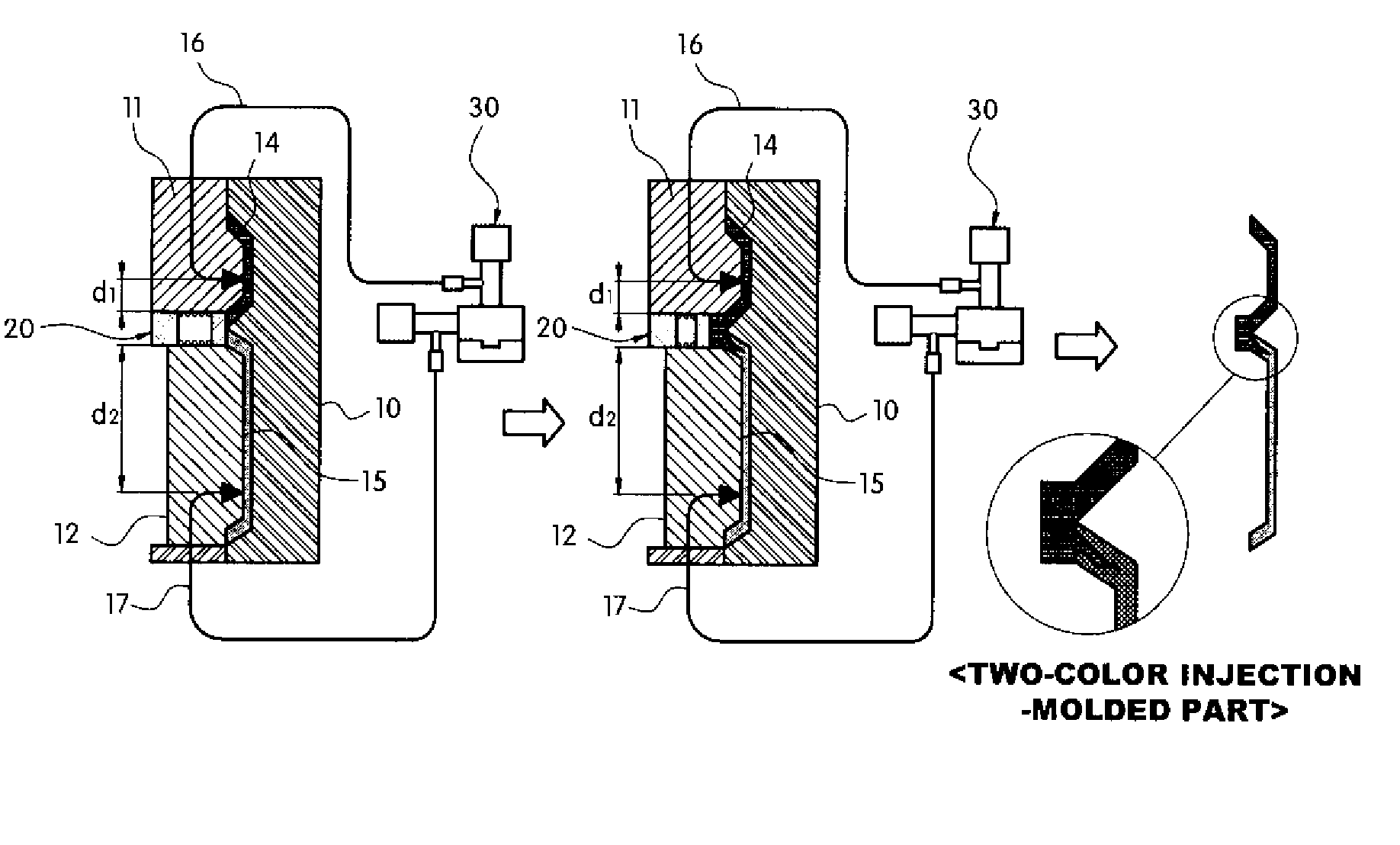

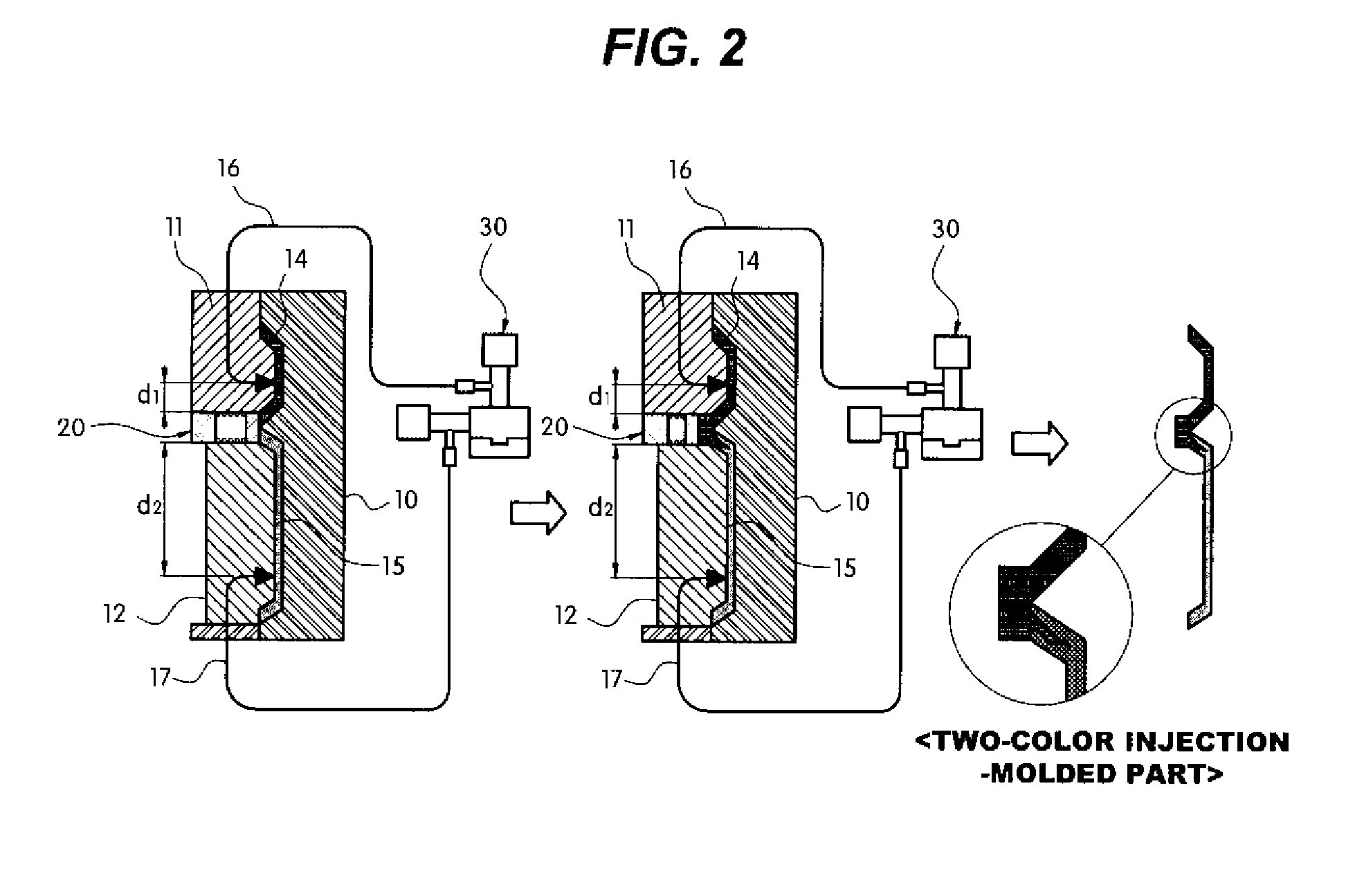

Mold and Method for Producing Two-Color Injection-Molded Parts

ActiveUS20100013124A1Shorten injection timeFood shapingDomestic articlesShell moldingPressure difference

A mold and a method for producing two-color injection-molded parts involves simultaneous injection of two kinds of molding material, in which a pressure difference between two kinds of molding materials is induced so that one of the molding materials is infiltrated into and bonded to the other molding material during solidification. The method for producing two-color injection-molded parts may include simultaneously injecting a first material and a second material to a first gate and a second gate to be filled in a first cavity and a second cavity, and closing the second gate such that the first molding material, which is not solidified, pushes a slide mold provided between a first mold block and a second mold block using a holing pressure of the first gate and is infiltrated into an unsolidified layer of the second molding material and solidified.

Owner:HYUNDAI MOTOR CO LTD

Complexes of phosphate derivatives

InactiveUS20100222305A1Improve bioavailabilityImprove propertiesCosmetic preparationsBiocidePhosphateNitrogen

There is provided a composition comprising the reaction product of: a) one or more phosphate derivatives of one or more hydroxylated actives; and b) one or more complexing agents selected from the group consisting of amphoteric surfactants, cationic surfactants, amino acids having nitrogen functional groups and proteins rich in these amino acids.

Owner:WEST SIMON MICHAEL +2

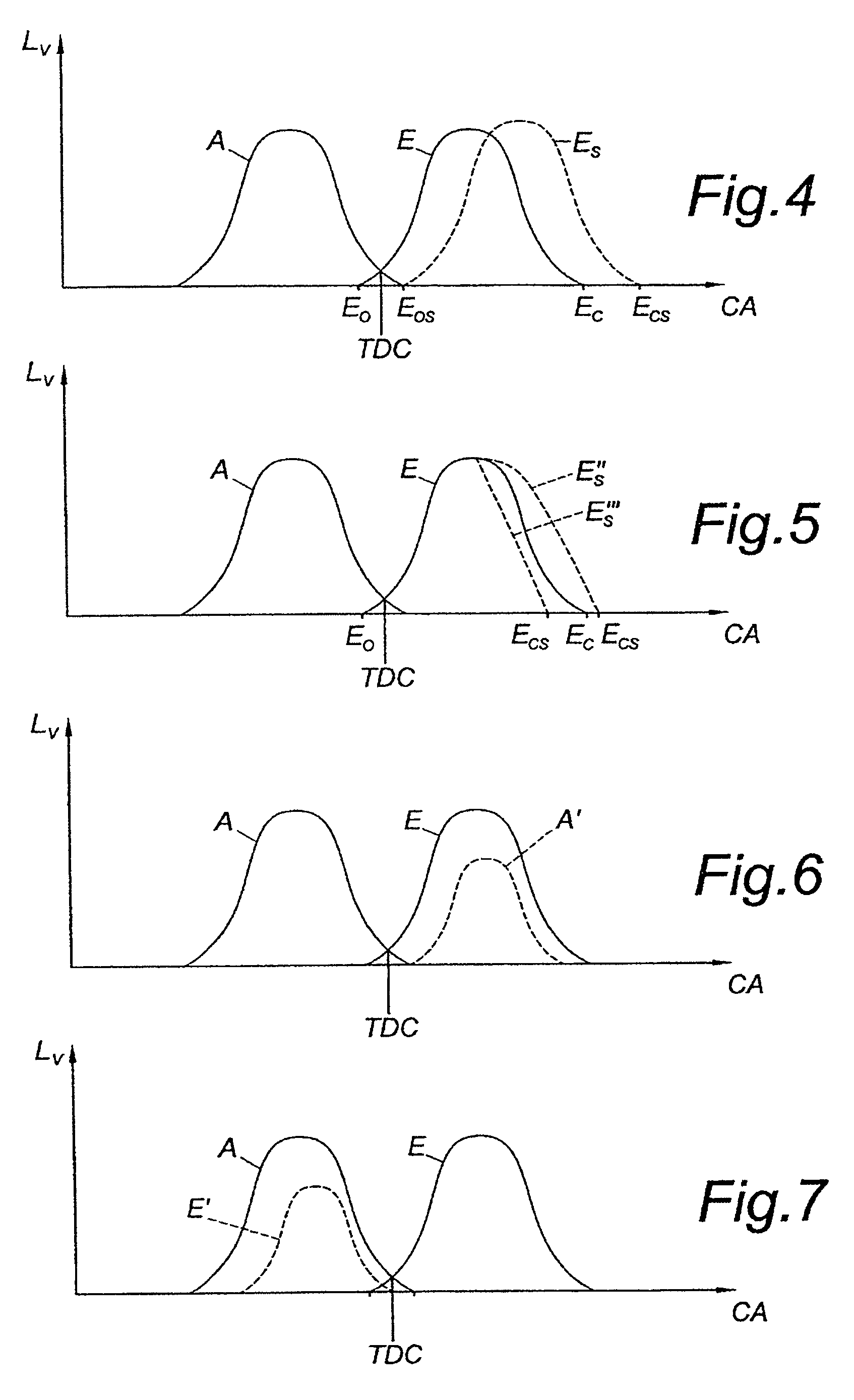

Method of operating an internal combustion engine

ActiveUS20070144480A1Smooth engine operationOptimal exhaust gas emissionElectrical controlInternal combustion piston enginesValve openingEngineering

In a method of operating an internal combustion engine with a switch-over capability between a compression ignition mode of operation and a spark ignition mode of operation in higher load ranges which includes a cam-operated valve drive with a valve control providing, in the compression ignition mode of operation, for an increased valve overlap of the valve opening times, smooth engine operation and optimal exhaust gas emissions are obtained also during rapid load changes upon changing the engine operating mode as the change-over is accompanied by changes of the injection parameters, the throttling parameter and the valve control, which are coordinated with respect to one another as the valve control is switched over by changing the amplitude and phase position of the valve stroke of at least one of the inlet and outlet valves.

Owner:DAIMLER AG

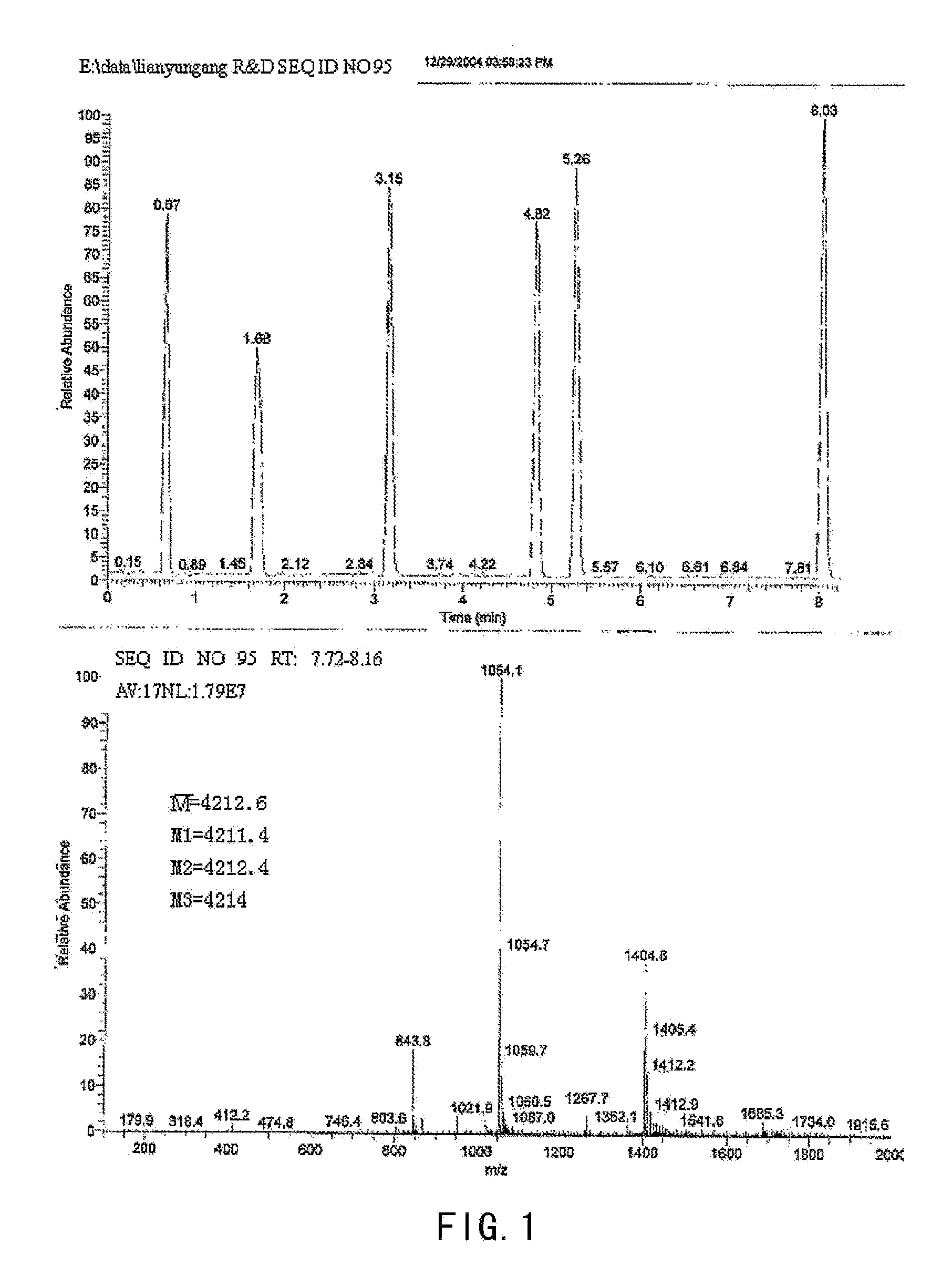

Modified exedins and uses thereof

ActiveUS8097586B2Long retention timeProlonged actionAntibacterial agentsPeptide/protein ingredientsPolyethylene glycolAgonist

Novel exendins with modifications at one or more of following positions: 2, 14, 27 or 28 and polyethylene glycol derivatives thereof are provided. These compounds are useful in treating type 2 diabetes as GLP-1 receptor agonists.

Owner:JIANGSU HANSOH PHARMA CO LTD

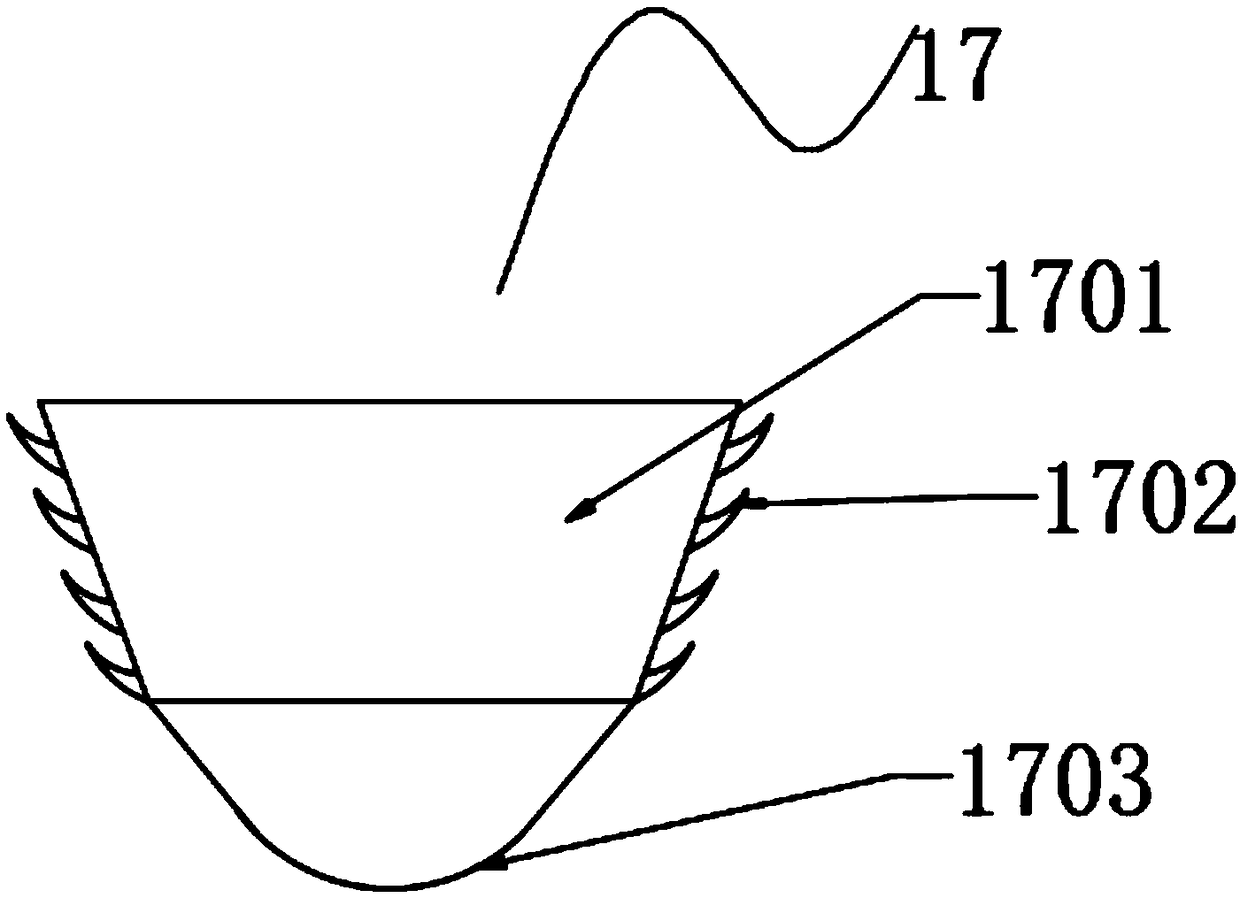

Pressure blank injecting, pressure drying gypsum mould and preparation method thereof

InactiveCN101284394AEasy accessIncrease productivityCeramic shaping apparatusMetallic materialsRebar

The invention provides a pottery production used pressurized casting and pressurized drying plaster mould and the preparation method thereof. The mould includes a mould body made of the plaster material and a mould shell made of the metal material; a plurality of hollow riser vents with the diameters of 0.3-3cm are formed in the thickness of the mould body, distributed as reticulation or pectination with the distances of 3-30cm, and connected with each other; and an aeration pipe, a grouting pipe and an exhaust pipe are arranged in the mould body. The preparation method comprises the following steps: reinforcing steel bars, steel tubes and tubes with backstops are distributed as reticulation or pectination according to the shape of the mould body to be cast; the reinforcing steel bars, the steel tubes and the tubes with backstops are adjusted to be better placed in the middle of the thickness of the mould body to be cast; the prepared plaster is grouted into the case mould with the reinforcing steel bars, the steel tubes and the tubes with backstops; the reinforcing steel bars, the steel tubes and the tubes with backstops are taken out quickly when the plaster is partially cured; the hollow mould body is formed after the case mould is removed when the plaster is totally cured; and the mould body is fastened in the mould shell.

Owner:崔学会

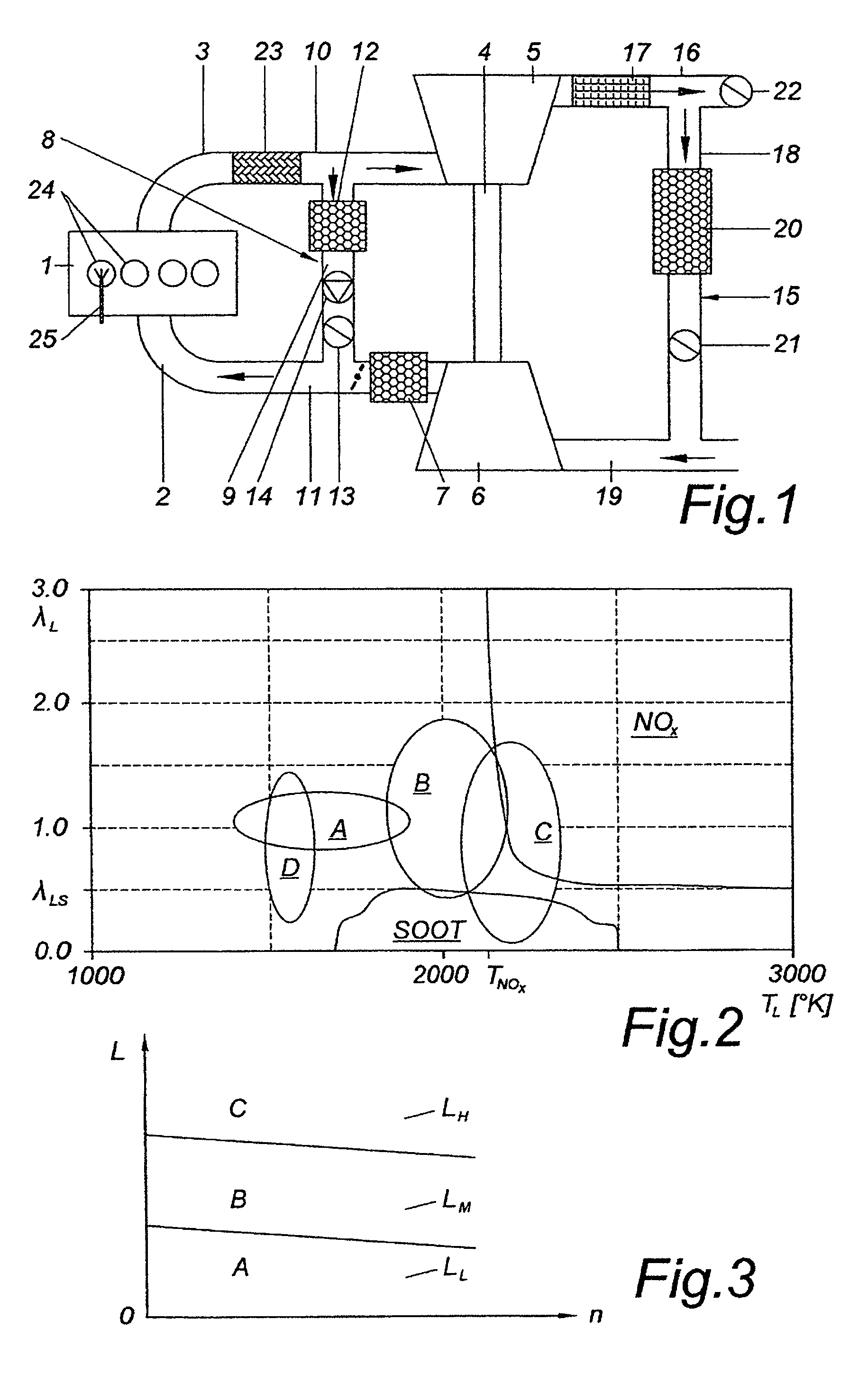

Method for operating an internal combustion engine

InactiveUS7415963B2Shorten injection timeEasy to igniteElectrical controlInternal combustion piston enginesNitrogen oxidesInternal combustion engine

The invention relates to a direct-injection internal combustion engine that is operated in a first operating range associated with the low part load, with largely homogeneous combustion of the mixture and subsequent injection. Said internal combustion engine is operated in a second operating range associated with the middle part load, with low-temperature combustion of the mixture. In this way, minimum nitrogen oxide and soot emissions and a high degree of efficiency can be achieved both in the lower part load region and up to the full load region.

Owner:AVL LIST GMBH

Complexes of phosphate derivatives

InactiveUS20100261670A1Easy to chargeEfficient transportBiocideCosmetic preparationsPhosphateNitrogen

Owner:WEST SIMON MICHAEL +2

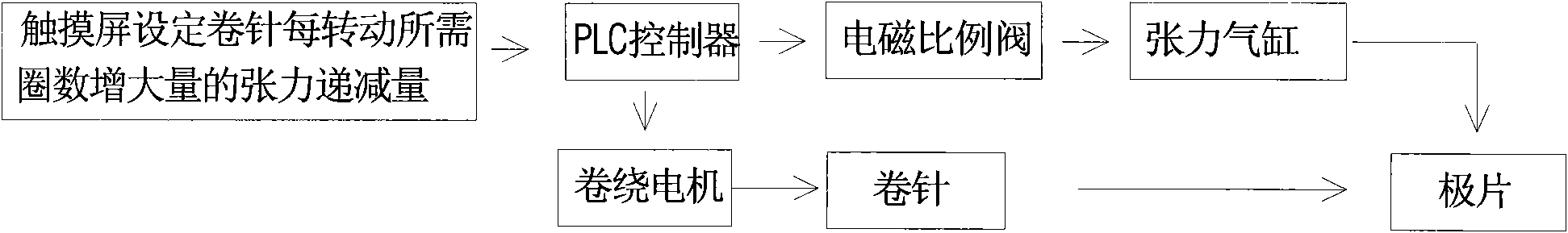

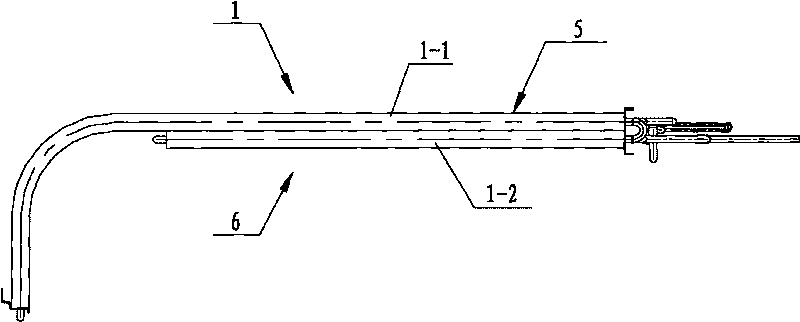

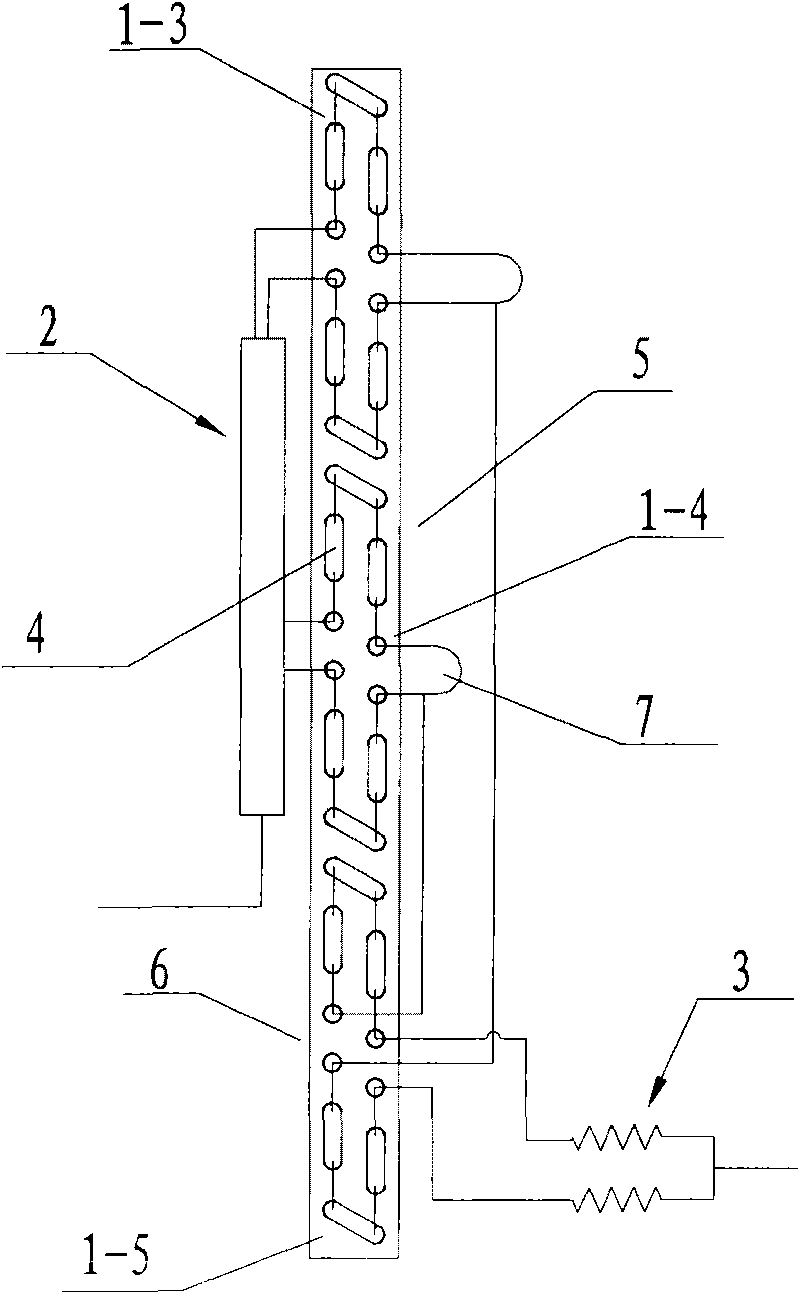

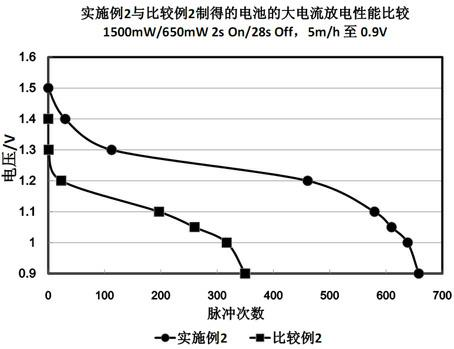

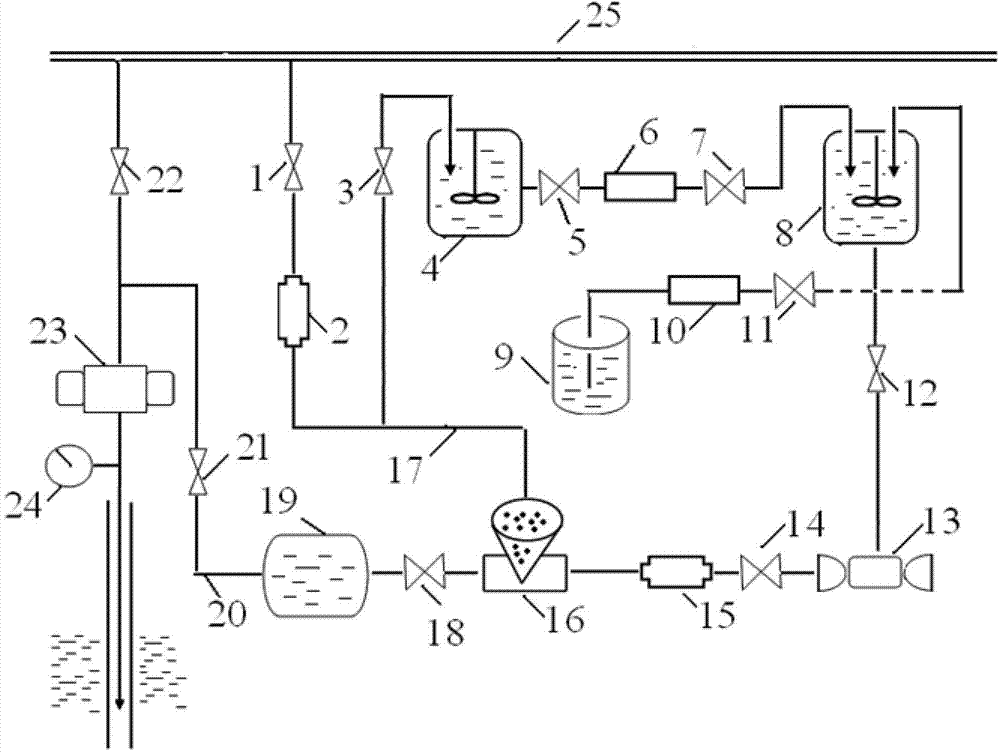

Cylindrical secondary battery bare electric core winding variable-tension control method

InactiveCN101567467AShorten injection timeShorten the production cycleFinal product manufactureSecondary cellsControl systemElectric machine

The invention provides a cylindrical secondary battery bare electric core winding variable-tension control method. An electric core winding variable-tension control comprises an indirect tension detection unit, a PLC controller, a tension cylinder for pushing the tension bar, and a winding electric machine for driving the rotation of the coiling needle and the PLC controller controls the winding electric machine to drive the winding needle to realize the unwinding tension control based on the detection information of the indirect tension detection unit and the air pressure in the tension cylinder is controlled by an electromagnetic proportioning valve for supplying gas into the tension cylinder. During winding the battery electric core, the PLC controller gradually controls the electromagnetic proportioning valve and reduces the air pressure in the tension cylinder based on the calculated winding cylinder number and the increase of the coiling needle according to the pole piece tension variance. The control method effectively solves the problems that the electric core is too tight due to the cylindrical electric core constant-tension winding and then the battery production efficiency is reduced, thereby ensuring that the electric core whole winding is tight inside and loose outside during winding process, in favor of electrolyte permeation and the charging time in the battery production procedure is obviously reduced.

Owner:GEESUN AUTOMATION TECH

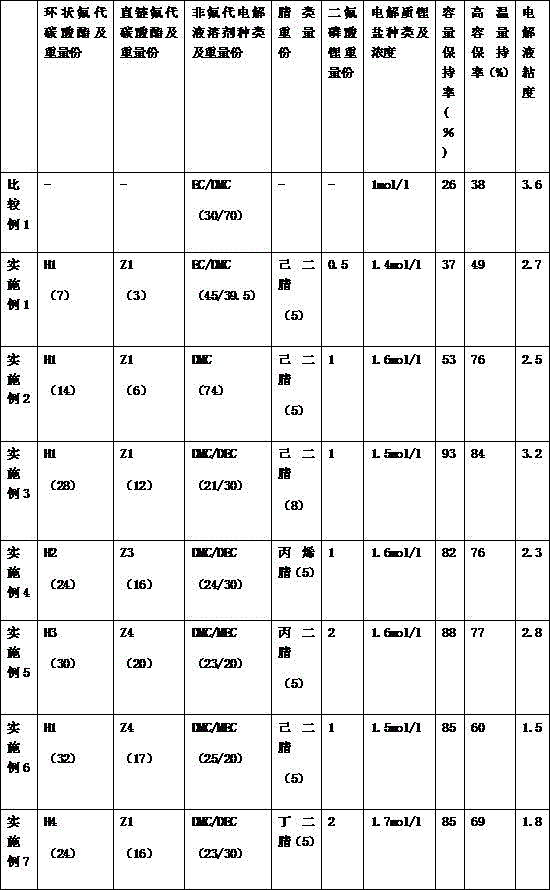

High-voltage electrolyte for lithium ion battery

InactiveCN106159328ALow viscosityImprove wettabilitySecondary cells servicing/maintenanceOrganic electrolytesHigh temperature storageDifluorophosphate

The invention provides high-voltage electrolyte for a lithium ion battery. The high-voltage electrolyte is composed of an electrolyte lithium salt, fluorocarbonate, nitriles, a solvent and an additive, wherein the electrolyte lithium salt is LiPF6 with the concentration of 1.2mol / L-1.6mol / L; a fluorocarbonate solvent accounts for 10%-60% of the total mass of the solvent; the nitriles account for 5%-15% of the total mass of the solvent; a non-aqueous organic solvent accounts for 23%-84.5% of the total mass of the solvent; the additive is lithium difluorophosphate and accounts for 0.5%-2% of the total mass of the solvent. By compounding and combining cyclic fluorocarbonate, straight-chain fluorocarbonate, the nitriles, the additive and the like, the high-voltage heat stability of the electrolyte is prone to improve and the problems that the high-temperature circulating stability of conventional electrolyte is poor and the high-temperature storage is not ideal are improved. Meanwhile, the electrolyte has small viscosity when the materials are matched; the wetting property of an electrode material is facilitated, the liquid injection time of the lithium ion battery is shortened and the rate performance of the battery is improved.

Owner:湖北诺邦科技股份有限公司

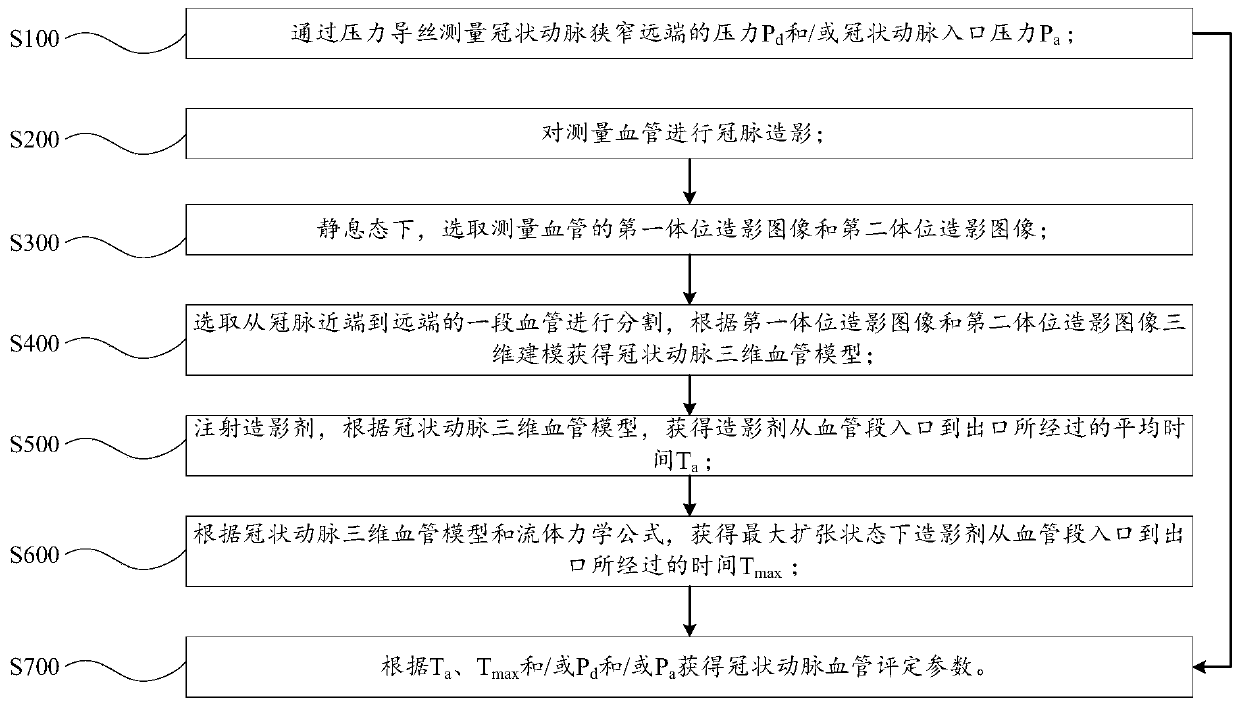

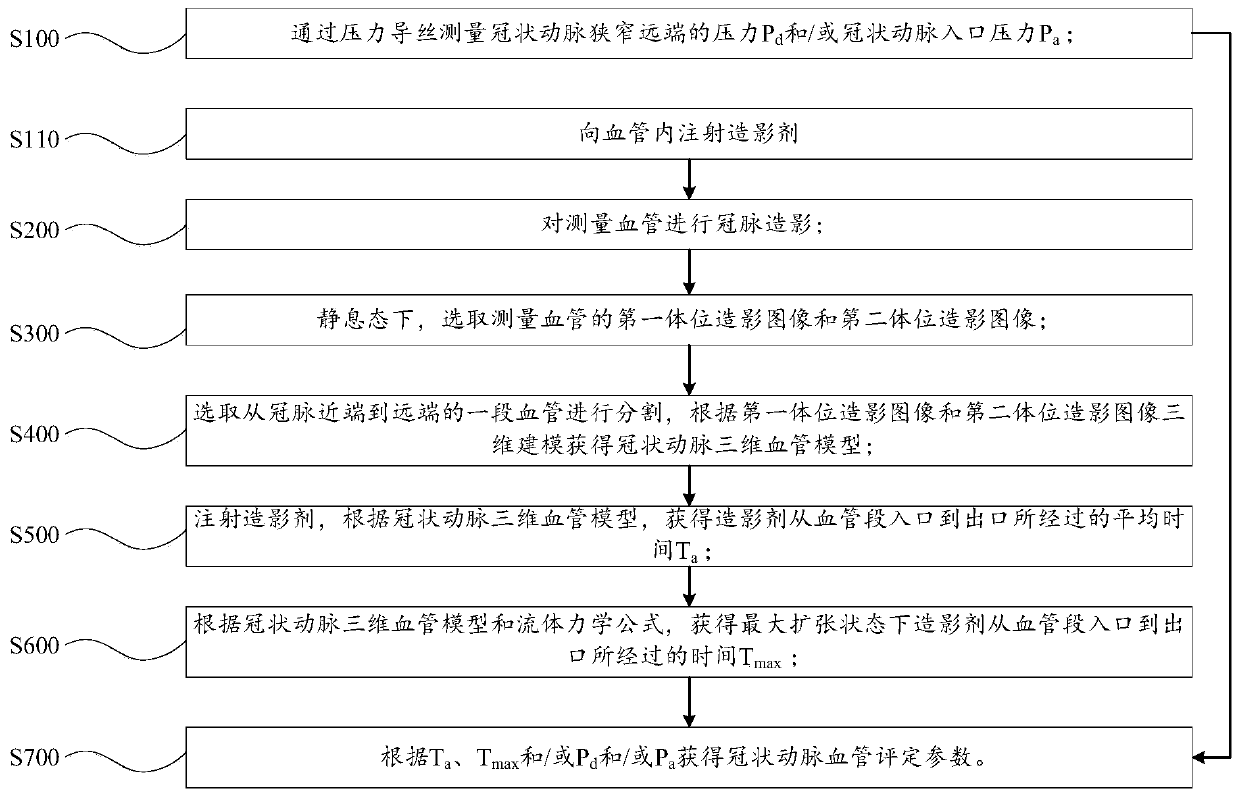

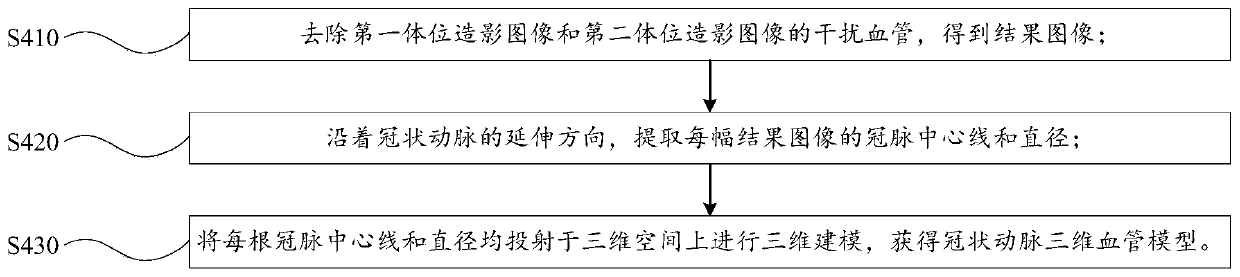

Method and device for conveniently measuring evaluation parameters of coronary arteries and system

ActiveCN110367965AEasy to measureShorten injection timeImage enhancementImage analysisCoronary angiographyDrug

The application provides a method and device for conveniently measuring evaluation parameters of coronary arteries and a system. The method comprises: measuring pressure Pd of the narrow distal end ofa coronary artery and / or inlet pressure Pa of the coronary artery through a pressure guide wire; performing coronary angiography on the coronary artery measured; selecting first and second position angiographic images of the coronary artery measured; segmenting a segment of the coronary artery from the proximal end and the distal end, and performing three-dimensional modeling to obtain a coronaryartery three-dimensional vascular model; injecting a contrast medium to obtain average time Ta in which the contrast medium passes from an inlet of the segment to an outlet; acquiring time Tmax in which the contract medium passes from the inlet of the segment to the outlet in maximum expanded state according to a hydromechanics equation; acquiring evaluation parameters of the coronary artery. Modeling can be performed according to angiographic images of any moment in a cardiac cycle; three-dimensional modeling is convenient; injection time of a dilator is shortened; the measuring process is simple; test results are accurate.

Owner:SUZHOU RAINMED MEDICAL TECH CO LTD

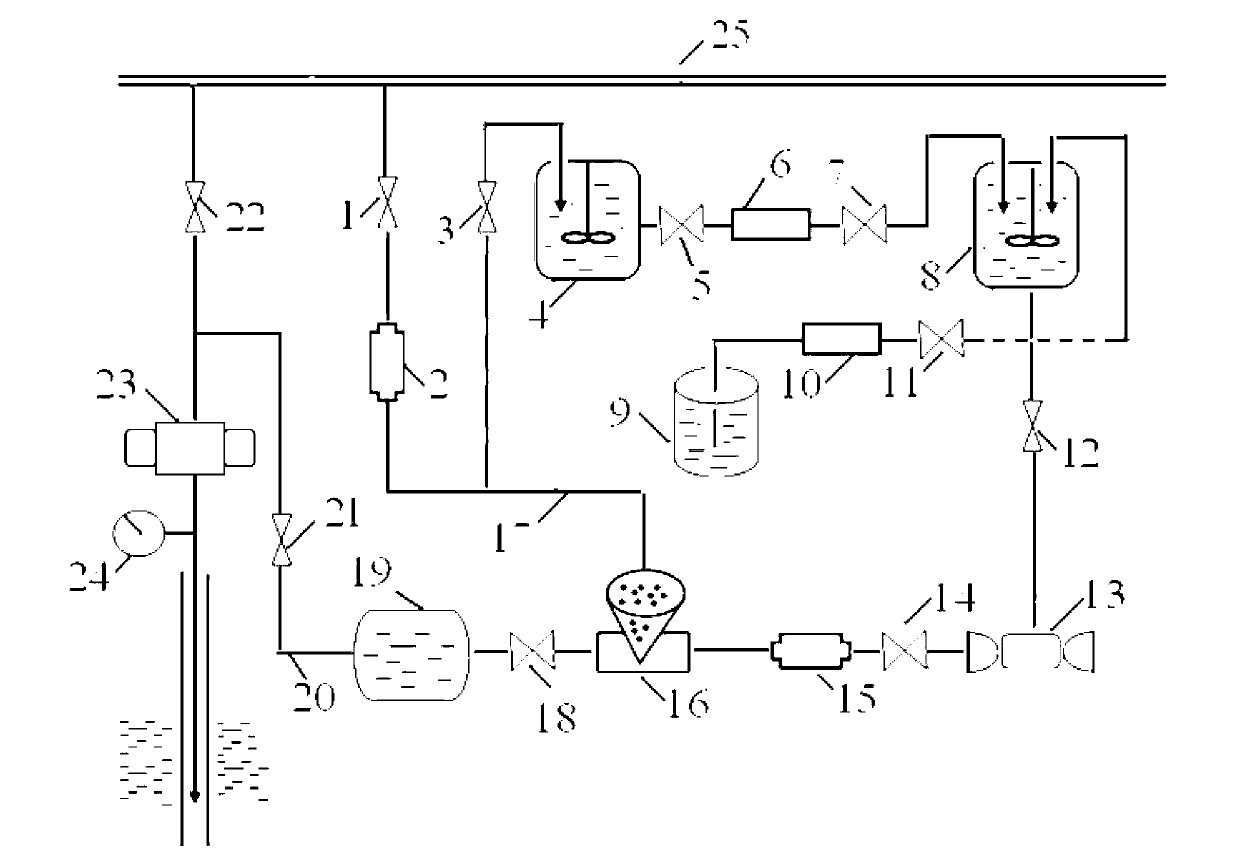

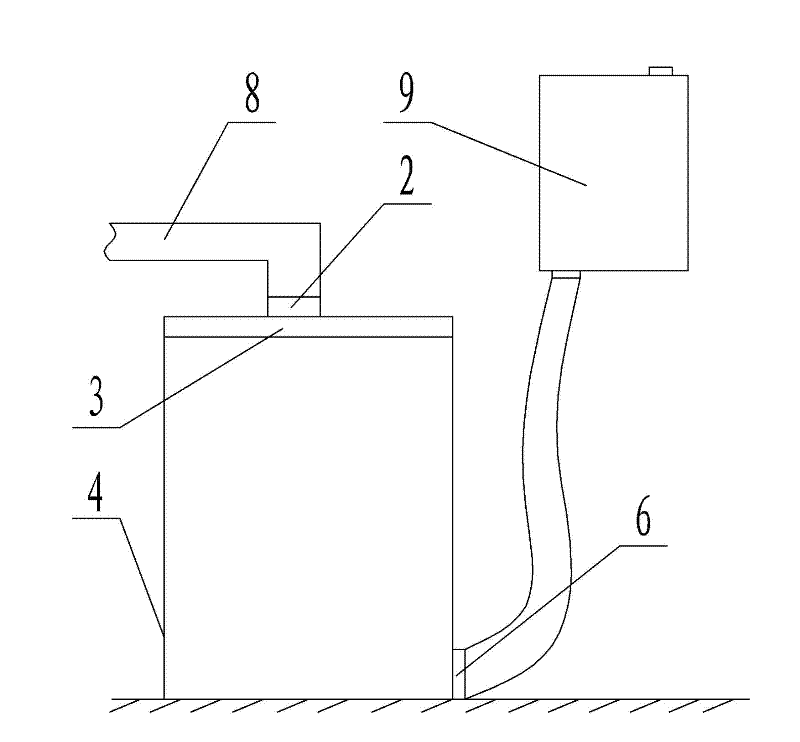

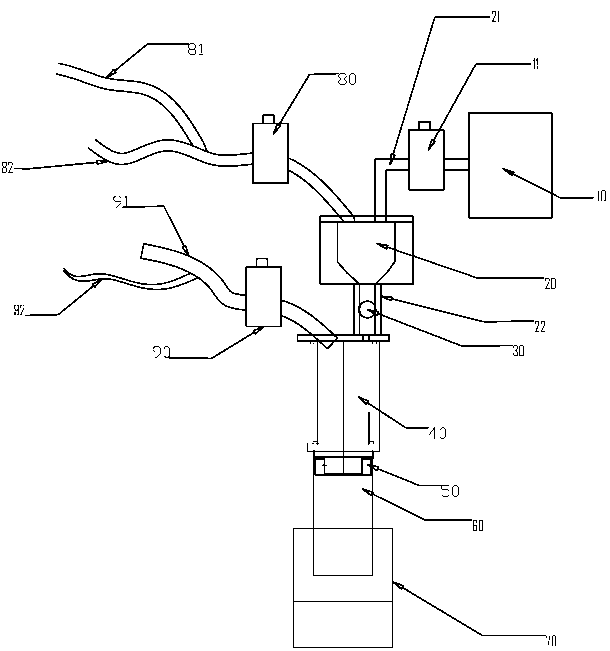

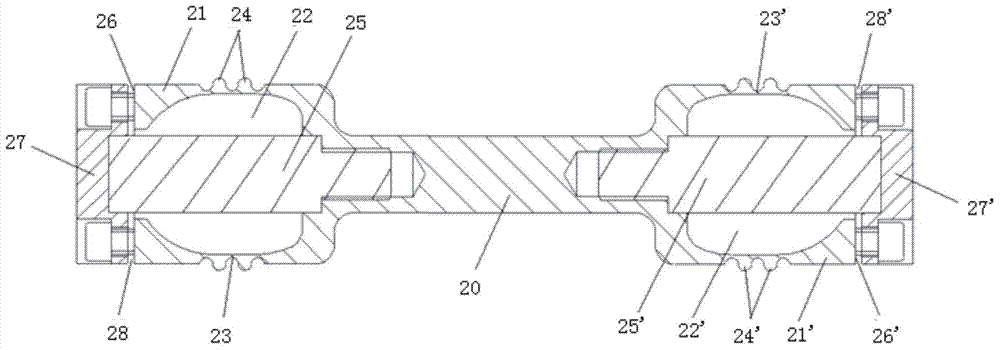

Online continuous production and injection integrating method and device for jelly dispersoid

ActiveCN102996106AShorten injection timeMeet the needs of continuous profile control (control and drive)Fluid removalBuffer tankColloid

The invention relates to an online continuous production and injection integrating method and device for a jelly dispersoid. The method comprises the following steps of: curing a polymer and preparing a jelly system; then, pumping the prepared jelly system into a colloid grinder through a flow meter, meanwhile, injecting water into the colloid grinder, and grinding by using the colloid grinder at the rotating speed of 1000-3000rpm for 3-5 minutes to prepare the jelly dispersoid; enabling the prepared jelly dispersoid to enter a buffer tank; and pumping the jelly dispersoid in the buffer tank into a water injection well through a high-pressure plunger pump. Production and injection integration of a profile control agent (profiling / flooding agent) is realized, the jelly system and the jelly dispersoid are prepared simultaneously while the jelly dispersoid is pumped into the water injection well, the production and the injection of the jelly dispersoid are continuously carried out on line, and production and injection are simultaneously carried out, so that the production and injection time of the jelly dispersoid is greatly shortened, and the large-dosage continuous profiling and flooding requirements of multiple well groups or blocks can be met.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

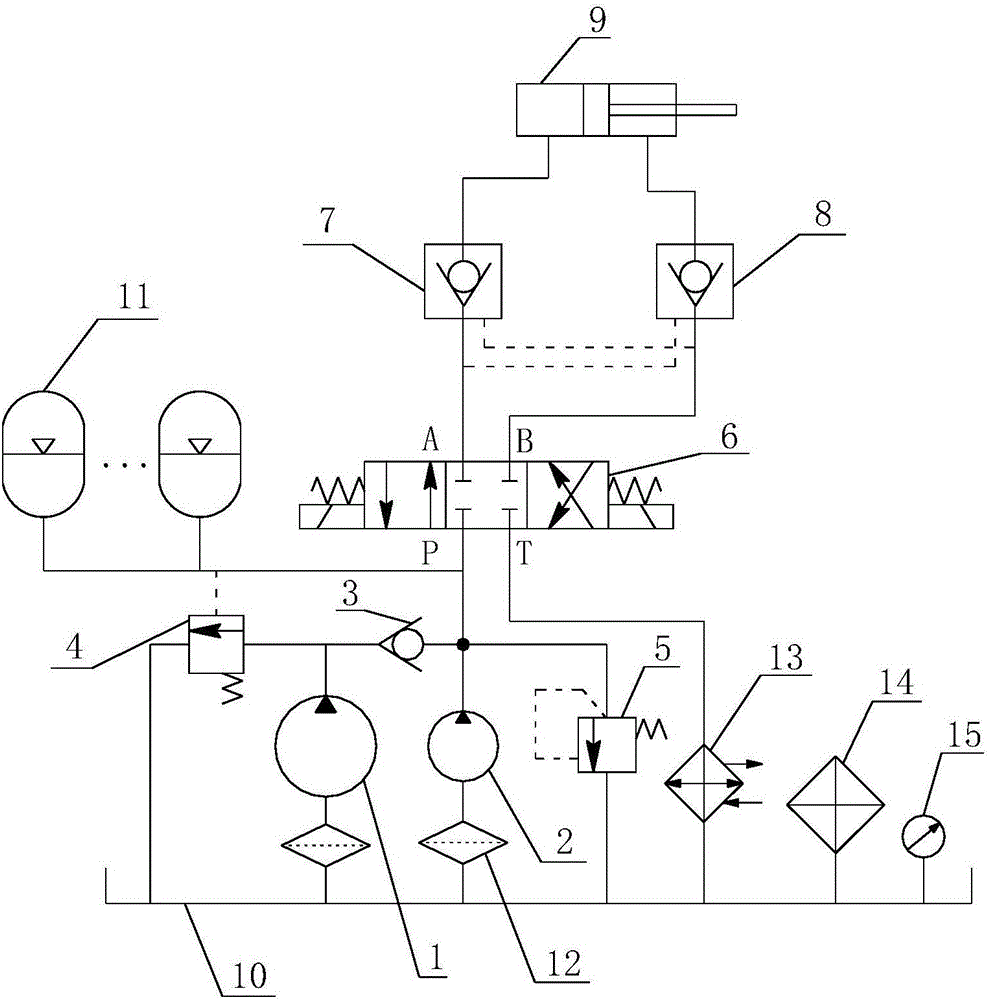

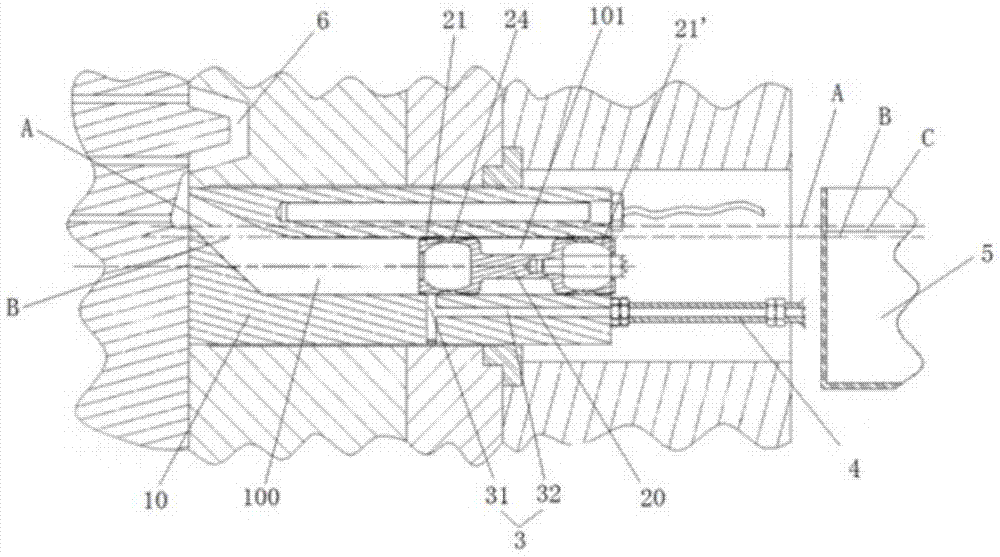

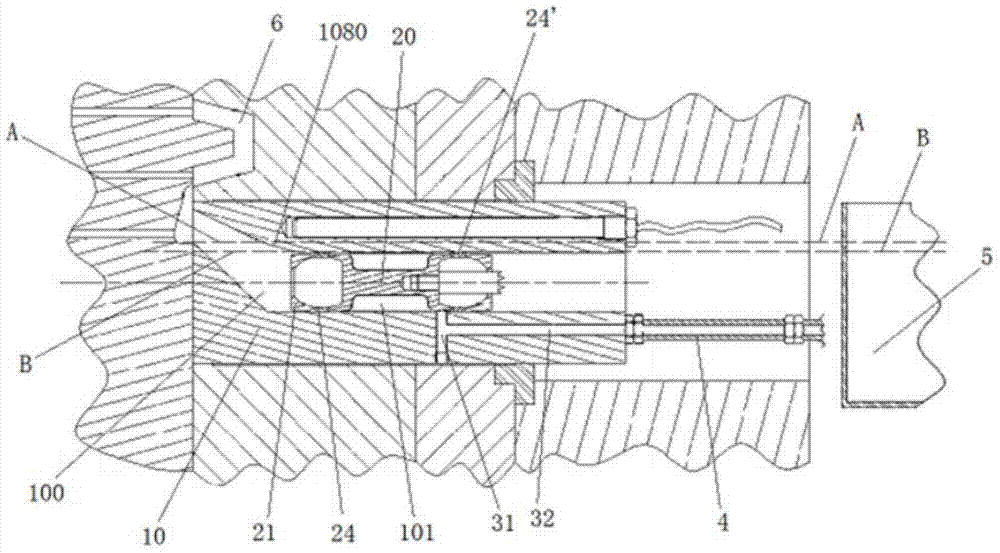

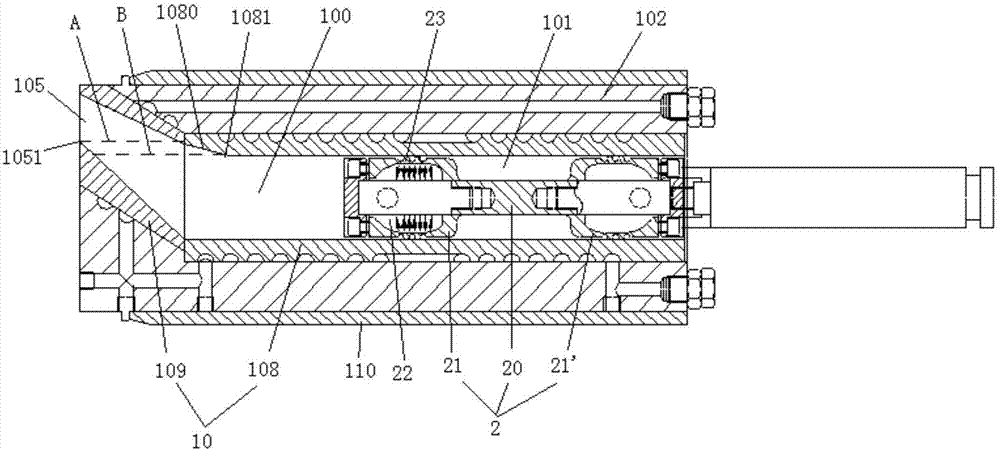

Hydraulic control system of high-speed injection molding machine

InactiveCN106378915AMove quicklySimple structureFluid-pressure actuator componentsHydraulic cylinderControl system

The invention relates to the technical field of high-speed injection molding machines, in particular to a hydraulic control system of a high-speed injection molding machine. The hydraulic control system of the high-speed injection molding machine comprises a low-pressure large-flow pump, a high-pressure small-flow pump, a check valve, a hydraulic control sequence valve, an overflow valve, a three-position four-way reversing valve, a first hydraulic control check valve, a second hydraulic control check valve, a hydraulic cylinder, an oil groove and multiple energy accumulators. The hydraulic control system of the high-speed injection molding machine is simple in structure and convenient to operate, lowers cost and improves the work efficiency. Through the double-pump oil supply manner, the injection molding time can be shortened, and the injection molding efficiency is improved. Besides, through cooperative use of the small-flow hydraulic pump and the energy accumulators, rapid movement of an executing element can be achieved.

Owner:成都源云机械有限公司

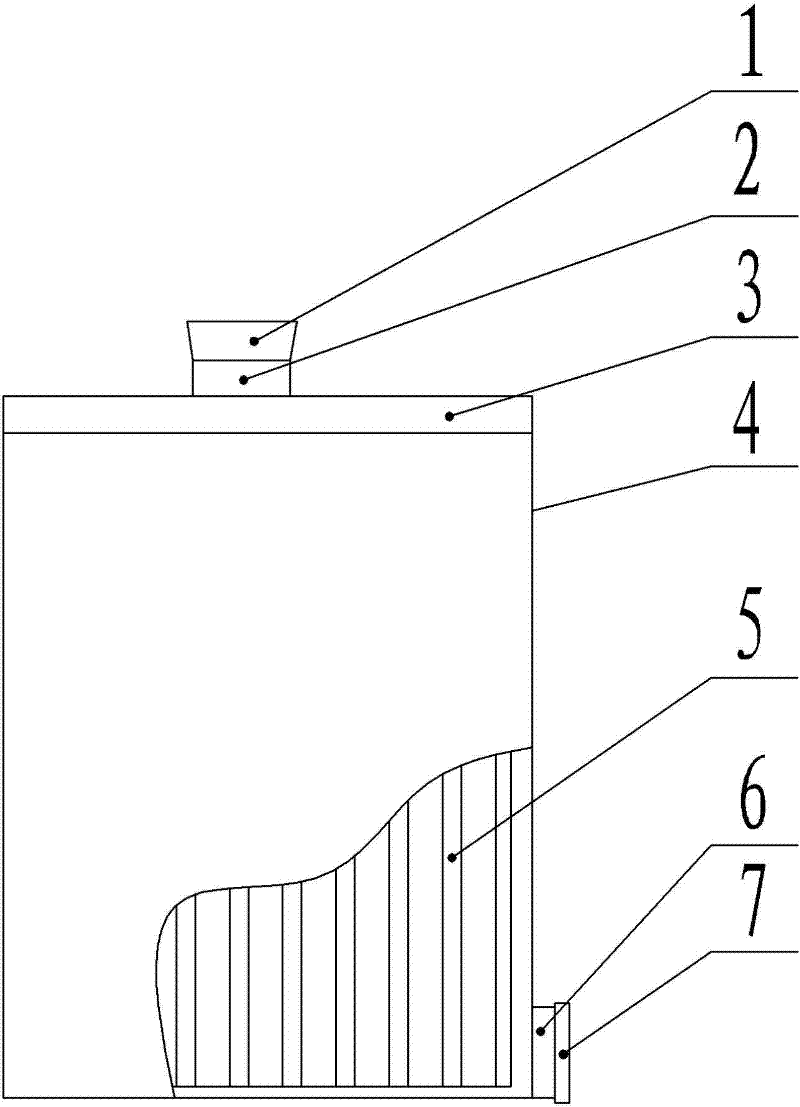

A battery and liquid injection method

ActiveCN102299272AIncrease capacityThorough infiltrationCell component detailsEngineeringSafety valve

The invention discloses a cell and an electrolyte injection method. The cell comprises a cell rolling core, a shell wrapped outside the cell rolling core, an end cover covering the upper part of the shell, a safety valve hole and an electrolyte injection hole, wherein the safety valve hole is arranged on the end cover, and the electrolyte injection hole is arranged at the lower part of the shell. In the cell, the safety valve hole is arranged on the end cover of the cell, and the electrolyte injection hole is arranged at the lower part of the shell of the cell. When the electrolyte is injected into the cell, the vacuumization is carried out from the safety valve hole, and the electrolyte is injected from the electrolyte injection hole at the bottom of the cell. The electrolyte injection efficiency of the cell is improved obviously, and because the electrolyte injection way that the electrolyte is injected from the bottom of the cell and the vacuumization is carried out at the upper part of the cell is adopted, air bubbles inside the cell are reduced. The infiltration effect of the cell rolling core is good, thus the cell capacity is greatly increased. By using the electrolyte injection method, the electrolyte injection time is shortened effectively, the working efficiency is improved, the infiltration of the cell rolling core is more thorough, the air bubbles between pole pieces can be discharged, and the cell capacity is increased.

Owner:中创新航科技(江苏)有限公司

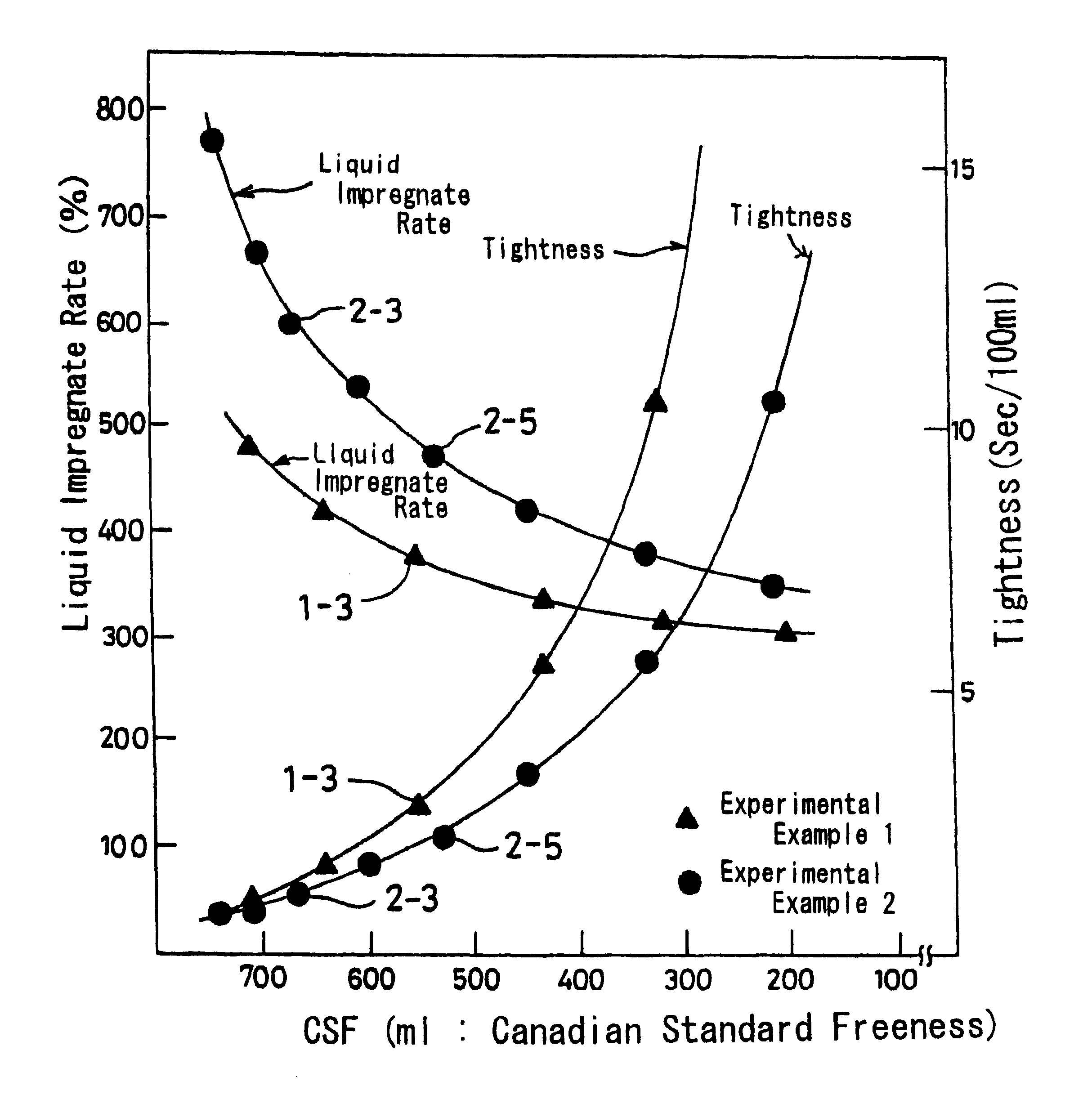

Separator paper for alkaline-battery

InactiveUS6379836B1Prevent internal shortagePrevent internalSpecial paperLayered productsCellulose fiberEngineering

A separator paper is provided which simultaneously satisfies the requirements to have a high denseness that can prevent internal shortage due to such as the deposition of the zinc oxide dendrite accompanied by not adding mercury, and a high liquid impregnate properties that can improve heavy discharging properties. Said separator paper comprises a dense layer having a certain degree of denseness, and a liquid impregnate layer having a certain degree of liquid impregnate properties, said dense layer and said liquid impregnate layer being integrally laminated, and said dense layer being made by mixing alkali proof cellulose fibers which is applicable for beating with synthetic fibers such that said alkali proof cellulose fibers be included in the range of 20 to 80 weight % with the beating degree of 500 ml to 0 ml at CSF value, and said liquid impregnate layer being made by mixing alkali proof cellulose fibers with synthetic fibers such that said alkali proof cellulose fibers be included in the range of 20 to 80 weight % with the beating degree of more than 700 ml at CSF value.

Owner:NIPPON KODOSHI

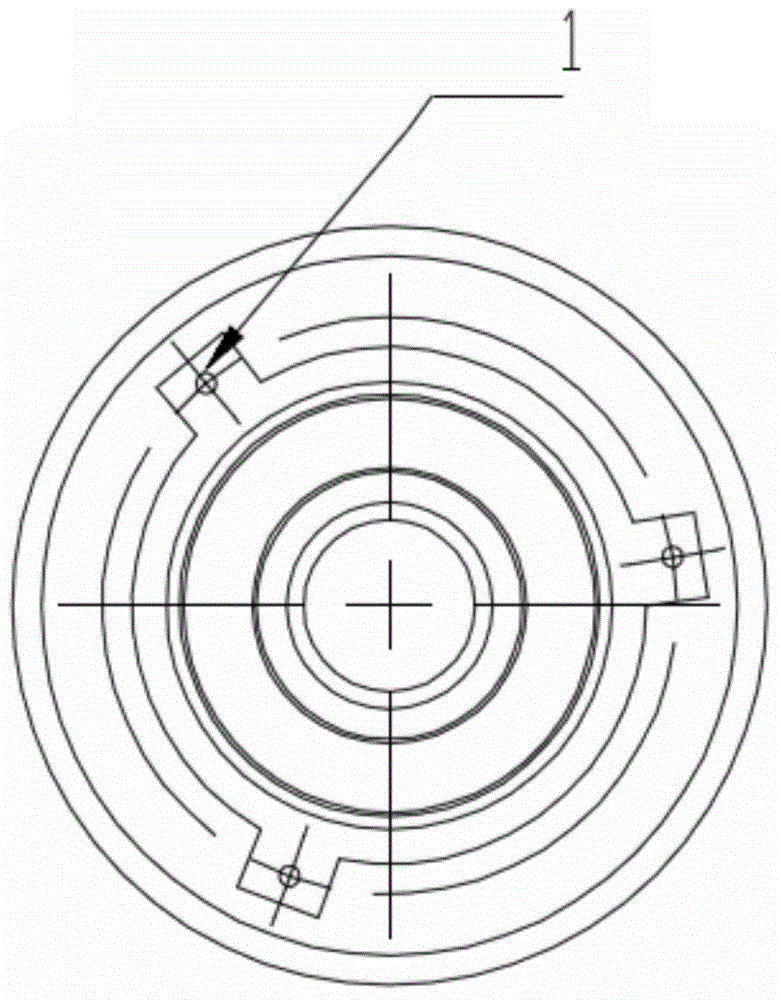

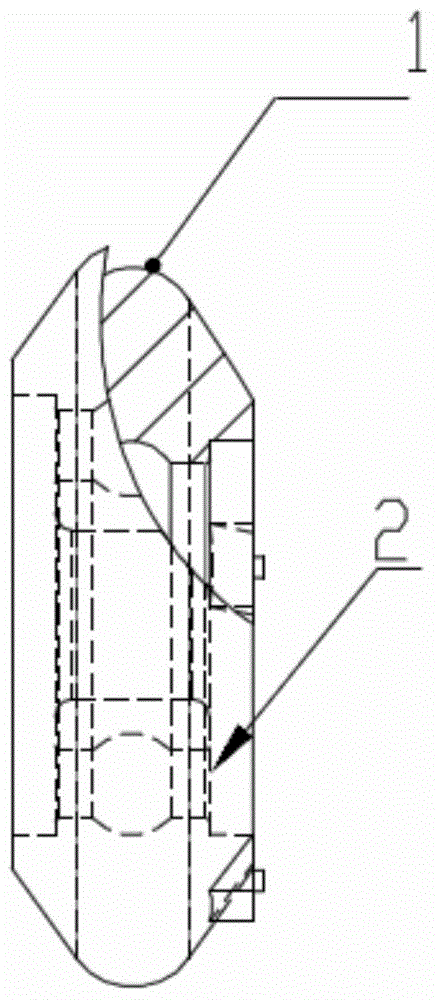

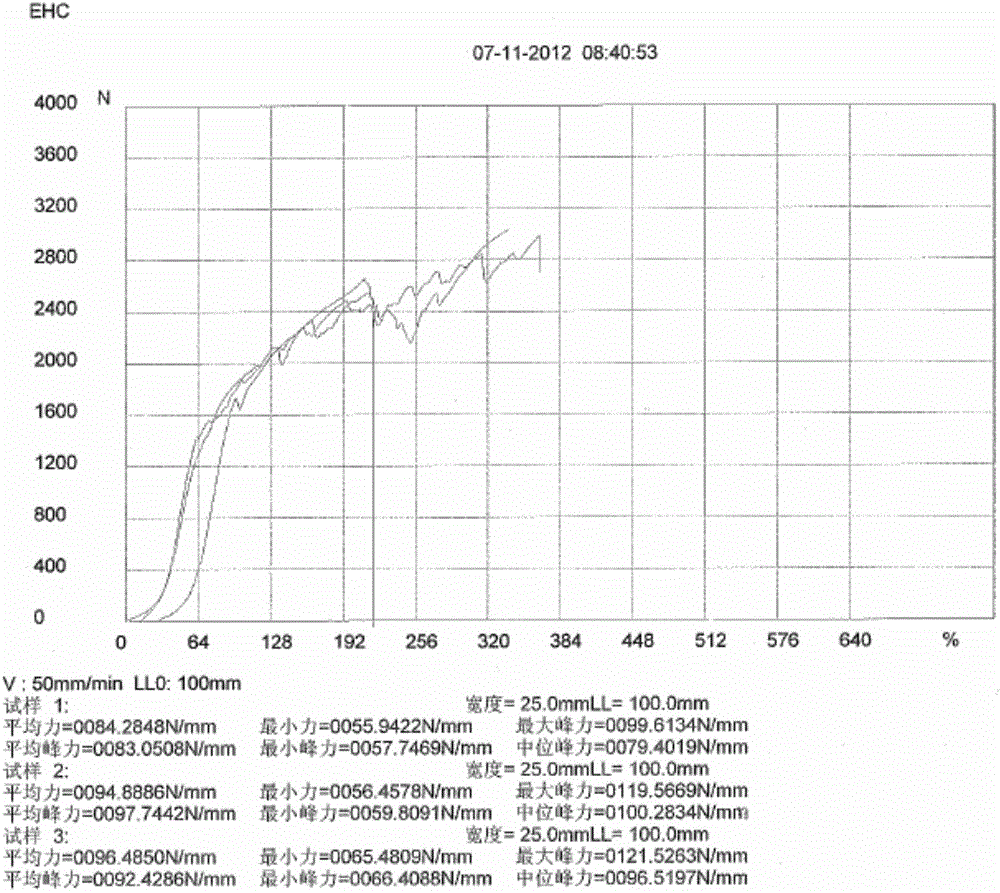

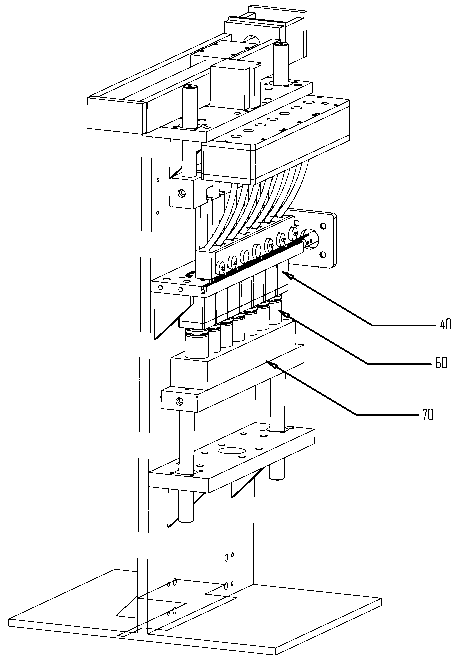

Roller product with high performance and high binding power between metal insert and PU tire bead, prepared by injection molding method

The invention relates to an injection molding process for manufacturing a roller product with high performance and high binding performance between a PU tire bead and a metal wheel hub. The injection process is widely applied in the fields of escalator rollera, door hanging wheels, etc.

Owner:EHC ELEVATOR RAIL SHANGHAI CO LTD

Feeding system of horizontal cold chamber die casting machine

ActiveCN104259429AEffective control amountThe injection volume is easy to controlReciprocating motionDie casting

The invention discloses a feeding system of a horizontal cold chamber die casting machine. The feeding system comprises a charging barrel, wherein a plunger is arranged in the charging barrel; the tail end of the plunger is connected with a driving mechanism; the side wall of the charging barrel is provided with a molten metal passage; the molten metal passage is communicated into a metal smelting chamber through a pipeline; the plunger comprises a first sealing part and a second sealing part which are axially spaced from each other; a cavity among the first sealing part, the inner wall of the charging barrel and the discharge port of the charging barrel form a pressure chamber for storing molten metal to be injected; a cavity among the first sealing part, the second sealing part and the inner wall of the charging barrel form a pressure-free chamber; the molten metal passage is suitable for communicating the pressure chamber when the plunger is positioned at an initial position and is suitable for communicating the pressure-free chamber when the plunger is used for performing injection or reciprocating motion. According to the feeding system of the horizontal cold chamber die casting machine, the quantity of the molten metal injected into the charging barrel is convenient to control, the injection time is shortened, and the die casting efficiency is improved.

Owner:苏州圣美特压铸科技有限公司

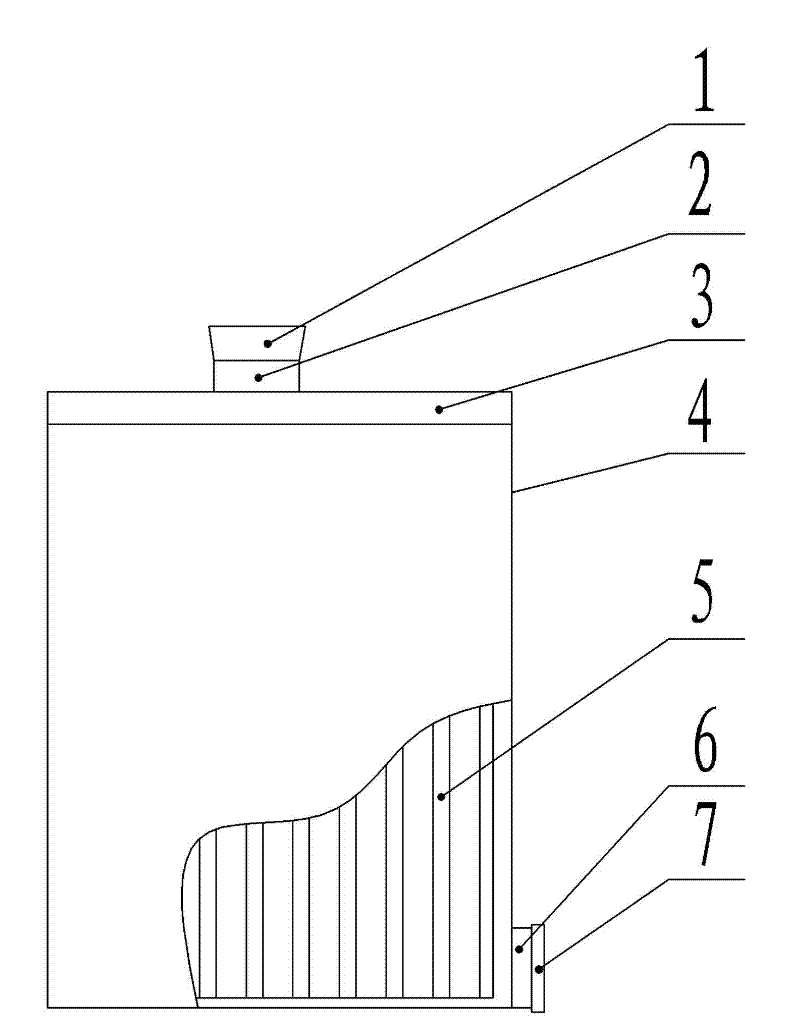

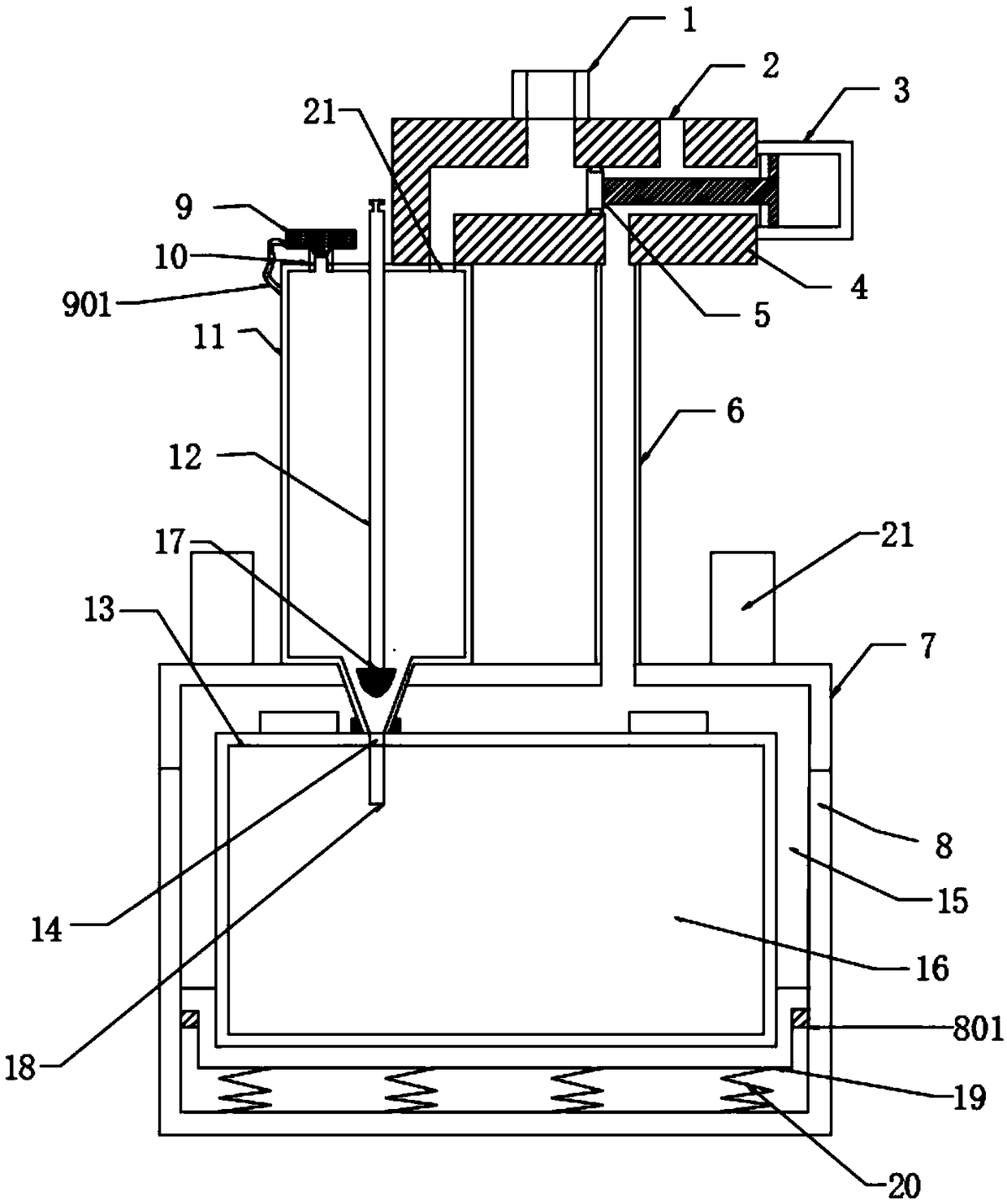

A constant pressure liquid injection device and a liquid injection method for a square power battery

ActiveCN109037579AAvoid bloatingSolve the deformationSecondary cellsCell component detailsPower batteryEngineering

The invention discloses a constant pressure liquid injection device and a liquid injection method for a square power battery, the device comprises a liquid injection device and a fixture, wherein thefixture comprises an upper cover of the fixture and a lower cover of the fixture, wherein the upper cover of the fixture and the lower cover of the fixture are of a separable structure and are in a locked and sealed state when closed and form a fixture inner cavity, the fixture inner cavity is used for fixing a battery, and the battery comprises a battery injection hole and a battery inner cavity;The liquid injection device is fixedly connected with the upper surface of the fixture; and the top of the infusion cup is also connected with a reversing valve, and one end of the reversing valve isconnected with an air pipe joint. The invention alternately injects liquid into the positive and negative pressure of the device through switching the reversing valve and connecting the external equipment through the gas pipe connector, which is fast and safe, and the battery is not easy to deform.

Owner:JIANGXI GANFENG BATTERY TECH

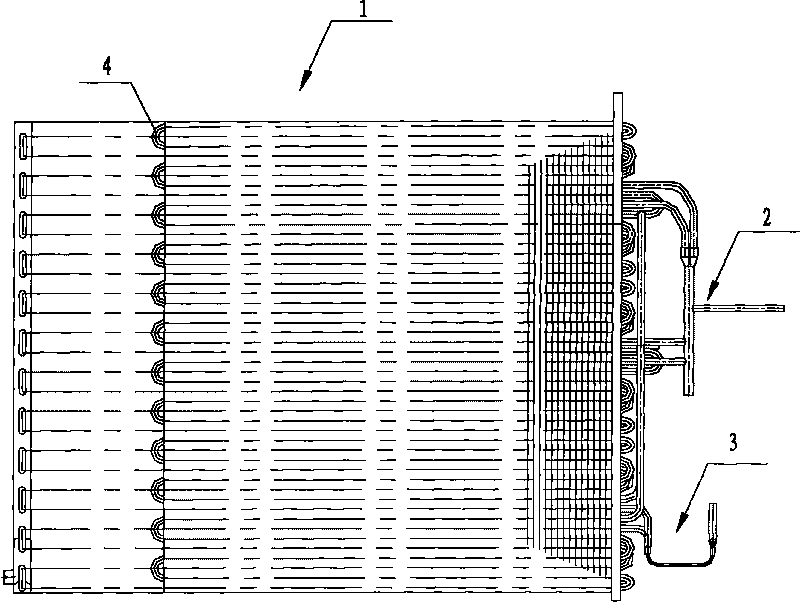

High-efficiency condenser and air conditioner with same

InactiveCN101738016ASimple processImprove heat transfer efficiencyEvaporators/condensersEngineeringRefrigerant

The invention provides a high-efficiency condenser and an air conditioner with the same. The high-efficiency condenser can solve the problem that a heat exchanger of the prior art cannot give full play to heat exchange capacity, and adopts the technical scheme that: the high-efficiency condenser comprises a front row condenser, a back row condenser, a U-shaped tube, a fin, an inlet tube stack, an intermediate liquid distributing tube stack and an outlet fluid diversion tube stack, wherein the front row condenser and the back row condenser are provided with a plurality of fluid diversion branches; the front row condenser has a long row; and the back row condenser has a short row. The high-efficiency condenser is characterized in that: the flow paths of the fluid diversion branches are set into a combination of inverted U shapes and regular U shapes. The high-efficiency condenser optimizes the flow path of the condenser, newly designs the inner row heat exchanger, the outer row heat exchanger, the inlet tube stack, the outlet tube stack and the intermediate liquid distributing tube, uniformly distributes refrigerants in each flow path of the heat exchanger, improves the overall heat exchange balance, improves the heat exchange efficiency of the condenser and reduces the manufacturing cost of the condenser.

Owner:HISENSE (SHANDONG) AIR CONDITIONING CO LTD

Battery fluid filling device and method

InactiveCN103236514AReduce wasteReduce volatilityCell component detailsElectrolytic agentEngineering

The invention is suitable for the field of battery production, and provides a battery fluid filling device and method. The battery fluid filling device comprises an upper fluid storage container, a lower fluid storage container, a fluid filling pump, a first vacuumizing pump and a second vacuumizing pump, wherein a first valve is arranged between the fluid filling pump and the upper fluid storage container, and a second valve is arranged between the upper fluid storage container and the lower fluid storage container. The battery fluid filling device also comprises a first air source connecting pipe and a second air source connecting pipe which are used for being connected with a dry air source, wherein a third valve is arranged among the first vacuumizing pump, the first air source connecting pipe and the upper fluid storage container, and a fourth valve is arranged among the second vacuumizing pump, the second air source connecting pipe and the lower fluid storage container. The battery fluid filling device is adopted in the battery fluid filling method. According to the battery fluid filling device and method provided by the invention, the fluid filling efficiency is improved, the production cost is lowered, the volatilization of electrolyte is reduced, and the safety is good.

Owner:江西佳沃新能源有限公司

Method for injecting electrolyte into shell of battery

The invention relates to a method for injecting electrolyte into a shell of a battery. The battery is a lithium-iron disulfide battery; the shell is provided with an open end and a closed end; and the inner side of the closed end is provided with a battery cell. The method comprises a first electrolyte injection step, wherein the electrolyte is injected into the shell through the open end, and then the shell is rotated around a vertical rotating shaft in a mode that the open end is inward and close to the rotating shaft, the closed end is outward and far away from the rotating shaft, and the open end is higher than the closed end. The electrolyte is injected into the shell of the battery by centrifugal force, so that the electrolyte is fully absorbed on the battery cell and electrode sheets, and the set discharge capacity of the battery can be realized to the greatest extent under a large-current discharge condition, and the injection time of the electrolyte can be remarkably shortened simultaneously, so that the production efficiency of the battery is greatly improved.

Owner:FUJIAN NANPING NANFU BATTERY

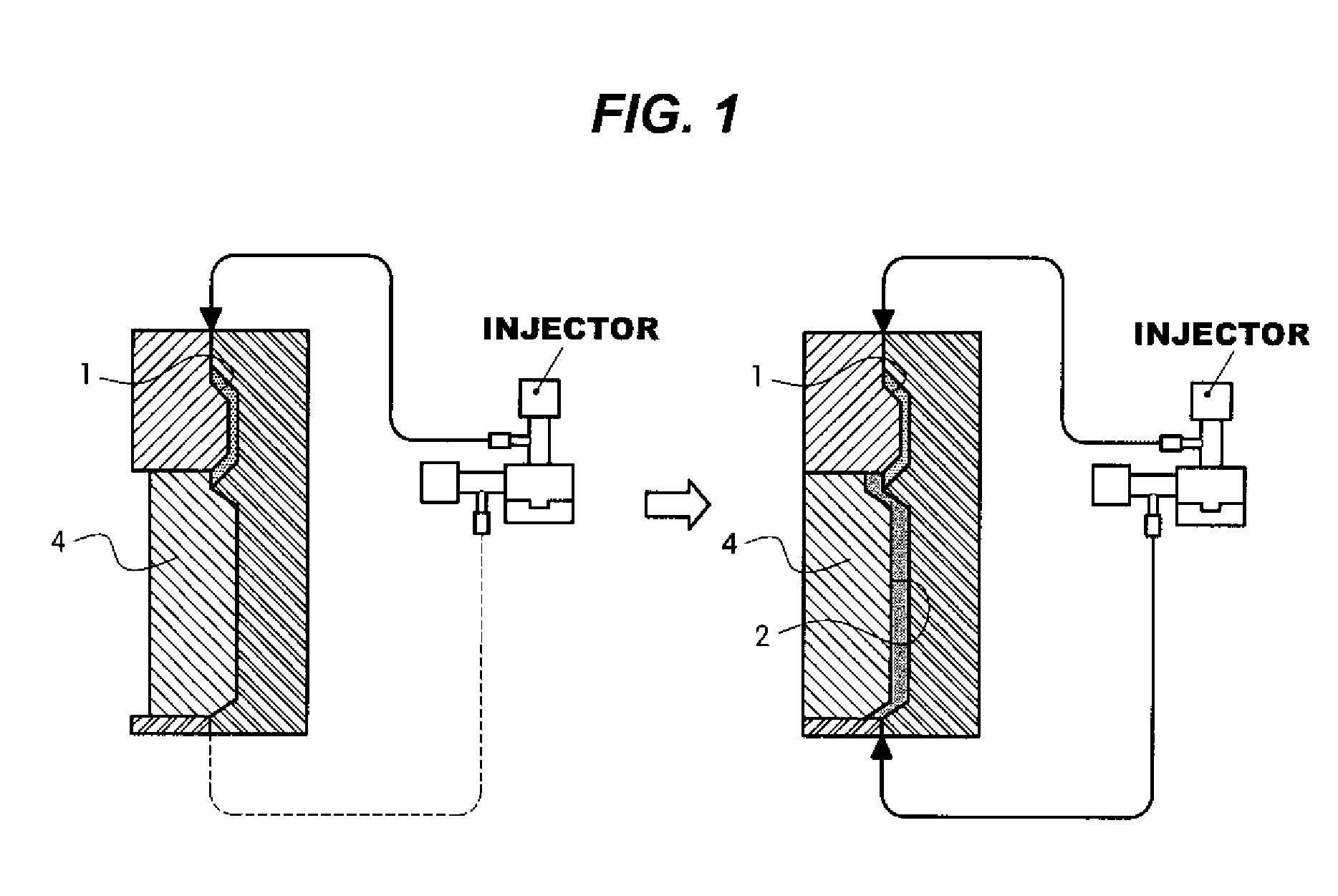

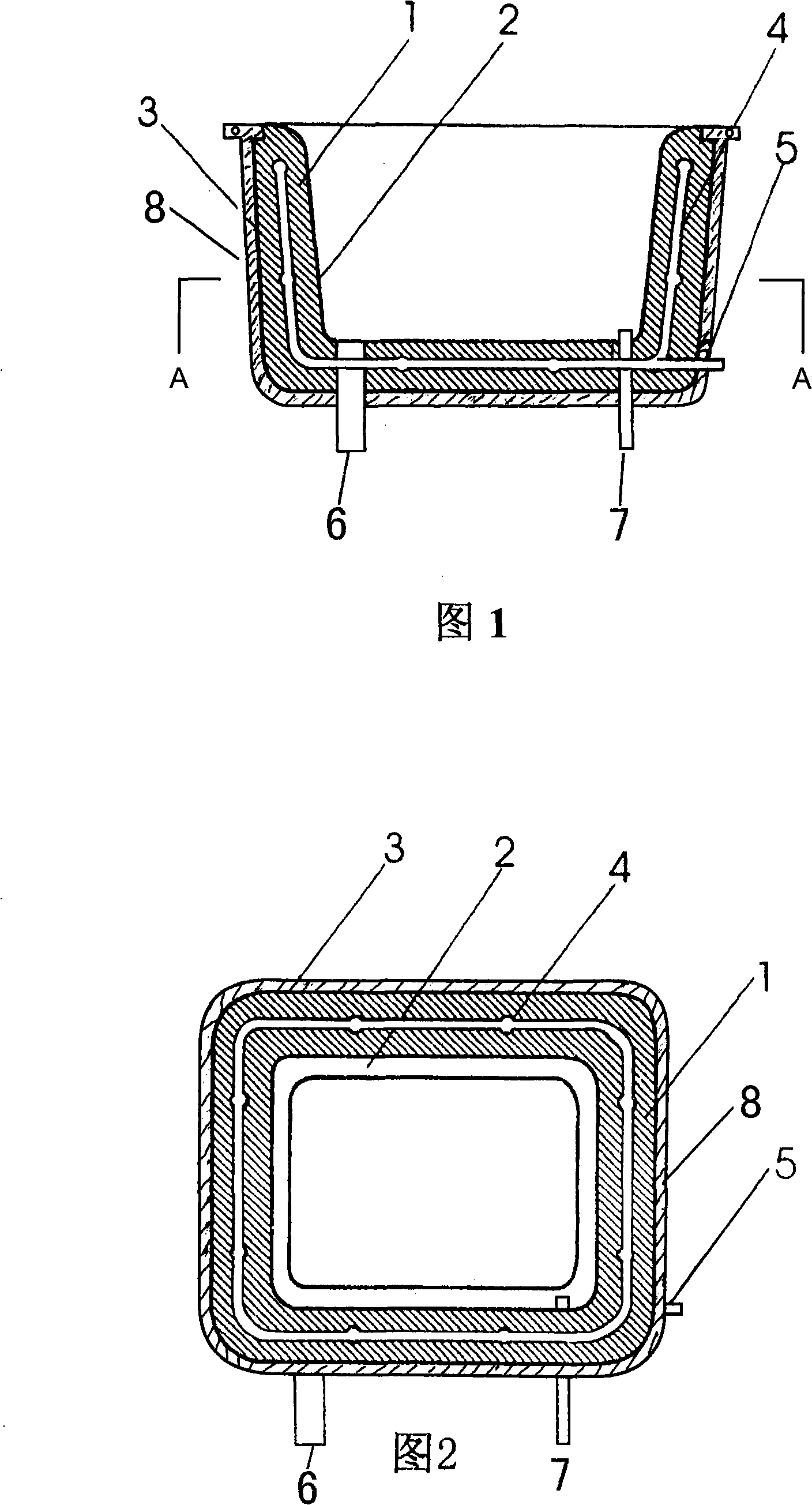

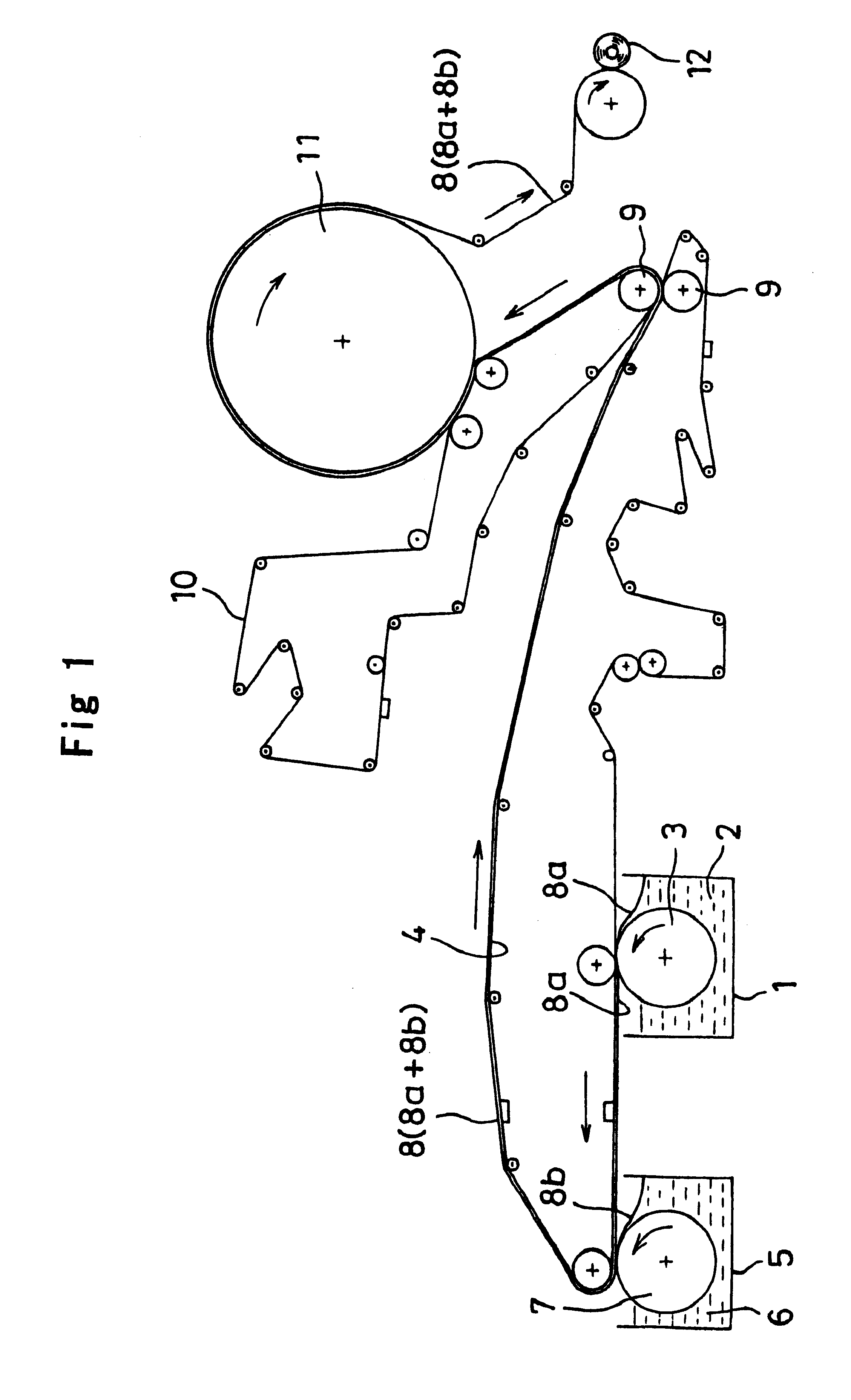

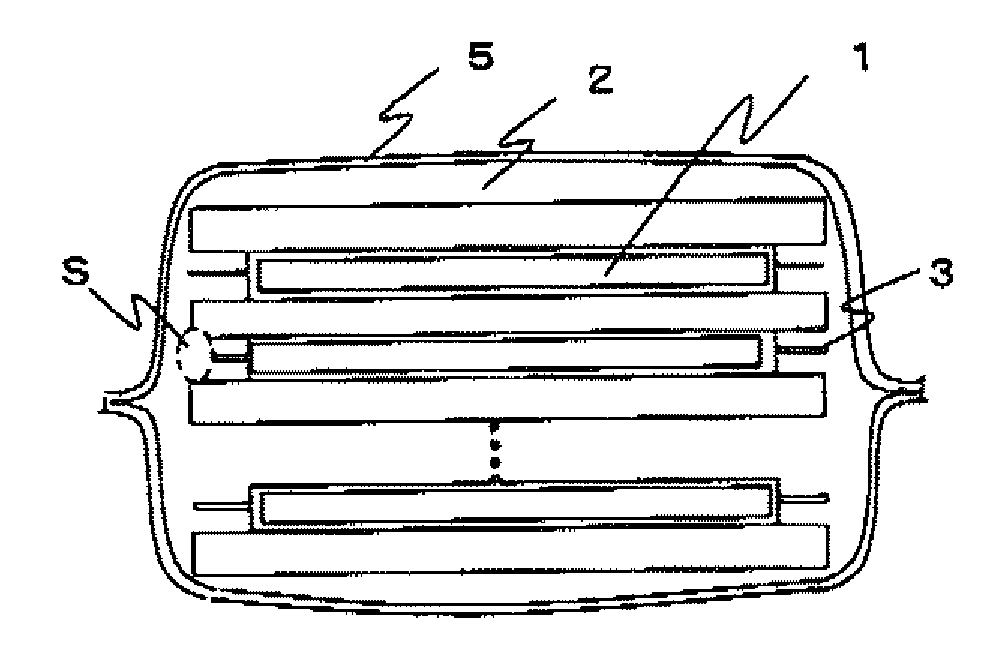

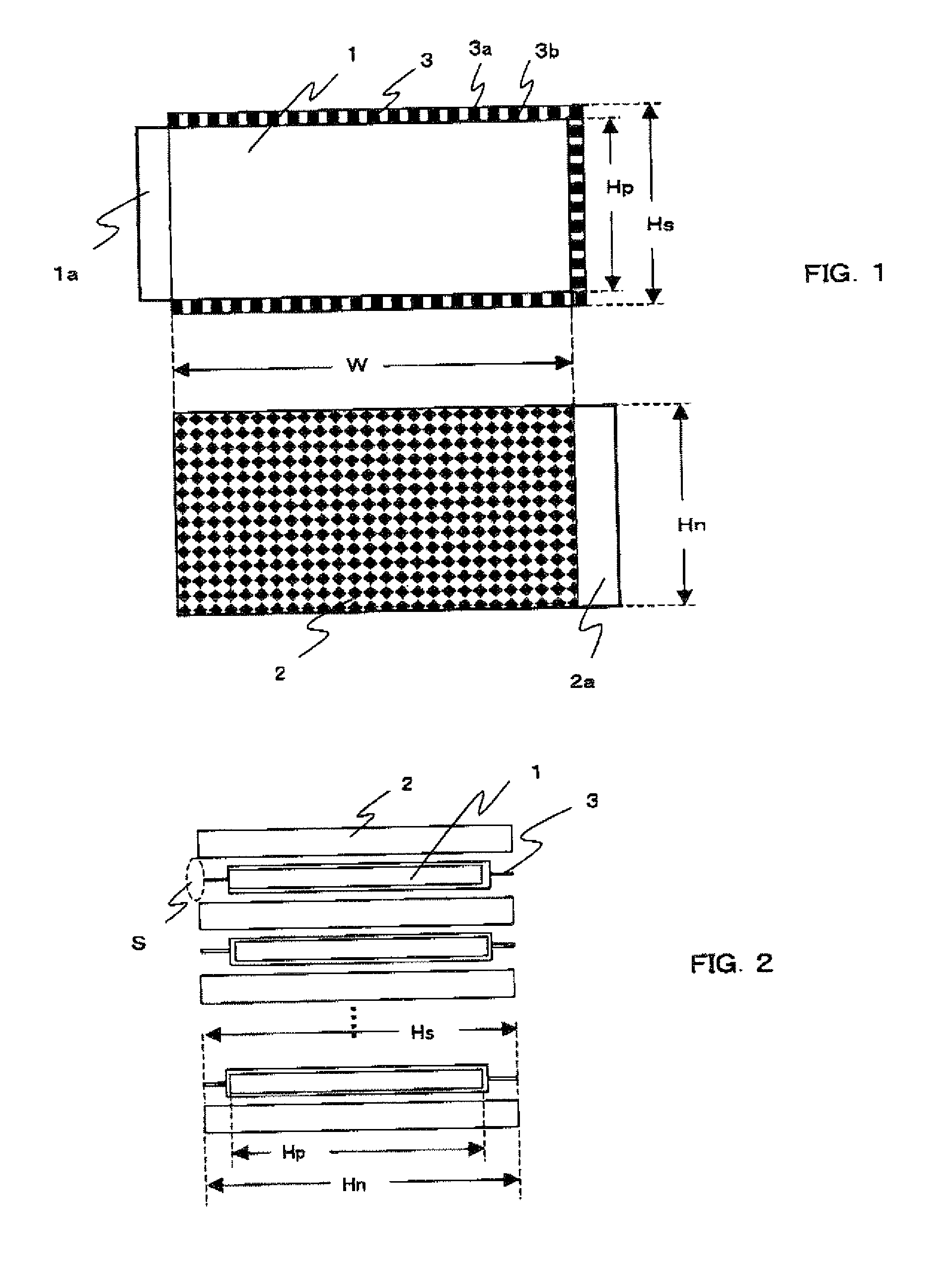

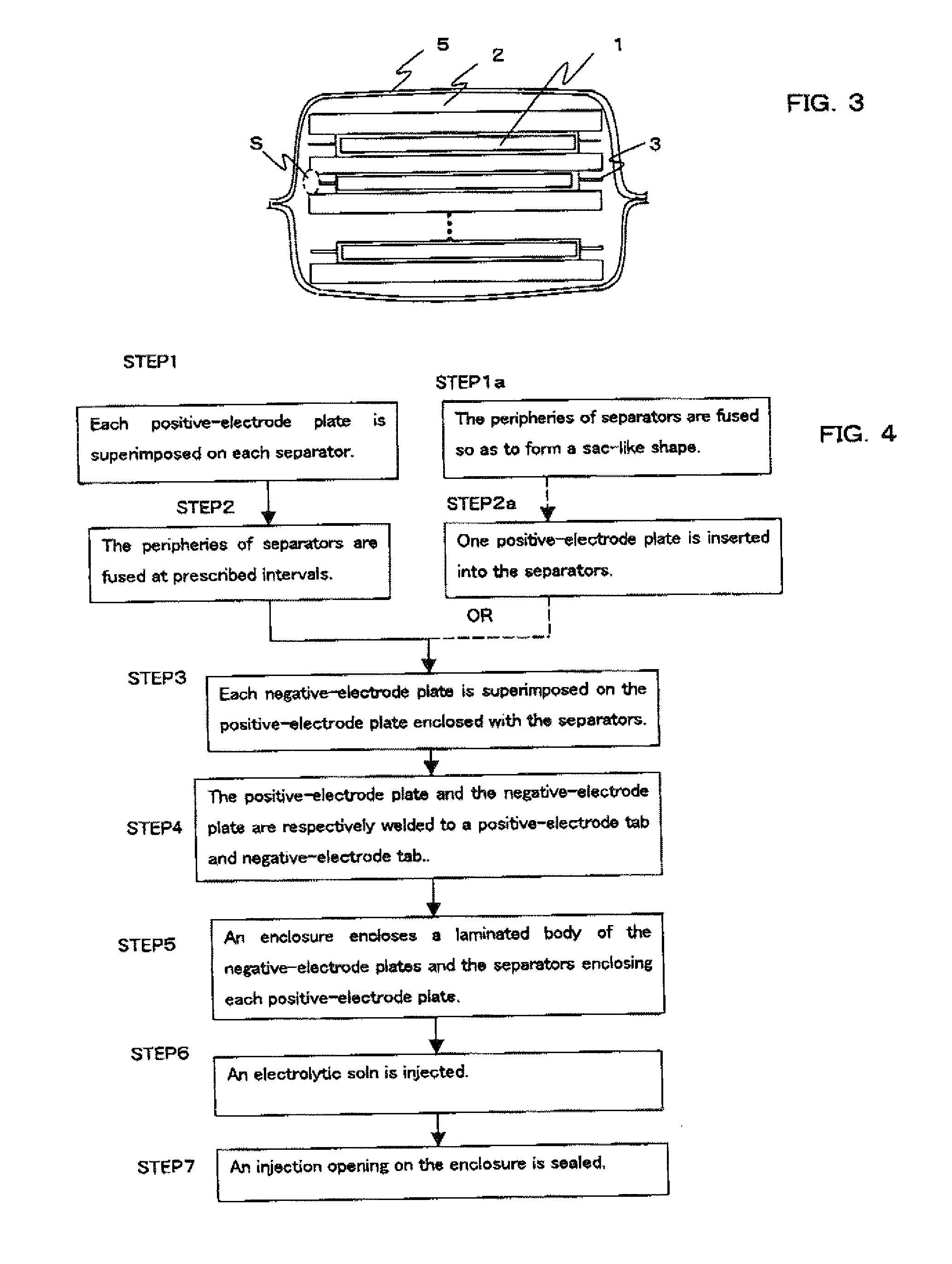

Nonaqueous electrolytic solution secondary battery and method for preparing the same

InactiveUS20080241672A1Injecting time for injecting solution can be shortenedShorten injection timeHollow inflatable ballsHollow non-inflatable ballsEngineeringElectrical and Electronics engineering

To provide a secondary battery that is capable of shortening injecting time for injecting an electrolytic solution, and infiltrating the electrolytic solution uniformly, during a process for preparing the secondary battery. Also, to provide the secondary battery in which discordance of layers of positive-electrode plates, negative-electrode plates, and separators does not easily occur during a process for laminating them and the following process.A nonaqueous electrolytic solution secondary battery of the present invention comprises: negative-electrode plates which are rectangular; positive-electrode plates which each have a pair of opposed sides shorter than a pair of opposed sides of each negative-electrode plate; separators which each are formed of a porous resin film enclosing each positive-electrode plate; an enclosure which encloses the negative-electrode plates and separators which are laminated alternately, in which a direction of the sides of the negative-electrode plates aligns with a direction of the shorter sides of the positive-electrode plates; and an injection pathway for the nonaqueous electrolytic solution, which the pathway being formed between the negative-electrode plates between which the separator is sandwiched, the pathway being formed at edges of opposed sides of the negative-electrode plates.

Owner:SHARP KK

Material injection device of die casting machine

The invention discloses a material injection device of a die casting machine. The material injection device comprise a material cylinder and a plunger, wherein the material cylinder is used for containing molten metal liquid, the plunger is arranged in an inner cavity of the material cylinder, the material cylinder comprises a flat part and a gooseneck part which are in transition connection by an inclining part, the lowest point of the inclining part is lower than the lowest point of a material outlet of the gooseneck part, the plunger comprises a plunger head and a second plunger head which are connected by a plunger rod, a non-pressure chamber for containing the molten metal liquid is formed among the plunger head, the second plunger head, the plunger rod and the flat part, a pressure chamber for containing to-be-injected molten metal liquid is formed among the plunger head, the gooseneck part and the flat part, and a one-way flowing device is arranged between the non-pressure chamber and the pressure chamber, is sealed during material injection, and is opened in the plunger resetting process. The material injection device of the die casting machine has the advantages that the die casting cycle is short, the production efficiency is high, the qualified rate of products is higher, the heating temperature of the metal liquid is lowered, and the service life of a die and other parts is prolonged.

Owner:苏州圣美特压铸科技有限公司

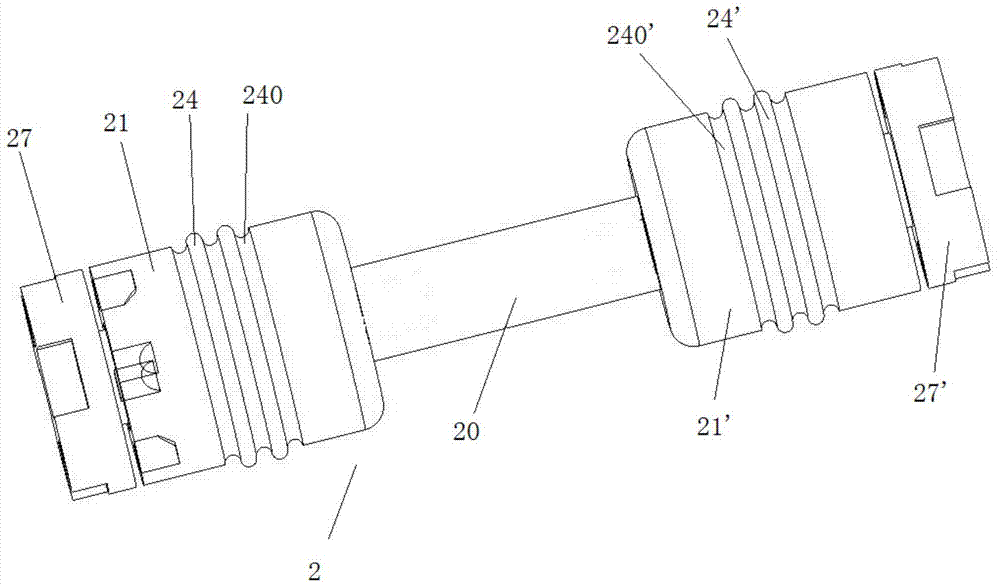

Conductive liquid silicon rubber composition and normal temperature shrinkage rubber assembly used for high-voltage cable

ActiveCN104341778AHigh strengthShorten injection timeNon-conductive material with dispersed conductive materialPolymer scienceGas phase

The invention provides an addition cure conductive liquid silicon rubber composition and a normal temperature shrinkage rubber assembly which comprises a curing molding object of the composition and is used for a high-voltage cable. Because the addition cure conductive liquid silicon rubber composition is low in viscosity, the addition cure conductive liquid silicon rubber composition is excellent in productbility and operationality, and can provide cured products which are excellent in electrical characteristics and rubber strength. The conductive liquid silicon rubber composition is used for being installed on a connecting part or terminal part of the high-voltage cable and holds the normal temperature shrinkage rubber assembly composition, of the connecting part or terminal part, used for the high-voltage cable. The conductive liquid silicon rubber composition comprises (A) organopolysiloxane molecule of which is provided with more than two silicon atom bonding allyl groups; (B) organic hydrogen-containing poiysiloxane molecule of which is provided with more than three silicon atom bonding hydrogen atoms; (C) gas phase made silicon dioxide BET specific surface area of which is 50-400 m<2> / g; (D) furnace black containing less than 0.1% by mass of sulfur; (E) addition reaction catalyst the viscosity of which is 200-2000 Pa*s at 23 DEG C at a 0.9 s<-1> shear velocity.

Owner:SHIN ETSU CHEM IND CO LTD

Online continuous production and injection integrating method and device for jelly dispersoid

The invention relates to an online continuous production and injection integrating method and device for a jelly dispersoid. The method comprises the following steps of: curing a polymer and preparing a jelly system; then, pumping the prepared jelly system into a colloid grinder through a flow meter, meanwhile, injecting water into the colloid grinder, and grinding by using the colloid grinder at the rotating speed of 1000-3000rpm for 3-5 minutes to prepare the jelly dispersoid; enabling the prepared jelly dispersoid to enter a buffer tank; and pumping the jelly dispersoid in the buffer tank into a water injection well through a high-pressure plunger pump. Production and injection integration of a profile control agent (profiling / flooding agent) is realized, the jelly system and the jelly dispersoid are prepared simultaneously while the jelly dispersoid is pumped into the water injection well, the production and the injection of the jelly dispersoid are continuously carried out on line, and production and injection are simultaneously carried out, so that the production and injection time of the jelly dispersoid is greatly shortened, and the large-dosage continuous profiling and flooding requirements of multiple well groups or blocks can be met.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

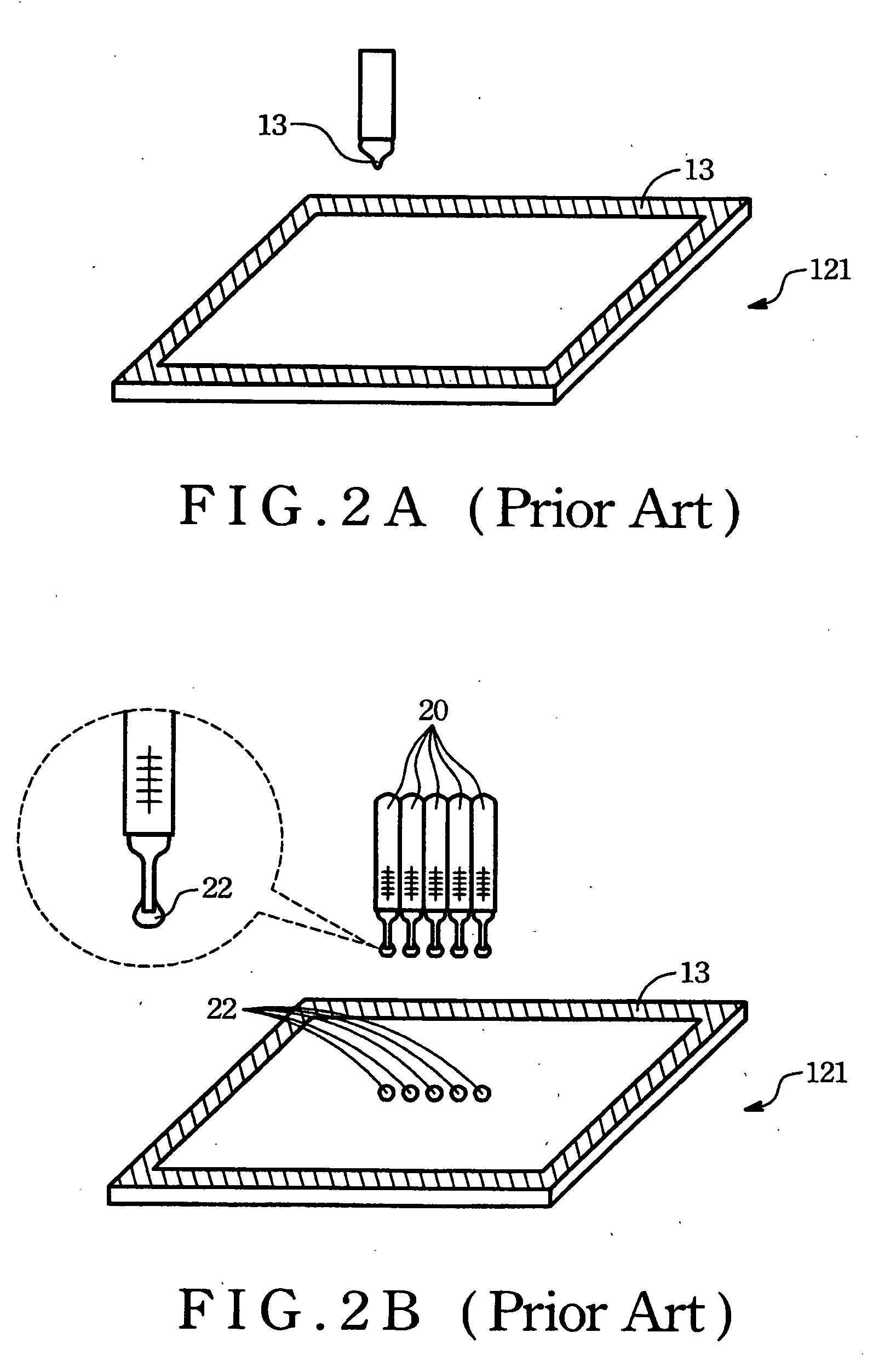

Method for producing a liquid crystal panel

InactiveUS20060132702A1Shorten liquid crystal injection timeImprove the phenomenonNon-linear opticsEngineeringSealant

A method of manufacturing an LCD panel, which the LCD panel includes a first substrate and a second substrate, includes following steps of: 1) forming an alignment layer on the first and second substrates, the alignment layer comprising PI and PAA; 2) post baking to convert PAA into PI, wherein the imidization rate of the alignment layer after the post baking is between 70% and 90%; 3) spreading a sealant in the margin area of the first substrate; 4) dropping a liquid crystal material upon the first substrate; and 5) gluing the first substrate and the second substrate under a low-pressure condition.

Owner:AU OPTRONICS CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com